Volkswagen 1.4 16v Polo 2003 Owner's Manual

The 1.4-ltr. 16V 55kW Engine

with roller-type cam follower

Design and Function

S

196

.

o

N

E

M

M

A

R

G

O

R

P

Y

D

U

T

S

-

F

L

E

Whether it’s a matter of better fuel economy, higher engine output or lower exhaust emissions - the

demands on engines are constantly increasing.

This presents our engineers with new tasks, with the result that the Volkswagen engine range is constantly

growing.

Example: weight saving

During development, the weight of the new 1.4-ltr. 16V 55kW engine was reduced by about 10 kg by

modifying its design.

This self-study programme explains the technical

innovations in our engine range using the 1.4-ltr.

16V 55kW engine as an example.

Apart from minor differences in the engine

mechanics, the 1.6-lr. 16V 88 kW engine for the

Polo GTI will have these new features, too.

The Self-Study Programme

is not a Workshop Manual.

2

196_168

These differences arise out of the various technical demands on the engines and are described

in this Self-Study Programme.

New Importan

t

Precise instructions for testing, adjustment and

repair can be found in the appropriate Workshop

Manual.

At a glance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Valve actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sealing flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Con rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Engine management . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Static high-voltage distribution . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hall sender G40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Self-diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Special-purpose tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3

Introduction

One of a “new generation”

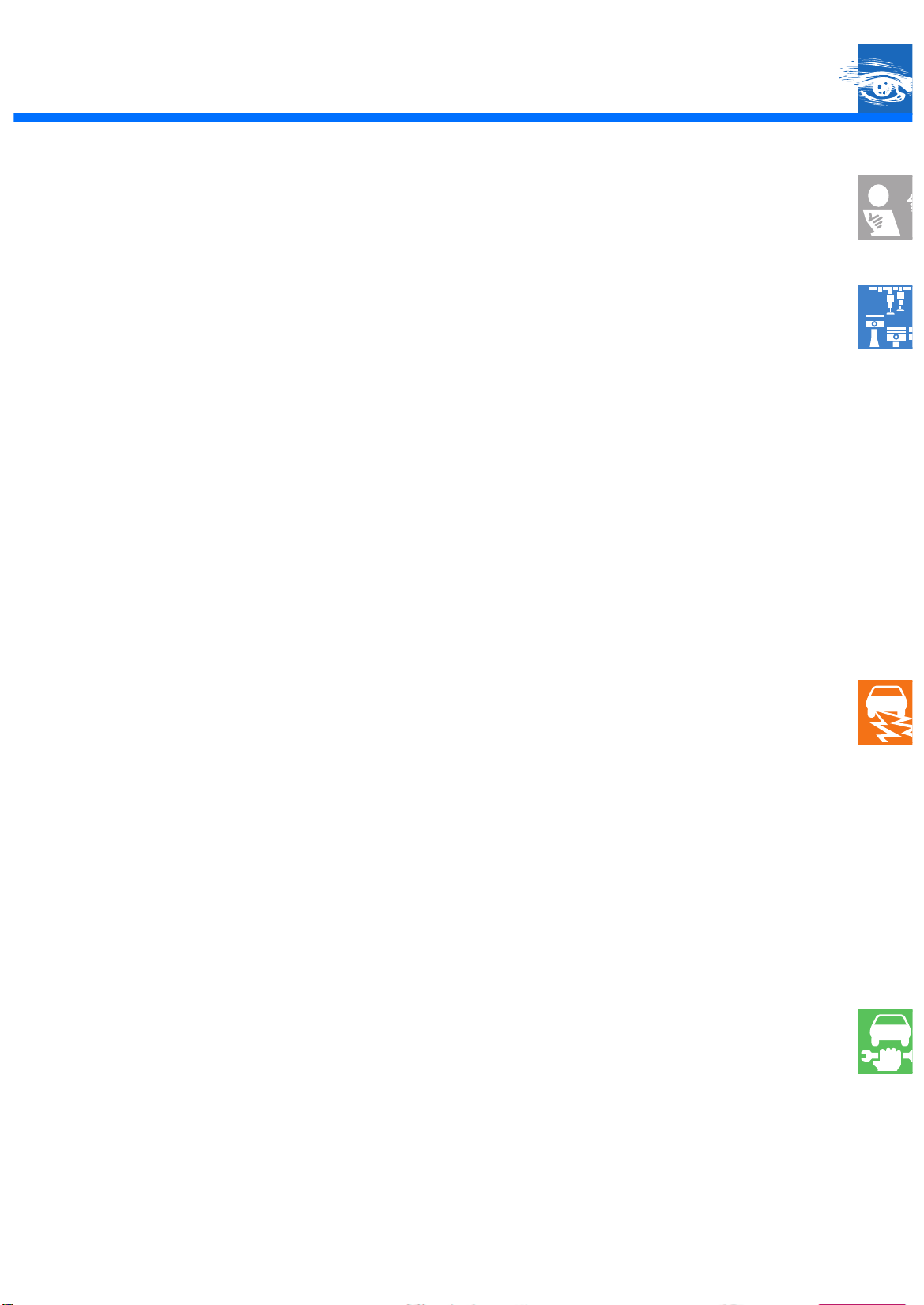

The 1.4-ltr. 16V 55kW engine is the first of a new

generation of engines featuring roller-type cam

followers.

It is fundamentally different from

the 1.4-ltr. 16V 74kW engine with bucket tappets.

The main differences are:

- the die cast aluminium crankcase

- the cylinder head, where only the existing

valve clearance and angle have been

adopted.

New and advanced developments include:

the plastic intake manifold

the cylinder head and

camshaft housing

valves are activated by

roller-type cam followers

the crankcase is made of

die cast aluminium

the duocentric oil pump

196_068

The overall effects of these design modifications are:

- significant reduction in fuel consumption,

- performance on a par with

predecessor models,

- weight savings and

- compliance with the more stringent

exhaust gas

limit values now in effect in Germany.

the exhaust manifold

the Magneti Marelli 4AV

engine management

system

4

Specifications

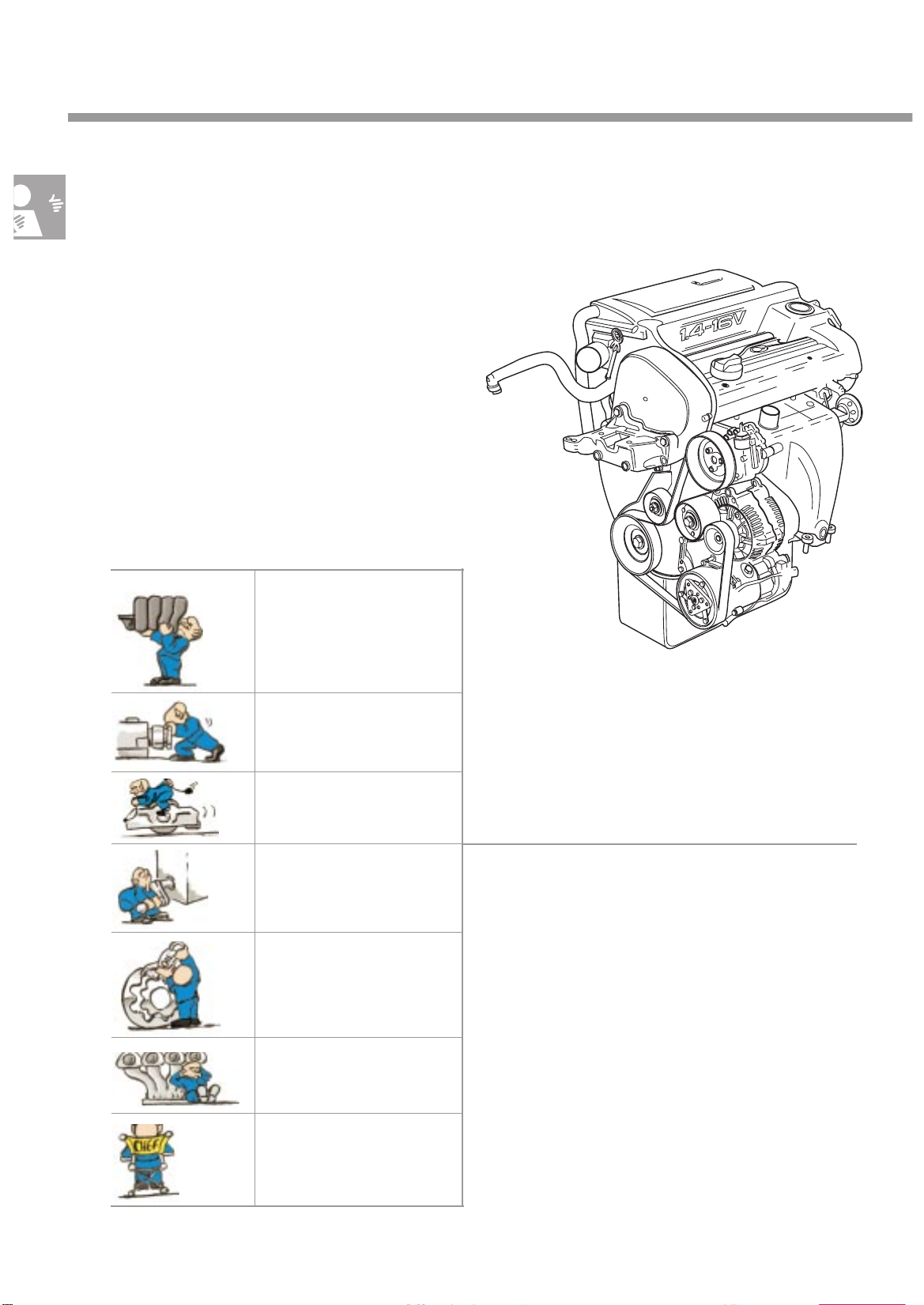

1.4-ltr. 16V 55kW engine

The 1.4-ltr. engine develops 128Nm of torque at

3200rpm. Maximum output is 55kW at

5000rpm.

1.6-ltr. 16V 88kW engine

By comparison, the 1.6-ltr. engine develops

148Nm of torque at 3400rpm and a maximum

output of 88kW at 6200rpm.

Torque

[Nm]

Torque

[Nm]

Output

[kW]

196_070

Engine speed [rpm]

Output

[kW]

1.6-ltr. engine1.4-ltr. engine

Engine code AHW

AKQ exhaust emission level D3

Displacement [cm

3

] 1390 1598

Bore/stroke [mm] 76.5 / 75.6 76.5 / 86.9

Compression ratio 10.5:1 10.6:1

Mixture preparation

Magneti Marelli 4AV Magneti Marelli 4AV

Engine management system

Fuel [RON] 95 / 91 98 / 95

Exhaust gas post-treatment Lambda control,

main catalytic converter for

MVEG-A II for the AHW engine

additional micro catalytic converter for exhaust emission level

D3 for the AKQ engine

AJV exhasut emission level D3

Lambda control,

primary and

main catalytic converters

for exhaust emission level D3

196_088

Engine speed [rpm]

The knock control lets you run the 1.4- ltr. and 1.6-ltr. engines on RON 91 and RON 95 fuel respectively. This may result in a slight loss of power and torque.

5

Engine Mechanics

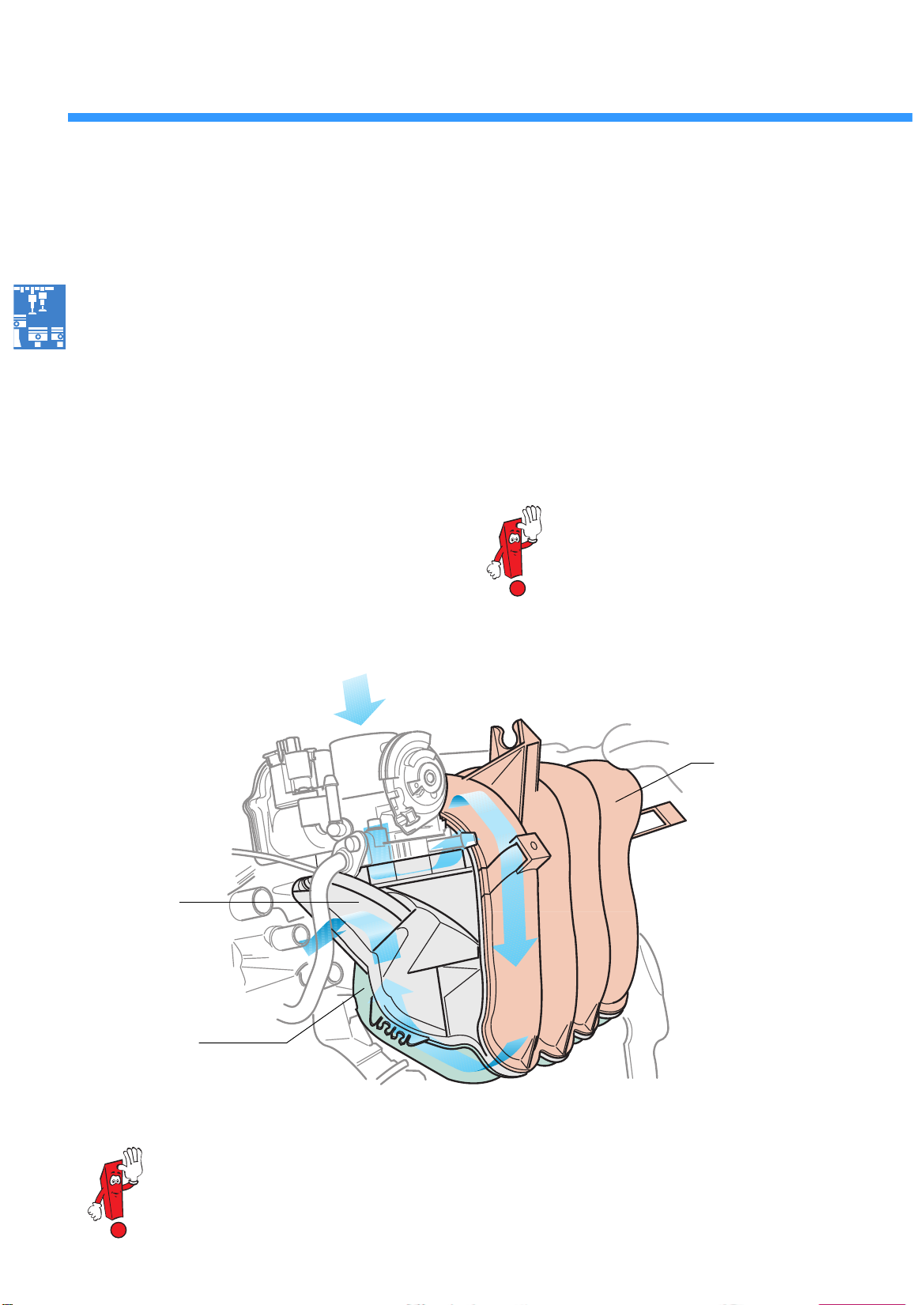

The plastic intake manifold

consists of three component parts which are welded together. The material is made of highgrade polyamide which is resistant to temperatures of up to 140°C for short periods of time.

The use of plastics has made it possible to keep

the weight of the intake manifold down to three

kilograms. As a result, the intake manifold is roughly 36% lighter than a comparable intake manifold made of aluminium.

The plastic intake manifold also has a very

smooth surface, and this improves the induced

air flow.

induced air

The following components are mounted in the

plastic intake manifold:

- the injectors,

- the fuel distributor,

- the throttle valve control unit and

- the intake manifold pressure sender and the

intake air temperature sender.

The air filter housing is secured to the plastic intake manifold by two screws.

The max. permissible tightening torque is

3.5Nm.

Middle section

Upper/lower parts of

intake manifold

An aluminium intake manifold is used for the 1.6-ltr. 16V 88kW engine.

It has been adapted to the engine’s requirements.

Upper shell

The plastic intake manifold

of the 1.4-ltr. engine

196_071

6

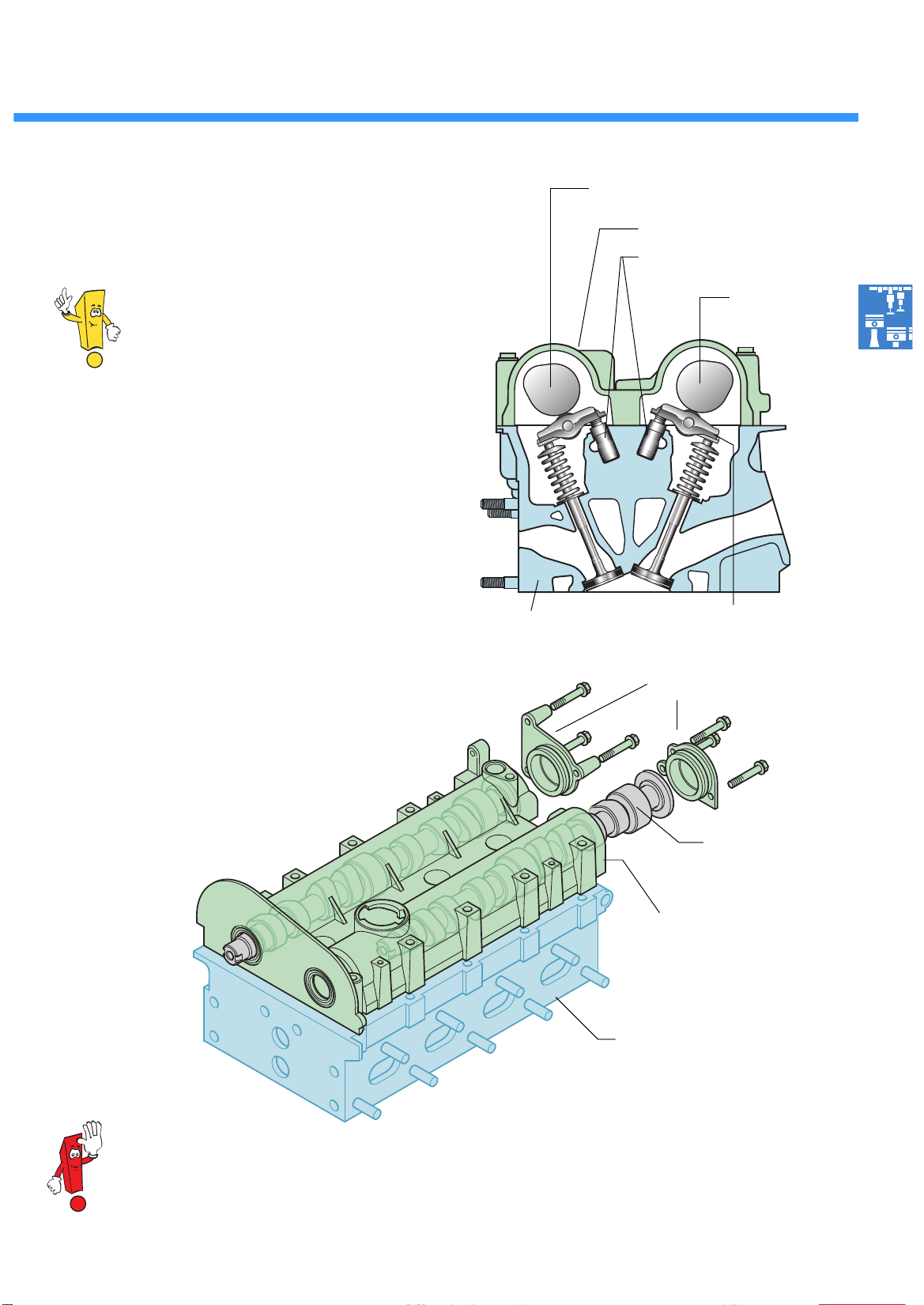

Valve gear

is accommodated in the cylinder head and

camshaft housing.

The camshaft housing is by and large

identical to the cylinder head cover

which was previously used as standard.

What’s new is that the camshafts are

now inserted into the housing. The bearing

covers and camshaft housing limit the axial clearance of the camshafts.

The camshafts run in three bearings.

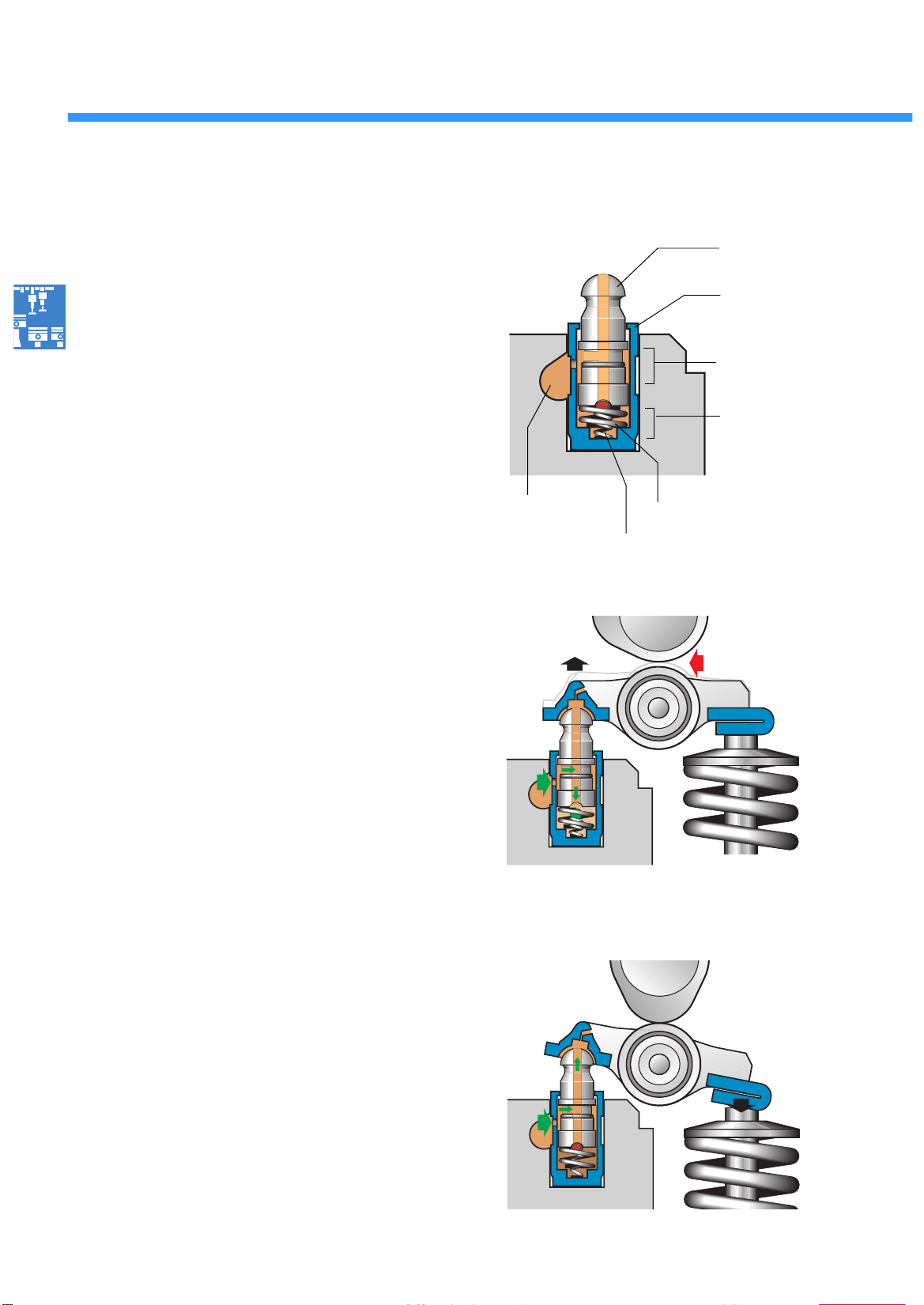

The valve assembly comprising valves, rollertype cam followers and hydraulic support elements

is located in the cylinder head.

Exhaust

camshaft

Camshaft housing

Hydraulic support element

Intake

camshaft

196_018

Roller-type cam followerCylinder head

Bearing cover

Camshaft housing

196_075

Cylinder head

Inserted camshaft

The gasket between the camshaft housing and the cylinder head is in the form of a fluid seal.

Do not apply the sealant too thickly, since this may cause excess sealant to enter the oil drillings

and damage the engine.

7

Engine Mechanics

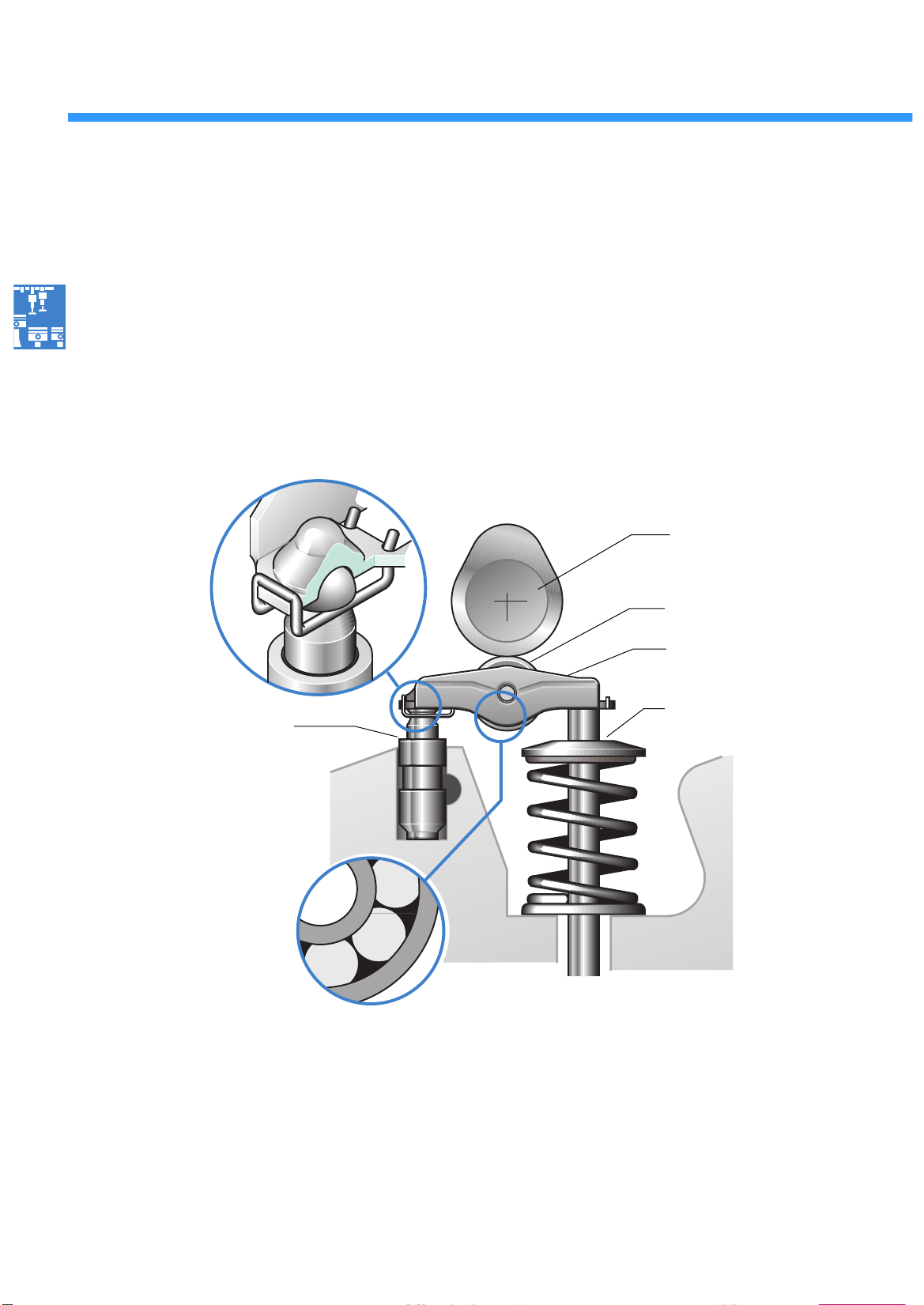

Valve activation

With this engine generation, the valves are activated via a roller-type cam follower with a

hydraulic

support element.

Advantages:

- less friction

- fewer moving masses.

Conclusion:

Less engine power is required to drive the camshafts.

support element

Low-friction

roller bearing

Camshaft

Cam roll

Roller-type

cam follower

ValveHydraulic

196_010

Design

The roller-type cam follower comprises a sheetmetal moulding acting as a lever and a cam roll

with a roller bearing.

The cam follower is clipped onto the support element and seated on the valve.

8

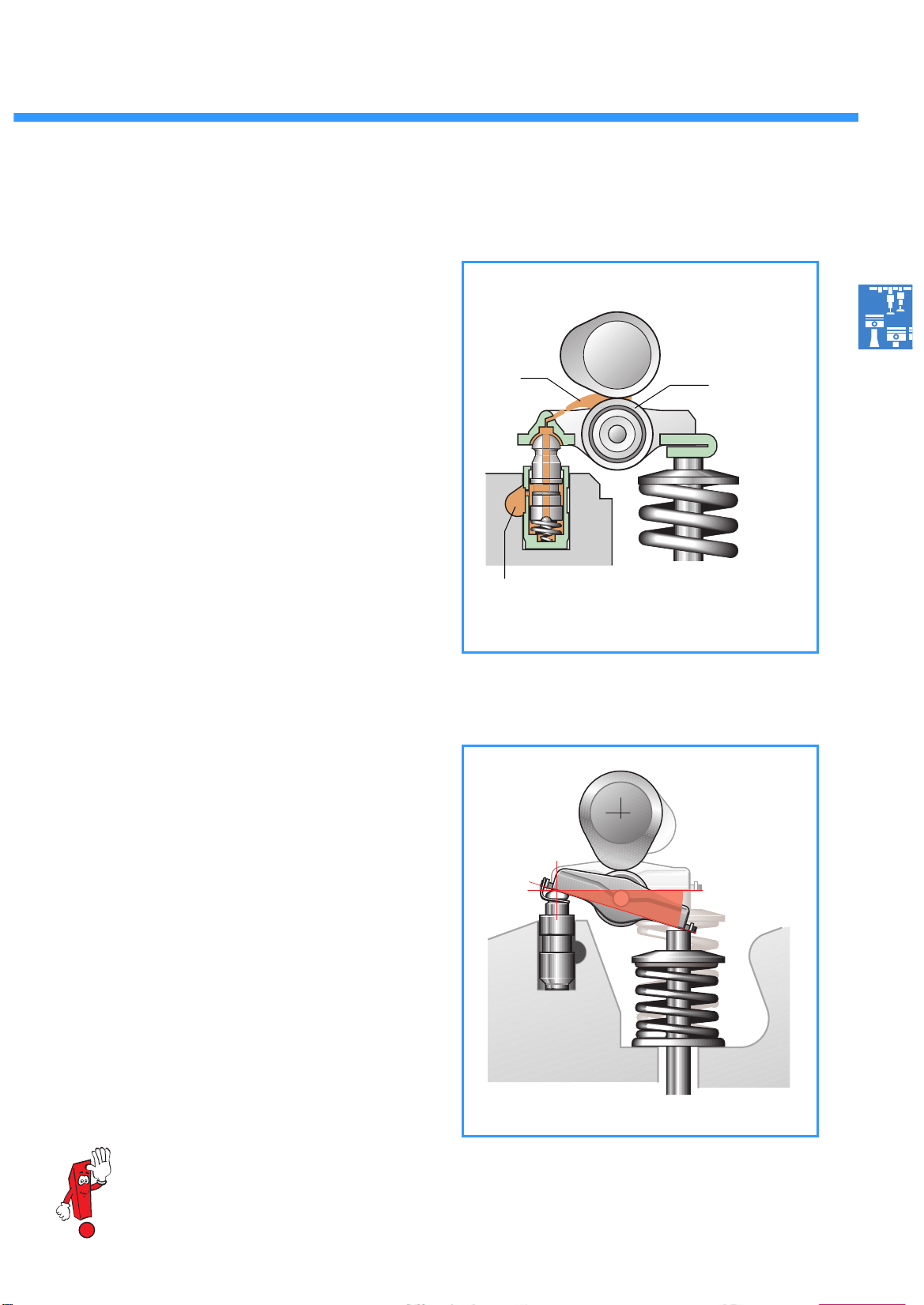

The hydraulic support element has the same

function as the hydraulic bucket tappet. It serves

as a hydraulic valve lifter and support for the

roller-type cam follower.

The lubrication system

Lubricant flows between the hydraulic support

element and the roller-type cam follower as well

as between the cams and the cam roll along an

oil duct integrated in the support element.

Oil is injected into the cam roll through a drilling

in the roller-type cam follower.

Oil

Cam roll

Function

The support element serves as a pivot for the roller-type cam follower. The cam contacts the cam

roll and presses the lever down. The lever in turn

activates the valve.

A high valve lift is achieved with a relatively

small cam due to the fact that the leverage between the cam roll and support element is smaller

than between the valve and support element.

Lubricant duct

196_009

It is not possible to inspect the hydraulic support elements.

196_011

9

Engine Mechanics

The hydraulic support element

serves as a support for the roller-type cam

follower and hydraulic valve lifter.

Design

The support element is connected to the oil

circuit. It comprises the following elements:

- a piston,

- a cylinder and

- a piston spring.

A small ball, in combination with a pressure

spring integrated in the lower oil chamber,

makes up the one-way valve.

Hydraulic valve lifter

If valve backlash occurs, the piston spring forces

the piston out of the cylinder until the cam roll

makes contact with the cam. When the piston is

pressed out of the cylinder, the oil pressure in the

lower oil chamber drops.

The one-way-valve opens and surplus oil flows

into the oil chamber.

The one-way-valve closes when the pressure

between the lower and upper oil chambers has

been equalised.

Oil inlet

Piston with

drilling

Cylinder

Upper

oil chamber

Lower

oil chamber

196_014

Piston spring

One-way valve

Valve clearance

196_016

10

Valve lift

When the cam contacts the cam roll, the pressure inside the lower oil chamber rises because

the oil here cannot be compressed. The piston

cannot be forced any further into the cylinder.

Thus, the support element acts as a rigid support

for the roller-type cam follower.

The inlet or exhaust valve opens.

196_017

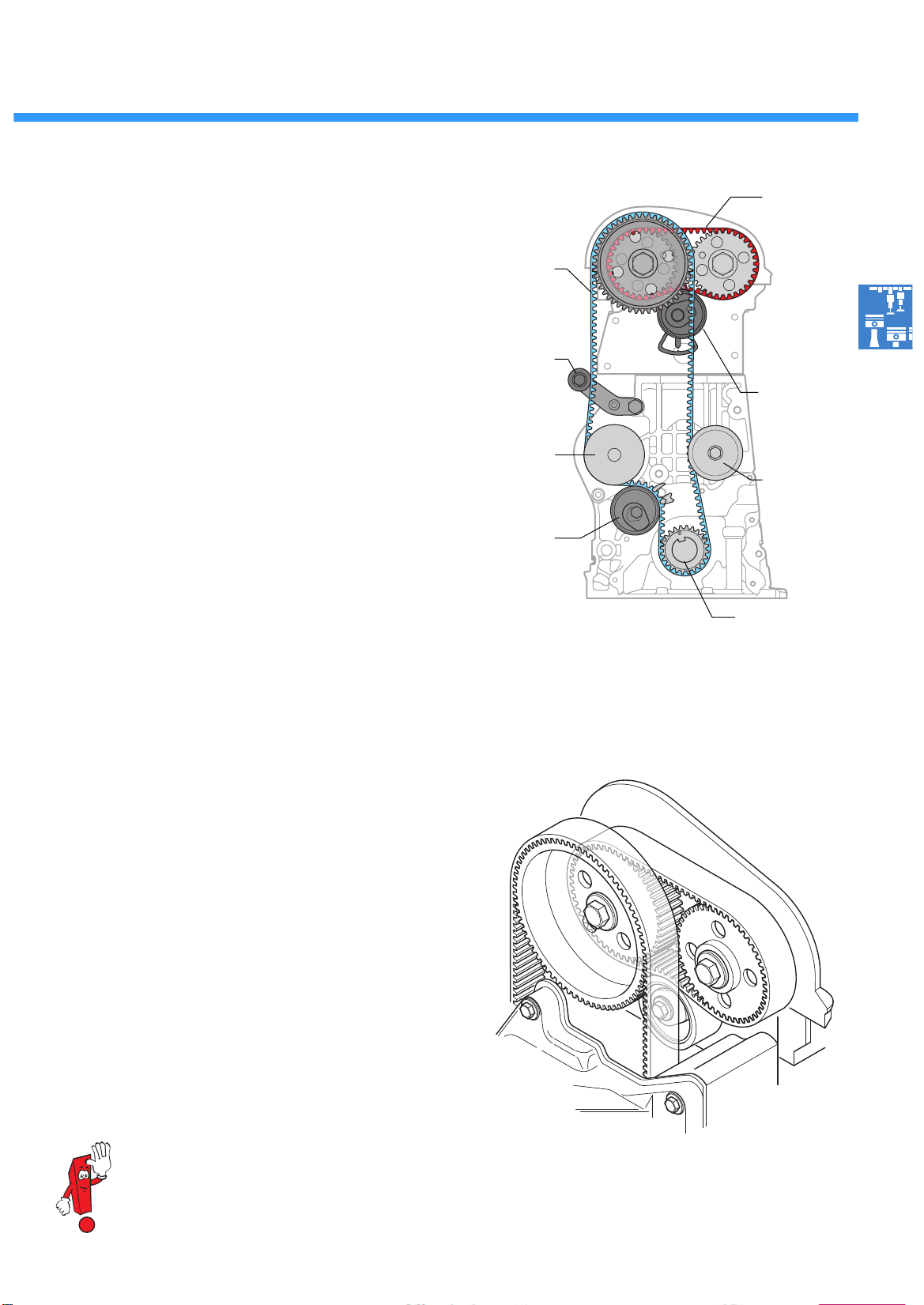

The toothed belt drive

The toothed belt drive is divided into a main

drive and a connecting drive on account of the

small overall width of the of the cylinder head.

Main drive

The coolant pump and the intake camshaft are

driven by the crankshaft by means of a toothed

belt integrated in the main drive. An automatic

tension pulley and two deflection pulleys reduce

toothed belt fluctuation.

Main drive

Deflection

pulley

Belt pulley

Coolant pump

Tension pulley

Main drive

Connecting drive

Tension pulley

Connecting drive

Deflection

pulley

196_021

Belt-driven

crankshaft gear

The connecting drive

is located outside the cylinder head.

The exhaust camshaft is driven by the

intake camshaft by means of a second toothed

belt integrated in the connecting drive.

Again, an automatic tension pulley reduces toothed belt fluctuation.

You can find exact instructions for adjustment the camshaft timing in the Workshop Manual.

196_024

11

Loading...

Loading...