Page 1

GE Fanuc Automation

Computer Numerical Control Products

Servo and Spindle Motors

Exposed to Liquids

GFK-1046E April 1999

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1999 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

Content of this Manual

Chapter 1. Protection Standards: Provides basic product information and how they relate

to IEC standards.

Chapter 2. User Specifications: Provides a tool that end users can use to help their

machine suppliers provide machines that meet consistent standards of protection.

Chapter 3. Application Guide: Provides a foundation for the machine tool builder by

pointing out the elements that can affect coolant entry, modes of motor failure,

and more extreme methods of keeping motors dry.

Chapter 4. Machine Runoff Checklist: This checklist can be used during machine design

and test or after installation at the user site.

Chapter 5. Preventive Maintenance: Describes the steps that can be used to identify

potential motor failures as well as basic preventive maintenance procedures.

Preface

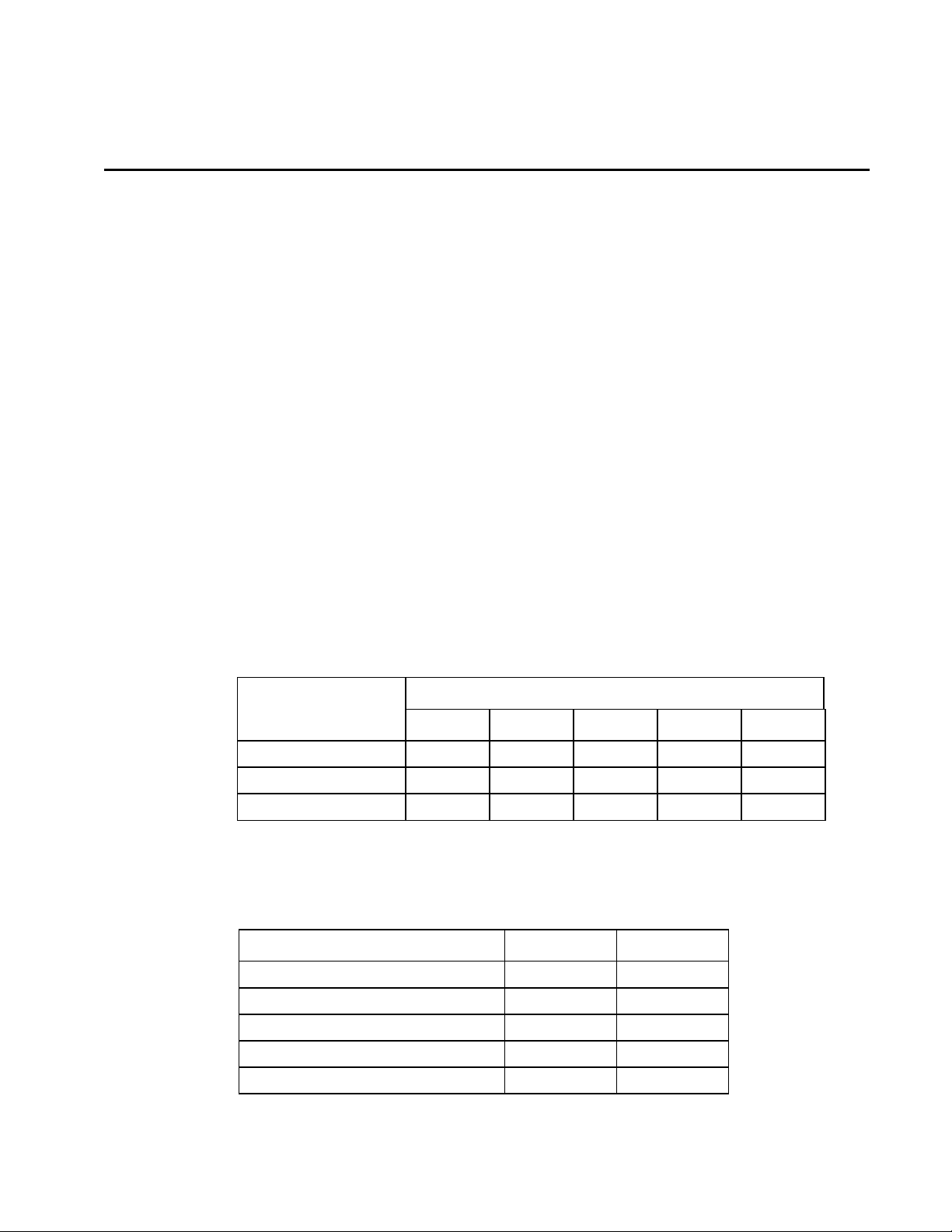

The following table identifies the chapters which will be most useful to each type of user.

Function 1 2 3 4 5

Machine Tool Builder Yes Yes Yes Yes No

End User / Specifier No Yes Yes Yes No

User Maintenance / Service No No Yes Yes Yes

Related Publications

Publication S Series αα ß Series

Servo Descriptions Manual GFZ-65002E GFZ-65142E

Servo Maintenance Manual GFZ-65005E GFZ-65165E

Spindle Descriptions Manual GFZ-65042E GFZ-65152E

Spindle Maintenance Manual GFZ-65045E GFZ-65165E

ß Series Servo Motor Descriptions Manual GFZ-65232EN

Refer to this Chapter:

GFK-1046E iii

Page 4

Contents

Chapter 1 Protection Standards............................................................................................ 1-1

Oil Seals............................................................................................................................1-1

Connectors.........................................................................................................................1-2

IEC Protection Standards...................................................................................................1-3

Chapter 2 User Specifications................................................................................................ 2-1

All Motor Applications ......................................................................................................2-1

Motors Subjected to Liquids...............................................................................................2-5

Chapter 3 Application Guide ................................................................................................. 3-1

Boot System.......................................................................................................................3-2

IEC Standards....................................................................................................................3-3

When Coolant Enters a Motor............................................................................................3-4

Drains and Pressurization...................................................................................................3-4

Fans and Derating..............................................................................................................3-4

Chapter 4 Machine Runoff Checklist.................................................................................... 4-1

Checklist............................................................................................................................4-2

Chapter 5 Preventive Maintenance....................................................................................... 5-1

Maintenance for Drives in a Normal Environment...............................................................5-2

Maintenance for Drives in a Wet Environment.................................................................... 5-3

Modification to the Motor ..................................................................................................5-4

GFK-1046E v

Page 5

Chapter

1

Oil Seals

Protection Standards

Developing and maintaining a highly efficient and productive system involves the machine tool

builder, the drives/controls supplier, and the end user. The system design, selected components,

and manner in which the equipment is installed, used, and maintained all contribute to the uptime

of the system.

Oil seals are designed to keep oil from entering the motor through the shaft end. Oil seals do not,

however, prevent the entry of any liquids under pressure.

Caution

When liquid is present during the cooling period of a motor, lower air

pressure in the motor may result in the motor breathing in the liquids.

GFK-1046E 1 - 1

Page 6

1

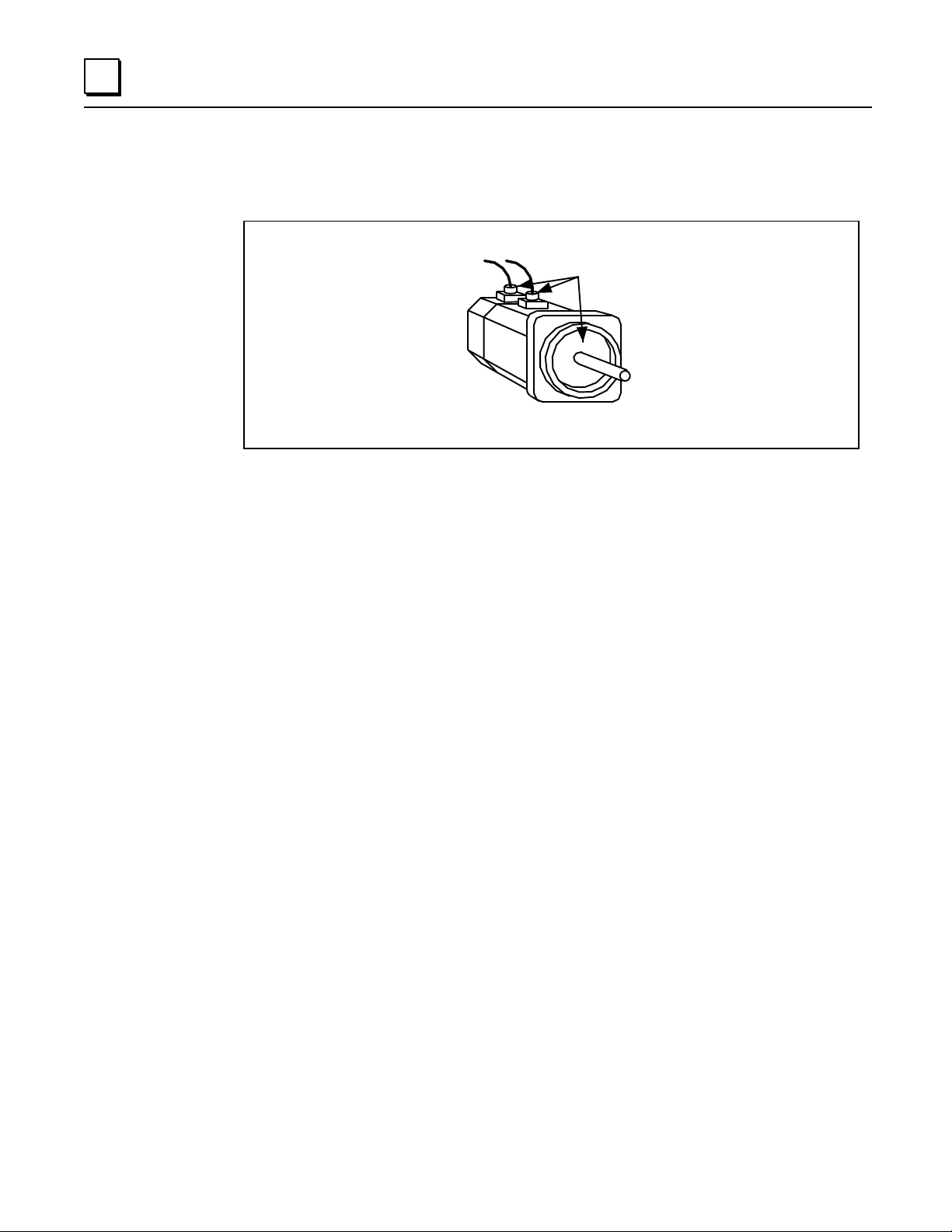

The following illustration identifies the most vulnerable areas for coolant entry.

a48031

Most Vulnerable

for Coolant Entry

Figure 1 - 1. Coolant Entry

Connectors

Note

Foot-mount style spindle motors are only supplied with shaft oil seals as an

available option.

Servo motor models 0S through 40S and α3 through α40 have the same type of cable connector

system (power, feedback, and brake). The cable connector system is designed to accept MS-type

connectors.

SP-style, α1, and α2 motors use a D-type connector system. The D-type connector system has

connectors that are as effective as MS-protected types.

1 - 2 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 7

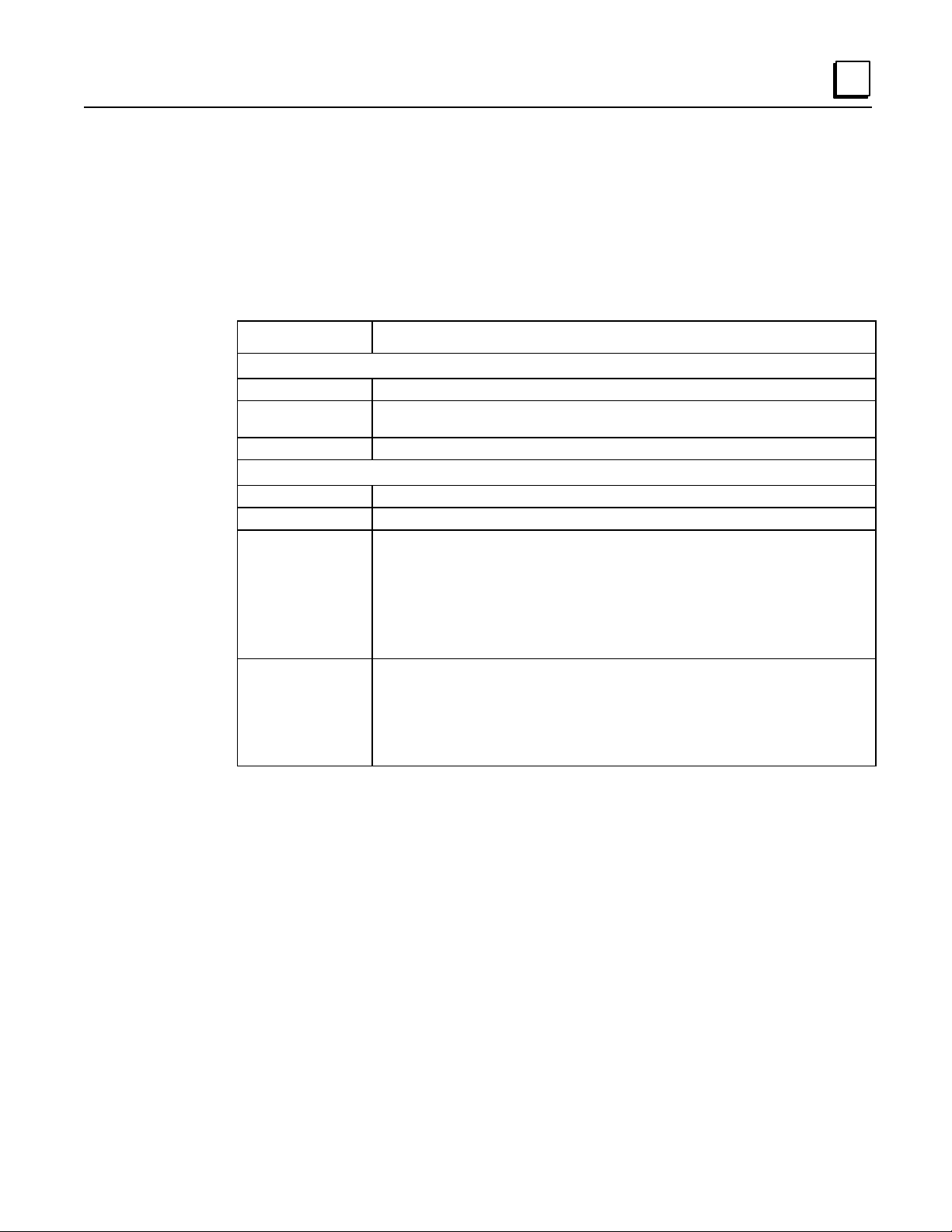

IEC Protection Standards

GE Fanuc motors are designed to meet the IEC protection standards listed in Table 1-1. These

standards are based on two characteristics, the first being protection from solid objects and the

second being protection from water.

Table 1 - 1. IEC Protection Standards

Standard * Description

IP4x Protected against solid objects greater than 1 mm thickness or diameter.

IP5x Protected against dust. "Ingress of dust is not totally prevented, but dust does not enter in sufficient

IP6x Dust tight. "No ingress of dust."

IPx2 Protected against dripping water, rate equivalent to 3-5 mm of rain per minute.

IPx4 Protected against splashing water from any direction.

IPx5 Protected from harmful damage due to water jets, according to the following test:

IPx7

(see note below)

* Each standard listed below also satisfies the requirements of the lower rated standards beneath it.

For example, IPx5 also meets the standards for IPx4, IPx3, IPx2, and IPx1. For more information, refer to CEI/IEC 34-5; 1991.

quantity to interfere with satisfactory operation of the equipment."

• Spray from all angles of 12.5 liters/minute.

• Nozzle diameter = 6.3 mm.

• Pressure = 30 kN/m2 (0.3 bar).

• Distance = 3 m.

• Duration = 3 minutes.

Protected against the effects of immersion, according to the following test:

• Surface of the water level shall be at least 150 mm above the highest point of the machine.

• Lowest point of the machine must be at least 1 meter below the surface of the water.

• Duration of the test must be at least 30 minutes.

• Water temperature must not differ from that of the machine by more than 5° C.

1

Protection from Solid Objects

Protection from Water

Note

By agreement between the manufacturer and the user, this test may be replaced

by the following procedure:

The machine should be tested with an inside air pressure of about 10 kPa (0.1

bar). The duration of the test is one minute. If no air leaks out during the test,

the test is satisfactory. Air leakage may be detected either by submersion, with

water just covering the machine, or by the application on to it of a solution of

soap in water.

GE Fanuc tests according to this alternate procedure. Using the other procedure

requires removing the end cap and checking for water in the motor. This

destroys the integrity of the seal.

GFK-1046E Chapter 1 Protection Standards 1 - 3

Page 8

1

IEC ratings provide a good indication of the expected performance of GE Fanuc motors because

they are test-based systems. However:

• To meet the standard, the shaft end and electrical connections (connector or terminal box)

must be appropriately protected by the customer.

• Because the second characteristic is based on water, the effect of various coolant materials

cannot be accurately predicted.

• Motors built to meet IP65 or IP67 go through a different manufacturing process. These

protection levels cannot be readily added in the field.

• If a motor is modified (i.e., by rotating the connector, by removing the end cap to change the

encoder, etc.), the protection rating is voided.

• Oil seals and connectors are the same in both standard motors and in those motors with

higher levels of protection.

• Compared to standard motors, IP67-rated motors have additional materials applied to mating

surfaces. Depending on the surfaces, these may include varnish, rubber-based gaskets, and

RTVs. In addition, a polyurethane-based paint is applied to the exterior painted surfaces, and

motor is tested by submersion for leak test.

To maximize the service provided by the motors, regardless of their protection

level, they should be protected from continuous wetting by coolants.

Table 1 - 2. Servo Motors

Hollow Shaft "T" Motors Not rated

5-0 Not rated

4-0S, 3-0S, 50S, 60S, 70S, α0.5

2-0SP through 30S IP55 Standard

α1 through α150, β0.5 through β6

40S and α40

Table 1 - 3. Spindle Motors

Model IEC Standard

Built-in Motors Not rated

Selected 1S through 3S IP65 Optional

All Others IP54 (excluding fan and terminal box)

Note

Model IEC Standard

Not rated

IP65 Standard (IP67 Optional)

IP55 Standard (excluding fan)

IP67 Optional (excluding fan)

IP44 (fan and terminal box included)

1 - 4 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 9

Chapter

User Specifications

2

All Motor Applications

For all motor applications, please follow this procedure:

1. Test machine runoff with all the equipment guards in place and with the same coolant

nozzles and pressures designed for production.

2. Orient the motor connectors down and/or away from the predominant source of liquids.

3. Use sealing-type connectors to keep moisture out. Where MS connectors are used, they must

be type F or R.

α1 and α2 and β1 through β6 motors use D sub 15P A068-6050-K115 for feedback.

MS connectors are available, in kit form, from GE Fanuc. The kit consists of a connector,

“O” ring, bushing, clamp, and grommet. These are listed as the "environmental type" in

Table 2-1.

4. An alternate way to waterproof the connector and cable termination is to use a heat shrink

boot. Boots are used on the GE Fanuc severe duty cables listed in Tables 2-2 and 2-3. (Boots

for connectors consisting of boot, gel disk (optional), and instructions for use are listed in

Table 2-1.)

Connector kits are also available. A connector kit includes both the CE95 connector and the

boot.

5. The severe duty cables, listed in Tables 2-2 and 2-3, are high flex, polyurethane jacketed

cables with sealed connectors. The polyurethane jacket resists degrading by the coolant.

6. Physical barriers, such as deflector plates, shrouds, and splash guards, should be used to

minimize liquids falling on or hitting the motor.

7. Cables should have drip loops to prevent liquids from traveling along the cable to the motor

connector.

8. Any removable cover, door, shield, or other device, which protects the motor from liquids or

other contaminants, should be clearly labeled to require the cover, door, or shield to be

replaced in its original position.

GFK-1046E 2 - 1

Page 10

2

Table 2 - 1. MS Connector Kits Supplied by GE Fanuc

Connector Kit

Catalog No.

44A739012-xxx

G07 G25 G09 G01 / G14 * Motor Brake or Fan, Straight

G01 G17 G03 G02

CE95 Catalog

No.

44A730464-xxx

Boot Catalog

No.

44C742396-xxx

Environmental

Catalog No.

44A730464-xxx

Description

Connector.

Motor Power 0, 5, 5/3, α3,

α6, β1 through β6, Straight

Connector.

G03 G19 G01 G03

Motor 10, 20, 30 α12, α22,

α30, Straight Connector.

G05 G21 G05 G04 Motor Power 20/3, 30/3, 40,

α22/3, α30/3. α40, Straight

Connector.

G09 G37 G07 G05 Encoder 17P, Straight

— — G11 G06 Encoder 19P, Straight

G08 G26 G10 G07 / G15 * Motor Brake or Fan, 90°

G02 G18 G04 G08

Connector.

Connector.

Elbow Connector.

Motor Power 0, 5, 5/3, α3,

α6, β1 through β6, 90°

Elbow Connector.

G04 G20 G02 G09

Motor Power 10, 20, 30, α12,

α22, α30, 90° Elbow

Connector.

G06 G22 G06 G10 Motor Power 20/3, 30/3, 40,

α22/3, α30/3, α40, 90°

Elbow Connector.

G10 G38 G08 G11

— — G12 G12

* 44A730464-G01 and G07 connectors for the brake or fan are 2-pin connectors; G14 and G15 are 3-pin connectors.

Encoder ENC 17P, 90° Elbow

Connector.

Encoder 19P, 90° Elbow

Connector.

Table 2 - 2. ββ0.5 Waterproof (IP67) Motor Connectors

FANUC Part No. Manufacturer’s Part No. Manufacturer

Power Connector A63L-0001-0780#4 RM15WTJA-4S Hirose Electric

Power Cable Clamp A63L-0001-0781#15-8 RM15WTP-CP8 Hirose Electric

Encoder Connector A63L-0001-0780#12 RM15WTJA-12S Hirose Electric

Encoder Cable Clamp A63L-0001-0781#15-7 RM15WTP-CP7 Hirose Electric

Brake Connector (with cable clamp) A63L-0001-0785 RM12WTJ-2S-(7) Hirose Electric

NOTE: The waterproof connectors of Beta 0.5/3000 do not have TUV approval.

2 - 2 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 11

Table 2 - 3. GE Fanuc Severe Duty Cables (S Series Motors)

2

Application/Motor Amplifier/Control Custom Cable Cable Length Comments

Servo Motor Power Cable

0S/5S Motors

Servo Motor Power Cable

10S, 20S, 20S/1500 Motors

Servo Motor Power Cable

30S Motor

Servo Motor Power Cable

20-30S/3000, 30, 40,

40S/2000, 7L Motors

Servo Motor Power Cable

1 and 2-OSP Motors

Servo Motor Brake Cable S and C Series 44C742205-001 14M E, SD

Encoder Feedback

A Quad B Incremental

0S – 70S Motors

Encoder Feedback

A Quad B – 10K

0S – 70S Motors

Encoder Feedback

A Quad B – Absolute

0S – 70S Motors

Encoder Feedback

A Quad B – Absolute

0-0SP – 2-OSP Motors

Encoder Feedback

40K Serial Incremental

Pulse Coder C

0S – 70S Motors

Encoder Feedback

1 MM Serial

Pulse Coder A

0S – 70S Motors

Encoder Feedback

Serial Incremental/Absolute

1 MM Serial

Pulse Coder A

0-0SP – 2-0SP Motors

Notes:

1

Cable Comments:

E = Elbow type MS connector.

NU = Feedback cable for systems not using a relay unit.

PMG = Premating ground pin in connector.

RU = Feedback cable for systems using a relay unit.

S = Straight type MS connector.

SD = Severe duty cable, resistant to alaphatic hydrocarbon and alkalai-based coolants (polyurethane jacket).

7W = 7 conductors in cable.

S and C Series 44C742201-001

44C742201-002

S and C Series 44C742201-003

44C742201-004

S and C Series 44C742202-001

44C742202-002

S and C Series 44C742003-001

44C742203-002

14M

14M

14M

14M

14M

14M

14M

14M

S, SD

E, SD

S, SD

E, SD

S, SD

E, SD

S, SD

E, SD

S and C Series 44C742204-001 14M SD

Series 0 CNC

Series 15-A CNC

Series 0 CNC

Series 15-A CNC

Series 0 CNC

Series 15-A CNC

44C742206-001

44C742206-002

44C742208-001

44C742208-002

44C742209-001

44C742209-002

14M

14M

14M

14M

14M

14M

S, SD

E, SD

S, SD

E, SD

S,. SD, NU

E, SD, NU

Series 0 CNC 44C742229-001 14M S, SD, NU

Series 0 CNC

Series 15-A CNC

Series 0 CNC

Series 15-A CNC

Series 0 CNC

Series 15-A CNC

Series 16/18 CNC

44C742210-001

44C742210-002

44C742211-001

44C742211-002

44C742207-001

44C742227-001

44C741355-001

14M

14M

14M

14M

14M

14M

14M

S, SD

E, SD

S, SD

E, SD

S, SD, NU

S, SD, RU

S, SD

Series 15-B CNC

Power Mate E and F

Power Mate G and H

1

GFK-1046E Chapter 2 User Specifications 2 - 3

Page 12

2

Table 2 - 4. GE Fanuc Severe Duty Cables (αα Motors)

Application /

Motor Cable Cable Length Comments

Control

Servo Motor Power Cables

α Series Servos

(SVM and SVU)

α3/3000

α6/2000

α6/3000

C3/2000

C6/2000

β1/3000

β2/3000

β3/3000

β6/2000

Servo Motor Power Cables

α Series Servos

(SVM and SVU)

α12/2000

α12/3000

α22/1500

α22/2000

Servo Motor Power Cables

α Series Servos

(SVM and SVU)

α22/3000

α30/2000

α30/3000

α40/2000

Feedback Cables

64K Serial Encoder

α Series Servos

Standard Honda Connector

Series 0 CNC

Series 15-A CNC

Feedback Cables

64K Serial Encoder

α Series Servos

Half-Pitch Connector

Series 15-B, 16-A, 16-B

Series 18 CNC

Power Mate D and E

Servo Motor Brake Cable

Premating Ground Pin

Notes:

1

Cable Comments:

E = Elbow type MS connector.

NU = Feedback cable for systems not using a relay unit.

PMG = Premating ground pin in connector.

RU = Feedback cable for systems using a relay unit.

S = Straight type MS connector.

SD = Severe duty cable, resistant to alaphatic hydrocarbon and alkalai-based coolants (polyurethane jacket).

7W = 7 conductors in cable.

All α Motors except

α0.5, α1 and α2.

α1 and α2 and β1

through β6.

All α Motors except

α0.5, α1 and α2.

All α and β Motors

except α0.5, α1, α2,

and β0.5.

44C742236-005

44C742236-006

44C742236-007

44C742236-008

44C742236-001

44C742236-002

44C742236-003

44C742236-004

44C742237-001

44C742237-002

44C742237-003

44C742237-004

44C742240-001

44C742240-002

44C742240-003

44C742240-004

44C742355-001

44C742355-002

44C742241-001

44C742241-002

44C742241-003

44C742241-004

44C742238-001

44C742238-002

44C742238-003

44C742238-004

7M

7M

14M

14M

7M

7M

14M

14M

7M

7M

14M

14M

7M

14M

7M

14M

14M

7M

7M

14M

7M

14M

7M

7M

14M

14M

1

S, SD, PMG

E, SD, PMG

S, SD, PMG

E, SD, PMG

S, SD, PMG

E, SD, PMG

S, SD, PMG

E, SD, PMG

S, SD, PMG, 7W

E, SD, PMG, 7W

S, SD, PMG, 7W

E, SD, PMG, 7W

S, SD, PMG

S, SD, PMG

E, SD, PMG

E, SD, PMG

S, SD

S, SD

S, SD, PMG

S, SD, PMG

E, SD, PMG

E, SD, PMG

S, SD, PMG

E, SD, PMG

S, SD, PMG

E, SD, PMG

2 - 4 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 13

Motors Subjected to Liquids

The requirements described on page 2-1 also apply to motors subjected to splash, spray, or drip, as

well. To re-emphasize item 2, in no instance should a connector be oriented upward.

Commercially available, environmentally resistant components should be used. On servo motors

rated between 6 inch-pounds and 1327 inch-pounds, the motors must meet IP67 protection level,

or higher. To meet the intent of the IP67 standard, the machine design and connection system

must appropriately protect the motor shaft end and electrical connectors.

The interface between a flange-mounted motor and the machine device or member must be

machined and gasketed to prevent liquids or other contaminants from entering the motor.

Where any liquids have the potential of entering the motor from the shaft end, appropriate

slingers or drains must be used.

If IP67-rated motors are not available or the appropriate measures cannot be taken to protect the

shaft end, the installation must be reviewed and approved by the user. With prior approval, it may

be acceptable to use drain plugs and/or air purge systems.

2

Caution

Liquids present in motors are not covered under the motor supplier's

warranty. The machine tool builder is responsible for full replacement of

the motor in case of a product failure due to liquid entry.

GFK-1046E Chapter 2 User Specifications 2 - 5

Page 14

Chapter

3

Application Guide

The best way to maximize a motor's service is to keep it dry, by design and in operation. If it

cannot be kept dry, then a system of protection, maintenance, and, in some cases, relief is needed.

This system may include:

• Motor orientation and location.

• Shaft exposure.

• Coolant pressures and types.

• Location of coolant nozzles and shape of the part.

• Connector types and orientation.

• Maintenance (covers left off, filters not cleaned, etc.).

• Motor protection level.

Figure 3 - 1. Four Layers of Defense for Best Reliability

a48033

1. Keep motor out of wet areas

2. Protect the motor

3. Use protected motors

4. Good maintenance practices

GFK-1046E 3 - 1

Page 15

3

Boot System

The standard MS environmental connector termination is hard to make and is also hard to insure

that it is done right. The solution is to use a heat-shrinkable boot over the connection area of the

connector. GE Fanuc offers a boot system to seal the cable/connector termination. The boot seals

the back of the connector, shapes the cable from the connector, provides the straight or right angle

connection for the cable, seals the cable end, and provides limited strain relief. The boot can be

used to replace connectors on environmental cables already in the field as well as on new cables.

The cable orientation on right angle connections can be changed one time by reheating the boot

(see boot rotation procedure below).

Rotating the Boot

If the cable on a right angle connection is not oriented the desired way, the boot can be heated to

allow the cable to be rotated. However, it is important to understand that the boot contains an

adhesive and sealant. It seals the boot to the connector and to the cable, making a watertight

connection. The sealant also fills the area inside the boot around the connections.

To rotate the cable, the sealant must be softened by reheating. To soften the boot, see Figure 3-2

below and the instructions which follow.

Rigid Elastomer Boot

Polyamide Seal

MS

Connector Polyamide Seal

(Adhesive to Cable)

(Adhesive to Connector)

GEL Interface Seal

a48032

Figure 3 - 2. Rigid Elastomer Boot

Caution

The following procedure should only be done once.

3 - 2 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 16

To rotate a sealed boot:

1. Engage the connector on the motor.

2. Determine the new position for the cable.

3. Using a heat gun with a deflector, heat the junction of the boot and the connector housing to

approximately 175 degrees C (temperature required for proper resealing).

Note

Recommended heat gun is HL1802E (Part Number 289759) with Adapter Part

Number 444817 and Reflector Part Numbers 991964 and 991989.

4. When the adhesive releases, maintain downward pressure on the boot to ensure that it stays

on the connector.

5. Rotate the boot to the desired position.

6. Remove the heat gun, and allow the boot to cool. The adhesive will reform the seal.

3

Replacing the Boot

The boot can be replaced by ordering the appropriate boot kit. A boot kit (44C742396) includes

the boot, sleeve insulation, emory cloth, and instructions for replacing the boot.

IEC Standards

IEC standards, such as IP65 and IP67 do not replicate the severity of the environments and

duration found on machine tools. While IP67-rated motors do offer additional protection, they are

not the only element in the solution.

GFK-1046E Chapter 3 Application Guide 3 - 3

Page 17

3

When Coolant Enters a Motor

A variety of coolant types (see following table for list of known types), exposure duration and

pressure, and maintenance practices have evolved as a result of a large installed base and a variety

of applications. While both standard servo motors (IP55) and motors with IP67 protection have

experienced degradation or failure, some IP55 motors have operated for extended periods under a

continuous coolant bath. Better protected motors provide better service.

When coolant enters a motor,

1. Coolants can break down the insulating materials on the windings and/or those used at the

connection and junction points. This degradation occurs over time, but failures can be

anticipated through changes in resistance. (For more information, see Chapter 5, "Servo and

Spindle Drive Preventive Maintenance".)

2. In brake motors, the coolant can interfere with the operation of the brake.

3. Coolants can attack electronic devices in the encoder.

4. Over time, motor fans will fail due to contamination.

5. Coolants can cause shorts between the pins of a connector.

Drains and Pressurization

Drains can extend the useful life of a motor by reducing the amount of contact time chemicals

have with the insulating materials in the motor. However, you must be concerned with correct

placement of the drain hole and also with the risk of metal filings entering the motor.

Positive air pressure can help when there is a high level of contaminants or as the motor

“breathes” during a cooling period, thus allowing liquids to enter the motor. In this case, you

must be concerned with the addition of another system requiring maintenance.

Drains and positive air pressure should be used only after all other preventive measures have

failed. For more advice with these procedures, consult GE Fanuc Application Engineering.

Fans and Derating

The 40S and α40 servo motors and most of the spindle motors use an air-over fan. These motors

are susceptible to coolant entry, contamination, and failure. The air-over fans affect the

continuous ratings of these motors. The systems could be operated, at reduced ratings, without the

fan. For more advice with these procedures, consult GE Fanuc Application Engineering.

3 - 4 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 18

Table 3 - 1. Coolants in Use with GE Fanuc Cables

COOLANT MANUFACTURER

2000 Argent Ferrohone Argent, Ltd.

Alumisol Blue Chip Metalworking Fluids

Castrol 908 Castrol Industrial East

Castrol WY2-402B Castrol Industrial East

ChemTool 250BB ChemTool, Inc.

390 Safety Cool Chem Trend, Inc.

ML-48-2326 Metal Lubricants Co.

1100 Metkool Metalworking Lubricants Co.

251 Metkool Soap Metalworking Lubricants Co.

3499 Metkool Metalworking Lubricants Co.

3

37A Metkut Oil Metalworking Lubricants Co.

711 Metkool Metalworking Lubricants Co.

F3C28A Metkut Metalworking Lubricants Co.

Metkool 1450 Metalworking Lubricants Co.

Metkool 3030-R Metalworking Lubricants Co.

Nat-Hone SC 4640 National Chem Oil Corp.

185-FB Kut Quaker Chemical

523 Cutting Fluid Van Stratten Chemical

NM5299 Van Stratten Chemical

GFK-1046E Chapter 3 Application Guide 3 - 5

Page 19

Chapter

4

Machine Runoff Checklist

The following checklist is not a comprehensive checklist. It should be used by both the machine

tool builder and the end user to supplement good engineering practices.

Observe each machine operating in a cutting mode, with all equipment guards in place, with the

same coolant nozzles and pressures as designed for production, and with parts of similar size and

form factor in the work position.

Relative to the work area where coolants are used, where is the motor located?

o Inside or

o Outside.

o Above or

o Level with or

o Below.

How is the motor connected to the machine?

o Belted or

o Gearbox.

o Coupling exposed or

o Flange mounted to machine member.

o Is it machined well or gasketed?

GFK-1046E 4 - 1

Page 20

4

Checklist

o Is coolant splashing, dripping, spraying, or flowing onto the motor?

o Are all the liquid “paths” to the motor identified?

o If the coupling area is exposed, is there a slinger on the shaft to expel coolant?

o Does the motor shaft get wet? Are liquids around the motor flange area, even when the

motor is turned off?

o With foot-mount spindle motors, is the shaft fully protected from any contact with

moisture?

o Can guards, deflectors, or shields be applied to reduce or eliminate the coolant attack?

o Are removable maintenance covers or shields in place? Are notices and warnings posted

to minimize the chances that they will be left off?

o Are motor fans protected or screened?

o Can the coolant get to the motor via the connectors?

o Are the connectors the environmental type? Is the “O” ring in place?

o If a strain relief is installed, did it strengthen or weaken the seal?

o Do any motor cables flex? Will this break down the cable insulation?

o Is there a drip loop in the cable?

o Are the connectors pointing down and/or away from the liquid source?

o Are the motors IP65 or IP67?

4 - 2 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 21

Chapter

5

Preventive Maintenance

Warning

The products described in this publication may use hazardous voltages or

create other conditions that could, through misuse, inattention, or lack of

understanding, result in personal injury, or damage to the product or to

other equipment. It is imperative that personnel involved in the installation,

maintenance, or use of these products understand the operation of the

products and the contents of this and related publications.

Some surfaces on the motors, servo amplifiers, and discharge resistors may

be extremely hot.

Different environments may require different maintenance procedures. Little maintenance is

required in normal, clean, dry environments. Where the drives, and especially the motors, are

exposed to coolants or other liquids, extra precautions must be taken to maintain the reliability of

the drives.

If a motor must be disassembled, i.e. encoder end cap or connector, the IEC IPxx specification is

voided. (For more information on IEC Standards, refer to Chapter 1, "Protection Standards and

Product Information".)

GFK-1046E 5 - 1

Page 22

5

Maintenance for Drives in a Normal Environment

When performing the following procedures, all motor cables that flex during operation should be

checked for damage to the insulation and for damage at the connection points.

Servo Motors

Servo motors do not require any maintenance in a clean, dry environment. They should be

inspected and cleaned, if necessary, every six months. Use factory air and a vacuum cleaner to

clean the servo motor.

Spindle Motors

For spindle motors, the following items should be checked and cleaned every six months, or more

often if contamination has built up:

• Four ventilation openings on the front of the motor.

• Fan guard on the rear of the motor.

• Cooling fan.

Servo and Spindle Amplifiers

For servo and spindle amplifiers, the following items should be checked and cleaned every six

months, or more often if contamination has built up.

• Cooling fan for the spindle amplifier and the servo amplifier, if provided.

• Heat sink cooling fins.

Use factory air and a vacuum cleaner to clean the servo and spindle amplifiers.

5 - 2 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 23

Maintenance for Drives in a Wet Environment

Test Equipment

Use a 250-volt DC battery-operated insulation tester. The tester may have higher voltages

available, but it must be able to limit to 250 volts.

Motor Inspection and Maintenance

Initially, the following checks should be performed weekly until a pattern of change is established,

and a different test period can be determined.

1. Verify that all machine guards, shields, etc., are in place to keep coolant off the motor. If

they are not in place, replace the guards and shields.

2. Inspect and clean the motor using factory air, a clean dry cloth, and/or a wet/dry vacuum.

3. Check all motor cables that flex during operation for damage to the insulation and also for

damage at the connection points.

5

Test Procedure

Test the motor insulation using the 250-volt DC tester. This test can be done without

disconnecting the motor from the amplifier. This assumes a good connection from the

amplifier to the motor.

1. Servos: Turn off power to the servo amplifier, and turn off the circuit breaker on the

amplifier.

2. Spindles: Turn off power to the spindle amplifier.

3. Connect the tester between one of the motor leads and ground at the amplifier.

4. Activate the tester to read the insulation resistance.

Note

For spindle motors, a reading of 0.5 megohm may be normal because there may

be a relatively low resistance path to ground through the amplifier. If so,

disconnect the motor leads from the amplifier, and perform the tests using the

motor leads rather than the terminal.

GFK-1046E Chapter 5 Preventive Maintenance 5 - 3

Page 24

5

Table 5 - 1. Insulation Resistance Readings

Reading Description

Infinity

< infinity but > 20 megohms

< 20 megohms

_1 megohm

Excellent insulation. No effect from coolant. Inspection period may be lengthened.

Good insulation; however, the insulation has been affected, probably by coolant. Continue

to monitor until a pattern is established.

Insulation is deteriorating and should be monitored closely. Continue to check weekly.

Insulation system has failed. Determine the source by disconnecting the motor power plug

or leads and checking the motor directly. If the motor resistance is low, replace the motor.

If the motor resistance is not low, check the plug or terminal box. If the plug or box is wet,

dry it out, retest, and take action to prevent liquid from entering the plug or box.

Note

Any subsequent reduction of insulation resistance will give advance notice of a

possible motor failure. The motor may function to zero ohms as long as it is the

only motor on the system with low ohms; but such operation is not recommended.

Servo or Spindle Amplifiers

Check and clean these items every six months, or more often if contamination has built up.

Carefully clean using factory air, a vacuum cleaner, and/or cleaning solvent and a clean, dry cloth.

• The cooling fan for the spindle amplifier and for the servo amplifier, if provided.

• The heat sink cooling fins.

If coolant is on the amplifier, check the enclosure seal for defects that are allowing coolant into

the enclosure. Possible defects might include missing or deformed gaskets or missing filters.

Correct or replace the missing or deformed items.

If there is coolant on the electronic boards, carefully remove the coolant. The contaminants may

damage components and/or cause shorts on the boards.

Modification to the Motor

In IP67 servo motors, changing the encoder or encoder connector direction will disturb the

materials used to provide additional protection. In the case of the end cap, a liquid seal material

equivalent to Three Bond #1215 is used. The encoder connector has a flourorubber-type gasket

between it and the encoder cover.

New materials should be applied to cleaned surfaces in order to attempt to regain the original

production integrity. However, this cannot be verified unless the motor is subjected to tests

similar to the ones defined by IEC for the appropriate protection level.

5 - 4 Servo and Spindle Motors Exposed to Liquids - April 1999 GFK-1046E

Page 25

M

Index

A

Air-Over Fan, 3-4

B

Boot System, 3-2

Replacing the boot, 3-3

Rotating the boot, 3-2

C

Cable Connectors, 1-2

Cables, Severe Duty, 2-3, 2-4

Connectors, Cable, 1-2

Coolant and its effect on a motor, 3-4

D

Drains, 3-4

E

Exposure to Liquids, 2-5

Machine Runoff Checklist, 4-1

Maintenance, Preventive, 5-1

For drives in a normal environment, 5-2

For drives in a wet environment, 5-3

Motor Modification, 5-4

MS Connector Kits Supplied by GE Fanuc, 2-2

O

Oil Seals, 1-1

P

Pressurization, 3-4

Preventive Maintenance, 5-1

Protection Standards, 1-3

S

Seals, Oil, 1-1

Severe Duty Cables, 2-3, 2-4

Standards, Protection, 1-3

F

Fans, 3-4

I

IEC Standards, 1-3, 3-3

IEC Standards for Servo Motors, 1-4

IEC Standards for Spindle Motors, 1-4

Insulation Resistance Readings, 5-4

L

Liquids, Exposure to, 2-5

GFK-1046E Index-1

Page 26

GE Fanuc Automation North America, Inc., Charlottesville Virginia

Loading...

Loading...