Page 1

TM

Easy Dome

INSTRUCTION MANUAL

Page 2

Easy Dome

INSTRUCTION MANUAL

CONTENTS

Starter Kit Pack p2

Set up

Preparing Applicator Gun p3

Preparing Transfers/Labels for Doming p5

Doming

Main Points When Doming p6

Applying Resin p6

Using Flame Gun p7

What to do if the resin over-spills p7

Doming Using Xpres Cut Plus (Ultragraphics) p8

Doming Using Versacamm p8

TM

Safety & Technical Data p9

Instructions in this manual refer to Windows 7 and CorelDRAW X5.

Other versions may differ.

Starter Kit

XP4902 Xpres Starter Kit includes following:

XP4905 10 x 50g Xpres Dome Cartridges

XP4907 10 x Xpres Dome Mixer Nozzles

XP4906 1 x Applicator Gun

XP4909 10 x Repair Sticks

XP4908 1 x Flame Gun

XP4910 Protective Gloves

Also available, XP4903 Doming Glass Tray 30cm x 40cm (Pack x 10)

You will also require:

General Purpose Butane Gas/Lighter Refiller for Flame Gun Mounting Spray Spirit Level

2

Page 3

Set up

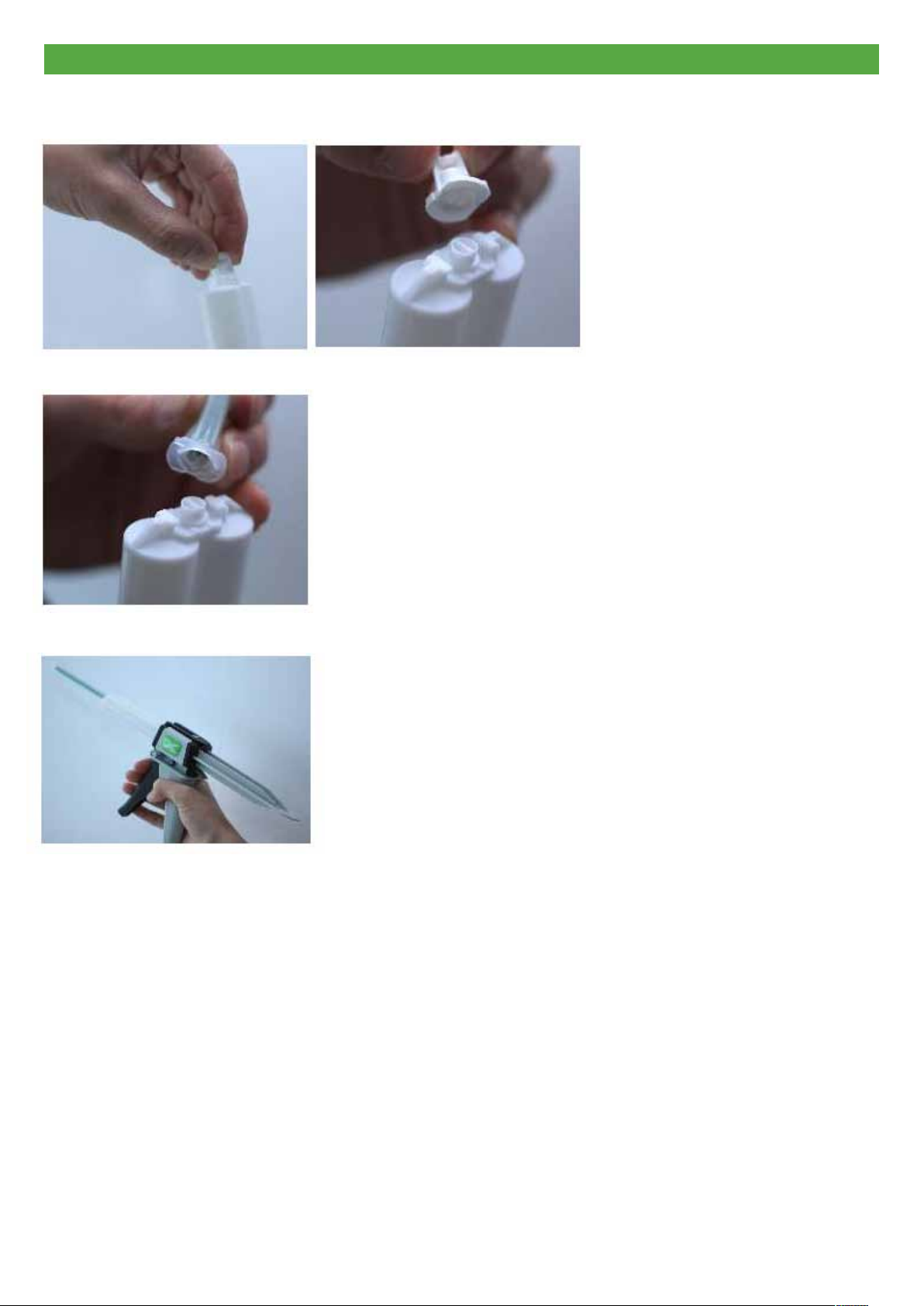

Preparing Applicator Gun

Ensure Plunger is fully retracted.

Open clip on the front of the Applicator Gun.

Slide the cartridge through the front clip of the Applicator Gun.

Close the retaining clip by pulling the cartridge down and wait for the click to signal the cartridge is secure.

3

Page 4

Set up

Preparing Applicator Gun continued

Remove the cartridge cap by twisting through 90 degrees anti-clockwise and pulling to seperate.

Attach the Mixer Nozzle to the cartridge by twisting the Mixer Nozzle 90 degrees clockwise into the groves on the cartridge tip.

The Cartridge and Mixer Nozzle is now installed, the Applicator Gun is now ready to use

4

Page 5

Set up

Preparing Transfers for Doming

Transfers should be rounded at the corners, and the corner angle

no less than 90 degrees. The ‘corner radius’ should be at least

3mm.

Although right angled corners can be domed when care is taken,

it is recommended that all relevant corners need to be curved.

The example right shows a design where the corners have been

adjusted. If left as shown in the ‘before’ diagram the Xpres Easy

Dome Resin could over-spill.

Curving Angles:

To curve the corners on a design ready to cut, select your Shape

Tool within CorelDRAW and click on your design or cutline. You

will see the nodes appear (Blue) - these nodes can be deleted,

moved, added etc as needed (you may need to convert the

object to curves if the nodes do not show). The example right

shows a square cutline with the nodes visible which we can edit.

Using the Shape Tool, double click on the cut line either side of

the node at the point we are trying to remove, this will add two

new nodes (Diagram 1). We can then double click on the original

node which made the point of the original angle, this node will

now be deleted and you will see the example right (diagram 2).

Before After

Diagram 1 Diagram 2

Now Right Click on the line directly between the two nodes

you have created with the Shape Tool, and select ‘to curve’ as

shown right.

With the Shape Tool you can now Left Click on the cutline

between the two nodes previously added, whilst holding the

Left Click down drag the cursor outwards, you will see that this

creates your curve, which you can fine tune with the Adjustment

Handles.

Continue this process around the design on internal and external

angles until the cutline has no sharp points - the cutline is now

ready for output.

Positioning Transfers:

Once cut, weed away the excess film and place the transfers

on to a Doming Glass Tray as shown below. Make sure that

the transfers lay flat on the surface of the glass (no air bubbles

underneath), and also make sure that the surface is level, we

recommend using a spirit level - this is important to create even

resin thickness over a transfer and also to reduce over-spill.

Mounting spray is recommended to keep the transfers flat on

the surface of the glass.

Tip: We recommend that transfers are produced with at least a

5mm gap between logos/transfers. This is to help prevent any

resin over-spills having a knock-on effect in to the next

logo/transfer, reducing waste.

Note: One 50g resin cartridge will be able to dome

approximately 50 25 x 25mm (1 inch)2 transfers.

5

Page 6

Doming

Main Points When Doming

• Ensure that the working area is well ventilated, clean & free of dust.

• Ensure that the working area is level.

• Ensure temperatures are kept consistent at all times during the Doming process. Xpres Easy Dome Resin operates best

between 17°C - 25°C, and Humidity of 40%.

Applying Resin

Before applying resin, it is important to hold the cartridge at a 45° upright angle and dispose of the first 1 - 2 grams of resin.

This is to allow any air bubbles within the cartridge to be released.

Apply resin to the transfer by pulling the Applicator Gun trigger at a constant, slow, comfortable rate. Good practise is to

apply slightly less resin than is anticipated. The resin will flow to the edges of the transfer by itself.

Occasionally the resin needs encouragement to fill the transfer. If the resin has not covered the transfer fully within 5-6

minutes you can use your Repair Stick (break in to two parts) to drag small amounts of resin into the corners and other places

the resin has not reached. This will apply more to detailed designs where the resin needs prompting in to certain areas.

After 5 - 10 minutes the transfer should be fully covered. If it is not, consider applying additional Resin.

Once the resin has spread across the transfers fully, the domed transfer can be left to cure. The finished domed transfer

should be left approximately 12 - 16 hours to cure fully. Depending on the room temperature curing times can vary from 12

hours upwards. Once cured the domed transfer is ready to be handled.

The Doming Glass Trays can be stacked. Always place a glass layer above your domed transfers to help prevent any dust

settling in the resin as the dome cures.

6

Page 7

Doming

Using Flame Gun

If there are any air bubbles in the resin, the Flame Gun should be used. Position the flame gun approximately 3-6 inches away

from the surface of the resin and momentarily pull the trigger. The short blast of heat will cause the air bubbles to heat up and

rise out of the resin.

Before After

What to do if the resin over-spills?

If the resin over-spills over the edge of the transfers, you can correct small errors using the supplied Repair Stick. It is

recommended to let the Xpres Easy Dome Resin cure for approximately 10 - 15 minutes before correcting over-spills.

This allows resin to ‘gel’ as the curing process begins, which will make any corrections much easier.

With the supplied Repair Stick (you may wish to break this in to two pieces, length ways to give you a point) you can scoop

or drag the excess resin back on to the transfer. You can then run the Repair Stick around the edge of the transfer to prevent

further over-spill.

7

Page 8

Doming using Xpres Cut Plus Doming using Versacamm

If using the Xpres Cut Plus (Ultragraphics) system, Xpres

Easy Dome can be used with the following transfer vinyls:

Self-Adhesive Doming Vinyl

XP4900 (A3) & XP4901 (A4)

To be used to create domed self-adhesive labels & signage

For best results print with the following quality settings:

Paper: Plain paper

Quality: Photo

Always place Silicon Sheet XP2028 below Self-Adhesive

Doming Vinyl before applying Easy Dome Resin in case of

overspill.

Dark Jet

XP3132 (A3) & XP3133 (A4)

To be used to create full colour domed transfer to be applied

to textiles (Cotton, Polyester & Nylon)

Application:

Position domed transfer over garment in the correct position

Apply at 175°C for 30 seconds

Turn garment inside out and press on to the back of the

transfer (inside of the garment) at 175°C for a further 30

seconds.

If using the Roland Versacamm or other Solvent / Eco

Solvent ink printers, Xpres Easy Dome can be used with the

following vinyls:

Tec Mark Digital Vinyl

XP2125 & XP2127

To create full colour domed labels & signage

Tec Mark Gloss Vinyl

XP2120 & XP2121

Gold & Silver vinyl to be used to create Domed Trophy Labels

and Centres at low cost

Easy Print

XP3030 / 3031 / 3033 / 3034

To create full colour domed transfers to be applied to textiles

(Cotton & Polyester)

Application to textiles:

Position domed transfer over garment in the correct position

Apply at 170°C for 30 seconds

Turn garment inside out and press on to the back of the

transfer (inside of the garment) at 170°C for a further 30

seconds.

Colour Cut

XP3001 XP3137

To create full colour domed transfers to be applied to textiles

(Cotton & Polyester)

Application to textiles:

Position domed transfer over garment in the correct position

Apply at 170°C for 30 seconds

Turn garment inside out and press on to the back of the

transfer (inside of the garment) at 170°C for a further 30

seconds.

8

Page 9

Safety & Technical Data

Important: Safety Guidelines

Always use protective gloves and safety glasses.

Avoid prolonged contact with skin. May cause sensitization

by skin contact.

Avoid contact with eyes.

Avoid breathing vapours.

Always use in well ventilated area.

After contact with skin, wash immediately with soap & water.

If swallowed seek medical advice.

If you experience any health related problems during use,

seek medical advise.

Data Sheet

Z-7250 Polyurethane Compound

Product Name: Z-7250 Revised 12/7/2001

Supersedes: 11/10/00

Description

Z-7250 is a clear polyurethane compound for use on decals,

labels, emblems and other decorated substrates. Z-7250 is

a low viscosity material with excellent flow is also suitable for

potting solar cells.

Hazards

Part A is manufactured for commercial use only. (See MSDS).

Part B contains aliphatic diisocyanate and polymeric

isocyanates. See MSDS for safe handling instructions.

Mixing Information

Ratio by Weight Part A 49

Part B 51

Ratio by Volume Part A 50

Part B 50

Curing

Gel Time 7-9 minutes, 100 grams @ 100°F

Cure Time 100-200oF 24-4 hrs (dependant on mass

and temp)

Development Associates, Inc DS Z-7250 Page 2 of 2

All information, recommendations and suggestions contained

herein are to the best of our knowledge true and accurate,

but are made without guarantee. No warranty of fitness for a

particular purpose is made. Nothing herein shall be

construed to allow infringement of any patent

Typical Physical Properties

Hardness 85-90 Shore A 40-45 Shore D

Heat Aging 7 days @ 85°C, no change

Weathering Accelerated weathering RS-4 sunlamp 200

hours with water spray, no change

Humidity Resistance 7 days 100%RH @ 100°F, no change

Storage

Both Part A and Part B are sensitive to moisture and

containers must be kept closed during storage. Storage

temperature can be ambient, however the material should be

warmed to 90 - 110°F before using.

Component Z-7250 Part A Typical Liquid Properties

Appearance Hazy liquid with a slight yellow tint

Specific Gravity 1.025 @ 100°F

Weight per Gallon 8.53 @ 100°F

Brookfield Viscosity 75-200 Cps. @ 100oF #2 Spindle RVT @

20 rpm

Hydroxyl Value 260-280

Acid Value less than 0.15

Water Content less than 0.1%

Component Z-7250 Part B Typical Liquid Properties

Appearance Clear liquid

Specific Gravity 1.10 @ 100°F

Weight per Gallon 9.13 @ 100°F

Brookfield Viscosity 100-600 cps. RVT #2 Spindle,

50 rpm @ 100°F

NCO Value 22.2-23.2

9

Page 10

Safety & Technical Data

Material Safety Data Sheet

Product Name:Z7250 ISO – Part B Date: 10/8/10

1. Product and Company Identification

Manufacturers Name Development Associates Inc.

300 Old Baptist Rd.

North Kingstown,

RI 02852

Emergency Phone No CHEMTREC: (800) 424-9300 24hr

Product Name Z-7250 ISO - Part B

Chemical Family/Name Aliphatic Polyisocyanate Mixture

Trade Name Polyurethane Compound

2. Composition/Ingredient Information

Component CAS # % Exposure limits(source)

Dicyclohexylmethane-4-4’Diisocyanate 5124-30-1 20-40 0.005 ppm(3)

Aliphatic polyisocyanate trade secret 60-80 n/e (5)

Source of Exposure Limit Data:

1. ACGIH Threshold Limit Values

2. Federal OSHA Permissible exposure limit

3. DAI Exposure Guidelines

4. Chemical Manufacturer Recommended Guidelines

5. None Established Abbreviations: n/a-not applicable, n/dnot determined, n/e-not established

3. Hazards Identification

HMIS HEALTH 2, FIRE 1, REACTIVITY 1

Threshold Limit Value: None established, 0.005 ppm is

recommended. 0.010 ppm is the ceiling TLV by OSHA and

0.005 ppm is the TWA TLV from ACGIH for

Dicyclohexylmethane-4-4’’-diisocyanate.

Routes of Entry: At room temperature by skin absorption. At

high temperatures or if the material is atomized, by inhalation

and skin absorption.

Signs and Symptoms of Exposure:

Eyes: Redness, irritation, tearing, burning sensation.

Skin: Rash, redness, itching.

Inhalation: Irritation of the respiratory tract, runny nose, sore

throat, coughing and reduction of lung function.

Hypersensitivity, indicated by asthmatic reaction is possible

in some individuals. Smarting and weeping of the nose and

throat indicate that the diisocyanate concentration in the air

is above acceptable limits.

Acute Effects of Overexposure:

Inhalation: Irritation of the respiratory tract, runny nose, sore

throat, coughing and reduction of lung function.

Hypersensitivity, indicated by asthmatic reaction is possible

in some individuals. Smarting and weeping of the nose and

throat indicate that the diisocyanate concentration in the air

is above acceptable limits. Once sensitized an individual may

react allergically to airborne levels below the exposure limits.

Skin: Prolonged or repeated contact may cause irritation,

redness, swelling and dermatitis. Some individuals may

become hypersensitized. Once sensitized an individual may

react allergically to airborne levels below the exposure limits.

Eyes: Liquid and vapors are irritating.

Ingestion: Irritation and burning of mouth, throat and

stomach.

Chronic Effects of Exposure: Some individuals may become

hypersensitized and react allergically with dermatitis or

asthma when exposed to airborne levels below the exposure

limits. Development Associates, Inc MSDS Z7250 ISO Page

2 of 3 Rev. Date: 10/8/10 Rev. 3.0 Ref: Z7250BMSV3.doc

Medical Conditions Aggravated by Exposure: Dermatitis,

Asthma, other respiratory ailments, skin conditions.

Carcinogenicity: This product and its constituents are not

listed as carcinogens by IARC, NTP or regulated as

carcinogens by OSHA at this time.

4. First Aid Measures

Emergency and First Aid Procedures:

Eyes: Flush with water for at least 15 minutes. Consult an

Ophthalmologist.

Skin Contact: Remove contaminated clothing. Wash

affected areas thoroughly, with soap and water. Cover

affected area with polyethylene glycol (300-500 mw.) or

glycerin and wash again with soap and water. Apply

moisturizing cream. Consult physician. Treat dermatitis

symptomatically. Wash clothing before reusing.

Inhalation: Move to fresh air. Administer oxygen or artificial

respiration as needed. Consult physician.

Treat symptomatically.

Ingestion: Do not induce vomiting. Give milk or water.

DO NOT GIVE ANYTHING BY MOUTH TO AN

UNCONSCIOUS PERSON. Consult a physician.

5. Fire and Explosion Data

Flash Point >395°F (202°C) TCC

Flammable Limits in Air % Volume: Upper: n/a Lower: n/a

Extinguishing Media: Foam, CO2, or Dry Chemical

Unusual Fire and Explosion Hazards: During a fire,

diisocyanate vapors and other irritating, highly toxic gasses

may be generated by thermal decomposition or combustion.

Extremely high temperatures may cause closed containers to

pressurize resulting in explosive rupture.

Special Fire Fighting Procedures: Use full emergency

equipment with self-contained breathing apparatus.

Use cold water to cool fire-exposed containers.

6. Accidental Release Measures

Steps to be Taken in Case Material is Released or Spilled:

Remove unnecessary personnel. Ventilate area.

Equip clean-up crew with appropriate protective gear. Leaks

should be stopped and spill dyked to control spreading.

Cover spill with absorbent material such as Zip-Zorb

(activated clay), diatomaceous earth, or saw dust. Sprinkle

on a decontaminating solution of 25% household ammonia,

73% water, and 2% detergent. Allow to react for 15 to 30

minutes, collect in containers, add more decontamination

solution, cover loosely. Wash down area with soap and

water, rinse.

10

Page 11

Safety & Technical Data

7. Handling and Storage

Precautions to be Taken in Storage and Handling: Store in

tightly closed containers to prevent moisture contamination.

Do not reseal if contamination is suspected. If container is

exposed to high heat, it can be pressurized and possibly

rupture. Diisocyanates react slowly with water to form CO2

gas. This can cause sealed containers to expand and

possibly rupture. Avoid contact with skin and eyes.

This material may crystallize at storage temperatures

below 15°C (50°F). Before using, melt crystals and mix

material by warming drum to 30o-60oC (86°-140°F) and

rolling the drum. When mixing, avoid inclusion of moist air.

Storage Temperature: 77°F (25°C) / 122°F (50°C)

Shelf Life: 12 months @ 77°F (25°C)

8. Exposure Controls/Personal Protection

Eye Protection: Liquid chemical goggles or full face screen.

Contact lenses should not be worn.

Skin Protection: Rubber Gloves, aprons and other

protective clothing as required to prevent contact. Remove

any contaminated clothing and wash before use. Routinely

wash hands, arms and face with soap and water after

handling. Do not smoke or eat until hands and face have

been washed.

Ventilation and Respiratory Protection: Ventilate as required

to maintain diisocyanate concentrations below 0.005 ppm.

At room temperature general mechanical ventilation is

adequate, at elevated temperatures additional ventilation

may be required. An organic vapor respirator may be used

for short periods as supplemental protection at levels below

the exposure level. At exposure levels above exposure limits

a supplied air respirator is required due to the poor warning

properties of this product. Other: Safety showers and eye

wash stations should be available.

9. Physical and Chemical Properties

Appearance clear liquid Development Associates, Inc MSDS

Z7250 ISO Page 3 of 3 Rev. Date: 10/8/10 Rev. 3.0 Ref:

Z7250BMSV3.doc

Color clear

Odor mild

Boiling Range decomposes over 150°C Melting Point sets to

glass <0°C. 5-40% of the material may crystallize at temps.

less than 15°C. Evaporation Rate(BuAcet=1) n/a

Vapor pressure 1 x 10-3 mm Hg @ 68°F (20°C) Vapor Density (air=1) heavier than air Weight per Gallon 9.13 Specific

Gravity 1.10 Solubility in Water(%) Insoluble/reacts with water

Percent Volatile negligible

10. Stability and Reactivity

Stability: Stable under normal conditions.

Conditions to Avoid: High heat, contamination.

Incompatibility (materials to avoid): Water, amines, strong

bases, alcohols.

Hazardous Polymerization: Will not occur under normal

conditions.

Hazardous Decomposition Products: By high heat and fires:

Diisocyanate vapors, CO, CO2, oxides of nitrogen, traces of

HCN.

11. Toxicological Information

CAS# 5124-30-1,Dicyclohexylmethane-4-4’-Diisocyanate:

Oral rat LD50: 1065 mg/kg; Dermal rabbit LD50: 10000 mg/

kg; Inhalation rat LC50 4 hr exposure periods: 434 mg/m3;

Eye rabbit: mild reversible irritation; Skin guinea pig: irritation

and potent skin sensitizer.

12. Ecological Information

This material reacts slowly with water and is not expected to

accumulate in the environment.

13.Disposal Considerations

Waste Disposal Method: If discarded in its purchased form,

this product is not hazardous waste either by listing or by

characteristic. However, processing, use or contamination of

this product may change its hazardous waste status. Under

RCRA, it is the responsibility of the product user to determine, at the time of disposal, whether a material is a hazardous waste. State and local disposal regulations may differ

from federal disposal regulations. Dispose in accordance with

all federal, state, and local waste disposal laws and regulations. Incineration is the preferred method.

14. Transport

D.O.T Shipping Name none

Technical Shipping Name Z-7250 ISO - Part B

(aliphatic polyisocyanate)

D.O.T Hazard Class not classified

UN/NA Number none

NMFC Item Plastic material liquid No. 156240 Class 60

15. Regulatory

All components of this mixture are listed in the TSCA

inventory. SARA III 313/EPCRA 313: CAS #5124-30-1

component listed in diisocyanate category N120.

For details on regulatory requirements you should contact the

appropriate agency in your state.

16. Other

This data is offered in good faith as typical values and not

as a product specification. The information in this data sheet

was compiled from information supplied by the vendors

of the components of this compound. No warranty, either

expressed or implied is hereby made. The recommended

industrial hygiene and safe handling procedures are

believed to be generally applicable. However, each user

should review these recommendations in the specific context

of the intended use and determine whether they are

appropriate.

The information on this data sheet is only to assist in the

safe handling of this material, and may contain trade secrets

which may not be divulged to anyone except the users of

this material and health care and hygiene professionals as

required for its safe use. No license or permission to infringe

any patent or breach any trade secret is given.

11

Page 12

Tel: 01332 85 50 85

www.xprestechnical.co.uk

Loading...

Loading...