Emerson 168, 168H Data Sheet

Bulletin 71.7:168

September 2009

Types 168, 168H, and 68-2 Three-Way, Snap-

Acting Switching Valves

Introduction

The Types 168 and 168H three-way, snap-acting switching valves provide fast, positive switching of pneumatic pressures in response to a predetermined change in a pneumatic input signal. These switches can be used to open and close pneumatically operated control valves, to load or exhaust pneumatic systems, or to operate a variety of pneumatic equipment.

Units are available for handling body pressures up to 150 psig (10,3 bar) with diaphragm pressures from 2 to 150 psi (0,14 to 10,3 bar). Maximum and minimum diaphragm pressure changes between switching points are shown in Table 1. The diaphragm pressures at which switching occurs are determined by the locations of the adjusting nuts. Types 168 and 168H switching valves are also available with a manual reset lever (see Figure 4).

The Type 68-2, shown in Figures 1 and 3, is a three-way, snap-acting switching valve that forms the valve body portion of the Types 168 and 168H switching valves. A manual reset switch, see Figure 4, may be adapted to the Types 168 and 168H switching valves to provide for manual reset. An extension of the trip lever allows the Type 68-2 to be used as a manual switching valve.

Features

• Fast, Positive Switching Action—Trip lever motion increases spring load on the seat until the lever and spring mechanism passes dead center; then valve spring force “snaps” the rocker to its alternate position. Soft seat construction and fast switching action minimize leakage and throttling between seat rings.

• Full Adjustability—High and low tripping pressures can be adjusted throughout diaphragm pressure range.

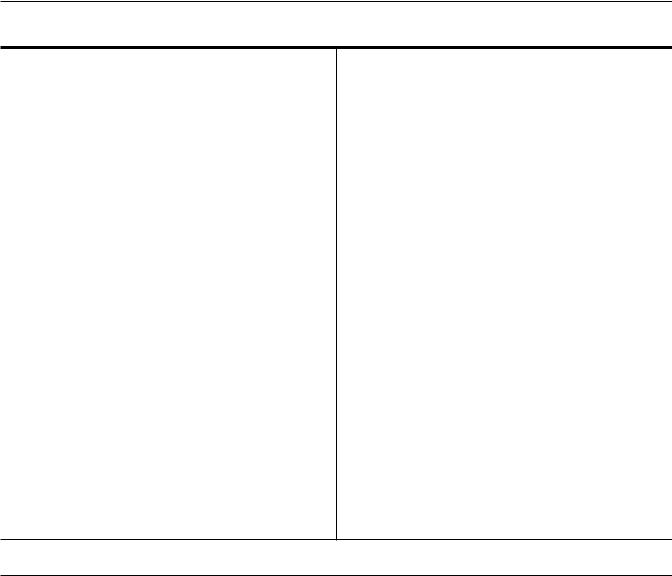

W1932 |

TYPE 68-2 |

|

|

|

TYPE 168 |

Figure 1. Type 168 Switching Valve and Type 68-2 Trip Lever

• Three-Way or On/Off Action—With one connection (either B or C) plugged, unit can be used as on/off switch.

• Suitable for Sour Gas Service—No brass or bronze in trim parts.

• Automatic or Manual Reset—Unit may be set to automatically reset after tripping, keeping

the pressure within the selected range. With both adjusting nuts in place, the unit trips at the upper (or lower) pressure limit and resets automatically when the lower (or upper) limit is reached. With one adjusting nut in place, the unit trips at the high (or low) pressure limit and remains in that position until it is reset. Reset may be achieved by removing the stem protector and tripping the switch or by tripping an optional reset lever (see Figure 4).

D200078X012

www.emersonprocess.com/regulators

Bulletin 71.7:168

Specifications

Available Configurations

Type 68-2: Manual three-way switching valve Type 168: Pneumatically operated three-way, snap-acting switching valve with diaphragm pressure range of 2 to 40 psig (0,14 to 2,8 bar) or 2 to 60 psig (0,14 to 4,1 bar)

Type 168H: Pneumatically operated three-way, snap-acting switching valve with diaphragm pressure range of 35 to 100 psig (2,4 to 6,9 bar)

or 50 to 150 psig (3,4 to 10,3 bar)

Maximum Allowable Pressures(1)

See Table 1

Temperature Capabilities(1, 2)

-10° to 150°F (-23° to 66°C)

Flow Coefficients

Cg: 7 Representative C1: 35

Port Diameter

3/32-inches (2,4 mm)

Types 168 and 168H Options

• Mounting bracket suitable for use with 2-inch

(51 mm) (nominal) pipestand

• Control valve yoke mounting parts

• Manual Reset switch

Pressure Connections

1/4 NPT internal

Mounting

Type 68-2: See Figure 3 for panel mounting Types 168 and 168H: Can be mounted using two tapped holes in the spring case, optional mounting bracket (see Figure 4), or optional control valve yoke mounting parts

Approximate Weights

Type 68-2: 0.5 pound (0,2 kg) Type 168: 3 pounds (1 kg) Type 168H: 5 pounds (2 kg)

Construction Materials

Body and Cases: Aluminum

Diaphragm: Dacron® covered with Nitrile (NBR) Seat Rings: Stainless steel

Rocker Assembly: Glass-filled nylon (PA) with polyurethane valve disks

Stem and Adjusting Nuts: Stainless steel

Stem Bushing: Steel and

Polytetrafluoroethylene PTFE

O-Rings: Nitrile (NBR)

Actuator Spring: Steel

Valve Spring: Stainless steel Trip Lever: Stainless steel

Stem Protector: Plastic

1. The pressure/temperature limits in this bulletin or any applicable standard limitation should not be exceeded.

2. This term is defined in ISA Standard S51.1-1979.

Dacron® is a mark owned by E.I. du Pont de Nemours and Co.

Table 1. Maximum Pressures and Spring Color Codes

|

DIAPHRAGM PRESSURE CHANGE |

DIAPHRAGM |

|

MAXIMUM |

|

|||||

|

BETWEEN SWITCHING POINTS, |

DIAPHRAGM |

ALLOWABLE |

BODY SPRING |

||||||

TYPE NUMBER |

|

PSIG (bar) |

|

PRESSURE RANGE, |

SPRING COLOR |

BODY PRESSURE, |

COLOR |

|||

|

|

|

|

|

PSIG (bar) |

|

PSIG (bar) |

|

||

|

Minimum |

Maximum |

|

|

||||||

|

|

|

|

|

||||||

68-2 |

- - - - |

- - - - |

- - - - |

- - - - |

150 |

(10,3) |

Unpainted |

|||

|

|

|

|

|

|

|

|

|

|

|

168-1 |

10 |

(0,69) |

58 |

(4,0) |

2 to 60 |

(0,14 to 4,1) |

Green |

150 |

(10,3) |

Unpainted |

168-2 |

10 |

(0,69) |

38 |

(2,6) |

2 to 40 |

(0,14 to 2,8) |

Yellow |

150 |

(10,3) |

Unpainted |

168-3 |

10 |

(0,69) |

58 |

(4,0) |

2 to 60 |

(0,14 to 4,1) |

Green |

40 |

(2,8) |

Yellow |

168-4 |

7 |

(0,48) |

38 |

(2,6) |

2 to 40 |

(0,14 to 2,8) |

Yellow |

40 |

(2,8) |

Yellow |

168H-1 |

20 |

(1,38) |

100 |

(6,9) |

50 to 150 |

(3,4 to 10,3) |

Green |

150 |

(10,3) |

Unpainted |

168H-2 |

20 |

(1,38) |

65 |

(4,5) |

35 to 100 |

(2,4 to 6,9) |

Yellow |

150 |

(10,3) |

Unpainted |

168H-3 |

20 |

(1,38) |

100 |

(6,9) |

50 to 150 |

(3,4 to 10,3) |

Green |

40 |

(2,8) |

Yellow |

168H-4 |

16 |

(1,10) |

65 |

(4,5) |

35 to 100 |

(2,4 to 6,9) |

Yellow |

40 |

(2,8) |

Yellow |

2

Loading...

Loading...