Burkert BBS-3F User Manual [en, de, fr]

Type BBS-3F

Inline inspection glass full view and standard design Linienschauglas Vollsicht und Standardausführung

Indicateur de débit en ligne indication totale et modèle standard

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet: www.burkert.com Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de Instructions de service et fiches techniques sur Internet : www.buerkert.fr

© 2014 Bürkert Werke GmbH

Operating Instructions 1402/00_EU-ML_00810320 / Original DE

www.burkert.com

1.THE OPERATING INSTRUCTIONS

The operating instructions contain important information.

•Read the instructions carefully and follow the safety instructions in particular.

•Keep the instructions in a location where they are available to every user.

•The liability and warranty for the product do not apply if the procedures in the instructions are not observed.

1.1. Symbols

→→designates a procedure which you must carry out.

Warning of injuries:

DANGER!

Immediate danger! Serious or fatal injuries.

Immediate danger! Serious or fatal injuries.

WARNING!

Possible danger! Serious or fatal injuries.

Possible danger! Serious or fatal injuries.

CAUTION!

Danger! Moderate or minor injuries.

Danger! Moderate or minor injuries.

Warning of damage:

NOTE!

2 |

english |

|

|

Type BBS-3F

2.INTENDED USE

Non-authorized use of the Type BBS-3F inline inspection glass may be dangerous to people, nearby equipment and the environment.

•Type BBS-3F has been designed as an inline inspection glass for pipelines for the flow of fluids in the sterile area.

•Use according to the authorized data, operating conditions, and conditions of use specified in the contract documents and operating instructions.

•Correct transportation, storage and installation, as well as careful use and maintenance are essential for reliable and faultless operation.

•Use the product only as intended.

2.1. Restrictions

If exporting the products, observe any existing restrictions.

2.2. Definitions of terms

The term “product” used in these instructions always refers to the inline inspection glass Type BBS-3F.

|

3. |

BASIC SAFETY INSTRUCTIONS |

4. GENERAL INFORMATION |

|

|

|||||||

|

These safety instructions do not take into account any contingencies and |

4.1. Contact address |

|

|

||||||||

|

events which may arise during the installation, operation and maintenance |

Germany |

|

|

|

|

|

|

|

|||

|

of the product. |

|

|

|

|

|

|

|

||||

|

Bürkert Fluid Control Systems |

|

|

|||||||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

Sales Center |

|

|

|

|

|

|

|

|

|

|

|

|

Christian-Bürkert-Str. 13-17 |

|

|

|||||

|

Danger – high pressure and discharge of medium! |

|

|

|

||||||||

|

|

D-74653 Ingelfingen |

|

|

||||||||

|

• Before loosening the nuts or screws, always turn off the pressure |

|

|

|

||||||||

|

|

Tel. + 49 (0) 7940 - 10 91 111 |

|

|

||||||||

|

and relieve the lines. |

|

|

|

||||||||

|

|

Fax + 49 (0) 7940 - 10 91 448 |

|

|

||||||||

|

• Wear protective equipment if media is hazardous. |

|

|

|

||||||||

|

|

E-mail: info@de.buerkert.com |

|

|

||||||||

|

General hazardous situations |

|

|

|

||||||||

|

|

International |

|

|

|

|

|

|

|

|||

|

• Do not make any internal or external changes to the product. |

|

|

|

|

|

|

|

|

|||

|

|

Contact addresses can be found on the final pages of the printed |

|

|

||||||||

|

• Ensure that the system cannot be activated unintentionally. |

|

|

|

||||||||

|

• Installation and maintenance work may be carried out only by |

|

operating instructions. And also on the Internet at: |

www.burkert.com |

|

|

||||||

|

authorized technicians with the appropriate tools. |

|

4.2. Warranty |

|

|

|

|

|

|

|

||

|

• The product may be operated only when in perfect condition and in |

|

|

|

|

|

|

|

|

|||

|

|

The warranty is only valid if the product is used as intended in |

|

|

||||||||

|

consideration of the operating instructions. |

|

|

|

||||||||

|

|

accordance with the specified application conditions. |

|

|

||||||||

|

• As far as inspection, maintenance and repairs are concerned, |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

observe national provisions of the country in which the connection |

|

4.3. Information on the Internet |

|

|

|||||||

|

elements are installed. |

|

The operating instructions and data sheets for Type BBS-3F inline |

|

|

|||||||

|

• The general rules of technology apply to application planning and |

|

|

|

||||||||

|

|

inspection glass can be found on the Internet at: www.burkert.com |

|

|

||||||||

|

operation of the product. |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

english |

|

3 |

|

|||

|

5. |

TECHNICAL DATA |

|

|

|

|

|

|||||

|

5.4. Sealing materials |

|

|

|||||||||

|

|

|

|

|

|

|||||||

|

5.1. Conformity |

Seal material |

Operating temperature |

|

|

|||||||

|

The inline inspection glass Type BBS-3F conforms to the EC direc- |

EPDM |

–40 °C to 90 °C, briefly up to 140 °C |

|

|

|||||||

|

tives according to the EC Declaration of Conformity. |

FKM |

–20 °C to 200 °C |

|

|

|||||||

5.2. Standards (if applicable) |

Tab. 1: Sealing materials BBS-3F inline inspection glass |

|

The applied standards which are used to demonstrate compliance with the EC Directives are listed in the EC type test certificate and/or the EC Declaration of Conformity.

5.3. Identification

Information on material, pipe and connection dimensions can be found on the stamping on the product. The identification number of the product can be found on the supplied 3.1 certificate.

|

|

|

|

|

|

|

|

|

|

|

|

|

Material Material |

Nominal connection |

|||

|

|

batch number |

diameter with pipe standard |

||

|

|

|

|

|

|

Fig. 1: |

Example of identification of the product |

||||

5.5. General technical data

|

comes into contact |

Stainless steel 1.4435 |

|||||

|

with medium |

BN2 (316L) |

|||||

Material |

does not comes into |

Stainless steel 1.4401 |

|||||

contact with medium |

or equivalent |

||||||

|

|||||||

|

Glass |

Borosilicate glass |

|||||

|

O-ring |

EPDM/FKM |

|||||

Pipe dimensions |

see identification on product (“Fig. 1”) |

||||||

Permitted application |

Depending on sealing material, |

||||||

temperature |

see “Tab. 1” |

|

|

|

|||

Ambient temperature |

–20 °C to +80 °C |

|

|

|

|||

Media |

Fluids |

|

|

|

|||

Operating pressure |

–1 to +8 bar (depending on the temperature) |

||||||

4 |

english |

|

|

6.ASSEMBLY

WARNING!

WARNING!

Danger – high pressure and discharge of medium!

•When working on the product or the system, always switch off the pressure and relieve the lines.

•Wear protective equipment if media is hazardous.

Risk of injury from improper assembly!

•Installation must only be carried out by authorized technicians and with the appropriate tools!

•Secure system from unintentional activation.

Type BBS-3F

6.1. Welding in the inline inspection glass

NOTE!

Leak due to damaged sealing elements!

•Do not weld in the assembled product. It is essential to remove the O-ring and glass tube before welding and to protect them from dust, flying sparks and other influences!

Leak due to damaged sealing contour!

•To ensure the sealing function, protect the sealing contour during installation, welding and cleaning procedures.

→→Connect the parts positively in a protective gas shield.

When cleaning the weld seam by grinding or acid cleaning, observe the following before assembling the connection:

•Carefully remove all grinding dust and acid-cleaning residue.

•Do not damage the label.

•There must be no material abrasion on the sealing edges. Material abrasion will result in sharp-edged sealing contours and a damaged seal.

•Check sealing contour for damage.

We recommend preparing a welding report.

english |

5 |

|

|

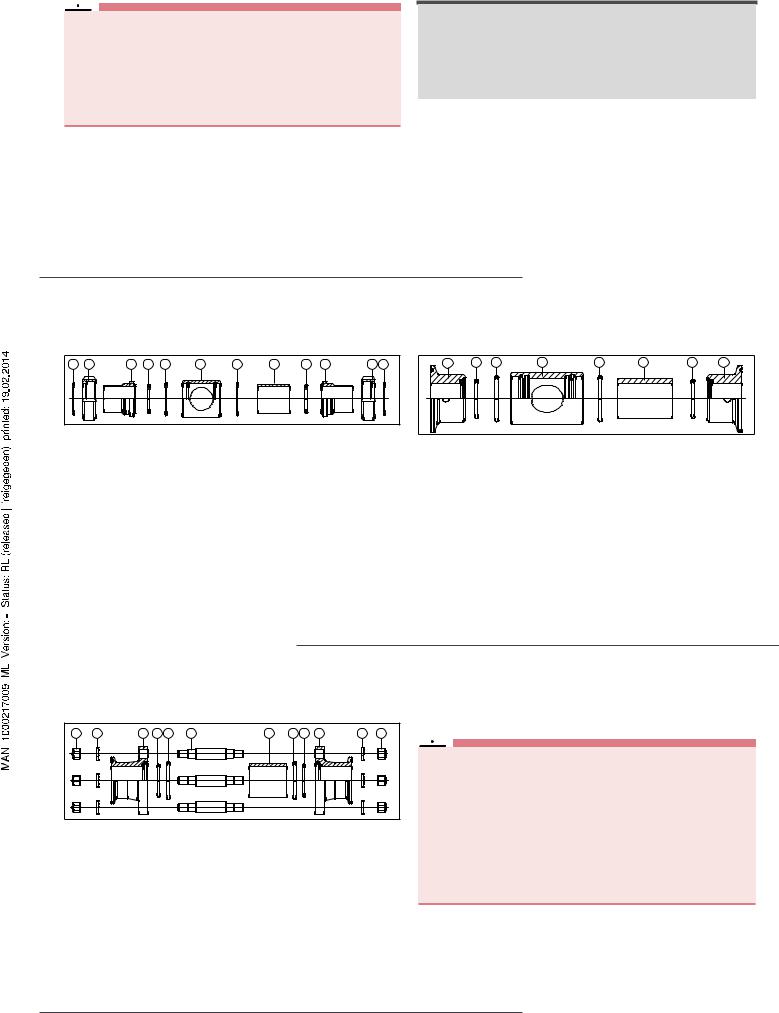

6.2. Assembling orbital inline inspection glass

7 |

6 |

5 |

4 |

2 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

Fig. 2: Assembling orbital inline inspection glass (with union nut)

→→Insert both O-rings (2) by hand (do not use any tools or sharp implements) into the two designated grooves in the inspection glass holder (1).

→→Carefully push glass (3) into the inspection glass holder. Ensure that the O-rings are in the correct position.

→→Attach an O-ring (4) and a liner (5) to each side (do not use any tools or sharp implements) and secure with the union nuts (6).

→→Tighten union nuts and secure with retaining rings (7).

6.3. Assembling standard inline inspection glass

5 |

4 |

2 |

1 |

2 |

3 |

4 |

5 |

Fig. 3: Assembling standard inline inspection glass

→→Insert both O-rings (2) by hand (do not use any tools or sharp implements) into the two designated grooves in the inspection glass holder (1).

→→Carefully push glass (3) into the inspection glass holder. Ensure that the O-rings are in the correct position.

→→Attach an O-ring (4) and a connecting piece (5) to each side (do not use any tools or sharp implements).

→→Tighten connecting pieces.

6 |

english |

|

|

6.4. Assembling full view inline inspection glass

6 |

5 |

1 |

3 |

4 |

2 |

7 |

4 |

3 |

1 |

5 |

6 |

Fig. 4: Assembling full view inline inspection glass

→→In each flange (1) insert two O-rings (3 +4) by hand (do not use any tools or sharp implements).

→→Push glass (7) into one of the two flanges. Ensure that the O-rings are in the correct position.

→→Also insert spacer bolts (2) into the designated bores, secure with washers (5) and nuts (6).

→→Attach second flange, secure with washers and nuts. →→Tighten nuts.

6.5. Disassembly

Disassembly is in reverse sequence to assembly.

7.START-UP

WARNING!

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the product and the surrounding area.

•Before start-up, ensure that the operating personnel are familiar with and completely understand the contents of the operating instructions.

•Observe the safety instructions and intended use.

•Only adequately trained personnel may start up the equipment/the product.

•Following assembly, ensure a controlled restart.

•When starting up the equipment, ensure that no unauthorized voltage increases and pressure surges can occur.

english |

7 |

|

|

NOTE!

Damage to the sealing elements when cleaning the pipeline systems.

•Clean the pipeline systems preferably with a cleaning agent which does not damage the sealing elements.

•Do not clean with wire brushes or machines which cause abrasion of the surface.

•When using mechanical pipeline monitoring devices, ensure that they do not damage the sealing elements (also the sealing contour).

Damaged sealing elements must be replaced!

8 |

english |

|

|

Type BBS-3F

8.MAINTENANCE

WARNING!

WARNING!

Danger – high pressure and discharge of medium!

•Before loosening the nuts or screws, always turn off the pressure and relieve the lines.

•Wear protective equipment if media is hazardous.

•Nuts or screws may be retightened on pressurized lines only by technicians in consideration of special precautions.

•When shutting down the equipment, ensure that no unauthorized voltage increases and pressure surges can occur.

•Following maintenance, ensure a controlled restart.

Have the product serviced regularly by technicians! We recommend a maintenance interval of 6 months.

Inspection and maintenance work includes in particular monitoring and ensuring the

•leak-tightness,

•identification,

•proper mode of operation of the safety and warning devices.

9.SPARE PARTS

CAUTION!

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries and damage the product and the surrounding area.

• Use only original accessories and original spare parts from Bürkert.

The spare part set for the inline inspection glass Type BBS-3F includes: O-rings, inspection glass

The order numbers for the spare part sets can be found on the corresponding data sheet on the Internet.

10. TRANSPORTATION, STORAGE, DISPOSAL

NOTE!

Transport damage!

Inadequately protected products may be damaged during transportation.

•Transport the product in a firmly assembled state, protected against moisture and dirt, in shock-resistant packaging.

Incorrect storage may damage the product.

•Prevent the temperature from exceeding or dropping below the permitted storage temperature.

•Store the product in a dry and dust-free location!

•Store O-rings dry and protected from UV radiation and for not longer than 3 years.

•Storage temperature –40 to +80 °C.

Damage to the environment caused by products contaminated with media.

•Dispose of the product and packaging in an environmentally friendly manner!

•Observe applicable disposal and environmental regulations.

english |

9 |

|

|

Loading...

Loading...