Page 1

Model TC-4

Test-N-Check®Valves

For Hot Water Boilers

Does in minutes what used to

take hours.

INSTRUCTION MANUAL

MM-802F

Applications:

For isolation of equalizing lines during low

water cut-off testing.

OPERATION

Maximum Operating Pressure: 160 psi (11 kg/cm2)

Maximum Operating Temperature: 250˚F (121˚C)

!

N

UTIO

A

C

G

NIN

R

A

W

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

TC-U Upper Valve TC-L Lower Valve

WARNING

• To prevent serious personal injury from steam blow-down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

!

&

'

Page 2

2

Simplify Testing of Low Water Cut-offs on Hot Water Boilers

TEST-N-CHECK®VALVES

IMPORTANT:

• When using tape sealant or thread joint compound on pipe or fittings with external threads follow

manufacturer’s instructions. Do not use tape sealant or thread joint compound on first thread.

To prevent serious personal injury from steam pipe blow down, connect a

drain pipe to the control opening to avoid exposure to steam discharge.

If vacuum breaker stem is accidentally depressed, hot water could be discharged causing burns.

Failure to follow this caution could cause personal injury.

!

CAUTION

TEST-N-CHECK VALVES

SIMPLIFY TESTING OF LOW WATER CUT-OFFS

ON HOT WATER BOILERS

Good operating practice requires installation of a low

water cut-off on a hot water boiler and that it be

checked regularly to make certain the control will

function properly in the event of a low water condition.

Boiler owners and installers need a quick and efficient

way to test a low water cut-off on a hot water boiler.

Simply opening a blow-off valve below the float

chamber may not serve as a valid test and is excessively

wasteful of boiler water and fuel. The water

level in the float chamber, and the float, must drop far

enough to start the control through its cycle of operation.

However, water flowing in through the equalizing

piping may replenish the level in the float chamber fast

enough to delay the necessary float drop, or prevent it

altogether.

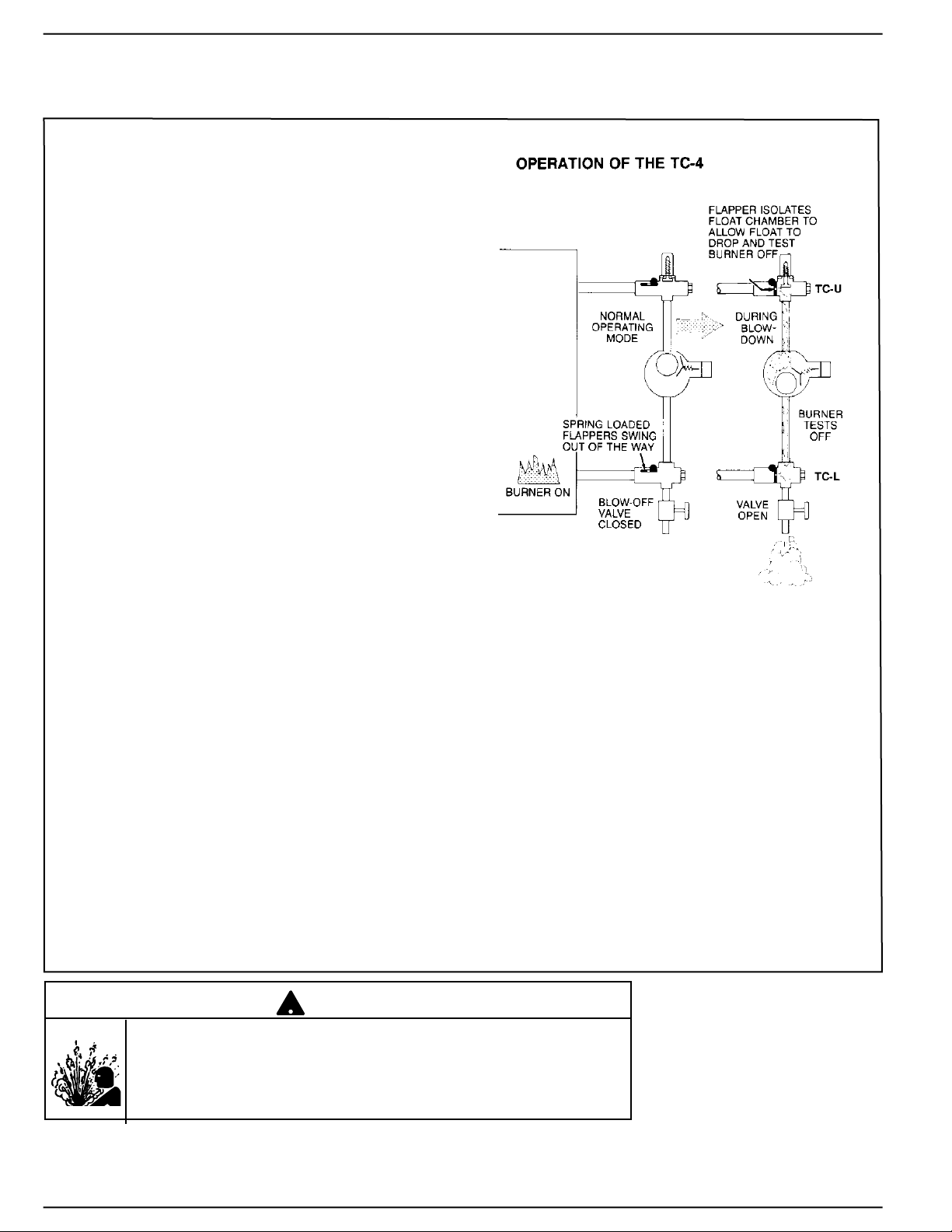

McDONNELL & MILLER Test-N-Check Valves have

been specially designed for such installations. In normal

operation, they allow free circulation of water through

the equalizing piping and float chamber. But any sudden

onrush of water, such as caused by opening the blowoff,

snaps shut a damper in each valve to restrict flow

to the float chamber. Water level in the float chamber

falls quickly to start the control through its operating

cycle, with a minimum loss of boiler water. When

blow-off is closed, dampers return to normally open

position.

McDONNELL & MILLER Test-N-Check Valves simply

replace the crosses above and below the control in the

equalizing lines. Valves have the same dimensions as

standard crosses and nipple in the horizontal leg, and

allow normal rod clean-out of pipe in both directions.

Connections are 1" NPT female tappings.

Upper and lower valves are identical, except that the

upper valve has vacuum breaker built in to allow for

rapid evacuation of the float chamber. They are furnished

in sets-one upper and one lower valve, to

equip one equalizing line. They can be used with all

McDONNELL & MILLER Low Water Cut-Offs for hot

water boilers.

®

LWCO

®

®

Page 3

1. Remove the existing low water cut-off by dis-

connecting the unions in the equalizing lines.

2. Remove the crosses from the upper and lower

equalizing lines.

3. Assemble the TC-U (the upper Test-N-Check

valve, with the vacuum breaker) into the upper

equalizing line replacing the cross. NOTE: The

vacuum breaker must be on the top and the

long leg must face the boiler.

4. Assemble the TC-L (the lower Test-N-Check

valve, without the vacuum breaker) into the

lower equalizing line replacing the cross.

NOTE: The brass cap must be located above

the center of the lower equalizing line, and the

long leg must face the boiler.

5. Assemble the blow-down valve into the bottom

port of the TC-L.

6. Assemble 1” NPT pipe plugs into the remaining

open port in both the TC-U and TC-L.

NOTE: The addition of the Test-N-Check valves

in place of standard crosses will extend the low

water cut-off approximately 2” farther from the

boiler.

7. Reassemble the low water cut-off and vertical

equalizing pipe to the upper and lower Test-NCheck valves.

8. After all piping assembly has been completed,

refill the system with water, turn on all electrical

supply and bring system to operating conditions. After system reaches operating pressure,

inspect to make sure no leaks exist at the

threaded connections. Test valves by opening

blow-down valve while burner is on to make

sure valves operate correctly and low water cutoff shuts burner off.

Installation of the TC-4 Test-N-Check Valve with an Existing Low Water Cut-off

IMPORTANT:

• When using tape sealant or thread joint compound on pipe or fittings with external threads follow

manufacturer’s instructions. Do not use tape sealant or thread joint compound on first thread.

To prevent serious personal injury from steam pipe blow down, connect a

drain pipe to the control opening to avoid exposure to steam discharge.

If vacuum breaker stem is accidentally depressed, hot water could be discharged causing burns.

Failure to follow this caution could cause personal injury.

!

CAUTION

®

®

®

LWCO

®

REMOVE CROSS

®

TC-U in Place

TC-L

in Place

LWCO

Brass

Cap

Blow-down Valve

Page 4

3

1. Assemble the TC-U (the upper Test-N-Check

valve, with the vacuum breaker) into the upper

equalizing line in place of the cross described

in the low water cut-off installation instructions.

NOTE: The vacuum breaker must be on the top

and the long leg must face the boiler. NOTE:

Make sure low water cut-off position is located

in accordance with the boiler manufacturer’s

recommended cut-off level.

2. Assemble the TC-L (the lower Test-N-Check

valve, without the vacuum breaker) into the

lower equalizing line in place of the cross

described in the low water cut-off installation

instructions. NOTE: The brass cap must be

located above the center of the lower equalizing

line, and the long leg must face the boiler.

3. Assemble the blow-down valve into the bottom

port of the TC-L.

4. Assemble 1” NPT pipe plugs into the remaining

open port in both the TC-U and TC-L.

5. Complete the installation as described in the

low water cut-off installation instructions.

6. After all piping assembly has been completed,

refill the system with water, turn on all electrical

supply and bring system to operating conditions. After system reaches operating pressure,

inspect to make sure no leaks exist at the

threaded connections. Test valves by opening

blow-down valve while burner is on, to make

sure valves operate correctly and low water cutoff shuts burner off.

Simplify Testing of Low Water Cut-offs on Hot Water Boilers

TEST-N-CHECK®VALVES

Installation of the TC-4 Test-N-Check Valves with a New Low Water Cut-off

To prevent serious personal injury from steam pipe blow down, connect a

drain pipe to the control opening to avoid exposure to steam discharge.

If vacuum breaker stem is accidentally depressed, hot water could be discharged causing burns.

Failure to follow this caution could cause personal injury.

!

CAUTION

IMPORTANT:

• When using tape sealant or thread joint compound on pipe or fittings with external threads follow

manufacturer’s instructions. Do not use tape sealant or thread joint compound on first thread.

®

®

TC-U in Place

®

LWCO

TC-L

in Place

Brass

Cap

Blow-down Valve

Page 5

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-802F July 2013 Part No. 210088

Loading...

Loading...