Page 1

- Data Brochure

Boiler Control 274

274_D

11/12

The Boiler Control 274 operates up to four on/off boilers to provide outdoor reset operation, domestic hot water and setpoint

operation with priority. When operating as a tN4 System Control, the 274 can connect with up to 24 tN4 devices on a single

boiler bus. The 274 has primary pump sequencing capabilities along with a flow proof or combustion air damper proof

demand.

Additional functions include:

tN4 Compatible

•

24 Hour, 5-1-1, 7 Day Schedule

•

Flow or Combustion Air Proof

•

Four On/Off Boilers

•

Equal Run Time Rotation

•

Primary Pump Sequencing

•

DHW Operation

•

Optional DHW Sensor

•

Setpoint Operation

•

tN4

Boiler

Bus

VIEW

1

Primary

DHW

13

24

Menu Item

Boiler Control 274

One tN4, Four Stage Boiler & DHW / Setpoint

Do not apply power

2513

46

BRet/

ComtN4

OutCom

Boil

+

–

DHW

Sup

Boiler Demand

DHW / Setpoint Demand

Proof Demand

Zone Load Shedding

Priority Override

EMS Input Signal

Relay1Relay2Relay3Relay4C.A. /

Setback

Rotate

Off

EMS

Demands

Exercise

Off

Test

Modes

1 Up to 4 On/Off Boilers

2 Up to 2 On/Off Boilers & 2 Pumps

3 Up to 2 Lo/Hi Boilers

4 1 Lo/Hi Boiler & 1 Pump

5 1 Three Stage Boiler & Pump

6 1 Four Stage Boiler

Made in Canada by

tekmar Control Systems Ltd

tektra 1020-02

Power 115 V ±10% 60 Hz 7 VA, 1150 VA max.

Relays 230 V (ac) 5 A 1/3 hp

Demands 20 to 260 V (ac) 2 VA

Signal wiring must be rated at least 300 V.

20

Alert

17 191091211 1413 1615

DHW

/ P2

18

Prim

Power

P1 L N

Boiler

Demand

222187

Pump Sequencer

Fixed Last

Fixed Lead

First On / Last Off

First On / First Off

off

red

red

For maximum heat,

press and hold Tes t

button for 3 seconds.

Meets Class B:

Canadian ICES

FCC Part 15

23

24

Com

DHW

/Setp

Dem

Dem

not testing

testing

testing paused

25

Pr.

Date Code

H2050A

Input

Flow OR

C.A. Proof

Input

DHW OR

Setpoint

Outdoor Sensor

Input

Demand

Signal

Included

OR

0-10 or 2-10 V (dc)

from EMS

Output

Up to 2

Boiler Pumps

OR

Input

Boiler

Demand

Signal

OR

Input

Universal

Sensor

Included

Input

Universal

Sensor

Included

Output

Up to 4

On/Off Boilers

Output

Combustion

Air Damper

OR Alert

Output

DHW Pump

OR

Primary Pump

Output

Primary

Pump

Input

115 V (ac)

Power Supply

1 of 44 © 2012 274_D - 11/12

Page 2

How to Use the Data Brochure

This brochure is organized into three main sections.

They are: 1) Sequence of Operation,

2) Installation,

3) Control Settings and

4) Testing and Troubleshooting.

Table of Contents

User Interface ...............................................................2

Display and Symbol Description ................................... 3

Access Level.................................................................4

Sequence of Operation .................................................4

Section A: Boiler Demand ........................................4

Section B: Outdoor Reset.........................................4

Section C: Boiler Operation ......................................6

Section D: Combustion Air and Alert Settings ..........8

Section E: Domestic Hot Water Operation ............... 9

Section F: Setpoint Operation ................................ 13

Section G: Energy Management System (EMS) .... 15

Section H: Pump Operation ................................... 16

Section I: Exercising ............................................... 17

Section J: Time Clock ............................................ 17

Section K: Setting the Schedule ............................. 18

Section L: Boost ..................................................... 18

The Control Settings section of this brochure describes

the various items that are adjusted and displayed by the

control. The control functions of each adjustable item are

described in the Sequence of Operation.

®

Section M: tekmarNet

4 Communication ............... 19

Installation .................................................................. 20

Control Settings ......................................................... 25

Cleaning the Control ..............................................25

DIP Switch Settings ................................................25

VIEW Menu ............................................................ 27

ADJUST Menu ....................................................... 29

TIME Menu .............................................................35

SCHEDULE Menu ..................................................36

MISC Menu ............................................................ 39

Testing the Control ...................................................... 40

Error Messages .......................................................... 41

Technical Data ............................................................ 44

Limited Warranty ....................................................... 44

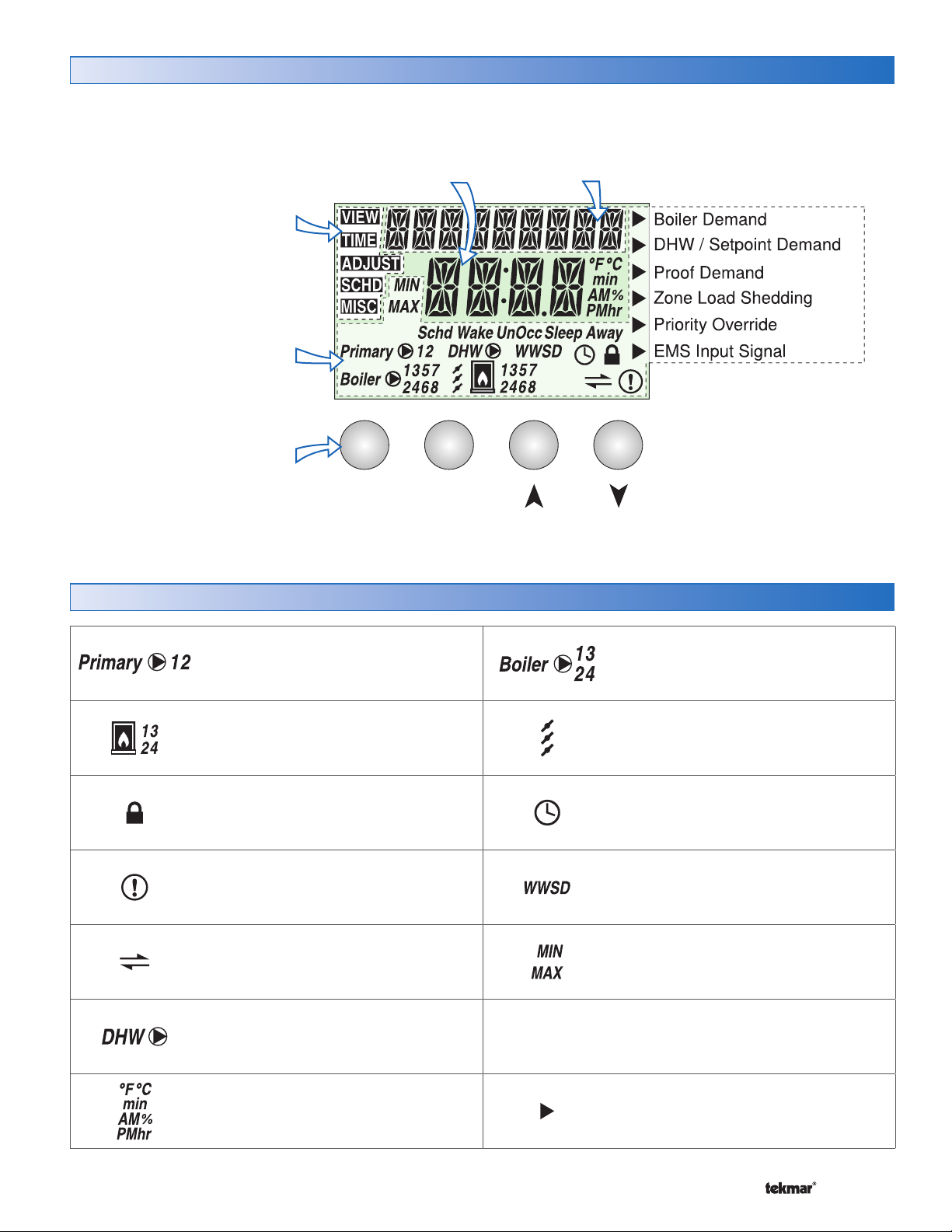

User Interface

The control uses a Liquid Crystal Display (LCD) as the

method of supplying information. You use the LCD in

order to setup and monitor the operation of your system.

The control has four push buttons (Menu, Item, ▲, ▼) for

selecting and adjusting settings. As you program your

control, record your settings in the ADJUST menu table,

which is found in the second half of this brochure.

Menu

All of the items displayed by the control are organized

into five menus (View, Adjust, Time, Schedule, and Misc).

These menus are listed on the top left hand side of the

display (Menu Field). To select a menu, use the Menu

button. By pressing and releasing the Menu button, the

display sequences between the five menus. Once a menu

is selected, there will be a group of items that can be viewed

within the menu.

Item

The abbreviated name of the selected item will be displayed

in the item field of the display. To view the next available

item, press and release the Item button. Once you have

reached the last available item in a menu, pressing and

© 2012 274_D - 11/12 2 of 44

releasing the Item button will return the display to the first

item in the selected menu.

The items can be quickly scrolled through by holding the

Item button and then pressing the ▼ button. To rapidly

scroll through the items in the reverse order, hold the

Item button and press the ▲ button.

Adjust

To make an adjustment to a setting in the control, begin by

selecting the ADJUST, TIME, SCHEDULE or MISC menu

using the Menu button. Then select the desired item using

the Item button. Finally, use the ▲, and / or ▼ button to make

the adjustment.

Additional information can be gained by observing the

Status field of the LCD. The status field will indicate

which of the control’s outputs are currently active. Most

symbols in the status field are only visible when the

VIEW menu is selected.

Page 3

Display

Menu Field

Displays the

current menu

Status Field

Displays the current

status of the

inputs, outputs and

control’s

operation

Buttons

Selects Menus, Items

and adjusts settings

Number Field

Displays the current value

of the selected item

Menu Item

Item Field

Displays the current

item selected

Symbol Description

PRIMARY PUMP

Displays when primary pump 1 or

primary pump 2 is in operation

BOILER

Displays which boiler stage is

operating

LOCK

Displays when adjusting Access level if

Switch is set to lock.

WARNING

Displays when an error exists.

COMMUNICATION BUS

Displays when tN4 thermostats are

connected.

DHW PUMP

Displays when the DHW Pump is

operating

Schd Wake

UnOcc Sleep

Away

BOILER PUMP

Displays when the boiler pump 1, 2, 3,

or 4 are operating

COMBUSTION AIR DAMPER

Displays when the combustion air

damper relay is closed

SCHEDULE MASTER

Displays when the 274 is a schedule

master

WARM WEATHER SHUT DOWN

Displays when the control is in warm

weather shut down

MINIMUM & MAXIMUM

Displays when the boil target or the boil

supply is at a minimum or maximum

Schd, Wake, UnOcc, Sleep, Away

Displays the current event of a

schedule or scene

°F, °C, MINUTES, AM, %, PM,

HOURS

Units of measurement.

3 of 44 © 2012 274_D - 11/12

POINTER

Displays the control operation as

indicated by the text

Page 4

Access Level

The access level restricts the number of Menus, Items,

and Adjustments that can be accessed by the user. The

Access Level setting is found in the Miscellaneous (MISC)

Menu. Select the appropriate access level for the people

who work with the control on a regular basis. There are

three Access Level Settings:

•

User (USER): Select this access level to limit the highest

number of settings available to the end user.

Installer (INST): Select this access level to limit some of

•

the settings available to the installer. This is the factory

default access level.

Advanced (ADV): Select this access level to have complete

•

access to all of the control settings. In the following menu

tables, the appropriate access level needed to view each

item is shown in the Access column.

Note: the Lock / Unlock switch on the front of the control

must be set to unlock to change the access level.

Sequence of Operation

In order for the control to have a target water temperature there must be a demand. There are three different demands the

control can have: boiler demand, DHW demand, and setpoint demand.

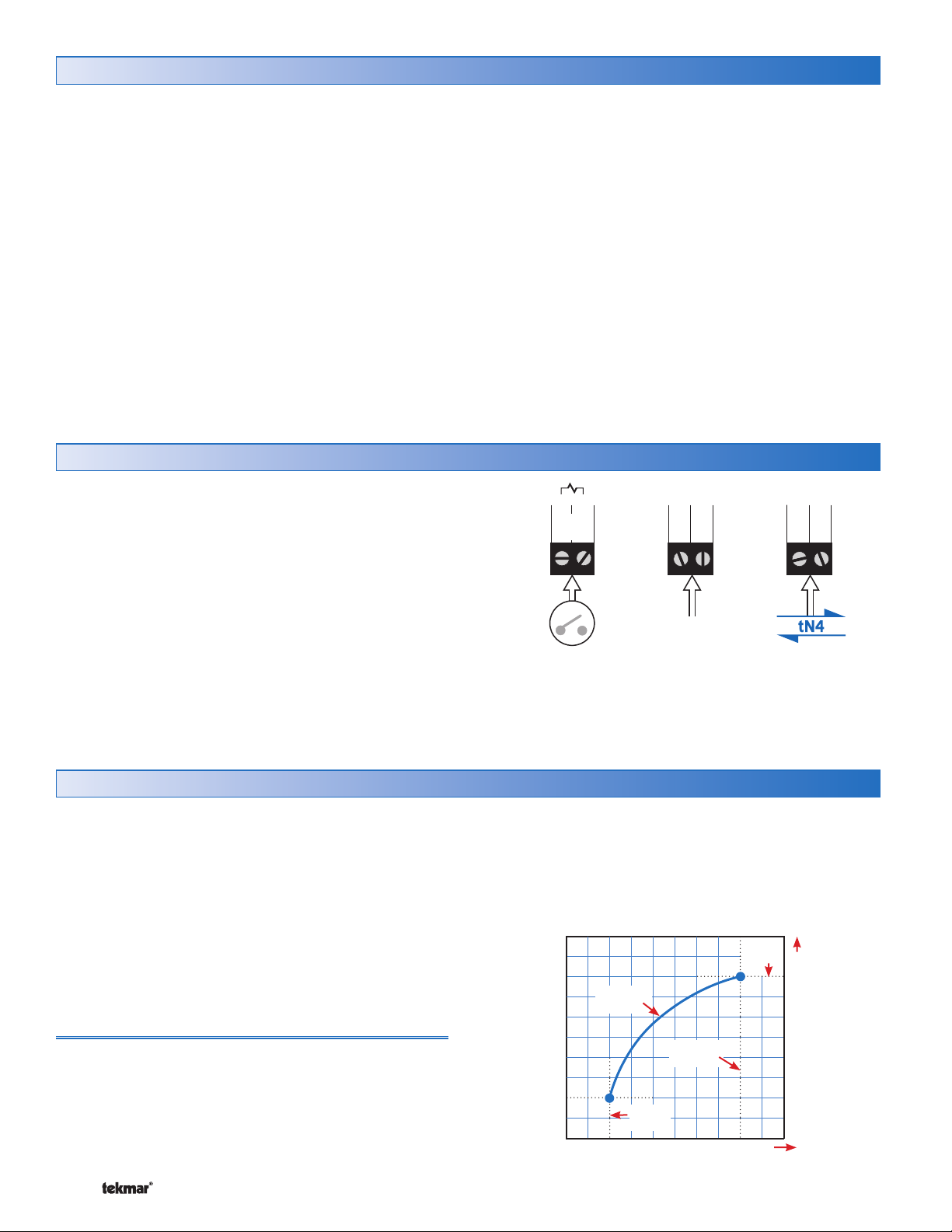

Boiler Demand Section A

Once the control receives a boiler demand it calculates a

target water temperature based on the characterized heating

curve to provide outdoor reset for space heating. The control

can receive a boiler demand three different ways:

1. By applying 20-260 V (ac) to the boiler demand

terminals (21 & 22) when the DIP switch is set to

Demands.

2. From an Energy Management System (EMS) by

applying a 0-10 or 2-10 V (dc) signal to terminals 2 &

3 when the DIP switch is set to EMS.

3. From a tN4 device. This requires a tN4 thermostat to

be wired to terminals 1 & 2 so that the call for heat

can go over the communication bus.

20-260 V (ac)

2221

Boiler

Demand

Demand

23

OutCom

+

–

OR OR

0-10 or

2-10 V (dc)

from EMS

21

tN4 Com

–

tN4

Demand

Outdoor Reset Section B

In a heating system, the rate of heat supplied to the building

must equal the rate at which heat is lost. If the two rates are

not equal, the building will either cool off or over heat.

The rate of building heat loss depends mostly on the outdoor

temperature. Outdoor Reset allows a hot water heating

system to increase the water temperature, adding heat to

the building, as the outdoor temperature drops. The rate

at which the water temperature is changed as a function

of outdoor temperature is defined by the characterized

heating curve.

Characterized Heating Curve

A characterized heating curve determines the amount the

target water temperature is raised for every 1° drop in outdoor

air temperature.

The characterized heating curve takes into account the

type of terminal unit that the system is using. Since different

types of heating terminal units transfer heat to a space using

© 2012 274_D - 11/12 4 of 44

different proportions of radiation, convection and conduction,

the supply water temperature must be controlled differently.

The control uses the terminal unit setting to vary the supply

water temperature to suit the terminal unit being used. This

improves the control of the air temperature in the building.

Boiler Characterized Heating Curve

Boiler

Design

Terminal

Unit

Outdoor

Design

Boiler

Indoor

Decreasing Outdoor Temperatures

Increasing Water Temperatures

Page 5

Terminal Unit Setting in Adjust Menu

Select the appropriate terminal unit in the adjust menu.

This will change the shape of the characterized heating

curve to better match the heat transfer properties of that

specific terminal unit.

Hydronic Radiant Floor (HRF1)

A heavy or high mass, hydronic radiant floor system. This

type of a hydronic radiant floor is embedded in either a thick

concrete or gypsum pour. This heating system has a large

thermal mass and is slow acting.

Hydronic Radiant Floor (HRF2)

A light or low mass, hydronic radiant floor system. Most

commonly, this type of radiant heating system is attached to

the bottom of a wood sub floor, suspended in the joist space,

or sandwiched between the subfloor and the surface. This

type of radiant system has a relatively low thermal mass

and responds faster than a high mass system.

Radiator (RAD)

A radiator terminal unit has a large heated surface that is

exposed to the room. A radiator provides heat to the room

through radiant heat transfer and natural convection.

Baseboard (BASE)

A baseboard terminal unit is similar to a radiator, but has

a low profile and is installed at the base of the wall. The

proportion of heat transferred by radiation from a baseboard

is greater than that from a fin-tube convector.

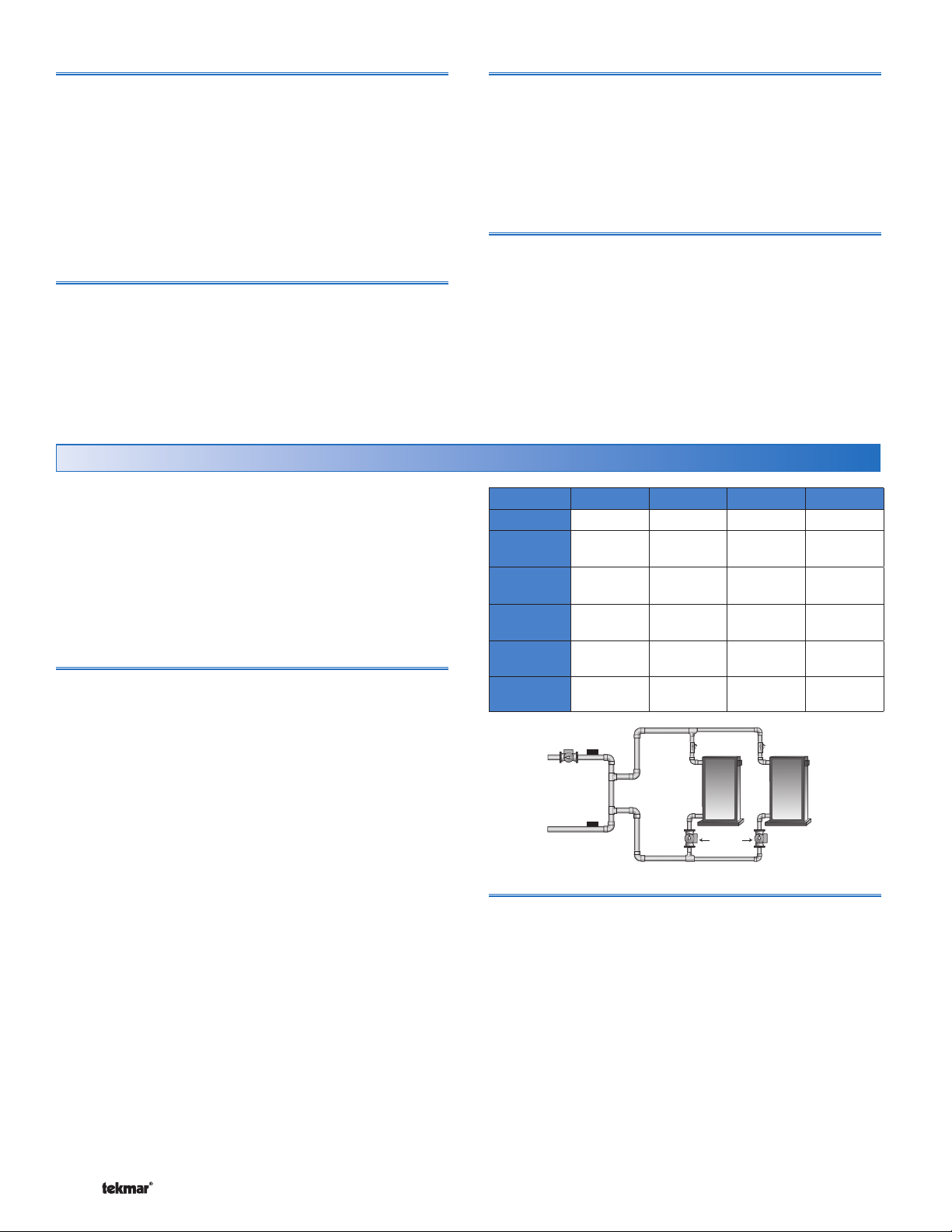

Boiler Terminal Unit Defaults

When a terminal unit is selected for boiler zones, the

control loads default values for the boiler design, boiler

maximum supply, and boiler minimum supply temperatures.

The factory defaults can be changed to better match the

installed system. Locate the Boiler Terminal Unit setting in

the Adjust menu.

Fancoil (COIL)

A fancoil terminal unit or air handling unit (AHU) consisting

of a hydronic heating coil and either a fan or blower. Air is

forced across the coil at a constant velocity by the fan or

blower and is then delivered into the building space.

Fin–tube Convector (CONV)

A convector terminal unit is made up of a heating element

with fins on it. This type of terminal unit relies on the natural

convection of air across the heating element to deliver

heated air into the space. The amount of natural convection

is dependant on the supply water temperature to the heating

element and the room air temperature.

Terminal Unit

High Mass Radiant

Low Mass Radiant

Fancoil

Fin-Tube Convector

Radiator

Baseboard

BOIL DSGN BOIL MAX BOIL MIN

120°F (49°C) 140°F (60°C) OFF

140°F (60°C) 160°F (71°C) OFF

190°F (88°C) 210°F (99°C) 140°F (60°C)

180°F (82°C) 200°F (93°C) 140°F (60°C)

160°F (71°C) 180°F (82°C) 140°F (60°C)

150°F (76°C) 170°F (77°C) 140°F (60°C)

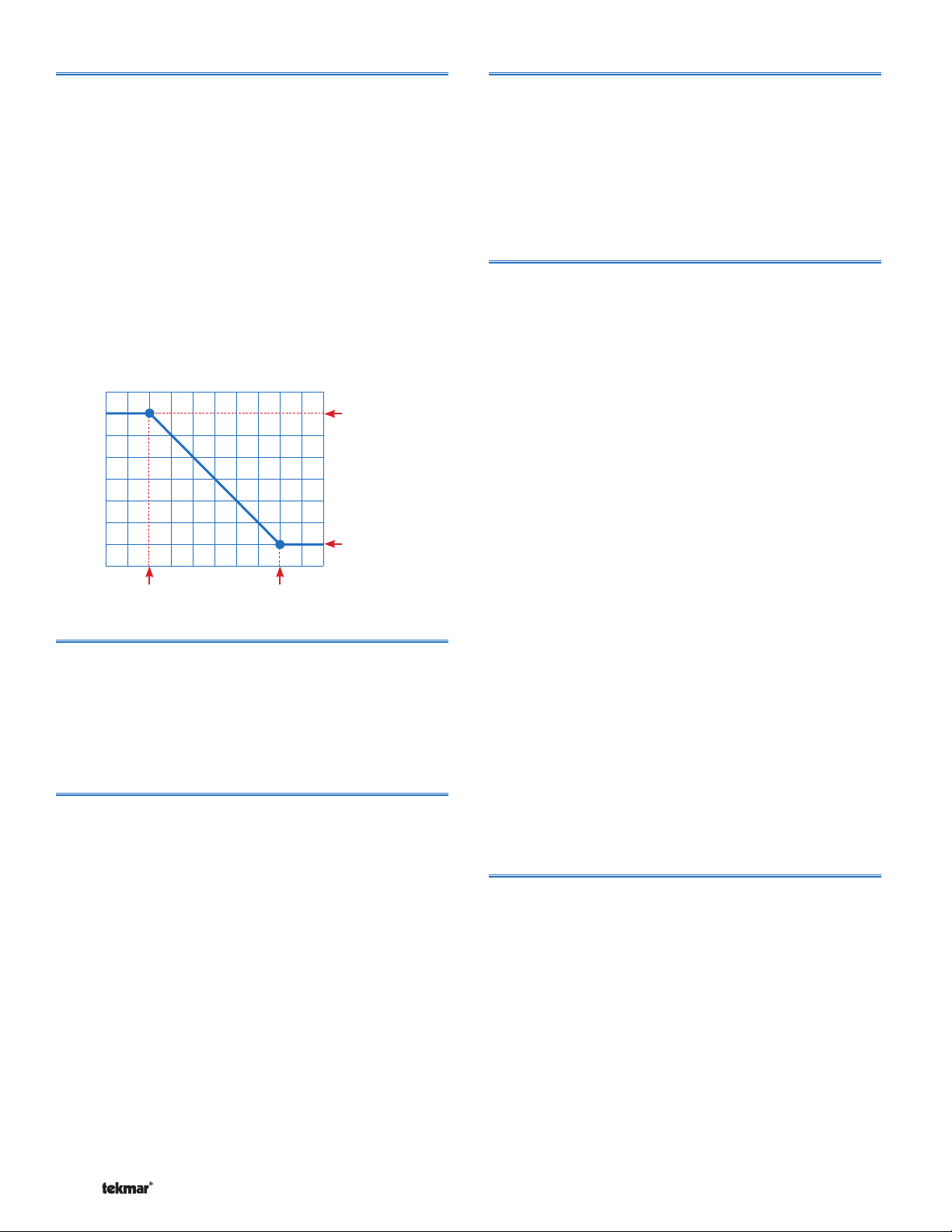

Room Setting in Adjust Menu

The Room setting is the desired room air temperature, but

it is not measuring a room temperature sensor. Instead,

the Room setting parallel shifts the heating curve up or

down to change the target water temperature. Adjust the

Room setting to increase or decrease the amount of heat

available to the building. Once the heating curve has been

set up properly, the Room setting is the only setting that

needs to be adjusted. The default Room setting is 70°F

(21°C), and it can be adjusted for both the occupied and

unoccupied periods.

5 of 44 © 2012 274_D - 11/12

Page 6

Outdoor Design Setting in Adjust Menu

The outdoor design temperature is typically the coldest

outdoor air temperature of the year. This temperature is

used when doing the heat loss calculations for the building

and is used to size the heating system equipment. If a cold

outdoor design temperature is selected, the supply water

temperature rises gradually as the outdoor temperature

drops. If a warm outdoor design temperature is selected,

the supply water temperature rises rapidly as the outdoor

temperature drops.

Boiler Indoor Setting in Adjust Menu

The boiler indoor design temperature is the indoor

temperature the heating designer chose while calculating the

heat loss for the boiler water heated zones. This temperature

is typically 70°F (21.0°C). This setting establishes the

beginning of the boiler characterized heating curve.

Boiler Design Setting in Adjust Menu

The boiler design supply temperature is the boiler water

temperature required to heat the zones at the outdoor design

temperature, or on the typical coldest day of the year.

(Default automatically changes based on terminal unit

setting)

Warm Weather Shut Down (WWSD) Setting in Adjust

Menu

Warm Weather Shut Down disables the heating system when

the outdoor air temperature rises above this programmable

setting. When the control enters into WWSD, the LCD will

indicate this in the status field. WWSD is only available

when the DIP switch = Demands. The boilers will operate

when a Domestic Hot Water (DHW) demand or a Setpoint

Demand is present.

Boiler Operation Section C

The 274 is able to operate up to four on/off boilers as a heat

source. For proper operation of the boilers, the 274 must be

the only control that determines when a boiler is to fire.

*Important note: The boiler operator, or aquastat, remains

in the burner circuit and acts as a secondary upper limit

on the boiler temperature. The boiler aquastat temperature

setting must be adjusted above the 274’s boiler maximum

setting in order to prevent short cycling of the burner.

Mode

The 274 control is capable of staging single stage, two

stage, three stage and four stage on/off heat sources. As

well, in certain modes of operation, the control is capable

of controlling the individual boiler pumps. The control has 6

modes of operation based on the type of staging and pump

operation that is desired. The following describes the modes

of operation.

Mode 1: 4 Single stage boilers and primary pump.

Mode 2: 2 Single stage boilers with individual boiler

pumps and primary pump.

Mode 3: 2 Two stage boilers and a primary pump.

Mode 4: 1 Two stage boiler and individual pump.

Mode 5: 1 Three stage boiler and individual pump.

Mode 6: 1 Four stage boiler and primary pump.

Relay 1 Relay 2 Relay3 Relay 4

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Boiler 1 Boiler 2 Boiler 3 Boiler 4

Boiler 1 Boiler 1

Boiler 1

Stage 1

Boiler 1

Stage 1

Boiler 1

Stage 1

Boiler 1

Stage 1

Supply

Supply

Sensor

Sensor

Primary

Primary

Pump

Pump

Return

Return

Sensor

Sensor

Pump

Boiler 1

Stage 2

Boiler 1

Stage 2

Boiler 1

Stage 2

Boiler 1

Stage 2

Boiler 2 Boiler 2

Boiler 2

Stage 1

Boiler 1

Pump

Boiler 1

Stage 3

Boiler 1

Stage 3

Boiler

Boiler

Pumps

Pumps

Pump

Boiler 2

Stage 2

not used

Boiler 1

Pump

Boiler 1

Stage 4

Boiler Target Temperature

The boiler target temperature is determined by connected tN4

devices or by a Boiler, DHW or Setpoint demand received

by the control. An Energy Management System (EMS) can

also give a boiler target. The tN4 devices determine the

highest water temperature required and then request this

temperature on the tN4 boiler bus. The temperature request

creates a Boiler Demand and this is indicated on the display.

A DHW demand and a Setpoint demand have temperature

settings to which the boilers are operated to meet and are

able to override the tN4 bus temperature if required. The

control displays the temperature that it is currently trying to

maintain as the boiler supply temperature in the View menu.

If the control does not presently have a requirement for heat,

it does not show a boiler target temperature. Instead, “– – –”

is displayed in the LCD.

© 2012 274_D - 11/12 6 of 44

Page 7

Boiler Minimum Setting in Adjust Menu

B

o

i

l

W

a

t

e

r

T

e

m

p

e

r

a

t

u

r

e

B

o

i

l

W

a

t

e

r

T

e

m

p

e

r

a

t

u

r

e

The boiler minimum is the lowest temperature that the

control is allowed to use as a boiler target temperature.

During mild conditions, if the control calculates a boiler

target temperature that is below the boiler minimum setting,

the boiler target temperature is adjusted to at least the

boiler minimum setting. The MIN segment is displayed in

the LCD while viewing the boiler supply or target and when

the boiler target is boiler minimum and the boiler supply is

less than boiler minimum plus 5°F (2.5°C). Set the Boiler

Minimum setting to the boiler manufacturer’s recommended

temperature.

Boil MIN + 5°F (2.5°C)

Boiler Differential

e

e

r

B

B

o

o

i

i

l

l

W

W

a

a

e

e

T

T

t

t

e

e

r

r

MIN segment on

r

u

u

t

t

a

a

r

r

e

e

p

p

m

m

Boil MIN

MED

The MED setting is selected if the boiler that is used has

a medium thermal mass. This means that the boiler either

has a large water content and a low metal content or a

low water content and a high metal content. This is typical

of many modern residential cast iron boilers or steel tube

boilers.

The Med mass setting provides a moderate response to

the heating system.

HI

The HI setting is selected if the boiler that is used has a

high thermal mass. This means that the boiler has both

large water content and a large metal content. A boiler that

has a high thermal mass is relatively slow in coming up to

temperature. This is typical of many commercial cast iron

and steel tube boilers.

The Hi mass setting provides a slow response to the

heating system.

Boiler Maximum Setting in Adjust Menu

The boiler maximum is the highest temperature that the

control is allowed to use as a boiler target temperature.

The MAX segment is displayed in the LCD while viewing

the boiler supply or target and when the boiler target is

boiler maximum and the boiler supply is greater than boiler

maximum minus 5°F (2.5°C). Set the boiler maximum

setting to the boiler manufacturer’s recommended temperature. At no time does the control operate the boiler

above 248°F (120°C).

MAX

segment

on

B

B

o

o

i

i

l

l

W

W

a

a

e

e

T

T

t

t

r

r

e

e

e

e

p

p

m

m

e

e

r

r

u

u

t

t

a

a

r

r

MAX

segment

on

Boil MAX

Boil MAX – 5°F (2.5°C)

Boiler Differential

Stage Delay Setting in Adjust Menu

The Stage Delay is the minimum time delay between the

firing of each stage. After this delay has expired the control

can fire the next stage if it is required. This setting can be

adjusted manually or set to an automatic setting. When the

automatic setting is used, the control determines the best

Rotation

The Rotate feature changes the firing order of the boilers

whenever one boiler accumulates 48 hours more run time

than any other boiler. Rotation will be forced if any boiler

accumulates 60 hours more run time. After each rotation,

the boiler with the least running hours is the first to fire and

the boiler with the most running hours is the last to fire.

This function ensures that all of the boilers receive equal

amounts of use. When the Rotate / Off DIP switch is set

to the Off position, the firing sequence always begins with

lowest boiler to the highest boiler.

1 2

720 hours

672 hours

2 1

672 hours

720 hours

To reset the rotation sequence (without regard to historical

running hours), toggle the Rotation DIP Switch Off for 3

seconds and on again. Note that the running hours (see

Run Time) in the View menu also need to be reset if you

want the rotation sequence and running hours display to

be synchronized.

stage delay based on the operation of the system.

Boiler Mass Setting in Adjust Menu (per boiler)

Match the boiler mass setting with the thermal mass

characteristics of each boiler. The boiler mass settings

also adjusts the inter-stage delay time when operating with

an automatic differential.

LO

The LO setting is selected if the boiler that is used has

a low thermal mass. This means that the boiler has very

small water content and has very little metal in the heat

exchanger. A boiler that has a low thermal mass comes

up to temperature quite rapidly when fired. This is typical

of many copper fin-tube boilers.

The Lo mass setting provides a fast response to the heating

system.

7 of 44 © 2012 274_D - 11/12

Fixed Last

In some applications, it may be desirable to have the last

boiler fire last at all times while the firing sequence of

the remaining boilers is changed using Equal Run Time

Rotation. This configuration is typical of installations where

the boiler plant includes higher efficient boilers and a single

less efficient boiler. The lesser efficient boiler is only desired

to be operated when all other boilers in the plant are on

and the load cannot be satisfied. This rotation option is

selected by setting the Fixed Last / Off DIP switch to Fixed

Last. With a fixed last rotation, the last boiler is the last to

stage on and the first to stage off.

Page 8

Fixed Lead & First On / First Off

In some applications, it may be desirable to have the first

boiler fire first at all times while the firing sequence of the

remaining boilers is changed using Equal Run Time Rotation.

This rotation option is selected by setting the Fixed Lead /

Off DIP switch to the Fixed Lead position.

When using the Fixed Lead rotation option, a selection must

be made between First On / Last Off and First On / First Off

using the DIP switch.

When First On / First Off is selected, the lead boiler is always

staged on first and staged off first. This configuration is typical

of installations where the boiler plant includes similar boilers

but the first boiler is required to be the first to fire in order to

establish sufficient draft for venting.

Fixed Lead & First On / Last Off

When First On / Last Off is selected, the lead boiler is always

staged on first and staged off last. This configuration is typical

of installations where the boiler plant includes a single higher

efficient boiler with lesser efficient boilers. The lead boiler

is the high efficiency boiler, therefore it is the last boiler to

be sequenced off.

Boiler Run Time in View Menu

The running time of each boiler is logged in the view menu.

To reset the running time, select the appropriate Boiler Run

Time in the View menu and press and hold the Up and Down

buttons simultaneously until CLR is displayed.

Boiler Differential Setting in Adjust Menu

An On/Off heat source must be operated with a differential

in order to prevent short cycling. The boiler differential can

be fixed or automatically determined by the control. The Auto

Differential setting balances the amount of temperature swing

in the boiler supply temperature with boiler on times, off times,

and cycle times. This reduces potential short cycling during

light load conditions.

Manual Differential

Differential = 10°F (6°C)

165°F (74°C)

160°F (71°C)

155°F (68°C)

Boiler

On

Boiler

On

Target + 1/2 Differential

Target

Target – 1/2 Differential

Automatic Differential

Off

Differential

Time

On

Heating Load

Boiler Staging Mode - Lo/Hi or Lo/Lo in Adjust Menu

When using multi-stage boilers, a selection must be made

regarding the staging order of the boiler(s). This adjustment

is made in the ADJUST menu of the control.

Lo/Hi: If the Lo/Hi staging option is selected the control stages

in sequence all of the stages in a single boiler. Once all of the

stages are turned on, the control then stages in sequence all

of the stages of the next boiler in the rotation sequence.

Lo/Lo: If the Lo/Lo staging option is selected, the control

stages all of the Lo stage outputs in all of the boilers first.

Once all of the boilers are operating on their Lo stages, the

control then operates the second stage in each boiler in the

same order.

Boiler Fire Delay Setting in Adjust Menu

(per boiler)

The Boiler Fire Delay sets the time it takes for the boiler to

generate flame from the time the boiler turns on.

Boiler Contact Closed

Fire Delay

Burner On

Time

Combustion Air and Alert Settings Section D

Relay Setting in Adjust Menu (C.A. Damper / Alert)

The control includes an auxiliary relay that can be used either

for a combustion damper/venting device or an Alert. Selection

is made through the Relay item in the Adjust menu.

© 2012 274_D - 11/12 8 of 44

Alert

When the Relay is set to Alert, terminals 15 and 16 close

whenever a control or sensor error is detected, or when a

warning or limiting condition is detected. When the alert

contact closes, refer to the Error Messages section of this

brochure to determine the cause of the alert and how to

clear the error.

Page 9

Boiler Alarm

For the Boiler Alarm item to appear in the Adjust menu, the

Relay must be set to Alert. If no temperature increase is

detected at the boiler supply sensor within this delay period,

the Alert relay will close and the control will display the Boiler

Alarm error message. All boilers continue to operate if this

error is present. To clear the error, press and hold the up and

down buttons simultaneously for 5 seconds while viewing the

error message in the View menu.

Combustion Air (C.A.) Damper

When the Relay is set to Damper, terminals 15 and 16 operate

a combustion air damper / fan motor or power vent motor. The

Relay closes once a demand is received and the control has

determined that one or more boilers need to be turned on.

Combustion Air Proof Demand Setting in Adjust Menu

The proof demand can be used to prove a combustion air

or venting device if set to C.A. Boiler operation cannot occur

until the proof demand is present. If the proof demand is lost

during operation, the boiler plant is sequenced off.

Combustion Air Proof Demand Delay Setting in Adjust

Menu

The control includes a time delay that is associated with

the proof demand feature in order to determine if the proof

device is functional. Once the C.A. relay closes, the control

allows for this delay to receive the proof demand. If the proof

demand is not received within the delay time, the control will

display an error message.

Combustion Air Damper Delay Setting in Adjust Menu

If the Proof Demand function is set to F P (flow proof) or

OFF, boiler sequencing only occurs once a user adjustable

time delay elapses.

Combustion Air Post Purge

There is a fixed 15 second post purge of the C.A. relay

after the last boiler has turned off, or demand is removed. If

there is a heat demand still present once the last boiler has

turned off, the control can look at the error and determine

if sequencing is to occur in a “short” period of time. If the

control does anticipate staging, the C.A. relay will remain

on. Otherwise, the C.A. relay will be turned off once the 15

second post purge elapses.

Combustion Air Proof Demand Test

The control includes a C.A. proof demand test in order to

determine if the proving device has failed. If the C.A. damper

contacts are opened, the flow proof demand should not be

present after 4 minutes. If the flow proof demand remains,

the control will display an error message.

Domestic Hot Water Operation Section E

DHW operation is only available when the Pump Sequencer

DIP Switch is set to Off.

DHW Demand

DHW Demands come from one of three sources: an external

aquastat, a DHW tank sensor, or a tN4 DHW control.

Once the control detects a DHW Demand, the DHW Demand

segment is displayed in the LCD. If an External Powered

DHW Demand is applied while the DHW sensor is enabled

in the 274, an error message is generated and both demands

are ignored.

A DHW demand from a tN4 Setpoint Control can coexist with

another DHW demand without generating an error message.

The 274 will then use the higher of the two targets.

Powered DHW Demand

The control registers a DHW Demand when a voltage

between 20 and 260 V (ac) is applied across the DHW

Demand terminals 23 and 24. An aquastat or setpoint control

is used to switch the DHW Demand circuit. Program a DHW

Exchange temperature for the Occupied and UnOccupied

events in the Adjust Menu.

• DHW Sensor must be set to Off.

DHW Sensor

The control can register a DHW Demand when A DHW

Sensor is wired to terminals 5 and 6. Once the DHW Sensor

drops 1/2 of the DHW Differential setting below the DHW

Setpoint, the control registers a DHW Demand. Program a

DHW Tank temperature for the Occupied and UnOccupied

events in the Adjust Menu.

The DHW Sensor must be set to On. There cannot be

•

an externally powered DHW demand when using a DHW

sensor.

tN4 Setpoint Control in DHW Mode

The control can register a DHW Demand when a tN4 Setpoint

Control in DHW Mode is wired to terminals 1 and 2. The

DHW Demand is sent over the tN4 communication bus when

the Setpoint Control calls for heat. Program a DHW tank

temperature for the Occupied and UnOccupied events and

the desired supply water temperature required on the tN4

bus in the Adjust Menu of the tN4 Setpoint Control.

9 of 44 © 2012 274_D - 11/12

Page 10

DHW Differential Setting in Adjust Menu

Due to large differences between the heating load and the

DHW load, a separate DHW differential should be used

whenever a DHW Demand is present. This will improve

staging and boiler cycling. When using a DHW Sensor, a

DHW Demand is registered when the DHW sensor drops 1/2

of the DHW Differential setting below the DHW setting. The

DHW Demand is satisfied once the DHW Sensor rises 1/2

of the DHW Differential setting above the DHW setting.

OFF

DHW

Differential

ON

DHW Target

Mode OFF / No DHW Generation

All DHW demands are ignored. If this mode is selected while

DHW generation is underway, all DHW operation stops.

Mode 1 - DHW in Parallel with No Priority

When a valid DHW Demand is present, the DHW relay

(terminal 17) turns on. The primary pump can operate

when a Boiler Demand is present. It is assumed that the

DHW pump will provide adequate flow through the heat

exchanger and the boiler. Heating zones are unaffected

by DHW operation.

Mode = 1

Boiler Target Temperature during a DHW Demand

If a Powered DHW Demand is present, the boilers are

operated to maintain the DHW Exchange temperature. If a

DHW sensor demand is present, the boilers are operated

to maintain a temperature 40°F above the DHW tank

temperature. If a tN4 demand is present, the primary

pump is turned on according to the device’s reported

requirements and the boilers are operated to maintain the

devices requested target on the bus. The DHW Demand

overrides the boiler reset target temperature, except when

the boiler reset target is higher than the DHW target.

Regardless of DHW settings and requested targets, the

boilers will maintain a supply temperature no higher than

the Boil MAX setting.

DHW During UnOccupied

When using a Powered DHW Demand, the control has a

DHW Exchange UnOccupied setting that allows the installer

to select On or Off. When set to On, and the control receives

a DHW Demand during an UnOccupied or Sleep period,

the control continues operation of the DHW system as it

would during the Occupied and Wake periods. When set to

Off, the control will ignore a DHW Demand for the duration

of the UnOccupied and Sleep periods.

When using a DHW Sensor, a second DHW temperature

setting is available for the UnOccupied or Sleep period.

DIP Switch must be set to Setback to view UnOccupied

items.

During the Away Scene, DHW demands are ignored.

DHW

Pump

Primary

Pump

Mode 2 - DHW in Parallel with Priority

When a valid DHW Demand is present, the DHW relay

(terminal 17) turns on. The primary pump can operate

when a Boiler Demand is present. If the boilers are unable

to maintain the boiler target temperature, space heating

zones are shut off sequentially using tN4 communication

in order to provide priority to the DHW tank. For non-tN4

systems, the primary pump shuts off to provide priority. It

is assumed that the DHW pump will provide adequate flow

through the heat exchanger and the boiler.

Mode = 2

OFF

DHW

Pump

Primary

Pump

DHW Mode Setting in the Adjust Menu

The control has six different DHW Modes that affect pump

operation. The required DHW Mode setting will depend on

the piping arrangement of the DHW tank and whether or

not priority for DHW is necessary. DHW Priority stops or

limits the delivery of heat to the building heating system

while the DHW tank calls for heat. This allows for quick

recovery of the DHW tank.

© 2012 274_D - 11/12 10 of 44

Page 11

Mode 3 - DHW in Primary/Secondary with No Priority

When a valid DHW Demand is present, the DHW relay

(terminal 17) and Primary Pump relay (terminal 18) turn

on. Heating zones are unaffected by DHW operation. This

mode can be used if the DHW tank is piped in parallel and

a DHW valve is installed (need to use an external relay to

power the valve with 24 V (ac) since the DHW pump output

is a 120 V (ac) powered output).

Mode = 3

DHW

Pump

Primary

Pump

Mode 4 - DHW in Primary/Secondary with Priority

When a valid DHW Demand is present, the DHW relay

(terminal 17) and Primary Pump relay (terminal 18) turn

on. If the boilers are unable to maintain the boiler target

temperature, space heating zones are shut off sequentially

using tN4 communication in order to provide priority to the

DHW tank.

Mode 5 - DHW in Parallel / Last Boiler with Priority

When a valid DHW Demand is present, the DHW relay

(terminal 17) turns on and boiler pump 4 turns off. The control

uses the DHW Exchange Supply Sensor in order to measure

the boiler supply temperature supplied to the indirect tank.

There are two boiler target temperatures, one for the heating

system (BOIL TARGET) and one for the indirect DHW system

(BOIL DHW TARGET). In this mode, the DHW Demand can

only be provided from an External Powered Demand or tN4

Setpoint Control in DHW mode.

All boilers are used for space heating requirements

•

Boiler 2 is used for DHW when there is a DHW demand

•

The dedicated DHW boiler is always boiler 2 (relay 3),

•

even if there are less than 4 boilers.

If boiler 2 is disabled and mode 5 is selected then the

•

dedicated DHW boiler (boiler 2) will not operate.

This DHW mode is only available when control is in

•

Mode = 2

Mode = 5

DHW Exchange

Supply Sensor

DHW Pump

ON

Boiler

OFF

Supply

Sensor

Mode = 4

DHW

Pump

Primary

Pump

OFF

Primary

Pump

Mode 6 – Dedicated DHW

When a valid DHW Demand is present from the DHW

Sensor, the primary pump relay turns on. The DHW Relay

in this mode is used as the DHW recirculation pump and

operates continuously in the Occupied period and cycles

with the primary pump in the UnOccupied period. The boiler

plant is sequenced based only on the DHW Sensor.

All boilers are used for DHW requirements

•

Requires DHW demand from DHW sensor

•

DHW Pump Relay is used for DHW recirculation pump

•

Boiler Supply Sensor Not Required

•

Mode = 6

On/

Off

On/

Off

DHW Sensor

Recirculation

Pump

11 of 44 © 2012 274_D - 11/12

Page 12

DHW Priority Override Setting in Adjust Menu

DHW Priority Override applies to DHW MODE 2 and 4, as

well as Mode 5 if there is a tN4 device with DHW. It prevents

the building from cooling off too much or the possibility of

a potential freeze up during DHW priority.

When set to auto, the priority time is calculated based

on outdoor temperature. At or below the design outdoor

temperature, 15 minutes are allowed for DHW priority. At

or above 70°F, 2 hours are allowed for DHW priority. The

time allowed for DHW priority varies linearly between the

above two points. There is a manual setting also available

in the adjust menu.

The priority timer does not start timing until priority is selected

and both a DHW Demand and a Boiler Demand exist together.

Once the allowed time for priority has elapsed, the control

overrides the DHW priority and resumes space heating.

Automatic Priority Override

2 hours

15 mins

70°F (21°C)

Design Temperature

Conditional DHW Priority

If the boiler supply temperature is maintained at or above

the required temperature during DHW generation, this

indicates that the boilers have enough capacity for DHW

and possibly heating as well. As long as the boiler supply

temperature is maintained near the target, DHW and heating

occurs simultaneously.

DHW Post Purge

After the DHW Demand is removed, the control performs

a purge. The control shuts off the boilers and continues to

operate the DHW Pump and the primary pump if applicable.

This purges the residual heat from the boilers into the

DHW tank. The control continues this purge until one of

the following occurs:

1. A Boiler Demand is detected

2. The boiler supply drops 20°F (11°C) below the DHW

target temperature

3. The DHW tank temperature rises above the DHW

setpoint plus 1/2 DHW Differential

4. Two minutes elapse

DHW Mixing Purge

After DHW operation, the boiler is extremely hot. At the same

time, the heating zones may have cooled off considerably

after being off for a period of time. When restarting the

heating system after a DHW demand with priority, the

control shuts off the boiler and continues to operate the

DHW pump while the primary pump is turned on. This allows

some of the DHW return water to mix with the cool return

water from the zones and temper the boiler return water.

DHW with Low Temperature Boilers

If DHW heating is to be incorporated into a low temperature

system such as a radiant floor heating system, a mixing

device is often installed to isolate the high DHW supply

temperature from the lower system temperature. If a mixing

device is not installed, high temperature water could be

supplied to the low temperature system while trying to

satisfy the DHW demand. This may result in damage to

the low temperature heating system.

The control is capable of providing DHW heating in such a

system while minimizing the chance that the temperature

in the heating system exceeds the design supply water

temperature. In order to do this, the following must be true:

tN4 Present

•

DHW MODE 2 or 4

•

Boil MIN OFF

•

On a call for DHW, the control provides DHW priority by

sending a message on the boiler temperature bus to the tN4

thermostats to shut off the heating zones for a period of time.

The length of time is based on the outdoor air temperature as

described in the DHW Priority Override section. However, if

the DHW Demand is not satisfied within the allotted time, the

boiler shuts off and the heat of the boiler is purged into the

DHW tank. A DHW mixing purge occurs in order to reduce

the boiler water temperature and once the boiler supply

temperature is sufficiently reduced, the DHW Pump contact

shuts off. The heating system zones are allowed to turn on for

a period of time to prevent the building from cooling off. After

a period of heating, and if the DHW Demand is still present,

the control shuts off the heating system and provides heat

to the DHW tank once again.

DHW Boilers Setting in Adjust Menu

Select the number of boilers to use for DHW generation.

© 2012 274_D - 11/12 12 of 44

Page 13

Setpoint Operation Section F

Setpoint operation is only available when DHW Mode is

set to Off.

The control can operate to satisfy the requirements of a

setpoint load in addition to a space heating load. A setpoint

load overrides the current outdoor reset temperature in

order to provide heat to the setpoint load.

Setpoint Demand

Setpoint Demands come from one of two sources: a

Powered Setpoint Demand, or a tN4 Setpoint Control.

Powered Setpoint Demand

The control registers a Setpoint Demand when a voltage

between 20 and 260 V (ac) is applied across the Setpoint

Demand terminals 23 and 24. An aquastat or setpoint

control is used to switch the Setpoint Demand circuit.

Program a Setpoint target for the Occupied and UnOccupied

events in the Adjust Menu.

• DHW Mode must be set to Off.

tN4 Setpoint Control

The control can register a Setpoint Demand when a tN4

Setpoint Control is wired to terminals 1 and 2. The Setpoint

Demand is sent over the tN4 communication bus when

the Setpoint Control calls for heat. Program a Setpoint

temperature for the Occupied and UnOccupied events and

the desired supply water temperature required on the tN4

bus in the Adjust Menu of the tN4 Setpoint Control.

• DHW Mode must be set to Off.

A demand from a tN4 Setpoint Control can coexist with another

setpoint demand without generating an error message. The

274 will then use the higher of the two targets.

DIP Switch must be set to Setback to view UnOccupied

items.

During the Away Scene, Setpoint demands are ignored.

Setpoint Mode Setting in the Adjust Menu

The control has four different Setpoint Modes that affect

pump operation. The required Setpoint Mode setting will

depend on the piping arrangement and whether or not

priority is necessary. Setpoint Priority stops or limits the

delivery of heat to the building heating system while the

Setpoint load calls for heat. This allows for quick recovery

of the Setpoint load.

Mode OFF - No Setpoint Operation

All Setpoint demands are ignored. If this mode is selected

while Setpoint operation is underway, all Setpoint operation

ceases.

Mode 1 - Setpoint in Parallel with No Priority

Whenever a Setpoint Demand is present, the boilers are

operated to maintain the setpoint target. The primary

pump does not turn on, but may operate based on a Boiler

Demand. It is assumed that the Setpoint pump will provide

adequate flow through the heat exchanger and the boiler.

Mode = 1

Setpoint

Primary

Pump

Boiler Target Temperature during a Setpoint Demand

If a Powered Setpoint Demand is present, the boilers are

operated to maintain the Setpoint target. If a tN4 demand

is present, the primary pump is turned on according to

the device’s reported requirements and the boilers are

operated to maintain the devices requested target on the

bus. The Setpoint Demand overrides the boiler reset target

temperature, except when the boiler reset target is higher

than the Setpoint target. Regardless of Setpoint settings

and requested targets, the boilers will maintain a supply

temperature no higher than the Boil MAX setting.

Setpoint During UnOccupied

When using a Powered Setpoint Demand, the control has

a Setpoint UnOccupied setting that allows the installer to

select On or Off. When set to On, and the control receives

a Setpoint Demand during an UnOccupied or Sleep period,

the control continues operation of the Setpoint system as

it would during the Occupied and Wake periods. When set

to Off, the control will ignore a Setpoint Demand for the

duration of the UnOccupied and Sleep periods.

Mode 2 - Setpoint in Parallel with Priority

When a Setpoint Demand is present, the boilers are

operated to maintain the setpoint target. The primary

pump can operate when a Boiler Demand is present. If the

boilers are unable to maintain the boiler target temperature,

space heating zones are shut off sequentially using tN4

communication in order to provide priority to the Setpoint

Load. For non-tN4 systems, the primary pump shuts off to

provide priority. It is assumed that the Setpoint pump will

provide adequate flow through the heat exchanger and

the boiler.

Mode = 2

Setpoint

OFF

Primary

Pump

13 of 44 © 2012 274_D - 11/12

Page 14

Mode 3 - Setpoint in Primary/Secondary with No Priority

Whenever a Setpoint Demand is present, the primary pump

is turned on and the boilers are operated to maintain the

setpoint target.

Mode = 3

Setpoint

Automatic Priority Override

2 hours

15 mins

Primary

Pump

Mode 4 - Setpoint in Primary/Secondary with Priority

Whenever a Setpoint Demand is present, the primary

pump is turned on and the boilers are operated to maintain

the setpoint target. Space heating zones will be shut

off if the boilers are unable to maintain the boiler target

temperature.

Mode = 4

Setpoint

OFF

Primary

Pump

Setpoint Priority Override Setting in Adjust Menu

Setpoint Priority Override applies to SETPOINT MODE 2 and

MODE 4. To prevent the building from cooling off too much or

the possibility of a potential freeze up during setpoint priority,

the control limits the amount of time for setpoint priority.

When set to auto, the priority time is calculated based

on outdoor temperature. At or below the design outdoor

temperature, 15 minutes are allowed for Setpoint priority.

At or above 70°F, 2 hours are allowed for Setpoint priority.

The time allowed for Setpoint priority varies linearly

between the above two points. There is a manual setting

also available in the adjust menu.

The priority timer does not start timing until priority is

selected and both a Setpoint Demand and a Boiler Demand

exist together. Once the allowed time for priority has

elapsed, the control overrides the Setpoint priority and

resumes space heating.

Design Temperature70°F (21°C)

Conditional DHW Priority

If the boiler supply temperature is maintained at or above

the required temperature during setpoint generation, this

indicates that the boiler has enough capacity for setpoint

and possibly heating as well. As long as the boiler target

temperature is maintained, setpoint and heating occur at

the same time.

Setpoint Post Purge

After a tN4 Setpoint Demand is removed, the control

performs a purge. The control shuts off the boilers and

continues to operate the Setpoint Pump and the primary

pump if applicable. This purges the residual heat from the

boilers into the Setpoint load. The control continues this

purge until one of the following occurs:

1. A Boiler Demand is detected

2. The boiler supply drops 20°F (11°C) below the Setpoint

target temperature

3. Two minutes elapse

© 2012 274_D - 11/12 14 of 44

Page 15

Energy Management System (EMS) Section G

The control can accept an external DC signal from an Energy

Management System (EMS) in place of the outdoor sensor.

The control converts the DC signal into the appropriate

boiler target temperature between 50°F (10°C) and 210°F

(99°C) based on the EMS Input Signal and Offset settings.

To use the external input signal, the EMS / Demands DIP

switch must be set to EMS.

An external signal is generated by applying a voltage

between 0 V (dc) and 10 V (dc) across the Out + and Com

– terminals (3 and 2). Voltages that exceed 10 V (dc) will

still be considered a 10 V (dc) signal.

Once voltage is applied, the EMS Input Signal pointer is

displayed in the LCD and the control calculates a boiler

target and closes the primary pump contact. The control

then activates the boiler(s), if required, to maintain the target

supply temperature.

If the EMS signal goes below the minimum voltage, the

EMS Input Signal pointer is turned off in the display. The

boiler target temperature is displayed as “– – –” to indicate

that there is no longer a call for heating. The primary pump

and boiler pumps operate as described in section I.

Input Signal

The control can accept either a 0 - 10 V (dc) signal or a

2 - 10 V (dc) signal. The External Input Signal setting must

be set to the proper setting based on the signal that is being

sent to the control.

0 - 10 V (dc) or 0 - 20 mA

When the 0 - 10 V (dc) signal is selected, an input voltage

of 1 V (dc) corresponds to a boiler target temperature of

50°F (10°C). An input voltage of 10 V (dc) corresponds

0 - 20 mA* 0 - 10 V (dc) Boiler Target

4 - 20 mA* 2 - 10 V (dc) Boiler Target

CONVERSION TABLE 0 - 10

0 0 – – – (OFF)

2 1 50°F (10°C)

4 2 68°F (20°C)

6 3 86°F (30°C)

8 4 103°F (39°C)

10 5 121°F (49°C)

12 6 139°F (59°C)

14 7 157°F (69°C)

16 8 174°F (79°C)

18 9 192°F (89°C

20 10 210°F (99°C)

*Requires 500 Ω Resistor in Parallel

CONVERSION TABLE 2 - 10

0 0 – – – (OFF)

4 2 50°F (10°C)

6 3 70°F (21°C)

8 4 90°F (32°C)

10 5 110°F (43°C)

12 6 130°F (54°C)

14 7 150°F (66°C)

16 8 170°F (77°C)

18 9 190°F (88°C)

20 10 210°F (99°C)

*Requires 500 Ω Resistor in Parallel

to a boiler target temperature of 210°F (99°C). As the

voltage varies between 1 V (dc) and 10 V (dc) the boiler

target temperature varies linearly between 50°F (10°C) and

210°F (99°C). If a voltage below 0.5 V (dc) is received the

boiler target temperature is displayed as “– – –” indicating

that there is no longer a call for heating.

A 0 - 20 mA signal can be converted to a 0 - 10 V (dc) signal

by installing a 500 resistor between the Out + and Com

– terminals (3 and 2).

2 - 10 V (dc) or 4 - 20 mA

When the 2 - 10 V (dc) signal is selected, an input voltage

of 2 V (dc) corresponds to a boiler target temperature of

50°F (10°C). An input voltage of 10 V (dc) corresponds

to a boiler target temperature of 210°F (99°C). As the

voltage varies between 2 V (dc) and 10 V (dc) the boiler

Offset Setting in Adjust Menu

For external input operation, the boiler target (determined

from the external input signal) may be fine tuned. The

Offset setting is used to provide the fine tuning. The Offset

setting may be adjusted ±10°F. When set to 0°F, if the

temperature determined from the external signal is 140°F,

the boiler target will be 140°F. When set to +5°F and with

the same external signal represents 140°F, the boiler target

will be 145°F.

Example

Range = 0 - 10 V (dc)

Input = 7 V (dc) 157°F (69°C)

Offset = +5°F (3°C) + 5°F (3°C)

Boiler Target = 162°F (72°C)

target temperature varies linearly between 50°F (10°C) and

210°F (99°C). If a voltage below 1.5 V (dc) is received the

boiler target temperature is displayed as “– – –” indicating

that there is no longer a call for heating.

A 4 - 20 mA signal can be converted to a 2 - 10 V (dc) signal

by installing a 500 resistor between the Out + and Com

– terminals (3 and 2).

The minimum and maximum settings also apply for external

input operation. For example, if a boiler minimum of 140°F

is set and the external signal received represents 80°F, the

boiler target will be 140°F. The MIN segment will also be

displayed to indicate that a limiting condition is in effect.

This also applies for the MAX segment limit.

Whenever an external signal is used, the control can still

provide all DHW OR Setpoint functions.

15 of 44 © 2012 274_D - 11/12

Page 16

Pump Operation Section H

Primary Pump Operation

The control includes two primary pump outputs with

capability for sequencing. Primary pump sequencing is

activated through a DIP switch. Only primary pump 1

is operated when pump sequencing is turned off, while

primary pumps 1 and 2 are operated in stand-by mode

when pump sequencing is turned on.

The running times of the primary pumps are logged in the

view menu. To reset these values back to zero, press and

hold the up and down button while viewing this item.

Note: once primary pump sequencing is selected, DHW

operation is not available. Setpoint operation, however, is

available if primary pump sequencing is selected.

The primary pumps will operate when the control receives

an appropriate demand:

External Boiler Demand

•

tN4 Boiler Demand and that zone’s thermostat has H1

•

Pump set to On.

DHW Demand and the control is set to DHW Mode 3,

•

4, or 6.

Setpoint Demand and the control is set to Setpoint Mode

•

3 or 4.

The primary pumps also operate when the control is

completing a DHW Purge.

tN4 thermostats can select whether the primary pump is

required to operate or not. tN4 thermostats also include a

thermal actuator setting which can delay the primary pump

for 3 minutes to allow thermal actuators to open.

Flow Proof

The control includes a flow proof demand in order to prove

flow once a primary pump has turned on. In order for

boiler operation to commence, the proof demand must be

present. A flow proof signal is required at all times during

pump operation. A flow proof is generated by applying a

voltage between 20 and 260 V (ac) across the Flow Proof

terminals (30 and 31). Once voltage is applied, the Proof

Demand indicator is turned on in the LCD.

Once a pump contact is turned on, a flow proof signal must

be present before the flow proof delay has expired.

The flow proof demand is selected by setting the Proof

Demand item in the Adjust menu to F P (flow proof).

A flow proof demand can come from a flow switch, pressure

differential switch, current sensing or power sensing device.

Stand-by Operation

The control only operates one primary pump at a time. A

flow proof device can be used to detect when stand-by

pump operation is required.

When a demand is registered, the lead pump is activated,

•

and the control waits for flow to be established within the

flow proof delay time.

If no flow is established, the lead pump is de-activated,

•

the lag pump is activated and the control waits again for

the flow to establish within the flow proof delay time.

If again no flow is established, the lag pump is de-activated

•

and the control stops operation until the error is cleared.

Verify that the pumps and flow proof device are working

correctly before clearing the error.

If the lead pump establishes flow, and fails during

•

operation, the lag pump is activated.

If at any time, one or both pumps fail to prove flow, an

•

error message is displayed.

Normal Operation

274

On

Flow Proof

Device

Off

Stand-by Pump Operation

274

Optional

Failed

On

Alert

Flow Proof

Device

2524

Pr.Com

DemDem

N

FS Flow Switch

KW Power Sensing Device

L

∆P Pressure Differential Switch

20 to 260 V (ac)

© 2012 274_D - 11/12 16 of 44

Amp Current Sensing Device

Page 17

Flow Proof Delay Setting in Adjust Menu

The control waits a period of time to receive a flow proof

demand from the time the primary pump turns on. If the

control does not receive a flow proof demand within that

period of time, the primary pump turns off and the stand-by

primary pump (if active) turns on. The control then waits

that period of time again for the stand-by primary pump to

prove flow. If flow is not proven, the stand-by pump turns

off. The period of time is set through the Proof Demand

‘Pump’ DLY item in the Adjust menu and it is adjustable

between 10 seconds and 3 minutes.

Primary Pump Purge

After the last valid demand is removed, the primary pump

is operated for an additional purging time of at least 20

seconds. If the last demand came from a tN4 zone, the

control sends out a purge message to override the zone

open for the duration of the boiler purge. At the end of

the purge, the zone override is removed so the zone is

allowed to close and turn off the primary pump. If the last

demand came from a non-tN4 zone, the purge period for

the primary pump is adjustable between 10 seconds and

19:55 minutes.

Flow Proof Demand Test

The control includes a flow proof demand test in order to

determine if the flow/pressure device has failed. A flow

proof failure is detected if a flow proof is present after the

pumps have been shut off for more than four minutes. This

can occur if the flow proof device sticks in the on position

even when flow has stopped in the system. A proof demand

error will latch when this condition exists.

Primary Pump Rotation Setting in Adjust Menu

The control rotates the pumps based on the Rotate item

in the Adjust menu. Frequency of Rotation is based on the

running time of the pumps. Rotation is done when the lead

pump is off. If the lead pump runs continuously, the rotation

is delayed for up to 12 hours. If the pump runs continuously

and rotation is required, the control shuts off the lead pump

and 1 second later the stand-by pump is turned on. This

eliminates overloading the pump electrical circuit. Upon

turning on the stand-by pump the flow proof input is checked

after the flow proof demand delay time.

Boiler Pump Operation

The control can operate individual boiler pumps when set

to Mode 2, 4 or 5. Refer to the Boiler Operation section for

more information about the mode settings.

A pre-purge operates the respective boiler pump for a period

of time before the boiler is ignited in order to purge potential

residual heat out of the boiler.

The pre-purge time is determined from the boiler mass

setting. As the boiler mass setting is increased, the boiler

pump pre-purge time is also increased. The pre-purge time

is fixed at 4 seconds whenever a DHW / Setpoint demand

is provided in order to reduce boiler pick-up times.

The control includes a boiler pump post-purge feature that

operates the respective boiler pump for a period of time

after the boiler is turned off. This feature will purge heat out

of the boiler and aid in reducing “kettling”. The amount of

time for the boiler pump post purge is adjustable between

10 seconds and 19:55 minutes. See the boiler pump purge

setting in the adjust menu.

Exercising Section I

The control will exercise the Combustion Air Damper, all

pumps, and tN4 zones (zone valves and zone pumps) for

10 seconds every three days of inactivity to prevent seizure.

To enable exercising, switch the Exercise / Off DIP to the

Exercise position.

Time Clock Section J

The control has a built-in time clock to allow the control to

operate on a schedule. A battery-less backup allows the

control to keep time for up to 4 hours without power. The

time clock supports automatic adjustment for Daylight

Saving Time (DST) once the day, month, and year are

entered. Use the Time menu to set the correct time, day,

month, and year.

Daylight Savings Time Modes

Mode DST Start DST End

1 1st Sunday in April Last Sunday in October

2 2nd Sunday in March 1st Sunday in November

17 of 44 © 2012 274_D - 11/12

Note: The Setback / Off DIP Switch must be set to Setback

before the Time menu can be accessed.

Page 18

Setting the Schedule Section K

•

• •

• •

•

•

•

•

•

•

To provide greater energy savings, you can operate the

control on a programmable schedule. The schedule is stored

in memory and is not affected by loss of power to the control.

If a tN4 network is detected the control can become either a

schedule member or schedule master.

Control (CTRL) Schedule (tN4 present)

The schedule only applies to the control. The control follows

its own schedule and the events are not communicated to

tN4 thermostats.

Master Schedule (tN4 present)

If the control is connected to tN4 thermostats, then the

control can operate on a master schedule. You can set up

a maximum of four master schedules on the tN4 Network.

A master schedule is available to all devices on the tN4

network. Master schedules simplify installation since one

master schedule may be used by multiple devices.

To create a master schedule:

Assign the control to be a schedule master by setting

•

the Heat Schedule item in the Schedule menu to Master

(MST) 1 to 4. After a master schedule is selected, a clock

symbol will appear in the View menu display.

Note: The 274 Setback /Off DIP Switch must be set to

Setback to access the Schedule Menu.

To follow a master schedule:

Assign the control to follow a master schedule by setting

•

the Heat Schedule in the Schedule menu to Member

(MBR) 1 to 4.

Member of

Schedule 1

Master

Schedule 1

None

Zone

Schedule

Master

Schedule 2

Members of

Schedule 2

Schedule Types

The schedule type determines when the schedule repeats

itself. This control includes three schedule types:

• 24 Hour: Repeats every 24 hours.

• 5-11: Repeats on a weekly basis. However, it breaks the

week into Saturday and Sunday followed by the weekdays.

This reduces the amount of schedule event settings.

• 7 Day: Repeats on a weekly basis and allows for separate

event times for each day.

Schedule Type

Day 24 Hour 5-11 7 day

Saturday

Sunday

Monday

Tuesday

Wednesday

Thursday

Friday

Schedule Mode

The schedule mode can have either 4 or 2 events per day.

An event is a time at which the control changes the target

temperature. The event time can be set to the nearest 10

minutes. If you wish to have the thermostat skip the event,

enter “--:--“ as the time. The “--:--“ time is found between

11:50 PM and 12:00 AM. See the table, Schedule Mode,

for more details regarding types of events.

274

Zone 1

23 4 56

Schedule Mode Event 24Hr Sat Sun Mon Tue We Thu Fri

6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM

8:00 AM 8:00 AM 8:00 AM 8:00 AM 8:00 AM 8:00 AM 8:00 AM 8:00 AM

6:00 PM 6:00 PM 6:00 PM 6:00 PM 6:00 PM 6:00 PM 6:00 PM 6:00 PM

10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM

4 events per day

Wake

Unoccupied

Occupied

Sleep

or

2 events per day

Occupied

Unoccupied

6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM 6:00 AM

10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM 10:00 PM

Boost Section L

When the control changes from the UnOccupied mode to

the Occupied mode, it enters into a boosting mode. In this

mode, the supply water temperature to the system is raised

above its normal values for a period of time to provide a

faster recovery from the setback temperature of the building.

The maximum length of the boost is selected using the

BOOST setting in the Adjust menu.

© 2012 274_D - 11/12 18 of 44

Typical settings for the boost function vary between 30

minutes and two hours for buildings that have a fast

responding heating system. For buildings that have a slow

responding heating system, a setting between four hours

and eight hours is typical. After a boost time is selected, the

setback timer must be adjusted to come out of setback some

time in advance of the desired occupied time. This time in

advance is normally the same as the BOOST setting.

Page 19

If the building is not up to temperature at the correct time,

the BOOST setting should be lengthened and the setback

timer should be adjusted accordingly. If the building is

up to temperature before the required time, the BOOST

setting should be shortened and the setback timer should

be adjusted accordingly. If the system is operating near

its design conditions or if the supply water temperature

is being limited by settings made in the control, the time

required to bring the building up to temperature may be

longer than expected.

tekmarNet®4 Communication Section M

tekmarNet®4 (tN4) communicates between tN4 devices

(thermostats, Reset Module and Expansion Modules). Each

tN4 device is connected to a tN4 communication bus using

two wires. Each tN4 bus adjusts a single water temperature

in the system using indoor temperature feedback. The Boiler

Control 274 allows for one tN4 bus. This allows you to control

a system with one water temperature. A system that has more

than one tN4 bus is referred to as a tN4 network.

Network

Bus 1

274

tekmarNet®4

Thermostats

Boiler Control 274

The Boiler Control 274 is the system control for a hydronic

heating system. The 274 operates up to 4 on/off boilers,

a domestic hot water tank, and responds to other heating

requirements such as pool heating and snow melting. The

274 also coordinates and optimizes the operation of all the

tN4 thermostats.

tN4 Thermostat

The tN4 thermostat operates heating, cooling, and or

ventilation equipment for a zone. Several tN4 thermostats

may work in a group when operating a cooling system. Up

to 24 tN4 devices can connect to a single tN4 bus.

Zone Load Shedding (tN4)

Zone load shedding helps protect non-condensing boilers

from sustained flue gas condensation damage. Zone load

shedding starts when the boiler supply temperature is below

the boiler minimum setting and all boilers are operating

at 100% output. Zones are shut off in order of their tN4

address.

Second stage heat zones are the first to shut off starting

with thermostat address b:24, continuing downward until

the last to shut off is b:01.

Once all second stage heat zones are shut off, first stage

zones shut off starting with highest thermostat address

b:24 and ending at the lowest b:01.

When the boiler supply temperature reaches the boiler

minimum, the first stage heating zones turn back on in

order from b:01 to b:24, and then the second stage in order

from b:01 to b:24.

Cycle Length Setting in Adjust Menu (tN4)

The control includes an adjustment for the cycle length.

The cycle length adjustment allows for synchronization of

tN4 zones. An Auto setting allows for the cycle length to

be automatically calculated to balance equipment cycling

and comfort.

In the tekmarNet®4 system, all of the tekmarNet®4

Thermostats determine the best cycle length for their

zone. The thermostats look at trying to maintain the longest

possible cycle length while keeping temperature swings to

a minimum. The Thermostats do this every cycle and send

their ideal cycle length time to the 274.

In order to operate the system as efficiently as possible,

all of the zones must operate based on the same cycle.

In order to do this, the 274 listens to all of the cycle length

requests from all of the tekmarNet®4 Thermostats. The 274

then determines the average cycle length and sends this

information to all of the tekmarNet®4 Thermostats, allowing

them to operate on the same cycle.

Indoor Temperature Feedback (tN4)

Indoor feedback applies when the 274 is connected to a

tN4 Thermostat network operating on a boiler bus. Indoor

temperature feedback fine tunes the water temperature of

the system based on the requirements of the thermostats.

Each thermostat tells the tN4 System Control the water

temperature that it requires to heat its zone.

If the zone is becoming too cool, the thermostat asks for

•

a higher water temperature.

If the zone is becoming too warm, the thermostat asks

•

for a cooler water temperature.

The 274 provides the highest water temperature required

by all of the thermostats.

The thermostat with the highest water temperature

•

requirement stays on 100% of its cycle.

The remaining thermostats stay on for a percentage of

•

their cycles.

100%

On Time

Reset Water

Temperature

85%

On Time

90%

On Time

Device Count (tN4)

The control includes a device count of all the tN4 devices