Page 1

Replacement Float

!

SA91-60

For Installation on Series 93/193 and

Series 94/194 Pump Controller/LWCO

INSTRUCTION MANUAL

MM-713B

Replacement Float

®

WARNING

CAUTION

ARNING

W

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

Failure to follow this warning could cause property damage, personal injury or death.

Page 2

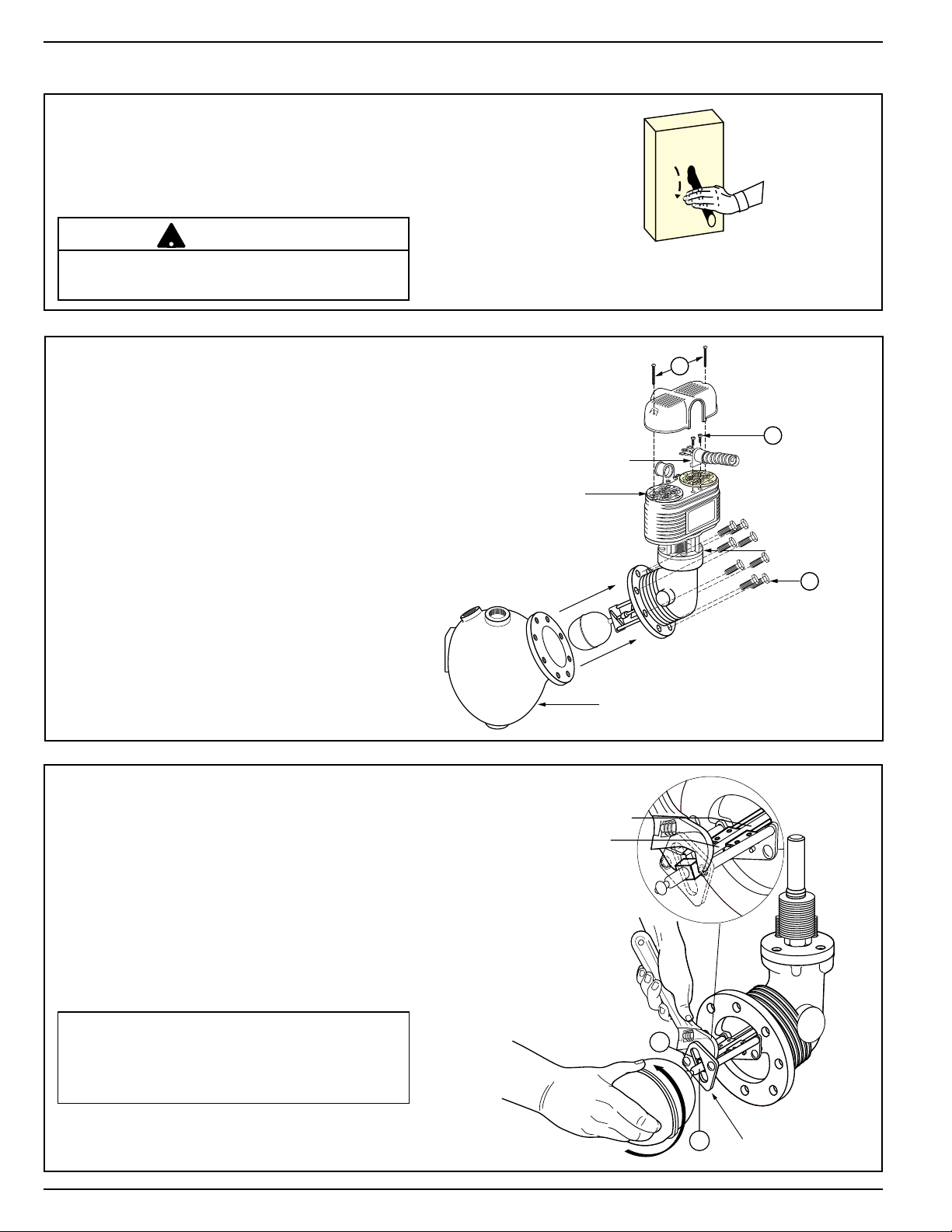

STEP 1 - Removal and Replacement Float

CONDUIT FITTING

TERMINAL PANELS

HEAD ASSEMBLY

CONTROL BODY

B

A

C

D

FLOAT ARM SPRINGS

FLOAT ARM ROD

E

!

a. Turn power off to boiler and all controls.

Allow boiler to cool to 80˚F (27˚C) and

reduce the pressure to 0 psi (0 bar).

Drain water in the boiler to a level that is

below the float chamber.

CAUTION

There may be more than one source of power to

the boiler.

b. Remove Head Assembly

• Remove two screws (A) and lift off

switch cover.

• Identify terminal connections for

rewiring and then disconnect all wires

from terminal panels.

• Remove two screws (B) and lift off

conduit fitting. Leave wires in conduit

for later reconnection.

• Remove head bolts (C). There are eight

(8) on Series 93/193 and ten (10) on

Series 94/194. Carefully remove head

assembly from control body.

• Carefully place head assembly in vice

where replacement work can be

performed

more conveniently.

ON

OFF

c. Remove and Replace Float

• Place open end of adjustable wrench on

square section of float arm (D) to keep it

from turning.

• Unscrew float ball from arm.

• Screw new float ball onto float arm rod

(E), holding square section of float arm

nut (D) with wrench and tighten securely.

IMPORTANT: Inspect condition of float

arm rod and float arm springs. If these

are damaged or bent, the entire head

assembly will need to be replaced.

2

FLOAT STOP PLATE

Page 3

d. Prepare Flange Surfaces

150-14

92-68

CONDUIT FITTING

TERMINAL PANELS

HEAD ASSEMBLY

CONTROL BODY

B

A

C

Scrape and clean flange surface on

control body and control head.

IMPORTANT: Care must be taken not to

damage flange surfaces. Nicks, scrapes

or gouges may cause the flange to leak

when in service.

e. Replace Head Assembly

• Slide flange gasket (150-14 for Series

93/193 units and 92-68 for Series 94/194

units) over float ball and float stop

plate.

•

Insert head assembly by carefully guiding

float ball into control body.

• Align Gasket and install head bolts (C).

• Using a torque wrench, tighten head bolts

in an alternating star pattern. Tighten to

14-20 ft•lbs for Series 93 models. Tighten

to 17-21 ft•lbs for Series 94 models.

• Install conduit fitting with attached

wires and secure with two screws (B).

• Reconnect wiring to terminal

panels in exactly the same position

as removed.

• Replace switch cover and fasten

with two screws (A).

3

Page 4

STEP 2 - Testing

!

!

– Dimensions shown are typical.

– The following testing procedure is only meant to serve as a verification of proper

operating sequence.

a. Turn on power to boiler and pump circuits.

With the boiler empty, the pump should turn on (5 or 5-M switch models) or the valve open

(7B or 7B-M switch models). The burner should remain off and boiler should begin to fill with water.

CAUTION

Immediately turn off all power if the burner turns on with no water in the gauge glass.

Investigate further before continuing procedure.

b. For Automatic Reset Models

When water level in the gauge glass is approximately 1 3/8” (35mm) above the horizontal cast line,

the burner should turn on.

For Manual Reset Models

When water level in the gauge glass is approximately 1 3/8” (35mm) above the horizontal cast line,

press the manual reset button and the burner should turn on.

c. For 5 or 5-M Switch Models

When water level in the gauge glass is approximately 2 1/8” (54mm) above the horizontal cast line,

the pump should turn off.

For 7B or 7B-M Switch Models

When water level in the gauge glass is approximately 2 11/16” (68mm) above the horizontal cast

line, the valve should be closed.

CAUTION

If pump does not turn off or valve close, turn off water supply to boiler. Investigate

further before continuing procedure.

d. With the water in the boiler at its normal level and burner on, SLOWLY open the blow-down valve

until it is fully open. As the water level in the gauge glass begins to drop, verify that the following

occurs.

For 5 or 5-M Switch Models

When water level drops to approximately 1 1/8” (29mm) above the horizontal cast line, the pump

should turn on.

When water level drops to the horizontal cast line, the burner should turn off.

For 7B or 7B-M Switch Models

As the water level drops, the valve should begin to open.

When the water level drops to approximately 7/8” (22mm) above the horizontal cast line, the valve

should be full open.

When the water level drops to the horizontal cast line, the burner should turn off.

e. Close the blow-down valve after burner turns off and restore water level to normal operating level.

f. Repeat testing procedure several times to ensure proper operation of control.

g. After testing and verification of control operation, the boiler can be returned to service.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-713B August 2012 Part No. 210421

Loading...

Loading...