Bendix QRV QR-1 QUICK RELEASE VALVES User Manual

-SD 901-03

Bendix® QRV™ and QR-1™ Quick Release Valves

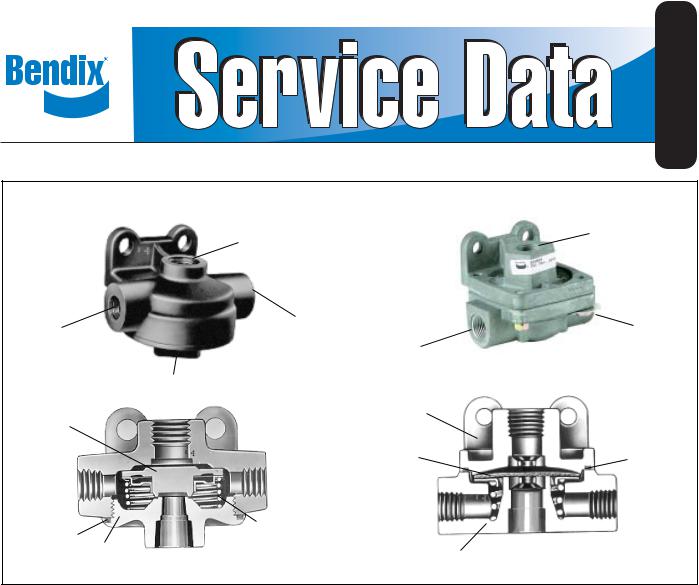

QRV™ Quick Release Valve |

QR-1™ Quick Release Valve |

Supply Port |

Supply Port |

Delivery Port |

Delivery Port |

Delivery |

|

Delivery Port |

|

Port |

|

|

|

|

|

|

||

|

|

|

|

|

|

Exhaust Port |

|

Exhaust Port |

|

|

|

|

|

|

Diaphragm |

|

Cover |

|

|

|

|

|

|

|

|

|

Diaphragm |

|

O-Ring |

|

|

|

|

|

O-Ring |

Spring |

|

|

|

|

|

|

Cover |

QRV™ Quick |

Body |

QR-1™ Quick |

|

ReleaseValve |

|

ReleaseValve |

FIGURE 1

DESCRIPTION

The function of the quick release valve is to speed up the exhaust of air from the air chambers. It is mounted close to the chambers it serves. In its standard configuration the valve is designed to deliver within 1 psi of control pressure to the controlled device; however, for special applications the valve is available with greater differential or zero hysteresis.

QR-1™ valves also come with optional noise reducing foam crosses or silencers.

Reference Figure 1, two styles of quick release valves are available and are functionally the same; the QRV™ valve, which is of older design and utilizes a spring and spring seat, and the QR-1™ valve, which in its standard configuration does not employ a spring or spring seat.

(Note: QR-1™ valves with a pressure differential employ a spring and spring seat.)

Porting consists of one supply port, two delivery ports and one exhaust port.

OPERATION

When a brake application is made, air pressure enters the supply port; the diaphragm moves down, sealing the exhaust. At the same time, air pressure forces the edges of the diaphragm down and air flows out the delivery ports.

When air pressure being delivered (beneath the diaphragm) equals the pressure being delivered by the brake valve (above the diaphragm), the outer edge of the diaphragm will seal against the body seat. The exhaust port is still sealed by the center portion of the diaphragm when the supply air is released; the air pressure above the diaphragm is released back through the brake valve exhaust; air pressure beneath the diaphragm forces the diaphragm to rise, opening the exhaust, allowing delivery air to exhaust.

1

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before performing any intrusive maintenance procedures.Awarranty may be voided if intrusive maintenance is performed during the warranty period.

No two vehicles operate under identical conditions, as a result, maintenance intervals may vary. Experience is a valuable guide in determining the best maintenance interval for air brake system components. At a minimum, the QR-1™ valve should be inspected every 12 months or 3600 operating hours, whichever comes first, for proper operation. Should the QR-1™ valve not meet the elements of the operational tests noted in this document, further investigation and service of the valve may be required.

OPERATING AND LEAKAGE TESTS

While holding a foot brake valve application:

1.Coat the exhaust port with a soap solution; leakage of a

1" bubble in 3 seconds is permitted.

2.Coat the body and cover with a soap solution. No leakage is permitted between body and cover.

If the valve does not function as described, or if leakage is excessive, it is recommended that it be replaced with a new or remanufactured unit, or repaired with genuine Bendix parts.

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW THESE INSTRUCTIONS TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following general precautions should be observed at all times.

1.Park the vehicle on a level surface, apply the parking brakes, and always block the wheels. Always wear safety glasses.

2.Stop the engine and remove ignition key when working under or around the vehicle. When working in the engine compartment, the engine should be shut off and the ignition key should be removed. Where circumstances require that the engine be in operation, EXTREME CAUTION should be used to prevent personal injury resulting from contact with moving, rotating, leaking, heated or electrically charged components.

3.Do not attempt to install, remove, disassemble or assemble a component until you have read and thoroughly understand the recommended procedures. Use only the proper tools and observe all precautions pertaining to use of those tools.

4.If the work is being performed on the vehicle’s air brake system, or any auxiliary pressurized air systems, make certain to drain the air pressure from all reservoirs before beginning ANY work on the vehicle. If the vehicle is equipped with an AD-IS® air dryer system or a dryer reservoir module, be sure to drain the purge reservoir.

5.Following the vehicle manufacturer’s recommended procedures, deactivate the electrical system in a manner that safely removes all electrical power from the vehicle.

6.Never exceed manufacturer’s recommended pressures.

7.Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a component or plug unless you are certain all system pressure has been depleted.

8.Use only genuine Bendix® replacement parts, components and kits. Replacement hardware, tubing, hose, fittings, etc. must be of equivalent size, type and strength as original equipment and be designed specifically for such applications and systems.

9.Components with stripped threads or damaged parts should be replaced rather than repaired. Do not attempt repairs requiring machining or welding unless specifically stated and approved by the vehicle and component manufacturer.

10.Prior to returning the vehicle to service, make certain all components and systems are restored to their proper operating condition.

11.For vehicles with Antilock Traction Control (ATC), the ATC function must be disabled (ATC indicator lamp should be ON) prior to performing any vehicle maintenance where one or more wheels on a drive axle are lifted off the ground and moving.

REMOVING AND INSTALLING

REMOVING

Block vehicle wheels and/or hold vehicle by means other than air brakes.

Drain all air brake system reservoirs.

Disconnect air lines from valve.

Remove mounting bolts, then valve.

2

Loading...

Loading...