Emerson 1301, 1301F, 1301G Instruction Manual

Instruction Manual

Form 1111

December 2013

Types 1301F and 1301G

1301 Series High-Pressure Regulators

!WARNING

Failure to follow these instructions or to properly install and maintain this equipment could result in an explosion, fi re and/or chemical contamination causing property damage and personal injury or death.

Fisher® regulators must be installed, operated, and maintained in accordance with federal, state and local codes, rules and regulations, and Fisher instructions.

If the regulator vents gas or a leak develops in the system, service to the unit may be required. Failure to correct trouble could result in a hazardous condition.

Installation, operation, and maintenance procedures performed by unqualifi ed personnel may result in improper adjustment and unsafe operation. Either condition may result in equipment damage or personal injury. Use qualifi ed personnel when installing, operating, and maintaining the 1301 Series highpressure regulator.

P1025

Figure 1. Type 1301F High-Pressure Regulator

Introduction

Scope of the Manual

This Instruction Manual provides instructions for the installation, adjustment, maintenance, and parts ordering of the Types 1301F and 1301G high-pressure regulators.

Product Description

Types 1301F and 1301G regulators are direct-operated, high-pressure regulators, which can be used where high-pressure gas must be reduced for use as pilot

supply pressure in pilot-operated regulators or as loading pressure in pressure-loaded regulators.

Types 1301F and 1301G regulators can also be used in many other applications due to their rugged design as high-pressure reducing regulators for various fl uids such as air, gas, water, and other liquids.

The Type 1301F can handle outlet pressures from

10 to 225 psig / 0.69 to 15.5 bar in three ranges and the Type 1301G can handle outlet pressures from 200 to 500 psig / 13.8 to 34.5 bar in one range.

D100341X012

www.fisherregulators.com

Types 1301F and 1301G

Specifications

Specifications section lists the specifications for Types 1301F and 1301G high-pressure regulators. The maximum outlet pressure for a given regulator as it comes from the factory is stamped on the regulator nameplate.

Available Configurations

Type 1301F: Direct-operated, high-pressure reducing regulator for inlet pressures to 6000 psig / 414 bar and outlet pressure ranges from 10 to 225 psig / 0.69 to 15.5 bar in three ranges

Type 1301G: Direct-operated, high-pressure reducing regulator for inlet pressures to 6000 psig / 414 bar and an outlet pressure range of

200 to 500 psig / 13.8 to 34.5 bar

Body Size and End Connection Style

1/4 NPT (one inlet and two or three outlet connections), CL300 RF, CL600 RF, and CL1500 RF; or PN 25 RF (all flanges are 125 RMS)

Maximum Allowable Inlet Pressure(1)

Brass Body:

Air and Gas:

6000 psig / 414 bar at or below 200°F / 93°C and 1000 psig / 69.0 bar above 200°F / 93°C

Liquid:

Polytetrafluoroethylene (PTFE) Disk:

1000 psig / 69.0 bar

Nylon (PA) Disk:

Water: 1000 psig / 69.0 bar Other Liquids: 2000 psig / 138 bar

Stainless Body:

Air and Gas: 6000 psig / 414 bar

Liquid:

Polytetrafluoroethylene (PTFE) Disk:

1000 psig / 69.0 bar

Nylon (PA) Disk:

Water: 1000 psig / 69.0 bar Other Liquids: 2000 psig / 138 bar

Outlet Pressure Ranges

See Table 1

Maximum Emergency Outlet Pressure(1)

Type 1301F: 250 psig / 17.2 bar Type 1301G: 550 psig / 37.9 bar

Wide-Open Flow Coefficients for Relief Valve Sizing

Cg: 5.0 Cv: 0.13 C1: 38.5

IEC Sizing Coefficients

XT: 0.938

FD: 0.50

FL: 0.85

Recovery Coefficient

Km: 0.72

Material Temperature Capabilities(1)

Nylon (PA) Valve Disk and

Neoprene (CR) Gaskets:

-20 to 180°F / -29 to 82°C

PTFE Valve Disk and Fluorocarbon (FKM)

Gaskets: -20 to 400°F / -29 to 204°C(2)

PTFE Valve Disk and Ethylenepropylene (EPDM)

Gaskets: -40 to 300°F / -40 to 149°C

Low Temperature Service

Service to -65°F / -54°C is available with low temperature bolting and special low temperature

Nitrile (NBR) O-rings to replace the gaskets.

Service to -80°F / -62°C is available with low temperature bolting and special low temperature Fluorosilicone (FVQM) O-rings to replace

the gaskets.

Pressure Registration

Internal

Orifice Size

5/64 inch / 2.0 mm

Spring Case Vents

Type 1301F Brass Spring Case:

Four 5/32-inch / 4.0 mm holes

Type 1301F Stainless Steel Spring Case:

One 1/4 NPT connection

Type 1301G Spring Case:

One 1/8 NPT connection with screen

Approximate Weight

8 pounds / 4 kg

1.The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2.Fluorocarbon (FKM) is limited to 180°F / 82°C hot water.

2

Types 1301F and 1301G

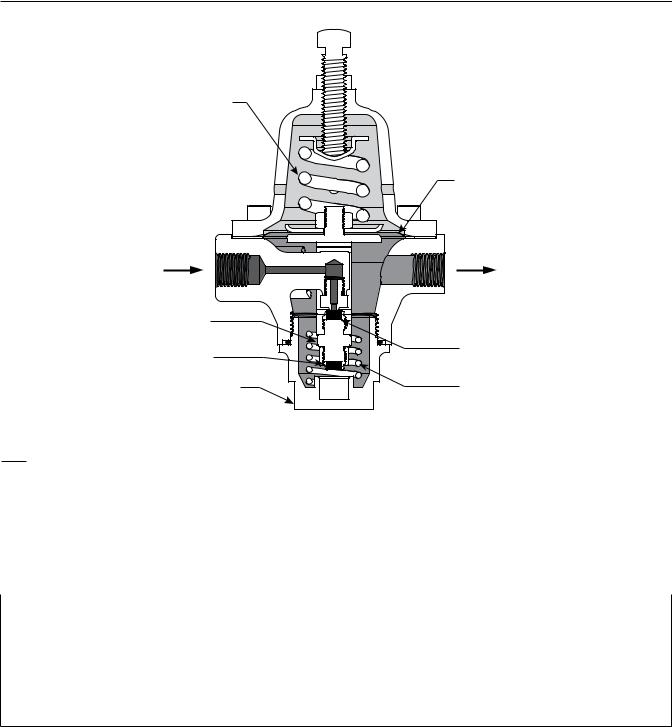

CONTROL SPRING

DIAPHRAGM

DISK HOLDER |

SPARE DISK |

VALVE DISK |

|

|

BOTTOM CAP |

VALVE SPRING |

M1015

Inlet pressure

Inlet pressure

Outlet pressure

Outlet pressure

atmospheric pressure

atmospheric pressure

Figure 2. Type 1301F Operational Schematic

Table 1. Outlet Pressure Ranges

|

OUTLET PRESSURE |

|

|

SPRING WIRE DIAMETER |

SPRING FREE LENGTH |

|||

TYPE |

RANGES(1) |

SPRING COLOR |

SPRING PART NUMBER |

|||||

|

psig |

bar |

|

|

Inch |

mm |

Inch |

mm |

|

10 to 75 |

0.69 to 5.2 |

Blue |

1D387227022 |

0.200 |

5.08 |

|

|

|

|

|

|

|

|

|

|

|

1301F |

50 to 150 |

3.4 to 10.3 |

Silver |

1B788527022 |

0.225 |

5.72 |

1.69 |

42.9 |

|

|

|

|

|

|

|

|

|

|

100 to 225 |

6.9 to 15.5 |

Red |

1D465127142 |

0.243 |

6.17 |

|

|

|

|

|

|

|

|

|

|

|

1301G |

200 to 500 |

13.8 to 34.5 |

Silver |

1K156027142 |

0.331 |

8.41 |

0.88 |

22.4 |

|

|

|

|

|

|

|

|

|

1. All springs can be backed off to 0 psig / 0 bar.

Principle of Operation

The 1301 Series regulators are direct-operated.

Downstream pressure is registered internally through the body to the underside of the diaphragm. When downstream pressure is at or above set pressure, the disk is held against the orifice and there is no flow through the regulator. When demand increases, downstream pressure decreases slightly allowing the

regulator spring to extend, moving the yoke and disk assembly down and away from the orifice. This allows flow through the body to the downstream system. As the downstream pressure reaches its setpoint, it starts to overcome the spring force, which is sensed by the diaphragm, moving the yoke and disk assembly up near its orifice, restricting flow across the regulator.

3

Loading...

Loading...