Volkswagen Amarok User Manual

Service Training

Self-study programme 464

The Amarok Powertrain and drive concept

Design and function

Commercial

Ve h i c le s

S464_002

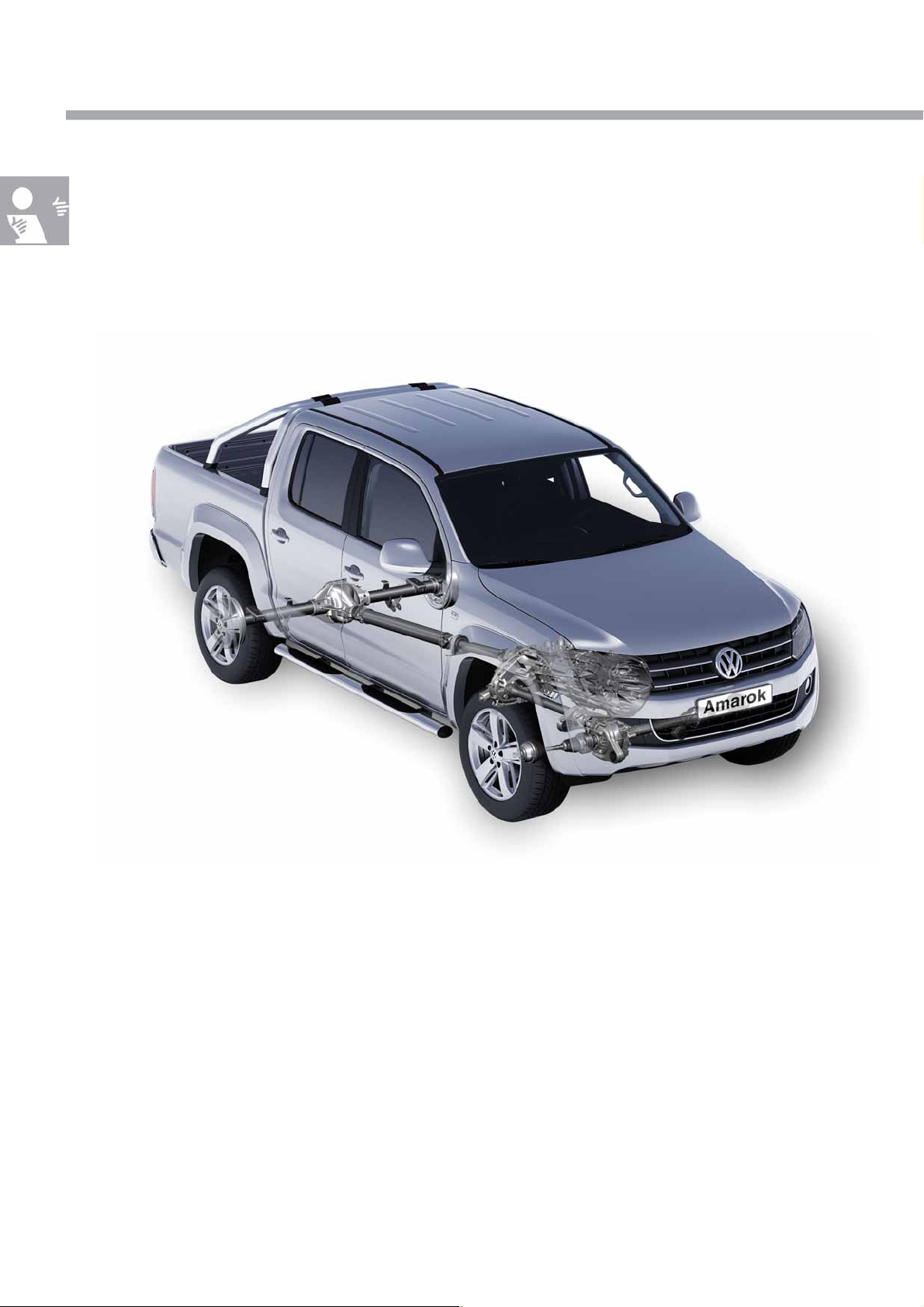

With the Amarok, Volkswagen Commercial Vehicles is deliberately and self-assuredly taking part in the global

trend towards multifunctional vehicle s.

As such, the company is making consistent use of its extensive experience in manufacturing vehicles with both rear

and front-wheel drive. The newly developed drive concept offers outstanding driving properties.

Comfortable handling and operation similar to a passenger car are features of the Amarok. Magnificent assistance

is given for everyday use through a range of support systems in order to provide road safety and handling benefits

when offroad.

In all cases and in all variants, the Amarok can be used both onroad and for heavy-duty offroad use. Depending

on use, the four-wheel drive version of the Amarok is available either with permanently or non-permanently

engaged four-wheel drive. The Amarok is also available in a standard version with rear-wheel drive. The entire

driveline of the Amarok is a new development and has been specifically adapted for use as a commercial vehicle.

Please also refer to self-study programme no. 463

"The Amarok".

The self-study programme presents the

design and function of

new developments!

The content will not be updated.

Current testing , setting an d repair instructions

can be found in the provided

service literature.

Important

note

2

At a glance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Four-wheel drive development at Volkswagen Commercial Vehicles . . . . . . . 4

The drive concept of the Amarok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The driveline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

The operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

The offroad drive programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6-speed manual gearbox 0C6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The 6-speed manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The gearbox structure and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

The gearbox sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

The powerflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

The external selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

The internal selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Transfer box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

The non-permanently engaged four-wheel drive with transfer box 0C7 . . . 32

The transfer box with limited-slip interaxle differential 0BU . . . . . . . . . . . . . . 46

Rear final drive 0CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

The rear final drive 0CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Front final drive 0C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

The front final drive 0C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Test your knowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3

Introduction

Four-wheel drive development at

Volkswagen Commercial Vehicles

Volkswagen Commercial Vehicles began to manufacture four-wheel drive vehicles in-house in 1983

in the form of the LT1 4x4.

This was an early response to the desire for as wide a range of vehicle applications as possible – from driving on

smooth roads through to use on very difficult ground.

The four-wheel drive is better able to overcome traction problems when used in sports applications and, in

particular, as a commercial vehicle.

LT1 4x 4

from 1983

T3 syncro

from 1985

T4 syncro

from 1993

4

Volkswagen Commercial Vehicles markets vehicles all over the world, therefore the company is used to taking

account of special conditions, such as in remote areas and difficult open ground – four-wheel drive represents an

ideal solution for this.

Amarok 4MOTION

from 2010

Caddy 4MOTION

from 2009

T5 4MOTION

from 2004

S464_051

5

Introduction

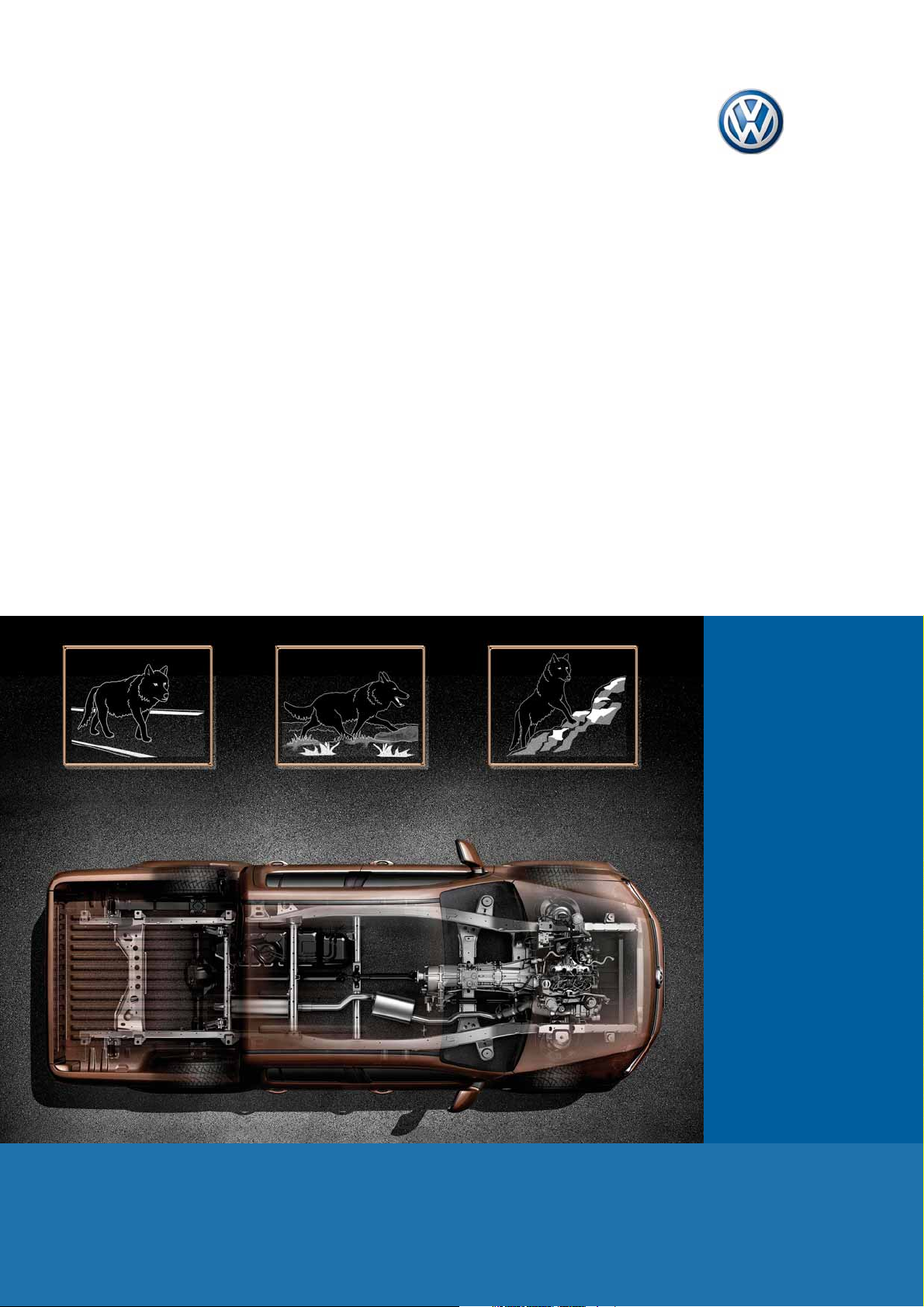

The drive concept of the Amarok

The drive concept of the Amarok offers 3 different drive variants.

The Amarok's powertrain is efficiently supported by intelligent vehicle dynamics programmes.

S464_058

Vehicle dynamics programmes

The Amarok is equipped with the following vehicle dynamics programmes:

● ABS (as standard)

● TCS (as standard)

MSR (as standard)

EDL (as standard)

● ESP

6

● Offroad drive programme (as standard)

● Hill-descent assist

● Hill-hold assist

Rear final drive

In the Amarok with rear-wheel drive, the power is

transmitted via a propshaft to the rear axle only.

Even with only rear-wheel drive, the Amarok can be

used on both consolidated and non-consolidated

roads as well as offroad.

Permanent four-wheel drive

with limited-slip interaxle

differential 0BU

In the Amarok with permanently engaged four-wheel

drive, the powerflow to both driven axles is distributed

by means of a transfer box with permanent

engagement using a limited-slip interaxle differential.

This offers improved traction compared to rear-wheel

drive, above all when offroad.

S464_006

Non-permanently engaged

four-wheel drive with part-time

transfer box 0C7

In the Amarok with non-permanently engaged fourwheel drive, the powerflow to the driven axle is

distributed using a transfer box with electrically

engaged front final drive. It is also possible to engage

a reduction stage (offroad ratio) in this transfer box.

In this version, the Amarok is even better suited for

use on difficult ground.

S464_074

S464_005

7

Introduction

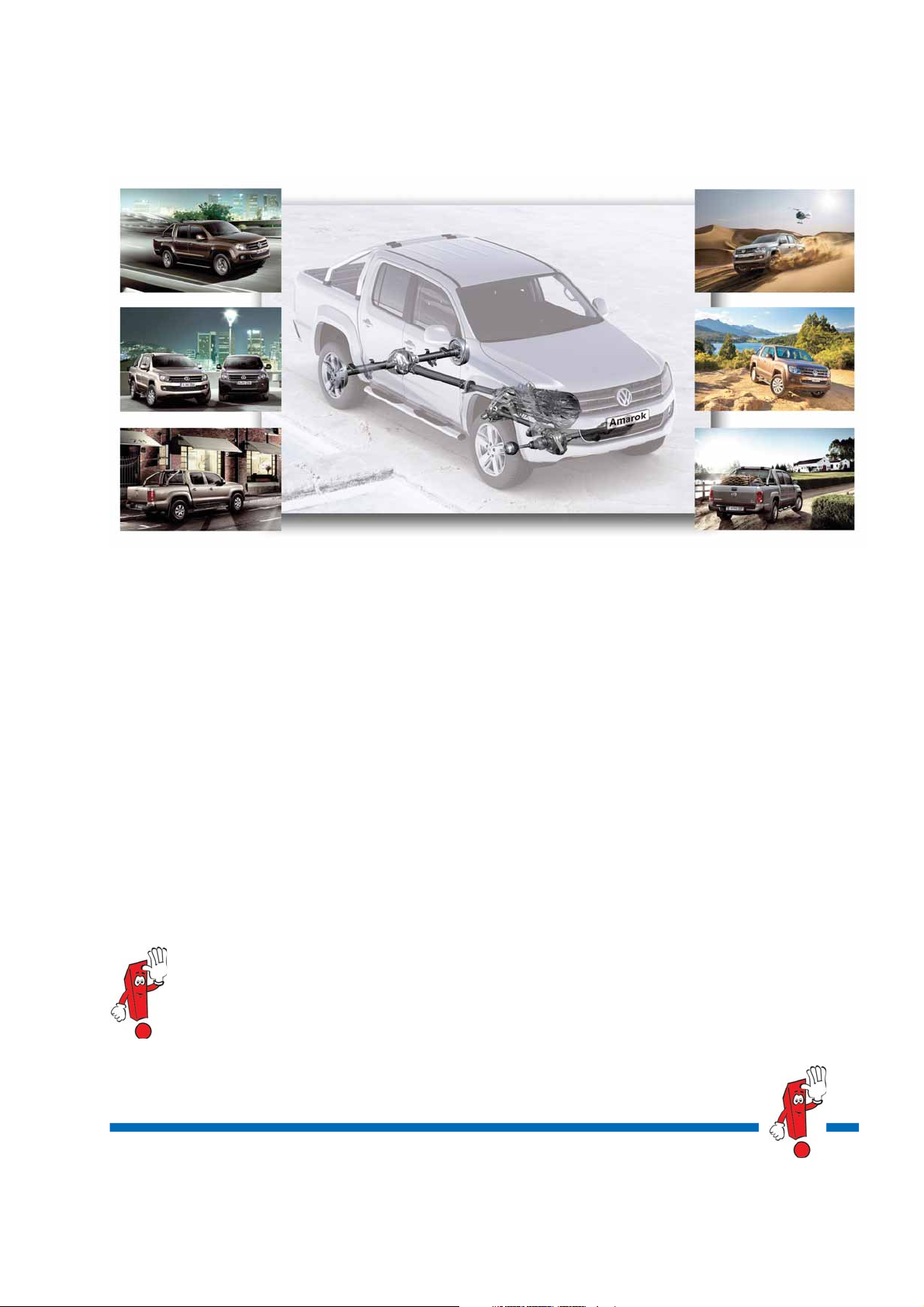

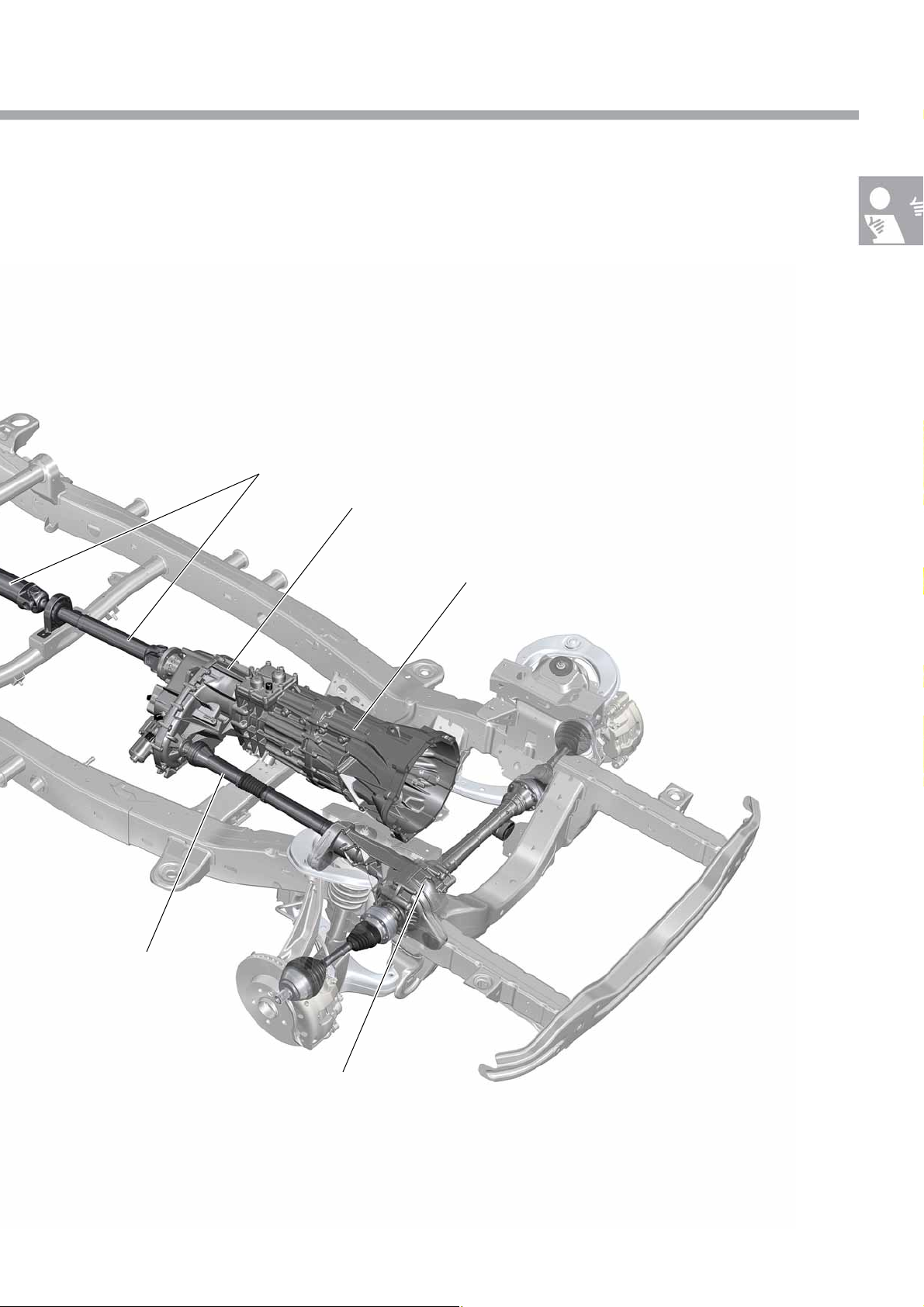

The driveline

The Amarok has a modular driveline in which the individual

components such as manual gearbox, front final drive, transfer

box and rear final drive are independent subassemblies.

Gearbox

At present, the 6-speed manual gearbox 0C6 is used

for transmitting power from the engine

Rear axle

Transfer box

Power is distributed to the final drives either by means

of the transfer box 0C7 (non-permanently engaged

four-wheel drive) or 0BU (permanently engaged

four-wheel drive).

Rear final drive

Lad der f ram e

Propshafts

Three different two-part propshafts are used for driving the rear axle.

The front part of the propshaft has a length that is adapted to the particular drive version.

A one-piece propshaft is fitted for driving the front axle. This is identical in both versions of the four-wheel drive.

8

Rear final drive, front final drive

The rear final drive 0CC arranged in a symmetrical installation position is used for driving the rear axle. The rear

axle differential can be locked up.

The front final drive 0C1 is used for driving the front axle, and is available in two different designs. The front final

drive is asymmetrically arranged.

Rear propshaft

Transfer box

6-speed manual gearbox

Front propshaft

Front final drive

The illustration shows the drivetrain with non-permanently engaged four-wheel drive.

S464_007

9

Operation

The operation

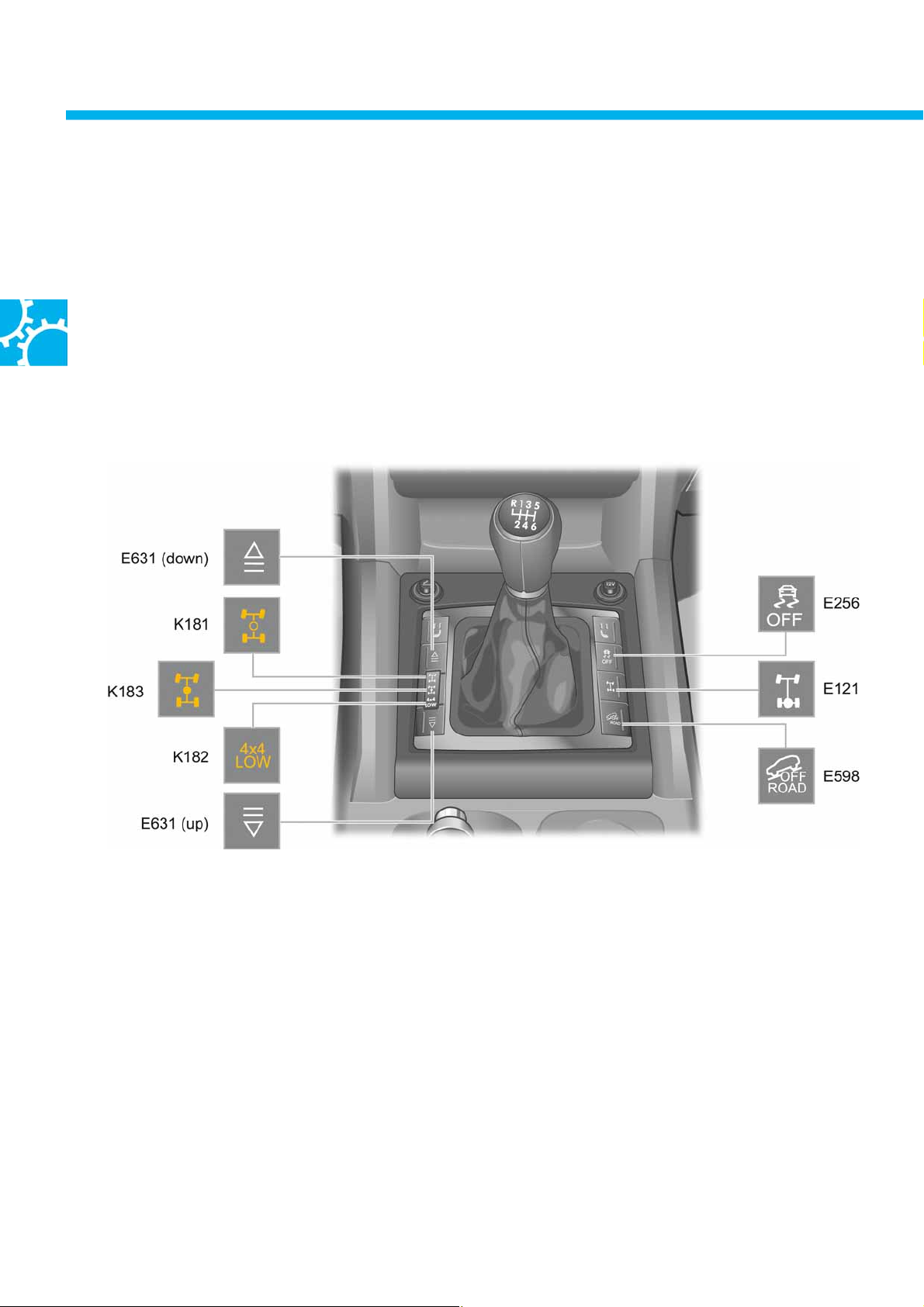

Four-wheel drive, the reduction ratio (offroad ratio), the differential lock and the offroad drive programme are

engaged and disengaged using a button panel in the centre console. The status is displayed by warning lamps

K181, K182 and K183.

The four-wheel drive components are each electrically connected to the gearbox.

This means no additional selector levers are required for operating the four-wheel drive ranges.

Centre console button assignments

10

Key

E631 (down) = Running gear programme switch

(switching on)

K181 Normal operation warning lamp in transfer box

operating unit (4x2)

K183 Longitudinal lock-up warning lamp in transfer

box operating unit (4x4 HIGH)

K182 Reduction gearing warning lamp in transfer box

operating unit

(4x4 LOW)

E631 (up) = Running gear programme switch

(switching off)

S464_049

E256 TCS and ESP button (TCS deactivation)

E121 Rear differential lock switch

E598 Driving programme button (offroad driving

programme)

E256, E121 and E598 do not have function

lighting

In right-hand drive vehicles, button panel E631 is fitted

on the other side of the selector lever.

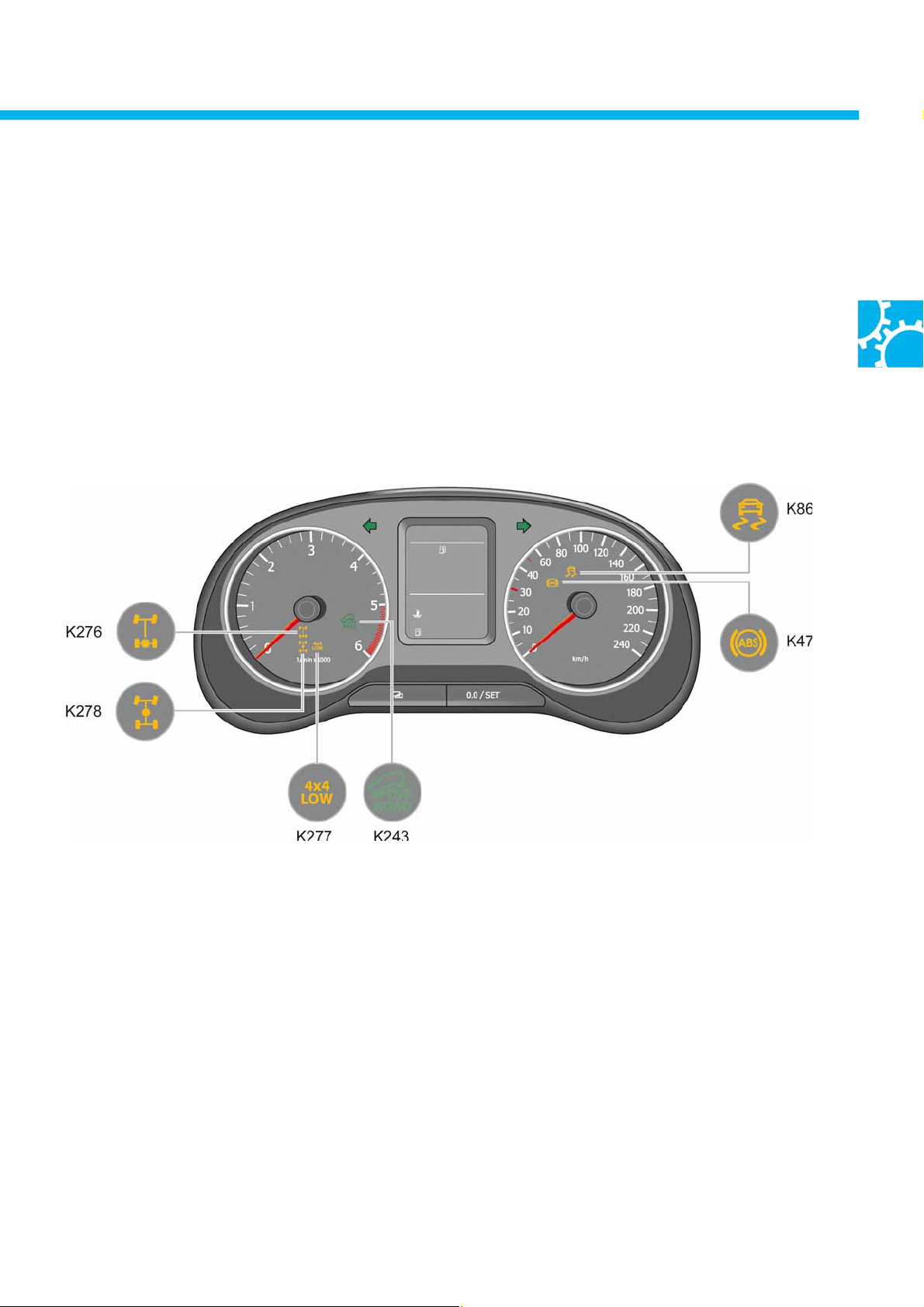

Displays on the dash panel insert

Each of the four-wheel drive statuses that are activated during operation is backlit in the button panel and also

shown in the dash panel insert as a status display.

The status of 4x2 rear-axle mode is only displayed in the centre console.

Key

K278 Longitudinal lock-up warning lamp (4x4 HIGH)

K277 Warning lamp for gearbox low range

K276 Warning lamp for rear transverse lock

K47 ABS warning lamp (ABS fault or ABS deactivated)

K86 Traction control system warning lamp (fault, control or deactivated)

K243 Driving programme warning light (offroad driving programme)

S464_050

11

Operation

Four-wheel drive 4x4 HIGH

Display in the dash panel insert

… four-wheel drive is engaged

(interaxle lock engaged)

S464_077

Switch-on conditions

● Ter m in al 1 5 " ON "

● E631 (up) pressed > 0.5 s

● Can be engaged at any vehicle speed

● No undervoltage

● No relevant error memory entry

Offroad range 4x4 LOW

Display in the dash panel insert

Switch-off conditions

● Ter m i n al 15 " O N"

● E631 (down) pressed > 0.5 s

● Can be switched off at any vehicle speed

● No undervoltage

● No relevant error memory entry

… four-wheel drive is engaged and LOW

reduction ratio engaged

12

S464_079

Switch-on conditions

● Engine speed < 1500 rpm

● E631 (up) pressed > 0.5 s

● Vehicle speed v < 1 km/h

● 4x4 HIGH engaged

● No undervoltage

● No relevant error memory entry

Switch-off conditions

● Engine speed < 1500 rpm

● E631 (down) pressed > 0.5 s

● Vehicle speed v < 1 km/h

● No undervoltage

● No relevant error memory entry

Differential lock

Display in the dash panel insert

… differential lock engaged

S464_081

Switch-on conditions

● Engine running

● E121 pressed > 0.5 s

● Can be engaged at any vehicle speed

● No undervoltage

● No relevant error memory entry

● With non-permanently engaged four-wheel drive:

Four-wheel drive range 4x4 LOW engaged

Switch-off conditions

● Button pressed > 0.5 s (E121)

● Can be switched off at any vehicle speed

● 30 s follow-on operation after tl. 15 "OFF".

If the engine stalls whilst driving with the

differential lock engaged, the lock remains

engaged for a period of 30 seconds after tl. 15

"OFF". This means restarting and moving off are

possible with the lock engaged. As a result , driving

comfort is increased when driving offroad.

The following applies to all variants 4x4 HIGH, 4x4 LOW and for the differential lock with regard to operation

The driver's request for engaging the required four-wheel drive range is stored for 10 s. If the required activation

conditions are met within this period then the four-wheel drive ranges 4x4 HIGH, 4x4 LOW and the differential lock

are engaged. Operating comfort is therefore improved.

ABS/ESP system statuses

ABS/ESP control is retained during four-wheel drive operation (4x4 HIGH and 4x4 LOW) in all equipment variants of

the Amarok. In vehicles with non-permanently engaged four-wheel drive, ABS/ESP control is deactivated when the

differential lock is engaged. The mechanical link-up between the two axles (4x4 HIGH /4x4 LOW) and the additional

link-up between the two rear wheels means that individual ABS/ESP control for individual wheels is no longer

possible. Deactivation is displayed by warning lamps K86 and K47 in the dash panel insert. In vehicles with

permanently engaged four-wheel drive, the ABS/ESP function is also retained when the differential lock is engaged.

13

Operation

The offroad drive programme

The offroad drive programme is used as standard in all vehicle variants of the Amarok.

It is intended to assist the driver in special driving situations when offroad. The possible extended functions of the

ABS/ESP control unit are used in this case.

● Offroad ABS (adaptations in the ABS control behaviour)

● Offroad ESP (adaptations in the ABS and ESP control behaviour)

● Hill-descent assist

Activation of the offroad programme and indication

The offroad programme is activated

● Manually – by pressing the driving programme button E598

(in the centre console, on the right of the selector lever) or

● Automatically – when 4x4 LOW drive range is activated

Display showing activation of the offroad drive programme

Activation of the offroad drive programme is indicated by the driving

programme warning light K243 in the dash panel insert.

Configurations

● Vehicles with ABS (MK25 E) have offroad ABS

● Vehicles with ESP (MK25 XT) have offroad ABS/ESP

and hill descent control

Activation conditions for the offroad

programme

The offroad drive programme remains active

● Ter m i na l 15 " O N "

● E598 pressed > 0.5 s

Special case in vehicles with non-permanently

engaged four-wheel drive

When 4x4 LOW drive range is engaged, the offroad

programme is activated automatically.

following activation until the next change of ignition

status, without interruption.

For example, if the engine is stalled when driving

offroad, the offroad drive programme also remains

activated after restarting, with a follow-on operation

of 30 s after a change of status on tl. 15.

This increases driving comfort.

E598

S464_073

S464_072

14

Features of the offroad drive programme

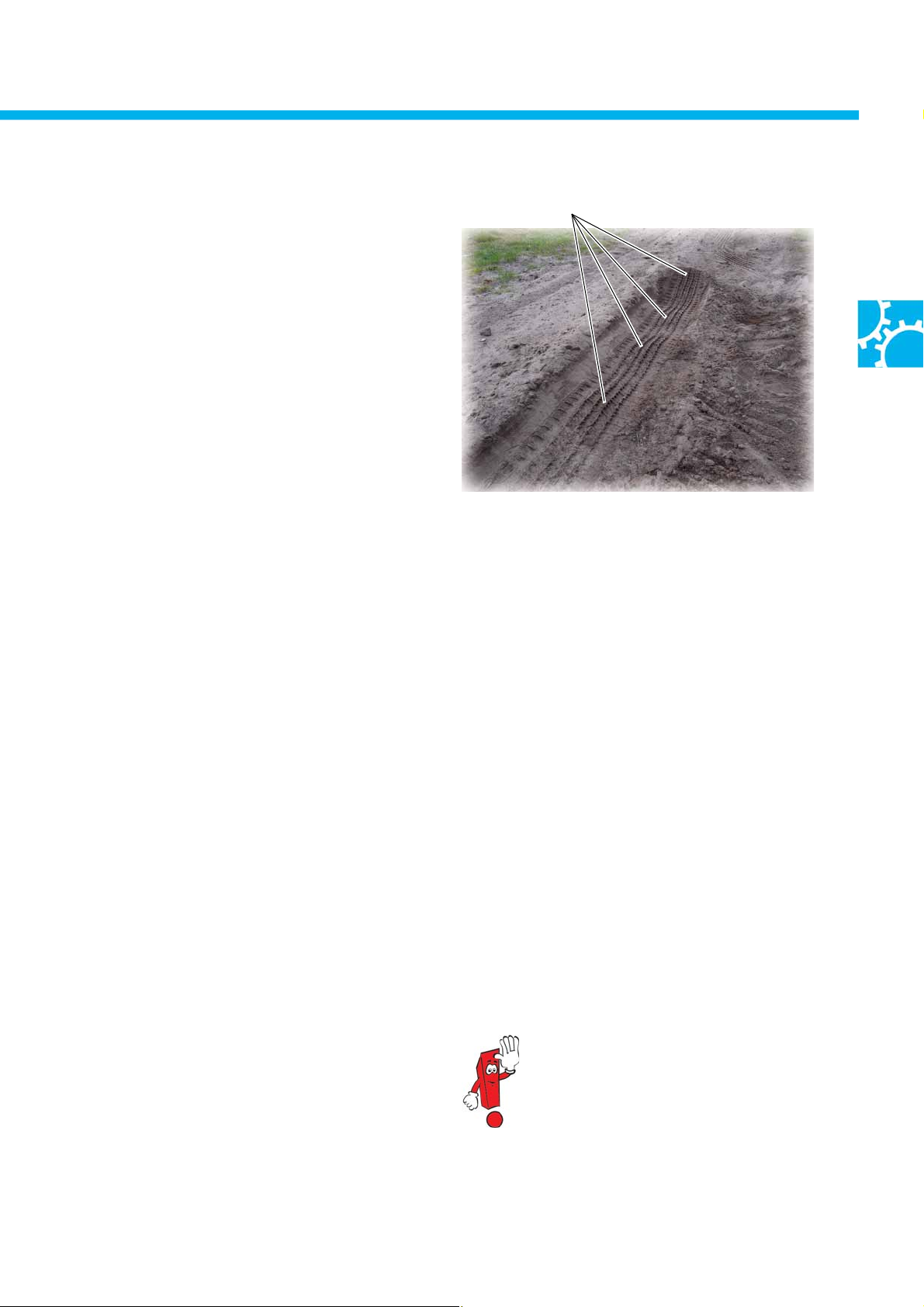

Offroad ABS

Vehicles with offroad ABS can brake better on

unconsolidated ground such as sand and gravel.

In ABS control, the pressure buildup and pressure

holding phases are extended. The depressurisation is

shorter and takes place later. This means wheel slip

can occur in each control phase, thereby building up

a skid wedge of loose material in front of the wheels.

The skid wedge brakes the vehicle additionally and

shortens the braking distance depending on the

composition of the ground.

Offroad ESP

Skid wedge

S464_076

Special information about using offroad ABS can be

found in the owner's manual .

Vehicles with ESP have adapted ESP control behaviour

as well as offroad ABS in order to improve traction:

● ESP intervenes somewhat later at speeds below

50 km/h when the vehicle is understeering.

● ESP intervenes somewhat later at speeds below

70 km/h when the vehicle is oversteering.

● ASR intervenes somewhat later at speeds below

70 km/h.

Hill-descent assist

The hill-descent assist makes descending steep hills more straightforward and more controllable. It limits the speed

by active brake intervention at all 4 wheel brakes using the ESP hydraulics. It keeps the speed constant after the

vehicle has started its descent. The driver can increase or reduce the speed at any time using the accelerator and

brakes. The hill-descent assist adjusts speed within its control range between 2 and max. 30 km/h. The system

functions when driving forwards and in reverse.

Switch-on conditions for hill-descent assist

● E598 pressed > 0.5 s

● Special feature with non-permanently engaged

four-wheel drive: automatic activation in 4x4 LOW

● Engine running

● Slope forwards > 10 %, reverse > 8 %

● Vehicle speed v < 30 km/h (> 30 km/h change to

standby mode)

● Driver brakes less than the downslope force

● Accelerator pedal is not pressed

For more information about the basic

function of the hill-descent assist, refer

to self-study programme 374

"Slip control and assistance systems".

15

6-speed manual gearbox 0C6

The 6-speed manual gearbox

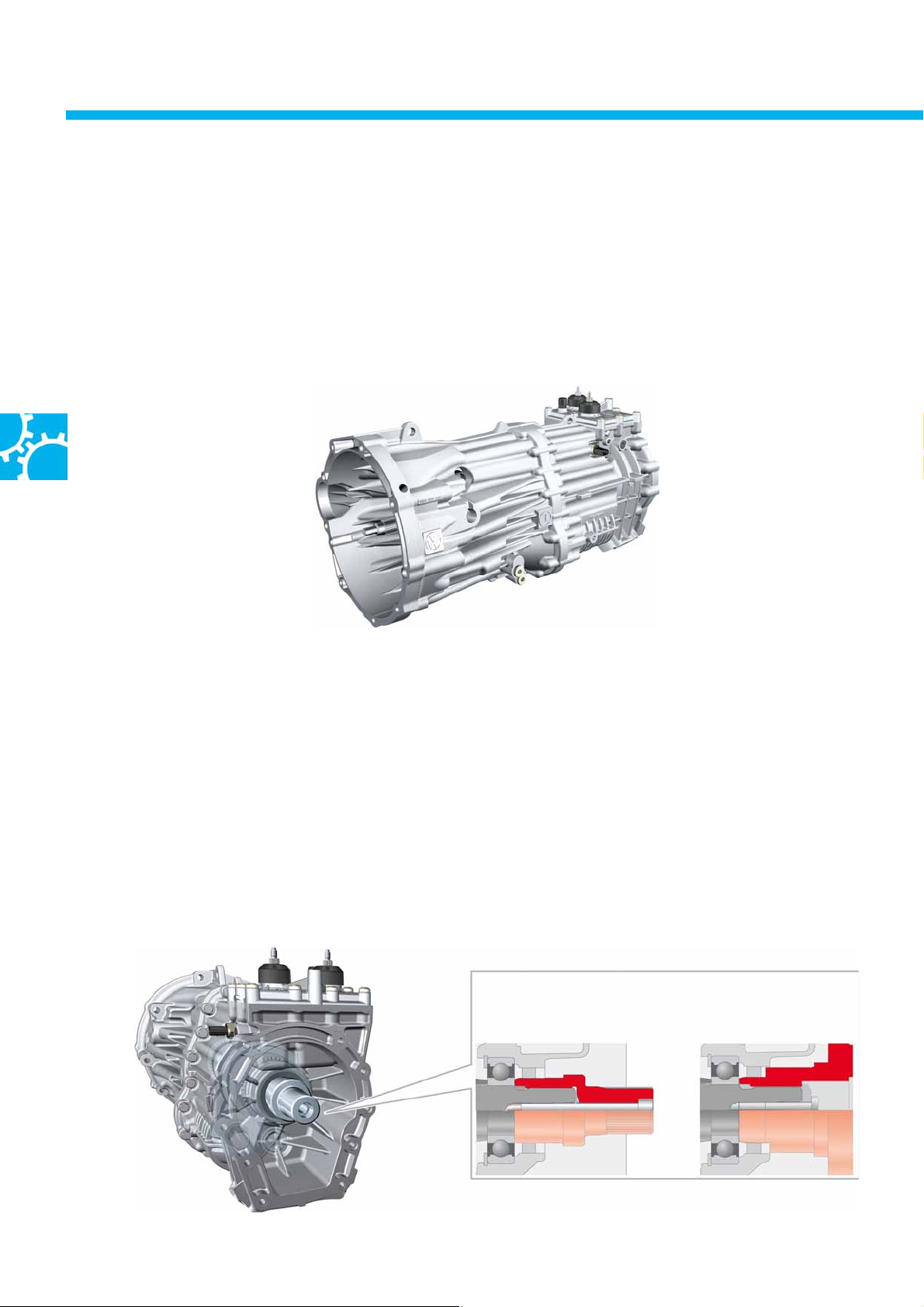

A modern, fully synchronised 2-shaft gearbox of conventional design is used for transmitting power. It has a robust

structure and is designed for the specific requirements of commercial vehicles. The developer and manufacturer of

the 0C6 gearbox is ZF-Getriebe GmbH

● The 6-speed manual gearbox has a uniform housing for all drive variants.

● The same gear ratios are used for all engines.

● The newly-developed 6-speed manual gearbox is exclusively used in the Amarok at present.

S464_052

Gearbox – output adapter

There are two different gearbox variants for the two drive variants of rear-wheel drive and four-wheel drive. These

only differ in the area of the connection to the propshaft in vehicles with rear-wheel drive or the transfer box in

four-wheel drive vehicles.

Four-wheel drive – The torque is transferred from the manual gearbox to the transfer box via an adapter shaft.

The adapter shaft is connected to the gearbox output shaft by means of splines with a light press-fit seat , and is

additionally bolted.

Rear-wheel drive – The torque is transmitted onto the propshaft to the rear axle by means of an output flange. The

output flange is mounted on the splines of the output shaft by means of a light press-fit seat, and is additionally

secured by a bolted connection.

Adapter shaft for

four-wheel drive

Output flange for

rear-wheel drive

Picture corresponds

to adapter shaft for

four-wheel drive

16

S464_062

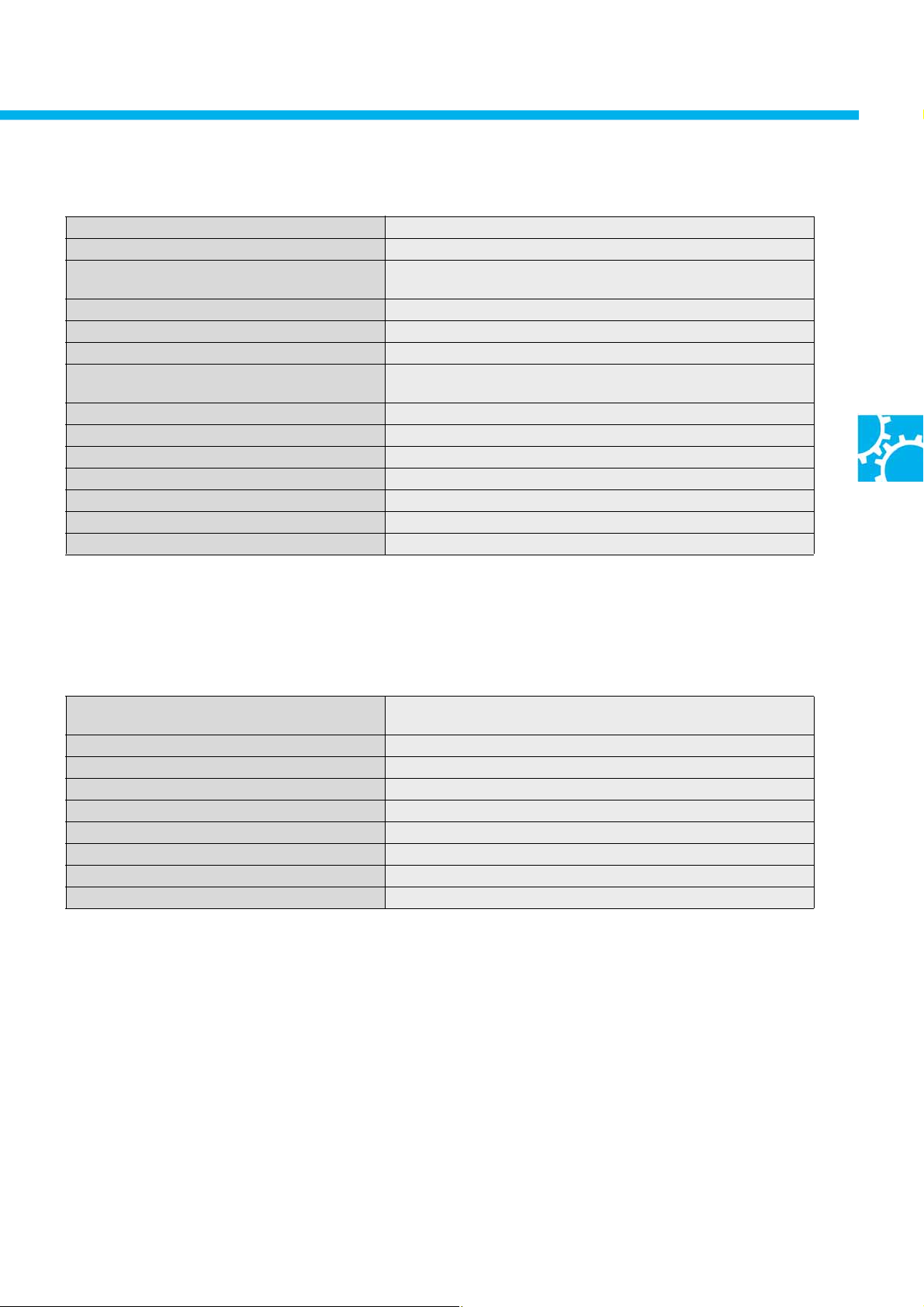

Techn ic al d ata

Gearbox designation 0C6

Gearbox type 6-speed manual gearbox

Gearbox code e.g. MQU (4x2) NFG, NCR

MQV, MJE (4x4) NFF, NCQ, MJE

max. transmissible torque 400 Nm

Shafts Input shaft and coaxial output shaft, layshaft, R-gear reverse shaft

Installation location Longitudinal installation

Use with the engines … 90/120kW TDI engines

118kW TSI engine

Shaft clearance 85 mm

Structural length 690 mm

Weigh t 61 kg

Gear oil specification Synthetic gear oil (SAE 75W-80)

Fill quantity of lifetime fill First fill: 1.5 l, change volume: 1.4 l

Change interval Lifetime fill

Clutch mechanism Hydraulic

Ratios

Gear ratio

1st gear 4.82

2nd gear 2.54

3rd gear 1.49

4th gear 1.0

5th gear 0.76

6th g ear 0.64

Reverse gear 4.37

Spread 7.5 3

The gear ratios in all gearbox variants are the same. 5th and 6th gears are configured as overdrive.

The vehicle's maximum speed is reached in 5th gear and also in 6th gear. 6th gear is an override used for saving

fuel, since the engine rpm is significantly lower.

This reduces CO2 emissions and reduces wear in the engine.

Example: 120kW TDI engine (calculated values)

– Vmax 5th gear = 179.5 km/h at 4135 rpm

– Vmax 6th gear = 178.9 km/h at 3457 rpm

1st gear has a relatively high mechanical advantage, specifically for a commercial vehicle. This is used for moving

off without overloading the clutch when the vehicles are heavily loaded and/or towing a trailer.

17

6-speed manual gearbox 0C6

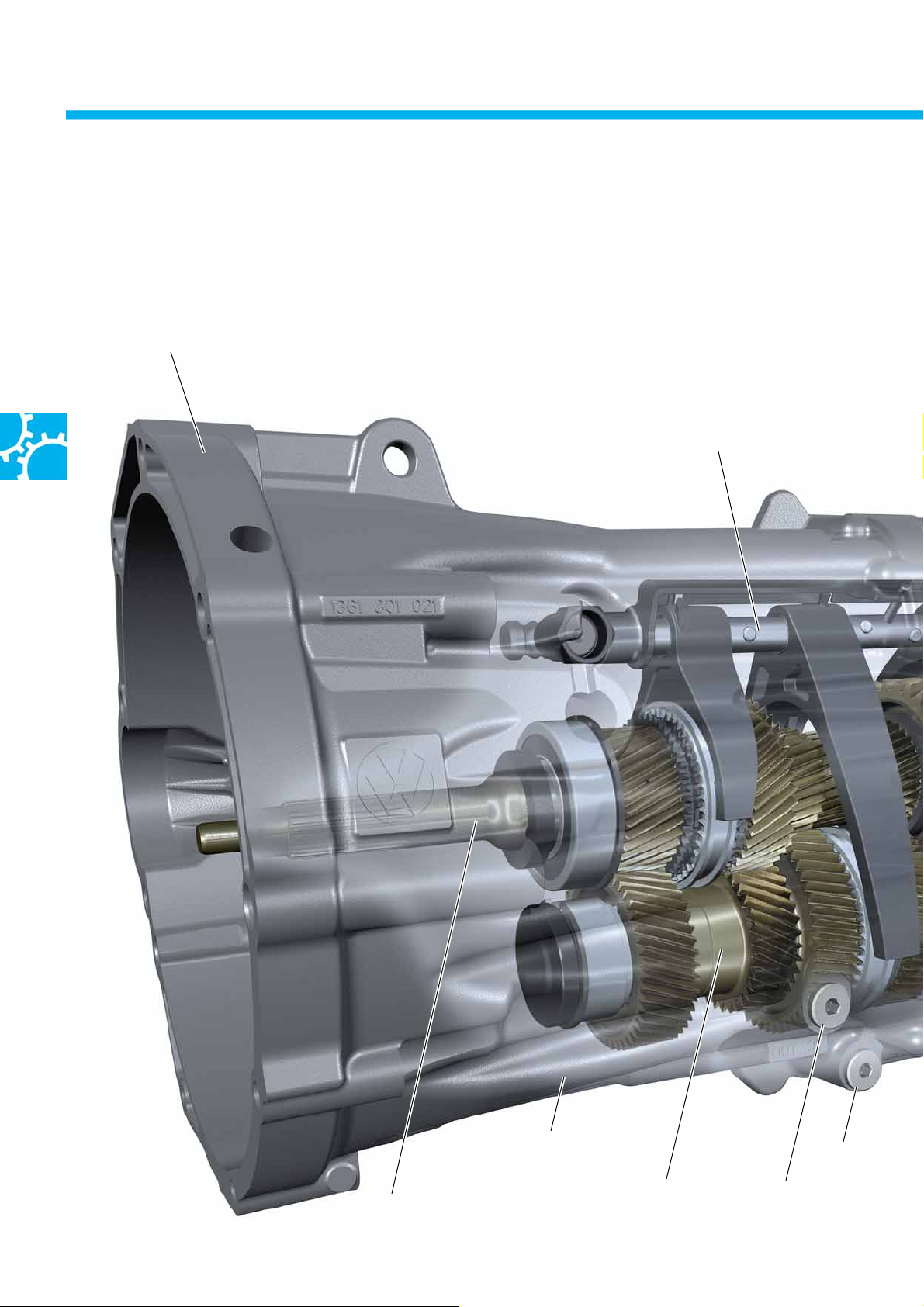

The gearbox structure and function

The two-part gearbox housing is made from aluminium diecastings.

Housing flange

for connection to the engine

Centre selector shaft

18

Input shaft

Front gearbox housing

Laysha ft

Oil drain plug

Oil filler plug

Loading...

Loading...