Bendix SR-4 SPRING BRAKE CONTROL VLV User Manual

SD-03-4514

Bendix® SR-4™ Spring Brake Control Valve

#2 RESERVOIR

CHARGING

PORT

#2 RESERVOIR |

#1 |

CHARGING |

RESERVOIR |

PORT |

CHARGING |

|

PORT |

SERVICE PORT |

|

SERVICE PORT

#1 |

|

|

|

|

RESERVOIR |

|

|

|

|

CHARGING |

|

|

|

|

PORT |

DELIVERY PORTS (4) |

DELIVERY |

|

|

|

|

|||

|

|

PORTS (4) |

TRAILER SUPPLY |

|

|

|

TRAILER SUPPLY |

||

|

|

PORT |

||

|

|

PORT |

||

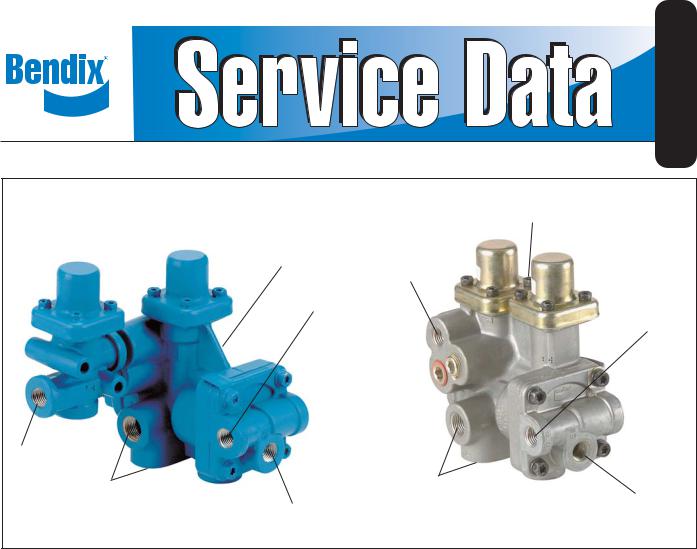

FIGURE 1A |

TYPE 1 |

TYPE 2 |

||

FIGURE 1B |

FIGURE 1 - SR-4™ SPRING BRAKE CONTROL VALVE TYPE 1 & TYPE 2

DESCRIPTION

The SR-4™ valve is provided in two different configurations. Type 1 (Fig. 1A) incorporates a nipple mounted PR-3™ valve. Type 2 (Fig. 1B) has the function of the additional PR-3™ valve integrated into the main housing. There is no difference in the operational performance of the two designs.

The SR-4™ trailer spring brake control valve is similar to the SR-2™ valve. It differs in function by utilizing both reservoirs for normal service braking but reserving sufficient air pressure to provide the required spring brake release in the event of a service system failure. As seen in Fig. 1, the complete assembly includes an SR-4™ valve sub-assembly similar in appearance to an SR-2™ valve. The SR-4™ valve subassembly is an SR-2™ valve modified by the addition of a check valve in the spring brake reservoir fitting which permits air to pass from the reservoir to the spring brake inlet valve but not in the opposite direction. AT NO TIME SHOULD AN SR-2™ VALVE BE SUBSTITUTED FOR THE SR-4™ VALVE SUBASSEMBLY. The SR-4™ valve may be identified by the metal tag affixed to the cover by one of four cap screws. Porting is as follows:

•1/2 inch NPT or 3/4 inch NPT spring brake supply port for reservoir mounting

•4-3/8 inch NPT delivery ports

•2-1/4 inch NPT reservoir charging ports

•1-1/4 inch NPT trailer supply port

•1-1/4 inch NPT service port (optional)

OPERATION (FIG. 2)

CHARGING

Air from the trailer supply line enters at the trailer supply port and depresses the control piston "D", opening the spring brake inlet valve "E". It also is conducted to the cavity under the pressure protection piston "F". When air pressure builds to approximately 60 p.s.i. beneath the pressure protection piston, the piston moves against the force of the pressure protection spring and opens the pressure protection inlet valve. The air pressure now flows past check valve “A” into the #2 reservoir and past check valve “B” through the open spring brake inlet valve and into the spring brake

1

|

|

|

SERVICE LINE |

|

|

PRESSURE PROTECTION |

|

|

PRESSURE |

PISTON SPRINGS |

ANTI-COMPOUND |

|

|

||

|

PROTECTION |

|

LINE |

|

INLET VALVES |

|

PRESSURE PROTECTION |

|

PRESSURE PROTECTION |

|

PISTON "F" |

|

PISTON "F" |

|

CHECK VALVE “A” |

|

CHECK VALVE "G" |

|

|

|

|

|

|

|

RES. |

|

|

RES. |

#2 |

|

CHECK VALVE “B” |

|

|

||

#1 |

|

|

|

|

|

|

ANTI-COMPOUNDING |

|

|

|

CHECK VALVE |

RELAY VALVE |

|

|

SUPPLY PORT |

CHECK VALVE “C” |

|

|

|

|

|

TRAILER SUPPLY LINE |

|

|

SPRING BRAKE |

|

CONTROL PISTON "D" |

|

INLET VALVE "E" |

|

|

|

|

|

|

|

SPRING BRAKE |

|

|

FIGURE 2 - SR-4™ VALVE CROSS-SECTIONAL SCHEMATIC

units. Air is prevented from flowing from the SR-4™ valve into reservoir #1 by check valve "C". Air simultaneously flows into the PR-3™ pressure protection valve, (Type 1 SR-4™ valve) or the second pressure protection piston (Type 2 SR-4™ valve). At approximately 70 psi piston "F" moves against the resistance of its spring, allowing air to flow through check valve "G" and into reservoir #1.

PARK APPLICATION

To apply the trailer spring brakes, the trailer supply line is exhausted by means of one of the cab controls. Air pressure is removed from the control piston and the internal pressure protection piston, closing the pressure protection valve and the spring brake inlet valve.

SERVICE SYSTEM FAILURE

If air pressure is reduced in the service system, pressure in the trailer supply line (and in the tractor) will be reduced until the internal pressure protection valve closes, maintaining 50-60 p.s.i. in the trailer supply line and the tractor service reservoir. This will maintain 50-60 p.s.i. on the control piston which will keep the spring brakes released. At the same time, the reduction in pressure in the tractor system will sound the low pressure signal, alerting the driver. If the service failure is in the #2 reservoir, the air which passes the pressure protection valve will escape through the #2 reservoir and will not be able to resupply the #1 reservoir. The #1 reservoir will retain full pressure because of the pressure protection check valve and check valve “B”. This

reserve supply of air will provide at least one spring brake release after a manual application. Service applications may still be made until the air in the #1 reservoir is exhausted.

If the service failure is in the #1 reservoir, the pressure protection valve will close and allow air to supply the #2 reservoir. This air will be available to release the spring brake through check valve “B”, although service applications may not be made.

EMERGENCY APPLICATION WITH SERVICE SYSTEM FAILURE

To brake the trailer after a service system failure, the remaining 55 p.s.i. pressure in the trailer supply line may be exhausted either manually or automatically by the trailer supply valve or parking control valve. The spring brakes are then exhausted through the control piston and thus applied. Sufficient pressure will be maintained in the trailer system to release the spring brakes at least once.

ANTI-COMPOUNDING OPTION

Under certain conditions when the tractor protection valve goes into the emergency mode during a service application, the trailer supply line will be exhausted but some air may be trapped in the service line, creating a service application plus a full spring application. This creates a false park situation and adds an extra load on the foundation brake components. This may be prevented by adding the optional anti-compounding piping as shown in Figs. 2 & 3.

2

R-12™

RELAY

VALVE

TRAILER SERVICE LINE

ANTI-COMPOUNDING

CONNECTION

SINGLE CHECK |

RES. #1 |

RES. #2 |

VALVE |

|

|

|

|

TRAILER SUPPLY LINE

FIGURE 3 - SR-4™ VALVE ANTI-COMPOUNDING PLUMBING

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before performing any intrusive maintenance procedures. A warranty may be voided if intrusive maintenance is performed during the warranty period.

No two vehicles operate under identical conditions, as a result, maintenance intervals may vary. Experience is a valuable guide in determining the best maintenance interval for air brake system components. At a minimum, the SR-4™ valve should be inspected every 6 months or 1500 operating hours, whichever comes first, for proper operation. Should the SR-4™ valve not meet the elements of the operational tests noted in this document, further investigation and service of the valve may be required.

SERVICE AND LEAKAGE TESTS

Check the tractor dash gauge against a test gauge known to be accurate prior to performing these tests. Connect the tractor air lines to the trailer on which the SR-4™ trailer spring brake valve is to be tested. Block all wheels or hold both vehicles by a means other than air brakes.

1.Install two separate test gauges or one dual test gauge with one line to the #1 reservoir and the other line to the #2 reservoir. Build the tractor and trailer to full system pressure by placing the trailer supply valve in the charge position and the parking control valve in the "brakes released" position.

Note: As system pressure reaches approximately 60 p.s.i., the #2 reservoir and the spring brakes should build up to approximately 60 p.s.i. before the #1 reservoir begins to charge (see Fig. 3). When full system pressure has been reached and the spring brakes fully released, it is acceptable to have a slightly lower pressure reading in the service reservoirs than is registered on the dash gauge. Apply a soap solution to the exhaust port and the vent. Leakage of a 1" bubble in 5 seconds is permissible.

2.Place the trailer supply valve in the exhaust position; the spring brakes should apply. Disconnect the trailer supply line and soap the hose coupling to check for leaks. A 1" bubble in not less than 5 seconds is permissible.

3.Reconnect the trailer supply hose coupling and recharge the trailer system. The spring brakes should release. Shut off the engine, leaving the ignition on and open the drain cock on the #1 reservoir. The tractor air system should bleed down to approximately 55 p.s.i. with low pressure, indication occurring at or before 60 p.s.i. The #2 reservoir on the trailer should also bleed down to approximately 55 p.s.i. but the spring brakes on tractor and trailer should remain released. After the system is stabilized, leakage at the open drain cock in the trailer should not exceed a 1" bubble in 5 seconds.

3

Loading...

Loading...