Page 1

Replacement Float

!

SA63-30

For Installation on Series 63

Low Water Cut-Off

SA60-30

For Installation on Series 65/165

Liquid Level Switch

SA64-30

For Installation on Series 64/764

Low Water Cut-Off

INSTRUCTION MANUAL

MM-715B

SA63-30 Replacement Float (Weighted)

SA60-30 Replacement Float (Not Weighted)

SA64-30 Replacement Float

®

WARNING

CAUTION

ARNING

W

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of plumbing, steam, and electrical equipment and/or systems

in accordance with all applicable codes and ordinances.

Failure to follow this warning could cause property damage, personal injury or death.

Page 2

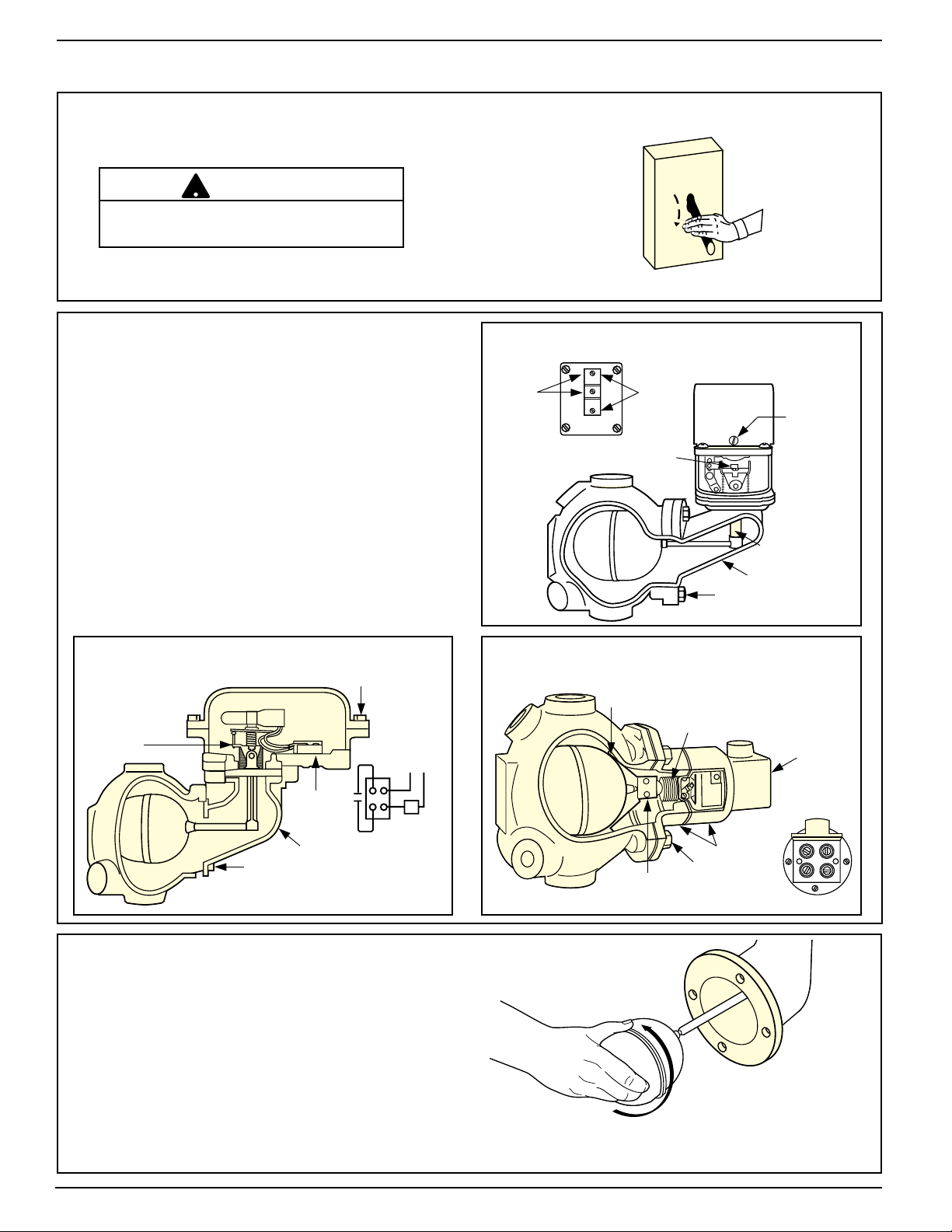

STEP 1 - Float Removal and Replacement

!

a. Turn power off to boiler and all controls.

Allow boiler to cool to 80˚F (27˚C) and

reduce the pressure to 0 psi (0 bar).

CAUTION

There may be more than one source of

power to the boiler.

Drain water in the boiler to a level that is

below the float chamber.

ON

OFF

b. Remove Head Assembly

• Remove screws (A) and lift off

switch cover.

• Identify terminal connections for

rewiring and then disconnect all wires

from terminal panels.

• Remove head bolts. Carefully remove

head assembly from control body.

• Carefully place head assembly in vice

where replacement work can be

performed

more conveniently.

MODEL 65-HD/165-HD

COVER

BOLTS (A)

SECURE THE FLOAT

ARM HERE

LINE

LOW

WATER

ALARM

TERMINALS

MODEL 63-HD

TERMINAL PANEL

C.

N.

O.

N. C.

SECURE THE

FLOAT ARM HERE

MODEL 64-HD

FLOAT STOP

BRACKET

LOW

WATER

CUT-OFF

TERMINALS

BELLOWS

FLOAT ARM

HEAD ASSEMBLY

HEX HEAD BOLTS

SWITCH COVER

SWITCH COVER

SCREW

(A)

TERMINAL

HEAD BOLTS

PANEL

HEAD ASSEMBLY

LOAD

HEX HEAD BOLTS

SECURE

FLOAT MOUNTING BLOCK

HERE

HEAD ASSEMBLY

TERMINAL PANEL

TOP

1

2

34

c. Remove and Replace Float

• While securely holding the arm or mounting

block, where indicated in the diagram

above, unscrew float ball from the assembly

Holding the arm or mounting block reduces

the risk of damaging the bellows from

unnatural stresses.

• Screw new float onto assembly.

On model 64 units, be sure the float stop

bracket is in proper position.

2

Page 3

d. Prepare Flange Surfaces

Scrape and clean flange surface on

control body and control head.

IMPORTANT: Care must be taken not to

damage flange surfaces. Nicks, scrapes

or gouges may cause the flange to leak

when in service.

e. Replace Head Assembly

• Slide flange gasket over float ball.

•

Insert head assembly by carefully guiding

float ball into control body.

• Align Gasket and install head bolts.

• Using a torque wrench, tighten head bolts

in an alternating star pattern. Tighten to

14-20 ft•lbs.

• Reconnect wiring to terminal

panels in exactly the same position

as removed.

• Replace switch cover and fasten

with screws. On Model #65, cover and

housing surfaces must be free of grit and

debris for proper seal. On Model #165,

replace the cover gasket.

MODEL

63-HD

MODEL

64-HD

MODEL

65-HD/165-HD

3

Page 4

STEP 2 - Testing the Control

a. Turn the boiler on.

b. Fill the control and check for gasket leakage.

c. Slowly open the blow-down valve which will

lower the water level in the float chamber.

When the water level drops to the horizontal

cast line, the burner should turn off. Close the

blow- down valve after the burner turns off

and restore the water level to normal operating

level. Repeat testing procedure several times to

ensure proper operation of control.

After testing and verification of control operation,

the boiler can be returned to service.

MAINTENANCE

SCHEDULE:

• Blow down control as follows when boiler is in

operation.

• Steam:

— Daily if operating pressure is above 15 psi.

— Weekly if operating pressure is below 15 psi.

• Hot Water:

— Quarterly

NOTE

More frequent blow-down may be necessary due to

dirty water and/or local codes.

• Disassemble and inspect annually. Replace the

low water cut-off if it is worn, corroded, or if

components no longer operate properly.

• Inspect the float chamber and equalizing piping

annually. Remove all sediment and debris.

• Replace head mechanism every 5 years.

More frequent replacement may be required

when severe conditions exist such as rapid switch

cycling, surging water levels, and use of water

treatment chemicals.

• We recommend head mechanism replacement

when the switch(es) no longer operate properly.

If you choose to replace the switch(es), order the

proper McDonnell & Miller replacement switch or

switch assembly and follow the repair procedure

provided.

CAUTION

Immediately turn off all power if the burner turns on with

no water in the gauge glass. Investigate further before

continuing procedure.

!

ON

OFF

PROCEDURE:

CAUTION

!

To prevent serious personal injury from

steam pipe blow down, connect a drain

pipe to the control opening to avoid

exposure to steam discharge.

Failure to follow this caution could cause

personal injury.

Blow down the low water cut-off when the water

level is at the normal level and the burner is on.

Slowly open the blow down valve until it is fully

open and observe the water level fall in the gauge

glass. Close the valve after verifying that the pump

contacts have closed and the burner shuts off. If this

does not happen, immediately shut off the boiler

and correct the problem.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-715B August 2012 Part No. 246001

Loading...

Loading...