Page 1

- Data Brochure

R

D 269

One Stage Steam Control 269

The tekmar One Stage Steam Control 269 is a microprocessor-based control which regulates the

firing time of a steam boiler based on user settings, outdoor air temperature, condensate return

temperature, and optionally, the indoor air temperature(s). The steam boiler can be operated in

the outdoor reset mode, or in Manual Override mode based on dial settings. The control has builtin diagnostics for sensor checking with a Warning output for error reporting. Other control

operation features include Auxiliary relay output, Steam Established and Lockout Differential

temperatures, and Early Start with setback limit when using the Unoccupied input.

70°F

70°F

(21°C)

(21°C)

40

40

100

(4)

(4)

(38)

Occupied

Unoccupied

One Stage Steam Control 259

with Early Start

Steam

Power

established

Heating

WWSD

cycle

Early Start

UnOcc.

Auxiliary

Warning

100

(38)

Boiler

R

R

LR 58233

E150539

Outdoor Reset Strategy . . pg. 2

Sequence of Operation . . . pg. 3

Installation . . . . . . . . . . . . . pg. 6

Settings . . . . . . . . . . . . . . . pg. 8

Early Start

into or

out of UnOcc.

System is in

Warm Weather

Shut Down

System is in

Unoccupied

mode

Sensor Fault

warning

Occupied

temperature

setting

Unoccupied

temperature

setting

Boiler is on

120Vac power

supply is on

70°F

(21°C)

40

100

(4)

(38)

Occupied

One Stage Steam Control 269

with Early Start

Use Nº 20 AWG or larger copper conductors rated for at least 75°C and 300V.

Heating Cycle

is in progress

70°F

(21°C)

40

100

(4)

(38)

Unoccupied

1234 5

Power

Warn.

NL

Aux.

Condensate

temperature is

established

6

Power

WWSD

UnOcc.

Warning

LR 58223

78

Boiler

Auxiliary relay

output is on

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Listed

R

5T62

R

E150539

Testing . . . . . . . . . . pg. 9

Error Messages . . . pg. 11

Technical Data . . . . pg. 12

Limited Warranty . . pg. 12

Operating Mode

selector switches

Indoor Sensor S1

Indoor Sensor S2

Early Start

45%

0

Auto

100

Man. Override

Test

Manufactured

in Canada by

Power: 120V 50/60Hz 3VA

Relays: 120Vac 10A 1/4 hp 240VA, 2A pilot duty

Enclosed Energy Management Equipment

9

10K

S1

Condensate Return Sensor

123 4

Off

0 °F

10

180 °F

Steam

11 12

UnO

Sw

1

40

Cycle Length

5

Off2550

Min. On Time (%)

Lockout Diff'l (°F)

13 14 15

Com

10K

Sen

S2

2093

1234567

Cnd Out

Sen

-40

Design Out

130 230

Established

Do not apply power here

10

Com

Sen

50 min

R

06/00

Manual

override setting

System design

outdoor

temperature

setting

Heating cycle

length setting

Steam

established

100

(condensate

temperature)

setting

Minimum on

time/lockout

differential

Date

S/N

setting

Test button and

LED to test main

control functions

H1099

Sen

Terminal Plugs:

Power and out-

put connections

120 Vac

power supply

Warning Relay

Output:

Output:

Auxiliary Relay

Output:

Turn on boiler

Input: Indoor

Sensor 074

Optional

Input:

Unoccupied

signal

Optional

Input: Outdoor

Sensor 070. Included

Input: Condensate

Return Sensor 071.

Included

Input: Indoor

Sensor 074

Copyright © D 269 - 06/001 of 12

Optional

Page 2

Outdoor Reset Strategy

Boiler

off

15 minutes

off time

15 minutes

off

on time

Boiler Operation

Boiler

on

30 minute cycle

Figure 1. 50% on time with a 30 minute heating cycle

Boiler on

off

Boiler Operation

30 minutes

on time

60 minute cycle

Figure 2. 50% on time with a 60 minute heating cycle

Boiler is turned off

WWSD

Point

90

70

(32)

(21)

Boiler is cycled on/off

Design

Outdoor

Temperature

50

(10)

Outdoor air temperature

30

(-1)10(-12)

-10°F

(-23)°C

Figure 3. Outdoor Reset of boiler % on time

on

15 minutes

on time

30 minute cycle 30 minute cycle 30 minute cycle

off

15 minutes

off time

on

15 minutes

on time

off

15 minutes

off time

on

15 minutes

on time

Boiler off

30 minutes

off time

on

30 minutes

on time

off

30 minutes

60 minute cycle

100%

90%

80%

70%

60%

50%

40%

30%

Boiler is turned on 100%

20%

10%

0%

on time

-30°F

(-34)°C

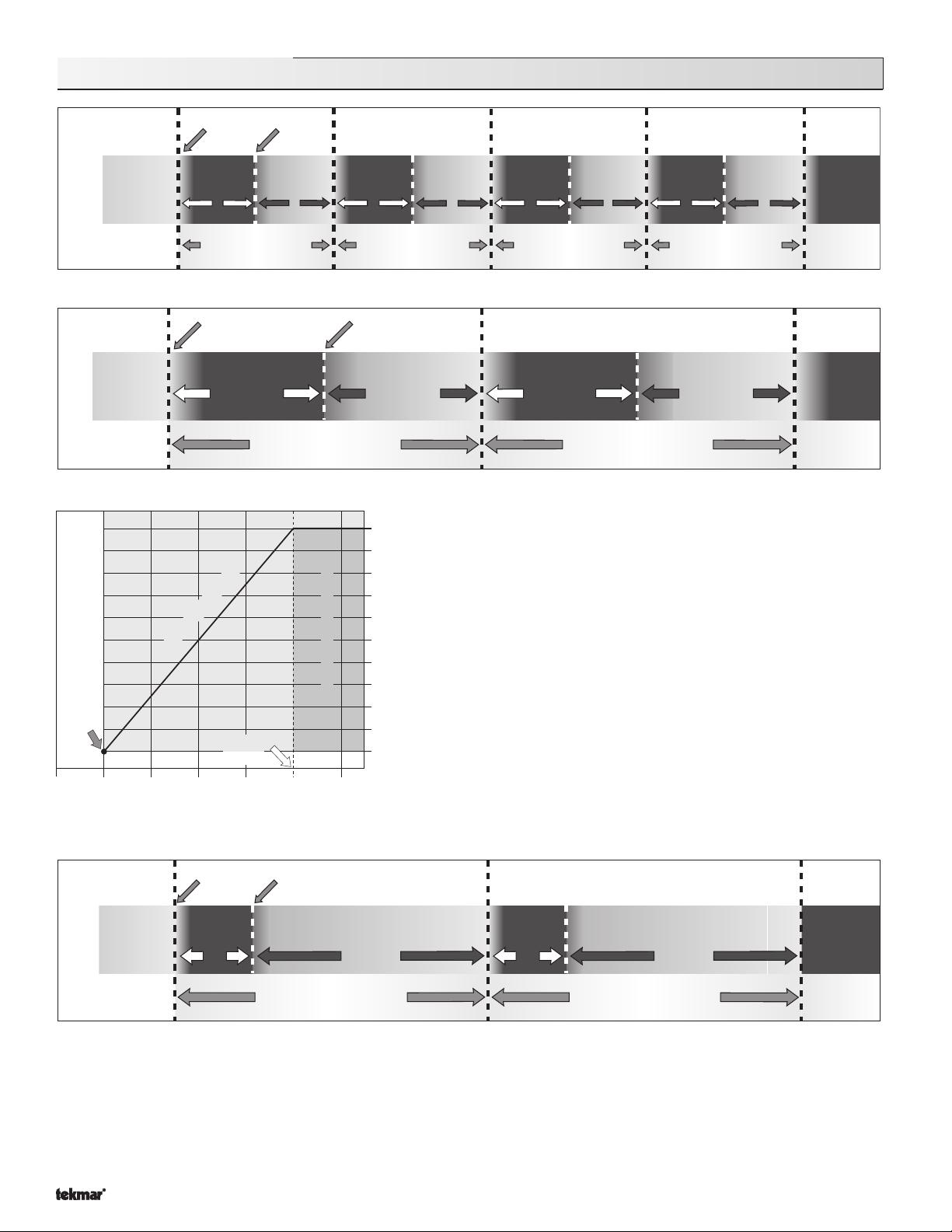

Most residential and small commercial steam systems can only produce

heat at a fixed rate and are either on (100% output), or off (0% output). When

100% output is not required (warmer weather), the boiler must be cycled on

and off in order to prevent overheating. Figures 1 and 2 illustrate the

operation of two heating systems with different heating cycle times.

Cycle times are selected based on the operating characteristics of each

individual heating system. Figure 1 shows a system where a 30 minute cycle

is required, and Figure 2 shows a system where a 60 minute cycle is required.

In both examples the heating plant output is exactly the same at 50%.

As the outdoor temperature changes, the % on time of the boiler should

be changed to match the changing heat losses of the building. Figure 3

illustrates how Outdoor Reset of a steam boiler changes the % on time from

Percentage of boiler on time per cycle

0% at the Warm Weather Shut Down point, to 100% at design outdoor

conditions (coldest day of the year). Applying this chart to the system

represented in Figure 1, we see that the outdoor temperature would be at

30°F with the 50% on time that is illustrated, and if the outdoor temperature

warmed up to 50°F, the system would operate with a 25% on time as

illustrated in Figure 4. Using outdoor temperature to reset the % on time in

this manner can help minimize the overheating and wide temperature swings

found in many systems that use only room temperature control.

off time

off

15 minutes

off time

on

on

Boiler

off

45 minutes off time

60 minute cycle

on

15 minutes

on time

off

45 minutes off time

60 minute cycle

on

15 minutes

off

on time

Boiler Operation

Boiler

on

Figure 4. 25% on time with a 60 minute cycle time

Before adding this control to a steam system, it is very important that the installer examine the

complete

system and how

it works. In order to properly install and setup this control, the installer must know: the optimum cycle length and minimum on

time of the system, the outdoor temperature at which 100% boiler on time will be required, and the best locations to install

sensors. In addition to examining the boiler operation,

all other

system components such as steam traps, air vents, radiators,

piping, etc. should be examined for correct operation to ensure that the system is working at its peak efficiency. If there are

existing faults that degrade the operation of the system, it is quite likely that the addition of this control could allow those faults

to have an even greater effect, making it important to correct such faults or at least point them out to the end user.

Copyright © D 269 - 06/00 2 of 12

Page 3

Sequence of Operation

Start-up

When the One Stage Steam Control 269 is powered-up, the "Power" light and all of the red

lights will come on. After 5 seconds the red lights will go out and the control will enter the

operating mode. If there is a sensor error detected, the control will display an error message

(see "Error Messages", page 11).

Power

WWSD

UnOcc.

Warning

Manual Override function

If the "Man. Override" dial is turned up from the "Auto" position, the WWSD, Heating Cycle, Early

Start and UnOcc. lights will cycle on and off in a clockwise, circular sequence and the control

will continually operate the system at the % on time setting of the "Man. Override" dial position.

Power

WWSD

UnOcc.

In this mode, the only two dial adjustments that will have any influence on the control's operation

will be the "Man. Override" and the "Cycle Length" dials, and the control will cycle the boiler on

Warning

and off as illustrated in Figures 1, 2 and 4 on page 2. Outdoor or room temperatures will have

no effect on the operation of the control when it is in "Man. Override" mode.

Auto (reset) function

If the "Man. Override" dial is set to the "Auto" (Outdoor Reset) operating mode, the control uses the Outdoor Sensor 070 to

continually monitor the outdoor temperature. As options, a Condensate Return Sensor 071 can continually monitor the temperature

of the condensate return line and one or two Indoor Sensors 074 can continually monitor the indoor air temperature. DIP switches

for Condensate Return Sensor and Indoor sensors must be switched on when these sensors are connected.

An Error Message

will be displayed if these switches are in the on position without sensors installed.

While monitoring all of these temperatures, the control recognizes the following inputs and will respond as described. During

operation, the lights of the control will indicate operational status as illustrated.

Outdoor Sensor 070 only

When an Outdoor Sensor 070 is connected to the control and the

"Design Out" dial set to the correct setting, the control will cycle

the boiler on and off based on the outdoor temperature and the

settings on the "Cycle Length" and "Min. On Time (%)" dials as

shown in Figure 5.

The "Min. on time (%)" dial must be set to at

least the minimum time required for the boiler to produce steam

and add heat to the building.

As soon as the outdoor temperature

drops below the setting of the "Occupied" dial (WWSD point), the

"WWSD" light will go out and the "Heating Cycle" and "Auxiliary"

lights will come on. The "Boiler" light will come on and the

123 4

Off

Power

WWSD

UnOcc.

Warning

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

123 4

Off

Power

WWSD

UnOcc.

Warning

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Condensate return sensor,

+ Indoor sensors S1 & S2

DIP switches = off

boiler will fire for at least the time set on the "Min. On Time (%)" dial, and then shut off for the remainder of the time set on the "Cycle

length" dial. This cycle will be repeated until the outdoor temperature becomes warmer than the "Occupied" dial setting, putting the

control back into WWSD. Adjusting the "Occupied" dial shifts the WWSD point and heating curve up or down as shown in Figure

6, and the indoor air temperature will be affected accordingly. The "UnOccupied" dial works the same way as the "Occupied" dial

when the control has been put into the UnOccupied mode, except the design outdoor temperature is also shifted down.

Indoor Sensor 074 function

When Indoor Sensor 074s are connected to this control, the control will still operate the boilers based on

outdoor temperature, but will also use one 074 sensor input, or the lower reading of two 074s to prevent

overheating. With these sensors, the "Occupied" and "UnOccupied" dial settings become the desired

indoor air temperatures.

The control will not allow the curve to be shifted up,

if windows or doors are left

open. Figure 7 shows how an Indoor Sensor will shift the heating curve and the WWSD point down to

prevent overheating, especially in milder weather when a Minimum On Time may cause overheating.

Boiler is cycled on/off

Boiler is turned off

Boiler is turned on 100%

-10°F

-30°F

(-23)°C

(-34)°C

90

(32)

WWSD

Point

70

(21)

(10)30(-1)10(-12)

20% minimum on time

50

Design

Outdoor

Temperature

Outdoor air temperature

Figure 5. Outdoor Reset with a

20% Minimum On Time setting

100%

90%

80%

70%

60%

50%

40%

30%

20%

20% Min. on time selected

10%

Percentage of boiler on time per cycle

0%

on time

Boiler is turned off

WWSD

Point

90

(32)

(21)

Figure 6. Shifting the heating curve

Boiler is cycled on/off

20% minimum on time

Design

Outdoor

70

Temperature

50

(10)30(-1)10(-12)

Outdoor air temperature

-10°F

(-23)°C

with the Occupied dial

100%

90%

80%

70%

60%

50%

40%

30%

Boiler is turned on 100%

20%

20% Min. on time selected

10%

Percentage of boiler on time per cycle

0%

on time

-30°F

(-34)°C

WWSD

90

(32)

Figure 7. Temporary shift to UnOc-

cupied mode or by Indoor Sensor

If the indoor temp. becomes

too warm, the Heating

Curve shifts down.

After the Heating

Cycle, the boiler is

kept off until the

indoor cools off

to the desired

room temp.

Boiler is turned off

Point

70

(21)

Early Start

123 4

Early Start

123 4

Indoor sensors S1 or

S1 & S2 DIP switches = on

Boiler is cycled on/off

20% minimum on time

Design

Outdoor

Temperature

50

(10)30(-1)10(-12)

Outdoor air temperature

Off

Off

-10°F

(-23)°C

074 room temperature feedback

Copyright © D 269 - 06/003 of 12

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Power

WWSD

UnOcc.

Warning

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

Boiler is turned on 100%

-30°F

(-34)°C

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

100%

90%

80%

70%

60%

50%

40%

30%

20%

20% Min. on time selected

10%

Percentage of boiler on time per cycle

0%

on time

Page 4

Condensate Return Sensor 071 function

Ind

S2

Setting a Minimum On Time for a steam system can

become problematic because a system takes more time to

reach operating temperature from a cold start than when it

is hot from a previous cycle. Use of the Condensate Return

Sensor included with the control is highly recommended

since the "Steam Established" dial can then be set to match

the operating characteristics of the system. The control will

turn on its "Boiler" light and fire the boiler for a warm-up

period, modifying the cycle to operate as in Figure 8.

Early Start

Establishing Steam

(Warm up)

Power

WWSD

UnOcc.

Warning

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

123 4

Off

oor Sensor

Condensate Return Sensor

Heating Cycle

(on time)

Steam

Power

established

Heating

WWSD

cycle

Early Start

UnOcc.

Auxiliary

Warning

Boiler

Condensate return sensor

DIP switch = on

Steam

Power

established

Heating

WWSD

cycle

Early Start

UnOcc.

Auxiliary

Warning

Boiler

Heating Cycle

(off time)

Steam

Power

established

Heating

WWSD

cycle

Early Start

UnOcc.

Auxiliary

Warning

Boiler

Boiler on

off

Boiler Operation

15 minutes

on time

Boiler off

Steam established - start cycle

45 minutes off time

60 minute cycle

Boiler on

15 minutes

on time

Steam established - start cycle

45 minutes off time

60 minute cycle

Boiler off

220°F

210°F

200°F

190°F

180°F

(Warm-up period)

Establishing Steam

170°F

temperature

160°F

Condensate return

150°F

est.

off

Steam established

temperature setting

(Warm-up period)

Establishing Steam

est.

on

off

140°F

on

Figure 8. 25% on time with Condensate Return Sensor and "Steam Established" dial set to 170°F

The control will not start to time out the Heating Cycle until the Condensate Return Sensor reaches the temperature set on the "Steam

Established" dial. When this occurs, the "Steam Established" light will come on and the control will operate the boiler until the on time of the

Heating Cycle has elapsed. This function ensures that steam has been established throughout the system before the Heating Cycle is started.

In a two pipe system, most installers will place the Condensate Sensor on the condensate return line of the radiator furthest from the boiler.

In one pipe systems the best location is usually on the pipe just before it enters the last radiator. These locations are usually good, but in

some larger systems with long runs it may be necessary to place the sensor closer to the boiler so that the first rooms in the system do not

overheat. Again, it is important to ensure that the system components are all working properly, since in a properly vented and drained system,

steam is established quickly throughout the system during each cycle, and sensor placement is not as critical as in some "problem" systems.

Boiler on

15 minutes

on time

Boiler off

Steam established - start cycle

45 minutes off time

Boiler on

15 minutes

on time

Steam established - start cycle

45 minutes off time

Boiler off

Boiler

Operation

60 minute cycle

220°F

210°F

200°F

190°F

180°F

170°F

160°F

temperature

150°F

Condensate return

140°F

Figure 9. 25% on time with Condensate Return Sensor, "Steam Established" dial set to 170°F and "Lockout Diff'l" set to 30°F

Copyright © D 269 - 06/00 4 of 12

off

Steam established

temperature setting

30°F Lockout differential setting

Lockout period

(Warm-up period)

Establishing Steam

est.

on

60 minute cycle

off

Lockout period

on

(Warm-up period)

Establishing Steam

Page 5

Lockout Differential function

Many steam systems require a Lockout (cool

down) period before each on cycle to ensure

that any remaining steam in the system

condenses and the condensate has time to

return to the boiler. This increases the efficiency of the system by removing the latent

heat from steam remaining after the burner

shutdown, and lengthening the cycle so that

the remaining heat is allowed to radiate into

the building. When using a Condensate Sen-

Establishing Steam

(Warm-up)

Power

WWSD

UnOcc.

Warning

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Heating Cycle

(on time)

Power

WWSD

UnOcc.

Warning

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Heating Cycle

(off time)

Power

WWSD

UnOcc.

Warning

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

sor, the "Min. On Time (%)" dial becomes the

"Lockout Diff'l (°F)" dial, and if the Condensate Return temperature has not dropped to the "Steam Established" temperature minus the setting of the "Lockout Diff'l (°F)" dial,

the control will keep the boiler off and leave the "Steam Established" light on, modifying the cycle as illustrated in Figure 9.

Auxiliary Relay function

The control turns on the "Auxiliary" light and closes the "Aux." relay contacts whenever it is not in WWSD. This relay can be used

for a variety of functions such as turning on a condensate pump or other auxiliary device(s), disconnecting power to the burner for

the summer and/or signalling to remote monitoring equipment that the heating system is enabled.

Warning Relay function

The control turns on the "Warning" light and closes the "Warn." relay contacts whenever an error message is generated due to

sensor failure. This relay can be used to turn on an alarm or other auxiliary device(s) or signal to remote monitoring equipment that

the control system has a fault and is in need of repair.

UnOccupied Options

Lockout

(cool down)

Power

WWSD

UnOcc.

Warning

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Without Early Start feature

Indoor Sensor S1

123 4

Off

Indoor Sensor S2

Condensate Return Sensor

The control turns on its "UnOcc." light and starts to go into the UnOccupied mode

whenever terminals

Com Sen — UnO Sw

(10 and 11) are shorted together. When

there are no Indoor Sensor 074s connected to the control, the "UnOccupied" dial

setting becomes the WWSD point. When one or two Indoor Sensors are connected,

Early Start

Early Start DIP switch = off

the "UnOccupied" dial setting is still the WWSD point, but the Heating Curve and

WWSD point can be shifted down by the room temperature feedback in order to

prevent overheating.

See Indoor Sensor 074 function, and Figures 6 and 7, page 3.

Note: When the outdoor temperature gets close enough to the design outdoor

Power

WWSD

UnOcc.

Steam

established

Heating

cycle

Early Start

Power

WWSD

UnOcc.

temperature (approximately 85% on time), the control is prevented from going

into the UnOccupied mode in order to avoid long pick-up times. If the control

is already in the UnOccupied mode and the outdoor temperature drops below

the setback limit, it will switch back into the Occupied mode.

With Early Start feature

When the "Early Start" DIP switch is in the up position, the control must receive an UnOccupied

signal

4 hours before

must be removed

the building is to be in UnOccupied mode and the UnOccupied signal

4 hours before

the building is to be back up to the Occupied temperature.

Warning

Boiler

Early Start

Early Start DIP switch = on

123 4

Off

Warning

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

Auxiliary

Going into Unoccupied

After receiving the Unoccupied signal, the control will calculate when to turn on its "Early Start" light based on the Cycle Length

setting. During the Early Start period, the boiler will be kept off so that the room temperature will begin to fall by the time the

Unoccupied period begins. At the beginning of the Unoccupied period, the "UnOcc." light will turn on and the "Early Start" light will

turn off. The "UnOccupied" dial setting becomes the new WWSD point. When one or two Indoor Sensors are connected, the

"UnOccupied" dial setting is still the WWSD point, but the Heating Curve and WWSD point can be shifted down by the room

temperature feedback to prevent overheating.

See Indoor Sensor 074 function, and Figures 6 and 7, page 3.

When the outdoor

temperature is above the UnOccupied dial setting, the control will go into WWSD when put into the UnOccupied mode, and the

WWSD light will come on.

Going out of Unoccupied

When the UnOccupied signal is removed from terminals

Com Sen — UnO Sw

(10 and 11), the control will calculate when to start

bringing the building out of setback based on the outdoor temperature and the amount and duration of the setback. At the time the

control has calculated for the "Early Start" period to begin, it will turn on its "Early Start" light and operate the boiler for an increased

% on time in order to have the building up to temperature at the start of the Occupied period. Four hours after the UnOccupied signal

has been removed, the control will turn off the "Early Start" and "UnOcc." lights and resume a normal % on time based on the outdoor

temperature. See Figure 10 on page 6. If one or two Indoor Sensor 074s are connected to the control, and the indoor temperature

is above the "Occupied" dial setting, the boiler will not be turned on for an Early Start period as Early Start will not be needed. In

colder weather the boiler may run almost continually during the Early Start period in order to recover the building temperature.

Copyright © D 269 - 06/005 of 12

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Page 6

Unoccupied

Switch Closed

c

o

n

U

o

t

s

r

u

o

H

4

9 P.M.

16 min. on

8 P.M.

7 P.M.

.M.

6 P

5 P.M.

15 min. on

13 min. on

10 min. on

9 min. on

8 min. on

7 min. on

6 min. on

5 min. on

4 min. on

3 min. on

4 P.M.

Figure 10

An example of the daily

cycle operation of a One

3 P.M.

Stage Steam Control 269

using the Early Start option

with a single Unoccupied period.

Cycle length setting = 30 minutes

e

i

p

u

c

10 P.M.

18 min. on

5 min. on

6 min. on

e

P

d

20 min. on

c

c

O

e

T

r

o

o

d

t

u

O

)

C

°

5

(

F

°

0

4

d

o

i

r

8 min. on

2 P.M.

d

o

i

r

21 min. on

d

e

i

p

u

u

t

a

r

e

p

m

)

C

°

7

(

e

P

d

e

i

9 min. on

11 P.M.

22 min. on

i

r

e

P

e

r

F

°

5

4

p

u

c

c

22 min. on

d

o

F

°

0

3

)

C

O

10 min. on

1 P.M.

Early Start

12 Midnight

12 min. on

Early start, 15 minutes off

)

C

°

1

-

(

°

5

(

F

10 min. on

°

0

4

10 min. on

e

12 min. on

12 Noon

12 min. on

U

2

5

°

e

r

a

t

u

r

14 min. on

"ON"

Early Start

UnOcc.

1 A.M.

14 min. on

n

O

c

c

F

(

-

4

°

C

)

o

r

T

e

m

p

16 min. on

"OFF"

"ON"

15 min. on

16 min. on

u

p

i

e

d

P

e

2

0

°

F

(

-

7

°

C

)

°

C

)

O

u

t

d

o

e

r

i

o

d

17 min. on

16 min. on

11 A.M.

2 A.M.

18 min. on

20 min. on

r

i

o

d

3

0

°

F

(

-

1

O

c

c

u

p

i

e

d

P

18 min. on

17 min. on

10 A.M.

UnOccupied

Switch Open

3 A.M.

20 min. on

20 min. on

20 min. on

20 min. on

Early start time

20 min. on

20 min. on

19 min. on

19 min. on

18 min. on

9 A.M.

4

H

o

u

r

s

t

o

O

c

c

u

4 A.M.

5 A.M.

30 min. on

7 A.M.

"OFF"

8 A.M.

p

i

e

UnOcc.

d

P

e

r

i

o

d

6 A.M.

"OFF"

Early Start

"ON"

Early Start

Installation

Caution

Improper installation and operation of this control could result in damage to equipment and possibly even personal injury.

It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards.

Step One Getting ready

Check the contents of this package. If any of the contents listed are missing or damaged, please refer to the Limited Warranty

and Product Return Procedure on the back of this brochure and contact your wholesaler or tekmar sales agent for assistance.

Type 269 includes:

Other information available:

Read Application Brochure A 269-1 and A 269-2 and select the correct Application for your job.

Note:

Carefully read the details of the Application, and the Sequence of Operation sections in all applicable brochures to ensure that you

have chosen the proper control, and you understand its functions within the operational requirements of your system.

Step Two

Mounting the base

The control should be removed from its base by pressing down on the release clip in the wiring chamber and sliding upwards

on the control. The base is then mounted in accordance with the instructions in the Data Brochure D 001.

Copyright © D 269 - 06/00 6 of 12

• One Control 269 • One Outdoor Sensor 070 • One Condensate Return Sensor 071

• One Data Brochure D 269 • One Data Brochure D 001 • Application Brochures A 269-1 & 2

• Essay E 001

Page 7

Step Three

Rough-in Wiring

All electrical wiring terminates in the control base wiring chamber. It has standard 7/8" (22mm) knockouts that will accept common

wiring hardware and conduit fittings. Before breaking out the knock-outs, check the wiring diagram and select those sections

of the chamber with common voltages, since the safety dividers will later prevent wiring from crossing between sections. Use

Nº 20 AWG to Nº 14 AWG copper wire rated for at least 60°C and 300 volts.

Power should not be applied to any of the wires, during this rough-in wiring stage.

• Install the Outdoor Sensor 070, Condensate Return Sensor 071, according to the instructions in the Data Brochure D 001 and

run the wiring back to the control.

Option:

Indoor Sensor(s) 074, can also be connected. See individual sensor instructions.

• Install the wiring from the other system components (Boiler, Warning device, Auxiliary device) to the base.

Step Four Electrical connection to the control

Power and output connections

The installer should test to confirm that no voltage is present at any of the wires.

• Install the control into the base, sliding it down until it snaps into place.

• All electrical connections are made directly to the plug terminals.

• Connect the 120 Vac power supply to terminals

N — L

(1 and 2).

Warning relay connection

Connect the Warning device to terminals

Warn

(3 and 4). These terminals lead to a dry

relay contact which closes when the control detects a sensor fault.

Auxiliary relay connection

Connect the Auxiliary device to terminals

Aux.

(5 and 6). These terminals lead to a dry relay

contact which closes when the control is operating in manual mode, is not in WWSD, or the

Outdoor Sensor is short or open circuited.

Boiler connection

If the boiler has a 120 Vac control circuit, make sure the safety divider is installed in

the space between the boiler terminals and sensor terminals;

Connect the boiler circuit to terminals

Boiler

(7 and 8). These terminals lead to a dry relay

contact which closes when the control requires boiler operation.

Sensor and unpowered input connections

Power should never be applied to these terminals. Damage to the control will result.

Outdoor Sensor connection

Connect the two wires from the Outdoor Sensor 070 to

Com Sen — Out Sen

(13 and 15).

Condensate Return Sensor connection

Connect the wires from the Condensate Return Sensor (071) to terminals

Com Sen — Cnd Sen

(13 and 14).

Option: Occupied/Unoccupied switch input

Connect the two wires from the Occupied/Unoccupied dry contact switch (eg. tekmar 030

Timer) to terminals

Com Sen — UnO Sw

(10 and 11).

Option: Indoor temperature feedback Sensor Room 1

Connect the two wires from an Indoor Room Sensor 074 to terminals

10K S1 — Com Sen

(9 and 10).

Option: Indoor temperature feedback Sensor Room 2

Connect the two wires from an Indoor Sensor 074 to terminals

10K S2 — Com Sen

(12 and 13).

1234

Power

N

L

1234

Power

N

L

1234

Power

N

L

91011

Com

10K

UnO

S1

Sen

Sw

91011

Com

10K

UnO

S1

Sen

Sw

9 10 11

10K

Com

UnO

S1

Sen

Sw

91011

10K

Com

UnO

Sen

S1

Sw

91011

Com

10K

UnO

S1

Sen

Sw

Warn.

Warn.

Warn.

78

Boiler

13

12

10K

Com

S2

Sen

13

12

10K

Com

S2

Sen

13

12

10K

Com

S2

Sen

13

12

10K

Com

S2

Sen

13

12

Com

10K

S2

Sen

56

Aux.

56

Aux.

6

5

Aux.

14

15

Cnd

Out

Sen

Sen

14 15

Cnd

Out

Sen

Sen

14 15

Cnd

Out

Sen

Sen

14 15

Cnd

Out

Sen

Sen

14 15

Cnd

Out

Sen

Sen

Maximum 120Vac

1234

Power

NL

120 Vac

Power

Supply

10A

56

Warn. Aux.

Auxiliary Relay

closes to turn on

auxiliary device

Warning Relay

closes to turn on

warning device

10A10A

Safety Divider

78

Boiler

Boiler Relay

closes to turn

on boiler

Safety Divider

10KS1Com

Unoccupied

Switch (optional)

to switch control to

Unoccupied mode

10K Indoor

Sensor 074

(optional)

type 269

Do not apply power here

910111213

UnO

Sen

Sw

10K Indoor

Sensor 074

(optional)

10K

Com

S2

Sen

Con-

densate

Sensor

071

14

Cnd

Sen

15

Out

Sen

Outdoor

Sensor

Electrical connections to the terminal plugs of the

269 control. The control's relays are shown in their

"power down" condition.

Note: This is not a wiring diagram. For a

detailed wiring schematic of your specific

application, refer to the Application

Brochure A 269.

070

Copyright © D 269 - 06/007 of 12

Page 8

Step Five Testing the wiring

Caution

• These tests are to be performed using standard testing practices and procedures and should only be carried out by a properly trained and experienced

technician.

9

10 K

S2

Com

Sen

Uno

Sw

10 K

S2

Com

Sen

Cnd

Sen

14

13

12

11

10

• Before applying power to the control for testing, each terminal plug must be

unplugged from its header on the control. Pull straight down to unplug.

• A good quality electrical test meter, capable of reading from at least 0 — 200

Volts AC, and at least 0 — 1,000,000 Ohms, is essential to properly test this

control during installation.

Test the Sensors

• These tests must be made

before

turning on the power supply, and with the

terminals unplugged.

• The sensors are to be tested according to the instructions in Brochure D 001.

Test the Power supply

Make sure exposed wiring or bare terminals are not in contact with any other wires

Terminal plug disconnected

from its header on the control

or grounded surfaces. Turn on the power to the control and use an AC voltmeter

to measure the voltage between terminals

Volts AC should be measured at these terminals.

Test the Warning device

If a Warning device is connected to the

N — L

(1 and 2). Between 105 and 125

Warn.

(3 and 4) terminals; make sure

9

10 K

S1

10

Com

Sen

11

Uno

Sw

12

10 K

S2

13

Com

Sen

14

Cnd

Sen

15

Out

Sen

power to the circuit is off and install a jumper in the terminal plug between terminals

3 and 4. When the Warning device circuit is powered-up, the Warning device

should operate. If it does not come on, check the circuit wiring for errors and

ensure that it is powered up and the voltage is correct.

operates properly when the circuit is powered up, disconnect the power, remove the

If the Warning device

Terminal plug pushed into

its header on the control

jumper and proceed to the next step.

Test the Auxiliary device

If an Auxiliary device is connected to the

Aux.

(5 and 6) terminals; make sure power to the circuit is off and install a jumper in

the terminal plug between terminals 5 and 6. When the Auxiliary device circuit is powered-up, the Auxiliary device should operate.

If it does not come on, check the circuit wiring for errors and ensure that it is powered up and the voltage is correct.

If the Auxiliary

device operates properly when the circuit is powered up, disconnect the power, remove the jumper and proceed to the next step.

Test the Boiler

Make sure power to the Boiler circuit is off and install a jumper in the terminal plug between the

Boiler

(7 and 8) terminals. When

the Boiler circuit is powered-up, the Boiler should operate. If it does not come on, check the circuit wiring for errors and ensure

that it is powered up and the voltage is correct. Check the devices in the circuit (limits, low water cut off, etc.) for faults.

Boiler operates properly when the circuit is powered up, disconnect the power, remove the jumper and proceed to the next step.

Connect the control

Turn the power off and make sure all test jumpers have been removed from the plugs.

Connect the plugs to the control by carefully aligning them with their respective headers and pushing them upwards into the

headers. The plugs should snap firmly into place. The control is now ready for setup and operation.

Caution

The tekmar One Stage Steam Control 269 is an operating control and is not certified or intended for use as

a safety device. Under no circumstances should safety limit devices be left disconnected after installation

of this control. The installer shall check all applicable code requirements and obtain necessary inspections

to ensure that the installation is in compliance with those requirements.

15

Out

Sen

If the

Settings

Step Six Essential control settings

For specific application details refer to Application Brochure A 269-1 or A 269-2.

Cycle Length dial

This dial is used to set the length of the Heating Cycle from 1 to 100 minutes. The installer must have

knowledge of the system operating characteristics in order to determine the optimum Cycle Length. If the

Heating Cycle is too short, the system may not come up to operating pressure or temperature before it is

shut down, causing inefficient operation of the boiler and uneven heating through the system since the

furthest radiators from the boiler may not get hot enough. Too long of a Cycle Length will lead to wider air

temperature swings in the building, creating discomfort for the occupants. In most systems, trial and error

is the only way that the correct Cycle Length can be determined, and the installer must be willing to manually

operate the system through a number of cycles before this setting can be finalized. A cycle time of between

30 and 60 minutes should be used as a trial setting

Copyright © D 269 - 06/00 8 of 12

(settings below 10 minutes are for testing purposes only)

.

50 min

10

1

Cycle Length

100

Page 9

Man. Override dial

When testing the operation of the control or setting up the system, the "Man. Override" dial can be set to a

Auto

fixed % On Time. When this dial is turned up from the

position, the only other dial setting that has any

effect on the control operation will be the "Cycle Length" dial. Reset operation will resume when the dial is

turned all the way back down to the

Auto

position.

Design Out dial

This dial is to be set to the design outdoor temperature of the heating system. A heating system should have

originally been designed and sized to meet the heating requirements of the building on all but the very coldest

of days. Unfortunately, in many older systems the calculations used to come up with a design outdoor

temperature (if any were actually done) were based on either sheer fantasy or on mathematical principles

long since lost to science. Once again, the installer may have to use trial and error to find this number. If the

building starts to become cold as the outdoor temperature gets colder, the dial should be turned up, and if

it becomes too hot as the outdoor temperature gets colder, the dial should be turned down.

Steam Established dial

When a Condensate Return Sensor is installed, the control monitors the sensor temperature and will keep

the Heating Cycle from starting until the sensor temperature rises to the temperature of the "Steam

Established" dial. To set this dial, turn off power to the 269 and allow the boiler to cool off if it has been running.

Set the "Steam Established" dial up to 230°F and power the control back up. The control will operate the boiler,

making the system temperature rise as it tries to establish steam. Monitor the temperature of the Condensate

Return Sensor (for sensor placement see

Condensate Return Sensor Function,

page 4), until the system has

come up to operating temperature. Reduce the setting on the "Steam Established" dial until the "Steam

Established" light comes on. If the Steam Established dial is set too low, system efficiency will suffer and

uneven heating will result as the boiler shuts down before heat reaches all of the radiators. If the dial is set

too high, the building will overheat during the milder weather unless an Indoor Sensor 074 is connected.

Min. On Time

Without Condensate Return Sensor, this dial = Min. On Time (%)

(%)

— Lockout Diff'l

(°F)

dial

When there is no Condensate Sensor installed to the control, this dial sets the minimum on time

for the boiler each heating cycle. The "Condensate Return Sensor" DIP switch must be in the off

position or an error message will occur. To set this dial, allow the boiler to cool off if it has been

running, and set the control on Manual Override with the maximum % On Time and maximum Cycle

Length. Locate the radiator that is the last one in the system to heat up and monitor its temperature

while you allow the boiler to fire. Time how long it takes for the radiator to get up to operating

temperature and use that time as the Minimum On Time trial setting. Set the "Man. Override" dial

back to

Auto

and the "Cycle Length" dial back to its proper setting. If the Minimum On Time is set

for too short a time, system efficiency will suffer and uneven heating will result as the boiler shuts

down before heat reaches all of the radiators. If the dial is set too for too long, the building will

overheat during the milder weather unless an Indoor Sensor 074 is connected.

With Condensate Return Sensor, this dial = Lockout Diff'l (°F)

When there is a Condensate Return Sensor installed to the control, the control monitors the

sensor temperature and will prevent the Establishing Steam (warm-up) period from starting

Early Start

until the temperature drops to the "Steam Established" dial setting temperature minus the

"Lockout Diff'l" dial setting temperature. To set this dial, turn it all the way up to 50°F during a

cycle on time and wait until the boiler shuts down. Monitor the temperature of the Condensate

Return Sensor (for sensor placement see

Condensate Return Sensor Function,

page 4), and

when the system cools down to the point where the useful heat has been extracted, turn the

dial down until the "Steam Established" light turns off. If this setting is too low, the system will

lose efficiency by not extracting all of the heat from each cycle, and if it is too high, there will

If: Steam Established dial = 170°F

be temperature swings and uneven heating in the building as the system is kept off for too long.

45%

0

Auto

Man. Override

-40

Design Out

130 230

Indoor Sensor S1

Early Start

To calculate Min. on time %

Min on time = 5 minutes

5

30

123 4

To calculate Lockout Diff'l (°F)

System cool down temp. = 140°F

170 – 140 = 30°F Lockout Diff'l

Indoor Sensor S2

Condensate Return Sensor

123 4

Off

5

Min. On Time (%)

Lockout Diff'l (°F)

If: cycle = 30 minutes

x 100 = 17% Min. on time

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

Off

5

Min. On Time (%)

Lockout Diff'l (°F)

0 °F

180 °F

Steam

Established

Off2550

Off2550

100

40

Testing the Control Functions

Indicator lights

There are ten LEDs on the front of the control that will aid in testing and troubleshooting. During normal operation, these lights

indicate the following functions:

Power light on

WWSD light on

Unoccupied light on

Steam Established

Heating Cycle

Early Start light on

Boiler light on

Warning

Auxiliary light on •

Test light on

• the 120 Vac power supply has been connected and the control is energized.

• the control has calculated that the outdoor temperature is warm enough to not require heat.

• the control is in the Unoccupied (setback) mode.

• the condensate temperature is hotter than the setting of the Steam Established dial.

• the system is operating in a normal Heating Cycle.

• the control is in transition into or out of the Unoccupied (setback) mode.

• the Boiler relay is on, closing the contacts between the

• the Warning relay is on, closing the contacts between the

the Auxiliary relay is on, closing the contacts between

Boiler

(7 and 8) terminals.

Warn.

(3 and 4) terminals.

Aux.

(5 and 6) terminals.

• the control is going through the Test routine.

Copyright © D 269 - 06/009 of 12

Page 10

Step Seven Operational test of control functions - Test button

Test Button

The One Stage Steam Control 269 has a Test button which can be used to test all of the main control

functions at any time. When the Test button is pushed the control automatically runs through the

following test procedure.

All red lights on

On power-up, and at the start of each test routine, all of the red status lights are switched on for

approximately 5 seconds. During this time the control searches for sensor faults and, if no faults are

found, proceeds to the next step. If a sensor fault exists, the control exits the test routine and indicates

the fault by flashing a combination of lights. These Error Messages are listed on page 11.

Power

WWSD

UnOcc.

Warning

Test

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Power light on — Boiler light on

The control turns on the Boiler relay for 10 seconds and proceeds to the next step or; if during the

10 seconds the Test button is pressed, the test routine will be halted, the "Test" light will flash, and

the control will be held in a pause mode for 5 minutes. After the 5 minutes, the control will

automatically exit the test routine and return to normal operating mode. Pushing the Test button

Power

WWSD

UnOcc.

Warning

during the 5 minute pause will allow the control to proceed to the next step of the test routine.

Power Light on — Auxiliary light on

The control turns on the Auxiliary relay for 10 seconds and proceeds to the next step or; if

during the 10 seconds the Test button is pressed, the test routine will be halted, the "Test" light

will flash, and the control will be held in a pause mode for 5 minutes. After the 5 minutes, the

control will automatically exit the test routine and return to normal operating mode. Pushing

Power

WWSD

UnOcc.

Warning

the Test button during the 5 minute pause will allow the control to proceed to the next step of

the test routine.

Power Light on — Warning light on

The control turns on the Warning relay for 10 seconds and proceeds to normal operation

mode, or if during the 10 seconds the Test button is pressed, the test routine will be halted,

the "Test" light will flash, and the control will be held in a pause mode for 5 minutes. After the

5 minutes, the control will automatically exit the test routine and return to normal operating

Power

WWSD

UnOcc.

Warning

mode. Pushing the Test button during the 5 minute pause will allow the control to proceed to

the normal operation mode.

Power Light on— Test light off

The control has exited the test routine, entered operating mode and will function according to the sequence of operation

described on pages 2 to 6.

One or more of the indicator lights may be on.

Refer to pages 3 to 5 for a description of the

possible indicator light combinations under operating conditions.

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Test

Test

Test

Test

Step Eight Troubleshooting

As in any troubleshooting procedure, it is important to isolate a problem as much as possible before proceeding. The Error

Messages and Test button greatly simplify troubleshooting of the One Stage Steam Control 269.

If a fault occurs during operating mode or during the test routine and the control is flashing an Error Message, identify the fault

from the look-up table on the next page and then follow standard testing procedures to confirm the problem.

If you suspect a wiring fault, return to steps four and five and carefully check all external wiring and wiring connections.

During normal operation, if the Outdoor Sensor develops either a short circuit or an open circuit, the control will cycle the boiler

50% on at a rate determined by the Cycle Length dial. Also, the Warning relay will turn on to indicate there is a fault and the

appropriate error lights will be flashing.

During normal operation, if one Indoor Sensor develops either a short circuit or an open circuit when two Indoor Sensors are used,

the control will use the operational Indoor Sensor reading. If one Indoor Sensor is installed, and it develops either a short circuit

or an open circuit, the control will default to the Occ./UnOcc dial setting. The Warning relay will turn on to indicate there is a fault

and the appropriate error lights will be flashing.

Copyright © D 269 - 06/00 10 of 12

Page 11

If a Condensate Return Sensor has been installed, and the sensor has become either short circuited or open circuit, the control

will not operate with any Steam Established /lockout functions. The control will default to the "Min. On Time (%)" dial setting. The

warning relay will turn on to indicate there is a fault and the appropriate error lights will be flashing.

After any repair has been completed, press the Test button to allow the control to cycle through the test routine. This

will allow you to confirm that correct operation has been restored.

Step Nine Before you leave

Install the wiring cover over the wiring chamber and secure it to the base with the two screws provided. Place the front cover

on the control to cover the setting dials and snap it into place. Install a lock if security is required.

Place this brochure and all other brochures relating to the installation in the protective plastic bag supplied with the control. Place

the bag in a conspicuous location near the control for future reference.

It is important to explain the operation and maintenance of this control and of the system to the end user and anyone else who

may be operating the system.

Error Messages

Whenever a fault is detected in any of the sensors, the indicator lights will flash in specific ways to indicate the problem and the Warning

relay will close to signal to the user that a fault has occurred.

The following look-up table describes each error condition and shows the flashing light sequence that results.

After repairing the problem, press the Test button to cycle the control through the test routine. This will confirm that the fault has been

repaired and that correct control action has been restored.

For detailed sensor testing instructions see Data Brochure D 001.

Indoor

Sensor S2

open circuit

(see

troubleshooting

notes)

Outdoor

Sensor

short circuit

(see

troubleshooting

notes)

Light on continually

Light flashing

Light off

Power

WWSD

UnOcc.

Warning

Power

WWSD

UnOcc.

Warning

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Test

Indoor

Sensor S1

open circuit

(see troubleshooting

notes)

Indoor

Sensor S2

short circuit

(see

troubleshooting

notes)

Condensate

Return

open circuit

(see

troubleshooting

notes)

Power

WWSD

UnOcc.

Warning

Power

WWSD

UnOcc.

Warning

Power

WWSD

UnOcc.

Warning

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Test

Test

Indoor

Sensor S1

short circuit

(see troubleshooting

notes)

Outdoor

Sensor

open circuit

(see

troubleshooting

notes)

Condensate

Return

short circuit

(see

troubleshooting

notes)

Power

WWSD

UnOcc.

Warning

Power

WWSD

UnOcc.

Warning

Power

WWSD

UnOcc.

Warning

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

Established

Heating

Cycle

Early Start

Auxiliary

Boiler

Steam

established

Heating

cycle

Early Start

Auxiliary

Boiler

Test

Test

Test

Test

Test

Copyright © D 269 - 06/0011 of 12

Page 12

Technical Data

One Stage Steam Control 269

Literature — D 269, A 269's, D 001, D 070.

Control — Microprocessor control; This is not a safety (limit) control.

Packaged weight — 3.1 lb. (1400 g), Enclosure A, blue PVC plastic

Dimensions — 6-5/8” H x 7-9/16” W x 2-13/16” D (170 x 193 x 72 mm)

Approvals — CSA C US, meets ICES & FCC regulations for EMI/RFI.

Ambient conditions — Indoor use only, 30 to 120°F (0 to 50°C), < 95% RH non-

condensing.

Power supply — 120 V (ac) ±10% 50/60 Hz 3 VA

Relay capacity — 120 V (ac) 10 A 1/4 hp, pilot duty 240 VA 2 A

Sensors included — NTC thermistor, 10 kΩ @ 77°F (25°C ±0.2°C) ß=3892

Outdoor Sensor 070 and Universal Sensor 071.

Optional devices — tekmar type #: 031, 071, 076, 077.

Occupied

Unoccupied

Manual Override

Design Out

Cycle Length

Steam Established

Min. On Time (%) —

Lockout Diff’l (°F) —

— 40 to 100°F (4 to 38°C)

— 40 to 100°F (4 to 38°C)

— Auto, 0 to 100% of boiler on time during Heating Cycle

— -40 to 40°F (-40 to 4°C)

— 1 to 100 minutes

— 130 to 230°F (54 to 110°C)

Off, 5 to 50% on

Off, 1 to 50°F (Off, 3 to 28°C)

100

(38)

70°F

(21°C)

40

(4

)

Unoccupied

12345

Power

Warn.

NL

70°F

(21°C)

40

(4

)

Occupied

One Stage Steam Control 269

with Early Start

Use Nº 20 AWG or larger

copper conductors rated

°

C and 300V.

for at least 75

Power

WWSD

UnOcc.

Warning

100

(38)

R

E150539

C US

158033

78

6

Aux.

Boiler

Early Start

Steam

Established

Heating

Cycle

Early Start

45%

Auxiliary

0

Auto

Man. Override

Boiler

Test

Made in Canada by

Listed

tekmar Control Systems Ltd.

5T62

R

Power: 120 V (ac)

Relays: 120 V (ac) 10A 1/4 hp pilot duty 240 VA 2 A

Enclosed Energy Management Equipment

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Regulations. However, if this control does cause harmful interference to radio or television reception,

which is determined by turning the control off and on, the user is encouraged to try to correct the interference by reorienting or relocating

the receiving antenna, relocating the receiver with respect to this control, and/or connecting the control to a different circuit from that

to which the receiver is connected.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Off

0 °F

-40

100

Design Out

180 °F

130 230

Steam

Established

±10% 50/60 Hz 3VA

Do not apply power here

9

10

11 1 2

10K

10K

Com

UnO

Sen

Sw

S1

Indoor Sensor S1

Indoor Sensor S2

Condensate Return Sensor

50 min

10

1

40

Cycle Length

5

Off2550

Min. On Time (%)

Lockout Diff'l (°F)

13 14 15

Cnd Out

Com

Sen

Sen

Sen

S2

100

Caution The nonmetallic enclosure does not provide grounding between conduit connections. Use grounding type bushings and jumper

wires.

Attention Un boîtier nonmétallique n’assure pas la continuité électrique des conduits. Utiliser des manchons ou des fils de accord

spécialement conçus pour la mise á la terre.

Limited Warranty and Product Return Procedure

Limited Warranty The liability of tekmar Control Systems Ltd. and tekmar

Control Systems, Inc. (“tekmar”) under this warranty is limited. The purchaser,

by taking receipt of the tekmar product (“product”), acknowledges receipt of

the terms of the warranty and acknowledges that it has read and

understands same.

tekmar warrants each tekmar product against defects in workmanship and materials, if the product is installed and used in compliance with tekmar's instructions. The

warranty period is for a period of twenty-four (24) months from the production date

if the product is not installed during that period, or twelve (12) months from the

documented date of installation if installed within twenty-four (24) months from the

production date.

The liability of tekmar under this warranty shall be limited to, at tekmar's sole discretion: the cost of parts and labor provided by tekmar to repair defects in materials

and/or workmanship of the defective product; or to the exchange of the defective

product for a replacement product; or to the granting of credit limited to the original

cost of the defective product, and such repair, exchange or credit shall be the sole

remedy available from tekmar, and, without limiting the foregoing in any way,

tekmar is not responsible, in contract, tort or strict product liability, for any

other losses, costs, expenses, inconveniences, or damages, whether direct, indirect, special, secondary, incidental or consequential, arising from ownership or use

of the product, or from defects in workmanship or materials, including any liability

for fundamental breach of contract.

This warranty applies only to those products returned to tekmar during the

warranty period. This warranty does not cover the cost of the parts or labor

to remove or transport the defective product, or to reinstall the repaired or

replacement product. Returned products that are not defective are not covered by this warranty.

This warranty does not apply if the product has been damaged by negligence

by persons other than tekmar, accident, fire, Act of God, abuse or misuse; or

has been damaged by modifications, alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the

product was not installed in compliance with tekmar’s instructions and the

local codes and ordinances; or if due to defective installation of the product;

or if the product was not used in compliance with tekmar’s instructions.

This warranty is in lieu of all other warranties, express or implied, which the

Governing Law (being the law of British Columbia) allows parties to contractually exclude, including, without limitation, warranties of merchantability,

fitness for a particular purpose, durability or description of the product, its

non-infringement of any relevant patents or trademarks, and its compliance

with or non-violation of any applicable environmental, health or safety legislation; the term of any other warranty not hereby contractually excluded is

limited such that it shall not extend beyond twenty-four (24) months from the

production date, to the extent that such limitation is allowed by the Governing Law.

Product Return Procedure Products that are believed to have defects in work-

manship or materials must be returned, together with a written description of the

defect, to the tekmar representative for that territory. If the address of the representative is not known, please request it from tekmar at the telephone number

listed below

.

tekmar Control Systems Ltd., Canada

Control Systems

tekmar Control Systems, Inc., U.S.A.

Head Office: 5100 Silver Star Road

Vernon, B.C. Canada V1B 3K4

Tel. (250) 545-7749 Fax. (250) 545-0650

Web Site: www.tekmarcontrols.com

Product design, software and literature are Copyright © 2000 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

12 of 12

All specifications are subject to change without notice.

Printed in Canada. D 269 - 06/00.

Loading...

Loading...