EPSON R1800 Continuous Ink Supply System

Troubleshooting & Support

Easy Flow III & IV

CONTENTS PAGE

Contents Page

Troubleshooting Guide……………………………………………………………………………………………………….. 3

Appendix A – Installation Instructions for the EPSON R1800 Easy Flow IV…………………………… 4

Appendix B – How to Get a Good Nozzle Check…………………………………………………………………… 9

Appendix C – Bad Nozzle Check Flow Chart…………………………………………………………………………. 12

Appendix D – Cartridge Removal Guide………………………………………………………………………………. 13

Appendix E – Power Clean Guide………………………………………………………………………………………… 14

Appendix F – How to Prime the Ink Cartridges and Check The Flow of Ink………………………….. 15

Contact Details……………………………………………………………………………………………………………………. 17

Page | 2

Troubleshooting Guide

In order to setup your Continuous Ink Supply System on you Epson R1800 you will need to

follow the instructions carefully.

1. The first step in order to setup your CISS is to follow the ‘Installation instructions for the

Epson R1800 Easy Flow IV’ (see Appendix A).

2. If you have followed the installation instructions carefully and you find that you cannot

print out a perfect nozzle check then please follow the ‘How to Get a Good Nozzle

Check’ instructions carefully (see Appendix B).

3. If still you cannot get a nozzle check follow the ‘Bad Nozzle Check Flow Chart’ (see

Appendix C).

4. If you have followed the ‘Bad Nozzle Check Flow Chart’ instructions without success

then you will need to make sure that the flow of the ink isn’t obscured in anyway. In

order to do this please follow the ‘How to Prime the Ink Cartridges and Check the Flow

of Ink’ instructions (see Appendix F).

Operating conditions are recommended to be within temperature range of 50 – 80 °F

or 10 - 30°C.

Page | 3

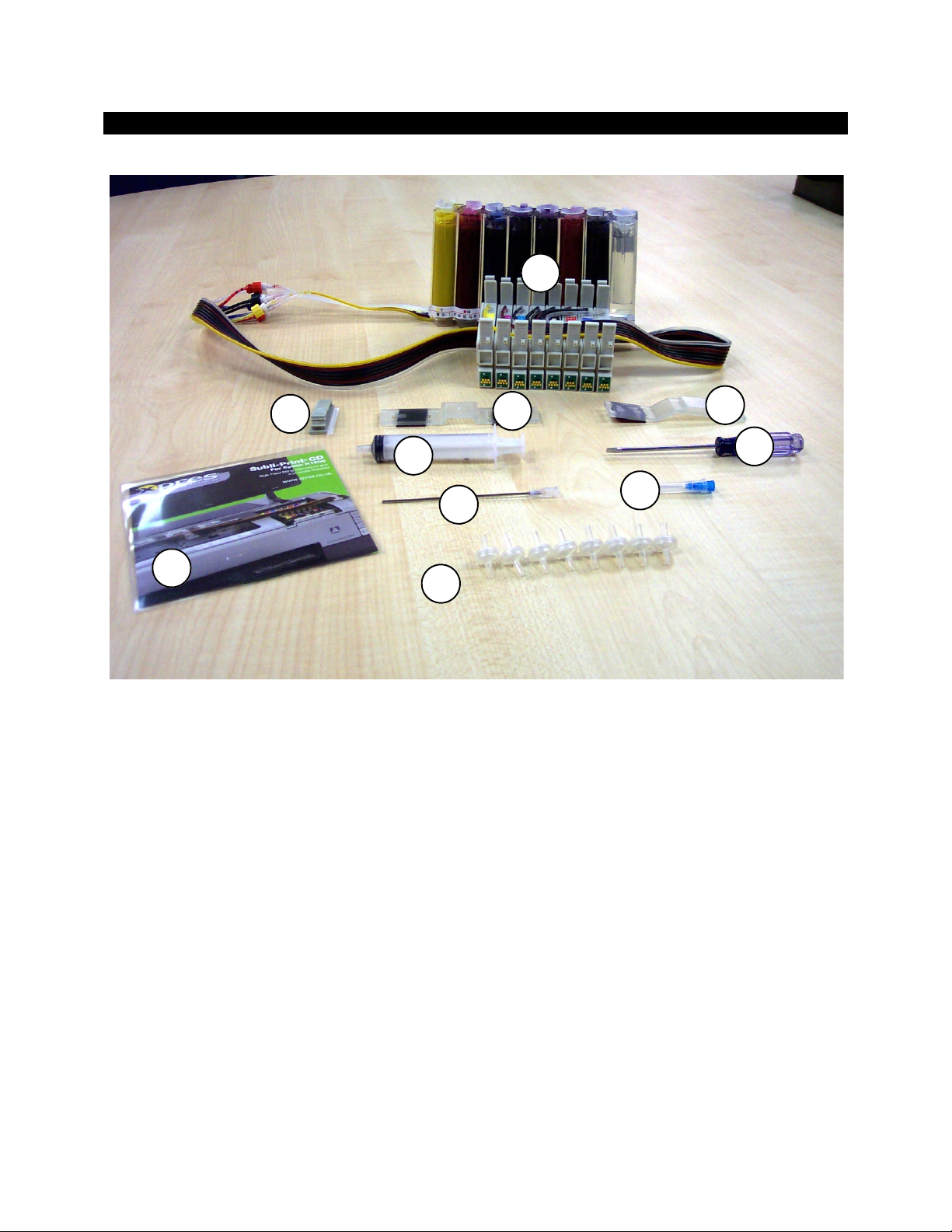

APPENDIX A - Installation Instructions for the Epson R1800 Easy Flow IV

1

3

2b

4

6

8

7

ITINERY

• (1) Bottles and cartridge assembly (pre-filled)

• (2a) Main tube support 1 (may vary in colour)

• (2b) Main tube support 2 (may vary in colour)

2a

9

5

Page | 4

• (3) Small clamp

• (4) 10ml Syringe

• (5) Small needle (only required for re-priming, see page 8)

• (6) Large extension

• (7) 8 x air filters

• (8) Subli-Print CD (including .ICC colour profile & Instructions)

• (9) Small screwdriver (for lid removal)

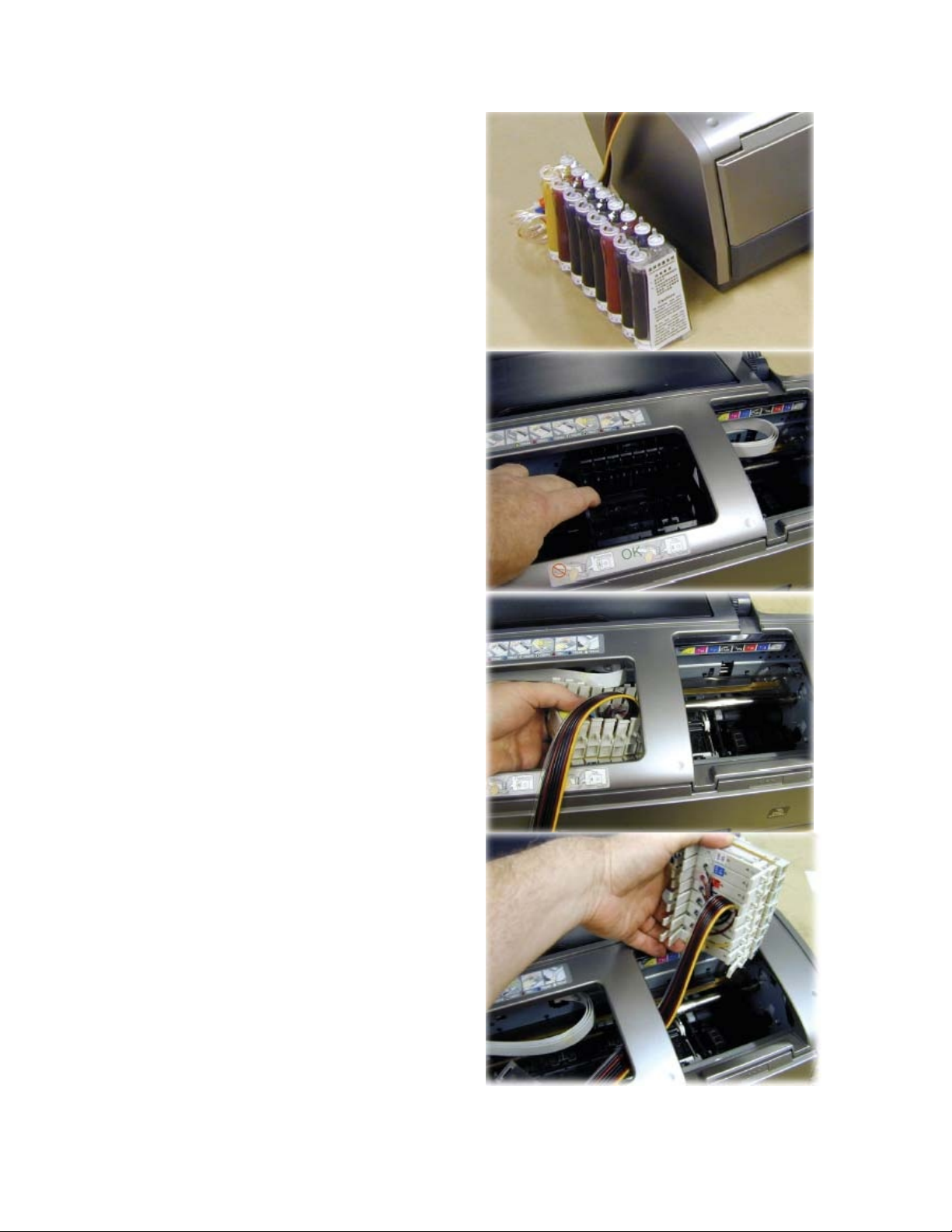

Press the ink button and as the cartridges

move to the left unplug the mains supply from

the printer.

This allows the print head to be moved

manually.

Take out any cartridges and remove the

cartridge lid using the supplied screwdriver as

shown.

Remove all the small bungs from the bottles.

(Do not throw these away as you will

need these for re-filling the bottles)

Using the long needle attachment on the 10ml

syringe draw any air out of the centre

chamber (through the small hole). Repeat this

on each color then fit the air filters supplied.

Page | 5

Place the bottles to the left of the printer as

shown.

NEVER PLACE THE BOTTLES

HIGHER THAN THIS

(If the bottles are placed higher than the ink

may siphon into the bottom of the printer.)

Move the print head as far to the left of the

carriage as possible.

Feed the cartridges under the printer housing.

Page | 6

Move the print head back to its cartridge

removal position.

Fit cartridges into their respective slots and

firmly press them down into place.

The tube support (2a) fits on the printer

housing 70mm (2¾”) from the edge of the

bridge as shown.

Remove the backing tape and firmly press the

tube support into position.

With the print head pushed to its furthest

position on the right, take up any slack in the

tubing by pulling it through the tube clamp.

Page | 7

Remove the backing tape from the tube

support (2b) and fit it to the printer housing as

shown.

Place the small tube clamp on the printer

housing on the left as shown and clamp the

tubes in place.

Plug the printer back into the mains supply

and the print head will move back and forth

then perform its initial ink charge.

The air you may see in the tubes is not

significant and will not affect the operation of

the system in any way.

Your system is ready to go…..

Page | 8

APPENDIX B - How to Get a Good Nozzle Check

DO NOT USE THE AUTO NOZZLE CHECK AND CLEANING FUNCTION

A perfect nozzle check should look like this:

A nearly perfect nozzle check will look like this

Note: if at any time your nozzle check is almost perfect like the one above, then you are ready to start printing,

it most likely that the remaining couple of nozzles will drop in during a print.

A bad nozzle check will look like this:

Page | 9

In order to get a perfect nozzle check please follow these instructions carefully:

1. Print a nozzle check; if not perfect perform a head clean, but if it is almost perfect

proceed with printing.

2. Print another nozzle check; if not perfect perform a head clean, but if it is almost perfect

proceed with printing.

3. Print another nozzle check.

4. If it is still not perfect send an image to print an appropriate sized image will be 8” x 10”

or 20cm x 25cm.

5. Whilst the image is printing hold down the ink button until the printer performs a head

clean.

This procedure must be completed 4 times within the same print, the first 2 times a

standard head clean will be preformed, the third time a more aggressive head clean will

be preformed and on the fourth time a ‘power clean’ will be carried out.

6. There should be a visible difference throughout the print from where the cleans have

taken place. Print a nozzle check in order to see if it is perfect.

7. If the nozzle check is not perfect send 6 decent sized images to print, approximately 8” x

10” or 20cm x 25 cm, but if it is almost perfect proceed with printing.

8. Print a nozzle check to see if the remaining nozzles have dropped in.

Page | 10

9. If the nozzle check is still not perfect or almost perfect, you MUST leave the printer

turned and let it stand for 1-2 hours, or if you can over night.

Note: It is extremely important that the printer is left to stand for at least 1-2 hours.

10. Print a nozzle check to see if the printer has settled down. If not repeat steps from 1 – 9

until a perfect or nearly perfect nozzle check is printed.

Page | 11

APPENDIX C – Bad Nozzle Check Flow Chart

Bad Nozzle Check

Has t h e pr in ter bee n

left fo r a lo n g per iod

w it h ou t prin tin g?

No

Have the car tridges

been r e m ove d

an d re pl aced ?

No

Have inks f allen be low

the recom mended

levels in the bot tl es?

Yes

No

Yes

No

Yes

Fo ll ow ‘How to G e t a G ood

Noz zle C h eck ’,

Did this cu re

th e pr oblem ?

Fo llow t h e ‘C a rtr idge Rem oval

G u ide’,

Did this cure

th e pr oblem ?

Fo ll ow ‘H ow t o Pr im e th e In k

C ar t ridges an d C h e ck th e Flow

of Ink ’,

Appendix A

Appendix D

Appendix F

Yes

Ye s

No

Fo llow th e ‘Power

C le an Guide’

Did this cure

th e pr oblem ?

Appendix E

No

Call technical

su pport

No

Did this cure

th e pr oblem ?

Yes

Yes

Proceed to

Prin tin g

Page | 12

APPENDIX D – Cartridge Removal Guide

If the cartridges have been removed and replaced for any reason, air may have been introduced

into the system (this is relevant with cartridge-based or bulk ink systems). Many cartridges are

foam filled to act as a baffle and avoid ink slopping from side to side during the print head

movement. If these cartridges are removed they are often stood so the ink will not spill out of

them (unlike Epson original cartridges they do not have a valve to block the ink on removal) the

ink therefore does not immediately fall to the bottom of a cartridge when replaced back into

the printer. During the initial head charge all the print head can do is suck air into the nozzles

and this will result in a terrible nozzle check. Multiple head cleans will do nothing to cure this

until the ink has slowly returned to the bottom of the cartridge.

If you have a Bulk Ink System fitted the best way of approaching this problem is to use the

guidelines laid out in ‘Power Clean Guide’ (see Appendix E). If too much air has been introduced

into the system then it is possible that the guidelines in ‘How to Prime the Ink Cartridges and

Check the Flow of Ink’ (see Appendix F) need to be applied.

The ‘Power Clean’ method is not recommended for a cartridge-based system more than a

couple of times, as it will drop the ink level reading severely even if ink is not coming through.

Once the chip is reading empty (irrespective on how much ink is still in the cartridge) the printer

will no longer print until the cartridge has been replaced. The best way to approach this

problem is to just let the printer settle for a while (at least an hour). Any air in the cartridge will

now have worked its way to the top and using the guidelines in ‘How to Get a Good Nozzle

Check’ (see Appendix A) you should get your printer working again.

Page | 13

APPENDIX E – Power Clean Guide

If you have tried 3 head cleans without success!

Occasionally a printer will stubbornly refuse to print a perfect nozzle check after going through

the routine described in ‘How to Get a Good Nozzle Check’ (see Appendix A). There can be a

number of reasons for this including the fitting of a dye sublimation system for the first time or

a printer being left for a long time without running any prints.

One way of curing this is to force the printer into a ‘power clean’. To do this you will need to

send a good size image to the printer (use an 8” x 10” [20cm x 25cm]) and when about a

quarter of the image has printed, press (and hold down) the ink button on your printer (this

usually has a droplet symbol on it). After you have held this button down for 5 or more seconds

the printer will pause printing, perform a head clean and then carry on printing where it left off

(some printers throw out the paper before doing this and carry on with a fresh piece of paper –

again it is not necessary to waste transfer paper on this exercise).

You may have to hold this button down again 1-2 more times during the print – you should be

able to see if the banding is disappearing. If you have had to press the button for the 3rdtime

the printer will now perform a ‘power clean’. Print a nozzle check immediately after this. If this

nozzle check is good, you are set to go. If there are still problems with it leave the printer to

settle for at least half an hour before printing out another nozzle check.

If there has still been no improvement you can carry out this ‘power clean’ exercise one more

time including the half an hour settling time afterwards. If you have had no luck at this point

check the troubleshooting flowchart.

Do not overuse this method with cartridge-based systems as it will ‘use’ large amounts of ink.

Page | 14

APPENDIX F - How to Prime the Ink Cartridges and Check the Flow of Ink

If ink is allowed to fall below the recommended minimum levels on the bottles it may be

possible for air to get into the tubing and ultimately into the cartridge. This will prevent the

printer working (colors completely missing on nozzle checks). This is completely different to the

tiny amount of air in the tube during first install and the air needs to be removed to re-prime

the system.

Also there may be a blockage within the system which will prevent the flow of ink and

eventually cause printing problems and bad nozzle checks.

To prime and check the flow of ink through the cartridges:

1. Remove the cartridges and distich the tubes from the printer.

2. If it is just one color that will not get the nozzle check, make sure that there is no

blockage with that color, in order to do this disconnect the lure from the tube running

from the bottles. Insert the syringe and draw the ink into the syringe, if the ink flows

into the syringe then there is no blockage with the flow from the bottle. If you dont get

a nozzle check on more than one color repeat this process for each color.

3. Ensure that there are no kinks in the tube between the lure and the cartridge as this

would reduce or completely stop the flow of ink.

If the flow of ink through the cartridge is fine then re-priming the cartridge may be necessary.

Note: This is only for Easy Flow IV systems

Page | 15

4. Use the syringe and needle provided. Push the needle through the hole (you will feel it

slide through a rubber grommet).

5. Draw the syringe back so that only ink (no air bubbles) is being pulled into the syringe.

If you are using the Easy Flow III system then you will need to re-prime the cartridges in the

following way.

6. Using a syringe, insert it into the bung in the bottom of the cartridge as shown in the

picture below. It may be a tight fit for the syringe but it will fit with a little pressure and

care.

7. Prime the cart by drawing the ink into the syringe

Page | 16

Contact Details

Technical Support

Sawgrass Europe

Unit 2 Jubilee House

Claywheels Lane

Sheffield

S6 1LZ

Tel: 0114 231 6887 ext 245 - Julian

ext 230 - Steven

ext 246 - Peter

email: support@sawgrasseurope.com

Or call Xpres technical support on 01332 858 333 after you have followed the instructions

in this guide.

Page | 17

Loading...

Loading...