Page 1

Troubleshooting Guide

Fuller® Heavy-Duty Transmissions

TRTS0910 EN-US

October 2007

Page 2

Models

FR-11210B

FR-12210B

FR-13210B

FR-14210B

FR-15210B

FR-9210B

FRF-11210B

FRF-12210B

FRF-13210B

FRF-14210B

FRF-15210B

FRF-9210B

FRO-11210B

FRO-11210C

FRO-12210B

FRO-12210C

FRO-13210B

FRO-13210C

FRO-14210B

FRO-14210C

FRO-15210B

FRO-15210C

RTXF-14615

RTXF-14708LL

FRO-16210B

FRO-16210C

FRO-17210C

FRO-18210C

FROF-11210B

FROF-11210C

FROF-12210B

FROF-12210C

FROF-13210B

FROF-13210C

FROF-14210B

FROF-14210C

FROF-15210B

FROF-15210C

FROF-16210B

FROF-16210C

RT-7608LL

RT-8608L

RT-8908LL

RTF-8608L

RTF-8908LL

RTLO-11610B

RTXF-14709H

RTXF-14710B

RTLO-11610B-T2

RTLO-12610B

RTLO-12610B-T2

RTLO-12713A

RTLO-12913A

RTLO-13610B

RTLO-13610B-T2

RTLO-14610A

RTLO-14610B

RTLO-14610B-T2

RTLO-14613B

RTLO-14618A

RTLO-14713A

RTLO-14718B

RTLO-14913A

RTLO-14918B

RTLO-14918B-T2

RTLO-15610B

RTLO-15610B-T2

RTLO-16610B

RTLO-16610B-T2

RTLO-16618A

RTXF-14710C

RTLO-16713A

RTLO-16713A-T2

RTLO-16718B

RTLO-16913A

RTLO-16913A-T2

RTLO-16918B

RTLO-16918B-T2

RTLO-17610B

RTLO-17610B-T2

RTLO-18610B

RTLO-18610B-T2

RTLO-18718B

RTLO-18718B-T2

RTLO-18913A

RTLO-18913A-T2

RTLO-18918B

RTLO-18918B-T2

RTLO-20913A

RTLO-20918B

RTLO-20918B-T2

RTLO-22918B

RTLOC-16909A-T2

RTXF-14715

RTLOF-11610B

RTLOF-11610B-T2

RTLOF-12610B

RTLOF-12610B-T2

RTLOF-12713A

RTLOF-12913A

RTLOF-13610B

RTLOF-13610B-T2

RTLOF-14610B

RTLOF-14610B-T2

RTLOF-14613B

RTLOF-14618A

RTLOF-14713A

RTLOF-14718B

RTLOF-14913A

RTLOF-14918B

RTLOF-14918B-T2

RTLOF-15610B

RTLOF-15610B-T2

RTLOF-16610B

RTLOF-16610B-T2

RTLOF-16618A

RTXF-15615

RTLOF-16713A

RTLOF-16713A-T2

RTLOF-16718B

RTLOF-16913A

RTLOF-16913A-T2

RTLOF-16918B

RTLOF-16918B-T2

RTLOF-17610B

RTLOF-17610B-T2

RTLOF-18610B

RTLOF-18718B

RTLOF-18913A

RTLOF-18913A-T2

RTLOF-18918B

RTLOF-18918B-T2

RTLOF-20913A

RTLOF-20918B

RTLOF-20918B-T2

RTLOF-22918B

RTLOFC-16909A-T2

RTO-11607L

RTO-11607L

RTXF-15710B

RTO-11607LL

RTO-11607LL

RTO-11608LL

RTO-11707DLL

RTO-11707LL

RTO-11708LL

RTO-11709MLL

RTO-11908LL

RTO-11909ALL

RTO-11909MLL

RTO-13707DLL

RTO-13707MLL

RTO-14608LL

RTO-14709MLL

RTO-14908LL

RTO-14909ALL

RTO-14909MLL

RTO-16908LL

RTO-16909ALL

RTOF-11607L

RTOF-11607LL

RTOF-11608LL

RTXF-15710C

RTOF-11707LL

RTOF-11708LL

RTOF-11709MLL

RTOF-11908LL

RTOF-11909ALL

RTOF-11909MLL

RTOF-13707DLL

RTOF-13707MLL

RTOF-14608LL

RTOF-14708LL

RTOF-14709MLL

RTOF-14908LL

RTOF-14909ALL

RTOF-14909MLL

RTOF-16908LL

RTOF-16909ALL

RTX-11509

RTX-11608LL

RTX-11609A

RTX-11609B

RTX-11609P

RTX-11609R

RTXF-15715

RTX-11610

RTX-11615

RTX-11708LL

RTX-11709A

RTX-11709B

RTX-11709H

RTX-11710B

RTX-11710C

RTX-11715

RTX-12509

RTX-12510

RTX-12515

RTX-12609A

RTX-12609B

RTX-12609P

RTX-12609R

RTX-12610

RTX-12709A

RTX-12709B

RTX-12709H

RTX-12710B

RTX-12710C

RTXF-16709B

RTX-13609A

RTX-13609B

RTX-13609P

RTX-13609R

RTX-13709H

RTX-13710B

RTX-13710C

RTX-14608LL

RTX-14609A

RTX-14609B

RTX-14609P

RTX-14609R

RTX-14610

RTX-14615

RTX-14708LL

RTX-14709A

RTX-14709B

RTX-14709H

RTX-14710B

RTX-14710C

RTX-14715

RTX-15615

RTXF-16709H

RTX-15710B

RTX-15710C

RTX-15715

RTX-16709B

RTX-16709H

RTX-16710B

RTX-16710C

RTXF-11509

RTXF-11608LL

RTXF-11609A

RTXF-11609B

RTXF-11609P

RTXF-11609R

RTXF-11610

RTXF-11615

RTXF-11708LL

RTXF-11709H

RTXF-11710B

RTXF-11710C

RTXF-11715

RTXF-12509

RTXF-12510

RTXF-16710B

RTXF-12515

RTXF-12609A

RTXF-12609B

RTXF-12609P

RTXF-12609R

RTXF-12610

RTXF-12709H

RTXF-12710B

RTXF-12710C

RTXF-13609A

RTXF-13609B

RTXF-13609P

RTXF-13609R

RTXF-13709H

RTXF-13710B

RTXF-13710C

RTXF-14608LL

RTXF-14609A

RTXF-14609B

RTXF-14609P

RTXF-14609R

RTXF-14610

RTXF-16710C

Page 3

Warnings

Warnings

WARNING

WARNING

WARNING

WARNINGS

Before starting a vehicle always be seated in the driver’s

seat, place the transmission in neutral, set the parking

brakes and disengage the clutch.

Before working on a vehicle, place the transmission in

neutral, set the parking brakes and block the wheels.

Before towing the vehicle, place the transmission in neutral

and lift the rear wheels off the ground or disconnect the

driveline to avoid damage to the transmission during

towing.

0

Page 4

Table of Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TRANSMISSION FUNCTION . . . . . . . . . . . . . . . 2

POWER FLOW . . . . . . . . . . . . . . . . . . . . . . . . . 4

TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Section . . . . . . . . . . . . . . . . . . . . . . . . 5

Auxiliary Section . . . . . . . . . . . . . . . . . . . . . 5

COMMON TRANSMISSION COMPLAINTS . . . . 6

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gear Slipout and Jumpout . . . . . . . . . . . . . . 7

Auxiliary Section . . . . . . . . . . . . . . . . . . . . . 8

Hard Shifting . . . . . . . . . . . . . . . . . . . . . . . . 8

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Transmission Noise . . . . . . . . . . . . . . . . . . . 9

GEARS AND SHAFTS . . . . . . . . . . . . . . . . . . . 11

Clashing . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gear Failures . . . . . . . . . . . . . . . . . . . . . . . 11

Manufacturing Marks . . . . . . . . . . . . . . . . . 11

Gear Rattle at Idle . . . . . . . . . . . . . . . . . . . . 12

Shaft Twist and Fracture . . . . . . . . . . . . . . 12

BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fatigue . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . 14

Brinelling . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fretting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Contamination . . . . . . . . . . . . . . . . . . . . . . 15

Misalignment . . . . . . . . . . . . . . . . . . . . . . . 16

Electric Arcing . . . . . . . . . . . . . . . . . . . . . . 16

TRANSMISSION ALIGNMENT . . . . . . . . . . . . .17

Concentric Alignment of

Transmission to Engine . . . . . . . . . . . . . . . .17

Worn Housings . . . . . . . . . . . . . . . . . . . . . .17

Engine Flywheel Housing Pilot . . . . . . . . . .18

Engine Flywheel Housing Face . . . . . . . . . .18

Flywheel Face . . . . . . . . . . . . . . . . . . . . . . .18

Flywheel Pilot Bore . . . . . . . . . . . . . . . . . . .19

Transmission Clutch Housing . . . . . . . . . . .19

DRIVELINE ANGULARITY . . . . . . . . . . . . . . . .20

Torsional Vibration . . . . . . . . . . . . . . . . . . .20

Taking Readings . . . . . . . . . . . . . . . . . . . . .21

PREVENTIVE MAINTENANCE . . . . . . . . . . . . . .24

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Every 10,000 Miles . . . . . . . . . . . . . . . . . . .24

Every 20,000 Miles . . . . . . . . . . . . . . . . . . .25

Every 40,000 Miles . . . . . . . . . . . . . . . . . . .26

Every *50,000 Miles . . . . . . . . . . . . . . . . . .26

Fuller® Preventive Maintenance

Recommendations. . . . . . . . . . . . . . . . . . . .26

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . .27

Proper Lubrication. . .

the key to long transmission life . . . . . . . . .27

TORQUE RECOMMENDATIONS . . . . . . . . . . . .30

TROUBLESHOOTER’S GUIDELINE . . . . . . . . . .32

CONVERSION TABLE . . . . . . . . . . . . . . . . . . . .35

TOWING OR COASTING . . . . . . . . . . . . . . . . . .37

Page 5

Foreword

FOREWORD

Foreword

The purpose of this publication is to provide basic technical

information for servicing and repairing heavy duty truck

transmissions. A guide to help the mechanic locate the

trouble, analyze the cause, and make the necessary repairs.

Emphasis is placed on servicing Fuller twin countershaft

transmissions; however, some sections are common to all

mechanical transmissions. If more in-depth diagnosis is

required, reference can be made to the following publications:

• Air System Troubleshooting Guide

• Understanding Spur Gear Life

• Service Manuals

• Rear Seal Maintenance Guide

Every effort has been made to ensure the accuracy of all information in this brochure. However, Eaton Transmission Division makes no expressed or implied

warranty or representation based on the enclosed information. Any errors or omissions may be reported to Training and Publications, Eaton Transmission

Division, PO. Box 4013, Kalamazoo, Ml 49003.

These programs and other forms of product service

information for Fuller transmissions and components are

available on request. You may also obtain Service Bulletins

detailing information on product improvements, repair

procedures, and other service related subjects by writing to

the following address:

EATON

TRANSMISSION DIVISION

Technical Service Department

PO. Box 4013

Kalamazoo, MI 49003

1

Page 6

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 7

Transmission Function

TRANSMISSION FUNCTION

The transmission must efficiently transfer the engine’s power,

in terms of torque, to the vehicle’s rear wheels. Torque is the

twisting or circular force delivered by the engine’s flywheel.

The transmission’s gear ratios increase or decrease torque

depending on the requirements needed to move or start the

load. Gearing also increases or decreases speed. The gear

ratios are correctly spaced so that the engine will operate in

its most efficient RPM range with progressive speed changes.

To meet the vehicle’s requirements, the transmission must

have ratios low enough to start the vehicle moving, to

maintain movement up grades, and to keep engine operating

in its peak efficiency range. The transmission, too, must

provide an easy method for gear selection.

2

Page 8

Transmission Function

Transmission Function

COUNTERSHAFT

DRIVE GEAR

MAINSHAFT

GEAR

OUTPUT

SHAFT

SLIDING

CLUTCH

GEAR

MAINSHAFT

COUNTERSHAFT

DRIVE GEAR

INPUT SHAFT

AND DRIVE GEAR

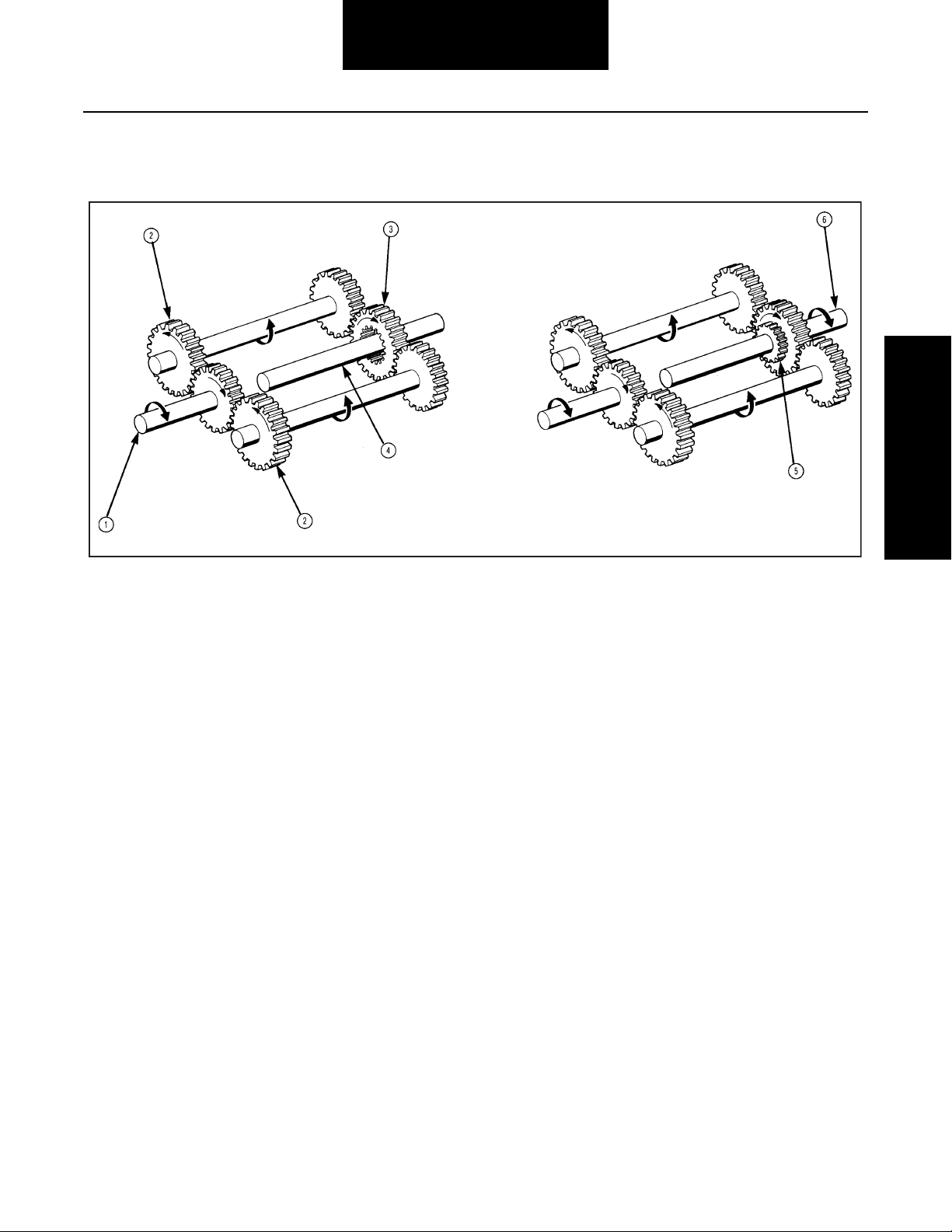

A simplified diagram of the power flow through a Fuller twin

countershaft transmission will help show how torque and

speed are changed, and how torque is divided between the

two countershafts.

The input shaft and drive gear (1) are in constant mesh with

both countershaft drive gears (2); when the input shaft turns,

the countershaft gears are in constant mesh with the

“floating” mainshaft gears (3). The mainshaft gears are

simply free-wheeling on the mainshaft (4). A sliding clutch

gear (5), which is splined to the mainshaft, is engaged into the

internal clutching teeth of the mainshaft gear, coupling it to

the mainshaft. The mainshaft will now be turning at the

selected gear ratio.

Fuller twin countershaft Roadranger® transmissions

commonly consist of a five speed front section and either a

two or three speed auxiliary section, both in one case.

3

Page 9

POWER FLOW

Power Flow

1. Power (torque) from the engine flywheel is

transferred to the input shaft.

2. Splines on input shaft engage internal splines in hub

of drive gear.

3. Torque is split between the two countershaft drive

gears.

4. Torque delivered by two countershaft gears to

mainshaft gear which is engaged. Diagram shows

first speed gear engaged.

5. Internal splines in hub of mainshaft gear transfers

torque to mainshaft through sliding clutch gear.

6. Mainshaft transfers torque to auxiliary drive gear

through a self-aligning coupling gear located in hub

of auxiliary drive gear.

7. Torque is split between the two auxiliary

countershaft drive gears. (In direct drive or high

range, power is delivered to the output shaft from

the auxiliary drive gear through a self-aligning

sliding clutch gear .)

8. Torque is delivered by the two countershaft low

range gears to the low range gear.

9. Torque delivered to output shaft through selfaligning sliding clutch gear.

10. Output shaft is attached to driveline.

4

Page 10

Timing

TIMING

Drive gear teeth correctly

marked for timing.

Cut 7300G-11/86

Tooth on countershaft

directly over keyway

marked for timing.

Cut 7300H-11/86

Countershaft gear teeth

meshed with drive gear

teeth for correct timing.

Cut 7300F-11/86

Timing

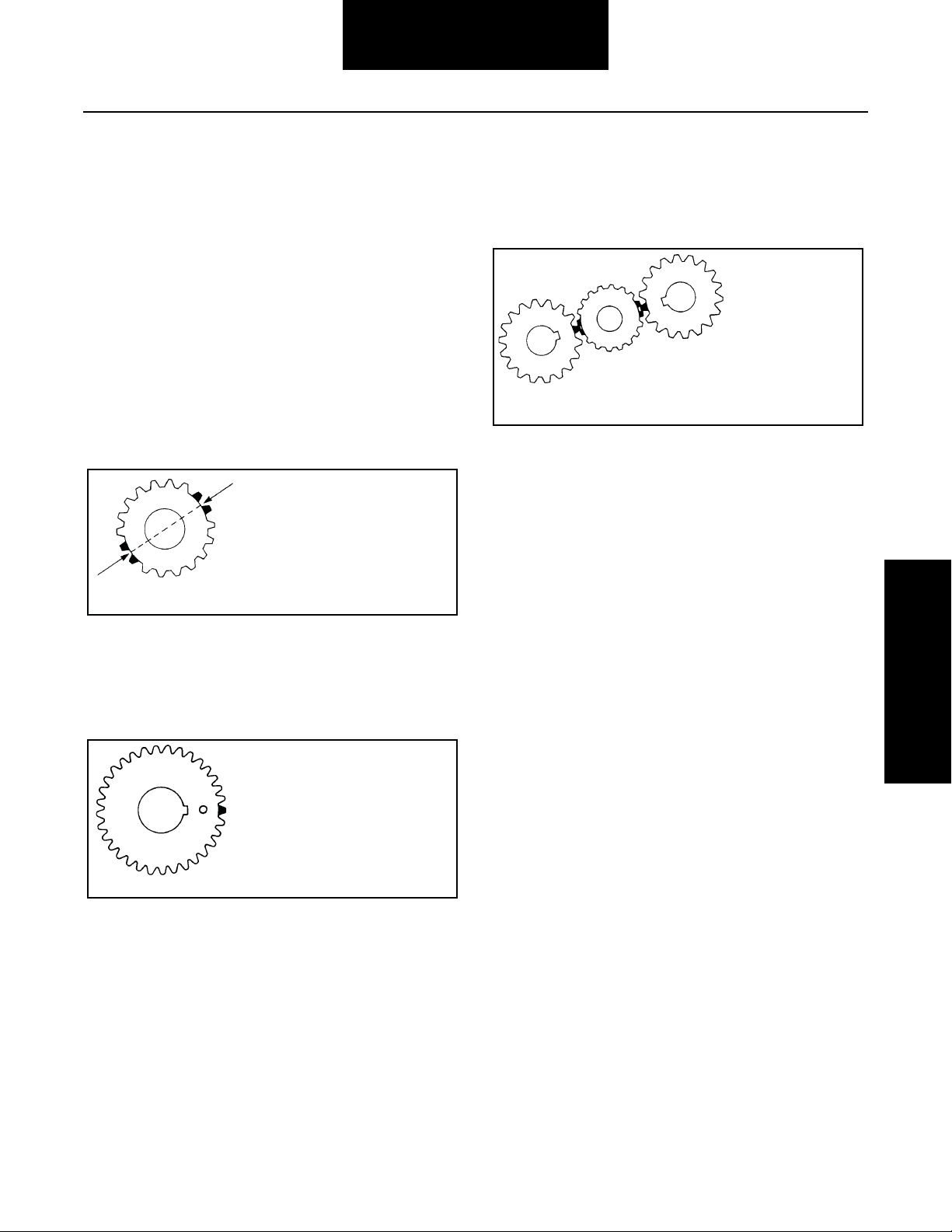

All Fuller twin countershaft transmissions are “timed” at

assembly. It is important that proper timing procedures are

followed when reassembling the transmission. Timing

assures that the countershaft gears will contact the mating

mainshaft gears at the same time, allowing mainshaft gears to

center on the mainshaft and equally divide the load.

One set of gears must be timed in the front section, and one

set the auxiliary section. Timing consists of marking the

proper teeth before installation and meshing the marked teeth

during assembly. The following is step by step procedure for

timing.

Front Section

1. Main Drive Gear – Mark any two adjacent teeth on

the drive gear, then mark the two adjacent teeth

which are directly opposite the first set marked.

There must be an equal number of teeth between the

markings on each side of the gear.

2. Countershaft Drive Gears – Mark on each drive gear

the gear tooth which is directly over the keyway. This

tooth is stamped with an “O” for identification.

3. Meshing Countershaft Gears and Main Drive Gear –

Install the drive gear assembly. Mesh the marked left

countershaft gear tooth between the two marked

teeth on the drive gear. Repeat the procedure with

right countershaft.

Auxiliary Section

The gear set which is marked for timing in the auxiliary

section varies, depending on the model. Usually the gear at

the rear of the auxiliary is used.

1. Mainshaft Gear – Mark any two adjacent teeth on the

mainshaft gear, then mark the two adjacent teeth

directly opposite.

2. Countershaft Gears – On each countershaft

assembly mark the gear tooth which is stamped with

“O”.

Note: Refer to the appropriate service manual for more

detailed timing instructions for the Fuller twin

countershaft transmission being assembled.

5

Page 11

Common Transmission Complaints

COMMON TRANSMISSION COMPLAINTS

Vibration

Although the effects of vibration will show up in the

transmission, vibration usually originates somewhere else in

the drive train. Vibration can usually be felt or heard by the

driver; however, in some cases, transmission damage caused

by vibration will occur without the driver’s knowledge. (Refer

to the “Torsional Vibration” section for the causes and cures

of vibration problems.)

Some Transmission Problems Due to Drive Train Vibration:

1. Gear rattle at idle. (See “Shafts” section.)

Fretted Splines

2. Gear and shaft splines “fretted”.

3. Noise. (See “Noise” section.)

4. Fretted bearings. (See “Bearing” section.)

5. Repeated rear seal leakage. Broken synchronizer

pins.

Broken Synchronizer Pins

6. Broken or loose synchronizer pins.

7. Continuous loosening of capscrews, brackets and

mountings.

Input Spline Wear

8. Worn shaft spline wear.

9. Worn universal joints. (Not a transmission

symptom, but an indicator of vibration.)

6

Page 12

Common Transmission

Complaints

Common causes of vibration:

1. Driveline imbalance or misalignment. (See

“Transmission Alignment” section.)

Common Transmission Complaints

2. Unbalanced wheels or brake drums.

3. Rough running engine.

4. Broken or worn engine mounts.

5. Worn suspension.

Gear Slipout and Jumpout

Front Section

When a sliding clutch is moved to engage with a mainshaft

gear, the mating teeth must be parallel. Tapered or worn

clutching teeth will try to “walk” apart as the gears rotate.

Under the right conditions, slipout will result. Some of these

conditions are:

1. Transmission mounted eccentrically with engine

flywheel pilot.

2. Excessive gear clashing which shortens clutching

teeth.

Detent

Spring

Cut 7233A-11/86

4. Insufficient pressure on detent ball from weak or

broken detent spring.

Worn Yoke Bar

Snubbed Clutching Teeth

3. Gear clutching teeth wearing to a taper.

5. Excessive wear on detent notch of yoke bar.

6. Incorrect adjustment of remote shift control linkage

resulting in partial engagement. Also check for loose

connections and worn bushings.

Slipout will generally occur when pulling with full power or

decelerating with the load pushing.

Jumpout will occur when a force sufficient to overcome the

detent spring pressure is applied to the yoke bar, moving the

clutch gear to a neutral position.

7

Page 13

Common Transmission Complaints

Cut 8005-11/88

Conditions Which May Produce Jumpout

1. Extra heavy and long shift levers which swing,

pendulum fashion, from operating over uneven

terrain. Whipping action of the lever overcomes

detent spring tension.

2. Mechanical remote controls with the master

mounted to the frame. Relative movement between

engine-transmission package and frame can force

transmission out of gear. Worn or broken engine

mounts increase the effects of this condition.

Auxiliary Section

Jumpout in the auxiliary section usually occurs with the

splitter gear set. If torque is not sufficiently broken during

splitter shifts, the sliding clutch gear may not have enough

time to complete the shift before torque is reapplied to the

gears. As torque is reapplied, the partially engaged clutch gear

“jumps” out of the splitter gear. Since the gears have torque

applied to them, damage will be done to the clutching teeth of

the mating gears.

Hard Shifting

The effort required to move a gear shift lever from one gear

position to another varies. If too great an effort is required it

will be a constant cause of complaint from the driver.

Most complaints are with remote type linkages used in cabover-engine vehicles. Before checking the transmission for

hard shifting the remote linkage should be inspected. Linkage

problems stem from worn connections or bushings, binding,

improper adjustment, lack of lubrication on the joints or an

obstruction which restricts free movement.

To determine if the transmission itself is the cause of hard

shifting, remove the shift lever or linkage from the top of the

transmission. Then, move the shift blocks into each gear

position using a pry bar or screwdriver. If the yoke bars slide

easily, the trouble is with the linkage assembly. If the trouble

is in the transmission, it will generally be caused by one of the

following:

Slipout in the auxiliary section may be caused by the clutching

teeth being worn, tapered, or not fully engaged. These

conditions cause the clutch gear to “walk” out of engagement

as the gears turn. Causes of these types of clutching defects

are clashing or normal wear after long life. Vibrations set up

by an improperly aligned driveline and low air pressure add to

the slipout problem.

Tapered Clutching Teeth

8

1. Splines of sliding clutch gear binding on mainshaft

as a result of a twisted mainshaft key , bent shift yoke

or bowed mainshaft key.

2. Yoke bars binding in the bar housing as a result of

cracked housing, over-torqued shift block lockscrew, sprung yoke bar, or swelled areas of the yoke

bar.

Page 14

Common Transmission Complaints

Common Transmission

Complaints

If hard shifting occurs only in first and reverse, the shift block

detent plunger movement may be restricted. This can result

from burrs on the plunger, or from overtightening the plunger

spring plug. With the plunger blocked in the depressed

position, the plug should be tightened until it bottoms out

against the spring, then backed out 1/4 to 1/2 turn.

Gear clashing should not be confused with hard shifting. Gear

clashing occurs when an attempt is made to engage the clutch

gear before it has reached synchronization with the mainshaft

gear. (See “Clashing”, this section.)

Heat

The transmission operating temperature should never exceed

250°F (120°C) for an extended period of time. If it does, the

oil will breakdown and shorten transmission life.

Because of the friction of moving parts, transmissions will

produce a certain amount of heat. In most cases normal

operating temperature is approximately 100°F (40°C) above

ambient. Heat is dissipated through the transmission case.

When conditions prevent the proper dissipation of heat, then

overheating occurs.

Transmission Oil Coolers are:

Recommended

- With engines of 350 H.P. and above with overdrive

transmissions

Required

- With engines 399 H.P and above with overdrive

transmissions and GCWs over 90,000 lbs.

- With engines 399 H.P. and above and 1400 Lb s.-Ft.

or greater torque

- With engines 450 H.P. and above

Noise

There will always be a certain level of noise due to normal

transmission operation. However , excessive noise, or unusual

noise such as whine, growl, or squeal indicates some kind of

a problem.

The transmission itself can be the cause of excessive or

unusual noise. Also noise can originate elsewhere in the

vehicle, but be picked up and amplified by the transmission.

Before checking for possible causes of overheating, the oil

temperature gauge and sending unit should be inspected to

make sure they are giving correct readings.

Causes of Overheating (See also “Lubrication”)

1. Improper lubrication. Oil level too low or too high,

wrong type of oil, or an operating angle of more than

12 degrees.

2. Operating consistently under 20 MPH.

3. High engine RPM.

4. Restricted air flow around transmission, due to

transmission being “boxed in” by frame rails, deck

lids, fuel tanks and mounting brackets, or by a large

bumper assembly.

5. Exhaust system too close to transmission.

6. High ambient temperature.

7. High horsepower, overdrive operation.

8. Coasting downhill with the clutch depressed.

In some cases an external oil cooler kit can be used to correct

overheating problems.

Transmission Noise

1. Knocking or Thudding

a. Gears – Bumps or swells on gear teeth. Such

bumps or swells can be removed with a hone or

small hand grinder; these areas can be identified

as highly polished spots on the face of the gear

tooth. Generally, this noise is more prominent

when the gear is loaded; thus, the problem gear

can be located as the noise occurs in a specific

gear position. Bumps or swells are caused by

9

Page 15

Common Transmission Complaints

improper handling of gears before or during

assembly.

b. Bearings – Noise comes in at low shaft speeds

in any position. It is caused by bearings with

damaged balls or rollers, or with pitted and

spalled raceways. (See “Bearings” section.)

c. Cracked Gear – A gear cracked or broken by

shock loading or by pressing on shaft during

installation will produce this sound at low

speeds. At high speeds a howl will be present.

2. High Pitched Whine or Squeal

Causes of Transmission Noise Originating Elsewhere in

Vehicle (see also “Alignment” section)

1. Rough idling engine. (See “Gears and Shafts” gear

rattle.)

2. Engine operating noise.

3. Clutch driven plates in which the dampening action

of springs or rubber blocks has been eliminated by

wear set or fracture.

4. Driveline out of balance.

5. Unequal joint working angles.

6. Worn crosses in universal joints.

7. Loose or worn center bearings.

8. Worn or pitted teeth on ring gear and pinion of

driving axle.

9. Rear axle bearing failure.

10. Wheels out of balance.

11. Worn spring pivot bearing.

12. Loose “U” bolts.

13. Brake drums warped or out of balance.

a. Gear Wear – Result of normal gear wear,

including gear tooth pitting from excessive use.

In advanced deterioration, a howl will result.

b. Mismatched Gear Sets – Such gear sets are

identified by an uneven wear pattern on the face

of gear teeth.

c. Bearings –“Pinched” bearings, having

insufficient axial or radial clearance. (See

“Bearing” section.)

3. Growling

a. Timing Error – Improper timing of the

transmission during reassembly, or improper

timing due to gear turning on the countershaft.

Both conditions produce error in tooth spacing.

10

Page 16

Gears and Shafts

GEARS AND SHAFTS

Gears and Shafts

Clashing

Snubbed Clutching Teeth

Snubbing and clashing gears while shifting are frequent

abuses to which unsynchronized transmissions are subjected.

Light snubbing will do little damage. The real damage is done

by the hard clash shift caused by engaging gears which are far

out of synchronization. This can break pieces of metal from

the ends of the clutching teeth.

Clashing gears can be traced to one of three causes:

Gear Failures

All gear teeth wear because of the sliding action which takes

place as mating teeth mesh. Normal wear is a constant and

slow wearing of the tooth surface. Transmission gear tooth

life can be shortened by various adverse conditions. These

conditions and the failures resulting from them are discussed

in the Fuller booklet entitled “Understanding Spur Gear Life”

(form no. 186).

Manufacturing Marks

Sometimes gears are replaced or thought to be defective

because of marks left on the gear by manufacturing

processes. These blemishes, however, do not contribute to

gear failure and the gear should not be replaced because of

these marks.

1. Improper shifting – This applies to drivers who are

not familiar with the shift pattern or have not learned

the RPM spread between shifts.

2. Clutch – Clashing when starting up in first or reverse

gear can be caused by insufficient clutch clearance

or a dragging clutch not releasing properly. This

makes the transmission countershafts and

mainshaft gears continue rotating while the clutch

pedal is depressed. Clashing results when the nonrotating sliding clutch is forced to mesh with a

rotating mainshaft gear. Double clutching during

lever shifts will also reduce snubbing and clashing.

3. Inertial Force – Countershafts and mainshaft gears

usually take from 3 to 5 seconds to stop rotating

after the clutch has been disengaged. Attempting to

mesh a clutch gear with a mainshaft gear before the

mainshaft gear stops will result in clashing. If the

transmission is not equipped with a clutch brake or

countershaft brake, it is necessary to pause a few

seconds after depressing the clutch pedal before

attempting initial engagement of the transmission.

1. Hob Marks – These are cutting marks or lines

formed during the initial cutting of the gear teeth.

Hob marks on the tooth face will be removed by the

shaving process, but hob marks in the root of the

tooth will most likely remain, and may be found even

on gears with much wear on them.

11

Page 17

Gears and Shafts

Gear Rattle at Idle

Mainshaft gears are designed to have a specified amount of

axial clearance which allows them to rotate freely on the

mainshaft. The amount of clearance is governed by the use of

washers. A rough idling engine can set up vibrations, causing

the mainshaft gears to rattle as they strike mating gears. This

condition can usually be cured by improving the idling

characteristics of the engine. Tolerance washers may have to

be changed to bring the axial gear clearance to within

tolerance on high mileage units.

See the service manual for procedure and specifications.

Shaft Twist and Fracture

2. Shaving Marks – The shaving operation leaves

distinct diagonal marks on the face of the gear tooth.

These marks can be distinguished from scoring

marks by the fact they are diagonal, while scoring

marks are more nearly vertical. Most shaving marks

are removed during normal gear operation.

3. Lipping – Lipping or shaving burrs, is the formation

of “lips” at the tip of the gear teeth machining. These

“lips” will do no harm to the gear.

Failure of transmission shafts through fracturing or twisting is

caused when stresses are imposed on them which are greater

than they were designed to withstand. The main causes for

these failures are:

1. Improper clutching techniques.

2. Starting in too high of gear (either front or auxiliary

section).

3. Lugging.

4. Attempting to start with brakes locked.

5. Transmission used for application it was not

designed to withstand.

6. Bumping into dock when backing.

7. Improper mounting of adjustable 5th wheel.

12

Page 18

Gears and Shafts

Fractured Mainshaft

Gears and Shafts

As with gear teeth, shafts may fracture as a result of fatigue or

impact.

Twisted Mainshaft

Loads not severe enough to cause shaft fractures may cause

the shaft to twist.

13

Page 19

BEARINGS

Bearings

Fatigue

Bearing Race “Flaking”

Bearing fatigue is characterized by flaking or spalling of the

bearing race. Spalling is the granular weakening of the

bearing steel which causes it to flake away from the race.

Because of their rough surfaces, spalled bearings will run

noisy and produce vibration.

Normal fatigue failure occurs when a bearing “lives out” its

life expectancy under normal loads and operating conditions.

This type of failure is expected and is a result of metal

breakdown due to the continual application of speed and load.

Premature fatigue failure may occur in transmissions when

the bearing bore is undersized or out of round due to poor

quality resleeving. Extreme care should be taken when

reboring the housing. Boring the housing off center will result

in misalignment of the shafts. Always use precision

equipment such as a jig boring machine. Never prick punch

the bearing bores to tighten the fit.

Lubrication

Burnt and Spalled Bearing

Bearing failure due to poor lubrication is characterized by

discoloration of the bearing parts, spalling of the race, and

possible breakage of the retainer. Failure may result not only

from a low oil level, but also from contaminated oil, improper

grade oil, or mixing of oil types (including the use of

additives).

Ball Path Pattern Caused by Out-of-Round Squeeze

14

T o prevent this type of failure, the transmission should a lways

be filled to the proper level, using a recommended type and

grade of oil, and changed at regular intervals. (See

“Lubrication” section.)

Page 20

Bearings

Bearings

Brinelling

Brinelled Race

Brinelling can be identified as tiny indentations high on the

shoulder or in the valley of the bearing raceway. They can be

caused by improper bearing installation or removal. Driving or

pressing on one race, while supporting the other is the

primary cause. To prevent brinelling always support the race

which has pressure applied to it. In addition to brinelling,

damage can also occur to the bearing shields, retainers and

snap rings by using a hammer and chisel to drive bearings.

This damage can be avoided by using correct drivers or

pullers.

Fretting

Contamination

Contaminated Race

When bearings fail as a result of contamination, it is due to

either contaminants entering the transmission case or the

bearings have been improperly handled during service or

storage. Bearings affected from contamination are identified

by scoring, scratching or pitting of the raceways and balls or

rollers, or a build up of rust or corrosion on the bearing parts.

In addition, the presence of very fine particles in the oil, such

as abrasive dust, or the use of overly active EP (extreme

pressure) oils, will act as a lapping compound and produce a

very highly polished surface on the raceways and balls or

rollers. This lapping process will significantly shorten the life

of the bearing.

Fretted Outer Race

The bearing outer race can pick up the machining pattern of

the bearing bore as a result of vibration. This action is called

fretting.

Many times a fretted bearing is mistakenly diagnosed as one

which has spun in the bore. Only under extreme conditions

will a bearing outer race spin in the bore.

Impurities will always enter the transmission during its

normal breathing process. This will not seriously affect the

bearings if the transmission oil is changed as recommended.

New bearings should be stored in their wrappers until ready

for use. Used bearings should be thoroughly cleaned in

solvent, light oil or kerosene, covered with a coat of oil and

wrapped until ready for use. Always use a new wrapping after

reoiling.

15

Page 21

Bearings

Misalignment

Bearing Misalignment

Misalignment can occur in the input shaft drive gear bearing if

the transmission is mounted eccentrically with the pilot

bearing bore in the flywheel. An indication of this condition

would be damage to the ball separators and shield.

The clutch housing, clutch housing mounting face, and pilot

bearing should be checked for eccentricity, foreign matter and

proper mounting position when trying to locate the cause of

the misalignment. (See “Alignment” section.)

Electric Arcing

Electric Arcing

When an electric current passing through a bearing is broken

at the contact surfaces of the ball or roller and races, arcing

results, which will pit the bearing components. In extreme

cases, the balls or rollers may actually be welded to the

bearing races, preventing the bearing from rotating.

This condition may occur in truck transmissions as a result of

electric welding on the truck with an improper ground. When

doing either A.C. or D.C. welding, never place the ground so

as to allow current to pass through the transmission.

16

Page 22

Transmission Alignment

TRANSMISSION ALIGNMENT

Cut 8005A - 11/86

IMPORTANT

Cut 8195 - 11/86

12

3

6

9

Transmission Alignment

Concentric Alignment of Transmission to

Engine

Common Concerns Resulting from Misalignment

• Direct gear slipout

• Drive gear bearing failure

• Premature input shaft spline wear from rear hub of

two plate clutches

Concentric alignment means that the engine and transmission

must have a common axis. The purpose of this section is to

set forth the procedures to use in checking for possible

misalignment.

Worn Housings

Cut 8005B - 11/86

Inspect for worn or fretted pilot on both the transmission

clutch housing and the engine flywheel housing. The 1/4" pilot

lip of transmission clutch housing can wear into the flywheel

housing either by transmission loosening up or after high

mileage just from road and engine vibration. Any appreciable

amount of wear on either part will cause misalignment and the

part should be replaced.

The basic instrument needed for taking readings is a taper

pointed dial indicator. Accuracy of readings is essential for

correcting alignment problems. Clean all surfaces thoroughly

before proceeding.

When taking the following readings, rotate engine by hand,

do not crank engine with starter. Remove spark plugs on

gasoline engines, and release compression on diesel

engines.

Note: Before dial indicating engine flywheel or flywheel

housing, make sure engine crankshaft does not have

excessive end-play. If it does, accurate readings cannot

be obtained. Place dial indicator finger against flywheel.

Force crankshaft back and forth with pry bar. If end-play

movement exceeds maximum as specified by engine

manufacturer, it will have to be corrected.

The wear will generally be found from the 3:00 o’clock to 8:00

o’clock position.

17

Page 23

Transmission Alignment

Cut 8195A-11/86

0

4

+

8

+

12

+

0

8

-

6

-

+ 12 - (-8) = + 20 TOTAL RUNOUT

Cut 8195B - 11/86

Engine Flywheel Housing Pilot

Dial indicate the pilot or bore of engine flywheel housing.

Secure dial indicator to engine flywheel with tapered point

against housing pilot. Rotate flywheel by hand. With chalk or

soap stone, mark high and low points of indicator as it is

being rotated.

Engine Flywheel Housing Face

Cut 8195C-11/86

Dial indicate the face of engine flywheel housing. With dial

indicator secured to flywheel, move tapered point to contact

face of flywheel housing.

Mark high and low points in the same manner as in previous

step. SAE maximum total runout for the flywheel housing face

is .008" with SAE No.1 and No. 2 housings.

Note: Mark the high and low runout readings in clock

positions if it is necessary to reposition the flywheel

housing.

The total runout will be the difference between the highest

plus and minus readings. SAE maximum total runout for

flywheel housing pilot is .008" with No.1 and No.2 SAE

housings.

Flywheel Face

Cut 8195D - 11/86

Dial indicate the flywheel face. Secure dial indicator to engine

flywheel housing near the outer edge. Turn flywheel to obtain

readings. Maximum allowed is .001" runout or face wobble

per inch of flywheel radius. For example, if vehicle has a 14"

clutch and readings are taken just off the outer edge of the

clutch disc wear, maximum tolerance would be .007".

18

Page 24

Transmission Alignment

Transmission Alignment

Cut 8195E-11/86

Flywheel Pilot Bore

Dial indicate pilot bearing bore of flywheel. With indicator

secured to flywheel housing, move gauge finger to contact

pilot bearing bore surface. Turn flywheel and obtain readings.

SAE maximum total runout for the pilot bearing is .005".

Transmission Clutch Housing

The transmission clutch housing face and pilot can not be

checked accurately in the field without special measuring

tools. Recommended maximum runout for the transmission

clutch housing face and pilot is .003" with SAE No.1 and No.2

housings.

19

Page 25

DRIVELINE ANGULARITY

Cut 8580A-11/86

Driveline Angularity

Torsional Vibration

Checking Driveline U-Joint Operation Angles

The action of a driveline with a universal joint at either end

working through an angle results in a peculiar motion. The

driveline will speed up and slow down twice for each

revolution. If the working angles at either end of the shaft are

unequal, torsional vibration results. This torsional vibration

will tend to cancel itself out if both joint working angles are

equal.

Types of Noise

Noise or vibration which occurs only at certain road speeds

and diminishes as speed increases is generally caused by

unequal working angles of driveline joints.

Noise or vibration which is persistent throughout the speed

range and varies in intensity with change of speed may be

caused by unbalanced drivelines, unbalanced brake drums or

discs, or drivelines with universal joints out of phase.

Preliminary Checks

Make checks of the following before taking angle readings:

1. Check companion flange or yoke nut for looseness

and torque to proper specification if necessary.

3. Unbalanced drivelines can cause vibration that

occurs throughout the speed range of vehicle and

varies in intensity with change of speed. The

driveline may be at fault in respect to balance and

concentricity . A quick field check to determine

driveline balance can be made by securing a small

piece of metal or similar weight with a hose clamp to

the front of the tube where the splined shaft is

welded. Road test the vehicle and continue to move

the weight around tube until balance point is found

and vibration disappears, or is minimized.

Cut 8580B - 11/86

Drivelines are dynamically balanced to their intended

rotational velocity and not to infinite speeds. Thus,

vibration can be expected when this rotational

velocity is exceeded.

Check concentricity of driveline by mounting on

lathe centers and dial indicating. Check

manufacturer’s specifications for runout allowance.

2. Driveline slip joints that do not have the arrows or

other markings pointing to each other will result in

the driveline universal joints being out of phase. In

other words, the transmission universal joint may be

turned one spline or more to the right or left of being

aligned with the universal joint at opposite end of the

driveline.

Note: Some computer designed drivelines are purposely built

with U-joints out of phase. Check manufacturer’s

specifications for proper setting. Also, check closely to

make certain no twist has occurred to the tubing,

causing these two joints to be out of phase

Make sure the slip joint works freely and is not

bound or seized. Slip joints must absorb axle

housing movements.

4. Engine supports that are worn, broken or loose, and

mounting pads that are worn or deteriorated must be

corrected to restore the engine suspension to its

original vibration tolerance.

20

Page 26

Driveline Angularity

Driveline Angularity

Cut 8580C - 11/86

Wing

Flange

Plain

Cut 8580D - 11/86

Taking Readings

Take readings with protractor from machined surfaces of

yokes or companion flanges. Plain, wing or flange type joints

may be encountered. Some will require partial disassembly to

obtain accurate readings.

On plain type joints, it may be necessary to remove the

bearing cap. When taking readings, make sure the universal

joint is in a vertical plane.

At the rear axle, take readings from a machined surface

differential carrier that is in the same plane as the axle pinion

shaft, or from machined surface that is perpendicular to

pinion shaft, whichever is easier.

If vibration occurs while operating empty, take readings in

empty condition. If it occurs when loaded, take readings when

loaded.

When it is necessary to measure driveline lengths, measure

from joint center to joint center.

Limits

Manufacturer’s specifications should be followed when

making initial angularity check. Some manufacturers have

found it necessary to vary from the ideal due to geometrical

limitations. If vibration persists after adhering to

manufacturer’s specifications , contact the manufacturer’s

representative.

Angularity Checks – Parallel Flanges or Yokes

1. Single Axle Vehicles

a. Transmission angle. Take reading of

transmission angle. This angle is the angle to

which the rear axle joint angle must match. The

transmission angle will have a declination

reading of from 0 to 5 degrees in most cases.

Cut 8580E - 11/86

Cut 8580F-11/86

b. Axle angle. T ake reading either from machined

surface of axle housing or pinion bearing

retainer. This angle must be within one degree

of the transmission angle.

c. Example: If transmission angle reading is 3

degrees down to the rear, the rear axle angle

should be 3 degrees up.

2. Tandem Axles or Vehicles with Auxiliary Units

a. Take transmission angle reading.

b. Take reading from joint of front tandem axle or

auxiliary joint. This reading should be within

one degree of transmission angle.

21

Page 27

Driveline Angularity

Cut 8580G-11/86

Note: The rear joint of front tandem axle will be the same as

the front joint.

c. Take reading of joint angle at tandem rear axle,

or axle to rear of auxiliary. This angle must be

within one degree of transmission angle.

Joint Working Angle Limits (Parallel)

Universal joints have a maximum working angle, depending

on type and manufacture. It is recommended that the joint

working angle for parallel joint assembly not exceed 8 degrees

for main drivelines over 40" long. For main drivelines under

40" the maximum angle should not exceed Length (L) divided

by 5. (This limit does not apply to interaxle drivelines.)

Example: For a 35" driveline, the maximum joint working

angle would be 35 plus 5 or 7degrees. This working angle

must not be exceeded.

Place protractor on driveline to obtain angle of driveline from

transmission to axle. The difference between the driveline

angle and the joint angle is the joint working angle. For

instance, if the transmission is 3 degrees down, and the

driveline angle is down 7 degrees, the transmission joint

working angle is 7 minus 3 or 4 degrees.

On tandem drive or auxiliary installations, take readings in the

same manner, comparing the universal joint angles to the

driveline angle to which it is attached.

Angularity Checks – Non-Parallel Compensating Angles or

Flanges or Yokes

With short wheel base vehicles which have a minimum

driveline length from transmission to axle, the driveline is

required to operate through very severe working angles on

some installations. This also applies to interaxle drivelines.

These severe joint working angles induce vibration.

When figuring non-parallel joint installations, it is necessary

to take the driveline angle readings as well as transmission

and axle angle readings.

1. Single Axle Vehicles

a. Take angle reading of transmission.

b. Take angle reading of driveline.

c. Take angle reading of axle joint.

d. To compute for correct angles:

(1) The difference between the driveline angle

and the transmission angle will be the

transmission joint working angle.

(2) The difference between the driveline angle

and the axle angle will be the axle joint working

angle.

(3) The two working angles of transmission and

axle must be equal.

e. Example:

Transmission is 3 degrees down.

Driveline is 7.5 degrees down.

Rear axle is 12 degrees down.

Thus 7.5 minus 3 equals 4.5 degrees.

12 minus 7.5 equals 4.5 degrees, giving 4.5

equal working angles.

2. Tandem Axles or Vehicles with Auxiliary Units

When taking readings on tandem drive axles or

between auxiliary and rear axle, the same principles

apply as with single axle vehicles. Take readings

between transmission and front tandem axle, or

auxiliary. Take readings between axles or between

auxiliary and axle. In other words, take angle

readings for each set of universal joints

Joint Working Angle Limits (Non-Parallel)

It is recommended that the maximum joint working angle for

non-parallel joint assemblies not exceed the main driveline

length divided by 10. For example, if the main driveline length

is 55, the maximum joint working angle is 55 divided by 10 or

5.5 degrees. (This limit does not apply to interaxle drivelines.)

T o decrease working angles, the axl e is tilted upward until the

pinion shaft centerline and transmission mainshaft centerline

intersect midway between the joint centers.

With tandem drive axles, the rearward axle is tilted upward

until its pinion shaft centerline and forward axle pinion shaft

centerline intersect midway between joint centers.

22

Page 28

Driveline Angularity

Driveline Angularity

Axle Adjustments

Axle angles may generally be adjusted by one of the following

ways, depending on the type of axle.

1. Adjust torque rods, if adjustable type.

2. Add to or reduce length of non-adjustable torque

rods.

3. Add or reduce the number of shims behind torque

rod brackets.

4. Use correct amount of wedge shims under spring to

axle pad.

Suspensions – Pinion Shaft Angle

There will be little or no change of axle pinion angle with types

of suspensions which have a parallelogram movement. These

allow differential housings to move up and down in a straight

vertical during operation.

Suspensions not having a parallelogram movement will allow

axle pinion shaft to oscillate in an arc, thereby constantly

changing pinion shaft angle during operation. A varying

amount of vibration can occur caused by working angles of

the universal joints being momentarily unequal.

Single drive axle vehicles have little or no change of axle

pinion angle during operation.

23

Page 29

PREVENTIVE MAINTENANCE

Preventive Maintenance

A good Preventive Maintenance (PM) program can avoid

breakdowns, or reduce the cost or repairs. Often,

transmission problems can be traced directly to poor

maintenance.

Following is an inspection schedule that may be helpful in

setting up a PM program. This schedule is not all inclusive as

inspection intervals will vary depending upon operating

conditions.

Daily

Air Tanks

Bleed air tanks to remove water or oil.

Oil Leaks

Check around bearing covers, PTO covers and other

machined surfaces. Also check for oil leakage on the ground

before starting truck in the morning.

Every 10,000 Miles

Check Oil Level

PROPER

OIL LEVEL

ONON

Cut 8192-10/85

24

Page 30

Preventive Maintenance

Preventive Maintenance

Every 20,000 Miles

Air System and Connections

Check for leaks, worn hoses and airlines, loose connections

and loose capscrews.

Clutch Housing Mounting

Capscrew

Cut 8195M-11/86

Check all capscrews in bolt circle of clutch housing for

looseness.

Lubricated Pedal Shafts

Zerk Fitting

Check for bushing wear .

Cut 8725-11/86

Check and clean or replace air filter element.

Universal Joint Companion Flange

Cut 8195N-11/86

Check Remote Control Linkage

Cut 8725-11/86

Check linkage U-joints for wear.

Check for binding.

Lubricate U-joints.

Cut 8580H-11/86

Check for proper torque, 450 to 500 lbs. ft. on twin

countershaft models.

Output Shaft

Pry upward against output shaft to check radial clearance in

mainshaft rear bearing.

Check splines for wear from movement and chucking action

of the universal joint companion flange.

Check connections for tightness.

25

Page 31

Preventive Maintenance

P M OPERATION

Bleed Air Tanks and Listen for Leaks X

XskaeL liO rof tcepsnI

XXXXXXXXXXleveL liO kcehC

XXXXXsnoitcennoC metsyS riA tcepsnI

Check Clutch Housing Capscrews for

XXXXXssenesooL

XX

XXXstfahS ladeP hctulC ebuL

XXXXXegakniL lortnoC etomeR kcehC

Check and Clean or Replace Air Filter Element X X X X X

XXXXXssenesooL rof tfahS tuptuO kcehC

XXt

nemtsujdA dna noitarepO hctulC kcehC

XXX*liO noissimsnarT egnahC

YLI

AD

000,5

000,

01

00

0,02

000,03

000,04

000,05

000,06

00

0,0

7

000,08

000,09

000,001

*Initial fill on new units. See LUBRICATION section.

REPEAT SCHEDULE AFTER 100,000 MILES

Fuller® Preventive Maintenance Recommendations

Every 40,000 Miles

Inspect Clutch

Note: Inspection should be made according to manufacturer’s

specifications.

Clutch

Check clutch disc faces for wear.

Check dampening action of clutch driven plate.

Release Bearing

Remove hand hole cover and check axial and radial clearance

in release bearing.

Check relative position of thrust surface of release bearing

with thrust sleeve on push type clutches.

Every *50,000 Miles

Change Transmission Lubricant

*Initial fill on new units should be changed at 5,000 miles

(see LUBRICATION).

26

Page 32

Lubrication

LUBRICATION

Lubrication

Proper Lubrication. . .

the key to long transmission life

Proper lubrication procedures are the key to a good all-around

maintenance program. If the oil is not doing its job, or if the

oil level is ignored, all the maintenance procedures in the

world are not going to keep the transmission running or

assure long transmission life.

Eaton® Fuller® Transmissions are designed so that the

internal parts operate in a bath of oil circulated by the motion

of gears and shafts.

Thus, all parts will be amply lubricated if these procedures are

closely followed:

1. Maintain oil level. Inspect regularly.

2. Change oil regularly.

3. Use the correct grade and type of oil.

4. Buy from a reputable dealer.

Lubrication Change and Inspection

Eaton® Roadranger® CD5O Transmission Fluid

HIGHWAY USE-Heavy Duty and Mid.Range

tilf yrotcaFselim 000,5 ot 000,3 tsriF

.niard laitini)mK 5408 ot 7284(

revE

Heavy Duty Highway Change Interval

.diulf)mk 633204(

Mid.Range Highway Change Interval

Every 100,000 miles (160,000 Km) Change transmission

or every 3 years whichever occurs first. fluid.

OFF-HIGHWAY USE

sruoh 005 yrevE

Check for leaks.

where severe dirt conditions exist.

(Normal off-highway use).

Heavy Duty Engine Lubricant or

Mineral Gear Lubricant

HIGHWAY USE

0,01 yrevE

OFF-HIGHWAY USE

oh 04 yrevE

Every 500 hours Change transmission lubricant where severe dirt conditions exist.

Every 1,000 hours Change transmission lubricant (Normal off-highway use).

.level diulf kcehCselim 000,01 y

.skael rof kcehC)mK 09061(

noissimsnart egnahCsetim 000,052 yrevE

.niard laitini llif yrotcaFsruoh 03 tsriF

.level diulf tcepsnIsruoh 04 yrevE

diulf noissimsnart egnahC

diulf noissimsnart egnahCsruoh 000,1 yrevE

llif yrotcaFselim 000,5 ot 000,3 tsriF

.niard laitini)mK 5408 ot 7284(

.level tnacirbul tcepsnIselim 00

.skaet rof kcehC)mK 09061(

noissimsnart egnahCselim 000,05 yrevE

.tnacirbul)mK 05408(

.stinu wen no tnacirbul noissimsnart egnahCsruoh 03 tsriF

.skael rof kcehC .level tnacirbul tcepsnIsru

Change the oil filter when fluid or lubricant is changed.

Recommended Lubricants

Fahrenheit

(Celsius)

Grade Ambient

Type (SAE) Temperature

®

Roadranger

Eaton

CD5O Transmission

Fluid 50 All

Heavy Duty Engine Oil

MIL-L-2104B, C or D or 50 Above 10°F(-12° C.)

API-SF or API-CD 40 Above 10°F(-12° C.)

(Previous API 30 Below 10°F(-12° C.)

designations acceptable)

Mineral Gear Oil with 90 Above 10°F(-12° C.)

rust and oxidation 80W Below 10°F(-12° C.)

inhibitor API-GL-1

®

27

Page 33

Lubrication

Improper Oil Level

Proper Oil Level

The use of mild EP gear oil or multipurpose gear oil is not

recommended, but if these gear oils are used, be sure to

adhere to the following limitations:

Do not use mild EP gear oil or multipurpose gear oil when

operating temperatures are above 230ºF (110ºC). Many of

these gear oils, particularly 85W140, break down above 230ºF

and coat seals, bearings and gears with deposits that may

cause premature failures. If these deposits are observed

(especially a coating on seal areas causing oil leakage),

change to Eaton Roadranger CD5O transmission fluid, heavy

duty engine oil or mineral gear oil to assure maximum

component life and to maintain your warranty with Eaton.

(Also see “Operating Temperatures”.)

Additives and friction modifiers are not recommended for use

in Eaton Fuller transmissions.

Proper Oil Level

Make sure oil is level with filler opening. Because you can

reach oil with your finger does not mean oil is at proper level.

One inch of oil level is about one gallon of oil.

Draining Oil

Drain transmission while oil is warm. To drain oil remove the

drain plug at bottom of case. Clean the drain plug before

reinstalling.

Refilling

Clean case around filler plug and remove plug from side of

case. Fill transmission to the level of the filler opening. If

transmission has two filler openings, fill to level of both

openings.

Operating Temperatures

– With Eaton® Roadranger® CD50 Transmission Fluid

Heavy Duty Engine Oil and Mineral Oil

The transmission should not be operated consistently at

temperatures above 250ºF (120ºC). However, intermittent

operating temperatures to 300ºF (149ºC) will not harm the

transmission. Operating temperatures above 250ºF increase

the lubricant’s rate of oxidation and shorten its effective life.

When the average operating temperature is above 250ºF, the

transmission may require more frequent oil changes or

external cooling.

The following conditions in any combination can cause

operating temperatures of over 250ºF: (1) operating

consistently at slow speeds, (2) high ambient temperatures,

(3) restricted air flow around transmission, (4) exhaust

system too close to transmission, (5) high horsepower,

overdrive operation.

External oil coolers are available to reduce operating

temperatures when the above conditions are encountered.

Transmission Oil Coolers are:

Recommended

- With engines of 350 H.P. and above with overdrive

transmissions

Required

- With engines 399 H.P. and above with overdrive

transmissions and GCWs over 90,000 lbs.

- With engines 399 H.P. and above and 1400 Lb s.-Ft.

or greater torque

- With engines 450 H.P. and above

The exact amount of oil will depend on the transmission

inclination and model. Do not over fill; this will cause oil to be

forced out of the transmission.

When adding oil, types and brands of oil should not be mixed

because of possible incompatibility.

28

– With EP or Multipurpose Gear Oil

Mild EP gear oil and multipurpose gear oil are not

recommended when lubricant operating temperatures are

above 230ºF (110ºC). In addition, transmission oil coolers are

not recommended with these gear oils since the oil cooler

materials may be attacked by these gear oils. The lower

temperature limit and oil cooler restriction with these gear

oils generally limit their success to milder applications.

Proper Lubrication Levels as Related to Transmission

Installation Angles

If the transmission operating angle is more than 12 degrees,

improper lubrication can occur. The operating angle is the

transmission mounting angle in the chassis plus the percent

of upgrade (expressed in degrees).

Page 34

Lubrication

Lubrication

22

20

18

16

14

12

10

8

6

4

2

0

0° 1° 2° 3° 4° 5° 6° 7°

12°

11°20’

10°13’

9°16’

8°

6°51’

5°48’

4°35’

3°26’

2°18’

1°8’

0°

T

R

A

N

S

M

IS

S

I

O

N

O

I

L

L

EV

E

L

T

O

B

O

T

T

O

M

O

F

F

IL

LE

R

H

O

L

E

T

R

A

N

S

M

IS

S

I

O

N

O

I

L

L

EV

E

L

1

/

2

”

B

EL

O

W

F

IL

LE

R

H

O

L

E

2

Q

U

A

R

T

S

L

O

W

Transmission Mounting Angle

Dotted line showing “2 Quarts Low” is for reference

only. Not recommended.

noit

acirbuL repo

r

P r

o

f

n

o

i

t

ati

m

i

L

edarG

f

o tnec

reP

Percent Grade Converted to Degrees

The chart below illustrates the safe percent of upgrade on

which the transmission can be used with various chassis

mounting angles. For example: if you have a 4 degree

transmission mounting angle, then 8 degrees (or 14 percent

of grade) is equal to the limit of 12 degrees. If you have a 0

degree mounting angle, the transmission can be operated on

a 12 degree (21 percent) grade.

Anytime the transmission operating angle of 12 degrees is

exceeded for an extended period of time the transmission

should be equipped with an oil pump or cooler kit to insure

proper lubrication.

Note on the chart the effect low oil levels can have on safe

operating angles. Allowing the oil level to fall 1/2" below the

filler plug hole reduces the degree of grade by approximately

3 degrees (5.5 percent).

Proper Lubrication Levels are Essential!

29

Page 35

TORQUE RECOMMENDATIONS

SLAVE VALVE CAPSCREWS

8-12 Lbs.-Ft., 1/4-20 Threads.

Use Lockwashers.

FRONT BEARING COVER CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

STUDS

60 Lbs.-Ft., 3/8-16 Minimum,

Driven Until Bottomed, 5/8-11 Threads.

CLUTCH HOUSING NUTS

5/8-18 Threads

Aluminum Housing:

140-150 Lbs.-Ft (Oiled)

With Nylon Locking Insert.

Use Plain Flat Washer.

Cast Iron Housing:

180-200 Lbs.-Ft Standard Nut.

Use Lockwasher

C’SHAFT FRONT BEARING

RETAINER CAPSCREWS

20-25 Lbs.-Ft., 3/8-24 or

25-35 Lbs.-Ft., 1/2-20

Threads, Secure with Lock Wire

90-120 Lbs.-Ft., 5/8-18 Threads.

All 1/8 Inch Compression

Fittings 25-30 Lbs.-Inch

CLUTCH HOUSING CAPSCREWS

1/2-13 Threads

Aluminum Housing:

70-80 Lbs.-Ft., Use Shakeproof Internal

Lockwasher.

Cast Iron Housing:

80-100 Lbs. Ft. Use Lockwasher

DRIVE GEAR NUT

250-300 Lbs.-Ft., 2-1/8-16 L.H. Threads, Clean

Threads with Solvasol or Equivalent Stake 2 Places.

REVERSE IDLER SHAFT NUTS

50-60 Lbs.-Ft., (Oiled)

5/8-18 Threads with Nylon Locking Insert.

AUX. DRIVE GEAR BEARING RETAINER CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

Secure with Lock Wire.

OIL DRAIN PLUG

45-55 Lbs.-Ft., 3/4 Pipe Threads.

REDUCTION/SPLITTER YOKE LOCKSCREW

35-45 Lbs.-Ft., 7/16-20 Threads.

Secure with Lock Wire.

AUXILIARY HOUSING CAPSCREWS

35-45 Lbs.-Ft., 3/8-6 Threads.

Use Lockwashers.

OUTPUT SHAFT NUT

450-500 Lbs.-Ft., (Oiled at Vehicle

Installation). 2-16 Threads with

Nylon Locking Insert.

(oiled at vehicle installation)

RANGE CYLINDER SHIFT BAR NUT

70-85 Lbs.-Ft., 5/8-18 Threads with

Nylon Locking Patch.

(610)6610 Model, 60-75 Lbs.-Ft.

1/2-13 Threads, Use Lockwasher.)

RANGE SHIFT YOKE CAPSCREWS

50-65 Lbs.-Ft., 1/2-20 Threads,

Secure with Lock Wire

SHIFT BAR HOUSING CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

SHIFT LEVER HOUSING CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

YOKE LOCKSCREWS

Start By Hand Until Cone Engages,

35-45 Lbs.-Ft., 7/16-20 Threads,

Secure with Lock Wire.

Cut 7190S 6/86

Torque Recommendations

30

Page 36

Torque Recommendations

SUPPORT STUD NUTS

170-185 Lbs.-Ft., (Oiled at Vehicle

Installation). 5/8-18 Threads,

Use Lockwashers

SUPPORT STUD

60 Lbs.-Ft., Minimum.

Drive Until Bottomed

5/8-11 Threads.

REAR BEARING COVER CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads,

Use Lockwashers.

REAR BEARING COVER ESLOK CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads,

Use Brass Flat Washer & Nylon Collar.

Torque Recommendations

REVERSE SIGNAL SWITCH PLUG

35-50 Lbs.-Ft., 9/6-18 Threads.

AIR FILTER/REGULATOR CAPSCREWS

8-12 Lbs.-Ft., 1/4-20 Threads.

AUX. RANGE CYLINDER

CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

AUX. RANGE CYLINDER

COVER CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

OIL FILL PLUG

35-45 Lbs.-Ft., 1-1/4 Pipe Threads.

LARGE P.T.O. COVER CAPSCREWS

50-60 Lbs.-Ft., 7/16-14 Threads.

REDUCTION/SPLITTER CYLINDER PLUG

40-50 Lbs.-Ft., 5/8-18 Threads.

REDUCTION/SPLITTER CYLINDER COVER CAPSCREWS

20-25 Lbs.-Ft., 5/16-18 Threads.

THREAD SEALING INSTRUCTI ONS

• Capscrews – Apply Loctite 242

• Drove Gear Nut, Clutch Housing Studs, and Support Studs – Apply Thread Sealant (Fuller Part No. 71204)

• Tapered Threads (Pipe Threads) and Airline Fittings – Ap ply Hydraulic Sealant (Fuller Part No. 71205)

SMALL P.T.O. COVER CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

AUX. C’SHAFT REAR BEARING

COVER CAPSCREWS

35-45 Lbs.-Ft., 3/8-16 Threads.

THERMOCOUPLE PLUG

40-50 Lbs.-Ft., 1/2 Pipe Threads.

SPEEDOMETER HOUSING PLUG

35-50 Lbs.-Ft., 13/16-20 Threads.

HAND HOLE COVER CAPSCREWS

20-25 Lbs.-Ft., 5/16-18 Threads.

Cut 7191S 6/86

31

Page 37

TROUBLESHOOTER’S GUIDELINE

Troubleshooter’s Guideline

Following is a basic procedure guideline for troubleshooting

transmissions:

1. Preliminary Inspection.

a. Personal Observation – look for signs of misuse

such as broken mounts, fittings or brackets;

check airlines.

b. Question the Owner or Operator – gather

information on operating conditions and vehicle

use, on history of problem, and on shifting

characteristics if affected.

c. Gather History of Unit – including maintenance

and lubrication procedures, past failures, and

mileage or hours of use.

2. Disassemble Transmission.

a. Keep oil sample for impurities, check if needed.

b. During disassembly, check for incorrectly

installed parts, missing parts, and nongenuine

parts.

c. Clean and inspect each piece closely.

3. Determine Type of Failure.

8. Check airlines or hoses.

9. Tighten part.

10. Correct the restriction.

11. Recheck timing.

12. Clean part.

13. Apply thin film silicone.

14. Apply sealant.

4. Determine and correct Cause of Failure.

To Use Guideline Chart

The T r oubleshooter’s Guideline Chart is used to locate and

correct transmission problems.

To use the guideline, 1) Locate the transmission problem in

the left hand column; 2) Trace line horizontally across the

page until a rectangle with a number in it is reached; 3) Trace

up vertical column to find a possible cause. The number in the

intersection of the vertical and horizontal lines tell which

corrections to use; 4) Possible corrections are listed below.

There may be more than one possible cause and possible

correction for each problem.

POSSIBLE CORRECTIONS

1. Instruct driver on proper driving techniques.

2. Replace parts (after trying other listed possible

corrections).

3. Loosen lock-screw and retighten to proper torque.

4. Look for resultant damage.

5. Smooth with emery paper.

6. Reset to proper specifications.

7. Install missing parts.

32

Page 38

Troubleshooter’s Guideline

Troubleshooter’s Guideline

PROBLEM

SLIP OUT (SPLITTER)

SLIP OUT (RANGE)

SLIP OUT OR

JUMP OUT (FRONT SECTION)

SLOW SHIFT (SPLITTER)

SLOW SHIFT OR

WON’T SHIFT (RANGE)

HARD SHIFT OR WON’T

SHIFT (FRONT SECTION)

ABLE TO SHIFT FRONT

SECTION INTO 2 GEARS AT ONCE

GRINDING ON INITIAL

LEVER ENGAGEMENT

LEVER LOCKS UP OR

STICKS IN GEAR

NOISE

ESUAC ELBISSOP

S

DAP

EKO

Y

N

R

OW

1

2

2

2

3

2

G

NIRPS TN

E

TED GNISSIM R

RAB EKOY NO

RAB

E

K

OY TNEB

O KAEW

RRUB

2

7

522

7

G

N

IS

GN

G

SI

IS

NIRP

M NIP

DEGGULP

UOH R

S TN

R

A

O

ETED GN

B T

LLAB K

F

IHS DEK

O

C

RTS

OL

RETNI

CA

OOT

RC

GNITTIF R

ALUGER EVITCEFE

RESNI DEGAM

E

L

O E

O

H REHTA

SOH ESOO

ERB

ADT

DROT

L

229

92

229

29

GEAR RATTLE AT IDLE

VIBRATION

BURNED MAINSHAFT WASHER

INPUT SHAFT SPLINES WORN OR

INPUT SHAFT BROKEN

CRACKED CLUTCH HOUSING

BROKEN AUXILIARY HOUSING

BURNED SYNCHRONIZER

BROKEN SYNCHRONIZER

HEAT

TWISTED MAINSHAFT

DRIVE SET DAMAGED

BURNED BEARING

OIL LEAKAGE

OVERLAPPING GEAR RATIOS

2

10

33

Page 39

Troubleshooter’s Guideline

NOTSIP EVLAV EVALS GNIKCITS

ESOH RIA DEHCNIP

GNIR ”O“ EGAMAD

101026

12

12

13

10

13

2

E

ECNARELOT RAEG TFAHSNIAM EVISSECXE

ECALP GNORW OT DEK

TEKSAG DETNUOM YLREPORPMI

OOH ESOH RIA

10

10

10

TFAH

ROTCENNOC RO ENIL RIA DEHCNIP

12

HTOOT NO RRUB RO RAEG DEKCARC

ESOOL TUN NOTSIP REDNILYC RIA

S NO EMIT FO TUO DETSIWT RAEG

DEKCARC NOTSIP REDNILYC RIA

2

4

2

4

2

4

2139

2

4

TFAHS

NIAM

DETSIWT

2

2

222

2

RAEG HC

)NOITCES

HTEE

T

U

LC

RAILIX

T

G

TNORF(

N

I TOL

N

IH

UA( YEK N

CTULC DEREPAT

S EKOY NROW

Y

EK NEKO

EKORB)Y

R

B

2

1

2

4

S/

C .

XUA FO

NEKORB G

SDRA

TNORF F

W

REZINORH

KCA

N

I

FO TFEL

RPS REZINORHCNY

B DELLATSNI EKO

Y

7

ERULIAF

ECAR RE

C

NYS DELIAF

GNIRA

NNI

EB

S

7

2

2

122

R

AEG FO HG

R

E

ETTILPS

N

I

GNE GNINNUR H

I

HCTULC GNISU

H

O

G

O

T

NITCELES-E

DAOL KC

NI GNITRAT

G

TO

UOR

1

1

O

R

H

P

N

S

S

1

4

1

4

1

4

1

4

KARB

)

)

L

L

L

LUP( DETS

UP

)HS

(

NEKORB S

UP

(

U

G

J

NIKROW TON EK

DA TON EKA

GN

A

T

E

K

A

RB

RB

A

HCTU

HCT

R

B

U

S/

L

LC

C

C

SGN

H

IS

C

U

TULC

TNE

O

TNEMTSUJDA HCT

H LOR

MTS

R

O

TN

S

U

SNOITCURTSBO EG

JDA EGAKNIL

/

C HTIW DEP

PIUQE TON

AKNIL

10

10

TNUOM E

OC N

I

NR

ULC REPORPMI

N

O

IGNE NE

W

RE

SGNIH

P

ORPM

KORB

SU

I

B

LIO YTI

E

L

R

LEVEL L

EVEL LIO H

U

LI

LAUQ RO

A

F HCTU

I

O WOL

G

IH

LC

O

P

26

2

6

4

S

SEV

GNIR ”O“ NO ENOCI

ELGNA GNITARE

PO

T

A

E

RG

O

O

T

I

TIDDA GNIS

SG

S

E

NIR ”O“ NO ENOCILIS ON

GNA

HC

U RO

LIO TNEU

L

I

S EVI

S

L

I

O G

S

Q

SEC

E

NIXIM

R

FNI

X

E

12

13

13

12

13

13

GNITSAOC

NOIS

SIM

S

R

NART OT E

SWERCSPA

O

KC

U

RT

F

N

LAES RAER D

I

C

O

GNIWOT R

G

GNIS

E

S

AC NI ELOH NIP

NE TNEMNGIL

S

IM RO E

EPORPMI

E

GAMAD

S

ASIM

O

O

L

2

6

STUN

G

U

L ESOOL

LR

EPORPMI TU

PU TE

,

S ENILEVIRD REP

ECNALAB FO TUO

N

OI

N TFAHS TUPTUODEUQROT Y

S

NE

PS

US

NRO

O

SERIT

RPM

I

W

2

2

4

245

2

6

2

7

2

4

2

6

267

1

8

10

1

662

1

10 6

242

2

4

2

4

4

66

6

2

66

6

262

6

2

2

4

6

121

2

2

2

6

6

2

4

1

22

2

6

272

6

2