GE Fanuc Automation

Computer Numerical Control Products

Series 16 i / 160 i–LA

Connection Manual

GFZ-63193EN/02 August 2000

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2000 GE Fanuc Automation North America, Inc.

All Rights Reserved.

B–63193EN/02

PREFACE

PREFACE

The following three connection manuals are prepared for F ANUC Series

16i–LA and Series 160i–LA:

Manual name

FANUC Series 16i/18i/160i/180i–MODEL A

CONNECTION MANUAL (Hardware)

FANUC Series 16i/18i/21i/160i/180i/210i–MODEL A

CONNECTION MANUAL (Function)

FANUC Series 16i/160i–LA CONNECTION MANUAL B–63193EN *

Specification

number

B–63003EN

B–63003EN–1

The “Hardware” and “Function” connection manuals provide general

connection information relating to the configuration of a processing

system.

FANUC Series 16i/160i–LA CONNECTION MANUAL provides

supplementary information about the laser functions which are not

explained in the above two connection manuals (“Hardware” and

“Function”).

In addition to the above connection manuals, laser oscillator manuals are

available. Refer to these manuals as necessary.

The laser functions are explained as described below.

1. Overview

This section outlines the various functions. For details, refer to the

operator’s manual as necessary.

2. Signal

Explains the names, functions, output conditions, and signal addresses

of the signals required to implement each function.

3. Parameters

Explains the parameters related to each function.

4. Alarms and messages

Lists the alarms and messages related to each function.

5. Reference

Lists the related manuals and items.

An address list and signal list are provided in the appendixes of this

manual. Refer to these appendixes as necessary.

p–1

PREFACE

B–63193EN/02

Applicable product

S Representation of bit

type and bit–axis type

parameters

S Representation of

parameters other than bit

type and bit–axis type

parameters

Related manuals

This manual explains the following product. In the manual, the following

abbreviation may be used.

Product name Abbreviations

FANUC Series 16i–LA 16i–LA

FANUC Series 160i–LA 160i–LA

Data (#0 to #7 indicate bit positions.)

Data No.

0000

Data No. Data

1023

#7

#6 #5

SEQ

#4 #3 #2

INI

#1

ISO#0TVC

The table below lists manuals related to FANUC series 16i–LA. In the

table, this manual is marked with an asterisk (*).

Manual name

FANUC Series 16i/18i/21i/160i/180i/210i–MODEL A

DESCRIPTIONS

Specification

number

B–63002EN

Re-

marks

FANUC Series 16i/18i/21i/20i/160i/180i/210i–

MODEL A CONNECTION MANUAL (Hardware)

FANUC Series 16i/18i/21i/160i/180i/210i–MODEL A

CONNECTION MANUAL (Function)

FANUC Series 16i/18i/160i/180i–MODEL A

P ARAMETER MANUAL

FANUC Series 16i/160i–LA DESCRIPTIONS B–63192EN

FANUC Series 16i/160i–LA CONNECTION MANUAL B–63193EN *

FANUC Series 16i/160i–LA OPERATOR’S MANUAL B–63194EN

FANUC Series 16i/160i–LA

MAINTENANCE MANUAL

FANUC Series 16i/160i–LA PARAMETER MANUAL B–63200EN

FANUC Series 16/18/20/21

PROGRAMMING MANUAL

(Macro compiler/Macro Executer)

FAPT MACRO COMPILER

PROGRAMMING MANUAL

B–63003EN

B–63003EN–1

B–63010EN

B–63195EN

B–61803E–1

B–66102E

p–2

B–63193EN/02

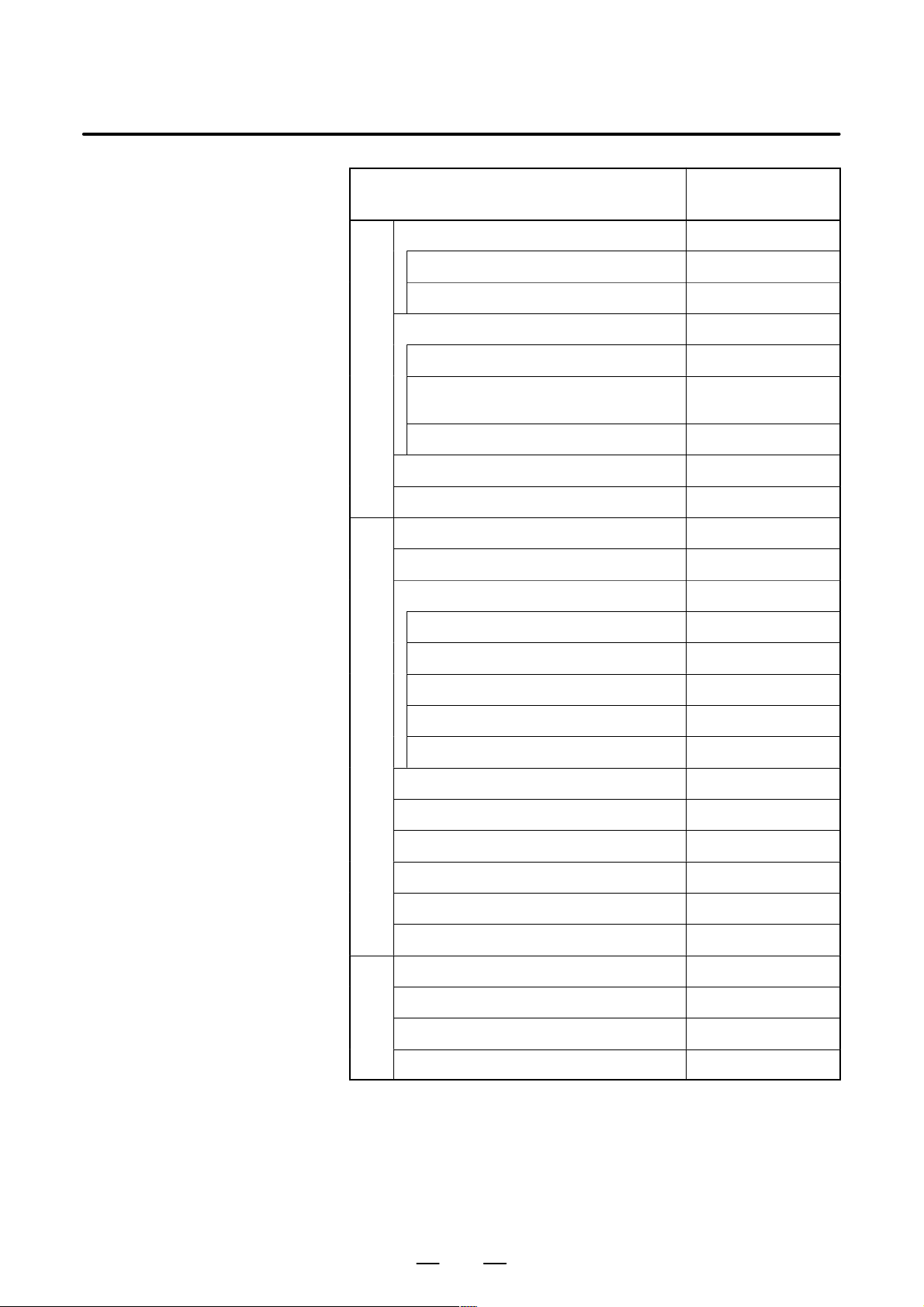

Table of Contents

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. HARDWARE

1. OVERVIEW 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 DIFFERENCES BETWEEN Series 16i–LA AND Series 16i 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 DIFFERENCES BETWEEN Series 16i–LA AND Series 16–LB 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONFIGURATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CONTROL UNIT 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 CONFIGURATION OF THE CONTROL UNIT 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TOTAL CONNECTION DIAGRAM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. POWER SUPPLY 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 CONTROL UNIT POWER SUPPLY 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. I/O LIMITATION BASED ON LASER OSCILLATOR CONNECTION 14. . . . . . . . . . . . . . .

7. LASER OSCILLATOR 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 CONNECTION OF THE LASER OSCILLATOR 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Connection of the Adaptor 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 LASER OSCILLATOR CONNECTION USING AN OPTICAL FIBER CABLE 17. . . . . . . . . . . . . . .

7.3 ASSIST GAS PRESSURE ANALOG OUTPUT 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 CONNECTION OF THE TRACING SENSOR 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. LASER FUNCTION

1. FUNCTIONS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. FUNCTIONS DIFFERING FROM THE M SERIES SPECIFICATIONS 30. . . . . . . . . . . . .

2.1 EMERGENCY STOP 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 FEED HOLD 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 TEST OPERATION 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Machine Lock 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Dry Run 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Single Block 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 PROGRAM RESTART (LASER SPECIFICATIONS) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. LASER SEQUENCE CONTROL 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 SEQUENCE CONTROL OF THE C SERIES AND Y SERIES LASER OSCILLATORS 38. . . . . . . .

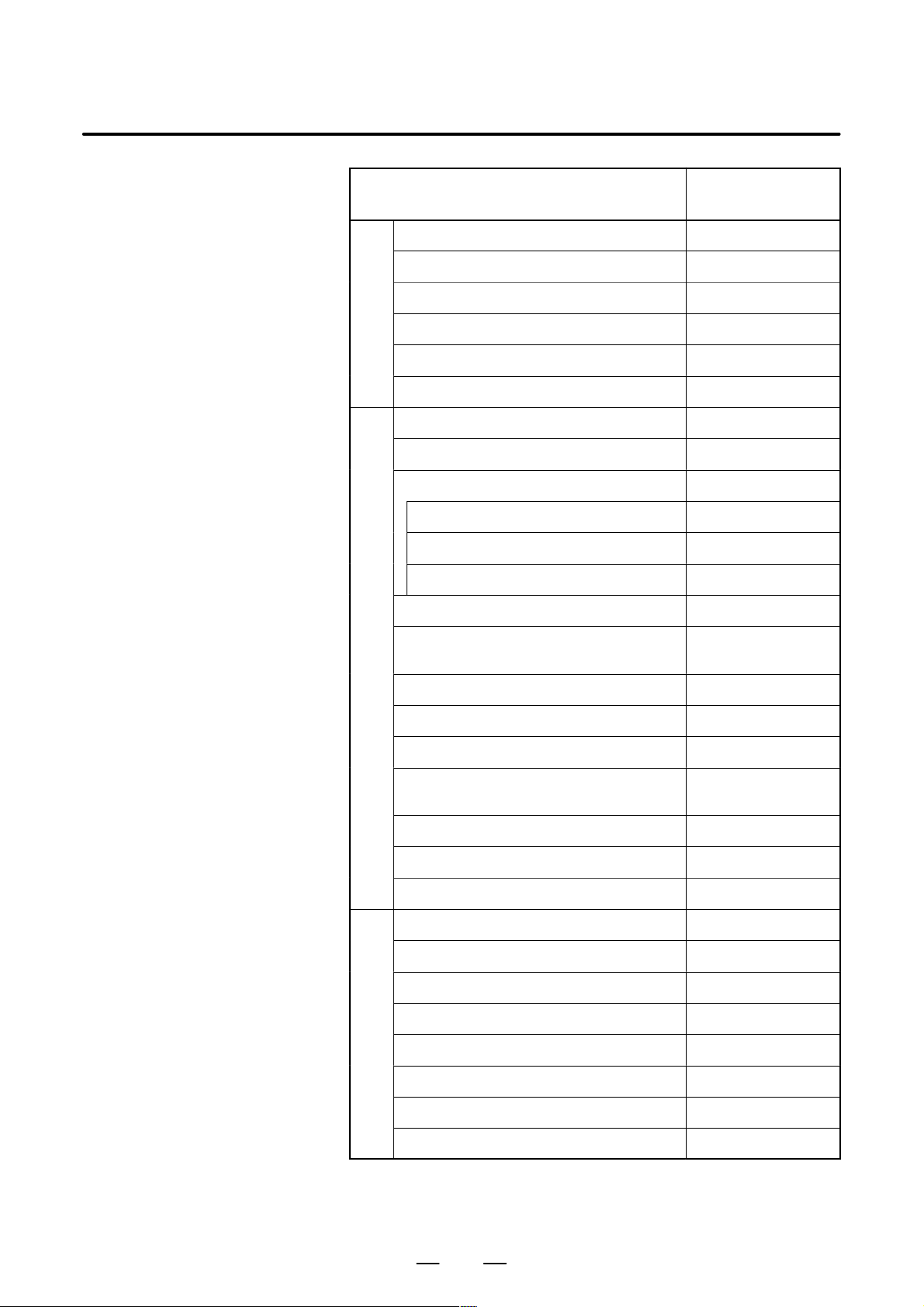

c–1

TABLE OF CONTENTS

B–63193EN/02

4. ASSIST GAS 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 ASSIST GAS CONTROL 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 ASSIST GAS PRESSURE ANALOG OUTPUT 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 ASSIST GAS PRESSURE OVERRIDE 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. LASER OUTPUT CONTROL 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 SHUTTER OPENING/CLOSING CONTROL 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 BEAM ON/OFF CONTROL 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 OUTPUT OVERRIDE 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Power Override Signal 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Frequency Override Signal 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Duty Override 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 CHANGING THE PIERCING TIME 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 GUIDE LIGHT ON SIGNAL 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 STATE OUTPUT SIGNAL 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Piercing Signal 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Laser Processing Signal 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Output Drop Alarm Signal 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.4 Laser Alarm Signal 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.5 Laser Oscillator Not Connected Signal 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TRACING CONTROL 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 TRACING CONTROL 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Tracing Function 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Tracing Control Adjustment 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Standard Shift 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4 Approach 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.5 Tracing Alarm 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.6 Tracing Gain Override 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 TRACING INTERLOCK SIGNAL 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 TRACING AXIS MACHINE LOCK 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. THREE–DIMENSIONAL MACHINING SYSTEM 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 POSITION CONTROL 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Position Control A (Zero–offset Head) 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Position Control B (Offset Nozzle) 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 TEACHING BOX INTERFACE 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 W–AXIS TRACING 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 TRACING FEED 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 APPROACH FEED 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 NEAR–POINT SEARCH FUNCTION 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 HAND COORDINATE SYSTEM MODE SELECT SIGNAL 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. CONTROL FUNCTION 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 CONSTANT–OPTICAL PATH CONTROL 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–63193EN/02

8.2 MACHINING CONDITION SETTING FUNCTION 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 PIERCING FUNCTION 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 EDGE MACHINING FUNCTION 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 START–UP FUNCTION 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 MACHINING RESTART FUNCTION 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 LASER POWER CONTROL 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 LASER GAS MIXTURE FUNCTION 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 REFLECTION BEAM MONITOR FUNCTION 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10 PULSE ENHANCED FUNCTION 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11 AI CONTOUR CONTROL 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

APPENDIX

A. INTERFACE BETWEEN CNC AND PMC 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LIST OF ADDRESSES 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 LIST OF SIGNALS 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1 List of Signals (In Order of Functions) 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 List of Signals (In Order of Symbols) 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.3 List of Signals (In Order of Addresses) 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

I. HARDWARE

B–63193EN/02

1

1. OVERVIEWHARDWARE

OVERVIEW

3

1. OVERVIEW

HARDWARE

B–63193EN/02

1.1

DIFFERENCES BETWEEN Series 16i–LA AND Series 16i

1.2

DIFFERENCES BETWEEN Series 16i–LA AND Series 16–LB

Configure the Series 16i–LA system by making connections as described

in the “Series 16i Connection Manual.”

For an explanation of the differences between the Series 16i–LA and

Series 16i, refer to this manual as necessary.

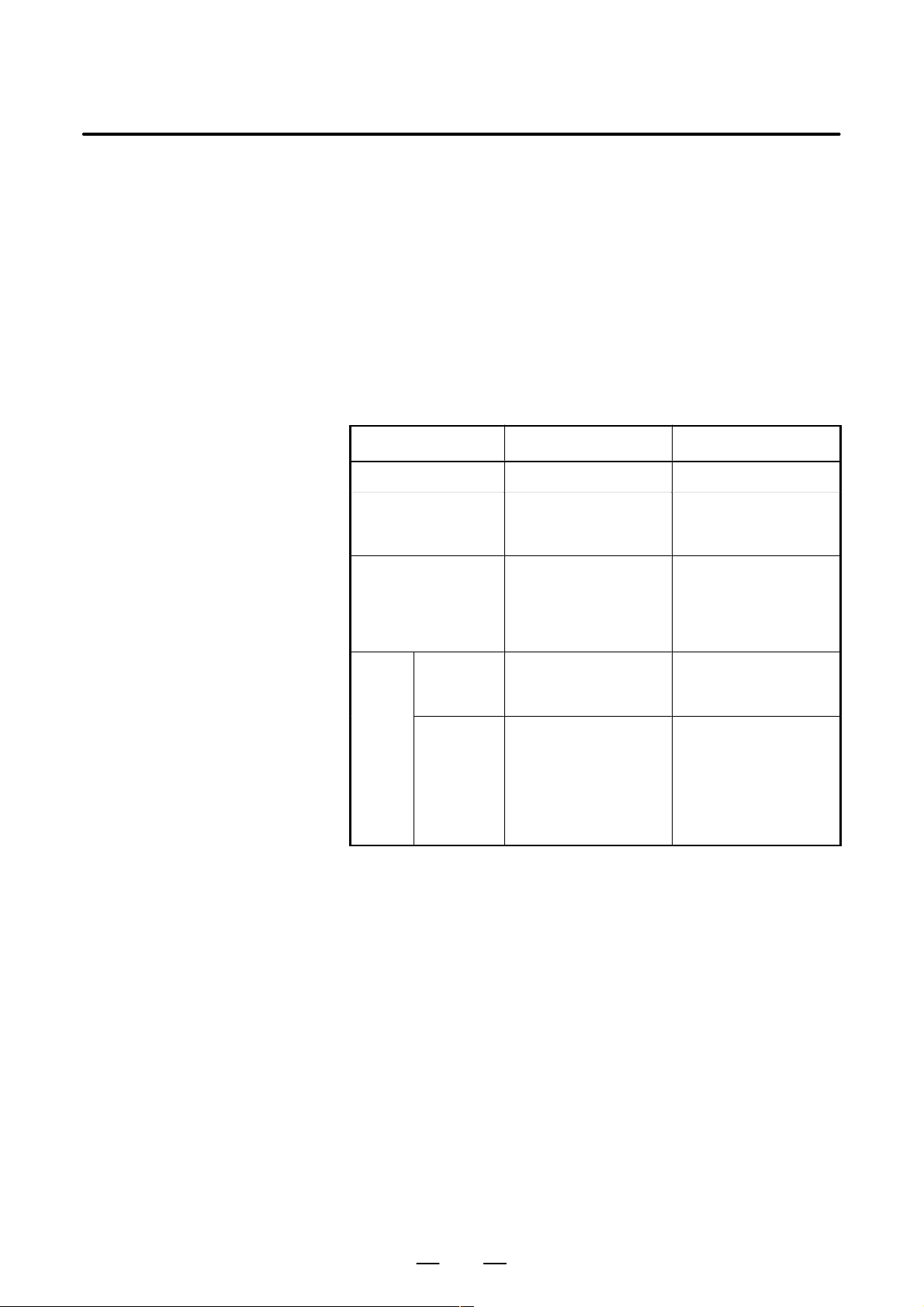

The following table lists the differences between the Series 16i–LA

(FS16i–LA) and Series 16–LB (FS16–LB):

Feature FS16i–LA FS16–LB

Power to control unit 24 VDC 200 VAC

Control unit on/off

switch

Laser oscillator on/off

signal

External control

(Power supply for control

unit is controlled.)

24 VDC (Power supply for

control unit is connected.)

Internal control

(Control unit is provided

with on/off circuit.)

200 VAC (EXR and EXS

signals of input unit, or

200A and 200B signals of

power supply unit are

used.)

I/O LINK

Connectable

DI/DO

Laser

oscillator

connection

Up to 13 groups

768 DI and 768 DO points

The laser oscillator is

connected in series to an

I/O link via the last I/O unit.

The I/O link is connected

to the I/O link connector of

the mother board.

Up to 16 groups

1024 DI and 1024 DO

points

The laser oscillator is

connected to the I/O link

connector of the main

board. The DI/DO points

are connected to the I/O

link connector for the

PMC–RC.

4

B–63193EN/02

2

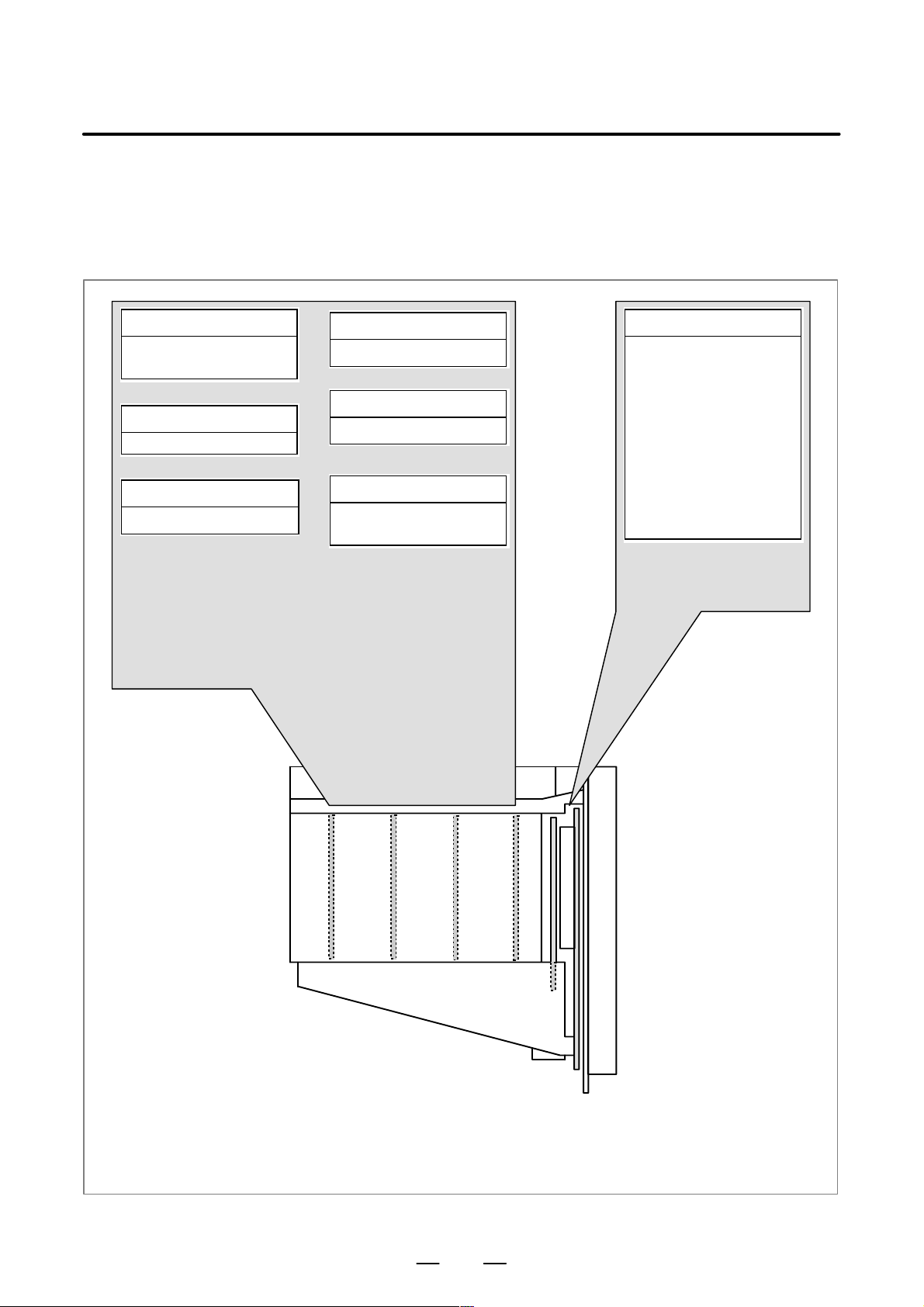

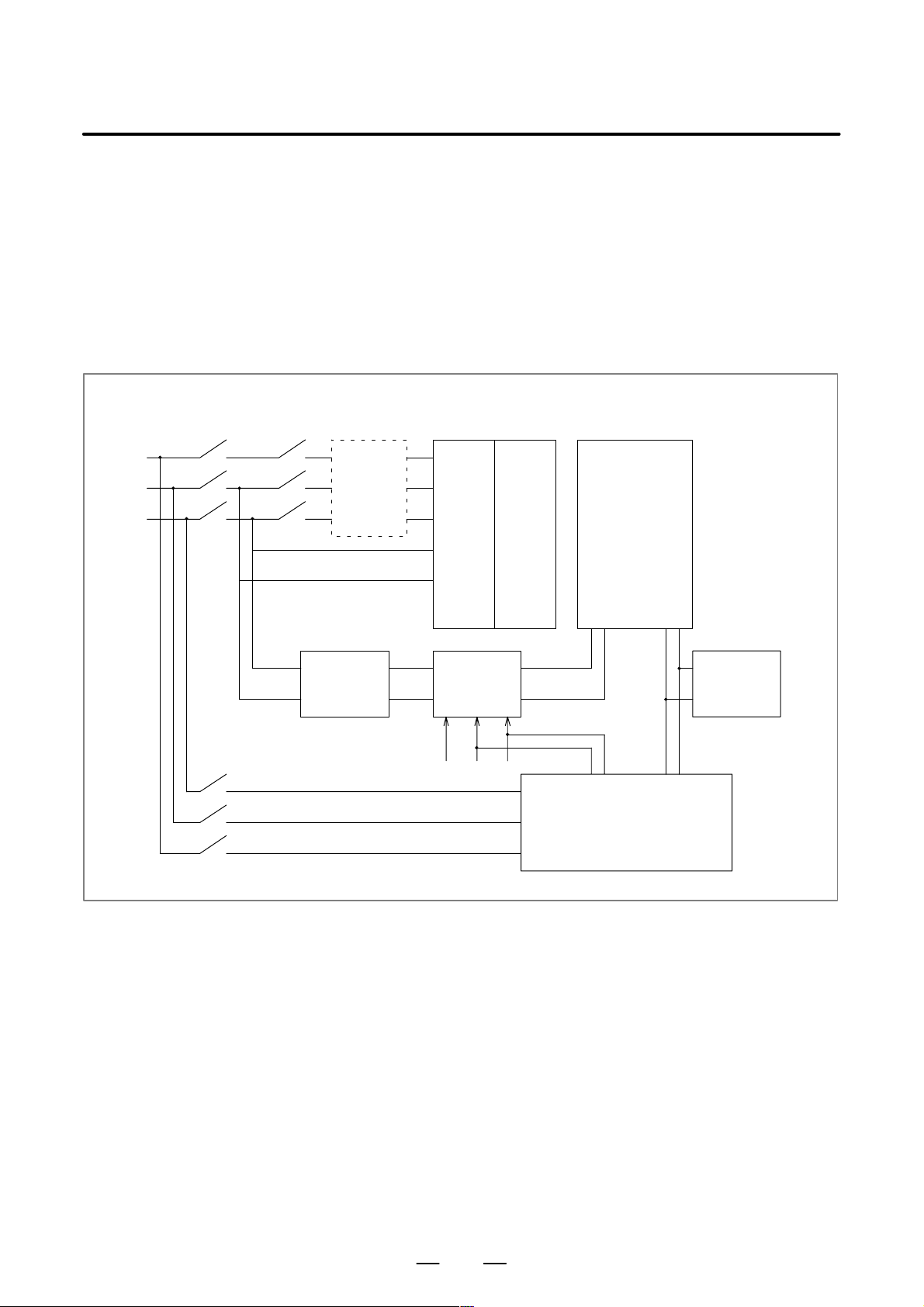

2. CONFIGURATIONHARDWARE

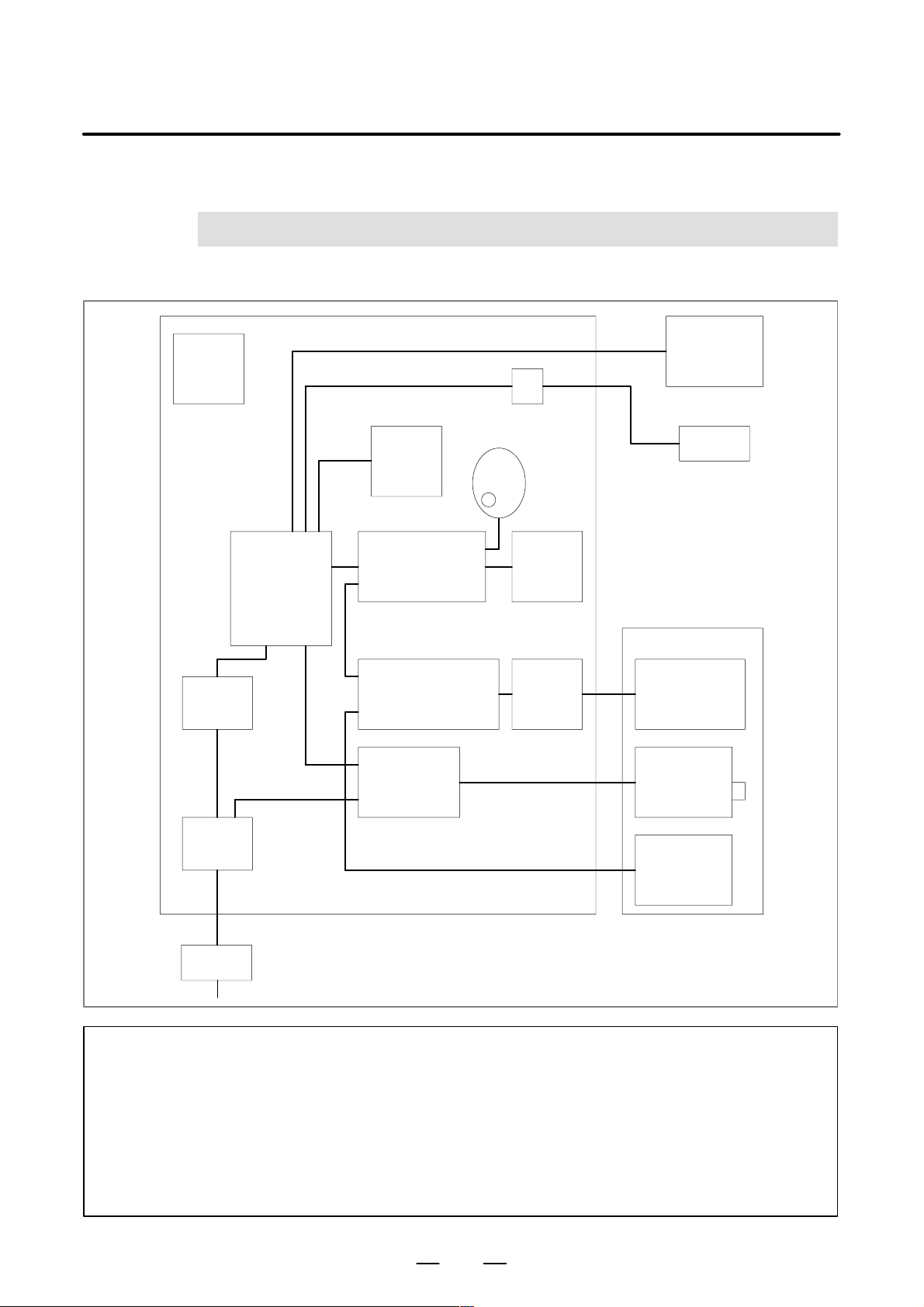

CONFIGURATION

Heat

exchanger

(3.7)

24 VDC

power

supply

Control unit

(3.9)

(7.3 to 7.6)

Relay connector (7.2)

Manual pulse generator

MDI unit

(7.1)

Operator’s panel

I/O module etc.

(6.4, 6.5, 6.7)

Connector panel I/O

module, I/O unit, etc.(*1)

(6.3, 6.6)

Servo amplifier

(7.9)

(6.3.6)

Machine

operator’s

panel

Power

magnetic

circuit

(*2)

Host computer

I/O device

Sensor/actuator

Servo motor

Multi–tap

transformer

Laser oscillator

Power supply

Distribution

board

NOTE

1 For information about the I/O unit, refer to the “FANUC I/O Unit Model A

Connection/Maintenance Manual (B–61813E)” and “FANUC I/O Unit Model B Connection

Manual (B–62163E).”

2 For an explanation of the connection between the amplifier and motor, refer to the following

manuals:

D FANUC AC Servo Motor α series Descriptions (B–65142E)

D FANUC Servo Amplifier α series Descriptions (B–65162E)

5

3. CONTROL UNIT

CONTROL UNIT

3

HARDWARE

B–63193EN/02

6

B–63193EN/02

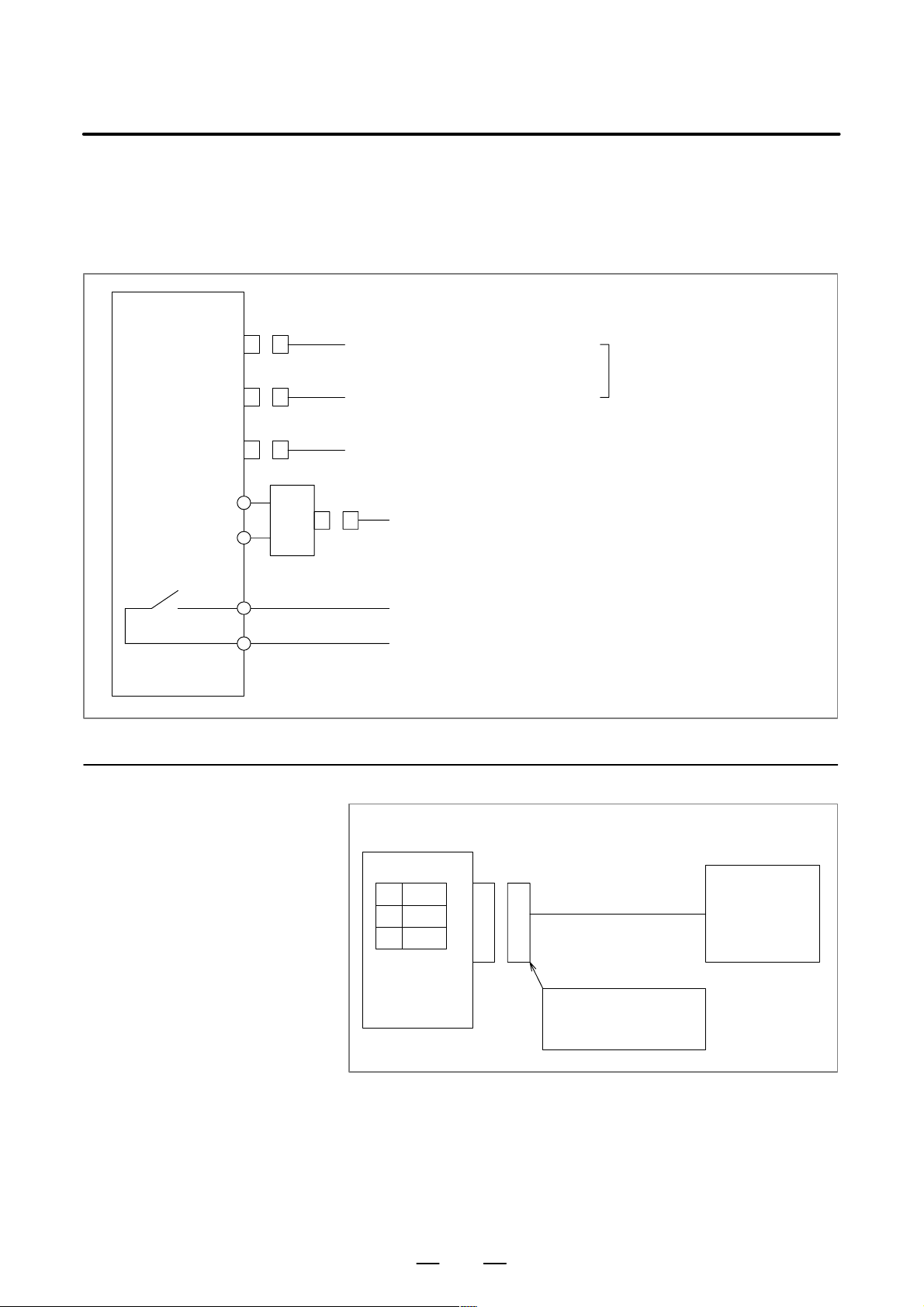

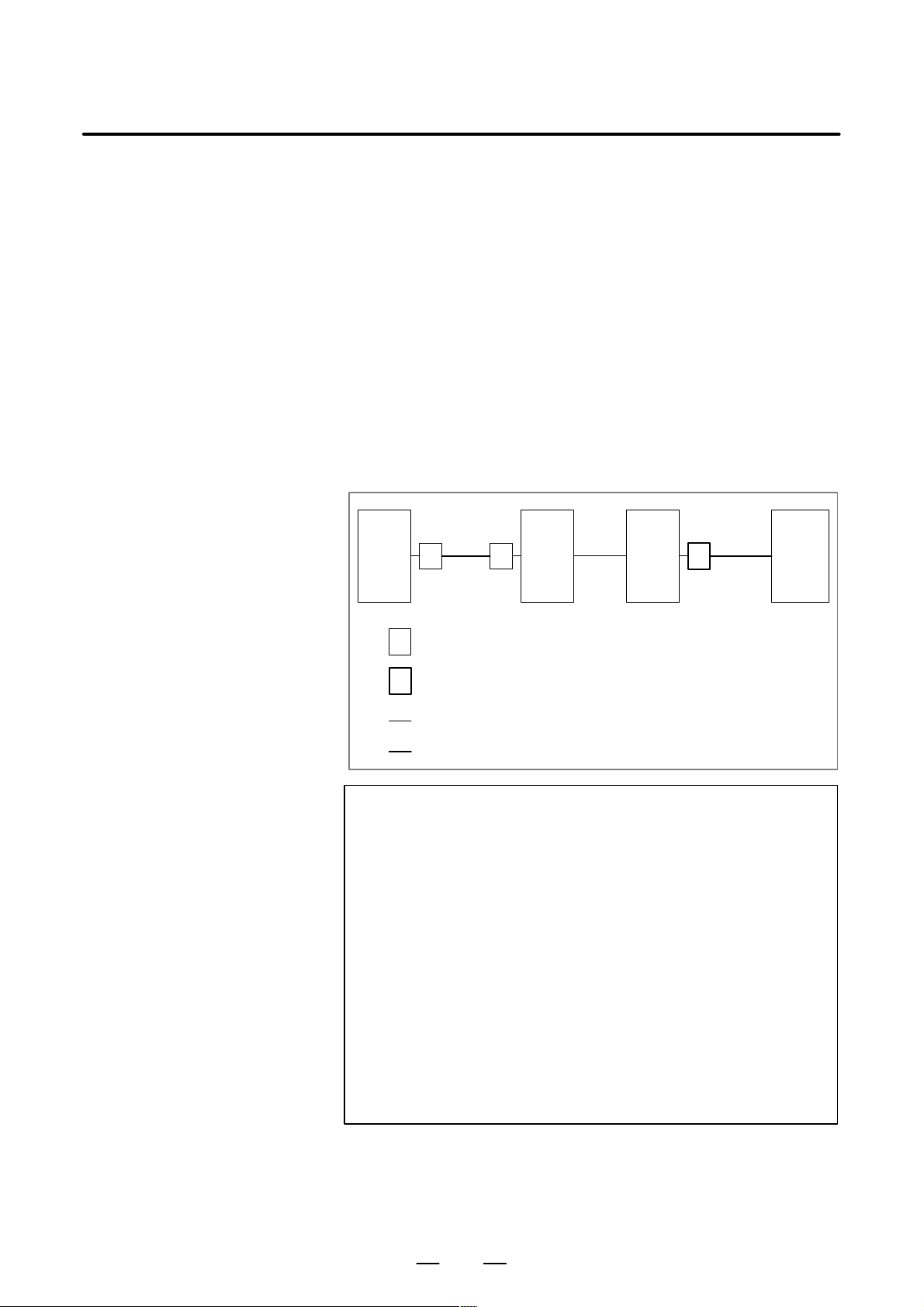

3.1

CONFIGURATION OF THE CONTROL UNIT

3. CONTROL UNITHARDWARE

Serial communication board

Remote buffer/

DNC1/DNC2/HDLC

C board

C functions for PMC

Analog input board

Tracing function

Data server board

Data server function

RISC board

High–precision contour control

function

HSSB interface board

High–speed serial bus

interface (for Series 160i only)

Options

Mother board

CPU for controlling CNC

· Power supply

· 2–axis to 8–axis control

· Spindle interface

· LCD/MDI

· I/O link

· PMC–SB6

· Analog output/high–

speed DI

· RS–232C × 2

· Memory card interface

· PC functions

(for Series 160i

with PC functions)

Basic system

The following types of units are

available:

D Unit without option slots

D Unit having two option slots

D Unit having four option slots

On a unit with option slots, as many option boards as the number of option slots can be mounted. (On a unit

having four option slots, only a data server board or HSSB interface board can fit into the slot furthest from the

LCD. On a unit having three option slots, only one of the above mentioned boards can fit into the center slot.)

7

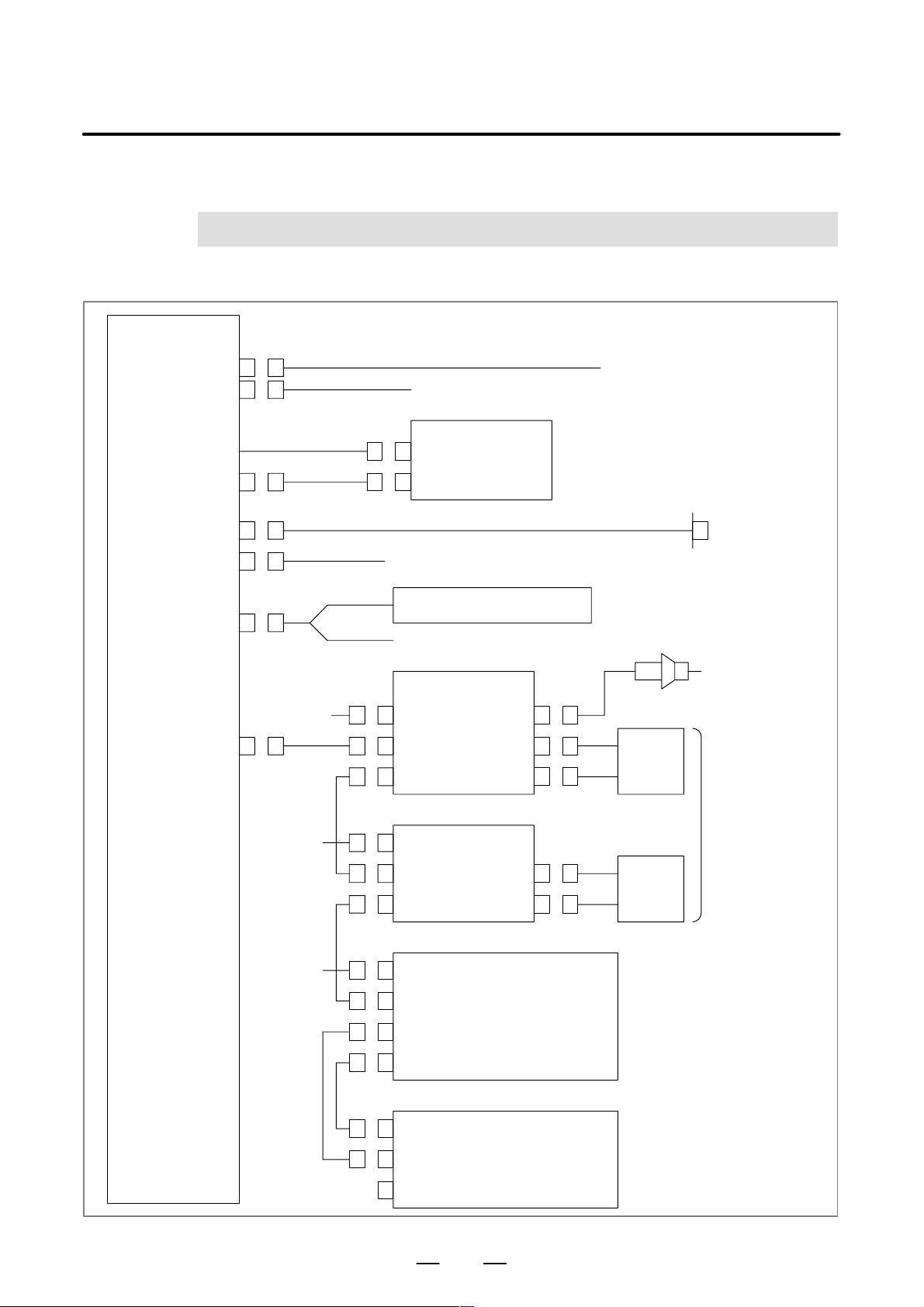

4. TOTAL CONNECTION DIAGRAM

TOTAL CONNECTION DIAGRAM

4

Mother board (1/2)

(with LCD)

24V–IN (CP1A)

24V–OUT (CP1B)

HARDWARE

To I/O device etc.

B–63193EN/02

24 VDC power

MDI (CA55)

R232–1 (JD36A)

R232–2 (JD36B)

A–OUT&HDI (JA40)

I/O LINK (JD1A)

Soft key cable

24 VDC

24 VDC

MDI UNIT

CK2

CK1

RS–232C

I/O device

Touch panel or RS–232C I/O device

(When the unit has PC functions, the touch panel is connected to JD33.)

Assist gas pressure analog output

High–speed skip input

Distributed

CP1A

JD1B

JD1A

CP1A

JD1B

JD1A

I/O board

JA3

Distributed

I/O board,

I/O unit, etc.

Manual pulse generator

Operator’s

panel

Up to 13 distributed

I/O units can be

connected.

Power

magnetics

cabinet

24 VDC

CP1A

JD1B

JD1A

(200 VAC)

(200 VAC)

JD1B

JD1A

Laser oscillator

Laser gas mixer

8

B–63193EN/02

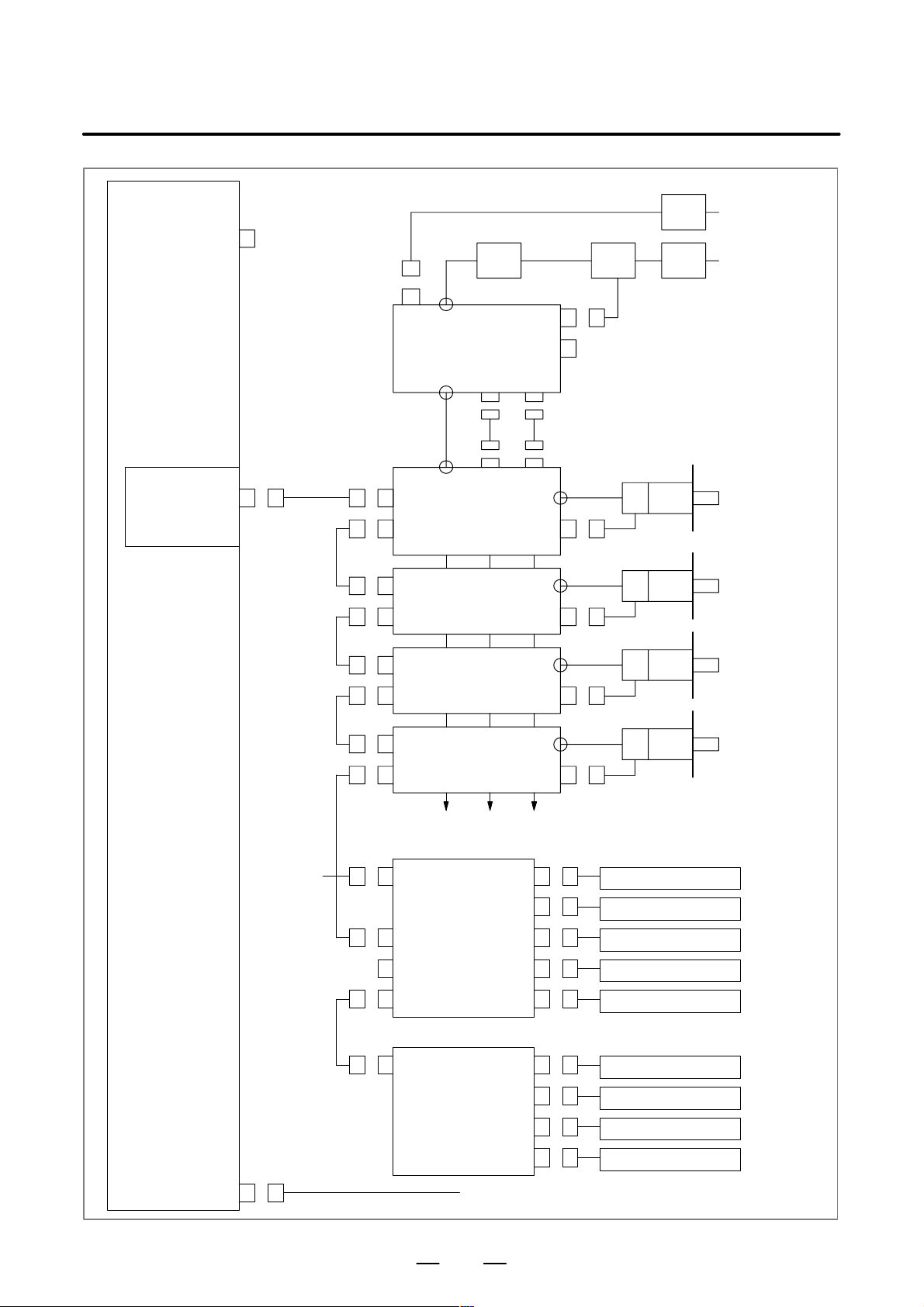

4. TOTAL CONNECTION DIAGRAMHARDWARE

Mother board (2/2)

SPDL&POS (JA41)

Servo card

FSSB

(COP10A) TB2COP10B

CX1A TB2

PSM

CX1B

TB1

TB2 CX2A JX1A

TB1 CX2B JX1B

COP10B

COP10A

AC reactor

CX3

CX4

CX2B JX1B

SVM

JF1COP10A

SVM

Breaker

200 VAC

200 VAC

MCC breaker

Axis 1 servo

motor

Axis 2 servo

motor

COP10B

COP10A

COP10B

COP10A

Up to six or eight axes, depending on the model

Separate detector interface unit 1

24 VDC CP1 1A

COP10B

COP10A

CNF1

Separate detector interface unit 2

CNF2 JF105

SVM

SVM

JF101

JF102

JF103

JF104

JA4A

JF106

Axis 3 servo

motor

Axis 4 servo

motor

Linear scale, axis 1

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

Absolute scale battery

Linear scale, axis 5

Linear scale, axis 6

SV–CHK (CA54)

JF107

JF108

Servo check

9

Linear scale, axis 7

Linear scale, axis 8

4. TOTAL CONNECTION DIAGRAM

Serial communication

board

Remote buffer board

DNC1 board

DNC2 board

R232–3 (JD28A)

R422–1 (JD6A)

Data server board

HARDWARE

RS–232C I/O device

(when the remote buffer board or DNC2 board is used)

RS–422 I/O device

(when the remote buffer board or DNC1 board is used)

B–63193EN/02

HDD (CNH1)

10BASE5 (CD27)

HSSB board

HSSB (COP7)

Analog option board

A–IN & A–OUT (JA6)

Hard disk unit

Ethernet

Personal Computer

Tracing sensor

Assist gas

pressure

analog output

The hard disk unit is mounted in the rear of the MDI unit.

The cable for the hard disk unit is provided by FANUC.

10

B–63193EN/02

5

5. POWER SUPPLYHARDWARE

POWER SUPPLY

11

5. POWER SUPPLY

HARDWARE

B–63193EN/02

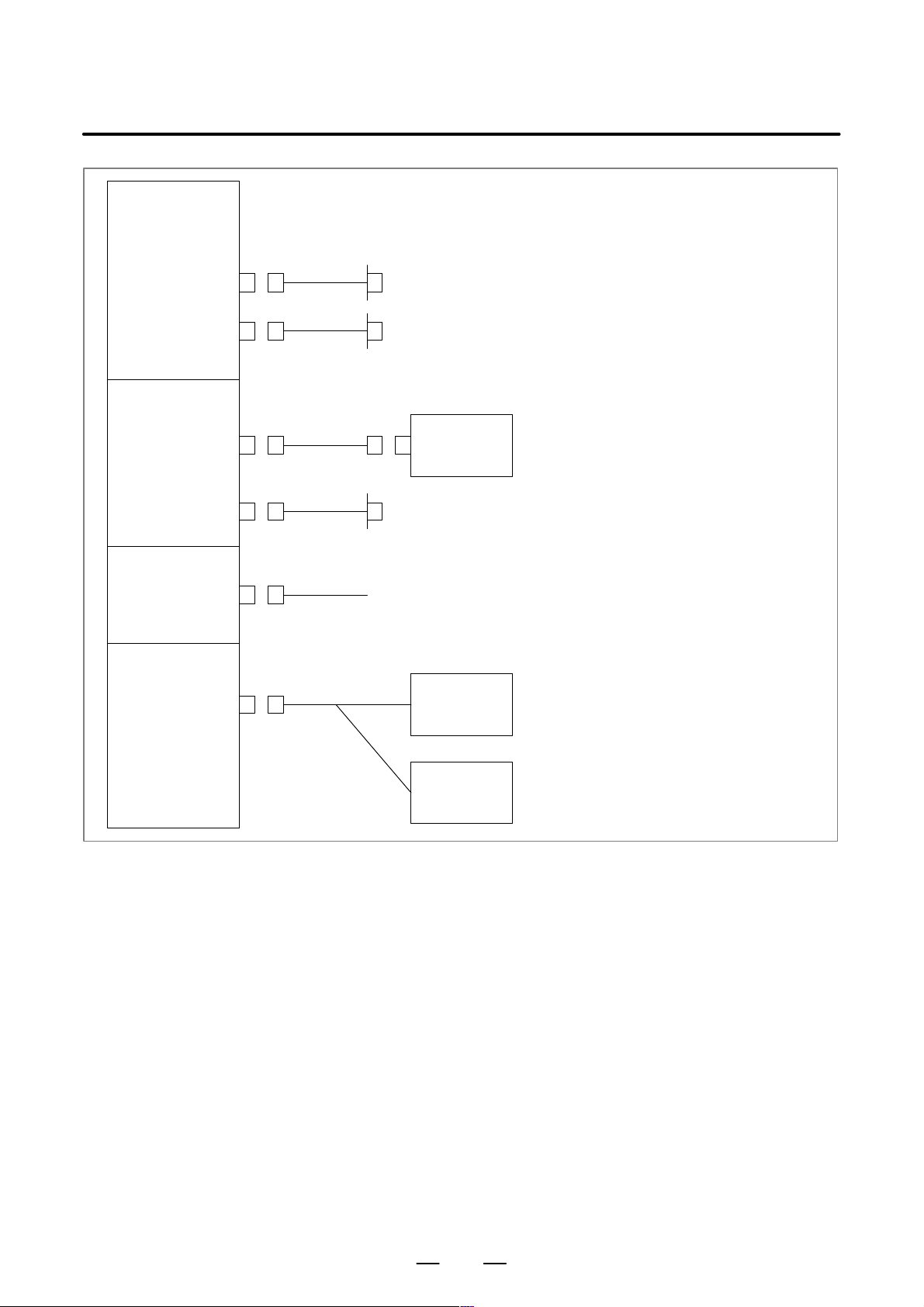

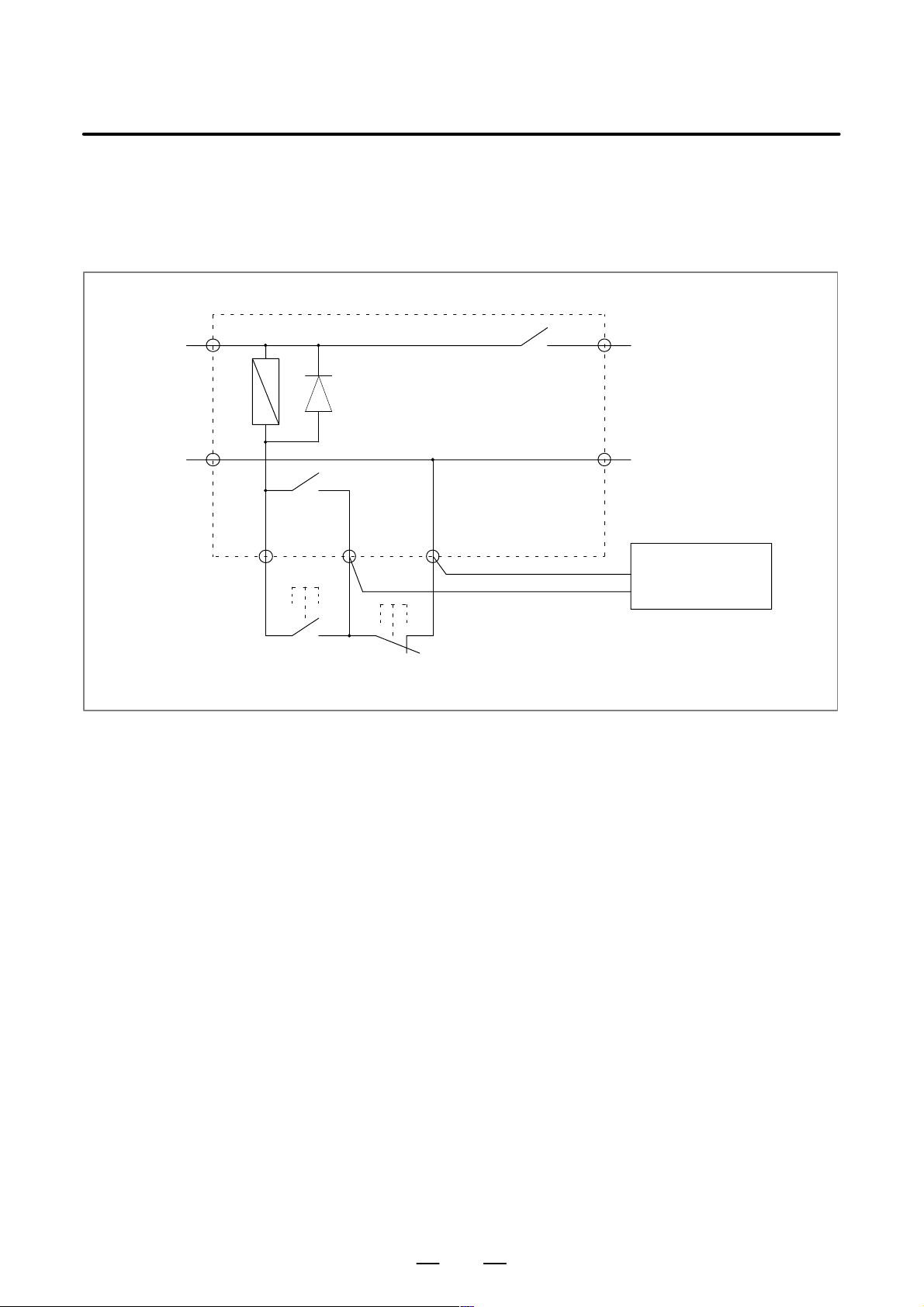

5.1

CONTROL UNIT POWER SUPPLY

Main breaker

Magnetic

contactor

Supply power (24 VDC) from an external source to the control unit of the

Series 16i–LA/160i–LA system. Install an external power–on/off switch

for the control unit, as shown in the figure below. When the Series

160i–LA system with PC functions is used, apply countermeasures to

guard against possible destruction of the data on the hard disk due to a

momentary power failure; for example, install an uninterruptible power

supply. The power rating is equal to the sum of the capacity of the control

unit (total power consumption in the unit indicated in Section 3.6 plus a

margin of about 20% to 30%) and the output via the control unit (output

from CP1B).

AC line filter

Servo

converter

3–phase

200 VAC

for power

line

Single–

phase

200 VAC

for control

line

Servo

inverter

Control unit

24 VDC

input

24 VDC

output

External

24 VDC

source

On/off circuit

ON COM OFF

3–phase

200 VAC

for power

line

Power–off

interlock

signals

OF1 1 and

OF12

I/O unit etc.

Start signal

(about 25 mA)

Laser oscillator

12

B–63193EN/02

5. POWER SUPPLYHARDWARE

Sample on/off circuit

The figure below shows a sample on/off circuit. Select the circuit devices

according to the actual power rating. Connect the OFF and COM lines

to the OF11 and OF12 contacts of the laser oscillator , respectively , so that

an interlock can be applied to the power–off switch.

+24V +24V

RY1

24 VDC

input

0V 0V

ry1

ON COM OFF

On button Off button

ry1

24 VDC output

The power rating is equal to

the sum of the capacity of

the CNC control unit and

the output from CP1B.

On/off circuit

OF11

OF12

Laser oscillator

Power–off

interlock signal

13

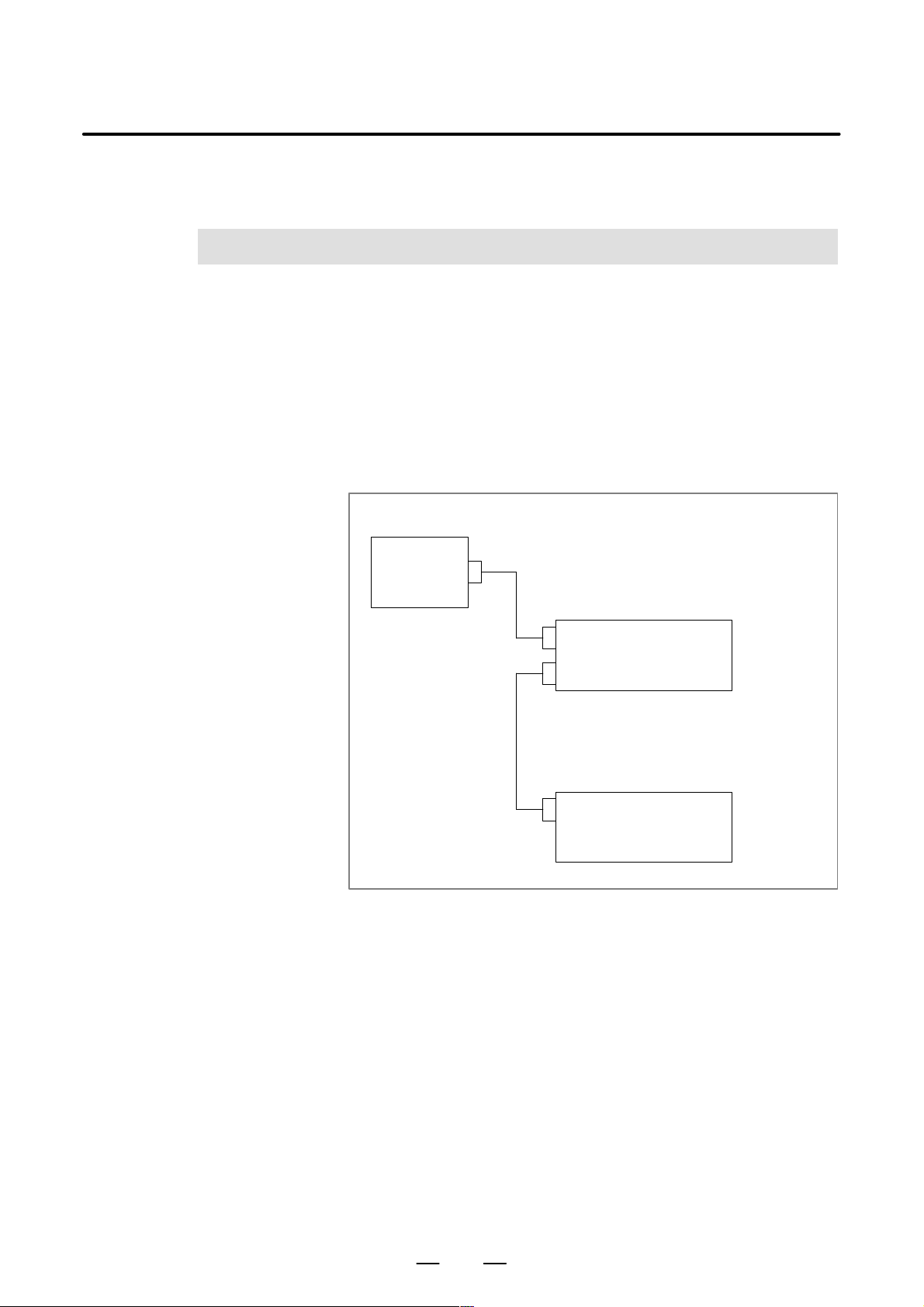

6. I/O LIMITATION BASED ON LASER

OSCILLATOR CONNECTION

I/O LIMITA TION BASED ON LASER OSCILLATOR CONNECTION

6

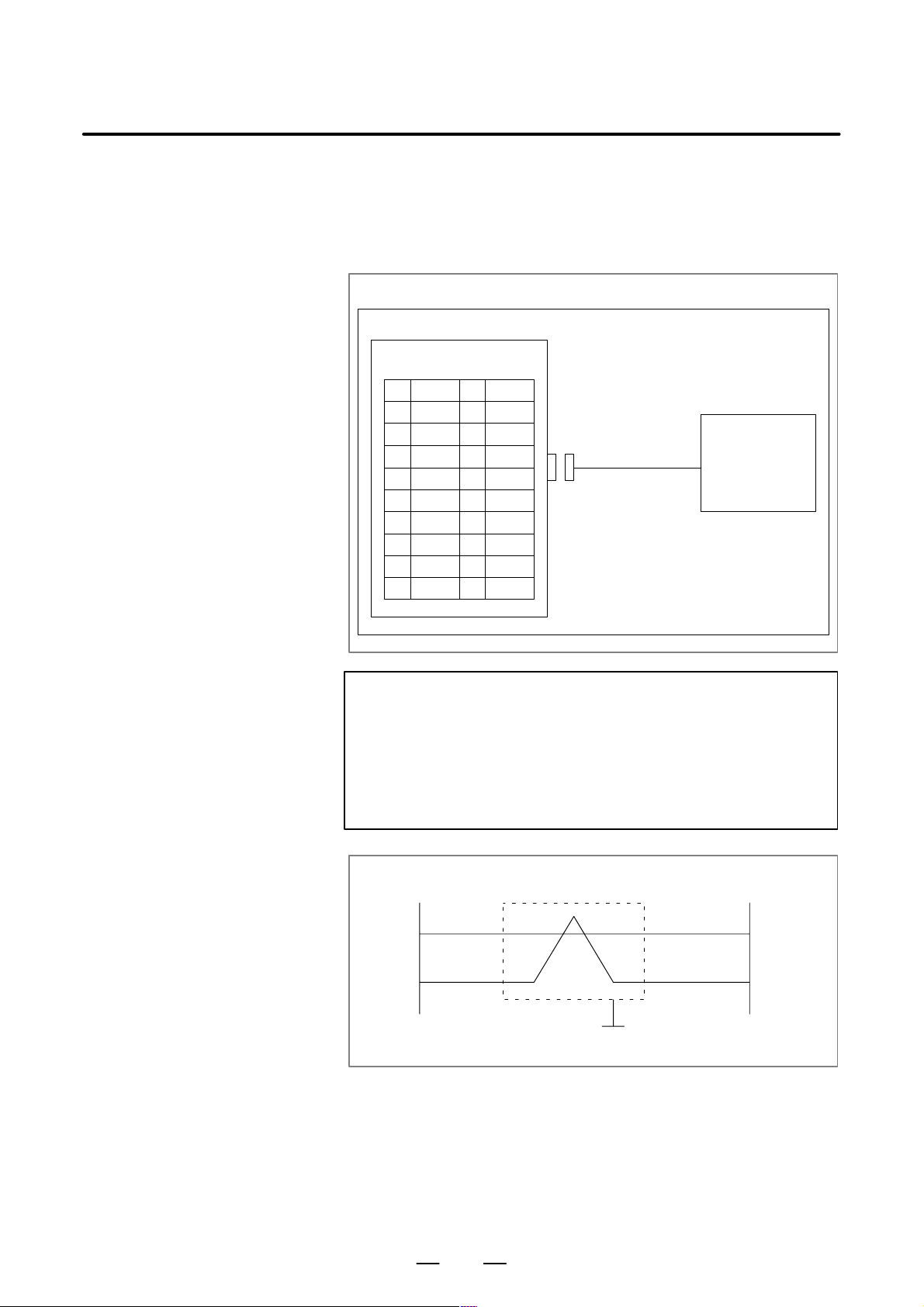

In the FS16i–LA system, the laser oscillator is connected in series via the

I/O unit.

For a laser oscillator interface, three groups with 256 DI and 256 DO

points are reserved.

The machine can therefore use up to 13 groups with 768 DI and 768 DO

points (X0 to X95 and Y0 to Y95).

Areas X96 to X127 and Y96 to Y127 cannot be used, even when a ladder

is used to specify writing to these areas.

HARDWARE

FS16i–LA

B–63193EN/02

Mother board

Up to 13 groups with 768 DI and

768 DO points

I/O board etc.

(Note) Areas X96 to X127 and

Y96 to Y127 cannot be

used with a ladder.

Three groups with 256 DI and 256

DO points (reserved by the CNC)

Laser oscillator

[User area]

X0 to X95

Y0 to Y95

14

B–63193EN/02

7

7. LASER OSCILLATORHARDWARE

LASER OSCILLATOR

15

7. LASER OSCILLATOR

7.1

CONNECTION OF THE LASER OSCILLATOR

Laser oscillator

HARDWARE

B–63193EN/02

JD1B

COP1

JD1A

ON

OFF

OF11

OF12

7.1.1

Connection of the

Adaptor

CP1A

Adaptor

I/O Link (when a metal cable is used)

Connected to the last I/O unit

I/O Link (when an optical fiber cable is used)

I/O Link Connected to the laser gas mixer

Oscillator on/off signal

(24 VDC, about 25 mA)

Power–of f interlock signal Connected to the external

Adaptor

Connected to CP1B of the CNC

power–on/off circuit

External source

CP1A

1 +24V

20V

3

24 VDC stabilized

power supply

24 VDC "10%

25 mA

AMP Japan, Ltd.

2–178288–3 (housing)

1–175218–5 (contact)

16

B–63193EN/02

7. LASER OSCILLATORHARDWARE

7.2

LASER OSCILLA T OR CONNECTION USING AN OPTICAL FIBER CABLE

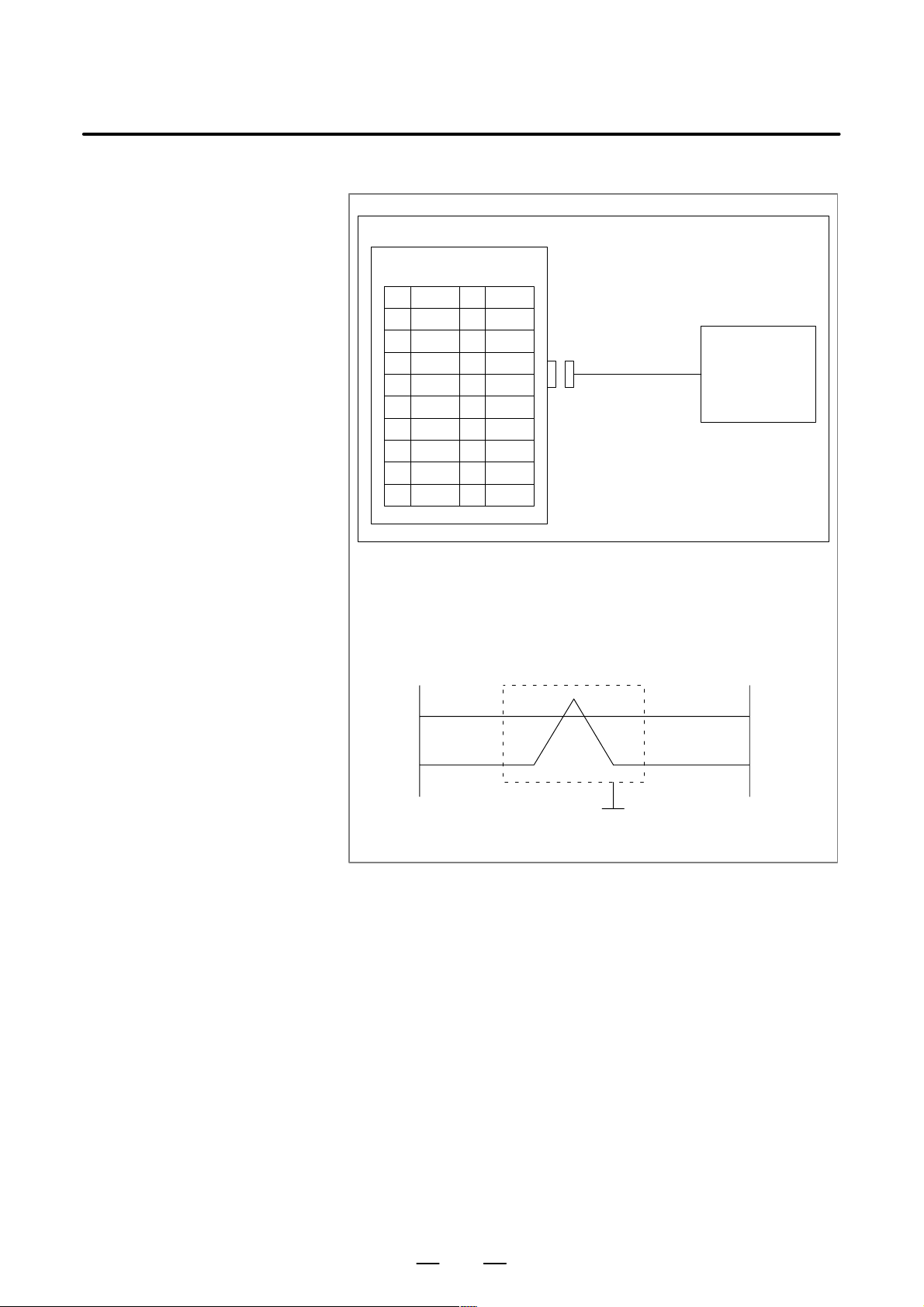

When one of the following conditions is satisfied, an optical fiber cable

must be used to connect the laser oscillator to the I/O link:

(1)The length of the required cable is at least 10 m.

2

(2) A 5.5–mm

grounding line cannot be used to establish a connection

between the CNC control unit and the cabinet housing the I/O unit etc.,

or a connection between the CNC control unit and the laser oscillator.

(3)The cable may be susceptible to high–level noise.

For example, when the cable is placed near any machine which

produces high–level magnetic noise, such as a welder . Or , when most

of the cable runs parallel to a power line or power magnetics cable.

(4) The laser oscillator to be connected is certified by the CE marking

system.

Optical I/O link adaptors

To use optical fiber cables for making connections, optical I/O link

adaptors must be used, as shown below.

CNC I/O

UNIT

I/O

UNIT

Laser

oscillator

Adaptor: Standard or high–speed type (Each optical fiber cable must

be connected between the same type of adaptors.)

Adaptor: Standard type

Electrical cable

Optical fiber cable

NOTE

1 T o daisy–chain I/O units to a single I/O link, both optical fiber

cables and electrical cables can be used.

2 When an optical fiber cable is used, an optical I/O link

adaptor must also be used.

3 Two types of optical I/O link adaptors are supported:

Standard and high–speed.

4 When four or more optical fiber cables are used (that is,

when four or more connections are established), the cables

should be of high–speed type.

5 Each laser oscillator contains a standard type adaptor. To

establish a connection to the laser oscillator, therefore, an

I/O unit must be provided with a standard type I/O link

adaptor, because only adaptors of the same type can be

connected to each other.

For an explanation of FANUC I/O link connection using electrical cables,

or the outside dimensions of optical I/O link adaptors, refer to Section 6.2,

“FANUC I/O Link Connection,” in the “Series 16i–MODEL A

Connection Manual.”

17

7. LASER OSCILLATOR

HARDWARE

B–63193EN/02

7.3

ASSIST GAS PRESSURE ANALOG OUTPUT

Assist gas pressure analog output signals are output from either the analog

spindle interface on the main board or the analog output interface on the

analog option board.

Which interface to use can be specified with the appropriate parameter.

For details, see ”ASSIST GAS CONTROL” in ”LASER FUNCTION.”

To output signals from the main board

CNC

JA40

PCR–E20MD

1 (HDI0)

20V

3 (HDI2)

40V

5ES

6 (HDI4)

7 SVC 17 (HDI6)

8 ENB1

9 ENB2

10 0V

11 (HDI1)

12 0V

13 (HDI3)

14 0V

15 (HDI5)

16 0V

18 0V

19 (HDI7)

20 0V

Assist gas

control unit

CAUTION

1 SVC, ES: Common lines are used for the SVC, ES, and

assist gas pressure analog output signals.

2 The signals in parentheses are high–speed DI input signals.

3 For details of the output voltage, see the section on assist

gas control in the function description.

Cable connection

JA40

7

SVC

5

ES

Shield

Output voltage range: 0 to 10 V

Ground

Assist gas

control unit

18

B–63193EN/02

To output signals from the analog option board

CNC

JA6

PCR–E20MD

1 AIN0

20V

3 (AIN2)

4 (0V)

5 AOUT

60V

7 17

8

9

10

11 (AIN1)

12 (0V)

13 (AIN3)

14 (0V)

15

16 (0V)

18

19

20

7. LASER OSCILLATORHARDWARE

Assist gas

control unit

CAUTION

1 AOUT, 0V: Common lines are used for the AOUT, 0V, and

assist gas pressure analog output signals.

2 The signals in parentheses cannot be used.

3 For details of the output voltage, see the section on assist

gas control in the function description.

Cable connection

JA6

5

AOUT

6

0V

Shield

Input voltage range: 0 to 10 V

Ground

Assist gas

control unit

19

7. LASER OSCILLATOR

7.4

CONNECTION OF THE TRACING SENSOR

HARDWARE

CNC

JA6

PCR–E20MD

1 AIN0

20V

3 (AIN2)

4 (0V)

5 (AOUT)

6 (0V)

7 17

8

9

10

Note 1) AIN0, 0V: Common lines are used for the AIN0, 0V, and analog input

Note 2) The signals in parentheses cannot be used.

Note 3) For details of the input voltage, see the section on tracing control in

11 (AIN1)

12 (0V)

13 (AIN3)

14 (0V)

15

16 (0V)

18

19

20

signals.

the function description.

B–63193EN/02

Tracing sensor

Cable connection

JA6

1

AIN0

2

0V

Shield

Input voltage range: –10 to +10 V

Tracing

sensor

Ground

20

II. LASER FUNCTION

B–63193EN/02

1

1. FUNCTIONSLASER FUNCTION

FUNCTIONS

Overview

Functions

For information about connections other than the laser functions, refer to

the “16i/18i/21i/20i/160i/180i/210i–MODEL A Connection Manual:

Function” (B–63003EN–1).

Most of the functions described in manual (B–63003EN–1) can be used

with the 16i–LA. Note, however , that some functions cannot be used with

the 16i–LA, while others require a different specification for use with the

16i–LA.

Whether the functions described in manual (B–63003EN–1) can be used

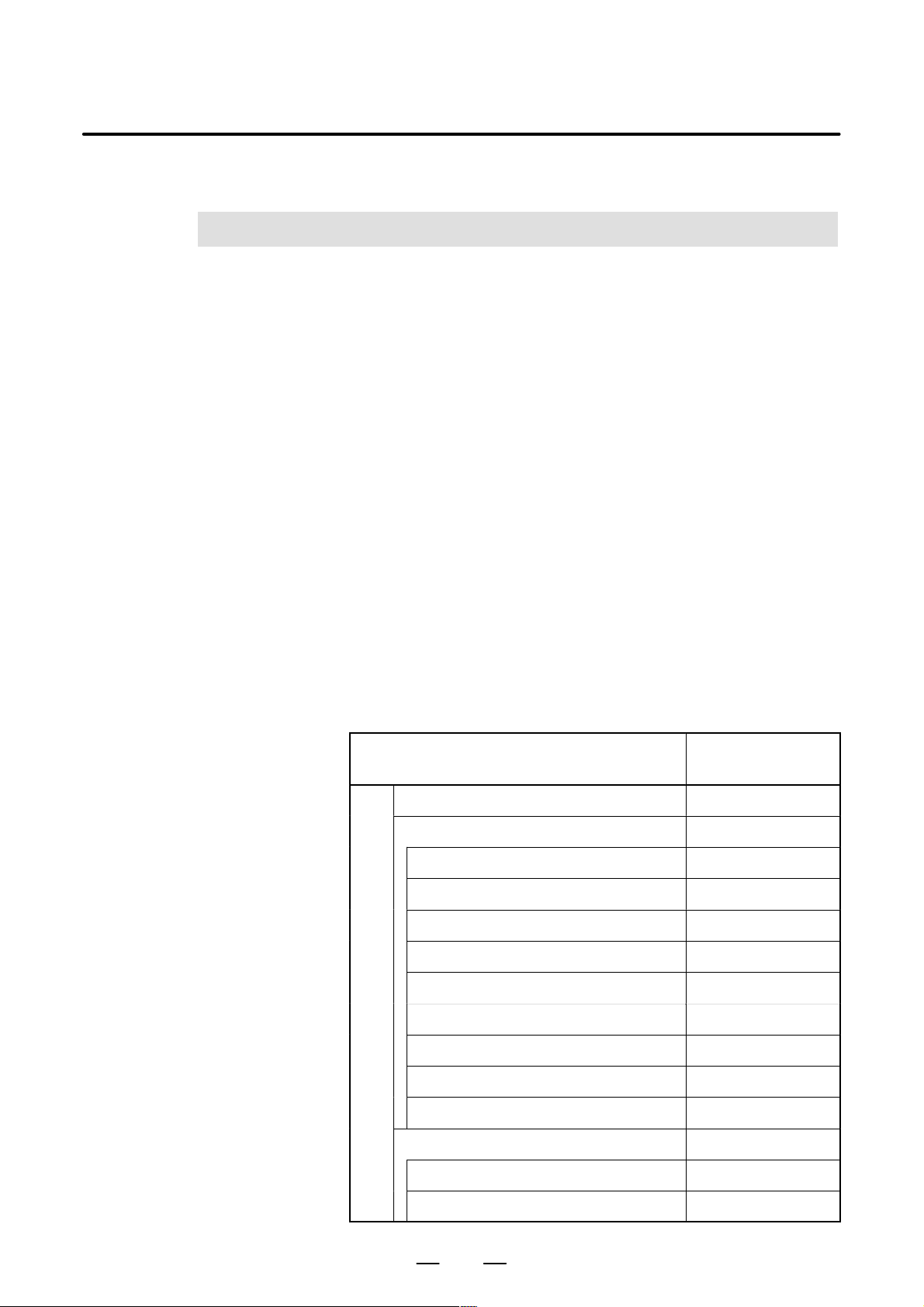

with the 16i–LA is listed below.

For details of those functions for which a different specification is

necessary, see Chapter 2. The functions are listed below.

The meanings of the symbols used in the table are as follows:

f : Usable with the 16i–LA

: Not usable with the 16i–LA

∆ : The specifications differ slightly.

Item Usable/not usable

with the 16i–LA

1

Controlled axis f

Each axis setting

Axis name f

Increment system f

Rotation axis specification f

Control axis detach f

Axis movement status output f

Mirror image f

Follow–up f

Servo off (mechanical handle feed) f

Position switch f

Error compensation

Stored pitch error compensation f

Backlash compensation f

23

1. FUNCTIONS LASER FUNCTION

Item Usable/not usable

1

Settings related to servo control axis

Servo parameters f

Absolute position detection f

Settings related to coordinate system

Machine coordinate system f

B–63193EN/02

with the 16i–LA

Workpiece coordinate system/Addition of

workpiece coordinate system pair

Rotary axis roll over f

Simple synchronous control f

Tandem control f

2

Emergency stop ∆ : Refer to chapter2

Ready signal f

Overtravel check

Overtravel signal f

Stored stroke limit 1 f

Stored stroke limit 2, 3 f

Chuck & tail stock barrier (T series)

Tool post interference check (T series)

Alarm signal f

Start lock/Inter lock f

f

Mode selection f

Tool post selection (T series)

Status output signal f

VRDY OFF alarm ignore signal f

3

Manual continuous feed/Incremental feed f

Manual handle feed f

Handle interruption f

Tool direction handle feed (M series)

24

B–63193EN/02

1. FUNCTIONSLASER FUNCTION

Item Usable/not usable

with the 16i–LA

4

Manual reference position return f

Reference position setting without DOG f

Reference position shift f

Reference position return f

2nd/3rd/4th reference position return f

Floating reference position return f

5

Cycle start/Feed hold ∆ : Refer to chapter2

Reset/Rewind f

Test operation

Machine lock ∆ : Refer to chapter2

Dry run ∆ : Refer to chapter2

Single block ∆ : Refer to chapter2

Manual absolute on/off f

Optional block skip/Optional block skip

addittion

Sequence number comparison and stop f

Program restart ∆

Tool retract & recover (M series)

Exact stop/Exact stop mode/Tapping mode/

Cutting mode

Balanced cutting (T series)

DNC operation f

Manual intervention and return f

6

Positioning f

Linear interpolation f

Circular interpolation f

Thread cutting

∆ : Tapping mode is

not usable.

f

Single direction positioning f

Helical interpolation f

Involute interpolation

Polar coordinate interpolation f

25

Loading...

Loading...