Sony hcd-sd1 User Manual

HCD-SD1

SERVICE MANUAL

AEP Model

UK Model

E Model

HCD-SD1 is the amplifier, CD and tuner section in CMT-SD1.

|

Model Name Using Similar Mechanism |

HCD-MD313 |

CD |

|

|

Mechanism Type |

CDM13B-5BD19 |

|

SECTION |

|

|

Base Unit Type |

BU-5BD19 |

|

|

|

|

|

Optical Pick-up Type |

KSS-213B/K-N |

|

|

|

SPECIFICATIONS

— Continued on next page —

COMPACT DISC RECEIVER

MICROFILM

– 1 –

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK !OR DOTTED LINE WITH MARK !ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Laser component in this product is capable of emitting radiation exceeding the limit for Class 1.

This appliance is classified as a CLASS 1 LASER product. The CLASS 1 LASER PRODUCT MARKING is located on the rear exterior.

This caution label is located inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

•Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C during repairing.

•Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

•Be careful not to apply force on the conductor when soldering or unsoldering.

MODEL IDENTIFICATION

– Specification Label –

MODEL NO. HCD-SD1

Parts No.

|

MODEL |

PARTS No. |

AEP, UK model |

4-212-711-0¹ |

|

SP, HK model |

4-212-712-0¹ |

|

• Abbreviation |

|

|

HK |

: Hong Kong model |

|

SP |

: Singapore model |

|

– 2 –

TABLE OF CONTENTS |

|

1. SERVICING NOTE .......................................................... |

4 |

2. GENERAL .......................................................................... |

7 |

3. DISASSEMBLY |

|

3-1. Loading Panel ....................................................................... |

8 |

3-2. Glass ASSY ........................................................................... |

8 |

3-3. Front Panel ........................................................................... |

9 |

3-4. Main Board and Tuner Unit .................................................. |

9 |

3-5. CD Mechanism Deck .......................................................... |

10 |

3-6. Back Panel ......................................................................... |

10 |

3-7. Disc Table .......................................................................... |

11 |

3-8. Optical Pick-up ................................................................... |

11 |

4. SERVICE MODE ............................................................. |

12 |

5. TEST MODE ..................................................................... |

13 |

6. ELECTRICAL ADJUSTMENTS ............................... |

14 |

7. DIAGRAMS |

|

7-1. Circuit Boards Location ...................................................... |

16 |

7-2. Block Diagrams |

|

• BD Section ....................................................................... |

17 |

• Main Section .................................................................... |

19 |

7-3. Schematic Diagram – BD Section – ................................... |

23 |

7-4. Printed Wiring Board – BD Section – ................................. |

25 |

7-5. Schematic Diagram – Main (1/2) Section – ........................ |

27 |

7-6. Schematic Diagram – Main (2/2) Section – ........................ |

29 |

7-7. Printed Wiring Board – Main Section – .............................. |

31 |

7-8. Schematic Diagram – Sub Trans Section – ......................... |

33 |

7-9. Printed Wiring Board – Sub Trans Section – ...................... |

34 |

7-10. Schematic Diagram – Panel Section – ............................. |

35 |

7-11. Printed Wiring Board – Panel Section – ........................... |

37 |

7-12. Schematic Diagram – AMP Section – .............................. |

39 |

7-13. Printed Wiring Board – AMP Section – ........................... |

41 |

7-14. Schematic Diagram – Connector Section – ...................... |

43 |

7-15. Printed Wiring Board – Connector Section – ................... |

45 |

7-16. Schematic Diagram – REG Section – .............................. |

47 |

7-17. Printed Wiring Board – REG Section – ............................ |

49 |

7-18. IC Block Diagrams ........................................................... |

51 |

7-19. IC Pin Functions ............................................................... |

54 |

8. EXPLODED VIEWS |

|

8-1. Front Panel Section ............................................................. |

56 |

8-2. Chassis Section ................................................................... |

57 |

8-3. Mechanism Deck Section (CDM13B-5BD19) ................... |

58 |

8-4. Base Unit Section (BU-5BD19) .......................................... |

59 |

9. ELECTRICAL PARTS LIST ........................................ |

60 |

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also use the procedure in the printed matter which is included in the repair parts.

The flexible board is easily damaged and should be handled with care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION CHECK

Carry out the “S curve check” in “CD section adjustment” and check that the S curve waveform is output two times.

– 3 –

SECTION 1

SERVICING NOTE

OPENING THE DISC TRAY WHEN POWER IS OFF

1Using a thin screwdriver, rotate the internal cam in the arrow direction completely.

2 Open the glass door, and pull out the loading panel.

ATTACHING THE GLASS ASSEMBLY

• Attach according to steps1 to 4.

2Pull up the glass door, in the arrow direction.

1

1

1

4 Screw (PTP 2.6x6)

3 Bracket (shaft)

(Bottom side)

When securing this part, position at the center to allow some play. Open and close the glass window several times, and check that the parts do not touch each other.

– 4 –

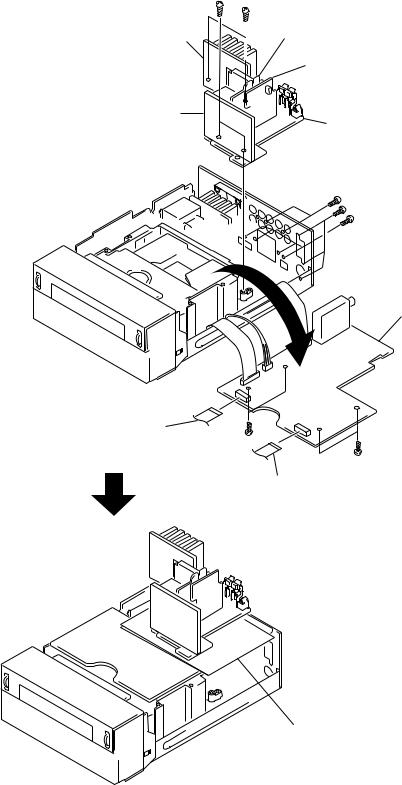

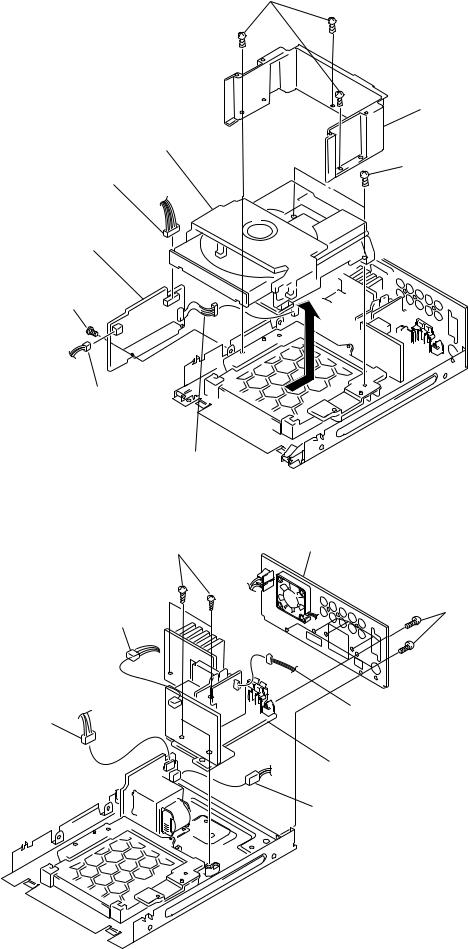

POSITIONS FOR SERVICING THE CONNECTOR BOARD, SUB-TRANS BOARD, CHEMI-CON BOARD, AND AMP BOARD

1Remove the four screws securing the upper cover, and remove the upper cover.

2Remove the loading panel. (Refer to SECTION 3 DISASSEMBLY.)

3 Remove the four screws Asecuring the MAIN board, five screws |

|

|

|

|

B securing the rear panel, two flat cables (CN701, CN702), |

|

|

|

|

and open the MAIN board as shown in the figure. |

|

|

|

|

4 Remove the two screws C securing the heat sink, and remove |

|

D C |

||

the AMP board and CHEMI-CON board. |

|

|||

5 Remove the two screws D securing the SUB-TRANS board |

|

|

|

|

and four screws E securing the CONNECTOR board, and re- |

Heat sink |

|

|

|

move the SUB-TRANS board and CONNECTOR board. |

|

|

|

|

|

|

|

|

|

6 Return the MAIN board to its original position. |

|

|

|

|

|

|

|

|

|

7 Insulate these boards and the MAIN board with paper, etc., and |

|

|

|

|

assemble the CONNECTOR board, SUB-TRANS board, |

|

|

|

|

CHEMI-CON board, and AMP board on these boards. |

|

|

|

|

SUB-TRANS board |

|

|

|

|

AMP board

CHEMI-CON board

CONNECTOR board

B

B

E

MAIN board

Flat type wire (CN701)

A

A

Flat type wire (CN702)

Should be insulatable with paper, etc.

– 5 –

POSITION FOR SERVICING THE CD MECHANISM

DECK

1 Remove the four screws securing the upper cover, and remove |

|

the upper cover. |

|

2 Remove the loading panel. (Refer to SECTION 3 DISASSEM- |

|

BLY.) |

|

3 Remove the four screws Asecuring the MAIN board, five screws |

|

B of the rear panel, and flat cables (CN701, CN702), and re- |

|

move the MAIN board. |

|

4 Remove the two screws D securing the SUB-TRANS board, |

D |

and remove the SUB-TRANS board. |

SUB-TRANS board |

5 Remove the two screws F securing the REG board. |

|

6 Remove the three screws G securing the CDM cover, and re- |

|

move the CDM cover. |

|

7 Remove the two screws H securing the CDM, move the CDM |

|

backwards by about 5 mm horizontally, and then lift upwards. |

|

8 Rotate the CDM in the counterclockwise direction by about 30˚ |

|

to remove. |

B |

9 Return the MAIN and SUB-TRANS boards to their original |

B |

positions. |

|

F |

|

MAIN board

G

CDM cover |

Flat type wire (CN701) A |

A

Flat type wire (CN702)

H

– 6 –

SECTION 2

GENERAL

Front Panel

1 |

2 |

3 |

15

14

4

13

|

12 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

|

|

Location of Parts and Controls |

|

|

|

|

|

|

|

|

|

|

1 |

1/u(Power) button |

|

6 |

/0/TUNING – button |

|

11 |

DISPLAY button |

|||

2 |

CD disc tray |

|

7 |

¹button |

|

|

|

12 |

PHONES jack |

|

3 |

§button |

|

8 |

flbutton |

|

|

|

13 |

tindicator |

|

4 |

VOLUME dial |

|

9 |

TUNER/BAND button |

|

|

14 |

uindicator |

||

5 |

±/)/TUNING + button |

|

10 |

FUNCTION button |

|

|

15 |

Display window |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This section is extracted from |

|

|

|

|

|

|

|

|

|

|

instruction manual. |

|

|

|

|

|

|

|

|

|

|

|

– 7 –

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

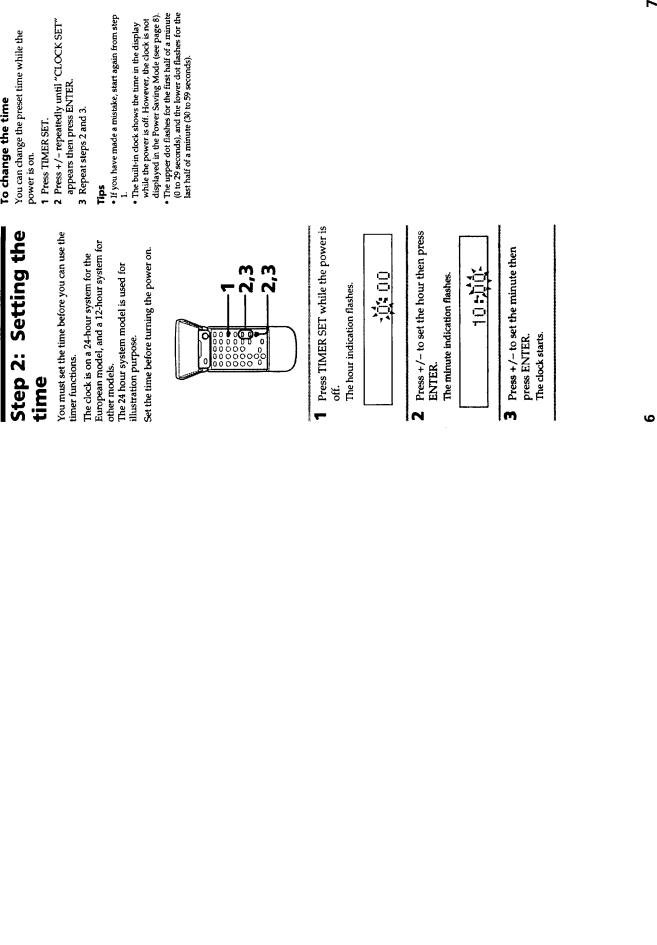

3-1. LOADING PANEL

1Turn ON the power, and press the EJECT button to open the tray.

2 Remove the loading panel in the arrow direction.

3 Press the EJECT button to close the tray.

• If the power cannot be turned ON, refer to “Opening the Disc Tray When the Power is OFF” of “Service Note”, and open the tray.

Loading panel

Power button

Eject button

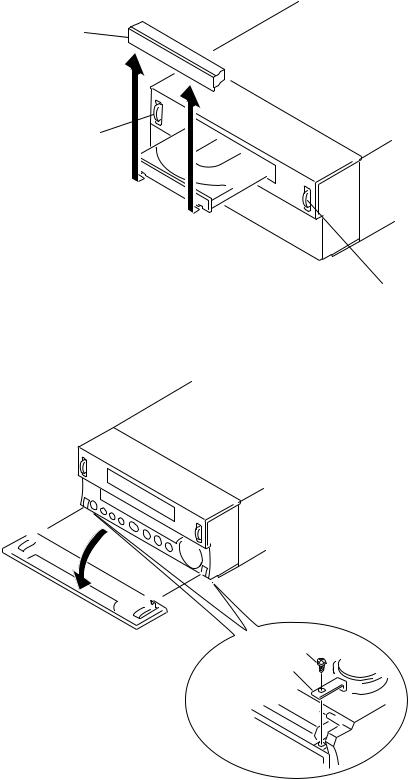

3-2. GLASS ASSY

4 3

4 3

4

4

1 Screw (PTP2.6x6)

2 Bracket (shaft)

(Bottom side)

– 8 –

3-3. FRONT PANEL

4 Flat type wire (11core) (CN702)

6 Front panel

3

2 Three claws

5 Flat type wire (13core) (CN701)

1 Three screws (BVTP3x8)

3-4. MAIN BOARD AND TUNER UNIT

1 Four screws (BVTP3x8)

4 Flat type wire (19core) (CN301)

7 MAIN board and Tuner unit

6 Flat type wire (19core) (CN705)

8 Connector (CN706)

5 Connector (CN351)

2 Six screws (BVTP3x8)

3

– 9 –

3-5. CD MECHANISM DECK |

6 Three screws |

|

(BVTP3x8) |

|

7 Dust cover |

9 CD mechanism deck |

|

3 Connector |

8 Two screws |

(CN942) |

(BVTP3x8) |

5 REG board

1 Two screws (BVTP3x8)

2 Connector

(CN945)

4 Connector

(CN994)

3-6. BACK PANEL

2 Four screws |

7 Back panel |

(BVTT3X8) |

5 Connector |

1 Six screws |

(CN901) |

(BVTP3X8) |

3 Connector

(CN992) 6 Connector

(CN551)

8 PC board block

4 Connector

(CN991)

– 10 –

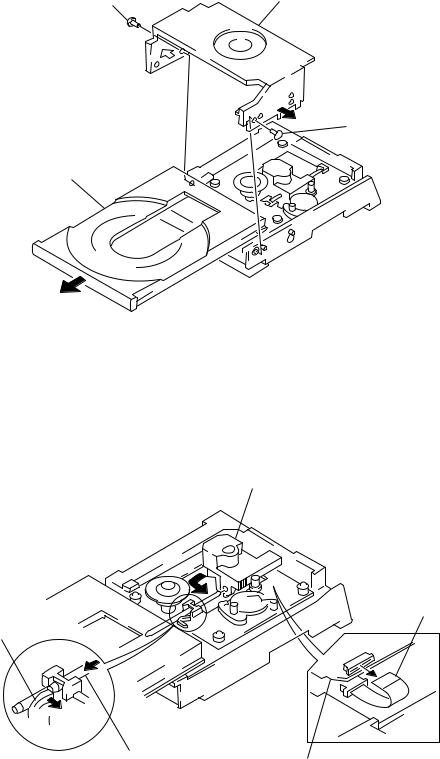

3-7. DISC TABLE

1 Screw (BV3x8) |

3 Holder (MG) assembly |

|

2 Screw (BV3x8)

4 Pull out the disc table.

3-8. OPTICAL PICK-UP

4 Remove the optical pickup in the arrow direction C.

C

3 Flat type wire (16 core)

(CNU101)

1 Move the claw

in the arrow A direction.

B

A

A

2 Remove the sled shaft in the

BD board

arrow direction B.

– 11 –

SECTION 4

SERVICE MODE

Key Check Mode for Complete Lighting of LED/Fluorescent Display Tube

• Perform this mode to analyze and check malfunctions such as display defects and when buttons do not work.

Procedure:

1.Press the 1/u button to turn on the power.

2.Press the DISPLAY button and ^ button together.

3.All LEDs and the fluorescent display tube will light up completely.

4.Pressing the FUNCTION button here will light the fluorescent display tube in the following order; Partial lighting 1 nPartial lighting 2 nComplete lighting nPartial lighting 1······

Turning the VOLUME dial will switch the lighting order of the LED.

To end without shifting to the key check mode, press the 1/u button to end.

5.Pressing the p button sets the key check mode.

6.During the key check mode, “KEY=0 JOG=0” will be displayed on the fluorescent display tube.

Pressing a button will increase the value of “KEY=”. However the value will not increase for buttons which have already been pr essed once.

Rotating the VOLUME knob in the clockwise direction increases the value of “JOG=” in the order of 1, 2, 3.... and rotating in the counterclockwise direction decreases in order of 10, 9, and 8.

7.To end the check mode, press all buttons (8 buttons). “KEY-OK” will be displayed. Then press any button, and disconnect the power cord from the outlet.

Checking the Sub-Clock

• Perform this mode to check clock operations.

Procedure:

1.Connect an oscilloscope and frequency counter between the pin (TP791) and ground of IC701 of the MAIN board.

2.Press the § and 1/u buttons together to display “91P = 32.768k” on the fluorescent display tube.

3.Check that the signal on the oscilloscope becomes a 32 kHz rectangular waveform and the reading of the frequency counter becomes 32.768 kHz.

4.Press the 1/u button to end.

Sled Servo Mode

• In this mode, the CD sled motor can be operated freely. Execute it when cleaning the pick-up.

Round holes can be seen on the topmost board when the case is opened. Move the pick-up and clean off the dirt in these round holes using a cotton swab.

Procedure:

1. |

Press the |

DISPLAY |

and § buttons with the power of the unit OFF. |

|

|||||

2. |

When the sled servo is set, “MANUAL” is displayed on the fluorescent display tube. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

3. |

Pressing the |

+/TUNING/) |

button when the CD is in the stop state moves the pick-up to the outer track. Pressing the |

=/ |

|

||||

|

|

TUNING/0 |

button moves it to the inner track. |

|

|||||

4.To end this mode, perform the following steps.

1)Move the If not, the disc cannot be removed.

2)Press the DISPLAY and § buttons together.

Note:

• When ending this mode, be sure to move the pick-up to the innermost circumference. If not, the disc cannot be removed.

• Do not move the sled motor more than required as this will damage the gears.

Round holes for cleaning

Initializing (Forced Reset)

•Perform this mode when resetting the unit or when returning the unit to the customer.

•The preset frequency of the tuner, etc. will be the settings at shipment.

Procedure:

While pressing the 1/u button, insert the power cord into the outlet.

– 12 –

SECTION 5

TEST MODE

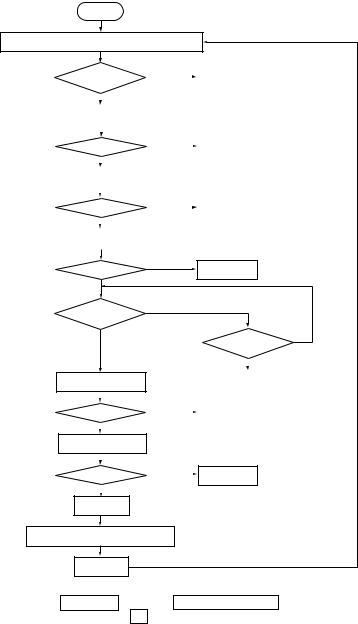

AGING MODE

This unit is equipped with an aging mode.

Use this mode for analyzing defects and for checks after completing repairs. After repairs, perform aging 100 times and check that the unit is normal. The aging mode is executed in the following sequence.

The aging mode will continue as long as the unit is normal.

If the unit becomes abnormal, it will display the state and number of cycles, and operations will stop. (Refer to Table 1.)

Sequence of Aging Mode:

Start

Sets the CD function and reads the CD TOC.

|

|

CD TOC OK? |

|

|

NO |

|

|

Message 1 |

||||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|||||||||||

|

|

Pauses first song. |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

OK? |

|

|

|

|||||||||||

|

|

|

|

Message 2 |

||||||||||||

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

||||||||||||

Last song search paused state |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

||

|

|

OK? |

|

|

|

|

||||||||||

|

|

|

|

Message 3 |

||||||||||||

|

|

|

|

|

||||||||||||

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|||||||||||||

|

Starts last song playback |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OK? |

NO |

Message 4 |

|

YES |

|

End playback? |

NO |

|

|

YES |

OK |

|

Is CD playing? |

|

|

|

|

|

|

|

|

|

NG |

||

|

|

|

|

|

|

|

|

|

|||

Opens the CD tray |

|

|

|

Message 4 |

|||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

NO |

|

|

|

|

||

OK? |

|

|

|||||||||

Message 5 |

|||||||||||

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Closes the CD tray |

|

|

|

|

|

|

|||||

|

|

|

|

|

NO |

||||||

|

|

|

|

|

|||||||

OK? |

|||||||||||

|

|

Message 6 |

|||||||||

|

|

||||||||||

YES |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||||

Power OFF |

|

|

|

|

|

|

|||||

Display of number of aging cycles

Power ON

Procedure:

1.Press the DISPLAY button and =/TUNING/0 button together.

2.To end aging, press the u button and end.

Table-1 Messages and Main Reasons for Stop of Aging

No |

Error Messages |

Details of Error |

Main Causes |

1 |

CD No Disc NG |

Cannot read CD TOC. |

Optical defect, spindle defect (including motor), cannot read |

|

|

|

Q data, disc defect (scratches, etc.), bad focus, bad GFS, etc. |

2 |

CD Pause NG |

Cannot set CD pause in |

Disc defect (scratches, etc.), cannot read Q data, etc. |

|

|

CD synchro mode. |

|

3 |

CD Search NG |

Cannot search last track on CD. |

Optical defect, sled, tracking defect (including motor), cannot |

|

|

|

read Q data, disc defect (scratches, etc.). |

4 |

CD Play NG |

Cannot play last track on CD. |

Optical defect, cannot read Q data, disc defect (scratches, etc.), |

|

|

|

etc. |

5 |

CD Open NG |

Cannot open CD tray. |

LOAD OUT SW defect |

6 |

CD Close NG |

Cannot close CD tray. |

LOAD IN SW defect |

|

|

|

|

– 13 –

SECTION 6

ELECTRICAL ADJUSTMENTS

CD SECTION

Note:

1.CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2.Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3.Use an oscilloscope with more than 10MΩ impedance.

4.Clean the object lens by an applicator with lens cleaning liquid when the signal level is low than specified value with the following checks.

5.Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

Perform this adjustment when the optical pick-up has been replaced or repaired.

|

oscilloscope |

BD (CD) board |

|

TP (RF) |

+ |

TP (VC) |

– |

Procedure:

1.Connect oscilloscope to test point TP (RF).

2.Turned Power switch on.

3.Put disc (YEDS-18) in and playback.

4.Adjust RV101 so that the waveform is clear.

(Clear RF signal waveform means that the shape “ ◊” can be clearly distinguished at the center of the waveform.)

5.After adjustment, check the RF signal level.

•RF signal VOLT/DIV: 200 mV TIME/DIV: 500 nS

level : 1.3 ± 0.3 Vp-p

S Curve Check

|

oscilloscope |

BD (CD) board |

|

TP (FEO) |

+ |

TP (VC) |

– |

Procedure :

1.Connect oscilloscope to test point TP (FEO).

2.Connect between test point TP (FOK) and Ground by lead wire.

3.Turn Power switch on.

4.Put disc (YEDS-18) in and turned Power switch on again and actuate the focus search. (actuate the focus search when disc table is moving in and out.)

5.Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 2.4 ± 0.7 Vp-p.

S-curve waveform

symmetry

A

within 2.4 ± 0.7 Vp-p

B

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness to obtain best waveform.

RF Level Check

|

oscilloscope |

BD (CD) board |

|

TP (RF) |

+ |

TP (VC) |

– |

Procedure :

1.Connect oscilloscope to test point TP (RF) on BD board.

2.Turned Power switch on.

3.Put disc (YEDS-18) in and playback.

4.Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note: Clear RF signal waveform means that the shape “ ◊” can be clearly distinguished at the center of the waveform.

•RF signal VOLT/DIV: 200 mV TIME/DIV: 500 nS

level : 1.3 ± 0.3 Vp-p

– 14 –

E-F Balance (1 Track Jump) Check (Without remote commander)

|

oscilloscope |

BD (CD) board |

|

TP (TEO) |

+ |

TP (VC) |

– |

Procedure :

1.Connect oscilloscpe to test point TP (TEO) on BD board.

2.Turn Power switch on.

3.Put disc (YEDS-18) in to play the number five track.

4.Press the “ P(Pause)” button. (Becomes the 1 track jump mode)

5.Confirm that the oscilloscope waveform is symmetrical on the top and bottom in relation to 0Vdc, and check this level.

1 track jump waveform

A

0V

B

LEVEL : 300 ± 100 mVp-p

A – B

Specified level: • 2 (A + B) x 100 = less than ± 7%

• A + B = 300 ± 100 mVp-p

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off. There is no problem.

Therfore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position when you moved and do not know original position.

Adjustment Location:

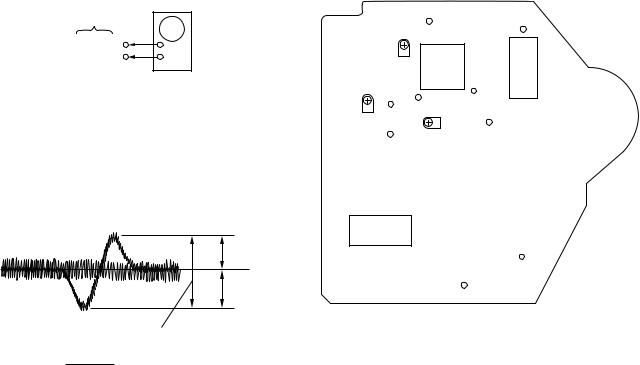

[BD (CD) BOARD] — Component Side —

RF

|

|

FOK |

|

(Focus Bias Adjust) |

|

RV101 |

|

IC102 |

|

TEI |

|

|

IC101 |

|

RV103 |

|

|

TEO |

FEO |

|

FEI |

|

|

VC |

RV102 |

|

|

|

IC104

PCK

GND

– 15 –

Loading...

Loading...