Atec SJ-410 User Manual

Form Measurement

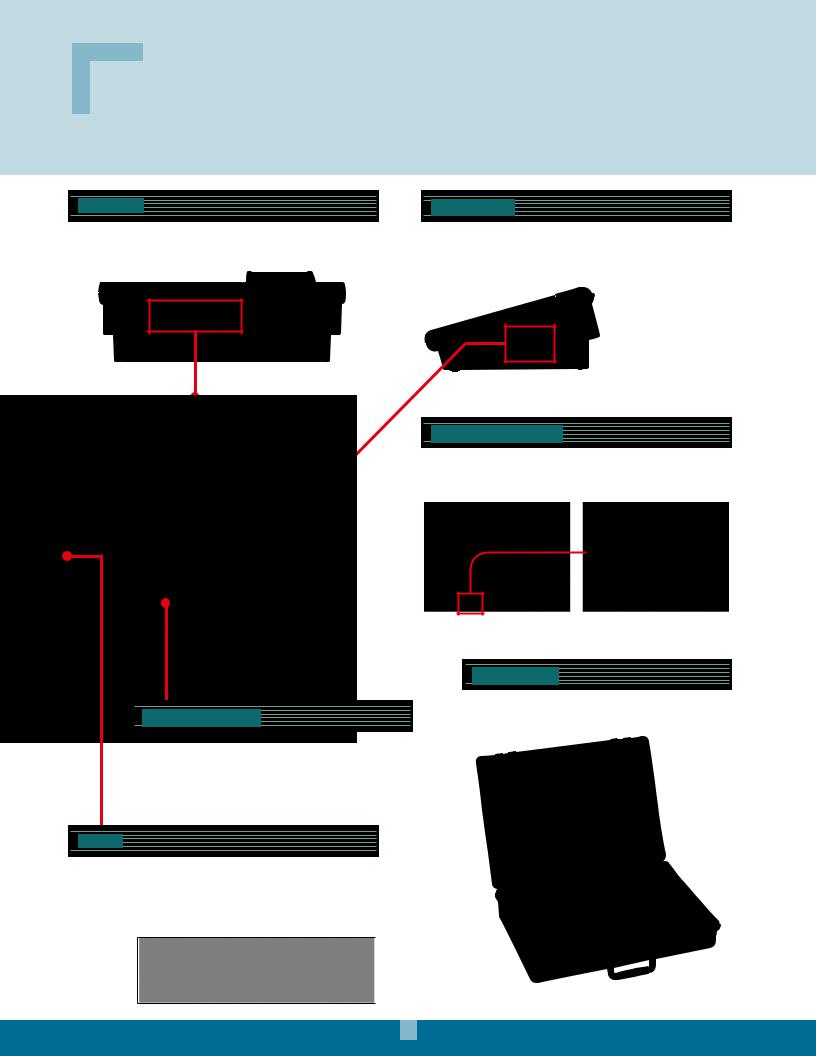

Portable Surface Roughness Tester

SURFTEST SJ-410 Series

Bulletin No. 2080

Portable surface roughness tester evolution

Rich choice of options provide easier, smoother and more accurate measurements

Portable surface roughness tester evolves!

The large touch-screen, color-graphic LCD ensures both intuitive control and advanced operability

Enhanced power for making measurements on site

Enhanced power for making measurements on site

Color-graphic LCD |

Backlight provided |

The color-graphic LCD with excellent visibility |

A backlight improves usability in dim testing |

displays calculated results and assessed |

environments. |

profiles even clearer. This is really useful for |

|

checking results without printing them out. |

|

Touch screen for easier operations

The screen display can be switched between icon display and text display. Successfully combining operability with utility and usability.

Applicable standards

Applicable standards

Complies with many industry standards

The Surftest SJ-410 complies with the following standards: JIS (JIS-B0601-2001, JIS-B0601-1994, JIS B0601-1982), VDA, ISO1997, and ANSI.

Icon display |

Text display |

Easy to use and highly functional

This portable surface roughness tester is equipped with analysis functionality rivaling that of benchtop surface roughness testers.

Data compensation

Simple contour analysis function

|

|

|

|

|

|

|

|

|

Multilingual support |

|

|

|

High accuracy measuring |

|

|

|

|

|

|

|

|

|

|

The display interface supports 16 languages. |

|

A wide range, high-resolution detector |

|||||

|

|

|

|

Measuring range/ resolution |

|

|

|

|

|

|

|

800µm /0.01µm |

|

|

|

|

|

|

|

80µm/0.001µm |

|

|

|

|

|

|

|

8µm/0.0001µm |

|

|

|

|

|

|

|

SJ-412 |

|||

|

|

|

|

High straightness |

|||

|

|

|

|

drive unit |

|

|

|

Straightness/ traverse length 0.3µm/25mm (SJ-411) 0.5µm/50mm (SJ-412)

SJ-411

2

Surftest SJ-410

Interfaces

Interfaces

A variety of interfaces supplied as standard

The external device interfaces that come as standard include USB, RS232C, SPC output and footswitch I/F.

Data storage

Data storage

Memory card (optional) is supported

The measurement conditions and data can be stored in a memory card (optional) and recalled as required. This enables batch analysis and printout of data after on-site measurement.

•Measurement condition

Internal memory: 10 sets Memory card: 500 sets

•Measurement result

Memory card: 1000 sets

Key-sheet buttons

Key-sheet buttons

A sturdy key-sheet-button panel with superior durability in any environment is provided. For repeat measurement of the same work, simply pressing the start switch can complete measurement, analysis and printout.

Printer

Printer

High-speed printer prints out measurement results on site

A high-quality, high-speed thermal printer prints out measurement results. It can also print a BAC curve or an ADC curve as well as calculated results and assessed profiles. These results and profiles are printed out in landscape format, just as they appear on the color-graphic LCD.

Password protection

Password protection

Access to functions can be restricted by a password

A pre-registered password can limit use of measurement conditions and other settings to the tester’s administrator.

→

Carrying case

Carrying case

The unit is easily transported in a dedicated carrying case which includes holders for the accessories as well as the tester itself. (Standard accessory.)

3

Enhanced measuring functions

Your choice of skidless or skidded measurement

Your choice of skidless or skidded measurement

•Skidless measurement

Skidless measurement is where surface features are measured relative to the drive unit reference surface. This measures waviness and finely stepped features accurately, in addition to surface roughnness, but range is limited to the stylus travel available. The SJ-410 series supports a variety of surface feature measurements simply by replacing the stylus.

Detector |

Traverse direction |

Patent registered in Japan, U.S.A.. Patent pending in Germany

•Skidded measurement

In skidded measurements, surface features are measured with reference to a skid following close behind the stylus. This cannot measure waviness and stepped features exactly but the range of movement within which measurement can be made is greater because the skid tracks the workpiece surface contour.

Detector |

Traverse direction |

Fulcrum point of Skid |

|

|

Stylus |

Fulcrum point of Stylus |

Skid |

Stylus |

Fulcrum point of Stylus |

Measuring example of stepped |

Measured profile |

Measuring example of stepped |

Measured profile |

|

features: Skidless |

|

features: Skidded |

|

|

Powerful support for leveling

Powerful support for leveling

Patent registered in Japan, U.S.A.. Patent pending in Germany

The height/tilt adjustment unit comes as standard for leveling the drive unit prior to making skidless measurements and, supported by guidance from the unique D.A.T. function, makes it easy to achieve highly accurate alignment.

• Height/tilt adjustment unit (Standard accessory)

Height adjustment knob

|

|

|

|

|

Preliminary measurement |

Amount of tilt adjustment |

|

|

|

|

|

Withi |

Preliminary |

DAT screen |

|

|

|

|

|

|

|||

|

|

|

|

|

|||

Height/tilt adjustment unit |

Tilt adjustment knob |

DAT |

measurement |

(adjustmentamount) |

|

||

|

|

|

|||||

Final measurement

Final measurement

Withouti |

Preliminary |

Intuitive adjustment |

|

DAT |

measurement |

using the tilt adjustment knob |

OK |

|

|

Repeat |

NG |

|

|

|

When the SJ-410 Series detector is mounted on the manual column stand*1 for measurement, it can be combined with any of the optional products for easier leveling: leveling table*1, 3-axis alignment table*1 or tilt adjustment unit*1.

*1: For details about optional products, see P6-7.

4

Loading...

Loading...