Page 1

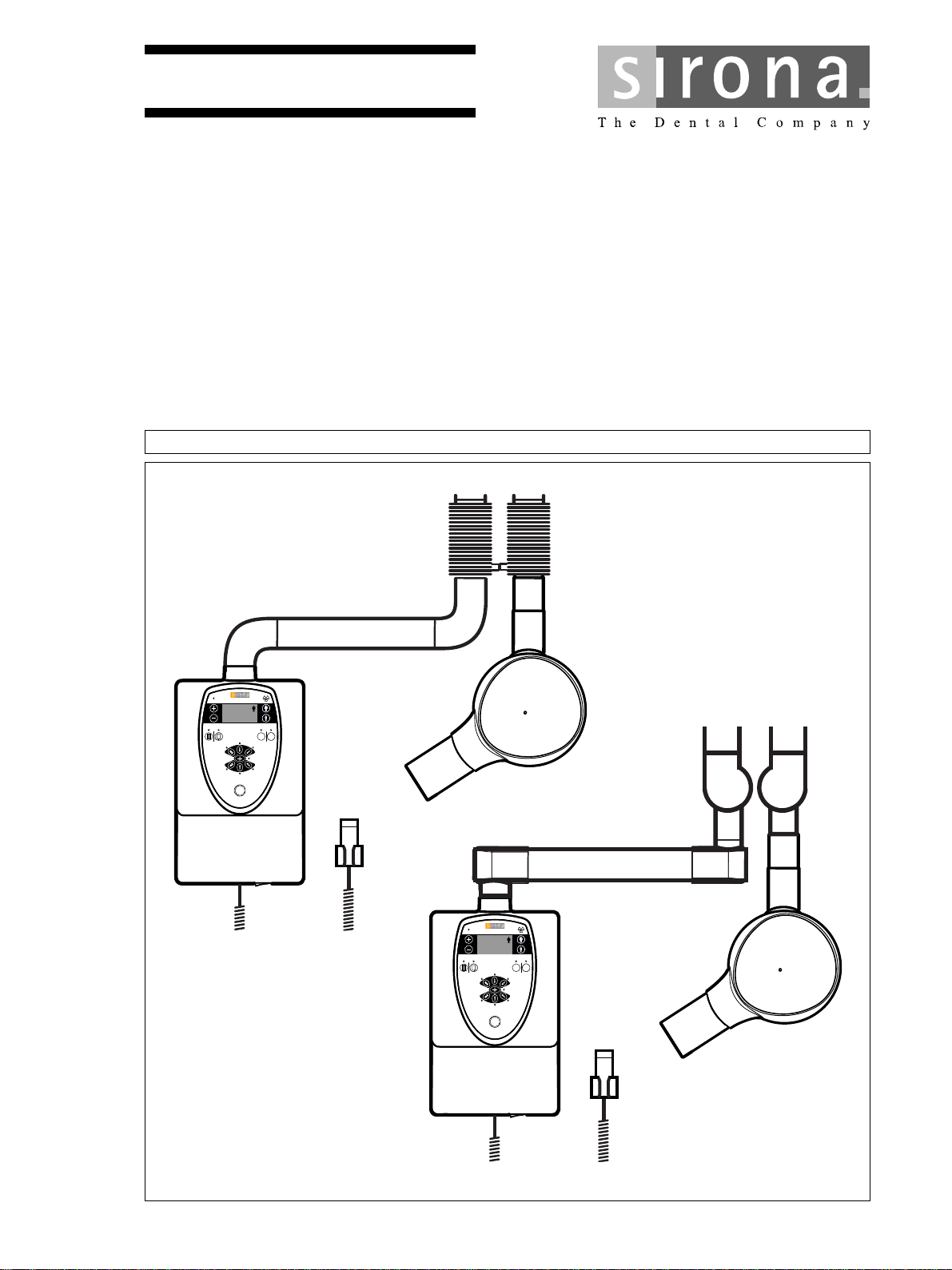

kÉï=~ë=çÑW=

HELIODENT

PLUS

7mA DC7mA DC

70kV 60kV

S

00

8

.

HELIODENTHELIODENT

PLUS

7mA DC

70kV 60kV

S

00

8

.

NMKOMNS

ebiflabkq

pЙкобЕЙ=j~ем~д

mirp

Cover page

bеЦдблЬ

bеЦдблЬ

=

Page 2

Page 3

Sirona Dental Systems GmbH Table of contents

Service Manual HELIODENT

PLUS

Table of contents

1

General information.................................................................................................. 7

1.1 Structure of the document............................................................................. 7

1.1.1 Identification of the danger levels..................................................... 7

1.1.2 Formats and symbols used .............................................................. 7

1.2 General safety information ............................................................................ 8

1.3 Operation notes............................................................................................. 9

1.4 Changing the device configuration................................................................ 11

1.4.1 Changing the cone length ................................................................ 11

1.4.2 Using and changing a diaphragm .................................................... 11

1.5 Measures when exchanging spare parts ...................................................... 12

1.5.1 Safety-related tests .......................................................................... 12

1.6 Demo mode................................................................................................... 13

1.7 List of software versions................................................................................ 14

1.8 Round and angular support arm system ....................................................... 14

1.9 The most important subassemblies .............................................................. 15

1.10 Labeling......................................................................................................... 17

1.11 Removing covers .......................................................................................... 19

1.11.1 Wall module ..................................................................................... 19

1.11.2 Remote control and remote timer..................................................... 20

1.11.3 X-ray tube unit.................................................................................. 21

bеЦдблЬ

1.12 Overview of PC boards ................................................................................. 22

1.12.1 Generator board DX1....................................................................... 22

1.12.2 Control board DX4 ........................................................................... 23

1.13 Required items .............................................................................................. 24

1.13.1 Additional documents....................................................................... 24

1.13.2 Tools and auxiliary materials............................................................ 24

2

62 15 102 D3507

D3507.076.01.13.02 10.2016

List of messages ...................................................................................................... 25

2.1 Error messages............................................................................................. 25

2.1.1 General ............................................................................................ 25

2.1.2 Structure........................................................................................... 25

2.1.3 List of error messages...................................................................... 26

3

Page 4

Table of contents Sirona Dental Systems GmbH

Service Manual HELIODENT

PLUS

3

Troubleshooting....................................................................................................... 29

3.1 Error message: NONE ................................................................................. 29

3.2 Error message: E5 01 02 / E5 01 14 / E5 01 12.......................................... 32

3.3 Error message: E5 01 22 ............................................................................. 33

3.4 Error message: E6 01 23 ............................................................................. 34

3.5 Error message: E7 01 01 ............................................................................. 36

3.6 Error message: E7 04 51 - Door contact error ............................................. 38

4

Maintenance............................................................................................................ 39

4.1 Checking the shielding ................................................................................. 39

4.1.1 Test ................................................................................................. 39

4.1.2 Positions.......................................................................................... 39

4.2 Checking the protective ground connections ............................................... 41

4.2.1 Test ................................................................................................. 41

4.2.2 Positions.......................................................................................... 41

4.3 Checking exposure time and high voltage kV .............................................. 43

4.4 Checking the deadman function................................................................... 44

4.5 Checking the release button......................................................................... 45

4.5.1 General............................................................................................ 45

4.5.2 Release button on PC board DX1 (coiled cable)............................. 45

4.5.3 Release button on PC board DX4 (coiled cable)............................. 46

4.5.4 Release button on front panel on PC board DX4............................ 47

4.6 Checking the front panel .............................................................................. 48

4.6.1 Visual check .................................................................................... 48

4.6.2 Front panel test ............................................................................... 48

4.7 Checking and adjusting the support arm...................................................... 50

4.7.1 Round support arm system ............................................................. 50

4.7.2 Angular support arm system ........................................................... 51

4.7.2.1 Checking and adjusting the angular scissor arm.............. 51

4.7.2.2 Checking and adjusting the angular scissor arm is parallel 52

4.8 Checking the X-ray tube assembly joint....................................................... 54

4.9 Checking the ceiling model .......................................................................... 57

4.10 Checking HELIODENT PLUS on the mobile stand...................................... 59

4.11 Checking the tube current ............................................................................ 60

4.12 Checking the protective ground wires .......................................................... 61

4.13 Checking the unit leakage current................................................................ 63

4.14 Checking insulation resistance on the power supply cord of the mobile stand 64

4 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 5

Sirona Dental Systems GmbH Table of contents

Service Manual HELIODENT

PLUS

5

Service routines........................................................................................................ 65

5.1 Operation ...................................................................................................... 65

5.2 Overview ....................................................................................................... 66

5.3 Service routines (list)..................................................................................... 67

5.3.1 Service routine S01.......................................................................... 67

5.3.2 Service routine S02.......................................................................... 67

5.3.3 Service routine S03.......................................................................... 67

5.3.4 Service routine S04.......................................................................... 67

5.3.5 Service routine S05.......................................................................... 68

5.3.6 Service routine S06.......................................................................... 68

5.3.7 Service routine S07.......................................................................... 69

5.3.8 Service routine S08.......................................................................... 69

5.3.9 Service routine S09.......................................................................... 69

5.3.10 Service routine S10.......................................................................... 70

5.3.11 Service routine S11.......................................................................... 70

5.3.12 Service routine S12.......................................................................... 70

bеЦдблЬ

5.3.13 Service routine S13.......................................................................... 71

5.3.14 Service routine S14.......................................................................... 71

5.3.15 Service routine S15.......................................................................... 72

5.3.16 Service routine S16.......................................................................... 73

5.3.17 Service routine S17.......................................................................... 73

5.3.18 Service routine S18.......................................................................... 74

5.3.19 Service routine S19.......................................................................... 74

5.3.20 Service routine S20.......................................................................... 75

5.3.21 Service routine S21.......................................................................... 75

5.3.22 Service routine S22.......................................................................... 75

5.3.23 Service routine S23.......................................................................... 76

5.3.24 Service routine S24.......................................................................... 76

5.3.25 Service routine S25.......................................................................... 76

5.3.26 Service routine S26.......................................................................... 77

5.3.27 Service routine S27.......................................................................... 77

5.3.28 S28 service routine .......................................................................... 78

5.3.29 Service routine S29.......................................................................... 78

62 15 102 D3507

D3507.076.01.13.02 10.2016

5

Page 6

Table of contents Sirona Dental Systems GmbH

Service Manual HELIODENT

PLUS

6

Repair....................................................................................................................... 79

6.1 Safety-related tests ....................................................................................... 79

6.2 Replacing X-ray tube assembly H1............................................................... 79

6.3 Replacing PC board DX1 .............................................................................. 85

6.3.1 Removing a defective board DX1 .................................................... 85

6.3.2 Installing the new board DX1 ........................................................... 86

6.3.3 Connection in the control panel for cable L2.................................... 87

6.3.4 Connecting the power cable............................................................. 87

6.3.5 Attach the EMC additional plate for the wall adapter to the power

88

supply

6.4 Replacing PC board DX4 .............................................................................. 89

6.5 Replacing the power supply cord for the mobile stand ................................. 90

6 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 7

Sirona Dental Systems GmbH 1General information

Service Manual HELIODENT

PLUS

General information

1

1.1Structure of the document

1.1

Structure of the document

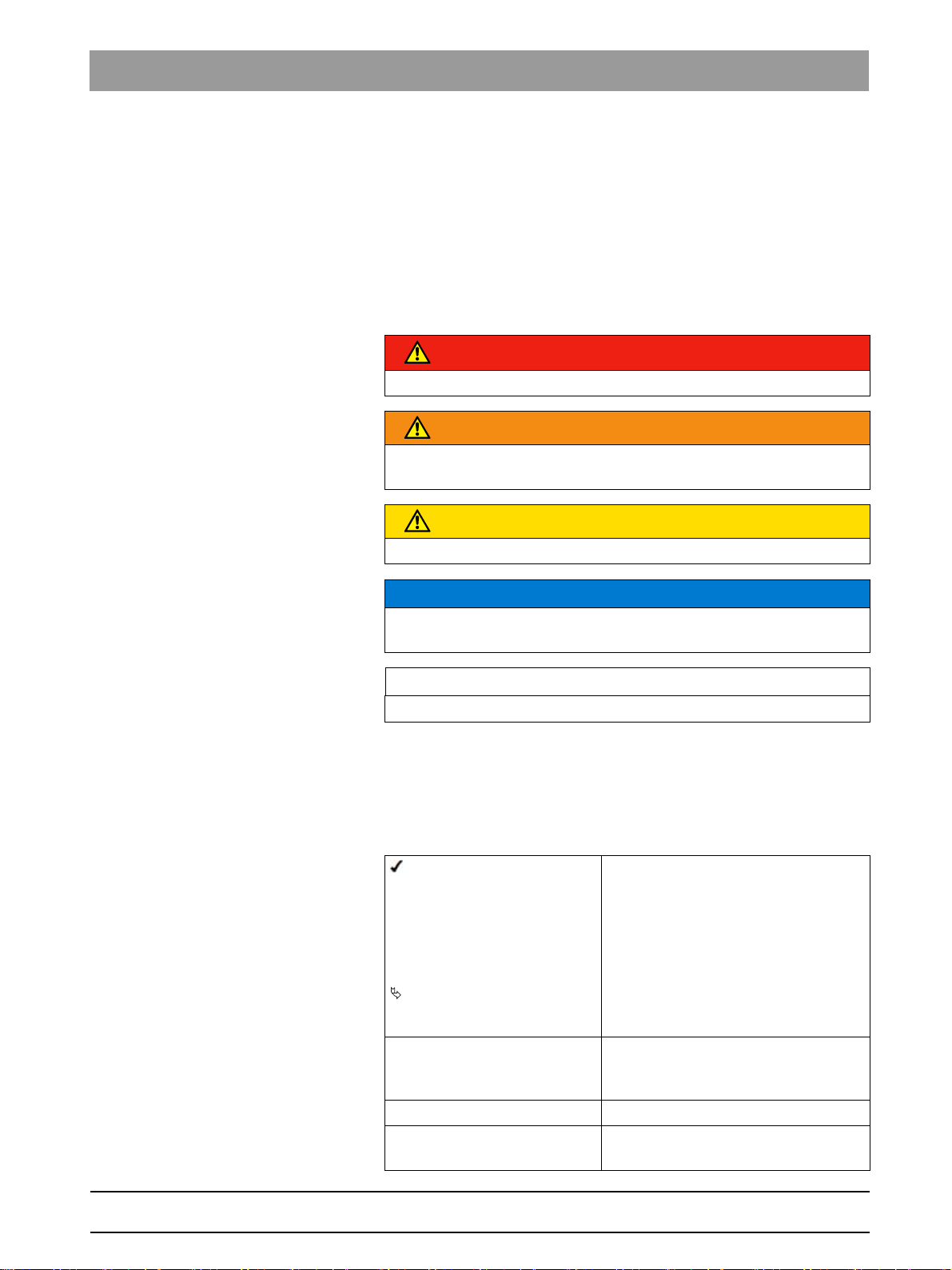

1.1.1 Identification of the danger levels

To prevent personal injury and material damage, please observe the

warning and safety information provided in these operating instructions.

Such information is highlighted as follows:

DANGER

An imminent danger that could result in serious bodily injury or death.

WARNING

A possibly dangerous situation that could result in serious bodily injury

or death.

CAUTION

A possibly dangerous situation that could result in slight bodily injury.

NOTICE

A possibly harmful situation which could lead to damage of the product

or an object in its environment.

bеЦдблЬ

IMPORTANT

Application instructions and other important information.

Tip: Information on making work easier.

1.1.2 Formats and symbols used

The formats and symbols used in this document have the following

meaning:

Prerequisite

1. First action step

2. Second action step

or

➢ Alternative action

Result

➢ Individual action step

See "Formats and symbols

used [ → 7]"

● List Designates a list.

"Command / menu item" Indicates commands, menu items or

Prompts you to do something.

Identifies a reference to another text

passage and specifies its page

number.

quotations.

62 15 102 D3507

D3507.076.01.13.02 10.2016

7

Page 8

1General information Sirona Dental Systems GmbH

1.2General safety information Service Manual HELIODENT

PLUS

1.2

General safety information

WARNING

Radiation protection

The valid radiation protection regulations and measures must be

observed. The statutory radiation protection equipment must be used.

In case of malfunctions, cancel the exposure immediately by letting go

of the exposure release button.

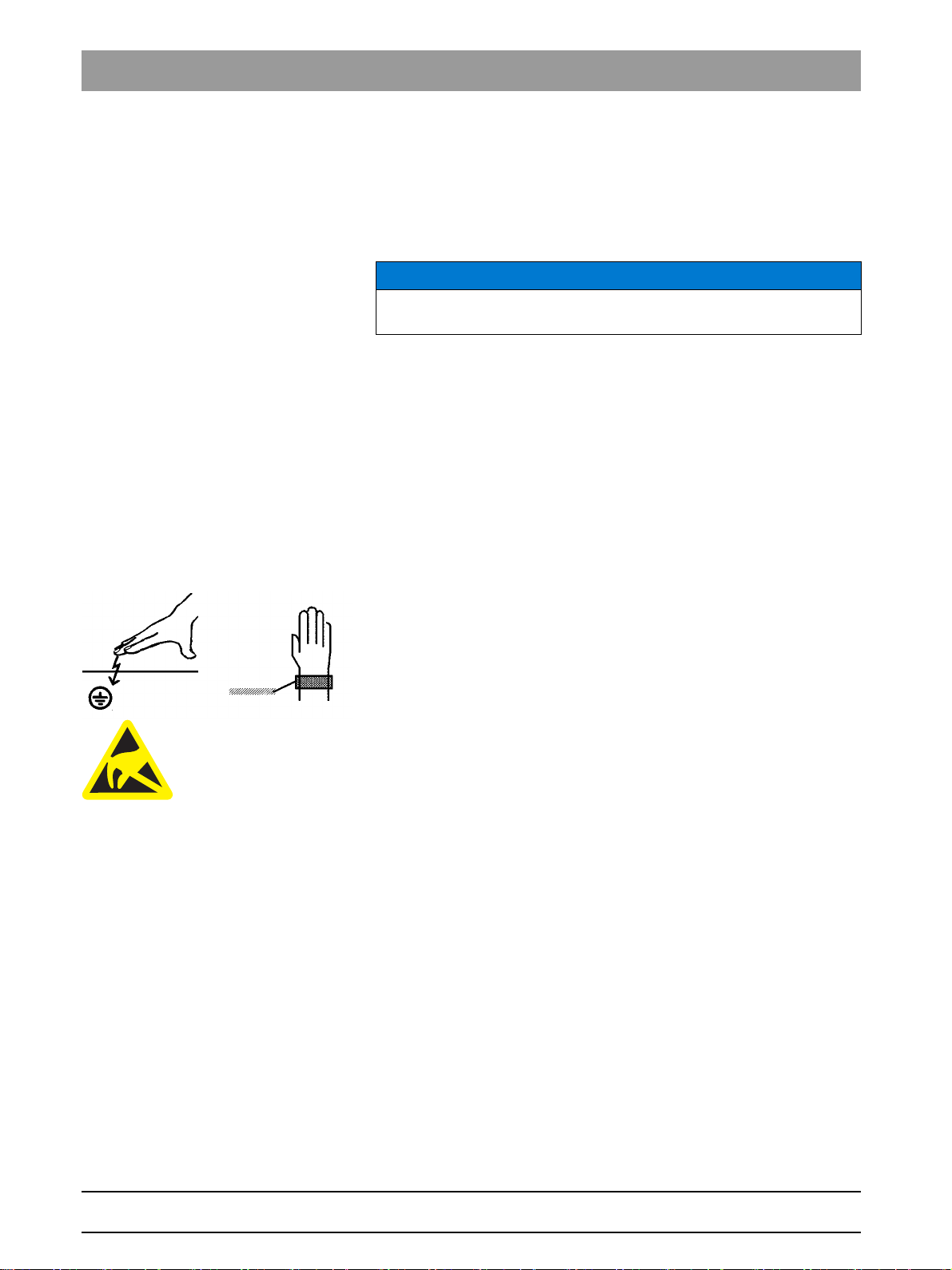

Handling boards

CAUTION

Electrical components of the unit can be destroyed.

Prior to opening the unit

➢ Please comply with the usual precautionary measures for handling

printed circuit boards (ESD).

➢ Make sure you touch a ground point to discharge yourself prior to

touching the components.

➢ Use an ESD wrist band and connect it to the protective ground wire.

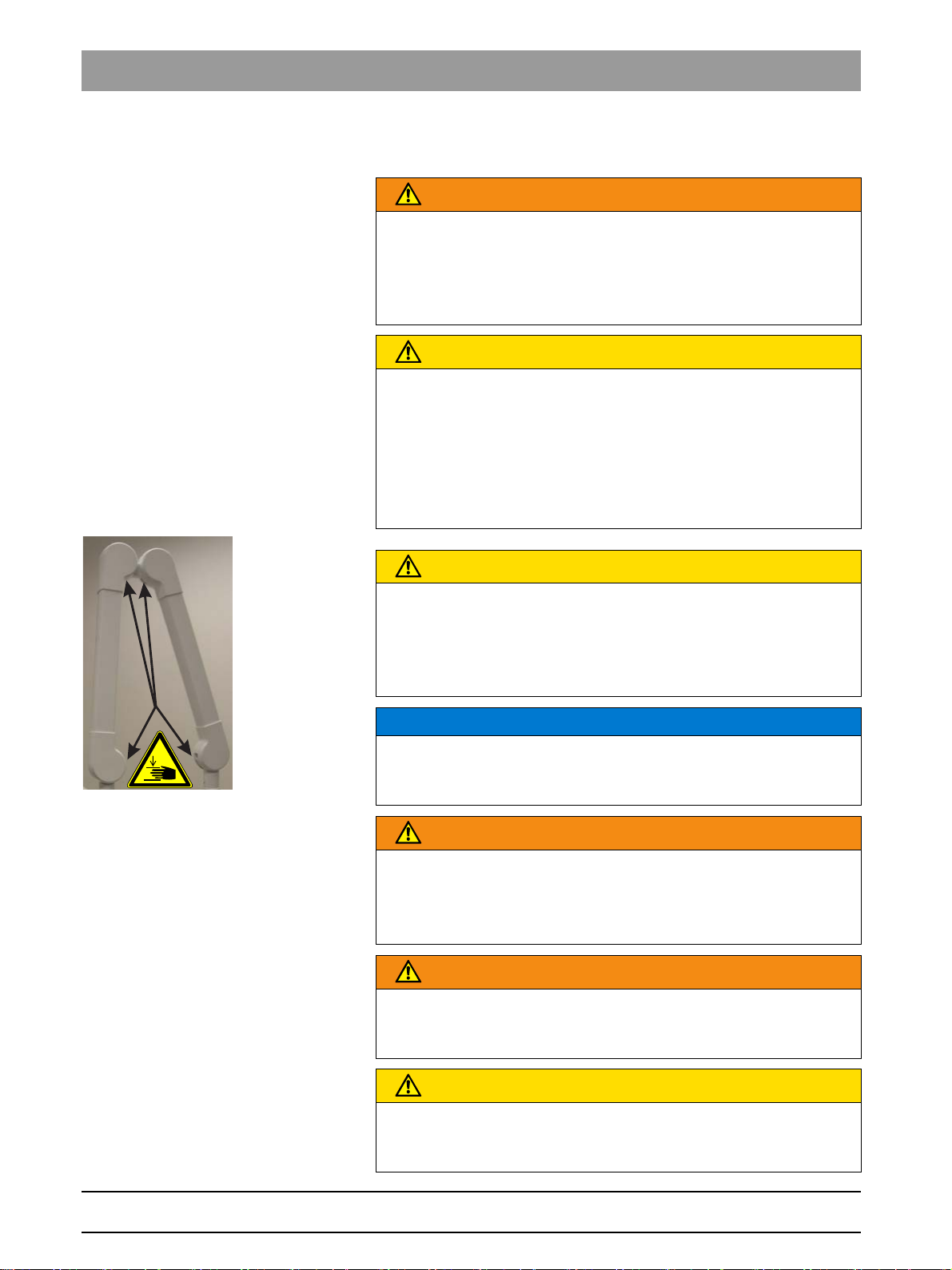

Risk of crushing

CAUTION

Gaps appear between the internal hinges when moving the angular

support arm.

Fingers may be crushed in these gaps.

➢ Ensure that you never place your fingers in the gaps between the

hinges, neither during operation nor for cleaning purposes.

Installation by authorized personnel

NOTICE

Operational reliability

Installation and servicing may be performed only be personnel

specifically authorized by Sirona.

Power connection

WARNING

Shock hazard

People can be injured or electrical components of the unit destroyed.

➢ It is essential that you switch off the unit PRIOR to beginning the

installation or servicing.

Modification to the product

WARNING

Modifications to the product

Modifications which may affect the safety of the operators or third

parties are prohibited by law!

Support arm system additiona l co mponents

CAUTION

No additional components on the support arm system

It is not permissible to fix additional components to the support arm

system.

62 15 102 D3507

8 D3507.076.01.13.02 10.2016

Page 9

Sirona Dental Systems GmbH 1General information

Service Manual HELIODENT

PLUS

1.3Operation notes

1.3

Nominal line voltage

Remote control The unit may be equipped with a remote control to be used inside the

Switch-on procedure

Operation notes

Nominal voltage: 120V, 200V– 240V

Permissible fluctuation: ± 10%

Rated current: At 120 V: 10 A

At 200 – 240 V: 6 – 5 A

Nominal frequency: 50/60 Hz

Internal line impedance: At 120 V 0.3 ohms

At 200 – 240 V 0.8 ohms

treatment room or outside of the X-ray room.

The release button with coiled cable can/must be removed from the

remote control and connected directly to the unit for testing.

Keep in mind that the disconnected cable may be the cause of defects.

NOTICE

Do not press any buttons when switching on the unit!

➢ Switch the unit on.

ª It will execute an electronic self-testing routine.

bеЦдблЬ

ª The operational readiness indicator must be lit up.

Cooling period The cooling period between two exposures is maintained by an automatic

exposure blocking function according to the pulse/pause ratio.

Software version The DX4 board determines the software version.

You can find the software version with the following steps:

● Start service routine "2."

● A label next to the main switch includes an imprint of the software

version.

Disturbance of electronic equipment

caused by cell phones

Disposal

To ensure safe operation of medical electrical equipment, the use of

mobile wireless phones in practice or hospital environments is prohibited.

General

Environmentally sound dis posal

In accordance with Directive 2012/19/EU and national disposal

regulations regarding old electrical and electronic devices, please be

advised that such items must be disposed of in a special way within the

European Union (EU). These regulations require environmental friendly

usage/disposal of old electrical and electronic devices. Such items must

not be disposed of as domestic refuse. This has been expressed using

the icon of the “crossed out trash can” since March 24, 2006, amongst

other methods.

62 15 102 D3507

D3507.076.01.13.02 10.2016

Please observe the disposal regulations applicable in your country.

9

Page 10

1General information Sirona Dental Systems GmbH

1.3Operation notes Service Manual HELIODENT

PLUS

X-ray tube unit

The X-ray tube assembly contains a tube which can implode, lead lining,

and mineral oil.

Removing covers Observe the section on "Removing covers".

Measurements Observe the following when taking measurements:

● Always switch the unit off before connecting a measuring instrument.

● Select the correct current/voltage type and adjust the measuring

range to match the expected readings.

● Perform continuity tests only on units which are switched off.

● If several exposures with radiation must be taken to check a

measurement, make sure that the prescribed cool-down intervals are

observed.

– They are maintained by an automatic exposure blocking function

(see Operating Instructions).

● Observe the radiation protection guidelines before releasing the

radiation.

10 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 11

Sirona Dental Systems GmbH 1General information

Service Manual HELIODENT

PLUS

1.4Changing the device configuration

1.4

Changing the device configuration

1.4.1 Changing the cone length

Explanation

If the cone length is changed, this change must be registered with service

routine S06 [ → 68].

1.4.2 Using and changing a diaphragm

Explanation

If a diaphragm needs to be used, this change must be registered with

service routine S07 [ → 69].

If a diaphragm is replaced or removed, this change must also be

registered with service routine S07 [ → 69].

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

11

Page 12

1General information Sirona Dental Systems GmbH

1.5Measures when exchanging spare parts Service Manual HELIODENT

PLUS

1.5

Measures when exchanging spare parts

Spare parts

The article numbers for ordering spare parts can be found in the spare

parts list, Order No. 62 34 111

NOTICE

The diagrams contained in the spare parts list provide a useful guide

when replacing parts.

Preparation

➢ Always switch the unit off before replacing parts.

Replacement

The following must be observed when replacing individual

subassemblies:

● The unit must be disconnected from the power supply before

replacing any parts near the power supply, the power switch, or the

power supply board.

Disconnect the unit from the junction box of the building installation.

● Always wear an ESD wrist band to protect sensitive components on

printed circuit boards (ESD) and attach it to a ground conductor

(green/yellow).

● Always check the unit after replacing PC boards DX1 and DX4 or the

X-ray tube assembly.

● For safety reasons, the support arm must be secured with the safety

belt when replacing the X-ray tube assembly.

1.5.1 Safety-related tests

A protective conductor test and a leakage current test must be performed

prior to the installation or the hand-over of the unit as well as after repair

work.

See Sections "Protective conductor test [ → 61]" and "Leakage current

test."

12 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 13

Sirona Dental Systems GmbH 1General information

X500

W

V

Service Manual HELIODENT

PLUS

1.6Demo mode

1.6

Demo mode

Activation

1. Set service routine "26" to "On".

2. Switch the unit off.

3. Open the protective cover of the wall module.

4. Attach cables V (blue) and W (pink) on terminal strip X500.

5. Close the protective cover of the wall module.

6. Switch the unit back on.

ª The message "E1 11 88" appears on the display.

7. Acknowledge this message by pressing any key (not a release

button).

ª The demo mode is now activated.

ª When a release button is activated, no X-ray radiation will be

generated.

Deactivation

✔ The unit is in "demo mode".

1. Set service routine "26" to "Off".

2. Switch the unit off.

3. Open the protective cover of the wall module.

4. Attach cable V (blue) to terminal strip X500.1.

5. Attach cable W (pink) on terminal strip X500.2.

6. Close the protective cover of the wall module.

7. Switch the unit back on.

ª The demo mode was deactivated.

ª When a release button is activated, X-ray radiation will be generated.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

13

Page 14

1General information Sirona Dental Systems GmbH

1.7List of software versions Service Manual HELIODENT

PLUS

1.7

1.8

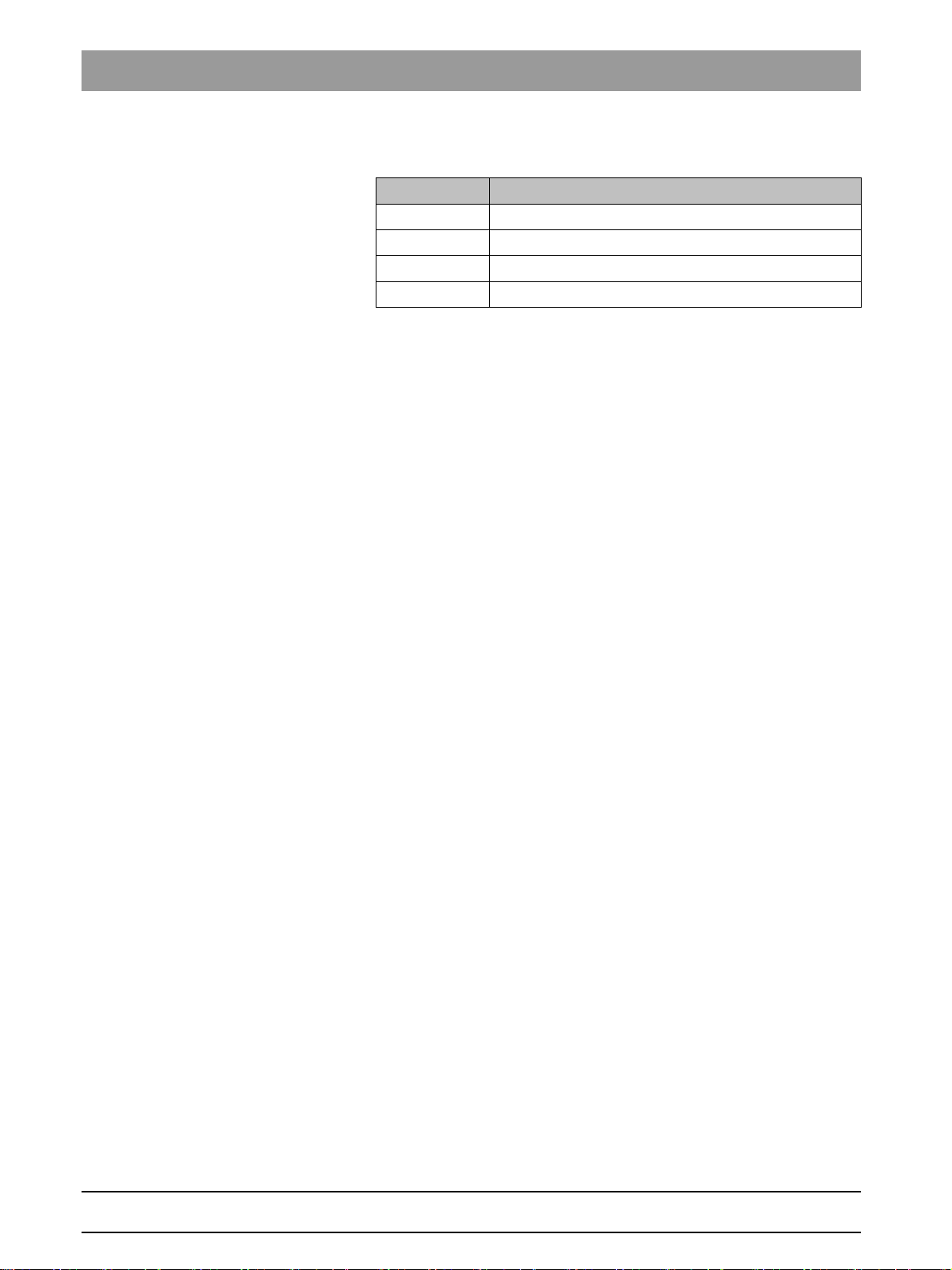

List of software versions

Software Remarks

V02.04.00 1. Series release

V02.05.00 from serial no. 3001

V02.07.00 from serial no. 20001

V02.08.00 new S28 and S29 service routine

Round and angular support arm system

Example of round suppor t arm

The HELIODENT Plus is available with a round and angular support arm

system.

In the images which do not exclusively demonstrate the angular support

arm system, the round support arm system is shown.

14 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 15

Sirona Dental Systems GmbH 1General information

A

B

Service Manual HELIODENT

PLUS

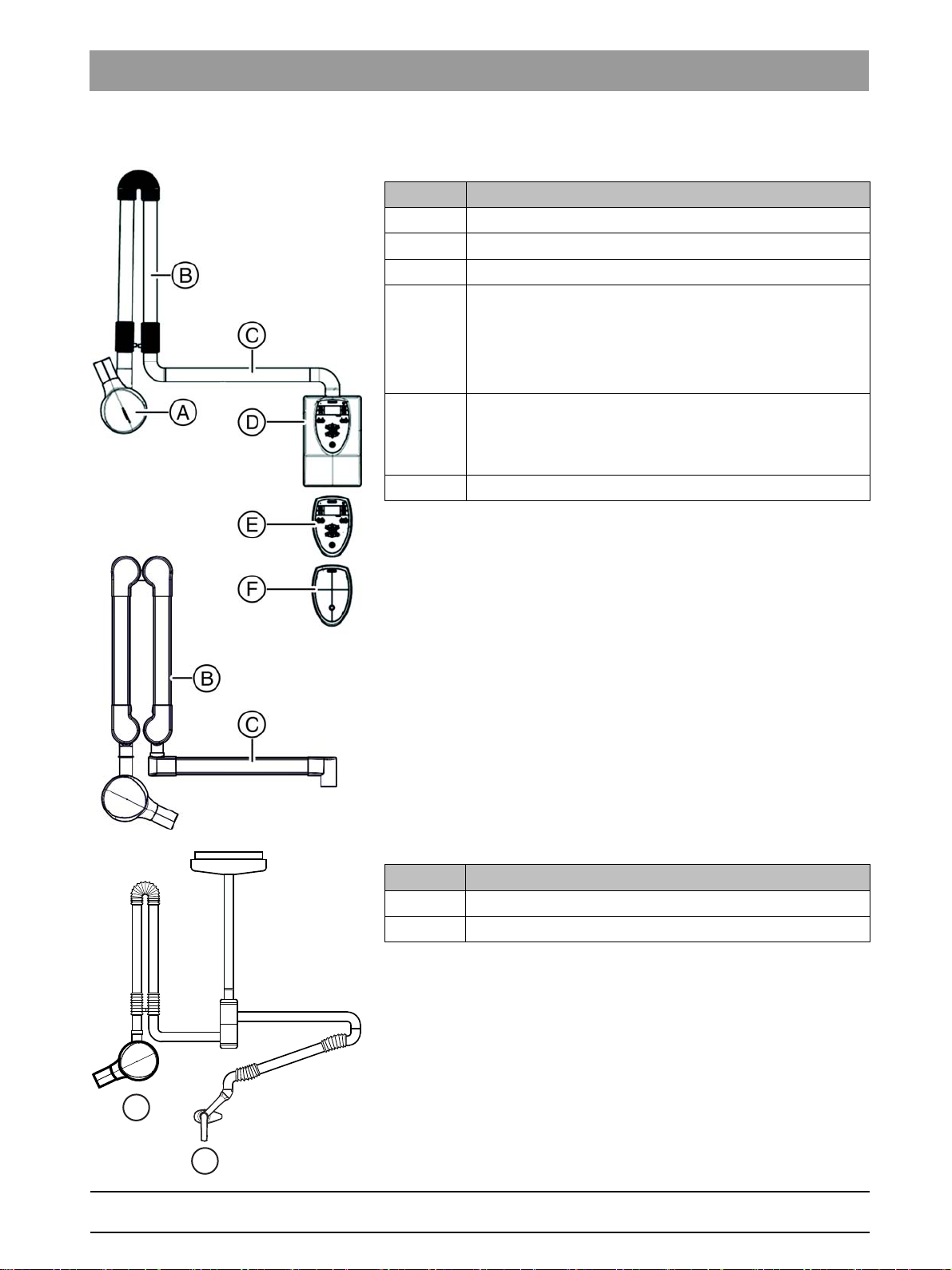

1.9The most important subassemblies

1.9

The most important subassemblies

Position Designation

A X-ray tube unit

B Scissor arm

C Support arm

D Wall module

● Board DX1

● Front panel

● Control board DX4

E Remote Timer (Optional)

● Front panel

● Control board DX4

F Remote control (optional)

bеЦдблЬ

Position Designation

A X-ray tube assembly on overhead support

B LEDview on overhead support

62 15 102 D3507

D3507.076.01.13.02 10.2016

15

Page 16

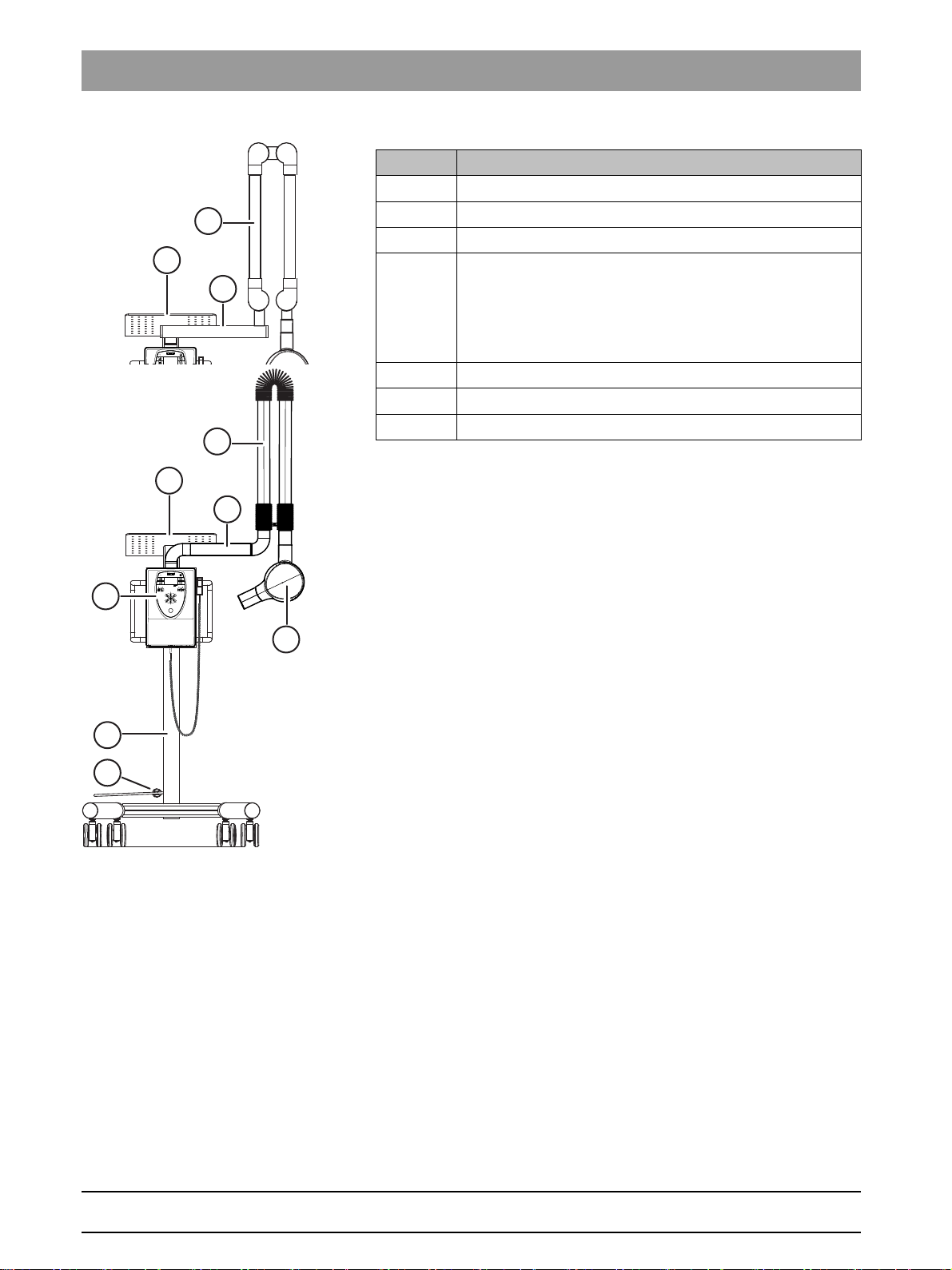

1General information Sirona Dental Systems GmbH

B

C

D

E

F

A

G

C

B

G

1.9The most important subassemblies Service Manual HELIODENT

Position Designation

A X-ray tube unit

B Scissor arm

C 410 mm support arm

D Wall module

● Board DX1

● Front panel

● Control board DX4

E Mobile stand

F Power supply cord

GTray

PLUS

16 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 17

Sirona Dental Systems GmbH 1General information

Service Manual HELIODENT

PLUS

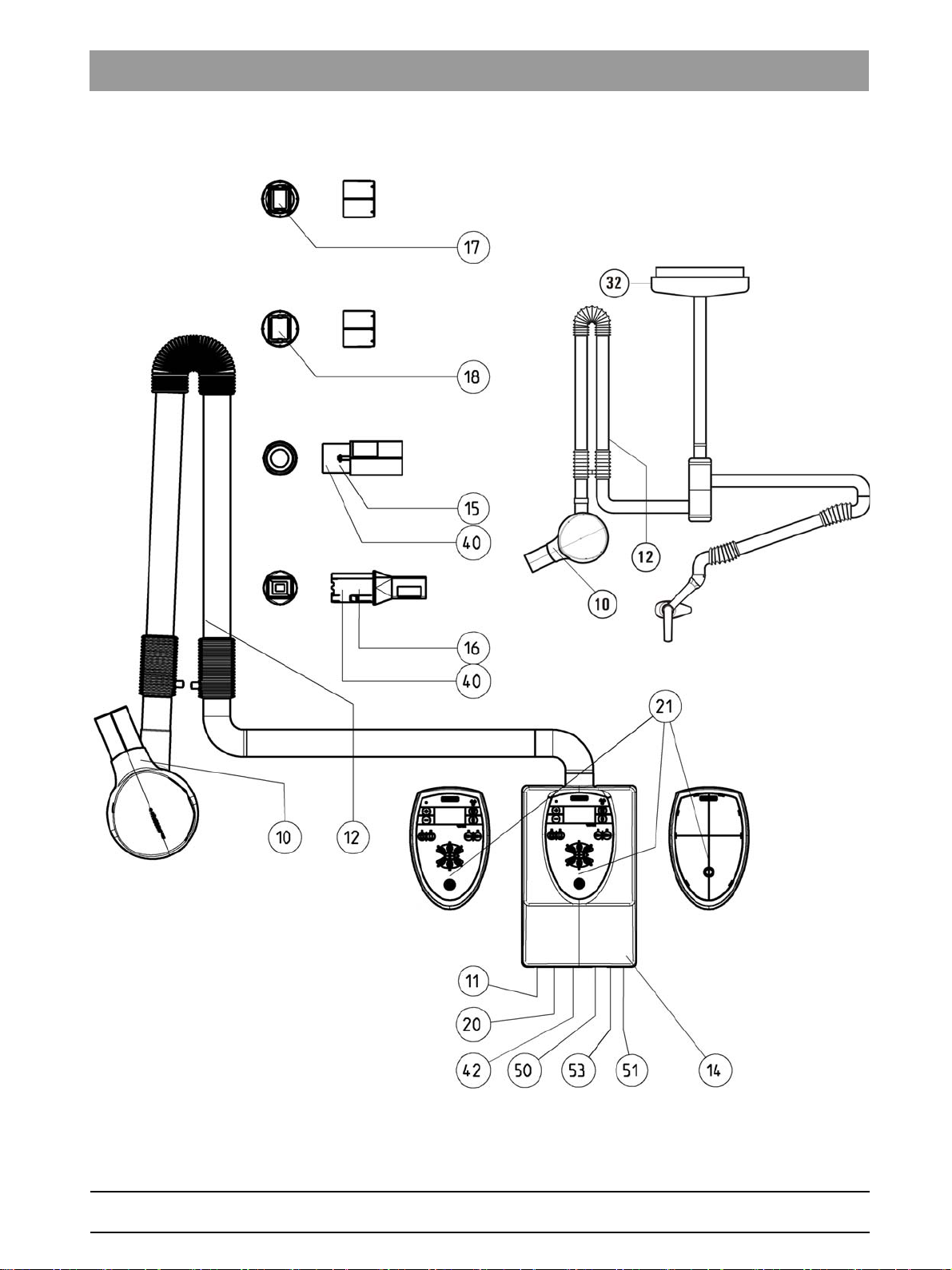

1.10Labeling

1.10

Labeling

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

17

Page 18

1General information Sirona Dental Systems GmbH

1.10Labeling Service Manual HELIODENT

PLUS

Item Designation Info

10 ID label of X-ray tube assembly attached inside the cone

11 ID label of wall adapter

12 ID label of scissor arm

14 "Follow the operating instructions" label

15 ID label of round cone extension transp. / white print

16 ID label of square cone extension transp. / white print

17 ID label of radiation field limiter 2x3

18 ID label of radiation field limiter 3x4

20 Warning label for HELIODENT PLUS yellow / black print

21 Warning label for X-ray unit Affixed on site

32 ID label of LEDview

40 DHHS label about Regulations 21CFR (45x27) transp. / white print

42 DHHS label UL-CSA white / black print

50 Chinese label for HELIODENT PLUS

51 Chinese label for HELIODENT PLUS (ID)

53 Chinese label for CCIB

18 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 19

Sirona Dental Systems GmbH 1General information

B

A

C

S

B

Service Manual HELIODENT

PLUS

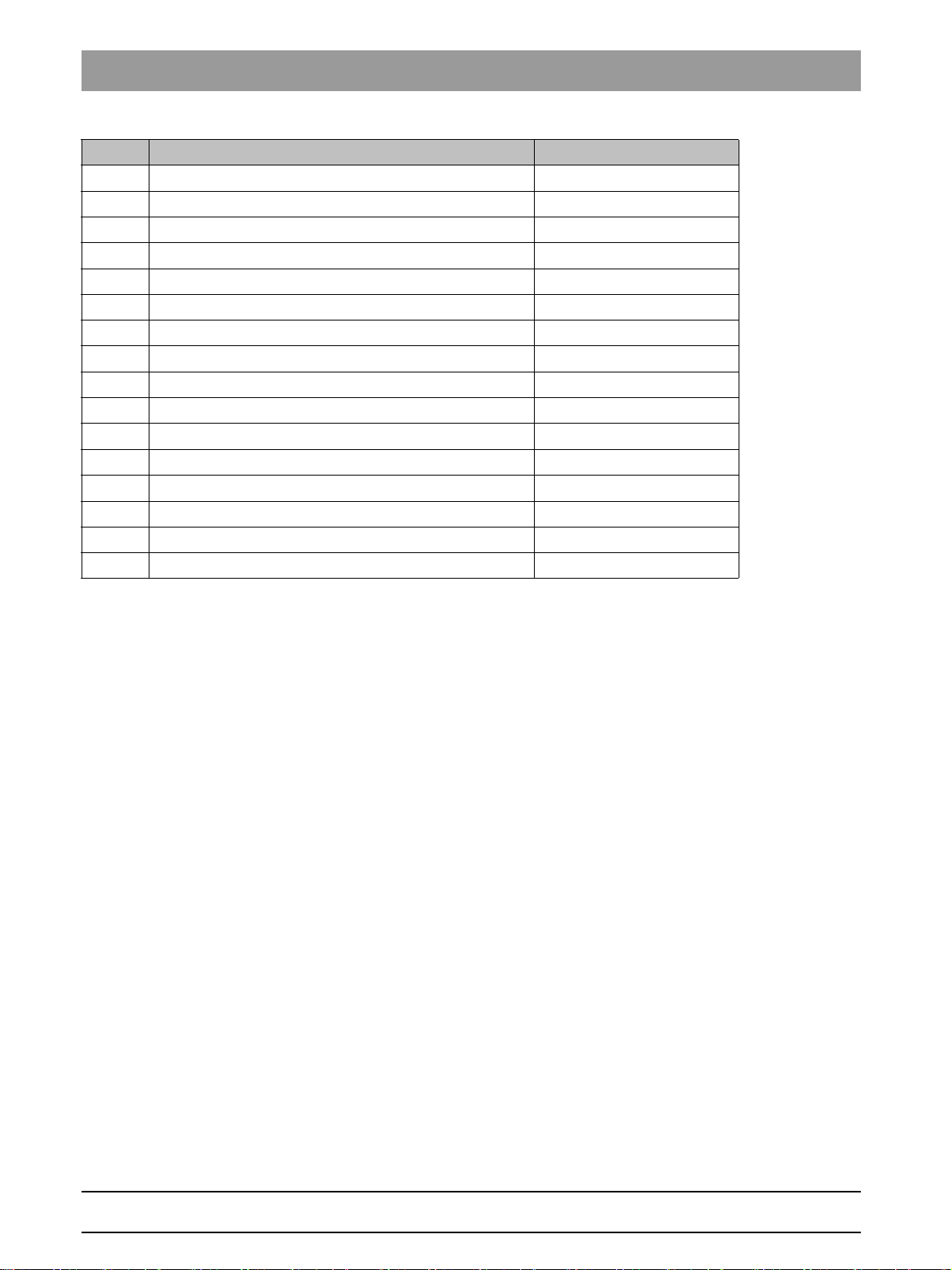

1.11Removing covers

1.11

Removing covers

1.11.1 Wall module

Removing the cover

1. Turn the unit off.

2. Unlock the housing shell (C) of the support arm above the wall

module by pinching the housing shells together at position (S).

3. Remove the housing shell (C) from the support arm.

4. Unscrew and remove the fastening screws (A) from the underside.

bеЦдблЬ

5. Pull the protective cover (B) slightly away from the wall and lift it up.

ª You can now remove the protective cover.

62 15 102 D3507

D3507.076.01.13.02 10.2016

19

Page 20

1General information Sirona Dental Systems GmbH

1.11Removing covers Service Manual HELIODENT

PLUS

Hanging up the cover

➢ Hang the cover on the side of the wall adapter plate so that it is

securely positioned (see illustration). To do this from serial no. 27 000

onwards, the EMC plate must be removed beforehand.

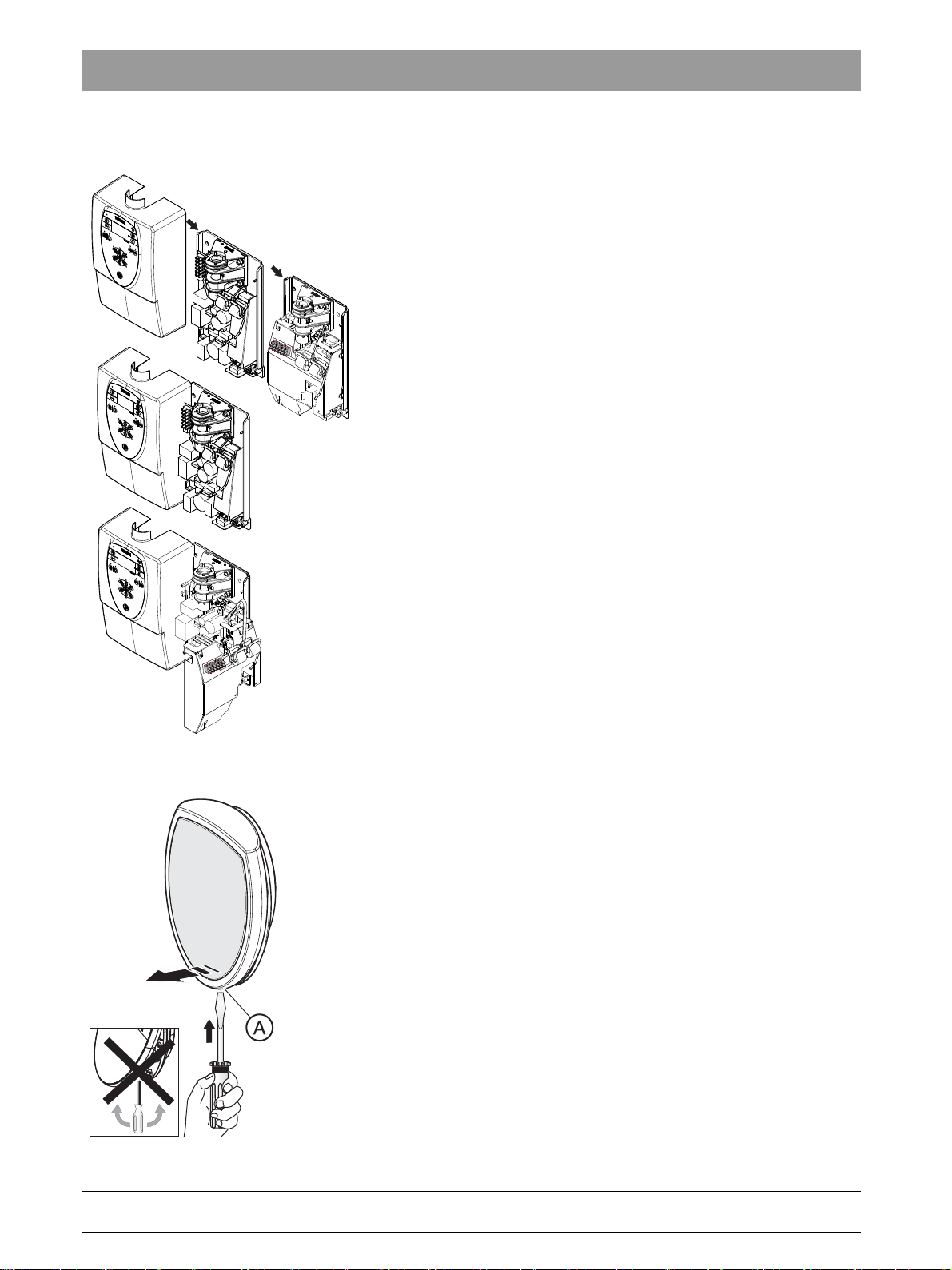

1.11.2 Remote control and remote timer

Open remote

➢ Detach the housing of the remote control or the Remote Timer by

carefully inserting the tip of a screwdriver in opening A and pressing

against the catch. Do not pry with or turn the screwdriver!

62 15 102 D3507

20 D3507.076.01.13.02 10.2016

Page 21

Sirona Dental Systems GmbH 1General information

A

L

Service Manual HELIODENT

PLUS

1.11Removing covers

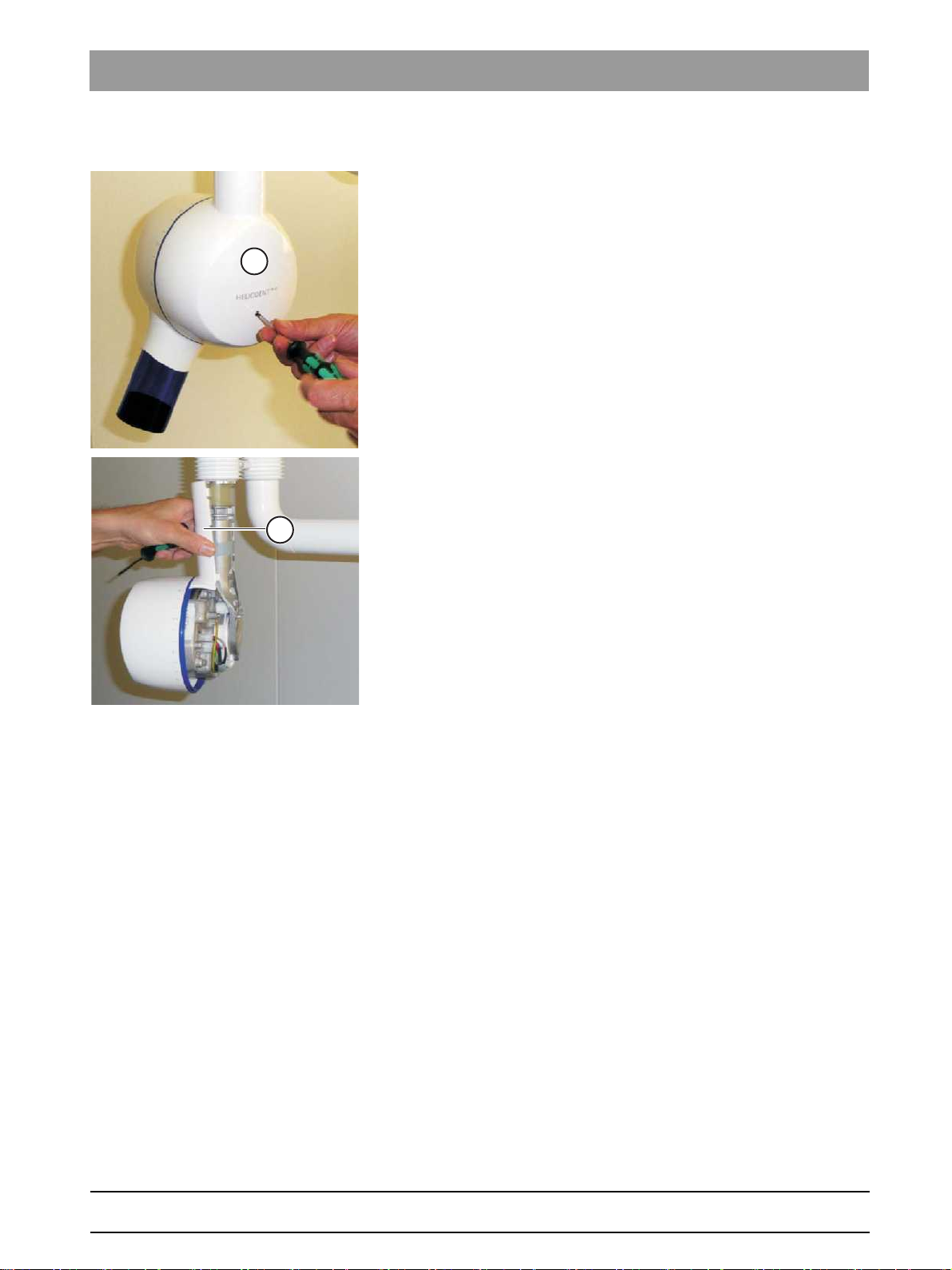

1.11.3 X-ray tube unit

1. Unscrew and remove the cover (A).

2. Remove the arm cover (L).

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

21

Page 22

1General information Sirona Dental Systems GmbH

X400 V413V316

V503

GY/BN

YE WH

GN

F201

X600

F200

X401

V414

PK

BU

PE

X500

X501

X200

V409 D500

F300

V611

N´

N

PE

L1

S1

X400 V413V316

V503

GY/BN

YE WH

GN

F201

X600

F200

X401

V414

PK

BU

X500

X200

V409

D500

F300

V611

N´

N

PE

L1

S1

X501

1.12Overview of PC boards Service Manual HELIODENT

PLUS

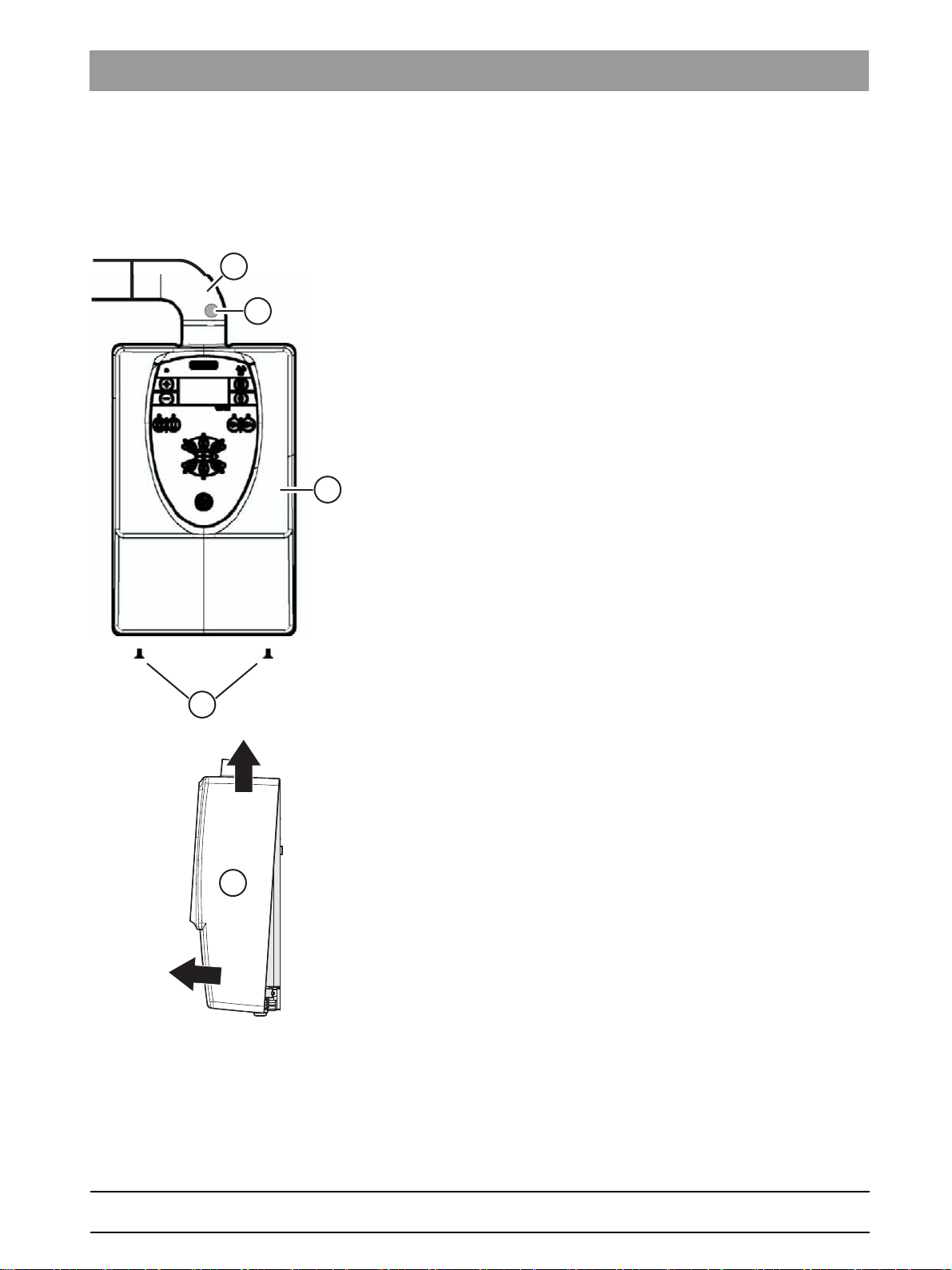

1.12

Overview of PC boards

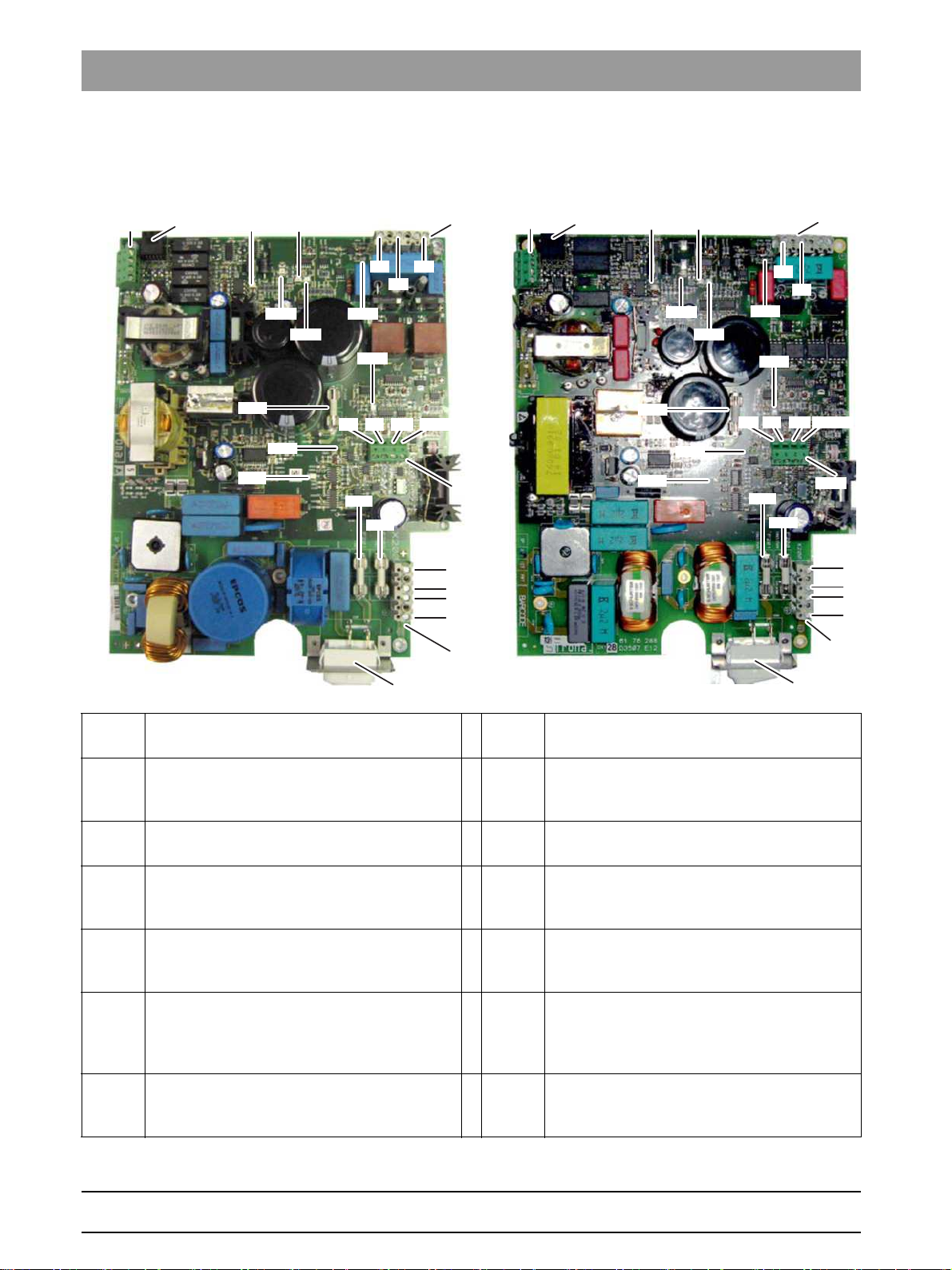

1.12.1 Generator board DX1

S1 Power switch F200 /

F201

F300 Fuse for switched-mode power supply

X400 Direct contact with control board DX4 [ → 23] /

V409 LED, setpoint generation

(1A 250V quick-blow, order no.: 10 77 304)

cable L2 or L6.

- LED lights up during an X-ray exposure.

V414 LED, kV controller

V316 LED, supply voltage +15V

X401 Release and safety circuit only for installation

V413 LED, basic heating

V503 LED, kVactual cable

- LED lights up during an X-ray exposure if the

kV controller is functioning correctly.

D500 Glow lamp, output stage

- The glow lamp lights up during an X-ray

exposure. The high-voltage transformer is

activated.

V611 LED, release

- LED lights up when the release button is

X600 Measuring points for the tube current

Fuse for PFC

(10A 250V slow-blow, order no.: 10 77 460)

- LED lights up when +15 V supply voltage is

present.

options 1, 2, 4, 6, and 6.1

- LED lights up when basic heating is correct.

- LED lights up during an X-ray exposure.

- LED lights up if the kVactual cable is

incorrectly connected.

measurement (see section “Checking the tube

current [ → 60]”).

pressed.

22 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 23

Sirona Dental Systems GmbH 1General information

Service Manual HELIODENT

PLUS

1.12Overview of PC boards

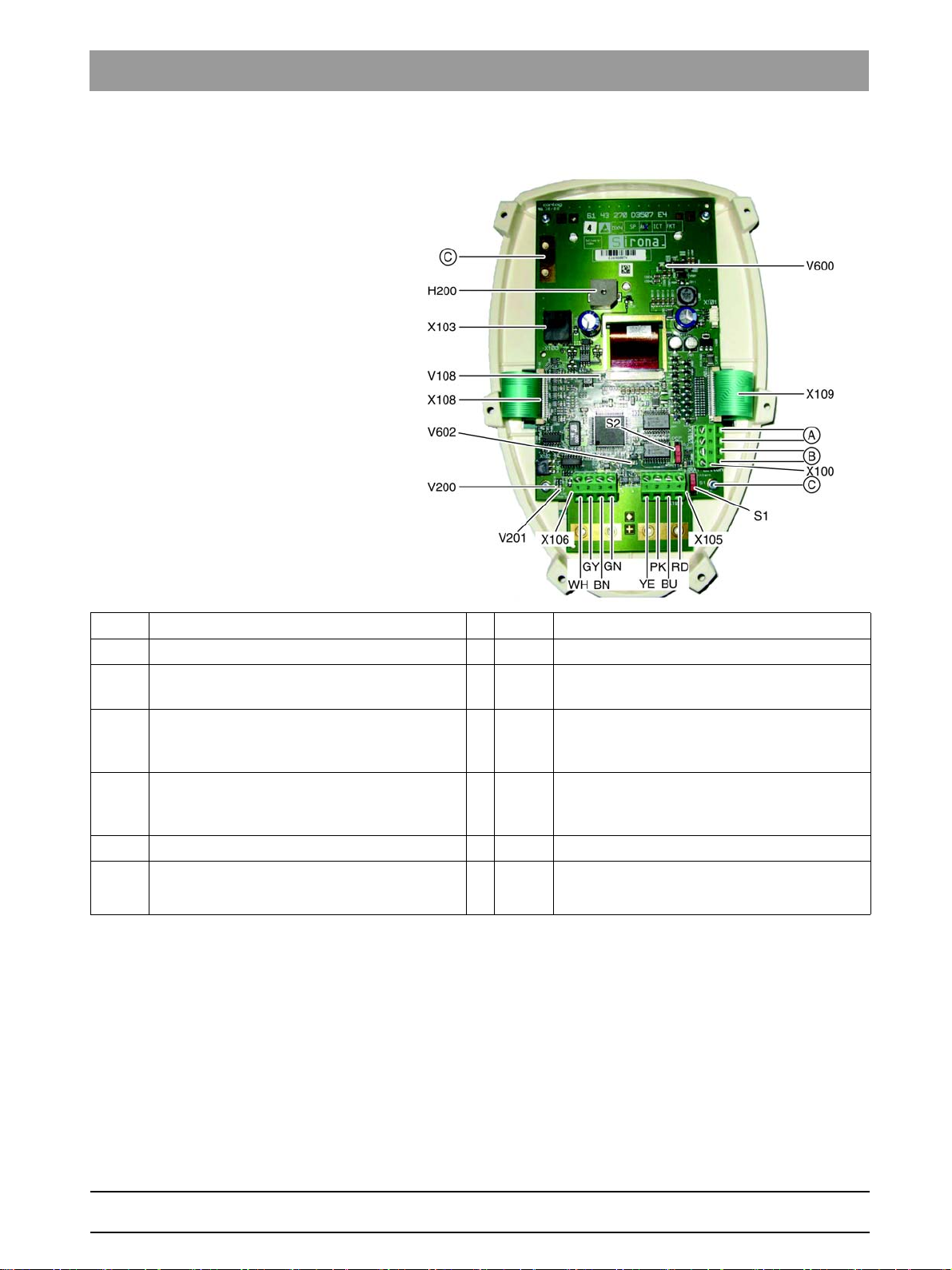

1.12.2 Control board DX4

(A) Protective circuit (door contact) (B) Release button

(C) EMC shielding V108 LED, +3.3 V for LCD

V200 LED, Debugging V201 LED, status indicator

- LED flashes with 100% unit function.

H200 Acoustic signal

- Acoustic signal sounds during an X-ray

exposure.

X103 Direct contact with generator board DX1

[ → 22] / cable L2

(installation options 1, 2, 4, 6 and 6.1)

V600 LED, +8V input voltage V602 LED, +3.3 V controller voltage

X100 Remote timer connection outside the X-ray

room

X108,

X109

X105,

X106

S1

S2

Connection to membrane keyboard

Direct contact with generator board DX1

[ → 22] as remote control / cable L6

(installation options 3, 5, 7 and 8)

Changeover switch, internal/external trigger

Changeover switch, safety circuit ON/OFF

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

23

Page 24

1General information Sirona Dental Systems GmbH

1.13Required items Service Manual HELIODENT

PLUS

1.13

Required items

1.13.1 Additional documents

● Spare parts list

– Order No.: 62 34 111

● Wiring diagrams

– Order No.: 62 15 086

1.13.2 Tools and auxiliary materials

Allen key / size 13:

● Allen key / size 13:

Spirit level (general purp ose)

● Spirit level

● Screwdriver, Torx

Side cutting pliers

● Side cutting pliers

General purpose adhesi ve tape

®

, sizes T10, T15, T20 and T30, 200 mm

● adhesive tape

● 2x multimeter or one of each of the following measuring instruments:

– 1x voltmeter

– 1x ammeter

Device leakage current

● Test unit for device leakage current measurement:

For measurements, Sirona recommends an automatic tester

(example illustration) which complies with standard IEC 62353.

If you do not use an automatic tester, please pay attention to the

specifications in the standard IEC 62353.

Power source

● Power source for protective ground wire test

Technical data:

– No-load voltage max. 6V

– Short-circuit current at least 5A - max. 25A

24 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 25

Sirona Dental Systems GmbH 2List of messages

Service Manual HELIODENT

PLUS

List of messages

2

2.1Error messages

2.1

Error messages

2.1.1 General

Explanation

The error messages appear on the display of the control electronics.

Recognition

Error messages can be recognized by a six-digit error code (Ex yy zz)

beginning with a large E.

The structure of the error messages is explained in the section entitled

"Structure [ → 25]".

Handling error messages

As a general rule, error messages are acknowledged via all buttons

except for the release button.

If trouble-free operation is possible after the error is acknowledged, then

no further action is necessary.

If error messages reoccur or occur frequently or trouble-free operation is

not possible, identify the error as described in the section "List of error

messages [ → 26]" and take appropriate action to eliminate the

corresponding error or fault.

bеЦдблЬ

2.1.2 Structure

Explanation

The codes provide you with error type, error location and troubleshooting

information. Plain text error output follows.

Configuration

The error codes are structured according to the following pattern: Ex yy zz

Explanation of abbreviations:

Ex – Error type

"Remedy" classification for the user. The x character provides a

foundation for making quick decisions as to how serious the error is and

how to handle the error.

yy – Locality

Describes the impacted functionality.

This functionality can be:

● Subassembly

● Subsystem

● Logical functional unit

zz – Identification

Describes a further specification of the error via a consecutive number

with error identification.

62 15 102 D3507

D3507.076.01.13.02 10.2016

25

Page 26

2List of messages Sirona Dental Systems GmbH

2.1Error messages Service Manual HELIODENT

PLUS

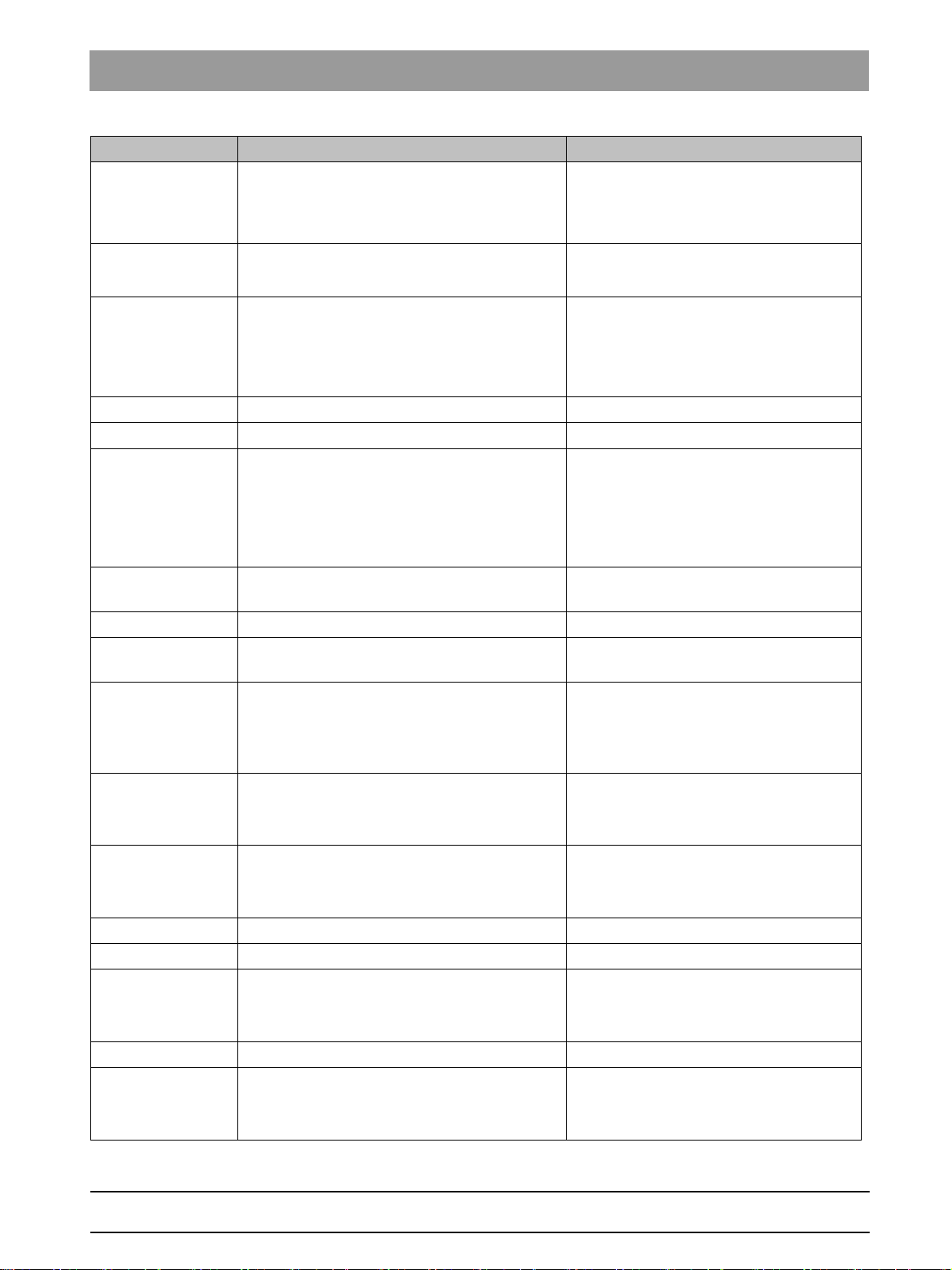

2.1.3 List of error messages

Error code Description Actions required

None Release does not result in any reaction/

exposure

E1 11 88 Demo mode ACTIVE Acknowledge the error message with any

E1 04 03 Acknowledge the error message with any

E1 04 04 Error programming the values. Acknowledge the error message with any

E1 04 60 Error of serial port Replace DX4.

E3 04 30 Power-up error

See Section

"Error message NONE [ → 29]

key.

For "normal operation" - change service

routine 26 [ → 77]

key.

If the error message reappears, DX4 must

be replaced.

key.

If the error message reappears, DX4 must

be replaced.

Switch unit OFF and ON again

Release button was actuated during power-on

E3 04 31 Error keys

A front panel key was actuated during power-on

E5 01 02

E5 01 12

No target values are generated

DX4 buzzer sounds, no exposure

E5 01 14

E5 01 32

E5 01 42

E5 01 02

E5 01 12

Buzzer sounds

No exposure

E5 01 14

If the error message reappears, remove

the release button.

If there are no more error messages, use a

new release button.

If the error message persists, check the

cable between DX1 and DX4. DX4 may

need to be replaced

Switch unit OFF and ON again

If the error reoccurs, perform a key test with

Service routine S22 [ → 75].

Key defective? Replace front panel

Check the cable between DX1 and DX4

(B4). Replace the entire cable if necessary.

If the error message reappears, DX1 must

be replaced.

Replace DX1

E5 01 32

E5 01 02

E5 01 12

Buzzer sounds

No exposure

See Section

""Error message E5 01 02 / E5 01 12 / E5

01 14 [ → 32]"

E5 01 14

26 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 27

Sirona Dental Systems GmbH 2List of messages

Service Manual HELIODENT

Error code Description Actions required

E5 01 02

PLUS

Buzzer sounds

2.1Error messages

Replace DX1

E5 01 14

E7 01 51

E5 01 22 Buzzer does not sound

E5 04 50 Internal software error Switch unit OFF and ON again

E6 01 13 Internal hardware error Replace DX1.

E6 01 31 Internal hardware error Replace DX1

E6 01 41 Buzzer sounds although the release was not

E6 01 23 Cable is incorrectly attached or internal

E6 01 11 Internal hardware error Replace DX1

E6 01 61 Error diagnosis not working Check the cable between DX1 and DX4.

E6 01 62 Error diagnosis not working Check the cable between DX1 and DX4.

no exposure temporarily

No exposure

actuated

hardware error

See Section

""Error message E5 01 22 [ → 33]"

Repeat the exposure with the same values

If the error message reappears, DX4 must

be replaced.

Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

If the error message reappears, DX1 must

be replaced

See Section

""Error message E6 01 23 [ → 34]"

Cable may need to be replaced

Cable may need to be replaced

bеЦдблЬ

If the error message reappears, DX1 must

be replaced

E6 04 01 Internal hardware error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E6 04 02 Internal error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E6 04 11 Internal error Replace DX4

E6 04 40 LCD is somewhat darker in some cases Replace DX4

E6 04 41 Power supply of DX4 is interrupted Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E6 04 42 Power supply of DX4 is interrupted Replace DX4

E6 04 10 Internal error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

62 15 102 D3507

D3507.076.01.13.02 10.2016

27

Page 28

2List of messages Sirona Dental Systems GmbH

2.1Error messages Service Manual HELIODENT

PLUS

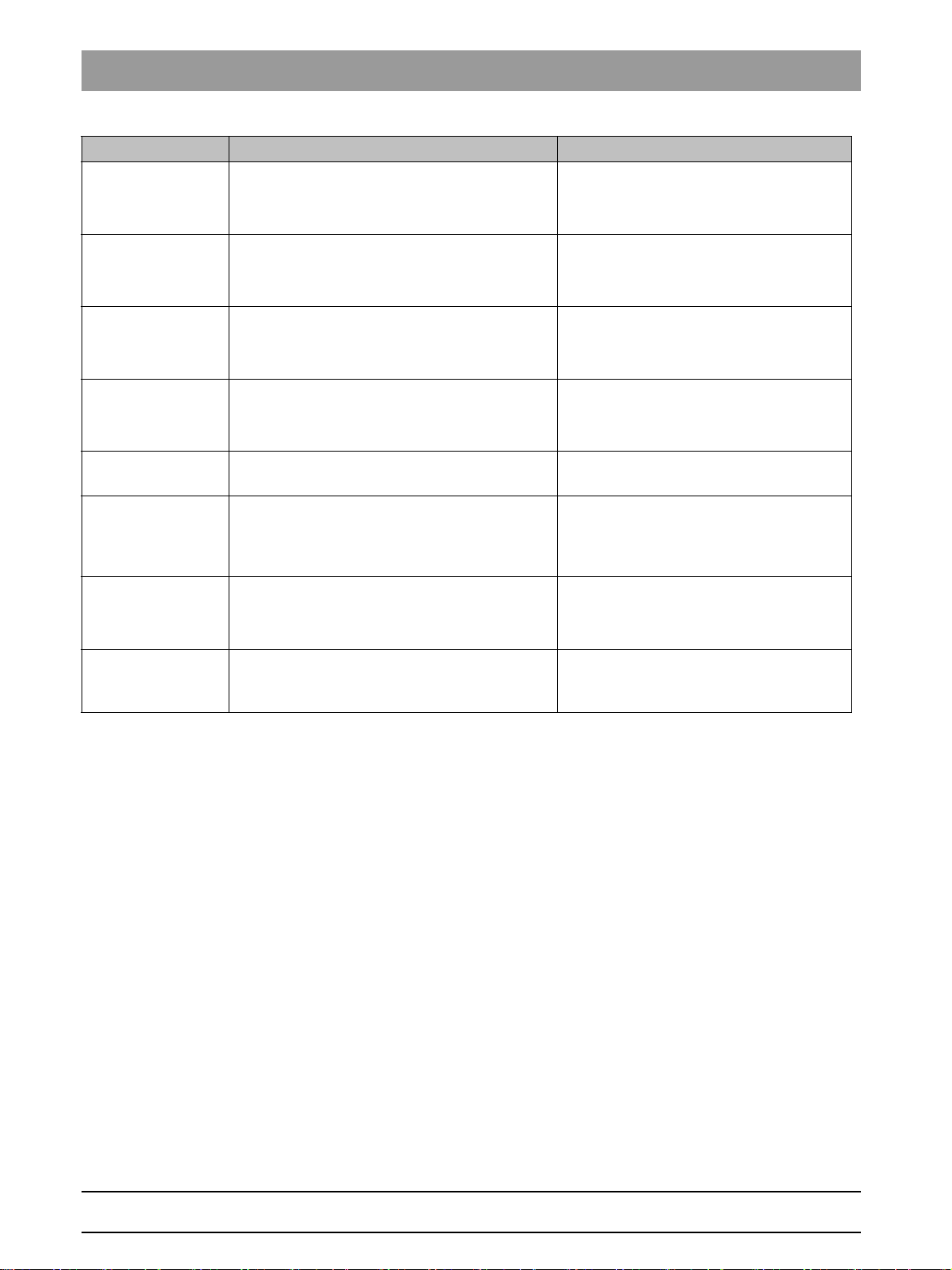

Error code Description Actions required

E6 04 06 Internal error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E6 04 12 Internal error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E6 04 20 Internal error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E6 04 21 Internal error Switch unit OFF and ON again

If the error message reappears, DX4 must

be replaced

E7 01 01 Cable is incorrectly attached or internal

hardware error

E7 01 21 Release actuated

See Section

""Error message E7 01 01 [ → 36]"

Check the cable between DX1 and DX4.

No buzzer sound

Cable may need to be replaced

No exposure

E7 01 51 Internal hardware error Switch unit OFF and ON again

If the error message reappears, DX1 must

be replaced

E7 04 51 Safety circuit (door contact) Go to section

“Error message: E7 04 51 - Door contact

error [ → 38]”

28 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 29

Sirona Dental Systems GmbH 3Troubleshooting

Service Manual HELIODENT

PLUS

Troubleshooting

3

3.1Error message: NONE

3.1

Error message: NONE

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

29

Page 30

3Troubleshooting Sirona Dental Systems GmbH

3.1Error message: NONE Service Manual HELIODENT

PLUS

30 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 31

Sirona Dental Systems GmbH 3Troubleshooting

Service Manual HELIODENT

PLUS

3.1Error message: NONE

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

31

Page 32

3Troubleshooting Sirona Dental Systems GmbH

3.2Error message: E5 01 02 / E5 01 14 / E5 01 12 Service Manual HELIODENT

PLUS

3.2

Error message: E5 01 02 / E5 01 14 / E5 01 12

32 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 33

Sirona Dental Systems GmbH 3Troubleshooting

Service Manual HELIODENT

PLUS

3.3Error message: E5 01 22

3.3

Error message: E5 01 22

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

33

Page 34

3Troubleshooting Sirona Dental Systems GmbH

3.4Error message: E6 01 23 Service Manual HELIODENT

PLUS

3.4

Error message: E6 01 23

34 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 35

Sirona Dental Systems GmbH 3Troubleshooting

Service Manual HELIODENT

PLUS

3.4Error message: E6 01 23

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

35

Page 36

3Troubleshooting Sirona Dental Systems GmbH

3.5Error message: E7 01 01 Service Manual HELIODENT

PLUS

3.5

Error message: E7 01 01

36 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 37

Sirona Dental Systems GmbH 3Troubleshooting

Service Manual HELIODENT

PLUS

3.5Error message: E7 01 01

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

37

Page 38

3Troubleshooting Sirona Dental Systems GmbH

3.6Error message: E7 04 51 - Door contact error Service Manual HELIODENT

PLUS

3.6

Explanation Depending on the installation type, there are different approaches to

Error correction (case 1) 1. Set switch S2 on PC board DX4 to ON.

Error correction (case 2) 1. Set switch S2 on PC board DX4 to OFF.

Error message: E7 04 51 - Door contact error

address error message E7 04 51.

● Error correction (case 1)

– Installation type "Wall box without door contact"

– Installation type "Remote without door contact"

● Error correction (case 2)

– Installation type "Wall box with door contact"

2. In service routine 015, set the value “1" and save it.

3. Switch the unit off and then on again.

2. In service routine 015, set the value "0" and save it.

3. Switch the unit off and then on again.

38 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 39

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

Maintenance

4

4.1Checking the shielding

4.1

Checking the shielding

4.1.1 Test

➢ Check whether the cable shieldings have contact with the shielding

clamps and are firmly in place.

4.1.2 Positions

Installation panel (wall module)

● If available: Manual release S3 on X401

–(B): Clamp

● If available: Cable L2 with ferrite core on X400

bеЦдблЬ

–(C): Clamp

● If available: Cable L6 on X400

–(D): Clamp

62 15 102 D3507

D3507.076.01.13.02 10.2016

39

Page 40

4Maintenance Sirona Dental Systems GmbH

4.1Checking the shielding Service Manual HELIODENT

PLUS

DX4 (wall module)

● X103 / L2 cable (wall mounting)

–(E): Clamp

DX4 (Remote Timer)

● Grounding tab of the front panel

–(F): Screw

● X106/X105 / L6 cable

–(G): Clamp

● X100 / Manual release S3

–(H): Clamp

–(I): Release button

40 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 41

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

4.2Checking the protective ground connections

4.2

Checking the protective ground connections

4.2.1 Test

➢ Check whether all protective ground connections are firmly in place.

4.2.2 Positions

DX1 and installation panel (wall module)

● X200 / Power input clamp

● X500* / Output stage and installation panel

bеЦдблЬ

–(A): Screw

* PE is only connected up to serial no. 26 999 on the X500

X-ray tube assembly

● Grounding of the support bracket

–(J): Screw

62 15 102 D3507

D3507.076.01.13.02 10.2016

41

Page 42

4Maintenance Sirona Dental Systems GmbH

4.2Checking the protective ground connections Service Manual HELIODENT

PLUS

● Grounding of the X-ray tube assembly

–(K): Screw

42 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 43

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

4.3Checking exposure time and high voltage kV

4.3

Checking exposure time and high voltage kV

Auxiliary devices required

● Suitable radiation meter.

Examples:

– Mini-X

– PMX I-D

–MOM

Preparation

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

1. Switch the X-ray unit on.

2. Wait until the self-test is finished (operational readiness signal must

be lit). The display reading shows the radiation time and a patient

symbol).

3. Set an exposure time between 0.25 and 0.4 seconds. The display of

control board DX4 must be clearly visible

4. Position the measuring instrument (B) in such a way that the active

sensor measuring surface has a distance of 50 cm (19.7") from the

focus (A) of the X-ray tube assembly.

5. Switch on the measuring instrument.

43

Page 44

4Maintenance Sirona Dental Systems GmbH

4.4Checking the deadman function Service Manual HELIODENT

PLUS

test

WARNING

X-ray radiation!

➢ Release an exposure with the release button.

● The buzzer must be audible during radiation release.

● The radiation indicator lights up.

– The radiation LED lights up yellow.

– The display background lights up yellow.

➢ Check the measures exposure time and the high voltage measured

at the measuring instrument.

Tolerance: The permitted tolerance of the exposure time and high voltage

is ±10%.

In case of error

● Radiation time outside of tolerance limits

4.4

– Replace board DX4.

● High voltage outside of tolerance limits

– Replace DX1.

Checking the deadman function

test

1. Set the radiation time to 3.2 seconds (display: "3.20 s").

WARNING

X-ray radiation!

2. Release an exposure with the release button and let go of the release

button prior to the end of the radiation.

ª The radiation must stop.

ª The actual radiation time must be shown as a flashing display.

In case of an error

The unit does not stop releasing radiation.

➢ Replace board DX4.

44 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 45

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

4.5Checking the release button

4.5

Checking the release button

4.5.1 General

Explanation

Depending on the installation type, there are different descriptions for

checking the release button.

Overview

● Release button on PC board DX1 (coiled cable) [ → 45]

● Release button on PC board DX4 (coiled cable) [ → 46]

● Release button on front panel on PC board DX4 [ → 47]

4.5.2 Release button on PC board DX1 (coiled cable)

NOTICE

Only one release button may be connected (active)!

Preparation

1. Switch the unit off.

2. Connect the measuring instrument:

bеЦдблЬ

● With installed door contact

– Connect the measuring instrument to DX1 X401.1 and X401.2.

● With no installed door contact

– Connect the measuring instrument to DX1 X401.1 and X401.4.

test

➢ Check the following points:

● Is the strain relief of the coiled cable fully functional?

● Is the release button easy to actuate?

● Does the release button return to its home position on its own after

letting go?

● With release button not pressed: Measured resistance exceeds

100k Ω .

● With release button pressed: Measured resistance is below 100 Ω .

● Do the measured resistance values remain constant when the coiled

cable is moved?

➢ After the test: Remove the measuring instrument.

In case of an error

62 15 102 D3507

D3507.076.01.13.02 10.2016

➢ Replace the release button with coiled cable.

45

Page 46

4Maintenance Sirona Dental Systems GmbH

4.5Checking the release button Service Manual HELIODENT

PLUS

4.5.3 Release button on PC board DX4 (coiled cable)

NOTICE

Only one release button may be connected (active)!

Preparation

1. Switch the unit off.

2. Connect the measuring instrument:

● With installed door contact

– Connect the measuring instrument to DX4 X100.1 and X100.2.

● With no installed door contact

– Connect the measuring instrument to DX4 X100.1 and X100.4.

test

➢ Check the following points:

● Is the strain relief of the coiled cable fully functional?

● Is the release button easy to actuate?

● Does the release button return to its home position on its own after

letting go?

● With release button not pressed: Measured resistance exceeds

100k Ω .

● With release button pressed: Measured resistance is below 100 Ω .

● Do the measured resistance values remain constant when the coiled

cable is moved?

➢ After the test: Remove the measuring instrument.

In case of an error

➢ Replace the release button with coiled cable.

46 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 47

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

4.5Checking the release button

4.5.4 Release button on front panel on PC board DX4

NOTICE

Only one release button may be connected (active)!

Preparation

1. Switch the unit off.

2. Connect the measuring instrument to DX1 X401.1 and X401.3.

test

➢ Check the following points:

● Is the release button easy to actuate?

● Does the release button return to its home position on its own after

letting go?

● With release button not pressed: Measured resistance exceeds 1k Ω .

● With release button pressed: Measured resistance is below 100 Ω .

➢ After the test: Remove the measuring instrument.

In case of an error

➢ Replace the front panel.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

47

Page 48

4Maintenance Sirona Dental Systems GmbH

D

C

B

A

S22

4.6Checking the front panel Service Manual HELIODENT

PLUS

4.6

Checking the front panel

CAUTION

Defective indicators and keys represent a risk to the safety of both the

patient and the operator/user.

The user is not permitted to operate the unit until the necessary repairs

have been made.

4.6.1 Visual check

Check

Visually check the front panel for external damage.

● Is the front panel of the user interface undamaged?

● Is the surface panel free of cracks or holes?

NOTICE

The transparent front panel over the light diodes must not be punctured,

otherwise there is a risk of ESD damage.

4.6.2 Front panel test

Explanation

In the front panel test, you can check the function of every individual key

on the front panel.

Command

➢ Open service routine S22 (see "Operation [ → 65]" in the Section

"Service routines").

Operation

➢ Actuate every key in sequence.

ª A code is indicated in a certain area on the display each time a key is

actuated.

Areas

48 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 49

Sirona Dental Systems GmbH 4Maintenance

+

_

60kV

70kV

Service Manual HELIODENT

PLUS

4.6Checking the front panel

Code table

Key Area Code Key Area Code

A1 B32

A2 B64

A4 B128

A8 C1

B2 C2

B4 C4

B8 C8

B16 D1

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

49

Page 50

4Maintenance Sirona Dental Systems GmbH

4.7Checking and adjusting the support arm Service Manual HELIODENT

PLUS

4.7

Checking and adjusting the support arm

CAUTION

Switch OFF the unit before connecting a measuring instrument or

replacing parts!

4.7.1 Round support arm system

Check

● Are all bellows intact?

– If the bellows are damaged, the support arm must be replaced.

See section “Replacing the support arm”.

● Does the X-ray tube assembly drift from its work position on its own?

– If the X-ray tube assembly drifts, the support arm must be

readjusted.

Setting

Adjusting the spring on the scissor arm (support arm side)

1. Invert the bellows over the half-shells (A) on both sides.

2. Pull off the half-shells.

3. Pull the scissor arm apart and slide the bellows over the bearing.

4. Set both support arms in vertical position.

5. Insert the Torx screwdriver (T30, 200 mm) into the drilling of the

bearing from the top and adjust the spring (right turn = tighter).

6. Reassemble the support arm by completing the same steps in

reverse order.

Adjusting the spring on the scissor arm (X-ray tube assembly side)

1. Invert the bellows over the upper half-shell (A).

2. Press the bellows downward.

3. Set the support arm into a horizontal position.

4. Insert the Torx screwdriver (T30, 200 mm) into the drilling of the

bearing from the front and adjust the spring (right turn = tighter).

5. Reassemble the support arm by completing the same steps in

reverse order.

62 15 102 D3507

50 D3507.076.01.13.02 10.2016

Page 51

Sirona Dental Systems GmbH 4Maintenance

A

B

Service Manual HELIODENT

PLUS

4.7Checking and adjusting the support arm

4.7.2 Angular support arm system

Risk of crushing

CAUTION

Gaps appear between the internal hinges when moving the angular

support arm.

Fingers may be crushed in these gaps.

➢ Ensure that you never place your fingers in the gaps between the

hinges, neither during operation nor for cleaning purposes.

4.7.2.1

Checking and adjusting the angular scissor arm

Check

● Does the X-ray tube assembly drift from its work position on its own?

– If the X-ray tube assembly drifts, the support arm must be

readjusted.

Setting

Adjusting the spring on the scissor arm (support arm side)

1. Remove the cover part (B).

2. Place the rear scissor arm in a vertical position.

3. Insert the Allen key (SW6, 200 mm) into the bearing hole from above

and adjust the spring (right turn = tighter).

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

51

Page 52

4Maintenance Sirona Dental Systems GmbH

A

B

A

B

4.7Checking and adjusting the support arm Service Manual HELIODENT

Adjusting the spring on the scissor arm (X-ray tube assembly side)

1. Remove the cover part (A).

2. Bring the front scissor arm into a horizontal position.

3. Insert the Allen key (SW6, 200 mm) into the bearing hole from the

front and adjust the spring (right turn = tighter).

4. Reattach the cover parts.

PLUS

4.7.2.2

Checking and adjusting the angular scissor arm is parallel

Check

● Is the boom of the scissor arm not parallel with the scissor arm?

– If a lateral or height offset is needed there, the scissor arm must

be recalibrated.

Setting

1. Remove the cover parts (A+B).

2. Release the internal locking pins on all 4 bolts using the Allen key

(SW-3).

62 15 102 D3507

52 D3507.076.01.13.02 10.2016

Page 53

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

4.7Checking and adjusting the support arm

3. Release the bolts slightly with the ring wrench (SW-13).

4. Open the locking pins on 2 joints slightly (SW-1,5).

5. Place both scissor arms in a vertical position.

Check the alignment

6. Set parallelism using the eccentric bolts.

7. Reassemble the support arm by completing the same steps in

reverse order.

8. Reattach the cover parts.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

53

Page 54

4Maintenance Sirona Dental Systems GmbH

A

L

4.8Checking the X-ray tube assembly joint Service Manual HELIODENT

PLUS

4.8

Checking the X-ray tube assembly joint

CAUTION

Switch OFF the unit before connecting a measuring instrument or

replacing parts!

Required tools

Torx screwdriver (size 10, 15 and 20)

Check

● Does the cone remain set in every position?

● Are the connecting cables intact?

– See section on "Checking the connection cables".

If the X-ray tube assembly fails any of these check points, it must be

replaced (see Section "Replacing X-ray tube assembly H1 [ → 79]").

Checking the connection cables

1. Switch the X-ray unit off.

2. Unscrew and remove the old cover (A).

3. Remove the arm cover (L).

54 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 55

Sirona Dental Systems GmbH 4Maintenance

K

B

Service Manual HELIODENT

PLUS

4.8Checking the X-ray tube assembly joint

4. Check the condition of the grounding strap.

ª No damage should be evident at position (K). Slight restriction at

the position (K) of up to 20% cross-section loss is acceptable.

5. Check the screw terminal on the grounding wire (B) for damage.

6. Check the plug contacts on the connector (X1) for damage.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

55

Page 56

4Maintenance Sirona Dental Systems GmbH

J

L

A

4.8Checking the X-ray tube assembly joint Service Manual HELIODENT

7. Check the scissor arm (J) to make sure it does not brush against a

cable when moved.

ª No cable should touch the scissor arm in any position. Fasten the

cable with a cable tie if necessary.

8. Attach the arm cover (L).

PLUS

9. Attach and secure the cover (A).

56 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 57

Sirona Dental Systems GmbH 4Maintenance

67

8

9

SXL

X4

X1

X2

B

A

KL 10

NL

88NNLL7

765 4321

65 432 1

L8

L7

Kl 10

67

8

9

X4

X1

X2

SXL

D

C

Service Manual HELIODENT

PLUS

4.9Checking the ceiling model

4.9

Checking the ceiling model

Check the overhead support

● Is the cover (A) fastening in safe condition?

● Are the cover parts (B) present and free of damage?

bеЦдблЬ

● Is the protective ground connection securely (C) positioned?

● Damage-free, tight and proper seating of the cables on clamp K10 (D)

in the ceiling model?

62 15 102 D3507

D3507.076.01.13.02 10.2016

57

Page 58

4Maintenance Sirona Dental Systems GmbH

X100

4.9Checking the ceiling model Service Manual HELIODENT

PLUS

Check the wall adapter

● Is the protective ground connection securely (F) positioned?

● Damage-free, tight and proper seating of the cables on clamp X100

(E) (X100 is positioned in a different position depending on the serial

number) in the wall adapter?

58 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 59

Sirona Dental Systems GmbH 4Maintenance

B

A

D

C

X100

Service Manual HELIODENT

PLUS

4.10Checking HELIODENT PLUS on the mobile stand

4.10

Checking HELIODENT PLUS on the mobile stand

Check the mobile stand

● Is the wall module fastening on the mobile stand (A) in a safe

condition?

● Is the power supply cord (C) with strain relief and bend protection on

the mobile stand in order?

● Are the 4 rollers (B) of the mobile stand, including brakes, in order

and free from contamination?

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

Check the wall module

● Is the protective ground connection securely (F) positioned?

● Damage-free, tight and proper seating of the cables on clamp X100

(E) (X100 is positioned in a different position depending on the serial

number) in the wall adapter?

● Are the cover parts (D) present and free of damage?

59

Page 60

4Maintenance Sirona Dental Systems GmbH

4.11Checking the tube current Service Manual HELIODENT

PLUS

4.11

Checking the tube current

Auxiliary devices required

● Ammeter

CAUTION

Only use battery-powered measuring devices.

Preparation

1. Switch the unit off.

2. Set the ammeter to the "10 mA DC" measuring range.

3. Connect the ammeter to the two outer X600 connectors on board

DX1.

4. Switch the unit on.

5. Set the radiation time to 3.2 seconds (display: "3.20 s").

test

WARNING

X-ray radiation!

➢ Release an exposure with the release button and read the tube

current from the ammeter.

Tolerance: The tube current must be 7 mA ±1.4 mA.

62 15 102 D3507

60 D3507.076.01.13.02 10.2016

Page 61

Sirona Dental Systems GmbH 4Maintenance

K

Service Manual HELIODENT

PLUS

4.12Checking the protective ground wires

Completion

1. Switch the unit off.

2. Remove the measuring wires of the ammeter from connector X600.

3. Reattach the housing on the wall module.

In case of an error

● The measurement value is not reached.

– Replace the X-ray tube assembly.

4.12

Checking the protective ground wires

Auxiliary devices required

● Power source

Technical data:

– No-load voltage max. 6V.

– Short-circuit current min. 5A - max. 25A

● Ammeter

– Observe the current intensity of the power source

● Voltmeter

Preparation

WARNING

Perilous shock hazard!

Switch the line voltage off.

1. Switch the line voltage off at the main switch of the building

installation.

2. Remove the power cable from connector X200 on PC board DX1.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

Visual check

1. Check the assembly and firm seating of the ground conductor.

2. Check the main fuse (F200, F201).

3. Check the condition of the grounding strap.

ª No damage should be evident at position (K). A slight restriction

at position (K) with a cross-section loss of max. 20% is still

acceptable.

61

Page 62

4Maintenance Sirona Dental Systems GmbH

4.12Checking the protective ground wires Service Manual HELIODENT

PLUS

Protective ground wire test

Explanation

This test checks the electrical resistance of conductive and exposed parts

of the X-ray unit against the protective wire connection.

Test assembly

See drawing.

Test

1. Set the test current for at least 5 seconds between protective wire

connection X200 / PE (board DX1) and ground connection B (X-ray

tube assembly).

2. Read the voltage drop on the voltmeter and the current on the

ammeter.

3. Calculate the protective conductor resistance with the formula "R = U

/ I."

Limit value

The calculated resistance value must not be greater than 0.2 Ω.

62 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 63

Sirona Dental Systems GmbH 4Maintenance

Service Manual HELIODENT

PLUS

4.13Checking the unit leakage current

4.13

Checking the unit leakage current

DANGER

Perilous shock hazard!

It is essential to switch the unit off and to wait at least one more 1 minute

before beginning the check!

Prevent the device from unintentionally switching back on.

NOTICE

Important information on building installation

The connection and disconnection of the unit (power cable) to/from the

building installation must be performed by a qualified expert in

compliance with the national regulations. DIN VDE 0100-710 applies in

Germany.

Automatic tester in accordance with IEC 62353

For measurements, Sirona recommends an automatic tester (example

illustration) which complies with standard IEC 62353. If you do not use an

automatic tester, please pay attention to the specifications in the standard

IEC 62353.

1. Switch the line voltage off at the main switch of the building

installation.

2. DANGER! Note the electrical safety rules without fail.

Disconnect the power cable and the second protective ground wire

from the building installation.

3. Attach a connector compatible with the tester (see the user’s manual

for the tester) to the unit’s power cable.

4. Plug the connector of your power supply unit into the intended socket

on the tester in accordance with the user’s manual for the tester.

5. Check whether the unit power switch is turned on.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

IMPORTANT

According to Note 2 in Table 3 of standard IEC 62353:2014, the

maximum device leakage current permitted by the manufacturer is 2 mA

for permanently connected units.

6. Perform the measurements according to the operating instructions of

the tester.

7. Document the measured value of the leakage current in the technical

document

to identify changes from the original value.

ª A maximum deviation of ±20% from the original value is

8. Reconnect the unit to the building installation (fixed connection) (see

the installation instructions for the unit).

"Inspection and maintenance and safety-related checks"

permitted for the measured leakage current.

Threshold value of wall-mounted model

The measured value must not exceed 2,0mA.

Threshold value of ceiling-mounted model

The measured value must not exceed 2.0mA.

Threshold value with mobile model

The measured value must not exceed 2.0mA.

63

,

Page 64

4Maintenance Sirona Dental Systems GmbH

X200

4.14Checking insulation resistance on the power supply cord of the mobile stand Service Manual HELIODENT

PLUS

4.14

Checking insulation resistance on the power supply cord of the mobile stand

Auxiliary devices required

● Safety tester for insulation resistance

Preparation

WARNING

Perilous shock hazard!

Switch the line voltage off.

✔ Measure the insulation resistance between each active conductor

and protective ground conductor.

✔ Switch the unit off and unplug the connector from the power socket.

1. To remove the cover, see Removing covers [ → 19].

Elect. connection 1 phase

2. Disconnect the power supply cord from clamp X200 on DX1.

3. Set a test voltage of 500 V on the safety test device and follow the

instructions in the test device's description.

ª The tester displays the insulation resistance of the short-circuited

power supply cords L and N against the protective ground

conductor.

The insulation resistance must be greater than 100 M Ω .

4. Re-connect the power supply cord to clamp X200 on DX1.

L1: brown

N: blue.

PE: green/yellow

5. Insert the connector into the socket, check the functioning of the unit.

Reattach the covers.

64 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 65

Sirona Dental Systems GmbH 5Service routines

++

+

_

Service Manual HELIODENT

PLUS

Service routines

5

5.1Operation

5.1

Operation

1. Switch the unit on.

2. Press the Film key, the Sensor key and the Bite Wing key

simultaneously.

ª The service routine "S01" is displayed in front of a white

background.

3. Scroll through the list of service routines by pressing the +/- keys.

4. Press the Film key to show the setting of the displayed service routine

and make any changes which then may be necessary.

ª The setting is displayed.

5. To change the setting, press the +/- keys.

6. To save the current service routine, press the Adult key.

7. To discard the settings of the current service routine and quit it, press

the Child key.

8. Finally, switch the unit off and then on again.

bеЦдблЬ

62 15 102 D3507

D3507.076.01.13.02 10.2016

65

Page 66

5Service routines Sirona Dental Systems GmbH

5.2Overview Service Manual HELIODENT

PLUS

5.2

Overview

Service routine Function

S01 Configuration of transparency compensation for

films [ → 67]

S02 Configuration of transparency compensation for

sensors [ → 67]

S03 Display of software version [ → 67]

S04 Selection of film type [ → 67]

S05 Selection of sensor type [ → 68]

S06 Selection of cone type [ → 68]

S07 Set diaphragm type [ → 69]

S08 Configuration of radiation time and dose display

after an X-ray exposure [ → 69]

S09 Configuration of time-out time of the radiation

time and dose display [ → 69]

S10 Configuration of display options: Area dose and

actual radiation time [ → 70]

S11 Configuration of power-save mode [ → 70]

S12 Configuration of time-out time of the power-save

mode [ → 70]

S13 Configuration of 60/70 kV toggle [ → 71]

S14 Configuration of detector medium toggle (film/

sensor) [ → 71]

S15 Configuration of safety circuit bypass [ → 72]

S16 Configuration of the dynamic pulse/pause ratio

(dynamic cooling) [ → 73]

S17 Dose rate correction [ → 73]

S18 Setting the display contrast [ → 74]

S19 Setting the display brightness and color [ → 74]

S20 Setting the LED brightness [ → 75]

S21 Display self-test [ → 75]

S22 Front panel test [ → 75]

S23 Display of the exposure and radiation time

counter [ → 76]

S24 Reading the status log [ → 76]

S25 Display of saved data [ → 76]

S26 Activation of demo mode [ → 77]

S27 Resetting the unit to factory default settings

[ → 77]

S28 Setting the overall X-ray filter strength [ → 78]

S29 Setting the maximum radiation time from 0.4 s -

3.2 s [ → 78]

66 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 67

Sirona Dental Systems GmbH 5Service routines

Service Manual HELIODENT

PLUS

5.3Service routines (list)

5.3

Service routines (list)

5.3.1 Service routine S01

Explanation

Configuration of transparency compensation for films

Configuration

You can adjust the transparency compensation in the range from -6 to +6

by pressing the +/- keys (factory default setting = "0").

5.3.2 Service routine S02

Explanation

Configuration of transparency compensation for sensors

Configuration

You can adjust the transparency compensation in the range from -6 to +6

with the +/- keys (factory default setting = "0").

5.3.3 Service routine S03

Explanation

bеЦдблЬ

Display of software version

5.3.4 Service routine S04

Explanation

Selection of film type

You can toggle between the following film types:

●FILM D

●FILM E

●FILM F

Operation

Toggle between the film types by pressing the +/- keys.

Legend

Display Film type

FILM D FILM D

FILM E FILM E (factory default setting)

FILM F FILM F

62 15 102 D3507

D3507.076.01.13.02 10.2016

67

Page 68

5Service routines Sirona Dental Systems GmbH

5.3Service routines (list) Service Manual HELIODENT

PLUS

5.3.5 Service routine S05

Explanation

Selection of sensor type

You can toggle between the following sensor types:

● Sirona sensor

● Non-Siemens sensor

● Imaging plate

Operation

Toggle between the sensor types by pressing the +/- keys.

Legend

Display Sensor type

Sirona

General

Scanner

Sirona XIOS/XIOS

(factory default setting)

Non-Siemens sensor

Imaging plate

Plus

sensor

5.3.6 Service routine S06

Explanation

Selection of focus type (cone length)

You can toggle between the following focus types (cone lengths):

● 200 mm (8")

● 300 mm (12")

Operation

Toggle between the focus types by pressing the +/- keys.

Legend

Display

(Focus type)

200mm (8")

300mm (12")

Cone length in mm

200 mm (8") (factory default setting)

300 mm (12")

68 D3507.076.01.13.02 10.2016

62 15 102 D3507

Page 69

Sirona Dental Systems GmbH 5Service routines

Service Manual HELIODENT

PLUS

5.3Service routines (list)

5.3.7 Service routine S07

Explanation

Selection of diaphragm type

Operation

Toggle between the diaphragm types by pressing the +/- keys.

Legend

Display

(Focus type)

Off

2x3cm

3x4cm

5.3.8 Service routine S08

Explanation

Configuration of radiation time and dose display after an X-ray exposure

Operation

Toggle between 0, 1, 2, and 3 by pressing the +/- keys.

Legend

Display Configuration

0 No radiation time and dose indication

1 Display until time-out

2 Display until key actuation

3 Display until time-out or key actuation

Diaphragm type

no diaphragm (factory default setting)

Diaphragm, 2x3cm

Diaphragm, 3x4cm

bеЦдблЬ

(factory default setting)

62 15 102 D3507

D3507.076.01.13.02 10.2016

5.3.9 Service routine S09

Explanation

Configuration of time-out time of the radiation time and dose display

Operation

Set the time-out time to a value from 0 to 255 seconds by pressing the +/

- keys (factory default setting = "10" seconds).

69

Page 70

5Service routines Sirona Dental Systems GmbH

5.3Service routines (list) Service Manual HELIODENT

PLUS

5.3.10 Service routine S10

Explanation

Configuration of display options: Area dose and actual radiation time

This option allows for the display of the area dose and actual radiation

time after an exposure.

Operation

Toggle between Off and On by pressing the +/- keys.

Legend

Display Option

Off

On

deactivated

activated (factory default setting)

5.3.11 Service routine S11

Explanation

Configuration of the power-save mode

Operation

Toggle between Off and On by pressing the +/- keys.

Legend

Display Power-save mode

Off

On

5.3.12 Service routine S12

Explanation

Configuration of time-out time of the power-save mode

You can set the time-out time for changing to power-save mode in

minutes.

Operation

You can adjust the time-out time in minutes with the +/- keys

(factory default setting = "30" minutes).

Inactive

active (factory default setting)

NOTICE

The smallest value is 1 minutes.

62 15 102 D3507

70 D3507.076.01.13.02 10.2016

Page 71

Sirona Dental Systems GmbH 5Service routines

Service Manual HELIODENT

PLUS

5.3Service routines (list)

5.3.13 Service routine S13

Explanation

Configuration of 60/70 kV toggle

You can activate or deactivate the kV toggle with the kV keys "60kV“ and

"70kV.“

Operation