STIEBEL ELTRON Accelera 300 E User Manual [en, es, fr]

OPERATION AND INSTALLATION FUNCIONAMIENTO E INSTALACIÓN MODE D’EMPLOI ET INSTALLATION

DHW heat pump water heater

Calentador de agua con bomba eléctrica de calor Chauffe-eau à thermopompe

»Accelera 220 E

»Accelera 300 E

Conforms to ANSI/UL 499, UL 1995, UL 94-5 VA, UL 174

Certified to CAN/CSA C22.2 No. 110

Conforme a ANSI/UL 499, UL 1995, UL 94-5 VA, UL 174

Certificación con CAN/CSA Std. C22.2 No. 110

Conforme à la norme ANSI/UL Std. 174

Certifié à la norme CAN/CSA Std. C22.2 No. 110

Tested and certified by WQA to NSF/ANSI 372 for lead free compliance.

Probado y certificado por WQA NSF/ANSI 372 para el cumplimiento de las regulaciones sin plomo.

Testé et certifié par WQA à la NSF/ANSI 372 pour une utilisation sans plomb.

CONTENTS

ACCELERA® 220 E QUICK START-UP GUIDE

OPERATION

1.General information _________________________________________7

2.Safety__________________________________________________________7

2.1Intended use ______________________________________________________ 7

2.2Incorrect use______________________________________________________ 7

2.3General safety instructions ____________________________________ 7

2.4ETL designation __________________________________________________ 8

2.5Appliance labels _________________________________________________ 8

3.Appliance description _____________________________________ 10

3.1Heating the DHW tank _________________________________________ 11

3.2Appliance operation outside the application limits______ 11

3.3Frost protection _________________________________________________ 11

4.Settings _____________________________________________________ 11

4.1Display and controls____________________________________________ 11

4.2Settings ___________________________________________________________ 11

4.3Calling up fault codes __________________________________________ 13

4.4Rapid heating key ______________________________________________ 13

4.5Emergency shutdown __________________________________________ 14

5.Maintenance and care _____________________________________ 14

6.Troubleshooting ____________________________________________ 14

6.1Fault codes _______________________________________________________ 15

INSTALLATION

7.Safety________________________________________________________ 16

7.1General safety instructions ___________________________________ 16

7.2Instructions, standards and regulations ___________________ 16

7.3Incorrect use_____________________________________________________ 16

7.4Qualification _____________________________________________________ 16

8.Appliance description _____________________________________ 16

8.1Standard delivery _______________________________________________ 16

8.2Required accessories __________________________________________ 16

8.3Further accessories_____________________________________________ 16

9.Preparations ________________________________________________ 16

9.1Transport _________________________________________________________ 16

9.2Storage____________________________________________________________ 17

9.3Installation site__________________________________________________ 17

9.4Siting the appliance ____________________________________________ 18

9.5Minimum clearances ___________________________________________ 18

10.Installation __________________________________________________ 19

10.1Water connection _______________________________________________ 19

10.2Condensate drain _______________________________________________ 19

10.3Power supply ____________________________________________________ 20

10.4Assembling the appliance ____________________________________ 21

11.Commissioning _____________________________________________ 21

11.1Commissioning __________________________________________________ 21

11.2Recommissioning _______________________________________________ 21

12.Shutting down______________________________________________ 22

13.Troubleshooting ____________________________________________ 22

13.1Fault table ________________________________________________________ 22

13.2Resetting the safety pressure limiter _______________________ 22

13.3Resetting the high limit safety cut-out _____________________ 22

13.4Motor overload relay___________________________________________ 22

14.Maintenance and cleaning ________________________________ 23

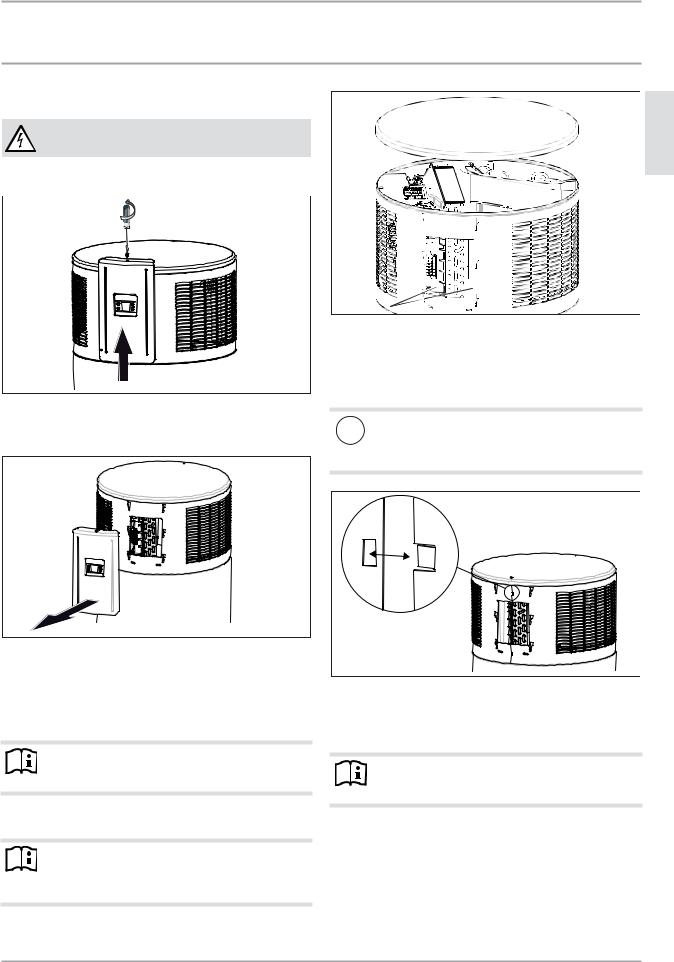

14.1Removing the appliance cover _______________________________ 23

14.2Removing the casing ring_____________________________________ 23

14.3Cleaning the evaporator_______________________________________ 24

14.4Draining the tank _______________________________________________ 24

14.5Descaling the electric booster element ____________________ 24

14.6Protective anode ________________________________________________ 24

14.7Valves _____________________________________________________________ 24

14.8Replacing the power cable ___________________________________ 24

14.9Fitting the casing ring _________________________________________ 24

14.10Fitting the appliance cover ___________________________________ 25

15.Specification ________________________________________________ 26

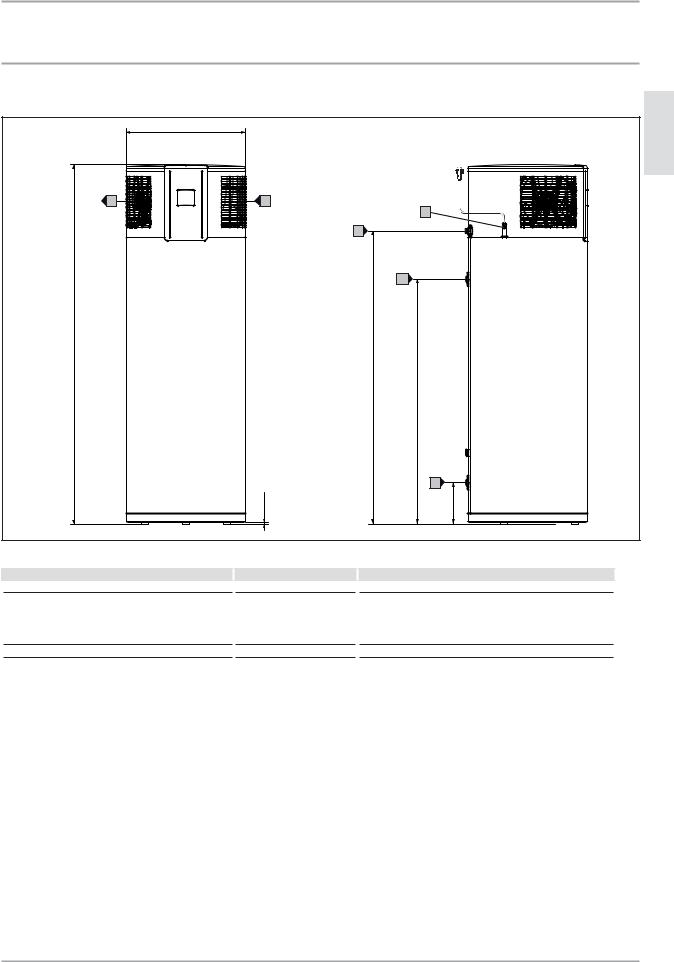

15.1Dimensions and connections _________________________________ 26

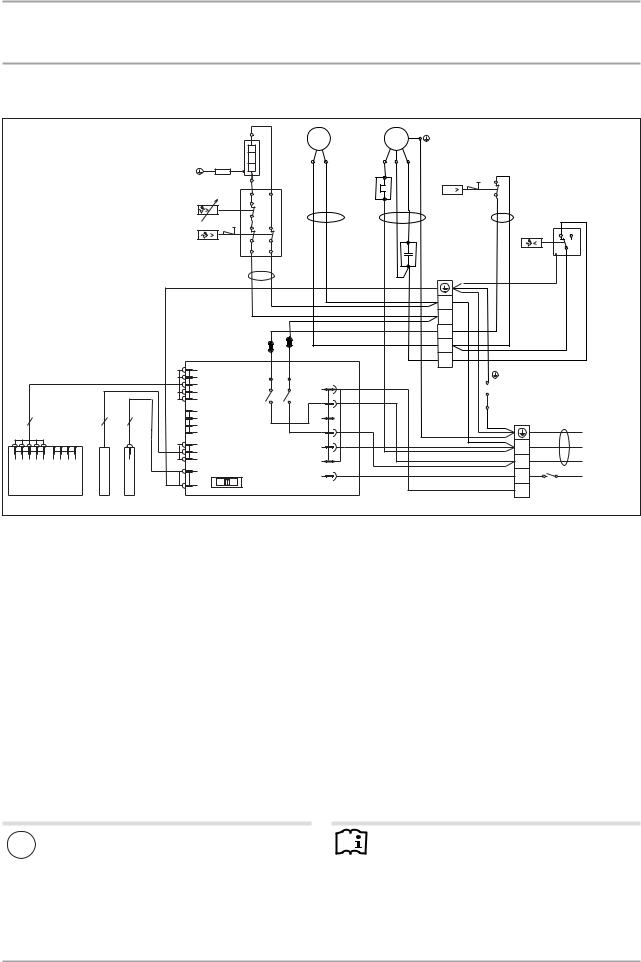

15.2Wiring diagram _________________________________________________ 28

15.3Data table ________________________________________________________ 29

16.Limited Warranty___________________________________________ 30

2 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

SPECIAL INFORMATION

This manual includes important information regarding the safe and efficient handling of the water heater. Keep this manual with the water heater at all times.

Work must only be carried out by a licensed installer who has read and understands these instructions. All federal, state and local codes must be followed. Failure to do so may result in equipment failure, serious injury, or death.

While working on the water heater, disconnect the power supply.

Illustrations in these instructions are designed to aid a general understanding and may deviate from the actual water heater version. No claims can be derived from such installations.

Limited liability:

We have collated all details and information in this manual in due consideration of applicable standards and regulations, the state of the art and our long-term know-how and experience.

Losses due to the following are excluded from our liability:

-Non-observance of these instructions

-Incorrect use

-Installation of water heater by unqualified personnel

-Unauthorized modifications

-Use of unauthorized spare parts

For more information on liability, see the warranty section at the back of this manual.

Copyright:

These operating and installation instructions are subject to copyright.

Transferring these instructions to third parties, copying of any kind, either in total or extracts therefrom, as well as their use and/or conveying its contents are prohibited without our written consent.

Violations are liable to claims for compensation. Further claims are reserved.

We hold the copyright:

Stiebel Eltron, Inc.

17 West Street | West Hatfield, MA 01088 Tel. 413-247-3380 | Fax 413-247-3369 Email info@stiebel-eltron-usa.com www.stiebel-eltron-usa.com

Should you have any questions regarding the installation or operation of the water heater, please contact our customer service. Tel. (USA) 800-582-8423 or 413-247-3380

Please record your serial number and information:

Serial No.:

Date of purchase:

Register your product |

|

||

|

|

|

ENGLISH |

|

NOTE: |

|

|

|

|

|

|

|

You must register this product within 90 days |

|

|

|

of purchase on our web site in order to acti- |

|

|

|

vate any standard warranty or to be eligible for |

|

|

|

the extended warranty. Go to our website at: |

|

|

|

www.stiebel-eltron-usa.com and click on “Register Your |

|

|

|

Product.” |

|

|

|

|

|

|

Before beginning the registration process, we suggest that you gather the necessary information as follows:

|

1 |

00000-0000-000000 |

D0000035352 |

1Serial number on the type plate

Type, Example: Accelera 220 E (the type plate can be found on the appliance above the “DHW outlet” connection). Number listed after “Nr.”

Place of Purchase Purchase Date First & Last Name Email address Physical Address Phone Number

If you have any questions concerning the registration process or warranty options, please contact Stiebel Eltron USA directly at (800)-582-8423.

www.stiebel-eltron-usa.com |

Accelera® 220-300 E | 3 |

QUICK START-UP GUIDE

General information

ACCELERA® 220 E QUICK START-UP GUIDE

Overview:

Installation of this water heater is similar to standard electric water heaters, with a few minor exceptions. Be sure to follow all state and local codes during installation. This Quick Start-up Guide is not intended to be a substitute for the complete installation manual. Be sure to follow all safety precautions.

Unpacking:

DO NOT unpack the water heater until it is located at the point of installation. Follow all instructions in the manual and be sure to use caution, as this unit is top heavy. After unpacking, DO NOT lay the unit down and DO NOT jar or tip the unit past 45 degrees on a hand truck. If the appliance has not been completely vertical during transport or setup, it must rest in a vertical position for at least one hour before commissioning.

Installation of water connections:

1.Find a suitable location that fits the room spacing guidelines on the next page. The minimum volume of the room is 10´ x 10´ x 10´. Be sure vents are parallel to the wall with the fan facing the most open area along that wall. Please note: a drain pan is recommended, and may be code in some areas.

2.The inlet & outlet plumbing connections on the unit are 1˝ male NPT. It is recommended to use union connections for easier serviceability. Install a boiler drain at the cold water inlet for easier draining of the tank.

3.The temperature & pressure (T&P) safety valve port is ¾˝ female NPT. A T&P valve is supplied which is rated to release water at 100 psi and/or 210°F. Plumb this connection to a bucket or directly to a drain. If it is plumbed to a bucket, check it often for any accumulated water.

For hook-up, follow all state and local codes for check valves, expansion tanks, shut off valves, gauges, etc. Install a 70 psi pressure reduction valve if the water pressure exceeds 70 psi (See 10.1, “Water connection”, pg. 19)

Condensate drain:

Run the condensate drain connection directly into a drain or use a condensate pump to drain into a suitable location (See 10.2, “Condensate drain”, pg. 19).

Fill & flush tank:

Run water and be sure the tank is full prior to turning on the electricity.

Installation/electrical:

Use a 240 Volt / 15 Amp double pole breaker and connect to the water heater L1,L2 & ground (See 10.3, “Power supply”, pg. 20).

4 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

QUICK START-UP GUIDE

Required room dimensions and clearances

› Do not install in a room |

|

|

with less than 800 cubic |

Minimum room volume: |

14˝ |

feet of total volume. |

800 ft2, 10´ x 10´ x 8´ |

|

› Do not install with the air |

(22.7 m2, 3 m x 3 m x 2.4 m) |

(0.4 m) |

exhaust pointing at a wall |

|

Air flow |

or any surface closer than |

Air flow |

intake |

6 feet away. |

|

|

exhaust |

|

|

|

|

› Do not install with the air |

6´ (1.8 m) |

2´ (0.6 m) |

||

|

intake pointing to a wall or |

|||

|

|

|

|

|

|

any surface closer than 2 |

|

An object |

|

|

feet away. |

|

|

|

› If you are installing the |

|

next to the |

|

|

|

unit must |

|

||

|

water heater next to |

|

|

|

|

≤42˝ |

be less than |

|

|

|

another appliance, it |

|

||

|

cannot be taller than 42 |

(1.1 m) |

42˝ high |

|

|

inches. Otherwise, it will |

|

|

|

|

obstruct air flow to and |

|

|

|

|

from the unit. |

|

|

|

› |

Failure to follow |

Acceptable positioning, vent parallel to a wall: |

||

|

installation instructions |

|

|

8˝ (0.2 m) |

|

will void the factory |

|

|

|

|

warranty. |

|

|

|

|

|

6´ (1.8 m) |

2´ (0.6 m) |

|

|

|

|

Air flow |

Air flow |

|

|

|

exhaust |

|

|

|

|

intake |

|

|

|

|

|

|

Acceptable positioning, vent parallel to a wall in a corner:

8˝ (0.2 m) |

|

|

Air flow |

|

intake |

8˝ |

2´ |

(0.2 m) |

(0.6 m) |

|

|

|

2´ |

|

(0.6 m) |

6´ |

Air flow |

(1.8 m) |

exhaust |

ENGLISH

www.stiebel-eltron-usa.com |

Accelera 220-300 E | 5 |

QUICK START-UP GUIDE |

|

|

|

|

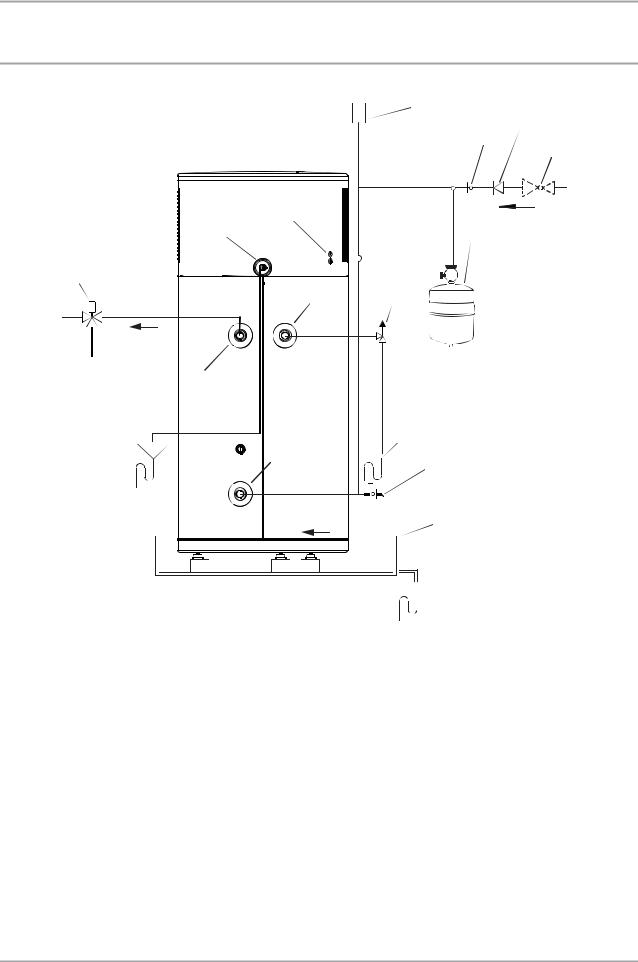

Plumbing connections |

|

|

|

|

|

|

1 |

|

8 |

|

|

|

7 |

|

|

|

|

9 |

|

|

|

|

|

|

|

14 |

6 |

|

Cold water |

|

11 |

|

||

|

|

|

||

3 |

|

5 |

|

|

|

4 |

|

|

|

C |

H |

|

|

|

|

M |

|

|

|

|

Hot water |

|

|

|

|

2 |

|

|

|

|

10 |

12 |

|

|

|

|

13 |

|

|

1Vacuum breaker

2Hot water connection (1˝ NPT)

3 Mixing valve (optional, supplied by installer)

4Connection for T&P valve ¾˝ NPT

5 T&P valve ¾˝ NPT, 0.69 MPa @ 99°C (100 psi @ 210°F) (supplied with unit)

6Expansion tank (required, supplied by installer)

7 Straight-through shut-off valve (supplied by installer)

8Check valve (required, supplied by installer)

9 0.48 MPa (70 psi) pressure reduction valve (optional, supplied by installer)

10Cold water connection (1˝ NPT)

11Condensate drain (elbow supplied with unit)

12Drain valve (supplied by installer)

13Drain pan (supplied by installer)

14Condensate spillover

6 | Accelera 220-300 E |

www.stiebel-eltron-usa.com |

OPERATION

General information

OPERATION

1.General information

The chapters “Special information” and “Operation” are intended for appliance users and qualified contractors.

The chapter “Installation” is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

2.Safety

This chapter provides an overview of all important actions required for a safe and trouble-free operation.

2.1Intended use

WARNING Electrocution

Contact with live components presents a threat to life. Damage to the electric insulation or to individual components may result in a threat to life.

If there is damage to the insulation, disconnect the power supply and arrange a repair.

All work on the electrical installation must be carried out by a qualified contractor.

WARNING Scalding

The water in the DHW tank can be heated to temperatures in excess of 149°F/65°C. There is a risk of scalding at outlet temperatures in excess of 110°F/43°C.

Ensure you do not come into contact with the water when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear protective working clothing and safety gloves.

The pipework connected to the DHW outlet of the appliance can reach temperatures in excess of 149°F/65°C.

The appliance is intended for DHW heating within the application |

|

|

WARNING Scalding |

|

|

The appliance is filled with refrigerant at the factory. |

|

limits (See 15.3, “Data table”, pg. 29). |

|

|

|

|

|

||

|

|

In case of leaking refrigerant, avoid coming into contact |

|

The appliance is intended for domestic use, i.e. it can be used |

|

|

|

|

|

with the refrigerant or inhaling the released vapors. Ven- |

|

safely by untrained persons. The appliance can also be used in a |

|

|

tilate the rooms affected. |

non-domestic environment, e.g. in a small business, as long as it |

|

|

|

|

|

|

|

is used in the same way. |

! |

CAUTION Injury |

|

|

|||

Any other use beyond that described shall be deemed inappropri- |

Never place any objects on top of the appliance. If objects |

||

ate. Observation of these instructions and of instructions for any |

|

|

are left on the appliance, noise emissions may increase |

accessories used is also part of the correct use of this appliance. |

|

|

due to resulting vibrations, and the objects could fall |

|

|

|

and cause injury. |

|

|

|

|

2.2Incorrect use

The following are not permitted: |

! |

CAUTION |

|

- Heating liquids other than potable water |

To reduce the risk of excessive pressures and tempera- |

||

|

tures in this water heater, install temperature and pres- |

||

- Operating the appliance with an empty DHW tank |

|

||

|

sure protective equipment required by local codes and |

||

- Operating the appliance outside the application limits (See |

|

||

|

no less than a combination temperature and pressure |

||

15.3, “Data table”, pg. 29) |

|

relief valve certified by a nationally recognized testing |

|

- Interrupting the power supply, as without power supply the |

|

laboratory that maintains periodic inspection of produc- |

|

appliance is not protected against corrosion |

|

tion of listed equipment or materials, as meeting the re- |

|

|

|

|

quirements for Relief Valves and Automatic Gas Shutoff |

2.3 |

General safety instructions |

|

Devices for Hot Water Supply Systems, ANSI Z21.22. This |

Only qualified contractors should carry out the electrical work and |

|

valve must be marked with a maximum set pressure not |

|

|

to exceed the marked maximum working pressure of the |

||

installation of this appliance. Qualified contractors are responsible |

|

water heater. Install the valve into an opening provided |

|

for adherence to all applicable regulations. |

|

and marked for this purpose in the water heater, and |

|

Operate the appliance only when fully installed and with all safety |

|

orient it or provide tubing so that any discharge from |

|

|

the valve exits only within 6 inches above, or at any |

||

equipment fitted. |

|

||

|

distance below, the structural floor, and does not contact |

||

|

|

|

|

|

WARNING Injury |

|

any live electrical part. The discharge opening must not |

! |

|

be blocked or reduced in size under any circumstances. |

|

The appliance may be used by children aged 8 and up and |

|

||

|

|

||

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided that they are supervised or they have been instructed on how to use the appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance or perform user maintenance unless they are supervised.

ENGLISH

www.stiebel-eltron-usa.com |

Accelera® 220-300 E | 7 |

OPERATION

Safety

! |

CAUTION |

Hydrogen gas is produced by this heater in a hot water |

|

|

system that has not been used for a long period of time |

|

(2 weeks or more). Hydrogen gas is extremely flamma- |

|

ble. To reduce the risk of injury under these conditions, |

|

it is recommended that the hot water faucet be opened |

|

for several minutes at the kitchen sink before using any |

|

electrical appliance connected to the hot water system. |

|

When hydrogen is present, there will probably be an |

|

unusual sound such as air escaping through the pipe as |

|

the water begins to flow. There should be no smoking or |

|

open flame near the faucet at the time it is open. |

|

|

! |

Material losses |

If you disconnect the appliance from the power supply, it |

|

|

is no longer protected against frost. |

|

Do not interrupt the power supply to the appliance. |

|

|

|

|

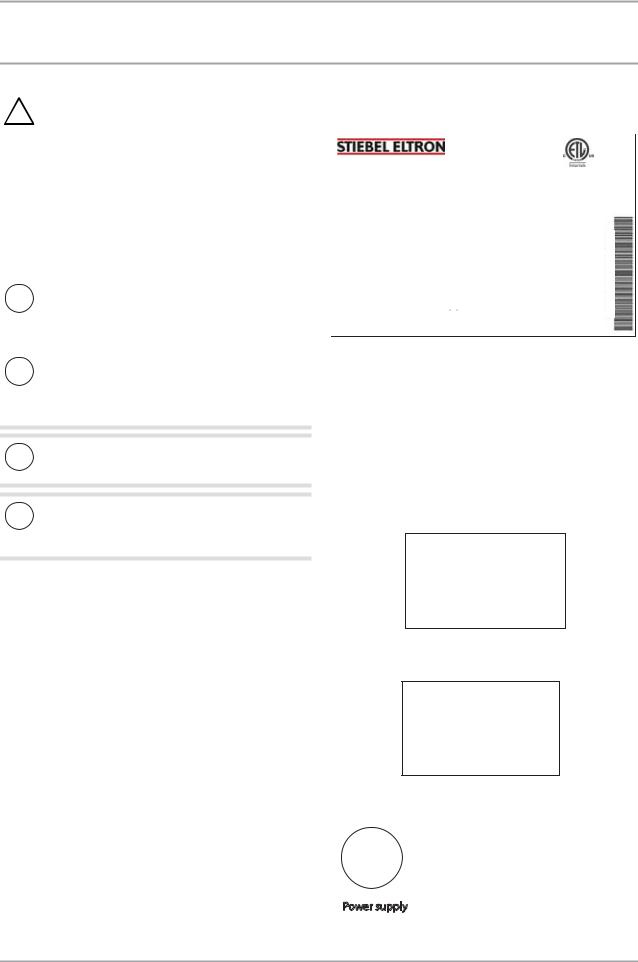

2.5Appliance labels

1. Type plate label for the Accelera 220 E

No.:#### / ######

Part number/code article: |

233058 |

Electrical/électrique |

|

Voltage/tension: |

Single phase 220-240 V |

Frequency/fréquence: |

50 / 60 Hz |

Breaker/disjoncteur: |

15 A |

Pnmax (rated power input)/puissance nominale: |

2200 W |

Maximum allowable ratings/courant nominal: |

2200 W, 9.17 A |

Protection class/indicie de protection: |

IP 24 |

Heat pump/pompe à chaleur: |

|

PN (Air 107.6°F / Water 149°F): |

0.54 kW |

Refrigerant/frigorigène: |

R-134a |

Refrigerant charge/frigorigène poids de remplissage: |

1.874 lb / 850g |

Max. operating pressure/max. pression de service: |

348.1 PSI / 2,400 kPa |

Lock rotor current/puissance blockade: |

15.3 A |

MCA: |

14 A |

Rated compressor load/courant nominale du compresseur: |

2.5 A |

Motor fan/moteur de ventilateur: |

24 W |

DHW cylinder/DHW cylindre: |

|

Backup heating element/chauffage d'appoint: |

1690 W |

Max. operating pressure/max. pression de service: |

87 PSI / 600 kPa |

Max. operating temperature/max. temperature de service: |

168.8°F / 76°C |

Tank material/matériau réservoir: |

Steel |

Nominal capacity/capacité nominale: |

58.12 gal / 220 l |

Tank test pressure/contrôle de réservoir: |

130.5 pSI / 900 kPa |

285872-34892

Read the instructions carefully. |

XXXX - XXXXXX |

|

Tested for leaks. |

- |

|

XXXXXX |

|

|

Lira attentivement la notice. |

|

|

Étanchéité testé. |

|

|

Made in EU/Fabriqué en UE |

|

|

Material losses

!Never cover this appliance. Covering the air intake or air discharge leads to a reduced air supply. If the air supply is restricted, the operational reliability of the appliance cannot be guaranteed.

Material losses

!Only operate the appliance when the DHW tank has been filled.

Material losses

!Keep the appliance installation room free from air contaminated with oil or salt and corrosive or explosive substances.

2.4ETL designation

The ETL designation shows that the appliance meets all essential UL and CAN/CSA requirements. This appliance conforms to:

-UL Standard 1995

-UL Standard 174

-CAN/CSA Standard C22.2 No.236-05

-CAN/CSA Standard C22.2 No.110-94

2. Condensate drain information label

Condensate |

|

|

Condenso |

38055- |

|

Condensat |

||

- |

||

|

3118015683 |

|

|

|

3. Hot water outlet location label

Hot Water Outlet

Salida de agua caliente

Sortie eau chaude

311803-38055

4. Cold water outlet location label

Cold Water Inlet

Entrada para agua fría

Entrée eau froide

311802-38055

5. Power connection information label

|

!Attention! |

|

Must connect to |

Power supply |

240 V, 15 A |

Disconect power supply |

Double-pole |

Before opening the cover |

Circuit breaker |

8 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

OPERATION

Safety

6. Scald risk information label

AQUA CALIENTE

AQUA CALIENTE

ABRASAR

ABRASAR

52

52 125

125

Une température de l'eau de plus de 52°C (125°F) peut causer des brûlures graves ou la mort par ébouillantage

Les enfants, les personnes handicapées et les personnes âgées courent le plus grand risque de brûlures.

Lire la notice d'emploi avant d'ajuster la température du chauffe-eau.

Vérifier la température de l'eau avant de prendre un bain ou une douche.

Des dispositifs de limitation de température sont disponibles. Voir la notice d'emploi.

ATTENTION

L'eau chaude peut provoquer des brûlures de 3ème degré:

En 6 secondes à 60°C (140°F). En 30 secondes à 54°C (130°F). Réglé à l'usine à 52°C (125°F).

Contacter le personnel de service après-vente qualifié pour toute modification.

Agua con temperatura de más de 52 °C (125 °F) puede al instante causar quemaduras graves o la muerte por escaldadura.

Niños, personas con discapacidades o mayores se encuentran en mayor peligro de escaldadura.

Mire las instrucciones de uso antes de ajustar la temperatura en el calentador de agua.

Pruebe el agua antes de bañarse o de ducharse.

Están disponibles válvulas para regular la temperatura. Mire las instrucciones de uso.

ADVERTENCIA

Agua muy caliente puede causar quemaduras de 3er grado. En 6 segundos A 60 °C (140 °F). En 30 segundos A 54 °C (130 °F).

La regulación fue ajustada en la producción

A 52 °C (125°F). Si necesita ajustar la regulación, contácte al técnico de servicio calificado.

7. Gasket connection information label

For reason of corrosion protection use flat gasket ring. Never seal threadshemp (equipment Damage!).

38055-311804 |

Para la protección contra la corrosión use |

sellos planos de los tubos. Una unión |

con cáñamo no está permitida (riesgo de daño del equipo!).

Pour des raisons de protection contre la corrosion, le raccordement est à réaliser par joints plats. L'étanchéïfication au chanvre n'est pas autorisée (dommages au matériel!).

8. Pressure & temperature relief valve information label

Relief valve

P lum ber:

The relief valve installation m ust be fitted to this socket. The pressure and tem perature relief valve has to m eet local codes and com ply with A NS I Z21 .22 .

Soupape de sûreté

Plombier:

L'installation de la soupape de sûreté doit être branchée sur cette prise. La soupape de sûreté pour la pression et la température doit être conforme à la réglementation locale et à ANSI Z21.22.

Válvula de seguridad

Plomero:

La válvula de seguridad debe instalarse en esta conexión.

Las válvulas limitadoras de presión y temperatura tienen que 38055 ajustarse al código local y cumplir con la norma ANSI Z21.22. -315321

9. Kyoto protocol information label

ES: Sistema herméticamente cerrado que contiene gases de efecto invernadero mencionados en el protocolo de Kioto. BG: Съдържа посочените в Протокола от Киото флуорирани парникови газове - херметически затворена система.

299581-36960

10. Supplemental heat element information label

If the water heater is retrofitted with a supplemental heat element make sure that both thermostat are adjusted on the same

water temperature set point.

Si le chauffe-eau est rénové avec un élément de chauffe supplémentaire, assurez-vous que les deux thermostats soient ajustés

à la même température de réglage de l'eau.

Si el calentador de agua está adaptado a un elemento calentador 38055 suplementario, asegúrese que ambos termostatos estén ajustados

a la misma temperatura de agua.

-315322

ENGLISH

www.stiebel-eltron-usa.com |

Accelera® 220-300 E | 9 |

OPERATION

Appliance description

11. Booster heater element information label

CAUTION :

for use only in water

ATTENTION:

pour l'utilisation dans l'eau

ATENCIÓN:

se usa sólo para en agua

315683-38055

12. Appliance must be vertical for at least one hour before commissioning information label

WARNING / WARNUNG

The unit must remain in vertical position for at least one hour before putting unit into operation.

Die Anlage muss min. 1 Stunde lang vor deren

Inbetriebnahme in senkrechter Position bleiben.

L’appareil doit être placé en position verticale au moins une heure avant sa mise en route.

La unidad tiene que quedar en la posición vertical al menos durante una hora antes de poner la unidad en funcionamiento.

315125-38055

3.Appliance description

The appliance is designed for indoor installation. The appliance recirculates ambient air and does not require outdoor air. The appliance extracts heat from the ambient air. This heat is utilized to heat the water in the DHW tank with added electric power. The amount of electric energy and time required to heat-up the DHW depends on the temperature and humidity of the ambient air.

This heat extraction results in a drop in the ambient temperature inside the installation room by between 2°F/1°C and 5.5°F/3°C. The appliance also extracts moisture from the air, which turns into condensate. The condensate is drained from the appliance via the condensate drain.

When a hot water draw-off point is opened, the hot DHW is pushed out of the appliance by the in-flow of cold DHW.

To protect against corrosion, the inside of the DHW tank is coated with special enamel and is additionally equipped with an impressed current anode.

The electronic control unit makes energy saving adjustments easier. Subject to the power supply and usage pattern, the water is heated up automatically to the set temperature.

Heat pump operating principle

A hermetic circuit within the appliance contains refrigerant (See 15.3, “Data table”, pg. 29). This refrigerant evaporates at low temperatures and collects heat from the ambient air.

In the evaporator, the refrigerant changes from its liquid into its gaseous state. A compressor draws in the gaseous refrigerant and compresses it. This increase in pressure raises the refrigerant temperature.

The compression process requires electrical energy. The energy (motor heat) is not lost, but is discharged to the downstream condenser. The cooled refrigerant passes a filter dryer. There, the refrigerant indirectly transfers heat to the DHW tank and the liquid refrigerant is routed to a two-flood evaporator. An expansion valve then reduces the still prevalent pressure and the cycle starts again.

Note

In the event of an interruption of the power supply, the compressor is blocked from operating for at least one minute. The electronic control board (ECB) delays electronic starting for one minute while the appliance goes through its initializing process.

If the compressor subsequently fails to start, it may be blocked by additional safety devices (Klixon and high pressure switch). If the compressor is switched off due to the Klixon, the pressure difference between the high and low pressure sides of the refrigerant circuit may be the cause. When the pressure difference is equalized (approximately 5 minutes), the compressor turns on. If a tripped high pressure switch caused the blocking of the compressor, this may be due to a failed thermostat or high ambient air temperature. After the power supply has been re-established, the appliance continues to operate with the parameters that were selected before the power supply was interrupted.

10 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

OPERATION

Settings

3.1Heating the DHW tank

The water is heated by the heat pump through the condenser wrapped around the tank. This is the appliance’s standard mode of operation.

An integral sensor in the tank is connected to an electronic device to measure the thermal energy content of the water in the DHW tank. The water in the DHW tank is heated if its temperature is lower than the set temperature.

For information on the heat-up time of the water in the DHW tank, See 15.3, “Data table”, pg. 29.

3.1.1 Electric booster element

The electric booster element is automatically activated in case of a damaged heat pump or to provide more hot water than the current tank supply.

In the event of an unexpectedly high hot water demand, the booster heater can be manually activated. See 4.4.1, “Comfort heating”, pg. 13.

In the event of an appliance fault, a backup mode can be set to activate the electric booster element. See 4.4.2, “Emergency back up mode”, pg. 13.

3.2Appliance operation outside the application limits

3.2.1 Ambient temperatures below the application limit

If hoar frost is growing on the evaporator fins, the hoar frost temperature monitor switches the heat pump compressor off. The compressor switches on automatically once the evaporator defrosts.

To guarantee fault-free operation of the appliance, make sure you operate the appliance within its application limits (See 15.3, “Data table”, pg. 29).

Note

Heat-up times are longer while the evaporator is defrosting.

3.2.2 Ambient temperatures above the application limit

The safety equipment switches the appliance off if the upper application limit is exceeded.

Following a cooling time of several minutes, the appliance is switched back on automatically. The appliance is switched off again if the ambient temperature rises above the permissible temperature value again.

To guarantee fault-free operation of the appliance, make sure you operate the appliance within its application limits (See 15.3, “Data table”, pg. 29).

3.3Frost protection

The appliance activates a frost protection function if the integral sensor in the DHW tank detects a temperature below 50°F/10°C. The appliance then heats the water in parallel mode by using both the heat pump and the electric booster element. The heat pump and electric booster element switch off once the temperature detected by the integral sensor is more than 65°F/18°C.

www.stiebel-eltron-usa.com

4.Settings

4.1 |

Display and controls |

ENGLISH |

|

||

|

|

|

|

Note |

|

|

|

|

|

The back-light of the display will illuminate for 15 seconds |

|

|

|

|

|

after pressing any button. |

|

|

|

|

12 |

1 |

|

|

|

e l c t r o n i c c |

2 |

11

3

10

9

9

8

4

7 |

|

|

0006_ |

|

|

|

|||

|

|

|||

5 |

03 13 |

|||

6 |

||||

|

|

26_ |

||

1 Set temperature symbol

2Amount of amount of mixed water display (l @ 40°C /gal @ 104°F)

Actual temperature display, upper tank section / Set temperature1display

Set temperature2display Fault code display

3 Plus key

4 Minus key

5 Service/error symbol

6 Electric booster element symbol

7 Heat pump symbol

8 Rapid heating key

9 Set temperature 2 symbol

10 Menu key

11 Amount of mixed water symbol

12 Actual temperature symbol

The "electric booster element" and "heat pump" symbols are displayed when these appliance components are active. The display of these symbols does not necessarily mean that the electric booster element and the heat pump are running.

Service/fault symbol

Note

Notify your contractor if the service/fault symbol appears on the display. Continuous illumination of the symbol indicates that the fault is not preventing appliance operation.

A flashing service/fault symbol indicates that the water is not being heated and that it is essential you notify your contractor.

4.2Settings

In standard display mode, the display shows the current amount of mixed water.

Accelera® 220-300 E | 11

OPERATION

Settings

Note

15 seconds after every adjustment, the appliance automatically switches back to the standard display and saves the set value.

With the menu key, all information and setting options are called up in sequence. The relevant symbol appears with each setting.

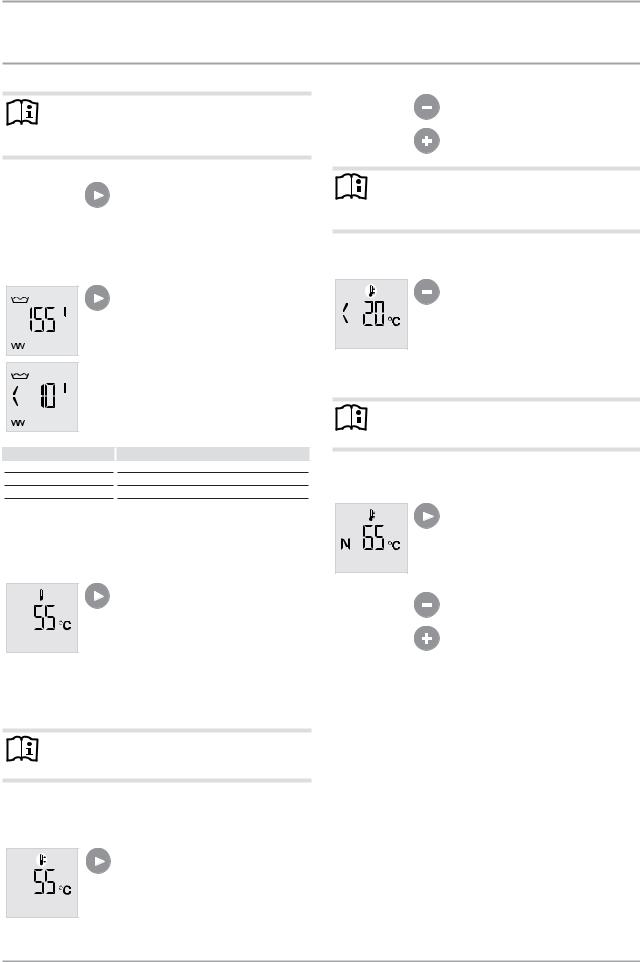

4.2.1 Amount of mixed water display (standard display)

DHW demand for

Bath

Shower

Hand washing

The currently available amount of mixed water at 104°F/40°C when mixed with 59°F/15°C cold water is shown.

If there is no usable hot water in the tank, the display shows < 10 l.

Amount of mixed water at 104°F/40°C)

32-40 gal (120-150 l)

9-13 gal (30-50 l)

½-1½ gal (2-5 l)

The amount of mixed water that can be achieved depends on the set point temperature.

4.2.2 Actual temperature display

In the mixed water menu, press the menu key once to get to the actual temperature menu.

The current actual temperature in the upper section of the DHW tank is

shown. This largely corresponds to the outlet temperature.

4.2.3 Set temperature 1

Note

For reasons of legionella prevention, never set the DHW temperature lower than 124°F/50°C).

The set temperature 1 is the DHW temperature to which the appliance regulates if no external signal transmitter is connected and active. Set temperature 1 is set to 131°F/55°C at the factory.

In the actual temperature menu, press the menu key once to get to the menu for set temperature 1.

The set temperature 1 symbol appears.

Adjust set temperature 1 from 69 to 149°F / 20.5 to 65°C using the plus and minus keys.

Note

Another way to adjust set temperature 1 is to press the plus or minus key when in standard display (amount of mixed water).

Frost protection

If the set temperature is set to less than 69°F/20.5°C, only frost protection remains active. The water heater will not run.

4.2.4 Set temperature 2

Note

For reasons of legionella prevention, never set the DHW temperature lower than 124°F/50°C).

Set temperature 2 is the DHW temperature to which the appliance regulates if an external signal transmitter is connected and active.

In the set temperature 1 menu, press the menu key once to get to the menu for set temperature 2.

The set temperature 2 symbol appears. The display of set temperature 2 is denoted with an "N".

Adjust set temperature 2 from 69 to 149°F / 20.5 to 65°C) using the plus and minus keys.

Operation with external signal transmitter (240 V input)

The connection of the heat pump to an external signal offers the possibility of heating water to a raised temperature set point during periods when electric rates are favorable, for example during times when PV power is available or low tariff utility rates are in effect.

The external signal may be offered by a PV system or low tariff transmission of a utility.

This set temperature 2 is activated when a phase (LF signal) is present at terminal X0/LF (See 10.3.1, “Connection with external signal transmitter”, pg. 20). While activated, set temperature 2 replaces the standard set DHW temperature ("set temperature 1").

If set temperature 2 has been activated by the external signal transmitter, this set temperature will then be active for at least 20 minutes. If the signal remains active after those 20 minutes passed, the compressor will run until the LF signal ends. If not, the selected set temperature 1 is activated again.

12 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

OPERATION

Settings

If the relevant set DHW temperature is accomplished, the compressor switches off and remains off for a minimum idle time of 20 minutes.

The following diagram illustrates the connections by means of a sample signal sequence of an external signal transmitter.

Example: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- DHW temperature = 131°F/55°C) |

|

|

|

|

|

|

|

|

|

|||||||||

- Set temperature 1 = 124°F/50°C) |

|

|

|

|

|

|

|

|

|

|||||||||

- Set temperature 2 = 149°F/65°C) |

|

|

|

|

|

|

|

|

|

|||||||||

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

t [min] |

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D0000034613 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

t [min] |

|

|

|

|

|||||||||||||||||

A LF signal

B Compressor

1 20 min. minimum runtime, set temperature 2

2 20 min. minimum compressor idle time

Note

An LF signal must be active for at least 60 seconds before the control unit responds to it. This prevents cycling of the compressor due to fast changing sun radiation condition.

4.3Calling up fault codes

Based on the set temperature 2 menu, press the menu key once to get to the fault code menu. A fault code will appear if a fault has occurred. If no error has occurred, this menu is not available.

See 6.1, “Fault codes”, pg. 15.

4.4Rapid heating key

Press the rapid heating key.

The heat pump and electric booster element symbols appear.

4.4.1 Comfort heating

Normally, the rapid heating key is used to activate the comfort heating function, which enables the water heater to satisfy an unexpectedly high DHW demand without changing any of the appliance's standard settings.

When comfort heating is activated by pressing the rapid heating key, the heat pump and the electric booster element will start in parallel, irrespective of the selected set temperature. To save energy, the electric booster element switches off as soon as a temperature of 149°F/65°C has been achieved in the upper tank section (rapid heating).

The heat pump remains on and the comfort heating function remains active until a temperature of 149°F/65°C) has been achieved in the entire DHW tank (comfort heating). The appliance then automatically switches back to the previously set parameters.

Note

The electric booster element and heat pump symbols are displayed until the comfort heating function has terminated.

During comfort heating, the electric booster element symbol is displayed until the heat pump has heated the entire tank to 149°F/65°C and the function is terminated, even though the electric booster element switches off when the 149°F/65°C) has been achieved in the upper tank section.

Note

If comfort heating has been activated, it can be canceled by reducing the set temperature.

Hold down the minus key, until you hear a clicking noise caused by the heat pump and booster heater switching off. The set temperature will jump back to the value that was selected before comfort heating was activated.

4.4.2 Emergency back up mode

If the heat pump is out of order, it is possible to use the electric booster element in back up mode to ensure hot water production. The electric supply to the compressor shuts down if the water temperature increase is less than 0.5°F/0.25°C) in a time frame of 13 hours. In this case the fault code is activated and will flash. The fault key flashes on the display and a fault code indicates that the appliance is not heating the water.

To activate the backup mode, press the rapid heating key. After the rapid heating key has been pressed, the indicated fault code increases by a value of 256, as the fault codes are summed together (See 6.1, “Fault codes”, pg. 15). The fault key continues to flash. The electric booster element is activated.

The current set temperature (set temperature 1 or set temperature 2) is ignored. In emergency mode, the appliance operates with a fixed set temperature of 104°F/40°C). After a one-off activation of the function via the rapid heating key, this function remains active for 7 days.

Following 7 days of backup operation, the electric booster element is deactivated. The fault code shown on the display decreases by 256.

If the rapid heating key is pressed again within the 7 days of backup operation, the 7-day run time for emergency mode will start afresh from that point.

Pressing the rapid heating key only activates backup mode if a fault with fault code 8 occurred previously. In standard mode pressing the rapid heating key only triggers a one-off heating of the DHW tank for a single instance.

An interruption of the power supply will disable the back up mode immediately. The heat pump will try to heat again for a duration of 13 hours after the power outage. After 13 hours without a water temperature increase, the flashing service key occurs again and the back up function may be activated.

ENGLISH

www.stiebel-eltron-usa.com |

Accelera® 220-300 E | 13 |

OPERATION Maintenance and care

4.5Emergency shutdown

In the event of an emergency, carry out the following steps:

Interrupt the power supply by unplugging the appliance or by shutting off the circuit breaker.

Shut off the cold water supply.

Immediately notify a qualified contractor, as the appliance is not protected against corrosion while the power supply is interrupted.

Drain the water out of the tank if there is a power outage longer than 2 days.

5.Maintenance and care

WARNING Electrocution

Do not insert objects through the grille into the interior of the appliance.

Never spray the appliance with water. Never spray water into the appliance.

WARNING Injury

! Maintenance work, such as checking the electrical safety, must only be carried out by a qualified contractor.

Appliance components

Casing

Air intake grille / air discharge grille

DHW tank

Electric booster element

Appliance

Condensate drain

Care and maintenance tips

Use a damp cloth to clean the casing sections. Never use abrasive or corrosive cleaning agents.

Clean the air intake grille and air discharge grille every six months. Cobwebs or other kinds of contamination can restrict the air supply to the appliance.

The DHW tank is equipped with a maintenance-free impressed current anode to safeguard against corrosion. The power supply must not be interrupted while the appliance is filled with water to enable the impressed current anode to provide protection. Otherwise there is a risk of corrosion.

Have the electric booster element descaled from time to time. This will extend the expected life of the electric booster element.

Have the safety assembly and the evaporator checked regularly by a qualified contractor.

Undo the condensate drain. Check that the condensate drain is clear and remove any dirt from the condensate drain connection of the appliance.

6.Troubleshooting

Problem |

Cause |

|

Remedy |

No hot water is |

No power to the appli- |

|

Check that the appliance |

available. |

ance. |

|

is connected to the power |

|

|

|

supply. |

|

The circuit breaker in the |

|

Check whether the circuit |

electric panel has tripped. breaker in the electrical panel has tripped. If required, disconnect the appliance from the power supply and replace the circuit breaker. Contact your contractor if the circuit breaker blows again after the appliance is connected to the power supply.

Problem |

Cause |

|

Remedy |

||

No hot water is |

The air intake or air dis- |

Check the air intake grille |

|||

available. |

charge of the appliance is |

and air discharge grille for |

|||

|

|

|

blocked. |

contamination. Remove any |

|

|

|

|

|

contamination (See 14, “Main- |

|

|

|

|

|

tenance and cleaning”, pg. |

|

|

|

|

|

23). |

|

|

|

|

|

|

|

|

|

|

The ambient temperature |

Wait for the appliance to cool |

|

|

|

|

exceeds the upper ap- |

down. Call a qualified con- |

|

|

|

|

plication limit (See 15.3, |

tractor if the appliance does |

|

|

|

|

“Data table”, pg. 29). |

not switch back on automat- |

|

|

|

|

The appliance safety |

ically. |

|

|

|

|

equipment has responded |

|

|

|

|

|

and the appliance has |

|

|

|

|

|

switched off automati- |

|

|

|

|

|

cally. |

|

|

|

|

|

The ambient temperature |

Wait until the appliance |

|

|

|

|

falls below the lower ap- |

switches back on automati- |

|

|

|

|

plication limit (See 15.3, |

cally. |

|

|

|

|

“Data table”, pg. 29). |

|

|

|

|

|

The evaporator is current- |

|

|

|

|

|

ly being defrosted. |

|

|

The appliance is |

The blocking time for |

|

|

||

not heating the |

compressor has not |

|

|

||

DHW tank although yet elapsed. Once the |

|

|

|||

the heat pump |

compressor has been |

|

|

||

symbol is illumi- |

switched off, it will only |

|

|

||

nated. |

be switched back on |

|

|

||

|

|

|

again after the 20 minute |

|

|

|

|

|

compressor blocking time |

|

|

|

|

|

has elapsed. |

|

|

The safety valve |

These units are under |

Notify a qualified contractor if |

|||

of the cold water |

water mains pressure. |

water continues to drip when |

|||

supply line is dripDuring the heat-up pro- |

heating is completed. Check |

||||

ping. |

cess, expansion water will the sealing of the P&T valve if |

||||

|

|

|

drip from the safety valve. a sand filter is used. |

||

|

|

|

|

|

|

The condensate |

|

The surface temperature |

The amount of condensate |

||

drain drips. |

of the evaporator is lower |

depends on the air humidity |

|||

|

|

|

than the dew point tem- |

level. |

|

|

|

|

perature of the ambient |

|

|

|

|

|

air. Condensate forms. |

|

|

The room tem- |

|

Due to the heat pump pro- |

|||

perature drops too |

|

cess the room temperature |

|||

low. |

|

drops. The temperature drop |

|||

|

|

|

|

depends on the hot water |

|

|

|

|

|

demand and the size of the |

|

|

|

|

|

installation room. If the |

|

|

|

|

|

temperature drop of the in- |

|

|

|

|

|

stallation room is more than |

|

|

|

|

|

7°F (4 °C) check the size of the |

|

|

|

|

|

installation room. |

|

|

|

|

|

|

|

Service symbol |

See 6.1, “Fault codes”, |

Notify a qualified contractor. |

|||

is continuously |

pg. 15 |

|

|

||

illuminated. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Service symbol |

|

See 6.1, “Fault codes”, |

It is imperative that you notify |

||

flashes and the |

|

pg. 15 |

a qualified contractor. |

||

water does not |

|

|

|

|

|

heat up. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

OPERATION

Troubleshooting

6.1Fault codes

If the service/fault symbol is flashing or continuously illuminated on the display, you can call up a fault code.

Repeatedly press the menu key until the fault code is shown following set temperature 2.

Fault code appears

Fault |

|

Service |

Fault description |

|

Remedy |

|

code |

|

symbol |

|

|

|

|

0 |

|

|

No fault |

|

|

|

|

|

|

|

|

|

|

2 |

|

continu- |

The dome sensor has failed. |

|

Call Stiebel Eltron for |

|

|

|

ously illu- |

The temperature displayed is |

|

more information if |

|

|

|

minated |

measured by the integral sen- |

|

this error occurs. |

|

|

|

|

sor. The appliance will continue |

|

|

|

|

|

|

to work properly. |

|

|

|

|

|

|

|

|

|

|

4continuThe integral sensor has failed. Call Stiebel Eltron for

|

|

ously illuThe mixed water display will |

|

more information if |

||

|

|

minated |

not show the correct amount |

|

this error occurs. |

|

|

|

|

but the appliance will continue |

|

|

|

|

|

|

to work properly. |

|

|

|

|

|

|

|

|

|

|

6 |

|

flashing |

Dome sensor and integral sen- |

|

Contact a qualified |

|

|

|

|

sor failed. The appliance stops |

|

contractor. |

|

|

|

|

heat delivery. |

|

|

|

|

|

|

|

|

|

|

8 |

|

flashing |

The appliance has recognized |

|

You can continue to use |

|

|

|

|

that the DHW tank is not heated |

|

the appliance by acti- |

|

|

|

|

for 13 hours, despite there |

|

vating backup mode. |

|

|

|

|

being a demand. |

|

See 4.4.2, “Emergency |

|

|

|

|

|

|

|

back up mode”, pg. |

|

|

|

|

|

|

13 |

16continuShort circuit impressed current Immediately inform a ously illuanode / protective anode failed qualified contractor,

|

|

minated |

|

as the appliance is not |

||

|

|

|

|

|

|

protected against cor- |

|

|

|

|

|

|

rosion if the impressed |

|

|

|

|

|

|

current anode is faulty. |

32 |

|

flashing The appliance is operating with |

|

Fill the appliance with |

||

|

|

|

an empty tank or the appliance |

|

water. The fault code |

|

|

|

|

is not delivering heat. |

|

disappears and the |

|

|

|

|

|

|

|

appliance starts. |

|

|

|

The anode current is inter- |

|

The contractor needs to |

|

|

|

|

rupted. The appliance does not |

|

check the connection of |

|

|

|

|

heat up. |

|

the impressed current |

|

|

|

|

|

|

|

anode and the internal |

|

|

|

|

|

|

wiring. |

128continuNo communication between ously illucontroller and display. The

|

|

minated |

most recently selected set val- |

|

|

|

|

|

|

ues are active. |

|

|

|

|

|

|

|

|

|

|

256 |

|

flashing |

Manually activated Emergency |

|

See 4.4.2, “Emergency |

|

|

|

|

backup mode (only electric |

|

back up mode”, pg. |

|

|

|

|

booster element active). |

13. |

||

|

|

|

|

|

|

|

If more than a single fault occurs, the fault code gets summed.

Example: If both the dome sensor and integral sensor failed, the display shows fault code 6 (=2+4).

Application scenarios for emergency mode |

ENGLISH |

|||||

If the appliance shows fault code 8, you can manually activate |

||||||

|

||||||

emergency mode. If a different fault occurred previously, but did |

|

|||||

not cause the appliance to switch off, the display may show a fault |

|

|||||

code that is the result of several faults added together. |

|

|||||

Listed below are the fault codes which will allow you to activate |

|

|||||

|

||||||

emergency mode. |

|

|

|

|

||

|

Fault code displayed |

Individual fault code(s) |

|

|||

|

8 |

8 |

|

|

||

|

|

|

|

|

|

|

|

10 |

Fault code 8 + fault code 2 |

|

|||

|

|

|

|

|

|

|

|

12 |

8+4 |

|

|

||

|

|

|

|

|

|

|

|

24 |

8+16 |

|

|

||

|

|

|

|

|

|

|

|

26 |

8+2+16 |

|

|

||

|

|

|

|

|

|

|

|

28 |

8+4+16 |

|

|

||

|

|

|

|

|

|

|

|

138 |

8+2+128 |

|

|

||

|

|

|

|

|

|

|

|

140 |

8+4+128 |

|

|

||

|

|

|

|

|

|

|

|

152 |

8+16+128 |

|

|

||

|

|

|

|

|

|

|

|

154 |

8+2+16+128 |

|

|

||

|

|

|

|

|

|

|

|

156 |

8+4+16+128 |

|

|

||

|

|

|

|

|

|

|

When the appliance is operating in emergency backup mode, the fault code shown is increased by 256.

Fault code displayed in |

|

Individual fault code(s) |

emergency backup mode |

|

|

264 |

8+256 |

|

|

|

|

266 |

8+2+256 |

|

|

|

|

268 |

8+4+256 |

|

|

|

|

280 |

8+16+256 |

|

|

|

|

282 |

8+2+16+256 |

|

|

|

|

284 |

8+4+16+256 |

|

|

|

|

394 |

8+2+128+256 |

|

|

|

|

396 |

8+4+128-256 |

|

|

|

|

408 |

8+16+128+256 |

|

|

|

|

410 |

8+2+16+128+256 |

|

|

|

|

412 |

8+4+16+128+256 |

|

|

|

|

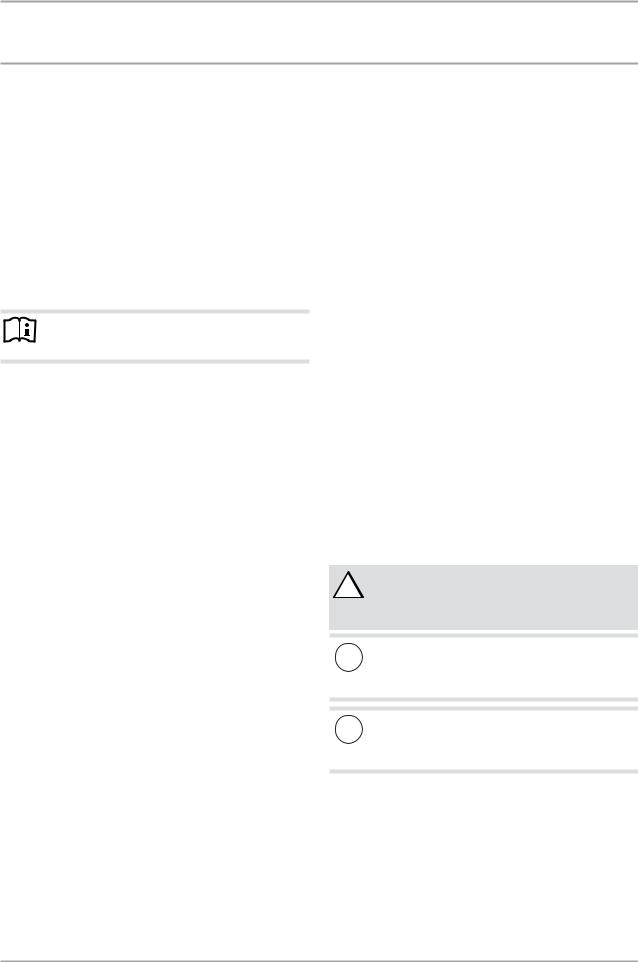

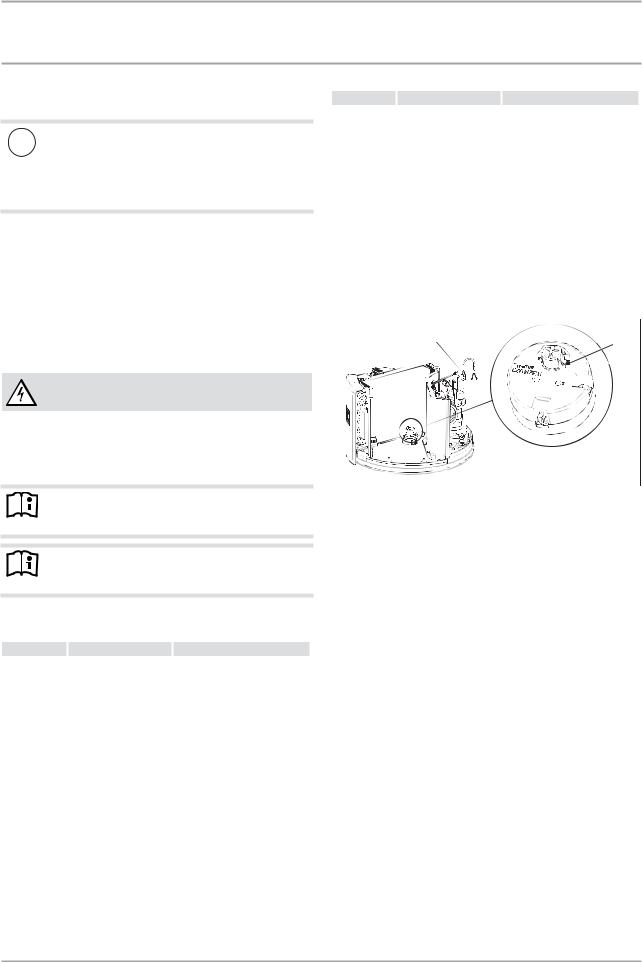

Notifying a qualified contractor

If you cannot remedy the fault, notify your qualified contractor. To facilitate and speed up your request, provide the serial number from the type plate (000000-0000-00000). The type plate can be found on the appliance above the "DHW outlet" connection.

Sample type plate

|

1 |

00000-0000-000000 |

D0000035352 |

1 Serial number on the type plate

www.stiebel-eltron-usa.com |

Accelera® 220-300 E | 15 |

INSTALLATION

Safety

INSTALLATION

7.Safety

Only a qualified contractor should carry out the installation, commissioning, maintenance and repair of the appliance.

7.4.4Customer service

For customer service inquiries, please contact Stiebel Eltron directly at 1-800-582-8423

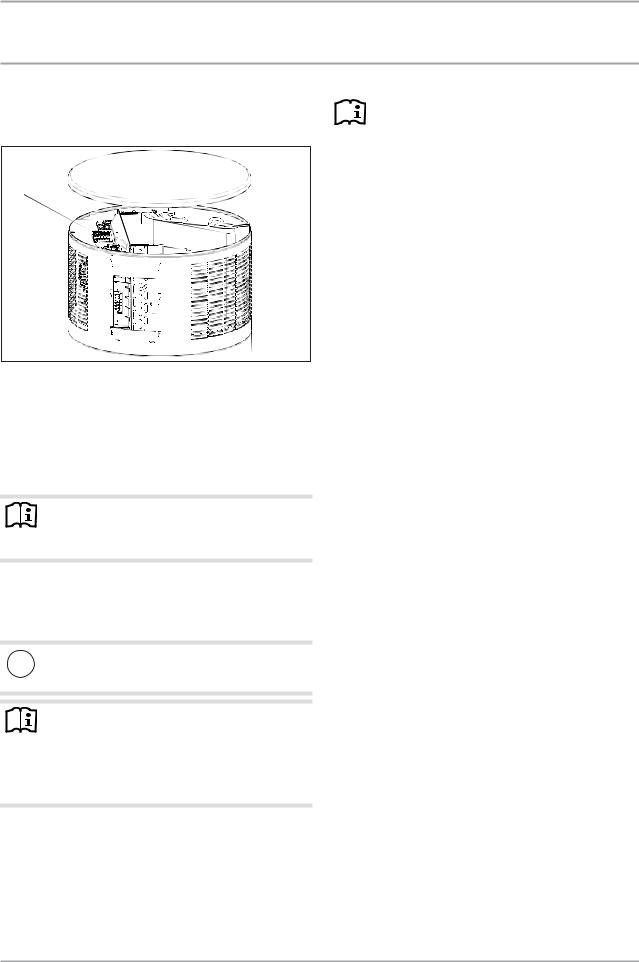

8.Appliance description

The heat pump unit is located in the upper section of the appliance. The DHW tank is located in the lower section of the appliance.

7.1General safety instructions

To prevent your warranty claim, use only original accessories and spare parts. If you need spare parts, call 800.582.8423.

7.2Instructions, standards and regulations

Note

Observe all applicable national and regional regulations and instructions.

Take note of the appliance type plate and chapter "Specification".

7.3Incorrect use

The following are not permitted:

-Do not install the water heater on non-load bearing floors

-Do not install the water heater where it is at risk from frost

-Do not install in rooms where the water heater is at risk from explosions as a result of dust, gases or vapors

-Do not ignore safety clearances and safety zones

-Do not incorrectly install the power connection

-Do not operate the water heater with an open casing

-Do not heat anything other than potable water

-Do not fill with any other Freon, use only R134a

7.4Qualification

In this manual, qualified individuals will be described as the “licensed installer”.

Licensed installers are responsible for adherence to all currently applicable regulations during installation and initial start-up.

7.4.1Licensed installer

Licensed installers are specially trained in their field. Licensed installers work on systems on the basis of their training, knowledge and experience, as well as their knowledge of applicable standards and regulations. They are able on their own to recognize and prevent possible problems.

7.4.2 Electrician (licensed)

An electrician is a licensed installer who meets the above requirements with regard to electrical-related installations.

7.4.3 Plumber (licensed)

A plumber is a licensed installer who meets the above requirements with regard to water-related installations.

8.1Standard delivery

The following are delivered with the appliance:

-Condensate drain

-T&P valve, 100 psi at 210°F/99°C

8.2Required accessories

Various safety assemblies are available that need to be selected subject to the respective static pressure. These type-tested safety assemblies protect the appliance against unacceptable excess pressure.

-Pressure reducing valve (70 psi) if the water mains pressure exceeds this

-Expansion tank

8.3Further accessories

– Condensate pump (if there is a minor base slope for draining the condensate, use a condensate pump)

9.Preparations

9.1Transport

CAUTION Injury

!Take note of the weight of the appliance.

Use suitable transport aids (e.g. a hand truck) and enough personnel for transportation.

Material losses

!The appliance is top heavy and can easily tip over. Make sure the unit is not tilted.

Only set the appliance down on an even base.

Material losses

!The appliance casing is not designed to withstand strong forces. Incorrect handling can lead to considerable loss. Observe the information on the packaging.

Leave the appliance in its packaging and on the pallet while transporting. This enables horizontal transport and protects the appliance during transport.

Remove the packaging shortly before the installation and do not unpack the appliance until it has arrived in the final installation room.

16 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

INSTALLATION

Preparations

Vehicular transport

Material losses

!Storing and transporting the appliance vertically is recommended.

The appliance may be transported horizontally on good roads. Strong shocks to the appliance are not permissible.

Material losses

!The duration in a horizontal position may not exceed more than 24 hours.

If the appliance was transported horizontally, leave it to rest in a vertical position for at least one hour before commissioning.

Observe the information on the packaging.

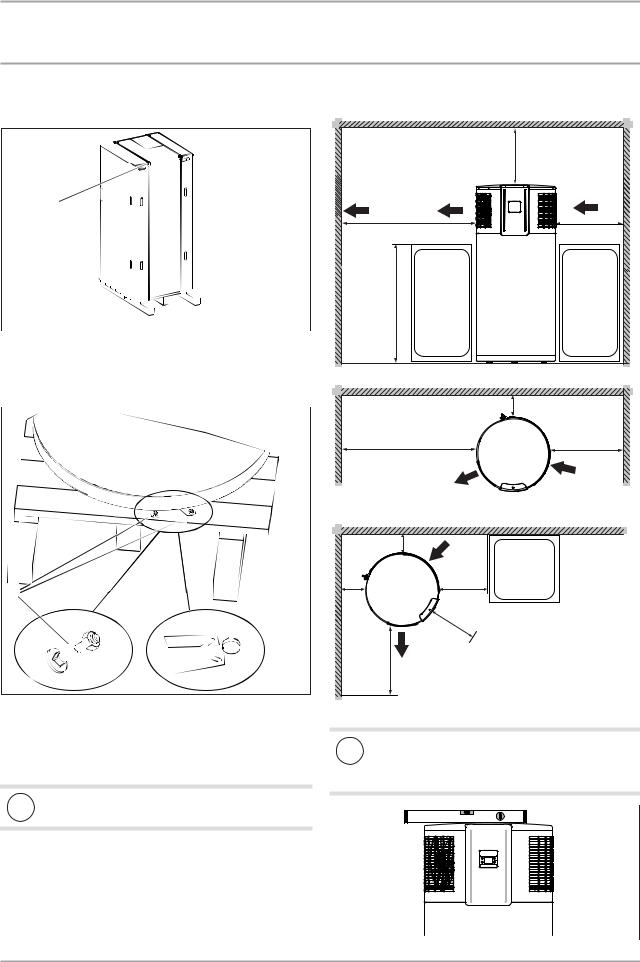

1

1

D0000034797

1 Recessed grips

Transport from vehicle to installation room

The cardboard box has reinforced recessed grips along the top of the appliance. You can use these recessed grips, as well as the pallet at the lower end, to carry the appliance into the installation room. Take note of the weight of the appliance and ensure a sufficient number of personnel is available for handling the appliance.

9.2Storage

If it is necessary to store the appliance for a prolonged period before installation, observe the following information:

-Only store the appliance in a vertical position. Never store the appliance horizontally.

-Store the appliance in a location that is dry and largely dust-free.

-Protect the appliance from coming into contact with corrosive substances.

9.3Installation site

The appliance is not approved for outdoor installation except for garages.

To prevent appliance damage:

-The installation location must be free from flammable, highly combustible gases and substances, as well as high levels of dust.

- The installation room must be free from the risk of frost. |

|

|

- The intake temperature of the appliance must be within the |

ENGLISH |

|

permissible application limits (See 15.3, “Data table”, pg. |

||

|

||

29). |

|

|

- The floor of the installation room must be level and have suf- |

|

|

ficient load bearing capacity. Take note of the weight of the |

|

|

|

||

appliance with a full DHW tank (See 15.3, “Data table”, pg. |

|

|

29). A floor with insufficient foundation pressure capacity |

|

|

is in danger of collapse. If the appliance is not evenly bal- |

|

|

anced, there may be a risk of appliance damage. |

|

|

- The size of the installation room must correspond to the |

|

|

application limits of the appliance (See 9.5, “Minimum clear- |

|

|

ances”, pg. 18 and See 15.3, “Data table”, pg. 29). |

|

|

- Observe the safety clearances and protection zones. |

|

|

- Always leave sufficient distance to provide access for instal- |

|

|

lation, maintenance and cleaning. Observe the required min- |

|

|

imum clearances (See 9.4, “Siting the appliance”, pg. 18). |

|

|

- Ensure that the operation of other equipment in the installa- |

|

|

tion room is not impaired. |

|

|

- To reduce the pipe runs, install the unit close to the kitchen |

|

|

or bathroom. |

|

|

- To prevent disturbance from operating noise, never install |

|

|

the appliance close to bedrooms. |

|

The following installation locations are not permissible, due to risk of appliance damage:

-Locations where the air is contaminated with oil or salt

-Saline environments

-Areas in proximity to high frequency machines

-Places where the air contains ammonia (e.g. sewage works)

-Places where the air contains chlorine (e.g. swimming pools)

-Generally places where the air is strongly contaminated, e.g. due to dust, or contains aggressive substances

Note

The performance data indicated for this appliance has been determined in line with the relevant standard at an air temperature of 59°F/15°C). Below this temperature, the efficiency of the appliance decreases.

Note

It is possible to improve the efficiency of the appliance by utilizing the waste heat and humidity from other appliances to heat the DHW tank, e.g. boilers, tumble dryers or freezers.

Sound emissions

The air intake and air discharge sides of the appliance emit more noise than other sides of the housing.

Never direct the air intake or air discharge towards noise-sensitive rooms of the house, e.g. bedrooms.

Note

For details on noise emission, see chapter "See 15.3, “Data table”, pg. 29".

www.stiebel-eltron-usa.com |

Accelera® 220-300 E | 17 |

INSTALLATION

Preparations

9.4Siting the appliance

Carefully undo the cardboard packaging at the clips.

1

D0000034797

1 Cardboard packaging clips

The appliance is secured to the pallet with metal brackets and screws. The metal brackets are hooked on to the feet underneath the floor plate of the appliance.

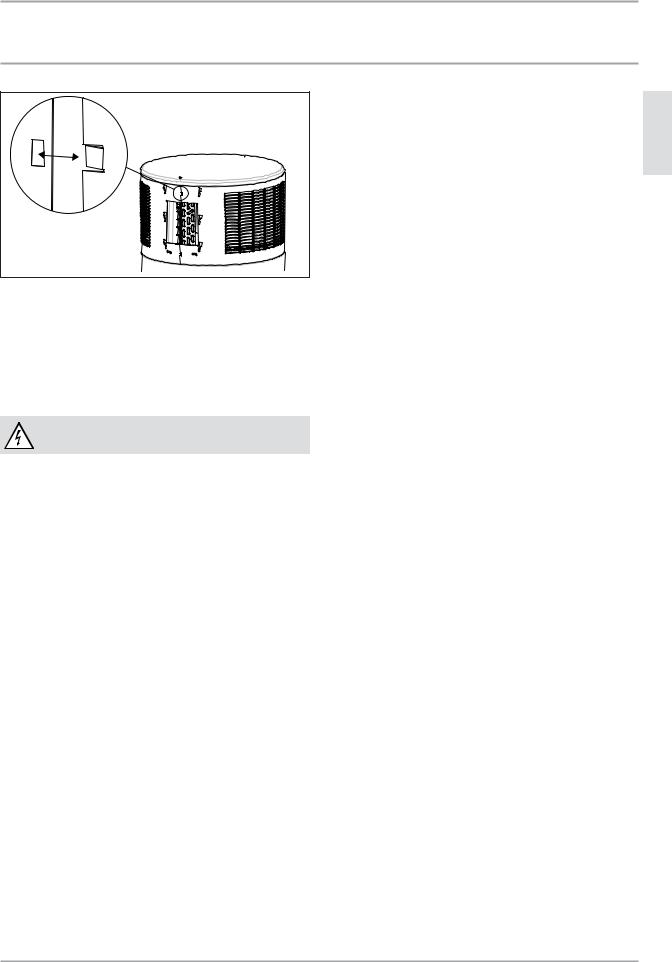

1

1. |

2. |

D0000034798

1 Metal bracket fixing bolt

Remove the fixing bolts of the metal brackets from the pallet.

Push the metal brackets a little towards the tank center, to unhook them from the appliance feet.

Pull the metal brackets out from underneath the appliance.

Material losses

!Take note of the appliance's weight and top-heaviness.

Slightly tip the appliance and carefully roll the appliance off the pallet.

Bring the appliance in its final location.

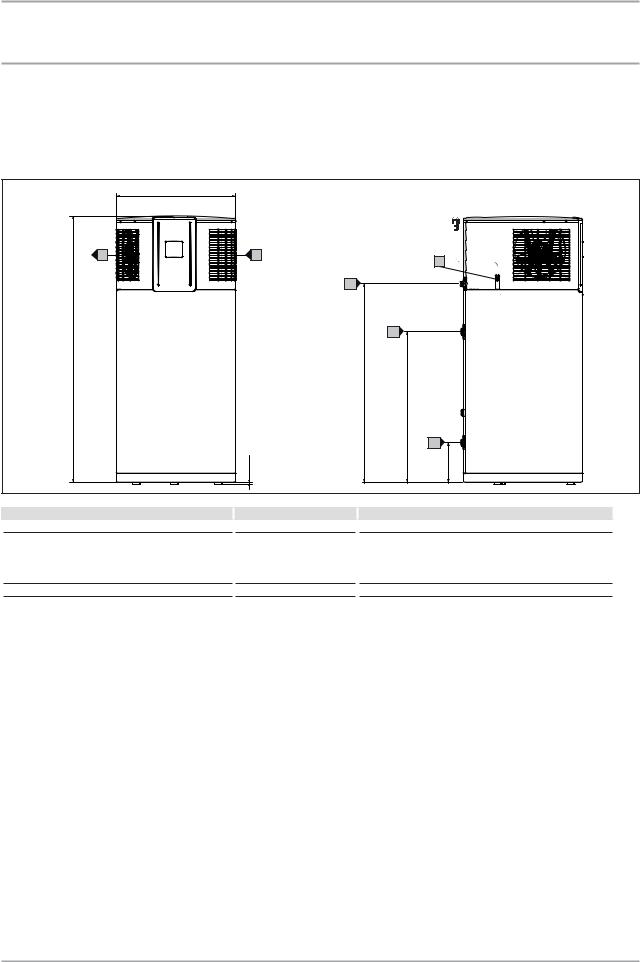

9.5Minimum clearances

Minimum room volume: |

14˝ |

|

800 ft2, 10´ x 10´ x 8´ |

||

(22.7 m2, 3 m x 3 m x 2.4 m) |

(0.4 m) |

|

|

|

Air flow |

Air flow |

intake |

|

|

||

exhaust |

|

|

6´ (1.8 m) |

2´ (0.6 m) |

|

|

An object |

|

|

next to the |

|

|

unit must |

|

≤42˝ |

be less than |

|

(1.1 m) |

42˝ high |

|

Acceptable positioning, vent parallel to a wall:

|

8˝ (0.2 m) |

|

6´ (1.8 m) |

2´ (0.6 m) |

|

Air flow |

Air flow |

|

exhaust |

||

intake |

||

|

Acceptable positioning, vent parallel to a wall in a corner:

8˝ (0.2 m) |

|

|

Air flow |

|

intake |

8˝ |

2´ |

(0.2 m) |

(0.6 m) |

|

|

|

2´ |

|

(0.6 m) |

6´ |

Air flow |

(1.8 m) |

exhaust |

Maintain the minimum clearances.

Material losses

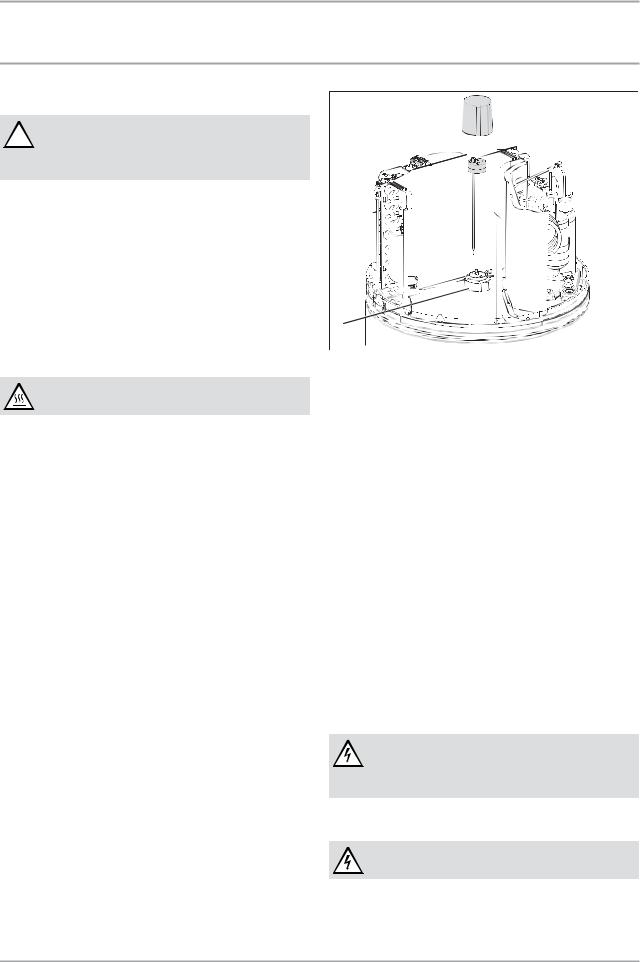

!The top of the appliance should be made horizontal. Level the appliance horizontally using the height-ad-

justable feet.

D0000034806

18 | Accelera® 220-300 E |

www.stiebel-eltron-usa.com |

INSTALLATION

Installation

10. Installation

WARNING Injury

! Incorrect installation can lead to serious personal injury or material losses.

Before any work, ensure sufficient clearances for the installation.

Handle sharp-edged components carefully.

10.1 Water connection

Material losses

!Carry out all water connection and installation work in accordance with local plumbing regulations.

The following material combinations are approved for pipework installations:

Cold water inlet |

|

DHW outlet |

Copper pipe |

|

Copper pipe |

maximum pressure in the cold water supply line is higher, install a pressure reducing valve.

Check valve

Install a check valve in the cold water line (after the pressure reducing valve if installed). This check valve is necessary to prevent water from flowing backwards into the cold water piping.

Drain valve

Install a suitable drain valve at the lowest point in the cold water inlet line.

DHW circulation

The heat losses incurred in a DHW circulation line and the electrical power consumption of the circulation pump reduce the efficiency of the system. The cooled water in a circulation line mixes with the tank content. Where possible, avoid installing a DHW circulation line. Where that is not possible, the DHW circulation pump must be controlled thermally or by time switch.

Steel pipe |

|

Steel pipe or copper pipe |

PEX tubing |

|

PEX tubing |

Thoroughly flush the pipework before connecting the appliance. Foreign bodies, such as welding pearls, rust, sand or sealant can impair the operational reliability of the appliance.

Material losses

!To protect the connection nipples against corrosion the water tube connection must be made with plumber’s thread seal tape (PTFE). The use of hemp on nipple threads is not permissible.

Safety valve

The appliance is a sealed unvented DHW tank. The appliance is supplied with a temperature and pressure relief valve that has been factory installed and leak-tested.

Install a type-tested safety valve in the cold water supply line. The response pressure of the safety valve must be below or equal to the permissible operating pressure of the DHW tank.

The safety valve protects the appliance against unacceptable excess pressure.

Ensure that the expansion water escaping from the safety valve can drip into a drain, e.g. a tank or sink.

Ensure the drain cannot be shut off.

Size the drain in a way that water can drain off unimpeded when the safety valve is fully opened.