Page 1

OPERATION MANUAL

Back to Home

FH550SX / FH630SX

HORIZONTAL MACHINING CENTER

F

ANUC - 30i

(

,31i

)

TOYODA MACHINE WORKS, LTD.

Page 2

You are requested to read this manual thoroughly, and comprehend its contents fully prior to

starting the operation of the machine

You are also requested to keep this manual in your designated place in order to get a help of the

manual

T

ransfer of this machine

.

.

Follow the steps below without fail when you transfer this machine to someone else

-

Give this manual and attached manuals to the transferee

-

Refer to the warning labels, and confirm them all

-

If you find there is no label, nor manuals, request for them to us

If you transfer the machine to someone, never fail to inform us of the transferring

You are requested to obey the followings

-

This machine may be in the category of restricted items under the ?Foreign Exchange and

Foreign Trade Control Law of Japan?

To export this machine you must get the export license according to the law

-

This machine was manufactured originally according to laws, regulations and standards of the

country, or the area

This means that you are not allowed to export it to any other country or area where law, regula

tions and standards are different from those of the original country or area

.

;

.

.

.

.

.

.

.

.

Warranty

Free-of-charge repair

-

A failure or damage resulting from using properly the machine according to the operational standards

(

described in the manual),

the warranty period

.

manuals and indicating labels may be repaired free of charge only if it is within

-

-

The warranty may cover only the main body of the machine delivered

The warranty does not cover the direct or indirect loss caused by a failure

-

The warranty period is one year, starting from the acceptance date of the machine after its delivery

Pay repair

-

Repair after the warranty period is charged

Despite the effective warranty period the repair described below is charged

1.

Any failure or damage resulted from the misapplication by a customer, or modifying or repairing by a

customer without our consents

2.

Unexpected failure or damage arising from a fire, act of God, lightning or abnormal voltage

3.

Failure or damage due to an improper handling such as a fall at the time of transporting or moving at a

customer?s

4.

Failure or damage caused by a customer who does not follow the handling procedures

5.

Consumption, abrasion or deterioration of expendables

6.

The malfunction and damage which were produced using the other oil when there was designation oil

Moreover, the malfunction and damage which were produced since the oil with which a consistency and

the purpose of use are different was used even when there was no designation oil

.

.

.

.

.

.

.

.

.

Introduction to this manual

-

This manual is subject to change without notice when this type of machine and its manual need improving

You are requested to be generous to a small discrepancy, if any, between the machine and its manual

If you find a difference between the machine and its manual, or if you have a question, please let us know

.

.

.

.

.

Page 3

Disposal

Dispose of the machine itself and its peripherals in accordance with the laws established by the country

and relevant administrative bodies

1. Disposal of the Machine and Peripherals

.

The disposal work must be entrusted to a specialist contractor

Specialist knowledge is required to disassemble the linear motor that drives wheel feed

Ask a person who has been trained in the disassembly and assembly of linear motors to do this work

When disposing of the accumulator, release the nitrogen gas from it, then disassemble it in such a way

that it cannot be reassembled

Sort parts for disposal on the basis of your own in-house regulations, and have a specialist contractor do

the disposal work from time to time

If you have any questions about the materials that parts are made of, or other matters, please contact us

This system may include devices which use CFC as the refrigerant

When CFC is used in a device, it is stated on the name plate of the device

It is prohibited to release kinds of CFC gas in the atmosphere by the CFC Recovery and Decomposition

Law

.

When disposing a device that uses CFC, you need to ensure that the gas is recovered safely by a

contractor who is authorized to recover kinds of CFC, Category 1,

.

.

.

.

.

by the municipal authority

.

.

2. Disposal of Consumable Parts

Sort the parts according to your in-house rules, and entrust the disposal work to a specialist contractor

from time to time

(1) Coolant

(2) Chips

(3) Spent lubricating oil and hydraulic oil

(4) Battery for memory back-up

.

.

.

When disposing of the battery for memory back-up (lithium battery),

handle the batteries in accordance with any local governmental regulations

(1)

Do not mix batteries up with each other and avoid the possibility of shorting by putting the each

battery into a separate plastic bag

(2)

Ensure that the container in which the batteries are collected is made of an insulating material

(3)

Make sure the batteries are not made wet by rain or other water

(4)

Do not mix the batteries with items identified as hazardous under the fire laws, or place these

items near the batteries

(5)

Do not place the batteries near fire or in any location where they will be subject to high tempera

tures

.

(6)

Do not disassemble the batteries, heat them, or throw them into fire

.

.

abide by the following points and

.

.

.

.

-

Page 4

FOREWORD

This operating manual was created in order to let you know about an everyday handling and safety matter of

horizontal machining center FH

This operation manual consists of the ?Safety Manual? and ?Operation Manual? mainly for the operators who

will use our horizontal machining center FH

tional safety are described in the former manual, while the contents regarding machine operation are de

scribed in the latter manual

Please note in advance that some of the optional functions described in this operation manual may not be

included in your machine

If necessary, refer the following documents as well

FH

550SX/

630

SX : Maintenance Manual

550SX/FH630

.

.

SX of our company

550SX/FH630

SX for the first time: the contents regarding opera

:

.

-

-

Page 5

BEFORE READING THIS MANUAL

1. How to See Manual

FH

550SX/

630

SX

This manual is consisted in the following constructions

3. Manually Operation

FH

550SX/

3.1 Zero Return

3.1.1 Automatic Zero Return of all axis

630

Symbols

.

CHAPTER

SX

Model

Section

Paragraph

Button, lamp etc

During the origin return

cycle, the START push

button lamp is light

.

Contents of operation

explanation etc

3-4

-

.

,

.

Page Number

Before Reading Manual

1

Page 6

BEFORE READING THIS MANUAL

Explanation of items on the previous page

FH

550SX/

630

SX

Chapter

Section

Paragraph

Model

Representation of Safety Caution Marks

This manual contains the following indications to enable you to use the machine

safely, and in order to prevent hazards to personnel and damage to property

DANGER

----------------------

----------------------

-------------------

------------------------

Failure to observe items in this category will result in death or severe

injury

.

Main Topics and title of the chapter

Sub-topics and items out of chapter

Task description and items out of chapter and section

The model name of this manual

.

Failure to observe items in this category can lead to death or severe

WARNING

CAUTION

In addition to the above, the following indications are also used in this manual

<

IMPORTANT>This is an item that requires attention during machine operation or other

injury

.

Failure to observe items in this category can lead to injuries or property

damage

work

Failure to observe such items can lead to damage to the machine

.

.

.

.

<

NOTE

>

This is information for reference during machine operation and program

ming

.

Before Reading Manual

2

-

Page 7

BEFORE READING THIS MANUAL

FH

550SX/

630

SX

Operation procedure & explanation

Buttons & lamps etc

. .......

.....

Operational procedure and explanation is described

* (1) (2)

* (a) (b)

* [

* {Cutting Feed} etc shows selectable switch

* <Power Source> etc shows lamp

*

Buttons, Lamps, etc are shown in picture or drawing

Button to be activated are shadowed, and easy to be

recognized

most current information at the time of publication. How

ever, there may be instances of configuration changes from

an actual machine, so read it carefully

•E•E•E

quential process

perform it in right order

•E•E•E ar e used when there i s several select i on

the operational procedures, and are written as per

of list

.

START] etc shows button

?TOUCH SENSOR? etc shows display on screen

.

•E•E•E ar e used t o s how the numbere.

Follow this sequence, then you can

.

.

.

.

Picture or drawing was prepared with the

.

.

title

.

.

-

Page number

.......3-4

means the 4th page in the chapter

3.

Before Reading Manual

3

Page 8

Foreword

Before Reading this Manual

1

.

Safety Precaution

1.1

Items to Keep Worker?s Safety

1.

2

Items to be Kept during the Machinery Operation and to Protect the Machine

1.

3

Safety Precaution for Each Work

1.3.

1

During Operation

1.3.

2

For Setup Change

1.3.

3

For Daily Inspection

1.3.

4

Upon an Error

1.

4

Label

1.4.

1

Warning Label Attaching Position

1.4.

2

Cautions on Warning Labels

1.

5

Relation Law, Standard, Datum

-----------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

CONTENTS

-------------------------------------------------------------------------------

--------------------

-----------------------------------------------------------------------------

--------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------

-----------------------------------------------------------------------

-----------------------------------------------------------------------------

-------------------------------------------------------------------------------

PAGE

1-1

1-1

1-1

1-2

1-2

1-2

1-3

1-3

1-4

1-4

1-5

1-8

2

.

Machine Outline

2.

1

General Configuration

2.

2

Controlled Axis

2.

3

Operation Panel

2.3.

1

Machine Controls Description

2.3.

2

Main Operation Panel

2.3.

3

Handle Feed Operation Panel

2.3.

4

Magazine Operation Panel

2.3.

5

Pallet Changer Operation Panel

2.3.

6

Chip Conveyor Operation Panel

2.3.

7

Lamps

2.

4

Door Interlock

2.4.1

Operator?s Door Interlock

2.4.

2

Magazine Door Interlock

2.4.

3

Pallet Changer Door Interlock

2.4.

4

Explanation of Operation Mode

3

.

Operation Method

3.

1

From Power ON to Pump ON

3.1.

1

Before Turning Power ON

3.1.

2

For Bringing the Machine into Operable Condition

3.1.

3

Pump ON

3.

2

Stopping the Machine

3.2.

1

For Stopping the Machine in an Emergency

3.2.

2

Stopping the Operation at the End of Work

3.2.

3

For Stopping the Machine during Memory-,

-----------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------

--------------------------------------------------------------------------------------

2-1

2-1

2-2

2-3

2-3

2-4

----------------------------------------------------------------------------2-16

-------------------------------------------------------------------------------2-17

-------------------------------------------------------------------------2-20

-------------------------------------------------------------------------2-22

-----------------------------------------------------------------------------------------------------2-24

-----------------------------------------------------------------------------------------------------2-25

---------------------------------------------------------------------------------2-25

----------------------------------------------------------------------------------2-25

----------------------------------------------------------------------------2-26

--------------------------------------------------------------------------2-27

-----------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------

---------------------------------------------------------------------------------

--------------------------------------------------

-----------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------

----------------------------------------------------------

-----------------------------------------------------------

Tape-,

and MDI-mode Operation

-----------------3-10

3-1

3-1

3-1

3-2

3-4

3-7

3-7

3-9

Page 9

3.

3

Turning Off the Power

3.3.

1

For Turning Off the NC Power

3.3.

2

For Turning OFF the Main Power

3.

4

Origin Return Operation

3.4.

1

For Returning All Axes to their Origins

3.4.

2

Each Axis Origin Return

3.4.

3

For Performing Zero Return in MDI Mode

3.

5

Feed Operate

3.5.

1

Handle Feed

3.5.

2

Jog Feed

3.5.

3

Rapid Feed

3.5.

4

Turning Operation of Table

3.

6

Spindle Rotating Operation

3.6.

1

Setting of Spindle Speed

3.6.

2

Spindle Rotating Operation

3.6.

3

Stopping the Spindle---------------------------------------------------------------------------------------3-38

3.6.

4

For Stopping the Spindle Orientation

3.

7

Magazine Operation

3.7.

1

For Rotating by Jogging

3.7.

2

For Rotating in Continuous Mode

3.

8

Mounting or Dismounting a Tool

3.8.

1

For Mounting a Tool

3.8.

2

For Pullout a Tool from the Magazine

3.

9

Tool Change Operation

3.9.

1

For Put the Tool from Magazine to Spindle

3.9.

2

For Replacing the Magazine Tool with the Spindle Tool

3.9.

3

For Stopping the Spindle Tool in the Magazine

3.

10

Pallet Operation

3.10.

1

For Turning the Pallet Manually

3.10.

2

Pallet Change

3.10.

3

Pallet Confirmation

3.

11

Discharge or Stop of Coolant, Tapping Oil, etc

3.11.

1

Coolant

3.11.

2

For Discharging Air Blow and Cleaning Air Blow

3.

12

Internal Chip Conveyor Operation

3.12.

1

For Turning the Internal Chip Conveyor

3.12.

2

For Stopping the Internal Chip Conveyor

3.

13

Take up Chip Conveyor Operation

3.13.

1

For Turning the Take up Chip Conveyor in Automatic Mode

3.13.

2

For Turning the Take up Chip Conveyor Normal Direction in Manual Mode

3.13.

3

For Turning the Take up Chip Conveyor Counterclockwise Direction in Manual Mode

-----------------------------------------------------------------------------------------------------3-19

-----------------------------------------------------------------------------------------------------3-20

-----------------------------------------------------------------------------------------------------3-70

-------------------------------------------------------------------------------------------3-13

----------------------------------------------------------------------------3-13

-----------------------------------------------------------------------------------------3-14

-----------------------------------------------------------------------------------3-15

-------------------------------------------------------------------------------------------------3-19

---------------------------------------------------------------------------------------------------3-21

--------------------------------------------------------------------------------3-22

-------------------------------------------------------------------------------------3-25

----------------------------------------------------------------------------------3-25

-------------------------------------------------------------------------------3-28

---------------------------------------------------------------------------------------------3-45

-----------------------------------------------------------------------------------3-45

------------------------------------------------------------------------------3-49

----------------------------------------------------------------------------------------3-49

------------------------------------------------------------------------------------------3-54

-------------------------------------------------------------------------------------------------3-63

----------------------------------------------------------------------------------------------3-64

----------------------------------------------------------------------------------------3-67

-----------------------------------------------------------------------3-13

-----------------------------------------------------------------3-14

--------------------------------------------------------------3-16

-------------------------------------------------------------------3-42

-----------------------------------------------------------------------3-47

------------------------------------------------------------------3-52

------------------------------------------------------------3-54

--------------------------------------------3-57

-------------------------------------------------------3-60

------------------------------------------------------------------------3-63

. ---------------------------------------------------------- 3-

70

---------------------------------------------------3-82

---------------------------------------------------------------------------3-86

---------------------------------------------------------------3-86

-------------------------------------------------------------3-86

---------------------------------------------------------------------------3-87

-------------------------------------3-87

------------------3-88

-----3-89

4

.

Auto Operation

4.

1

Operation by MDI Program

4.

2

Operation from Calling Memory Program

-----------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------

-------------------------------------------------------------------

4-1

4-1

4-3

Page 10

4.

3

Continuous Operation

4.3.

1

4.3.

2

4.3.

3

4.3.

4

How to Continuous Operation

4.

4

Setting of Various Data

4.4.

1

To Input Tool Offset

4.4.

2

To Input Work Coordinate

4.4.

3

To Input Common Variables

5

.

Editing Program

5.

1

Display of Program List

5.

2

Program Search

5.

3

Program New Make

5.

4

Program Appends a Part, Change, Delete

5.

5

Program Delete

5.6

Each Data Input/Output by Memory Card

5.6.

1

Output of Machining Program

5.6.

2

Input of Machining Program

5.6.

3

5.6.

4

5.6.

5

5.

7

Display of WINDOW

5.7.

1

5.7.

2

5.7.

3

5.7.

4

------------------------------------------------------------------------------------------Before Processing 2 Pallets Same Workpiece

Before Processing 2 Pallets Different Workpiece

Before 1 Pallet Cycle

--------------------------------------------------------------------------------------

----------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

---------------------------------------------------------------------------------4-11

------------------------------------------------------------------------------4-14

-----------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------

------------------------------------------------------------------

---------------------------------------------------------------------------------------------------

-----------------------------------------------------------------5-10

----------------------------------------------------------------------------5-10

------------------------------------------------------------------------------5-13

Input/Output of Offset

Input/Output of Macro

Output of Parameter

--------------------------------------------------------------------------------------5-15

--------------------------------------------------------------------------------------5-16

----------------------------------------------------------------------------------------5-17

---------------------------------------------------------------------------------------------5-18

Display Lamp Illumination

Display Function Switch

Display NC Switch

Display OP Supporter

---------------------------------------------------------------------------------5-18

----------------------------------------------------------------------------------5-19

------------------------------------------------------------------------------------------5-20

--------------------------------------------------------------------------------------5-21

------------------------------------------------------

---------------------------------------------------

4-5

4-5

4-5

4-6

4-6

4-8

4-8

5-1

5-1

5-2

5-4

5-6

5-8

6

.

Daily Check

6.

1

Check before Turning Power ON

7

.

NC Function List

7.

1

Preparatory Function (G code

7.

2

Auxiliary Function (M code

7.2.

1

Auxiliary Function List

7.2.

2

Explanation of Auxiliary Function

7.

3

Spindle Speed Function (S code)-----------------------------------------------------------------------------7-15

7.

4

Cutting Feed Rate Function (F code

7.

5

Tool Offset Amount

7.

6

Tool Function (T code

-----------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------) -------------------------------------------------------------------------------- 7-1

)------------------------------------------------------------------------------------ 7-6

-------------------------------------------------------------------------------------

-----------------------------------------------------------------------

) ------------------------------------------------------------------------ 7-

(H/

D code

) -------------------------------------------------------------------------------- 7-

) ------------------------------------------------------------------------------------------ 7-

6-1

6-1

7-1

7-7

7-9

15

15

15

Page 11

8

.

Special Function

8.

1

Heat Displacement Compensation Function for Spindle

8.

2

Tool Breakage Detection

8.2.

1

Magazine Tool Inspection

8.2.

2

Cycle Diagram

8.2.

3

Tool Inspection Unit Jog Mode

8.2.

4

Machining Program

8.2.

5 M06

8.2.

6

Tool Inspection Traveling Amount Calculation Program

8.2.

7

Tool Inspection Unit Parameter

-----------------------------------------------------------------------------------------------------

-------------------------------------------------

----------------------------------------------------------------------------------------

---------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------

---------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

Macro Program

---------------------------------------------------------------------------------------

---------------------------------------------

--------------------------------------------------------------------------

8-1

8-1

8-3

8-3

8-4

8-4

8-5

8-6

8-8

8-9

Page 12

1. SAFE PRECAUTION

1.1 Items to Keep Workers Safety

(1)

The factory controller (equipment controller) must prohibit everyone other than those

who have undergone sufficient safety education, from entering the factory and the

machine installation site for safety reasons. If those who have not undergone sufficient

safety education carelessly enter the factory and the machine installation site, a fatal

accident may result

(2)

Prior to machine operation, always confirm the safety of the other personnel in the

immediate vicinity of the machine. Negligence of this precaution may lead to accidents

such as getting caught in rotating parts or getting jammed between movable parts

resulting in injuries

(3)

Do not leave objects on the floor near the machine. Keep the area organized and tidy

Also, keep the area clean so that the floor is free from oil or water. Negligence of this

precaution will lead to the operators or other people slipping and falling, resulting in

injuries

(4)

When you walk around the machine, watch your step as you may stumble on the lever

of a leveling block, foundation parts or other object, and get injured

(5)

Do not operate the machine when the protective covers, interlocks, or any other safety

devices have been removed. When the machine is operated with these devices re

moved, it can move in an unexpected way and can cause accidents, resulting in

injuries

.

.

.

.

FH

.

550SX/

630

-

SX

,

.

(6)

Wear clothes or protective gear so that you can work safely

operation in mind and make sure of safety before starting work as you may get en

tangled in the machine or be unexpectedly injured

(7)

Do not enter the machine working area while it is in operation. Negligence of this

precaution may lead to accidents such as getting caught in rotating parts or getting

jammed between movable parts, resulting in injuries

(8)

Do not turn on the circuit breaker while a door of the control cabinet is open as you

may carelessly touch devices in the control cabinet, and get an electric shock or

burns, resulting in serious injuries and possibly leading to death in some cases

(9)

Receive education according to the manual or the like before operating or servicing the

machine. If those who have not received sufficient safety education carelessly touch

the machine, a fatal accident may result

(10)

Only suitably qualified personnel must operate a crane or a forklift, and perform slinging

work. If those who have not received sufficient safety education try to do such work, a

fatal accident may result

.

.

.

.

, and keep the correct

-

.

1.2 Items to be Kept during the Machinery Operation and to Protect the Machine

(1)

Do not change the settings of the parameters as they have been set to your specifica

tions before shipment of the machine

.

-

(2)

Check that switches and lamps function properly before operating them, or the ma

chine may be damaged due to a malfunction

(3)

When moving each axis in the manual mode operation, make sure that there are no

obstacles between the cutting tool or spindle head and the table, jigs and workpiece

Negligence of this precaution will lead to mechanical damage

1-1

.

.

-

.

Page 13

1. SAFE PRECAUTION

1.3 Safety Precaution for Each Work

1.3.1 During Operation

(1)

Before starting the machine, familiarize yourself with the locations of [EMERGENCY

STOP] buttons so that you can press them as a reflex, at any time and anywhere

Having obstacle objects in front of the [EMERGENCY STOP] buttons will delay the

timing of pressing the button and can lead to injuries and mechanical damage

(2)

Never touch the switches, buttons, and keys with wet hands. Negligence of this

precaution can lead to electrocution if the grounding effect is insufficient or if there is

any electric leak

(3)

Confirm that there are not obstacles within the machine?s working area before operating

the machine. Negligence of this precaution will lead to accidents such as getting

caught in rotating parts or getting jammed between movable parts, resulting in injuries

(4)

Refer to the - Tooling Manual - for details regarding the area of interference within the

axis travel range

(5)

When carrying out machine operations in the manual mode, never operate the

pushbutton switches located on the operation panel while your feet, legs, hands or

other parts of the body are touching the machine. Negligence of this precaution will

lead to accidents such as getting caught in rotating parts or getting jammed between

movable parts, resulting in injuries

.

.

FH

550SX/

.

630

.

SX

.

.

(6)

Do not place your hand or body inside the guard while a pallet is being unloaded. Being

trapped inside the machine will lead to serious injuries to your body

(7)

Before turning the power on, close the door of the control cabinet and the lid of the

terminal box, or you may get an electric shock or burns, resulting in serious injuries

and possibly leading to death in some cases

1.3.2 For Setup Change

(1)

Before removing or mounting a workpiece, check that the [NEXT CYCLE START] lamp

has gone out, and that the pallet changer has stopped

(2)

Change a tool on the side of the magazine. As it is hard to obtain a safe footing on the

spindle side, you may tumble or get injured on the tool edges

(3)

During the setup change work and when handling a heavy workpiece, take a rest

halfway as necessary, taking the weight of the workpiece into account

(4)

To handle a tool, secure a safe footing taking its weight and the gripping position into

consideration, and take care not to drop it. For a heavy tool, take necessary actions

such as hoisting it with a ceiling crane or the like. If not, you may tumble or get injured

on the tool edges

.

.

.

.

.

.

1-2

Page 14

1. SAFE PRECAUTION

1.3.3 For Daily Inspection

(1)

Before entering the machine without an external cover, turn the power off. Otherwise, if

you are trapped in the machine, you will receive serious injuries to your body

(2)

Before entering the machine, wear safety shoes, and watch your step during work as

the floor is wet and slippery with oil or coolant so you may tumble and get injured

(3)

To clean away chips, do not touch them directly by hand. When using compressed air

wear protective goggles, or you may be cut by chips or your eyes may be injured

(4)

Before entering the machine or pallet changer to clean away chips, clean off chips

water, oil and the like from the footing, and secure a place where you can stand safely

or you may tumble, get injured or break a bone

(5)

When you open or close the control cabinet door, operator door, and magazine door, be

careful so that your fingers or other parts of your body are not caught

(6)

Do not splash oil, water and so on over the operation panel, terminal box or the like as

you could receive an electric shock due to power leakage or a machine failure will

result

.

FH

550SX/

.

.

.

630

.

.

SX

,

,

,

1.3.4 Upon an Error

(1)

Upon an error with the machine, press the [EMERGENCY STOP] button and follow the

instructions of qualified personnel appointed by your company. If those who have not

received sufficient safety education carelessly touch the machine, a fatal accident may

result

.

1-3

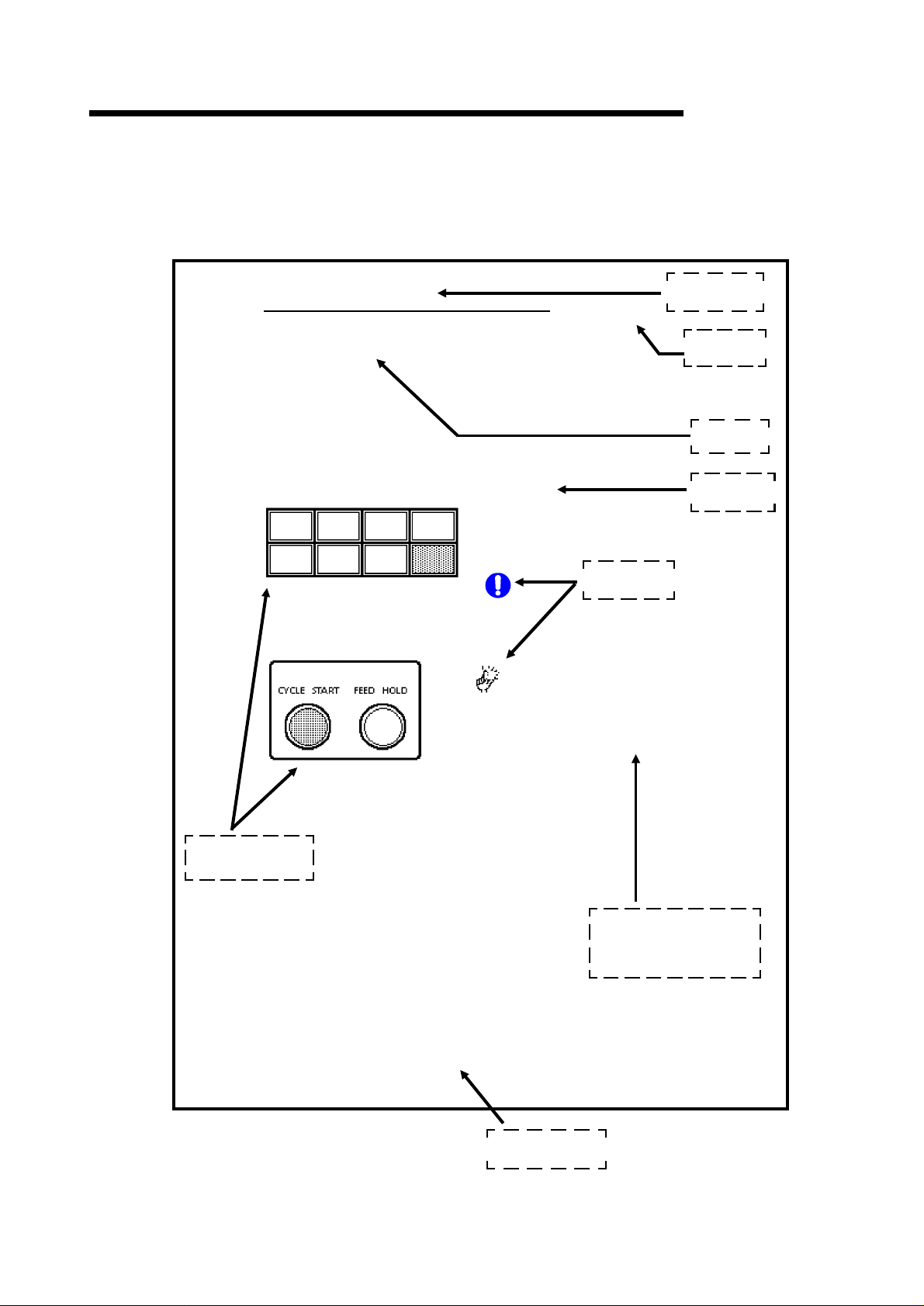

Page 15

1. SAFETY MANUAL

1.4

.

Label

1.4.

1

Warning Label Attaching Position

FH

550SX/

630

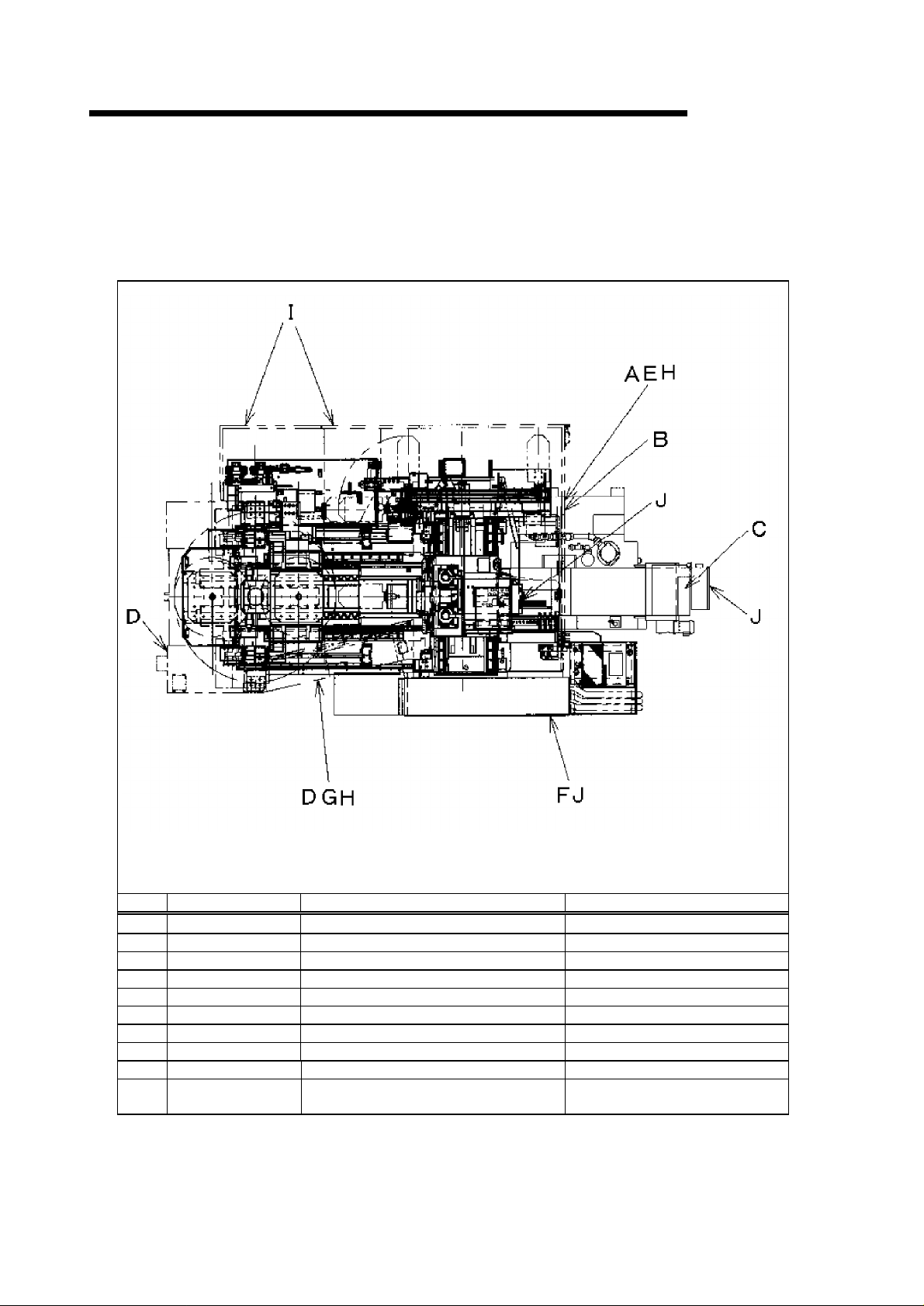

SX

Type Warning label No

A PD-CA111004

B PD-CA611002

C PD-CA611004

D PD-CA611007

E PD-CA011039

F PD-CA016002

G

29-08080224-1

H PD-CA010014

I PD-CA011016

J

20-99951984-0

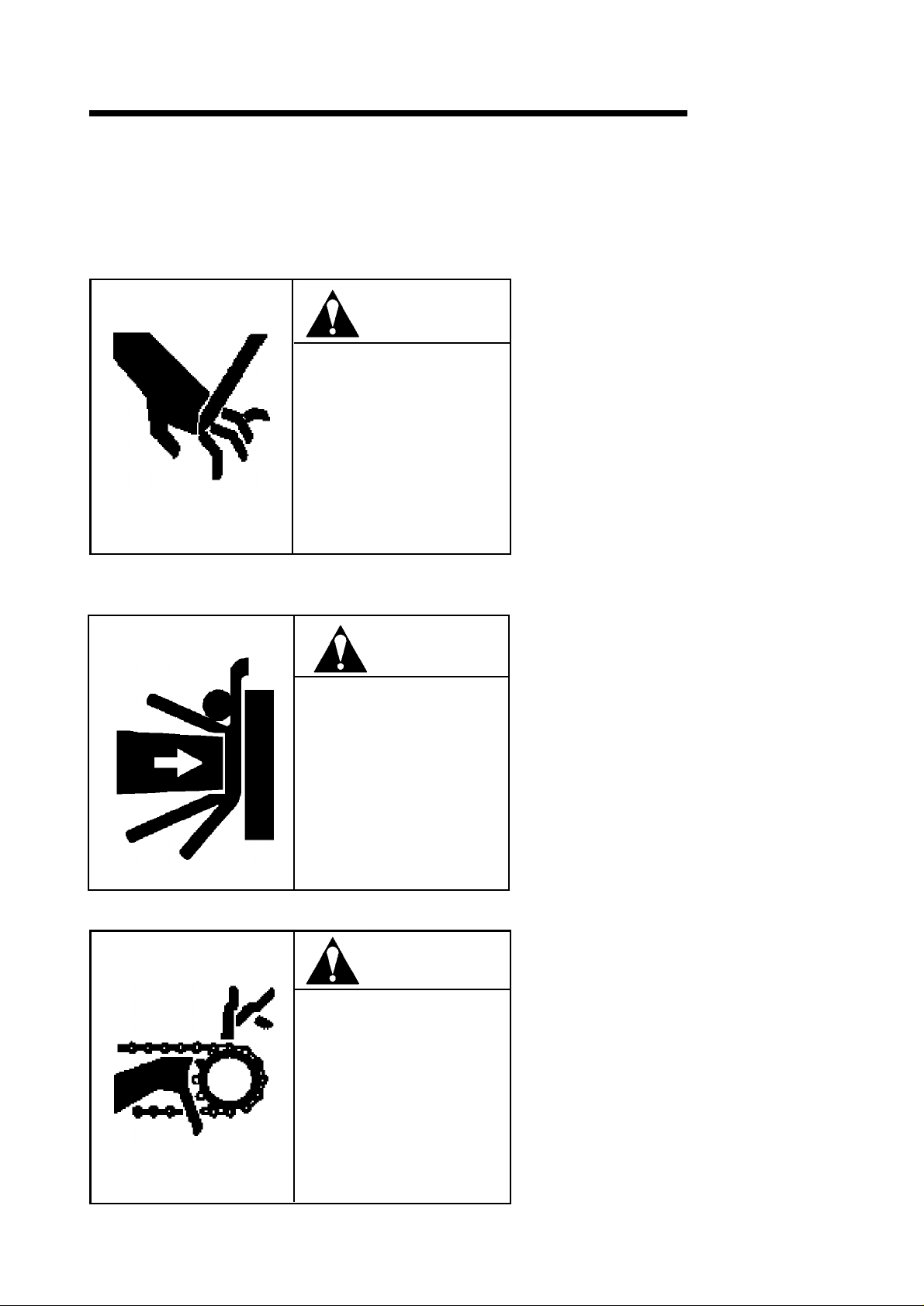

-A Hand may be injured

-A Body may be crushed (

-A Hand may be crushed Crush the hand Coolant tank

-A Body may be crushed (

-B Tool limit M/

-A Total name plate Control panel

-A Slippery Operator?s door

-B Body may be crushed (

.

Hand may be injured Operator?s door

High voltage

Contents Attached position

M/

G door

rear of machine) Rear panel

interlock

don?t remove

)

Operator, P/

G door

)

Each door

Control panel, Spindlehead

Coolant

1-4

C door

,

Page 16

1. SAFETY MANUAL

1.4.

2

Cautions on Warning Labels

FH

550SX/

630

SX

The warning labels show in the table below are attached to this machine

Fully understand the contents of each warning label and observe the mentioned items

<

Factor

>

WARNING

It cannot be defined when this machine starts

to operate during automatic operation

TOOLS INSIDE ENCLOSURE MAY

<

MOVE AUTOMATICALLY WITHOUT

WARNING

TOOLS CAN CAUSE SERIOUS CUTS

AND INJURIES

DO NOT OVERRIDE THE SAFETY

INTERLOCK

.

.

.

Incidental Results

The tool inside the magazine may cause

serious damage to the human body

<

Method of avoiding these accidents

Do not enter the safety fence during auto

matic operation.The safety interlock should

>

not be made invalid (OFF

.

.

.

.

>

).

PD-CA111004-A

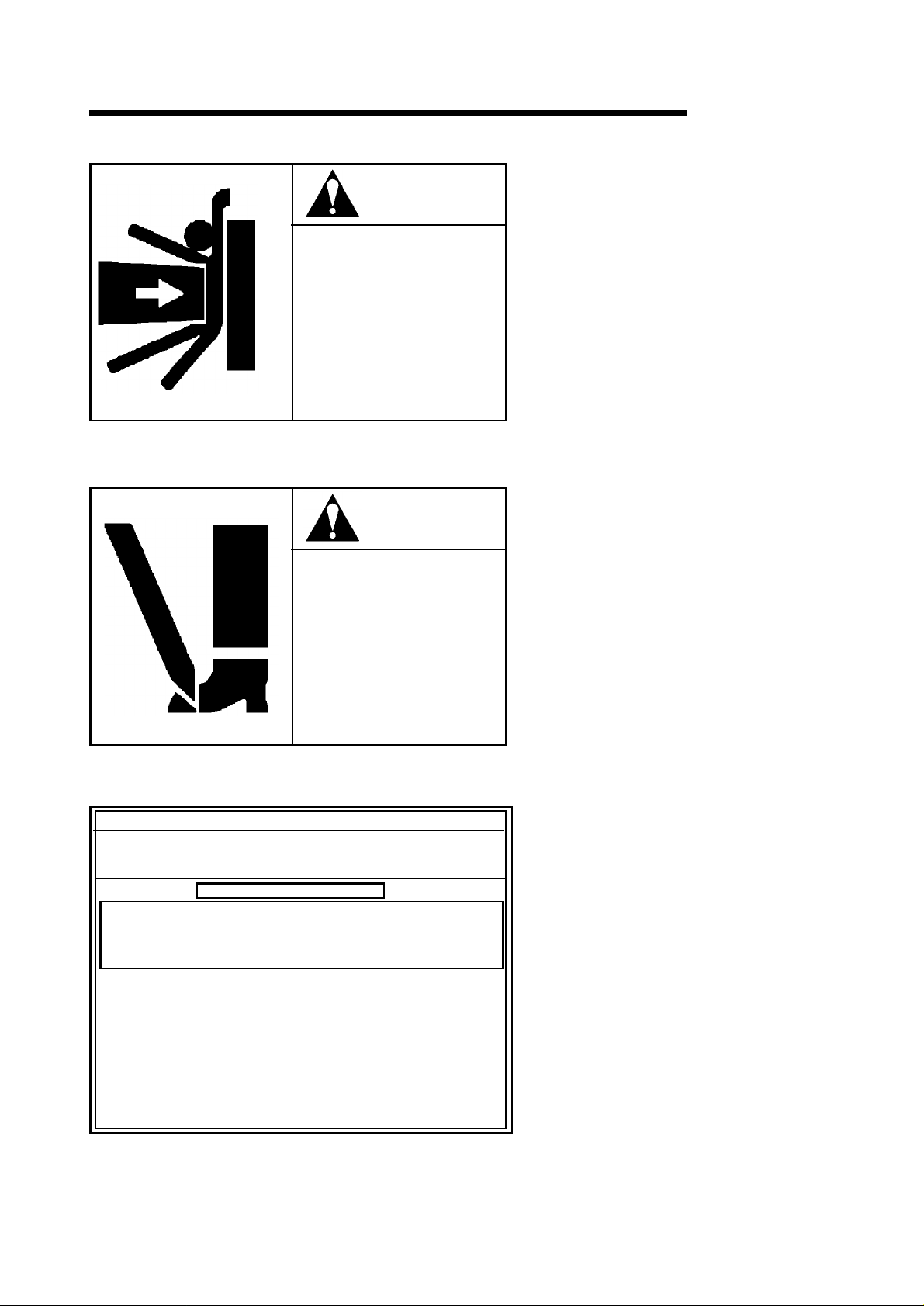

<

Factor

>

DANGER

TOOLS AND PARTS IN THIS AREA

MAY MOVE AUTOMATICALLY

WITHOUT WARNING

CAN CAUSE SEVERE CRUSHING

INJURIES AND DEATH

DO NOT ENTER THIS AREA

UNLESS YOU CAN DO SO SAFELY

LOCK OUT POWER WHEN

WA

RNING IN THIS AREA

.

.

.

If cannot be defined when this machine starts

to operate during automatic operation

<

Incidental Results

>

If your hand or leg is caught in the machine

serious damage may be caused to the

human body, thereby leading to death

.

<

Method of avoiding these accidents

It is not allowed to get inside the machine

rear section with the power switch ?ON?

.

.

>

.

PD-CA611002-A

-

,

WARNING

CHIP CONVEYOR HAS NIP AND

PINCH POINT HAZARDS

MAY CAUSE SERIOUS HAND

INJURIES

PROCEED WITH CHIP CONVEYOR

CLEANING AND INSPECTION AFTER

POWER OFF

.

.

.

PD-CA611004-A

1-5

<

Factor

>

Your hand or leg may be caught in the chip

conveyor

<

Incidental Results

If it should be caught in the machine, dam

.

>

ages, such as a blow and bone fracture may

be caused

<

Method of avoiding these accidents

.

>

Proceed with chip conveyor cleaning and

inspection after power OFF

.

Page 17

1. SAFETY MANUAL

PALLET CHANGER MAY MOVE

AUTOMATICALLY WITHOUT

WARNING

CAN CAUSE SEVERE CRUSHING

INJURIES

DO NOT WORK IN THIS AREA

UNLESS YOU CAN DO SO SAFELY

DO NOT OVERRIDE THE SAFETY

INTERLOCK

WARNING

.

.

.

PD-CA611007-A

CAUTION

FH

550SX/

<

Factor

>

It cannot be defined when this machine starts

to operate during automatic operation

<

Incidental Results

>

If your hand or leg is caught in the machine or

contacts the machine, serious damage may

be caused to the human body

.

<

Method of avoiding these accidents

.

The safety interlock should not be made

invalid (OFF

<

Factor

).

>

Do not exceed following tool specifications

630

.

>

SX

.

DO NOT EXCEED FOLLOWING TOOL

SPECS

.

LENGTH

WEIGHT 27kg

MOMENT 29N?m

IMBALANCE WEIGHT 70kg

EXCEEDING SPECS

MAY CAUSE TOOLS TO FALL AND

RESULTS IN SEVERE INJURIES

545

mm

.

PD-CA011039-B

GENERAL SAFETY CAUTIONS

1. Read all manuals and receive the necessary training before operating or

sevicing this machine.

2. Receive special training, required for a machine with manipulators and

memory equipment before operating machine.

SAFETY OPERATION CAUTIONS

1. Use proper safety equipment.

2. Confirm that all safety guards and switches are in position. Do not attempt to

operate or service without proper training.

3. Confirm that no one is in machine?s working area before starting machine.

4. Emergency-stop machine upon trouble. Recovery procedure should be

performed by authorized personnel only.

A. CAUTIONS PERTAINING TO

MACHINE OPERATION

1. Do not open doors and covers on

electrical boxes.

2. Do not touch any moving parts.

3. Watch your step and hand position

when loading and unloading parts, and

whe n m a nua l ly oper atin g t he

machine.

4. Power should be turnd off prior to

the cleaning of chips or machine.

5. Don?t touch by hand to chips or

cutting tools? edge.

B. CAU TIONS P E RTAIN ING TO

MAINTENANCE AND INSPECTION

1. Maintenance and inspection should

be performed by authorized personnel

only

2. Turn off air and electrical power before

servicing machine.

3. Always turn off primary power before

servicing machine.

4. Support the vertical travelling unit with

a pole when service it.

5. Watch your step.

<

Incidental Results

>

Exceeding specifications may cause tools to

break and result in severe injuries

<

Specifications

Length

545

>

mm

.

Weight 27kg

Moment 29N?m

Imbalance weight 70kg

<

Training

>

Before machine operation start, the engineers

handling this machine should receive ?special

training?

<

.

Hints on operation

>

Wear working clothes and protectors that

enable safe operation, and always start

correct machine operation after checking for

operational safety

<

Caution

>

During operation, avoid dangerous action

.

.

Maintenance check should be carried out by

the qualifed person, and every description

should be observed strictly

.

PD-CA016002-A

1-6

Page 18

1. SAFETY MANUAL

TOOLS CAN CAUSE SERIOUS CUTS

AND INJURIES

HANDLE CAREFUL

CAUTION

.

LY.

29-08090224-1

CAUTION

FH

<

Factor

>

The tool and cutter are sharp

<

Incidental Results

>

550SX/

.

630

If your body touches the tool, damage may

be caused

<

Method of avoiding these accidents

Carefully handle the tool

<

Factor

The floor is slippery

.

>

.

>

.

SX

WET AND SLIPPERY SURFACE

SLIPPING CAN CAUSE BRUISES OR

FRACTURES

WATCH YOUR STEP AND WEAR

SAFETY SHOES

.

.

.

PD-CA010014-A

DANGER

TOOLS AND PARTS IN THIS AREA

MAY MOVE AUTOMATICALLY

WITHOUT WARNING

CAN CAUSE SEVERE CRUSHING

INJURIES AND DEATH

TURN OFF THE POWER AND STOP

MACHINE BEFORE TAKING COVER

OUT

.

DO NOT OPERATE MACHINE WHEN

COVER IS TAKEN OUT

.

.

.

<

Incidental Results

>

You may fall down, being injured or breaking

your bone

<

Method of avoiding these accidents

.

>

Wear the safety shoes, and perform operation

while watching your step

<

Factor

>

.

Do not operate machine when cover is taken

out

.

<

Incidental Results

If your hand or leg is caught in the machine

>

,

serious damage may be caused to the

human body, thereby leading to death

<

Method of avoiding these accidents

Do not take out the cover

.

.

>

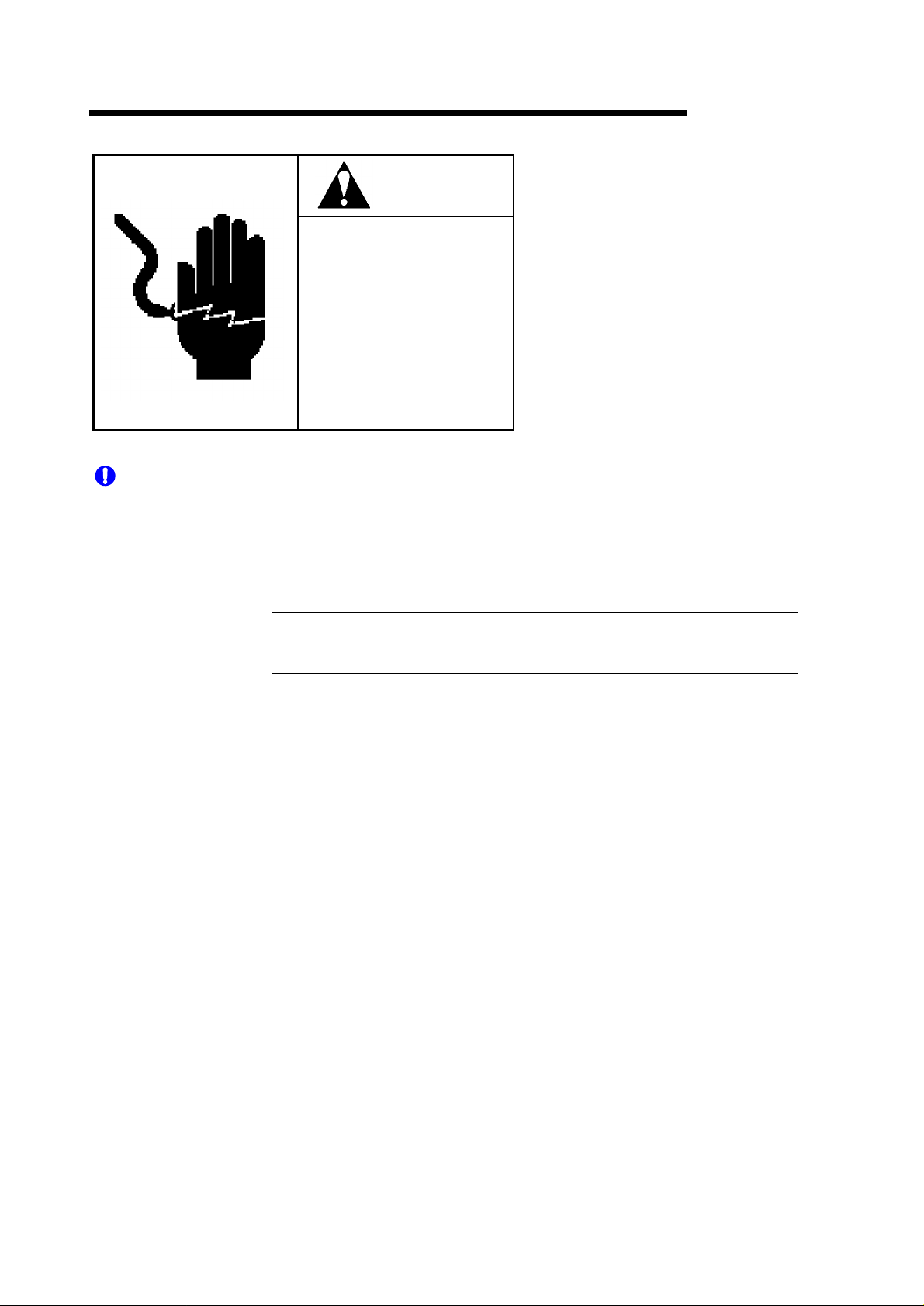

PD-CA010016-B

1-7

Page 19

1. SAFETY MANUAL

HAZARDOUS

HIGH V

OR CAUSE DEATH

DO NOT OPENARY DOOR OR

COVER WHILE IN OPERATION

ONLYQUALIFIED PERSONNEL

PERFORM MAINTENANCE AFTER

LOCKING OUT POWER

DANGER

!

OLT

AGE MAYSHOCK, BURN

.

.

29-99951984-1

FH

<

Factor

550SX/

>

630

SX

Dangerous high voltage is applied to the

machine

<

Incidental Results

.

>

Electric shocks or burns may cause serious

damage to the human body, thereby leading

to death

.

<

.

Method of avoiding these accidents

>

Do not open the doors and lids during

TO

operation.Maintenance check should be

carried out by the qualified person after the

power is turned OFF

.

<

IMPORTANT

Check to see that the warning label is attached when the product is delivered

>

Clean the machine periodically in order to clearly read the description on the label

If the warning label cannot be read or it is missing, immediately ask us to supply the label

and attach it at your end

In that case, select a warning label from the warning label number list shown above accord

ing to the machine specifications to request us to supply it

When reselling your machine, always inform us of the company to which

you resell the machine

1.

5

Relation Law, Standard, Datum

A personnel, who may operate the machine (Examples : Industrial Robots, Carrying - IN

OUT Loader etc

sequence controller and fixed sequence memory storage are included, and makes a

complex and / or automatic motion / a swing motion / a extension and construction / an up

and down motion / right-&

memory storage, must get a special education due to the rules for Industrial Safety and

Health Act the third clause of Article 59.

prepared at your country or at your company to the personnel, who will pursue the operation

/

maintenance etc

.

.

.

.

.),

that has manipulators and has memory storage, in which rewritable

leftward transportation according to the information out of

On this kind of machines, give a special education

.

.

-

/

1-8

Page 20

2. MACHINE OUTLINE

2.1 General Configuration

The basic configuration of the machine is described below.

The data is not only input by the key but data input/output with the external equipment via the

memory card is also available.

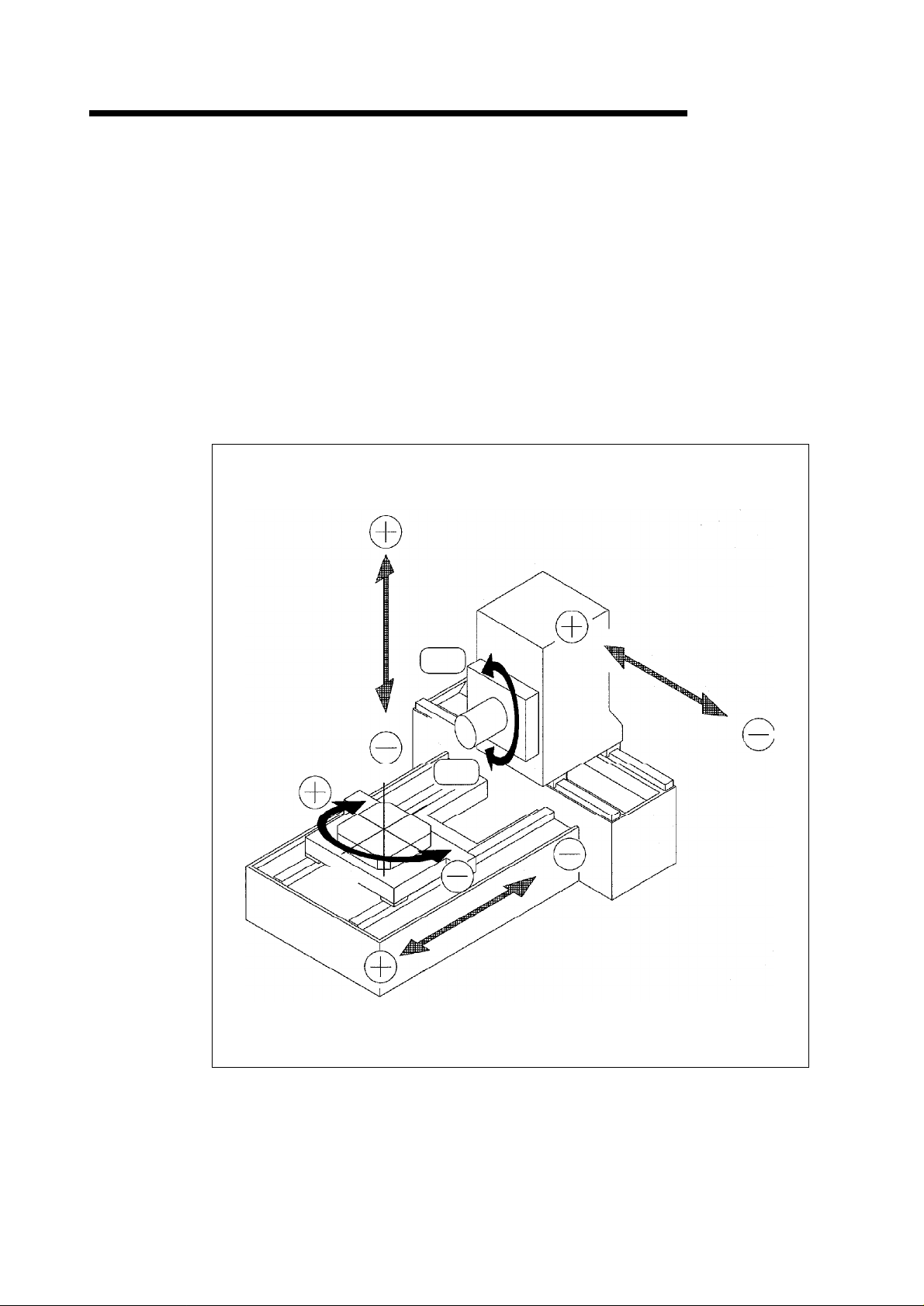

The number of NC controllable axes is 4, and 3 axes can be controlled simultaneously: these

NC control axes are X axis - longitudinal movement of column, Y axis - vertical movement of

spindle head, Z axis - transverse movement of table, and B axis - table rotation.

Spindle rotation can be set steplessly by the use of AC servo motor.

FH

550SX/

630

SX

Y-axis

B-axis

CW

X-axis

Spindle

CCW

Z-axis

2-1

Page 21

2. MACHINE OUTLINE

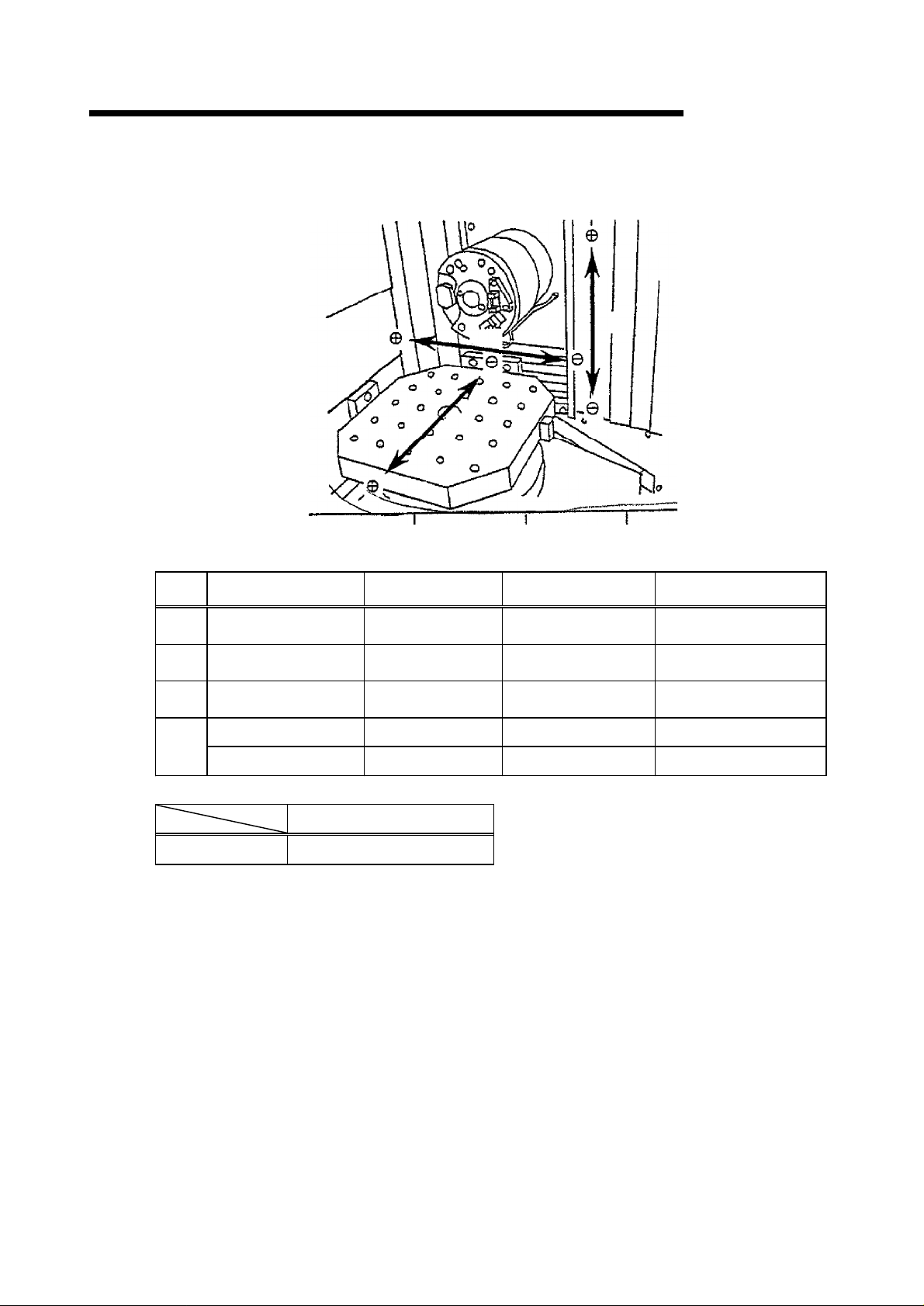

2.2 Controlled axis

Z-

axis

X-

axis

Y-

axis

FH

550SX/

630

SX

Axis Traveling direction

Longitudinal

X

movement of column

Vertical movement of

Y

spindlehead

Transverse movement

Z

of table

NC table rotation

B

1

•‹ table rotation

Spindle rotating speed (

Standard S35~S6,

Min. command

increment

1/

1000

mm

1/

1000

mm

1/

1000

mm

1/

1000

•‹

1

•‹

min-1)

000

Rapid traverse rate

(m/

min

)

60 m/min

60 m/min

60 m/min

90

ø/2

sec

. -------

90

ø/2

sec

. -------

Cutting speed (mm/min

1~30,000

1~30,000

1~30,000

)

2-2

Page 22

2. MACHINE OUTLINE

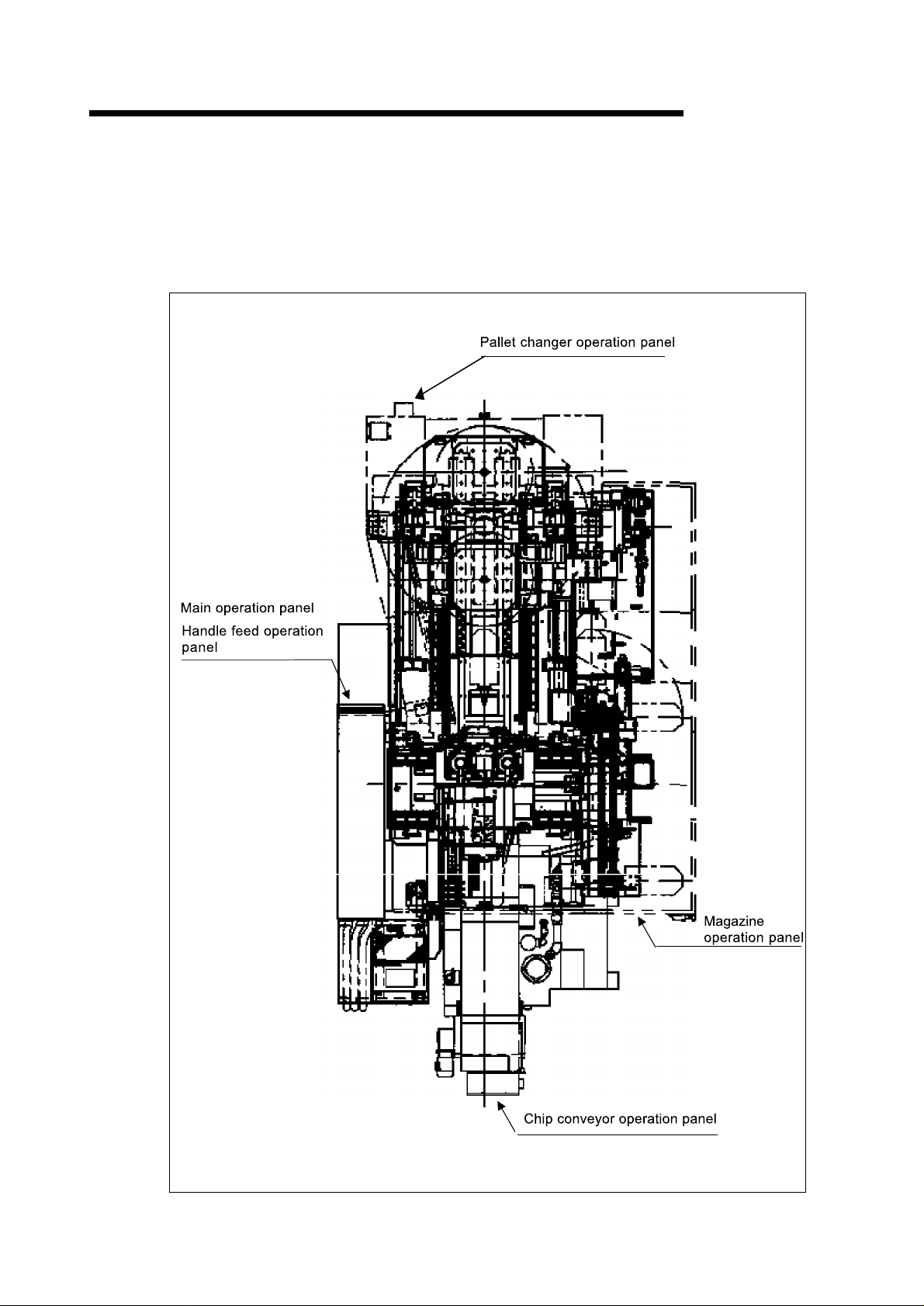

2.

3

Operation Panel

2.3.

1

Machine Controls Description

FH

550SX/

630

SX

This machine has Main Operation Panel and other operation panels of Handle

Operation,

Tool Magazine, Pallet Change Operation and Chip Conveyor Operation

Feed

.

2-3

Page 23

2. MACHINE OUTLINE

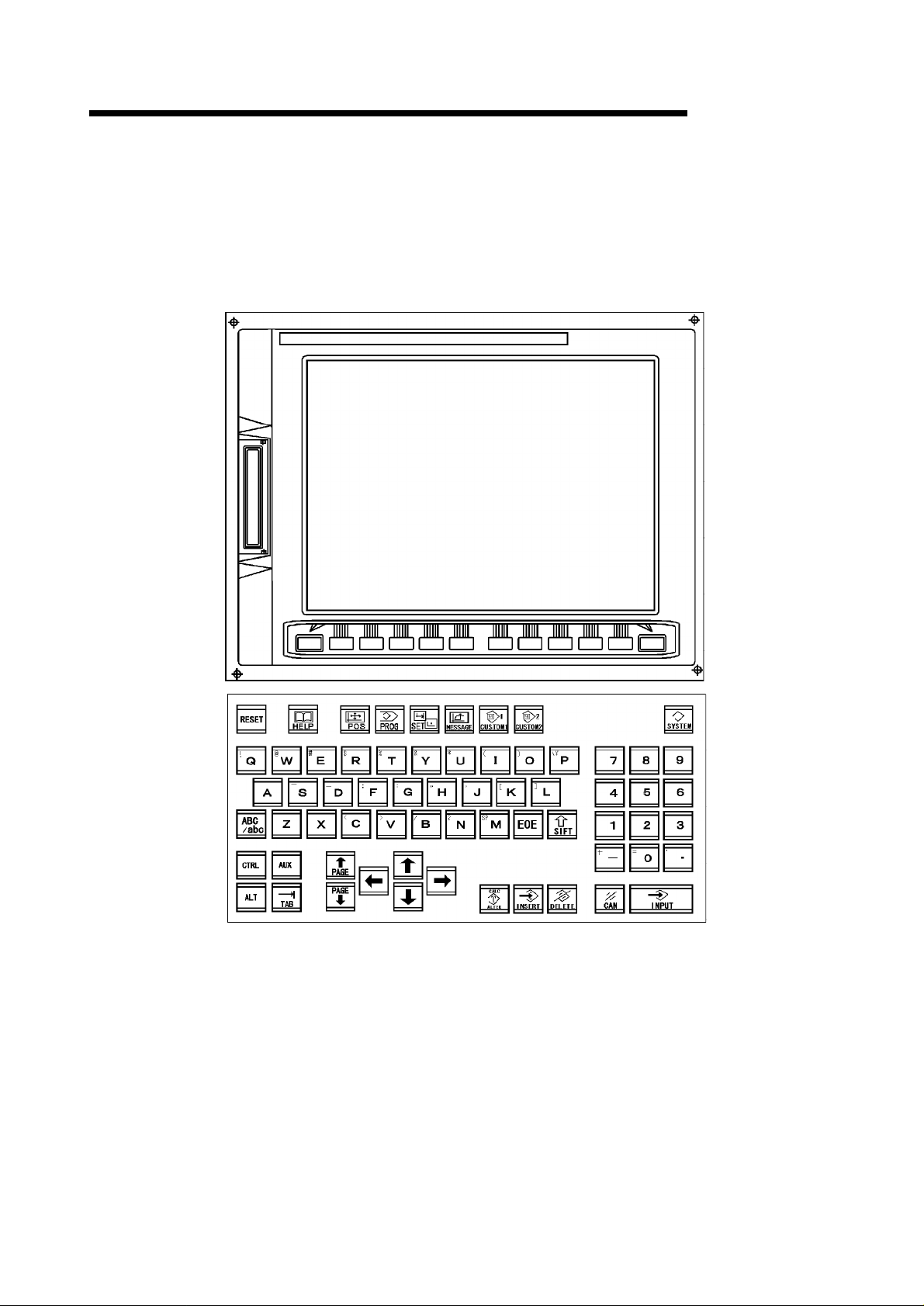

2.3.2 Main Operation Panel

2.3.2.1 NC Operation Panel

FH

550SX/

630

SX

2-4

Page 24

2. MACHINE OUTLINE

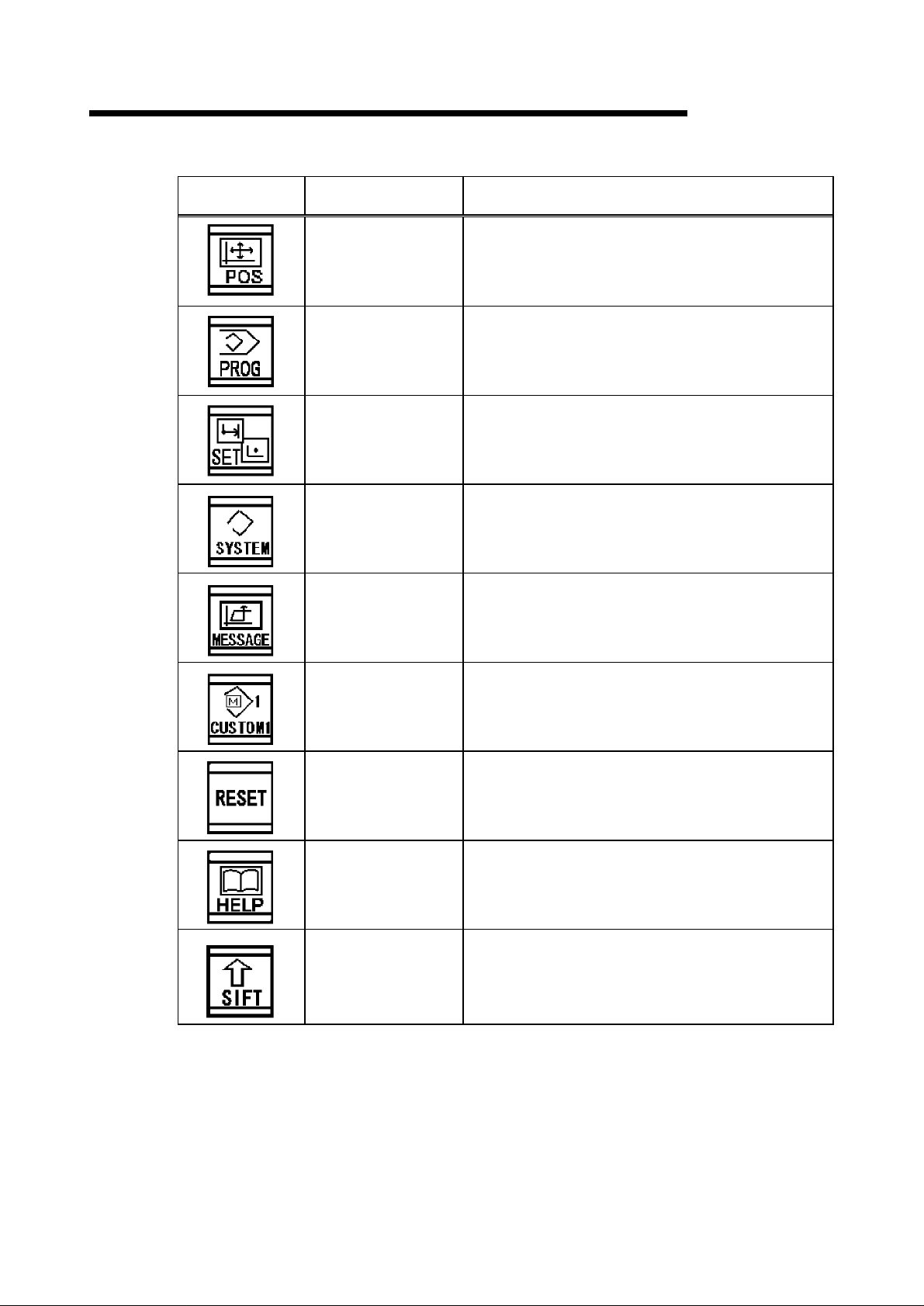

POS

Key

key

Nam

FH

550SX/

e

Press

thisto

display theposition displayscr

Descripti

on

630

een

SX

.

PROG

key

OFFSET

SETTIN

SYSTEM key

MESSAGE key

CUSTOM key

RESE

T k

G k

ey

ey

Theviewin

registered intome

A viewi

the amount of workpiece zero offsets, a macro

frequency, tool

Press

A viewi

compensation, self-diagnostics data, etc. are

performed

A viewi

message, and alarm hysteresis is performed

OP s

T

his

cancel release of an alarm etc

•E If a butt on i s pushe, NC will be reset and it will

be in an initial state

g a

nd editof aprogramwhi

mory ar

ng andsetup ofthe

-life data, etc. are performed

thisto

display thesystemscreen

ng andsetup of a

.

ng ofan

upp

orterscr

buttonispushedto res

alar

een is

e pe

para

m me

ssage,PCala

displayed.

.

ch are

rfor

med

.

amountof tool

.

meter, apit

et an

NC unitfora

.

offsets

.

ch error

rm

.

,

HELPkey

SH

IFT

key

T

his

keyisus

as control method and alarm contents generated in

CNC when MDI control method is not sure

Theaddress key by

is in one key

inputted if a shift key is pushed

right letter can be inputted, ? ^ ? is displayed on a

screen

2-5

ed torequestdi

.

.

splay forsuch deta

whi

ch two l

A letter can be changed and

ette

rs were pr

.

When a lower

.

ils

inted

Page 25

2. MACHINE OUTLINE

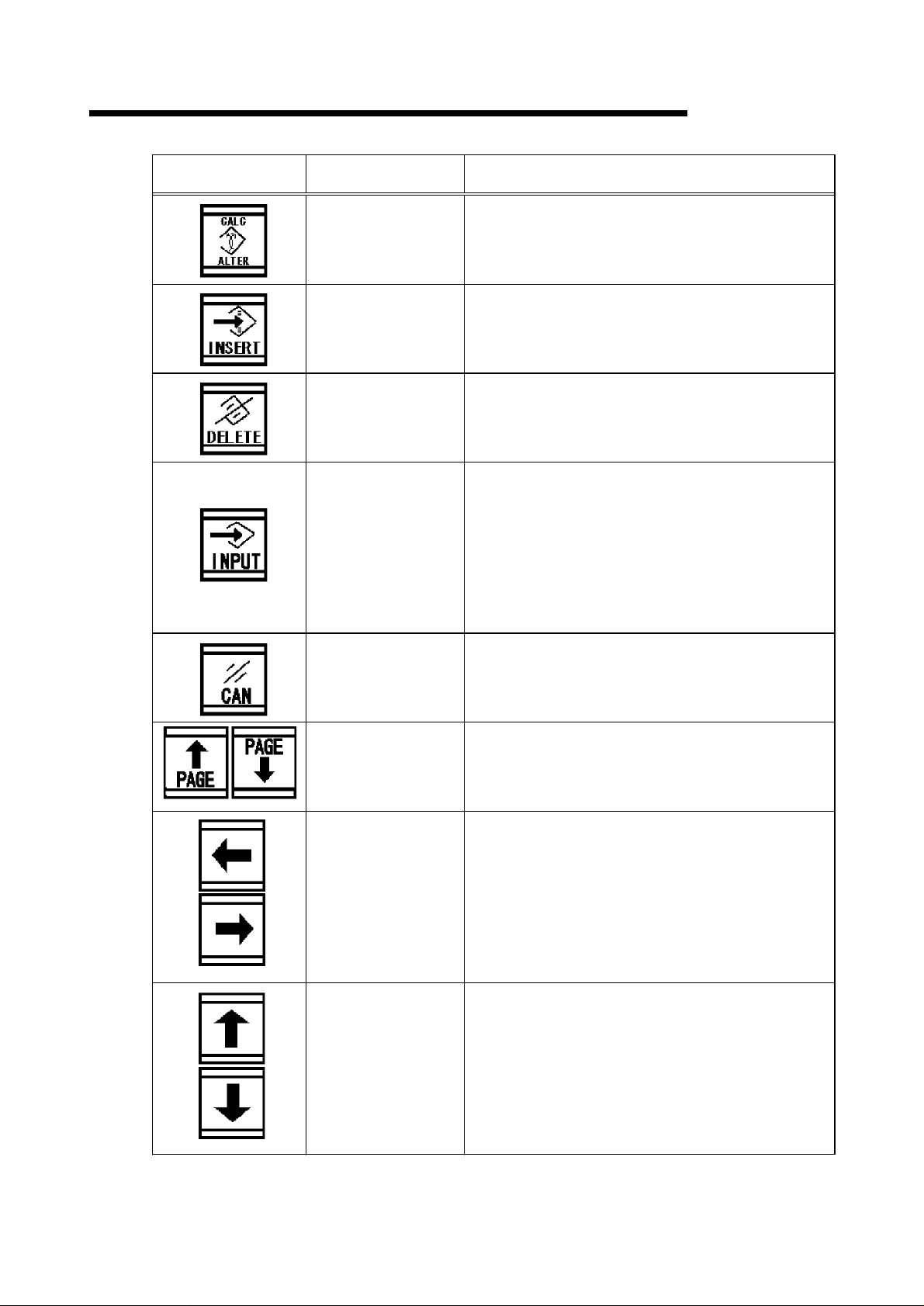

ALTER key

INSERT key

DELETE key

INPUT key

CAN key

Name Description

T

hisisa key to cha

data di

splay are

T

hisisa key to ins

ar

ea.

T

hisisa key to deleteo

di

splay ar

T

he data

the

ar

e di

offs

the

It isequ

whi

han

screen.

T

hisisa key to deleteonele

input area.

T

he letteredit m

ba

ckspac

ea.

whichpu

numeric

et airregisteretc. the informat

key inpu

che

dli

al

splayed."I

t buf

ivale

ver

may b

ng ofmoving

e.

nge the

a.

ert t

he d

n t

she

d and i

keypadare i

NPUT" keyispushe

fer.

nt to

theinput of

e u

sed.

a folderon aprogramlist

ode be

comesthe ope

dataonthecursorof the

ata ofthe datainp

he curs

nputtedt

nput

a softkey

It isusedalso f

tter

FH

550SX/

or of

thedata

he add

tedint

o a buf

d to set to

ion inputtedinto

and

of the da

ta in d

ratio

or

n of

630

ut

ress

fer,

SX

or

and

an

ata

a

PAGE change over

key

Cursor shifting key

Cursor shifting key

T

hisisa key to cha

øThe

page to

prev

iouspageorthe next p

T

hisisa key to mov

ø

A pushon

andlef

ø

In a small par

di

rectionanda reverse direct

T

hisisa key to mov

ø

A push on

upper

ø

In a

di

rectionanda reverse direct

a key m

t, and a reve

a key m

and lower,and a

large

par

nge

be pressedby keyischange

e t

he cursor.

oves

rsedirection.

titionun

e t

he cursor.

oves

titi

on unit,it

the

pag

e.

age.

cursorto theorderofri

it,

it movest

cursorto theorder

reverse direct

movest

o the right

ion.

ion.

o the right

ion.

d to the

ght

of

2-6

Page 26

2. MACHINE OUTLINE

FH

550SX/

630

SX

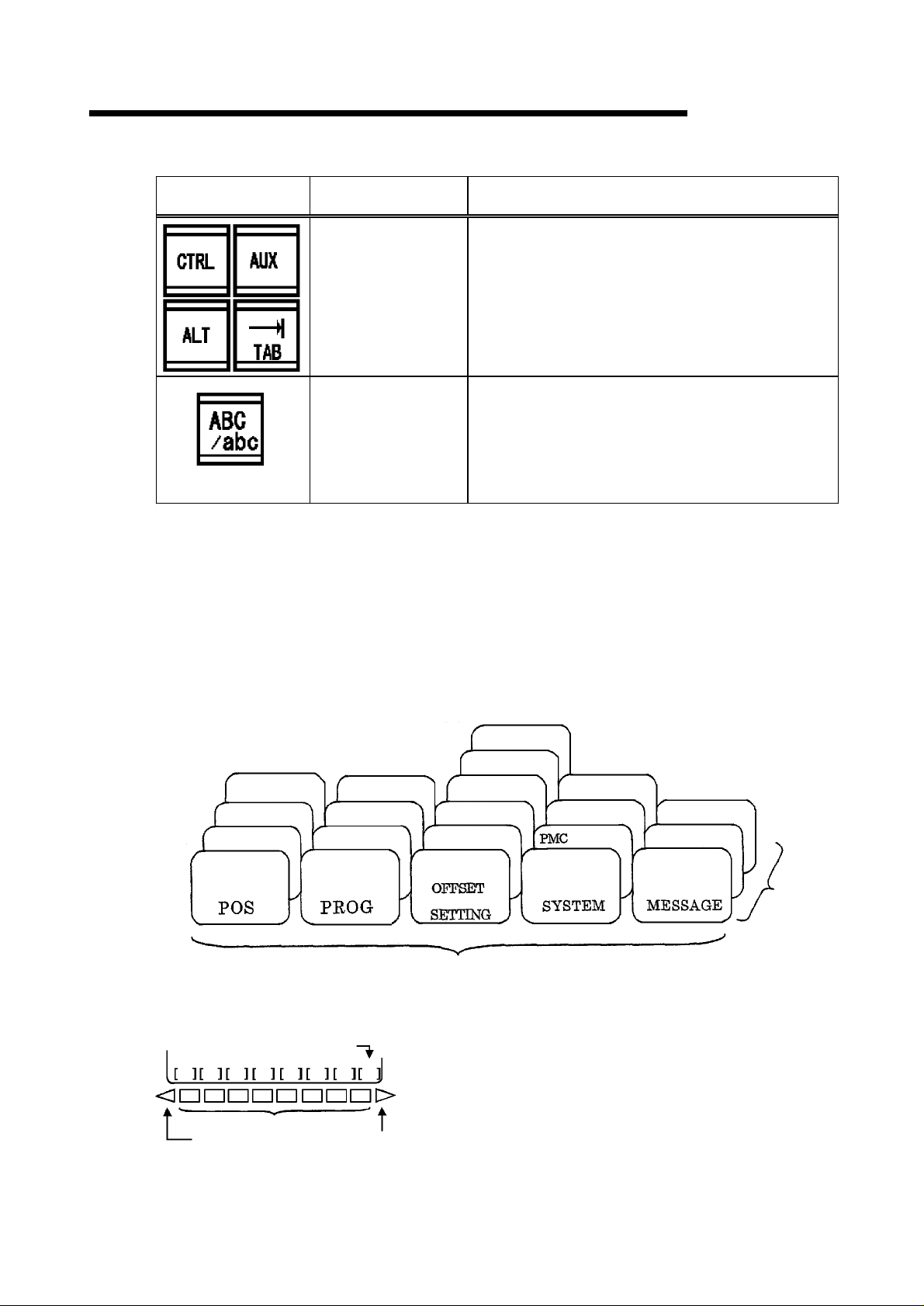

Name

Personal computer

function key

Upper case/Lower

case

It is used by the personal computer function of

3

10i/310iS

.

The upper case/lower case at the time of an

alphabet input are switched.

De

scripti

on

Change-over key

(1) By pushing the function key on the console panel, the soft key for chapter selection

belonging to the function is displayed on a screen.

(2) A push on one of the soft keys for chapter selection displays the screen of the chapter.

A chapter key is pushed when the soft key of the chapter which you want to display is

not displayed.

Screen configuration image

A screen structure changes with some specification of a machine.

Operation panel

Life management

Machine

Relative

Absolute

General

Monitor

List

Program

Check

Macro variable

Setting

Work offset

Tool offset

Function key

Parameter

(3) When the screen of the chapter which you want to

display is displayed, a menu key is pushed. And the

Chapter

softkey of the description to operate is displayed.

(4) A chapter key is pushed to return to the softkey for

Function

menu key

Soft key

Operation

menu key

chapter selection.

The above is the viewing procedure of a common

screen. An actual viewing procedure changes with each

screens. Refer to the operation manual instruction of

FANUC for the concrete operating procedure.

Message

Alarm

Chapter

select soft

key

2-7

Page 27

2. MACHINE OUTLINE

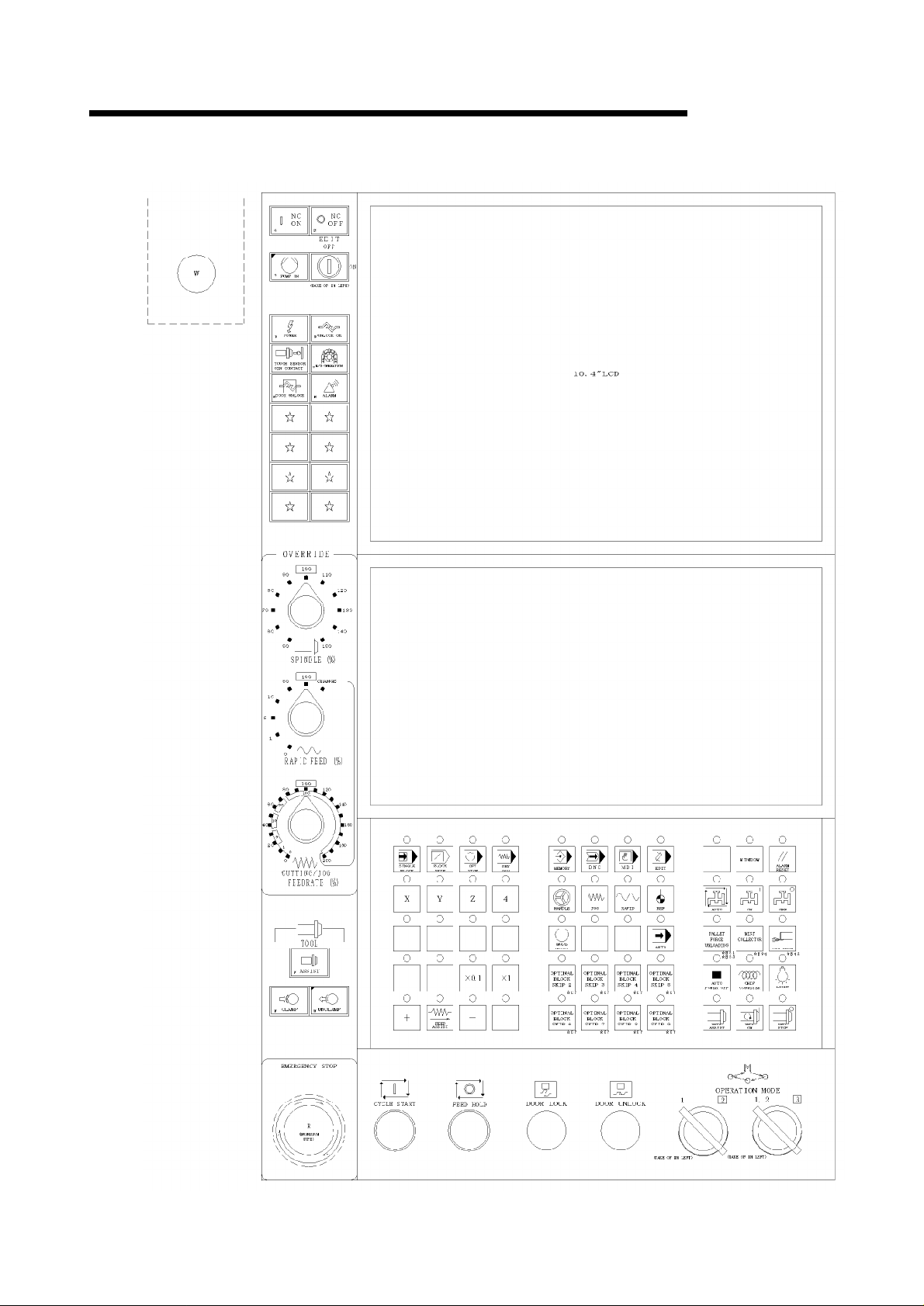

2.3.2.2 Machine Operation Panel

FH

550SX/

630

SX

2-8

Page 28

2. MACHINE OUTLINE

FH

550SX/

630

SX

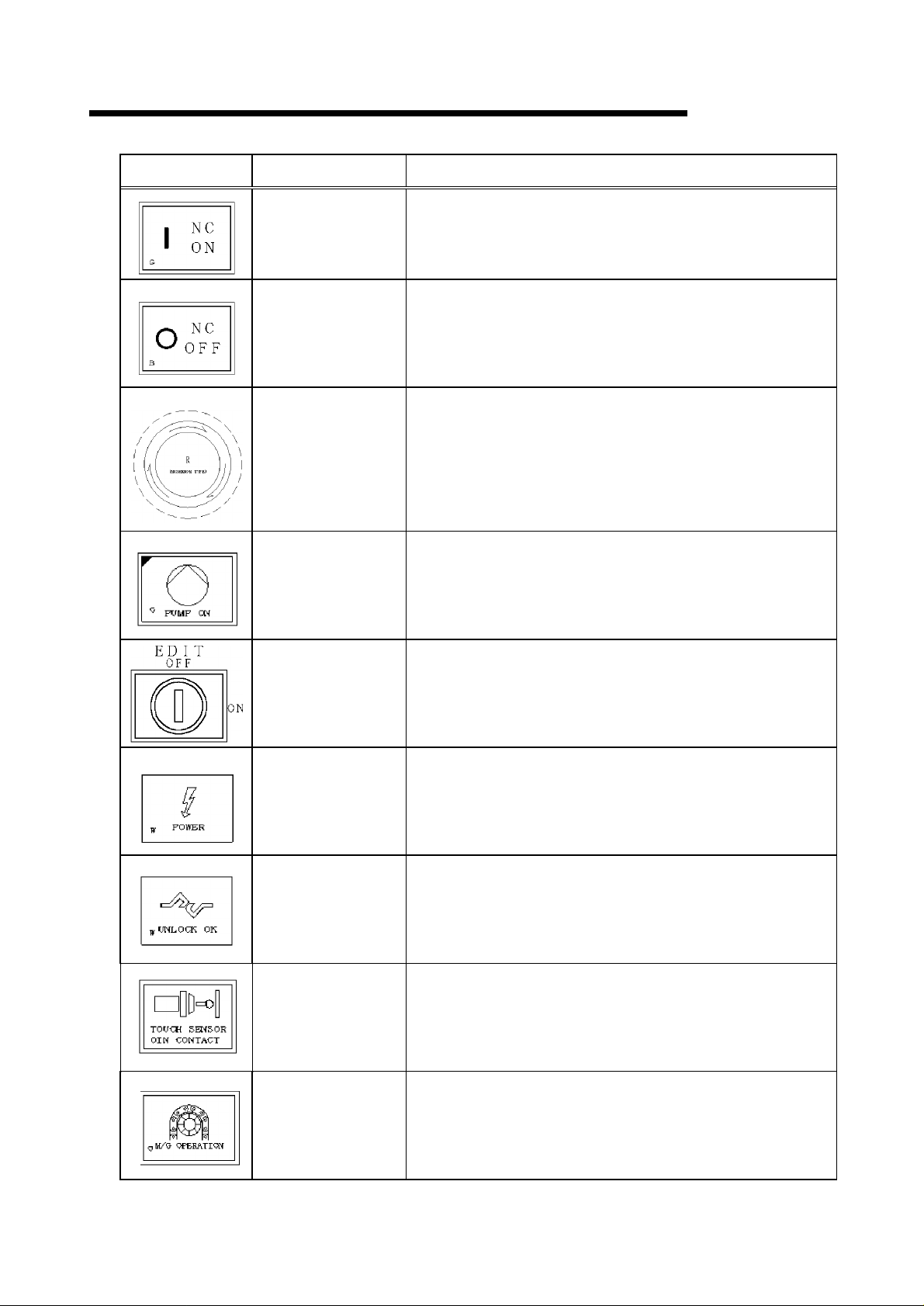

Name

NC

ON

NC

OFF

EMERGENCY

STOP

PUMP

ON

button, lamp

button

(

Green

button

(

White

button

(

Red

(

Green

Function &Descri

This button is used to supply electric power to the NC device

After pushing this button, LCD

)

10

sec. NC device is thus ready to go

This button is used to shut electic power down to NC device

After pushing this button, LCD

)

has no electric power

machining or editing is active

This button is used to shut off machine power and hydraulics

After pushing this button, machine preparatory circuits are

shut off, [

)

•E This button is locked at pressed state upon activatio

•E Turn to arrowed direction(CW) to be released

This button prepares the machine for operation

•E Pressing this button starts the hydraulic pum, lubricating

)

and spindle lubricating pump

PUMP ON] turns off, and all motions stop

.

Never push this button when

.

ption

screen gets display in about

.

screen turns off, NC device

.

.

.

.

.

.

.

.

,

EDIT

ON/OFF

key switch

POWER

(

UNLOCK

TOUCH

OIN CONTACT

M/G

SENSOR

OP

OK

(

(

(

Orange

Orange

lamp

White

lamp

White

lamp

lamp

This key is used to select edit mode active or not

•E Select ON positio, then edit mode is active

•E Select OFF positio, then edit mode is not active

This lamp goes on when turning ON the handle of the

no-fuse breaker on the control cabinet

)

This lamp is used to release the lock of the operator door

)

This lamp goes on when detecting the contact between the

spindle (tool) and the table (fixture, workpiece

)

This lamp goes on when the MANUAL at magazine

operation panel

)

was selected.

.

.

.

.

).

.

2-9

Page 29

2. MACHINE OUTLINE

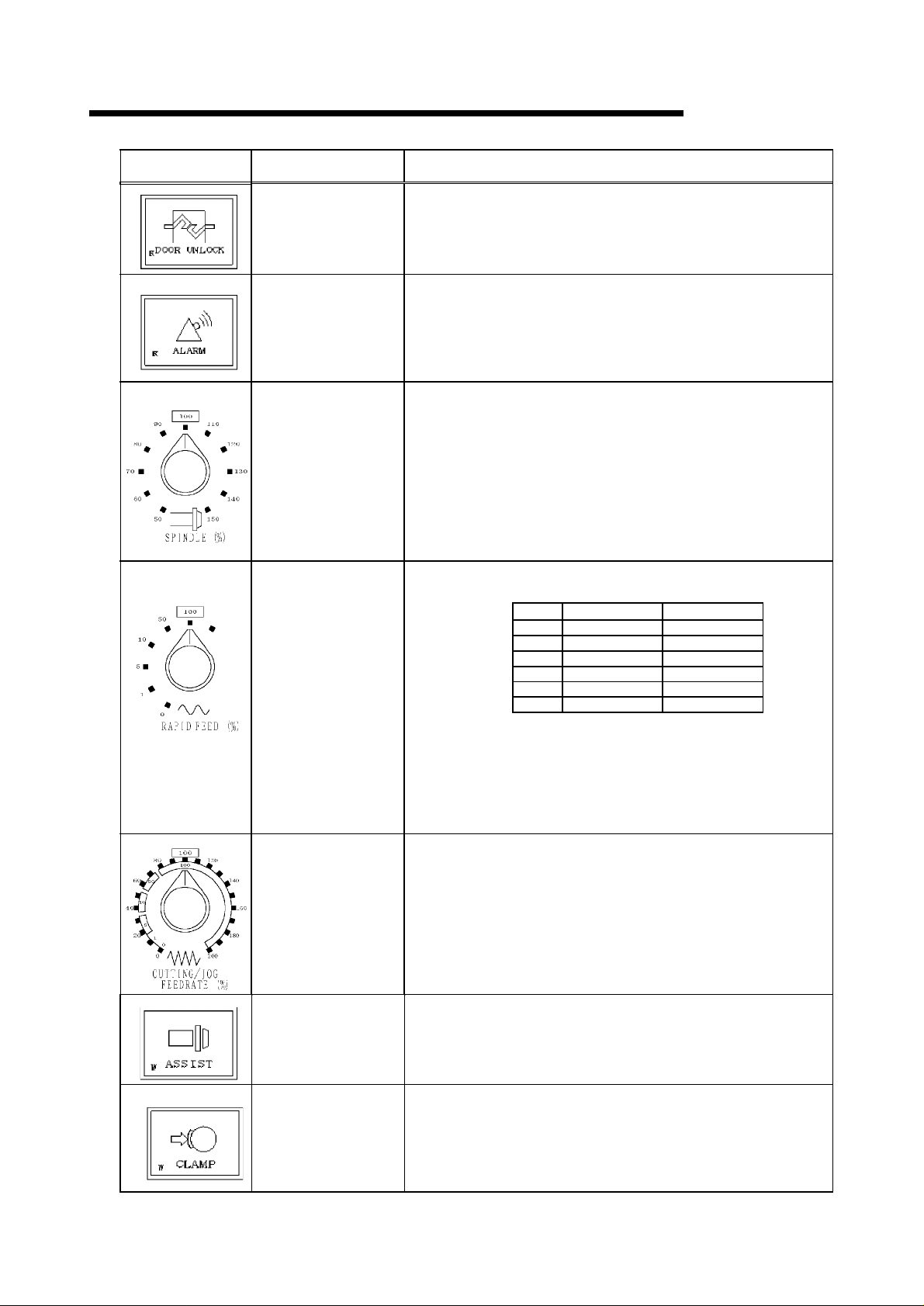

Name Function & Description

FH

550SX/

630

SX

DOOR UNLOCK

ALARM

SPINDLE

OVERRIDE

RAPID FEED

OVERRIDE

CHANGE

lamp

(Red)

lamp

(Red)

selection switch

(Gray)

selection switch

(Gray)

This lamp goes on when releasing the electromagnetic type

interlock at operator?s door, magazine door and APC door

This lamp goes on when any abnormal is occurred.

This lamp blinks at alarm.

This lamp turns off when releasing the alarm or warning

condition.

•E Thi s swit ch can change t he speed fro m 50 t o 150 % of t he

programmed rotation speed (S command). But in tapping

cycle (G84), the spindle speed is fixed in 100%.

•E When t he spi ndl e speed i s max. t he speed i s fi xed t o max.

even if up the speed by the override switch.

•E When t he spi ndl e speed i s mi n. t he speed i s fi xed t o mi n.

even if down the speed by the override switch.

This selection switch changes the feed switch for G00 and

G28, namely rapid feed and Zero-return speed.

% FH550S

0% 0 mm/min 0 mm/min

1% 600 mm/min 600 mm/min

5% 3000 mm/min 3000 mm/min

10% 6000 mm/min 6000 mm/min

50% 30000 mm/min 30000 mm/min

100% 60000 mm/min 60000 mm/min

X

FH630SX

.

CUTTING/JOG

FEEDRATE

override selection

ASSIST

button, lamp

(White)

CLAMP

button, lamp

(White)

switch

(Gray)

* CHANGE

In case of turn to CHANGE position

It operates according to the % of CUTTING/JOG

FEEDRATE.

An inner side follows "RAPID FEED", an outside follows

"CUTTING FEED OVERRIDE", and it operates.

It is a switch for modifying 0 to 200% of a rate to the rate of

CUTTING FEED maximum speed (30000mm/min) and JOG

FEED maximum speed (10000mm/min). However, the midst

of a tap cycle is fixed to 100%.

Moreover, X1 changes by JOG select button, and a cutting

feed speed changes by X0.1.

In X1, it is clamped by the cutting feed maximum speed is

110% or more.

This button is used for effective the spindle tool "CLAMP" and

"UNCLAMP" buttons.

•E " CLA MP" and " UNCLAMP" butt on i s pr essed, pr essi ng t hi s

button.

This button is used for attaching a tool to the spindle.

•E It beco mes eff ecti ve, when t he l a mp of " HANDLE", "J OG",

"RAPID" or, and "REF" is on and "ASSIST" button is

pressed.

•E If t he butt on i s pr essed, t he spi ndl e will be cl a mped and air

will be stopped.

2-10

Page 30

2. MACHINE OUTLINE

FH

550SX/

630

SX

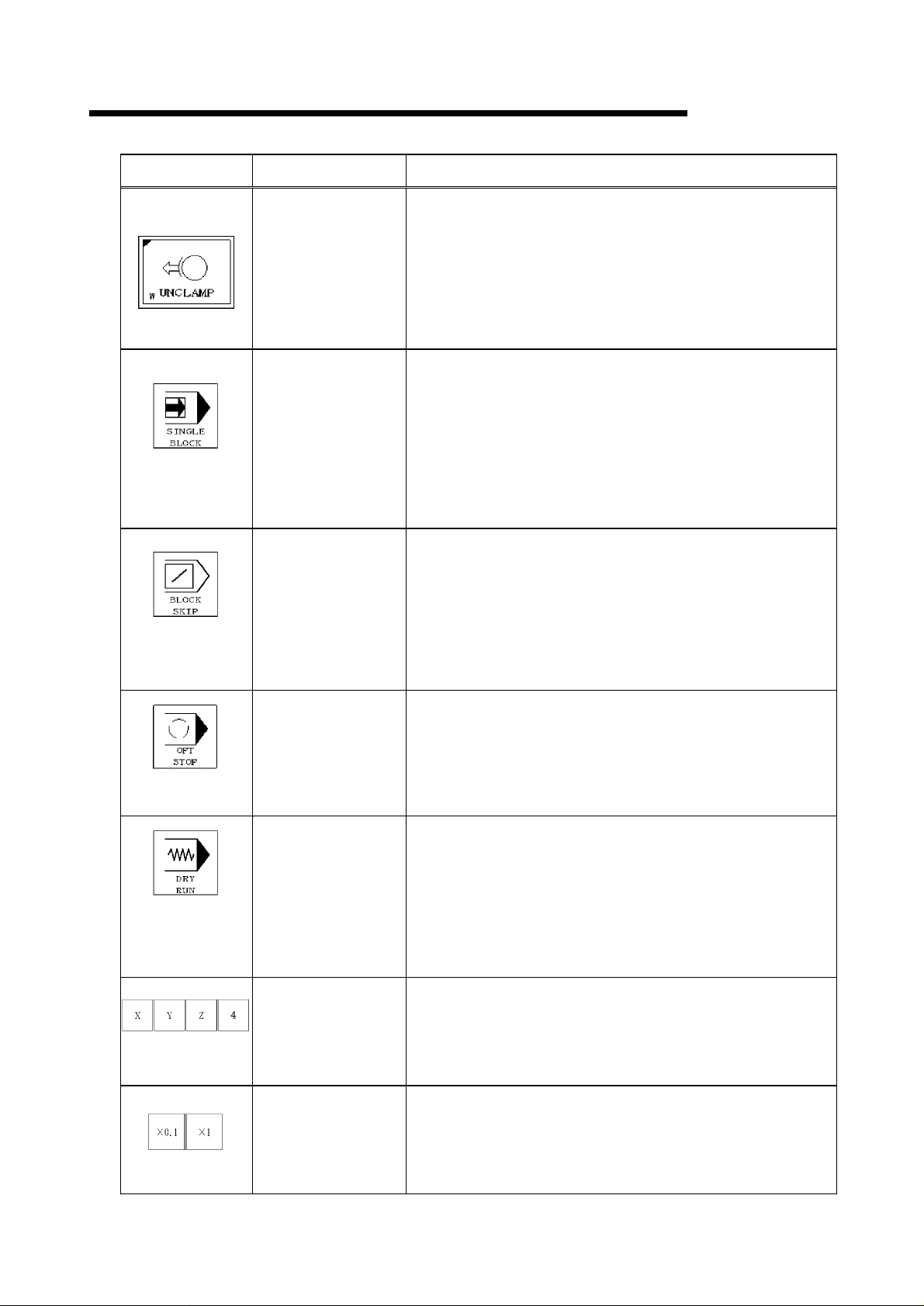

Name

UNCLAMP

button, lamp

(White)

SINGLE

BLOCK

OPT

DRY RUN

X, Y, Z, 4-axis (axis

select)

BLOCK

button, lamp

(Green)

SKIP

button, lamp

(Green)

STOP

button, lamp

(Green)

button, lamp

(Green)

button, lamp

(Green)

Fun

ctio

n &Descr

This button is used for removing a tool from the spindle.

•E

It becomes effective, when the lamp of "HANDLE", "JOG",

"RAPID" or, and "REF" is on and "ASSIST" button is

pushed.

ø

If the button is pressed, the spindle will be unclamped and

air will be come out.

ø

When demounting a tool from a spindle, before pressing

the button, the tool is clamped certainly. When a

clamping is inadequate, the tool falls.

This button SINGLE BLOCK makes a block stop at

MEMORY, TAPE and/or MDI operations.

•E When the SINGLE BLOCK lamp turns on, and the butto

[CYCLE START] is pressed, the specified block is

executed and the cycle stops.

•E When the SINGLE BLOCK lamp turns off, and the butto

[CYCLE START] is pressed, the rest of the program is

executed accordingly.

•E When the SINGLE BLOCK button is pressed, the lam

turns on or off.

This BLOCK SKIP button is used to disregard the block,

when command line starts with / (slash), is MEMORY, TAPE

and/or MDI operation.

ø

When the BLOCK SKIP lamp turns on, the block with /

(slash) is neglected.

ø

When the BLOCK SKIP lamp turns off, the block with /

(slash) is executed.

ø

When the BLOCK SKIP button is pressed, this lamp turns

on or off.

This button is used to stop at the block of ?M01 signal in the

MEMORY, TAPE or MDI operation.

ø

When the lamp is lit, the operation stops at the block of

?M01 signal

ø

When the lamp is not lit, the operation stops at the block of

?M01 signal

ø

When pressing the button, this lamp is lit or not lit.

This DRY RUN button is used to move a feed unit with JOG

speed instead of cutting speed in MEMORY, TAPE and/or

MDI operation.

ø

When the DRY RUN lamp turns on, the feed unit moves

with JOG speed instead of cutting speed.

ø

When the DRY RUN lamp turns off, the feed unit moves

with cutting speed.

ø

When the DRY RUN button is pressed, the lamp turns on

or off.

This button is used to choosing JOG, RAPID FEED, ZERO

RETURN, and MOVE AXIS.

ø

The axis which the lamp has turned on is effective.

.

.

iption

X0.1,

X1

button, lamp

(White)

This button is used to changes the magnification of the

maximum speed (10000mm/min) of JOG feed.

ø

When JOG OVERRIDE is 100%

X0.1 •E•E•E•E•E 1000m

X1 •E•E•E•E•E 10000m

2-11

Page 31

2. MACHINE OUTLINE

Na

me Functio

AXI

S DIRECTION

button, lamp

FEED

ASSIST

button, lamp

(Green)

(Green)

FH

550SX/

n &Description

These buttons can indicate the direction of movement in

JOG, RAPID FEED, ZERO RETURN, MOVE DIRECTION.

•E When this button is pressed, axial feed is executed

It is a button for confirming the button of "+" and "-" at the

time of an axial move of JOG, RAPID FEED and ZERO

RETURN.

The button of "+" and "-" is pushed, pushing this button.

630

SX

MEMORY

DND

MDI

EDIT

HANDLE

JOG

button, lamp

(Green)

button, lamp

(Green)

button, lamp

(Green)

button, lamp

(Green)

button, lamp

(Green)

button, lamp

(Green)

This button is used to run the machine with the program, that

has been registed in memory storage of NC device.

•E After pushing this button, the lamp turns on, or off

This button is use to run from an external instrument.

•E After pushing this button, the lamp turns on, or off

This button is used to run the machine with the program, that

may be simple program through MDI.

•E After pushing this button, the lamp turns on, or off

This button is used to edit program operating with memory

(registered program in the NC unit).

•E After pushing this button, the lamp turns on, or off

This button is used to make axial traverse with handle

(manual pulse generator).

•E After pushing this button, the lamp turns on, or off

This button is used to make axial traverse with jog (speed

can be preset separately).

•E After pushing this button, the lamp turns on, or off

RAPID

button, lamp

(Green)

This button is used to make axial traverse in rapid feed

speed.

•E After pushing this button, the lamp turns on, or off

2-12

Page 32

2. MACHINE OUTLINE

FH

550SX/

630

SX

Name

REF

button, lamp

MODE ASIST

button, lamp

AUTO

button, lamp

WINDOW

button, lamp

(Green)

(Green)

(Green)

(Green)

Functio

This button is used to make each axis go back to its origin.

•E After pushing this button, the lamp turns on, or off

This is a button for changing the mode of MEMORY, DNC,

MDI, EDIT, HANDLE, JOG, RAPID FEED and ZERO

RETURN.

•E The button to choose is pushed, pushing this button

This button makes a continuous cycle to prepare, to

finishloading, to transport a pallet into the M/C, to machine

workpieces, and to transport a pallet.

•E When this button is pressed, the lamp turns on or turns off

When this button is flashing and the button of [CYCLE

START] is pressed.

This button is used to display the panel displaying WINDOW.

(Each lamp, function switch)

n &Descr

iption

ALARM

COOLANT

COOLANT ON

COOLANT

RESET

AUTO

button, lamp

OFF

button, lamp

button

(Green)

button

(Green)

(Green)

(Green)

This button is used to reset mechanical alarms without NC

alarm.

•E When this button is pressed, the alarm is released

This button is used to dispense (discharge) coolant (cutting

lubricant) from the coolant nozzle and chip throuwer when

M08/M12/M14 are commanded during memory operation,

tape operation and MDI operation.

•E When this button is depressed, coolant is discharged

•E When this button is depressed, the lamp lights up

This button is used to discharge coolant from the coolant

nozzle and

•E When this button is depressed, coolant is discharged

•E When this button is depressed, the lamp lights up

This button is used to stop coolant.

•E When this button is depressed, coolant stops

•E When this button is depressed, the lamp lights up

the chip flowing nozzle.

2-13

Page 33

2. MACHINE OUTLINE

Name Function & Description

FH

550SX/

630

SX

PALLET FORCE

UNLOADING

button, lamp

(Green)

(option)

MIST COLLECTOR

button, lamp

(Green)

AIR BLOW

button, lamp

(Green)

AUTO POWER OFF

button, lamp

(Green)

CHIP CONVEYER

button, lamp

(Green)

LIGHT

button, lamp

(Green)

This switch is used to unload forcebly the pallet.

This button is used to start the mist collector.

•E When t hi s butt on i s pr essed, t he l a mp will li ght up and t he

mist collector will start. (In the case of "coolant ON" while

memory and DNC are working, it becomes valid.)

•E When t he butt on i s pr essed agai n, a l a mp will t ur n off and

stop.

This button is used to make the air blow breathe out.

•E When t hi s butt on i s pr essed, t he l a mp will li ght up and t he

air blow will be breathed out.

•E When t he butt on i s pr essed agai n, a l a mp will t ur n off and

the air blow will stop.

This switch is used to intercept the main power source about

10 seconds after completing a machining. (It becomes valid

in the working of memory and DNC or at the working of

memory and DNC after pressing the button.)

•E M30 or M02 ar e read duri ng a dri vi ng, and when t he l a mp

of the {NEXT CYCLE START} button of pallet changer

operation panel is not on, the main power source

intercepts about 10 seconds after.

ø When thef

will

stop

This button is used to start the chip conveyer.

•E When t hi s butt on i s pr essed, t he l a mp will li ght up and t he

chip conveyer will rotate.

•E When t he butt on i s pr essed agai n, a l a mp will t ur n off and

stop.

This switch is used to be executed lighting ON/OFF.

aultoccursdu

ring the drivi

ng,PUMP

ON

SPDL ASSIST

button, lamp

SPDL CW

button, lamp

(Green)

(Green)

This button is used to be confirming a start up of the spindle.

The [CYCLE START] button is pushed, pushing this button.

This button is used for normal rotation of spindle.

•E When t he l a mp <HANDLE>, <J OG>, <RAPI D> or <REF>

in the operation mode is lighting, this button becomes

effective. In addition, this button is pressed, pressing

[ASSIST] button.

•E When t hi s butt on i s depr essed, t he spi ndl e r ot at es

normally.

•E When t hi s butt on i s depr essed, t he l a mp li ght s up.

2-14

Page 34

2. MACHINE OUTLINE

FH

550SX/

630

SX

CYCLE

FEED

DOO

DOOR

Name

START

button, lamp

HOLD

button, lamp

R LOCK

UNLOCK

(Green)

(Yellow)

button

button

Functio

This button makes the start of MEMORY, TAPE and MDI

operation, and ZERO Return. And also restart of the cycle

after Feed Hold, M00, M01, Single block.

•E

When this button is pressed, the lamp turns on.

•E

When this lamp turns on, the cycle starts.

This button makes the unit feeding to stop in MEMORY,

TAPE, MDI operation and Zero Return.

•E

When the button is pressed, the lamp turns on.

•E

When this lamp turns on, the unit feeding is decelerated.

After M-S-T function are executed, the cycle stops as a

single block.

This button makes locking the electromagnetic lock type door

lock of the operator door.

•E

The operator door electromagnetic lock type door switch is

locked, and it becomes impossible to open a door, if a

button is pushed after shutting an operator door.

This button makes canceling the electromagnetic lock type

door lock of the operator door.

•E

When the lamp of {UNLOCK OK} is on, if a button is

pushed, an electromagnetic lock type door lock is

canceled and a door can be opened.

n &Descr

iption

OPERATION

1-2

key switch

OPERATION

1, 2-3

key switch

POWER

MODE

MODE

lamp

(White)

This switch makes changes the operation mode to 1 or 2.

(

2.4.4

?Explanation of operation mode?

This switch makes changes the operation mode to 3.

(

2.4.4

?Explanation of operation mode?

This lamp goes on when turning ON the handle of the

no-fuse breaker on the control cabinet.

)

)

2-15

Page 35

2. MACHINE OUTLINE

2.3.3 Handle Feed Operation Panel

FH

550SX/

630

SX

Name

Axis

Select

Selector switc

Feed

Multiply

Selector switch

Handle

(

Manual Pulse

Generator

Handle

)

Valid

button

(

Black

Function &Descri

This switch is used to select desired axis be moved

h

This switch is used to select the minimum increment ratio per

one division at the handle

•E

The minimum increment is designed as below

ø1 •E•E•E to ma0.001

ø

10

•E•E•E to ma0.01

ø

100

•E•E•E to ma0.1

ø For rotational axis, 0.

accordingly

(

Only NC table

This handle is used to make axial traverse

ø

Clockwise brings table to + direction, counterclockwise

brings table to ? direction, for the axis selected by [Axis

Select] at the feed speed preset by [Feed Multiply

•E This handle has

This button is used for opening a door and performing an

axial move by the handle

)

The axial move only of the time of feed multiply P1 and N

is carried out

•E When the deadman switch is pushe

•E When pushing a switc, it pushes on two phases. If it turns

on by the 1st time and it pushes still strongly, it will be

turned off and will not operate

.

)

100

.

.

mm movement per 1 div

mm movement per 1 div

mm movement per 1 div

001, 0.01 and 0.1

divisions around it

.

ption

.

:

.

.

.

is applied

.

].

.

.

10

2-

16

Page 36

2. MACHINE OUTLINE

2.3.4 Magazine Operation Panel

FH

550SX/

630

SX

2-

17

Page 37

2. MACHINE OUTLINE

Na

me F

MAGAZI

NE A

UTO

button

(Black)

FH

550SX/

unction& Description

This button is usedtochange to the Automatic mode.

øInordertorun in automa

øThetoolma

au

to.

gazinemay

tic

mode, press the button.

move any time, w

hen

630

sel

ectthe

SX

MAGAZI

MANUAL

MAGAZI

UNLO

CK

MAGAZI

LO

CK

CW

CCW

INCHING

NE

button

(Red)

NE D

OOR

button, lamp

(White)

NE D

OOR

button, lamp

(White)

button, lamp

(White)

button, lamp

(White)

button, lamp

(White)

Thisbuttonis used to change to th

øIn order to run in manualmode, press t

øThem

followingstate :

In automatic mode øøø TC & Toolmagazine are i

waiting

This buttonis usedto resettheinterlock of the magazi

door.

øIncase the lamp of <MAGAZINE UNLOCK OK> turn on,

lock can be reset.

øWhenpressingthis button, lock is resetandthelamp go

on

øWhenclosingthe d

LOCK] button, the lamp g

øWhenpressing the[MAGAZINE DOOR LOCK] buttonin t

state of impletion of doorclosing, the lamp blink.

Thisbuttonis used to interloc

Un

is not reset

Thisbutton is usedtomake Tool Magazine rotateCW.

øAfterpushing this button, the lamp blinkand Tool Magazine

rotates CW.

øIncase the lamp of [INCHING] turn on, Tool Magazine

rotatesCW

this button, Tool Magazine stops withdeceleration.

øWhen the lamp of [INCHING] turns off, Tool Magazine