Page 1

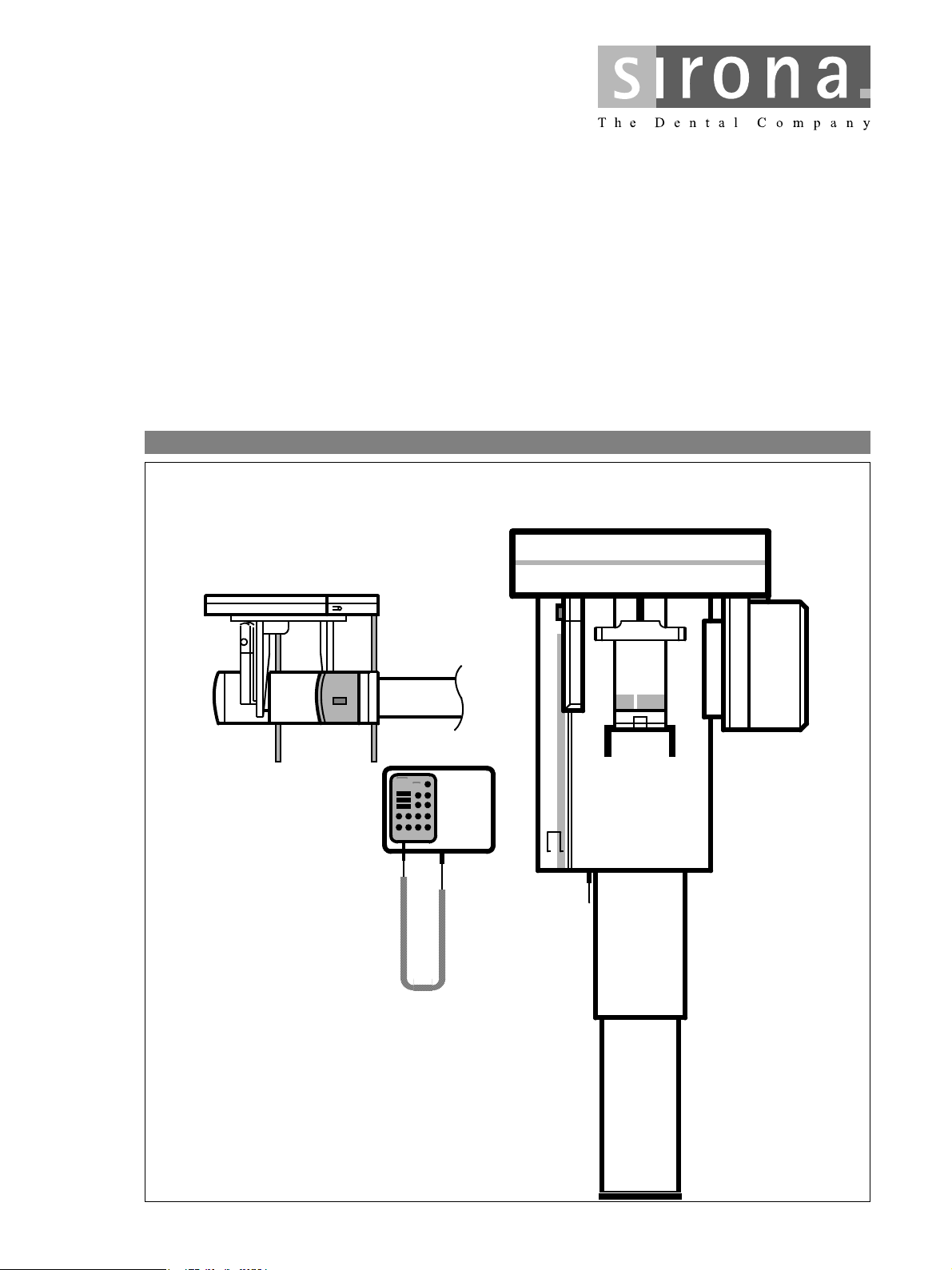

loqelmelp=RLmäìëLmäìë`ÉéÜ

loqelmelp=mäìëapLmäìëap`ÉéÜ

pЙкобЕЙ=j~ем~д

sЙклбзе=RKO

Page 2

The following are also required:

• Spare parts list

Order no. 41 63 841

• Circuit diagrams

ORTHOPHOS Plus DS/Plus DS Ceph ORTHOPHOS 5/Plus/Plus Ceph

Order no. 41 62 751 Order no. 54 71 839

• Tools

– Hexagonal-head screwdrivers, angled, sizes 1, 5, 2 – 10

– Allen key, size 4, length 200 mm, for socket head screws

– Set of hexagonal wrenches, sizes 4 – 14 with 1/4” ratschet, extension and

4 socket head (Allen) inserts 3 – 6 mm

– Spirit level

– Open-end wrenches, sizes 5.5, 7, 8, 10, 13, 30, and 19, 22 for Ceph

– Torx screwdrivers, sizes 10, 20, 25

– Phillips)-head srewdriver, size 1

– Insulated slot-head screwdrivers, sizes 0, 1, 2, 3, 4, 6

– Pliers for retaining ring

• Auxillary means

– Digital multimeter, accuracy class 1

– Soldering iron for cable repairs

– Diagonal cutter

– Cable ties

– Teflon insulating tape

Page 3

Important Notes 1

List of Messages

Troubleshooting

Checks and Adjustments

2

3

4

Service Routines

Repairs

Maintenance

Technical modifications

5

6

7

8

Page 4

Page 5

Contents

1 Important Notes ................................................................................................................... 1 - 1

1.1 Important Notes ......................................................................................................... 1 - 3

1.2 List of software versions ........................................................................................... 1 - 5

1.3 Major Assemblies and Components .......................................................................... 1 - 6

1.4 Removing Panels ...................................................................................................... 1 - 9

1.5 Photographs of PC Boards ...................................................................................... 1 - 11

2 List of Messages................................................................................................................... 2 - 1

2.1 List of Help Messages .............................................................................................. 2 - 3

2.2 List of Error Messages ............................................................................................. 2 - 4

2.3 List of Service Routines ............................................................................................ 2 - 9

2.4 List of Error Messages for SIDEXIS ....................................................................... 2 - 10

3 Troubleshooting.................................................................................................................... 3 - 1

3.1 Unit cannot be switched on ....................................................................................... 3 - 7

3.2 Demonstration mode cannot be turned ON/OFF ...................................................... 3 - 9

3.3 Correcting error of help message H3 01. ............................................................... 3 - 11

3.4 Correcting errors of help messages H3 05 and H3 06. ........................................... 3 - 13

3.5 Correcting error of help message H3 07. ................................................................ 3 - 15

3.6 Correcting error of help message H3 12. ................................................................ 3 - 17

3.7 Correcting error of help message H3 16. ................................................................ 3 - 19

3.8 Correcting error of messages E1 01, E1 02, E2 03: Signal paths to

control board DX1 are interrupted. .......................................................................... 3 - 21

3.9 Correcting error of message E2 01: X-ray tube assembly overheated. .................. 3 - 23

3.10 Correcting error of message E2 04: Zero power range has been re-initialized. ...... 3 - 25

3.11 Correcting error of message E2 10: Max. radiation time of the

program is exceeded. .............................................................................................. 3 - 27

3.12 Correcting error of message E2 11: Anode voltage too high. ................................. 3 - 29

3.13 Correcting error of message E2 12: Anode current too high. .................................. 3 - 31

3.14 Correcting error of message E2 13: Filament voltage too high. .............................. 3 - 33

3.15 Correcting error of message E2 14: Short-circuit in bridge .................................... 3 - 35

3.16 Correcting error of message E2 15: VH

3.17 Correcting error of message E2 16: kV

3.18 Correcting error of message E2 20: Interrupted exposure lead in

Multitimer cable. ...................................................................................................... 3 - 41

3.19 Correcting error of message E2 40: VH setpoint out of tolerance. .......................... 3 - 45

3.20 Correcting error of message E2 45: mA setpoint out of tolerance. ......................... 3 - 47

3.21 Correcting error of messages E3 01, E3 02: Actuator M2 has not

left/reached the tripping position. ............................................................................ 3 - 49

3.22 Correcting error of messages E3 03, E3 04: Actuator M3 has

not left/reached the tripping position. ...................................................................... 3 - 51

continuously present. .......................... 3 - 37

max

ACTUAL

– Cable is interrupted. ................... 3 - 39

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

V

Page 6

Contents

3.23 Correcting error of messages E3 05, E3 06: Cassette carriage has not

left/reached the reference point. ............................................................................... 3 - 53

3.24 Correcting error of message E3 09: Pulses for height adjustment are not

within allowed time. .................................................................................................. 3 - 55

3.25 Correcting error of messages E3 10, E3 11: Count for height adjustment

too high/too low for reference setting. ...................................................................... 3 - 59

3.26 Correcting error of message E3 12: Key for height adjustment pressed

during unit self-adjustment. ...................................................................................... 3 - 61

3.27 Correcting error of messages E3 27, E3 28: Zero point of forehead

support was not exited/reached. .............................................................................. 3 - 63

3.28 Correcting error of messages E3 32, E3 33: Start position for rotation was

not exited/reached. ................................................................................................... 3 - 65

3.29 Correcting error of message E3 36: Cassette holder was swivelled from the

Pan position during Pan exposure. ........................................................................... 3 - 69

3.30 Correcting error of message E3 39: Light barrier for Ceph position rotation

indicates invalid status ............................................................................................. 3 - 73

3.31 Correcting error of message E3 46: Position of cassette holder cannot

be determined. ......................................................................................................... 3 - 75

3.32 Correcting error of message E3 51: Faulty signals output by the

film drive control. ...................................................................................................... 3 - 77

3.33 Correcting error of message E4 01: Exposure aborted by SIDEXIS (with XOP) ..... 3 - 79

3.34 Correcting error of message E4 01: Exposure aborted by SIDEXIS (with XAB) ...... 3 - 81

3.35 Correcting error of message E4 02: Fault indicated by control unit of

Ceph motor. ............................................................................................................. 3 - 83

3.36 Correcting error of message E4 03: Light barrier for Ceph control not

emitting any pulses. ................................................................................................. 3 - 87

3.37 Correcting error of message E4 04: Motor M8 for secondary

diaphragm not moving. ............................................................................................. 3 - 89

3.38 Correcting error of message E4 06: Fault at one of the supply voltages

(with XOP) ................................................................................................................ 3 - 93

3.39 Correcting error of message E4 06: Fault at one of the supply voltages

(with XAB) ................................................................................................................ 3 - 95

3.40 Correcting error of message E4 08: Aborted by SIDEXIS during radiation

(with XOP) ................................................................................................................ 3 - 97

3.41 Correcting error of message E4 08: Aborted by SIDEXIS during radiation

(with XAB) .............................................................................................................. 3 - 101

3.42 Correcting error of message E4 09: Faulty signal from limit switches of

Ceph drive. ............................................................................................................. 3 - 105

3.43 Correcting error of message E4 11: Image receptor not ready for exposure

(with XOP) .............................................................................................................. 3 - 107

3.44 Correcting error of message E4 11: Image receptor not ready for exposure

(with XAB) .............................................................................................................. 3 - 111

3.45 Correcting error of message E4 14: Ceph holder not moving. ............................... 3 - 115

3.46 Correcting error of message E4 15: Ceph holder has not moved to the

upper/lower limit switch. ......................................................................................... 3 - 119

VI D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 7

Contents

3.47 Correcting error of message E4 16: Active signal present when switching ON

(with XOP) ............................................................................................................. 3 - 121

3.48 Correcting error of message E4 16: Active signal present when switching ON

(with XAB) ............................................................................................................. 3 - 123

4 Checks and Adjustments...................................................................................................... 4 - 1

4.1 Phantom radiograph — Adjusting actuators M2/M3 .................................................. 4 - 5

4.2 Checking and adjusting the X-ray beam for panorama radiograph ......................... 4 - 13

4.3 Checking and adjusting the X-ray beam for cephalometry..................................................

Cephalometer model No 33 14 320 ....... 4 - 19

4.4 Checking and adjusting the X-ray beam for cephalometry..................................................

Cephalometer model No 15 38 177 ....... 4 - 21

4.5 Checking the symmetry on the Cephalometer

Cephalometer model No 33 14 320 ....... 4 - 23

4.6 Checking the symmetry on the Cephalometer

Cephalometer model No 15 38 177 ....... 4 - 25

4.7 Checking and adjusting the ear olives Cephalometer model No 33 14 320 ....... 4 - 27

4.8 Checking and adjusting the ear olives Cephalometer model No 15 38 177 ....... 4 - 29

4.9 X-ray tube assembly: action to be taken during/after replacement ......................... 4 - 31

4.10 Radiographic density of spinal column not correct .................................................. 4 - 33

4.11 Checking exposure times ........................................................................................ 4 - 35

4.12 Checking the tube current ....................................................................................... 4 - 37

4.13 Adjusting board DX1 ............................................................................................... 4 - 39

4.14 Adjusting the correction switch for height adjustment ............................................. 4 - 41

4.15 Adjusting board DX8 (ABV adjustment) .................................................................. 4 - 43

4.16 Change anomaly basic setting ................................................................................ 4 - 45

5 Service Routines .................................................................................................................. 5 - 1

5.1 Selecting Service routines ......................................................................................... 5 - 7

5.2 Setting exposure readiness on the PC ...................................................................... 5 - 9

5.3 Service routine S.01 Radiation without rotation ...................................................... 5 - 11

5.4 Service routine S.02 Radiation without rotation for Ceph ........................................ 5 - 13

5.5 Service routine S.03 Setpoints: kV, mA, preheating ................................................ 5 - 15

5.6 Service routine S.04 Actual values: kV, mA, preheating .......................................... 5 - 19

5.7 Service routine S.05 Heating adjustment ................................................................ 5 - 23

5.8 Service routine S.06 Radiation counter (decimal display) ....................................... 5 - 27

5.9 Service routine S.07 Erasing the error memory ...................................................... 5 - 29

5.10 Service routine S.09 Erasing EEPROM DX1 .......................................................... 5 - 31

5.11 Service routine S.11 Setting the kV increase correction value for

Panorama radiographs ............................................................................................ 5 - 33

5.12 Service routine S.13 Hardware service ................................................................... 5 - 35

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

VII

Page 8

Contents

5.13 Service routine S.14 Rotation functions ................................................................... 5 - 37

5.14 Service routine S.15 Checking the actuators ........................................................... 5 - 41

5.15 Service routine S.16 Film holder service .................................................................. 5 - 45

5.16 Service routine S.17 Unit identification .................................................................... 5 - 49

5.17 Service routine S.18 Checking the height adjustment .............................................. 5 - 51

5.18 Service routine S.19 Checking the forehead support ............................................... 5 - 59

5.19 Service routine S.20 Checking the forehead support width ..................................... 5 - 61

5.20 Service routine S.21 Programming the diaphragm numbers (without TSA) ............. 5 - 63

5.21 Service routine S.21 Programming the TSA diaphragm numbers ........................... 5 - 65

5.22 Service routine S.24 Software-Update of EEPROMS J115 ..................................... 5 - 67

5.23 Service routine S.25 Adjusting the film/screen combination or

the kVmA step series ............................................................................................... 5 - 69

5.24 Service routine S.26 Checking and adjusting AES

(Automatic Exposure Preselection) .......................................................................... 5 - 71

5.25 Service routine S.32 Image receptor service: Panorama /

Service routine S.33 Image receptor service: Ceph ................................................. 5 - 77

5.26 Service routine S.34 Ceph arm service Cephalometer model No 33 14 320 ...... 5 - 83

5.27 Service routine S.35 PC service .............................................................................. 5 - 89

5.28 Service routine S.36 Acceptance test dose measurement ...................................... 5 - 91

5.29 Service routine S.37 XAB OP service ...................................................................... 5 - 93

6 Repairs ..................................................................................................................................6 - 1

6.1 Replacing the gas-operated spring ............................................................................ 6 - 5

6.2 Replacing the rotation motor M1 ................................................................................ 6 - 9

6.3 Replacing the actuators M2/M3 ............................................................................... 6 - 13

6.4 Replacing the height adjustment motor M5 .............................................................. 6 - 15

6.5 Replacing the forehead support and/or the forehead support motor M6 ................. 6 - 17

6.6 Replacing the catch for the bite block/support segment .......................................... 6 - 21

6.7 Replacing the halogen lamp of the light-beam localizer ........................................... 6 - 23

6.8 Replacing the lamp of the Cephalometer Cephalometer model no. 15 38 177 ...... 6 - 27

6.9 Replacing/adjusting the sensor potentiometer of the Cephalometer

Cephalometer model no. 15 38 177 ...... 6 - 29

6.10 Replacing the cassette holder for panoramic radiographs ....................................... 6 - 33

6.11 Replacing the rope and/or the cassette drive motor M4 .......................................... 6 - 35

6.12 Replacing motor M7 and potentiometer R2 ............................................................. 6 - 39

6.13 Replacing motor M8 and potentiometer R3 ............................................................. 6 - 41

6.14 Replacing socket contact for image receptor ........................................................... 6 - 43

6.15 Replacing rotary knob and sensor ejector ................................................................ 6 - 45

6.16 Replacing ring cable L10 .......................................................................................... 6 - 47

VIII D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 9

Contents

7 Maintenance ........................................................................................................................7 - 1

7.1 Checking the height adjustment ............................................................................... 7 - 7

7.2 Checking the forehead support .............................................................................. 7 - 11

7.3 Checking the diaphragm wheel .............................................................................. 7 - 13

7.4 Checking the cassette holder ................................................................................. 7 - 15

7.5 Checking the image receptor ................................................................................. 7 - 17

7.6 Checking the bite block/contact segment/chin rest in the bite block holder ........... 7 - 19

7.7 Checking the light localizer ..................................................................................... 7 - 21

7.8 Checking the conventional cephalometer ............................................................... 7 - 23

7.9 Checking the digital cephalometer ......................................................................... 7 - 25

7.10 Checking X-ray exposures ..................................................................................... 7 - 27

7.11 Checking the actual kV/mA values and the preheating .......................................... 7 - 29

7.12 AES/phantom/needle phantom exposure with ORTHOPHOS Plus/Plus Ceph ...... 7 - 31

7.13 Phantom/needle phantom exposure with ORTHOPHOS Plus DS/Plus DS Ceph . 7 - 35

7.14 Checking cables for damage .................................................................................. 7 - 37

7.15 Checking the grounding straps ............................................................................... 7 - 39

7.16 Checking the shielding of the cables ...................................................................... 7 - 41

7.17 Checking light barrier housings V2 to V8/ring cable ............................................... 7 - 43

7.18 Checking the toothed belt, deflection roller and toothed roller on

height adjustment motor M5 ................................................................................... 7 - 45

7.19 Checking the flat belt on rotation motor M1 ............................................................ 7 - 49

7.20 Checking the protective ground wire and the unit’s leakage current ...................... 7 - 51

8 Technical modifications .......................................................................................................8 - 1

8.1 History - Service Manual D3297 ............................................................................... 8 - 3

8.2 Additional Documentation: ....................................................................................... 8 - 4

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

IX

Page 10

Contents

X D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 11

1 Important Notes

Page 12

Contents Sirona Dental Systems GmbH

Important Notes

Contents

1.1 Important Notes ................................................................................................................... 1 - 3

1.2 List of software versions ..................................................................................................... 1 - 5

1.3 Major Assemblies and Components .................................................................................... 1 - 6

1.4 Removing Panels ................................................................................................................ 1 - 9

1.5 Photographs of PC Boards ................................................................................................ 1 - 11

1 - 2 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 13

1.1 Important Notes

1.1 Important Notes

• The ORTHOPHOS® Plus DS / Plus DS Ceph / 5 / Plus / Plus Ceph

operates with the following nominal line voltages: 208 V, 230 V, 50/60 Hz.

The permissible line voltage fluctuations

The internal line resistance

• Remote control

The unit can be equipped with a remote control inside the treatment room or outside an X-ray room.

For the tests the Multitimer can/must be removed from the remote control module and is to be connected directly to the

unit (for remote control with the Multitimer without coiled cable, the coiled cable has to be connected for the tests according to the installation instructions).

Remember that the fault can then be in the deactivated cable.

• Warm-up time, self-adjustment, cool-down time,

After power-up the unit always requires a warm-up time of one minute.

During this time, the self-adjustment routine for the mechanical elements and electronics of the unit is executed. Pressing

a key during the self-adjustment causes an error indication at the Multitimer and on the lateral operating panel. The cooldown time between two consecutive exposures is ensured by the automatic exposure blockage determined by the pulse/

pause ratio. The count down of the waiting time required is indicated on the Multitimer. The turn-off time of board XABOP must be at least 60s; otherwise the unit will not function correctly (no exposure readiness).

• For demonstration units

Now, no X-ray radiation is generated. Upon completion of the self-adjustment S.88 is indicated on the Multitimer → the

forehead support has reached position 10.00.

must not exceed 0.8 Ω.

set the test switch S1/S88 on board DX31 to position 2. LED V3 must not light up. Pull plug X2.

are 230 V + 6%, –10%, and 208 V ± 10%.

turn-off time

1.1

• The overall software version

Multitimer D4 as well as the version number of the memory card. Refer to the list of software versions. When switching

the unit ON the versions are indicated on the Multitimer for about three seconds after the segment test.

• Interference of radio telephones with electromedical equipment

The use of mobile telephones in the area of the medical practice or clinic is prohibited in order to ensure the

operational reliability and safety of electromedical equipment.

• Disposal

The X-ray tube assembly contains a tube which can implode, a small amount of beryllium, a lead lining and some mineral

oil.

• Removal of the unit

Prior to the disassembly and removal of the unit the transport safety screw must be screwed into the vertical column

(see Installation Instructions).

• Error messages

Error messages are indicated on the Multitimer and on the lateral control panel.

• Help messages H if radiographic readiness is not reached

Help messages are displayed on the Multitimer and on the lateral control panel.

, WARNING, risk of injury

of the unit is determined by the software versions of the EPROMs on board DX1 and of the

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

1 - 3

Page 14

1.1 Important Notes

• If you have to remove panels from the unit.

Refer to section "Removing panels".

With the panels removed, remember that incident direct sunshine or bright room light can cause unit malfunctions by ac-

tivating the light barriers.

Therefore: Avoid direct sunshine and bright lighting above the unit

NOTE: For ORTHOPHOS Plus DS TSA, take TSA image receptor out of side holder before removing the panels.

Remember when reattaching the panels:

Secure sheet metal covers with screws.

IMPORTANT: For reasons of EMC it is essential

Reinstall all panels.

• Do not move the secondary diaphragm by hand or subject it to any stress when

removing from the package.

• Measurements

Before connecting a measuring instrument, always switch the unit OFF.

Select the required current/voltage type and set the measuring range according to the expected value.

Carry out continuity tests only with the unit switched off.

If the release of several exposures with radiation is required for checking the measuring results, you must observe the

specified cool-down intervals. This is ensured by the automatic exposure blockage (see Operating Instructions).

The pulse/interval ratio is 1:10, which means a 10 second pause has to follow after 1 second of radiation. This pulse/interval ratio is automatically guaranteed by the automatic exposure blockage.

However, preferable for the X-ray tube is a pulse/pause ratio of 1:20.

to insert all screws.

!

Adhere to the radiation protection guidelines before generating radiation.

Test runs initiated by pressing the T key on the Multitimer followed by actuation of the exposure release button are executed without radiation, i.e. the kV/mA displays remain blank. l

• Replacing parts

Always turn the unit OFF before replacing any parts.

When parts located close to the line transformer are to be replaced, switch off the power at the distributor box for the onsite electrical system for safety reasons

To protect electrostatic sensitive devices (ESD) on boards, always

wear the wrist band found inside the unit.

The unit must be checked and newly adjusted following the replacement of the DX1 electronics,

the X-ray tube assembly or a diaphragm.

The article numbers for ordering spare parts can be found in the spare parts list, order no. 41 63 841.

The figures in the spare parts list offer valuable assistance when replacing spare parts.

.

1 - 4 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 15

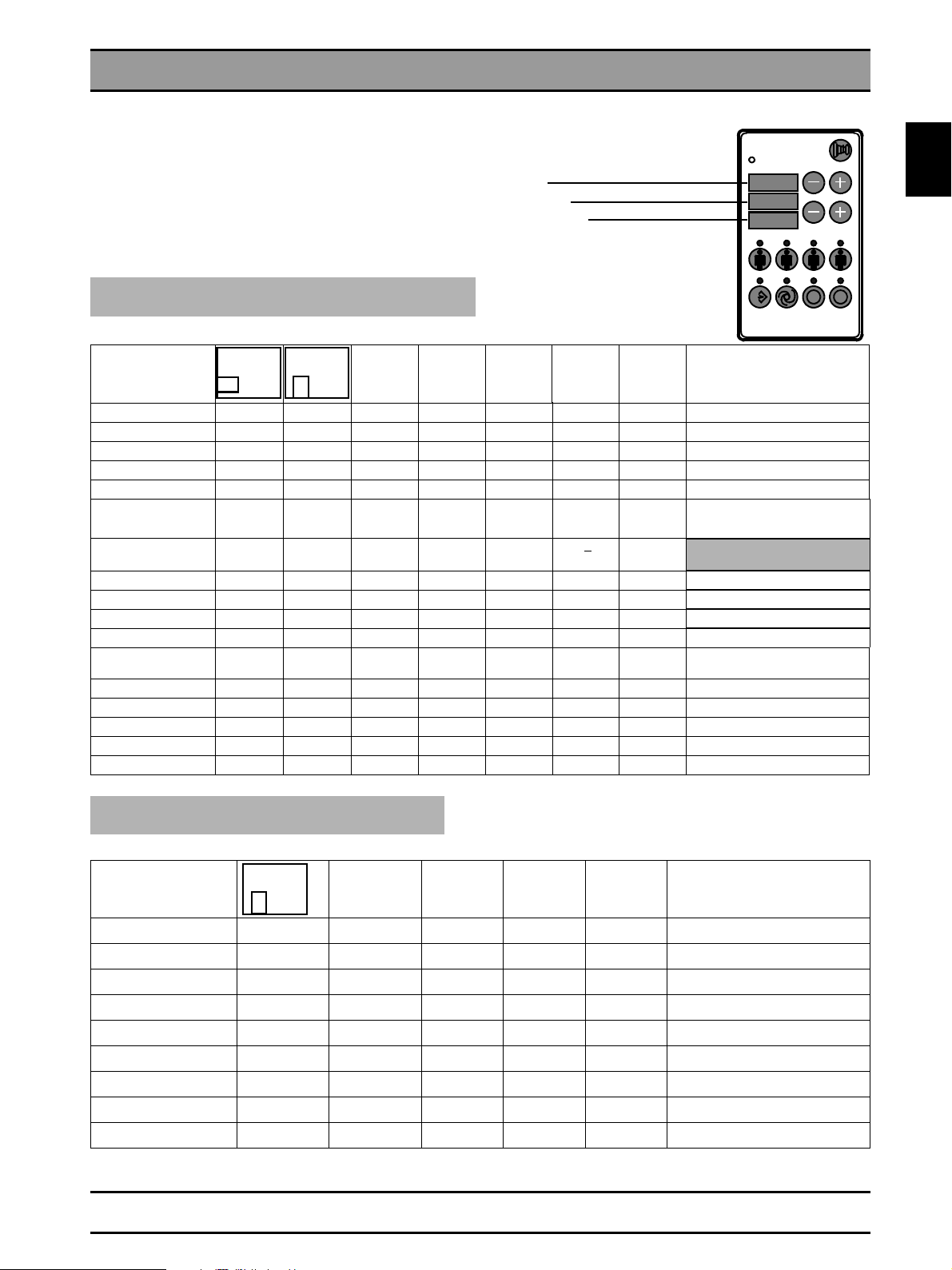

1.2 List of software versions

1.2 List of software versions

IMPORTANT:

No other combinations of software are allowed

since these could result in undefined faults.

ORTHOPHOS Plus DS / Plus DS Ceph

Multitimer

Versions no. memory card

Software Multitimer D4

Software board DX1

0 2 3

kV

mA

X-RAY

0 6

I 4

T

Unit identification e.g. 10

Overall software

Version 02.1 013 06 18 2.2 1.0

Version 02.2 013 06 20 2.2

Version 02.3 10.96 013 06 21 2.2 2.0

Version 02.4 12.96 013 06 22 2.2

Version 02.4 02.97 013 06 22 2.21 2.1

Version 02.5 06.97 014 06 23 2.21

Version 02.6 01.98 014 06 25 3.2 < to

Version 02.7 06.98 20 06 26 3.2/4.2

Version 02.8 01.99 20 06 27 3.2/4.2 Reduced kV/mA steps

Version 03.10 08.99 20 06 30.10 4.2

Version 04.10 09.99 20 06 31.10 4.2/5.2 kV/mA steps adjustable

Version 05.10 11.00 20 06 35.10 5.28/5.3/

Version 06.10 04.02 21 06 36.10 5.52/5.54 Correcting error E4 04/E3 48

Version 01.12 07.01 20 06 10.12 5.5 Supports TSA digital

Version 02.12 02.02 20 06 10.12 5.52 USB-Box

Version 03.12 05.02 21 06 11.12 5.52/5.54 Correcting error E4 04/E3 48

Version 03.12 08.02 21 06 36.10 11.12 5.55

DX1

EEPROM

M M

J115

DX1

EEPROM

J115

D4

EEPROM

J4

Memory

Card

Memory

Card

TSA

SIDEXIS Service-

disk

5.55

5.5

3.2 General update has been sent

Pulse/interval blockage 1:10.

LEDs of ORTHOPHOS symbol are

active during service routines.

to all customers.

Supports XAB-OP

Remarks

1.2

R

ORTHOPHOS 5 / Plus / Plus Ceph

Unit identification e.g. 50

Overall software DX1

Ver si on

01.50

Ver si on

01.51

Ver si on

01.52

Ver si on

02.50

Ver si on

02.51

Ver si on

02.52

03.52

Ver si on

Ver si on

04.50

Ver si on

05.52

EEPROM

M

J115

020 06 011.50

020 06 010.51

020 06 010.52

020 06 012.50

020 06 011.51

020 06 012.52

020 06 013.52

021 06 13.50

021 06 014.52

D4

EEPROM J4

Memory

Card

ORTH. Plus

Memory

Card

ORTH.

ATTENTION! Invalid data are indicated if DX1 switch S101 is in the wrong position.

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

Memory

Card

ORTH. TS

Remarks

1 - 5

Page 16

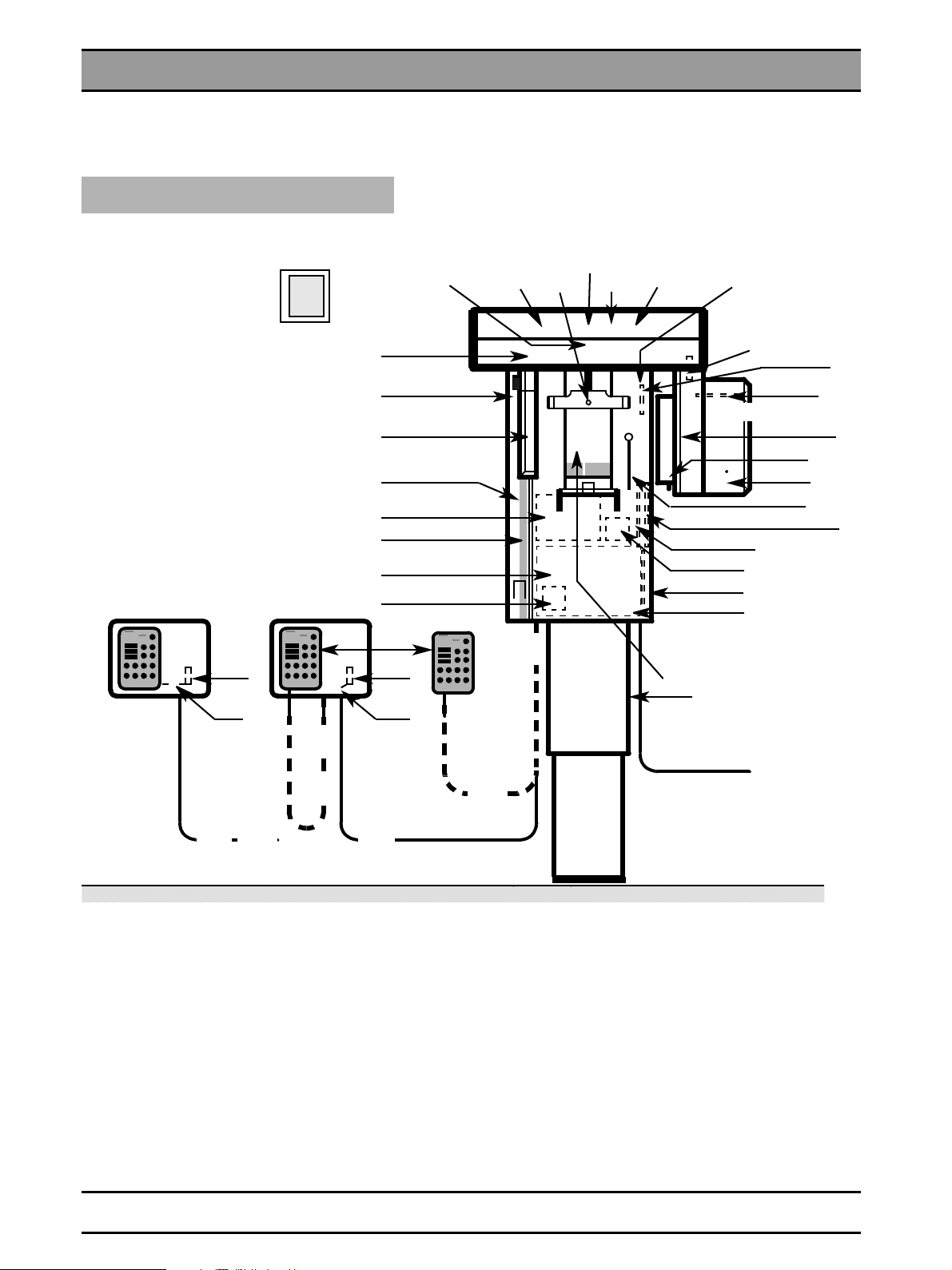

1.3 Major Assemblies and Components

1.3 Major Assemblies and Components

ORTHOPHOS Plus DS

Main switch

ON

OFF

S1

I

O

Terminal strip K1,

transformer T1 and board

DX31 behind door and cover.

Remote control . . .

K10

L11

K11

. . . without

coiled cable

. . . with

coiled cable

L9

L8

K2

Rear

panel

L9

M6

V2

RHB

DX31

BE, EDC

DX7, A

DX32

F1,

DX1

DX20, M

D4

K10

L12

Control cable of

remote control

L8

M3

V4

R1 V5, V7

K2

M1

M2

V3

M5

V6, V8

K3

DX5

D6

X-ray tube assembly

S3, S4

S2

H1

EGB

XAB OP / DEB

XAB D

DX71

DX91

S

HV

H1, H2 light localizer

Serial no.

hardware

software

L30/L31/L32/LAN

DX71 and DX20 omitted from serial no.

1400 (ORTHOPHOS Plus DS),

50400 (ORTHOPHOS Plus DS Ceph)

DEB discontinued as of serial no.

2000 (ORTHOPHOS Plus DS),

52000 (ORTHOPHOS Plus DS Ceph)

and replaced by XAB OP, XAB D

A = Membrane keypad

BE = Image receptor

DEB, EDC,

RHB, D,

DX, XAB= PC boards

M = Memory card

H1 = X-ray tube assembly

F1, F2 = Main fuses

M1 = Motor for rotation

M2/3 = Actuators

M5 = Motor for height adjustment

M6 = Motor for forehead support movement

H1/H2 = Light localizer

K = Connector/terminal strips on/in the unit

L = Leads/cables

R1 = Potentiometer for forehead support

S = Switch

S

X = Connectors on boards

V2 - V8 = Light barriers

V2 = Forehead support, zero position

V3 = Start position for actuator M2

V4 = Start position for actuator M3

V5 = Start position for rotation

V6 = Height adjustment pulses

V7 = Rotation ring in Ceph position

V8 = Ceph synchronization pulses

= Correction switch for height adjustment

HV

54 53 571 D 3297

1 - 6 D 3297.077.01.10.02 04.2007

Page 17

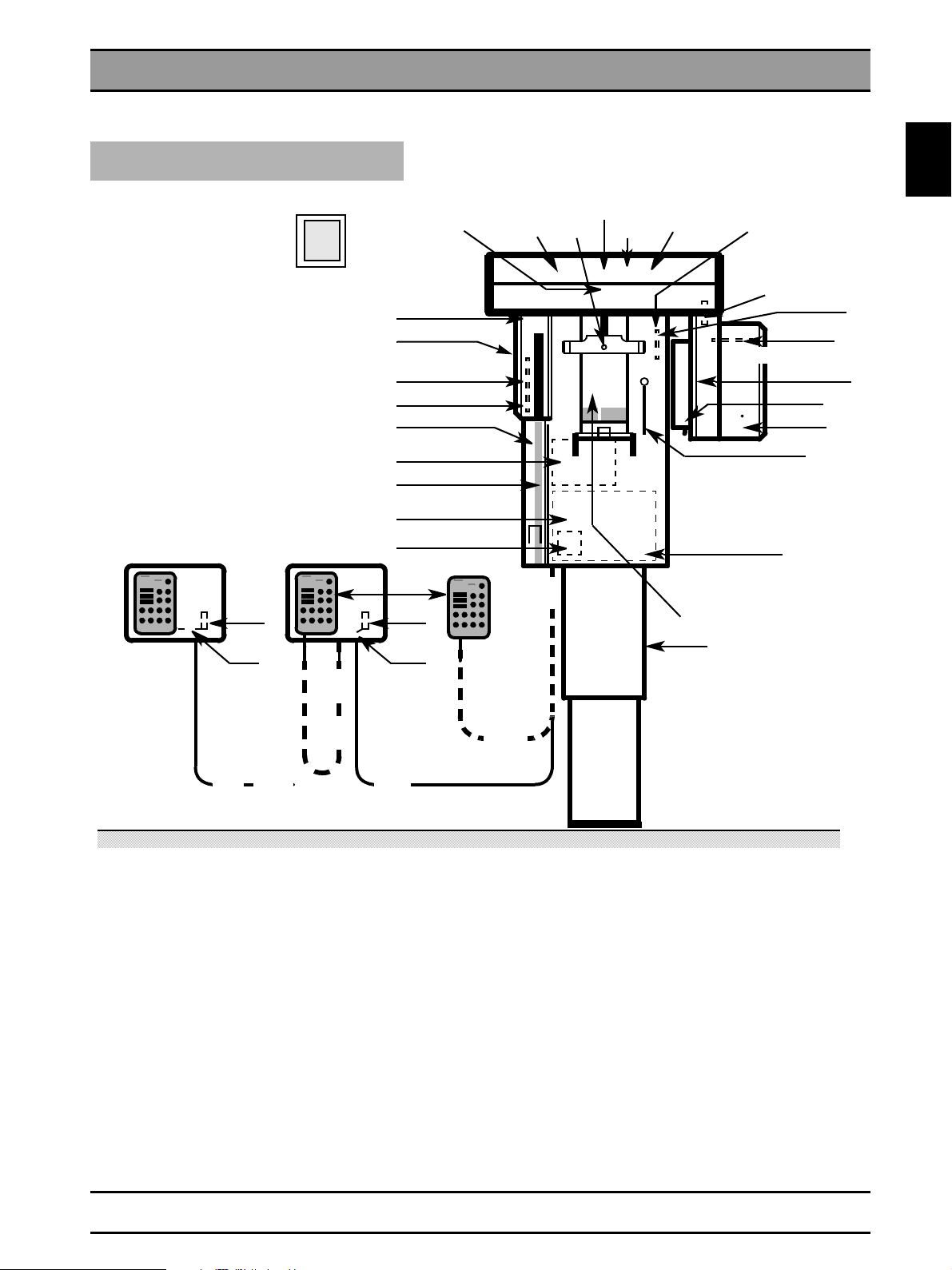

1.3 Major Assemblies and Components

ORTHOPHOS PLUS

Main switch

ON

OFF

S1

O

I

Rear

panel

Terminal strip K1,

transformer T1 and board

DX31 behind door and cover.

Remote control . . .

K10

M6

V2

V11, V12

DX31

DX8, M4,

V10

DX7, A

DX32

F1,

DX1

M

D4

K10

M3

V4

R1 V5, V7

K2

M1

M2

V3

M5

V6, V8

X-ray tube assy

EGB

S

HV

H1, H2 Light localizer

K3

1.3

DX5

D6

S3, S4

S2

H1

L11

K11

. . . without

coiled cable

A = Membrane keypad

D, DX = PC boards

M = Memory card

H1 = X-ray tube assembly

F1, F2 = Main fuses

M1 = Motor for rotation

M2/3 = Actuators

M4 = Motor for cassette movement

M5 = Motor for height adjustment

M6 = Motor for forehead support movement

H1/H2 = light localizer

K = Connector/terminal strip on/in the unit

L = Leads/cables

. . . with

coiled cable

L9

K2

L8

L9

L12

Control cable of

remote control

Serial no.

hardware

software

L8

R1 = Potentiometer for forehead support

S = Switch

S

X = Connectors on boards

V2 - V8 = Light barriers

V2 = Forehead support, zero position

V3 = Start position for actuator M2

V4 = Start position for actuator M3

V5 = Start position for rotation

V6 = Height adjustment pulses

V7 = Rotation ring in Ceph position

V8 = Ceph synchronization pulses

= Correction switch for height adjustment

HV

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

1 - 7

Page 18

1.3 Major Assemblies and Components

ORTHOPHOS Plus Ceph and ORTHOPHOS Plus DS Ceph

ORTHOPHOS Plus DS Ceph

Serial number

DAB

BE, EDC

M7

H3

D10

D11

ORTHOPHOS Plus Ceph

DAB = Image receptor supply board, Ceph

BE = Image receptor

EDC = Image receptor electronics

M7 = Motor for Cephalometer with brake

and encoder

M8 = Motor for patient diaphragm

H3 = Light localizer

D10 = Control board

D11 = Control panel

M8

V7

V4

V6

LED indication of help messages

V1 = Cool-down interval

V2 = X-ray tube assembly position Pan / Ceph

V3 = Setting of diaphragm

V4 = Position of forehead support

V5 = Height adjustment

V6 = Image receptor plug-in position /

exposed film inserted

V7 = Readiness for exposure SIDEXIS /

cassette holder not in position

V2

V1

V3

V5

1 - 8 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 19

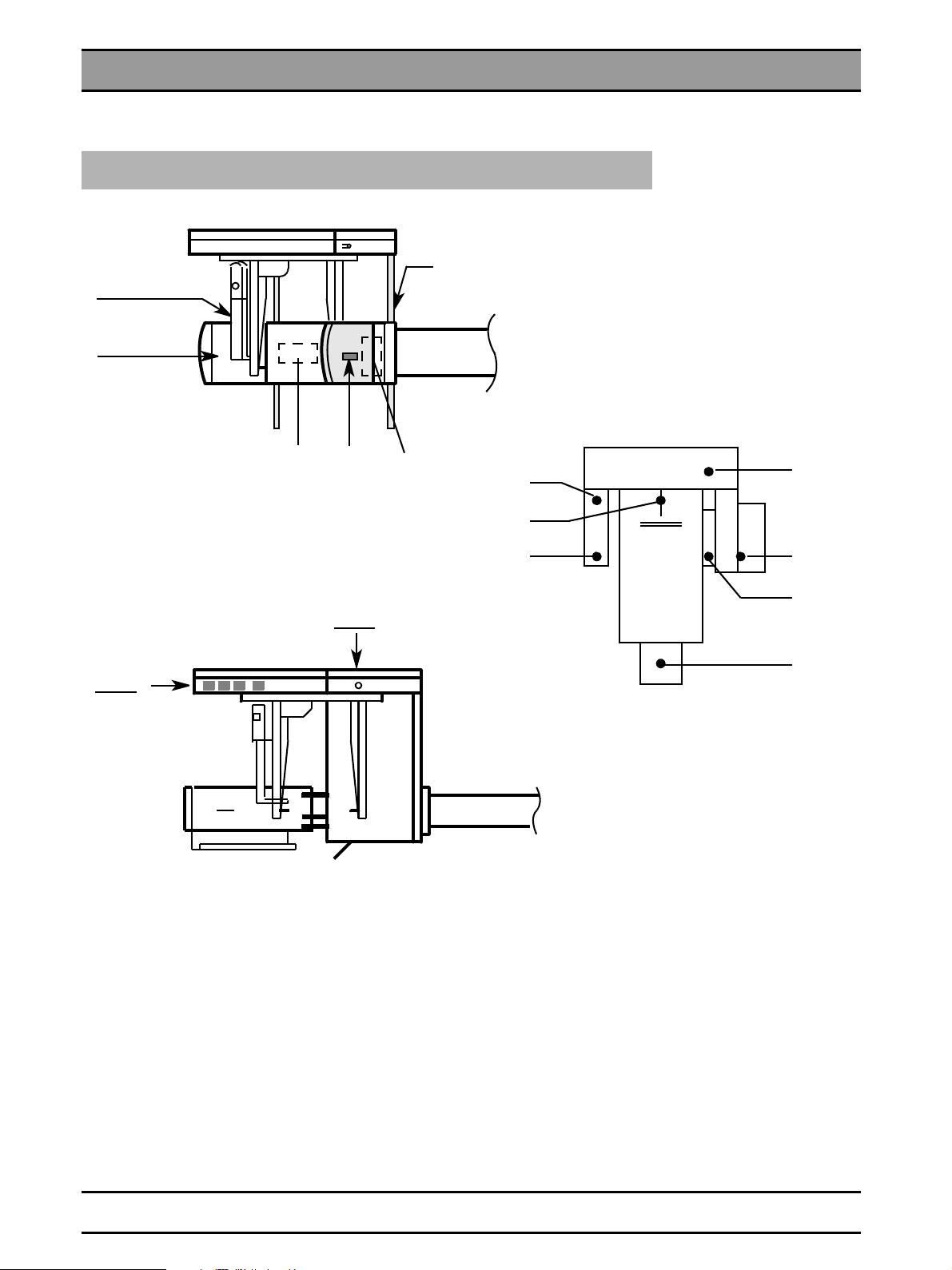

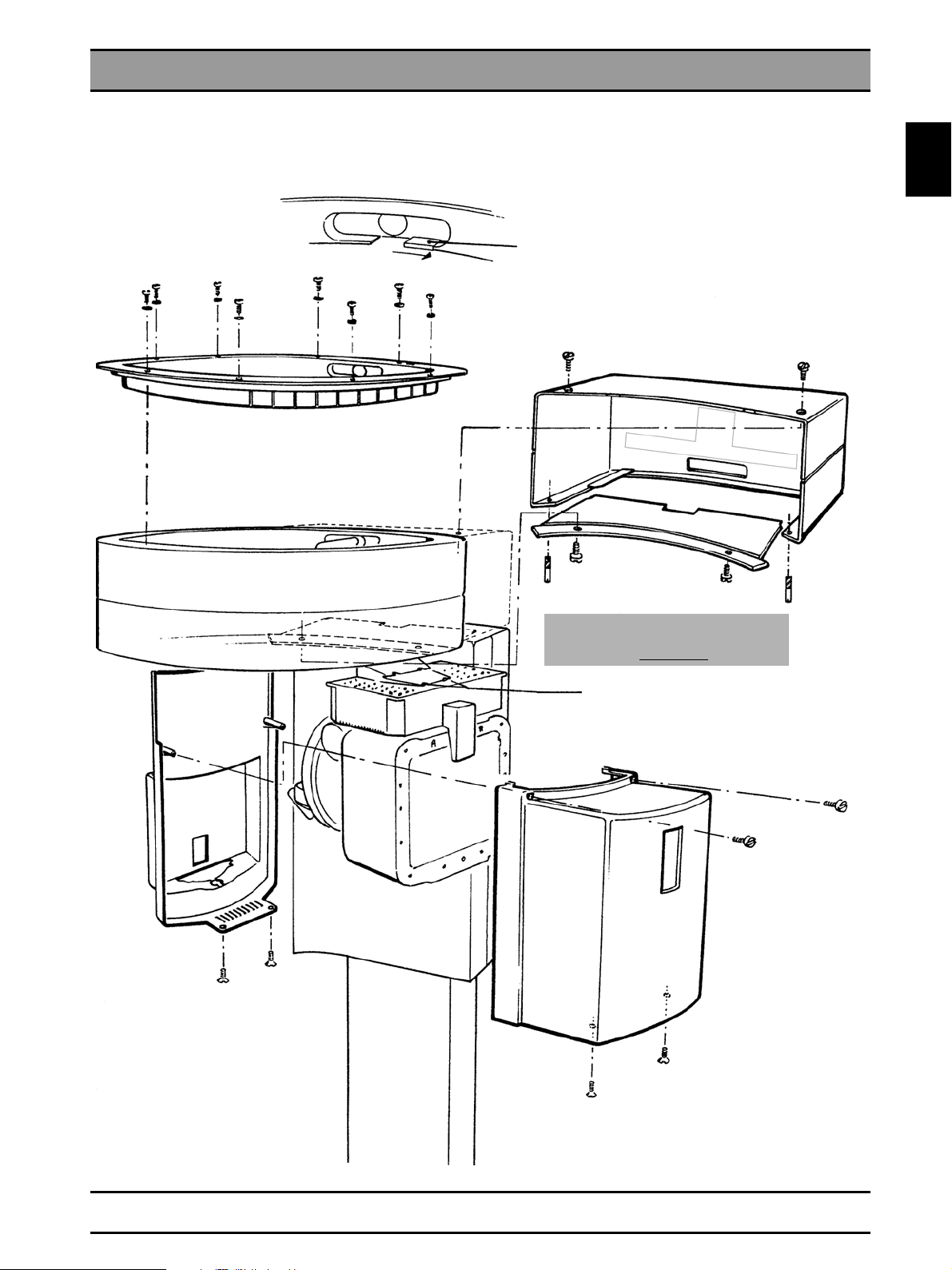

1.4 Removing Panels

1.4 Removing Panels

X-ray tube assembly, rotation ring

1.4

Push this cuff aside before lifting off

the panel!

Align lower panel to the rotation ring

(gap of equal width).

Secure with 2 M4 screws from below.

Always tighten the four

mounting screws!

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

1 - 9

Page 20

1.4 Removing Panels

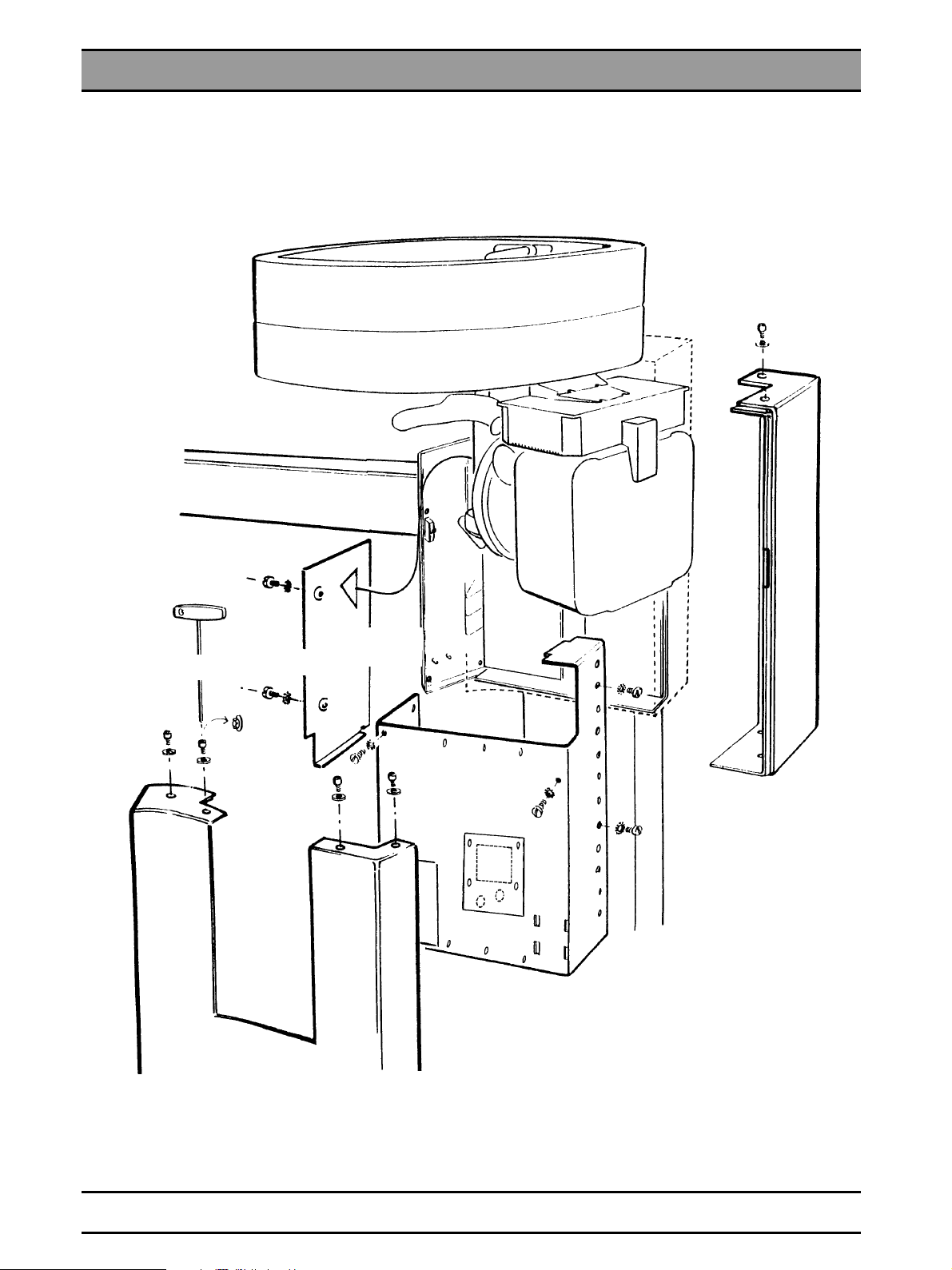

Unit carriage

Special screwdriver

Transformer

cover

Spare fuses

5 – 29 screws

This cover can only be removed after the panels behind the

rotation ring have been taken off.

NOTE: For ORTHOPHOS Plus DS TSA, take TSA imagereceptor out of side

holder before removing the panels.

54 53 571 D 3297

1 - 10 D 3297.077.01.10.02 04.2007

Page 21

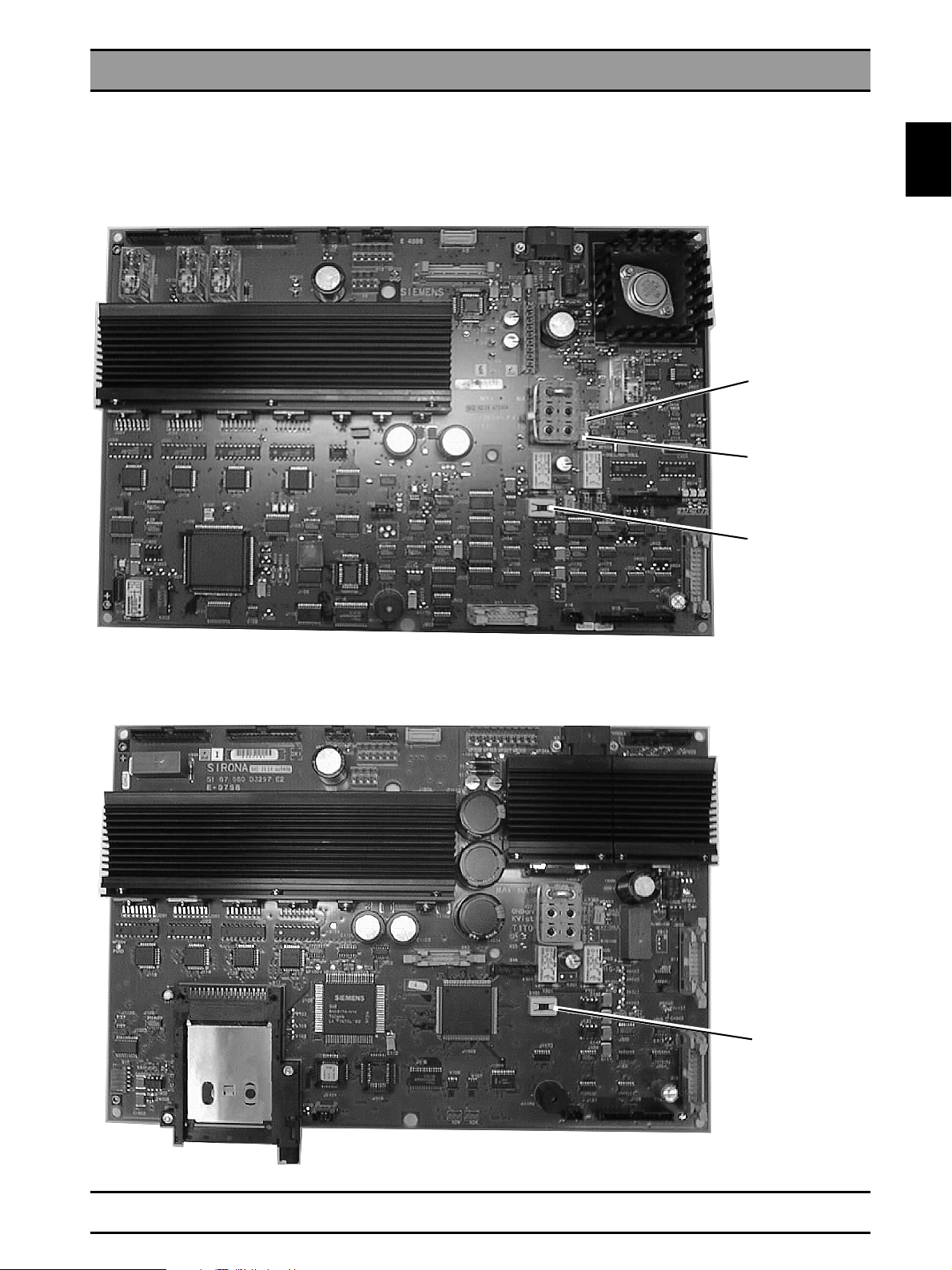

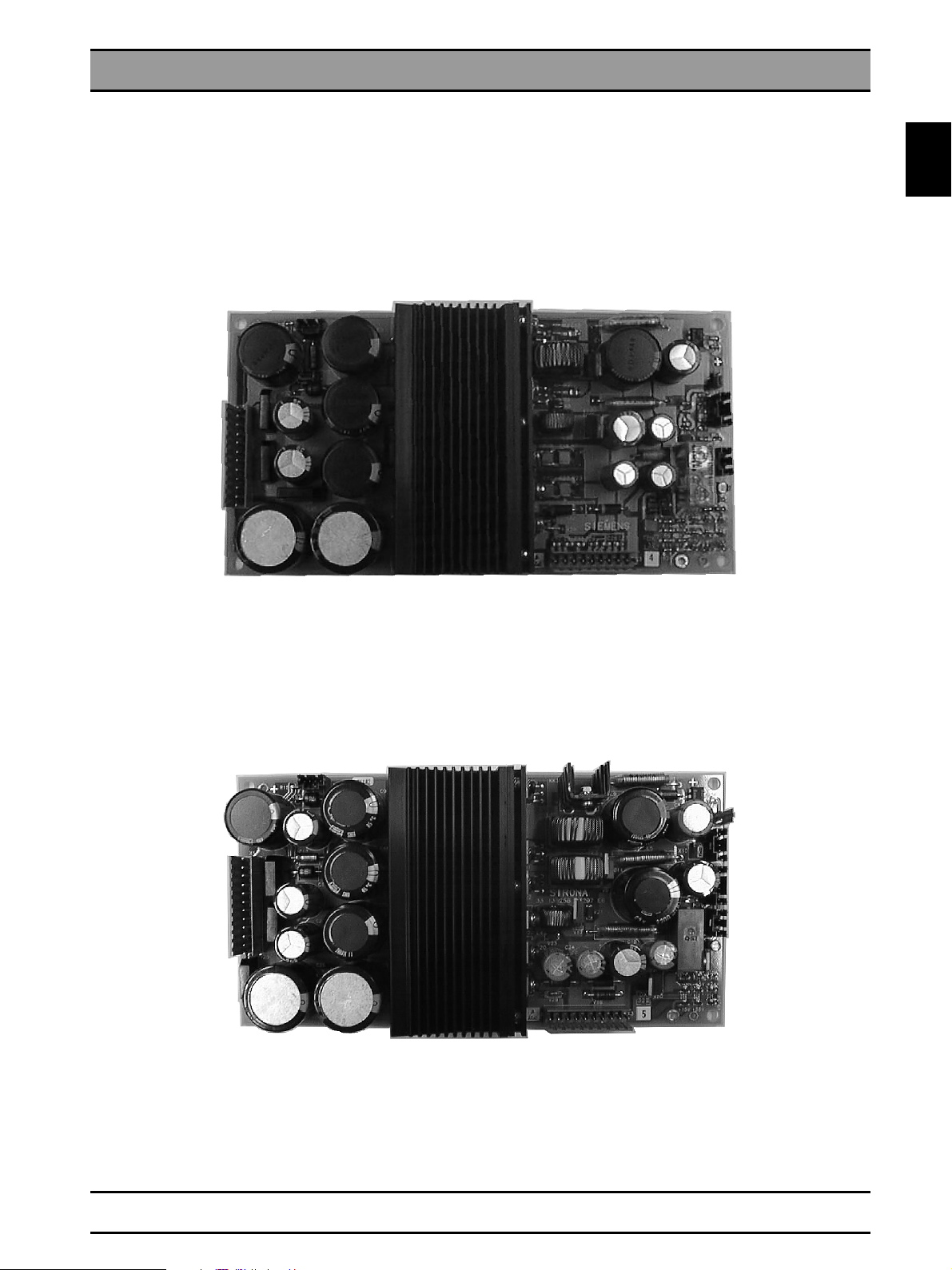

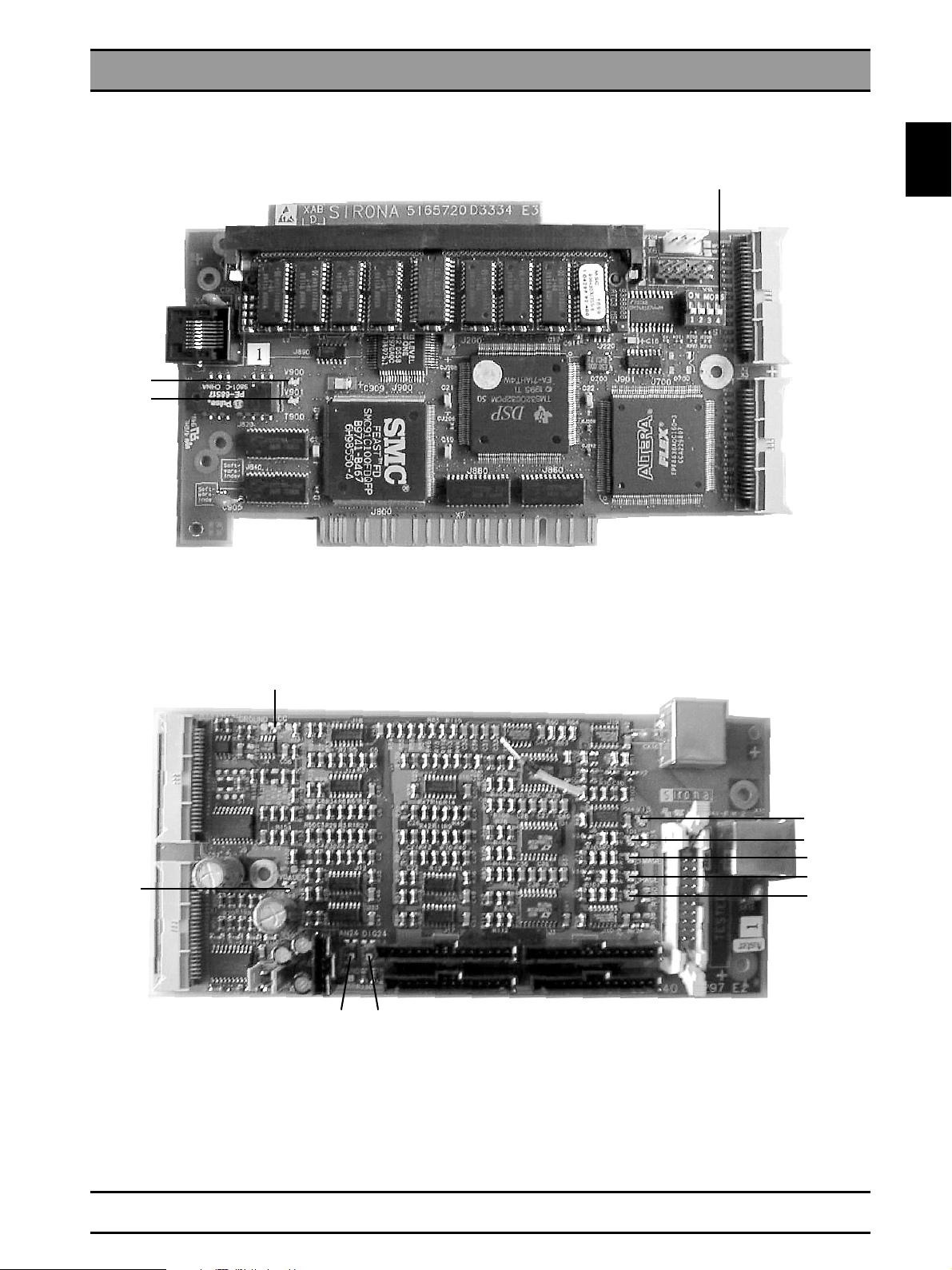

1.5 Photographs of PC Boards

)

1.5 Photographs of PC Boards

DX1 board

33 13 108

1.5

with Memory Card 256kB

MA setpoint

VH setpoint

Switch S101

Position 2 (at right)

otherwise reading

from memory card

not possible

51 67 080

with Memory Card 256KB or 2MB

Switch S101

Position 2 (at right

otherwise reading

from memory card

not possible

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

1 - 11

Page 22

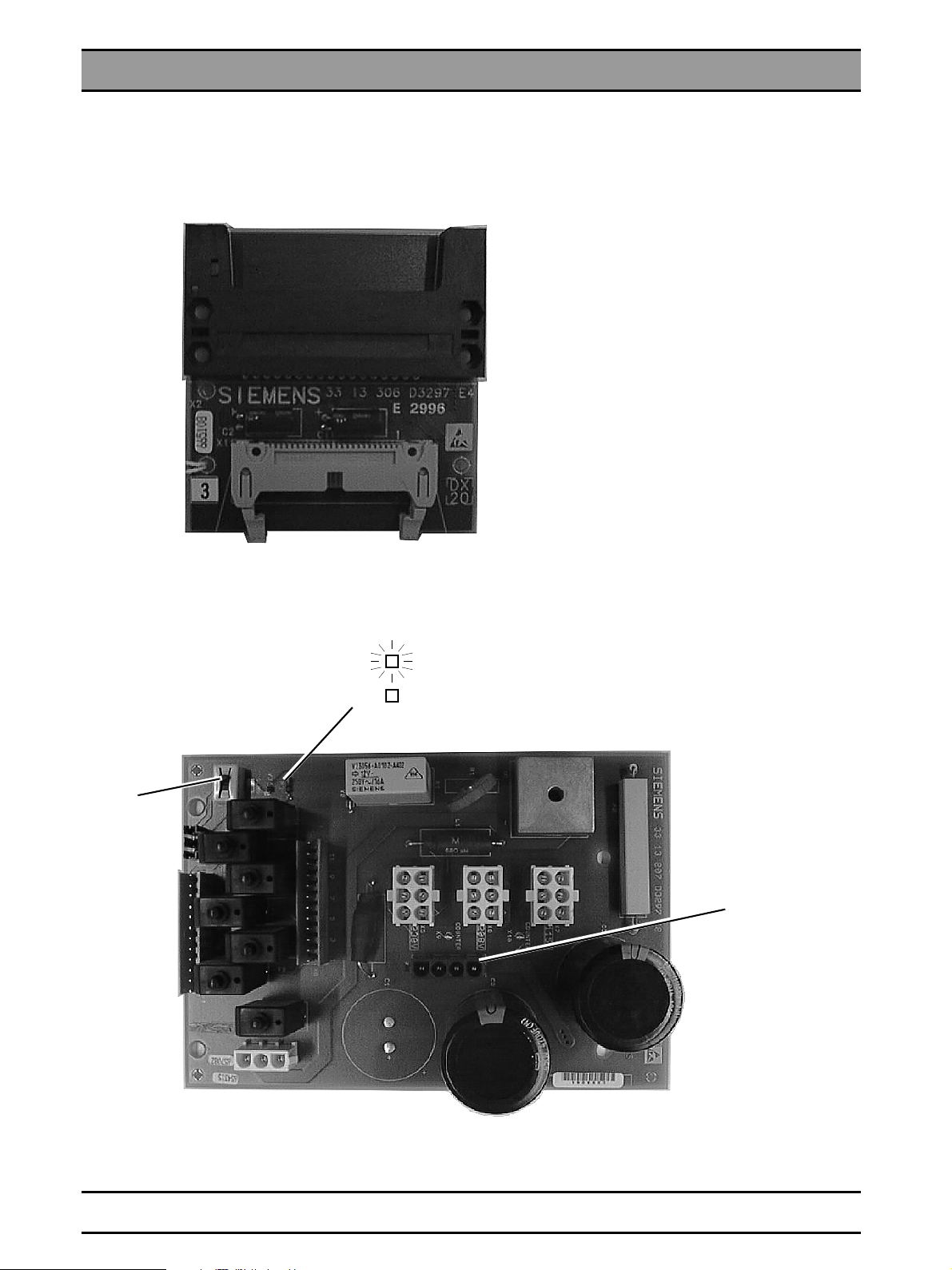

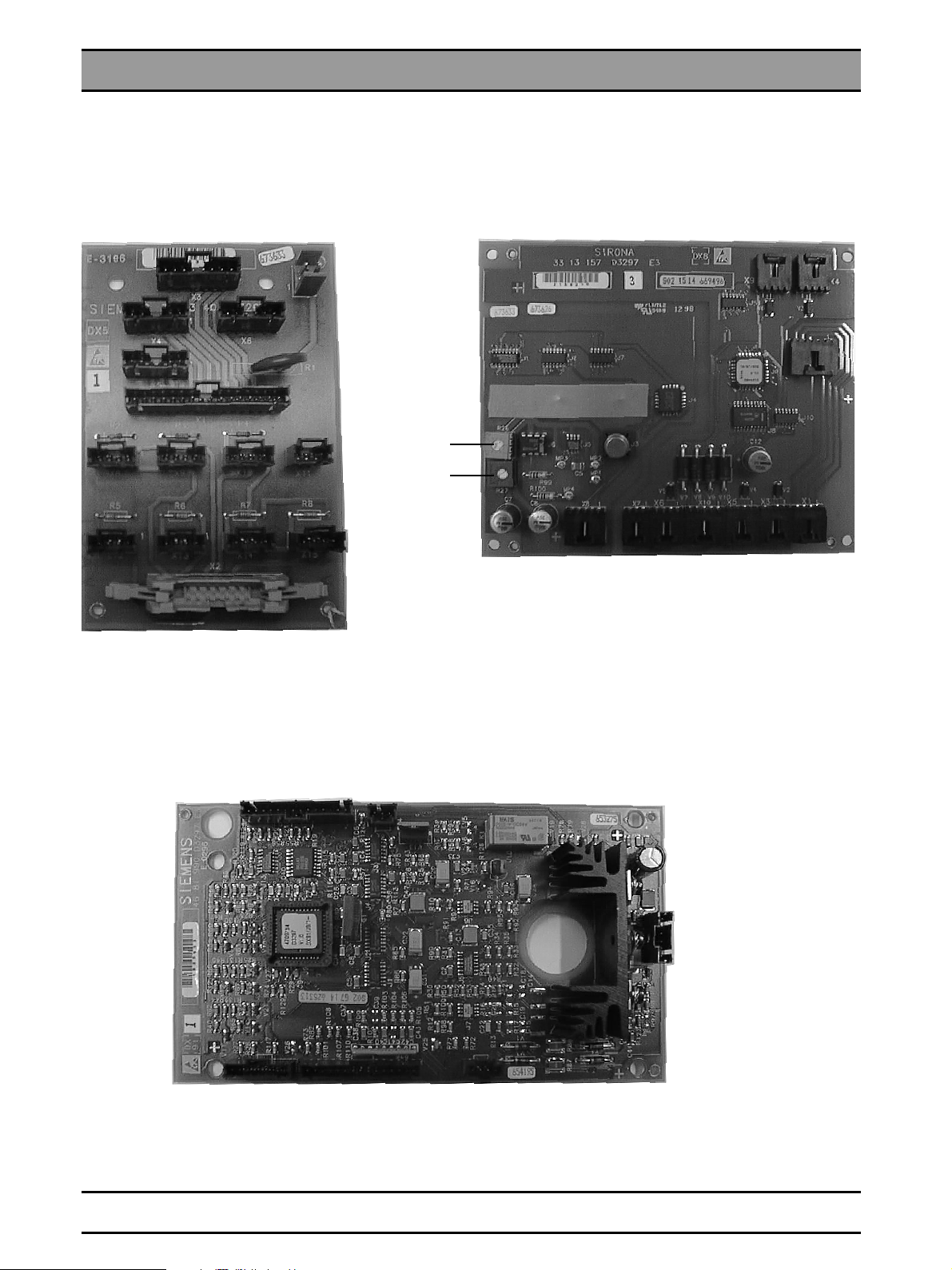

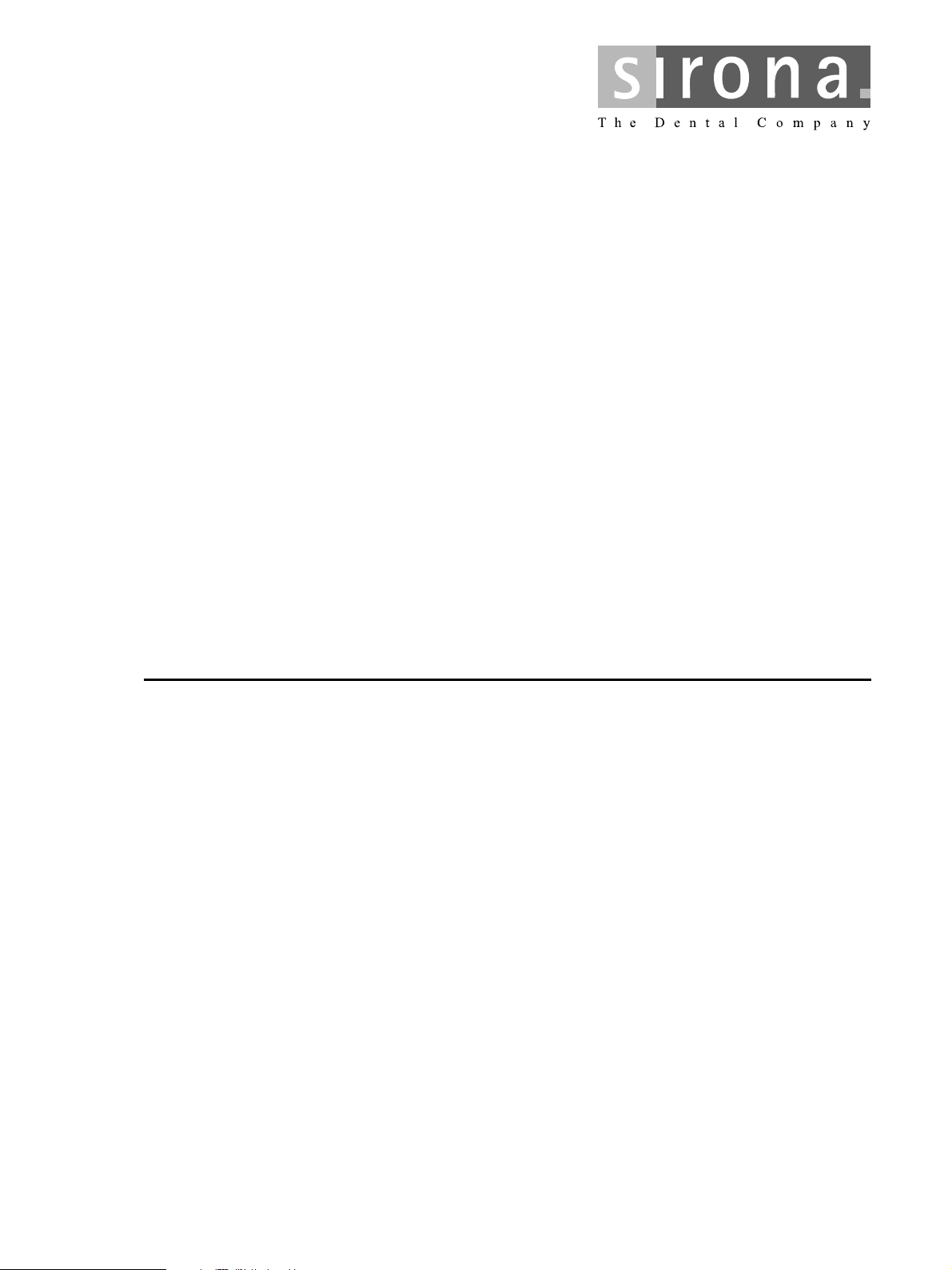

1.5 Photographs of PC Boards

DX20 / DX31 boards

DX20

S.88

Position 2

Demonstrationmode

DX31

V3

Radiation

S.88 Demonstration mode

X2 High voltage

1 - 12 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 23

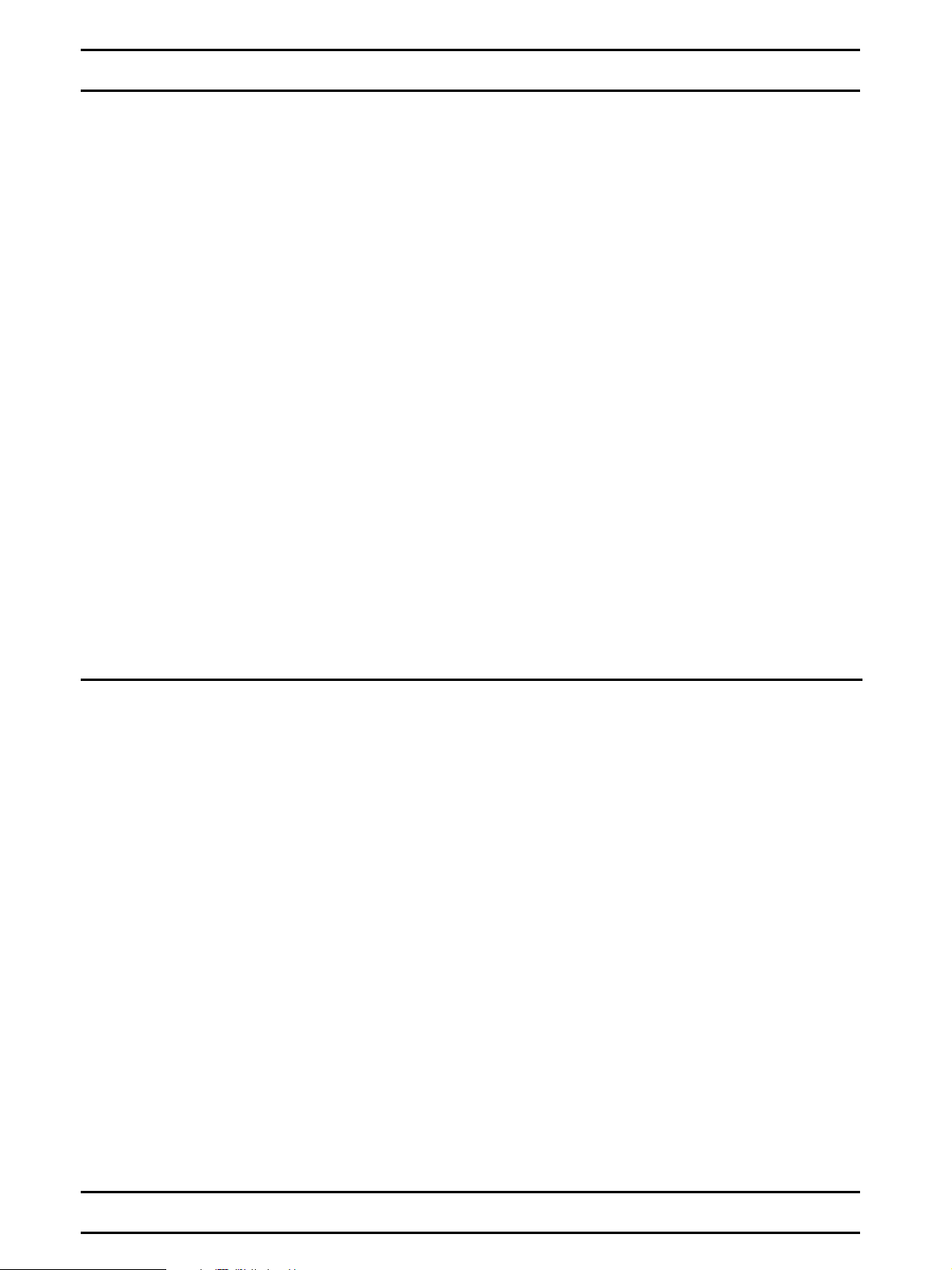

DX32 board

1.5 Photographs of PC Boards

1.5

DX32 E4

DX32 E5

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

1 - 13

Page 24

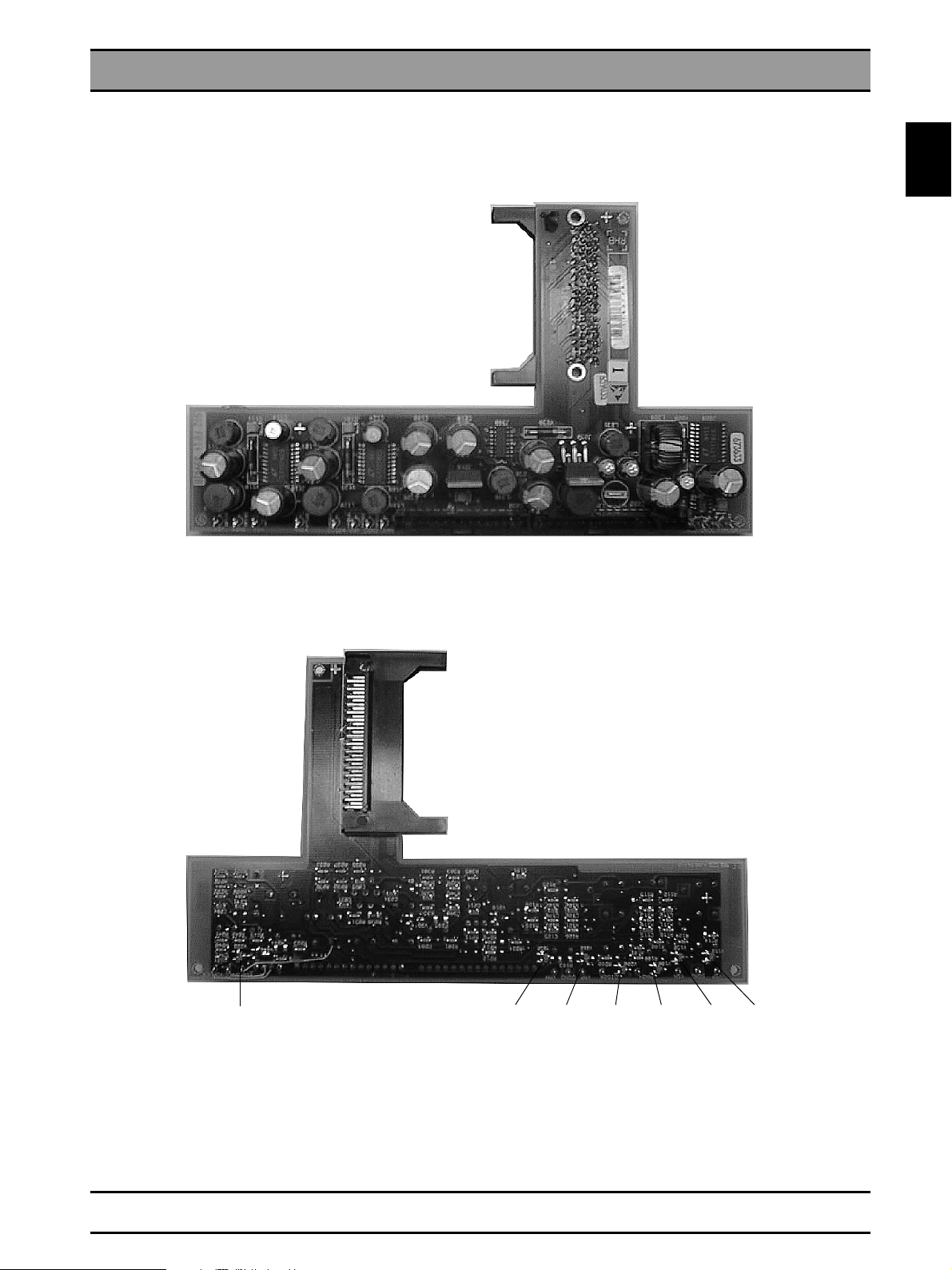

1.5 Photographs of PC Boards

DX5 / DX8 / DX91 boards

DX5

DX8

R26

R27

DX91

1 - 14 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 25

RHB board

1.5 Photographs of PC Boards

1.5

RHB

D+5V A+5VA-5VA+24VD+24V+18V-18V

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

V200 V100 V112V122V212V232V222

1 - 15

Page 26

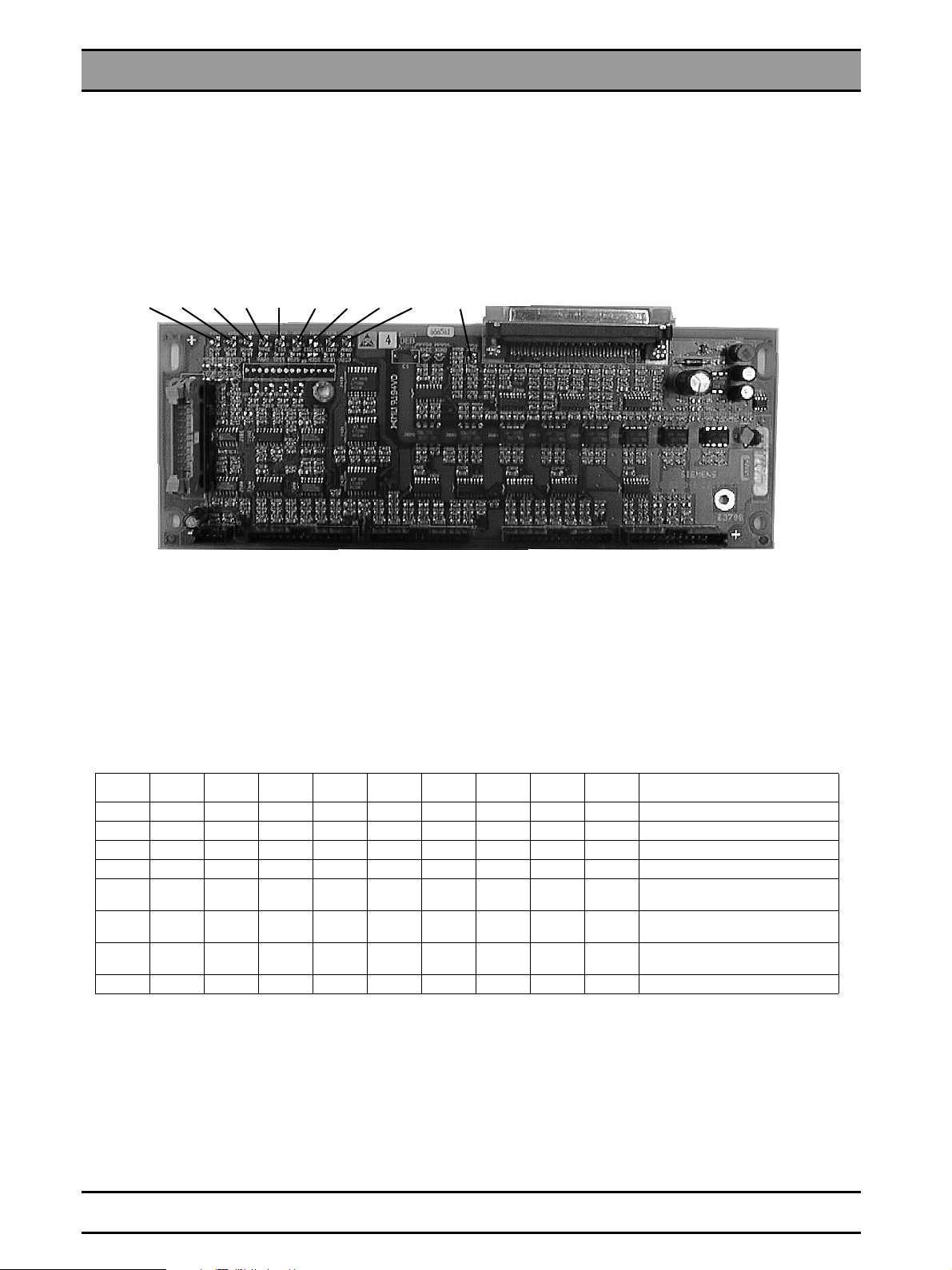

1.5 Photographs of PC Boards

DEB board

DEB

V905 V900 V216V221V910 V670 V350 V232V231

V950

V216 LED, Out clock pulses TDI

V221 LED, radiographic mode

V231 LED, Ceph radiography mode

V232 LED, Panoramic radiography mode

V350 LED, EDC Reset (not inserted)

V670 LED, PC exposure readiness ACTIVE signal

V900 LED, digital supply voltage RHB +24V

V905 LED, analog supply voltage RHB +24V

V910 LED, supply voltage DEB +5V ORTHOPHOS

V950 LED, supply voltage DEB +5V PC (if XOP not correctly configured)

V905 V900 V910 V221 V216 V670 V350 V231 V232 V950 Status

XXXStandby Pan

X X X Standby Ceph

X X X X X Panoramic radiography mode

X X X X X Ceph radiography mode

XXXX X XX

XXXX X X X

XXXXglowsX XX

XXXXglowsX X XCeph radiography mode X-ray

Panoramic radiography mode

Image generation test image

Ceph radiography mode

Image generation test image

Panoramic radiography mode

X-ray

1 - 16 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 27

XAB OP and XAB D boards

1.5 Photographs of PC Boards

XAB D

V900

V901

V900 = RD Transmit, GN Receive

V901 = RD Link (adress recognition), GN 100Mbps (Megabits per sec)

Coding switch

1.5

XAB OP

V10

V9

V12 V11

V5 LED, TDI distance pulses

V6 LED, IMAGE radiographic mode

V7 LED, radiographic mode Pan/Ceph

V8 LED, Panorama-Aufnahmemodus

V9 LED, V continuous

V10 LED, VCC +5V

V11 LED, Digital supply voltage +24V

V12 LED, Analog supply voltage +24V

V13 LED, PC exposure readinesst ACTIVE signal

V13

V5

V6

V7

V8

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

1 - 17

Page 28

1.5 Photographs of PC Boards

1 - 18 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 29

2 List of Messages

Page 30

Contents Sirona Dental Systems GmbH

List of Messages

Contents

2.1 List of Help Messages ........................................................................................................ 2 - 3

2.2 List of Error Messages ........................................................................................................ 2 - 4

2.3 List of Service Routines ...................................................................................................... 2 - 9

2.4 List of Error Messages for SIDEXIS ................................................................................. 2 - 10

2 - 2 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 31

2.1 List of Help Messages

If the Ready LED above the R key on the Multitimer flashes when you try

to trigger an exposure, you can call up H3 help messages on the Multitimer:

• Press the X-ray key on the Multitimer.

CAUTION: Take radiation protection measures.

The H3 . message then appears on the kV/mA display.

• Find in the following list the actions required to return the unit

to readiness for exposure.

• Before

carrying out the required action clear the help message

by pressing the R key on the Multitimer.

Help

message

H3 01

Rotation unit not in the start position. V2 Press the Return key R, see page 3 - 11.

Film cassette not inserted or not engaged. V7 Slide loaded film cassette into the cassette tray

Description Required action

H3 02

H3 03

Exposed film cassette not replaced after last

exposure. V6

Cassette holder not in Panorama position. V7 Swivel cassette holder to stop position. For error

H3 04

H3 05

H3 06

Panorama

H3 07

No Panorama diaphragm set with the diaphragm

wheel. V3

Locking button on diaphragm wheel not engaged

(Panorama diaphragm). V3

Forehead support is in an incorrect position for the

selected program. V4

Cassette holder not in Ceph position. V7 Swivel cassette holder to stop position. For error

H3 11

H3 12

H3 16

H3 20

H4 01

H4 03

H4 05

Rotation unit not in start position for cephalometry. V2Drive rotation unit to cephalometry position (press

Ceph function not selected. V3 Select Ceph function by pressing the C key, see

Radiographic data not acknowledged. V7 Acknowledge radiographic data with Return key R.

Image receptor not inserted according to selected

exposure. V7

SIDEXIS not ready for exposure. V6 Make SIDEXIS ready for exposure.

Height adjustment not in the range for Ceph exposures. V5

Patient fixation on Ceph not in the basic position. V5Move Cephalometer without a patient to position

H4 06

until it engages. For error correction follow service

routine S.16, see page 5 - 45.

Remove exposed film from the cassette and insert

a fresh film.

correction follow service routine S.16, see page

5 - 45.

Set diaphragm wheel to diaphragm for the

selected program, see page 3 - 13.

Correctly engage locking button on diaphragm

wheel, see page 3 - 13.

Move forehead support to correct position, see

page 3 - 15.

correction follow service routine S.16, see page

5 - 45.

R key) and lock it, see page 3 - 17.

page 3 - 19.

Insert image receptor according to exposure set.

For error correction follow service routine S.32/

S.33, see page 5 - 77.

See SIDEXIS Service Manual.

Move stand without a patient to a position accept-

able for cephalometry. For error correction follow

service routine S.18, see page 5 - 51.

for cephalometry. If the error occurs repeatedly,

correct by performing service routine S.34.1,

see page 5 - 83.

H4 10

Ceph oder SIDEXIS

H4 20

Image receptor not suitable for exposure set. Replace the image receptor in the plug-in location

Image could not be transferred to SIDEXIS.

according to the programmed acquisition.

Transfer exposure by SiRescue service program

to the PC, see SIDEXIS User Manual.

CAUTION Do not switch off the unit until the help

message goes out.

V7

V4

V6

V2

V1

V3

V5

2.1

The above mentioned actions will eliminate help messages caused by operating errors.

If the help message cannot be eliminated by the above actions, the fault is of another nature. Proceed with

troubleshooting as described on the following pages.

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

2 - 3

Page 32

2.2 List of Error Messages

Error

message

E1 01

E1 02

E2 03

Multitimer

E1 03

E2 01

E2 03

E2 04

E2 10

E2 11

E2 12

E2 13

E2 14

E2 15

E2 16

X-ray tube assembly E2 . . .

E2 18

E2 20

E2 35

E2 40

Description

A key on the Multitimer was pressed during selfadjustment or is defective.

Signal paths to control board D1 are interrupted. Proceed according to section "Correcting error E1

Faulty communication with the unit. Acknowledge the fault by pressing the R key on

Appears upon pressing the exposure button.

Overheated X-ray tube assembly, pulse/pause

ratio not observed.

See LED Orthophos symbol.

Proceed according to section "Correcting error E1

01", see page 3 - 21.

02, see page 3 - 21.

the Multitimer.

Acknowledge the fault by pressing the R key on

the Multitimer. Allow the X-ray tube assembly to

cool down. If the error message reoccurs, proceed

according to section "Correcting error E2 01",

Required action

see page 3 - 23.

See E1 02 see page 3 - 21

Zero power range has been re-initialized. Acknowledge the fault by pressing the R key on

Max. radiation time of the program exceeded. Only possible in service mode; acknowledge the

kV

(tube voltage) exceeded. Proceed according to section "Correcting error E2

max.

mA

(tube current) exceeded. Proceed according to section "Correcting error E2

max.

VH

(filament voltage) exceeded. Proceed according to section "Correcting error E2

max.

Short-circuit of an output stage on D6 with voltage/frequency converter on DX1 deactivated.

VH

continuously present. Proceed according to section "Correcting error E2

max.

kV

cable is interrupted. Proceed according to section "Correcting error E2

actual

Non-localizable fault in obtaining the DC/AC signals.

Occurs upon pressing the exposure button e.g.

with the X-ray room door contact open - exposure

release lead in the Multitimer cable is broken.

Invalid data in the data memory. Erase data in the EEPROM with 'Service Routine

VH setpoint out of tolerance ± 10 %. Proceed according to section "Correcting error E2

the Multitimer. Unfortunately, the freely

programmed values will be lost. and must be

reprogrammed. If not possible: correct the error

with E2 04, see page 3 - 25.

fault by pressing the R key on the Multitimer. Or

Ceph mode is too slow: proceed according to section "Correcting error E2 10", see page 3 - 27.

11", see page 3 - 29.

12", see page 3 - 31.

13", see page 3 - 33.

Proceed according to section "Correcting error E2

14", see page 3 - 35.

15", see page 3 - 37.

16", see page 3 - 39.

Acknowledge the fault by pressing the R key on

the Multitimer. If fault reoccurs, DX1 board is

defective → replace. Perform "Adjusting board

DX1”, see page 4 - 39.

Close X-ray room door. Acknowledge the fault by

pressing the R key on the Multitimer. If the fault

reoccurs, proceed according to section "Correcting error E2 20", see page 3 - 41.

09'. Then press the R key. If the message reoccurs, DX1 board is defective → replace and perform "Adjusting board DX1”, see page 4 - 39.

40", see page 3 - 45.

2 - 4 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 33

2.2 List of Error Messages – Continued

Error

message

E2 41

E2 42

E2 43

E2 44

E2 45

E2 46

E2 47

X-ray tube assembly E2 . . .

E2 48

E3 01

E3 02

E3 03

E3 04

E3 05

E3 06

E3 08

E3 09

Unit E3 . . .

E3 10

E3 11

E3 12

E3 21

E3 22

Description

kV setpoint out of tolerance ± 5 %. Adjust board DX1. If not possible, DX1 board is

defective → replace and adjust, see page 4 - 39.

mA setpoint out of tolerance ± 5 %. Adjust board DX1. If not possible, DX1 board is

defective → replace and adjust, see page 4 - 39.

VH actual value out of tolerance ± 10 %. Adjust board DX1. If not possible, DX1 board is

defective → replace and adjust, see page 4 - 39.

kV actual value out of tolerance ± 10 %. Adjust board DX1. If not possible, DX1 board is

defective → replace and adjust, see page 4 - 39.

mA actual value out of tolerance ± 10 %. Proceed according to section ”Correcting error E2

45", see page 3 - 47.

Error while increasing or decreasing the kV value. Software error or DX1 board defective → replace

and perform "Adjusting board DX1”,

Required action

see page 4 - 39.

Incorrect setpoint value after automatic setpoint

adjustment.

Faulty user offset while increasing the kV value. Acknowledge the fault by pressing the R key. Cau-

Operating element for light barrier V3 of actuator

M2 has not left/reached the tripping position.

Operating element for light barrier V4 of actuator

M3 has not left/reached the tripping position.

Cassette carriage has not left/reached the reference point.

Fault in film motor counter. Acknowledge the fault by pressing the R key. If the

Adjust board DX1. If not possible, DX1 board is

defective → replace and perform "Adjusting board

DX1”, see page 4 - 39. EEPROM defective.

tion: If the offset was changed by the user (possible in the range from -6 to +3) it will be reset to

zero. If the fault reoccurs, the DX1 board is defective → replace and perform "Adjusting board

DX1”, see page 4 - 39.

Proceed according to section "Correcting error E3

01/02", see page 3 - 49.

Proceed according to section "Correcting error "

E3 03/04”, see page 3 - 51.

Proceed according to section "Correcting error E3

05 /06", see page 3 - 53.

fault reoccurs, the DX1 board is defective →

replace and perform "Adjusting board DX1”,

see page 4 - 39.

Pulses for height adjustment are not within the

allowed time.

Count for height adjustment too high/too low for

reference setting.

Key for height adjustment ↑↓ was pressed during

self adjustment or is defective.

Key for anomaly A (control panel A) was pressed

during switch-on procedure or before completion

of unit self-adjustment.

Key for light localizer (control panel A) was

pressed during switch-on procedure or before

completion of unit self-adjustment.

Proceed according to section "Correcting error E3

09/E4 03", see page 3 - 55.

Proceed according to section "Correcting error E3

10/11", see page 3 - 59.

Proceed according to section "Correcting error E3

12", see page 3 - 61.

Acknowledge the fault by pressing the R key on

the Multitimer or the key/lead is defective.

Acknowledge the fault by pressing the R key on

the Multitimer.

2.2

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

2 - 5

Page 34

2.2 List of Error Messages – Continued

Unit E3 . . .

Error

message

E3 23

E3 24

E3 25

E3 26

E3 27

E3 28

E3 29

E3 30

E3 31

E3 32

E3 33

E3 35

E3 36

E3 37

E3 38

E3 39

E3 41

E3 42

E3 43

E3 45

Description

Return key R on control panel A was pressed during the switch-on procedure or before completion

of unit self-adjustment.

"“X-Ray Control” is indicated at switch-on. a) If error message occurs in combination with

Incorrect data for exposure control. Memory card or DX1 defective → replace and per-

Data in EEPROM not compatible with software

version of memory card.

Zero point of forehead support was not exited/

reached.

Software limit switch of forehead support was

reached before zero point.

Counter IC of forehead support not counting correctly.

One of the keys ← → for forehead support adjustment was pressed during switch-on procedure or

before completion of unit self-adjustment.

Start position for rotation was not exited/reached. Proceed according to section "Correcting error E3

Rotation counter not counting correctly. Software error or DX1 board defective → replace

Acknowledge the fault by pressing the R key on

the Multitimer.

E1 02: button was recognized on Multitimer as

actuated - check buttons or replace Multitimer.

b) If error message occurs alone, pull out Multitimer and switch on again. If error message

occurs again: DX1 defective → replace and perform “Adjusting board DX1”, see page 4 - 39. If

error message no longer occurs: replace Multitimer.

form "Adjusting board DX1”, see page 4 - 39.

Check for compatibility of software versions

according to the list, see page 1 - 5. Install the

correct software combination, or the memory card

or DX1 is defective. Adjust unit identification with

Service routine S.17, see page 5 - 49.

Proceed according to section "Correcting error E3

27/28/29", see page 3 - 63.

Acknowledge the fault by pressing the R key on

the Multitimer.

DX1 board defective → replace and perform

"Adjusting board DX1, see page 4 - 39”.

Acknowledge the fault by pressing the R key on

the Multitimer. Key defective?

32/33", see page 3 - 65.

and perform "Adjusting board DX1”,

Required action

see page 4 - 39.

Cassette holder was swivelled from the Pan position during the Pan exposure.

Counter IC of actuators not counting correctly. DX1 board defective → replace and perform

Light barrier for Ceph position rotation indicates

invalid status.

Error with counter for kV increase. DX1 board defective → replace and perform

Rotation has not reached Ceph position. Light barriers V7/V8 maladjusted/defective.

Error with counter for radiation times. DX1 board defective → replace and perform

Diaphragm inserted not recognized. After service routine 09, after replacing DX1 or

Proceed according to section "Correcting error E3

36", see page 3 - 69.

"Adjusting board DX1”, see page 4 - 39.

Proceed according to section "Correcting error E3

39", see page 3 - 73.

"Adjusting board DX1”, see page 4 - 39.

"Adjusting board DX1”, see page 4 - 39.

EEPROM → reprogram the diaphragm. Check

function of diaphragm switch!

2 - 6 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 35

2.2 List of Error Messages – Continued

Error

message

E3 46

E3 47

E3 48

E3 49

E3 50

Unit E3 . . .

E3 51

E3 52

E3 53

E4 01

E4 02

E4 03

E4 04

E4 06

E4 07

E4 08

E4 09

Ceph or SIDEXIS

E4 10

E4 11

E4 12

E4 13

E4 14

Description

Position of cassette holder cannot be determined. Proceed according to section "Correcting error E3

Memory card not inserted. Insert memory card.

Memory card which is plugged in is not valid or is

not always detected.

Watchdog reset performed. Acknowledge the fault by pressing the R key. Fault

46",

If the error message occurs frequently, order conversion kit: Replace memory card and GAL

J1121.

occurs with voltage fluctuations; if reoccurring frequently: DX32 or DX1 board is defective →

replace and perform "Adjusting board DX1”,

Required action

see page 3 - 75.

see page 4 - 39.

This service exposure is not possible in the demonstration mode.

Inaccurate signals indicated by the film drive control.

Unit identification does not match the inserted

memory card.

Switch S101 in left-hand position. Turn switch S101 to right-hand position.

Exposure aborted by SIDEXIS. Proceed according to section "Correcting error E4

Fault indicated by control unit of Ceph motor. Proceed according to section "Correcting error E4

Light barrier for Ceph control not emitting any

pulses.

Motor for secondary diaphragm not moving. Proceed according to section "Correcting error E4

Fault at one of the supply voltages. Proceed according to section "Correcting error E4

Fault in TDI pulse generation. DX1 board defective → replace and perform

Aborted by SIDEXIS during radiation. Proceed according to section "Correcting error E4

Fault at limit switches of Ceph drive. Proceed according to section "Correcting error E4

Communication fault with image acquisition card

XOP (in PC) or XAB OP (in ORTHOPHOS).

Image receptor not ready for exposure. Proceed according to section "Correcting error E4

Image receptor is not logged in. Load contents of image receptor floppy.

Pan image receptor in Ceph plug-in position. Insert Ceph image receptor in Ceph slot.

Ceph holder not moving (Ceph Pot.) Proceed according to section "Correcting error E4

Deactivate demonstration mode. Turn test switch

S1/S88 on DX31 to position 1. V3 on DX31 must

light up. Observe section "Demonstration mode

cannot be switched ON/OFF", see page 3 - 9.

Proceed according to section "Correcting error E3

51", see page 3 - 77.

Always perform service routine S.17 when replacing DX1 or changing from ORTHOPOS 5 to Plus

or TS or DS, see page 5 - 49.

01", see page 3 - 79.

02", see page 3 - 83.

Proceed according to section "Correcting error E4

03/E3 09", see page 3 - 87.

04", see page 3 - 89.

06", see page 3 - 93.

"Adjusting board DX1”, see page 4 - 39.

08", see page 3 - 97. In service program →

make SIDEXIS ready for exposure;

factory service 2.

09", see page 3 - 105.

With image acquisition card XOP: check cable

L30/L31 and DEB board.

With XAB OP: XAB OP does not respond or has

crashed. Switch unit off and on again.

Or not in correct service mode in SIDEXIS.

11", see page 3 - 107.

14", see page 3 - 115.

2.2

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

2 - 7

Page 36

2.2 List of Error Messages – Continued

Error

message

E4 15

E4 16

E4 17

E4 18

E4 19

Ceph or SIDEXIS

E4 21

E4 30

E4 31

–

–

–

– – –

–

–

–

– – –

Description

Ceph holder has not moved to limit switch. Proceed according to section "Correcting error E4

Active signal present when switching ON. Check SIDEXIS readiness for exposure.

Software versions of DX1 and XAB OP boards are

not compatible.

Image receptor could not be addressed prior to

exposure.

A software download of XAB OP is performed (no

acknowledgement of error message possible).

The XAB OP is in the initialization phase (Boot

Service) (proceed as described in SIDEXIS service manual; SIXABCON description). The XAB

OP has no valid IP address.

The image receptor has an initialization error or

incorrect setting data.

Error on sensor adjustment of TSA image receptor.

Indication at Multitimer.

Communication between control board DX1 and

Multitimer / board D4 is faulty.

Indication for height adjustment:

Height adjustment data not present.

Indication at Multitimer

and

indication for height adjustment

simultaneously.

15", see page 3 - 119.

With XOP board: Check line path from XOP board

in PC to DEB/DX1 board.

With XAB OP board: Check line path from DX1

board to XAB OP board.

Proceed according to section "Correcting error E4

16", see page 3 - 121.

Establish a valid software combination by replacing the memory card; load a new XAB-OP software version (see SIDEXIS service manual);

SIXABCON description.

Proceed according to section "Correcting error E4

11", see page 3 - 107.

Wait until the 4 LEDs above the patient symbols

start flashing; then switch the unit off. Software

download is completed.

After a valid IP address has been assigned by

SIXABCON the error message can be acknowledged on the unit (R key).

Read out error memory of EDC, replace image

receptor if necessary. Check installation of

SIDEXIS.

Perform service routine S.32, test step 06.

Check mains voltage and terminal strip K1. Check

Multitimer cable. Measure supply voltage at DX1

X1; if OK, DX1 board is defective; if not, DX31,

DX32 or cable is defective.

Press key ↑ or ↓:

error message E3 10 or E3 11 .

↑ E3 10 : unit above the correction switch.

Press R key on Multitimer. Press ↓ key until the

height indication appears.

↓ E3 11 : unit below the correction switch.

Press R key on Multitimer. Press key ↑ until the

height is indicated.

DX1 board is defective → replace and perform

"Adjusting board DX1”, see page 4 - 39.

Required action

2 - 8 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 37

2.3 List of Service Routines

Service

routine

S.01

S.02

S.03

S.04

S.05

S.06

S.07

S.09

S.11

S.13

S.14

S.15

S.16

S.17

S.18

S.19

S.20

S.21

S.24

S.25

S.26

S.30/31

S.32

S.33

S.34

S.35

S.36

S.37

S.88

Description

Radiation without rotation All adjustments of X-ray tube assembly, e.g. accep-

Radiation without rotation for Ceph See S.01.

Adjustment of kV setpoint, mA setpoint and VH setpoint

Test of actual values kV, mA, VH. After replacing DX1 or X-ray tube assembly.

Heating adjustment After replacing DX1 or X-ray tube assembly.

Reading/deleting the radiation counter After replacing the X-ray tube assembly or in war-

Deleting the error memory After replacing the X-ray tube assembly.

Erasing EEPROM on DX1 (deletes all data) In case of software problems (all software adjust-

Adjusting the kV increase to customer’s request Too much kV increase in the spine region.

Hardware service Problems with DX1 board.

Rotation functions Mechanical malfunctions of rotation, and test of the

Check of actuators Mechanical malfunctions, layer correction, light bar-

Check of film holder Film holder problems.

Unit identification Changing the unit identification.

Height adjustment Checking freedom of movement, adjustment after

Forehead support motor See S.15 and removal of forehead support.

Jaw width Adjusting DX1, functional test of potentiometer for

Diaphragm service Adjusting DX1, fitting a diaphragm.

Software update of EEPROM on DX1 Replacing the EEPROM J115 up to software version

Check and adjustment of film-screen combination Changing the film-screen combination.

Check of automatic exposure system (AES) Adjustment of DX8 for stability testing.

Diaphragm service, Pan/Ceph

(omitted as of memory card V35.1 remote selection

still possible only via SIDEXIS).

Image receptor test, Pan For checking the image receptor.

Image receptor test, Ceph For checking the image receptor.

Ceph arm service Ceph arm problems.

PC service Problems with readiness for exposure.

Acceptance testing, dose measurement Dose measurement.

XAB OP service Read out and delete IP addresses

Demonstration mode Selected with switch S1 on DX31. Switches the unit

tance testing, functional test, head adjustment, diaphragm adjustment.

After replacing the DX1 board, or malfunction of the

X-ray tube assembly.

ranty cases

ments are deleted and must be reprogrammed).

light barriers.

rier adjustment.

replacing gas-operated spring, adjustment of Ceph

movement, test of correction switch and of light barrier pulses.

forehead support.

04.50 / 05.52

Diaphragm adjustment, selected by SIDEXIS.

to demonstration mode (no radiation).

When required

2.3

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

2 - 9

Page 38

2.4 List of Error Messages for SIDEXIS

The following descriptions should always be seen in relation to the ORTHOPHOS Plus DS unit.

With error message E4 01, ORTHOPHOS Plus DS is generally functional and the SIDEXIS messages must be observed.

With other error messages on ORTHOPHOS Plus DS, the SIDEXIS messages indicate secondary faults.

OP: ORTHOPHOS Plus DS

XOP/XAB: Image acquisition card for Panorama X-rays

EDC: Image receptor electronics on ORTHOPHOS Plus DS

Error

message

up to

SIDEXIS 5.2x

Multitimer

Break 1

Multitimer

Break 2

OP

Break 1

OP

Break 2

EDC

Break XXX

XOP

Break 1/2/3

**

XOP

Break 10 **

XOP

Break 30

XOP

Break 40

XOP

Break 50 **

XOP

Break

60/70

Error

message

from

SIDEXIS 5.3

Multitimer

Break

0xA001

Multitimer

Break

0xA002

OP Break

0xB001

OP Break

0xB002

EDC Break

0xCxxx

XAB OP

Break

0xD001/002/

003 **

XAB OP

Break

0xD010 **

XAB OP

Break

0xD030

XAB OP

Break

0xD040

XAB OP

Break

0xD050 **

XAB OP

Break

0xD060/070

Description

Interruption caused by releasing the X-ray

button on the Multitimer during radiation.

Interruption caused by releasing the X-ray

button on the Multitimer between two partial exposures.

Interruption by OP. Check error message on Multitimer.

Interruption by OP. Check error message on Multitimer.

Voltage problem/failure at image receptor,

see Appendix A.

Timeout on the XOP/XAB, no defined functional call from OP within a preset time.

(only for ORTHOPHOS Plus DS Ceph)

Incorrect communication between XOP/

XAB and image receptor.

OP pulses are more than intended for the

exposure.

Image acquisition card holds insufficient

storage space for the intended exposure.

Image acquisition card receives no image

information.

ORTHOPHOS emits incorrect exposure ID. Check the software versions of OP and

The displayed number XXX is an indication

of several error numbers, see Appendix A.

Check for mechanical obstruction of the

OP movement.

Check the software version of OP and

SIDEXIS for compatibility.

Remove the image receptor from its holder

and reinsert it firmly.

Check signal path with XOP:

XOP – cable connection – OP – image

receptor.

Check signal path with XAB:

XAB – image receptor.

Check the voltages at the image receptor.

Check the software versions of OP and

SIDEXIS for compatibility. Check whether

OP is "hung up".

Check the software versions of OP and

SIDEXIS for compatibility.

Check the memory configuration of XOP/

XAB.

Remove EDC from its holder and reinsert it

firmly. Check the signal path:

Check signal path with XOP:

XOP – cable connection – OP – image

receptor.

Check signal path with XAB:

XAB – image receptor.

Check the voltages at the image receptor.

SIDEXIS for compatibility.

Check the error message displayed by the

OP. (data or address bus error?)

Required action

** see Correcting error of message E4 08 and E4 01

54 53 571 D 3297

2 - 10 D 3297.077.01.10.02 04.2007

Page 39

The error message indicates a combination of several fault causes:

e.g. display on SIDEXIS 3 ¦ C

HEX 3 C

2.4 EDC Break Annex A

Valence

8

3

2

4

2

2

2

1

2

1

0

2

8

3

2

4

2

2

2

1

2

1

0

2

Bit76543210

Error

EDC

RESET

EDC

VSP

EDC

VSN

EDC

VDD

EDC

VAN

EDC

VAP

001 1 1 100

These voltages are not present

Bit = 0 Ok, fault has not occurred

Bit = 1 Error, fault has occurred, signal is missing

Bit number Error

0

1

2

3

4

5

EDC VAP ERROR V212 0x01 Voltage VAP +18 V not present/too low

EDC VAN ERROR V232 0x02 Voltage VAN – 18 V not present/too low

EDC VDD ERROR ------- 0x04 Voltage VDD not present/too low

EDC VSN ERROR V122 0x08 Voltage VSN – 5 V not present/too low

EDC VSP ERROR V112 0x10 Voltage VSP +5 V not present/too low

EDC RESET ERROR V222 0x20 Voltage VCC +5 V not present/too low

6

7

LED

RHB

Meaning

or digital section is in reset state

0x40 Internal message

0x80 Internal message

2.4

54 53 571 D 3297

D 3297.077.01.10.02 04.2007

2 - 11

Page 40

2.1

2 - 12 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 41

3 Troubleshooting

Page 42

Contents Sirona Dental Systems GmbH

Troubleshooting

Contents

3.1 Unit cannot be switched on ............................................................................................... 3 - 7

3.2 Demonstration mode cannot be turned ON/OFF ............................................................... 3 - 9

3.3 Correcting error of help message H3 01. ....................................................................... 3 - 11

3.4 Correcting errors of help messages H3 05 and H3 06. ................................................... 3 - 13

3.5 Correcting error of help message H3 07. ........................................................................ 3 - 15

3.6 Correcting error of help message H3 12. ........................................................................ 3 - 17

3.7 Correcting error of help message H3 16. ........................................................................ 3 - 19

3.8 Correcting error of messages E1 01, E1 02, E2 03: Signal paths to

control board DX1 are interrupted. .................................................................................. 3 - 21

3.9 Correcting error of message E2 01: X-ray tube assembly overheated. ........................... 3 - 23

3.10 Correcting error of message E2 04: Zero power range has been re-initialized. .............. 3 - 25

3.11 Correcting error of message E2 10: Max. radiation time of the program

is exceeded. .................................................................................................................... 3 - 27

3.12 Correcting error of message E2 11: Anode voltage too high. .......................................... 3 - 29

3.13 Correcting error of message E2 12: Anode current too high. .......................................... 3 - 31

3.14 Correcting error of message E2 13: Filament voltage too high. ...................................... 3 - 33

3.15 Correcting error of message E2 14: Short-circuit in bridge ............................................ 3 - 35

3 - 2 D 3297.077.01.10.02 04.2007

54 53 571 D 3297

Page 43

Sirona Dental Systems GmbH Contents

3.16 Correcting error of message E2 15: VH

3.17 Correcting error of message E2 16: kV

continuously present. .................................. 3 - 37

max

ACTUAL

– Cable is interrupted. ............................ 3 - 39

3.18 Correcting error of message E2 20: Interrupted exposure lead in Multitimer cable. ....... 3 - 41

3.19 Correcting error of message E2 40: VH setpoint out of tolerance. .................................. 3 - 45

3.20 Correcting error of message E2 45: mA setpoint out of tolerance. .................................. 3 - 47

3.21 Correcting error of messages E3 01, E3 02: Actuator M2 has not

left/reached the tripping position. .................................................................................... 3 - 49

3.22 Correcting error of messages E3 03, E3 04: Actuator M3 has not

left/reached the tripping position. .................................................................................... 3 - 51

3.23 Correcting error of messages E3 05, E3 06: Cassette carriage has not

left/reached the reference point. ...................................................................................... 3 - 53

3.24 Correcting error of message E3 09: Pulses for height adjustment are not

within allowed time. ......................................................................................................... 3 - 55

3.25 Correcting error of messages E3 10, E3 11: Count for height adjustment too

high/too low for reference setting. .................................................................................... 3 - 59

3.26 Correcting error of message E3 12: Key for height adjustment pressed

during unit self-adjustment. ............................................................................................. 3 - 61

3.27 Correcting error of messages E3 27, E3 28: Zero point of forehead support

was not exited/reached. ................................................................................................... 3 - 63

3.28 Correcting error of messages E3 32, E3 33: Start position for rotation

was not exited/reached. ................................................................................................... 3 - 65

3.29 Correcting error of message E3 36: Cassette holder was swivelled from the

Pan position during Pan exposure. .................................................................................. 3 - 69

3.30 Correcting error of message E3 39: Light barrier for Ceph position rotation

indicates invalid status ..................................................................................................... 3 - 73

3.31 Correcting error of message E3 46: Position of cassette holder

cannot be determined. ..................................................................................................... 3 - 75

3.32 Correcting error of message E3 51: Faulty signals output by the film drive control. ....... 3 - 77

3.33 Correcting error of message E4 01: Exposure aborted by SIDEXIS (with XOP) ............. 3 - 79

3.34 Correcting error of message E4 01: Exposure aborted by SIDEXIS (with XAB) ............. 3 - 81

3.35 Correcting error of message E4 02: Fault indicated by control unit of Ceph motor. ........ 3 - 83

3.36 Correcting error of message E4 03: Light barrier for Ceph control not

emitting any pulses. ......................................................................................................... 3 - 87

3.37 Correcting error of message E4 04: Motor M8 for secondary

diaphragm not moving. .................................................................................................... 3 - 89

3.38 Correcting error of message E4 06: Fault at one of the supply voltages (with XOP) ...... 3 - 93

3.39 Correcting error of message E4 06: Fault at one of the supply voltages (with XAB) ....... 3 - 95

3.40 Correcting error of message E4 08: Aborted by SIDEXIS during radiation

(with XOP) ....................................................................................................................... 3 - 97

3.41 Correcting error of message E4 08: Aborted by SIDEXIS during radiation

(with XAB) ...................................................................................................................... 3 - 101

3.42 Correcting error of message E4 09: Faulty signal from limit switches of