Sony HCD-M100, HCD-M300AV Service manual

HCD-M100/M300AV

SERVICE MANUAL

HCD-M100/M300AV is the tuner, deck, CD and

amplifier section in MHC-M100/M300AV.

SPECIFICATIONS

COMPACT COMPONENT SYSTEM

— Continued on next page —

Model Name Using Similar Mechanism HCD-MC3AV

CD Mechanism Type CDM-46B1

Optical Pick-up Name KSM-213BFN/C2NP

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type TCM-230AWR21

CD

SECTION

TAPE DECK

SECTION

US Model

Amplifier section

U.S.A models:

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

With 6 Ω loads both channels driven, from 120 – 10,000 Hz; rated 75 W per

channel minimum RMS power, with no more than 10% total harmonic

distortion from 250 mW to rated output.

MHC-M300AV

Front Speaker:

Continuous RMS power output

75 + 75 W

(6 Ω at 1 kHz, 10% THD)

Total harmonic distortion

less than 0.09%

(6 Ω at 1 kHz, 40 W)

Center Speaker:

Continuous RMS power output

35 W

(6 Ω at 1 kHz. 10% THD)

Rear Speaker:

Continuous RMS power output

17.5 + 17.5 W

(12 Ω at 1 kHz, 10% THD)

MHC-M100

Continuous RMS power output

75 + 75 W

(6 Ω at 1 kHz, 10% THD)

Total harmonic distortion

less than 0.09%

(6 Ω at 1 kHz, 40 W)

Inputs

VIDEO/MD IN (phono jack):

voltage 250 mV/450 mV,

impedance 47 kΩ

Outputs

PHONES (stereo phone jacks):

accepts headphones of 8 Ω or more

FRONT SPEAKER: accepts impedance of 6 to 16 Ω

REAR SPEAKER: (M300AV only):

MHC-M300AV accepts impedance of 12 to 16 Ω

CENTER SPEAKER: (M300AV only):

accepts impedance of 6 Ω

SUPER WOOFER: (M300AV only):

voltage 1 V, impedance 1 kΩ

Manufactured under license from Dolby

Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; and

“PRO LOGIC” are trademarks of Dolby

Laboratories Licensing Corporation.

Photo: HCD-M300AV

Ver 1.1 2001. 07

9-929-271-12

2001G0200-1

© 2001.7

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

2

CD player section

System Compact disc and digital audio system

Laser Semiconductor laser (λ =780 mm)

Emission duration: continuous

Laser output Max. 44.6 µW*

* This output is the value measured at a

distance of 200 mm from the objective lens

surface on the Optical Pick-up Block with

7 mm aperture.

Frequency response 2 Hz – 20 kHz (± 0.5 dB)

Wavelength 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Wave length 600 nm

Output level –18 dBm

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (± 3 dB),

using Sony TYPE I cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 Ω unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz

(with the interval set at 10 kHz)

531 – 1,710 kHz

(with the interval set at 9 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements 120 V AC, 60 Hz

Power consumption

MHC-M300AV: 190 W

MHC-M100: 150 W

Dimensions (w/h/d) Approx. 280 × 373 × 468 mm

Mass

MHC-M300AV: Approx. 10.9 kg

MHC-M100: Approx. 10.5 kg

Supplied accessories: AM loop antenna (1)

Remote commander (1)

Batteries (2)

FM lead antenna (1)

Speaker cords (for MHC-M300AV only) (2)

Center speaker pads (for MHC-M300AV

only) (4)

Design and specifications are subject to change without notice.

3

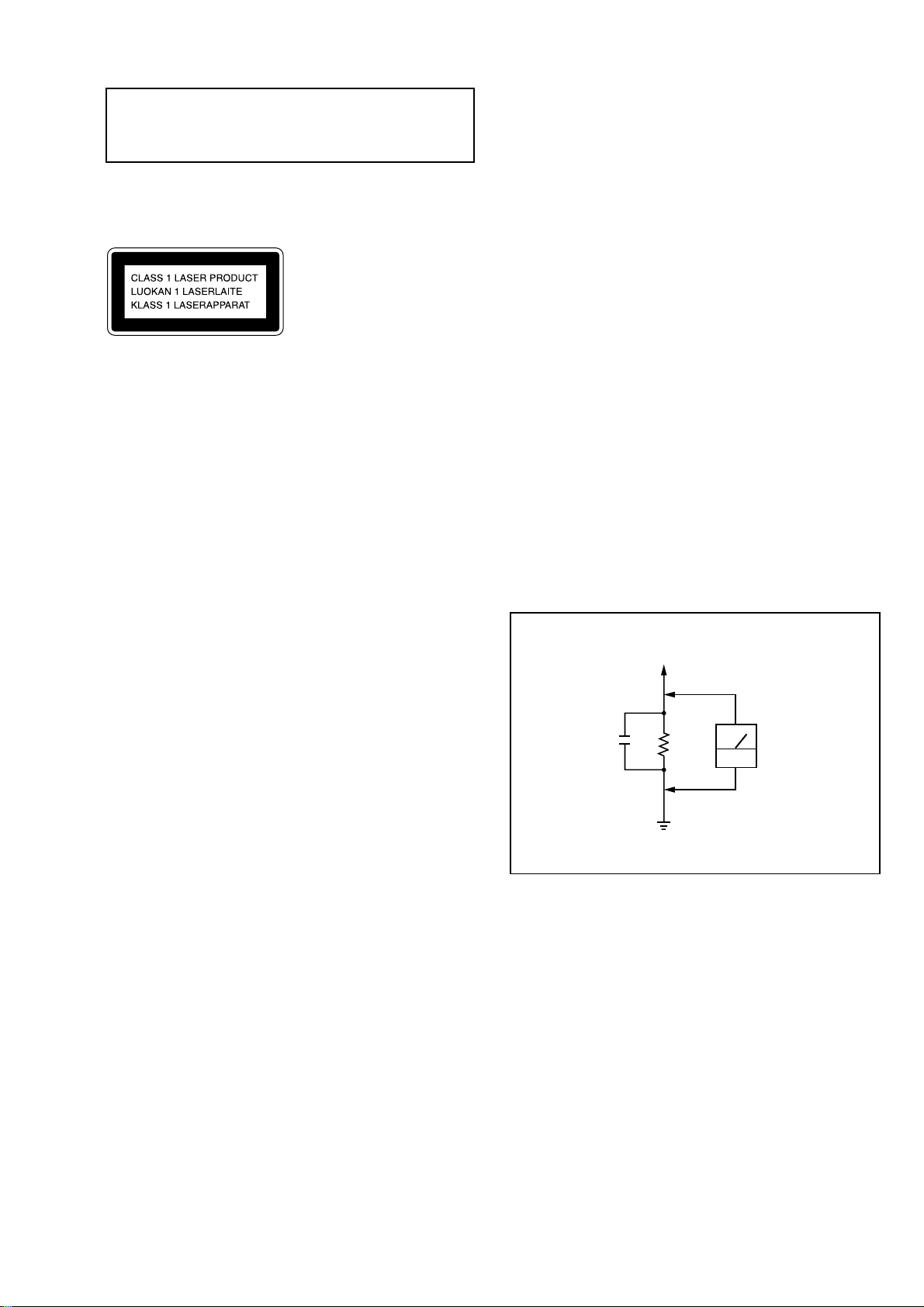

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

SAFETY CHECK-OUT

(US model only)

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

0.15µF

To Exposed Metal

Parts on Set

1.5kΩ

AC

voltmeter

(0.75V)

Earth Ground

4

TABLE OF CONTENTS

1. GENERAL

Font Panel ··············································································· 5

Rear Panel ·············································································· 6

2. DISASSEMBLY ······························································· 8

3. TEST MODE ··································································· 16

4. MECHANICAL ADJUSTMENTS ···························· 18

5. ELECTRICAL ADJUSTMENTS

Deck Section ········································································ 21

CD Section ··········································································· 23

6. DIAGRAMS

6-1. Block Diagram – CD Section – ········································ 24

Block Diagram – Main Section – ····································· 25

Block Diagram – Audio Section –···································· 26

6-2. Circuit Boards Location ··················································· 27

6-3. Printed Wiring Board – BD Section – ······························ 28

6-4. Schematic Diagram – BD Section – ································· 29

6-5. Printed Wiring Board – CD Motor Section – ··················· 30

6-6. Schematic Diagram – CD Motor Section – ······················ 31

6-7. Printed Wiring Board – Audio Section – ·························· 32

6-8. Schematic Diagram – Audio Section –····························· 33

6-9. Printed Wiring Board – Main Section – ··························· 34

6-10. Schematic Diagram – Main (1/6) Section – ····················· 35

6-11. Schematic Diagram – Main (2/6) Section – ····················· 36

6-12. Schematic Diagram – Main (3/6) Section – ····················· 37

6-13. Schematic Diagram – Main (4/6) Section – ····················· 38

6-14. Schematic Diagram – Main (5/6) Section – ····················· 39

6-15. Schematic Diagram – Main (6/6) Section – ····················· 40

6-16. Printed Wiring Board – Power Section – ························· 41

6-17. Schematic Diagram – Power Section – ···························· 41

6-18. Printed Wiring Board – Panel Section – ··························· 42

6-19. Schematic Diagram – Panel Section – ····························· 43

6-20. Printed Wiring Board – Front Amp Section – ·················· 44

6-21. Schematic Diagram – Front Amp Section – ····················· 45

6-22. Schematic Diagram – Rear Amp Section – ······················ 46

6-23. Printed Wiring Board – Rear Amp Section – ··················· 47

6-24. Waveforms ········································································ 48

6-25. IC Pin Function Description ············································· 48

6-26. IC Block Diagrams ··························································· 56

7. EXPLODED VIEWS ····················································· 60

8. ELECTRICAL PARTS LIST ····································· 67

SERVICING NOTES

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pick-

up block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output repeatedly.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

5

SECTION 1

GENERAL

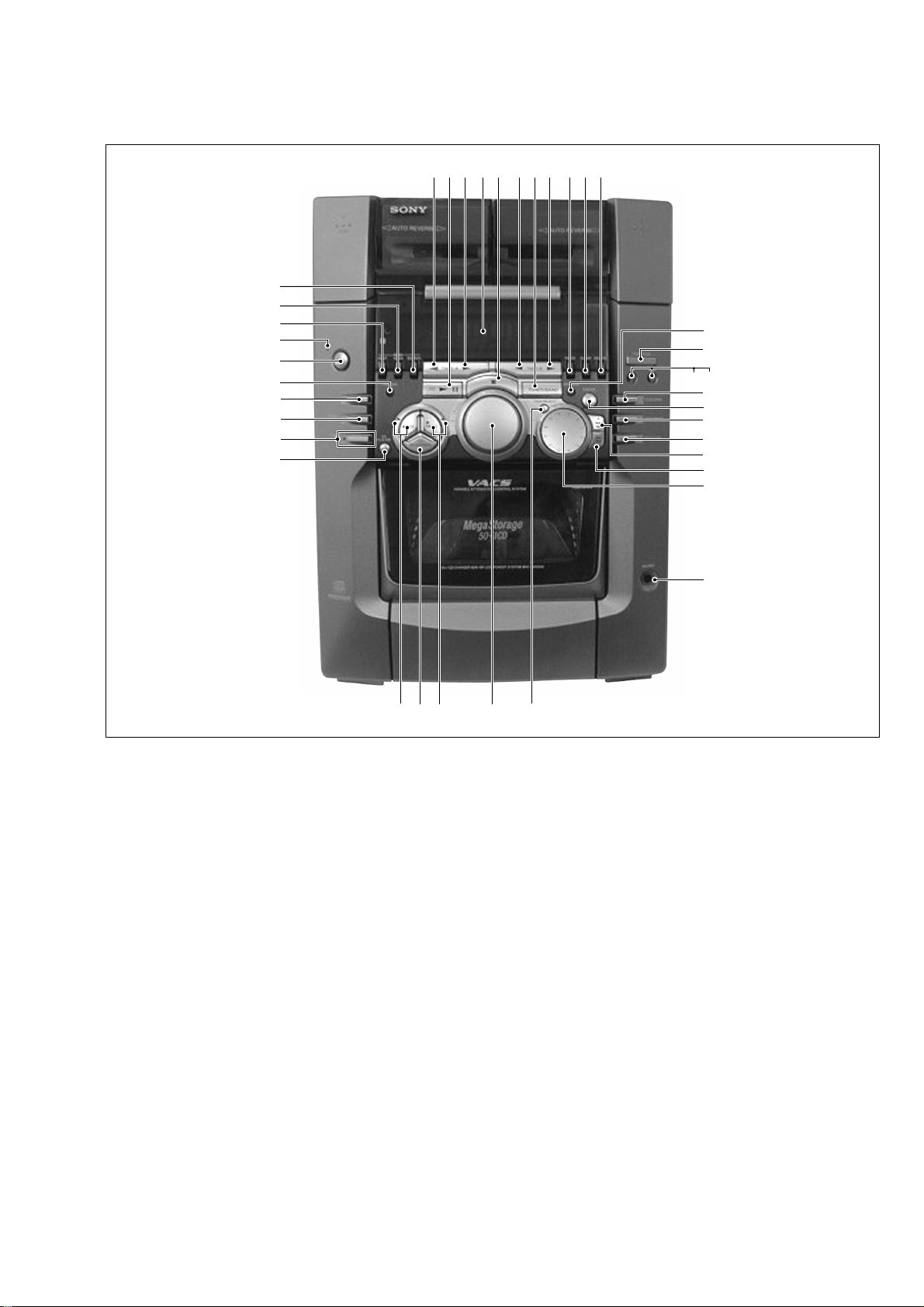

FRONT PANEL

1 @/1 button

2 STANDBY indicator

3 MEMO INPUT button

4 MEMO SCAN button

5 MEMO SEARCH button

6 TAPE A h button and indicator

7 CD 7 button and indicator

8 TAPE A H button and indicator

9 Display window

0 x (STOP) button

qa TAPE B h button and indicator

qs TUNER/BAND button

qd TAPE B H button and indicator

qf CHECK button

qg CLEAR button

qh DELETE button

qj GROOVE button and indicator

qk FUNCTION button

ql DSP button and indicator

w; DBFB button

wa CONTINUE/STEREO/MONO button

ws ENTER button

wd PROGRAM/TUNER MEMORY button

wf SHUFFLE/DIRECTION button

wg + M > button

wh m .– button

wj SELECTOR dial

wk PHONES jack

wl FILE SELECT button

e; VOLUME knob

ea X PAUSE button and indicator

es CD SYNCHRO button

ed z REC button

ef CD PLUS ONE button

eg TIMER SELECT button and indicator

eh CLOCK TIMER SET button

ej DISPLAY button

ek PROLOGIC button and indicator

(HCD-M300AV only)

1

ef

eg

eh

ej

ek

2

3

4

5

678 90 qaqsqd qfqgqh

qj

qk

w;

wa

ws

wd

wf

wg

wh

wj

wk

wle;eaesed

ql

Photo: HCD-M300AV

6

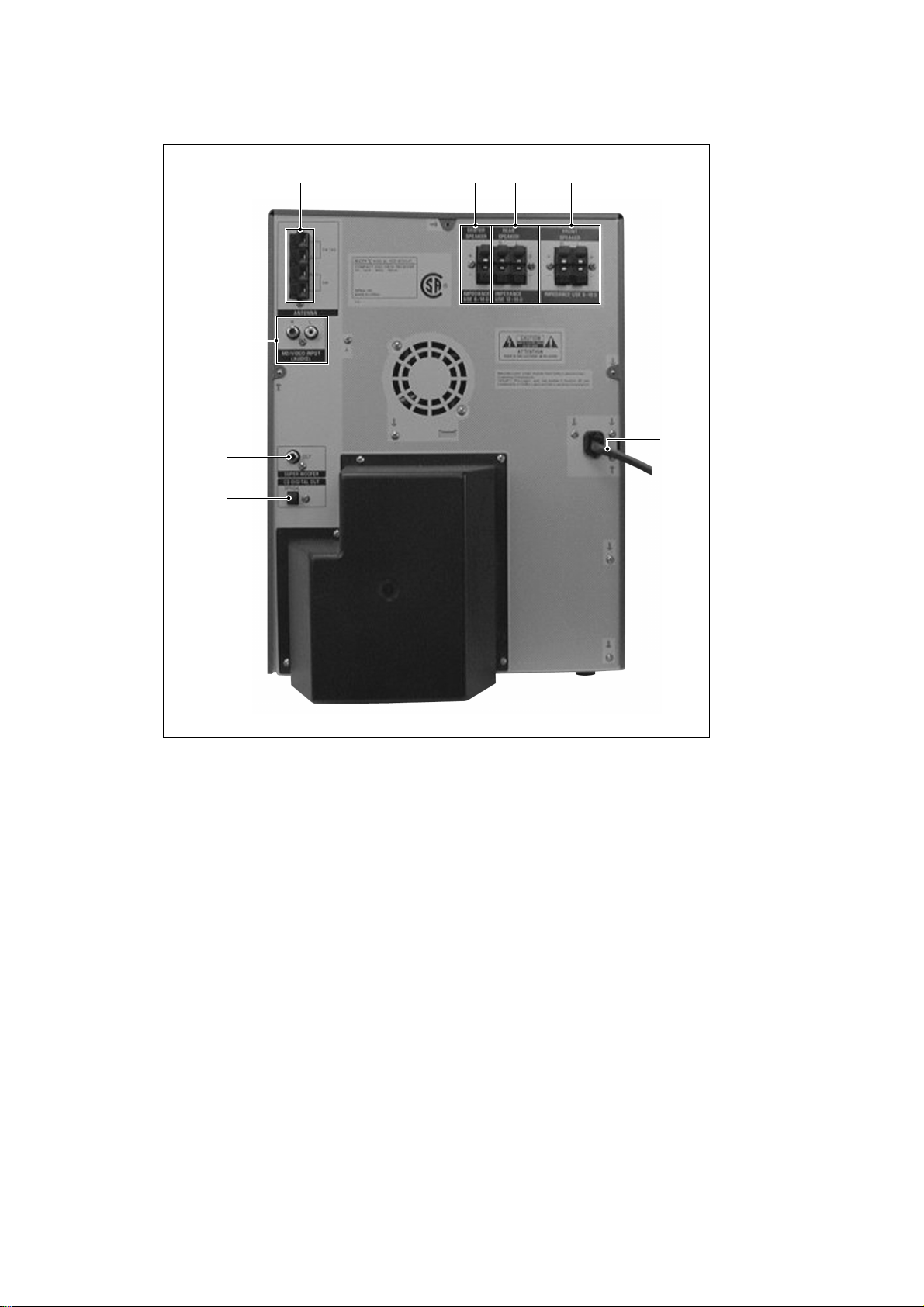

REAR PANEL

1 CD DIGITAL OUT connector

2 SUPER WOOFER jack (HCD-M300AV only)

3 MD/VIDEO INPUT (AUDIO) jack

4 ANTENNA terminal

5 CENTER SPEAKER terminal (HCD-M300AV only)

6 REAR SPEAKER terminal (HCD-M300AV only)

7 FRONT SPEAKER terminal

8 AC power cord

1

2

3

4 5 6 7

8

Photo: HCD-M300AV

7

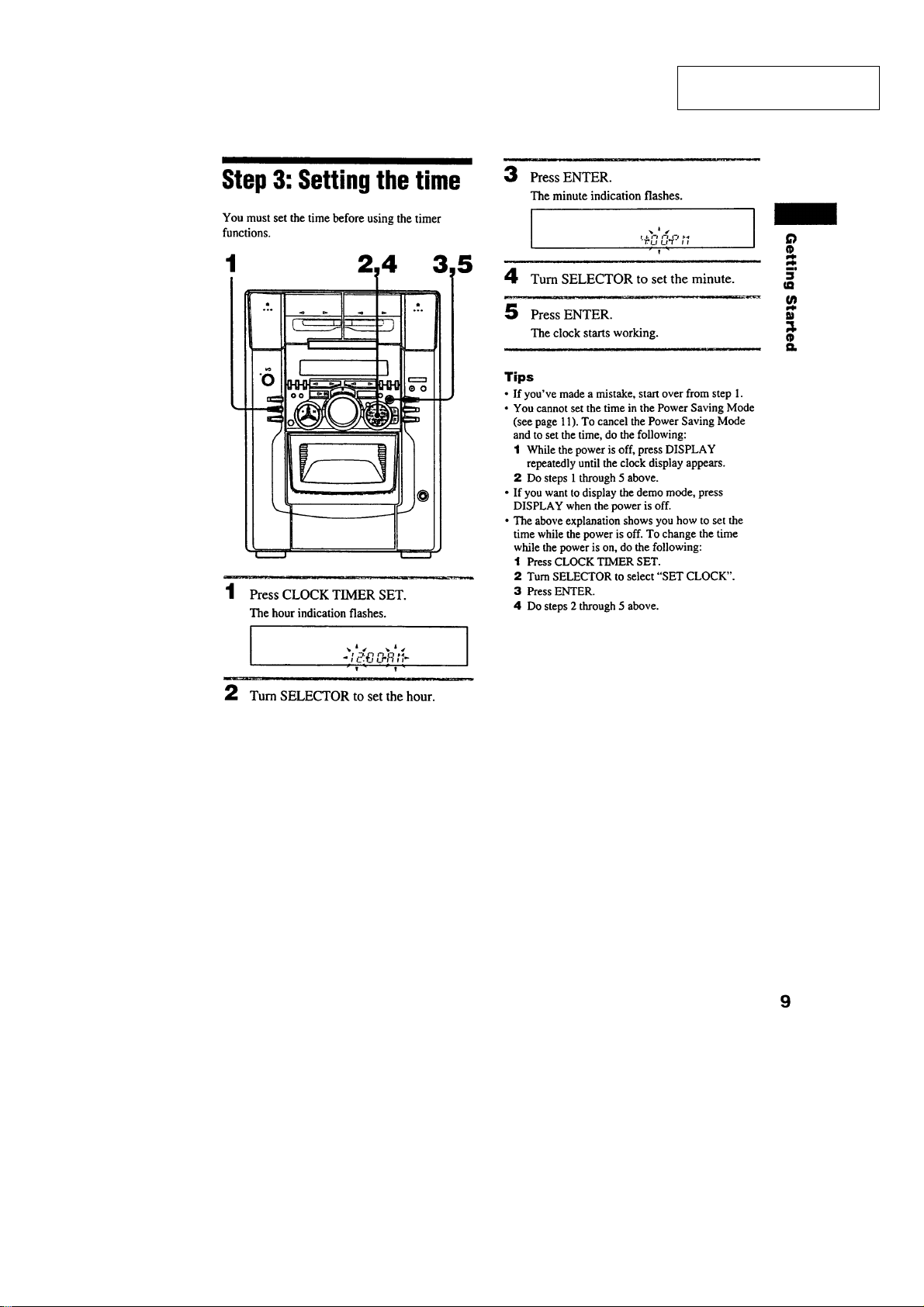

This section is extracted from

instruction manual.

8

SECTION 2

DISASSEMBLY

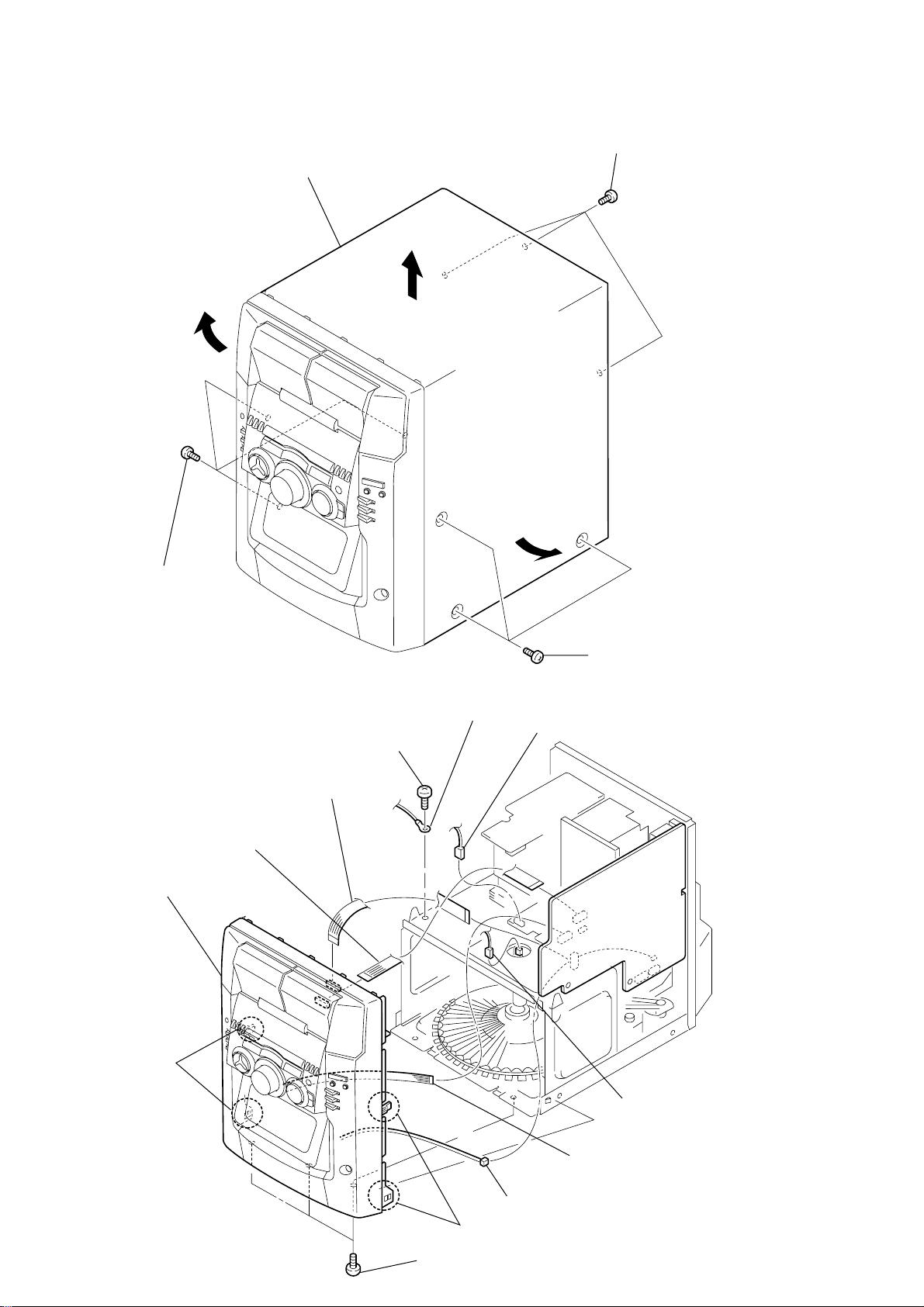

2-1. CASE

2-2. FRONT PANEL SECTION

Note : Follow the disassembly procedure in the numerical order given.

1 Three screws

(CASE3 TP2)

1 Three screws

(CASE3 TP2)

2 Three screws

(BVTP 3 × 8)

3 Case

7 Screws

(BVTT 3 × 8)

8 Lug

4 Connector(CN804)

5 Connector(CN604A

)

6 Connector(CN453)

1 Wire (flat type)

(17 core)

2 Wire (flat type)

(15 core)

0 Two claws

qa Front panel assy

0 Two claws

9 Three screws

(BVTP 3 × 8)

3 Wire (flat type) (10 core)

9

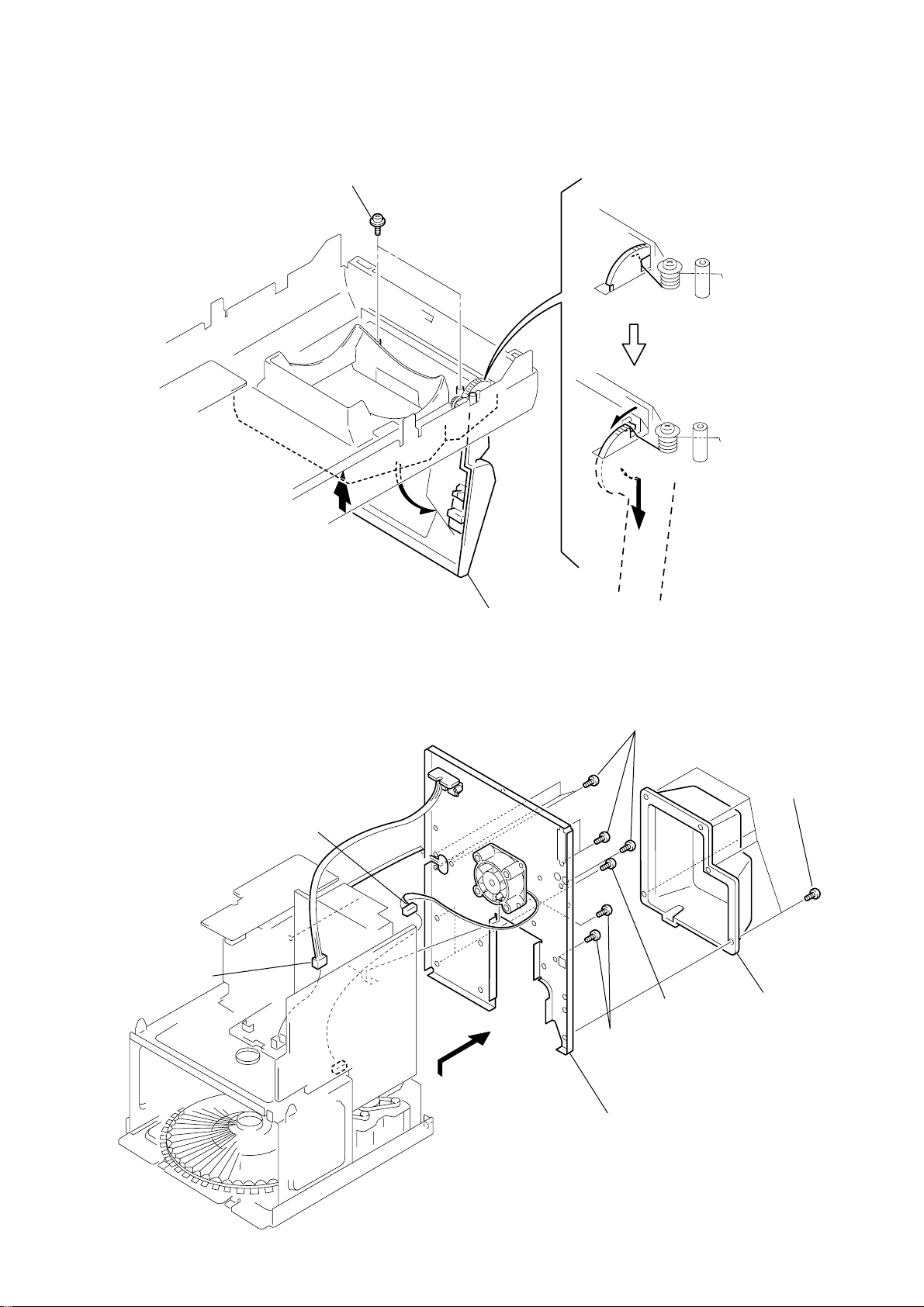

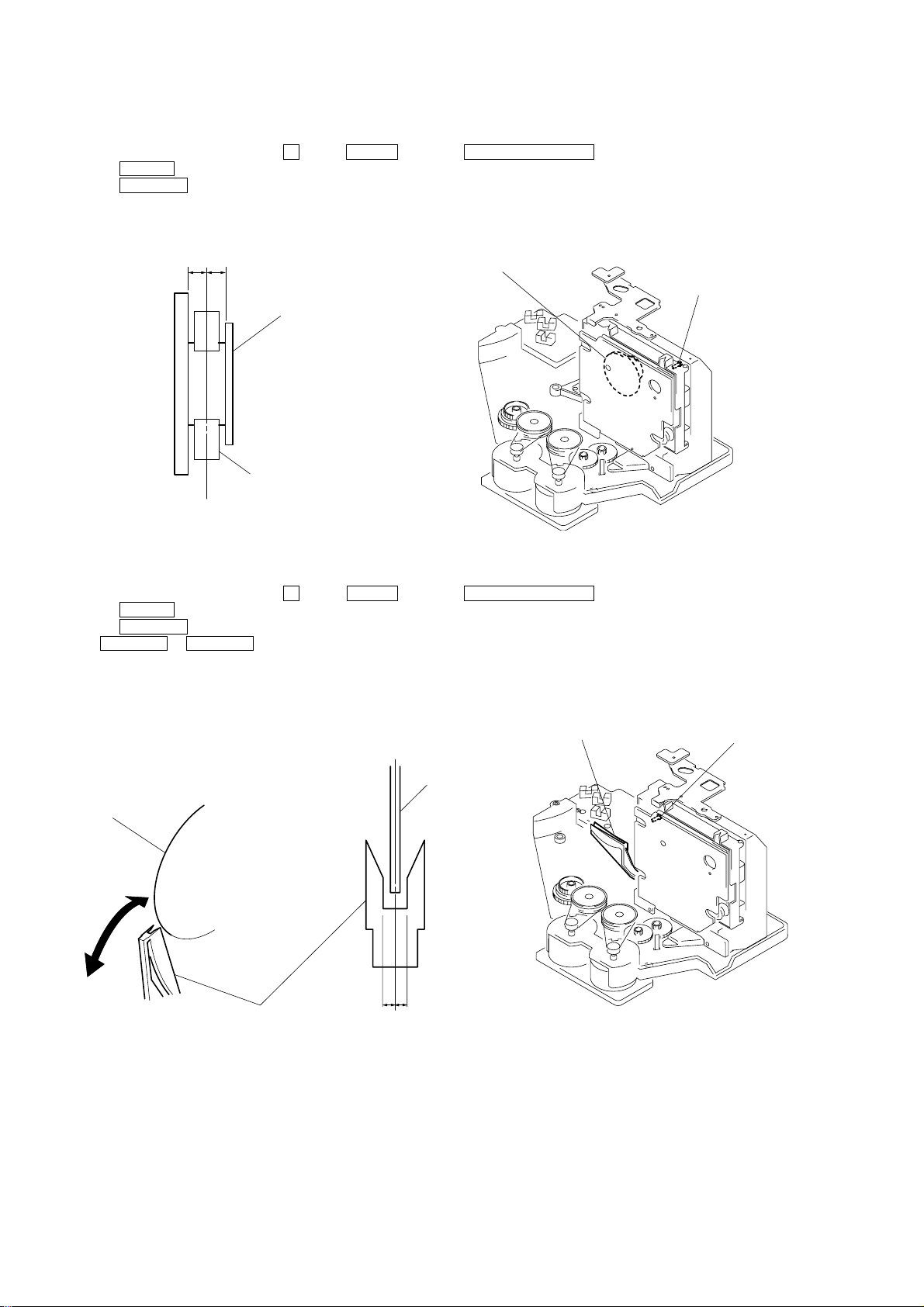

2-3. DOOR ASSY

2-4. BACK PANEL

2 Open the door ass'y

1 Two screws

(PTPWH 2.6 × 8)

A

3 Remove the door ass'

y

to direction of the

arrow A.

7 Six screws

(BVTP 3 × 8)

5 Two screws

(BVTP 3 × 8)

6 Two screws

(BVTP 3 × 8)

3 Five screws

(BVTP 3 × 8

)

4 Cover

8 Remove the back panel

to direction of the arrow.

2 Connector(CN751)

1 Connector

(CN802)

10

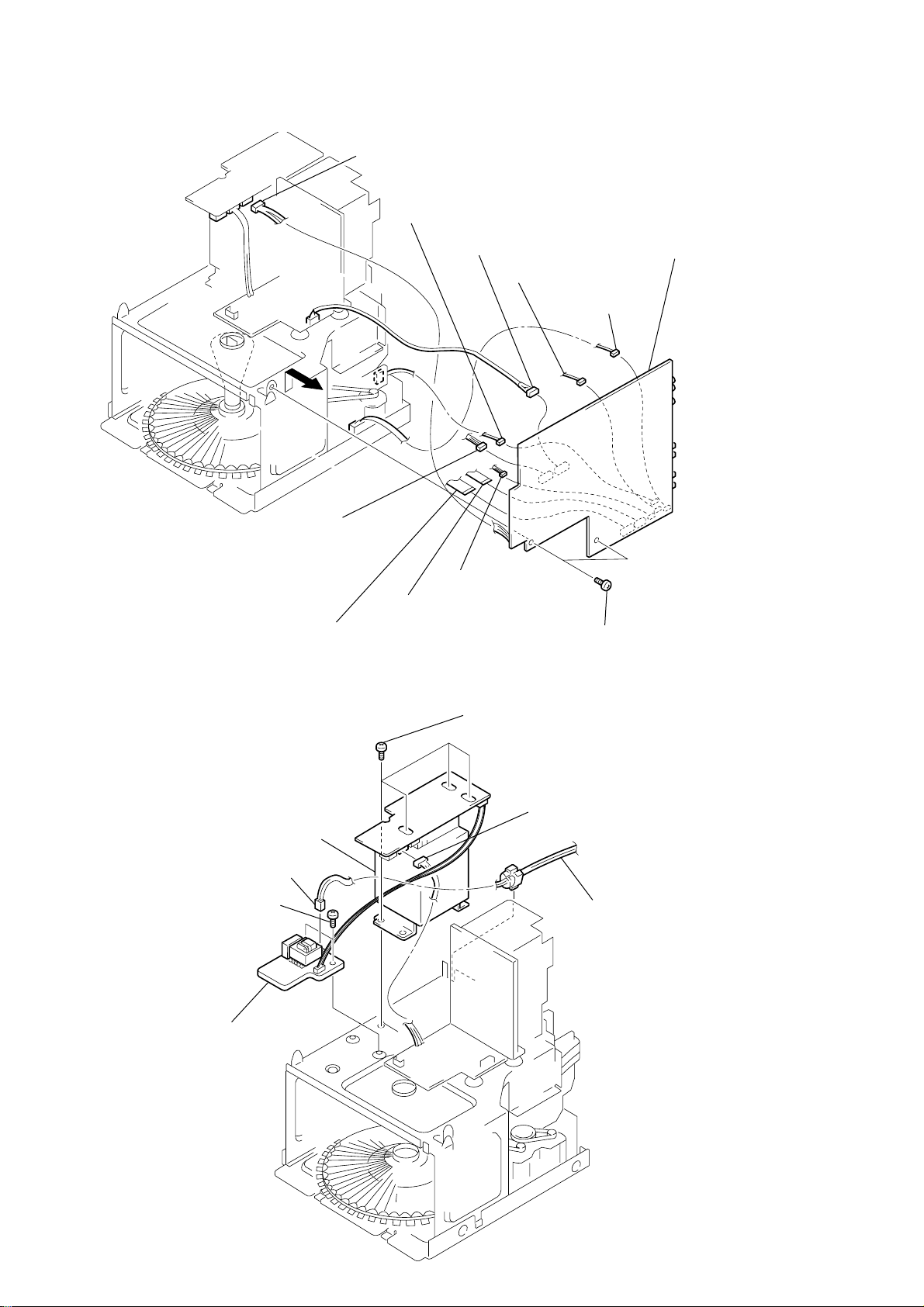

2-5. MAIN BOARD

2-6. POWER TRANSFORMER (T991)

qa Remove the MAI

N

board to direction

of the arrow.

0 Two screws

(BVTP 3 × 8)

2 Wire (flat type) (9 core)

1 Wire (flat type) (16 core)

7 Connector(CN451)

3 Connector(CN902)

4 Connector(CN801B)

6 Connector(CN461)

8 Connector(CN403)

5 Connector(CN454)

9 Connector(CN454)

6

Four screws

(BVTT 3 × 8)

7 Power transforme

3 Connector CN995

4 Two screws

(BVTT3 x 8)

5 Sub trans board

1 Connector CN992

2 Power cor

d

11

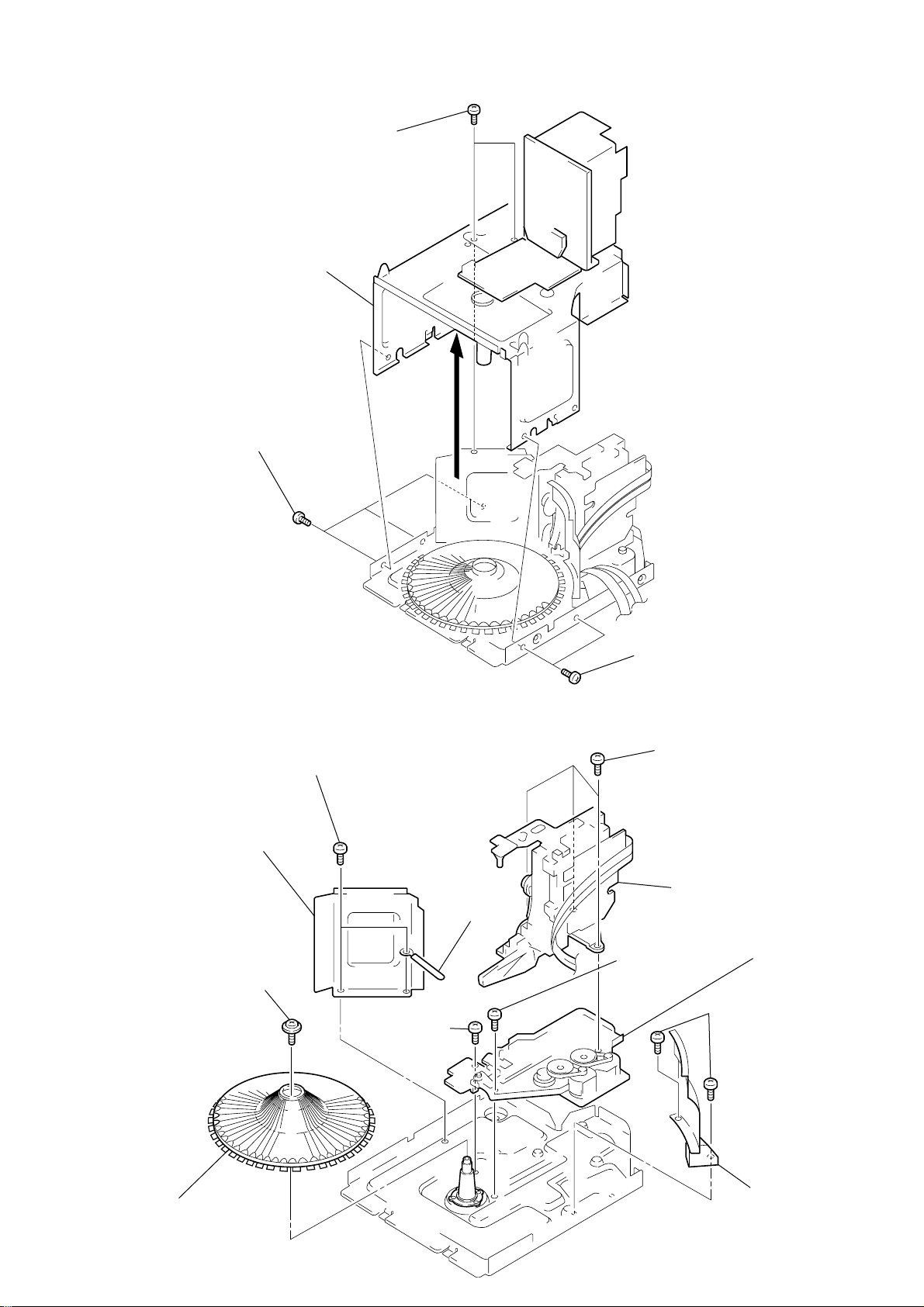

2-7. SUB CHASSIS

2-8. CD MECHANISM DECK SECTION

1 Two screws

(BVTT 3 × 8)

3 Sub chassis

2 Three screws

(BVTP 3 × 8)

2 Two screws

(BVTP 3 × 8)

8

Three screws

(BVTT 3 × 10)

9 Base (LOADING)

3 Two screws

(BVTP 3 × 8)

4 Cover (CD)

qs Base (CDM)

qa Screw

(BVTT 3 × 10)

0 Screw

(BVTT 3 × 14)

5 Two screws

(BVTT 3 × 6)

7 Reinforcement

1 Screw

(PTPWH 2.6 × 8)

2 Table (50)

6 Wire holder

12

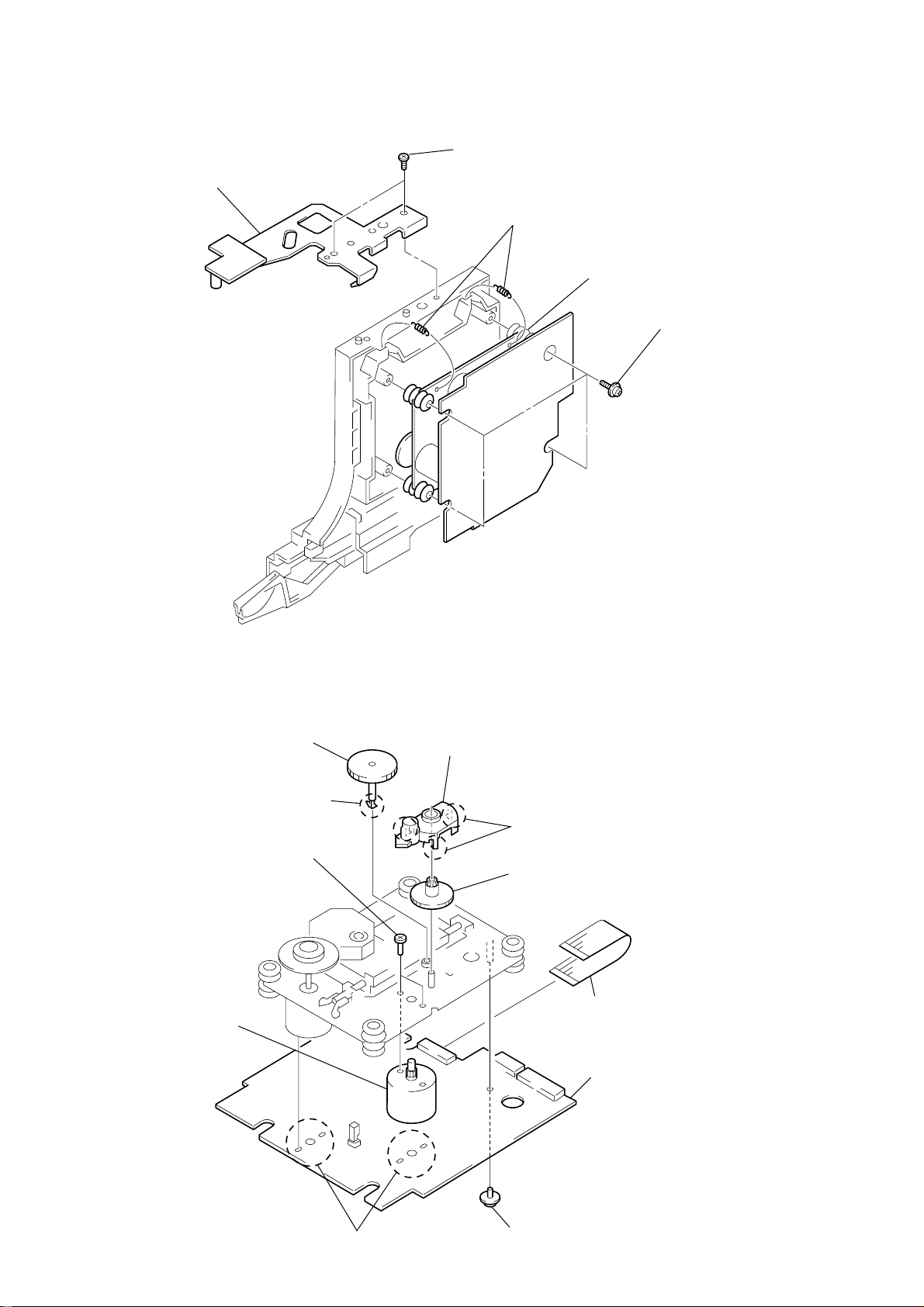

2-9. CD BASE UNIT

2-10. BD BOARD, SLED MOTOR (M102)

1 Two screws

(BTVP 3 × 8)

2 Bracket

3 Two tention springs

5 Base unit

4 Four screws

(PTPWH 2.6 × 8)

6 Gear (A) (S)

5 Claw

0 Two screws (P 2 × 3)

qa Sled motor

(M102)

3 Removal

four solders.

2 Screw (PTPWH 2 × 5)

4 BD board

1 Wire (flat type) (16 core)

9 Gear (B) (RP)

7 Three claws

8 Gear cover

13

2-11. OPTICAL PICK-UP

2-12. TAPE MECHANISM DECK SECTION

3 Remove the optical

pick-up to direction

of the arrow A.

2 Sled shaft

1 Claw

A

2 Remove the cassette lid (L) ass'y

to direction of the arrow B.

1 Remove the cassette lid (R) ass'y

to direction of the arrow A.

A

B

3 Three screws

(BVTP 2.6 × 8)

3 Three screws

(BVTT 3 × 6)

4 Remove the tape mechanism

deck section.

14

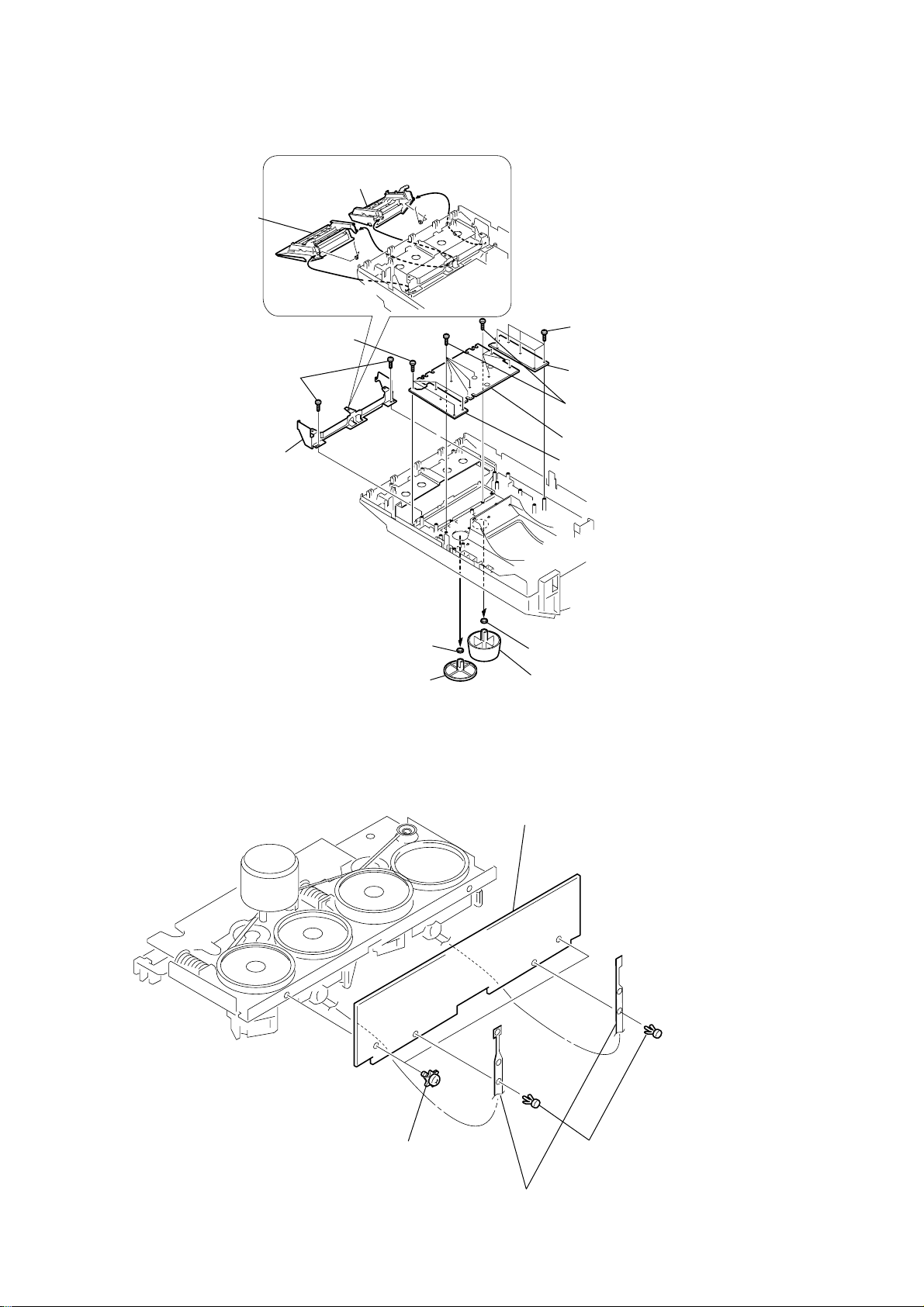

2-13. PANEL BOARD

2-14. CASSETTE BOARD

0 Five screws

(BVTP 2.6 × 8)

0 Seven screws

(BVTP 2.6 × 8)

7 Volume ring

6 Volume knob

8 Selector ring

9 Selector ring

0 Five screws

(BVTP 2.6 × 8)

3 Remove the

cassette lid (R) assy

3 Remove the

cassette lid (L) assy

TORSION SPRING

(DOOR2)

TORSION SPRING

(DOOR1)

4 Two screws

(BVTP 2.6 × 8)

5 Remove the

TC bracket

qa Remove the panel (L) boar

d

qd Remove the panel board

qs Remove the panel (R) board

1

2

2

1

3 Two screws

(BVTT 2 × 4 (S))

2 Break the soldering of tw

o

flexible flat cables.

1 Four rivets

4 CASSETTE board

15

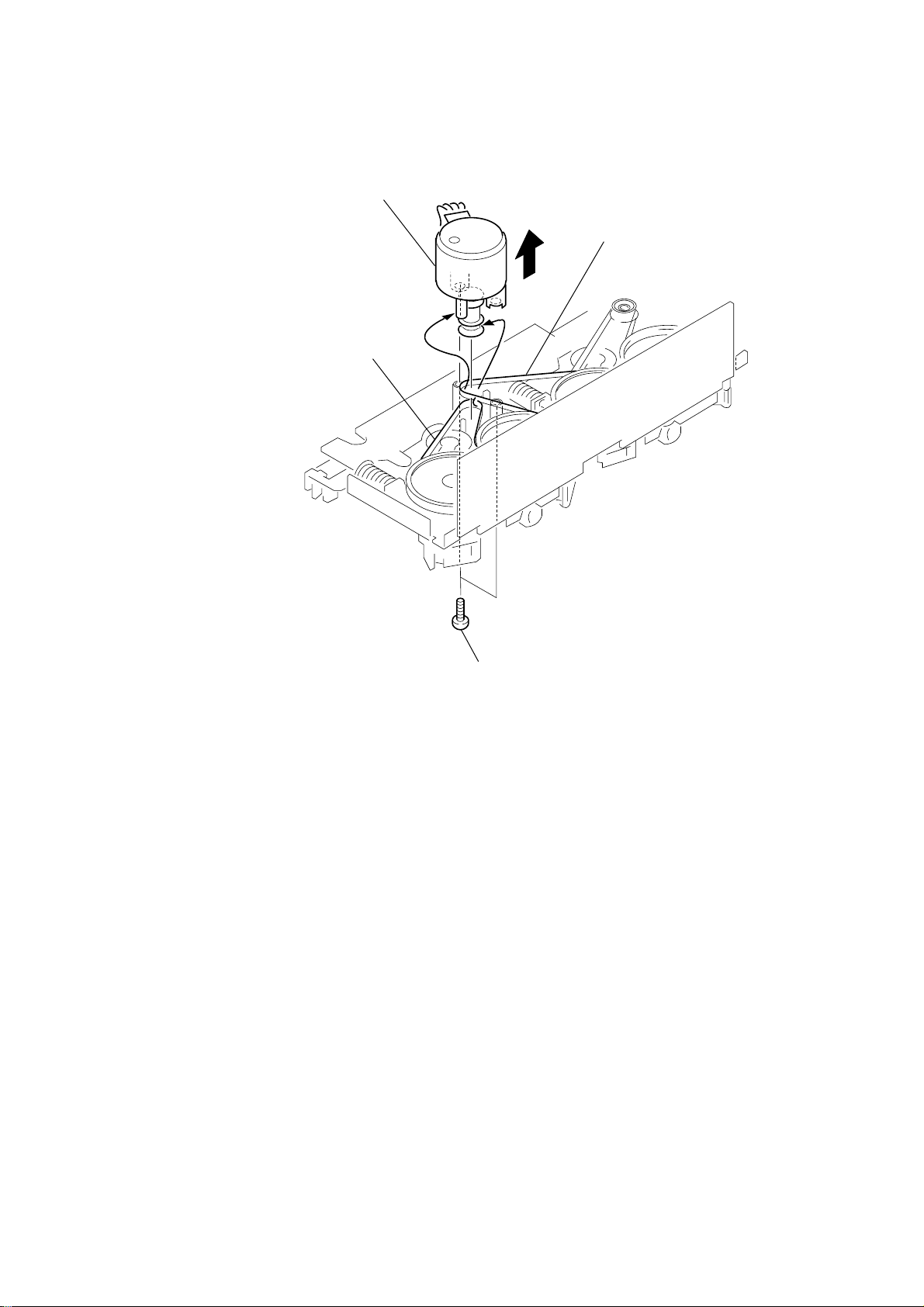

2-15. CAPSTAN MOTOR (M1)

3 Remove the belt.

1 Two screws

(PS 2.6 × 5)

2 Remove the belt.

4

Remove the capstan motor

to direction of the arrow.

16

SECTION 3

TEST MODE

[MC Cold Reset]

* The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press the three buttons x , ENTER and @/1 at the same

time.

2. The fluorescent indicator tube turns off for a moment and the

RAM is reset to the initial conditions.

[MC Hot Reset]

* This mode resets the set with the preset data kept stored in the

memory. This hot reset mode is performed also when the power

cord is plugged in and out.

Procedure:

1. Press the three buttons x , ENTER and FUNCTION at the

same time.

2. The fluorescent indicator tube turns off for a moment and the

RAM is reset to the initial conditions.

[CD Initial]

* The CD INITIAL clears all of the CD related data. Execute

this mode when returning the set to the customer.

Procedure:

1. Press the three buttons x , ENTER and CONTINUE/

STEREO/MONO at the same time.

2. The message “STANDBY” appears on the fluorescent indicator

tube and the CD related data is reset to the initial conditions.

[CD Line Test]

* The CD Line test displays the rotating time required for one

rotation by rotating the disc tray.

Procedure:

1. Press the three buttons x , ENTER and CLOCK/TIMER SET

at the same time. The CD PLAY LED and the CD PAUSE LED

flash alternately and the disc tray starts rotation.

2. The message “xx << y.y” appears on the fluorescent indicator

tube. The left numbers count up the discs starting from 1 to 51.

The left numbers “y.y” indicate the rotating time required for

one rotation by rotating the disc tray.

3. To exit the CD LINE test mode, execute the MC Hot Reset.

[CD Memo All Clear]

* The mode clears all contents of the CD disc memo. Execute

this mode when returning the set to the customer.

Procedure:

1. Press the two buttons MEMO INPUT and ENTER at the

same time.

2. The message “ALL ERASE” appears on the fluorescent indicator

tube and the CD disc memo is all cleared.

[GC Test Mode]

* This mode checks microprocessor version number, keys,

fluorescent tubes, LEDs and VACS (Variable Attenuation

Control System).

Procedure:

1. Press the three buttons x , ENTER and DISPLAY at the

same time. The set enters the GC test mode, and all of the

fluorescent tubes and LEDs turn on.

2. From this state, any one of the three modes MODEL NAME,

KEY CHECK and VACS can be selected. Go to step 3 to enter

the MODEL NAME test mode. Go to step 5 to enter the KEY

CHECK test mode. Go to step 11 to enter the VACS test mode.

3. [MODEL NAME test mode ] From the state of step 2, press the

CONTINUE/STEREO/MONO button. Every pressing of the

CONTINUE/STEREO/MONO button advances the following

check modes and displays in the given order. Model name

display, destination display, MC version display, GC version

display, DC version display, VC version display and CC version

display.

4. To exit the GC test mode and to return to the STANDBY mode,

press the x , ENTER and DISPLAY buttons again.

5. [KEY CHECK test mode ] You can enter this mode directly

from step 2. When you performed steps 3, perform steps 4,

then 1 and 2 before starting the step 5.

[KEY CHECK test mode ] From the GC test mode, press the

PROGRAM button to enter the key check mode.

The display: K 1, J 0, V 0 appears.

6. The value after K indicates the number of times that the key is

pressed. 1 is displayed because the PROGRAM button has

already been pressed.

7. When other keys are pressed one after another, the key count

increases up to 43. The keys which have already been pressed,

are not counted.

8. The value after J indicates the number of clicks that the JOG

dial is rotated. The clockwise rotation increases the count value.

The counter-clockwise rotation decreases the count value.

9. The value after V also indicates amount of rotation of volume

control. The clockwise rotation increases the count value. The

counter-clockwise rotation decreases the count value.

10. To exit the GC test mode and to return to the STANDBY mode,

press the x , ENTER and DISPLAY buttons again.

11. [VACS test mode ] You can enter this mode directly from step

2. When you performed steps 3, perform steps 4, then 1 and 2

before starting the step 5.

[VACS test mode ] From the GC test mode, press the SHUFFLE

button to enter the VACS attenuation check mode. The display:

VOL NORMAL appears.

12. To exit the GC test mode and to return to the STANDBY mode,

press the x , ENTER and DISPLAY buttons again.

[Aging Mode]

The decks A and B are operated automatically for aging purpose.

When errors occur during aging, causes of errors are displayed and

the aging mode is stopped.

How to enter the aging mode

1. Turn on the main power. Install a playback tape to deck A and

install a blank tape to deck B.

2. Select TAPE A with the FUNCTION button.

3. Press the three buttons of x , ENTER and SHUFFLE at the

same time to enter the aging mode.

How to exit the aging mode.

Turn off the main power.

1. Rewind the tapes A and B. Tapes stop at the shut-off of tape A

and the aging mode advances to the next step.

The message: TAPE A AG-1 appears.

2. The tape A is played back in the FWD mode. After two minutes

of the FWD playback, the aging mode advances to the next

step.

The message: TAPE A AG-2 appears.

17

3. The tape A runs in fast forward. After two minutes of fast

forward, or at the shut-off point, the tape is stopped and the

aging mode advances to the next step.

The message: TAPE A AG-3 appears.

4. The tape A is played back in the RVS mode. After two minutes

of the RVS playback, the aging mode advances to the next step.

The message: TAPE A AG-4 appears.

5. The tape A is rewound and stops at the shut-off. The aging

mode advances to the next step.

The message: TAPE A AG-5 appears.

6. The tape B is played back in the FWD mode. After two minutes

of the FWD playback, the aging mode advances to the next

step.

The message: TAPE B AG-2 appears.

7. The tape B runs in fast forward. After two minutes of fast

forward, or at the shut-off point, the tape is stopped and the

aging mode advances to the next step.

The message: TAPE B AG-3 appears.

8. The tape B is played back in the RVS mode. After two minutes

of the RVS playback, the aging mode advances to the next step.

The message: TAPE B AG-4 appears.

9. The tape B is rewound and stops at the shut-off. The aging

mode advances to the next step.

The message: TAPE B AG-5 appears.

[AM TUNER STEP 9 kHz/10 kHz Selection Mode]

* Either the 9 kHz step or 10 kHz step can be selected for the AM

channel step.

Procedure:

1. Turn on the power and select TUNER using the FUNCTION

button.

2. Select AM with the TUNER/BAND button and turn off the

power.

3. Press the two buttons ENTER and @/1 at the same time. The

main power is turned on and the other frequency step of the

previous mode is selected and displayed. “AM 9 k STEP” or

“AM 10 k STEP”

[CD SRAM Test Mode]

Procedure:

1. Turn on the power and select CD using the FUNCTION button.

2. Press the three buttons x , ENTER and DBFB at the same

time.

3. The message “SRAM OK” appears on the fluorescent indicator

tube.

[GC VACS ON/OFF Mode]

Procedure:

1. Press the two buttons DELETE and @/1 at the same time.

2. The message “VACS ON” or “VACS OFF” appears on the

fluorescent indicator tube.

18

3.06 N • m to 6.96 N • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

3.06 N • m to 6.96 N • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

6.96 N • m to 14.02 N • m

71 to 143 g • cm

(0.98 – 1.99 oz • inch)

9.80 N • m

100 g or more

(3.53 oz or more)

9.80 N • m

100 g or more

(3.53 oz or more)

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

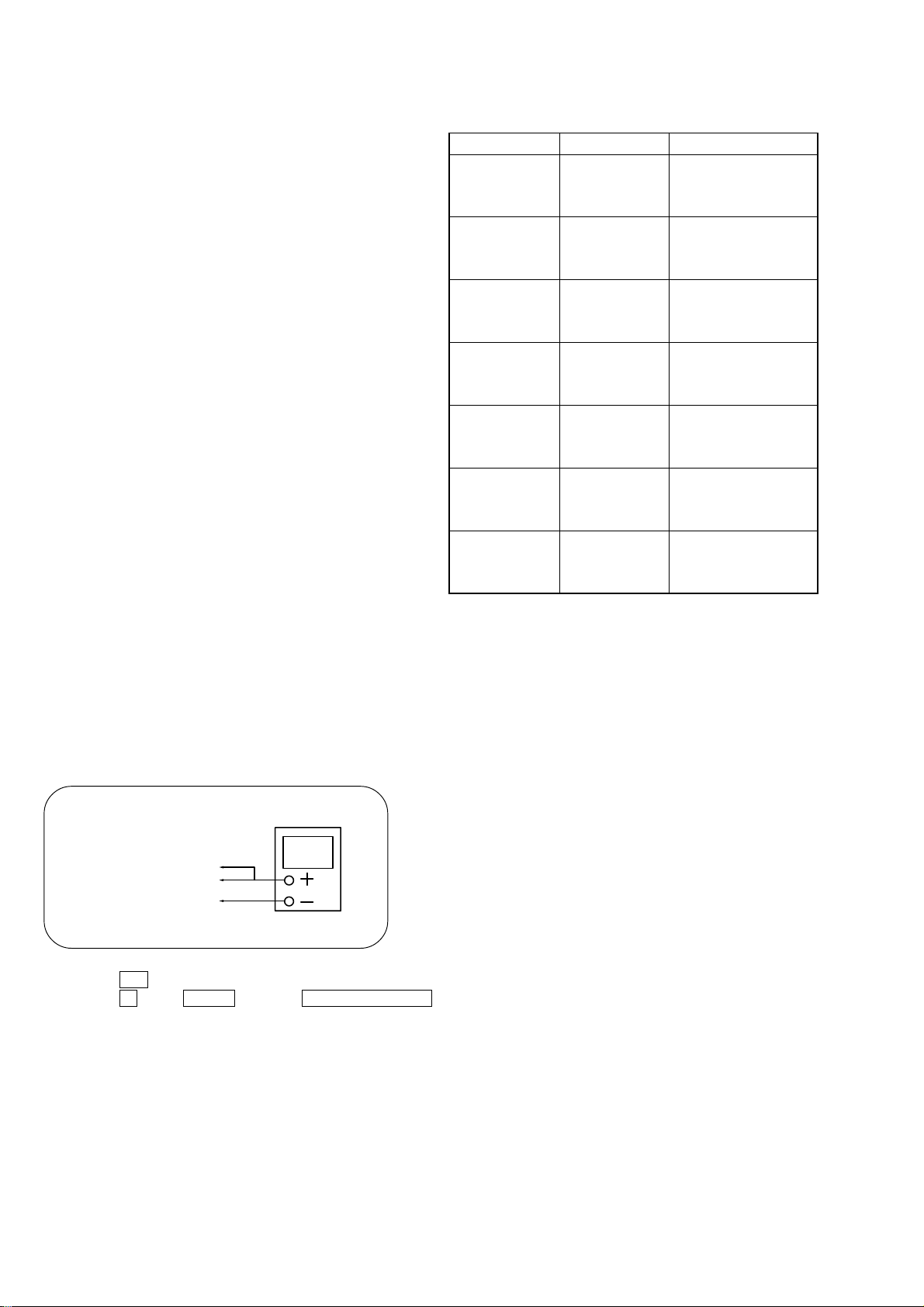

SECTION 4

MECHANICAL ADJUSTMENT

• TAPE MECHANISM DECK SECTION

• Torque Measurement

• CD MECHANISM DECK SECTION

To adjust the mechanism section, enter the mechanism section adjustment mode.

For how to enter the mechanism section adjustment mode, refer to each adjustment section.

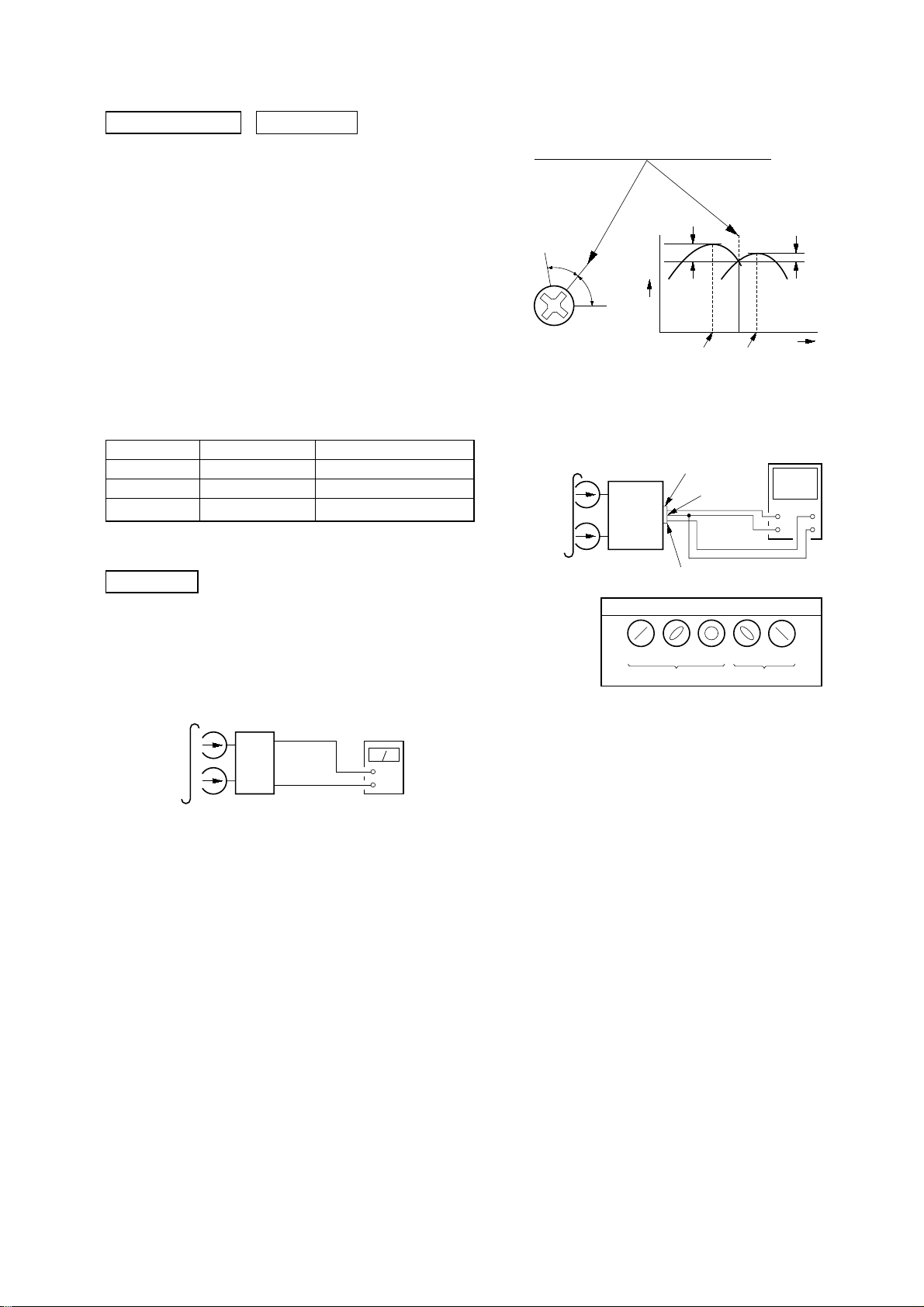

DISC SENSOR ALIGNMENT

1. Make sure that there is no disc in the unit.

2. Connect an oscilloscope to IC401rs, IC4014 of the MAIN board.

3. Press the @/1 button to turn ON the power.

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagne-

tizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

Mode

Torque meter Meter reading

4. Press the x button, ENTER button and CLOCK/TIMER SET button simultaneously.

oscilloscope

IC401rs D.SENS (CH1)

IC4014 HHOUT (CH2)

GND

19

5. The disc table rotates in the clockwise direction. The disc table rotation time is displayed with “PLUS ONE” slit as a measuring point.

6. Measure the waveform of the oscilloscope when the disc table is rotating.

7. Move the holder (sensor) center so that the flat portion center at the top of the D.SENS (CH1) input waveform and the “H” center of

HHOUT (CH2) coincide.

8. Tighten the fixed screw to fix the disc table, then press the CLEAR button.

9. The disc table rotates in the counterclockwise direction. Measure the waveform and make sure that the flat portion center at the top of the

D.SENS (CH1) input waveform and the “H” center of HHOUT (CH2) coincide.

10. If the adjustment is not successful, press the CLEAR button to rotate the disc table in the clockwise direction, and perform steps 6 to 9.

Note: During the adjustment mode, the rotational direction is switched each time the CLEAR button is pressed.

Pressing the CHECK button enters the loading mode which will be described later. Pressing the CLEAR button rotates the disc table

again.

PLUS ONE

HHOUT (CH2) waveform

D.SENS (CH1) waveform

Flat portion center of

D.SENS (CH1) waveform

Fixed screw

Holder (sensor)

20

MAGNET ASSY ALIGNMENT

1. Check that there is no disc in the unit and then turn ON the power. Open the door, and set a disc in the PLUS ONE slit.

2. Close the door, and while pressing the x button, ENTER button and CLOCK/TIMER SET button simultaneously.

3. Press the CHECK button, and set the loading mode.

4. Press the +

J L button and chuck the disc.

5. Adjust the magnet assembly and magnet holder so that A = B as shown in the figure.

DISC HOLDER A ALIGNMENT

1. Check that there is no disc in the unit and then turn ON the power. Open the door, and set a disc in the PLUS ONE slit.

2. Close the door, and while pressing the x button, ENTER button and CLOCK/TIMER SET button simultaneously.

3. Press the CHECK button, and set the loading mode.

4. Press the + J L button and chuck the disc.

5. Press + J L or l j – button to stop the disc holder A slightly away from the disc.

6. Rotate and adjust the adjusting screw so that the center of the disc and that of the disc holder coincide.

AB

Magnet ASSY

Magnet holder

Magnet ASSY

Screw (For adjustment)

Disc

Disc holder A

Disc holder A

Screw (For adjustment

)

Disc

a = b

a

b

21

SECTION 5

ELECTRICAL ADJUSTMENTS

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1 dB of peak.

3. Mode: Playback

4. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location: Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

0 dB = 0.775 V

DECK SECTION

1. Demagnetize the record/playback head with a head demagne-

tizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit ad-

justment.)

6. The adjustments should be performed for both L-CH and R-

CH.

7. Switches and controls should be set as follows unless otherwise

specified.

• Test Tape

Record/Playback Head Azimuth Adjustment

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

DECK A/B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

set

main board

CN301B

Pin qs (L-CH)

Pin qa (R-CH)

main board

CN301B

Pin 0 (GND)

+

–

level meter

test tape

P-4-A100

(10 kHz, –10 dB)

Screw

position

L-CH

peak

within

1dB

Output

level

L-CH

peak

R-CH

peak

within

1dB

Screw

position

R-CH

peak

MAIN

board

CN301B

set

test tape

P-4-A100

(10 kHz, –10 dB)

pin

qa

oscilloscope

L-CH

R-CH

V

H

waveform of oscilloscope

in phase 45° 90° 135° 180 °

good

wrong

pin 0

pin qs

L

R

22

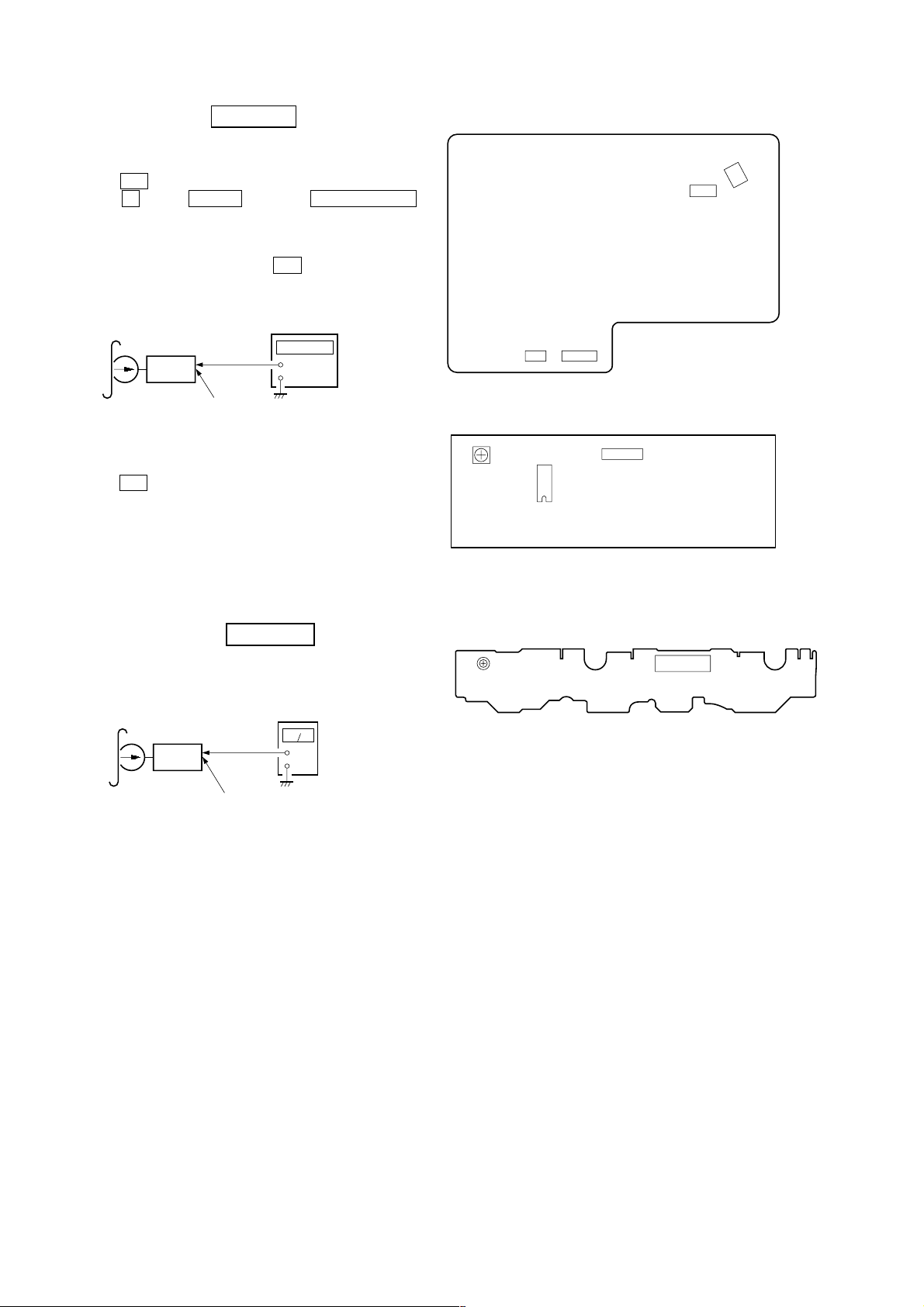

[MAIN BOARD] (Component Side)

[CASSETTE BOARD] (Component Side)

[LEAF SW BOARD] (Component Side)

Tape Speed Adjustment DECK A/B

Note: Start the Tape Speed adjustment as below after setting to the test

mode.

Procedure:

1. Press the @/1 button to turn ON the power.

2. Press the x button, ENTER button and TIMER SELECT

button simultaneously.

(The “VOLUME” on the fluorescent indicator tube will blink

while in the test mode.)

To exit from the test mode, press the @/1 button.

Mode: Playback

1. Insert the WS-48B into the deck.

2. Press the H button on the deck.

3. Adjust RV1002 on the LEAF SW board so that frequency

counter reads 3,000 ± 90 Hz.

Adjustment Location: LEAF SW board

Sample Value of Wow and filter

W, RMS (JIS) within 0.3%

(test tape: WS-48B)

Playback level Adjustment DECK A/B

Procedure:

Mode: Playback

Adjust DECK A/B: VR301 (R-CH) so the level meter reading

becomes the adjustment limits below.

Adjustment Level:

CN301 PB level: 155 to 275 mV (– 14 to – 9 dB) level difference

between the channels: within ± 0.5 dB

Adjustment Location: CASSETTE board

+

–

set

test tape

WS-48B

(3 kHz, 0 dB)

main board

CN301B (Pin qs : L-CH)

(

Pin qa : R-CH

)

frequency counte

r

+

–

set

test tape

P-4-L300

(315 Hz, 0 dB)

Phones jack (HP801)

level meter

CN401

CN301B

IC501

CN402

19

28

115

216

12 2

11 1

VR301

PB

LEVEL

IC301

CN301

1

2

11

12

TAPE SPEED

RV1002

(NORMAL)

CN1001

23

23

When a general remote commander is used:

1. Press the @/1 button to turn ON the power.

2. Open the front cover, and press the CD PLUS ONE button.

3. Set the disc (YEDS-18) into the “PLUS ONE” slit.

4. Close the front cover, and chuck the disc.

5. Press the @/1 button to turn OFF the power.

6. Connect the oscilloscope to TP (TE) of the BD board.

7. Connect TP (ADJ) of the MAIN board and connect TP (GND)

with a lead wire.

8. Press the @/1 button to turn ON the power.

9. Playback the fifth track of the disc.

10. Press the 3 button on the remote commander. (The tracking

servo and the sledding servo are turned OFF.)

11. Check the level B of the oscilloscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 10%

10. Confirm that oscilloscope waveform is clear and check RF sig-

nal level is correct or not.

11. Turn OFF the power, and remove the lead wire connected at

step 7.

Note : A clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

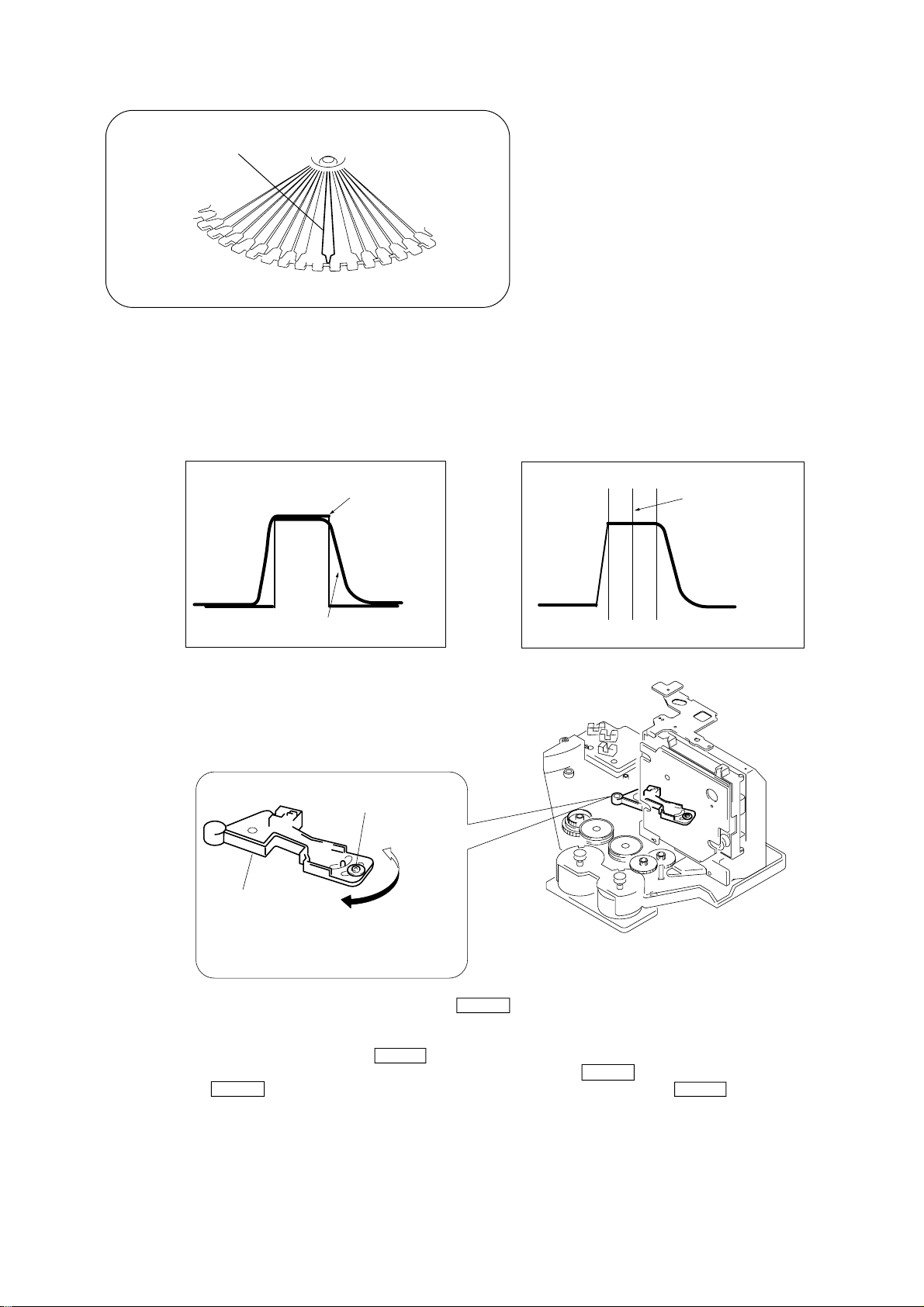

E-F Balance (Traverse) Check

The procedure for this checking method differs for when a general

remote control unit is used and not used.

12. Press the 8 button on the remote control unit. (The tracking

servo and sledding servo are turned ON.) Confirm the C (DC

voltage) is almost equal to the A (DC voltage) is step 11.

13. Turn OFF the power, and remove the lead wire connected at

step 7.

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MW impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S Curve Check

Procedure :

1. Press the @/1 button to turn ON the power .

2. Open the front cover, and press the CD PLUS ONE button.

3. Set the disc (YEDS-18) into the “PLUS ONE” slit.

4. Close the front cover, and chuck the disc.

5. Press the @/1 button to turn OFF the power.

6. Connect the oscilloscope to TP (FE) of the BD board.

7. Connect TP (ADJ) of the MAIN board and connect TP (GND)

with a lead wire.

8. Press the @/1 button to turn ON the power.

9. The first track will be played back automatically. When the

CHECK button is pressed, “S JI” will be displayed on the

fluorescent indicator tube, and focus search will be repeated.

10. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 1.8 ±

0.6 Vp-p.

11. Turn OFF the power, and remove the lead wire connected at

step 7.

Note : • Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

Procedure :

1. Press the @/1 button to turn ON the power.

2. Open the front cover, and press the CD PLUS ONE button.

3. Set the disc (YEDS-18) into the “PLUS ONE” slit.

4. Close the front cover, and chuck the disc.

5. Press the @/1 button to turn OFF the power.

6. Connect the oscilloscope to TP (RF) of the BD board.

7. Connect TP (ADJ) of the MAIN board and connect TP (GND)

with a lead wire.

8. Press the @/1 button to turn ON the power.

9. Playback the fifth track of the disc.

oscilloscope

BD board

TP (FE)

TP (VC)

S-curve waveform

symmetry

within 1.8 ± 0.6Vp-p

A

B

oscilloscope

BD board

TP (RF)

TP (VC)

RF signal waveform

level : 1.8 ± Vp-p

VOLT/DIV : 200mV

TIME/DIV : 500ns

+0.3

–0.2

TP (TE)

TP (VC)

BD board

oscilloscope

Traverse wavefor m

A (DC voltage)

B

Center of the waveform

level : 0.7 ± 0.3 Vp-p

0V

Traverse wavefor m

0V

C (DC

voltage)

Tracking servo

Sled servo

ON

Tracking servo

Sled servo

OFF

When a general remote commander is not used:

1. Solder lead wires to TP (DVDD) and TP (TOFF) on the BD

board severally.

2. Connect the oscilloscope to TP (TE) of the BD board.

3. Press the @/1 button to turn ON the power.

4. Open the front cover, and press the CD PLUS ONE button.

5. Set the disc (YEDS-18) into the “PLUS ONE” slit.

6. Close the front cover, and chuck the disc.

7. Playback the fifth track of the disc.

8. Short-circuit the lead wire connected at step 1. (The tracking

servo is turned OFF)

9. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B × 100 = less than ± 10%

10. Disconnect the lead wire short-circuited at step 8. (The tracking

servo is turned ON.) Confirm the C (DC voltage) is almost

equal to the A (DC voltage) is step 8.

11. Turn OFF the power, and remove the lead wire connected at

step 1.

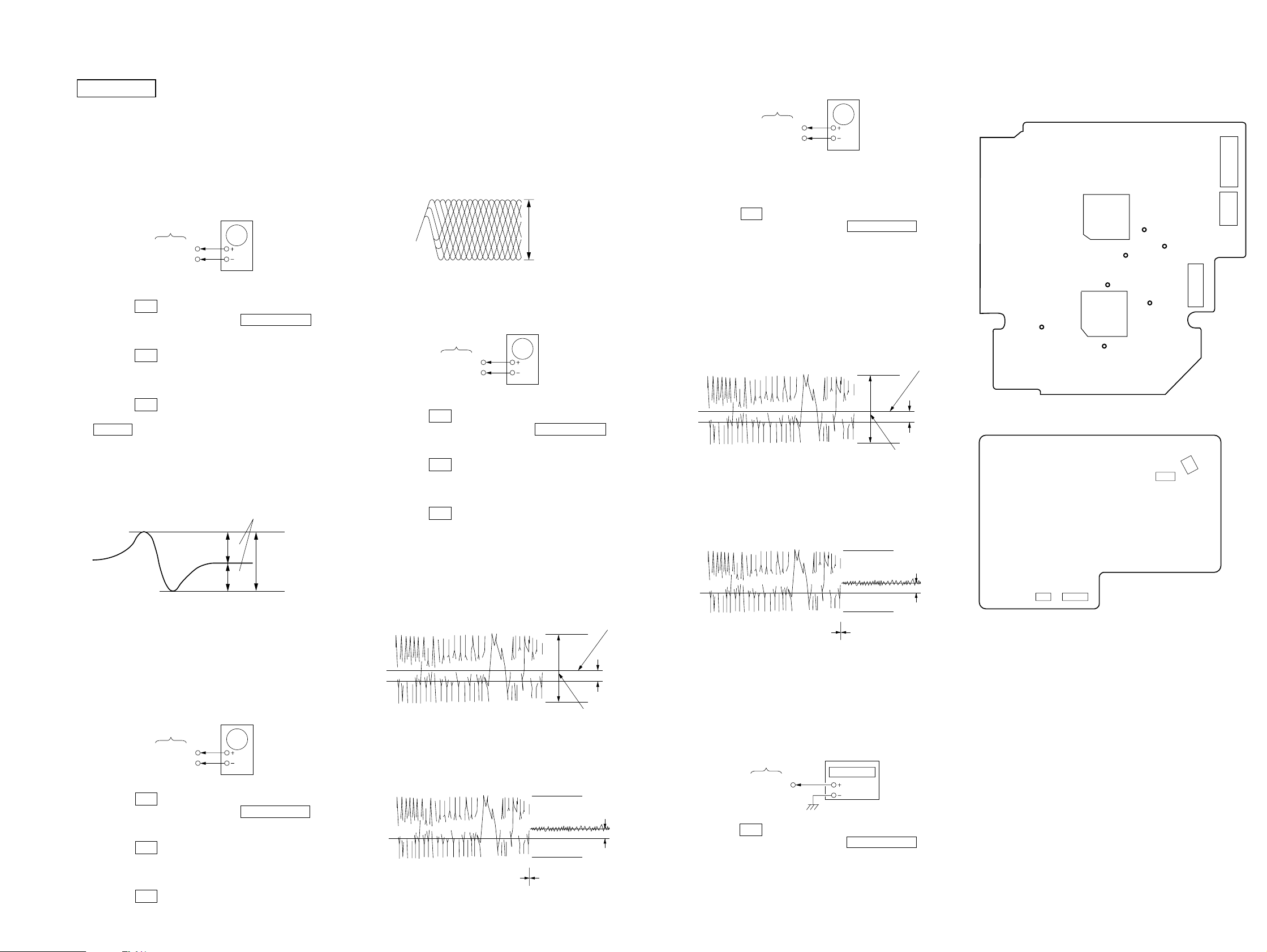

RF PLL Free-run Frequency Check

Procedure :

1. Connect the frequency counter to TP (PLCK) of the BD board.

2. Press the

@/1 button to turn ON the power.

3. Open the front cover, and press the CD PLUS ONE button.

4. Set the disc (YEDS-18) into the “PLUS ONE” slit.

5. Close the front cover, and chuck the disc.

6. Playback the fifth track of the disc.

7. Confirm that reading on frequency counter is 4.3218 MHz ±

30 kHz.

Adjustment Location :

[ BD BOARD ] — CONDUCTOR SIDE —

[ MAIN BOARD ] — COMPONENT SIDE —

oscilloscope

BD board

TP (TE)

TP (VC)

Traverse wavefor m

A (DC voltage)

B

Center of the waveform

level : 0.7 ± 0.3 Vp-p

0V

Traverse waveform

0V

C (DC

Tracking servo

OFF

Tracking servo

ON

voltage)

frequency counter

BD board

TP (PLCK)

IC102

IC101

TP

(VC)

TP

(TE)

TP

(FE)

TP

(RF)

TP

(PLCK)

CN101

CN102

CN103

TP

(DVDD)

TP

(TOFF)

CN401

CN301B

IC501

CN402

19

28

115

216

12 2

11 1

HCD-M100/M300AV

24

24

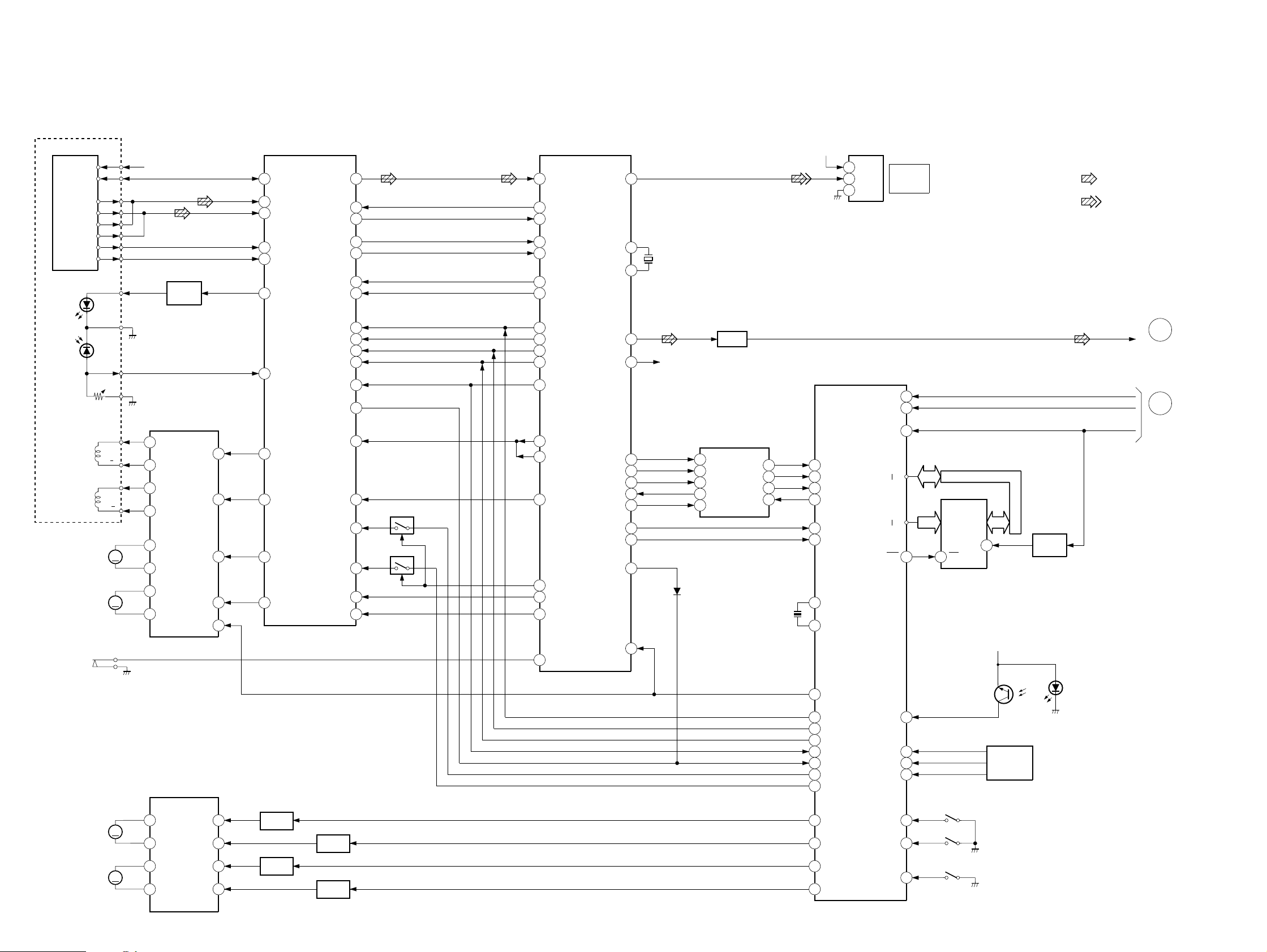

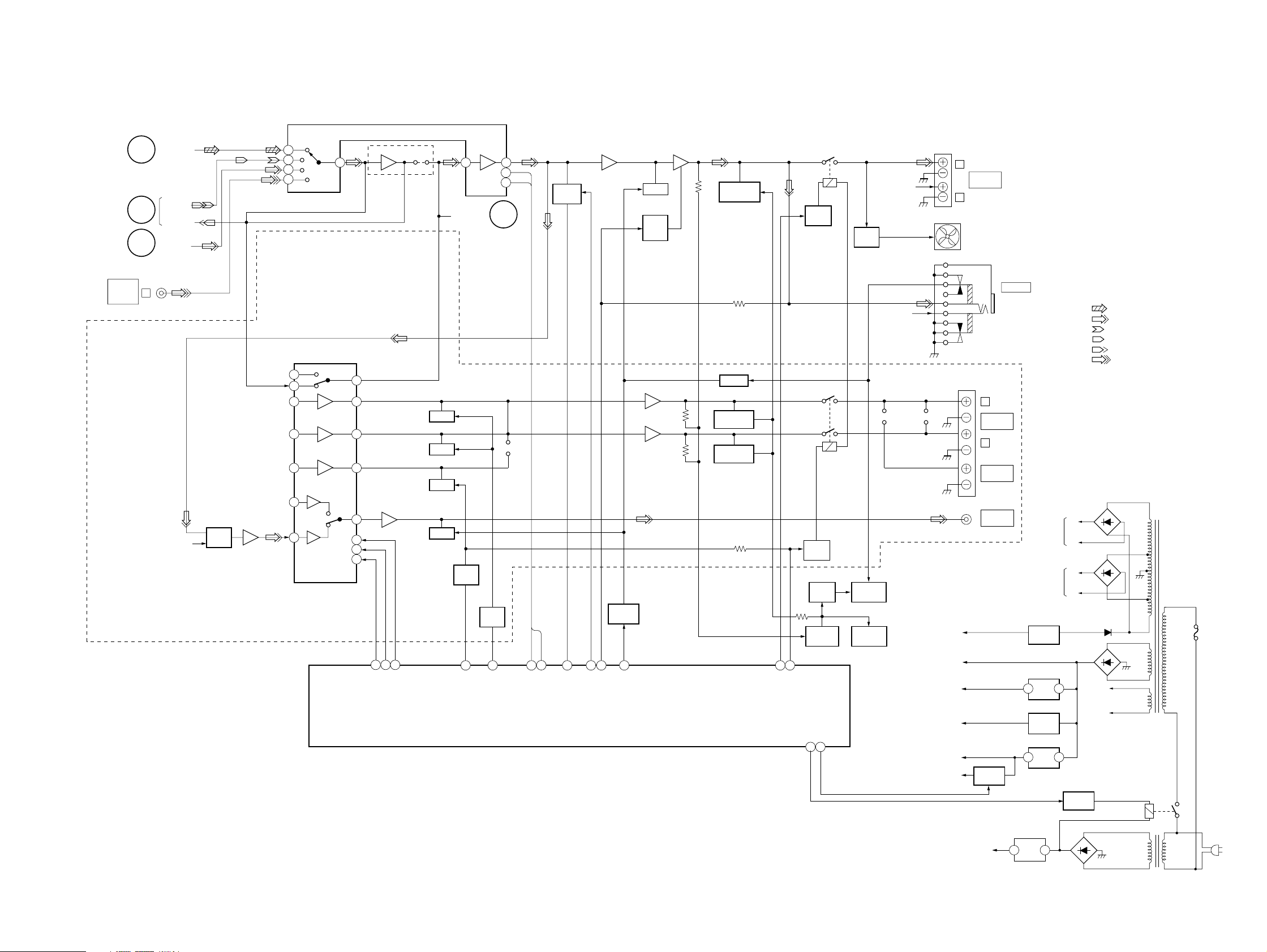

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – CD SECTION –

OPTICAL PICK-UP

BLOCK

(KSM-213BFN/C2NP)

LD

DRIVER

Q103

A+5V

LD

GND

FOCUS

COIL

F+

F

T+

T

TRACKING

COIL

IC103

FCS/TRK COIL

SL/SP MOTOR

DRIVER

SLED/SPINDLE SERVO

RF AMP

IC101

18

22

17

19

20

VR

PD

8

7

6

5

15

10

V02

V IN 4

V IN 3

3

V IN 1

2

MUTE

V06

V05

V07

V08

V04

V03

V02

V01

M

M

MOTOR

M102

SLED

MOTOR

M101

SPINDOL

S101

LIMIT

VDD

D IN

GND

A+5V

CD

DIGITAL

OUT

IC402

09

:CD

:DIGITAL OUT

• SIGNAL PATH

41

RF SM

VR

58

VCC

VC

A

B

C

D

E

F

DETECTOR

FOCUS/TRACKING/

FIN 1

2

FIN 2

1

E

3

F

4

LDD

62

LDS

63

FD

16

TO

15

SLD

29

SPD

27

52DATA

50

CLK

51

CL

53

CE

34

TGL

54

DRF

39

CV-

40CV+

Q101

30

SL-

Q102

31

SL+

35TOFF

44SLI

49DEF

36

TES

37

HFL

33JP+

32JP-

DIGITAL SIGNAL

PROCESSOR

IC102

EFMI

10

EFMO

9

DEFI

1

TES

16

HFL

15

JP+

19

JP-

20

COIN

56

4.2M

61

CQCK

57

RWC

54

TGL

18

SLOF

V/P

14

CONT2

25

TOFF

17

CONT3

26

CLV+

12

CLV-

13

CONT4

27

31

D OUT

49

PW

CD TEXT

DECODER

IC104

SBSO

2

WFCK

4

MCK

5

EXCK

1

SCOR

3

12

SRDT

11

SCLK

13DQSY

6XMODE

50

SFSY

60

16M

51

SBCK

47

SBSY

53

WRQ

55

SQOUT

3

PDO

45

XI

44

XO

X101

16.9344MHz

37

L CH

40

R CH

R CH

58

RESET

CD CHANGER

CONTROL

IC401

80

IIC DATA

78

IIC CLK

66

65

64

67

55

49

SRDT

SCLK

DQSY

XMODE

WRQ

SQOUT

COIN

50

BD RESET

2

COCK

48

RWC

58

TGL

57

DRF

54

SL+

47

SL-

59

XTAL

32

EXTAL

31

X401

10MHz

D151

IC461

MOTOR DRIVER

8

9

11

10

OUT1+

OUT1-

OUT2+

OUT2-

M

M

MOTOR

M601

LOADING

MOTOR

M602

TABLE

3

2

16

17

R IN 1

F IN 1

R IN 2

F IN 2

LD OUT

76

LD IN

77

TBL L

75

TBL R

74

30

RESET

42D SENS

Q471

815

8

D0

D7

A0

A14

SRAM

IC411

WE

27

20

CE

29

WE

RESET

SW

Q411

+5V

Q51 D51

DISC

SENSOR

DISC

SENSOR

62

TSENS 1

61

TSENS 2

70

UP SW

71

DOWN SW

69

DOOR SW

63

TSENS 3

TABL

SENSOR

IC51-53

S51

(UP)

S52

(DOWN)

S413

(DOOR)

RESET

IIC DATA

IIC CLK

CD L

MAIN

SECTION

(Page 26)

B

AMP

SECTION

(Page 25)

A

38

1

2

3

BUFFER

MOTOR

CONTROL

Q464,468

MOTOR

CONTROL

Q461,465

MOTOR

CONTROL

Q463,467

MOTOR

CONTROL

Q462,466

HCD-M100/M300AV

25

25

– MAIN SECTION –

• R-CH is omitted

• SIGNAL PATH

: CD

: AUDIO

: PB (DECK A)

: PB (DECK B)

: REC

: MD/VIDEO

21

22

MUTE

SWITCH

MUTE

Q293

MUTE

Q292

MUTE

Q291

MUTE

Q131

Q294,295

72

74

77

78

76

9

14

17

22

23

24

3

79

MUTE

SWITCH

OVER LOAD

DET.

Q263,

264

MUTE

SWITCH

67

70 71 1

6566

Q171,172

MUTE

CONTROL

POWER

AMP

MUTE

MUTE

SWITCH

MUTE

SWITCH

OVER LOAD

DET.

OVER LOAD

DET.

CD L

PB L

REC IN L

TUNER L

J01

MD/VIDEO

IN

(AUDIO)

L

L

R

REAR

SPEAKER

CENTER

SPEAKER

SUPER

WOOFER

79

63 62 75 74 61 68

27 28

LATCH

DRIVER

LATCH

DRIVER

LATCH

DRIVER

PROTECT

DC AMP

PROTECT

SWITCH

OVER HEAT

DET.

3 1

3 1

+7V

REG

+9V

REG

+5V

REG

T992

D951

D961

AC IN

3 1

+5.6V

REG

-30V

REG.

B+

SWITCH

RELAY

DRIVER

RY771

Q841

Q842

1

80

MIX

AMP

Q161,162

R CH

57

16

15 10

4

5

6

7

8 9 27

Q141,143 Q145

31 1

12

6

Q741-743

Q197

IC831(1/3)

IC831(2/3)

Q771,772

Q703 Q721

Q711,712Q701,702

J801

L

R

FRONT

SPEAKER

JK801

(FAN)

M751

HP801

PHONES

J103

IC101

SOUND PROCESSOR

57

IC121

JP101

M100

MODEL

SCL

SDA

IC141 IC801

Q801

Q732,733

Q751,752

RY731

+VE

-VE

+VE

-VE

-VP

VF2

VF1

M+13V

M+7V

A+9V

P+5V

+5.6V

P+5V CD

FOR

FRONT

AMP

FOR

REAR

AMP

Q931 D836

IC922

Q901-904

IC921

Q921,922

PWR SAVE

CD POWER

PL RELAY

F RELAY

LINE MUTE

PL CE

PL CLK

PL DOUT

MUTE CENTER

MUTE REAR

TDA DATA

TDA CLK

DBFB H/N

DBFB ON/OFF

STK MUTE

JW840

JW838

JW832

IC931

D831,832

D931,932

RY991

D901-904

R CH

R CH

IC501(2/2)

MASTER

CONTROL

IC201

PRO LOGIC PROCESSOR

MAIN

SECTION

D

(Page 26)

CD

SECTION

A

(Page 24)

MAIN

SECTION

E

(Page 26)

MAIN

SECTION

C

(Page 26)

IC251

3

DATA

SCK

REQ

1

IC251

M300AV MODEL

09

SPEANA

T991

POWER

TRANSFORMER

F992

Q991

Loading...

Loading...