Page 1

Guidelines for machine configuration

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________

___________________

___________________

___________________

___________________

___________________

SINUMERIK, SINAMICS

SINUMERIK 840D sl, SINAMICS

S120

Guidelines for machine

configuration

System Manual

Valid for NCU SW 4.5 SP1 and higher

MA 01/2013

6FC5397

Preface

Fundamental safety

instructions

1

System overview

2

SINUMERIK 840D sl

3

SINAMICS drive line-up

4

Communication within the

system

5

Line connection

6

DC link

7

Connection of the

components in SINAMICS

drive system

8

Safety Integrated

9

Signal Interconnection

10

Typical circuit diagrams

11

Activate/Deactivate Drive

System

12

Appendix

A

-6CP10-0BA2

Page 2

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMAN

Order number: 6FC5397-6CP10-0BA2

Ⓟ

Copyright © Siemens AG 2006 - 2013.

All rights reserved

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

Legal information

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Y

11/2013 Technical data subject to change

Page 3

Preface

SINUMERIK/SINAMICS documentation

Further information

My Documentation Manager

Training

FAQs

Product

Support

The SINUMERIK and SINAMICS documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Click the following link to find information on the the following topics:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (finding and searching in manuals/information)

http://www.siemens.com/motioncontrol/docu

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following email address:

docu.motioncontrol@siemens.com

Using the following link, you can find information on how to create your own individual

documentation based on Siemens' content, and adapt it for your own machine

documentation:

http://www.siemens.com/mdm

Using the following link, you can find information on SITRAIN - training from Siemens for

products, systems and automation engineering solutions:

http://www.siemens.com/sitrain

You can find Frequently Asked Questions in the Service&Support pages under

http://support.automation.siemens.com

:

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

3

Page 4

Preface

Target group

Use and standard scope

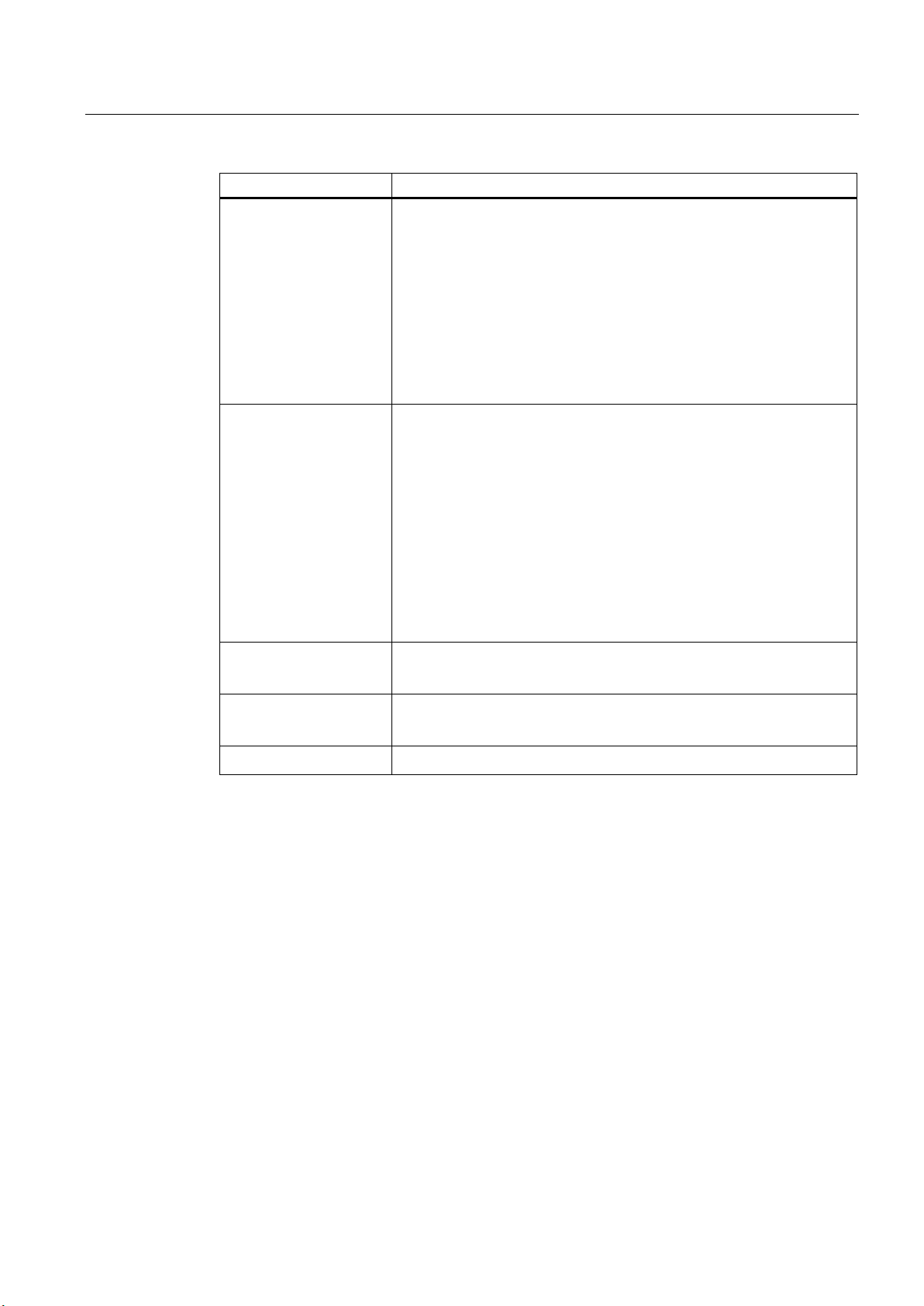

Utilization phases and the available tools/documents

Utilization phase

Tools

Orientation

SINAMICS S sales documentation

This manual is intended for experienced drive and CNC configuration engineers. Its purpose

is to give you a compact guide to integrating the components of SINAMICS S120 and

SINUMERIK 840D sl.

This document supplements product-related equipment, software installation, and function

manuals for SINAMICS S120 and SINUMERIK 840D sl. It shows examples of the

mechanical layout of components, functional integration, as well as logical connections to the

signal interfaces of a processing machine.

This documentation is limited to the following series or functions:

● SINUMERIK 840D sl Type 1B (NCU 7x0.3, NX1x.3)

● SINAMICS in booksize format

● Communication between SINUMERIK NCU and the SINAMICS drives (communication

with operating, programming, and visualization units is not part of this documentation)

For reasons of clarity, this documentation does not contain all of the detailed information on

all of the product types. It also cannot take into consideration every conceivable type of

installation, operation, and service/maintenance. If you have any questions that go beyond

the scope of the information provided here, please contact your local representative.

Where necessary for the understanding and for important general conditions, this guide

contains extracts from the product manuals listed below. You can find there detailed

descriptions for the product-internal functions and properties, and for the mechanical and

electrical user interfaces.

Table 1 Utilization phases and the available tools/documents

Planning/engineering

Decision making/ordering SINAMICS S120 catalogs

• SIZER configuration tool

• Configuration manuals, motors

• SIMOTION, SINAMICS S120 and Motors for Production Machines

(Catalog PM 21)

• SINAMICS and Motors for Single-Axis Drives (catalog D 31)

• SINUMERIK 840D sl Type 1B

Equipment for Machine Tools (Catalog NC 62)

Guidelines for machine configuration

4 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 5

Preface

Utilization phase

Tools

Functionality

Technical Support

SINUMERIK

Configuring/installation

Commissioning

Using/operating

Maintenance/Service

References

• SINAMICS S120 Equipment Manual for Control Units and Additional

System Components

• SINAMICS S120 Booksize Power Units Equipment Manual

• SINAMICS S120 Chassis Power Units Equipment Manual

• SINAMICS S120 Equipment Manual Liquid Cooled Chassis Power

Units

• SINAMICS S120 Equipment Manual for AC Drives

• SINAMICS S120M Equipment Manual Distributed Drive Technology

• SINUMERIK 840D sl Equipment Manual NCU 7x0.3 PN

• STARTER commissioning tool

• SIMATIC S7 Manager

• SINAMICS S120 Getting Started

• SINAMICS S120 Commissioning Manual

• SINAMICS S120 CANopen Commissioning Manual

• SINAMICS S120 Function Manual

• SINAMICS S120 Safety Integrated Function Manual

• SINAMICS S120/S150 List Manual

• SINUMERIK 840D sl Commissioning Manual CNC: NCK, PLC, drive

• SINUMERIK 840D sl Safety Integrated Function Manual

• SINAMICS S120 Commissioning Manual

• SINAMICS S120/S150 List Manual

• SINAMICS S120 Commissioning Manual

• SINAMICS S120/S150 List Manual

• SINAMICS S120/S150 List Manual

This documentation may also mention components that have not been released for use with

SINUMERIK 840D sl. The NC62 catalog is binding for the permitted combinations.

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

http://support.automation.siemens.com

You can find information on SINUMERIK at:

http://www.siemens.com/sinumerik

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

5

Page 6

Preface

SINAMICS

EC Declarations of Conformity

15257461

You can find information on SINAMICS at:

http://www.siemens.com/sinamics

The EC Declaration of Conformity for the EMC Directive can be found on the Internet at:

http://support.automation.siemens.com

Enter there the number

as a search term or contact your local Siemens office.

Guidelines for machine configuration

6 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 7

Table of contents

Preface ................................................................................................................................................... 3

1 Fundamental safety instructions ............................................................................................................ 15

2 System overview ................................................................................................................................... 21

3 SINUMERIK 840D sl ............................................................................................................................. 33

4 SINAMICS drive line-up ........................................................................................................................ 55

1.1 General safety instructions .......................................................................................................... 15

1.2 Safety instructions for electromagnetic fields (EMF) ................................................................... 18

1.3 Handling electrostatic sensitive devices (ESD) ........................................................................... 18

1.4 Residual risks of power drive systems ......................................................................................... 19

2.1 Application .................................................................................................................................... 21

2.2 System configuration ................................................................................................................... 22

2.3 Variants ........................................................................................................................................ 24

2.4 SINAMICS S120 / SINUMERIK 840D sl Component Overview .................................................. 25

2.5 User interface software (HMI software) ....................................................................................... 30

2.6 Function of installation altitude and ambient temperature ........................................................... 32

3.1 Control Unit NCU 7x0.3 PN ......................................................................................................... 33

3.1.1 Description ................................................................................................................................... 33

3.1.2 Interface description ..................................................................................................................... 34

3.1.3 Interfaces and their terminal assignments ................................................................................... 35

3.1.3.1 DRIVE-CLiQ interfaces X100-X105 (X103) ................................................................................. 35

3.1.3.2 Digital inputs/outputs X122, X132 and X142 ............................................................................... 37

3.1.3.3 PROFINET interface X150 P1, P2 ............................................................................................... 40

3.1.3.4 PROFIBUS interface X126 .......................................................................................................... 41

3.1.4 LED displays ................................................................................................................................ 43

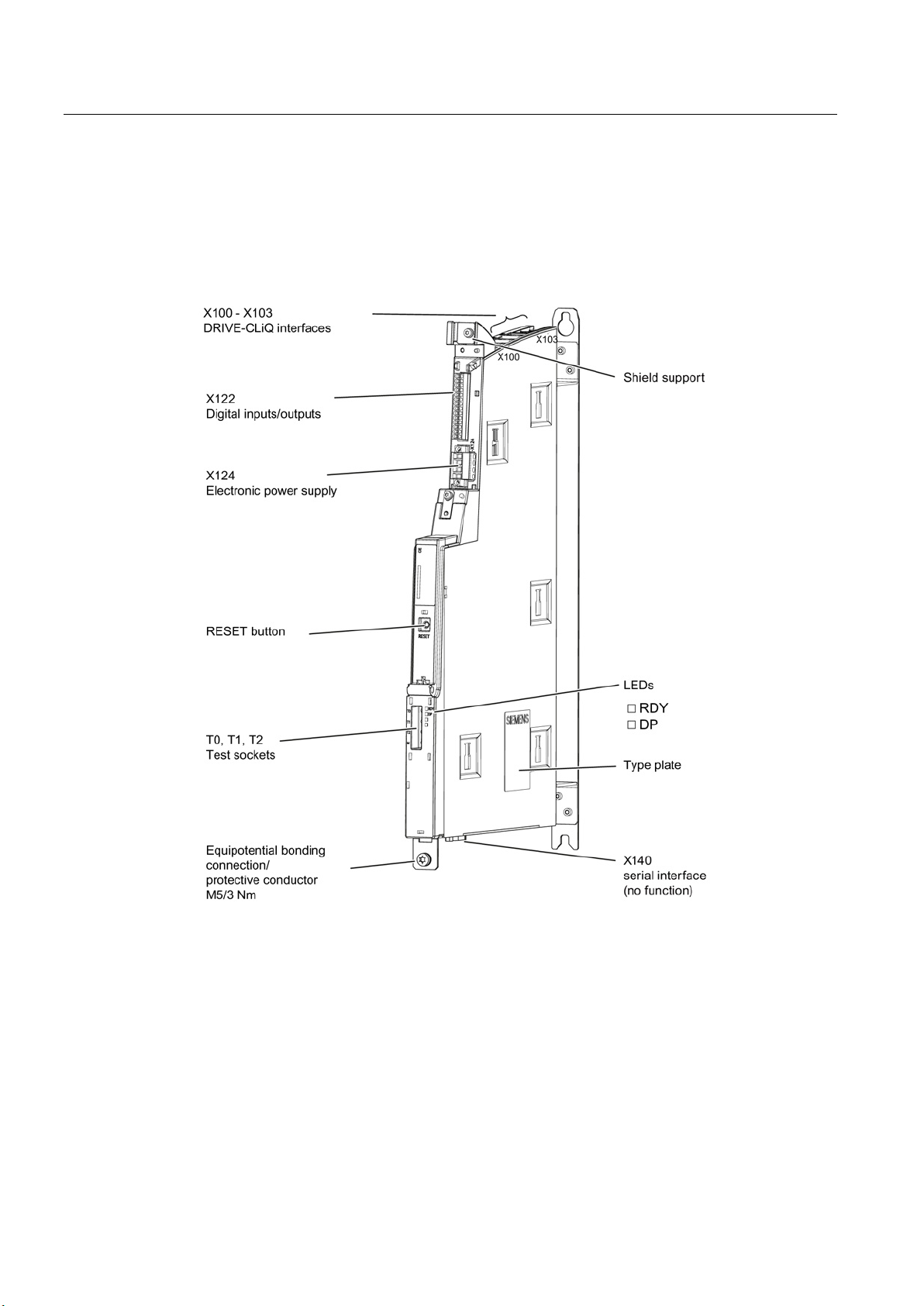

3.2 NX1x.3 extension units ................................................................................................................ 45

3.2.1 Description ................................................................................................................................... 45

3.2.2 Representation of the NX1x.3 ...................................................................................................... 46

3.2.3 Interfaces and their terminal assignments ................................................................................... 48

3.2.3.1 X122 digital inputs/outputs ........................................................................................................... 48

3.2.4 NX1x3 wiring ................................................................................................................................ 50

3.3 Option Board CBE30-2 ................................................................................................................ 52

3.3.1 Description ................................................................................................................................... 52

4.1 Structure of the drive line-up ........................................................................................................ 55

4.1.1 Description ................................................................................................................................... 55

4.1.2 Single row layout .......................................................................................................................... 57

4.1.3 Two-row/Multiple-row construction .............................................................................................. 59

4.1.4 Center infeed (single row construction) for 16 to 120 kW Line Modules ..................................... 62

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

7

Page 8

Table of contents

5 Communication within the system ......................................................................................................... 95

6 Line connection .................................................................................................................................... 107

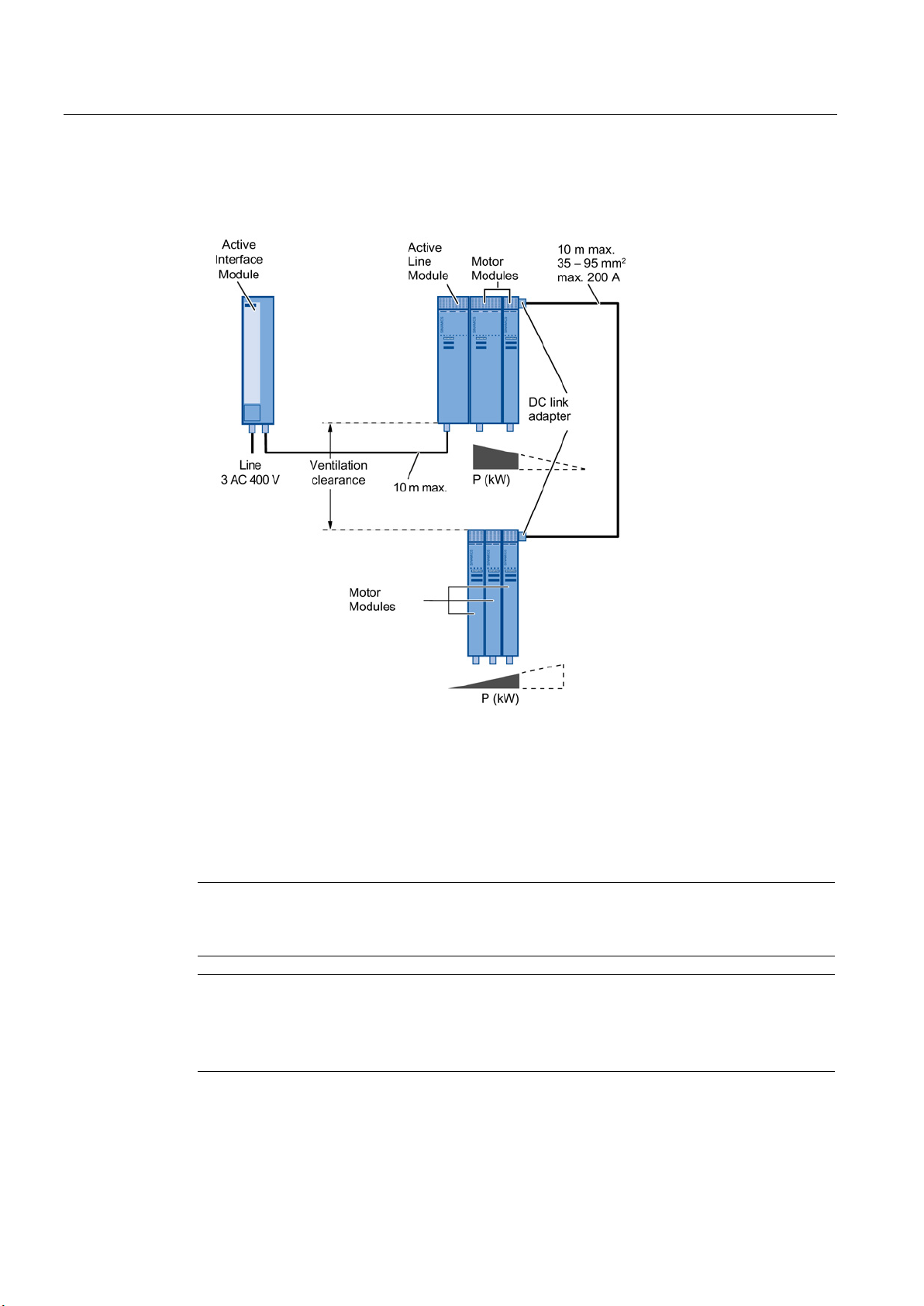

4.1.5 Distributed configuration ............................................................................................................. 63

4.2 Connection of the SINUMERIK components .............................................................................. 66

4.2.1 Layout and fastening of the NCU/NX modules ........................................................................... 66

4.2.2 Layout of the NX for single row construction integrated in the power unit group ....................... 67

4.2.3 NCU/NX layout as offset solution ................................................................................................ 68

4.2.4 Direct installation of a CU-/NCU-/NX module on the Line Module.............................................. 68

4.3 Shield Connection ....................................................................................................................... 69

4.3.1 SINAMICS Components Dimension Drawings (Internal Air Cooling) ......................................... 69

4.3.2 SINAMICS Components Dimension Drawings (External Air Cooling) ........................................ 73

4.3.3 Shield Connection for Internal Heat Dissipation ......................................................................... 77

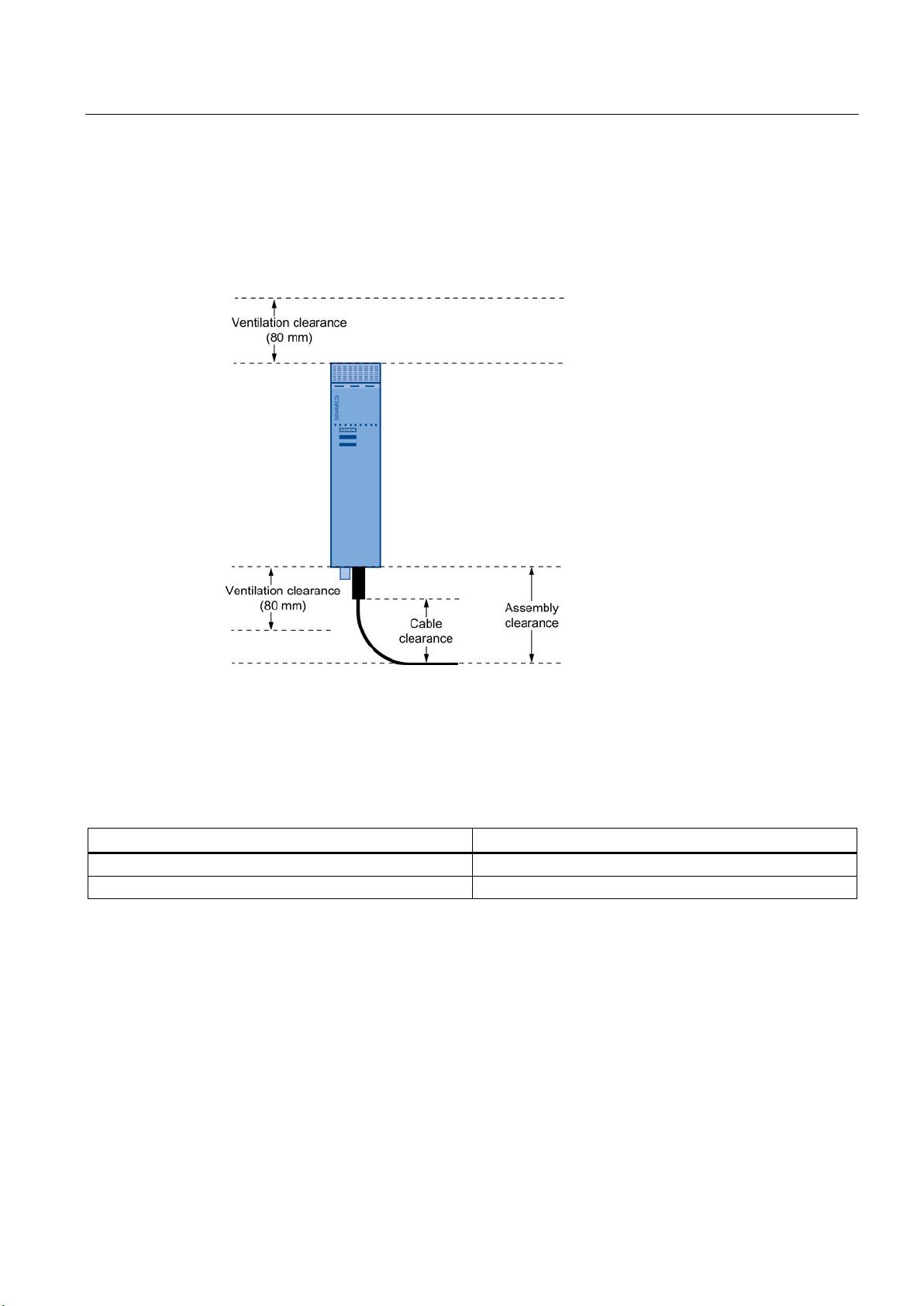

4.4 Note for the installation clearance for the connection cables ..................................................... 78

4.4.1 General information ..................................................................................................................... 78

4.4.2 Clearance of the Power Components ......................................................................................... 79

4.4.3 Ventilation Clearances of the SINUMERIK Components ........................................................... 79

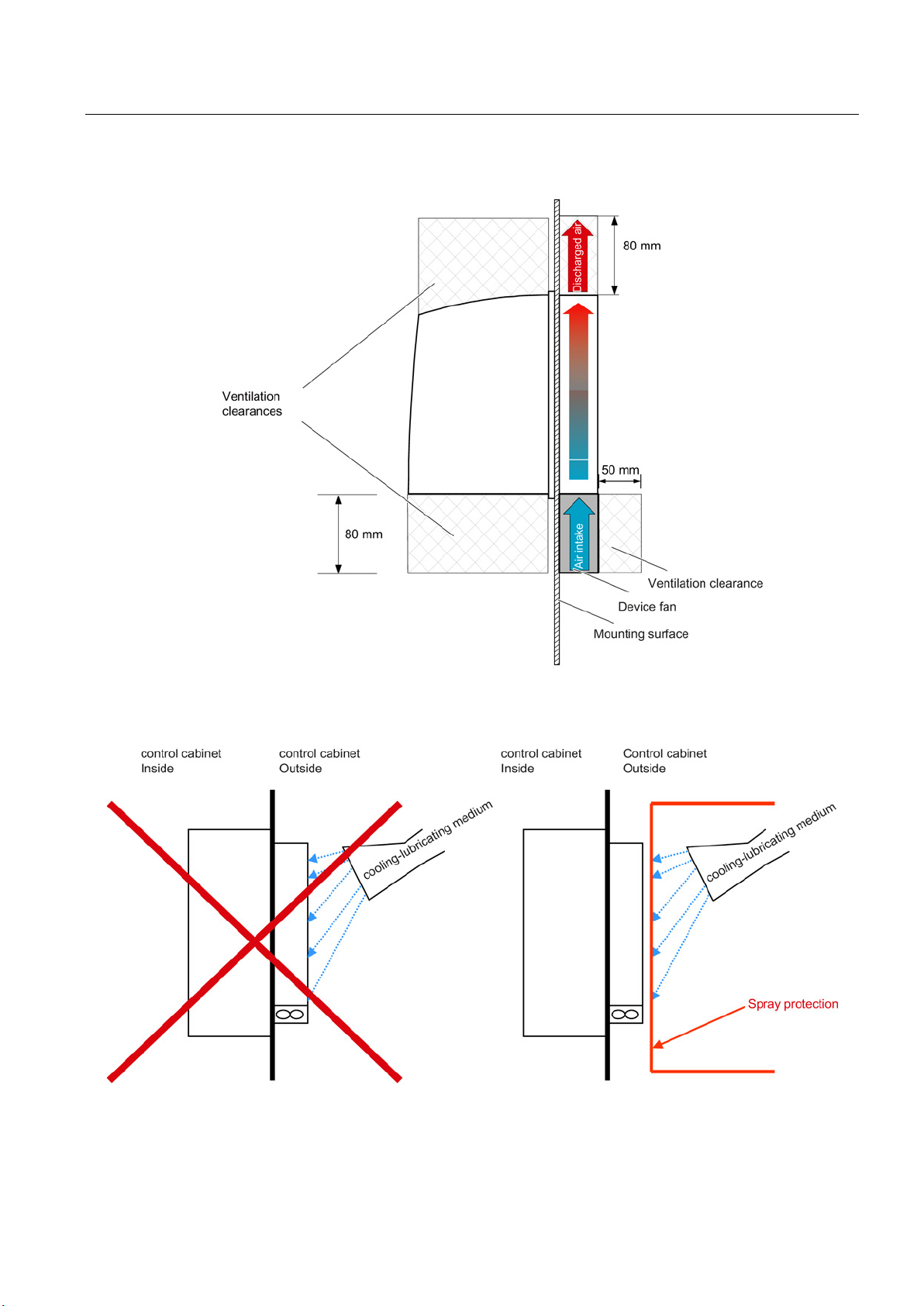

4.5 Heat Dissipation of the Control Cabinet ...................................................................................... 80

4.5.1 Control cabinet cooling options ................................................................................................... 80

4.5.2 General information on ventilation .............................................................................................. 81

4.5.3 Cooling clearances ...................................................................................................................... 83

4.5.4 Dimensioning Climate Control Equipment .................................................................................. 89

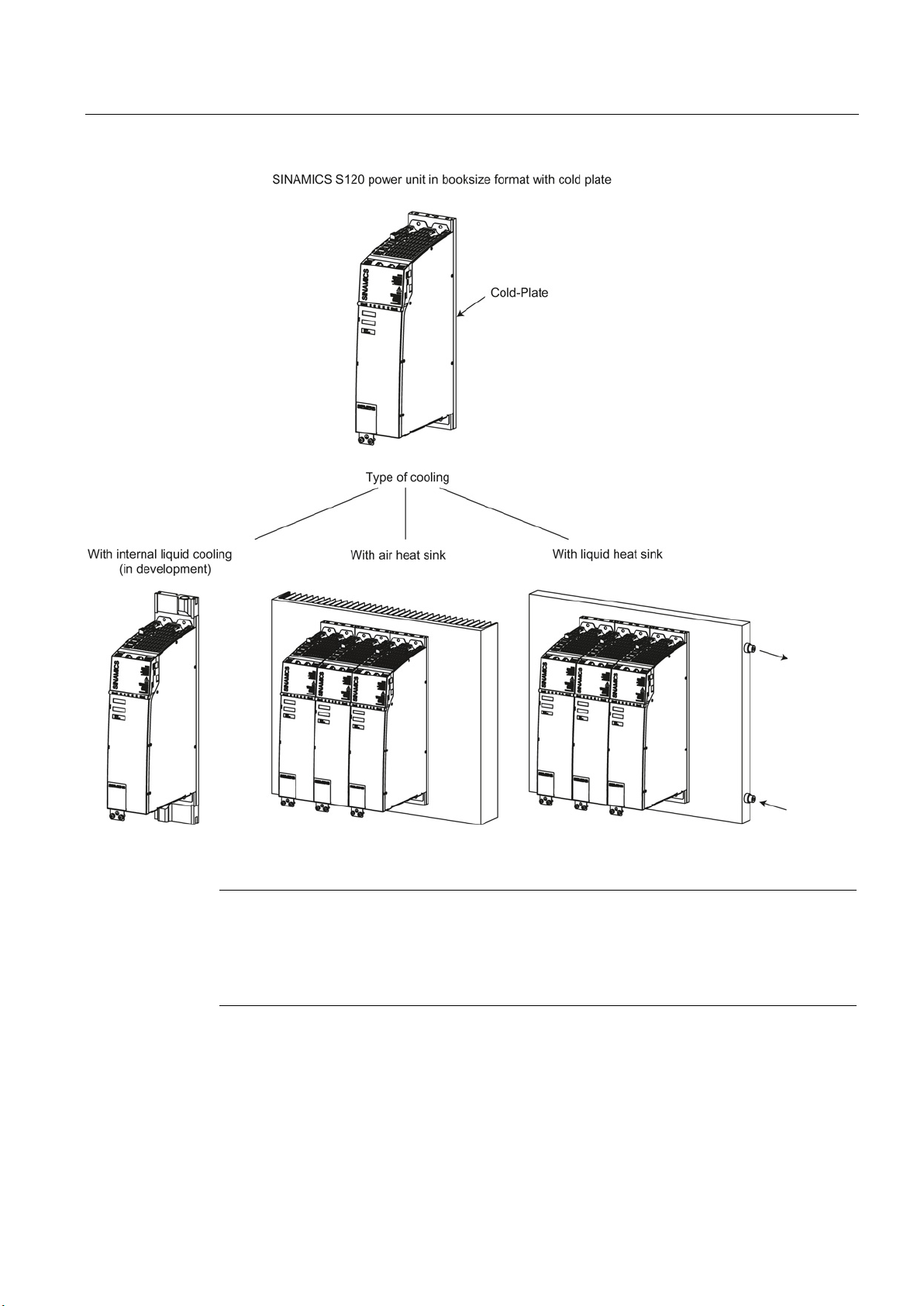

4.6 Cooling of power units ................................................................................................................. 90

4.6.1 Internal Air Cooling ...................................................................................................................... 90

4.6.2 External Air Cooling .................................................................................................................... 91

4.6.3 Cold plate cooling ........................................................................................................................ 92

4.6.4 Liquid cooling (liquid cooled) ....................................................................................................... 94

5.1 Communication overview ............................................................................................................ 95

5.2 DRIVE-CLiQ Topologies ............................................................................................................. 99

5.2.1 DRIVE-CLiQ topology ................................................................................................................. 99

5.2.2 DRIVE-CLiQ wiring ................................................................................................................... 101

6.1 Power Supply Interface Variants ............................................................................................... 107

6.1.1 Ways of connecting the line supply ........................................................................................... 107

6.1.2 Operation of the line connection components on the supply network ...................................... 108

6.1.3 Operating line connection components via an autotransformer ............................................... 109

6.1.4 Operating line connection components via an isolating transformer ........................................ 110

6.1.5 Residual-current operated circuit breakers (RCD) .................................................................... 112

6.1.6 Residual-current monitors (RCM) ............................................................................................. 114

6.2 Overcurrent protection by means of line fuses and circuit breakers ......................................... 116

6.3 Line Contactor Control .............................................................................................................. 117

6.3.1 Line contactor control for Line Modules without DRIVE-CLiQ interface (5 kW and 10 kW

versions) .................................................................................................................................... 118

6.3.2 Line Contactor Control for Line Modules with DRIVE-CLiQ Interface ...................................... 120

6.3.3 Line Contactor Control Commissioning using an Example ....................................................... 121

6.4 Line filters .................................................................................................................................. 123

6.4.1 Safety instructions for line filters ............................................................................................... 123

6.4.2 Overview of line filters ............................................................................................................... 125

Guidelines for machine configuration

8 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 9

Table of contents

7 DC link ................................................................................................................................................ 159

8 Connection of the components in SINAMICS drive system .................................................................. 167

6.4.3 Wideband Filter for Active Line Modules ................................................................................... 126

6.4.4 Basic Line Filters for Active Line Modules ................................................................................. 127

6.4.5 Basic Line Filter for Smart Line Modules ................................................................................... 128

6.5 Active Interface Module (AIM) .................................................................................................... 129

6.5.1 Description ................................................................................................................................. 129

6.5.2 Safety instructions for Active Interface Modules ........................................................................ 130

6.5.3 Interface description ................................................................................................................... 132

6.5.3.1 Overview .................................................................................................................................... 132

6.5.3.2 Line/load connection .................................................................................................................. 136

6.5.3.3 X121 temperature sensor and fan control ................................................................................. 136

6.5.3.4 Electronics power supply X124 .................................................................................................. 137

6.5.4 Operation on an isolated-neutral system (IT system) ................................................................ 137

6.5.4.1 IT systems .................................................................................................................................. 137

6.5.4.2 Operating an Active Interface Module on an isolated-neutral line supply (IT line supply) ......... 138

6.5.5 Connection example .................................................................................................................. 139

6.5.6 Technical data ............................................................................................................................ 140

6.6 Line reactors .............................................................................................................................. 141

6.6.1 Safety instructions for line reactors ............................................................................................ 141

6.6.2 HFD line reactors for Active Line Module .................................................................................. 142

6.6.2.1 Description ................................................................................................................................. 142

6.6.2.2 Interface description ................................................................................................................... 143

6.6.2.3 Dimension drawings ................................................................................................................... 146

6.6.2.4 Technical data ............................................................................................................................ 151

6.6.3 Line reactors for Smart Line Modules ........................................................................................ 152

6.6.3.1 Interface description ................................................................................................................... 152

6.6.3.2 Dimension drawings ................................................................................................................... 154

6.6.3.3 Technical data ............................................................................................................................ 157

6.7 Possible combinations of line reactors and line filters ............................................................... 158

7.1 Function of the DC link ............................................................................................................... 159

7.2 DC link components ................................................................................................................... 159

7.2.1 Braking Module .......................................................................................................................... 160

7.2.2 Capacitor Module ....................................................................................................................... 161

7.3 Current Carrying Capacity of the DC Link Busbar ..................................................................... 161

7.4 DC link rectifier adapter ............................................................................................................. 164

7.5 DC link adapter .......................................................................................................................... 165

8.1 Electronics Power Supply .......................................................................................................... 167

8.1.1 External power supply (SITOP) ................................................................................................. 167

8.1.1.1 Selection of the Power Supply Devices ..................................................................................... 168

8.1.1.2 24 V current consumption of the components ........................................................................... 169

8.1.1.3 Calculation of the 24 VDC Power Requirement Example ......................................................... 171

8.1.1.4 Assignment of the power supply to other components .............................................................. 172

8.1.1.5 Overcurrent protection ............................................................................................................... 174

8.1.1.6 Line formation ............................................................................................................................ 175

8.1.1.7 Power Supply Connection Example........................................................................................... 177

8.1.2 Internal power supply via the Control Supply Module (CSM) .................................................... 178

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

9

Page 10

Table of contents

8.1.2.1 Connection ................................................................................................................................ 180

8.1.2.2 Single operation ........................................................................................................................ 181

8.1.2.3 Parallel operation ...................................................................................................................... 182

8.2 Connection of a SINAMICS Control Unit CU320-2 ................................................................... 187

8.3 Connection of line modules ....................................................................................................... 189

8.3.1 Introduction................................................................................................................................ 189

8.3.2 Safety instructions for Line Modules Booksize ......................................................................... 192

8.3.3 Active Line Modules with internal air cooling ............................................................................ 197

8.3.3.1 Description ................................................................................................................................ 197

8.3.3.2 Interface description .................................................................................................................. 198

8.3.3.3 Connection example ................................................................................................................. 203

8.3.3.4 Meaning of LEDs ....................................................................................................................... 204

8.3.3.5 Dimension drawings .................................................................................................................. 205

8.3.3.6 Installation ................................................................................................................................. 209

8.3.3.7 Technical specifications ............................................................................................................ 211

8.3.4 Active Line Modules with external air cooling ........................................................................... 217

8.3.4.1 Description ................................................................................................................................ 217

8.3.4.2 Interface description .................................................................................................................. 218

8.3.4.3 Connection example ................................................................................................................. 223

8.3.4.4 Meaning of LEDs ....................................................................................................................... 224

8.3.4.5 Dimension drawings .................................................................................................................. 225

8.3.4.6 Installation ................................................................................................................................. 228

8.3.4.7 Technical data ........................................................................................................................... 234

8.3.5 Active Line Modules with cold plate .......................................................................................... 240

8.3.5.1 Description ................................................................................................................................ 240

8.3.5.2 Interface description .................................................................................................................. 241

8.3.5.3 Connection example ................................................................................................................. 245

8.3.5.4 Meaning of LEDs ....................................................................................................................... 246

8.3.5.5 Dimension drawings .................................................................................................................. 247

8.3.5.6 Installation ................................................................................................................................. 249

8.3.5.7 Technical specifications ............................................................................................................ 252

8.3.6 Active Line Modules Liquid Cooled ........................................................................................... 257

8.3.6.1 Description ................................................................................................................................ 257

8.3.6.2 Interface description .................................................................................................................. 258

8.3.6.3

Connection example ................................................................................................................. 262

8.3.6.4 Meaning of LEDs ....................................................................................................................... 263

8.3.6.5 Dimension drawing .................................................................................................................... 264

8.3.6.6 Installation ................................................................................................................................. 265

8.3.6.7 Technical specifications ............................................................................................................ 266

8.3.7 Smart Line Modules with internal air cooling ............................................................................ 270

8.3.7.1 Description ................................................................................................................................ 270

8.3.7.2 Product-specific safety information for the Smart Line Modules in booksize format ................ 271

8.3.7.3 Interface description .................................................................................................................. 273

8.3.7.4 Connection examples ................................................................................................................ 283

8.3.7.5 Meaning of LEDs ....................................................................................................................... 285

8.3.7.6 Dimension drawings .................................................................................................................. 287

8.3.7.7 Installation ................................................................................................................................. 291

8.3.7.8 Technical specifications ............................................................................................................ 292

8.3.8 Smart Line Modules with external air cooling ........................................................................... 295

8.3.8.1 Description ................................................................................................................................ 295

8.3.8.2 Product-specific safety information for the Smart Line Modules in booksize format ................ 296

Guidelines for machine configuration

10 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 11

Table of contents

8.3.8.3 Interface description ................................................................................................................... 298

8.3.8.4 Connection examples ................................................................................................................ 308

8.3.8.5 Meaning of LEDs........................................................................................................................ 310

8.3.8.6 Dimension drawings ................................................................................................................... 312

8.3.8.7 Installation .................................................................................................................................. 316

8.3.8.8 Technical specifications ............................................................................................................. 321

8.3.9 Smart Line Modules with cold plate ........................................................................................... 324

8.3.9.1 Description ................................................................................................................................. 324

8.3.9.2 Product-specific safety information for the Smart Line Modules in booksize format ................. 325

8.3.9.3 Interface description ................................................................................................................... 327

8.3.9.4 Connection example .................................................................................................................. 331

8.3.9.5 Meaning of LEDs........................................................................................................................ 332

8.3.9.6 Dimension drawings ................................................................................................................... 333

8.3.9.7 Installation .................................................................................................................................. 334

8.3.9.8 Technical data ............................................................................................................................ 336

8.4 Connection of motor modules .................................................................................................... 341

8.4.1 Safety instructions for Motor Modules Booksize ........................................................................ 341

8.4.2 Motor Modules with internal air cooling ..................................................................................... 345

8.4.2.1 Description ................................................................................................................................. 345

8.4.2.2 Interface description ................................................................................................................... 346

8.4.2.3 Connection examples ................................................................................................................ 353

8.4.2.4 Meaning of LEDs........................................................................................................................ 355

8.4.2.5 Dimension drawings ................................................................................................................... 356

8.4.2.6 Installation .................................................................................................................................. 361

8.4.2.7 Technical specifications ............................................................................................................. 363

8.4.3 Motor Module with external air cooling ...................................................................................... 369

8.4.3.1 Description ................................................................................................................................. 369

8.4.3.2 Interface description ................................................................................................................... 370

8.4.3.3 Connection examples ................................................................................................................ 377

8.4.3.4 Meaning of LEDs........................................................................................................................ 379

8.4.3.5 Dimension drawings ................................................................................................................... 380

8.4.3.6 Mounting .................................................................................................................................... 385

8.4.3.7 Technical data ............................................................................................................................ 392

8.4.4 Motor Modules with cold plate ................................................................................................... 398

8.4.4.1 Description .................................................................................................................................

398

8.4.4.2 Interface description ................................................................................................................... 399

8.4.4.3 Connection examples ................................................................................................................ 405

8.4.4.4 Meaning of LEDs........................................................................................................................ 407

8.4.4.5 Dimension drawings ................................................................................................................... 408

8.4.4.6 Mounting .................................................................................................................................... 412

8.4.4.7 Technical specifications ............................................................................................................. 415

8.4.5 Motor Modules Liquid Cooled .................................................................................................... 421

8.4.5.1 Description ................................................................................................................................. 421

8.4.5.2 Interface description ................................................................................................................... 422

8.4.5.3 Connection example .................................................................................................................. 426

8.4.5.4 Meaning of LEDs........................................................................................................................ 427

8.4.5.5 Dimension drawing .................................................................................................................... 428

8.4.5.6 Installation .................................................................................................................................. 429

8.4.5.7 Technical specifications ............................................................................................................. 430

8.5 DRIVE-CLiQ Hub Modules (DMC20, DME20) ........................................................................... 435

8.5.1 DMC20 ....................................................................................................................................... 435

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

11

Page 12

Table of contents

8.5.1.1 Description ................................................................................................................................ 435

8.5.1.2 Overview ................................................................................................................................... 435

8.5.1.3 Electronics power supply X524 ................................................................................................. 436

8.5.1.4 DRIVE-CLiQ interface ............................................................................................................... 436

8.5.1.5 Significance of the LED on the DMC20 .................................................................................... 437

8.5.1.6 Dimension drawing .................................................................................................................... 437

8.5.1.7 Technical data ........................................................................................................................... 438

8.5.2 DME20 ...................................................................................................................................... 438

8.5.2.1 Description ................................................................................................................................ 438

8.5.2.2 Safety information ..................................................................................................................... 438

8.5.2.3 Overview ................................................................................................................................... 439

8.5.2.4 Electronics power supply X524 ................................................................................................. 440

8.5.2.5 DRIVE-CLiQ interface ............................................................................................................... 440

8.5.2.6 Cable lengths ............................................................................................................................ 441

8.5.2.7 Specifications for use with UL approval .................................................................................... 441

8.5.2.8 Dimension drawing .................................................................................................................... 443

8.5.2.9 Installation ................................................................................................................................. 444

8.5.2.10 Technical data ........................................................................................................................... 444

8.6 Connecting Terminal Modules .................................................................................................. 445

8.6.1 TM15: Terminal expansion for digital inputs/outputs ................................................................ 445

8.6.2 TM41: Emulating an incremental encoder ................................................................................ 445

8.6.3 TM120: DRIVE-CLiQ component for temperature evaluation with safe electrical

separation.................................................................................................................................. 446

8.7 Sensor Systems Connection ..................................................................................................... 447

8.7.1 Introduction................................................................................................................................ 447

8.7.2 Overview of Sensor Modules .................................................................................................... 448

8.7.3 X200-X203 DRIVE-CLiQ interface ............................................................................................ 450

8.7.4 Examples of encoder connections ............................................................................................ 451

8.8 Motor Connection ...................................................................................................................... 452

8.8.1 Motor connection plug ............................................................................................................... 452

8.8.1.1 Introducing the motor connector ............................................................................................... 452

8.8.1.2 Installation of the motor connection plug with locking mechanism ........................................... 452

8.8.1.3 Installation of the motor connection plug with screwed joint ..................................................... 455

8.8.1.4 Removing the motor connector plug from prefabricated power cables .................................... 456

8.8.2 Brake connection ...................................................................................................................... 457

8.8.2.1 General Notes ................................

........................................................................................... 457

8.8.2.2 Motor and brake connection...................................................................................................... 457

8.8.2.3 Connection of the Brake Directly on the Motor Module ............................................................ 459

8.8.2.4 Connection of the Brake using Interface Relay......................................................................... 460

8.8.2.5 Brake Control ............................................................................................................................ 461

8.8.3 X21/X22 EP terminals / temperature sensor Motor Module ..................................................... 466

8.9 Voltage Protection Module (VPM), external .............................................................................. 467

8.10 Cables ....................................................................................................................................... 471

8.10.1 General information ................................................................................................................... 471

8.10.2 Cable shielding and routing....................................................................................................... 471

8.10.3 Equipotential Bonding ............................................................................................................... 473

8.10.4 Protective Ground Connection .................................................................................................. 473

8.10.5 Maximum cable lengths ............................................................................................................ 474

8.11 DRIVE-CLiQ cabinet bushings .................................................................................................. 475

Guidelines for machine configuration

12 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 13

Table of contents

9 Safety Integrated ................................................................................................................................. 483

10 Signal Interconnection ......................................................................................................................... 503

11 Typical circuit diagrams ....................................................................................................................... 505

12 Activate/Deactivate Drive System ........................................................................................................ 507

A Appendix............................................................................................................................................. 513

Index................................................................................................................................................... 531

8.11.1 Description ................................................................................................................................. 475

8.11.2 Interface description ................................................................................................................... 476

8.11.2.1 Overview .................................................................................................................................... 476

8.11.3 Dimension drawings ................................................................................................................... 477

8.11.4 Installation .................................................................................................................................. 478

8.11.4.1 DRIVE-CLiQ cabinet bushing for cables with RJ45 connectors ................................................ 478

8.11.4.2 DRIVE-CLiQ cabinet bushing for cables with M12 plug/socket ................................................. 480

8.11.5 Technical data ............................................................................................................................ 481

9.1 Safety Integrated terminology .................................................................................................... 483

9.2 SINAMICS Safety Integrated ..................................................................................................... 485

9.2.1 Safety functions.......................................................................................................................... 485

9.2.2 Basic Functions .......................................................................................................................... 486

9.2.2.1 Safe Torque Off (STO) ............................................................................................................... 486

9.2.2.2 Safe Stop 1 (SS1) ...................................................................................................................... 494

9.2.2.3 Safe Brake Control (SBC) .......................................................................................................... 495

9.3 SINUMERIK Safety Integrated ................................................................................................... 497

9.3.1 Safety functions.......................................................................................................................... 497

9.3.2 Connecting safe sensors and actuators to the SINUMERIK ..................................................... 498

12.1 Overview of the Status Signals .................................................................................................. 507

12.2 Drive Group with Several Axes .................................................................................................. 508

A.1 Screw terminals.......................................................................................................................... 513

A.2 Spring-loaded terminals ............................................................................................................. 515

A.3 Power loss of components ......................................................................................................... 516

A.3.1 Power Loss of the SINUMERIK Components ............................................................................ 516

A.3.2 Power loss of SINAMICS components ...................................................................................... 516

A.3.2.1 Power loss for Control Units, Sensor Modules, and other system components ........................ 516

A.3.2.2 Power loss for line filters and line reactors ................................................................................ 517

A.3.2.3 Power loss for power units with internal air cooling ................................................................... 518

A.3.2.4 Power loss for power units with external air cooling .................................................................. 520

A.3.2.5 Power loss for power units with cold plate ................................................................................. 521

A.3.2.6 Power loss for liquid-cooled power units ................................................................................... 522

A.3.3 Electronics losses of power units ............................................................................................... 523

A.3.4 Losses for power units in the partial load range ........................................................................ 525

A.3.5 Typical power losses for Motor Modules ................................................................................... 526

A.4 Abbreviations ............................................................................................................................. 528

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

13

Page 14

Table of contents

Guidelines for machine configuration

14 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 15

1

1.1

General safety instructions

DANGER

Danger to life when live parts are touched

WARNING

Danger to life through a hazardous voltage when connecting an unsuitable power supply

Death or serious injury can result when live parts are touched.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase

conductor and phase conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other hazardous energy sources, e.g. compressed air, hydraulic systems,

water.

4. Isolate or neutralize all hazardous energy sources, e.g. by closing switches, grounding

or short-circuiting or closing valves.

5. Secure the energy sources against switching on again.

6. Make sure that the right machine is completely locked.

After you have completed the work, restore the operational readiness in the inverse

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

sequence.

Death or serious injury can result when live parts are touched in the event of a fault.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV-

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

15

Page 16

Fundamental safety instructions

WARNING

Danger to life when live parts are touched on damaged devices

WARNING

Danger of fire spreading due to inadequate housing

WARNING

Danger to life through unexpected movement of machines when using mobile wireless

devices or mobile phones

WARNING

Fire hazard for the motor due to overload of the insulation

1.1 General safety instructions

Improper handling of devices can cause damage.

Hazardous voltages can be present at the housing or exposed components on damaged

devices.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged devices.

• Protect the components against conductive pollution, e.g., by installing them in a control

cabinet with IP54 degree of protection according to IEC 60529 or NEMA 12. Provided

conductive pollution can be prevented at the installation site, the degree of protection for

the cabinet can be decreased accordingly.

Fire and smoke development can cause severe personal injury or material damage.

• Install devices without a protective housing in a metal control cabinet (or protect the

device by another equivalent measure) in such a way that contact with fire inside and

outside the device is prevented.

• Additionally, select the installation site so that an uncontrolled spreading of smoke can

be avoided in the case of a fire.

• Ensure that smoke can escape via designated paths.

Using mobile wireless devices or mobile phones with a transmitter power > 1 W closer than

approx. 2 m to the components may cause the devices to malfunction and influence the

functional safety of machines, therefore putting people at risk or causing material damage.

• Switch the wireless devices or mobile phones off in the immediate vicinity of the

components.

There is a greater load on the motor insulation through a ground fault in an IT system. A

possible result is the failure of the insulation with a risk for personnel through smoke

development and fire.

• Use a monitoring device that signals an insulation fault.

• Correct the fault as quickly as possible so the motor insulation is not overloaded.

Guidelines for machine configuration

16 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 17

Fundamental safety instructions

WARNING

Fire hazard due to overheating because of inadequate ventilation clearances

WARNING

Danger to life through electric shock due to unconnected cable shields

WARNING

Danger to life when safety functions are inactive

Note

Important safety notices for safety functions

If you want to use sa

manuals.

1.1 General safety instructions

Inadequate ventilation clearances can cause overheating with a risk for personnel through

smoke development and fire. This can also result in increased downtime and reduced

service lives for devices / systems.

• Ensure compliance with the specified minimum clearance as ventilation clearance for

the respective component. They can be found in the dimension drawings or in the

"Product-specific safety instructions" at the start of the respective section.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• Connect cable shields and unused conductors of power cables (e.g., brake conductors)

at least on one side to the grounded housing potential.

Safety functions that are inactive or that have not been adjusted accordingly can cause

operational faults on machines that could lead to serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing

• Run a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

fety functions, you must observe the safety notices in the safety

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

17

Page 18

Fundamental safety instructions

1.2

Safety instructions for electromagnetic fields (EMF)

WARNING

Danger to life from electromagnetic fields

1.3

Handling electrostatic sensitive devices (ESD)

NOTICE

Damage through electric fields or electrostatic discharge

1.2 Safety instructions for electromagnetic fields (EMF)

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment

such as transformers, converters or motors.

People with pacemakers or implants are at a special risk in the immediate vicinity of these

devices/systems.

• Keep a distance of at least 2 m.

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

Guidelines for machine configuration

18 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 19

Fundamental safety instructions

1.4

Residual risks of power drive systems

Residual risks of power drive systems

1.4 Residual risks of power drive systems

The control and drive components of a drive system are approved for industrial and

commercial use in industrial line supplies. Their use in public line supplies requires a

different configuration and/or additional measures.

These components may only be operated in closed housings or in higher-level control

cabinets with protective covers that are closed, and when all of the protective devices are

used.

These components may only be handled by qualified and trained technical personnel who

are knowledgeable and observe all of the safety instructions on the components and in the

associated technical user documentation.

When assessing the machine's risk in accordance with the respective local regulations (e.g.,

EC Machinery Directive), the machine manufacturer must take into account the following

residual risks emanating from the control and drive components of a drive system:

1. Unintentional movements of driven machine components during commissioning,

operation, maintenance, and repairs caused by, for example:

– Hardware defects and/or software errors in the sensors, controllers, actuators, and

connection technology

– Response times of the controller and drive

– Operating and/or ambient conditions outside of the specification

– Condensation / conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of radio devices / cellular phones in the immediate vicinity of the controller

– External influences / damage

2. In the event of a fault, exceptionally high temperatures, including an open fire, as well as

emissions of light, noise, particles, gases, etc. can occur inside and outside the inverter,

e.g.:

– Component malfunctions

– Software errors

– Operating and/or ambient conditions outside of the specification

– External influences / damage

Inverters of the Open Type / IP20 degree of protection must be installed in a metal control

cabinet (or protected by another equivalent measure) such that the contact with fire inside

and outside the inverter is not possible.

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

19

Page 20

Fundamental safety instructions

Note

The components must be protected against conductive contamination (e.g. by installing them

in a control cabinet with degree of protection IP54 according to IEC 60529 or NEMA 12).

Assuming that conductive contamination at the installation site

lower degree of cabinet protection may be permitted.

1.4 Residual risks of power drive systems

3. Hazardous shock voltages caused by, for example:

– Component malfunctions

– Influence of electrostatic charging

– Induction of voltages in moving motors

– Operating and/or ambient conditions outside of the specification

– Condensation / conductive contamination

– External influences / damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc. if they are too

close.

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly.

can definitely be excluded, a

For more information about residual risks of the components in a drive system, see the

relevant sections in the technical user documentation.

Guidelines for machine configuration

20 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 21

2

2.1

Application

Features

Fields of application

SINUMERIK 840D sl is a universal and flexible CNC system in which the SINAMICS S120

drive system is integrated.

● Maximum performance and flexibility, above all for complex multi-axis systems.

● Uniform openness from operation up to the NC core.

● Optimum integration into networks.

● Uniform structure in respect of operation, programming and visualization.

● Integrated safety functions for man and machine: SINUMERIK Safety Integrated

● Operating and programming software such as SINUMERIK Operate and SINUMERIK

The SINUMERIK 840D sl can be used worldwide for turning, drilling, milling, grinding, laser

machining, nibbling, punching, in tool and mold making, for high-speed cutting applications,

for wood and glass processing, for handling operations, in transfer lines and rotary indexing

machines, for mass production and Job Shop production.

The SINUMERIK 840DE sl is available as an export version for use in countries requiring an

export authorization.

Integrate can be used for the production sector.

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

21

Page 22

System overview

2.2

System configuration

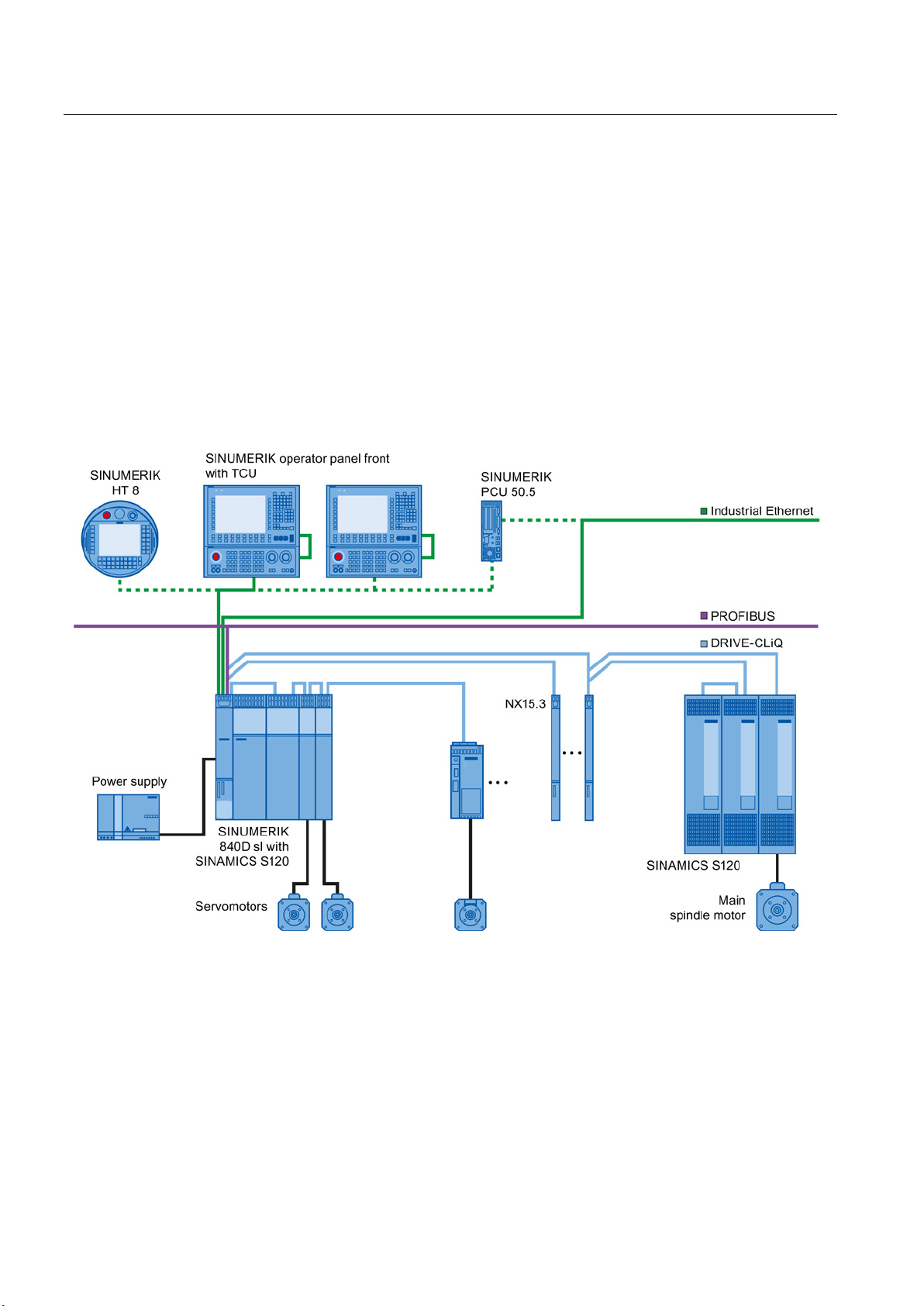

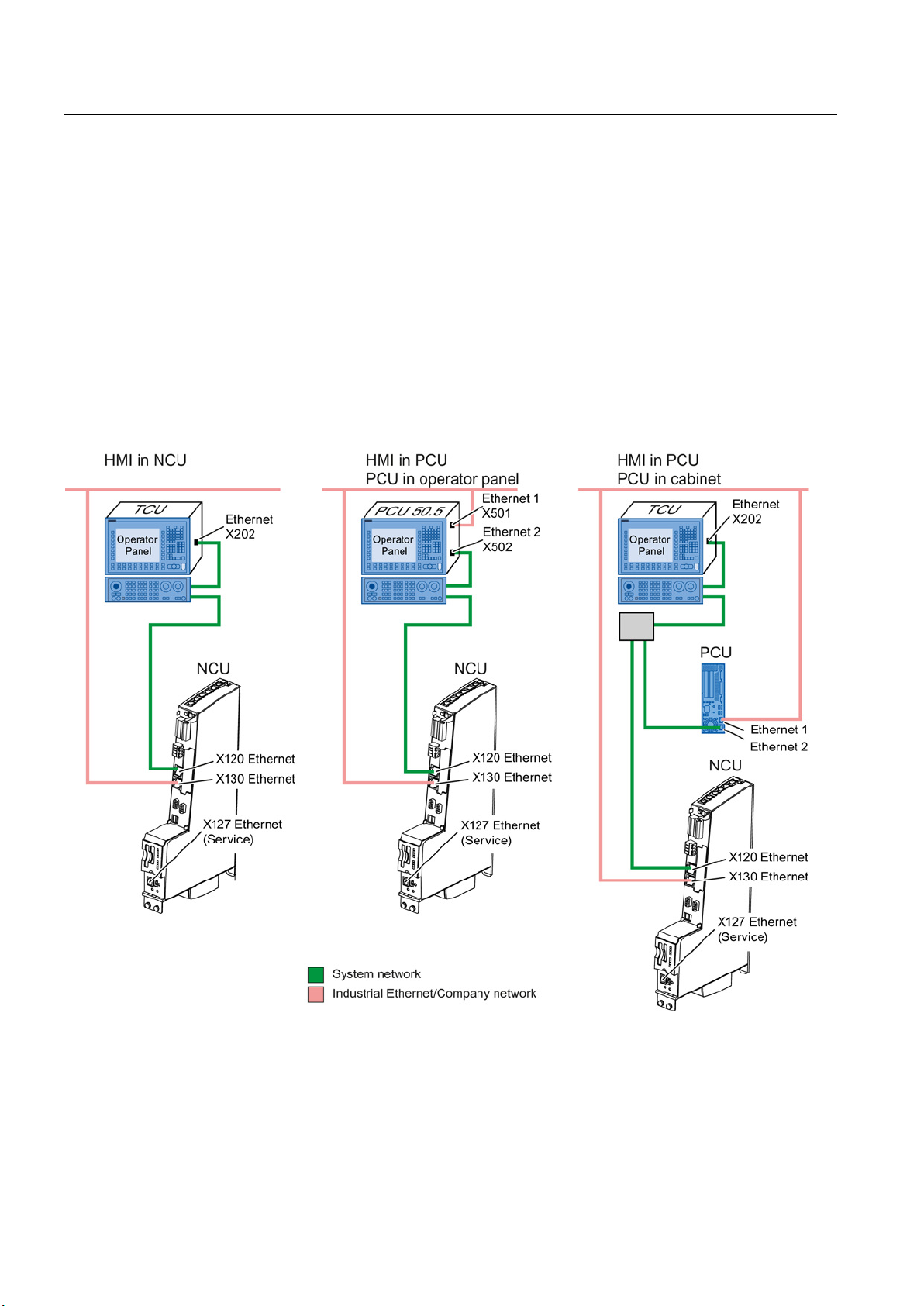

Components

2.2 System configuration

The heart of the SINUMERIK 840D sl is the Numerical Control Unit (NCU). It combines NCK,

HMI, PLC, closed-loop control and communication tasks.

For operation, programming, and visualization purposes, the corresponding operating

software is already integrated into the CNC software for the NCU and therefore runs on the

high-performance NCU multi-processor module. For increased operating performance

requirements, the SINUMERIK PCU 50.5 industrial PC can be used.

With the TCU (Thin Client Unit), the operator panel can be installed as much as 100 meters

away. Up to four distributed operator panel fronts can be operated on an NCU or PCU 50.5.

Figure 2-1 Typical topology of the SINUMERIK 840D sl complete system

Guidelines for machine configuration

22 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 23

System overview

2.2 System configuration

The following components can be connected to the PPU:

● SINUMERIK operator panel front with TCU/PCU 50.5 and machine control

panel/pushbutton panel

● Handheld units

● SIMATIC CE panel

● SIMATIC S7-300 I/O

● Distributed PLC I/O via PROFIBUS DP connection or PROFINET IO

● Programming device

● SINAMICS S120 drive system with feed and main spindle motors, such as

– 1FT/1FK/1FN/1FW6/1FE1/2SP1 synchronous motors

– 1PH/1PM asynchronous motors

The SINUMERIK 840D sl offers integrated PROFINET functionality.

The following are supported:

● PROFINET CBA functionality (CBA = Component Based Automation)

The CBA functionality integrated in the NCU allows users to modularize machinery and

systems: Rapid real-time communication (up to 10 ms) between the controllers means

that systems lend themselves better to standardization and can be reused or expanded

more easily. Response to customer demands is faster and more flexible and startup is

simplified and speeded up by pretesting at component level.

● PROFINET IO

As part of PROFINET, PROFINET IO is a communication concept that is used to

implement modular, distributed applications. PROFINET IO is based on Industrial

Ethernet and allows distributed field and I/O equipment to be connected to the central

processing unit.

128 PROFINET IO devices can be operated on the NCU as an IO controller.

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

23

Page 24

System overview

2.3

Variants

Application areas and performance

Note

Connection of SINAMICS S120 Combi

An NCU 710.3 PN is required in order to use a SINAMICS S120 Combi drive system.

This version is not discussed in this document.

Further information

2.3 Variants

Thanks to the scalability of the hardware and software, both in the controller and operating

areas, the SINUMERIK 840D sl can be used in many sectors. The possibilities range from

simple positioning tasks up to complex multi-axis systems.

● Up to eight axes can be implemented on an NCU 710.3 PN in SERVO control mode, with

a sampling time of 125 µs for both the speed and current controllers. In order to achieve

this maximum number of axes, the NCU 710.3 PN must be extended by up to two NX

modules.

● On the NCU 720.3 PN/730.3 PN, the number of axes can be increased to as many as 31

● Using the Option Board CBE30-2, three NCU 7x0.3 PN can be linked to each other by

● The NCU 730.3 PN is recommended for maximum dynamics and accuracy in mold

Please refer to the following for detailed information on the number of axes and controller

axis performance:

/FH1/ SINAMICS S120 Function Manual Drive Functions, 01/2012 edition, Chapter 12.12.

and/or the drive control performance can be improved in SERVO control mode, with a

sampling time of 125 µs for both the speed and current controllers. This is achieved by

using the NX10.3/NX15.3 module. The NCU 720.3 PN/730.3 PN can be extended by up

to five NX10.3/NX15.3 modules for the purposes of drive control performance and

number of axes.

means of the NCU link functionality, so that 93 axes in total can be controlled by an NCU.

making applications or the high-speed cutting sector. Since it has the highest PLC

capacity, it represents the most advanced configuration within the SINUMERIK 840D sl

range.

Guidelines for machine configuration

24 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 25

System overview

2.4

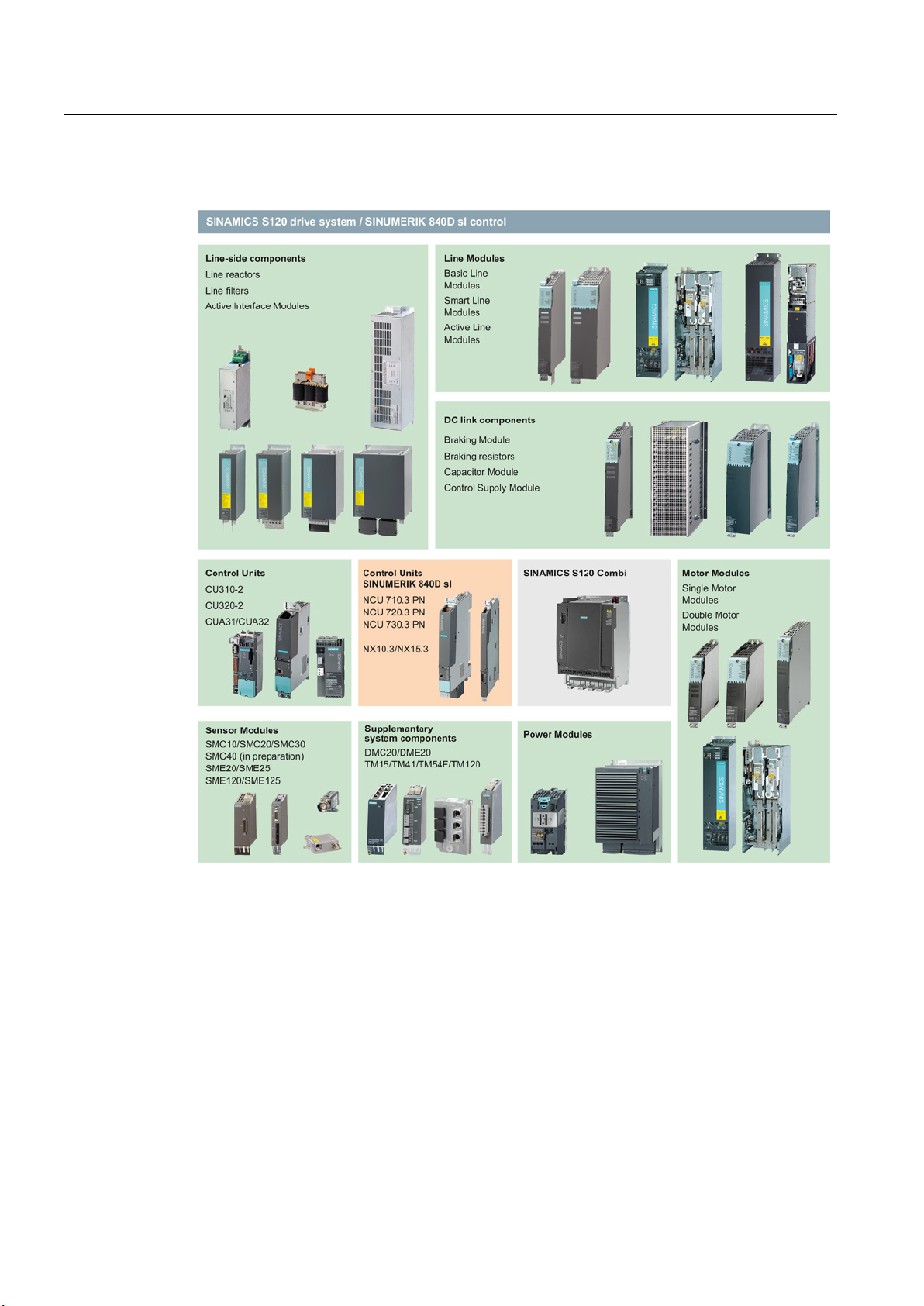

SINAMICS S120 / SINUMERIK 840D sl Component Overview

Introduction

2.4 SINAMICS S120 / SINUMERIK 840D sl Component Overview

Coordinated drives that carry out a drive and motion task together are used in many

mechanical and plant engineering applications. These require drives with a coupled DC link,

which allows for cost-saving energy compensation between braking and driving axes.

SINAMICS S120 features Line Modules (infeed modules) and Motor Modules (inverter

modules) covering a wide performance range which, having been designed in booksize

format for seamless installation, pave the way for compact multi-axis drive configurations.

The SINAMICS S120 control module, the CU320-2 Control Unit, is able to handle simple

technological tasks by itself. For challenging numerical tasks, it is replaced by or extended to

include powerful modules from the SINUMERIK 840D sl product range.

The SINUMERIK NCU 7x0.3 PN Numerical Control Units can be positioned in or next to the

SINAMICS S120 drive line-up and connected via DRIVE-CLiQ.

In the case of tasks that require a greater number of motion axes due to the machine

kinematics, the system base units can be expanded with the additional NX10.3/NX15.3

Control Units.

Guidelines for machine configuration

System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

25

Page 26

System overview

Components of the SINAMICS S120 drive system and SINUMERIK 840D sl control

2.4 SINAMICS S120 / SINUMERIK 840D sl Component Overview

Figure 2-2 SINAMICS and SINUMERIK components

Guidelines for machine configuration

26 System Manual, MA 01/2013, 6FC5397-6CP10-0BA2

Page 27

System overview

Function of components

Overview

Product family

Component group

Component/function

Types

CLiQ interfaces)

2.4 SINAMICS S120 / SINUMERIK 840D sl Component Overview

● Line-side power components such as fuses, contactors, reactors, and filters are used for

switching the energy supply and meeting EMC requirements.

● Line Modules generate DC voltage from the three-phase line voltage, and transfer the

central energy supply to the DC link and, if necessary, the regenerative feedback to the

network.

– Basic Line Modules (BLM) generate a non-stabilized DC link voltage and are not

capable of regenerative feedback. They are not generally used for multi-axis drive

configurations.