Fanuc 0I-*D Connection Manual(Harware)

FANUC Series 0 -MODEL D

*

FANUC Series 0 Mate-MODEL D

*

CONNECTION MANUAL (HARDWARE)

B-64303EN/03

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

The products in this manual are manufactured under strict quality control. However, when

using any of the products in a facility in which a serious accident or loss is predicted due to

a failure of the product, install a safety device.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

B-64303EN/03 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

B-64303EN/03 PREFACE

PREFACE

This manual describes the electrical and structural specifications required for connecting the CNC control

unit to a machine tool. The manual outlines the components commonly used for FANUC CNC control

units, as shown in the configuration diagram in Chapter 2, and supplies additional information on using

these components.

The manual outlines the I/O unit, servo, spindle, and other components common to FANUC CNC

control units, and supplies additional information on using these components in this CNC control unit.

For detailed specifications, refer to the manuals of these components.

For options not covered in this manual, also refer to the manuals of these components.

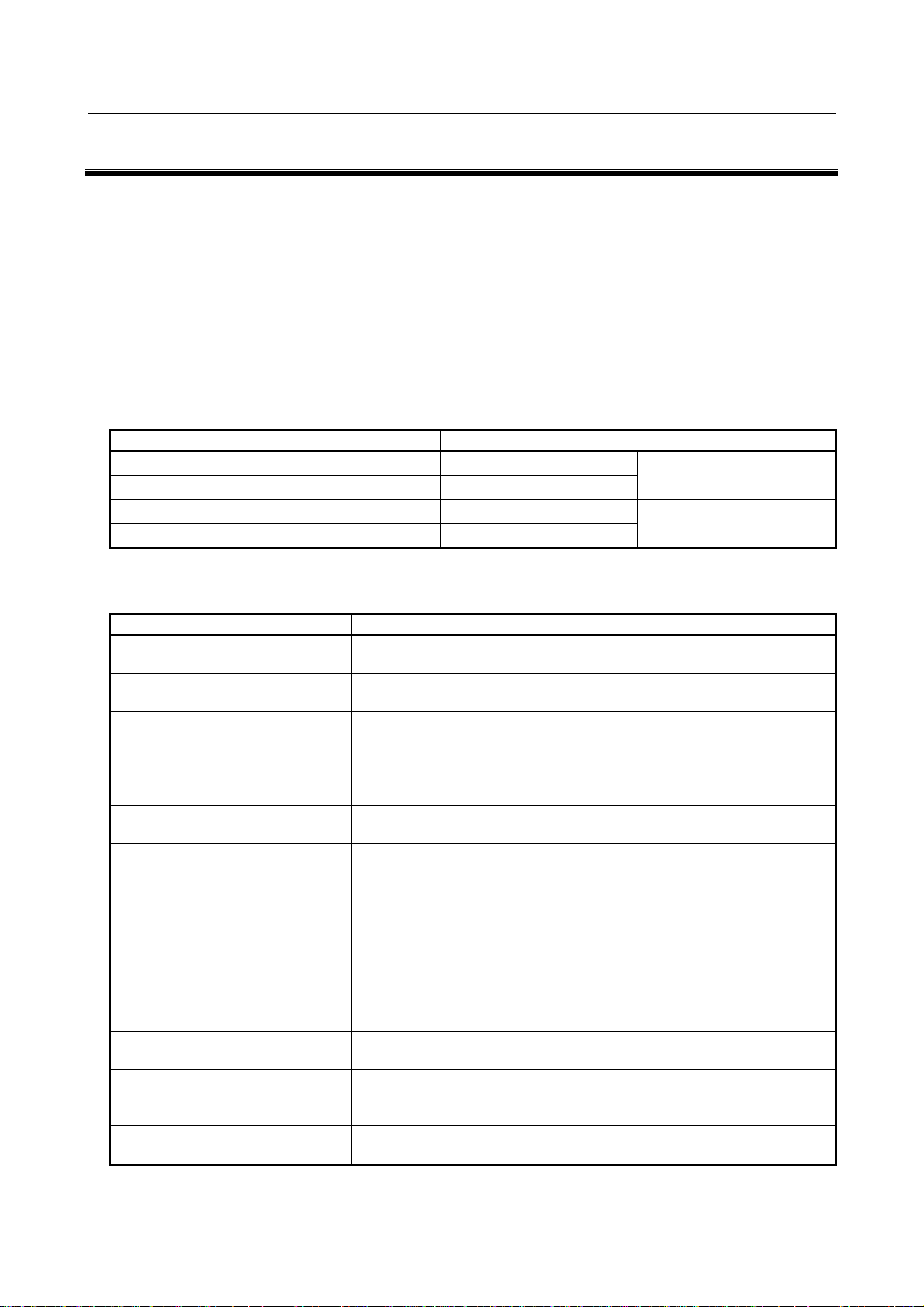

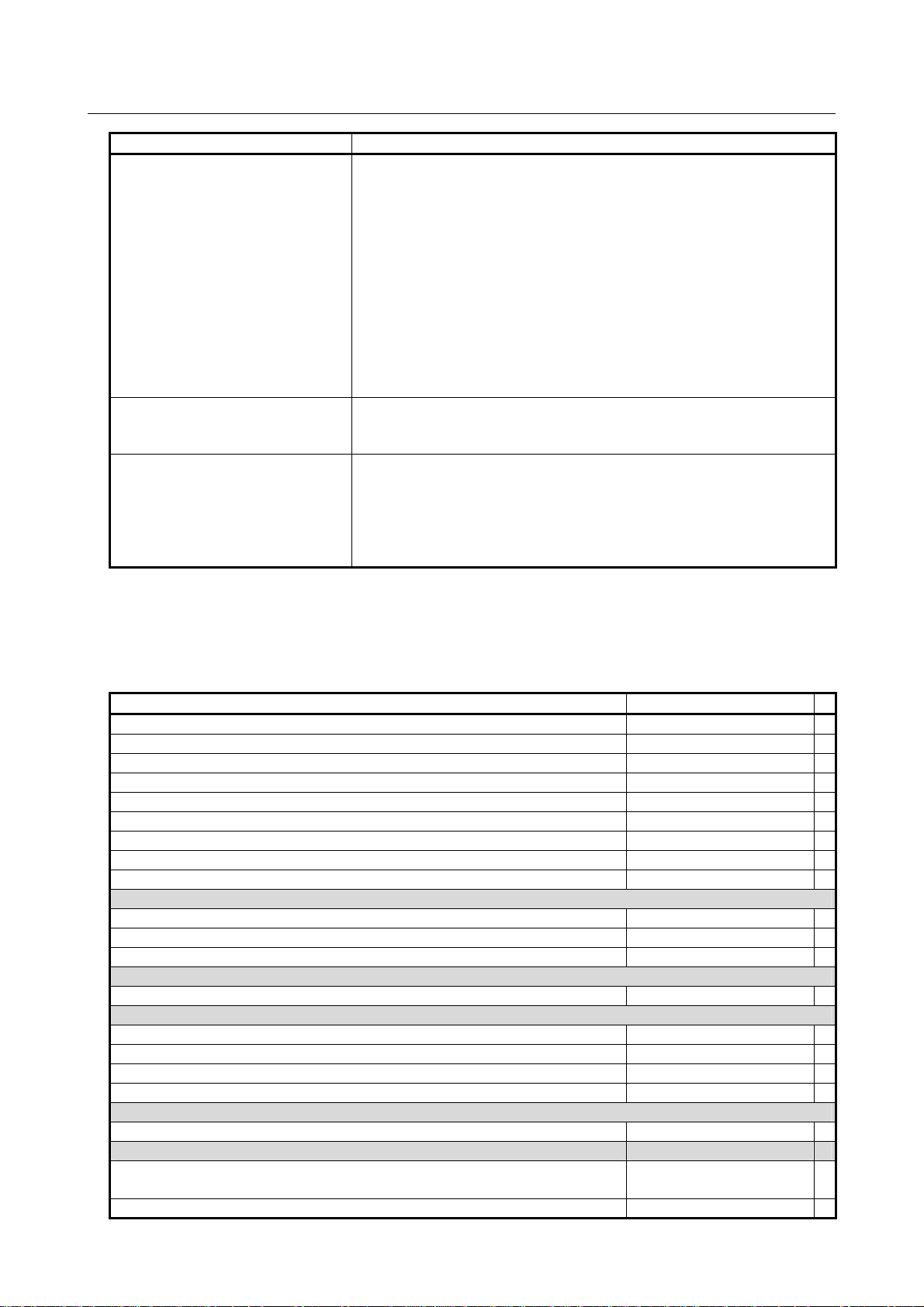

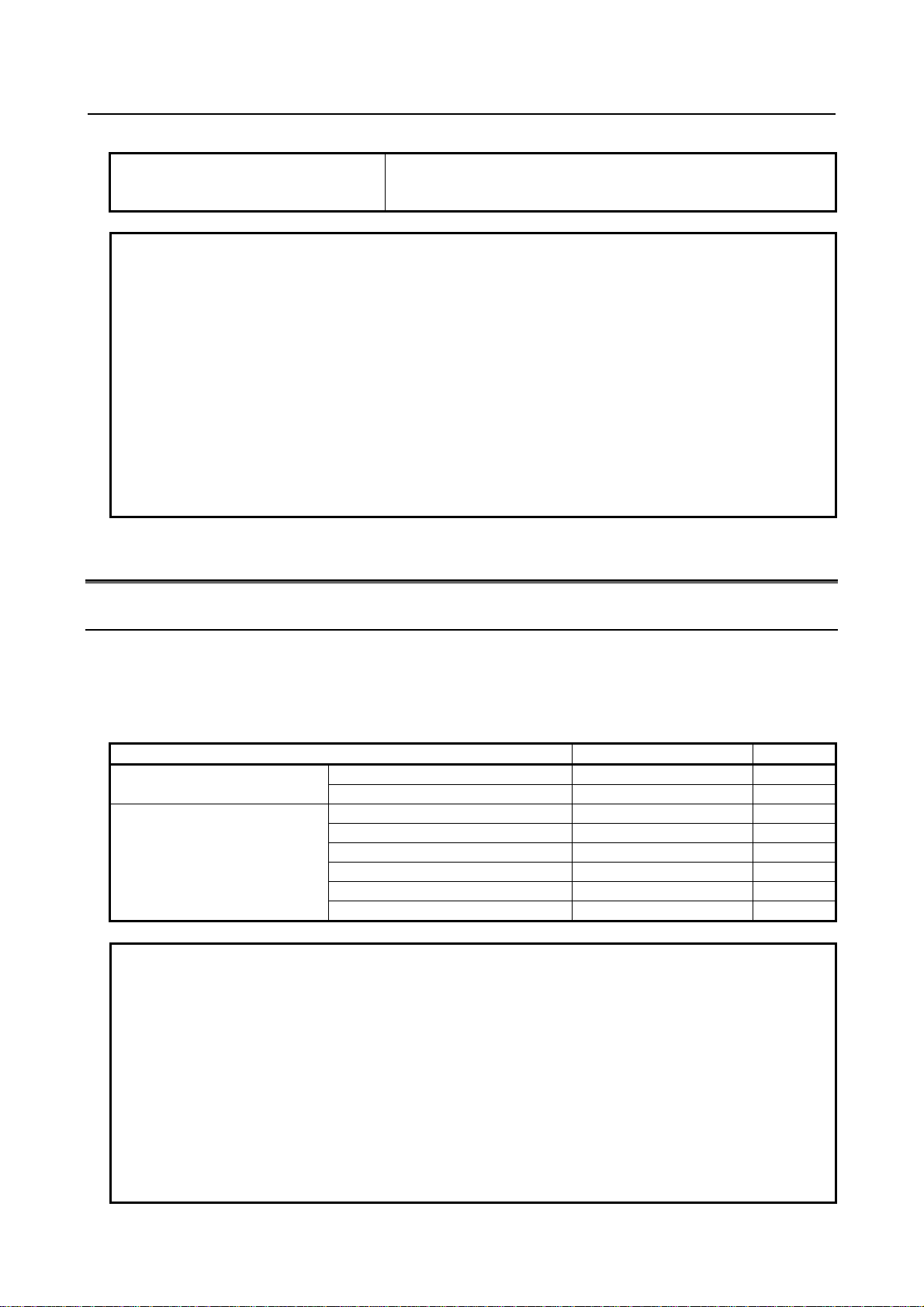

Applicable models

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 0i-TD 0i –TD

FANUC Series 0i-MD 0i –MD

FANUC Series 0i Mate-TD 0i Mate-TD

FANUC Series 0i Mate-MD 0i Mate-MD

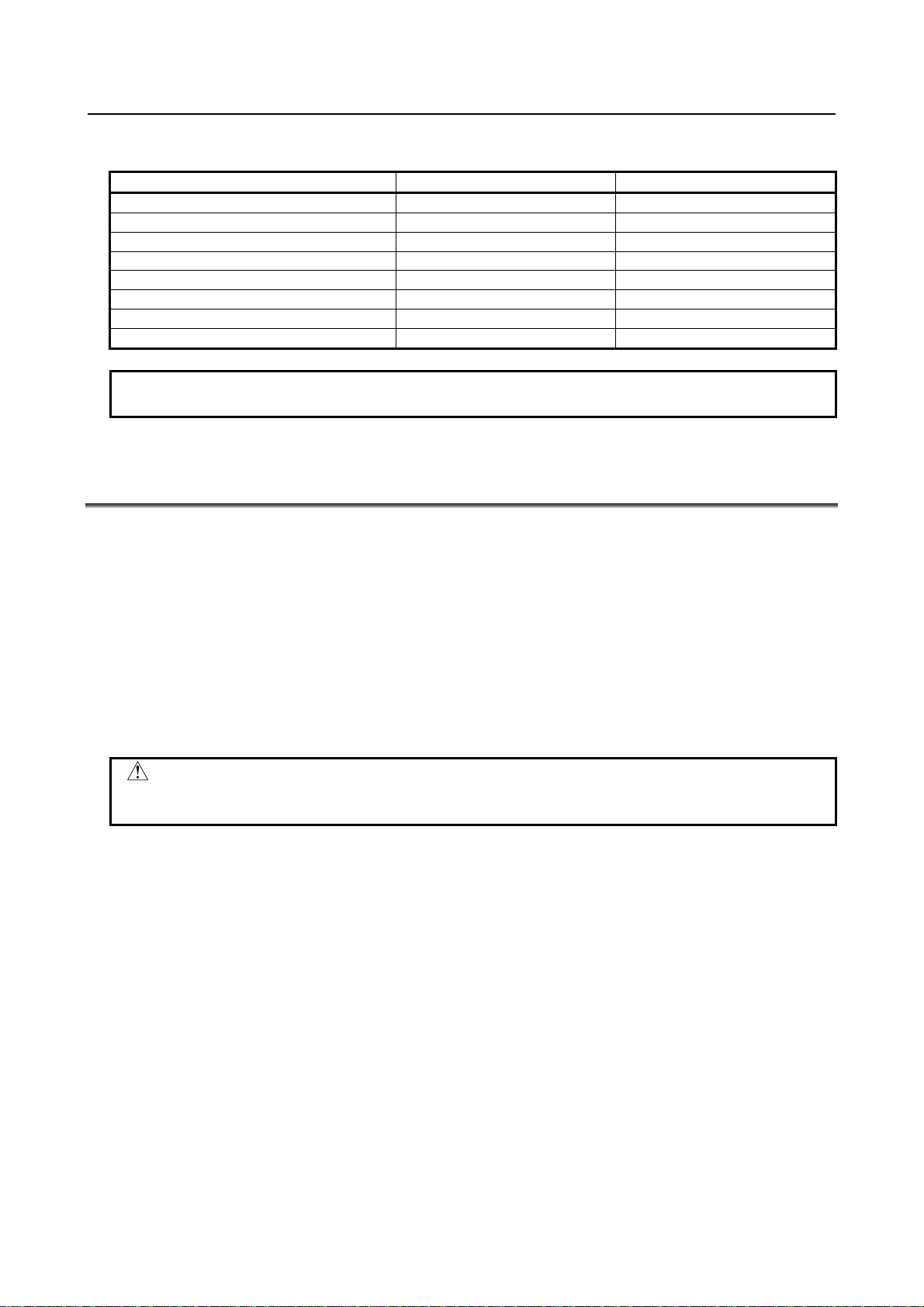

Organization of this manuals

This manual consists of chapters 1 to 12 and appendixes at the end of the book.

Chapter and title Contents

Chapter 1

CONFIGURATION

Chapter 2

TOTAL CONNECTION DAIGRAMS

Chapter 3

INSTALLATION

Chapter 4

POWER SUPPLAY CONNECTION

Chapter 5

CONNECTION TO CNC

PERIOHERALS

Chapter 6

SPINDLE CONNECTION

Chapter 7

SERVO INTERFACE

Chapter 8

CONNECTION TO FANUC I/O Link

Chapter 9

CONNECTION OF I/O Link SLAVE

DEVICES

Chapter 10

STOP AND EMERGENCY STOP

Provides general information related to the connection of the CNC, as well

as an introduction to detailed information.

Describes how to connect peripheral units to the CNC.

Describes the installation requirements for using the CNC.

1) Required power supply capacity

2) Heat output

3) Locations of connectors on the control unit

4) Action against noise

Describes how to make connections related to the power supply of the

CNC.

Describes how to connect the following peripheral devices to the CNC:

1) Display unit / MDI unit

2) I/O device (RS-232-C)

3) High-speed skip (HDI)

4) Embedded Ethernet

5) Connection to the touch panel

Describes how to connect spindle-related units to the CNC.

Describes how to connect servo-related units to the CNC.

Describes how to connect machine interface I/O with the FANUC I/O Link.

Describes how to connect various I/O Link slave devices.

It also describes I/O units for the 0i.

Describes how to handle the emergency stop signal.

Be sure to read this chapter.

Series 0

Series 0i Mate

i

p-1

PREFACE B-64303EN/03

Chapter and title Contents

Chapter 11

CONNECTION TO OTHER

NETWORKS

Chapter 12

CONNECTION OF THE

STAND-ALONE TYPE

APPENDIX A) OUTLINE DRAWINGS OF UNITS

Describes connection to the following networks.

For details on the connection, refer to the following manuals provided

separately.

Manual name (Specification number)

• FANUC Fast Ethernet / Fast Data Server For FANUC Series

0i-MODEL D OPERATOR’S MANUAL (B-64414EN)

• FANUC Series 0i-MODEL D PROFIBUS-DP Board CONNECTION

MANUAL (B-64403EN)

• FANUC Series 0i-MODEL D DeviceNet Board CONNECTION

MANUAL (B-64443EN)

• FANUC Series 0i-MODEL D FL-net Board CONNECTION MANUAL

(B-64453EN)

Provides descriptions specific to connection of the stand-alone type Series

0i-D.

B) 20-PIN INTERFACE CONNECTORS AND CABLES

C) CONNECTION CABLE (SUPPLIED FROM US)

D) OPTICAL FIBER CABLE

E) LIQUID CRYSTAL DISPLAY (LCD)

F) MEMORY CARD INTERFACE

Related manuals of Series 0i -D, Series 0i Mate -D

The following table lists the manuals related to Series 0i -D, Series 0i Mate -D. This manual is indicated

by an asterisk(*).

Table 1 Related manuals of Series 0i-D, Series 0i Mate-D

Manual name Specification number

DESCRIPTIONS B-64302EN

CONNECTION MANUAL (HARDWARE) B-64303EN *

CONNECTION MANUAL (FUNCTION) B-64303EN-1

USER’S MANUAL (Common to Lathe System/Machining Center System) B-64304EN

USER’S MANUAL (For Lathe System) B-64304EN-1

USER’S MANUAL (For Machining Center System) B-64304EN-2

MAINTENANCE MANUAL B-64305EN

PARAMETER MANUAL B-64310EN

START-UP MANUAL B-64304EN-3

Programming

Macro Executor PROGRAMMING MANUAL B-64303EN-2

Macro Compiler PROGRAMMING MANUAL B-64303EN-5

C Language Executor PROGRAMMING MANUAL B-64303EN-3

PMC

PMC PROGRAMMING MANUAL B-64393EN

Network

PROFIBUS-DP Board CONNECTION MANUAL B-64403EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64414EN

DeviceNet Board CONNECTION MANUAL B-64443EN

FL-net Board CONNECTION MANUAL B-64453EN

Dual Check Safety

Dual Check Safety CONNECTION MANUAL B-64303EN-4

Operation guidance function

MANUAL GUIDE i (Common to Lathe System/Machining Center System)

OPERATOR’S MANUAL

MANUAL GUIDE i (For Machining Center System) OPERATOR’S MANUAL

p-2

B-63874EN

B-63874EN-2

B-64303EN/03 PREFACE

Manual name Specification number

MANUAL GUIDE i Set-up Guidance OPERATOR’S MANUAL

MANUAL GUIDE 0i OPERATOR’S MANUAL

TURN MATE i OPERATOR’S MANUAL

CNC Screen Display function

CNC Screen Display Function OPERATOR’S MANUAL B-63164EN

B-63874EN-1

B-64434EN

B-64254EN

Related manuals of SERVO MOTOR αis/βis/αi/βi series

The following table lists the manuals related to SERVO MOTOR αis/βis/αi/βi series

Table 2 Related manuals of SERVO MOTOR αis/βis/αi/βi series

Manual name Specification number

FANUC AC SERVO MOTOR αi series DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS

FANUC AC SERVO MOTOR βi series DESCRIPTIONS

FANUC AC SPINDLE MOTOR βi series DESCRIPTIONS

FANUC SERVO AMPLIFIER αi series DESCRIPTIONS

FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series MAINTENANCE MANUAL

FANUC SERVO MOTOR βis series

FANUC AC SPINDLE MOTOR βi series

FANUC SERVO AMPLIFIER βi series MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βi series

FANUC LINEAR MOTOR LiS series

FANUC SYNCHRONOUS BUILT-IN SERVO MOTOR DiS series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series

FANUC AC SPINDLE MOTOR βi series

BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

B-65262EN

B-65272EN

B-65302EN

B-65312EN

B-65282EN

B-65322EN

B-65285EN

B-65325EN

B-65270EN

B-65280EN

This manual mainly assumes that the FANUC SERVO MOTOR αi series of servo motor is used. For

servo motor and spindle information, refer to the manuals for the servo motor and spindle that are actually

connected.

Related manuals of FANUC PANEL i

The following table lists the manuals related to FANUC PANEL i.

Table 3 Related manuals of FANUC PANEL i

Manual name Specification number

FANUC PANEL i CONNECTION AND MAINTENANCE MANUAL

B-64223EN

p-3

B-64303EN/03 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE .................................s-1

PREFACE....................................................................................................p-1

1 CONFIGURATION ..................................................................................1

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT NAMES ..............1

1.1.1 Configurations of Control Units...............................................................................1

1.2 HARDWARE OVERVIEW.............................................................................. 5

1.2.1 Control Unit Overview.............................................................................................5

2 TOTAL CONNECTION DIAGRAMS .......................................................6

3 INSTALLATION ......................................................................................9

3.1 ENVIRONMENTAL REQUIREMENTS .......................................................... 9

3.1.1 Environmental Conditions External to Cabinets ......................................................9

3.1.2 Environmental Conditions of the Control Unit ........................................................9

3.2 POWER SUPPLY CAPACITY ..................................................................... 10

3.2.1 Power Supply Capacities of CNC-related Units.....................................................10

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETIC CABINET ................................................................................. 11

3.4 THERMAL DESIGN OF THE MACHINE TOOL MAGNETIC CABINET ......12

3.4.1 Temperature Rise within the Machine Tool Magnetic Cabinet..............................12

3.4.2 Heat Output of Each Unit.......................................................................................12

3.4.3 Thermal Design of Operator's Panel.......................................................................13

3.5 COUNTERMEASURES AGAINST NOISE .................................................. 15

3.5.1 Grounding...............................................................................................................15

3.5.1.1 About grounding types ......................................................................................15

3.5.1.2 Grounding methods ........................................................................................... 15

3.5.1.3 Cable clamp and shield processing.................................................................... 19

3.5.1.4 Cabinet............................................................................................................... 21

3.5.2 Connecting the Ground Terminal of the Control Unit ...........................................23

3.5.3 Separating Signal Lines..........................................................................................26

3.5.4 Noise Suppressor....................................................................................................27

3.5.5 Measures Against Surges due to Lightning............................................................28

3.6 CONTROL UNIT..........................................................................................29

3.6.1 Installation of the Control Unit ..............................................................................29

3.7 SEVERE DUST/LIQUID PROTECTION OF CABINETS AND PENDANT

BOXES ........................................................................................................ 30

4 POWER SUPPLY CONNECTION.........................................................32

4.1 GENERAL ...................................................................................................32

4.2 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT.............32

4.2.1 Power Supply for the Control Unit.........................................................................32

4.2.2 External 24 VDC Power Specification and Circuit Configuration.........................32

4.2.3 Power-on Sequence ................................................................................................36

4.2.4 Power-off Sequence ...............................................................................................36

4.3 CABLE FOR POWER SUPPLY TO CONTROL UNIT ................................. 37

4.4 BATTERIES................................................................................................. 37

4.4.1 Battery for Memory Backup in the CNC Control Unit (3 VDC) ...........................37

c-1

TABLE OF CONTENTS B-64303EN/03

4.4.2 Battery for Separate Absolute Pulsecoders (6VDC) ..............................................42

4.4.3 Battery for Absolute Pulsecoder Built into the Motor (6VDC)..............................42

5 CONNECTION TO CNC PERIPHERALS .............................................43

5.1 CONNECTION WITH DISPLAY UNIT/MDI UNIT ........................................ 43

5.1.1 Overview ................................................................................................................43

5.1.2 Connection to the MDI Unit...................................................................................44

5.1.3 Connection with the Standard MDI Unit................................................................45

5.1.4 Key Layout of MDI................................................................................................46

5.2 CONNECTION WITH INPUT/OUTPUT DEVICES ......................................49

5.2.1 Overview ................................................................................................................49

5.2.2 Connecting I/O Devices .........................................................................................50

5.2.3 RS-232-C Serial Port..............................................................................................51

5.2.4 RS-232-C Interface Specification...........................................................................53

5.3 CONNECTING THE HIGH-SPEED SKIP (HDI)........................................... 60

5.3.1 Connecting the High-speed Skip (HDI) .................................................................60

5.3.2 Input Signal Rules for the High-speed Skip (HDI) ................................................61

5.4 LINKING THE EMBEDDED ETHERNET INTERFACE................................ 62

5.4.1 Connection to the Ethernet Interface......................................................................62

5.4.2 Specification of Twisted-Pair Cable.......................................................................64

5.4.3 Anti-Noise Measure ...............................................................................................66

5.4.4 Network Installation ...............................................................................................66

5.5 CONNECTION TO THE TOUCH PANEL .................................................... 68

5.5.1 Connection of the LCD Unit with a Touch Panel ..................................................68

5.5.2 External Touch Panel Interface ..............................................................................69

6 SPINDLE CONNECTION ...................................................................... 71

6.1 SERIAL SPINDLE........................................................................................ 73

6.1.1 Connection of One to Two Serial Spindles ............................................................73

6.1.2 Connecting Three Serial Spindles ..........................................................................75

6.2 ANALOG SPINDLE .....................................................................................80

6.3 POSITION CODER...................................................................................... 81

7 SERVO INTERFACE............................................................................. 82

7.1 CONNECTION TO THE SERVO AMPLIFIERS...........................................82

7.1.1 Overview ................................................................................................................83

7.1.2 Interface to the Servo Amplifiers ...........................................................................83

7.2 SEPARATE DETECTOR INTERFACE........................................................ 84

7.2.1 Separate Detector Interface Unit Specification ......................................................85

7.2.2 Connection of Power Supply..................................................................................86

7.2.3 Separate Detector Interface (Serial Interface) ........................................................88

7.2.4 Separate Detector Interface (Parallel interface)......................................................90

7.2.5 Input Signal Requirements (Parallel interface) ......................................................91

7.2.6 Connection of Battery for Absolute Position Detector...........................................93

7.2.7 Connection Between the Basic Unit and Additional Unit......................................95

7.2.8 Connector Locations...............................................................................................95

7.2.9 Installation..............................................................................................................96

7.2.10 Notes on Installing a Separate Detector Interface Unit ..........................................97

7.3 ANALOG INPUT SEPARATE DETECTOR INTERFACE .......................... 100

7.3.1 Overview ..............................................................................................................101

7.3.2 Analog Input Separate Detector Interface Unit Specification ..............................103

7.3.3 Connection of Power Supply................................................................................104

7.3.4 Analog Input Separate Detector Interface (Analog 1Vp-p Interface) ..................106

c-2

B-64303EN/03 TABLE OF CONTENTS

7.3.5 Input Signal Specifications...................................................................................107

7.3.6 Connection of Battery for Absolute Position Detector.........................................108

7.3.7 Connection Between the Analog Input Separate Detector Interface Unit and

Additional Unit.....................................................................................................109

7.3.8 Connector Locations.............................................................................................109

7.3.9 Installation............................................................................................................110

7.3.10 Notes on Installing an Analog Input Separate Detector Interface Unit................111

8 CONNECTION TO FANUC I/O Link ...................................................113

8.1 OVERVIEW ............................................................................................... 113

8.2 CONNECTION........................................................................................... 113

8.2.1 Connection of FANUC I/O Link by Electric Cable .............................................116

8.2.2 Connection of FANUC I/O Link by Optical Fiber Cable ....................................117

8.2.3 Connection when Multiple Channels of FANUC I/O Links are Used .................120

8.2.4 Power Supply Precautions....................................................................................123

9 CONNECTION OF I/O Link SLAVE DEVICES................................... 124

9.1 UNITS CONNECTABLE WITH THE FANUC I/O LINK.............................. 124

9.2 CONNECTION OF CONNECTOR PANEL I/O MODULE.......................... 125

9.2.1 Configuration .......................................................................................................125

9.2.2 Connection Diagram.............................................................................................126

9.2.3 Module Specifications..........................................................................................127

9.2.4 DI/DO Connector Pin Assignment.......................................................................129

9.2.5 DI (Input Signal) Connection ...............................................................................130

9.2.6 DO (Output Signal) Connection...........................................................................132

9.2.7 DI/DO Signal Specifications ................................................................................133

9.2.8 2A Output Connector Pin Allocation ...................................................................134

9.2.9 2A DO (Output Signal) Connection.....................................................................135

9.2.10 2A Output DO Signal Specifications ...................................................................136

9.2.11 Analog Input Connector Pin Allocation...............................................................137

9.2.12 Analog Input Signal Connections.........................................................................138

9.2.13 Analog Input Signal Specifications......................................................................139

9.2.14 Analog Input Specifications .................................................................................139

9.2.15 Manual Pulse Generator Connection....................................................................141

9.2.16 Cable Length for Manual Pulse Generator...........................................................142

9.2.17 Connection of Basic and Expansion Modules......................................................142

9.2.18 Module Installation...............................................................................................144

9.2.19 Other Notes...........................................................................................................148

9.2.20 Distribution I/O Setting........................................................................................151

9.3 CONNECTION OF OPERATOR'S PANEL I/O MODULE (FOR MATRIX

INPUT)....................................................................................................... 153

9.3.1 Overall Connection Diagram................................................................................153

9.3.2 Power Connection ................................................................................................154

9.3.3 DI/DO Connector Pin Arrangement.....................................................................155

9.3.4 DI (General-purpose Input Signal) Connection ...................................................156

9.3.5 DI (Matrix Input Signal) Connection ...................................................................157

9.3.6 DO (Output Signal) Connection...........................................................................159

9.3.7 Manual Pulse Generator Connection....................................................................163

9.3.8 External View.......................................................................................................163

9.3.9 Specifications .......................................................................................................164

9.3.10 Other Notes...........................................................................................................165

9.4 CONNECTION OF OPERATOR'S PANEL I/O MODULE AND POWER

MAGNETICS CABINET I/O MODULE.......................................................169

9.4.1 Overall Connection Diagram................................................................................169

c-3

TABLE OF CONTENTS B-64303EN/03

9.4.2 Power Connection ................................................................................................170

9.4.3 DI/DO Connector Pin Arrangement.....................................................................171

9.4.4 DI (General-purpose Input Signal) Connection ...................................................172

9.4.5 DO (Output Signal) Connection...........................................................................176

9.4.6 Manual Pulse Generator Connection....................................................................177

9.4.7 External View.......................................................................................................178

9.4.8 Specifications .......................................................................................................179

9.4.9 Other Notes...........................................................................................................180

9.5 I/O MODULE TYPE-2 FOR CONNECTOR PANEL...................................183

9.5.1 Configuration .......................................................................................................183

9.5.2 Connector Layout Diagram ..................................................................................184

9.5.3 Connection Diagram.............................................................................................185

9.5.4 Module Specifications..........................................................................................186

9.5.5 DI/DO Connector Pin Assignment.......................................................................187

9.5.6 DI (Input Signal) Connection ...............................................................................188

9.5.7 DO (Output Signal) Connection...........................................................................194

9.5.8 DI/DO Signal Specifications ................................................................................198

9.5.9 Power Supply Connection ....................................................................................199

9.5.10 Manual Pulse Generator Connection....................................................................199

9.5.11 Cable Length for Manual Pulse Generator...........................................................199

9.5.12 Connection between Modules ..............................................................................200

9.5.13 Unit Dimensions...................................................................................................201

9.5.14 Mounting the Module...........................................................................................201

9.5.15 Connector Panel Printed Circuit Board ................................................................203

9.5.16 Other Notes...........................................................................................................205

9.6 CONNECTION OF I/O UNITS FOR 0i.............................................................. 207

9.6.1 Overview ..............................................................................................................207

9.6.2 Cautions................................................................................................................209

9.6.3 Cable for Power Supply to Control Unit ..............................................................210

9.6.4 Connector Pin Arrangement.................................................................................211

9.6.5 Connecting DI/DO ...............................................................................................212

9.6.6 I/O Signal Requirements and External Power Supply for DO .............................221

9.6.7 Connecting the Manual Pulse Generator..............................................................226

9.7 FANUC I/O LINK CONNECTION UNIT .....................................................230

9.7.1 Overview ..............................................................................................................230

9.7.2 Specification.........................................................................................................231

9.7.3 Connection ...........................................................................................................234

9.7.3.1 I/O Link interface ............................................................................................ 234

9.8 CONNECTING THE FANUC SERVO UNIT β SERIES WITH I/O LINK ....236

9.8.1 Overview ..............................................................................................................236

9.8.2 Connection ...........................................................................................................237

9.8.3 Maximum Number of Units that can be Connected.............................................237

9.8.4 Address Assignment by Ladder............................................................................237

9.9 CONNECTION TO STANDARD MACHINE OPERATOR'S PANEL..........238

9.9.1 Overview ..............................................................................................................238

9.9.2 Total Connection Diagram ...................................................................................239

9.9.3 Each Connections .................................................................................................240

9.9.3.1 Pin assignment................................................................................................. 240

9.9.3.2 Power supply connection................................................................................. 241

9.9.3.3 I/O Link connection......................................................................................... 242

9.9.3.4 Emergency stop signal connection .................................................................. 243

9.9.3.5 Power ON/OFF control signal connection....................................................... 243

9.9.3.6 General-purpose DI signal connection ............................................................ 244

9.9.3.7 General-purpose DO signal connection........................................................... 246

c-4

B-64303EN/03 TABLE OF CONTENTS

9.9.3.8 Manual pulse generator connection ................................................................. 246

9.9.3.9 Connector (on the cable side) specifications ...................................................249

9.9.4 I/O Address...........................................................................................................250

9.9.4.1 Keyboard of main panel................................................................................... 250

9.9.4.2 Override signals............................................................................................... 250

9.9.5 I/O Mapping .........................................................................................................251

9.9.5.1 Connector locations of main panel ..................................................................252

9.9.6 Specifications .......................................................................................................254

9.9.6.1 Environmental requirement ............................................................................. 254

9.9.6.2 Order specification........................................................................................... 254

9.9.6.3 Main panel specification.................................................................................. 254

9.9.6.4 Sub panel A/B1 specification .......................................................................... 254

9.9.6.5 Power supply specification .............................................................................. 255

9.9.6.6 General-purpose DI signal definition .............................................................. 255

9.9.6.7 General-purpose DO signal definition............................................................. 255

9.9.7 Key Symbol Indication on Machine Operator’s Panel.........................................255

9.9.7.1 Meaning of key symbols.................................................................................. 255

9.9.7.2 Detachable key top .......................................................................................... 257

9.10 CONNECTION TO THE SMALL MACHINE OPERATOR'S PANEL OR

SMALL MACHINE OPERATOR'S PANEL B ............................................. 258

9.10.1 Overview ..............................................................................................................258

9.10.2 Overall Connection Diagram................................................................................258

9.10.3 Connection of Each Section .................................................................................260

9.10.3.1 Power connection ............................................................................................ 260

9.10.3.2 Emergency stop switch .................................................................................... 260

9.10.3.3 I/O Link connection......................................................................................... 261

9.10.3.4 Manual pulse generator connection ................................................................. 261

9.10.4 DI Signal Connection (Rotary Switch Connection) .............................................263

9.10.5 General-purpose DI/DO Connection (Only for the Small Machine Operator's

Panel B) ................................................................................................................264

9.10.5.1 Connector pin allocation.................................................................................. 264

9.10.5.2 General-purpose DI (input signal) connection................................................. 265

9.10.5.3 General-purpose DO (output signal) connection............................................. 267

9.10.6 I/O Address...........................................................................................................268

9.10.6.1 Keyboard of the operator's panel ..................................................................... 268

9.10.6.2 Override signals............................................................................................... 269

9.10.7 I/O Address Allocation.........................................................................................270

9.10.7.1 For small machine operator's panel .................................................................270

9.10.7.2 For small machine operator's panel B.............................................................. 271

9.10.8 External Dimensions ............................................................................................274

9.10.8.1 Outline drawing and panel-cut drawing of the small machine operator's

panel................................................................................................................. 274

9.10.8.2 Layout of the key sheet (Same for both the small machine operator's panel

and small machine operator's panel B) ............................................................ 276

9.10.9 Connector Layout of the Small Machine Operator's Panel ..................................278

9.10.10 Specifications .......................................................................................................279

9.10.10.1 Environmental requirement ............................................................................. 279

9.10.10.2 Order specification........................................................................................... 279

9.10.10.3 Operator's panel specification.......................................................................... 280

9.10.10.4 Power supply specification.............................................................................. 280

9.10.11 Key Symbol Indication on Machine Operator's Panel .........................................280

9.10.11.1 Meaning of key symbols.................................................................................. 280

9.10.11.2 Customization of the key sheet........................................................................ 281

9.10.12 Maintenance Parts ................................................................................................282

9.11 CONNECTION OF TERMINAL TYPE I/O MODULE ................................. 282

9.11.1 Overview ..............................................................................................................282

c-5

TABLE OF CONTENTS B-64303EN/03

9.11.2 Module Specifications..........................................................................................283

9.11.2.1 Types of modules............................................................................................. 283

9.11.2.2 Installation conditions...................................................................................... 284

9.11.2.3 I/O signal specifications .................................................................................. 284

9.11.2.4 Power supply capacity ..................................................................................... 286

9.11.2.5 Heat dissipation ............................................................................................... 286

9.11.2.6 Weight ............................................................................................................. 286

9.11.2.7 Applicable wire................................................................................................ 287

9.11.3 External View and Dimensions............................................................................288

9.11.3.1 Dimensions (common to the modules) ............................................................ 288

9.11.3.2 Dimensions in a maximum configuration (one basic module + three

expansion modules) ......................................................................................... 288

9.11.3.3 Component names ........................................................................................... 289

9.11.4 Installation............................................................................................................294

9.11.5 Connection ...........................................................................................................296

9.11.5.1 Overall connection diagram............................................................................. 296

9.11.5.2 Power connection ............................................................................................ 297

9.11.5.3 Signal assignment on terminal blocks.............................................................. 298

9.11.5.4 DI/DO connection............................................................................................ 301

9.11.5.5 Manual pulse generator connection ................................................................. 305

9.11.5.6 Inter-module connection.................................................................................. 305

9.11.5.7 Cable connection to a terminal block .............................................................. 306

9.11.5.8 Detaching a terminal block.............................................................................. 307

9.11.6 Settings .................................................................................................................308

9.11.6.1 Address map .................................................................................................... 308

9.11.6.2 DO alarm detection.......................................................................................... 310

9.11.6.3 Setting the rotary switch .................................................................................. 312

9.11.7 Others ...................................................................................................................314

9.11.7.1 Method of common pin expansion .................................................................. 314

9.11.7.2 DO signal reaction to a system alarm .............................................................. 315

9.11.7.3 Parallel DO (output signal) connection ........................................................... 316

9.12 CONNECTION OF THE I/O LINK-AS-i CONVERTER ..............................317

9.12.1 Overview ..............................................................................................................317

9.12.1.1 Features............................................................................................................ 317

9.12.1.2 AS-i versions and ordering information .......................................................... 317

9.12.1.3 Applicable CNC............................................................................................... 318

9.12.1.4 Specification of the I/O Link side.................................................................... 318

9.12.1.5 Support for AS-i profiles ................................................................................. 318

9.12.2 Specifications .......................................................................................................318

9.12.2.1 Specifications of the AS-i converter................................................................ 318

9.12.2.2 Installation conditions...................................................................................... 319

9.12.2.3 Dimensions and connector layout.................................................................... 319

9.12.2.4 Installation ....................................................................................................... 320

9.12.3 Connection ...........................................................................................................323

9.12.3.1 Overall connection diagram............................................................................. 323

9.12.3.2 Power connection ............................................................................................ 323

9.12.3.3 I/O Link connection......................................................................................... 325

9.12.3.4 AS-i connection ............................................................................................... 325

9.12.4 DI/DO Mapping on the I/O Link..........................................................................326

9.12.4.1 For AS-i Ver. 2.0 (A03B-0817-C001)............................................................. 326

9.12.4.2 For AS-i Ver. 2.1 (A03B-0817-C002)............................................................. 327

9.12.5 Details of I/O Link DI/DO ...................................................................................329

9.12.5.1 Input/output data area ...................................................................................... 329

9.12.5.2 AS-i master status indication ........................................................................... 330

9.12.5.3 Board status ..................................................................................................... 331

9.12.5.4 Slave list .......................................................................................................... 331

9.12.6 Command Execution by a Ladder Program .........................................................333

c-6

B-64303EN/03 TABLE OF CONTENTS

9.12.6.1 Types of commands executable by a ladder program...................................... 333

9.12.6.2 Command interface with a ladder program .....................................................333

9.12.6.3 Details of command flags and status ...............................................................334

9.12.6.4 Error codes....................................................................................................... 334

9.12.6.5 Command handshake sequence ....................................................................... 334

9.12.6.6 Details of commands .......................................................................................335

9.12.7 LED Status Indication and Setting Switch Operation ..........................................338

9.12.7.1 LED indication ................................................................................................ 338

9.12.7.2 7-segment LED indication............................................................................... 339

9.12.7.3 Setting/display switch...................................................................................... 340

9.12.7.4 Error processing............................................................................................... 341

9.12.8 How to Use the I/O Link-AS-i Converter ............................................................343

9.12.8.1 Installation ....................................................................................................... 343

9.12.8.2 Normal operation............................................................................................. 344

9.12.9 Others ...................................................................................................................345

9.12.9.1 CE marking...................................................................................................... 345

9.12.9.2 Fuse.................................................................................................................. 345

10 STOP AND EMERGENCY STOP .......................................................346

10.1 STOP MODES........................................................................................... 346

10.2 SHUTTING OFF THE MOTOR POWER ................................................... 346

10.3 STOPPING THE SPINDLE MOTOR .........................................................347

10.4 STOPPING THE SERVO MOTOR ............................................................ 347

10.5 EMERGENCY STOP SIGNAL................................................................... 348

11 CONNECTION TO OTHER NETWORKS ........................................... 351

12 CONNECTION OF THE STAND-ALONE TYPE ................................. 352

12.1 OVERVIEW ............................................................................................... 352

12.2 CONTROL UNIT CONFIGURATION AND COMPONENT NAMES ..........353

12.3 CONTROL UNIT OVERVIEW.................................................................... 354

12.4 TOTAL CONNECTION DIAGRAMS.......................................................... 355

12.5 INSTALLATION ......................................................................................... 356

12.5.1 Environmental Conditions of the Control Unit ....................................................356

12.5.2 Power Supply Capacity ........................................................................................356

12.5.3 Heat Output of Each Unit.....................................................................................356

12.5.4 Connecting the Ground Terminal of the Control Unit .........................................357

12.5.5 Installing the Control Unit....................................................................................357

12.6 POWER SUPPLY CONNECTION ............................................................. 358

12.6.1 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT ..............358

12.6.1.1 Power-on Sequence ......................................................................................... 358

12.6.1.2 Power-off Sequence......................................................................................... 359

12.6.2 Cable for Power Supply to Control Unit ..............................................................359

12.6.3 Batteries................................................................................................................360

12.7 HIGH-SPEED SERIAL BUS (HSSB) ......................................................... 361

12.7.1 Overview ..............................................................................................................361

12.7.2 Cautions................................................................................................................361

12.7.3 Connection Diagram.............................................................................................361

12.7.4 Personal Computer Specification .........................................................................362

12.7.5 Installation Environment ......................................................................................362

12.7.6 Procedure for Installing Personal Computer Interface Boards.............................362

12.7.7 Handling Precautions ...........................................................................................363

12.7.8 Recommended Cables ..........................................................................................363

12.8 PERIPHERAL EQUIPMENT AND CONNECTION .................................... 363

c-7

TABLE OF CONTENTS B-64303EN/03

12.8.1 Connection with the MDI Unit.............................................................................363

12.9 EXTERNAL DIMENSIONS OF EACH UNIT.............................................. 364

12.9.1 External Dimensions of Stand-alone type Control Unit.......................................364

12.9.2 Punch Panel (for Stand-alone Type Control Unit) ...............................................365

APPENDIX

A EXTERNAL DIMENSIONS OF EACH UNIT ....................................... 369

B 20-PIN INTERFACE CONNECTORS AND CABLES ......................... 411

B.1 BOARD-MOUNTED CONNECTORS ........................................................ 411

B.1.1 Vertical-type Connectors......................................................................................411

B.1.2 Straight and Right-angled Connectors (for Spring and Screw-fixing Connector

Housings) .............................................................................................................411

B.2 CABLE CONNECTORS ............................................................................ 411

B.2.1 Strand Wire Press-mount Connector ....................................................................412

B.2.2 Soldering Type Connector....................................................................................412

B.3 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND

CABLES .................................................................................................... 413

B.3.1 Recommended Connectors ...................................................................................414

B.3.2 Applicable Cables.................................................................................................415

C CONNECTION CABLE (SUPPLIED FROM US).................................422

D OPTICAL FIBER CABLE.................................................................... 425

E LIQUID CRYSTAL DISPLAY (LCD) ...................................................434

F MEMORY CARD INTERFACE............................................................ 435

G ANALOG SERVO ADAPTER .............................................................437

G.1 OVERVIEW ............................................................................................... 437

G.2 SPECIFICATIONS.....................................................................................437

G.3 ORDER SPECIFICATIONS....................................................................... 437

G.4 CONNECTION DIAGRAM......................................................................... 438

G.5 CONNECTION OF TYPE F ANALOG SERVO INTERFACE..................... 439

G.5.1 System Structure...................................................................................................439

G.5.1.1 In case of using the built-in pulse coder .......................................................... 439

G.5.1.2 In case of using the separate detector .............................................................. 439

G.5.2 Detail of Connection ............................................................................................440

G.5.2.1 Cable J155 ....................................................................................................... 440

G.5.2.2 Cable J156A (A quad B interface)................................................................... 441

G.5.2.3 Cable J156B (FANUC serial interface)........................................................... 442

G.5.2.4 Cable J37 ......................................................................................................... 443

G.5.2.5 Detail of signals............................................................................................... 443

G.6 CONNECTION OF TYPE M ANALOG SERVO INTERFACE.................... 446

G.6.1 System Structure...................................................................................................446

G.6.1.1 In case of using the built-in pulse coder .......................................................... 446

G.6.1.2 In case of using the separate detector .............................................................. 447

G.6.2 Detail of Connection ............................................................................................447

G.6.2.1 Cables J156A/B ............................................................................................... 447

G.6.2.2 Cable J37 ......................................................................................................... 447

G.6.2.3 Cable J157 ....................................................................................................... 447

G.6.2.4 Cable J158 ....................................................................................................... 449

c-8

B-64303EN/03 TABLE OF CONTENTS

G.6.2.5 Detail of signals............................................................................................... 449

G.7 POWER AND HEAT GENERATED........................................................... 451

G.7.1 Power Supply Rating............................................................................................452

G.7.2 Heat Generated .....................................................................................................452

G.8 SELECT SWITCH SW1............................................................................. 453

G.9 EXTERNAL DIMENSION .......................................................................... 453

G.10 NOTICE .....................................................................................................453

G.11 PARAMETER SETTING ............................................................................ 454

c-9

B-64303EN/03 1.CONFIGURATION

1 CONFIGURATION

NOTE

See Chapter 12, “CONNECTION OF THE STAND-ALONE TYPE”, for

stand-alone type CNC.

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT

NAMES

The configuration and component names of control units are shown in the figures given below. This

manual explains how to attach the connectors shown in these figures to devices. The numbers in

parentheses () in the figures are keyed to the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

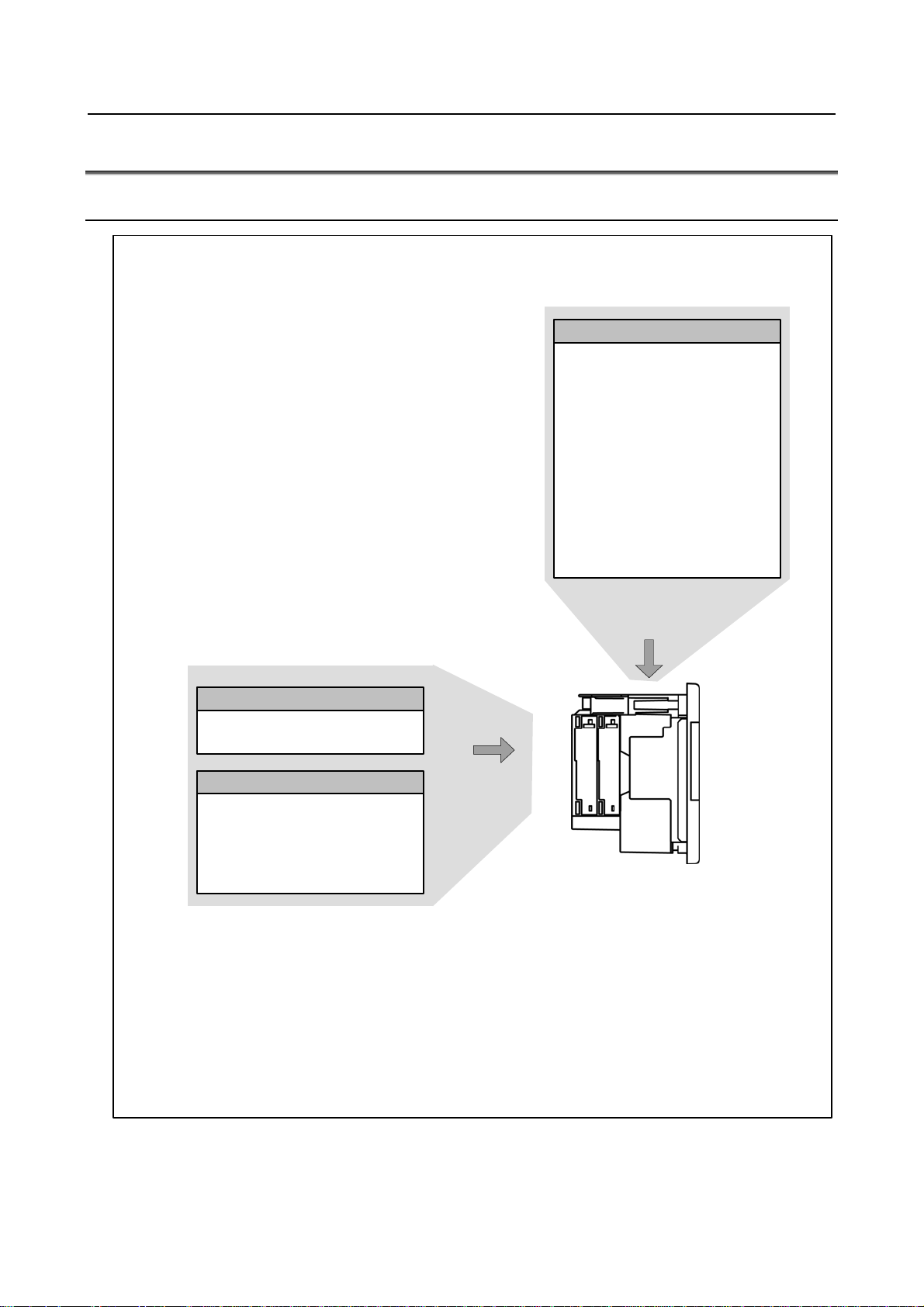

1.1.1 Configurations of Control Units

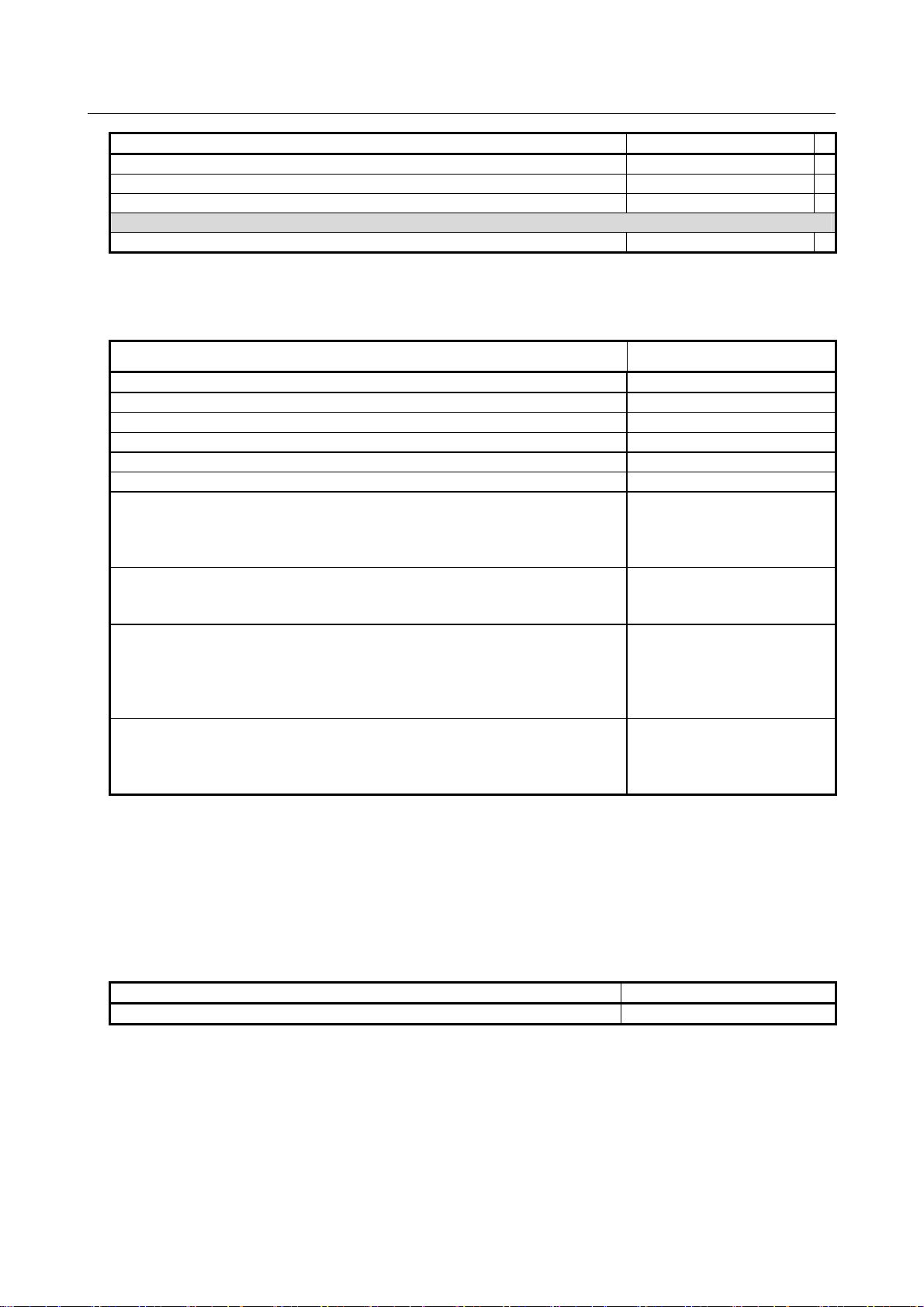

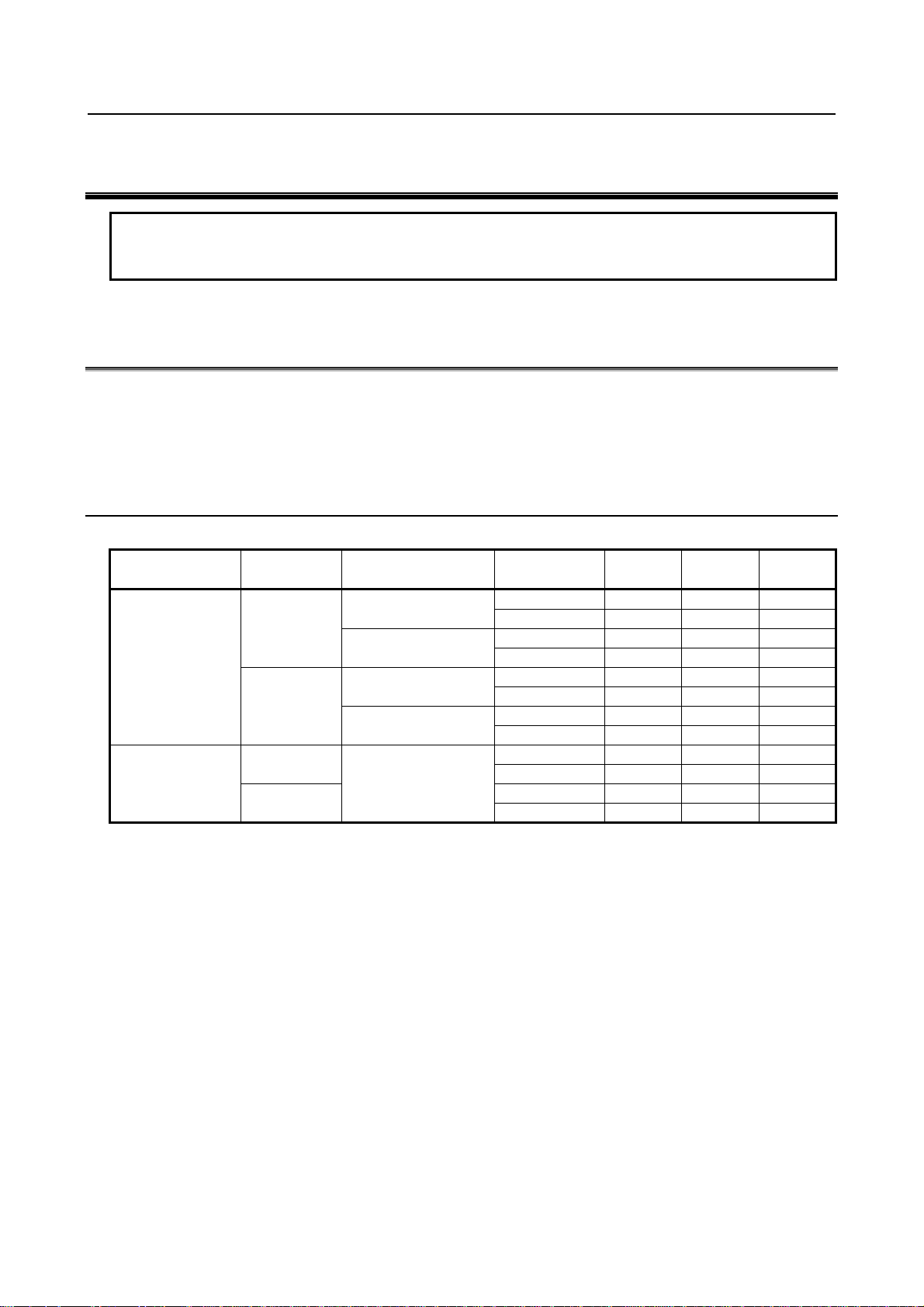

Control units (A circle indicates that the corresponding unit is available.)

Display unit Touch panel MDI

(Horizontal)

LCD-mounted type

(Vertical)

(Horizontal)

LCD-mounted type

(Vertical)

Stand-alone type

(Vertical / Horizontal)

8.4-inch

color LCD

10.4-inch

color LCD

Absent

Present

Absent

Present

Expansion

slot

Absent 5+2 Available AvailableLCD-mounted type

2 5+2 Available N/A

Absent 5+2 Available Available

2 5+2 Available N/A

Absent 5+2 Available AvailableLCD-mounted type

2 5+2 Available N/A

Absent 5+2 Available Available

2 5+2 Available N/A

Absent 10+2 Available N/A

2 10+2 Available N/A

Absent Absent Available N/A

2 Absent Available N/A

Soft key

For the 8.4-inch color LCD, the touch panel is attached to only lathe system CNCs.

0i 0i Mate

- 1 -

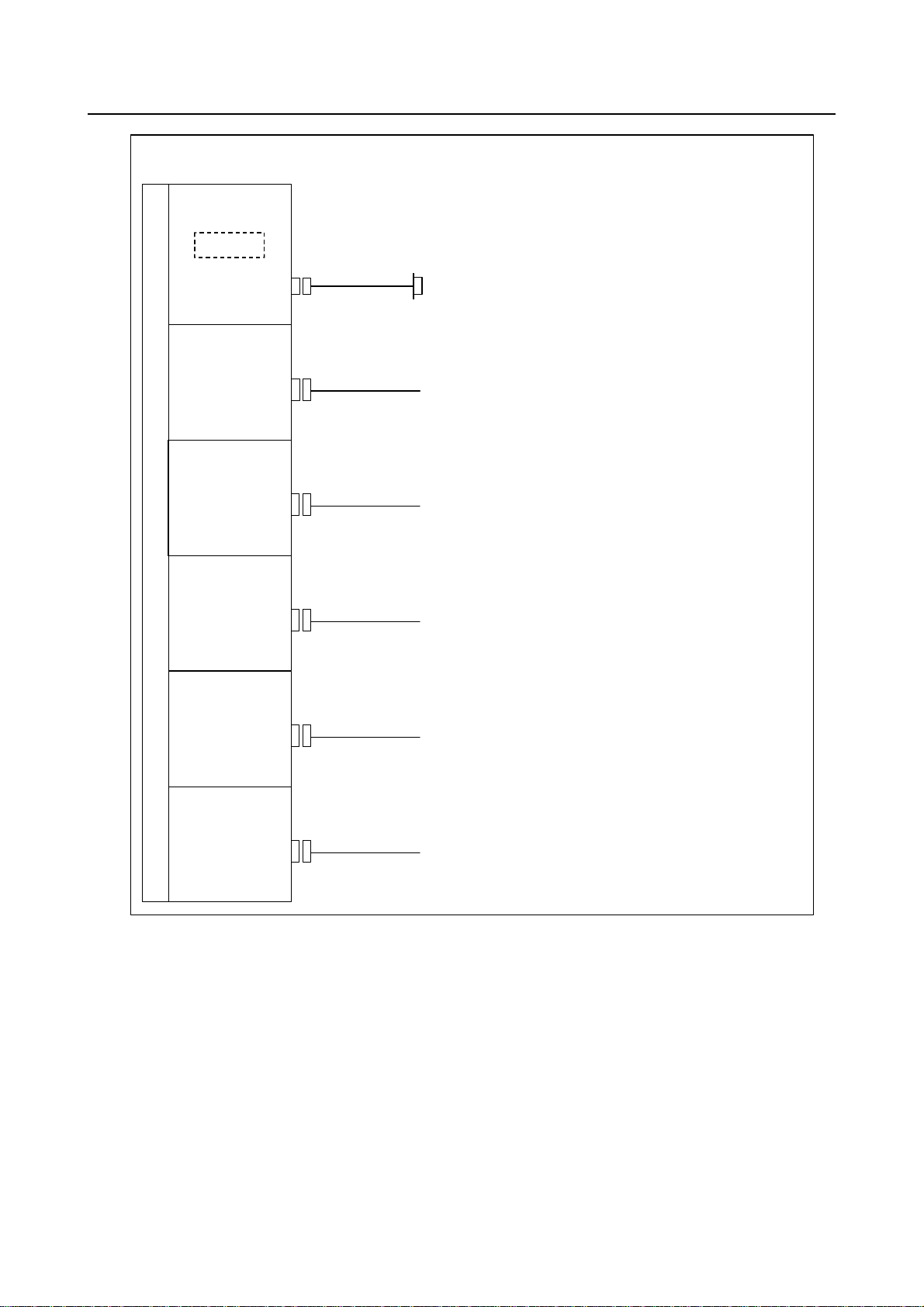

1.CONFIGURATION B-64303EN/03

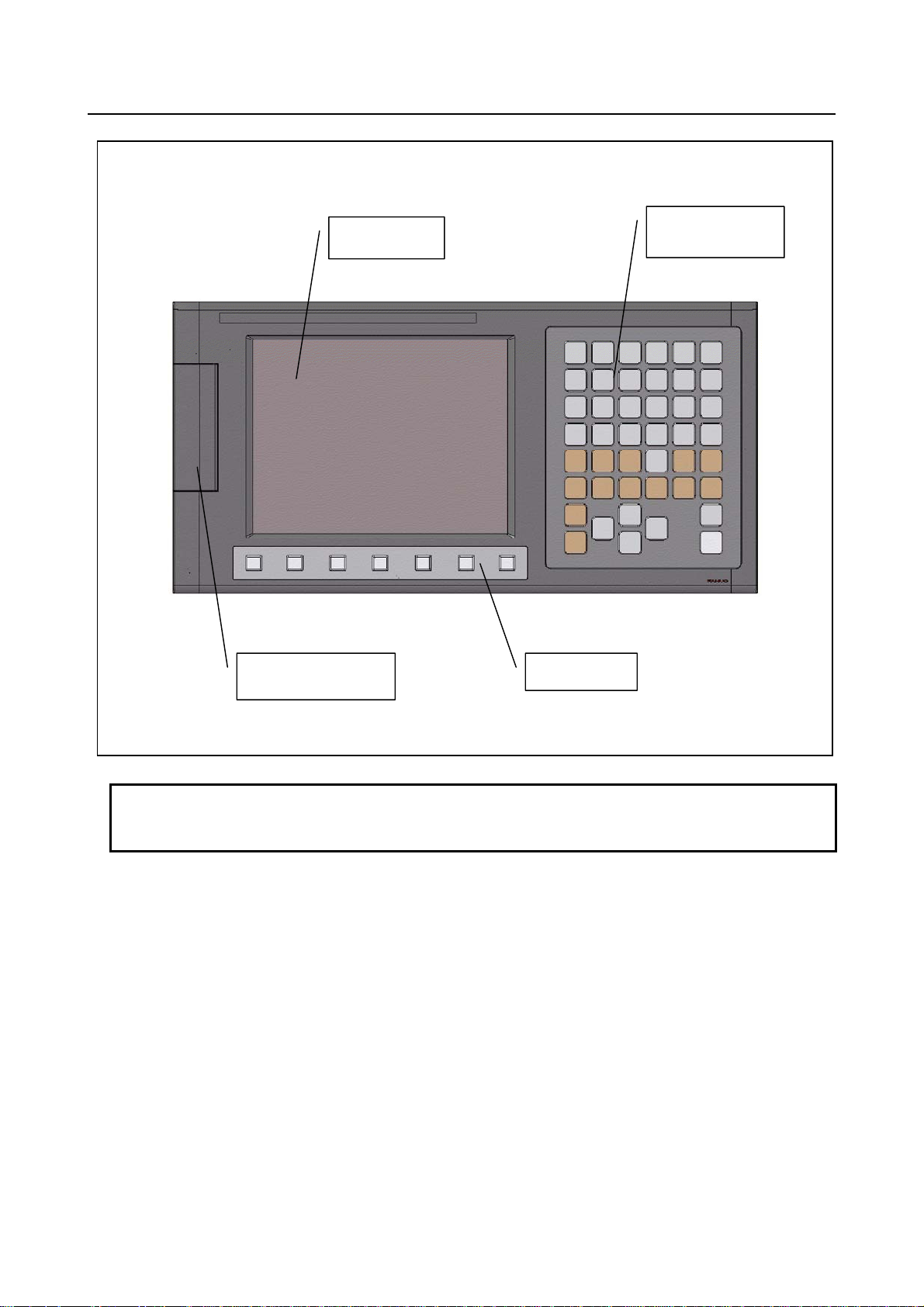

terface

Control unit

LCD

MDI

(See Section 5.1)

Memory card

in

Soft key

NOTE

This figure is a front view of the 8.4-inch color LCD/MDI (horizontal) type control

unit.

- 2 -

B-64303EN/03 1.CONFIGURATION

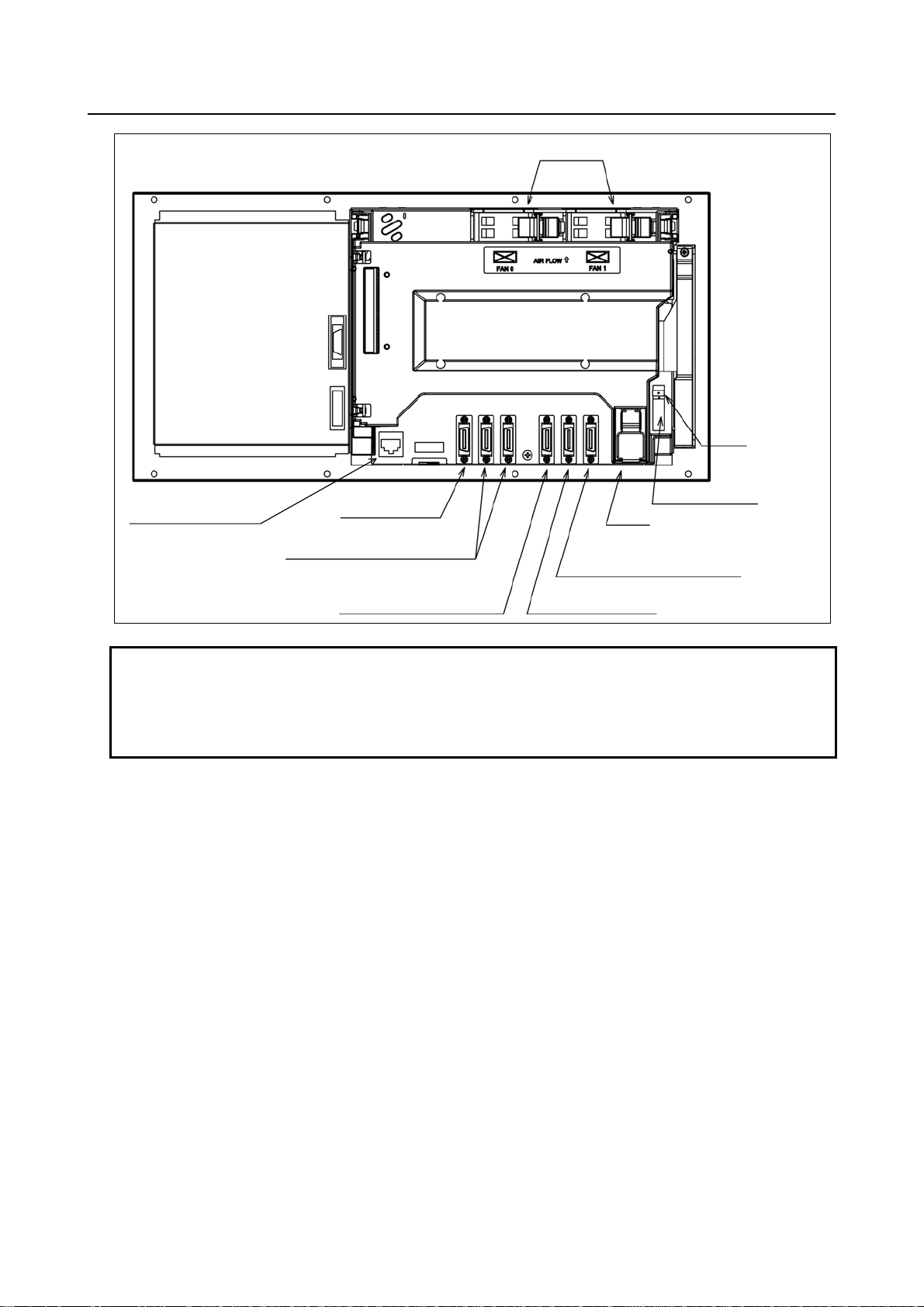

A

Control unit

Ethernet connector

[CD38A](See Section 5.4.)

Rear of unit

MDI connector

[JA2]

I/O device interface connector

[JD36A(left)/JD36A(right)]

nalog spindle connector or

high-speed skip conne c tor

[JA40] (See Section 5.3 or 6.2.)

Fan unit

Fuse

Power supply connector [CP1]

Battery

Serial spindle connector or position

coder connector

[JA41] (See Section 6.1 or 6.3.)

I/O-Link connector

[JD51A] (See Chapter 9.)

NOTE

This figure is a rear view of the control unit without option slots.

The numbers in parentheses () in the figures are keyed to the item numbers of

the descriptions in this manual. The numbers in brackets [] in the figures are

connector numbers.

- 3 -

1.CONFIGURATION B-64303EN/03

(See Chapter 9.)

(See Chapter 9.)

(See Chapter 9.)

(See Chapter 9.)

(See Chapter 9.)

- 4 -

B-64303EN/03 1.CONFIGURATION

A

1.2 HARDWARE OVERVIEW

1.2.1 Control Unit Overview

Fast Ethernet board

Data s erver func tion

Ethernet communication function

• CPU fo r c ontrolling C NC

• Power supply

• Axis control

• Spindle in te r fa c e

• LCD/MDI inte rfa ce

• I/O Link

• PMC control fu n ction

• High-speed DI

• RS-232C

• Memo ry card interface

• Ethernet (

Main board

Series 0i only)

Basic system

Various types of network boards

Profibus master board

Profibus slave board

FL-net board

DeviceNet master board

DeviceNet slave board

The control unit of the Series 0i Mate has no optional slots, so no option board can be inserted.

unit with optional slots can have as many option boards as option slots.

The Fast Ethernet board can be inserted into only the slot on the LCD side.

Options

Unit without op tio nal slots

or

Unit having two optional slots

- 5 -

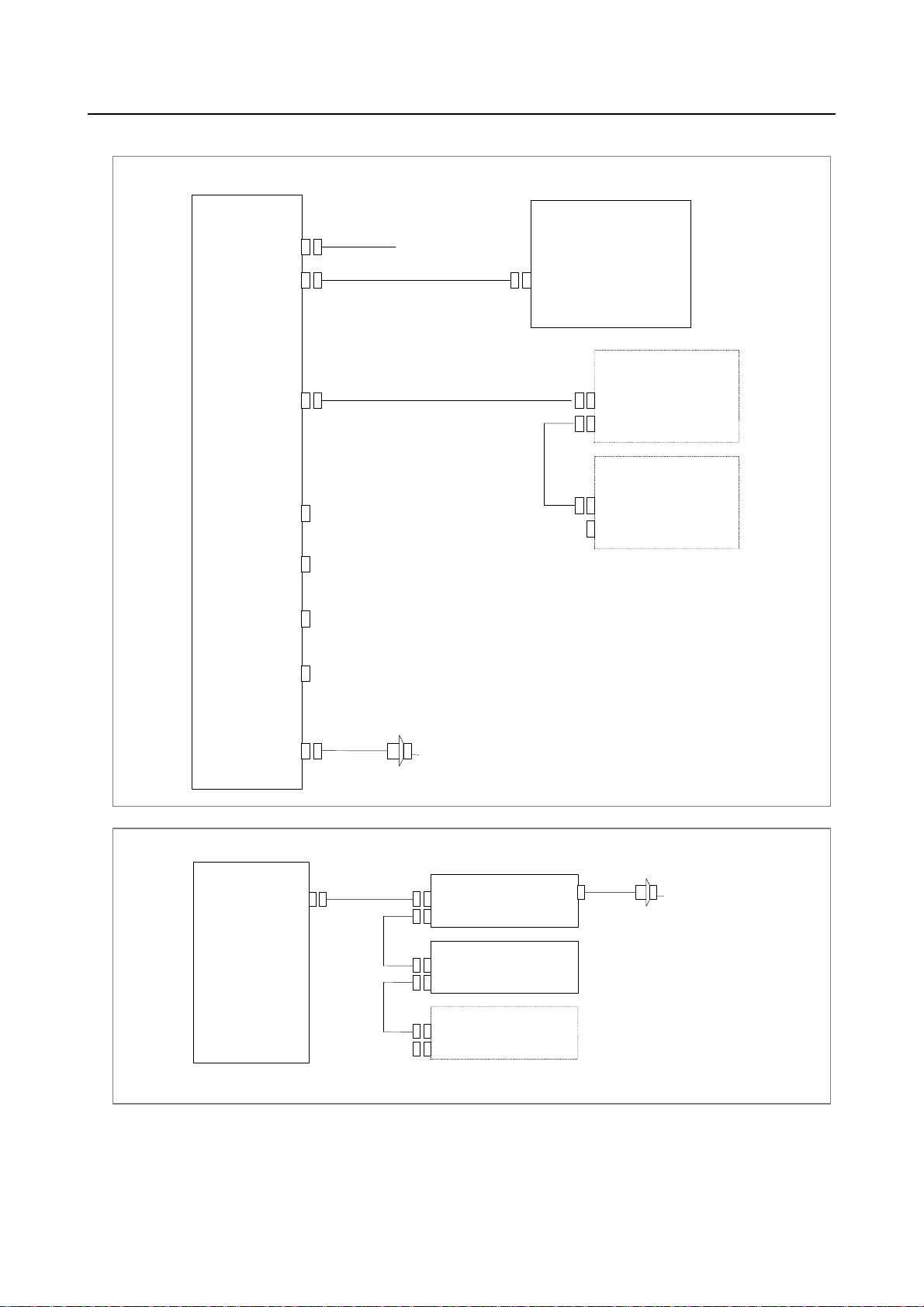

2.TOTAL CONNECTION DIAGRAMS B-64303EN/03

p

A

A

r

A

2 TOTAL CONNECTION DIAGRAMS

LCD-mounted type control unit

Main board

LCD display unit

24V-IN(CP1)

(CA122)

MDI(JA2)

Soft key cable

MDI UNIT

CK1

24 VDC power supply

R232-1(JD36A)

R232-2(JD36B)

A-OUT&HDI(JA40)

I/O Link(JD51A)

SPDL(JA41)

FSSB(COP10A)

24VDC

24VDC

To 3rd spindle

To 2nd spindle

RS-232-C I/O device

{

nalog output for tool drives

High-peed skip input

Distributed I/O

board

CPD1

JD1B

JD1A

CPD1

JD1B

JD1A

COP10B

COP10A

RS-232-C I/O device

Touch panel

JA3

Distributed

I/O board,

I/O unit, etc.

C reacto

αi PS

i

SP

α

i

SV

α

Manual pulse generator

Operator's

anel

Power

magnetics

cabinet

Circuit breaker

200VAC

MCC

Position coder

Serial spindle motor

200VAC

Circuit breaker

Servo motor

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

(In this figure, a 1-axis amplifier is used.)

Separate detector interface unit 1

24VDC

ETHERNET(CD38A)

CP11A

COP10B

COP10A

CNF1

Separate detector interface unit 2

CP11A

Ethernet

α

αi SV

α

JF101

JF102

JF103

JF104

JA4A

JF101

JF102

JF103

JF104

i

SV

i

SV

Linear scale, axis 1

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

bsolute scale battery

(Required only when an absolute scale is used)

Linear scale, axis 1

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

Servo motor

Servo motor

Servo motor

- 6 -

B-64303EN/03 2.TOTAL CONNECTION DIAGRAMS

A

A

A

A

When optional functions are provided

Fast Ethernet board

Optional slot

Memory card

ETHERNET(CD38R)

PROFIBUS-DP

master board

PROFI(CN1)

PROFIBUS-DP

slave board

PROFI(CN2)

DeviceNet

master board

DVNET(TBL)

DeviceNet

slave board

Prepare the memory card recommended by FANUC.

Ethernet

nother NC or Profibus device

nother NC or Profibus device

nother NC or Profibus device

DVNET(TBL)

FL-net board

FLNET(CD38N)

nother NC or Profibus device

FL-net device

- 7 -

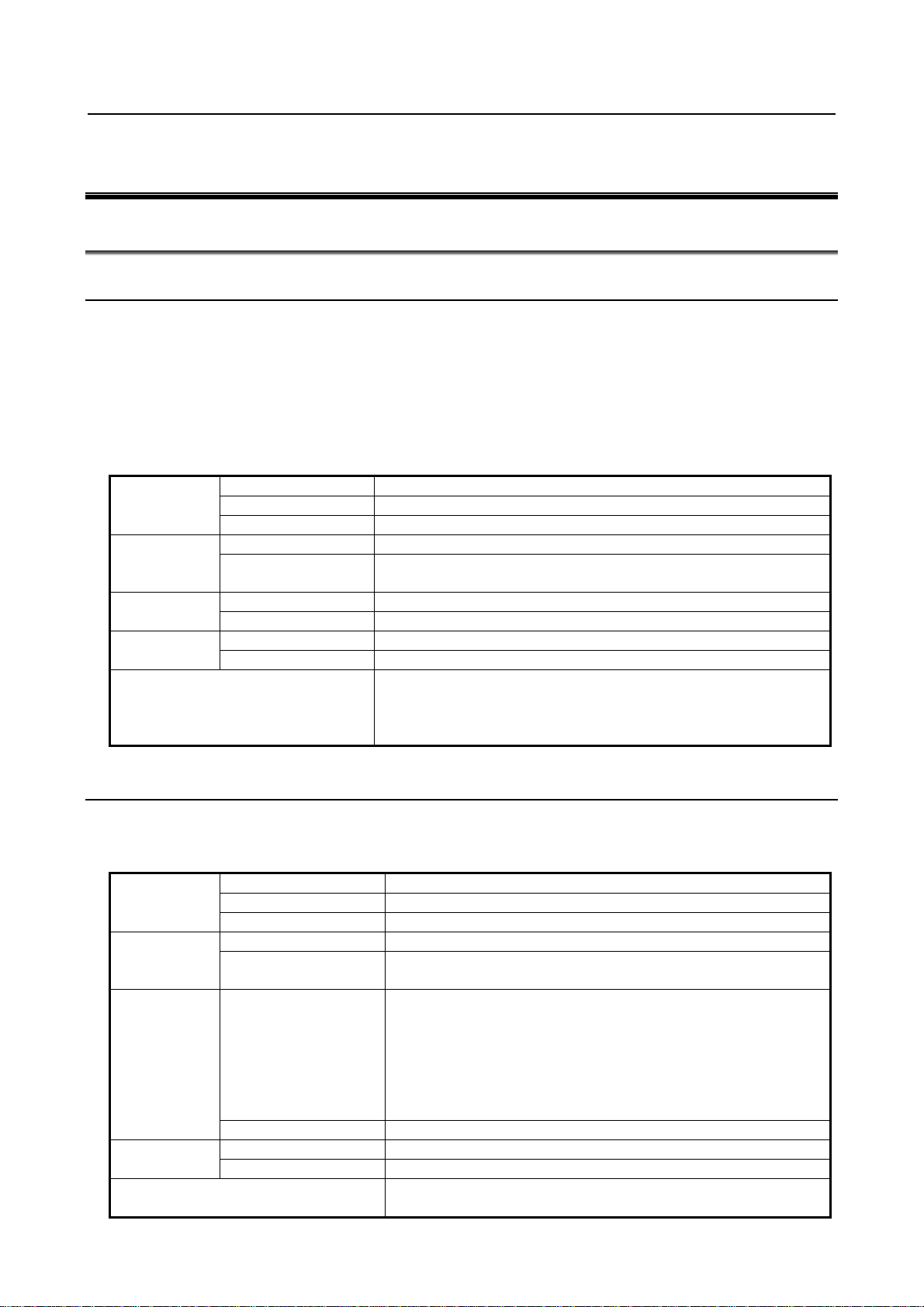

2.TOTAL CONNECTION DIAGRAMS B-64303EN/03

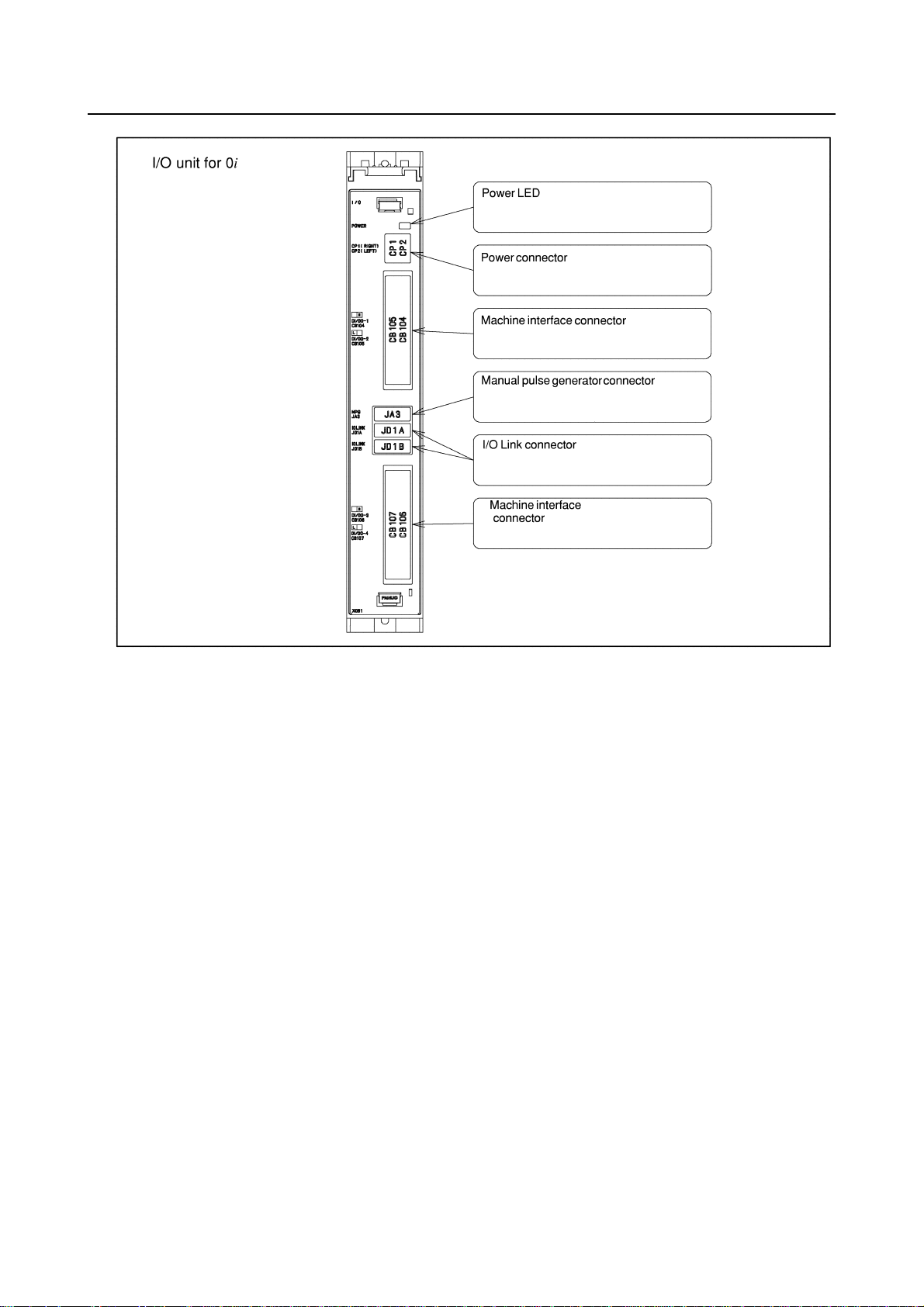

Example of I/O Link connection

Series 0

i

I/O Unit for 0i

(CP1)

I/O Link (JD1B)

I/O Link (JD1A)

DI : 96 points

DO : 64 points

DI/DO-1

(CB104)

DI/DO-2

(CB105)

DI/DO-3

(CB106)

DI/DO-4

(CB107)

Series 0i

Main board

24VDC

JD51A

I/O for operator’s

I/O Link

panel

JD1B

JD1A

I/O Link βi

servo amplifier

JD1B

JD1A

The order in which slave devic es are

connected via I/O Link can be

determined freely.

MPG(JA3)

Manual pulse generator (up to three units)

Series 0i Mate

Series 0i Mate

Main board

I/O Link (JD51A)

I/O Link

I/O for operator’s panel(with MPG)

JD1B

JD1A

I/O for operator’s panel

JD1B

JD1A

I/O Link βi servo

amplifier

The order in which slave de vices are connected via

I/O Link can be determined free ly.

JA3

(without MPG)

Manual pulse generator

(up to three units)

(For the 0i Mate, the numbe r of co nn ec table

amplifiers depends on the model.)

- 8 -

B-64303EN/03 3.INSTALLATION

3 INSTALLATION

3.1 ENVIRONMENTAL REQUIREMENTS

3.1.1 Environmental Conditions External to Cabinets

The peripheral units and the control unit have been designed on the assumption that they are housed in

closed cabinets. In this manual "cabinet" refers to the following:

• Cabinet manufactured by the machine tool builder for housing the control unit or peripheral units;

• Operation pendant, manufactured by the machine tool builder, for housing the LCD/MDI unit or

operator's panel.

• Equivalent to the above.

The environmental conditions when installing these cabinets shall conform to the following table.

Ambient

temperature of

cabinets

Humidity

Vibration

sea level

Environment

Operating 0°C to 45°C

Storage, Transport −20°C to 60°C

Temperature change 0.3°C/minute or less

Normal 75%RH or less, no condensation

Short period

(less than 1 month)

Operating 0.5G or less

Non-operating 1.0G or less

Operating Up to 1000 m (Note) Meters above

Non-operating Up to 12000 m

Normal machine factory environment (These conditions need to be

reviewed separately when the cabinets are installed in an environment

where the concentrations of dust, coolant, organic solvent, and

corrosive gases are relatively high.)

95%RH or less, no condensation

3.1.2 Environmental Conditions of the Control Unit

The environmental conditions for installing the control unit in the cabinets are shown in the following

table. Section 3.3 describes the installation and design conditions of a cabinet satisfying these

conditions.

Ambient

temperature

Humidity

Vibration

sea level

Environment

Operating 0°C to 58°C

Storage, Transport −20°C to 60°C

Temperature change 0.3°C/minute or less

Normal 75%RH or less, no condensation

Short period

(less than 1 month)

A FANUC evaluation test is performed under the following conditions.

10 to 58Hz: 0.075 mm (amplitude)

Operating

Non-operating 1.0G or less

Operating Up to 1000 m (Note) Meters above

Non-operating Up to 12000 m

58 to 500Hz: 1 G

Vibration directions: X, Y, and Z directions

Scanning frequency: 10 cycles

IEC68-2-6 compliant

Prevent coolant, lubricant, and chippings from being applied directly

to on the control unit. Make sure that corrosive gas is not present.

- 9 -

95%RH or less, no condensation

0.5G or less

3.INSTALLATION B-64303EN/03

Normal machine factory environment (take protective measures when

Atmosphere outside the cabinet

the control unit is used in an environment where the concentration of

dust, coolant, organic solvent, corrosive gas is relatively high.)

NOTE

1 If the CNC is installed 1000 m or higher above sea level, the allowable upper

ambient temperature of the CNC in the cabinet is changed as follows.

Assume that the allowable upper ambient temperature of the CNC in the cabinet

installed 1000 m or higher above sea level decreases by 1.0°C for every 100 m

rise in altitude.

Example)

The upper allowable ambient temperature of the CNC in the cabinet installed

1750 m above sea level is:

58°C-(1750-1000)/100×1.0°C=50.5°C

Therefore, the allowable ambient temperature range is from 0°C to 50.5°C.

2 When using a unit for which the installation conditions are specified separately,

the conditions also need to be met.

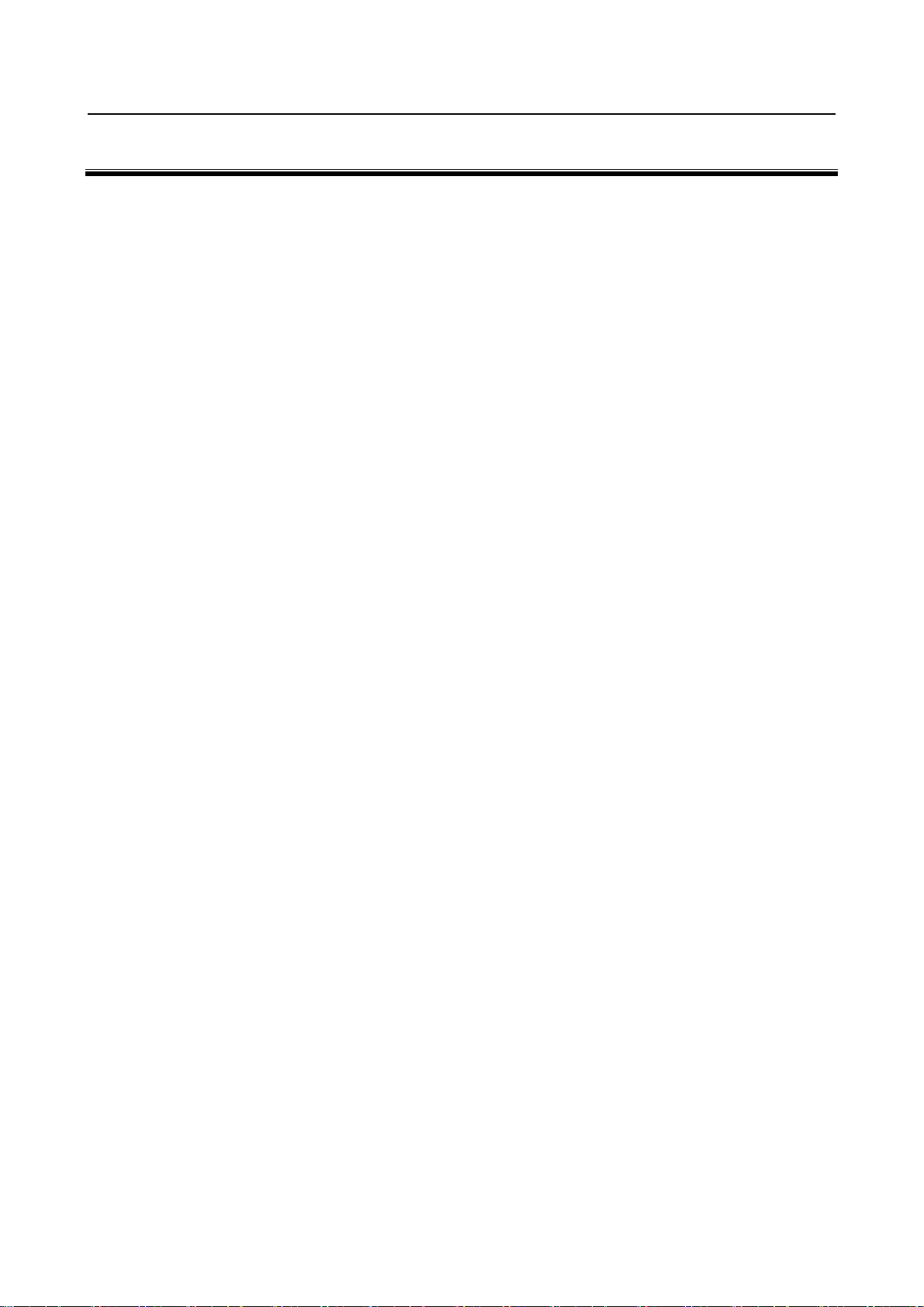

3.2 POWER SUPPLY CAPACITY

3.2.1 Power Supply Capacities of CNC-related Units

The following CNC-related units require an input power supply that satisfies the indicated current

capacities with a power supply voltage of 24 VDC ±10%. Here, note that momentary voltage changes

and ripples are also within ±10% of the power supply voltage.

Table 3.2.1 (a) Power supply capacity

Unit Power supply capacity Remarks

With no-optional slot

With two optional slots

Optional board

Fast Ethernet board

Profibus master board

Profibus slave board

FL-net board

DeviceNet master board

DeviceNet slave board

NOTE

1 The liquid-crystal display and MDI unit are included. Optional boards are not

included.

2 When connecting an RS-232-C unit (powered by the NC) to the RS-232-C port,

add the current capacity of the unit. Up to 1 A can be supplied from the two

channels of the port.

3 Use memory cards that consume no more than 2 W.

4 For other peripheral units (such as I/O units), see Table 3.2.1 (b) and also refer

to the relevant manuals.

5 When you select the input DC power supply for the CNC control section,

consider the restrictions other than the power supply capacity. Be sure to see

also Subsection 4.2.2.

1.5A

1.7A

0.2A

0.2A

0.1A

0.2A

0.1A

0.1A

Note 1) Control unit

Note 1)

- 10 -

B-64303EN/03 3.INSTALLATION

Table 3.2.1 (b) Power supply rating (peripheral units)

Unit Power supply capacity Remarks

MDI unit 0A

Standard machine operator’s panel 0.4A

Operator's panel I/O module 0.3A+7.3mA×DI

Connector panel I/O module (basic) 0.2A+7.3mA×DI

Connector panel I/O module (additional) 0.1A+7.3mA×DI

I/O unit for 0i

Separate detector interface unit 0.9A Basic 4-axis unit only

Separate detector interface unit 1.5A Basic 4 axes + additional 4 axes

0.3A+7.3mA×DI

NOTE

The power supply capacity for DO is not assumed for I/O units.

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE

MACHINE TOOL MAGNETIC CABINET

When a cabinet is designed, it must satisfy the environmental conditions described in Section 3.1. In

addition, the magnetic interference on the screen, noise resistance, and maintenance requirements must be

considered. The cabinet design must meet the following conditions :

(1) The cabinet must be fully closed.

The cabinet must be designed to prevent the entry of airborne dust, coolant, and organic solvent.

(2) The cabinet must be designed so that the permissible temperature of each unit is not exceeded. For

actual heat design, see Section 3.4.

(3) A closed cabinet must be equipped with a fan to circulate the air within. (This is not necessary for

a unit with fan.)

The fan must be adjusted so that the air moves at 0.5 m/sec along the surface of each installed unit.

CAUTION

If the air blows directly from the fan to the unit, dust easily adheres to the unit.

This may cause the unit to fail. (This is not necessary for a unit with fan.)

(4) For the air to move easily, a clearance of 100 mm is required between each unit and the wall of the

cabinet.

(5) Packing materials must be used for the cable port and the door in order to seal the cabinet.

(6) The display unit must not be installed in such a place that coolant would directly fall onto the unit.

The control unit has a dust-proof front panel, but the unit should not be placed in a location where

coolant would directly fall onto it.

(7) Noise must be minimized.

As the machine and the CNC unit are reduced in size, the parts that generate noise may be placed

near noise-sensitive parts in the magnetics cabinet.

The CNC unit is built to protect it from external noise. Cabinet design to minimize noise

generation and to prevent it from being transmitted to the CNC unit is necessary. See section 3.5

for details of noise elimination/management.

(8) When placing units in the cabinet, also consider ease of maintenance.

The units should be placed so that they can be checked and replaced easily when maintenance is

performed.

(9) The installation conditions of the I/O unit and connector panel I/O module must be satisfied.

To obtain good ventilation in the module, the I/O unit and connector panel I/O module must be

installed in the direction shown in the following figure. Clearances of 100 mm or more both above

and below the I/O unit are required for wiring and ventilation.

- 11 -

3.INSTALLATION B-64303EN/03

Equipment radiating too much heat must not be put below the I/O unit and connector panel I/O

module.

Top

Connector panel I/O module or

I/O base unit

(No screws or protrusions shall extend

from the bottom of this unit.)

Bottom

3.4 THERMAL DESIGN OF THE MACHINE TOOL MAGNETIC

CABINET

The internal air temperature of the cabinet increases when the units and parts installed in the cabinet

generate heat. Since the generated heat is radiated from the surface of the cabinet, the temperature of the

air in the cabinet and the outside air balance at certain heat levels. If the amount of heat generated is

constant, the larger the surface area of the cabinet, the less the internal temperature rises. The thermal

design of the cabinet refers to calculating the heat generated in the cabinet, evaluating the surface area of

the cabinet, and enlarging that surface area by installing heat exchangers in the cabinet, if necessary.

Such a design method is described in the following subsections.

3.4.1 Temperature Rise within the Machine Tool Magnetic Cabinet

The cooling capacity of a cabinet made of sheet metal is generally 6 W/°C per 1m2 surface area, that is,

when the 6W heat source is contained in a cabinet having a surface area of 1 m

in the cabinet rises by 1°C. In this case the surface area of the cabinet refers to the area useful in

cooling , that is, the area obtained by subtracting the area of the cabinet touching the floor from the total

surface area of the cabinet. There are two preconditions : The air in the cabinet must be circuited by the

fun, and the temperature of the air in the cabinet must be almost constant.

In the case of the operator's panel cabinet for example, to limit the temperature within the operator's panel

cabinet to 58°C or less when the ambient temperature is 45°C, satisfy the following expression.

Internal heat loss P [W] ≤

2

6[W/m

⋅°C] × surface area S[m2] × 13[°C] of rise in temperature

(A cooling capacity of 6 W/°C assumes the cabinet is so large that agitation with the fan motor does not

make the temperature distribution uniform. For a small cabinet like the operator's panel, a cooling

capacity of 8 W/°C, indicated in Subsection 3.4.4, may be used.)

For example, a cabinet having a surface area of 4m

2

has a cooling capacity of 24W/°C. To limit the

internal temperature increase to 13°C under these conditions, the internal heat must not exceed 312W.

If the actual internal heat is 360W, however, the temperature in the cabinet rises by 15°C or more.

When this happens, the cooling capacity of the cabinet must be improved using the heat exchanger.

In the case of the power magnetics cabinet for housing cabinet the I/O unit for 0i, limit the internal

temperature increase to 10°C or less, not 13°C or less.

2

, the temperature of the air

3.4.2 Heat Output of Each Unit

Table 3.4.2 (a) Heat output

Unit Heat output Remarks

With no-optional slot

With two optional slots

- 12 -

33W

37W

Note 1) Control unit

Note 1)

Loading...

Loading...