Page 1

SINUMERIK 840Di sl/840D sl/840D

HMI-Advanced

Operating Manual

Introduction

Operator Components/

Operating Sequences

Example of Operation

Machine

Parameters

Program

1

2

3

4

5

6

Services

Diagnostics

operating area

Valid for

Control

SINUMERIK 840D sl / 840 DE sl

SINUMERIK 840Di sl / 840 DiE sl

SINUMERIK 840D powerline / 840DE powerline

Software Software version

HMI-Advanced 7.5

Commissioning

operating area

Maintenance

Appendix

7

8

9

10

A

01/2008 Edition

Page 2

SINUMERIK® Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each version is indicated by the code in the "Remarks" columns.

Status code in the "Remarks" column:

A .... New documentation.

B .... Unrevised reprint with new order number.

C .... Revised edition with new status.

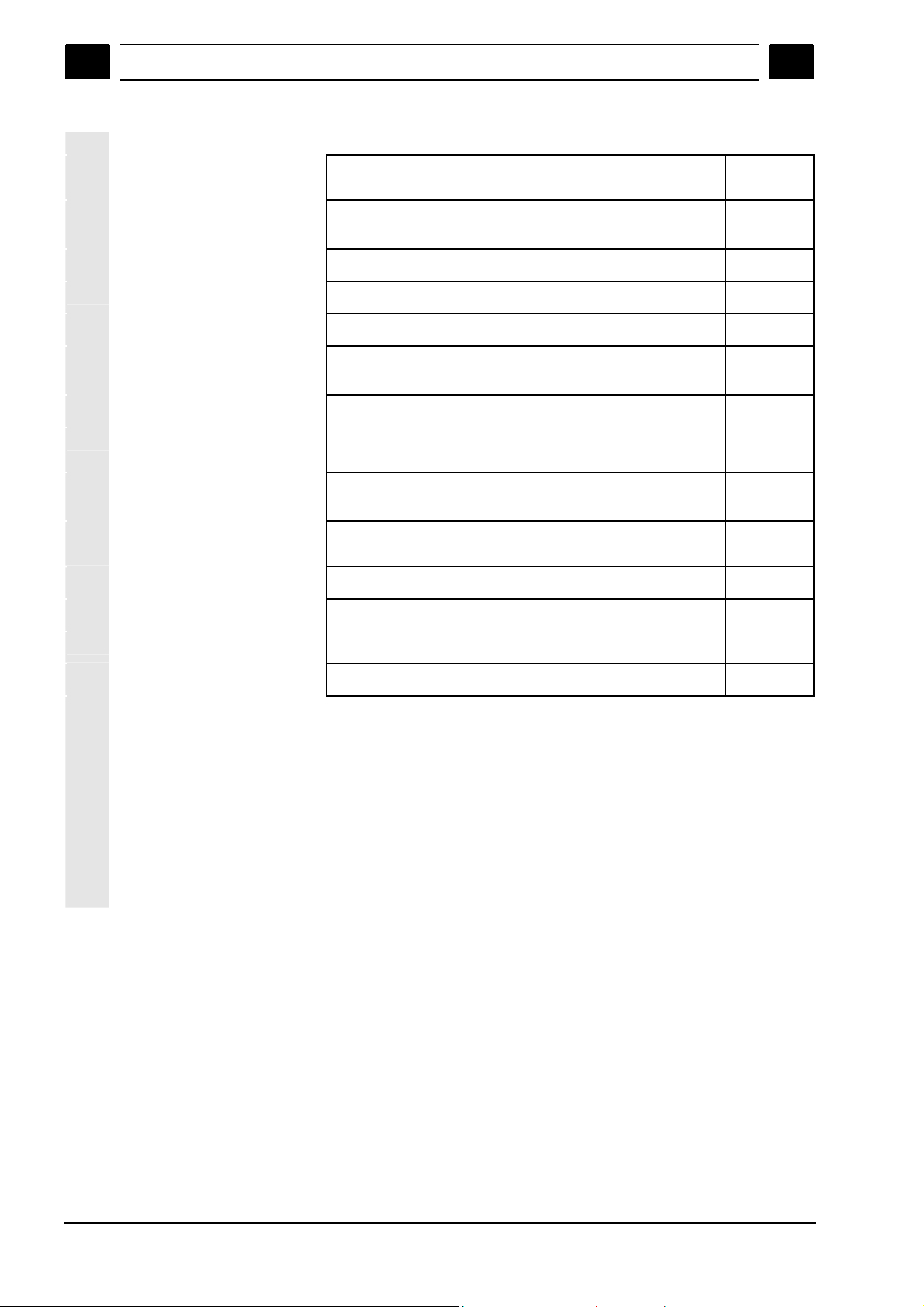

Edition Order No. Remarks

SW assignment

02.01 6FC5298-6AF00-0BP0 C

11.02 6FC5298-6AF00-0BP2 C

03.04 6FC5298-6AF00-0BP2 C NCU system software 7

08/2005 6FC5398-2AP10-0BA0 C HMI-Advanced V 7.1

01/2006 6FC5398-2AP10-1BA0 C HMI-Advanced V 7.2 SP1

11/2006 6FC5398-2AP10-2AA0 C

01/2008 6FC5398-2AP10-

3BA0

C

Registered trademarks

All names with the protective right label ® are registered trademarks of the Siemens AG. The

other product and system names in this document may be registered trademarks of their

respective companies and must be treated accordingly. .

Disclaimer of liability

We have checked that the contents of this document correspond to the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee full

agreement. The information contained in this document is, however, reviewed regularly and

any necessary changes will be included in the next edition.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NUREMBERG

GERMANY

Order No. 6FC5398-2AP10-

3BA0

Copyright © Siemens AG 1995 - 2008

Subject to change without prior notice

Page 3

01/2008 Preface

Layout of manual

0

Preface

SINUMERIK

Documentation

Target readership of this

documentation

Standard scope

0

The SINUMERIK documentation is organized in 3 parts:

• General documentation

• User documentation

• Manufacturer/Service Documentation

An overview of publications, which is updated on a monthly basis and

provides information about the language versions available, can be

found on the Internet at:

http://www.siemens.com/motioncontrol

Follow the menu items "Support" "Technical Documentation"

"Overview of Publications".

The Internet version of DOConCD (DOConWEB) is available at:

http://www.automation.siemens.com/doconweb

Information about training courses and FAQs (Frequently Asked

Questions) can be found in internet under:

http://www.siemens.com/motioncontrol

This manual is intended for machine-tool users. The document

describes in detail all the technical information an operator needs to

operate the SINUMERIK 840Di sl/840D sl/840D controls.

This Operator’s Guide describes only the functionality of the standard

version. Extensions or changes made by the machine manufacturer

are documented by the machine manufacturer.

under menu item "Support"

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition iii

Questions on the manual

EC Declaration of

Conformity

If you have any questions about the documentation (suggestions,

corrections) please send

a fax or e-mail to the following address:

Fax: +49 (0) 9131 / 98 - 63315

E-mail: docu.motioncontrol@siemens.com

The EC Declaration of Conformity for the EMC Directive can be

viewed/downloaded from the Internet at:

http://support.automation.siemens.com

under the Product Order No. 15257461 or at the relevant branch

office of the A&D MC Division of Siemens AG.

Page 4

Preface 01/2008

Layout of manual

0

0

Hotline

Internet address

Safety information

Danger Indicates that death or severe personal injury will result if proper

Warning This warning notice indicates that death or severe personal injury can

If you have any questions, please contact the following hotline:

Europe and Africa time zone:

A&D Technical Support

Tel.: +49 (0) 180 / 5050 - 222

Fax: +49 (0) 180 / 5050 - 223

Internet: http://www.siemens.de/automation/support-request

E-mail: adsupport@siemens.com

Asia and Australia time zone

A&D Technical Support

Tel.: +86 1064 719 990

Fax: +86 1064 747 474

Internet: http://www.siemens.com/automation/support-request

E-mail: adsupport@siemens.com

America time zone

A&D Technical Support

Tel.: +1 423 262 2522

Fax: +1 423 262 2289

Internet: http://www.siemens.com/automation/support-request

E-mail: adsupport@siemens.com

http://www.siemens.com/motioncontrol

This Manual contains information which you should carefully observe

to ensure your own personal safety and the prevention of material

damage. The notices referring to your personal safety are highlighted

in the manual by a safety alert symbol, notices referring to property

damage only, have no safety alert symbol. Depending on the hazard

level, warnings are indicated in a descending order as follows:

precautions are not taken.

result if proper precautions are not taken.

iv SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

© Siemens AG 2008 All rights reserved.

Page 5

01/2008 Preface

Layout of manual

0

Caution

Caution

Notice

Qualified persons

Correct use

Warning

0

means that there can be slight physical injury if the corresponding

safety measures are not followed.

without a safety alert symbol, indicates that property damage may

result if proper precautions are not taken.

This means that an undesirable result or an undesirable state can

occur if the information is ignored.

If multiple levels of hazards can occur, the warning is always

displayed with the highest possible level. If a warning with a warning

triangle is to indicate physical injury, the same warning may also

contain information about damage to property.

The associated device/system may only be set-up and operated in

conjunction with this documentation. The device/system must be

commissioned and operated by qualified personnel only. Qualified

personnel as referred to in the safety guidelines in this documentation

are those who are authorized to start up, earth and label units,

systems and circuits in accordance with the relevant safety standards.

Please observe the following:

The device must only be used for the applications specified in the

catalog and in the technical description. The device must only be used

in conjunction with external devices and components recommended

or approved by Siemens. Correct, reliable operation of the product

required proper transport, storage, positioning and assembly, as well

as careful operation and maintenance.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition v

Page 6

Preface 01/2008

Layout of manual

0

0

Export versions

Function

840DE sl

840DE

840DiE sl

Helical interpolation 2D+6

(Basic version, no options)

Milling machining package

Five axis machining package

Handling transformation package

Multi-axis interpolation

(> 4 interpolating axes)

OA NCK compile cycles

Clearance control 1D/3D in position-control

1)

cycle

Synchronized actions 1)

(Basic version, no options)

Master-value coupling and curve table

interpolation

Sag compensation, multi-dimensional # #

Synchronized actions, stage 2

Electronic gear

1)

1)

− −

− −

− −

− −

− −

− −

− −

# #

# #

−

−

#

#

Electronic transfer

−

# Restricted functionality

− Function not possible

1) In the case of the SINUMERIK 840DE sl/840DE/840DiE powerline

export versions, the restricted functions are limited to "max. 4

interpolating axes“

#

vi SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

© Siemens AG 2008 All rights reserved.

Page 7

01/2008 Preface

Layout of manual

0

0

Structure of descriptions

All functions and operating options have been described according to

the same internal structure as far as this is meaningful and

practicable. The various levels of information have been organized

such that you can selectively access the information you need for the

task in hand.

1. Function

The theoretical section is primarily intended as learning material for

the NC entry-level user and includes important information to assist

the user to understand the operator functions.

You should work through the manual at least once to get an idea of

the operational scope and capability of your SINUMERIK control.

2. Sequence of operations

This section contains the sequence of keys required for operation at a

glance. If inputs have to be made at individual stages of the sequence

or if you require additional information, you will find this next to the key

illustrations.

3. Additional information

For safety reasons, some functions are disabled to protect them from

unauthorized access. The machine manufacturer can customize or

modify the described functionality. Please comply fully with the

instructions of the machine-tool manufacturer.

In this documentation, you will find this symbol with a reference to an

ordering data option. The described function can only run if the control

contains the designated option.

Notes This symbol appears in this documentation whenever it is necessary

to draw your attention to an important item of information.

References This symbol appears whenever specific information can be found in

other documentation.

A complete list of available literature is included in the Appendix of this

Operator’s Guide.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition vii

Page 8

Preface 01/2008

Layout of manual

0

0

Explanation of symbols:

Function

Sequence of operations

Additional information

Cross-references to other documentation or sections

Danger notices

Additional notes or background information

Ordering data option

Explanation

Description of syntax

Programming Examples

viii SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

© Siemens AG 2008 All rights reserved.

Page 9

01/2008 Contents

0

Contents

Introduction......................................................................................................1-17

1.1 Product overview ...................................................................................................... 1-18

1.2 Handling information................................................................................................. 1-19

1.3 Switching on/switching off the control....................................................................... 1-20

Operator Components/Operating Sequences...............................................2-23

2.1 Operator panel front..................................................................................................2-24

2.1.1 Keys on the operator panel front ..............................................................................2-24

2.1.2 Standard full keyboard.............................................................................................. 2-29

2.2 Machine control panel (MCP) ................................................................................... 2-30

2.2.1 EMERGENCY STOP button..................................................................................... 2-31

2.2.2 Operating modes and machine functions................................................................. 2-31

2.2.3 Feedrate control........................................................................................................ 2-33

2.2.4 Spindle control .......................................................................................................... 2-35

2.2.5 Key-operated switch .................................................................................................2-36

2.2.6 Program control ........................................................................................................ 2-37

0

2.3 SINUMERIK HT 8 ..................................................................................................... 2-39

2.4 Screen layout ............................................................................................................ 2-42

2.4.1 Displaying the control states..................................................................................... 2-42

2.4.2 Global machine status display.................................................................................. 2-43

2.4.3 Program control display ............................................................................................ 2-48

2.5 General operating sequences................................................................................... 2-50

2.5.1 Program overview and program selection................................................................ 2-50

2.5.2 Changing the menu window ..................................................................................... 2-51

2.5.3 Selecting a directory/file............................................................................................ 2-52

2.5.4 Editing inputs/values ................................................................................................. 2-53

2.5.5 Confirm/cancel input ................................................................................................. 2-54

2.5.6 Edit the part program in the ASCII editor.................................................................. 2-55

2.5.7 Switching over the channel....................................................................................... 2-61

2.5.8 Packet calculator....................................................................................................... 2-62

2.6 Calling the help function............................................................................................ 2-63

2.6.1 Editor help................................................................................................................. 2-65

2.6.2 Quick help for program commands........................................................................... 2-66

2.6.3 Extended help for program commands..................................................................... 2-69

2.7 Job list....................................................................................................................... 2-70

2.7.1 Syntax description for job lists ..................................................................................2-72

2.7.2 Example of a job list with two-channel 1:1 links .......................................................2-75

2.7.3 Example of a job list with multi-channel m:n links ....................................................2-76

2.7.4 “Execute job list” operating sequence....................................................................... 2-77

© Siemens AG 2006 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition ix

Page 10

Contents 01/2008

0

2.7.5 Re-naming workpieces with job lists .........................................................................2-79

2.7.6 Copying workpieces with job lists .............................................................................2-80

2.7.7 Archiving workpieces with job lists in the case of M:N..............................................2-80

Example of Operation..................................................................................... 3-81

3.1 Typical operating sequence ...................................................................................... 3-81

Machine operating area .................................................................................. 4-83

4.1 CNC data structure ...................................................................................................4-85

4.1.1 Modes and machine functions ..................................................................................4-86

4.1.2 Modes group and channels....................................................................................... 4-88

4.1.3 Cross-channel status display via symbols ................................................................ 4-89

4.1.4 Two-channel display .................................................................................................4-90

4.1.5 Mode selection, mode change ..................................................................................4-91

4.2 General functions and displays.................................................................................4-94

4.2.1 Start/stop/abort/continue part program .....................................................................4-94

4.2.2 Displaying the program level.....................................................................................4-95

4.2.3 Switching over the machine/workpiece coordinate system (MCS/WCS) .................4-96

4.2.4 Displaying several transverse axes ..........................................................................4-98

4.2.5 Displaying axis feedrates ..........................................................................................4-99

4.2.6 Display G functions, transformations and swivel data ............................................ 4-100

4.2.7 Displaying auxiliary functions..................................................................................4-101

4.2.8 Displaying modal M functions .................................................................................4-101

4.2.9 Displaying spindles .................................................................................................4-103

4.2.10 Handwheel ..............................................................................................................4-104

4.2.11 Status of the synchronized actions .........................................................................4-105

4.2.12 Preset ......................................................................................................................4-107

4.2.13 Setting the actual value...........................................................................................4-108

4.2.14 Inch ↔ Metric switchover........................................................................................4-109

0

4.3 Reference point approach.......................................................................................4-111

4.4 JOG mode ...............................................................................................................4-114

4.4.1 Function and main screen.......................................................................................4-114

4.4.2 Traversing axes....................................................................................................... 4-117

4.4.3 Inc: Increment..........................................................................................................4-118

4.4.4 REPOS (repositioning)............................................................................................4-119

4.4.5 SI (Safety Integrated): User agreement..................................................................4-120

4.4.6 Scratching ...............................................................................................................4-121

4.4.7 Displaying system frames .......................................................................................4-124

4.5 MDA mode ..............................................................................................................4-127

4.5.1 Function and main screen.......................................................................................4-127

4.5.2 Saving the program, file function.............................................................................4-129

4.5.3 Teach in...................................................................................................................4-130

4.6 Automatic mode ......................................................................................................4-132

4.6.1 Function and main screen.......................................................................................4-132

x SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2006 All rights reserved.

Page 11

01/2008 Contents

0

4.6.2 Program overview ................................................................................................... 4-134

4.6.3 Loading and unloading the workpiece/part program .............................................. 4-135

4.6.4 Protocol: Program loading list................................................................................. 4-136

4.6.5 Executing from the hard disk ..................................................................................4-137

4.6.6 Accessing an external network drive ...................................................................... 4-138

4.6.7 Program editing....................................................................................................... 4-140

4.6.8 Setting the block search/search target ................................................................... 4-141

4.6.9 Accelerated external block search..........................................................................4-145

4.6.10 Block search in Program test mode, multi-channel ................................................4-148

4.6.11 Overstore ................................................................................................................4-150

4.6.12 Program control ...................................................................................................... 4-152

4.6.13 DRF offset............................................................................................................... 4-156

Parameters operating area............................................................................5-157

5.1 Tool data ................................................................................................................. 5-159

5.1.1 Tool offset structure ................................................................................................ 5-159

5.1.2 Tool types and tool parameters .............................................................................. 5-159

0

5.2 Tool offset ...............................................................................................................5-174

5.2.1 Function and main screen Tool offset.....................................................................5-174

5.2.2 New tool .................................................................................................................. 5-176

5.2.3 Display tool.............................................................................................................. 5-177

5.2.4 Deleting a tool ......................................................................................................... 5-178

5.2.5 New cutting edge .................................................................................................... 5-179

5.2.6 Deleting a cutting edge ........................................................................................... 5-180

5.2.7 Determining a tool offset......................................................................................... 5-180

5.2.8 Make tool offset immediately effective....................................................................5-181

5.3 Tool management ................................................................................................... 5-182

5.3.1 Main tool management functions............................................................................5-183

5.3.2 Displaying/editing tool data..................................................................................... 5-191

5.3.3 Change in the significance/representation of tool wear values .............................. 5-195

5.3.4 Grinding data expansion......................................................................................... 5-198

5.3.5 Load ........................................................................................................................ 5-200

5.3.6 Unload..................................................................................................................... 5-204

5.3.7 Relocating ............................................................................................................... 5-206

5.3.8 Tool master data in the tool catalog........................................................................ 5-207

5.3.9 Tool offset data in the tool cabinet..........................................................................5-210

5.3.10 Job processing of tools ........................................................................................... 5-213

5.4 R parameters (calculation parameters) ..................................................................5-221

5.5 Setting data............................................................................................................. 5-222

5.5.1 Working area limitation ...........................................................................................5-222

5.5.2 JOG data................................................................................................................. 5-223

5.5.3 Spindle data ............................................................................................................ 5-224

5.5.4 Dry run feedrate for dry run operation DRY............................................................ 5-225

5.5.5 Starting angle for thread cutting.............................................................................. 5-226

5.5.6 Miscellaneous setting data ..................................................................................... 5-227

© Siemens AG 2006 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition xi

Page 12

Contents 01/2008

0

5.5.7 Protection zones .....................................................................................................5-228

5.5.8 Electronic gear ........................................................................................................5-229

5.6 Zero/work offset.......................................................................................................5-230

5.6.1 Function...................................................................................................................5-230

5.6.2 Edit the settable work offset (G54 ...)......................................................................5-232

5.6.3 Global zero offset/frame..........................................................................................5-232

5.6.4 Displaying an active settable work offset................................................................5-235

5.6.5 Displaying an active programmable work offset .....................................................5-236

5.6.6 Displaying an active external work offset................................................................ 5-237

5.6.7 Display the sum of the active work offsets..............................................................5-237

5.6.8 Activate active work offset and basic frame immediately .......................................5-238

5.6.9 Actual value display: Settable zero system, SZS....................................................5-238

5.7 Define user data......................................................................................................5-239

5.7.1 Define variables (GUD, PUD, LUD) ........................................................................5-239

5.7.2 Editing/finding user data..........................................................................................5-240

5.7.3 Activate user data (GUD) ........................................................................................5-242

0

5.8 Display system variables.........................................................................................5-244

5.8.1 Creating variable views ...........................................................................................5-245

5.8.2 Managing variable views.........................................................................................5-247

5.8.3 Logging system variables........................................................................................5-248

"Program" operating area.................................................................................6-251

6.1 Program types .........................................................................................................6-253

6.1.1 Part program ...........................................................................................................6-253

6.1.2 Subprogram.............................................................................................................6-253

6.1.3 Workpiece ...............................................................................................................6-253

6.1.4 Cycles...................................................................................................................... 6-253

6.1.5 Storing programs.....................................................................................................6-253

6.1.6 Templates................................................................................................................6-254

6.2 Main screen program ..............................................................................................6-256

6.3 Edit programs iin the standard ASCII Editor ..........................................................6-258

6.3.1 Undo and redo in the standard ASCII editor...........................................................6-260

6.3.2 Additional optional editors .......................................................................................6-261

6.3.3 Selective program protection *RO* .........................................................................6-261

6.4 Structured step sequence display (option)..............................................................6-263

6.5 Multi-channel step sequence programming (option)...............................................6-267

6.5.1 Multi-channel workpiece program views.................................................................6-270

6.5.2 Activating timing ......................................................................................................6-276

6.5.3 Activating simulation ...............................................................................................6-277

6.6 Multiple editor (option).............................................................................................6-281

6.6.1 Operator/display functions in the ASCII full views ..................................................6-281

6.6.2 Alignment of the channels/MPFs to be displayed...................................................6-285

6.7 Free contour programming......................................................................................6-287

xii SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2006 All rights reserved.

Page 13

01/2008 Contents

0

6.7.1 Programming a contour ..........................................................................................6-288

6.7.2 Undercuts for turning technology............................................................................ 6-293

6.7.3 Parameterizing contour elements ........................................................................... 6-296

6.7.4 Graphically displaying the contour..........................................................................6-298

6.7.5 Symmetrical contours with milling technology ........................................................ 6-299

6.7.6 Specifying contour elements in polar coordinates, closing the contour ................. 6-302

6.7.7 Support for contour programming........................................................................... 6-307

6.7.8 Parameter description of the contour elements straight line/circle......................... 6-308

6.7.9 Programming examples for freely programming a contour .................................... 6-309

6.7.10 Cycle support .......................................................................................................... 6-313

6.8 Program simulation ................................................................................................. 6-314

6.8.1 Using the simulation function..................................................................................6-316

6.8.2 Simulation settings.................................................................................................. 6-325

6.8.3 Setting downtimes................................................................................................... 6-331

6.8.4 Display and colors................................................................................................... 6-332

6.8.5 Section-by-section simulation ................................................................................. 6-333

6.8.6 Quick display in the simulation for mold making..................................................... 6-334

6.8.7 Simulation with external network drive ...................................................................6-336

6.8.8 Simulation for orientable toolholder ........................................................................ 6-337

0

6.9 Managing programs................................................................................................ 6-337

6.9.1 New workpiece/part program..................................................................................6-339

6.9.2 Create programs/data in a workpiece directory...................................................... 6-341

6.9.3 Saving setup data ................................................................................................... 6-342

6.9.4 Selecting a program to be executed....................................................................... 6-343

6.9.5 Loading/unloading a program ................................................................................. 6-346

6.9.6 Manage programs...................................................................................................6-347

6.9.7 Copying/inserting .................................................................................................... 6-348

6.9.8 Deleting................................................................................................................... 6-351

6.9.9 Renaming................................................................................................................ 6-352

6.9.10 Enabling .................................................................................................................. 6-353

6.9.11 Protocol................................................................................................................... 6-354

6.10 Accessing an external network drive/computer ...................................................... 6-355

Services operating area ................................................................................7-357

7.1 Services main screen.............................................................................................. 7-359

7.1.1 Reading-in data....................................................................................................... 7-362

7.1.2 Reading-out data .................................................................................................... 7-363

7.1.3 Displaying the log.................................................................................................... 7-364

7.2 Managing data ........................................................................................................ 7-366

7.2.1 New file/new directory.............................................................................................7-367

7.2.2 Loading and unloading............................................................................................ 7-367

7.2.3 Copying and inserting ............................................................................................. 7-368

7.2.4 Deleting................................................................................................................... 7-369

7.2.5 Changing properties................................................................................................ 7-370

7.3 Data selection .........................................................................................................7-373

© Siemens AG 2006 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition xiii

Page 14

Contents 01/2008

0

7.3.1 Special directories and memory areas....................................................................7-376

7.3.2 Data on the hard disk..............................................................................................7-377

7.4 Transfer display MD from HMI Embedded..............................................................7-380

7.5 V.24 interface .......................................................................................................... 7-382

7.5.1 Parameterizing the V.24 interface...........................................................................7-382

7.5.2 Using the V.24 interface.......................................................................................... 7-386

Diagnostics operating area ...........................................................................8-391

8.1 Diagnostics main screen.........................................................................................8-392

8.2 Remote diagnostics.................................................................................................8-394

8.3 Alarms and messages.............................................................................................8-394

8.4 Service displays ......................................................................................................8-396

8.4.1 Service axis .............................................................................................................8-398

8.4.2 Service drive............................................................................................................8-399

8.4.3 Service SI (Safety Integrated).................................................................................8-400

8.4.4 Systemressourcen anzeigen................................................................................... 8-412

8.4.5 Configuration data output........................................................................................8-413

8.4.6 Communication error log.........................................................................................8-413

8.4.7 Action log.................................................................................................................8-414

0

8.5 Calling theversion screen........................................................................................8-414

8.5.1 Sorting and saving version data..............................................................................8-415

8.5.2 Display the version screens for cycles.................................................................... 8-416

8.5.3 Cycle version output................................................................................................8-419

8.5.4 Displaying loadable compile cycles ........................................................................8-419

8.6 Interrogating the PLC status ...................................................................................8-421

8.6.1 Changing/deleting a value.......................................................................................8-422

8.6.2 Assign symbolic PLC addresses.............................................................................8-423

8.6.3 Select operand screens for PLC status ..................................................................8-427

8.6.4 File functions ...........................................................................................................8-428

Commissioning operating area.....................................................................9-429

9.1 Startup main screen ................................................................................................9-430

9.2 Machine data...........................................................................................................9-432

9.3 NC ...........................................................................................................................9-434

9.4 PLC .........................................................................................................................9-435

9.5 Optimization/test (SINUMERIK powerline) .............................................................9-436

Maintenance..................................................................................................10-439

10.1 Operating data.......................................................................................................10-440

10.2 Cleaning ................................................................................................................10-441

xiv SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2006 All rights reserved.

Page 15

01/2008 Contents

0

Appendix ....................................................................................................... A-443

A Abbreviations ..........................................................................................................A-444

B Terms......................................................................................................................A-448

Index ................................................................................................................I-463

I.1 Index ........................................................................................................................ I-463

I.2 Commands and Identifier......................................................................................... I-468

0

© Siemens AG 2006 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition xv

Page 16

Contents 01/2008

0

0

xvi SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2006 All rights reserved.

Page 17

01/2008 Introduction

1

1.1 Product overview

Introduction

1.1 Product overview ...................................................................................................... 1-18

1.2 Handling information ................................................................................................. 1-19

1.3 Switching on/switching off the control....................................................................... 1-20

1

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 1-17

Page 18

Introduction 01/2008

1.1 Product overview

1

1

1.1 Product overview

The SINUMERIK controller is a CNC control system (Computerized

Numerical Control) for machine tools.

You can use the CNC control system to implement the following basic

functions in conjunction with a machine tool:

• Creation and adaptation of part programs

• Execution of part programs

• Manual control

• Reading in and reading out of part programs and data

• Editing of data for programs

• Displaying and troubleshooting alarms

• Editing of machine data

• Setting up of communication links between 1 or more operating

units (m) or 1 or more NCs (n)

(m:n, m operating units and n NCK/PLC units).

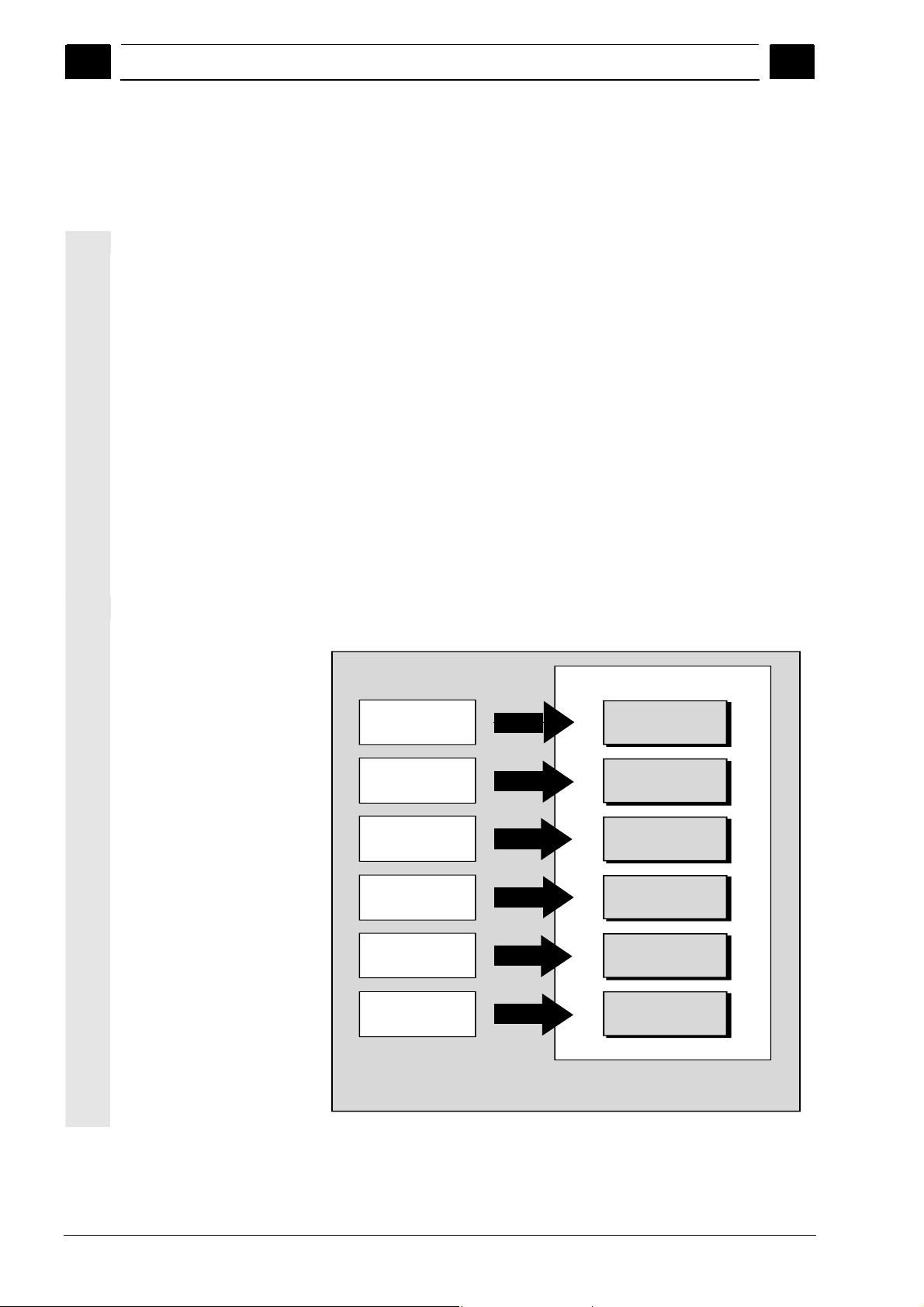

Operating areas

The basic functions are grouped in the following operating areas in the

control (in gray boxes):

Execution

of part program s,

manual control

Editing data

fo r p ro gra m s/

tool ma nagem ent

Development

and ad aptation

of part program s

Reading in/out

and archivin g

programs an d data

Alarm display s,

service displays

Adaptation of NC

data to m ac h ine ,

system settings

Operating areas

MACHINE

PARAMETERS

PROGRAM

SERVICES

DIAGNOSIS

START-UP

1-18 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

© Siemens AG 2008 All rights reserved.

Page 19

01/2008 Introduction

1

The user can call up all the functions via the user interface.

The user interface consists of:

• Display units such as screen, LEDs, etc.

• Control elements such as keys, switches, handwheels, etc.

Read Chapter 2 "Operation" carefully before proceeding with further

chapters.

All subsequent chapters are written on the assumption that you have

done so!

1.2 Handling information

1.2 Handling information

Caution

1

The operator panel front/machine control panel may only be opened

by trained personnel for servicing purposes.

Before operating any of the control elements on this operator panel

Danger

Never open the operator panel front/machine control panel unless the

power supply has been disconnected! Failure to comply could result in

fatal injury!

Warning

Electronic components inside the operator panel/machine control

panel can be destroyed by electrostatic discharge if they are handled

incorrectly.

front:

Please first read the explanations supplied in this documentation!

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 1-19

Page 20

Introduction 01/2008

A

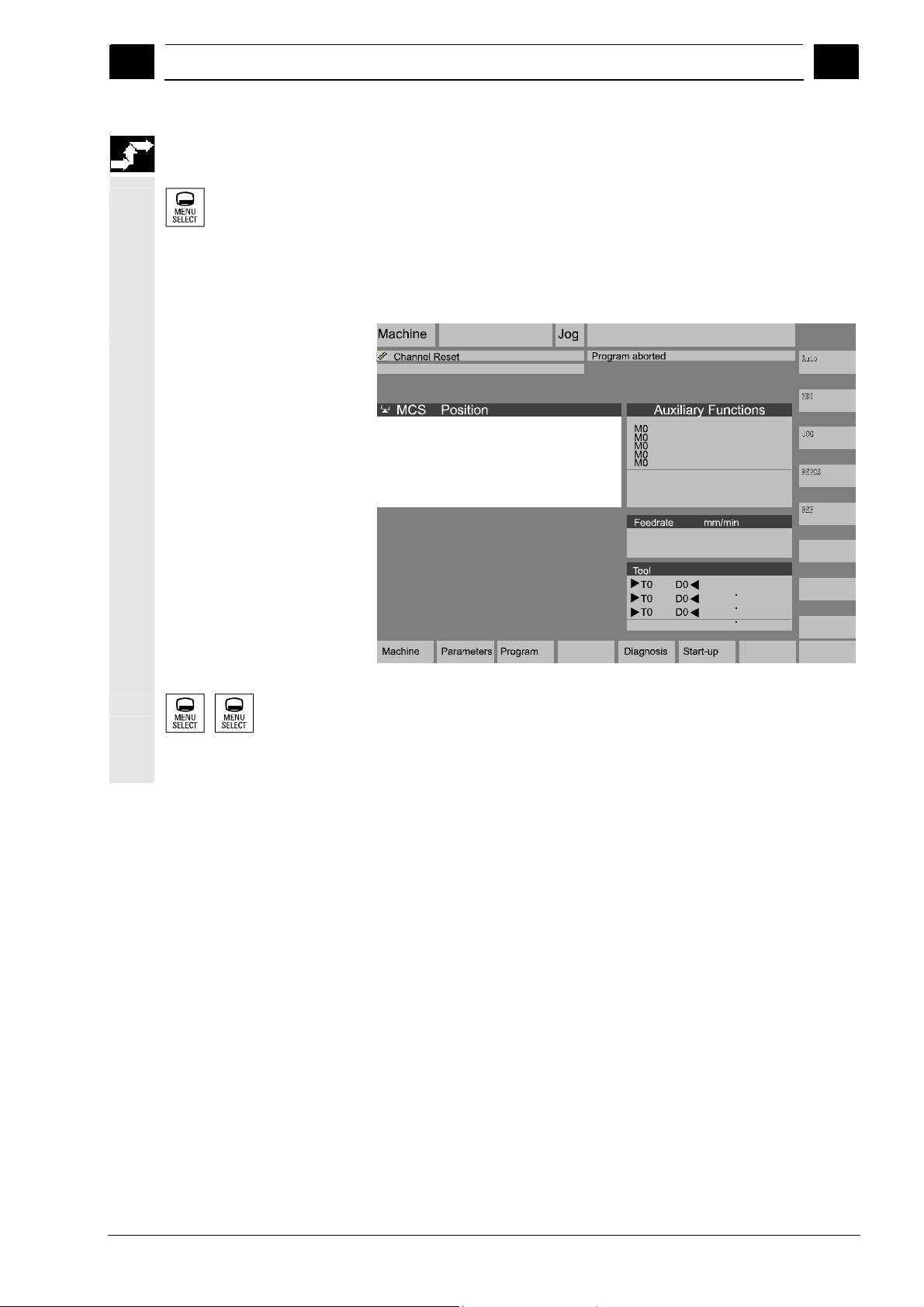

1.3 Switching on/switching off the control

1

1.3 Switching on/switching off the control

Switching on

Function

A variety of methods can be employed to switch on the power supply

to the control system or to the whole plant.

Machine manufacturer

1

Switching off

Please follow the machine manufacturer's instructions!

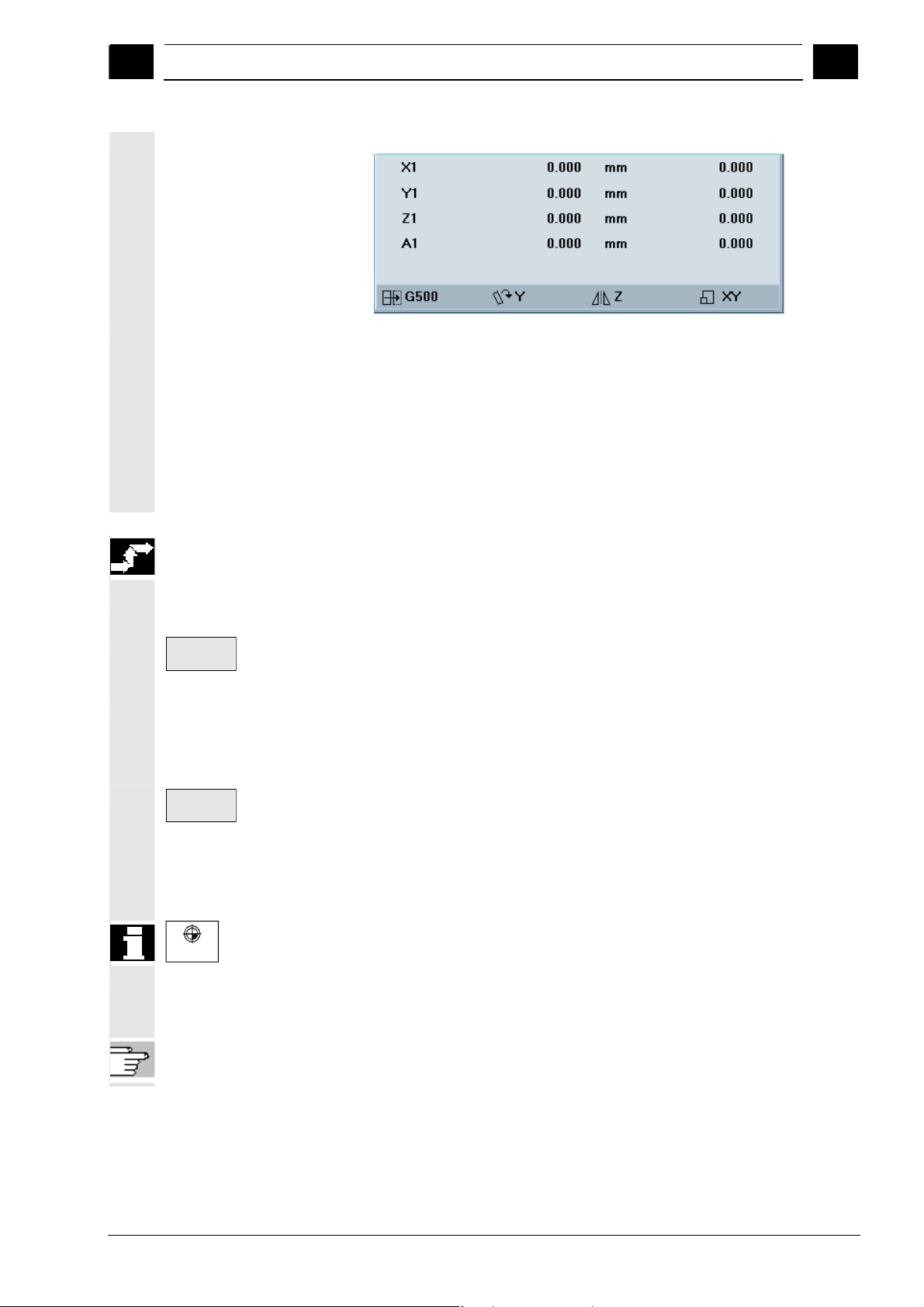

fter the control has been switched on, the "Reference point

approach" display or another main screen programmed by the

machine manufacturer will appear.

Machine

Channel Reset

Program aborted

MKS Position.Repos-Versch.

MCS Position

-X 0.000 mm

+X900.000mm0.000

+ X 900.000 mm 0.000

+Y 0.000 mm

- Y -156.000 mm 0.000

-Y-156.000mm0.000

+Z 0.000 mm

+ Z 230.000 mm 0.000

+Z230.000mm0.000

+0.000mm

Jog

Master spindle S1

Act. + 0.000 rev./min

Set 0.000 rev./min

Pos. 0.000 deg.

0.000 %

Power [%\

Feedrate mm/min

Act. 0.000 0.000 %

Set 0.000

Tool

preselected tool :

G0 G91

REF

Please follow the instructions below for switching off the control or the

entire system!

Machine manufacturer

Please follow the machine manufacturer's instructions!

1-20 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

© Siemens AG 2008 All rights reserved.

Page 21

01/2008 Introduction

1

1.3 Switching on/switching off the control

1

Sequence of operations

When you press the "Area switchover" key, operating areas are

displayed on the horizontal softkey bar and operating modes are

displayed on the vertical softkey bar. You can use this key to go to the

area menu bar from any location in the menu hierarchy if you wish to

select another operating mode or a different operating area.

+ X 900.000 mm

- Y -156.000 mm

+ Z 230.000 mm

H0.000000

H0.000000

H0.000000

Act. 3000.000 0.0 %

Set. 3000.000

G1

Services

By pressing the "Area switchover" key twice, you can toggle between

the operating areas last selected, e.g. between the "Parameters" and

"Machine" areas.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 1-21

Page 22

Introduction 01/2008

1.3 Switching on/switching off the control

1

Notes

1

1-22 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

© Siemens AG 2008 All rights reserved.

Page 23

01/2008 Operator Components/Operating Sequences

2

2.1 Operator panel front

Operator Components/Operating Sequences

2.1 Operator panel front.................................................................................................. 2-24

2.1.1 Keys on the operator panel front............................................................................... 2-24

2.1.2 Standard full keyboard.............................................................................................. 2-29

2.2 Machine control panel (MCP) ...................................................................................2-30

2.2.1 EMERGENCY STOP button ..................................................................................... 2-31

2.2.2 Operating modes and machine functions ................................................................. 2-31

2.2.3 Feedrate control........................................................................................................ 2-33

2.2.4 Spindle control ..........................................................................................................2-35

2.2.5 Key-operated switch ................................................................................................. 2-36

2.2.6 Program control......................................................................................................... 2-37

2.3 SINUMERIK HT 8 ..................................................................................................... 2-39

2.4 Screen layout ............................................................................................................ 2-42

2.4.1 Displaying the control states..................................................................................... 2-42

2.4.2 Global machine status display .................................................................................. 2-43

2.4.3 Program control display ............................................................................................ 2-48

2

2.5 General operating sequences...................................................................................2-50

2.5.1 Program overview and program selection ................................................................ 2-50

2.5.2 Changing the menu window...................................................................................... 2-51

2.5.3 Selecting a directory/file............................................................................................ 2-52

2.5.4 Editing inputs/values ................................................................................................. 2-53

2.5.5 Confirm/cancel input ................................................................................................. 2-54

2.5.6 Edit the part program in the ASCII editor.................................................................. 2-55

2.5.7 Switching over the channel....................................................................................... 2-61

2.5.8 Packet calculator....................................................................................................... 2-62

2.6 Calling the help function............................................................................................ 2-63

2.6.1 Editor help................................................................................................................. 2-65

2.6.2 Quick help for program commands........................................................................... 2-66

2.6.3 Extended help for program commands..................................................................... 2-69

2.7 Job list ....................................................................................................................... 2-70

2.7.1 Syntax description for job lists ..................................................................................2-72

2.7.2 Example of a job list with two-channel 1:1 links........................................................ 2-75

2.7.3 Example of a job list with multi-channel m:n links..................................................... 2-76

2.7.4 “Execute job list” operating sequence....................................................................... 2-77

2.7.5 Re-naming workpieces with job lists......................................................................... 2-79

2.7.6 Copying workpieces with job lists .............................................................................2-80

2.7.7 Archiving workpieces with job lists in the case of M:N.............................................. 2-80

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-23

Page 24

Operator Components/Operating Sequences 01/2008

2.1 Operator panel front

2

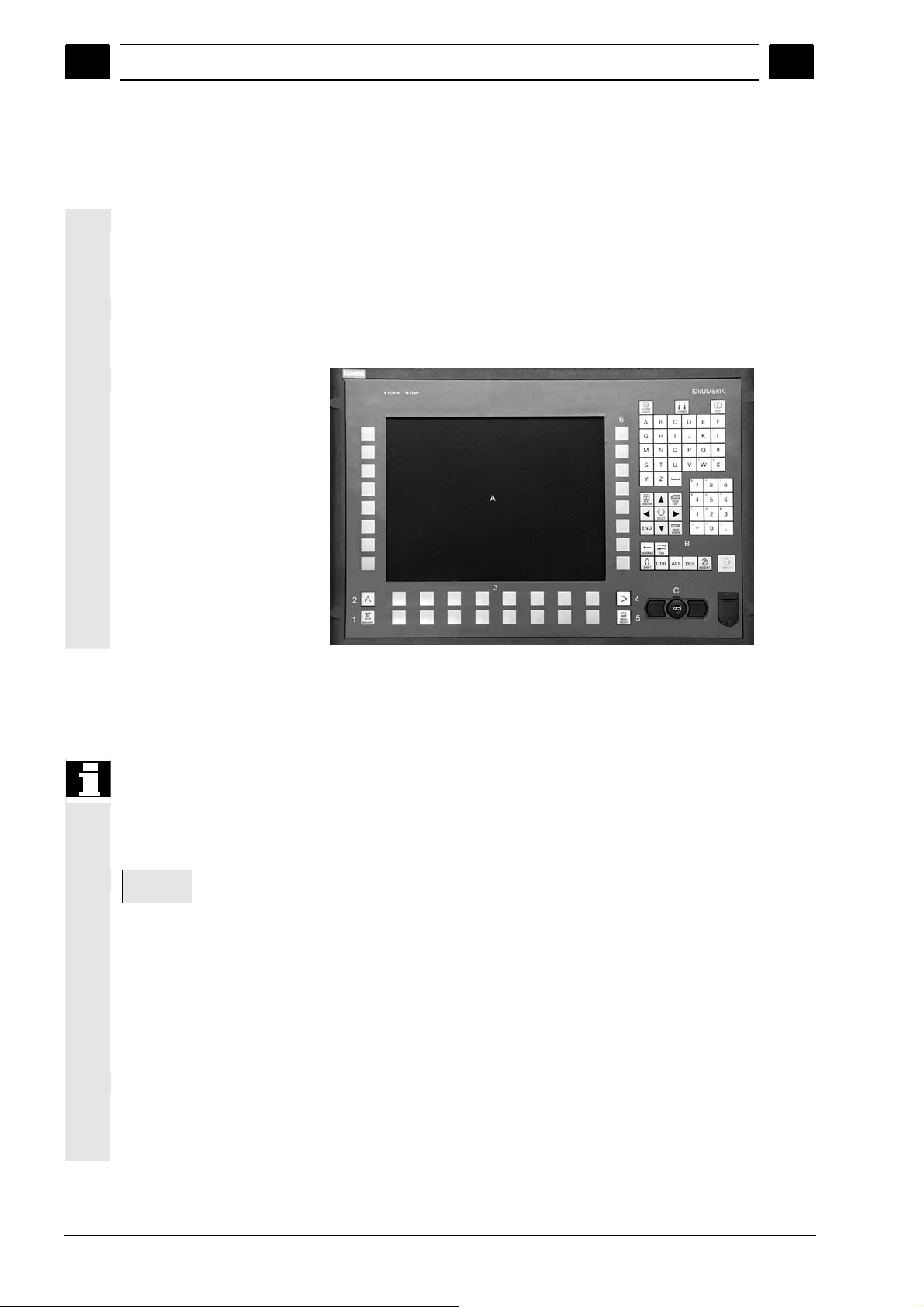

2.1 Operator panel front

A Display

Example

Properties

B Alphanumeric keypad

Correction/cursor keys

C Mouse and mouse keys

1 Machine area key

2 Recall (return)

3 Softkey bar (horizontal)

4 ETC key

(menu extension)

5 Area switchover key

6 Softkey bar (vertical)

In this example, the OP 012 SINUMERIK operator panel front is used

to illustrate the operator components, which are available for operating

the SINUMERIK control and machine tool.

The OP 012 operator panel front with 12.1" TFT color display with a

resolution of 800 x 600 pixels (SVGA) features a 59-key membrane

keypad as well as 2 x (8 + 2) horizontal and 2 x 8 vertical softkeys and

a built-in mouse.

2

2.1.1 Keys on the operator panel front

Keys on the operator

panel front

A function is called up by pressing one of the vertical softkeys. The

The elements of the operator panel keyboard and the symbols used to

represent them in this manual are shown and explained below.

The keys marked with an * correspond to the key symbols in US

layout.

Softkeys

Keys to which functions are assigned by means of a menu bar

displayed on the screen.

• It is possible to access further menu levels via the horizontal

softkeys in any operating area. Each horizontal menu item has a

vertical menu bar/softkey assignment.

• The vertical softkeys are assigned functions for the currently

selected horizontal softkey.

assignments of the vertical softkey bar can change if further subsidiary

functions are classified under a function.

2-24 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 25

01/2008 Operator Components/Operating Sequences

2

2.1 Operator panel front

2

Parameter

Softkey (horizontal or vertical):

This key symbol indicates that you must have selected an operating

area or a menu item or have already performed certain functions

before you are able to execute the function described in the relevant

section.

Machine area key

Direct branch to the "Machine" operating area.

Recall key

Return to the higher-level menu. Recall closes a window.

ETC key

Expansion of the horizontal softkey bar in the same menu.

Area switchover key

You can call the main menu from any operating area by pressing this

key. Pressing the key twice in succession changes from the current

operating area to the previous one and back again.

The standard main menu branches into the following operating areas:

1. Machine

2. Parameters

3. Program

4. Services

5. Diagnostics

6. Commissioning

Shift key

Switches between functions on keys with double assignment.

Switch over channel

In a configuration with several channels, it is possible to switch

between channels (switch from channel 1 through to channel n).

When a "Channel menu" is configured, all existing communication

links to other NCUs plus the associated channels are displayed on

softkeys.

(See Section "Switch over channel")

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-25

Page 26

Operator Components/Operating Sequences 01/2008

2.1 Operator panel front

2

2

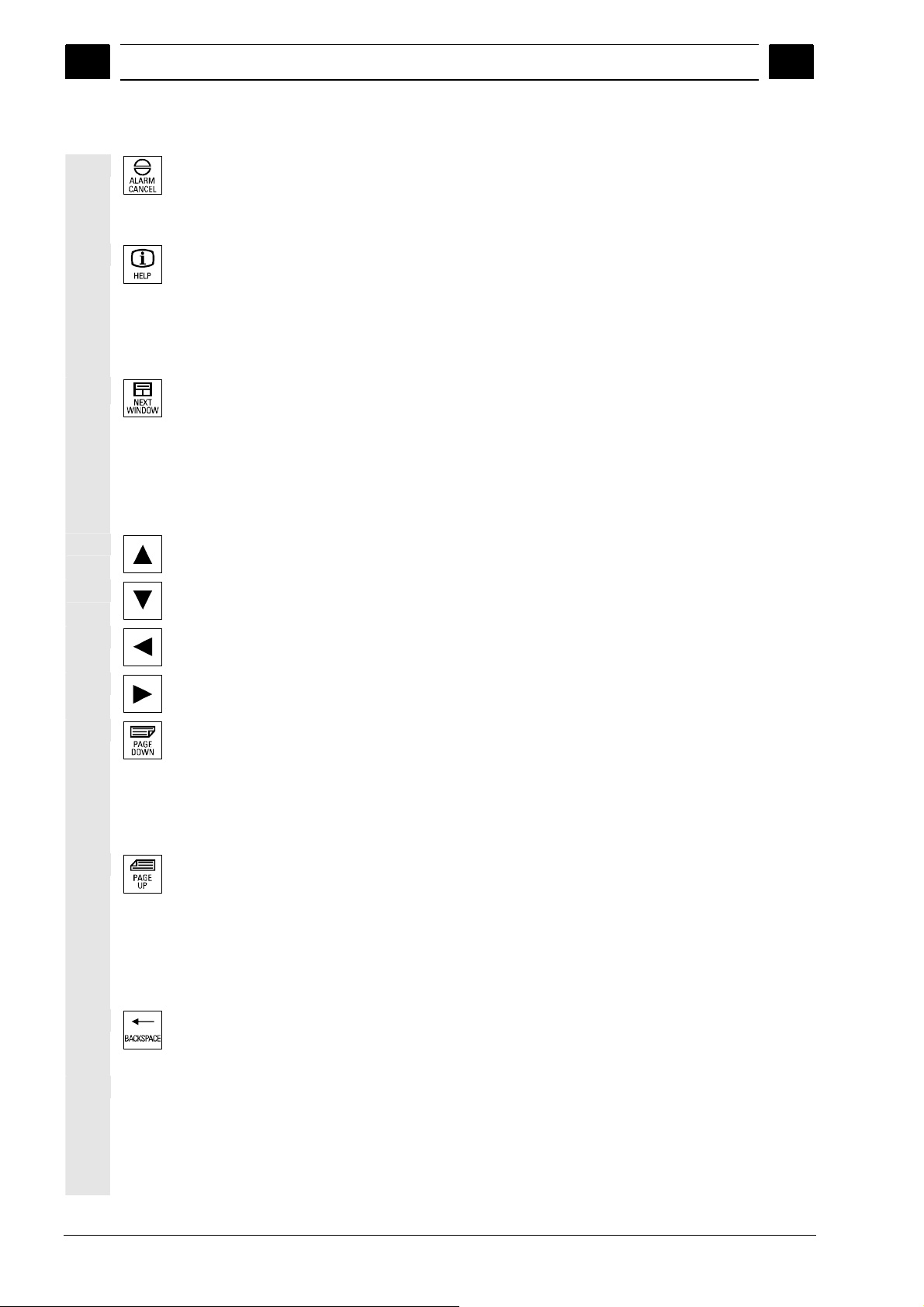

Acknowledge alarm key

By pressing this key, you can acknowledge the alarm marked by this

Cancel symbol.

Information key

This key displays explanatory information about the current operating

status (e.g. support for programming, diagnostics, PLC, alarms).

The letter "i" displayed in the user response line indicates that

information is available.

Window selection key

If several windows are displayed on the screen, it is possible to make

the next window the active one using the window selection key (the

active window has a thicker border).

Keyboard input e.g. the page keys, is possible only in the active

window.

Cursor up

Cursor down

Cursor to the left

Cursor to the right

PAGE DOWN

You "scroll" down by one display.

In a part program, you can "scroll" the display down (to end of

program) or up (to start of program).

PAGE UP

You "scroll" up by one display.

With the page keys you scroll the visible/displayed area of the window

that is active. The scroll bar indicates which part of the

program/document/... is selected.

Backspace

Delete characters from right

Space character (Blank)

2-26 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 27

01/2008 Operator Components/Operating Sequences

2

2.1 Operator panel front

2

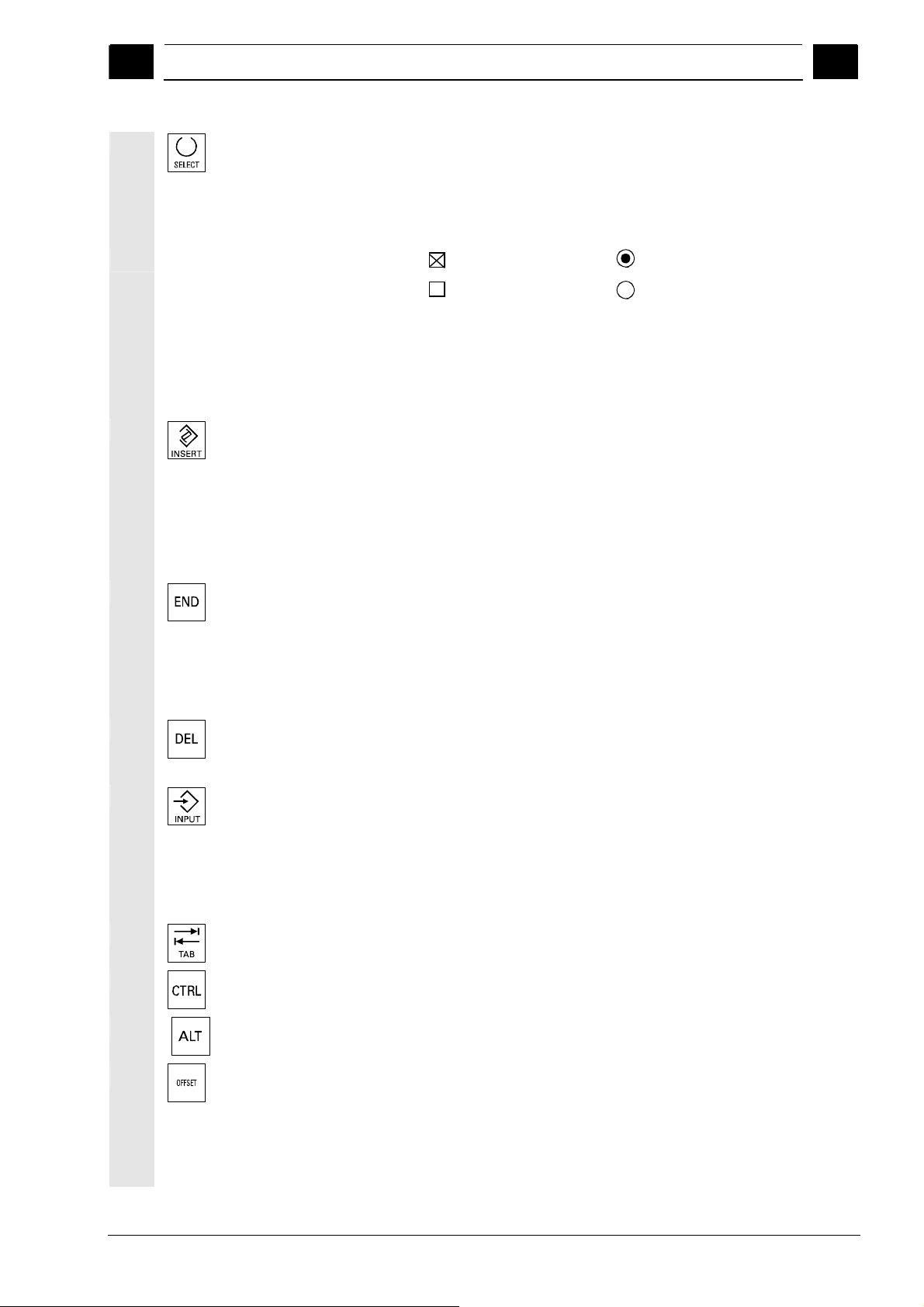

*

Selection key

• Selection key for values set in input fields and selection lists

labeled with this key symbol.

• Activate/deactivate a field:

Multiple option button

(you can select several options or

none)

Edit key / undo key

• Switch over to edit mode in tables and input fields (in this case, the

input field is in insert mode) or

• UNDO function on table elements and input fields (the value is not

validated when you exit a field using the edit key; instead it is reset

to the previous value = UNDO).

End of line key

• With this key, the cursor is moved to the end of the line in the

• Rapid positioning of the cursor on a group of related input fields.

• Has same effect as Tab key.

Delete key

The setting in a parameterization field is deleted.

The field remains blank.

Input key

• Accepts an edited value

• Opens/closes a directory

• Opening a file

Tab key

Ctrl key

Alt key

Tool offset Takes you directly to the tool offset

= active

= not active

page opened in the editor.

= active

= not active

Single-option button/option

(only one option can be active at a

time)

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-27

Page 28

Operator Components/Operating Sequences 01/2008

2.1 Operator panel front

2

“PROGRAM” hardkey

*

*

2

Program management program overview

A program can be opened in the text editor.

Interrupt Takes you directly to the Alarms

screen

User key Can be configured by the customer

Notes

The keys marked with an * also have a function in conjunction with

ShopMill/ShopTurn.

For this function to work, at least one recently edited program must be

found with sufficient read rights. The program must not be already

open in either a simulation or any other application. Actions such as

load, copy, select, etc. must not be in progress and the part program

must not be running on the NC.

In the above cases, the operation is denied with alarms 1203xx.

Press this hardkey in any operating area to reopen and display the

part program or file last edited in the Program operating area:

• If you are already in the Program operating area and the editor is

open, the program you last edited is displayed.

• If you are in any other operating area, and the editor is open, you

jump back to the editor in the Program operating area and the

most recent editor status is displayed.

If the editor is not open:

• If you are in another user application, you jump back to the

Program operating area and the editor is opened with the program

you last edited.

2-28 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 29

01/2008 Operator Components/Operating Sequences

2

2.1.2 Standard full keyboard

Softkey assignment

2.1 Operator panel front

2

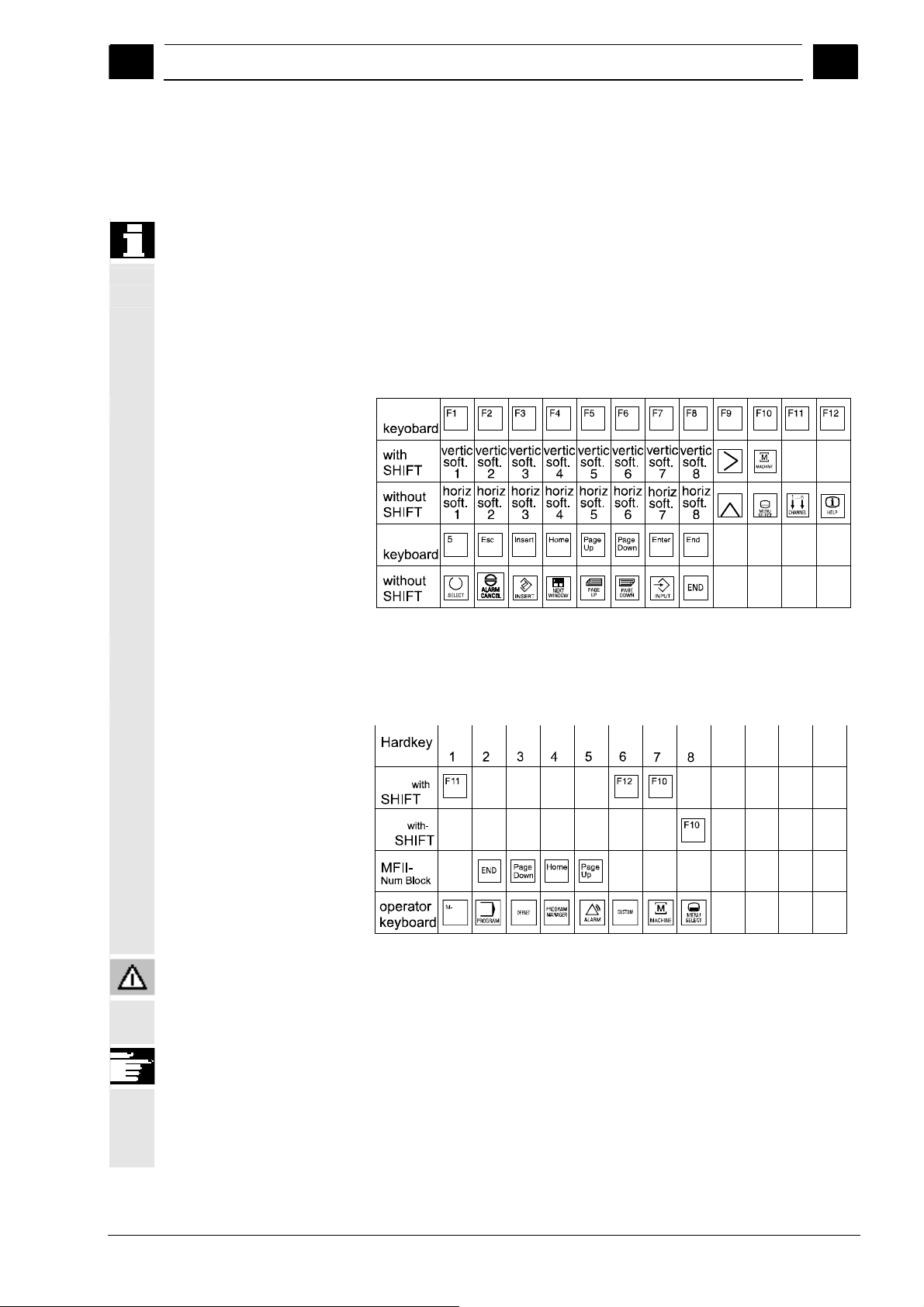

A full standard keyboard can be connected. However, a machine

control panel is required in addition to this keyboard.

The special function keys of the operator keyboard can also be used

with the full PC keyboard. The following table shows how the

horizontal and vertical softkeys and the special keys for the operator

panels are mapped onto the PC keyboard keys:

Full

Hardkey assignment

Caution

Full

The following table shows how the hardkeys of the MF 2 keyboard on

the PC are mapped onto the keys for the operator panels:

Hard-

Hard-

Hard-

Hard-

Hard-

MFII

MFII

out

key

Position

key

key

key

key

Hard key

Hard-

key

Hard key

The full standard keyboard does not meet the requirements (EMC) of

a SINUMERIK control. For this reason, it can be used only for

installation and service purposes.

Additional information

Since the English version of Windows is used in the control, the

keyboard language is English. A different keyboard language cannot

be set.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-29

Page 30

Operator Components/Operating Sequences 01/2008

2.2 Machine control panel (MCP)

2

2.2 Machine control panel (MCP)

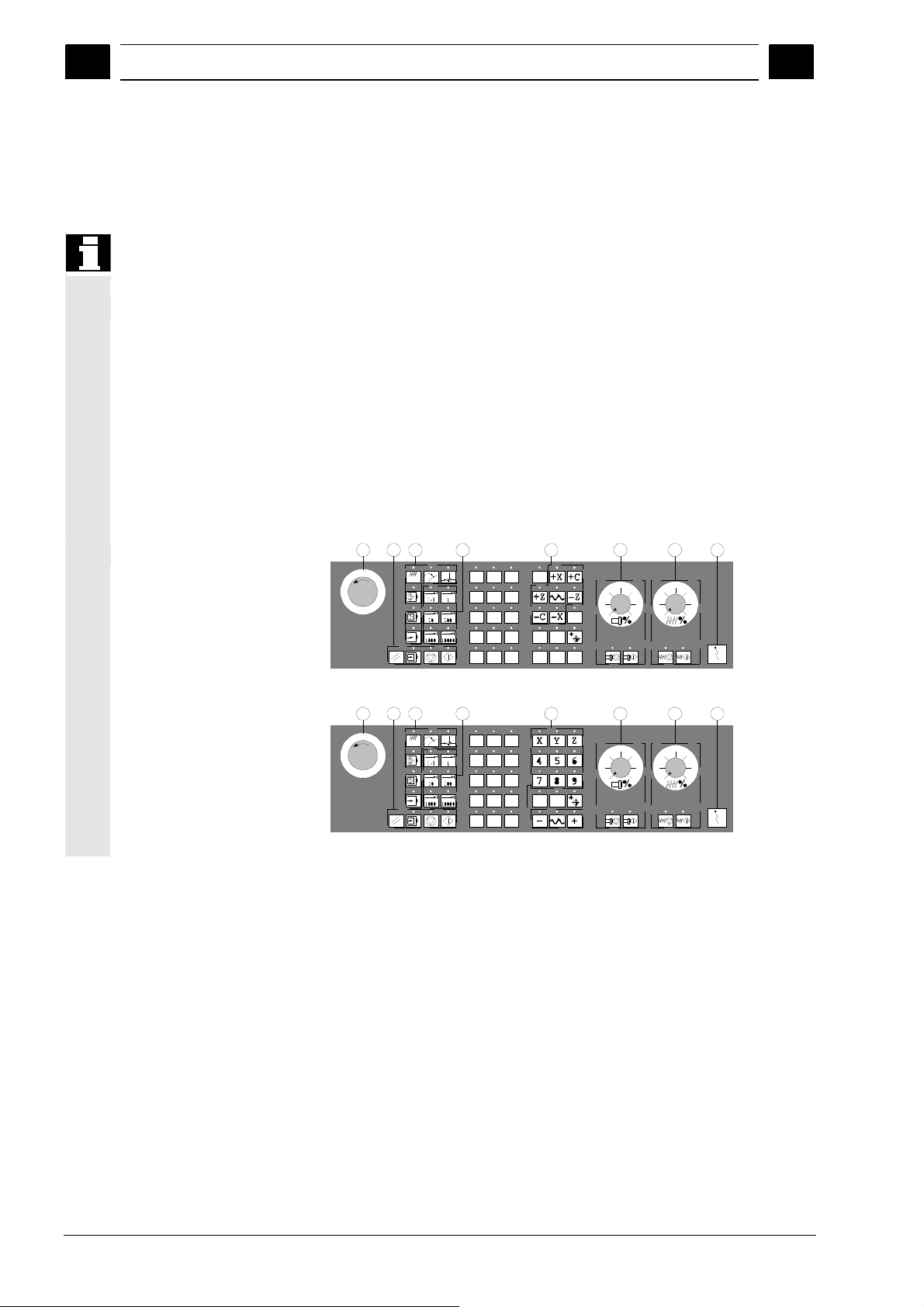

The machine tool can either be equipped with a standard machine

1 EMERGENCY STOP

button

2 Operating modes (with

machine functions)

3 Incremental mode

4 Program control

instructions

5 Direction key with rapid

traverse override

6 Spindle control

7 Feedrate control

8 Key-operated switch

Actions on the machine tool, for example traversing the axes or

program start, can only be initiated via a machine control panel.

control panel from SIEMENS (ordering data option) or with a specific

machine control panel from the machine-tool manufacturer.

The following description applies to the 19" machine control panel

supplied by SIEMENS (= standard). If you are using another machine

control panel, please consult the operating instructions of the

machine-tool manufacturer.

The standard machine control panel is equipped with the following

control elements:

4

1

Machine control panel for turning machines

1 4 2 3 5 6 7 8

Machine control panel for milling machines

2 3 5 6 7 8

2

2-30 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 31

01/2008 Operator Components/Operating Sequences

2

2.2.1 EMERGENCY STOP button

EMERGENCY STOP button

2.2 Machine control panel (MCP)

2

Machine manufacturer

Press this red key in emergency situations:

1. if life is at risk

2. When there is a danger of the machine or workpiece being

damaged.

As a rule, when operating the EMERGENCY STOP button, all drives

are brought to a standstill with max. braking torque.

For details of other or additional responses to an EMERGENCY

STOP:

Please read the information supplied by the machine tool

manufacturer!

2.2.2 Operating modes and machine functions

Modes of operation

The keys marked with an * correspond to the key symbols in US

Jog

MDA

Auto

*

The active mode is signaled and confirmed by the associated LED,

which lights up.

layout.

If you press a "Mode key", the corresponding mode is selected if

permissible, and all other modes and functions are deselected.

JOG

(Jogging)

Axis travel in jog mode via:

• Continuous motion of the axes using the direction keys, or

• Incremental motion of the axes using the direction keys, or

• Handwheel

MDA

(Manual Data Automatic)

Control of machine through execution of a block or a sequence of

blocks. The blocks are entered on the operator panel front.

Automatic

Control of machine through automatic execution of programs.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-31

Page 32

Operator Components/Operating Sequences 01/2008

2.2 Machine control panel (MCP)

2

2

A machine data code defines how the incremental dimension is

Inc keys

You can activate the Inc functions in conjunction with the following

VAR

1

1000 10000

Machine functions

10

100

modes:

• "JOG" mode

• "MDA/Teach-in" operating mode

Inc VAR (Incremental feed VARiable)

Incremental mode with variable increment size

(see operating area Parameters, Setting data).

Inc (Incremental feed)

Incremental mode with fixed increment size of 1, 10, 100, 1,000,

10,000 increments.

interpreted.

MDA

JOG

JOG

Teach In

Repos

Ref Point

Teach In

Creation of programs in interactive mode with the machine in

"MDA" mode.

Repos

Repositioning

Reposition, re-approach contour in "JOG" mode.

Ref

Approaching a reference point

Approach the reference point (Ref) in "JOG" mode.

2-32 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 33

01/2008 Operator Components/Operating Sequences

2

2.2.3 Feedrate control

Feed Stop

Feed Start

2.2 Machine control panel (MCP)

2

Feedrate rapid traverse override (feedrate override switch)

Control range:

0% to 120% of programmed feedrate.

In rapid traverse, the 100% value is not exceeded.

Settings,

0%, 1%, 2%, 4%, 6%, 8%, 10%, 20%, 30%, 40%, 50%, 60%, 70%,

75%, 80%, 85%, 90%, 95%, 100%, 105%, 110%, 115%, 120%

Feed stop

If you press the "Feed stop" key:

• Execution of the current program is stopped

• The axis drives are brought to a standstill under control,

The associated LED lights up as soon as feed stop has been

accepted by the control and

The following appears in the header (program control display):

FST (= Feed Stop)

Example:

− In "MDA" mode, an error is detected during execution of a block.

− A tool change is to be carried out.

Feed start

If you press the "Feed start" key:

• The part program is continued in the current block,

• The feedrate is accelerated to the value specified by the program,

• The associated LED lights up as soon as feed start has been

accepted by the control.

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-33

Page 34

Operator Components/Operating Sequences 01/2008

2.2 Machine control panel (MCP)

2

2

+X +Z

X

X

+

Rapid

Machine manufacturer

WCS MC S

...

Z

9th Axis

Axis keys (for turning machines):

Press these keys to traverse the selected axis (X ... Z) in the positive

direction.

Press these keys to traverse the selected axis (X ... Z) in the negative

direction.

Axis keys (for milling machines):

Select the axis (X ... 9) for traversing

in the positive direction by pressing the "+" key or

in the negative direction by pressing the "-" key.

Rapid traverse override

If you press this key together with key "+" or "-", the axis moves in

rapid traverse mode.

• The specified increments and control range apply to standard

machines.

• Increments and control range can be modified by the machine tool

manufacturer to suit specific applications.

• Feedrate/rapid traverse feedrate and the values for the feedrate

override positions (if the feedrate override switch is also active for

rapid traverse) are defined in the machine data (see the

information supplied by the machine manufacturer).

MCS/WCS

You can switch between the machine and workpiece coordinate

systems in the Machine operating area using softkeys (MCS)/(WCS)

or the corresponding key on the machine control panel.

2-34 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 35

01/2008 Operator Components/Operating Sequences

2

2.2.4 Spindle control

2.2 Machine control panel (MCP)

2

Spindle override (spindle speed override switch)

The rotary switch with latch positions allows you to increase or

decrease the programmed spindle speed "S" (equivalent to 100%).

The set spindle speed value "S" is output as an absolute value and a

percentage in the "Spindles" display (vertical softkey on main screen).

Control range:

50% to 120% of programmed spindle speed

Increment:

5% between latch positions

Spindle Stop

Spindle Start

Machine manufacturer

Spindle stop

*

When you press the "Spindle stop" key:

The spindle is decelerated down to zero speed and

The associated LED lights up as soon as "Spindle stop" is reached.

Example:

To change a tool

To enter S, T, H, M functions during setup

Spindle start

When you press the "Spindle start" key:

The spindle speed is accelerated to the value defined in the program

and

The associated LED lights up as soon as "Spindle start" has been

accepted by the control.

• The specified increment and the control range apply to standard

machine data (MD). These MD can be edited by the machine-tool

manufacturer to suit the specific application.

• The maximum spindle speed and the values for the spindle speed

override position are defined in the machine data and setting data

(see information supplied by the machine-tool manufacturer).

© Siemens AG 2008 All rights reserved.

SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition 2-35

Page 36

Operator Components/Operating Sequences 01/2008

2.2 Machine control panel (MCP)

2

2.2.5 Key-operated switch

Machine manufacturer

SIEMENS key-operated

switch

Changing access rights

2

Functions can be assigned to key-operated switch positions by the

machine manufacturer. Using machine data, it is also possible to set

access to programs, data and functions to suit the user's

requirements.

The key-operated switch on the SINUMERIK 840D has 4 settings,

assigned to protection levels 4 to 7.

The key-operated switch has three different colored keys which can

be removed in the specified positions:

Switch positions

Position 0

No key

Protection level 7

Position 1

Key 1 black

Protection level 6

Position 2

Key 1 green

Protection level 5

Position 3

Key 1 red

Protection level 4

The screen is not automatically updated after a change in access

authorization (e.g., when the key-operated switch position is

changed), but only when the screen is next refreshed (e.g., on closing

and opening a directory).

The currently valid access authorization is checked every time a

function is executed.

If the PLC is in the STOP state, the input image of the machine control

panel is not scanned. For this reason, the key-operated switch

positions are not evaluated during commissioning.

Access authorization

Access authorization

Lowest

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

⏐

↓

Highest

2-36 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

©Siemens AG 2008 All rights reserved.

Page 37

01/2008 Operator Components/Operating Sequences

2

Passwords As an additional option for setting access authorization, it is possible

to enter three passwords in the "Commissioning" operating area.

If the password is set, the key-operated switch positions are irrelevant.

References /IAD/, Commissioning Manual 840D.

2.2 Machine control panel (MCP)

2

2.2.6 Program control

Cycle Start

Cycle Stop

Single Block

NC Start

If you press the "NC Start" key, the selected part program (part

program name is displayed in header) is started at the current block

and the associated LED lights up.

NC stop

If you press the "NC Stop" key, processing of the active part program

is halted and the associated LED lights up.