Volkswagen Crafter User Manual

Service Training

Self-study Programme 370

The Crafter

Electrical system

Design and function

Commercial

Vehicles

Innovations in automotive engineering are also taking

place in the commercial vehicle segment.

The Volkswagen Crafter is therefore fitted with

extensive electrical equipment and with electrical and

optical data bus systems.

In comparison with the predecessor model,

these systems enable familiar electrical

functions to be actuated in different ways and

new functions to be implemented.

This self-study programme is intended to explain

these functions and help you to understand

their interconnections better.

The self-study programme shows the design and

function of new developments.

The contents will not be updated.

2

S370_087

NEW Important

Note

For current testing, adjustment and repair

instructions, refer to the relevant

service literature.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Vehicle electrical system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ignition lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Anti-theft system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Dash panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Convenience systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Tachograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Special control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Test yourself . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3

Introduction

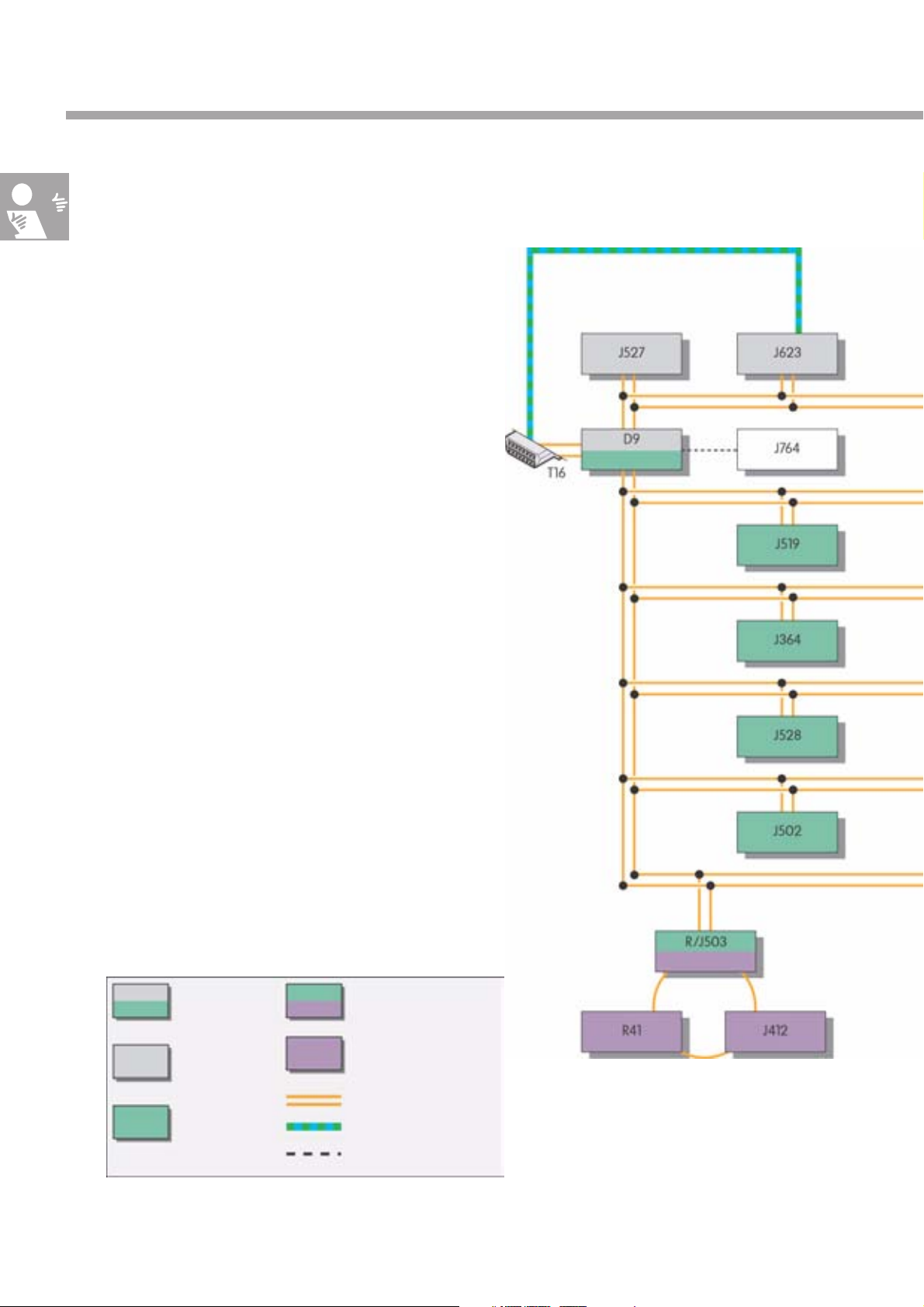

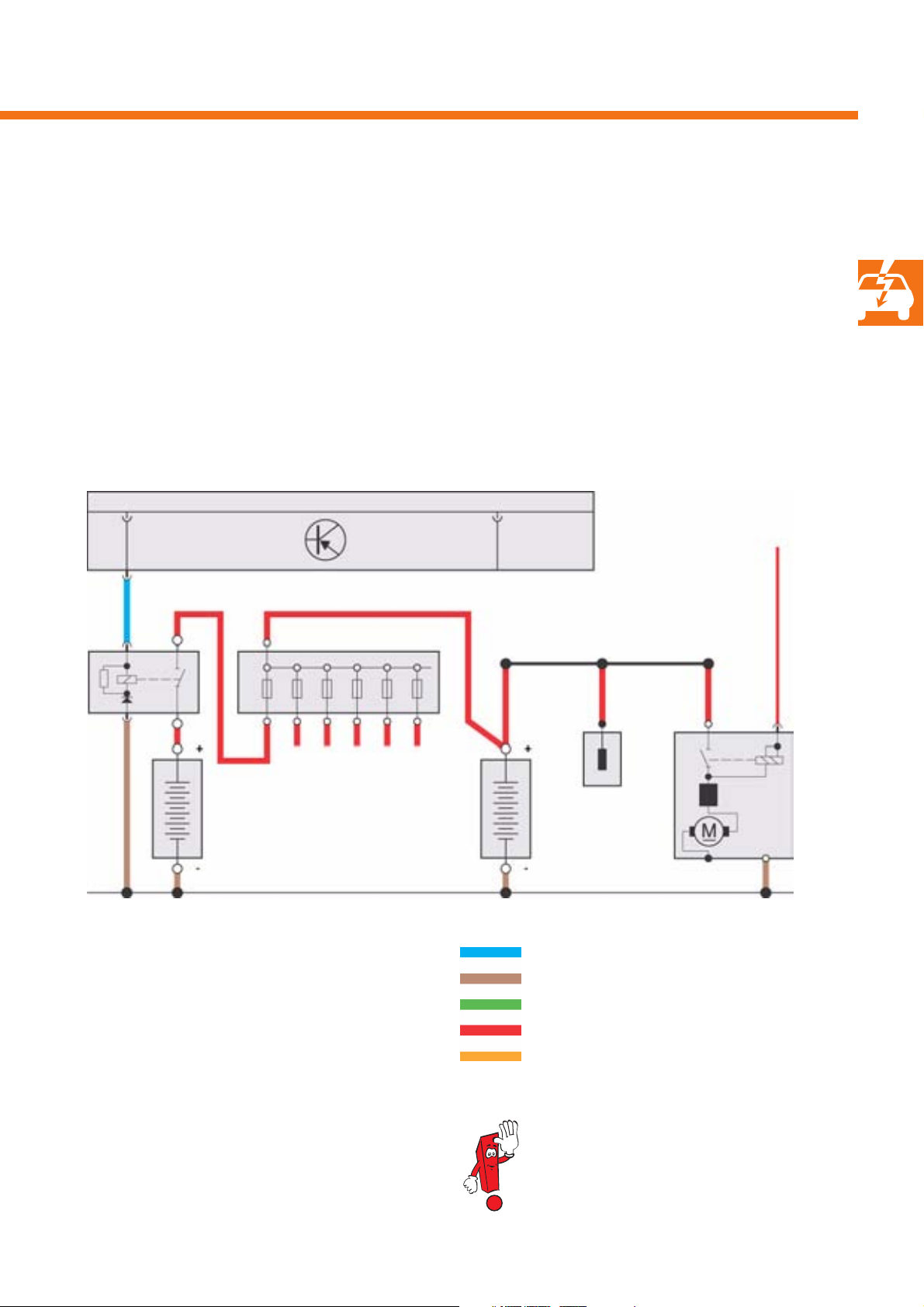

Data bus systems

Data bus networking

The Volkswagen Crafter's control units are networked

via the CAN data bus and the MOST data bus.

Networking enables data to be exchanged between

the individual control units.

Instead of using conventional (discrete) cable

connections, the data are transmitted via the data

buses in digital form as an electrical signal or

as a light signal. This makes it possible to make data

available to several control units.

The CAN data bus is sub-divided into three individual

systems, the CAN drive data bus, the CAN

convenience data bus and the CAN diagnostic data

bus.

All three bus systems are connected to each other via

the electronic ignition lock D9, and are therefore able

to exchange information.

Diagnostic

interface

CAN drive

data bus

CAN

convenience

data bus

MOST data bus

interface

MOST data bus

Data bus

K-wire

Serial data cable

S370_080

4

Legend

D9 Electronic ignition lock

E16 Heater/heat output switch

J104 ABS control unit

J234 Airbag control unit

J285 Control unit in dash panel insert

J301 Air conditioning system control unit

J345 Trailer detector control unit

J364 Auxiliary heater control unit

J386 Driver door control unit

J412 Mobile telephone operating electronics control unit

J446 Parking aid control unit

J502 Tyre pressure monitor control unit

J503 Control unit with display for radio and navigation

J514 Electronic manual gearbox control unit

J519 Onboard supply control unit

J527 Steering column electronics control unit

J528 Roof electronics control unit

J604 Auxiliary air heater control unit

J621 Tachograph control unit

J623 Engine control unit

J764 Electronic steering column lock control unit

J819 Control unit for middle of dash panel

J820 Control unit for programmable special functions

S370_001

R Radio

R41 CD changer

T16 16-pin connector (diagnostic connection)

5

Introduction

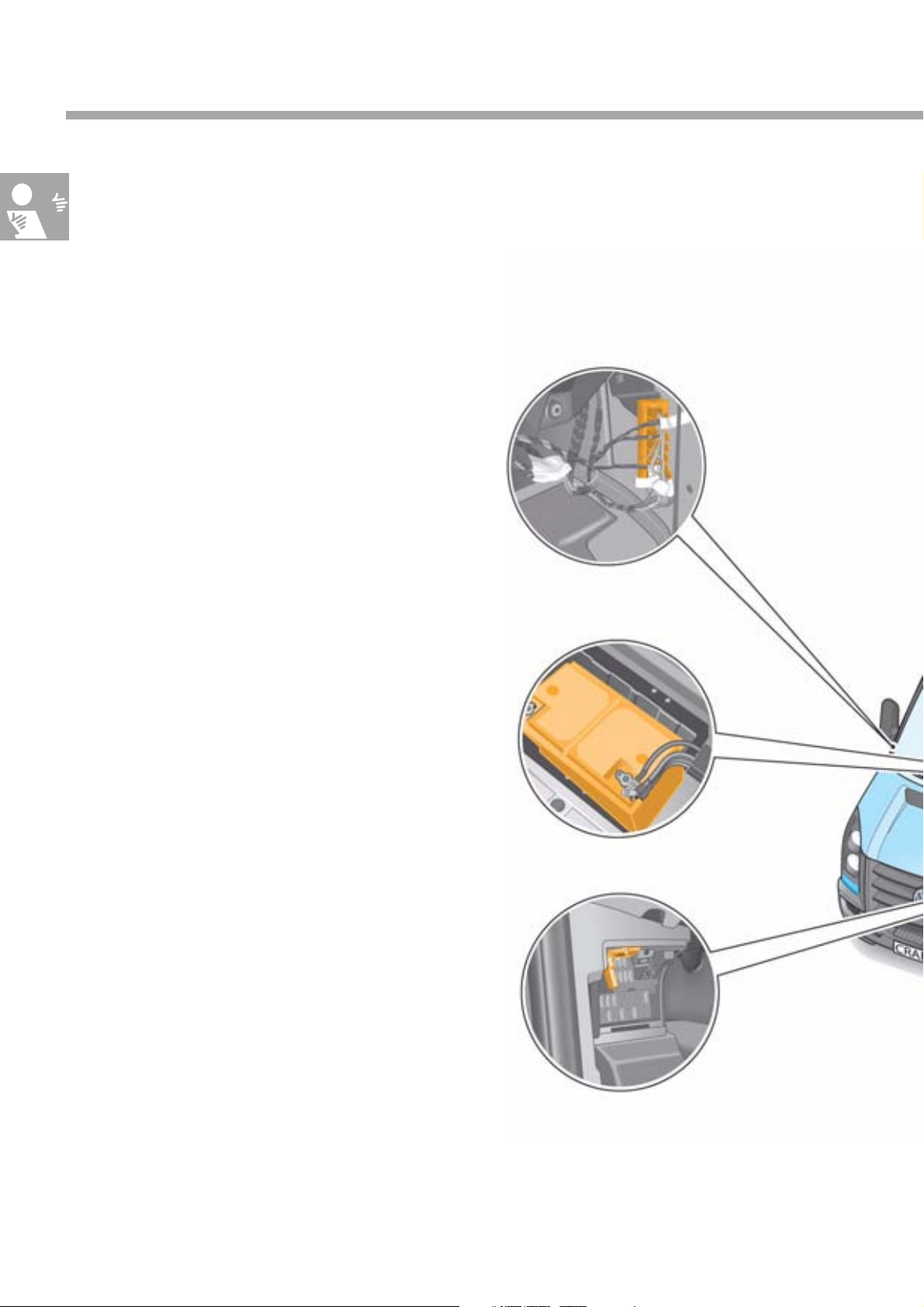

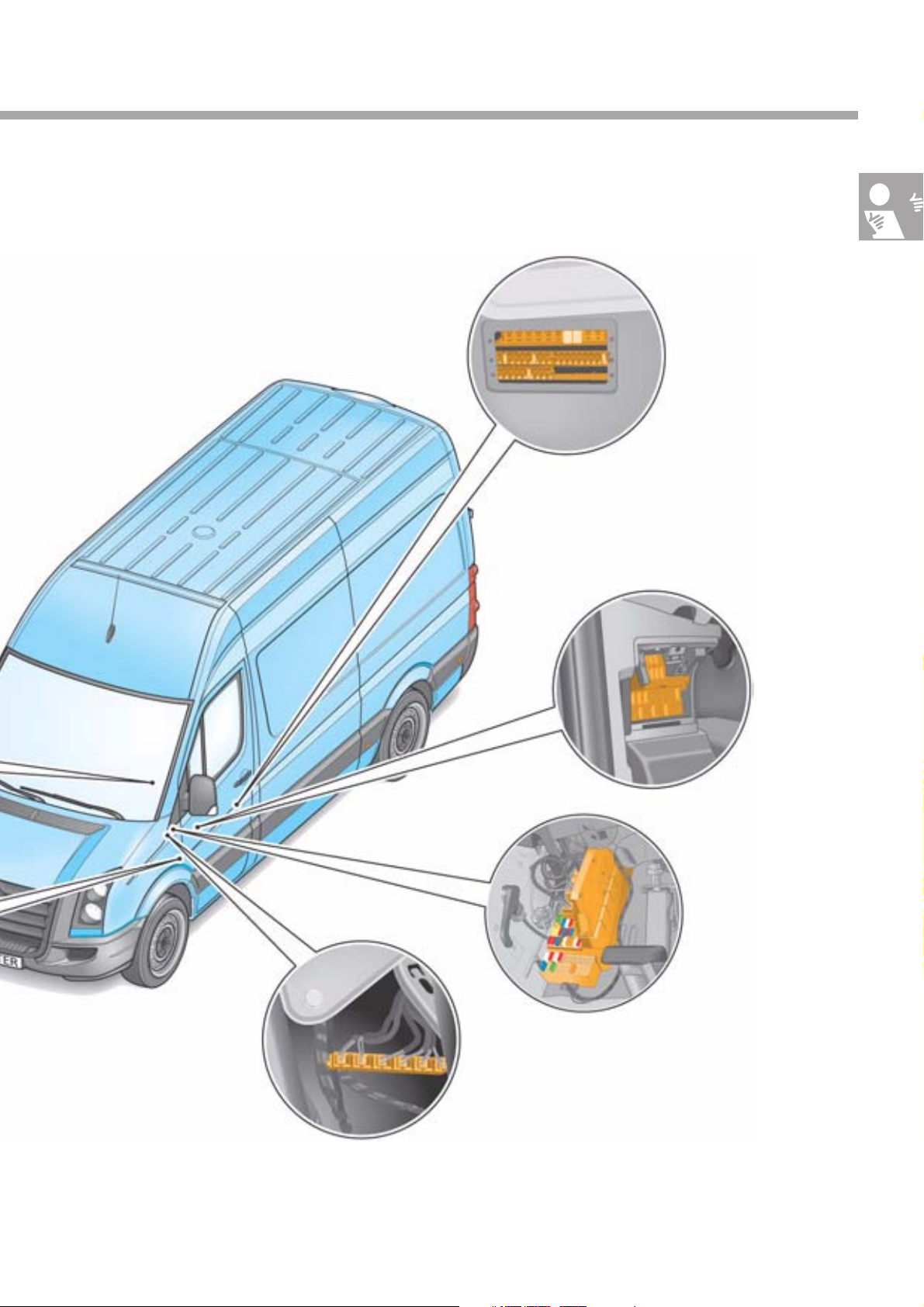

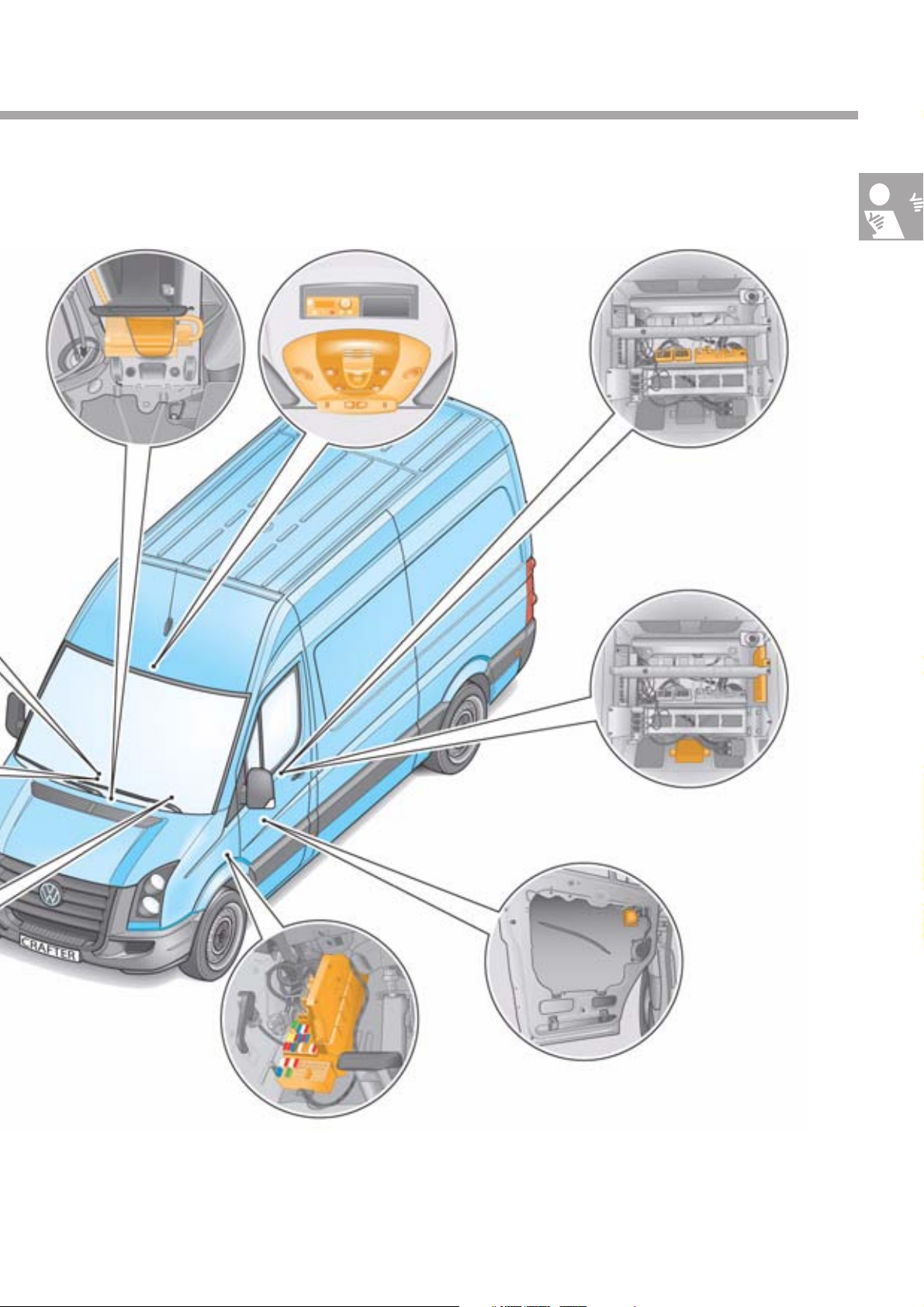

Installation locations of the electrical components

Overview of installation locations

The vehicle electrical system has a decentralised

structure; the fuse and relay installation locations are

therefore in different locations throughout the vehicle.

Junction boxes 2 and 3 for

bus systems,

on the right A pillar

Fuse holder (SA),

on right-hand side of battery, visible only following

removal

Connector (T16, diagnostic connection),

on the left A pillar

6

Fuse holder D (SD),

beneath the driver's seat

Fuse holder B (SB),

left A pillar

Junction box 1 for bus systems,

beneath the front left dash panel

Fuse holder C (SC),

on the left A pillar

S370_002

7

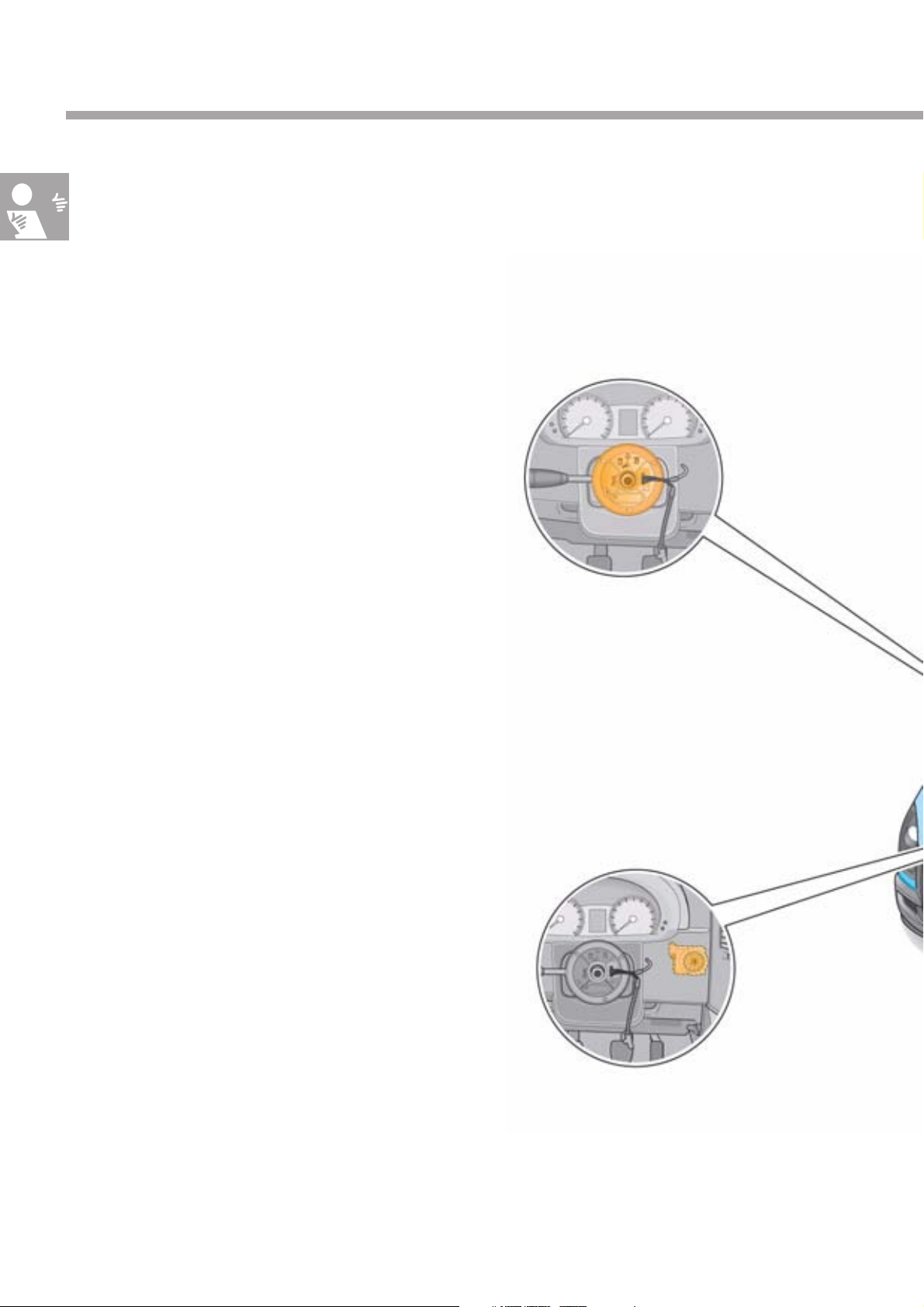

Introduction

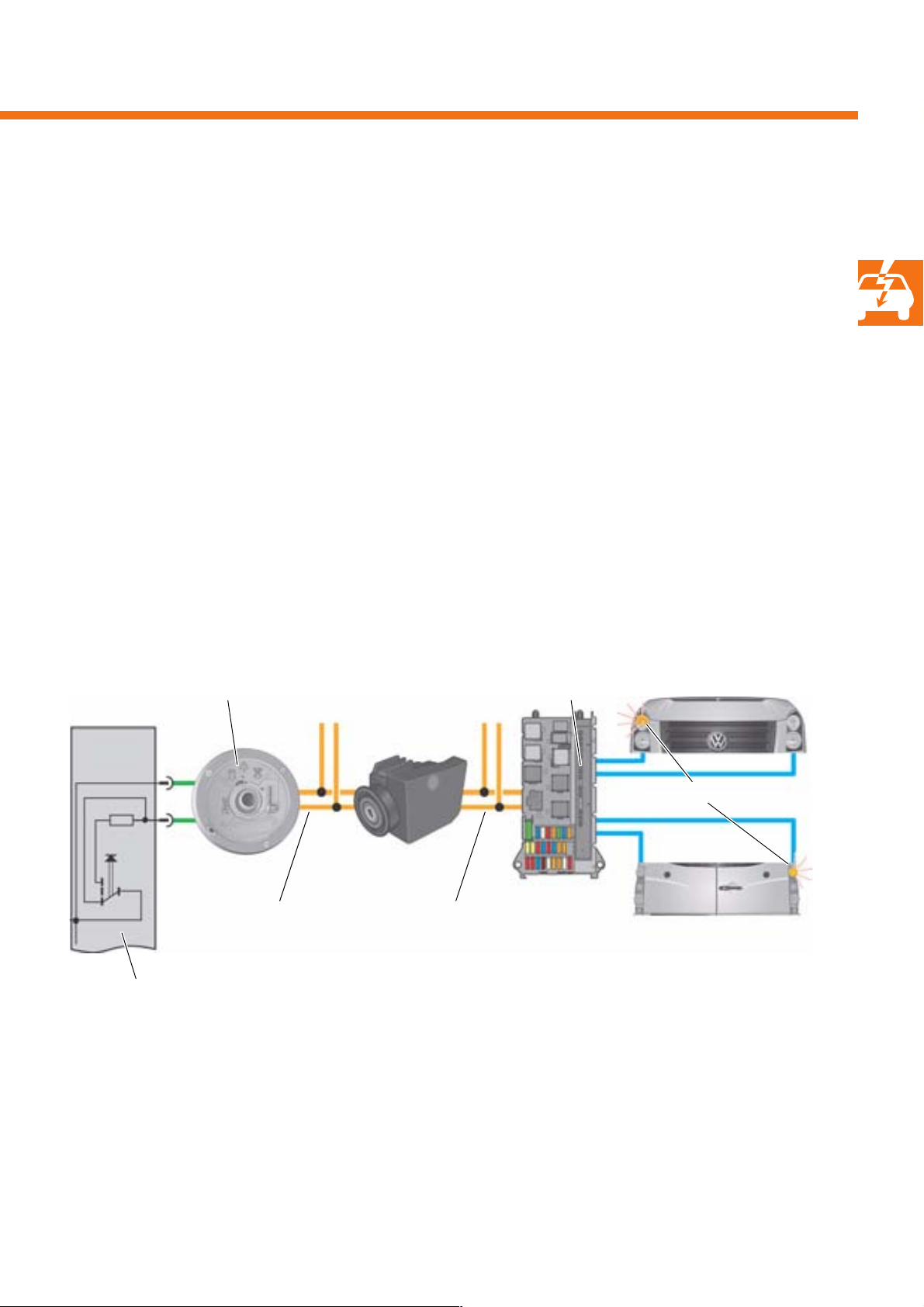

Installation locations of the control units in the CAN drive data bus

Control units and installation

locations

The adjacent illustration shows the control units which

take part in CAN drive data bus data communication

and their installation locations.

Data are transmitted at a speed of

500 kbit/s. Transmission is carried out via the

CAN high cable and the CAN low cable.

CAN high cables are green/white and the

CAN low cables are green.

To ensure reliable data transmission,

the CAN cables are twisted together.

The CAN drive data bus is not 1-wire-capable;

if a CAN cable fails, no data transmission is possible.

Steering column electronics control

unit J527,

on the steering column

Electronic ignition lock D9,

on the right next to the steering wheel

8

ABS control unit J104,

on the left in the engine compartment

Engine control unit J623,

on the left in the engine

compartment

S370_004

9

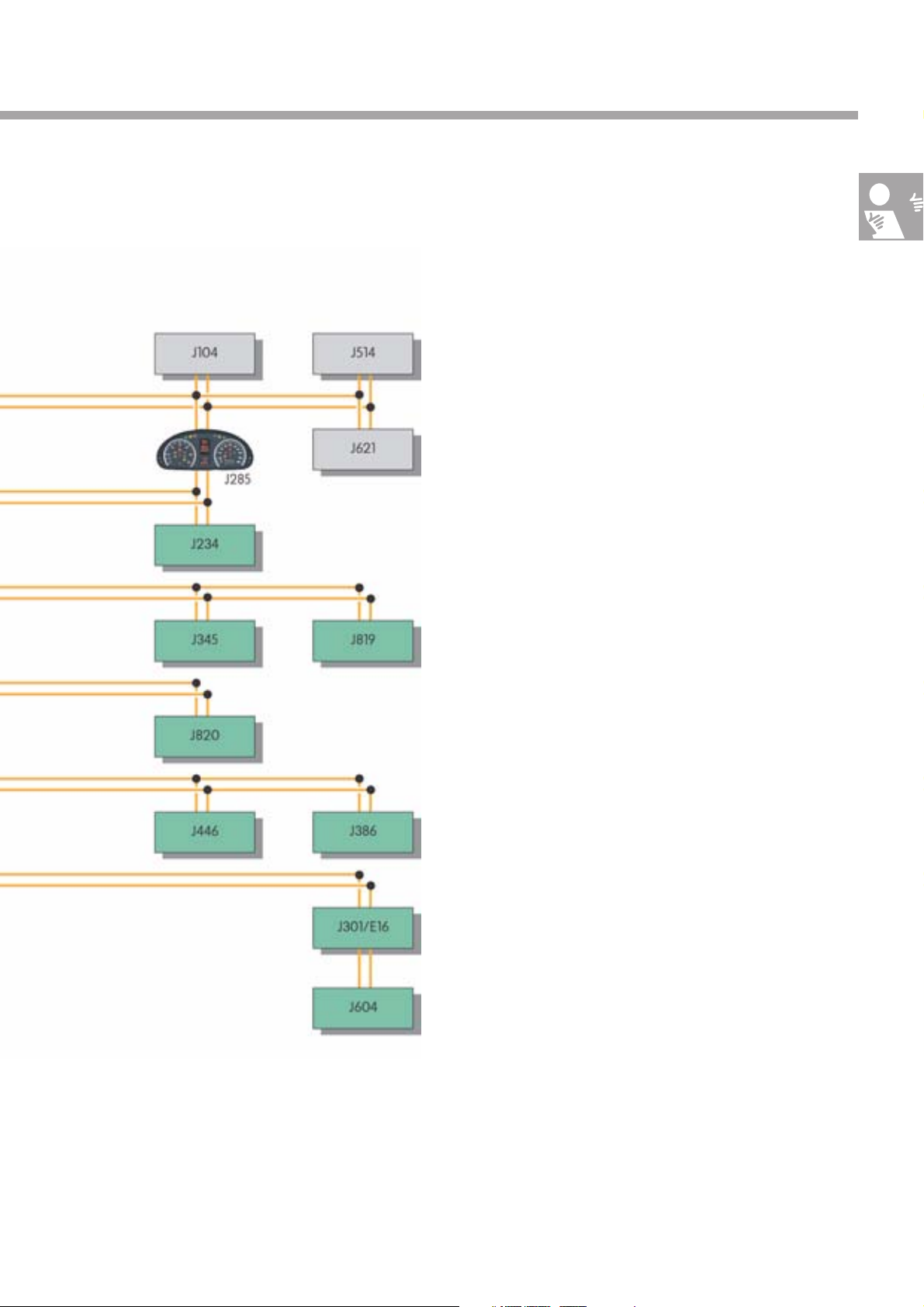

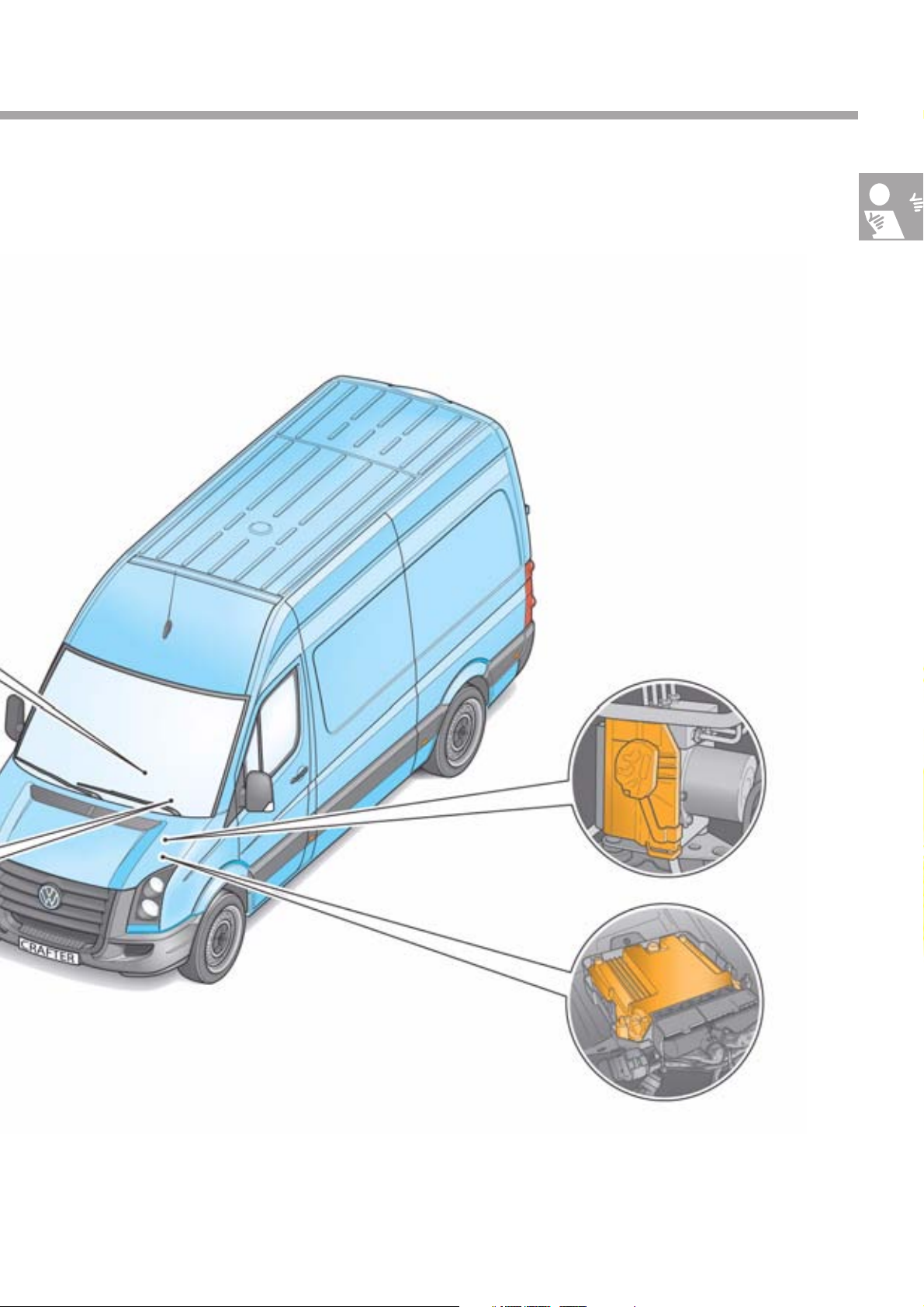

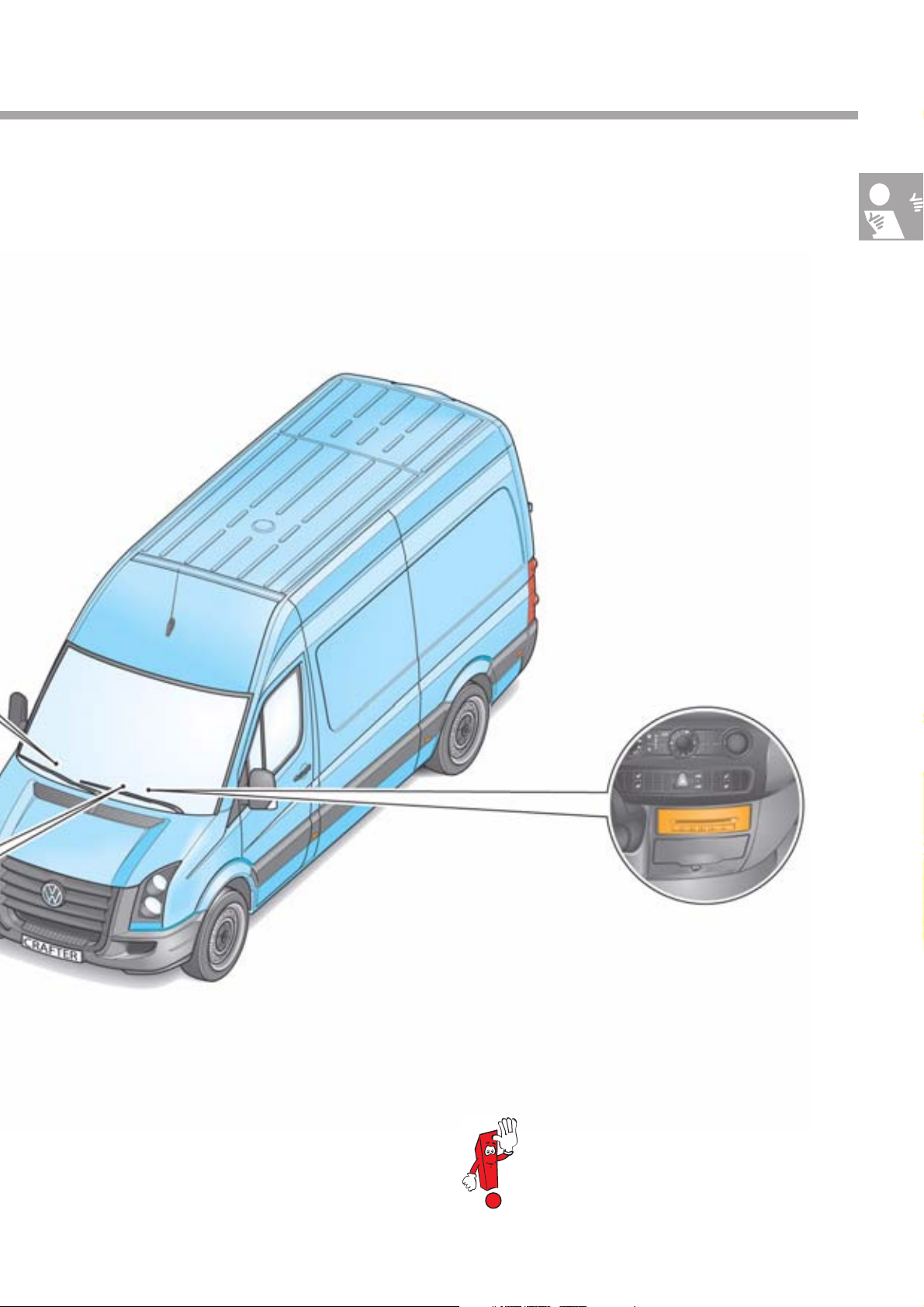

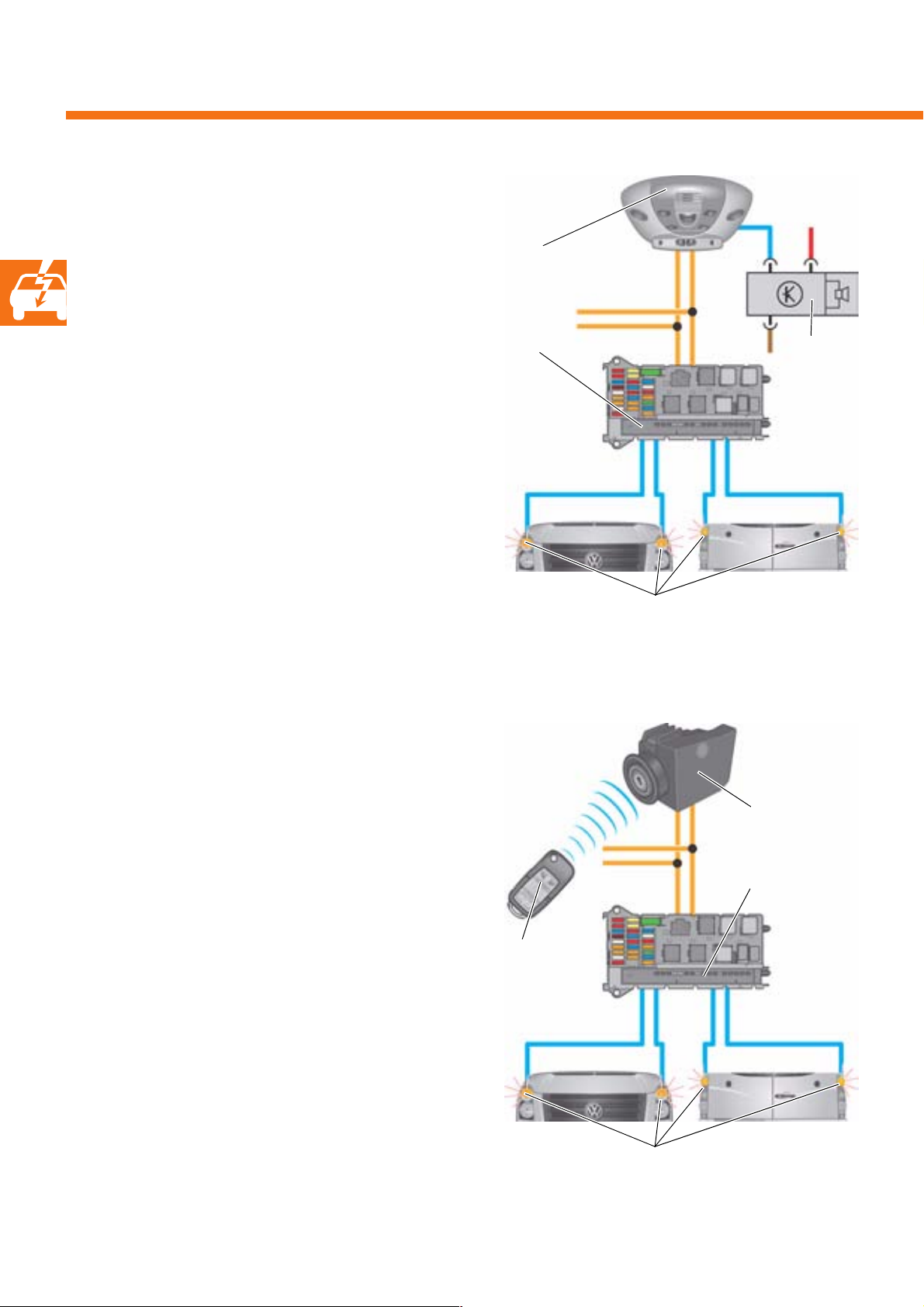

Introduction

Installation locations of the control units in the CAN convenience

data bus

Control units and installation

locations

The adjacent illustration shows the control units which

take part in CAN convenience data bus data

communication and their installation locations.

Data are transmitted at a speed of

83.3 kbit/s. Transmission is carried out via the CAN

high cable and the CAN low cable.

CAN high cables are brown/red and the CAN low

cables are brown.

To ensure reliable data transmission, the CAN

cables are twisted together.

Air conditioning system control unit J301,

in centre of dash panel

The CAN convenience data bus is 1-wire-capable;

if a CAN cable fails, data transmission remains

possible.

Control unit for middle of dash panel J819,

in centre of dash panel

Radio R/control unit with display for radio and

navigation J503 *,

in centre of dash panel

10

* Acts as the interface for the MOST

infotainment data bus

Electronic ignition lock D9,

on the right next to the steering

wheel

Airbag control unit J234,

beneath the centre console

Auxiliary heater control unit J364,

in moulded headlining near to the interior mirror

Roof electronics

control unit J528,

in moulded

headlining near to

the interior mirror

Trailer detector control

unit J345,

beneath the front left seat

Control unit for programmable

special functions J820,

beneath the front left seat

Parking aid control unit J446,

beneath the front left seat

Onboard supply control unit J519,

on the left A pillar

Tyre pressure monitor control unit J502,

beneath the front left seat

Driver door control unit J386,

in the front left door

S370_003

11

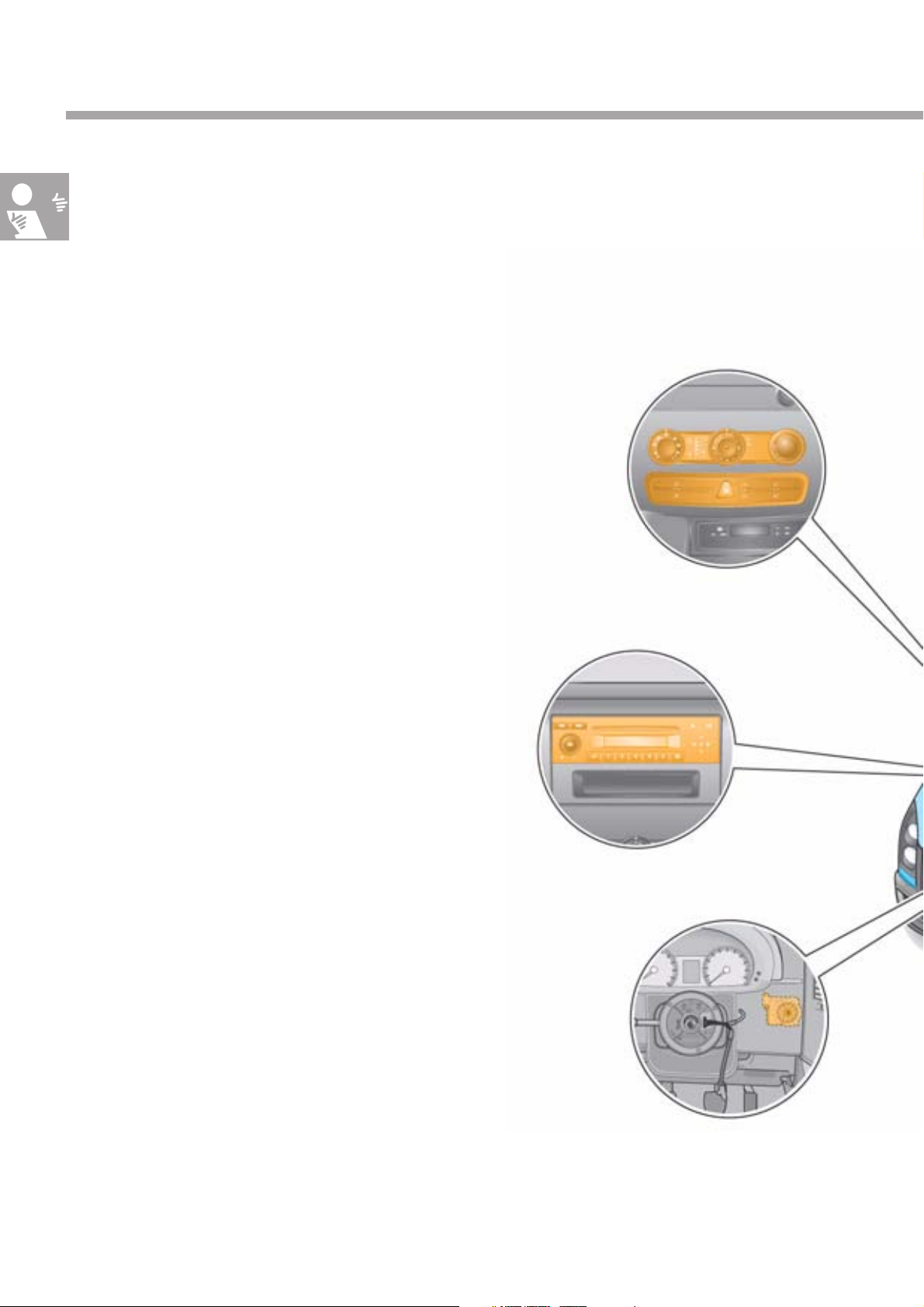

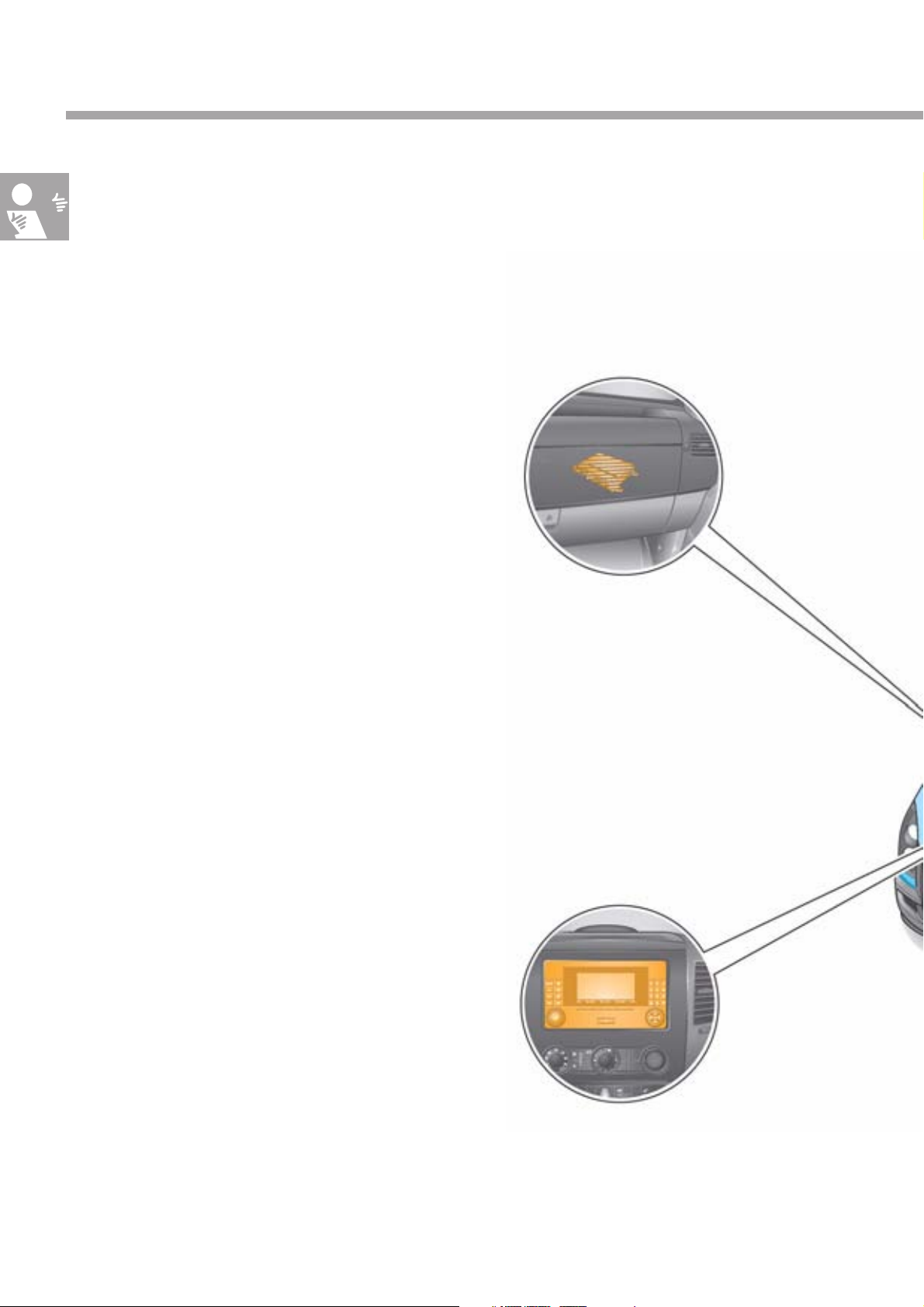

Introduction

Installation locations of the control units in the MOST infotainment

data bus

Control units and installation

locations

Besides the familiar CAN data bus systems,

the Volkswagen Crafter is also equipped with an

optical data bus system.

This data bus system has been named according

to the "Media Oriented Systems Transport" (MOST)

cooperation.

This co-operation has been established by various car

manufacturers, their suppliers and software

companies in order to implement a standardised

system for fast data transmission.

The optical MOST data bus is used to exchange data

between the radio/control unit with display for radio

and navigation, the CD changer and the mobile

telephone operating electronics control unit by means

of light waves.

In comparison with radio waves, light waves have

very short wavelengths, do not generate

electromagnetic interference waves, are

simultaneously insensitive to these and have

a significantly higher data transmission rate than

electronic data bus systems.

On routing, the radius of the fibre optical cable must

be at least 25 mm.

Mobile telephone operating

electronics control unit J412,

behind the glove box

12

Control unit with display unit for radio and

navigation J503/radio R,

in centre of dash panel

CD changer R41,

centre of vehicle interior

S370_071

During diagnosis, please observe the

Guided Fault Finding instructions.

13

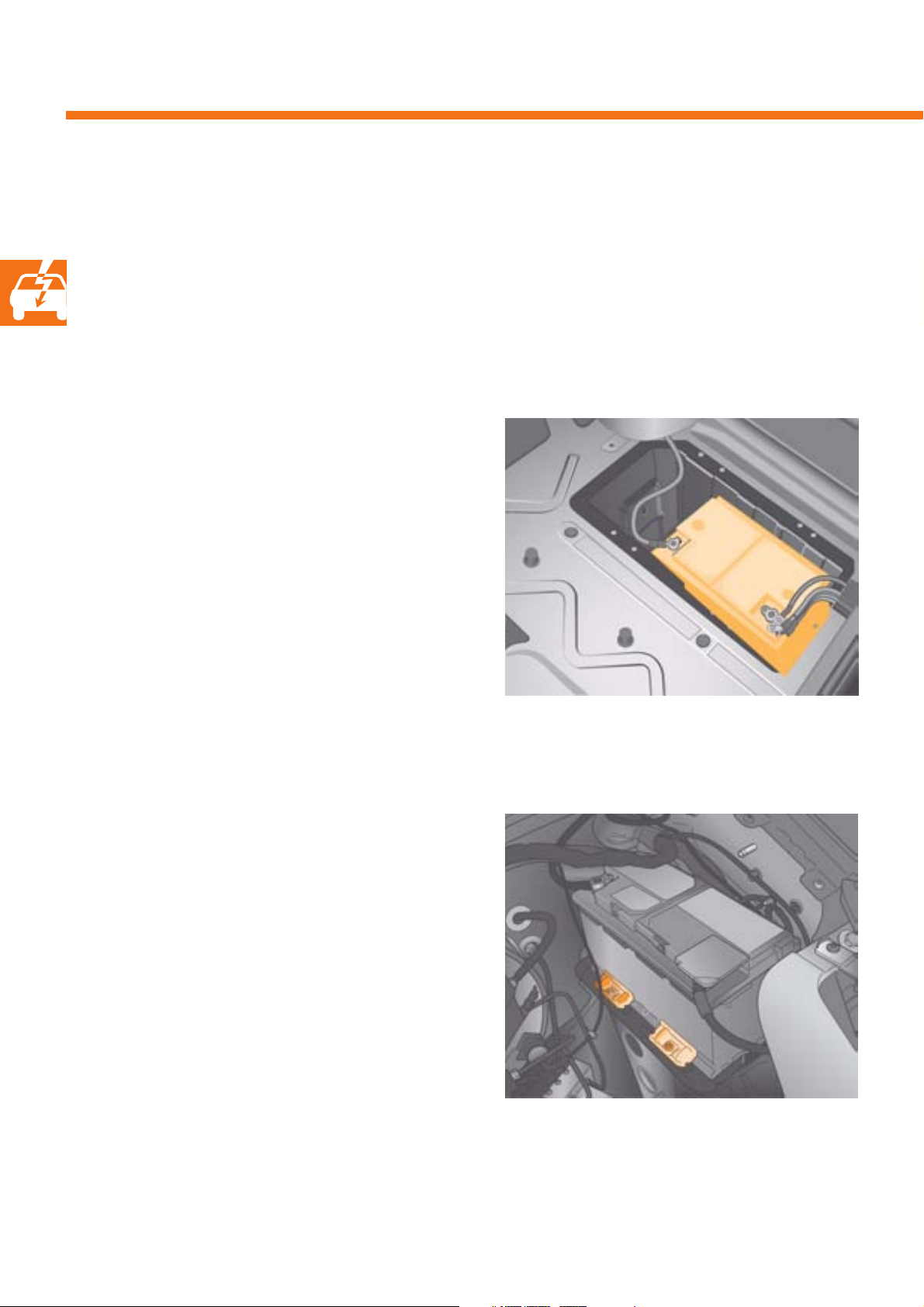

Vehicle electrical system

Batteries

Equipment

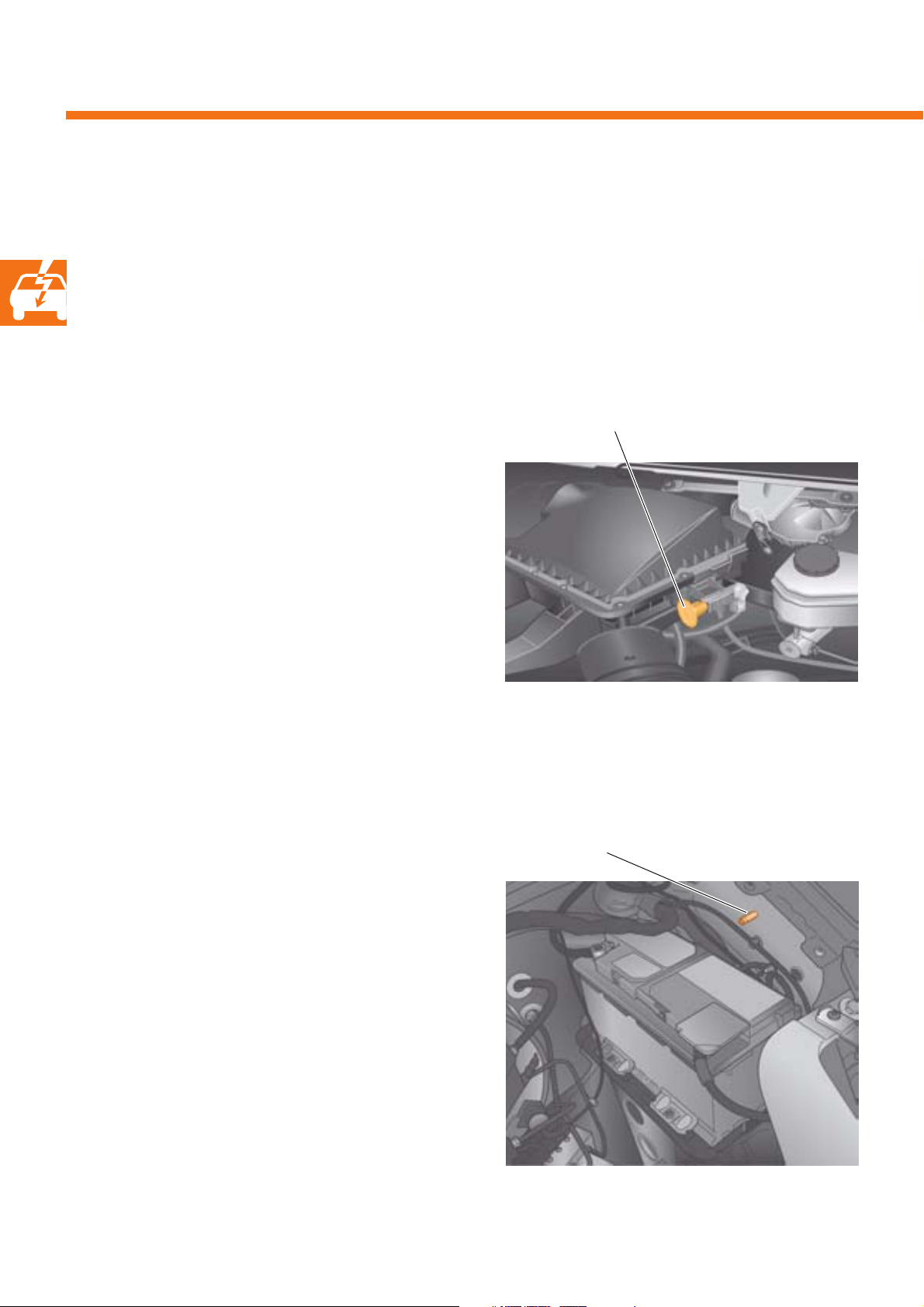

The Volkswagen Crafter can be optionally equipped

with a dual-battery vehicle electrical system; in this

case, a starter and a vehicle electrical supply battery

are installed.

Starter battery

The vehicle electrical system's standard 12 V vehicle

voltage is supplied by the maintenance-free starter

battery. The starter battery is installed in the covered

battery recess in front of the driver's seat (left-hand

drive vehicle) or the front passenger's seat (right-hand

drive vehicle).

A vent pipe emerges into the open air from the recess.

Vehicle electrical system battery

To supply high-current, body-side consumers,

a second battery, located on the left of the engine

compartment, is available in addition to the starter

battery (left-hand drive vehicles only). This second

battery is not intended as a starter battery.

By supplying the high-current consumers, it is instead

intended to protect the starter battery from discharge,

thereby maintaining the vehicle's ability to start.

S370_049

S370_050

14

Functional diagram

The second battery A1 is only available in

combination with the battery isolation relay J7.

This prevents battery A from being drained by

consumers which are connected to the second battery.

At the same time, drainage of the second battery

by the standard consumers is prevented.

J519

J7 SA

A1 A

Legend

ABattery

A1 Second battery

BStarter

J7 Battery isolation relay

J519 Onboard supply control unit

SA Fuse holder A

TV32 Jump start connection

SSSSSS

TV32

B

S370_051

Signal output

Ground

Signal input

Positive

CAN data bus cable

The signal cable colours shown in the illustration

apply to all subsequent functional diagrams.

15

Vehicle electrical system

Jump start connections

Equipment

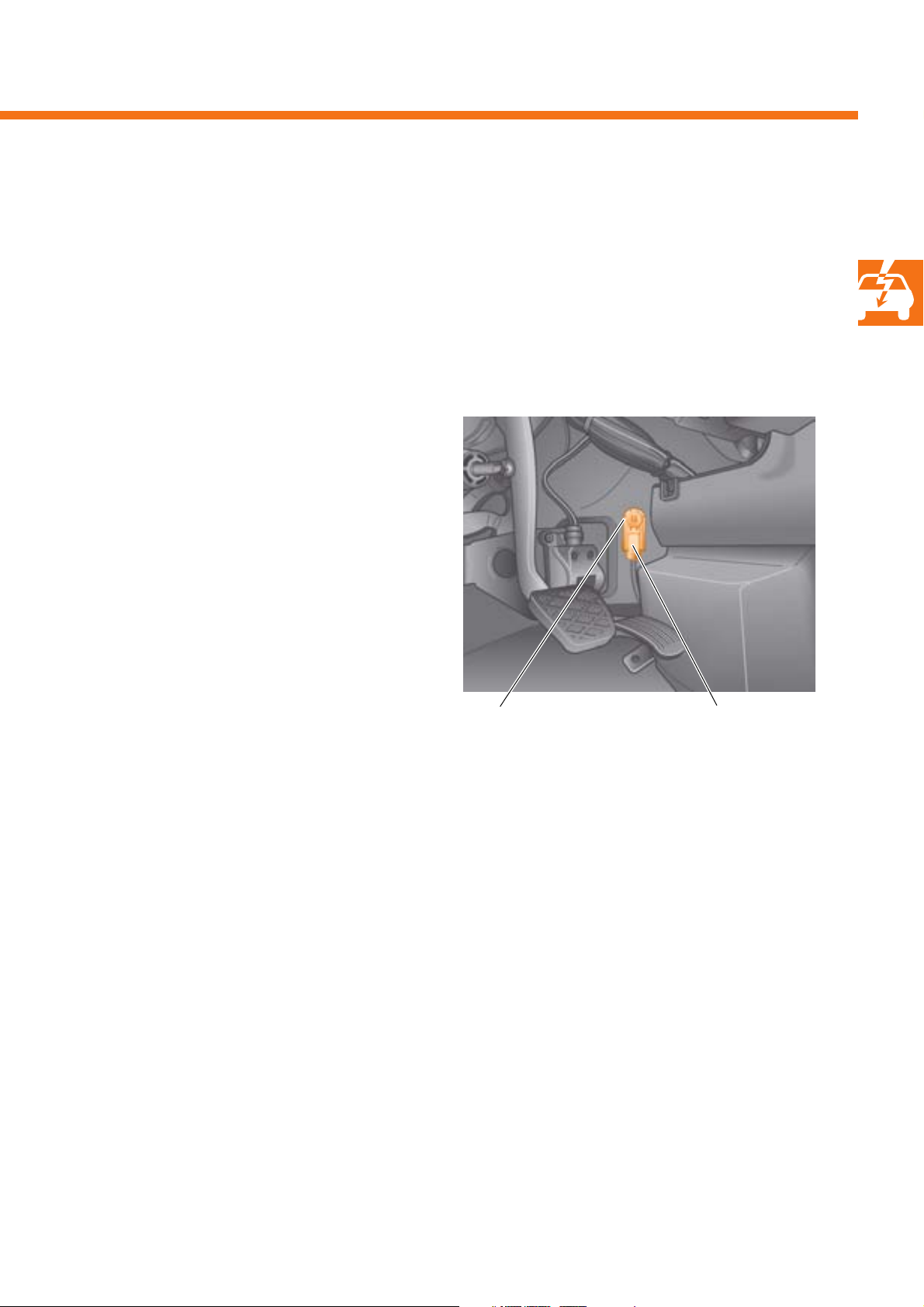

The Volkswagen Crafter is equipped with a positive

and a negative connection for jump-starting and for

charging the battery.

Positive jump start connection

To connect a jump-starting cable or a battery charger,

a connection point for the positive cable is located on

the left-hand side of the air filter housing in the

engine compartment.

Negative jump start connection

Jump start connection

S370_052

Jump start connection

16

To connect a jump-starting cable or a battery charger,

a connection point for the negative cable is located

on the left-hand wing in the engine compartment.

S370_053

Negative main connection

The optional, main connection for the battery

negative cable is located on the right next to the

accelerator pedal.

The connection and the ground bolt can be separated

by pulling the red actuation tab.

This enables the battery to be isolated from the

vehicle electrical system if necessary or prescribed for

repair work.

Main connection Actuation tab

S370_054

17

Vehicle electrical system

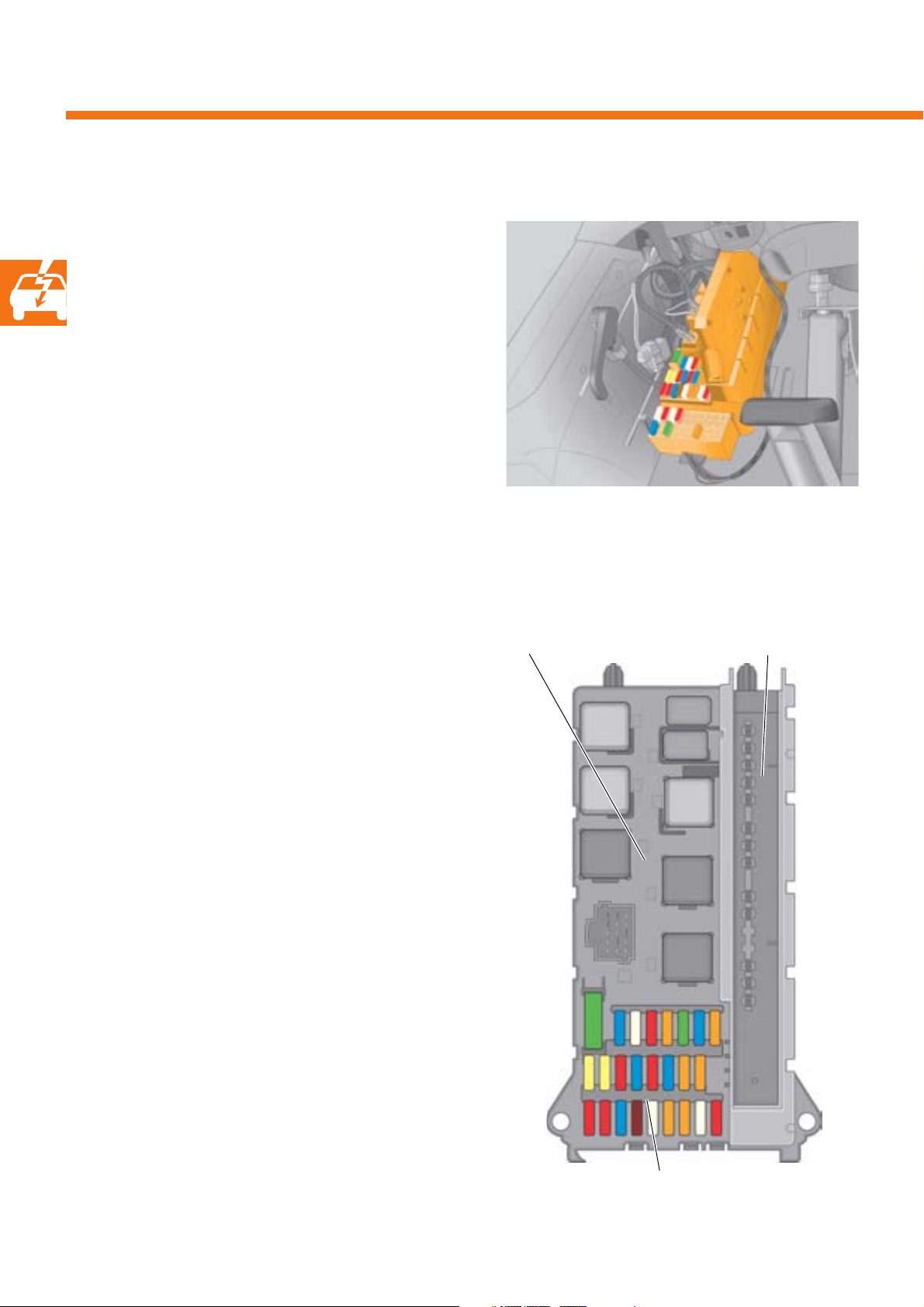

Onboard supply control unit

Installation location

The onboard supply control unit (OBSCU) J519 is

located, together with the fuse and relay box, on

the left of the vehicle interior in the footwell beneath

the instrument panel.

S370_006

Variants

It is available in the following variants:

-Standard

- Low line

-Mid line and

- High line

The different variants offer various functions.

Relay box

Onboard supply control unit

18

Fuse box

S370_007

Functions

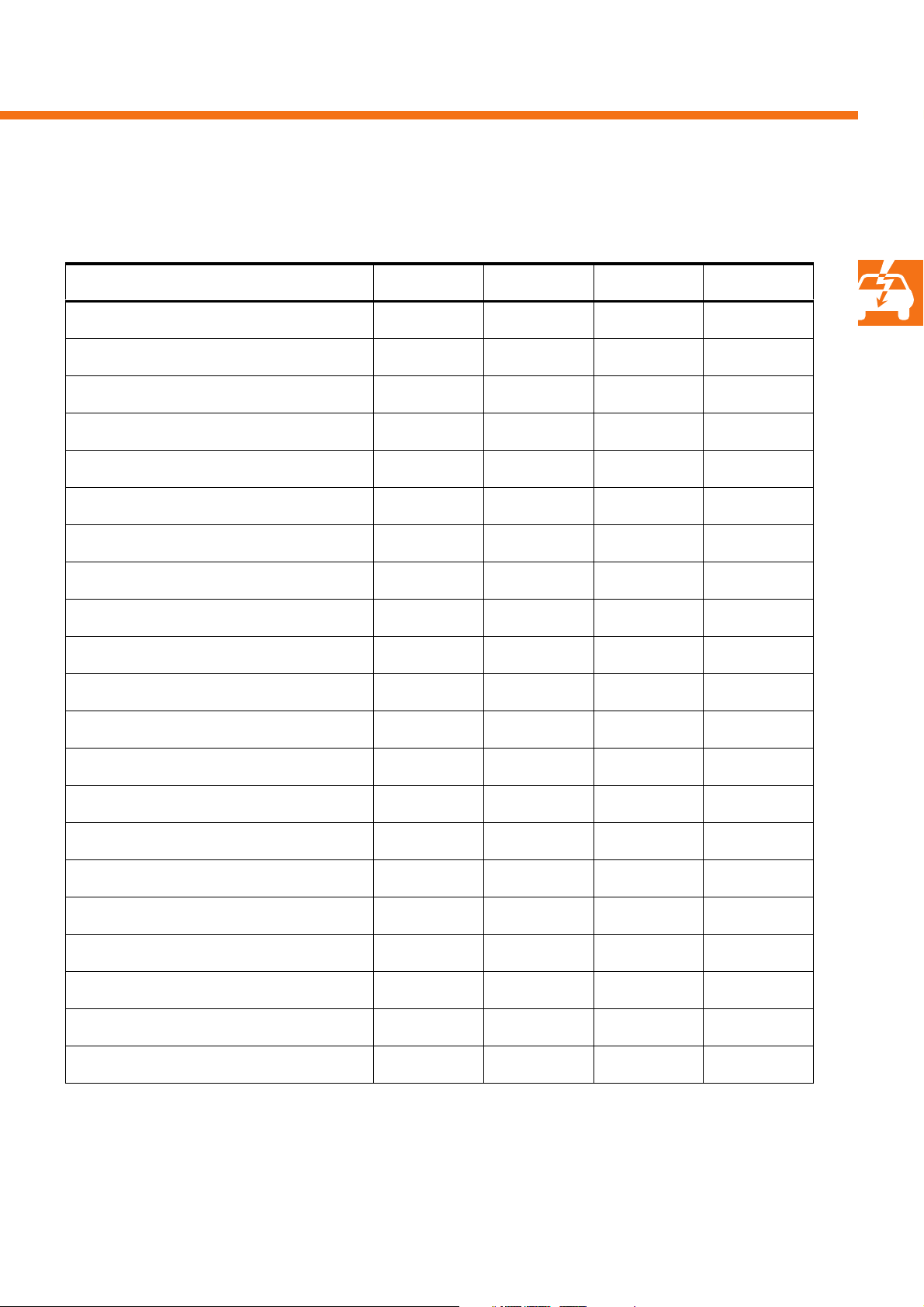

Function Standard Low line Mid-line High-line

Exterior light control system with bulb monitoringXXXX

High-level brake light X X

Fog lights XX

Turn signal actuation XXXX

Interior light control system XXXX

Interior convenience light X

Windscreen wiper and washer systemXXXX

Rear window wiper and washer system X X

Heated rear window X X

Heated windscreen X

Central locking: Sliding door, hinged rear door X X X

Central locking: 2nd sliding door X X

Rotary light switch input XXXX

Sensor signal and switch input XXXX

Vent windows X

Headlight washer system X X

Auxiliary turn signal module X X

Alarm function XXXX

ATA function XXXX

Central locking: Front passenger door XXXX

Window regulator: Front passenger door XXXX

19

Vehicle electrical system

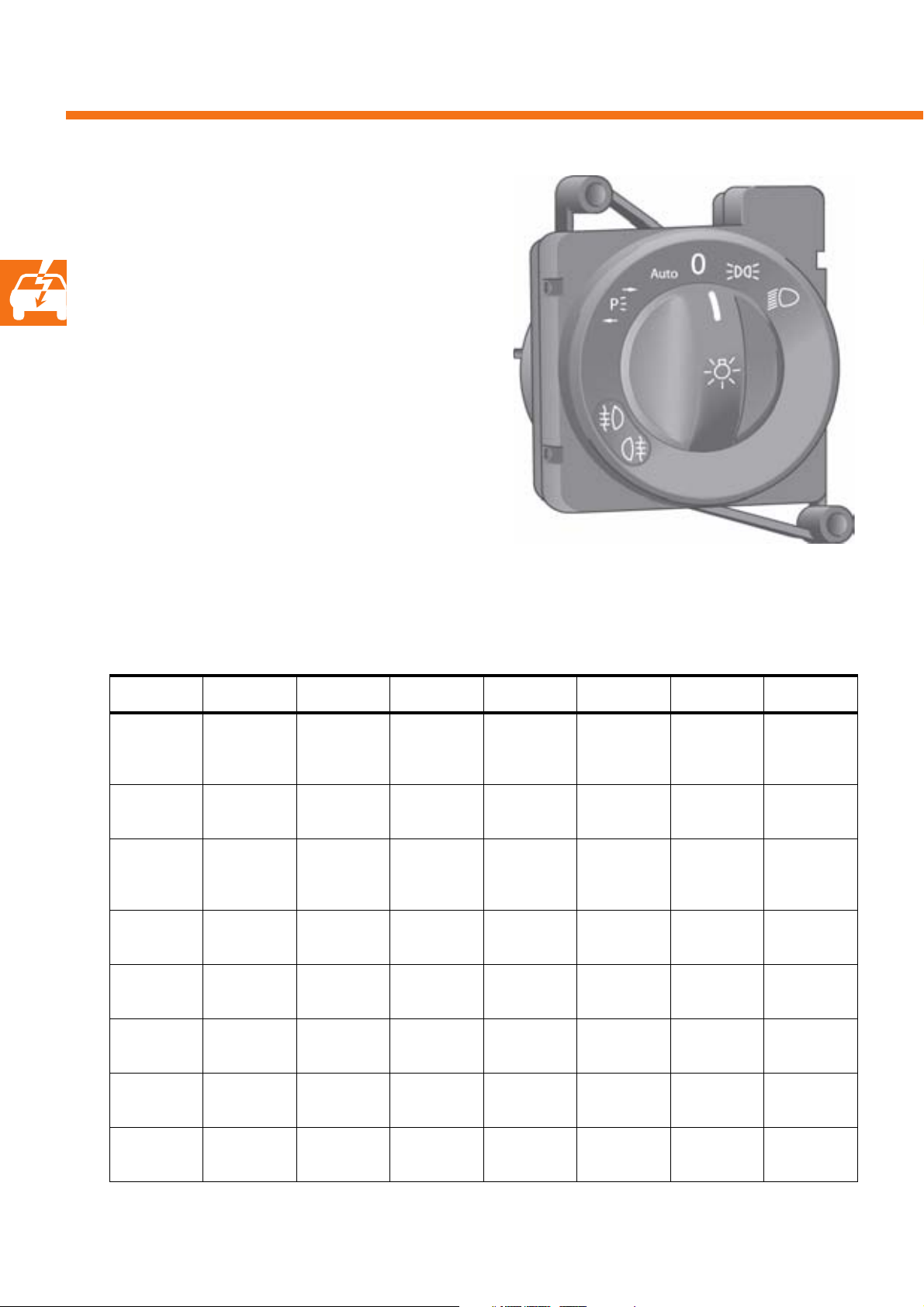

Light switch

Function

The light switch E1 is responsible for actuating the

exterior light functions. The onboard supply control

unit reads in the signals from the voltage-coded light

switch directly.

The signals for the turn signal and main beam

functions are transmitted from the steering column

electronics control unit via the CAN drive data bus

and the CAN convenience data bus.

S370_005

Variants

The light swicth is available in eight different variants.

Variant 1 Variant 2 Variant 3 Variant 4 Variant 5 Variant 6 Variant 7 Variant 8

Off Autom.

driving

lights

Side light Off Side light Off Right

Dipped

beam

Rear fog

light

Side light Dipped

Dipped

beam

Rear fog

light

Off Autom.

driving

lights

Side light Off Autom.

beam

Rear fog

light

Fog light Rear fog

Dipped

beam

light

Left parking

light

parking light

Side light Off Side light Off

Dipped

beam

Left parking

light

Right

parking light

driving

lights

Side light Dipped

Left parking

light

Right

parking light

Off Autom.

beam

Left parking

light

Right

parking light

driving

lights

Side light

20

Fog light Rear fog

light

Dipped

beam

Rear fog

light

Rear fog

light

Fog light Rear fog

Dipped

beam

light

Fog light

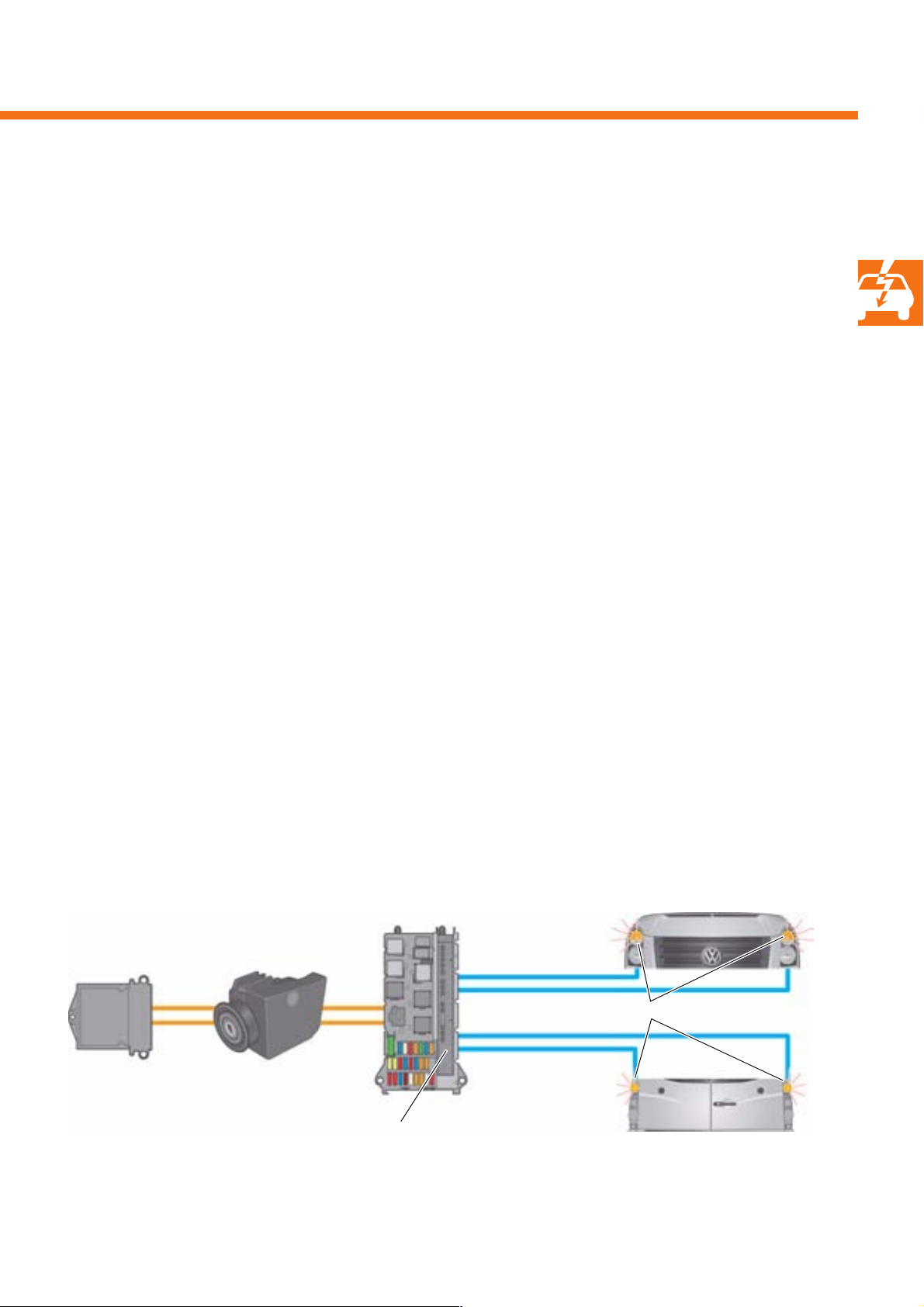

Turn signal control system

Function description

The onboard supply control unit is the master for the

turn signal function and carries out the various turn

signal functions. It receives all requests to actuate the

turn signals, prioritises these and is the only control

unit to implement a turn signal pulse on the CAN data

bus. All of the other involved control units evaluate

this turn signal pulse.

Turn signal actuation priority

The turn signals are actuated according to the

following piority:

● 1 Airbag hazard warning flashing

● 2 Special alarm flashing

● 3 Direction indication or hazard warning flashing

Airbag hazard warning flashing

In the event of airbag deployment, the airbag control

unit transmits a CAN message to the onboard supply

control unit. The hazard warning flashing function is

then triggered.

Electronic ignition lock D9

● 4 ATA alarm flashing

● 5 Central locking feedback flashing

This function is deactivated by actuating the hazard

warning lights button (E229) once or by switching the

ignition off, on and off again.

Airbag control

unit J234

Turn signal bulbs

Onboard supply control unit J519

S370_008

21

Vehicle electrical system

Special alarm flashing

The control unit for programmable special functions

can request alarm flashing with a pre-specified on/off

phase from the onboard supply control unit.

Switch

Depending on the way in which the control unit for

programmable special functions is programmed, the

following lighting facilities can be actuated in the

event of special alarm flashing:

- Main beam,

- Fog lights and

-Turn signals

The special alarm flashing function is used,

e.g. in emergency vehicles.

Hazard warning flashing

The onboard supply control unit receives the hazard

warning flashing signal from the control unit for

middle of dash panel J819, which reads in the signals

from the hazard warning lights button E229. The

onboard supply control unit then actuates all turn

signals.

No bulb monitoring is carried out during hazard

warning flashing. The hazard warning flashing

function is always operational.

Control unit for

programmable special

functions

Onboard supply control unit

Bulbs

S370_009

Control unit for middle of dash panel

Hazard warning lights

button E229

Onboard supply control

unit J519

22

Turn signal bulbs

S370_010

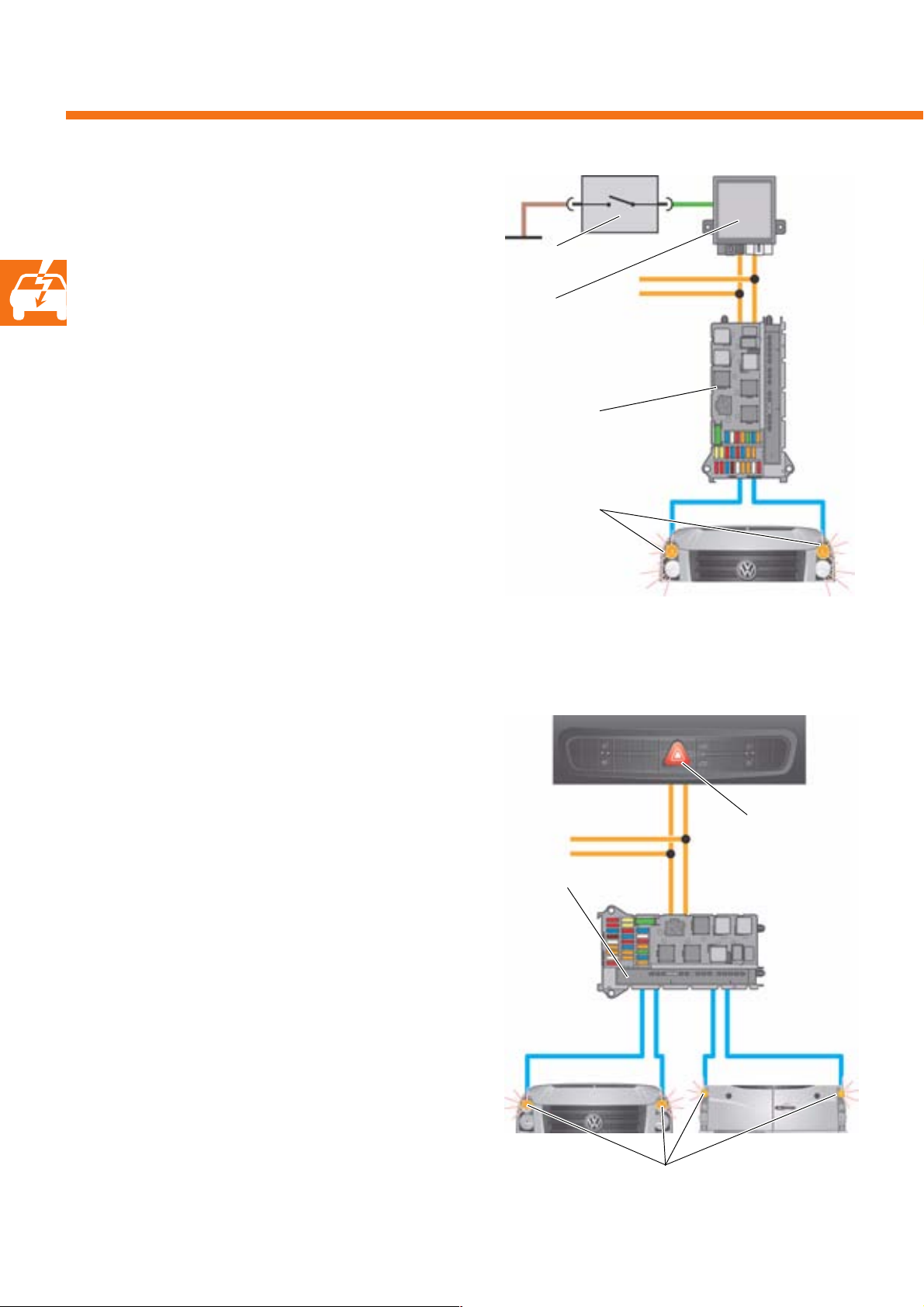

Direction indication

The signal for direction indication is received by the

onboard supply control unit from the steering column

electronics control unit J527, which reads in the signals

from the turn signal switch E2 in voltage-coded form.

The electronic ignition lock (EIL) D9 transfers the

signals from the CAN drive data bus to the CAN

convenience data bus. The onboard supply control

unit actuates the turn signal bulbs as requested.

During direction indication, the turn signal bulbs are

monitored for bulb failure.

The bulbs' flashing frequency is doubled in the event

of bulb failure. Actuation of the turn signal warning

lamps is carried out via the CAN convenience data

bus and the control unit in the dash panel insert. The

direction indication function is only active in the case

of "terminal 15 on".

Steering column electronics control unit J527

Turn signal switch E2

Onboard supply control unit J519

Turn signal bulbs, right

CAN drive data bus CAN convenience data bus

S370_011

23

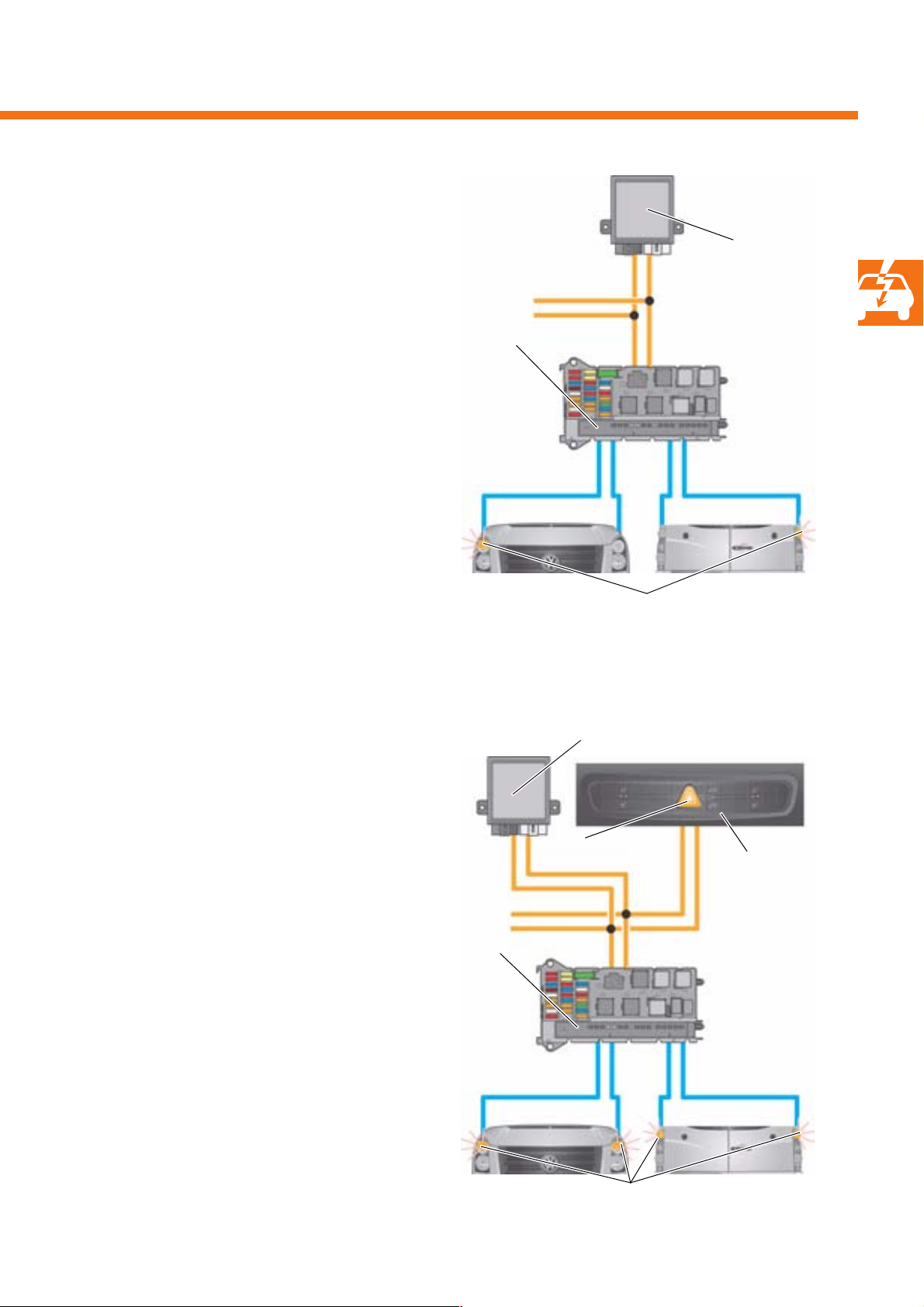

Vehicle electrical system

ATA alarm flashing

The ATA alarm flashing function is active if no

authorised key is located in the electronic

ignition lock (EIL).

The alarm is output via the alarm horn H12 and the

turn signals.

In this case, the roof electronics control unit transmits

a request to the onboard supply control unit via the

CAN convenience data bus. Bulb monitoring is not

carried out during ATA alarm flashing.

Roof electronics

control unit

Onboard supply control

unit

Alarm horn

Central locking feedback flashing

Unlocking the vehicle is indicated by all of the turn

signals' flashing twice. Locking the vehicle is indicated

by all of the turn signals' flashing once.

The request for central locking feedback flashing is

transmitted by the electronic ignition lock via the CAN

convenience data bus. This function is only active if no

authorised key is located in the electronic ignition

lock.

S370_012

Turn s i gnal s

Electronic

ignition lock

Onboard supply control

unit

Radio

remote control

24

S370_013

Turn s i gnals

Special direction indication

The control unit for programmable special functions is

able to request direction indication from the onboard

supply control unit. The onboard supply control unit

handles this request like a request from the steering

column electronics control units, although these

requests have priority.

The control unit for programmable special functions

does not send a request, or ends its request, as soon

as it detects a request for direction indication from the

steering column electronics control unit.

Control unit for

programmable

special functions

Onboard supply control

unit

S370_014

Turn sig n a l s

Special hazard warning flashing

The control unit for programmable special functions is

able, like the control unit for middle of dash panel,

to request hazard warning flashing from the onboard

supply control unit.

It withdraws its request as soon as it detects a request

from the control unit for middle of dash panel.

This function is deactivated either by the control unit

for programmable special functions or by actuating

the hazard warning lights button.

Control unit for programmable special functions

Hazard warning

lights button

Onboard

supply

control

unit

Control unit for

middle of dash

panel

Turn sig n a l s

S370_015

25

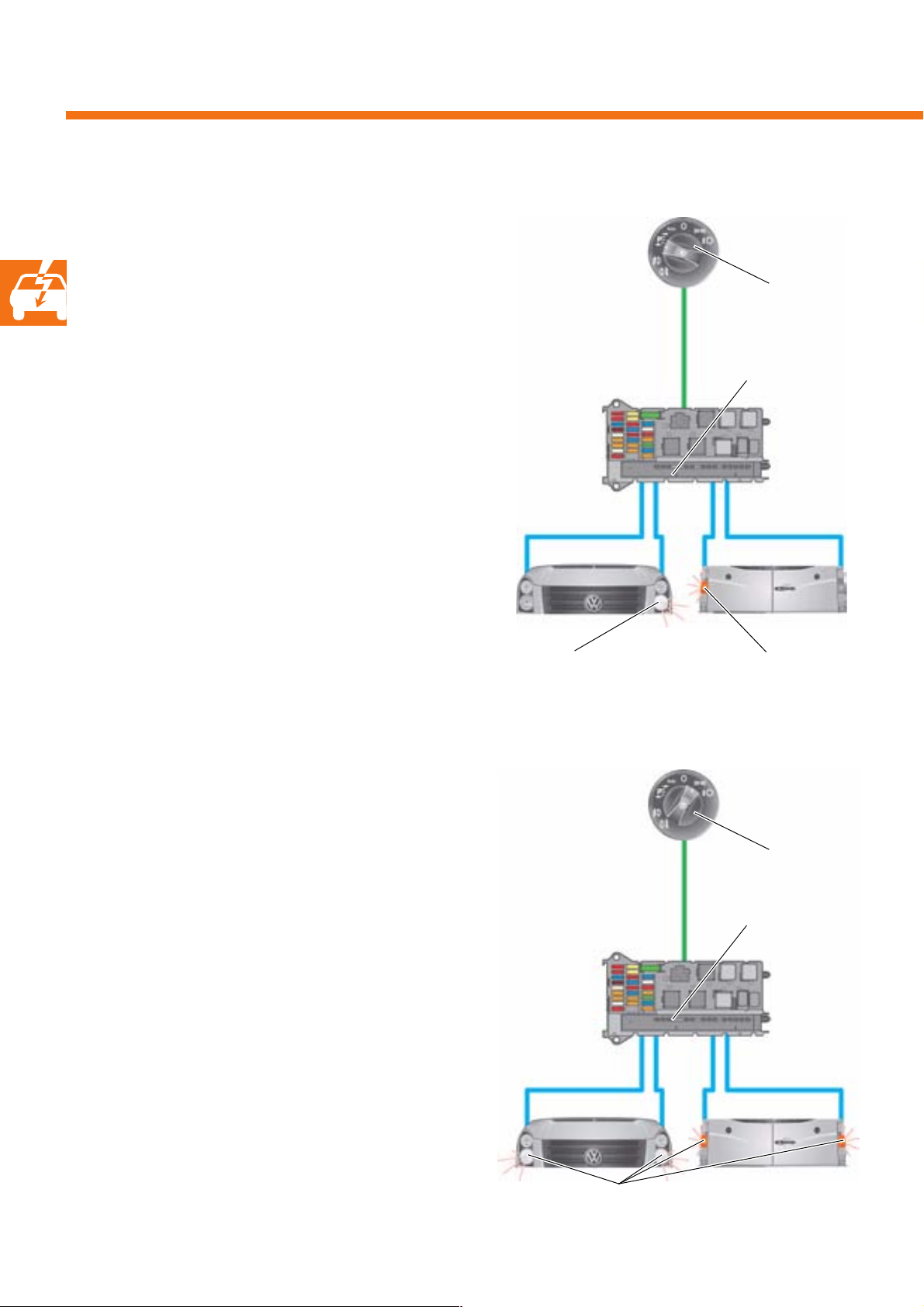

Vehicle electrical system

Lighting

Parking light

The left or right side light bulbs and the left or right

tail light bulbs are actuated by the onboard supply

control unit.

Light switch

The request to switch on the parking lights comes

directly from the light switch.

The parking light function is active if no authorised

key is located in the EIL.

Bulb monitoring is carried out when the parking light

function is on.

Side light and tail light

Onboard supply

control unit

S370_016

Left side light bulb Left tail light bulb

26

The left and right side and tail light bulbs are

actuated by the onboard supply control unit.

The request to switch on comes directly from the light

switch. The side and tail lights can also be switched on

if the ignition key has been removed, in which case an

acoustic signal is emitted.

Side light and tail light bulbs

Light switch

Onboard supply

control unit

S370_017

Loading...

Loading...