Volkswagen Eos 2006 User Manual

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

Workshop Manual

Eos 2006 ➤

Golf 2004 ➤

Golf Plus 2005 ➤

Touran 2003 ➤

Brake systems

Edition 05.2008

Service Department. Technical Information

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

45 - Anti-lock brake system

46 - Brakes - mechanism

47 - Brakes - hydraulics

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Volkswagen AG, Wolfsburg K0058970520

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Brake allocation via PR No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Front brakes, Touran . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Front brakes, Golf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Front brakes, Eos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Rear brakes, Touran . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Rear brakes, front-wheel drive Golf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Rear brakes, four-wheel drive Golf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7 Rear brakes, Eos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Technical data for brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Brake master cylinder and brake servo, Touran . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Brake master cylinder and brake servo, Golf, Eos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Front brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Rear brakes (disc brakes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Brake test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Test for vehicles with front-wheel drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Test for vehicles with four-wheel drive via a Haldex coupling . . . . . . . . . . . . . . . . . . . . . . 9

45 - Anti-lock brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 General notes on anti-lock brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Notes for repair work on anti-lock brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Connecting VAS 5051 and selecting functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Electrical/electronic components and fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 ABS Mark 70 (ABS/TCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 ABS Mark 60 (ABS/EDL/TCS/ESP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 ABS Mark 60 (ABS/EDL/TCS/ESP) up to week 22/2008 . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 ABS Mark 60 (ABS/EDL/TCS/ESP) from week 22/2008 . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Fault display via warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Assembly overview - hydraulic unit, brake servo/brake master cylinder . . . . . . . . . . . . . . 26

6.1 ABS Mark 70 (ABS/TCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 ABS Mark 60 (ABS/EDL/TCS/ESP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 ABS Mark 60 (ABS/EDL/TCS/ESP) up to week 22/2008 . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4 ABS Mark 60 (ABS/EDL/TCS/ESP) from week 22/2008 . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7 Removing and installing parts of ABS system on front and rear axle . . . . . . . . . . . . . . . . 56

7.1 Removing and installing parts of ABS system on front axle . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2 Removing and installing parts of anti-lock brake system on rear axle (front-wheel drive) . . 57

7.3 Removing and installing parts of anti-lock brake system on rear axle (four-wheel drive) . . 58

8 Removing and installing parts of ESP system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1 Removing and installing ESP sensor unit G419 (Touran) . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2 Removing and installing ESP sensor unit G419 (Golf, Eos) . . . . . . . . . . . . . . . . . . . . . . . . 60

8.3 Removing and installing steering angle sender G85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.4 Removing and installing brake servo vacuum sender G483 . . . . . . . . . . . . . . . . . . . . . . . . 62

46 - Brakes - mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1 Repairing front brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.1 Repairing front brakes, FS III brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.2 Removing and installing brake pads/linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.3 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1.4 Repairing front brake, FN 3 brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1.5 Removing and installing brake pads/linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Contents i

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

1.6 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

1.7 Repairing front brake, FNR-G brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1.8 Removing and installing brake pads/linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1.9 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2 Repairing rear brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.1 Repairing rear brake CI 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.2 Removing and installing brake pads/linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

2.3 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2.4 Repairing rear brake CII 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2.5 Removing and installing brake pads/linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.6 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2.7 Repairing rear brake CII 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.8 Removing and installing brake pads/linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.9 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

2.10 Adjusting handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3 Assembly overview - handbrake lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.1 Removing and installing handbrake cable up to model year 2007 . . . . . . . . . . . . . . . . . . . . 103

3.2 Removing and installing handbrake cable from model year 2008 . . . . . . . . . . . . . . . . . . . . 106

4 Assembly overview - brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.1 Separating brake pedal from brake servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.2 Removing and installing brake light switch F from week 45 of 2005 . . . . . . . . . . . . . . . . . . 110

47 - Brakes - hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1 Repairing front brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1.1 Repairing brake caliper FS III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1.2 Removing and installing piston for brake caliper FS III . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1.3 Repairing brake caliper FN 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

1.4 Removing and installing piston for brake caliper FN 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.5 Repairing FNR-G brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

1.6 Removing and installing piston for FNR-G brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . 120

2 Repairing rear brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2.1 Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

2.2 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

2.3 Pre-bleeding brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

3 Pressurised leak test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.1 Test prerequisites: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4 Bleeding brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

4.1 Bleeding brake system using brake filling and bleeding equipment VAS 5234 or V.A.G 1869

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4.2 Changing brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

5 Brake servo and master brake cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.1 Assembly overview - brake servo/brake master cylinder (left-hand drive vehicle) . . . . . . . . 133

5.2 Assembly overview - brake servo/brake master cylinder (right-hand drive vehicle) . . . . . . 134

5.3 Overview - exhauster pump for brake servo (diesel vehicles) . . . . . . . . . . . . . . . . . . . . . . 136

5.4 Checking non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

5.5 Removing and installing brake servo pressure sensor G294 . . . . . . . . . . . . . . . . . . . . . . 137

5.6 Vacuum pump for brakes V192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

5.7 Removing and installing brake light switch F as of week 45/05 . . . . . . . . . . . . . . . . . . . . . . 138

6 Removing and installing brake master cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

6.1 Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

6.2 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

7 Removing and installing brake servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7.1 Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7.2 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

ii Contents

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

8 Brake lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8.1 Separating point on underbody . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8.2 Repairing brake lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Contents iii

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

iv Contents

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

00 – Technical data

1 Brake allocation via PR No.

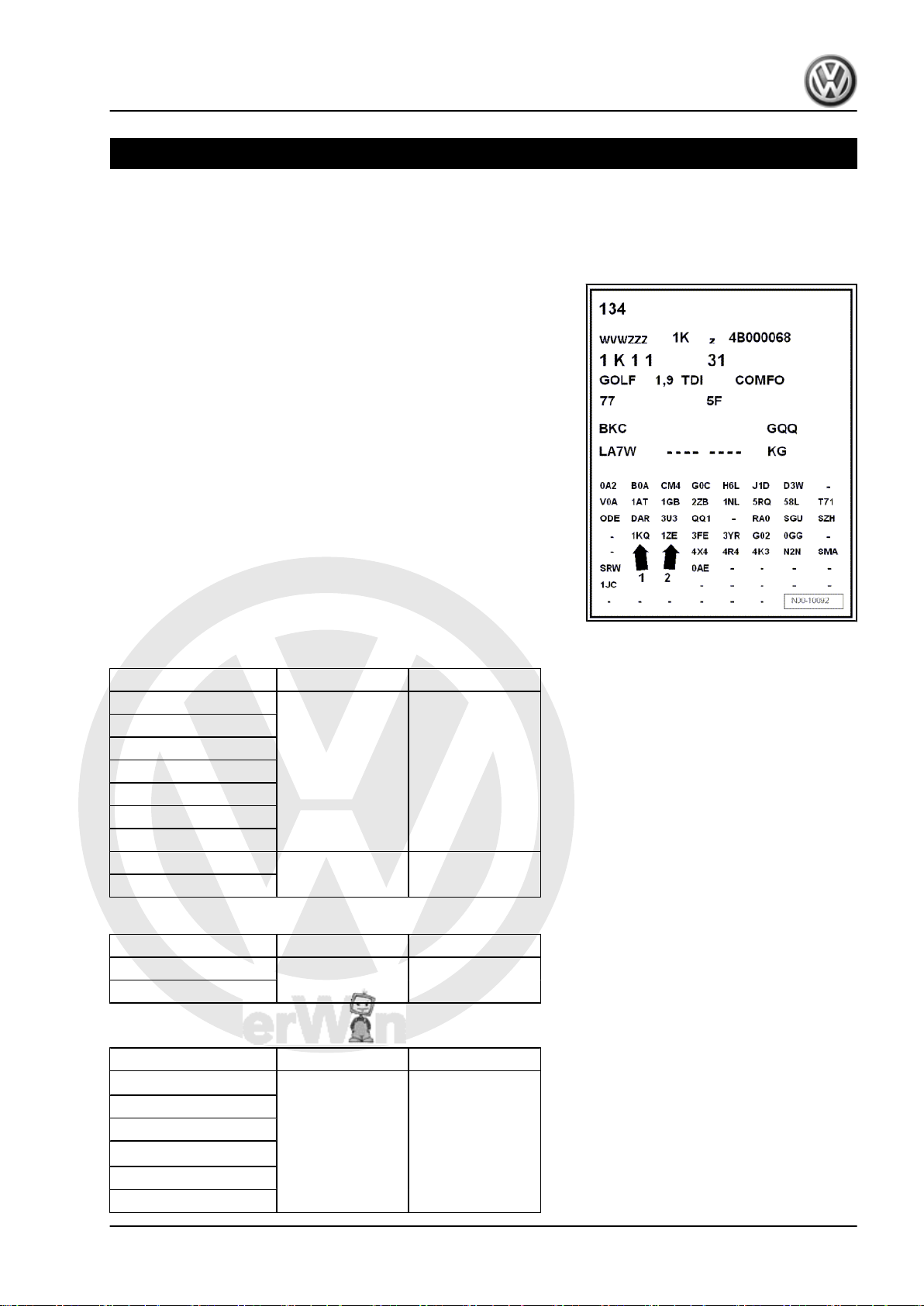

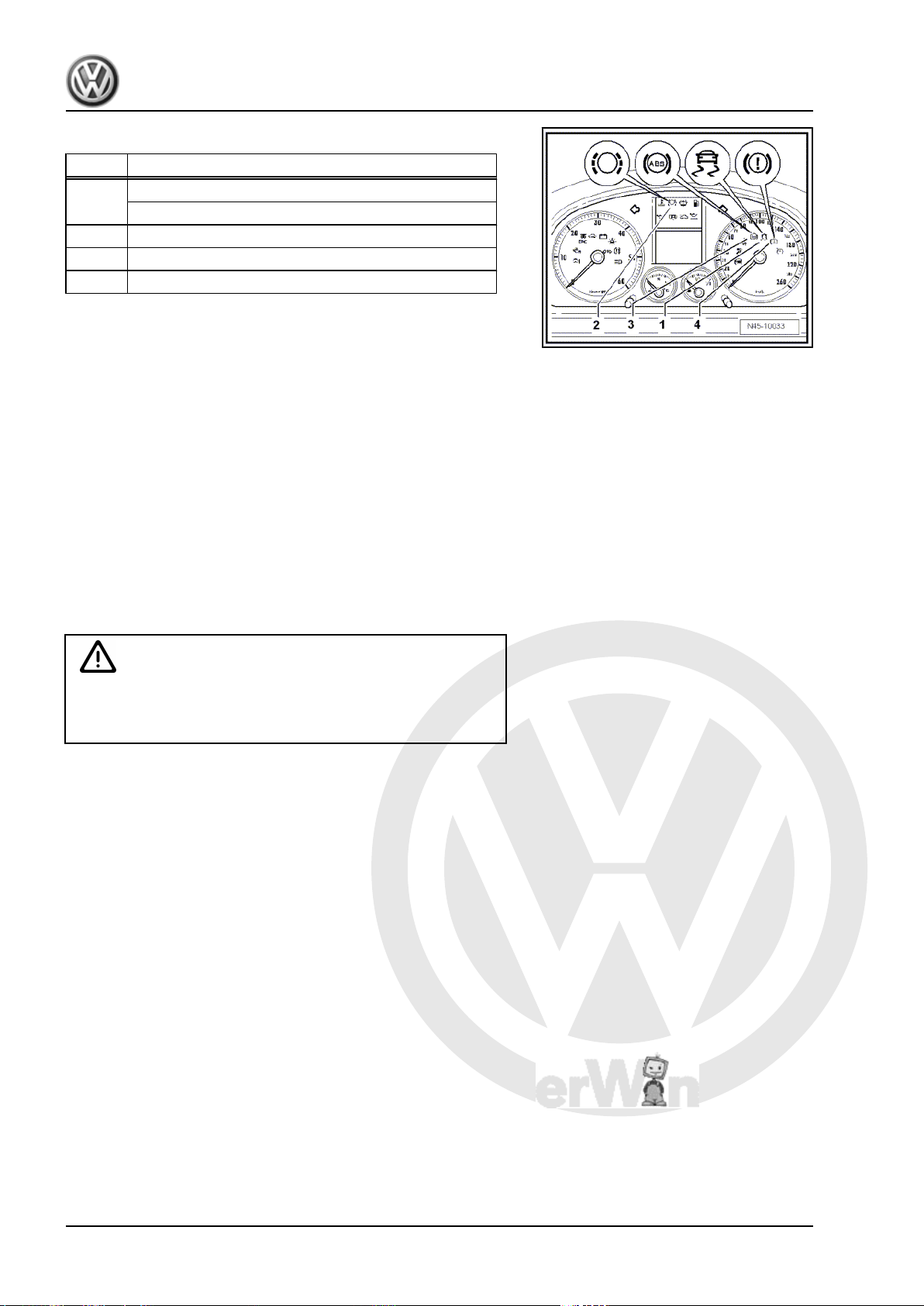

The type of brake system installed in the vehicle is indicated

among other things by the corresponding PR number on the ve‐

hicle data sticker.

Example of a vehicle data sticker:

In this example the vehicle is equipped with the following brakes:

♦ Arrow 1 - Rear brakes -1KQ

♦ Arrow 2 - Front brakes -1ZE

The vehicle data sticker can be found in the spare wheel well and

in the service booklet.

♦ Allocation ⇒ Electronic Parts Catalogue (ETKA) .

♦ The following tables explain the PR numbers. These are rel‐

evant for the brake caliper/brake disc and brake pads.

Brake systems - Edition 05.2008

1.1 Front brakes, Touran

Engine PR No. Front brake

1.6 l - 75 kW 1ZE FN3 (15”)

1.6 l - 85 kW FSI

1.4 l - 103 kW FSI

2.0 l -110 kW FSI

1.9 l - 66 kW TDI

1.9 l - 74, 77 kW TDI

2.0 l - 100, 103 kW TDI

1.4 l -125 kW FSI 1LJ FN3 (16”)

2.0 l - 125 kW TDI

Country-specific brake for Japan:

Engine PR No. Front brake

1.6 l - 85 kW FSI 1ZP FN3 (15”)

2.0 l -110 kW

1.2 Front brakes, Golf

Engine PR No. Front brake

1.4 l - 55, 59 kW

1ZF1) / 1ZM

1.4 l -66 kW FSI

1.6 l - 75 kW

1.6 l - 85 kW FSI

2)

2.0 l - 85 kW

1.9 l - 66 kW TDI

FS III (15”)

1. Brake allocation via PR No. 1

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

1.9 l - 77 kW TDI

3)

2.0 l -55 kW SDI

1.6 l - 85 kW FSI

4)

1.4 l - 88, 90 kW FSI

1.4 l - 103, 110 kW FSI

2.0 l -110 kW FSI

1.9 l - 77 kW TDI

5)

2.0 l - 100, 103 kW TDI

1ZE FN3 (15”)

2.0 l -147 kW FSI 1LJ / 1LL FN3 (16”)

1.4 l -125 kW FSI 1LJ

2.0 l - 125 kW TDI

3.2 l -184 kW 1LM FNR-G (17”)

1)

the 1ZE brake was installed at the start of series production.

2)

Golf

3)

with 5-speed manual gearbox 0A4.

4)

Golf Plus

5)

with Direct Shift Gearbox 02E - 6-speed or four-wheel drive.

Country specific brake for North America / Japan:

Engine PR No. Front brake

1.6 l -75 kW 1ZP FN3 (15”)

1.6 l - 85 kW FSI

2.0 l -110 kW

2.5 l -110 kW

1.9 l - 74 kW TDI

2.0 l -147 kW FSI 1ZD / 1LV FN3 (16”)

1.3 Front brakes, Eos

Engine PR No. Front brake

1.6 l - 85 kW FSI 1ZE FN3 (15”)

2.0 l -110 kW FSI

2.0 l -147 kW FSI 1LJ FN3 (16”)

2.0 l - 100, 103 kW TDI

3.2 l -184 kW

Country specific brake for North America / Japan:

Engine PR No. Front brake

2.0 l -147 kW FSI 1ZD FN3 (16”)

3.2 l -184 kW

1.4 Rear brakes, Touran

Engine PR No. Rear brake

1.6 l - 75 kW 1KF CII 41 (15”)

1.6 l - 85 kW FSI

1.4 l -103 kW FSI

2.0 l -110 kW FSI

1.9 l - 66 kW TDI

2 Rep. Gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

1.9 l - 74, 77 kW TDI

2.0 l - 100, 103 kW TDI

1.4 l -125 kW FSI

2.0 l - 125 kW TDI

1)

Gradual switch to 1KF from the end of 2006

1)

1KJ

CII 41 (16”)

Country-specific brake for Japan:

Engine PR No. Rear brake

1.6 l - 85 kW FSI 1KE CII 41 (15”)

2.0 l -110 kW

1.5 Rear brakes, front-wheel drive Golf

Without Golf Variant:

Engine PR No. Rear brake

1.4 l - 55, 59 kW 1KQ / 1KD CI 38 (15”)

1.4 l - 66 kW FSI

1.6 l - 75 kW

1.6 l - 85 kW FSI

2.0 l - 85 kW

1.4 l - 88, 90 kW FSI

1.4 l - 103, 110 kW FSI

2.0 l -110 kW FSI

2.0 l - 55 kW SDI

1.9 l - 66 kW TDI

1.9 l - 77 kW TDI

2.0 l - 100, 103 kW TDI

2.0 l - 147 kW FSI 1KY CII 38 (16”)

1.4 l - 125 kW FSI

2.0 l - 125 kW TDI

1)

Gradual switch to 1KD from the end of 2006

Golf Variant only:

Engine PR No. Rear brake

1.6 l - 75 kW 1KF CII 41 (15”)

1.6 l - 85 kW FSI

2.0 l - 110 kW FSI

1.9 l - 74, 77 kW TDI

2.0 l - 100, 103 kW TDI

1)

1KZ

Country specific brake for North America / Japan:

Engine PR No. Rear brake

1.6 l - 75 kW 1KE CII 41 (15”)

1.6 l - 85 kW FSI

2.0 l -110 kW

2.5 l - 110 kW

2.0 l - 147 kW FSI

1.9 l - 77 kW TDI

2.0 l - 100, 103 kW TDI

1. Brake allocation via PR No. 3

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

2.0 l - 147 kW FSI 1KV CII 38 (16”)

1.6 Rear brakes, four-wheel drive Golf

Engine PR No. Rear brake

2.0 l - 110 kW FSI 1KF CII 41 (15”)

1.9 l - 77 kW TDI

2.0 l - 100, 103 kW TDI

3.2 l - 184 kW 2EL CII 41 (17”)

Country-specific brake for Japan:

Engine PR No. Rear brake

2.0 l - 110 kW 1KE CII 41 (15”)

1.7 Rear brakes, Eos

Engine PR No. Rear brake

1.6 l - 85 kW FSI 1KD CI 38 (15”)

2.0 l - 110 kW FSI

2.0 l - 100, 103 kW TDI

2.0 l - 147 kW FSI 1KZ CII 38 (16”)

3.2 l - 184 kW

Country specific brake for North America / Japan:

Engine PR No. Rear brake

2.0 l - 147 kW FSI 1KJ CII 41 (16”)

3.2 l - 184 kW

4 Rep. Gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

2 Technical data for brakes

2.1 Brake master cylinder and brake servo, Touran

Brake master cylinder ∅ in mm 22

Brake servo (LHD) ∅ in inches 11

Brake servo (RHD) ∅ in inches 7 / 8

2.2 Brake master cylinder and brake servo, Golf, Eos

Brake master cylinder ∅ in mm 22

Brake servo (LHD) ∅ in inches 10

Brake servo (RHD) ∅ in inches 7 / 8

2.3 Front brakes

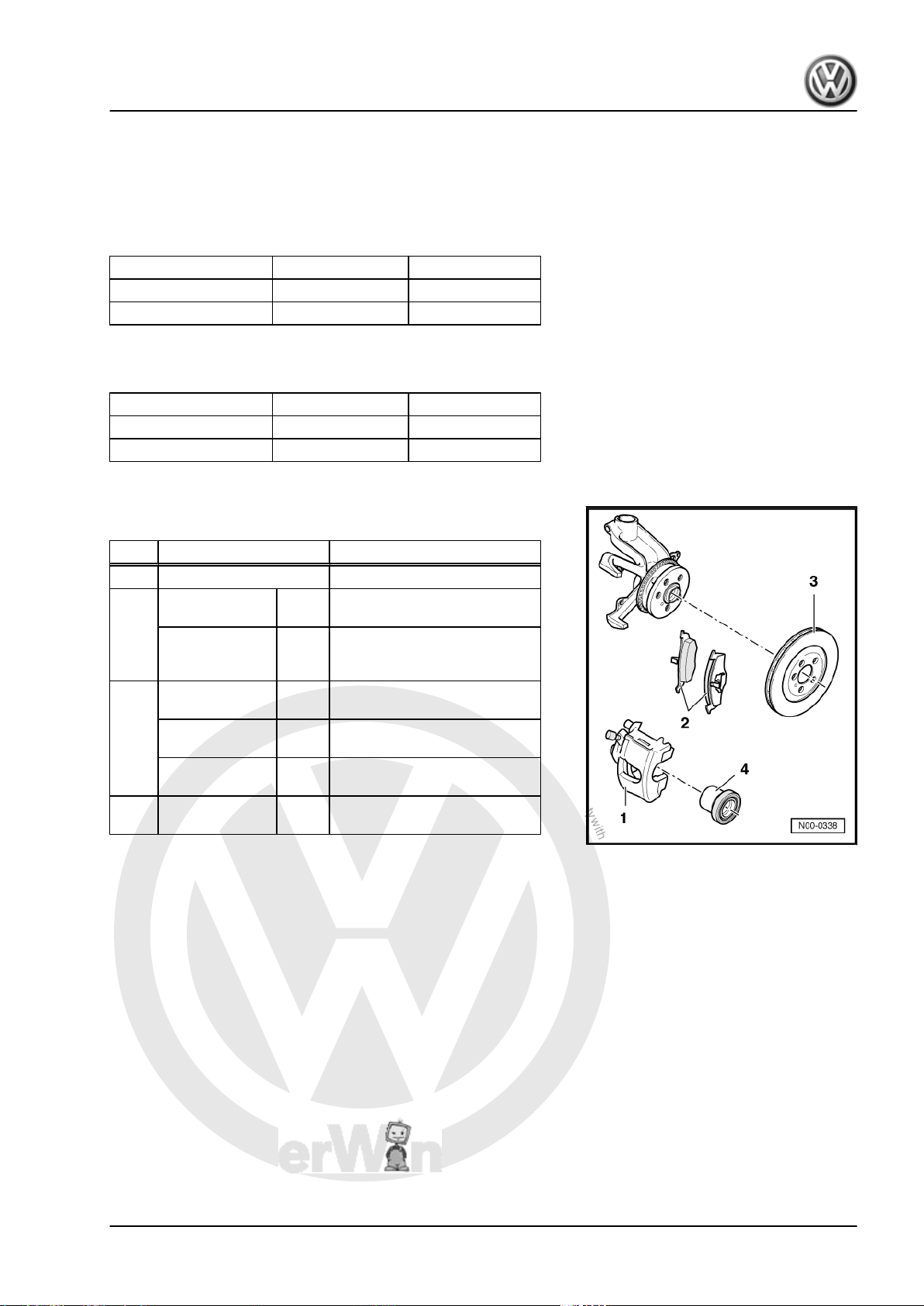

2.3.1 Front brakes FS III

Brake systems - Edition 05.2008

Item PR No.

1ZF / 1ZM

1 Brake caliper FS III (15”)

2 Brake pad,

mm 14

thickness

Brake pad, wear

mm 2

limit without

back plate

3 Brake disc ∅ in

Brake disc,

thickness

Brake disc,

wear limit

4 Brake caliper

piston

mm

mm 22

mm 19

∅ in

mm

280

54

2. Technical data for brakes 5

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

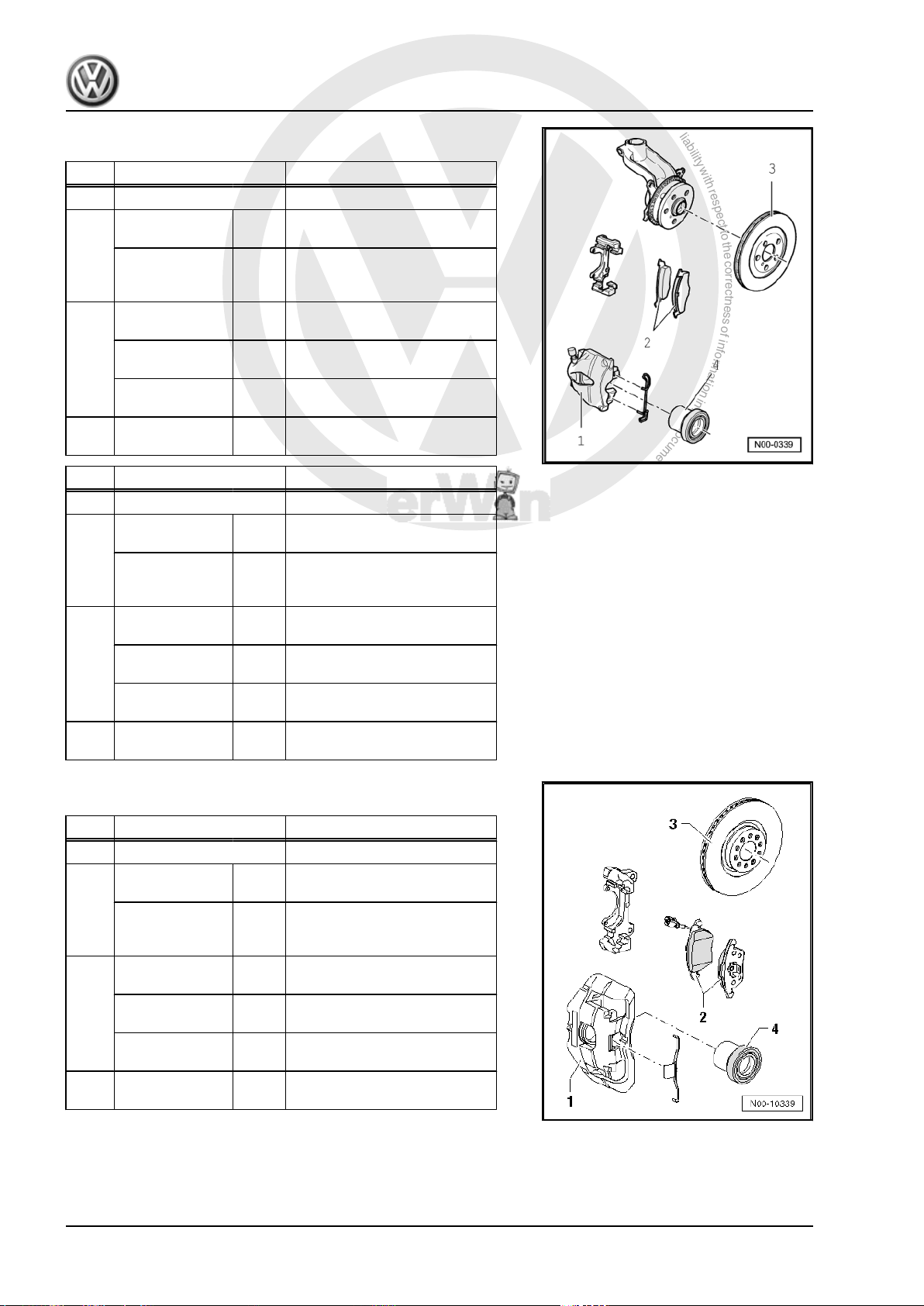

2.3.2 Front brakes FN 3

Item PR No.

1 Brake caliper FN3 (15”)

2 Brake pad,

thickness

Brake pad, wear

limit without

back plate

3 Brake disc ∅ in

Brake disc,

thickness

Brake disc,

wear limit

4 Brake caliper

piston

Item PR No.

1 Brake caliper FN3 (16”)

2 Brake pad,

thickness

Brake pad, wear

mm 14

mm 2

mm

mm 25

mm 22

∅ in

mm

mm 14

mm 2

1LJ / 1LL / 1ZD / 1LV

limit without

1ZE / 1ZP

back plate

3 Brake disc ∅ in

mm

Brake disc,

mm 25

thickness

Brake disc,

mm 22

wear limit

4 Brake caliper

piston

∅ in

mm

288

54

312

54

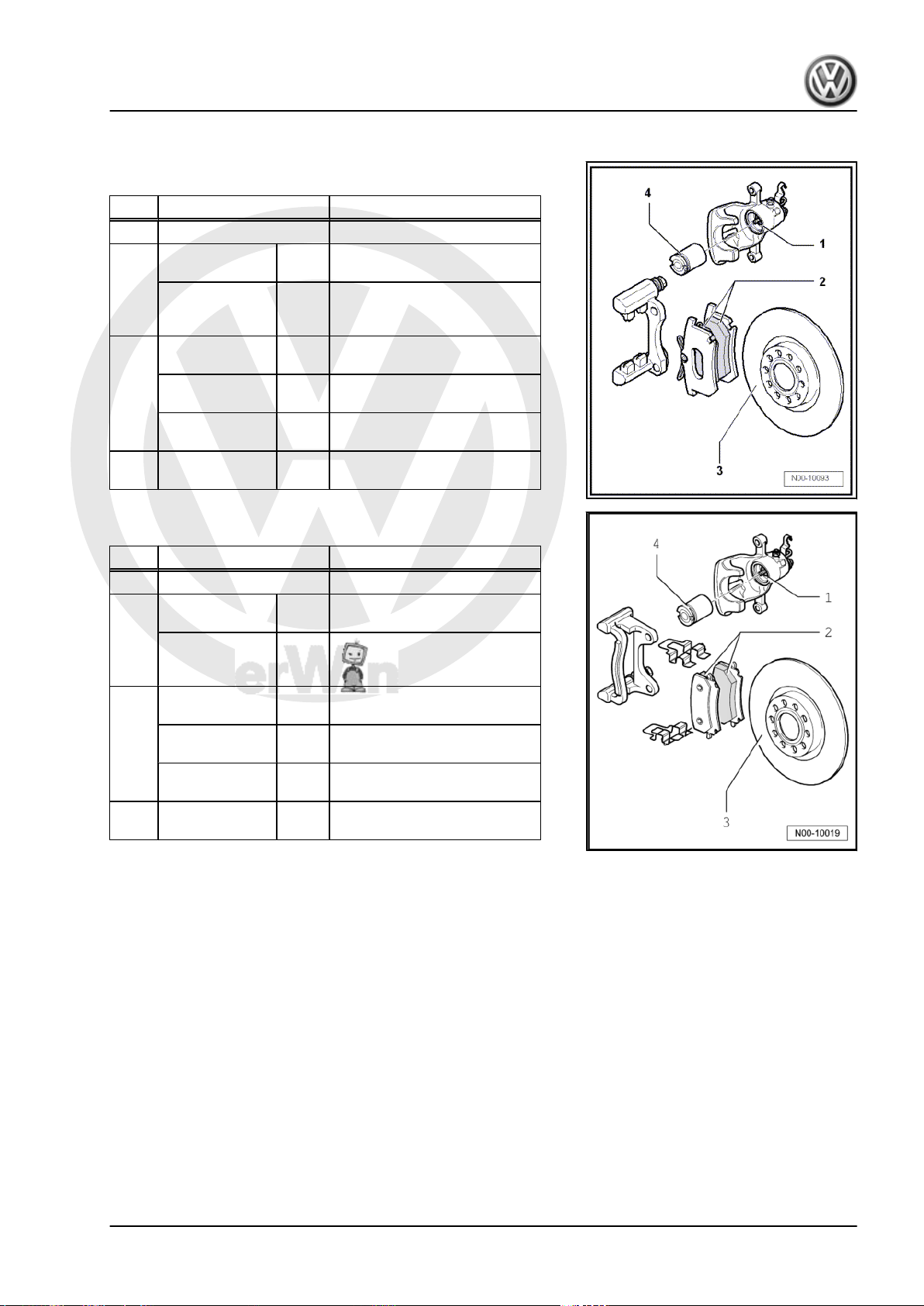

2.3.3 Front brakes FNR-G

Item PR No.

1 Brake caliper FNR-G (17”)

2 Brake pad,

thickness

Brake pad, wear

limit without

back plate

3 Brake disc ∅ in

Brake disc,

thickness

Brake disc,

wear limit

4 Brake caliper

piston

1LK / 1LM

mm 14

mm 2

mm

mm 30

mm 27

∅ in

mm

345

57

6 Rep. Gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

2.4 Rear brakes (disc brakes)

2.4.1 Rear brakes CI 38

Item PR No.

1 Brake caliper CI 38 (15”)

2 Brake pad,

3 Brake disc ∅ in

4 Brake caliper

2.4.2 Rear brakes CII 38

Item PR No.

1 Brake caliper CII 38 (16")

2 Brake pad,

thickness

Brake pad, wear

limit without

back plate

Brake disc,

thickness

Brake disc,

wear limit

piston

thickness

Brake pad, wear

limit without

back plate

3 Brake disc ∅ in

Brake disc,

thickness

Brake disc,

wear limit

4 Brake caliper

piston

mm 11

mm 2

mm

mm 10

mm 8

∅ in

mm

mm 11

mm

mm 12

∅ in

mm

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

1KQ / 1KD

255

38

1KY / 1KZ / 1KV

286

2

10

38

2. Technical data for brakes 7

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

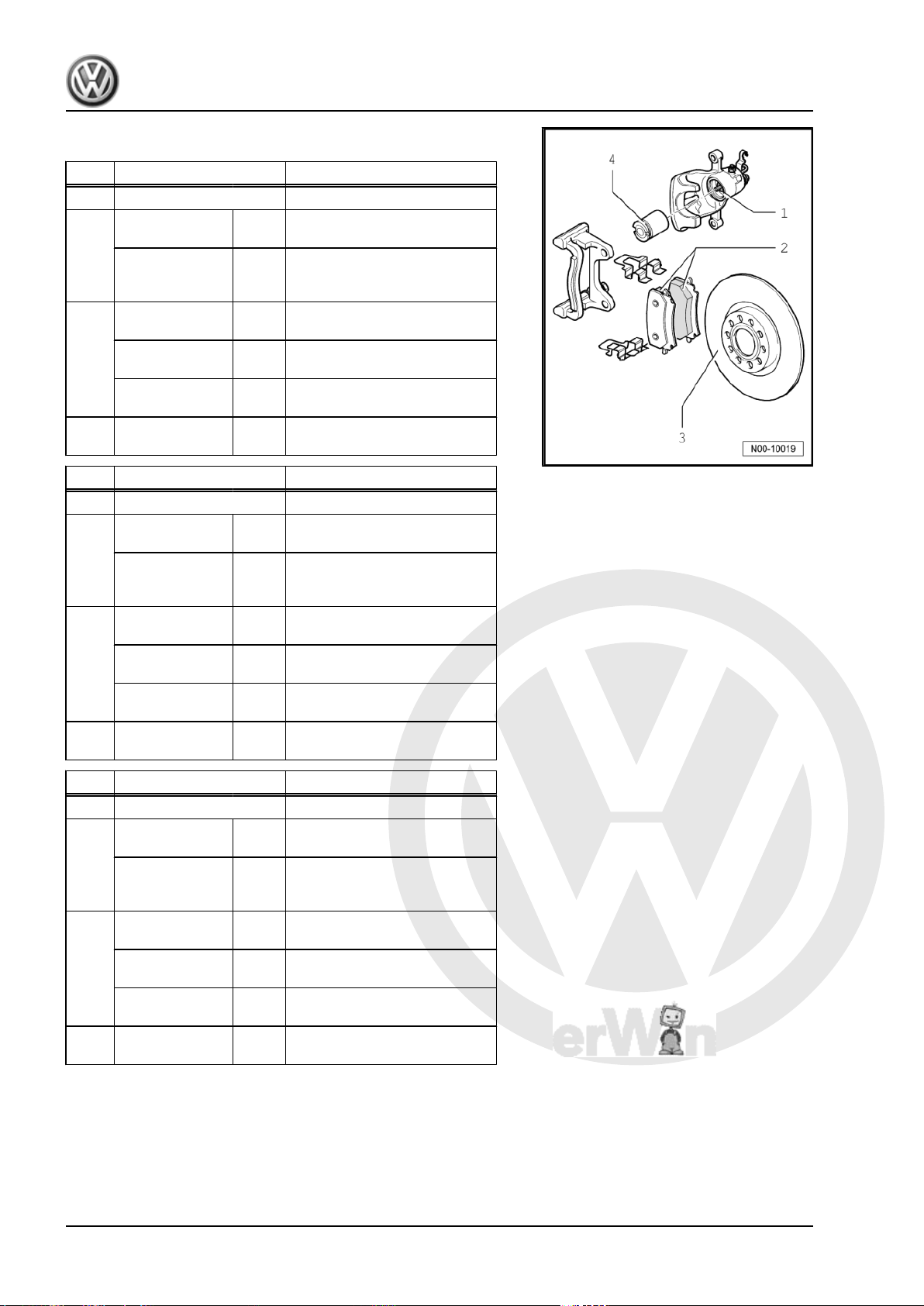

2.4.3 Rear brakes CII 41

Item PR No.

1KF / 1KE

1 Brake caliper CII 41 (15")

2 Brake pad,

mm 11

thickness

Brake pad, wear

mm 2

limit without

back plate

3 Brake disc ∅ in

260

mm

Brake disc,

mm 12

thickness

Brake disc,

mm 10

wear limit

4 Brake caliper

piston

Item PR No.

∅ in

mm

41

1KJ

1 Brake caliper CII 41 (16")

2 Brake pad,

mm 11

thickness

Brake pad, wear

limit without

back plate

3 Brake disc ∅ in

Brake disc,

thickness

Brake disc,

wear limit

4 Brake caliper

piston

Item PR No.

1 Brake caliper CII 41 (17")

2 Brake pad,

thickness

Brake pad, wear

limit without

back plate

3 Brake disc ∅ in

Brake disc,

thickness

Brake disc,

wear limit

4 Brake caliper

piston

mm 2

mm

mm 12

mm 10

∅ in

mm

mm 11

mm 2

mm

mm 22

mm 20

∅ in

mm

2EL / 2EA

286

41

310

41

8 Rep. Gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

3 Brake test

3.1 General

♦ The drive is provided by the roller dynamometer.

♦ For the test, ensure for vehicles with a manual gearbox that

the gear lever is in neutral and for vehicles with an automatic

gearbox, that the selector lever is in “N”.

♦ For test, observe specifications provided by manufacturer of

roller dynamometer.

Note

The brake regulation systems do not function when ignition is off.

3.2 Test for vehicles with front-wheel drive

The brake test must be performed on a single-axle roller dyna‐

mometer.

The maximum test speed must not exceed 6 km/h.

The test rigs authorised by Volkswagen fulfil these requirements.

3.3 Test for vehicles with four-wheel drive

3.3.1 The brake test should be performed on

Contra-rotating means that the dynamometer rollers are driven

via a Haldex coupling

a single-axle roller dynamometer with

contra-rotating rollers for four-wheel

drive vehicles.

forwards on one side and backwards on the opposite side.

This prevents brake forces being transferred to the drive train.

The forward rotating wheel is measured during the test, which

means two brake tests per axle must be performed.

The maximum test speed must not exceed 6 km/h.

The test rigs authorised by Volkswagen fulfil these requirements.

3.3.2 If no test rig is available for four-wheel drive vehicles, the brake test can also be carried out on a standard single-axle roller dynamometer as follows:

Brake systems - Edition 05.2008

– Drive vehicle forwards onto the rollers.

– Switch engine off and wait for 2 seconds.

– Carry out front brake test.

– Start engine and wait for approx. 5 seconds until sufficient

vacuum has been built up.

– Drive vehicle forwards until rear wheels are positioned on roll‐

ers.

3. Brake test 9

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

– Switch engine off and wait for 2 seconds.

– Carry out rear brake test.

– Start engine and wait for approx. 5 seconds until sufficient

vacuum has been built up.

10 Rep. Gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

45 – Anti-lock brake system

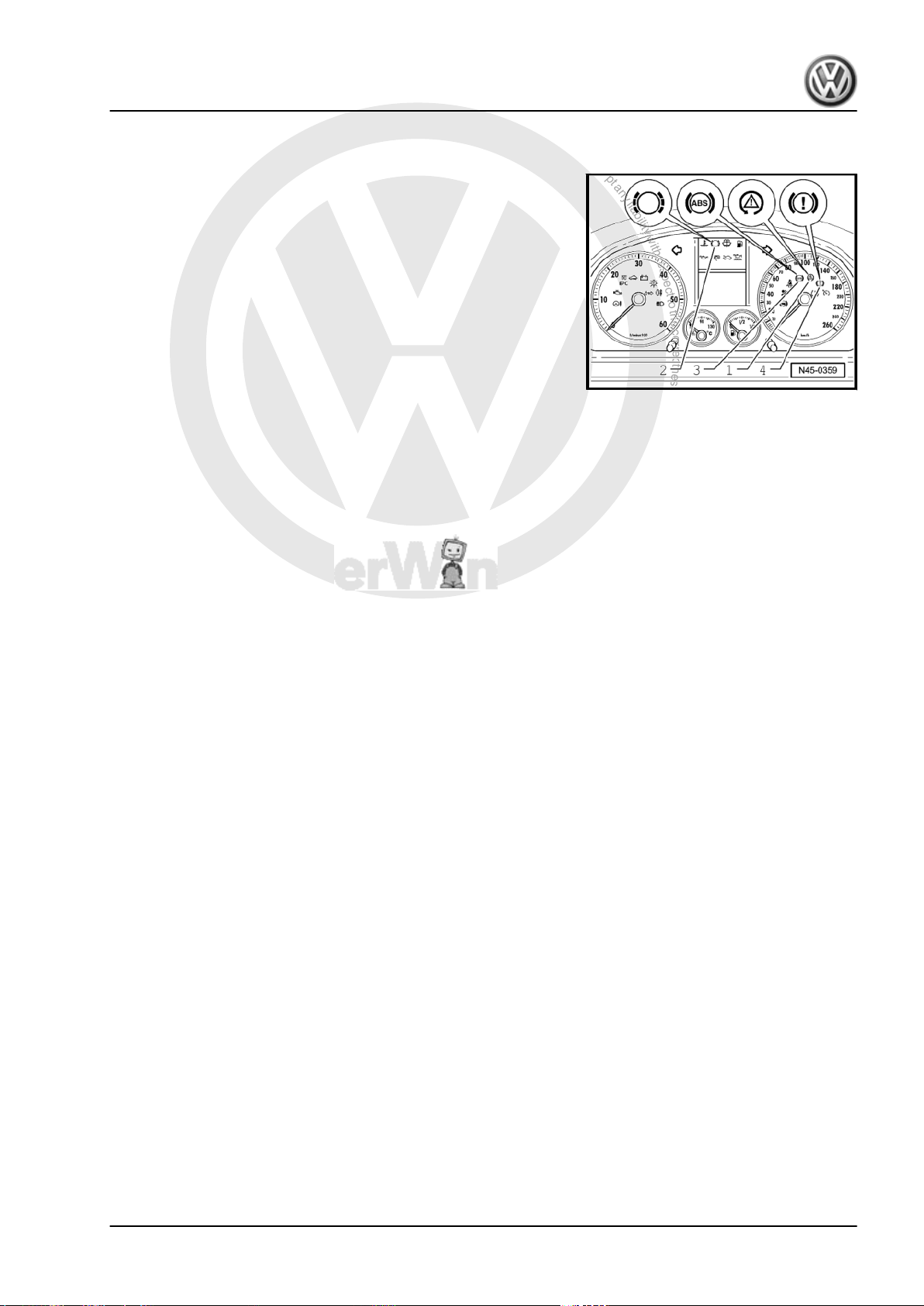

1 General notes on anti-lock brake sys‐

tem

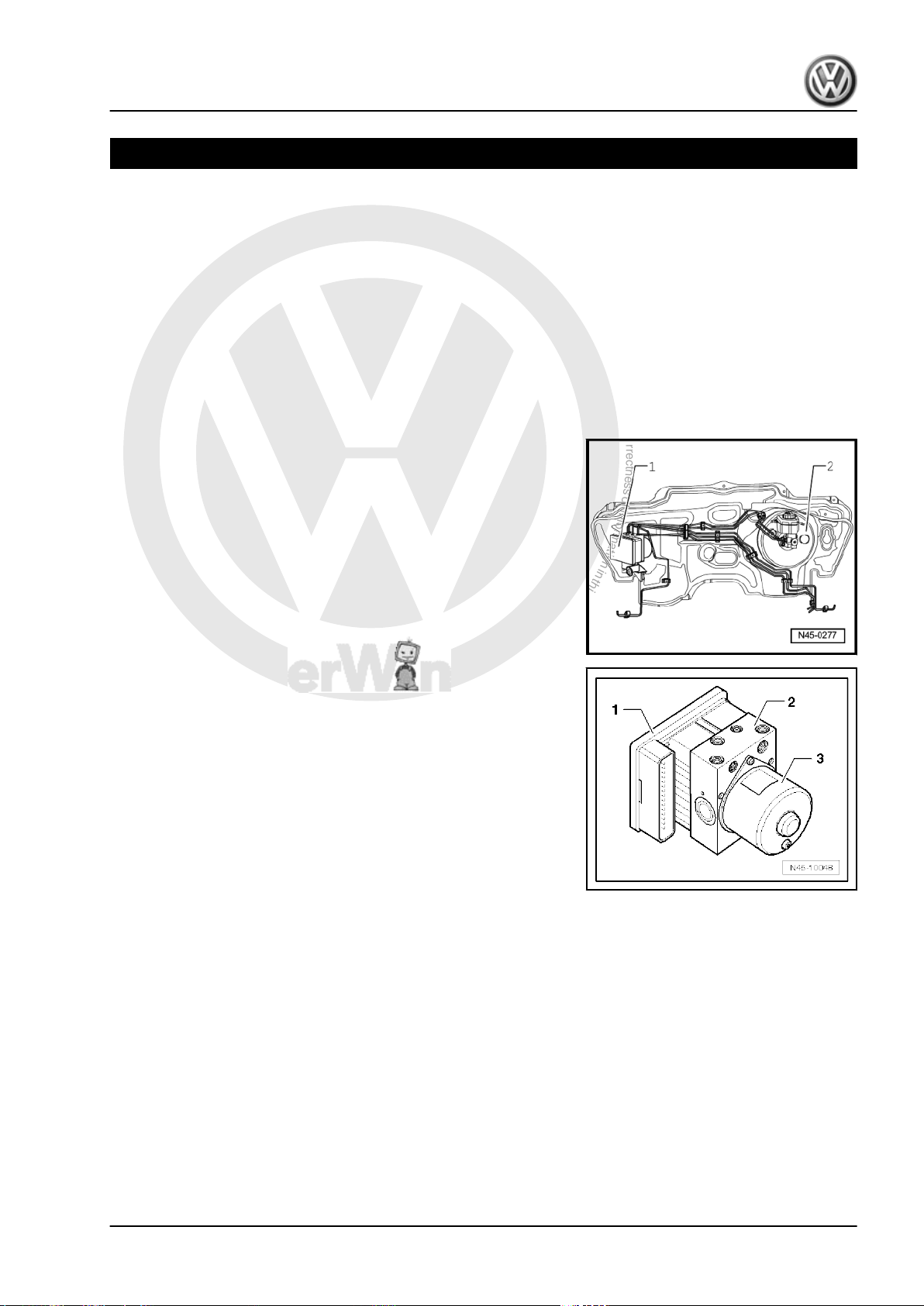

The ABS brake system is divided diagonally. The servo-assis‐

tance is effected pneumatically by the vacuum brake servo unit.

Vehicles with ABS are not fitted with a mechanical brake pressure

regulator. Specially matched software in the control unit regulates

the brake force distribution on the rear axle.

Faults in the ABS do not influence the brake system and servo

assistance. The conventional brake system remains functional

even without ABS. A change in braking behaviour is to be reck‐

oned with. After the ABS warning lamp comes on, the rear wheels

may lock prematurely during braking!

ABS layout in left-hand drive vehicle.

1 - Hydraulic unit and control unit

2 - Brake servo

The hydraulic unit -2- and control unit -1- form one component.

They can be separated only when removed. Hydraulic pump -3must not be separated from hydraulic unit.

With ABS/EDL/TCS/ESP - separation is not possible in vehicles

with hydraulic brake servo or hill hold assist.

Brake systems - Edition 05.2008

1. General notes on anti-lock brake system 11

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

2 Notes for repair work on anti-lock

brake system

♦ Before carrying out repair work on the anti-lock brake system,

determine the cause of the fault as well as the control unit code

using “Guided Fault Finding”.

“Guided Fault Finding” is carried out with the vehicle diagnostic,

testing and information system -VAS 5051- .

♦ Disconnect battery earth strap with ignition switched off.

♦ Before carrying out welding work with an electric welding unit,

note ⇒ General Information; Body Repairs, General Body Re‐

pairs .

♦ When working with brake fluid, observe the valid, relevant

safety precautions and notes ⇒ page 130 .

♦ After work for which the brake system had to be opened, bleed

the brake system with brake filling and bleeding equipment VAS 5234- or -V.A.G 1869- ⇒ page 130 .

♦ During the final road test, ensure that a controlled brake test

is performed at least once (pulsations must be felt at the brake

pedal).

♦ Absolute cleanliness is required when working on the anti-lock

brake system. It is not permitted to use any products which

contain mineral oil, such as oils, greases etc.

♦ Thoroughly clean all unions and the adjacent areas before

loosening. Do not use aggressive cleaning agents such as

brake cleanser, petrol, thinners or similar.

♦ Place removed parts on a clean surface and cover.

♦ After separating the control unit/hydraulic unit, use the trans‐

port protection for the contact pins.

♦ If repairs cannot be carried out immediately, carefully cover or

seal open components. (Use sealing plugs from repair kit

1 H0 698 311 A).

♦ Only use lint-free cloths.

♦ Only unpack replacement parts immediately prior to fitting.

♦ Only use genuine packed parts.

♦ When the system is open, do not work with compressed air

and do not move the vehicle.

♦ Make sure not to touch any contact surfaces on the connector,

pressure sensor and control unit as well as the silicone gel by

hand or with objects.

♦ During painting operations, the electronic control unit can be

exposed to a maximum temperature of 95 °C for only a short

period, and to a maximum of 85 °C for longer periods (approx.

2 hours). Ensure that no brake fluid enters connectors.

12 Rep. Gr.45 - Anti-lock brake system

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

3 Connecting -VAS 5051- and select‐

ing functions

Special tools and workshop equipment required

♦ Vehicle diagnosis, testing and information system -VAS 5051-

♦ Diagnosis cable -VAS 5051/1- or -VAS 5051/3-

WARNING

♦ During a road test, you must always secure testing and

measuring equipment on the back seat.

♦ These devices may be operated only by a passenger while

the vehicle is in motion.

– Connect connector of diagnosis cable -VAS 5051/1- or -

VAS 5051/3- to diagnostic connection.

Brake systems - Edition 05.2008

3. Connecting VAS 5051 and selecting functions 13

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

Brake systems - Edition 05.2008

– Switch on tester -arrow-.

The tester is ready for operation when the selector buttons for the

operating modes appear on the screen.

– Switch on ignition.

– Touch Guided Fault Finding on screen.

– Select one after another:

♦ Brand

♦ Type

♦ Model year

♦ Body version

♦ Engine code

– Confirm data entered.

Wait until tester has interrogated all control units in vehicle.

– Press Go to and select function “Function/component selec‐

tion”.

– Select “Running gear” on display.

– Select “Brake systems” on display.

– Select “01 Self-diagnosis capable system …” shown on dis‐

play.

– Select “Anti-lock brake system …” shown on display.

– Select “Function” shown on display.

Now all possible functions from the anti-lock brake system instal‐

led in the vehicle will be displayed.

– Select desired function on display.

14 Rep. Gr.45 - Anti-lock brake system

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Eos 2006 ➤ , Golf 2004 ➤ , Golf Plus 2005 ➤ , Touran 2003 ➤

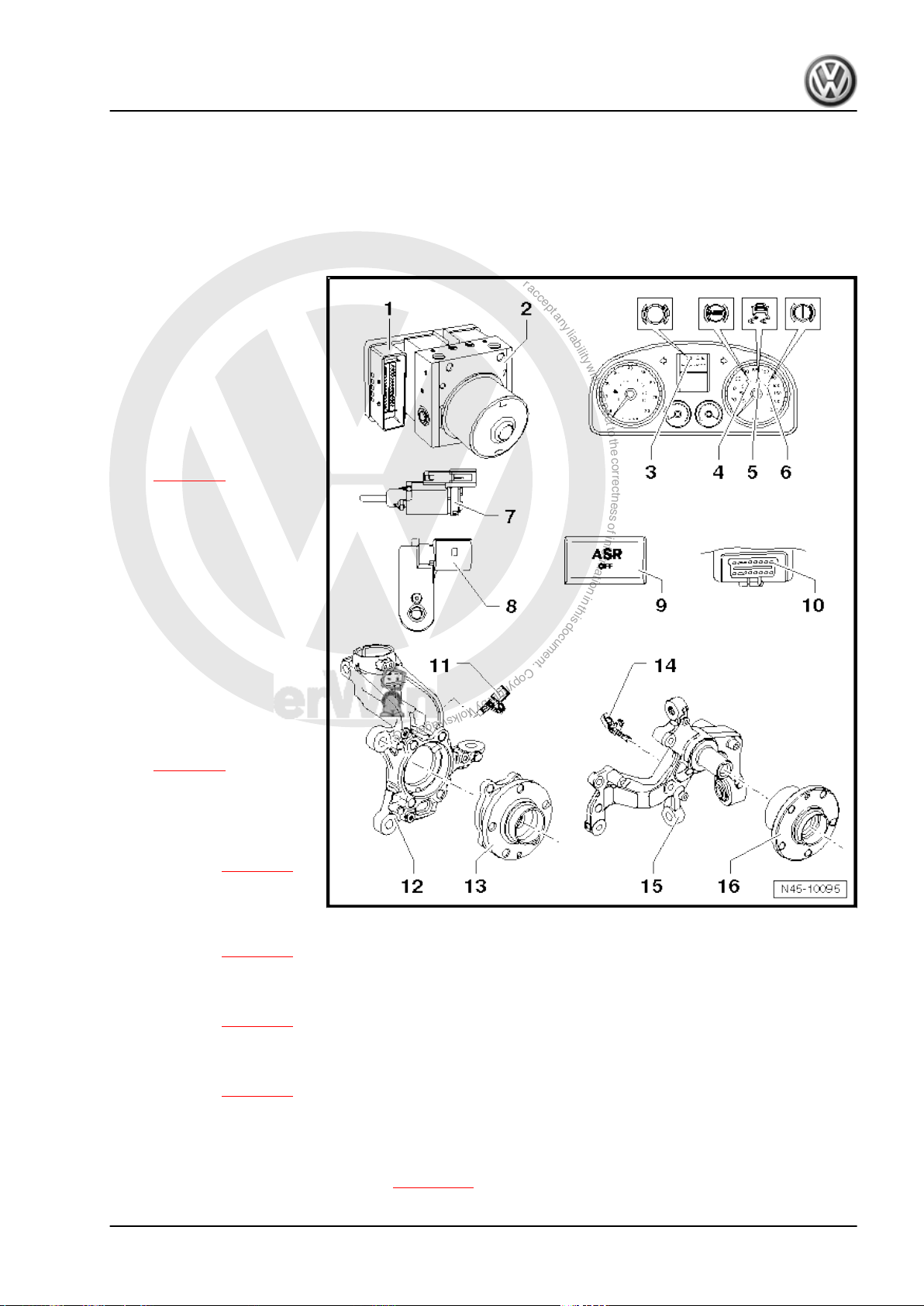

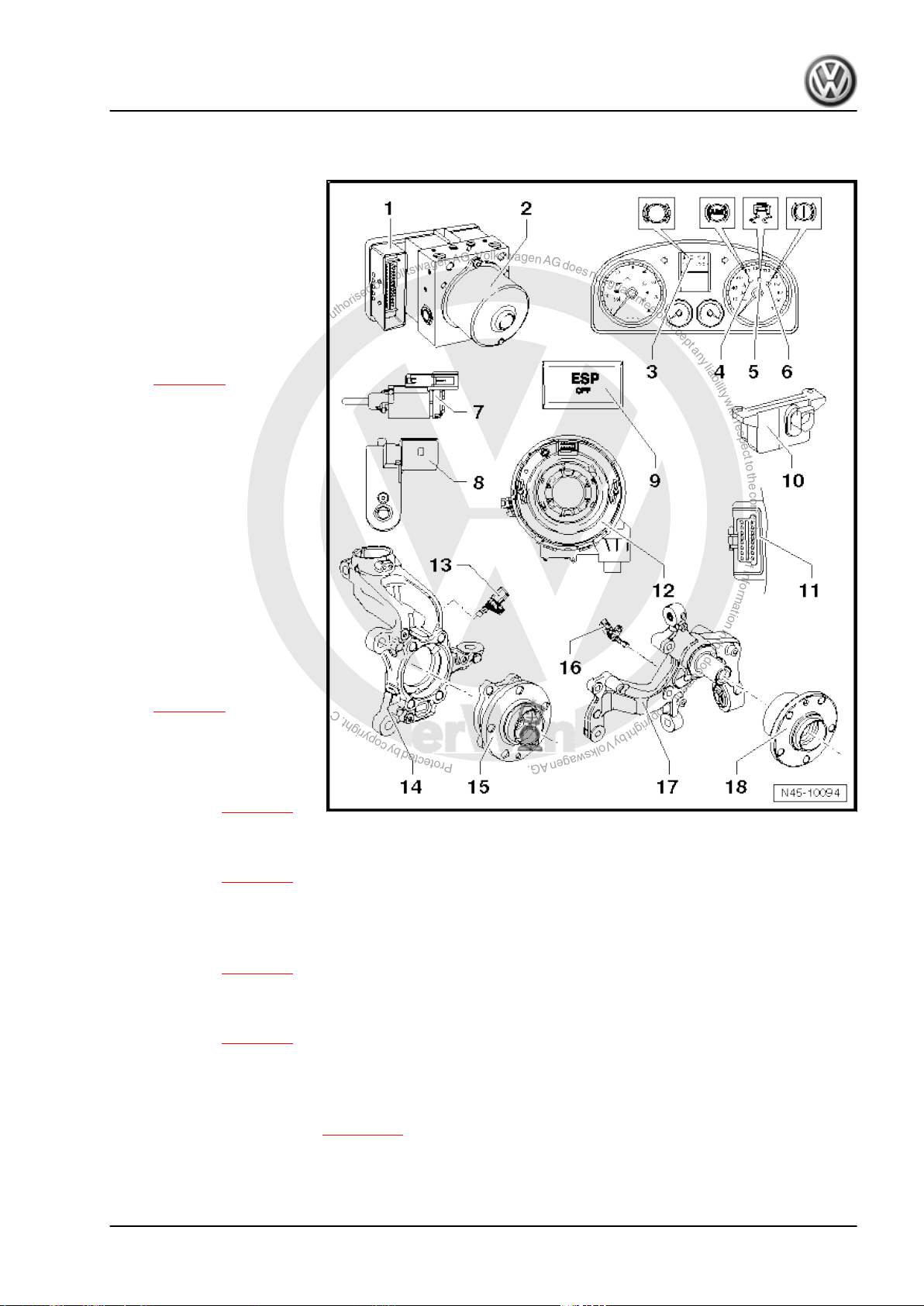

4 Electrical/electronic components and

fitting locations

4.1 ABS Mark 70 (ABS/TCS)

1 - ABS control unit -J104-

❑ Fitting location: on the

❑ Do not separate con‐