Bernina Funlock 004D, Funlock 004 Instruction Manual

Retyped by Mastersewusa.co

m

Important

Dear customer

Congratulations on your choice!

Your Bernette Funlock 004D/004 is made to the highest standards. It will cut, sew and neaten for you in one smooth

operation giving a professional look to anything you make.

The 4 thread Bernette Funlock is particularly suited to sewing stretch fabrics. Let your wardrobe and home benefit

from the Bernette’s superb sewing qualities. Our comprehensive Instruction Manual introduces you step by step to

the joys of overlocking and also gives you some useful sewing tips.

We wish you many happy hours of overlocking pleasure.

Safety Regulations

The following safety regulations must be observed without fail: It is important to pay attention to the needle and knife

while sewing as these are potential sources of injury to fingers. Movements within the area of the needle, knife or

looper such as threading, changing needles or presser feet, or raising the knife, may only be done with the machine

switched off (power switch at “O”). When cleaning or lubricating the machine replacing the bulb or when sewing is

finished, machine should be disconnected from the electricity supply. All repair work, especially electrical repairs

(e.g. renewing the cable connection out by one of our authorized service agencies.

Please note:

Funlock 004 is not equipped with differential feed. All points relating exclusively to Funlock 004D are marked with

the symbol. ✱

1

Retyped by Mastersewusa.co

m

Contents

Safety regulations 1

Contents 2

Details of the machine 3

● Accessories 4

Preparing the machine 5

● Foot control 5

● Assembling the thread stand 5

● Thread, cones, spools 6

Using the machine 7

● Main switch 7

● Handwheel 7

● Looper cover, cloth plate 7

● Presser foot lifter 8

● Changing the presser foot 8

● Inserting the needles 9

● Raising the upper knife 9

Threading 10

● Preparations 10

● Upper and lower looper 11/12

● Right-hand and left-hand needle 13/14

Threading/trial sewing 15

● 3 thread Overlock 15

● Sewing test/tension 15/16

● Adjusting tension 17

Adjustments and settings 18

● Stitch length 18

● Cutting width 18

● Differential feed ✱ 19/20

● Gathering ✻ 20

Setting/Practical sewing 21

● Presser foot pressure 21

● Roll hemming 22

● Sewing in tape 23

● Thread breakage, unpicking seams 23

Maintenance 24

● Changing knifes and light bulb 24

● Cleaning and lubricating 24

Trouble shooting guide 25

Technical data 26

2

Retyped by Mastersewusa.co

m

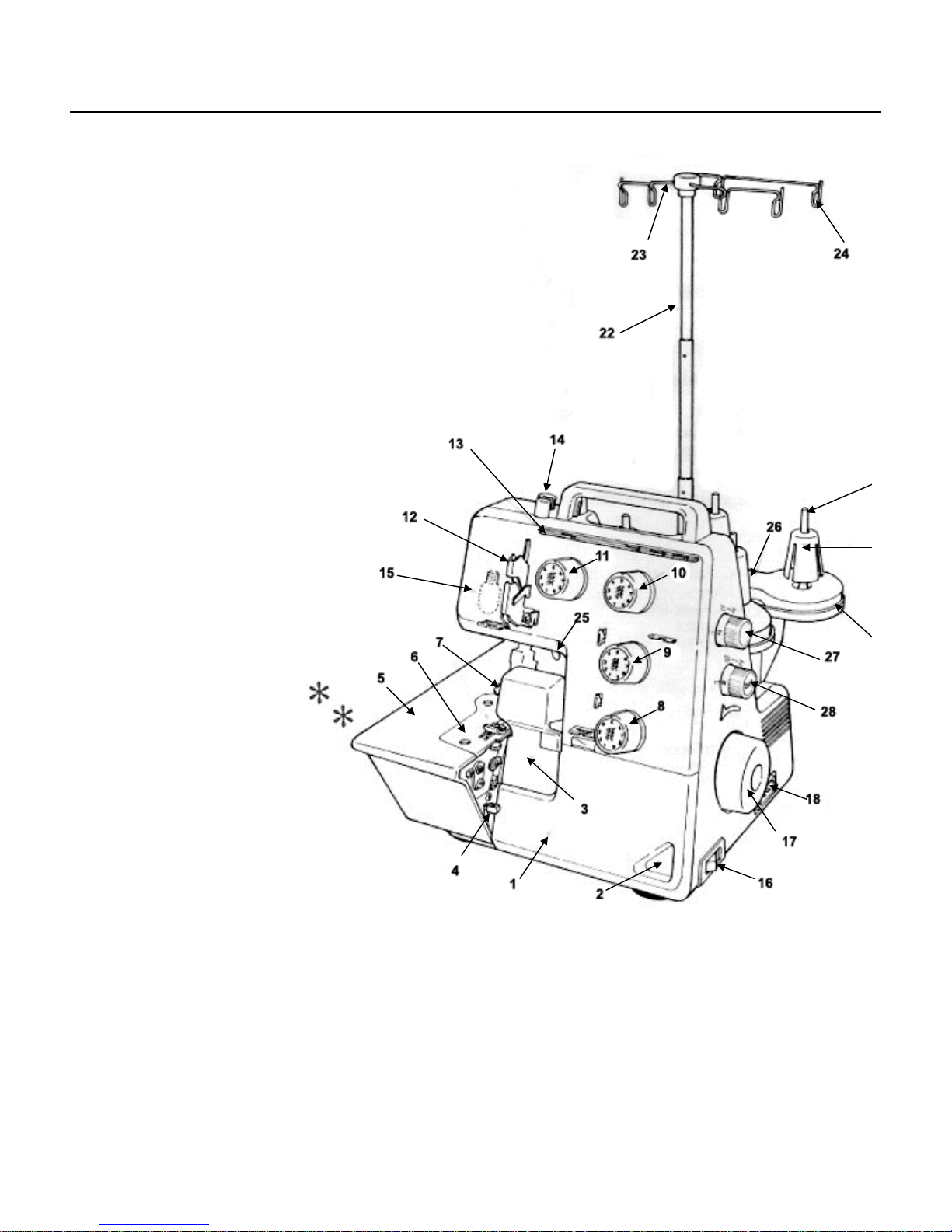

Details of the machine

Details of the machine

1. Looper cover

2. Looper cover opening indent

3. Knife guard

4. Cloth plate opening lever

5. Cloth plate

6. Stitch plate

7. Presser foot

8. Lower looper thread tension dial

9. Upper looper thread tension dial

10. Right needle thread tension dial

11. Left needle thread tension dial

12. Thread take-up cover

13. Thread guide plate

14. Presser foot adjusting screw

15. Sewing light

16. Power/light switch

17. Handwheel

18. Machine socket

19. Thread stand

20. Anti-vibration cone

21. Spool holder pin

22. Retractable support rod

23. Thread guide

24. Open thread guide

25. Presser foot lifter

26. Foam pad

27. Stitch length adjustment knob

28. Differential feed adjustment knob

3

21

20

19

Details of the machine

View with looper cover open

1. Upper looper

2. Upper knife

3. Lower knife

4. Selection lever for overlocking or roll hemming

5. Lower looper

6. Lower knife setscrew

View with cloth plate open

1. Cutting with adjustment knob

2. Stitch length adjustment knob (004)

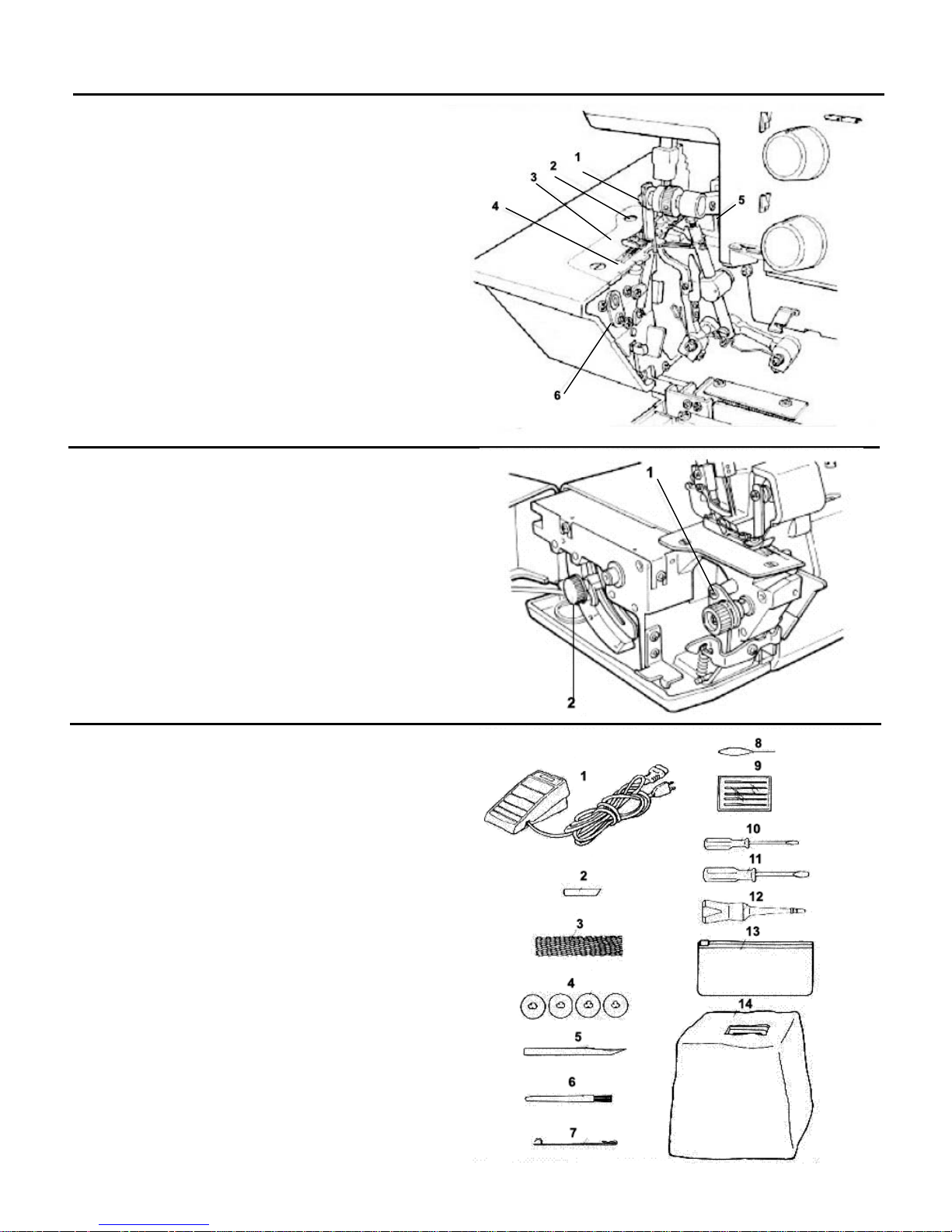

Accessories

1. Electronic foot control

2. Lower knife

3. Net

4. Spool caps

5. Tweezers

6. Cleaning brush

7. Looper threader

8. Needle threader

9. Set of household needles

10. Small screwdriver

11. Large screwdriver

12. Oiler

13. Accessory bag

14. Dust cover

4

Preparing the machine

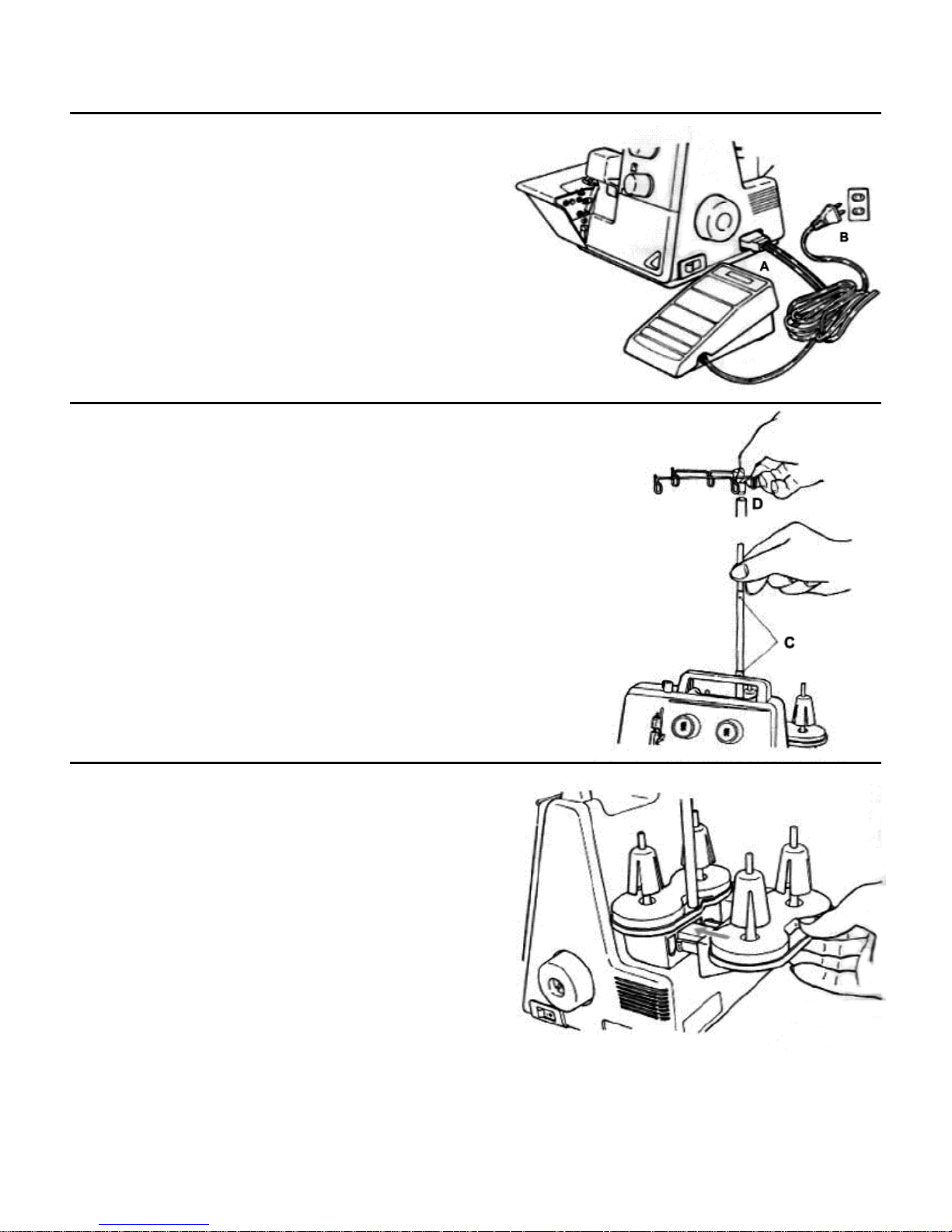

Attaching the foot control

Plug foot control into machine socket (A) and then into main

socket (B). The foot control regulates the sewing speed. The

sewing speed can be adjusted by increasing or decreasing the

pressure on the foot control.

Thread guide

Raise, the support rod fully, turning slightly until the

positioning catches engage (C). Position the thread guide on

the thread stand so that the arrow is to the front (D).

Thread Stand

Attach the separately packed spool holder to the fixed spool

holder.

5

Preparing the machine

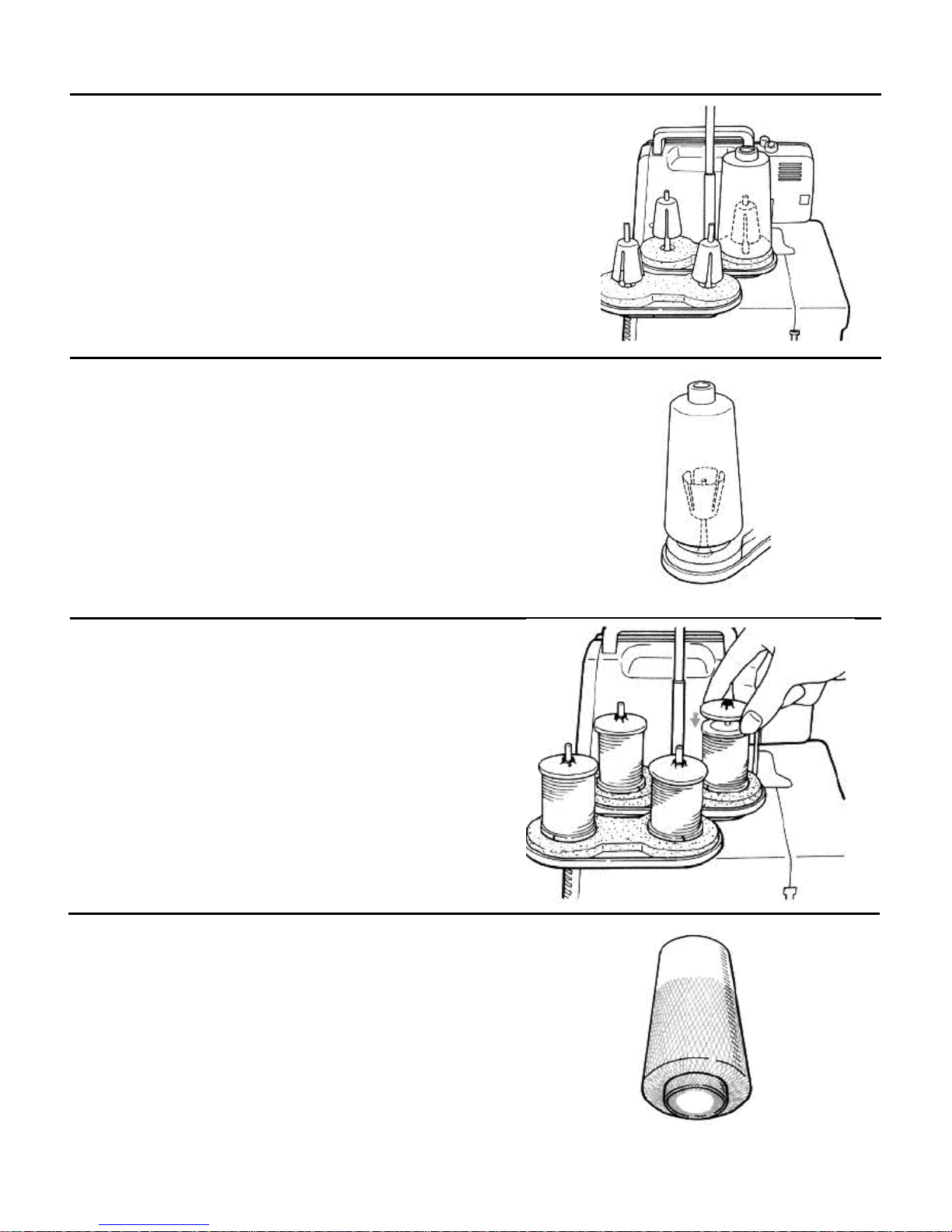

Thread cones/spools

The anti-vibration cone should be used with the wider edge

at the bottom on the spool holder pin when sewing with

cones.

Large spools

If large industrial spools are used, position the anti-vibration

cone upside down on the spool holder pin, i.e. with the wider

edge at the top.

Household spools

Remove the anti-vibration cones. Place spools on spool

holder pins and push the spool capon with the rounded side

downwards.

Thread net

If threading slip and get twisted, cover the spools of upper

and lower looper with the nets supplies in the accessory bag.

6

Using the machine

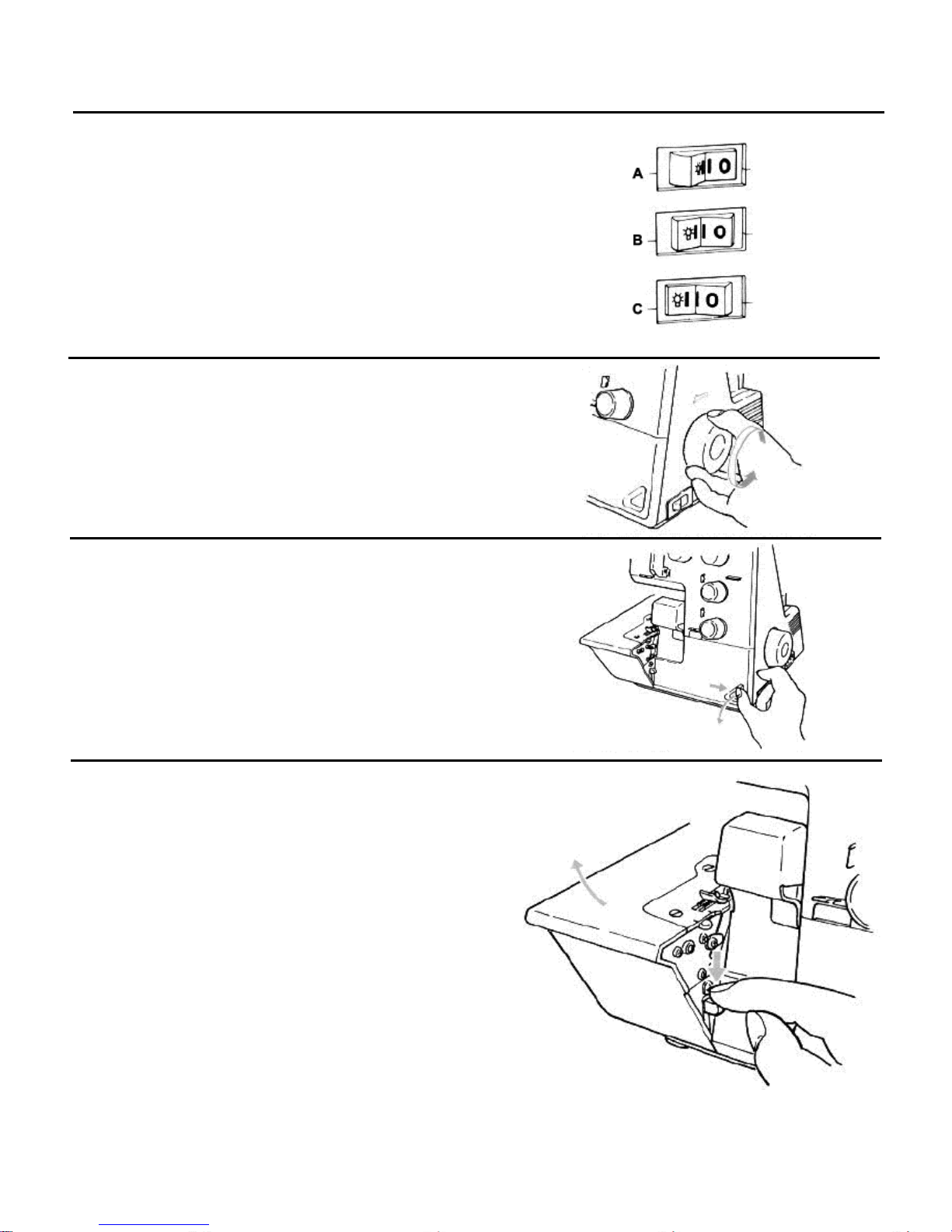

Power/light switch

The power/light switch is conveniently placed on the handwheel side of the machine in front of the socket.

• Off (A)

• On without light (B)

• On with light (C)

Handwheel

The handwheel turns forward, i.e. in the same direction as on

a household sewing machine.

Looper cover

To open press to the right with your thumb in the indent

provided and tilt the cover towards you. To close, push it up

and press lightly to the right. The cover engages

automatically.

Cloth plate

The cloth plate opens automatically by pushing the lever

downwards. To close the cloth plate, push it towards the

machine and press gently until the cover engages.

7

Using the machine

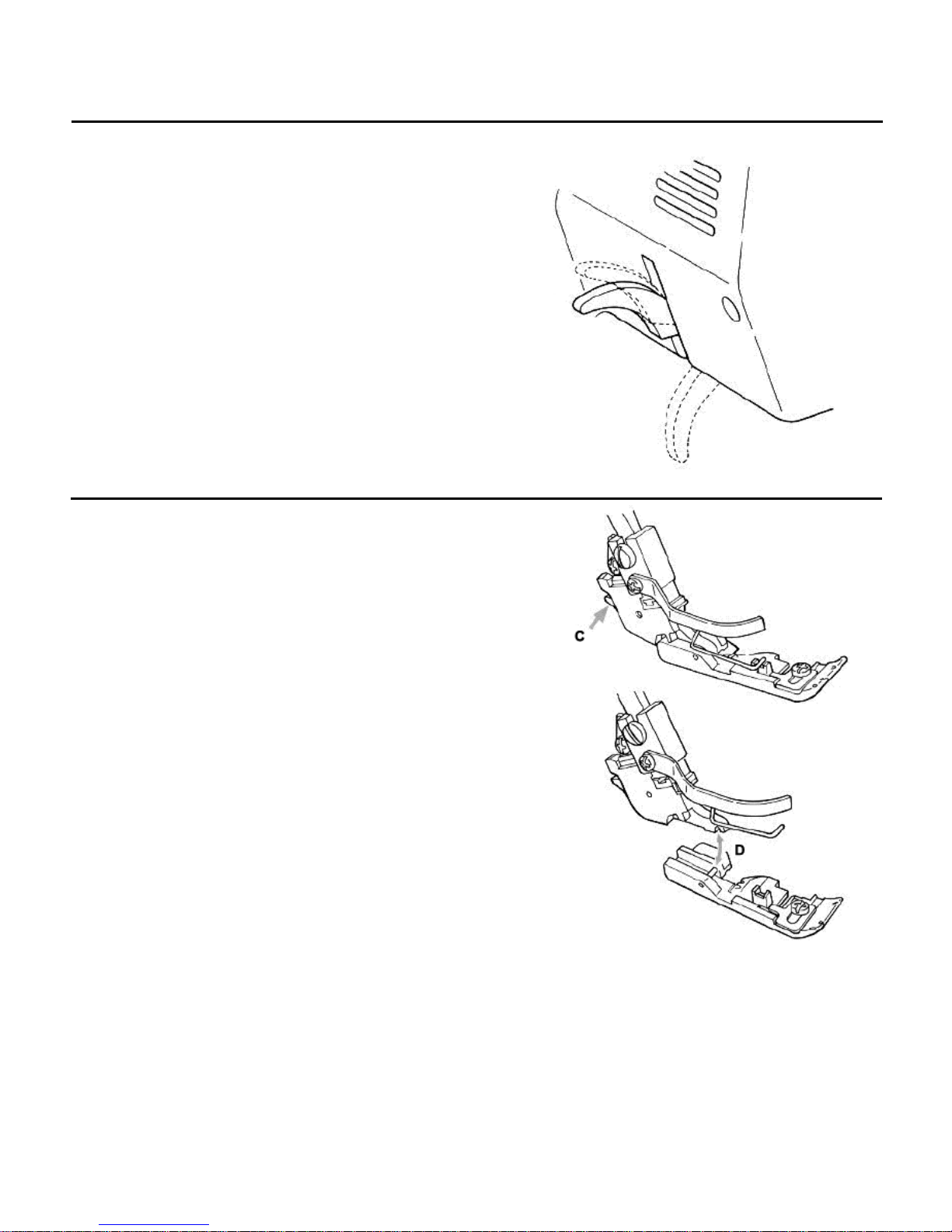

Two-step presser foot lifter

To raise the presser foot, raise the presser foot lever on the

rear of the machine, until it engages (A). It can be raised

again to maximum height and held in this position to provide

more space between presser foot and stitch plate (B).

Changing the presser foot

• Turn power switch to “O”

• Raise the presser foot

• Turn handwheel towards you until needles are fully

raised.

Press the catch (C) to release the presser foot from the

clamp. Raise the presser foot to the highest position (B)

and remove the presser foot to the left. To attach the

presser foot, place it under the shaft. The groove in the

shaft should line up exactly with the presser foot pin

(D). Lower the shank and the presser foot will engage

automatically.

8

Loading...

Loading...