Volkswagen 01M User Manual

AUTO TRANS DIAGNOSIS - 01M

Article Text

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

AUTOMATIC TRANSMISSIONS

Volkswagen Type 01M

Cabrio, Golf, Golf III, GTI Jetta, Jetta III, Passat

APPLICATION & LABOR TIMES

APPLICATION & LABOR TIMES

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Vehicle Labor Times Trans.

Application (1) R & I (2) Overhaul Model

1995-96

Cabrio ............... 4.4 ......... 6.3 .... 01M (CLK)

Golf, GTI & Jetta

4-Cylinder

Gas ................. 4.4 ......... 6.3 .... 01M (CLK)

Turbo Diesel ........ 4.4 ......... 6.3 .... 01M (CKZ)

V6 ................... 4.4 ......... 6.3 .... 01M (CLB)

Passat

4-Cylinder

Gas ................. 4.9 ......... 6.3 .... 01M (CLK)

Turbo Diesel ........ 4.9 ......... 6.3 .... 01M (CKZ)

V6 ................... 4.9 ......... 6.3 .... 01M (CLB)

Thursday, August 19, 1999 11:28PM

(1) - Removal and installation of transmission from vehicle

chassis.

(2) - On bench overhaul for transmission and differential.

DOES NOT include removal and installation.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

IDENTIFICATION

Volkswagen Audi Group (VAG) transaxle type is cast into top

of transaxle case, next to ATF cooler. Transaxle code and build date

are located on top of transaxle case, next to starter.

DESCRIPTION & OPERATION

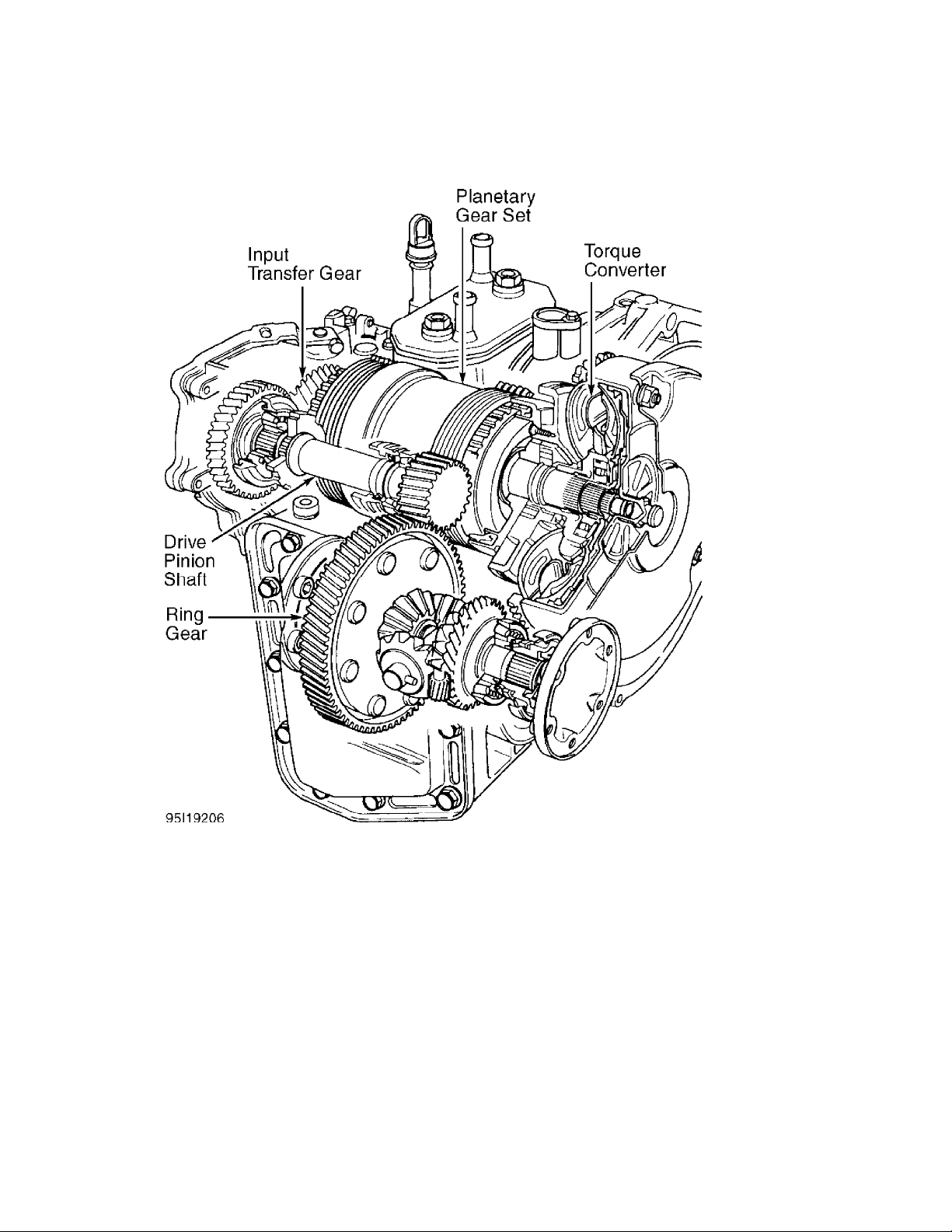

Transaxle includes a 4-speed automatic transmission, lock-up

torque converter, final drive and solenoid-operated valve body. See

Fig. 1. Under normal conditions, all shifts are controlled by a

Transaxle Control Module (TCM). See Fig. 2. Fourth gear is an

overdrive gear.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 2)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 1: Cross-Sectional View Of Transaxle Components

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 3)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 2: Identifying TCM & Shift Lock Electrical Components

Courtesy of Volkswagen United States, Inc.

The transmission elements consist of a planetary gear set,

one-way roller clutch, 3 apply clutches, 2 brake clutches and a torque

converter lock-up clutch. See Figs. 1 and 3.

All 4 forward gears are hydraulically activated. When the

lock-up clutch is engaged, the forward gears become mechanically

driven by eliminating torque converter slip. The lock-up clutch is

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 4)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

engaged depending on engine load and vehicle speed.

Power from the transmission is connected to the drive pinion

through transfer gears. A ring gear and differential assembly are

connected to flanges which spin the drive axles.

The electronic control consists of a TCM (located under rear

seat), control solenoids, various sensors and switches. The control

solenoids direct oil pressure inside the valve body. Solenoid valves

No. 1-4 control the apply and brake clutches. Solenoid valves No. 5

and 7 control shift smoothness. Solenoid valve No. 6 is a frequency

valve and controls the main hydraulic pressure. The TCM controls the

main hydraulic pressure by varying the duty cycle.

The TCM monitors input and output signals. If electrical

problems occur, TCM will record faults in TCM memory and may go into

fail-safe mode (also known as emergency running mode). If TCM enters

fail-safe mode, the transaxle will operate manually in reverse, 1st or

3rd gear. In fail-safe mode, 3rd gear operates with gear selector in

2nd, 3rd or "D". If engine is started with TCM in fail-safe mode, TCM

activates 3rd gear hydraulically. The TCM memory can only be read

using Scan Tool (VAG 1551) and Adapter (VAG 1551/3).

The TCM also controls shift lock system. This system locks

the gear selector in Park or Neutral position unless the brake pedal

is pressed. The TCM uses a shift lock control relay to release a gearselector mounted solenoid. See Fig. 2.

Thursday, August 19, 1999 11:28PM

Fig. 3: View Of Transaxle Clutch Elements

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 5)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

LUBRICATION & ADJUSTMENTS

NOTE: See appropriate AUTOMATIC TRANSMISSION SERVICING article in

TRANSMISSION SERVICING section.

TROUBLE SHOOTING

SYMPTOM DIAGNOSIS

Leak At Torque Converter

Check drive plate clearance, torque converter bushing, oil

seal or oil pump assembly. Repair as necessary.

Transaxle Fluid In Coolant

Faulty transaxle oil cooler. Replace transaxle oil cooler and

friction plates in transaxle. Clean transaxle.

Thursday, August 19, 1999 11:28PM

Transaxle & Differential Oils Mixed

Replace "O" ring and drive pinion seal on inner bearing

support.

Gear Selector Hard To Move

Check gear selector between shifter and transaxle. Repair as

necessary. Check parking lock assembly inside transaxle. Repair as

necessary.

No Drive In 1st Gear

Check for faulty 1st-3rd apply clutch or reverse brake

clutch.

No Drive In "D", "2" Or "3"

Check for faulty 1st-3rd apply clutch or one-way clutch.

No 2nd Gear In "D", "2" Or "3"

Check for faulty 2nd-4th brake clutch.

No 3rd Gear In "D" Or "3"

Check for faulty reverse apply clutch.

No 4th Gear In "D"

Check for faulty 2nd-4th brake clutch.

No Reverse

Check for faulty reverse apply clutch or reverse brake

clutch.

No Drive In All Forward Gear Positions

Check for faulty 1st-3rd apply clutch, reverse brake clutch

or one-way clutch.

Missing Shifts Up Or Down

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 6)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Check valve body for sticking valve(s) or faulty shift

solenoid(s).

Erratic Or Harsh Shifts

Short in wiring to shift solenoid(s) or faulty shift

solenoid(s). Check for proper throttle angle adjustment. See TECHNICAL

SERVICE BULLETINS.

Harsh Shift In One Gear Only

Determine elements involved. Air check elements. Check for

faulty shift solenoid or shift valve.

Stuck In Emergency Running Mode

Check for incorrect TCM installed, faulty wiring, bad

solenoid electrical strip (inside oil pan) or stuck valve.

Park Lock Will Not Engage

Check for misadjusted selector lever cable. Check for faulty

locking mechanism.

Thursday, August 19, 1999 11:28PM

Bucking Or Poor Idling

Check throttle housing and air ducts for leaks. Check for

possible air entering oil pump pickup.

Excess Engine RPM Drop When Shifting Into 1st Gear

Faulty Powertrain Control Module (PCM).

Engine Starts In Gear Or No Start In Park/Neutral

Check for faulty Park/Neutral safety switch.

Shift Lock Not Holding Selector In Park/Neutral

Check for faulty shift lock solenoid, shift lock mechanism or

bad TCM.

MECHANICAL, HYDRAULIC & ELECTRICAL COMPONENTS

1) If gear selector is stuck in Park or Neutral position, go

to SHIFT LOCK SYSTEM under TROUBLE SHOOTING. If gear positions are

missing, shift quality is poor or no shifts are possible, ensure all

electrical connections are okay and fluid level is correct.

2) If problems are still present, disconnect electrical

connector at transaxle. Test drive vehicle. Check if transaxle will

operate manually in reverse and 1st gear. Move gear selector to 2nd,

3rd or "D" position. Transaxle should operate in 3rd gear (2nd, 3rd or

"D").

3) If transaxle operates as described, problem may be

electrical. See ELECTRONIC SELF-DIAGNOSTICS. If transaxle does not

operate as described, problem may be mechanical or hydraulic. See

ROAD TEST.

NOTE: If transaxle does not operate in manual 1st gear, check

1st-3rd apply clutch and reverse brake clutch for damage or

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 7)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

wear. If transaxle does not operate in manual reverse gear,

check reverse apply clutch and reverse brake clutch for

damage or wear.

ROAD TEST

WARNING: DO NOT exceed safe or legal speed limits during road test.

1) Road test vehicle with transaxle in "D" range. With

vehicle at a speed above kickdown speed, press throttle pedal down and

note kickdown shift speeds. Compare kickdown shift speeds to kickdown

shift speed specifications. See KICKDOWN SHIFT SPEED SPECIFICATIONS

table.

NOTE: In the following table, letter suffix following gear

application refers to Hydraulic ("H") or Mechanical ("M")

gear operation. Hydraulic or manual gear operation depends

on operating mode of torque converter lock-up clutch.

Thursday, August 19, 1999 11:28PM

KICKDOWN SHIFT SPEED SPECIFICATIONS

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application Kickdown (MPH)

4-Cylinder (CLK)

1H-1M ............................................ 30-34

1M-2H ............................................ 30-34

2H-2M ............................................ 61-65

2M-3H ............................................ 61-65

3H-3M ............................................ 85-89

3M-4H ............................................ 85-89

4H-4M ............................................ 85-89

4M-4H ............................................ 86-83

4H-3M ............................................ 86-83

3M-3H ............................................ 61-57

3H-2M ............................................ 61-57

2M-2H ............................................ 61-57

2H-1M ............................................ 26-22

1M-1H ............................................ 26-22

Turbo Diesel (CKZ) .................................. (1)

V6 (CLB)

1H-1M ............................................ 37-41

1M-2H ............................................ 37-41

2H-2M ............................................ 76-80

2M-3H ............................................ 76-80

3H-3M .......................................... 111-115

3M-4H .......................................... 111-115

4H-4M .......................................... 111-115

4M-4H .......................................... 112-108

4H-3M .......................................... 112-108

3M-3H ............................................ 75-71

3H-2M ............................................ 75-71

2M-2H ............................................ 75-71

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 8)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

2H-1M ............................................ 32-28

1M-1H ............................................ 32-28

(1) - Information not available from manufacturer.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

2) Connect scan tool and appropriate adapter to diagnostic

connector. Select function 08 "READ MEASURING VALUE BLOCK". Test

solenoid valves and upshift speeds following scan tool manufacturers

instructions.

3) If transaxle does not shift within specified MPH range,

and scan tool values are within specification, determine affected

elements. See APPLY & BRAKE CLUTCH APPLICATION.

4) If all apply and brake clutch elements are affected, check

oil pump, oil filter, cooler lines, solenoid valve No. 6, and

condition of torque converter and/or engine. Repair as necessary.

5) If one or more apply and brake clutch elements are

affected, remove valve body. Locate appropriate fluid circuit in

transaxle case and valve body. Check for leaks and/or blockage. Repair

as necessary.

6) If hydraulic circuits are okay, or problems with apply and

brake clutch elements are mechanical, repair transaxle.

Thursday, August 19, 1999 11:28PM

NOTE: If transaxle does not operate in manual 1st gear, check

1st-3rd apply clutch and reverse brake clutch for damage or

wear. If transaxle does not operate in manual reverse gear,

check reverse apply clutch and reverse brake clutch for

damage or wear.

APPLY & BRAKE CLUTCH APPLICATION

APPLY & BRAKE CLUTCH APPLICATION (1)

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Gear Application Elements In Use

1st Gear .......... 1st-3rd Apply & One-Way Clutch Holding

2nd Gear ................... 1st-3rd Apply & 2nd-4th Brake

3rd Gear .................... 1st-3rd & 4th Apply Clutches

4th Gear ....................... 4th Apply & 2nd-4th Brake

Reverse .................... Reverse Apply & Reverse Brake

Park & Neutral ................ All Apply & Brake Clutches

Released Or Ineffective

(1) - All forward gear elements shown are in "hydraulic-state".

Forward gear elements switch to a "mechanical-state"

with the addition of torque converter lock-up clutch

apply.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

SHIFT LOCK SYSTEM

Operation

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 9)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

All models are equipped with an electronic shift lock system.

TCM controls shift lock system. See Fig. 2. This system locks gear

selector in Park or Neutral position unless brake pedal is pressed.

TCM uses shift lock control relay to release a solenoid mounted on

gear selector assembly.

NOTE: Shift lock relay will not lock gear selector when vehicle

speed is greater than 3 MPH.

A mechanical control cable prevents ignition key from being

removed unless gear selector is in Park position. With ignition key

removed, gear selector locks in Park position.

NOTE: If battery is disconnected or discharged, gear selector can

be moved out of Park position by turning ignition key to

START position.

Functional Check

1) With ignition key removed, ensure gear selector cannot be

moved from "P" position. Insert key in ignition switch.

2) Turn ignition on. Ensure gear selector can only be moved

with brake pedal pressed. Move gear selector to "N" position.

3) Without pressing brake pedal, ensure gear selector cannot

move out of "N" position. Press brake pedal down. Ensure it is now

possible to move gear selector.

4) If shift lock system does not operate as described, adjust

gear selector, solenoid and control cable. If shift lock system does

not operate after adjustments are made, check shift lock electrical

system with Scan Tool (VAG 1551).

5) See testing information under ELECTRONIC SELF-DIAGNOSTICS.

See Figs. 10-13. If any problems are found, service harness or

components. If no problems are found, TCM may be defective. If shift

lock system still does not operate correctly, check for worn or

damaged parts and replace as necessary. See Figs. 2 and 4.

Thursday, August 19, 1999 11:28PM

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 10)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 4: Exploded View Of Shift Lock & Gear Selector Assembly

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 11)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

NOTE: Perform the following adjustments in order given.

Control Cable Adjustment

Loosen lock screw at gear selector lever on transaxle. Move

gear selector in center console to Park position. Ensure front wheels

are locked. Tighten cable housing to gear selector lever lock screw.

Shift Lock Solenoid Adjustment

Place gear selector in "N" or "P" position. Loosen shift lock

solenoid mounting screws. Insert a .019" (.30 mm) feeler gauge between

shift lock solenoid push rod and shift lever. See Fig. 5. If

necessary, move shift lock solenoid and tighten screws.

Thursday, August 19, 1999 11:28PM

Fig. 5: Adjusting Shift Lock Solenoid

Courtesy of Volkswagen United States, Inc.

Shift Lock Cable Adjustment

1) Move gear selector to "1" position. Remove steering column

covers. Turn ignition key to START position and release. Check

clearance between shift lock cable lever and ignition switch locking

pin.

2) Clearance should be .028" (.70 mm). If clearance is not

correct, loosen lock nut on shift lock cable sheath. Position shift

lock cable lever to obtain correct clearance. Tighten lock nut. See

Fig. 6. Tighten gear selector housing screws and install steering

column covers.

Fig. 6: Adjusting Shift Lock Cable

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 12)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Removal & Installation (Control Cable)

Remove lower cover from center console. Remove circlip from

control cable end. Remove exhaust covers. On models equipped with V6

engines, remove catalytic converter. On all models, loosen lock nut

and remove control cable from shift lever on transaxle. To install,

reverse removal procedure. Adjust control cable. See CONTROL CABLE

ADJUSTMENT under SHIFT LOCK SYSTEM.

Removal & Installation (Shift Lock Cable)

1) Remove shift lever handle. Remove center console cover.

Disconnect negative battery cable and wait 30 seconds.

2) Using Torx wrench, remove air bag retaining screws from

rear side of steering wheel. Lift off air bag unit from steering

wheel, and tilt air bag unit downward. Disconnect wiring connector

from air bag unit. Remove steering wheel. Remove dash panel.

3) Place gear selector in rear position. Loosen screw holding

cable sheath to gear selector support. Remove cable from lever. See

Fig. 7.

4) Remove cover from ignition switch. Remove spring clip

holding cable housing to ignition assembly. Lift and tilt shift lock

cable housing upward. Pull up shift lock cable until shift lock cable

unhooks from ignition switch. See Fig. 8.

Thursday, August 19, 1999 11:28PM

Fig. 7: Removing Shift Lock Cable From Shift Lever Support

Courtesy of Volkswagen United States, Inc.

Fig. 8: Removing Shift Lock Cable From Ignition Switch

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 13)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

5) Remove shift lock cable from under dash near A/C-heater

housing and remove from vehicle. To install, position shift lock cable

through under-dash panels. See Fig. 9. To complete installation,

reverse removal procedure. Adjust shift lock control cable. See SHIFT

LOCK CABLE ADJUSTMENT under SHIFT LOCK SYSTEM.

Thursday, August 19, 1999 11:28PM

Fig. 9: Routing Shift Lock Cable To Ignition Switch

Courtesy of Volkswagen United States, Inc.

ELECTRONIC SELF-DIAGNOSTICS

RETRIEVING TROUBLE CODES

1) Electronic control consists of a TCM (located under rear

seat), control solenoids, and various sensors and switches. TCM

monitors input and output signals. See Fig. 2.

2) If TCM detects problems in transaxle-related circuits or

devices, TCM may record a trouble code in memory. To retrieve obtain

trouble codes, use Scan Tool (VAG 1551) and Adapter (VAG 1551/3). All

trouble code and related testing information is contained in scan

tool.

TESTING

ELECTRICAL

NOTE: Manufacturer does not provide electrical component tests or

specifications. All testing information is contained in Scan

Tool (VAG 1551).

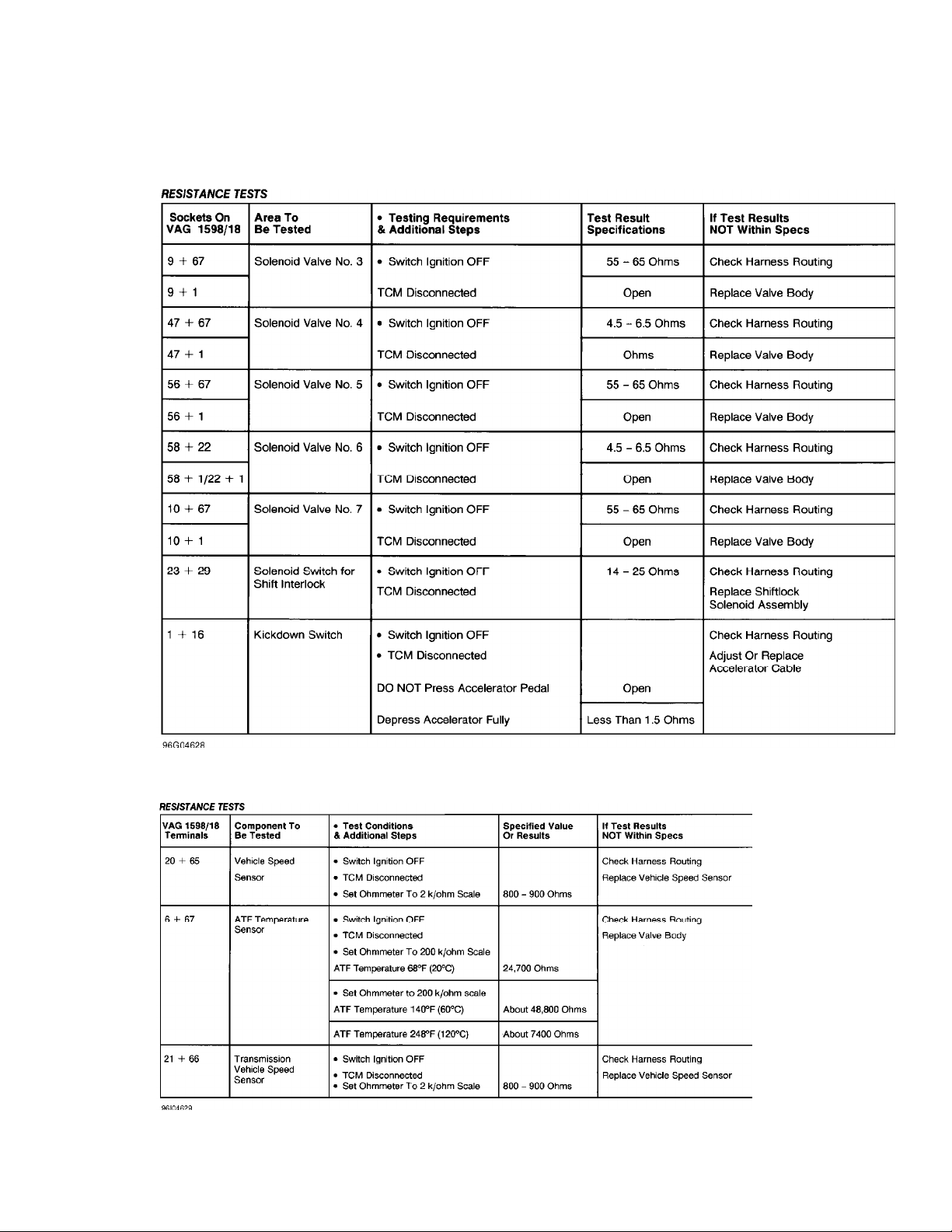

1) To isolate TCM circuit problems without a scan tool,

circuit resistance and voltage can be checked by using Test Box (VAG

1598/18).

2) When checking circuit voltage, leave battery connected

with test box connected to TCM and TCM vehicle harness. When checking

circuit resistance, disconnect negative battery cable and connect test

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 14)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

box to TCM vehicle harness. Leave TCM disconnected.

3) Measure voltage and resistance between specified sockets

on test box. See Figs. 10-13. If a problem is found, service harness

or components as necessary. If no problem is found, TCM may be

defective.

Thursday, August 19, 1999 11:28PM

Fig. 10: Testing TCM Harness & Components (1 Of 4)

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 15)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 11: Testing TCM Harness & Components (2 Of 4)

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 16)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 12: Testing TCM Harness & Components (3 Of 4)

Courtesy of Volkswagen United States, Inc.

Fig. 13: Testing TCM Harness & Components (4 Of 4)

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 17)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

HYDRAULIC PRESSURE

Check operation of apply and brake clutches by air checking

fluid passages of valve body and transaxle case. Install Pressure

Gauge (VAG 1702) to transaxle pressure tap located near dipstick tube.

Check main hydraulic pressure under normal driving conditions. See

MAIN PRESSURE table. If main hydraulic pressures are not correct,

check for incorrect idle speed, problem with pump or sticking valves

in valve body. Repair as necessary.

MAIN PRESSURE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application psi (Bar)

"D"

Idle RPM ............................... 49-55 (3.4-3.8)

2000 RPM (1) ....................... 146-164 (10.1-11.3)

"R"

Idle RPM .............................. 94-109 (6.5-7.5)

2000 RPM (1) ....................... 334-348 (23.0-24.0)

Thursday, August 19, 1999 11:28PM

(1) - With solenoid valve connector disconnected. After test,

reconnect solenoid valves and using appropriate scan tool,

erase trouble codes from memory.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

STALL SPEED

CAUTION: DO NOT operate engine at stall speed for more than 5

seconds. If you need to repeat stall speed test, wait 20

seconds.

1) Engage parking brake and block drive wheels. Connect

tachometer to engine. Warm engine to normal operating temperature.

2) Firmly press brake pedal. Move gear selector to "D"

position. Open throttle to wide open throttle position. Note engine

speed and release throttle pedal.

3) Compare measured stall speed with stall speed

specification. See STALL SPEED SPECIFICATIONS table. If stall speed is

within range, test is complete.

4) If stall speed is up to 200 RPM too low, check engine

condition and adjustments. If stall speed is greater than 200 RPM too

low, torque converter is faulty. If stall speed is too high, check

1st-3rd apply clutch or one-way clutch for slipping or damage.

STALL SPEED SPECIFICATIONS

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application RPM

CLK ............................................ 2600-2900

CLB & CKZ ...................................... 2250-2550

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 18)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

ON-VEHICLE SERVICE

DRIVE AXLE SHAFTS

See appropriate AXLE SHAFTS article in AXLE SHAFTS & TRANSFER

CASES section.

OIL COOLER FLUSHING

1) Remove external oil filter. Remove oil lines and allow

fluid to drain. Using pressurized solvent, flush remaining fluid and

debris from oil lines and cooler. Repeat flushing if necessary.

2) Use pressurized shop air to remove solvent from oil lines

and oil cooler. Install a new external oil filter.

TRANSAXLE COMPONENTS

Thursday, August 19, 1999 11:28PM

Following components may be serviced with transaxle in

vehicle. For removal and installation procedures, see

TRANSAXLE DISASSEMBLY.

* Drive Flanges

* External Oil Filter

* Gear Selector Lever

* Multifunction Switch, Speedometer Drive Shaft & Speed Sensor

* Oil Pan & Valve Body Assembly

* Planetary Gear Cover

REMOVAL & INSTALLATION

See appropriate AUTOMATIC TRANSMISSION REMOVAL article in

TRANSMISSION SERVICING section.

TORQUE CONVERTER

1) Remove torque converter. Check torque converter for any

wear or damage, and replace if necessary. If torque converter is being

reused, drain old fluid.

2) Extract ATF from torque converter using Torque Converter

Service Station (VAG 1358 A) and Probe (VAG 1358 A/1).

TRANSAXLE DISASSEMBLY

TRANSAXLE UNIT

1) Remove torque converter. Remove oil pan and valve body

assembly. Remove sealing plug from transaxle case. See Fig. 14.

2) Measure and record turbine shaft end play. See Fig. 15.

Remove oil pump bolts. Using two M8 bolts, remove oil pump from front

of transaxle. See Fig. 16.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 19)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

3) Remove all clutches with support tube, 2nd-4th gear clutch

plates, springs and spring caps together. See Figs. 17 and 18.

4) Lock drive shell in place by inserting a screwdriver

through hole of large sun gear into side of transaxle case. See

Fig. 19. Loosen and remove small planetary drive shaft bolt, washer

and shim. See Fig. 20. Remove small planetary drive shaft.

5) Remove large drive shaft and sun gear. Remove Vehicle

Speed Sensor (VSS) from transaxle case. Remove supporting tube and

one-way clutch circlips. Remove one-way clutch assembly.

6) Remove planetary carrier with dished spring. Remove

reverse brake clutch assembly. See Figs. 17, 20 and 21. DO NOT remove

input gear assembly, unless bearing or gear damage is present.

Thursday, August 19, 1999 11:28PM

Fig. 14: Exploded View Of Oil Pan & Valve Body

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 20)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 15: Checking Turbine Shaft End Play

Courtesy of Volkswagen United States, Inc.

Fig. 16: Removing Oil Pump

Courtesy of Volkswagen United States, Inc.

AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 21)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

Fig. 17: Exploded View Of Transaxle Components

Courtesy of Volkswagen United States, Inc.

Fig. 18: Removing Turbine Shaft With 2nd-4th Brake Clutch & 1st3rd Apply Clutch

Courtesy of Volkswagen United States, Inc.

Loading...

Loading...