Page 1

SINUMERIK 840D

Configuring the NCU

Manual

System Overview 1

Connection Conditions 2

Structure and Installation 3

Description of the NCU 4

I/O Modules 5

Terminal Block 6

Valid for

Control

SINUMERIK 840D

SINUMERIK 840DE (export version)

SINUMERIK 840D powerline

SINUMERIK 840DE powerline

DMP Compact Modules 7

Maintenance and Service 8

Abbreviations A

Index

Drive

SIMODRIVE 611 digital

03/2006 Edition

Page 2

SINUMERIK® documentation

y

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A New documentation.. . . . .

B Unrevised reprint with new Order No.. . . . .

C Revised edition with new status. . . . . .

Edition Order No. Remarks

06.94 6FC5297-0AC10-0BP0 A

08.94 6FC5297-0AC10-0BP1 C

02.95 6FC5297-2AC10-0BP0 C

04.95 6FC5297-2AC10-0BP1 C

09.95 6FC5297-3AA01-0BP0 Description of differences

03.96 6FC5297-3AC10-0BP0 C

08.97 6FC5297-4AC10-0BP0 C

12.97 6FC5297-4AC10-0BP1 C

12.98 6FC5297-5AC10-0BP0 C

08.99 6FC5297-5AC10-0BP1 C

04.00 6FC5297-5AC10-0BP2 C

10.00 6FC5297-6AC10-0BP0 C

09.01 6FC5297-6AC10-0BP1 C

11.02 6FC5297-6AC10-0BP2 C

11.03 6FC5297-6AC10-0BP3 C

12.04 6FC5297-7AC10-0BP0 C

03.06 6FC5297-7AC10-0BP1 C

Trademarks

All product names mentioned may be trademarks or product designations of Siemens AG or their suppliers,

whose use by third parties for their own purposes may infringe the rights of the trademark owners.

Other functions not described in this documentation might be

Further information is available in the Internet under:

http://www.siemens.com/motioncontrol

This publication was produced with Interleaf V 7.

©

Copyright

Order No. 6FC5297-7AC10-0BP1

Printed in German

Siemens AG, 2006.

executable in the control. However, no claim can be made regarding

the availability of these functions when the equipment is first supplied

or in the event of servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nevertheless, differences

might exist and therefore we cannot guarantee that they are

completely identical. However, the information contained in this

document is reviewed regularly and any necessary changes included

in subsequent editions. We welcome suggestions for improvement.

Subject to change without prior notice.

Siemens AG

Page 3

Preface

SINUMERIK

Documentation

Target group

Benefits

The SINUMERIK documentation is subdivided into 3 parts:

General Documentation

User documentation

Manufacturer/Service documentation

A list of documents with the respective available languages is updated on a

monthly basis and is available on the Internet at:

http://www.siemens.com/motioncontrol

Select “Support” → “Technical Documentation” → “Overview of Documents”.

The Internet version of the DOConCD (DOConWEB) is available at:

http://www.automation.siemens.com/doconweb

Information on the training offerings and on FAQs (frequently asked questions)

can be found in the Internet under:

http://www.siemens.com/motioncontrol

This documentation is intended for:

and menu item “Support”.

Project engineers, electricians and installers

Maintenance and service personnel

The information in this manual enables installation of the SINUMERIK 840D

Numerical Control and measures for maintenance and service to be carried out.

Standard version

Technical Support

This documentation only describes the functionality of the standard version.

Extensions or changes made by the machine tool manufacturer are documented by the machine tool manufacturer. Other functions not described in this

documentation might be executable in the control. This does not, however, represent an obligation to supply such functions with an initial delivery or when servicing.

For the sake of simplicity, this documentation does not contain all detailed information about all types of the product and cannot cover every conceivable case

of installation, operation, or maintenance.

If you have any questions about the control, please contact the hotline:

Europe and Africa time zone

A&D Technical Support

Tel.: +49 (0) 180 / 5050 222

Fax: +49 (0) 180 / 5050-223

Internet: http://www.siemens.com/automation/support-request

E-mail: mailto:adsupport@siemens.com

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

iii

Page 4

Preface

03.06

Asia and Australia time zone

A&D Technical Support

Tel.: +86 1064 719 990

Fax: +86 1064 747 474

Internet: http://www.siemens.com/automation/support-request

E-mail: mailto:adsupport@siemens.com

America time zone

A&D Technical Support

Tel.: +1 423 262 2522

Fax: +1 423 262 2289

Internet: http://www.siemens.com/automation/support-request

E-mail: mailto:adsupport@siemens.com

Note

Country-specific telephone numbers for technical support are provided under

the following Internet address:

http://www.siemens.com/automation/service&support

Questions about

the manual

SINUMERIK

Internet address

EC Conformity

Declaration

Safety information

For questions on the documentation (suggestions, corrections), please send a

fax or e-mail to the following address:

Fax: +49 (0) 9131 / 98 - 63315

E-mail: mailto:motioncontrol.docu@siemens.com

Fax form: See the reply form at the end of the brochure

http://www.siemens.com/sinumerik

The EC conformity declarations on EMC are to be found at/can be obtained

from:

In the Internet:

http://www.ad.siemens.com/csinfo

under the product/order no. 15257461

At the relevant branch office of the A&D MC group of Siemens AG.

This manual contains information which you should observe in order to ensure

your own personal safety, as well to avoid material damage. Notices which are

relevant to your own personal safety are highlighted by a safety alert symbol;

notices which are relevant only to equipment and property damage have no

safety alert symbol. The warnings appear in decreasing order of risk as given

below.

Danger

!

iv

Indicates that death or serious injury will result if proper precautions are not

taken.

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 5

03.06

Preface

Warning

!

!

Indicates that death or serious injury may result if proper precautions are not

taken.

Caution

With a safety alert symbol, indicates that minor personal injury may result if

proper precautions are not taken.

Caution

Without a safety alert symbol, indicates that property damage can result if

proper precautions are not taken.

Qualified

personnel

Proper use

Notice

Indicates that an undesirable event or state may arise if the relevant notes are

not observed.

If several hazards of different degrees occur, the hazard with the highest degree

must always be given priority. If a warning note with a warning triangle warns of

personal injury, the same warning note can also contain a warning of material

damage.

Startup and operation of the device / equipment / system in question must only

be performed using this documentation. Only qualified personnel should be

allowed to commission and operate the device/system. Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag

circuits, equipment, and systems in accordance with established safety practices and standards.

Please note the following:

Warning

!

The equipment may only be used for single purpose applications explicitly

described in the catalog and in the technical description and it may only be

used along with third-party devices and components recommended by

Siemens. To ensure trouble-free and safe operation of the product, it must be

transported, stored and installed as intended and maintained and operated with

care.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

v

Page 6

Preface

03.06

Danger notes

!

!

Should it be necessary to test or take measurements on live equipment, then

the specifications and procedures defined in Accident Prevention Regulation of

the Berufsgenossenschaft BGV A3 (German employer’s liability insurance association) must be adhered to, in particular § 8 “Permissible deviations when

working with live components”. Suitable electric tools should be used.

Danger

Operating electrical equipment has parts and components that are at

hazardous voltage levels.

After disconnecting all the supply voltages, a hazardous voltage will be present

in the DC link of all SIMODRIVE modules for another 5 minutes!

See Operating Guide

Danger

Repairs to devices that have been supplied by our company must only be

carried out by SIEMENS Customer Service or by repair centers

authorized by SIEMENS. When replacing parts or components, only use

those parts that are included in the spare parts list.

Before opening the equipment, always ensure that the power is off.

EMERGENCY STOP devices complying with EN 60204 (VDE 0113 Part 1)

must remain effective in all automation equipment modes. Resetting the

EMERGENCY STOP device must not cause an uncontrolled or undefined

restart.

Anywhere in the automation equipment where faults might cause major

material damage or even physical injury, in other words, where faults could

be dangerous, additional external precautions must be taken, or facilities

must be provided, that guarantee or enforce a safe operational state, even

when there is a fault (e.g. using an independent limit value switch,

mechanical interlocks etc.).

Warning

!

Connecting cables and signal lines should be installed so that inductive and

capacitive interference does not in any way impair the automation functions.

Warning

The modules contain electrostatically sensitive devices. Discharge yourself of

electrostatic energy before touching the components. The easiest way to do

this is to touch a conductive, grounded object immediately beforehand (for

example, bare metal parts of control cabinet or the protective ground contact of

a socket outlet).

vi

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 7

03.06

Preface

ESDS information

!

Electrostatically Sensitive Devices

Important

Handling of modules containing devices sensitive to

electrostatic discharge:

When handling components which can be destroyed by electrostatic

discharge, it must be ensured that personnel, the workstation and

packaging are well grounded!

Generally, electronic modules must not be touched unless work has to be

carried out on them. Only touch electronic modules after you have

grounded yourself.

Touch components only if:

– you are constantly grounded via an ESD arm band,

– ESD-shoes or ESD-shoe grounding strips if there is an ESD floor.

Modules may be placed only on electrically conductive surfaces (table with

ESD top, conductive ESD foam plastic, ESD packing bags, ESD transport

containers).

Keep modules away from visual display units, monitors or TV sets

(minimum distance from screen 10 cm).

Do not bring ESD-sensitive modules into contact with chargeable and

highly-insulating materials, such as plastic, insulating table tops or clothing

made of synthetic materials.

Additional notes

!

Measurements on modules are allowed only if

– the measuring instrument is properly earthed (e.g. equipment grounding

conductor), or

– before measuring with a potential-free measuring instrument, the probe

is briefly discharged (e.g. touch the unpainted metal parts of the control

housing).

Important

This notice indicates important facts that must be taken into consideration.

Note

This note contains additional important information.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

vii

Page 8

Preface

03.06

Notes

viii

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 9

Contents

1 System Overview 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 System configuration 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Labels and stickers 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Non-Siemens keyboards 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Connection Conditions 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Secondary electrical conditions 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Power supply 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Safe isolation to EN 61800–5–1 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Grounding concept 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 RI suppression measures 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Climatic and mechanical environmental conditions 2-26. . . . . . . . . . . . . . .

2.2.1 Transport and storage conditions 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Operating conditions 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 MPI/OPI network rules 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Structure and Installation 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Structure of the SINUMERIK 840D 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Installation of the SINUMERIK 840D 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Description of the NCU 4-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Components 4-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mounting 4-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 NCU box without a fan box 4-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 NCU box with a fan box 4-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 NCU module interfaces 4-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Cable distributor (distributor box) 4-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Technical data 4-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 I/O Modules 5-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Single I/O module 5-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Terminal Block 6-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 NCU terminal block 6FC5211-0AA00-0AA0 6-71. . . . . . . . . . . . . . . . . . . . . .

7 DMP Compact Modules 7-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 DMP compact module 16E 6FC5111-0CA01-0AA0 7-77. . . . . . . . . . . . . .

7.2 DMP compact module 16 A 6FC5111-0CA02-0AA1 7-79. . . . . . . . . . . . . .

7.3 DMP compact module 8 A 6FC5111-0CA03-0AA1 7-81. . . . . . . . . . . . . . .

7.4 DMP compact module 1I analog 6FC5 111-0CA04-0AA0 7-83. . . . . . . . . .

7.5 DMP compact module 1E NC analog 6FC5211-0AA10-0AA0 7-86. . . . . .

7.6 DMP compact module 1A analog 6FC5111-0CA05-0AA0 7-88. . . . . . . . . .

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

ix

Page 10

8 Maintenance and Service 8-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Battery and fan replacement 8-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Abbreviations A-93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Index Index-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

03.06

x

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 11

System Overview

1.1 System configuration

1

Introduction

NCU

Battery and fan slide-in module

Infeed/Regenerative feedback module Feed DriveMain Spindle DriveNCU box

Fig. 1-1 Central control units SINUMERIK 840D

A numeric control is modular in design. The central control units of an 840D

system are shown in Fig. 1-1:

I/R FDMSD

Round cable to the

NCU terminal block

Device bus

The subject of this document is the NCU, the central processing unit of the

840D controller. It contains the NC-CPU and the PLC-CPU.

The NCU has the following tasks:

Execute the NC program

Maintain communication with the peripherals.

Note

When using I/O devices, ensure that they are suitable for industrial use!

The NCU is installed in a housing called the NCU box. This housing also contains a power supply and a fan subassembly.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

1-11

Page 12

Ä

1 S

y

stem Overview

1.1 System configuration

03.06

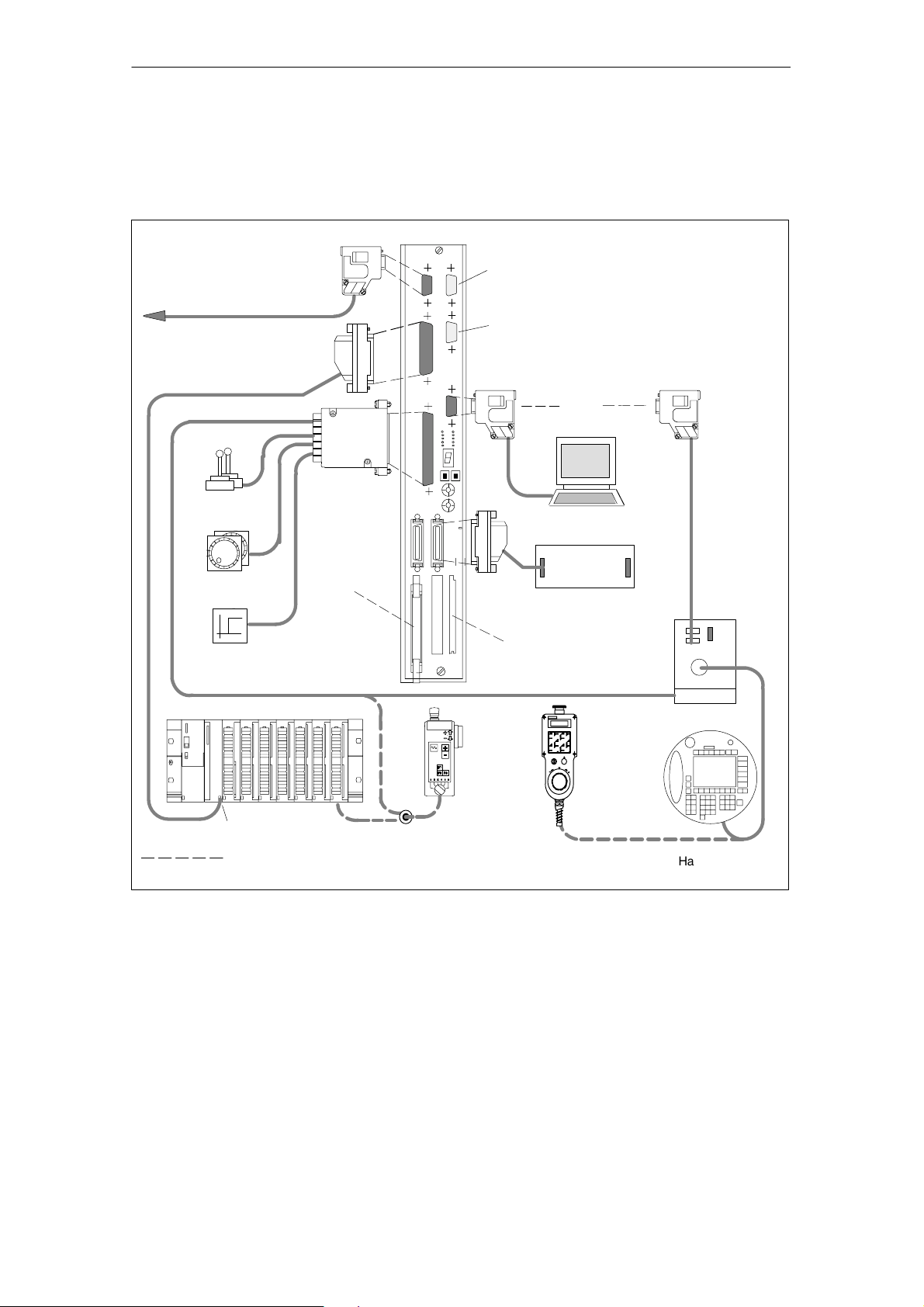

Connection

configuration

MPI bus

for PCU / MCP (see Fig. 1-3)

2x sensor

2x handwheel

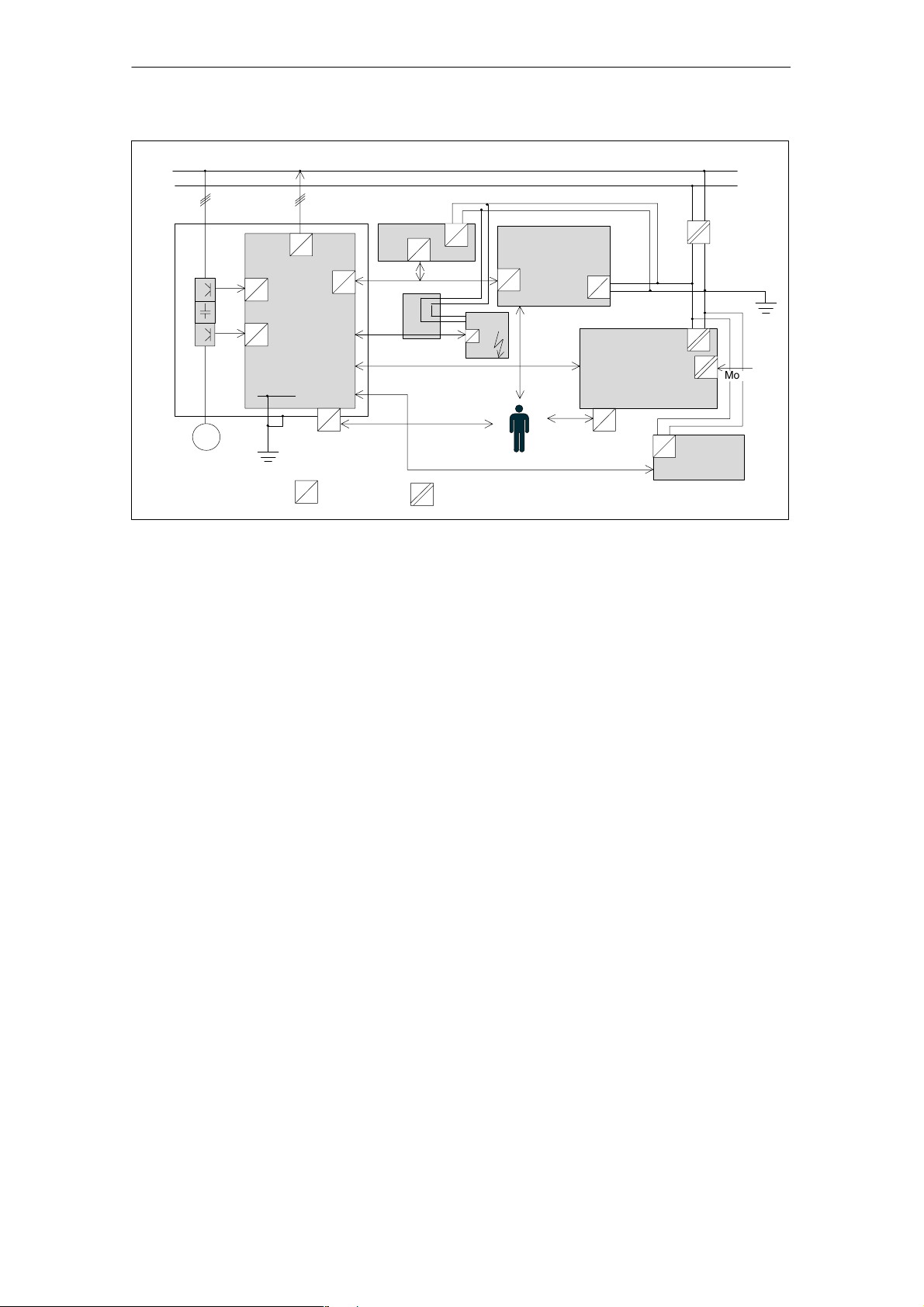

The NCU can communicate with the peripheral components via numerous interfaces. These are shown in Fig. 1-2 with their connections to the NCU and explained in more detail in Table 1-1:

NCU

–X102

–X101

PROFIBUS DP I/Os

Reserved for service

–X111

–X112

–X122

or

Cable

distribut

or

SIMODRIVE

components

–X121

X130B

X130A

*)

PG / PC, e.g. Field PG

IN OUT

X20 X21

NCU terminal block

MPI cable

4x digit. input

4x digit. output

IM

SIMATIC

S7-300

X2

: Optional

*) MPI cable or MPI PG cable

Fig. 1-2 SINUMERIK 840D system overview

–X172

Mini-

handheld unit

Memory card

(PCMCIA)

Handheld unit

Type B-MPI

X1

X2

Distribution

box

or

X4

X3

Handheld terminal

HT 6

1-12

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 13

03.06

1 System Overview

1.1 System configuration

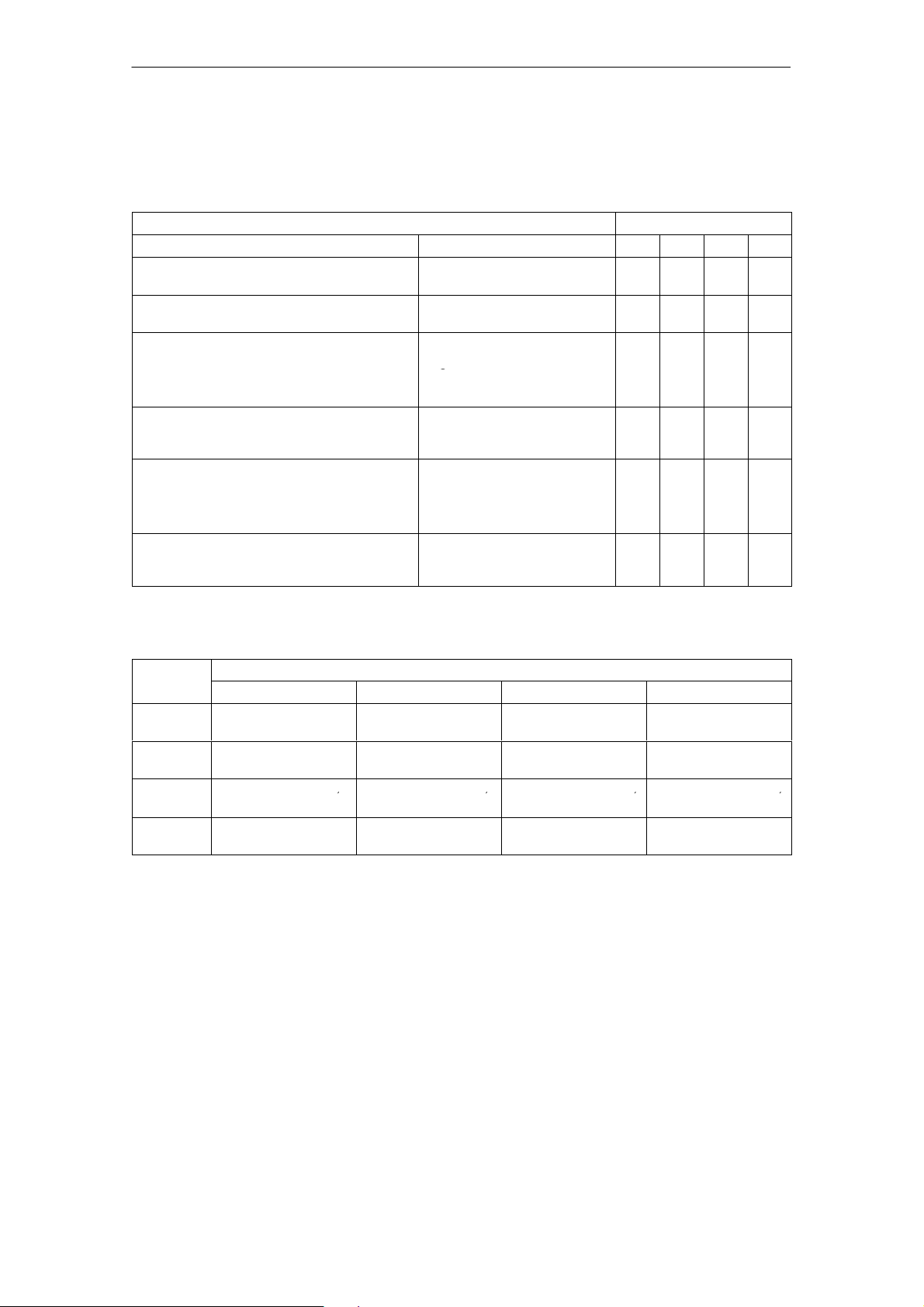

Table 1-1 Components of the 840D

Component

NCU Central processing unit of 840D

Cable distributor

Connection of up to 2 probes

Description

Connection of up to 2 handwheels

Connection of up to 4 digital inputs and outputs

24V supply for connection to MPI connector

SIMODRIVE

components

NCU terminal block High-speed NC I/Os

References: /PJU/, Configuration Manual Converters

Analog I/Os

Digital I/Os

Memory card (PCMCIA)

Contains the system program

Can be plugged into the NCU

Distribution box

For linking the handheld unit/handheld terminal to the

MPI bus

Connection for EMERGENCY STOP circuit, enable

keys, handwheel, 24 V DC

Mini-handheld unit see 1)

Handheld unit 1)

Connect handheld unit/handheld terminal via MPI

Handwheel, EMERGENCY STOP button, key-actuated

switch, override, agreement buttons, display, unas-

signed keys

Handheld Terminal HT 6 1) see 1)

The components marked with 1) are described in:

References: /BH/, Operator Components Manual

Note

If additional SIMODRIVE monitoring modules are used, they must be switched

at the same time as the infeed unit. In a multi-tier configuration, all the infeed

supply units must be connected simultaneously.

For cable, see

Reference: Catalog NC 60, MOTION-CONNECT cables and

connections

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

1-13

Page 14

1 S

y

stem Overview

1.1 System configuration

03.06

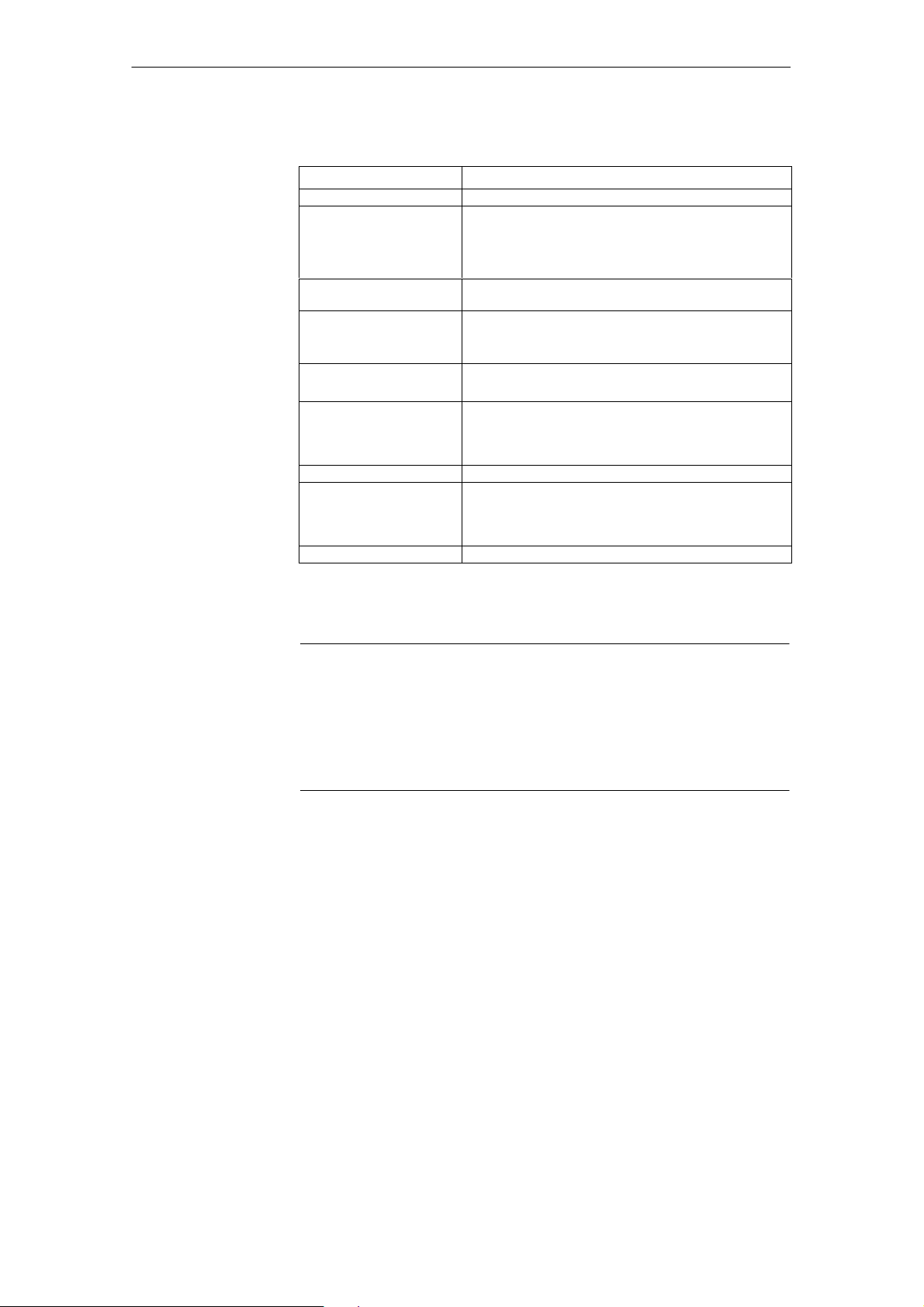

PCU–MCP

configuration

3.5” Floppy Disk Drive

3.5” floppy disk drive,

USB

VGA monitor

Fig. 1-3 shows an OP 012-PCU 50 combination. It is connected to the NCU via

the MPI bus (see Fig. 1-2).

Rear side

Ethernet

Operator panel front OP 012PCU 50

SIEMENS

* TEMP* POWER

Machine control panel

SINUMERIK

X20 (rear side)

MPI bus

for NCU

(see Fig.

1-2)

USB

(mouse/keyboard/

USB device)

Printer

PS/2 mouse

Fig. 1-3 Components of the OP 012-PCU 50 configuration

All the components, except for the printer, mouse and monitor are described in:

Reference: /BH/, Operating Components Manual

USB mouse Full CNC keyboard USB

Full CNC keyboard PS/2

Optional

1-14

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 15

03.06

,

,

,

,

y

1 S

stem Overview

1.1 System configuration

SW – HW

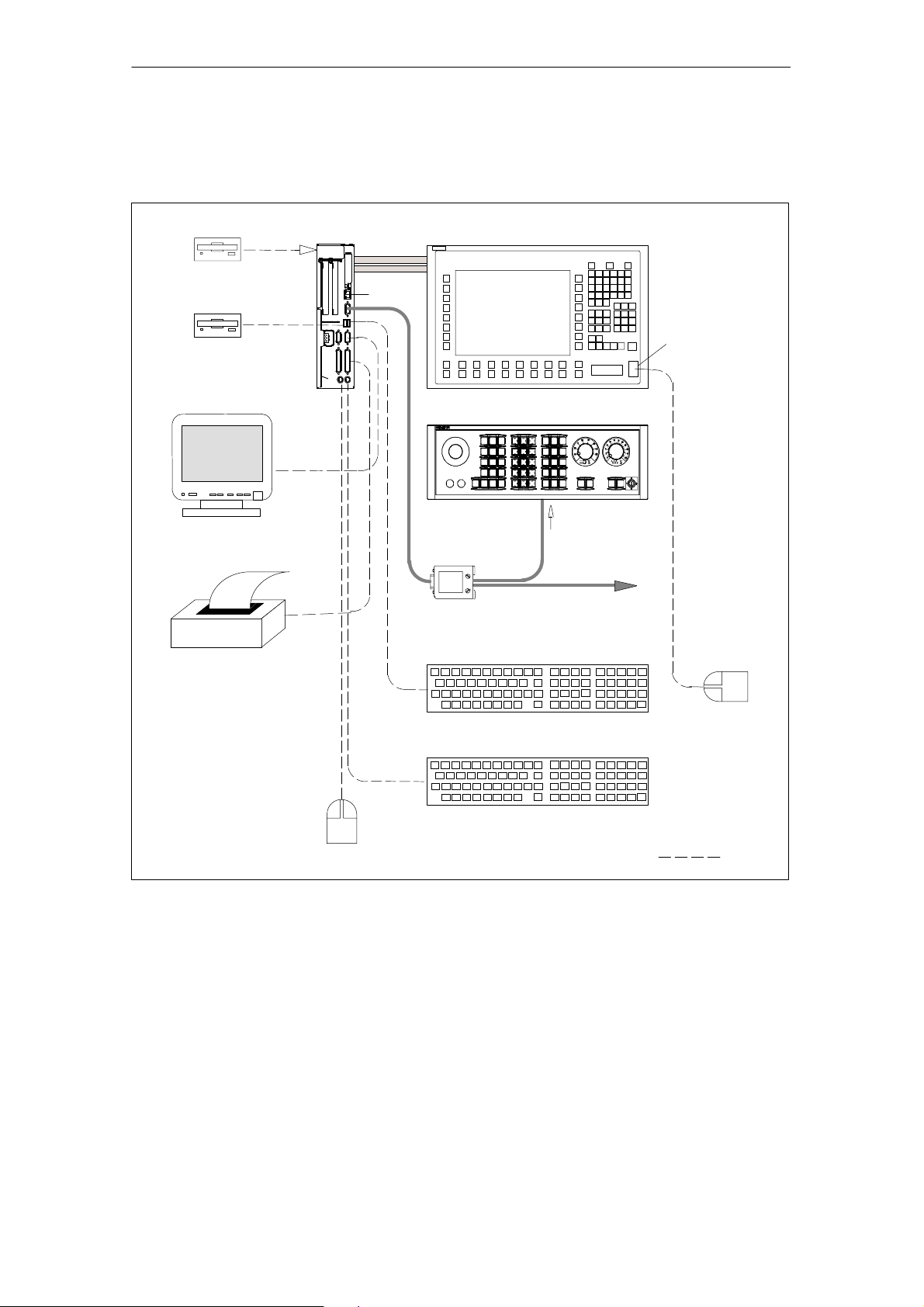

The following tables show the possible combinations of software and hardware:

combinations

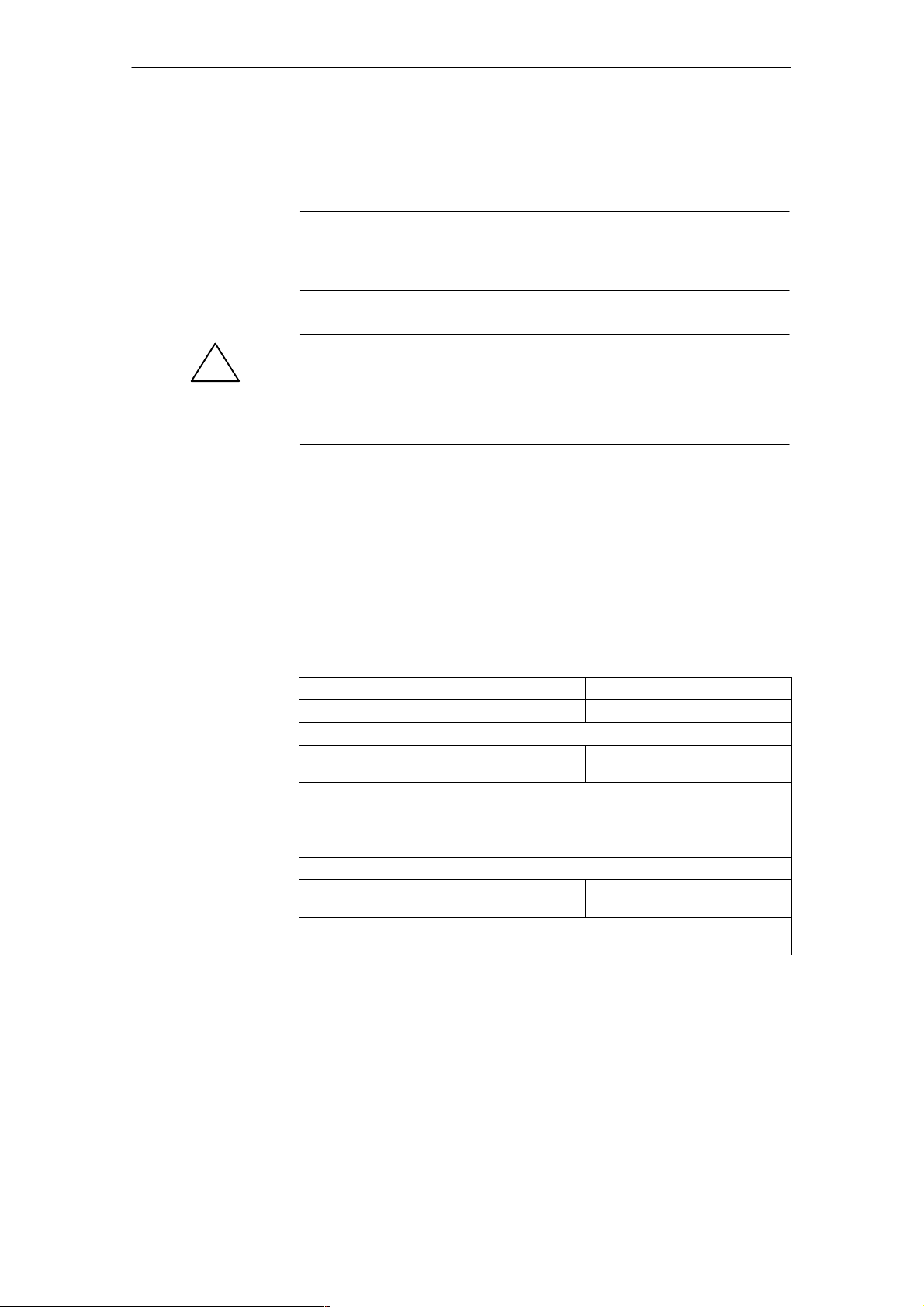

Table 1-2 Software - hardware combination options for NCU 5xx.3 to SW 6.4

NCU system software

Designation Order No. 561.3 571.3 572.3 573.3

NCU system software 2 axes

on PC card, Export 840DE

NCU system software 6 axes

on PC card, Export 840DE

NCU system software 12 axes

on PC card

Standard 840D

Export 840DE

NCU system software 12 axes

on PC card, standard 840D

incl. software version-specific additional functions

NCU system software 31 axes

on PC card

Standard 840D

Export 840DE

NCU system software 31 axes

on PC card, standard 840D

incl. software version-specific additional functions

combination possible; – combination not possible

6FC5250-PX10-AH – –

6FC5250-BX10-AH – – –

6FC5250-BX30-AH

6FC5250-BY30-AH

6FC5270-BX30-AH – –

6FC5250-AX30-AH

6FC5250-AY30-AH

6FC5270-AX30-AH

6FC5270-AX31-AH

6FC5270-AX32-AH

NCU hardware

–

–

–

–

–

–

–

–

– –

Table 1-3 Combination possibilities for software and hardware for NCU 5xx.4 and NCU 5xx.5, SW 6.5 or higher

NCU hard-

ware

561.4/.5 max. 2 out of 2 axes,

571.4/.5 max. 2 out of 2 axes,

572.4/.5 max. 2 out of 2 axes, max. 6 out of 31 axes, max. 12 out of 31 axes, max. 31 out of 31 axes,

573.4/.5 max. 2 out of 2 axes,

*) for SW 7.2 or higher: max. 4 channels

2 axes 6 axes 12 axes 31 axes

max. 2 channels

max. 2 channels

max. 2 channels

max. 2 channels

max. 2 out of 2 axes,

max. 2 channels

max. 6 out of 31 axes,

max. 2 channels

max. 2 channels

max. 6 out of 31 axes,

max. 2 channels

NCU system software

max. 2 out of 2 axes,

max. 2 channels

max. 6 out of 31 axes,

max. 2 channels

max. 2 channels *)

max. 12 out of 31 axes,

max. 2 channels *)

max. 2 out of 2 axes,

max. 2 channels

max. 6 out of 31 axes,

max. 2 channels

max. 10 channels

max. 31 out of 31 axes,

max. 10 channels

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

1-15

Page 16

1 S

y

stem Overview

1.2 Labels and stickers

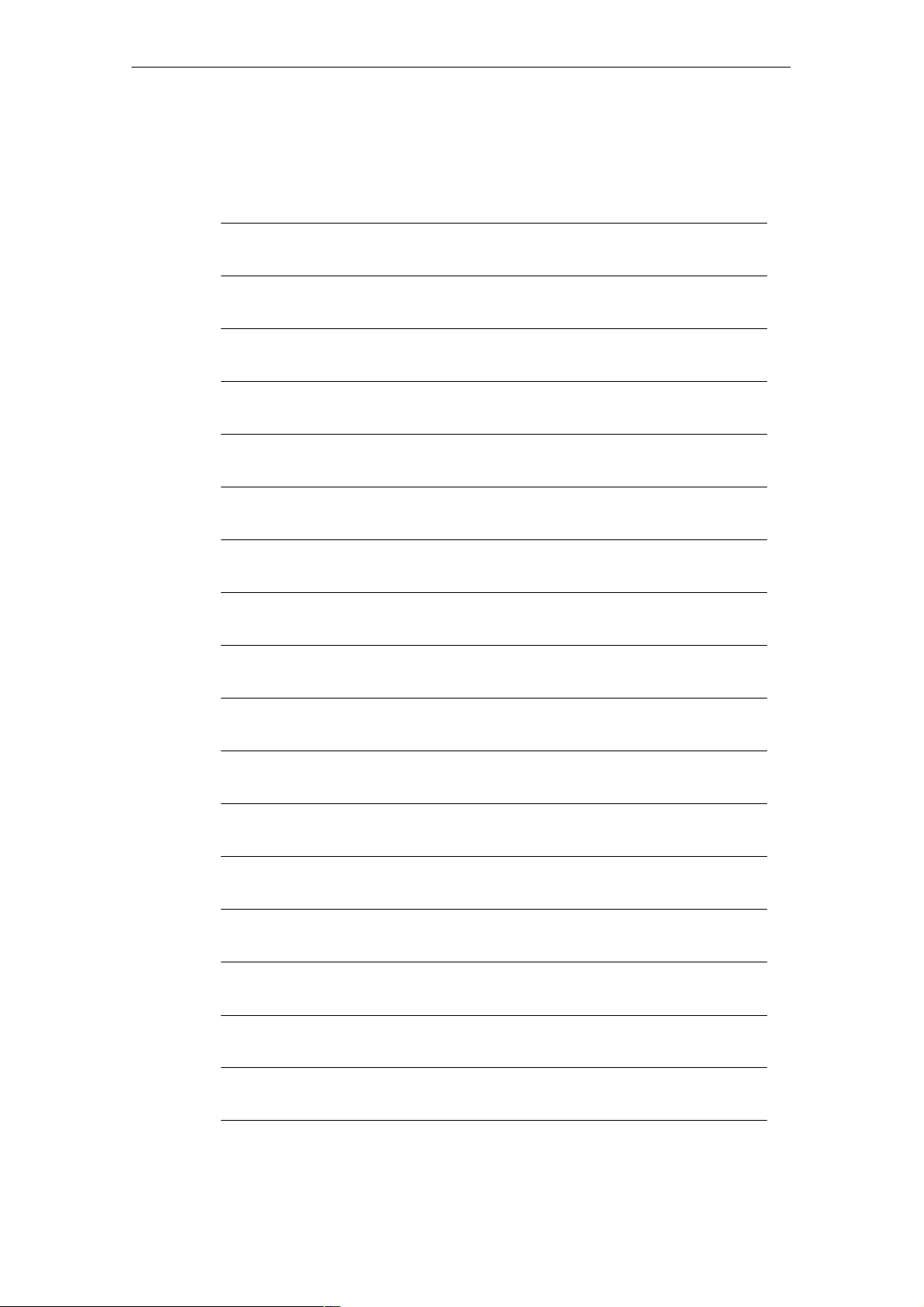

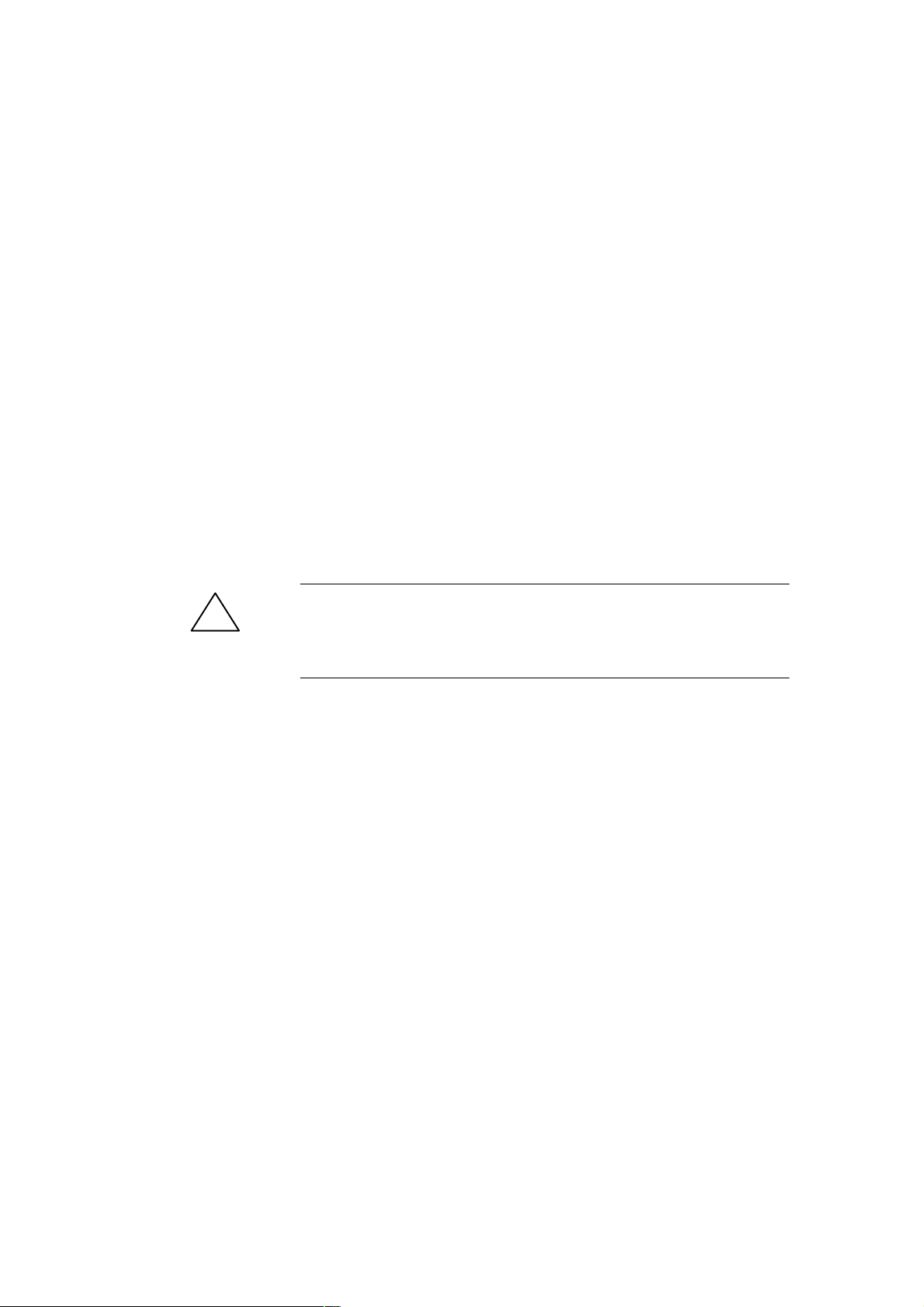

1.2 Labels and stickers

In case of technical queries or service, please quote all data on the rating plate

to the local SIEMENS office responsible for your equipment.

One of the following labels is attached to the components and modules:

03.06

PCBs with screen

printing

NCU

NCU box

Example: Component number: 570 573.9001.00

Product version: B (last cross)

E

C

D

B

SIEMENS

A

570 573.9001.00

Example: Component name: NCU 573.4

MLFB: 6FC5357-0BB34-0AE0

Component number: GWE-570038963520

Version F (printed)

Example: Component name: NCU box

MLFB: 6FC5247-0AA00-0AA2

Component number: GWE-570038901611

Version H (printed)

1-16

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 17

03.06

y

1.3 Non-Siemens keyboards

1 S

stem Overview

1.3 Non-Siemens keyboards

Standard PC

keyboard

When standard PC keyboards are used, ensure that they have a CE symbol

and correspond to industrial requirements. Otherwise, there may be problems

with the PC keyboard.

If you encounter problems, contact the relevant regional office.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

1-17

Page 18

1 System Overview

1.3 Non-Siemens keyboards

Notes

03.06

1-18

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 19

Connection Conditions

2.1 Secondary electrical conditions

2

Compliance with

the connection

conditions

!

Assistance and

support

The controller is tested for compliance with the environmental conditions specified below. Fault-free operation is only ensured if:

These environmental conditions are maintained when storing, transporting

and operating the equipment,

Original components and spare parts are used. This applies in particular to

the use of specified cables and plug connectors,

The equipment has been correctly mounted/installed.

Danger

The equipment may not be commissioned until it has been clearly identified

that the machine in which the controller is installed is in full conformance with

the specifications in EC Machinery Directive 98/37/EC.

The connection conditions must be carefully maintained for the complete system. Please contact your local Siemens office or representative for any assistance.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

2-19

Page 20

2 Connection Conditions

2.1 Secondary electrical conditions

2.1.1 Power supply

Demands on DC

power

supplies

Warning

!

The DC power supply is always referenced to ground and must be

generated by a safety transformer.

User interfaces must be powered via a DC power supply with safe isolation

to EN 61800–5–1.

In the case of supply cables > 10 m, protective elements must be fitted at

the device input in order to protect against lightning (surge voltage).

The DC power supply must be connected to the ground/shield of the NC for

EMC and/or functional reasons. For EMC reasons, this connection should

only be made at one point. As a rule, the connection is provided as

standard in the S7-300 I/Os. If this is not the case in exceptional

circumstances, the ground connection should be made to the grounding rail

of the NC cabinet; also refer to /EMC/ EMC Configuration Guideline.

03.06

Table 2-1 Requirements of the DC power supply

Rated voltage

In accordance with EN 61131–2

Voltage range (mean value)

Voltage ripple peak-to-peak

Booting time at POWER ON

Non-cyclic

overvoltage

Duration

Recovery time

Events per hour

Transient voltage interruptions

Idle time

Recovery time

Events per hour

24 VDC

20.4 VDC to 28.8 VDC

5% (unfiltered 6-pulse rectification)

Any value

35 V

500 ms

50 s

10

3 ms

10 s

10

2-20

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 21

03.06

2.1.2 Safe isolation to EN 61800–5–1

The complete system includes user interfaces (UIs) and interfaces for servicing,

startup and maintenance.

2 Connection Conditions

2.1 Secondary electrical conditions

End user

interfaces (UI)

Interfaces for

servicing, startup

and maintenance

!

!

UIs are all the interfaces that are freely accessible to the machine operator without the need for tools or aids. These user interfaces are designed with safe

isolation to EN 61800–5–1.

Danger

The interfaces for servicing, start-up and maintenance purposes are provided

without safe isolation.

If necessary, these interfaces can be isolated safely using a supplementary

adapter (insulation voltage 230 V AC). Although these adapters are not included

in the Siemens scope of delivery, you can buy these parts from your local

dealer, who will be happy to advise you.

Danger

Safe isolation can only be ensured if the system configuration specified below

is strictly adhered to. When mounting additional components (e.g., S7-300 FM,

IP) with a UI, please make sure that the UI has basic insulation for at least

230 V AC.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

2-21

Page 22

2 Connection Conditions

2.1 Secondary electrical conditions

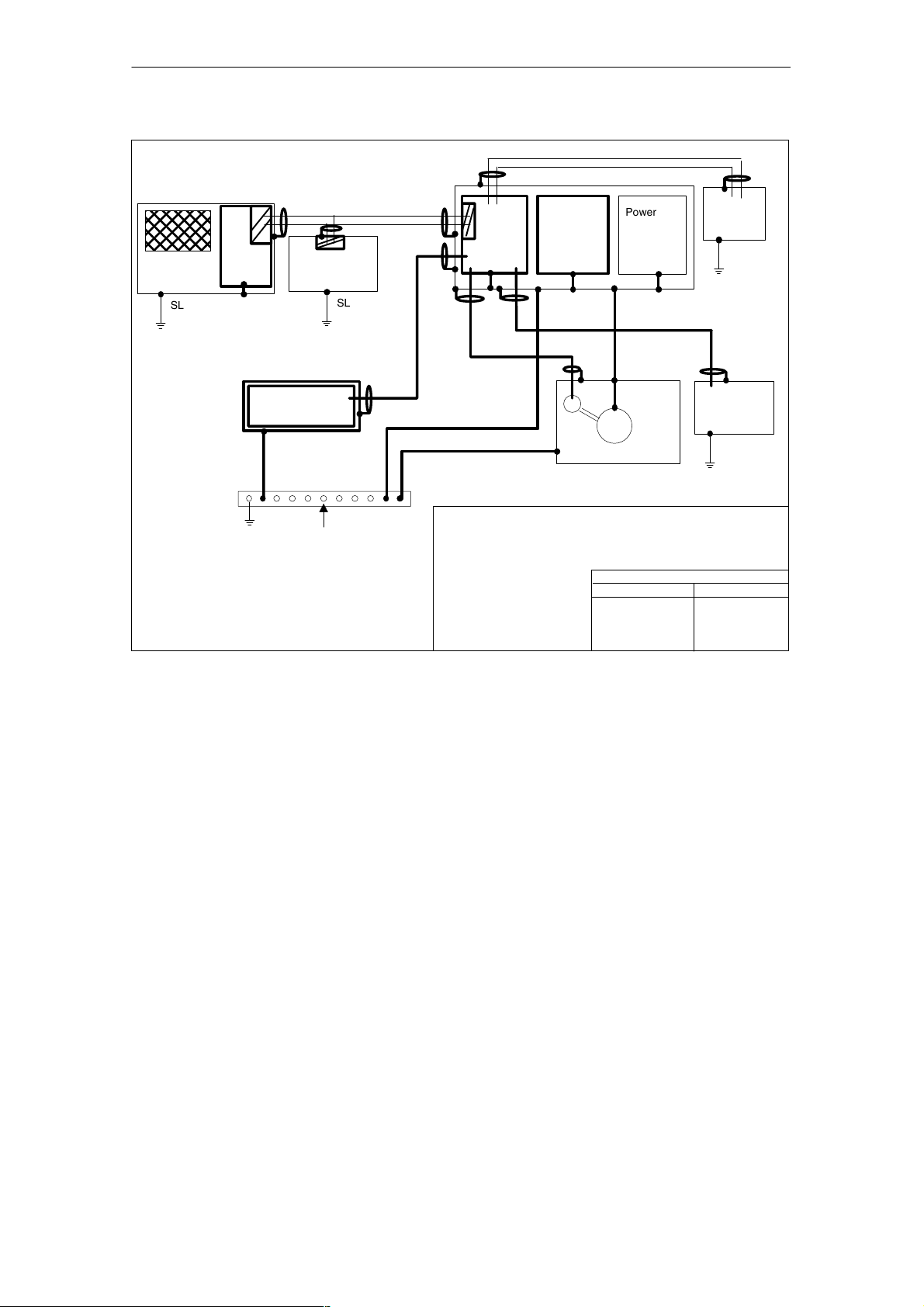

3ph 400 V AC

N

03.06

Housing/shield

1

2

3

840D / 611 digital

G

4

10

Basic insulation Safety isolation

Fig. 2-1 Safe isolation to EN 61800–5–1

Fig. 2-1 shows the various electrical potentials of the 840D/611D/S7-300 system. Legend:

1. Floating power supply of the SIMODRIVE electronics unit with

230 V AC basic insulation.

2. Floating transistor triggers for the three-phase rectifier bridge with 230 V AC

basic insulation.

3. Floating transistor triggers for each axis of the three-phase inverter bridge

with 230 V AC basic insulation.

4. Floating signal connection from the NCU to the PCU or HHU with 230 V AC

basic insulation.

5. Non-floating signal connection between NCU and I/O devices.

6. Non-floating end user interface with protective separation for 230 VAC

through interfaces 1 to 4 and 7.

7. Protectively separated 5 V DC power supply, fed from a protectively separated 24 V DC supply.

8. 24 V DC power supply unit for external devices and for the machine adaptation control according to applicable standards in the form of a PELV (Protective Extra Low Voltage) circuit featuring safe isolation.

9. Floating interfaces to the machine (not accessible to the end user).

10. Floating signal interfaces directly accessible to the end user (e.g., V.24). For

these interfaces, you must always make sure that there is either safe isolation with respect to the line supply voltage or that there are two basic insulation levels, for 230 V AC each.

11. 5 V DC power supply with basic insulation, fed from a safely-isolated

24 V DC supply.

MSTT/MCP

4

Distribution box

5

5

8

PCU

11

4

HHU/

HT 6

4

6

Person

11

S7-300 I/Os

10

24 V

7

11

Terminal

G

Motor

9

block

2-22

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 23

03.06

2.1.3 Grounding concept

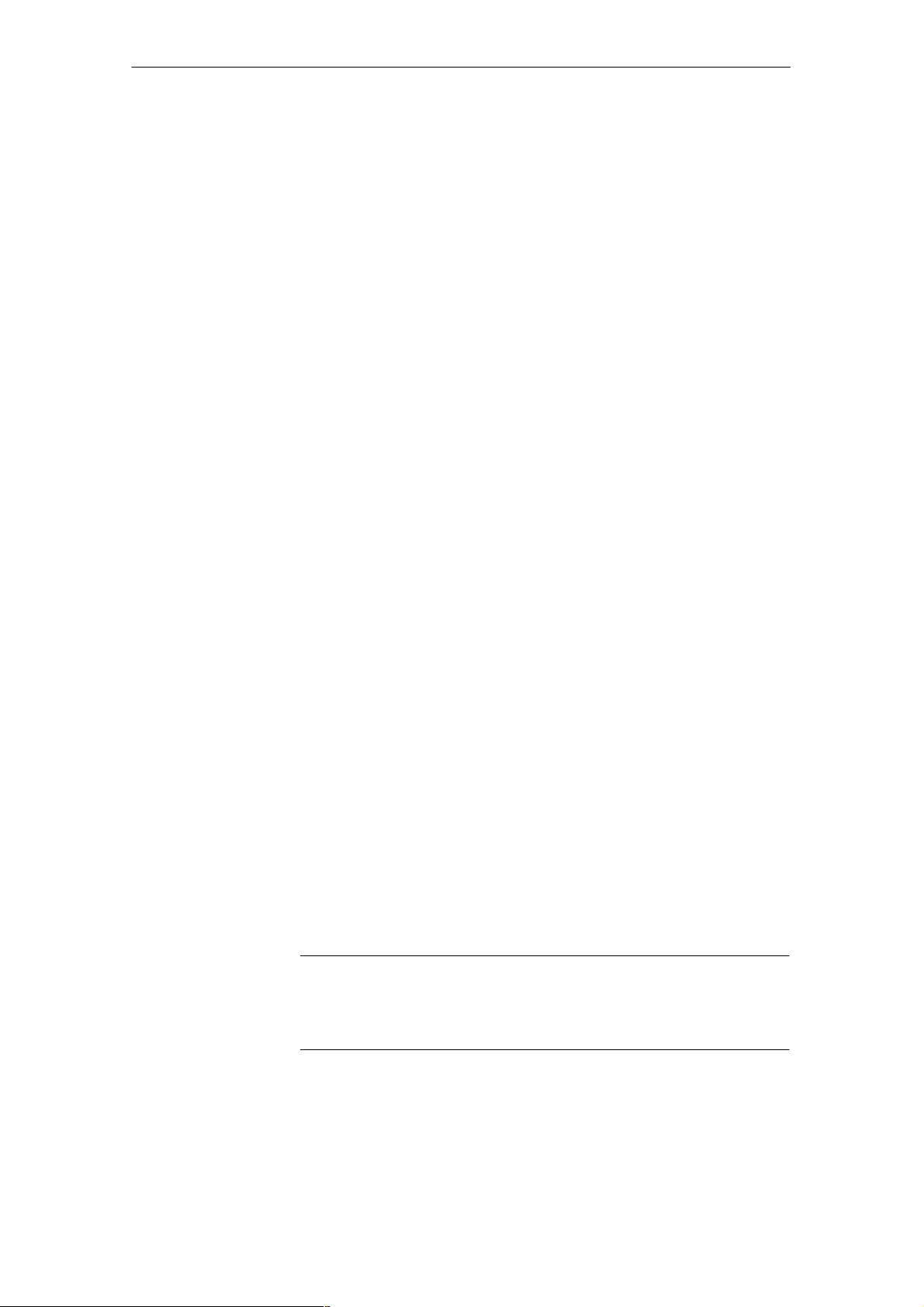

The SINUMERIK 840D system consists of a number of individual components,

each of which must comply with the appropriate EMC and safety standards. The

individual system components are:

NCU box

Machine control panel MCP

Keyboard

Operator panels (operator panel front + PCU/TCU)

NCU terminal block

Distributor box and handheld unit

S7-300 I/O with IM 361 interface module

Single I/O module

The NCU box is a 50 mm wide cassette that is integrated into the infeed/regenerative feedback (I/RF) unit, FSD and MSD.

The individual modules are attached to a metal cabinet panel by means of

screws. Make sure that near the screws a low-impedance contact of the NCU

box with the cabinet wall can be made. Insulating paints at the contact point

must be removed. The electronic grounding points of the modules are interconnected via the device and drive bus and at the same time conducted to the

X131 terminal of the I/RF module.

The ground and module ground M should be connected at the power supply

terminal of the IM 361. Further, for the EFP, “SHIELD” and “M24” must be connected in connector X1.

2 Connection Conditions

2.1 Secondary electrical conditions

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

2-23

Page 24

2 Connection Conditions

2.1 Secondary electrical conditions

03.06

Operator panel

front

SL

Grounding bar

PCU/

TCU

– Ground (frame) –

S7-300 peripherals

IM 361

/single I/O module

PA

Central ground connection

conductor/protective

conductor

Machine

control panel

SL

Gating

NCU

MB

MB

PA

PA

MB: Shielded signal cable with reference ground

M: Motor

G: Encoders

PA: Equipotential bonding conductor

SL: Protective conductor

electronics

SL in the motor cable

MB

G

G

Machine bed

Line supply conn. S

S v 16

16 v S v 35

S w 35

Power

electronics

Cross-sections (mm2)

w10

Distribu–

tion box

SL

Terminal

block

SL

SL minimum

S

16

S/2

Fig. 2-2 Grounding concept

References: /EMC/ EMC Configuring Guidelines

2.1.4 RI suppression measures

In addition to the protective grounding of system components, special precautions must be taken to ensure safe, fault-free operation of the system. These

measures include shielded signal cables, special equipotential bonding, isolation, and shielding measures.

Shielded

signal cables

To ensure safe, interference-free operation of the installation, it is essential to

use the cables specified in the individual diagrams.

For digital signal transmission, the shield must have a conductive connection at

both sides of the housing.

Exception:

Standard shielded cables grounded on only one side can be used for devices

from other manufacturers (printers, programming devices, etc.).

2-24

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 25

03.06

2 Connection Conditions

2.1 Secondary electrical conditions

These external devices may not be connected to the control during normal operation. However, if the system cannot be operated without them, then the cable

shields must be connected at both ends. Furthermore, the external device must

be connected to the control via an equipotential bonding cable.

Cable definitions

Rules for routing

cables

Definition:

Signal cables (example)

– Data cables (MPI, sensor cables, etc.)

– Binary inputs and outputs

– EMERGENCY OFF lines

Load cables (example)

– Low-voltage supply cables (230 V AC, +24 V DC etc.)

– Supply cables to contactors (primary and secondary circuit)

In order to achieve the best possible noise immunity of the complete system

(control, power module, machine), the following EMC measures must be carefully observed:

Signal cables and load cables must be routed at the greatest possible dis-

tance from one another.

If necessary, signal and load cables may cross one another (if possible, at

an angle of 90°), but must never be laid close or parallel to one another.

Only cables provided by the manufacturer should be used as signal cables

from and to the NCU.

Signal cables may not be routed close to strong external magnetic fields

(e.g. motors and transformers).

Pulse-carrying HC/HV cables must always be laid completely separately

from all other cables.

If signal lines cannot be routed a sufficient distance away from other cables,

they must be installed in grounded cable ducts (metal).

The clearance (interference injection area) between the following lines must

be kept to a minimum:

– Signal line and electrical circuit signal line (twisted)

– Signal line and associated equipotential bonding conductor

– Equipotential bonding conductor and PE conductor (routed together)

Important

!

For further notes on interference suppression measures and the connection of

shielded cables, please refer to

References: /EMC/ EMC Configuring Guidelines

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

2-25

Page 26

2 Connection Conditions

2.2 Climatic and mechanical environmental conditions

2.2 Climatic and mechanical environmental conditions

03.06

Test standards

Vibration load: EN 60068–2–6

Shock load: EN 60068–2–27

Climate: EN 60068–2–1/EN 60068–2–2/EN 60068–2–14

EN 60068–2–30/EN 60068–2–31/EN 60068–2–32/

EN 60068–2–33/EN 60068–2–34

Requirement

standards

Long-term storage: EN 60721–3–1

Transport: EN 60721–3–2

Stationary operation: EN 60721–3–3

2.2.1 Transport and storage conditions

Components in

original packaging

The following specifications apply to components in transport packaging:

Table 2-2 Ambient climatic conditions per EN 60721–3–1/–3–2,

Temperature range –40 ... 70 °C –25 ... 55 °C

Temperature change < 18 K < 18 K Within one hour

Relative humidity 10 to 95% 10 to 95%

Permissible change

in relative humidity

class 1K3/2K4

Transport Bearings

max 0.1 % max 0.1 % Within 1 minute

Table 2-3 Test limits for mechanical environmental conditions

Vibration

to EN 60068–2–6

Shock resistance

to EN 60068–2–27

g 9.81 m/s

2 (acceleration due to gravity)

Frequency range 5 to 9 Hz

Constant deflection 7.5 mm

Acceleration amplitude 9 to 200 Hz: 2g

Acceleration 30g

Duration of nominal shock 6 ms

Number of nominal shocks 18 shocks

Shock form Half-sine

2-26

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 27

03.06

2 Connection Conditions

2.2 Climatic and mechanical environmental conditions

Shipment of

backup batteries

!

Backup batteries must only be transported in the original packaging. No special

authorization is required to ship backup batteries. The lithium content is approximately 300 mg.

Note

The backup battery is classified as a hazardous substance, Class 9, in

accordance with the relevant air-freight transportation regulations.

Danger

Incorrect handling of backup batteries can lead to a risk of ignition, explosion

and combustion. The stipulations of EN 60086-4, in particular regarding

avoidance of mechanical or electrical tampering of any kind, must be complied

with.

For more information on handling batteries, see Chapter 8.1.

2.2.2 Operating conditions

Climatic

environmental

conditions

If the specified values cannot be maintained, then a heat exchanger or air conditioner must be provided.

Table 2-4 Climatic environmental conditions to EN 60721–3–3, Class 3K3

Temperature range

Temperature change max. 0.5 K Within 1 minute

Relative humidity 5 to 90 %

Permissible change in the

relative air humidity

Moisture condensation

and ice formation

Dripping water, spray,

splash water, water jets

Supply air Without caustic gases, dusts and oils

Air pressure 1060 to 920 kPa 0 to 1000 meters above mean sea

Derating At altitudes of 1000 to 4000 m above SL, the upper limit

0 to 55 °C

max. 0.1% Within 1 minute

Not permitted

Not permitted

level

temperature is to be lowered by 3.5 °C/500 m.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

2-27

Page 28

2 Connection Conditions

2.2 Climatic and mechanical environmental conditions

Mechanical

environmental

conditions

Table 2-5 Test limits for mechanical environmental conditions

03.06

Gases that can

adversely affect

the function

Dust that can

adversely

affect the function

Vibration

to EN 60068–2–6

Shock resistance

to EN 60068–2–27

g 9.81 m/s

2 (acceleration due to gravity)

Frequency range 10 to 58 Hz

Constant deflection 0.075 mm

Acceleration amplitude 58 to 200 Hz: 1g

Acceleration 5g

Duration of nominal shock 30 ms

Number of nominal shocks 18 shocks

Shock form Half-sine

Degree of severity 3C2 as per EN 60721–3–3

When working in areas where gases, dust and oils may be hazardous to functionality, the controller must be operated in a control cabinet with a heat exchanger or with suitable supply air.

Maximum permissible dust contents in the air circulating in the cabinet:

– Suspended solids 0.2 mg/m

3

– Deposits 1.5 mg/m2/h

Note

The dust precipitate must be removed at appropriate time intervals.

Radio interference

Relevant standards: EN 61000–6–3 and –4

Table 2-6 Limit values for radio interference in industrial environments

Limit class as per EN 61000–6–4

Conducted radio interference A (industry)

Interference radiation A (industry)

Note

The user must consider interference radiation for the complete system.

Particular attention should be paid to cabling. Please contact your sales

representative for assistance and support.

If compliance with limit class B (residential areas) is required, please contact

your local Siemens office or sales representative.

2-28

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 29

03.06

2.3 MPI/OPI network rules

2 Connection Conditions

2.3 MPI/OPI network rules

Use

Network

installations

The following devices can be interconnected across the MPI bus:

NCU

PCU

HT 6

HHU

MSTT/MCP

The MPI interconnecting cables are available in different lengths.

When installing a network, observe the following basic rules:

1. The MPI connection can be routed from one user to the next by plugging the

MPI connector of the outgoing cable onto the MPI connector of the incoming

cable.

2. The bus line must be terminated at both ends. To do this, enable the terminating resistor in the MPI connector of the first and last node and disable the

remaining terminating resistors (see Fig. 2-3).

Note

Only two inserted terminating resistors are permitted.

In the case of the HHU/HT 6, bus terminating resistors are permanently

integrated in the device.

3. At least 1 terminal must be supplied with 5 V.

This is done by connecting an MPI connector with the terminating resistor

connected to an energized device.

Note

The NCU must be located at the end of the connection.

4. Drop cables (feeder cable from bus segment to node) should be as short as

possible.

Note

Unused spurs must be removed.

5. Every MPI node must first be connected and then activated.

When disconnecting an MPI node, first deactivate the connection and then

remove the connector.

6. A maximum of two of the HHU and HT 6 components can be connected for

each bus segment.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

2-29

Page 30

2 Connection Conditions

2.3 MPI/OPI network rules

7. The following cable lengths for MPI or OPI for standard use without repeater

03.06

Another possibility is two identical components, provided they have different

node addresses.

For setting the addresses (also see corresponding component section):

– HHU: Via DIP switch or display (see “Handheld unit” section),

– For HT 6, by adapting the address before commissioning (refer to Oper-

ating Components “Handheld Terminal HT 6”).

No bus terminating resistors may be inserted at the distributor boxes of an

HHU or HT 6 (refer to the note on item 2.)

If required, more than one HHU/HT 6 can be connected to a bus segment

using intermediate repeaters.

may not be exceeded:

MPI (187.5 kbaud): Max. total cable length is 1000 m

OPI (1.5 Mbaud): Max. total cable length is 200 m.

46

OFF ON

O

N

46

O

N

55

Terminating resistor

Fig. 2-3 MPI connector

Reference: Catalog IK PI – Industrial Communication for Automation

and Drives

2-30

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 31

Structure and Installation

3.1 Structure of the SINUMERIK 840D

3

SINUMERIK 840D

The SINUMERIK 840D consists of two components:

1. NCU box (sheet metal housing with a combined battery/fan slide-in module)

for housing the NCU module.

2. NCU module (Numeric Control Unit)

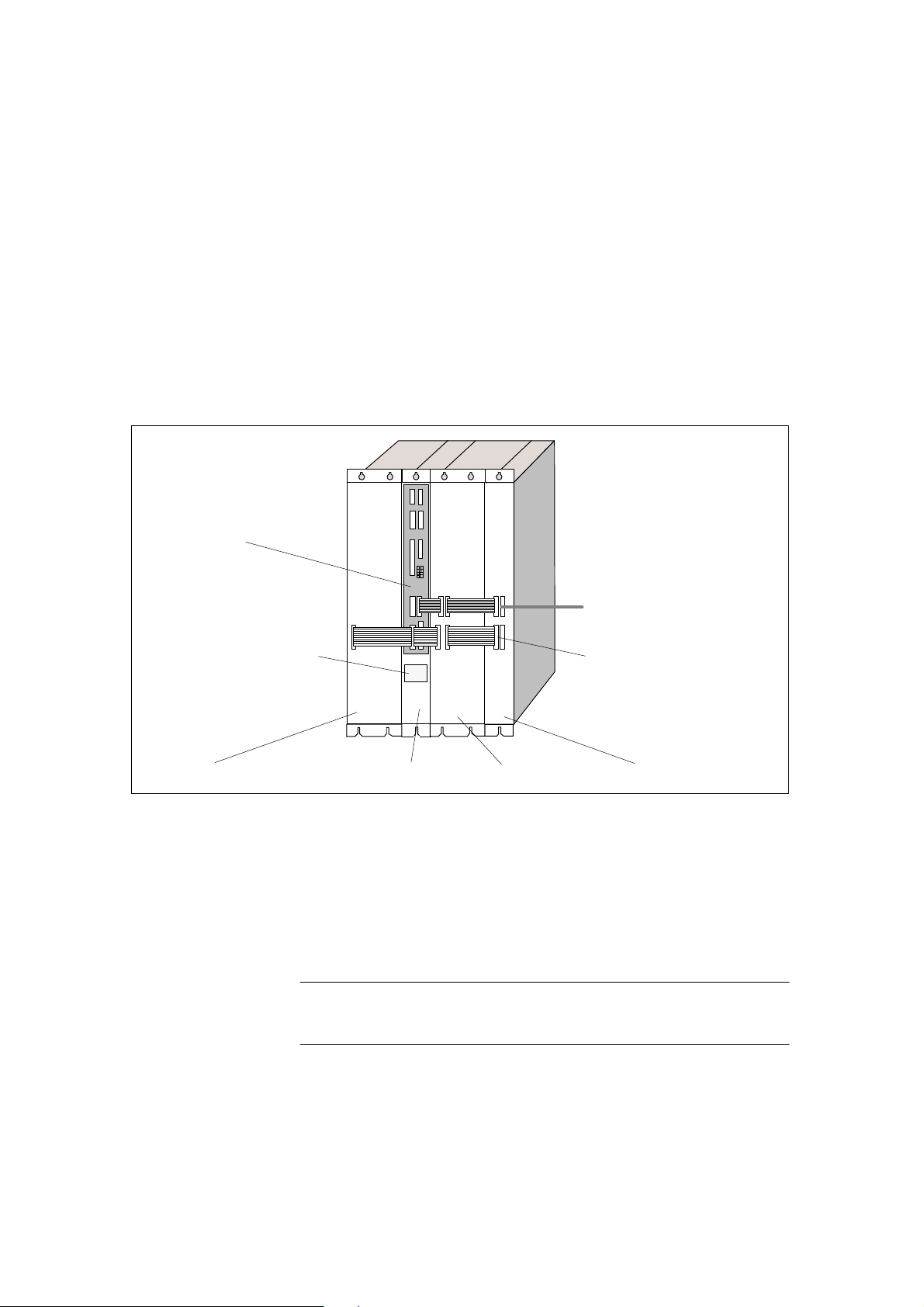

NCU box

NCU module

Fig. 3-1 Components of the SINUMERIK 840D

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

3-31

Page 32

3 Structure and Installation

3.2 Installation of the SINUMERIK 840D

3.2 Installation of the SINUMERIK 840D

03.06

Preparing for

installation

Assembly of the

NCU box

You need the following tool to assembly the SINUMERIK 840D:

Screwdriver for slot-head screws sizes 0 and 1

Screwdriver for Torx screws M4 and M5

Note

The NCU is exclusively intended for installation in ESD-protected zones. The

ESD interference immunity limits relevant to CE compliance can only be

achieved by installation in a cabinet. Make contact only while taking suitable

ESD protective measures (see ESD information in the preface).

The NCU box is installed between the SIMODRIVE power supply and the first

SIMODRIVE drive module. To secure the NCU box, two M5 screws are recommended.

3-32

SIEMENS

SIMODRIVE

Power supply

(I/R or OI)

Fig. 3-2 Position of the NCU in the overall configuration

Danger

!

A hazardous voltage will be present for a further 5 minutes after the system has

been shut down.

NCU MSD

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

FD

Page 33

03.06

Mounting the DC

link busbar

3 Structure and Installation

3.2 Installation of the SINUMERIK 840D

1. Remove the plastic cover over the DC link busbars by loosening it with a flat

screwdriver in the gap on the top and then folding it forward and down.

2. Remove the DC link busbars at the module to the right of the NCU box.

3. Now mount the DC link busbars from the accessory kit of the NCU box between the power module and the first drive module. Use the screws located

on the modules (observe tightening torque, M4: 1.8 Nm, M5: 3 Nm).

4. Place the cover into the matching cut-outs with the plastic lugs facing downward and close the DC link by folding the cover backward until the topside

latch clicks.

Inserting the NCU

The NCU module is secured when it clicks into the NCU box.

In order to guarantee the vibration resistance, both slotted screws (1) must be

tightened (see Fig. 3-3).

The battery/fan module is delivered completely assembled with the NCU box.

NCU box

NCU module

1

Memory card

Fig. 3-3 Installation of the NCU module in the NCU box

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

1

Battery/fan

slide-in module

End-to-end

DC link

busbars

PE conductor connection

3-33

Page 34

3 Structure and Installation

3.2 Installation of the SINUMERIK 840D

03.06

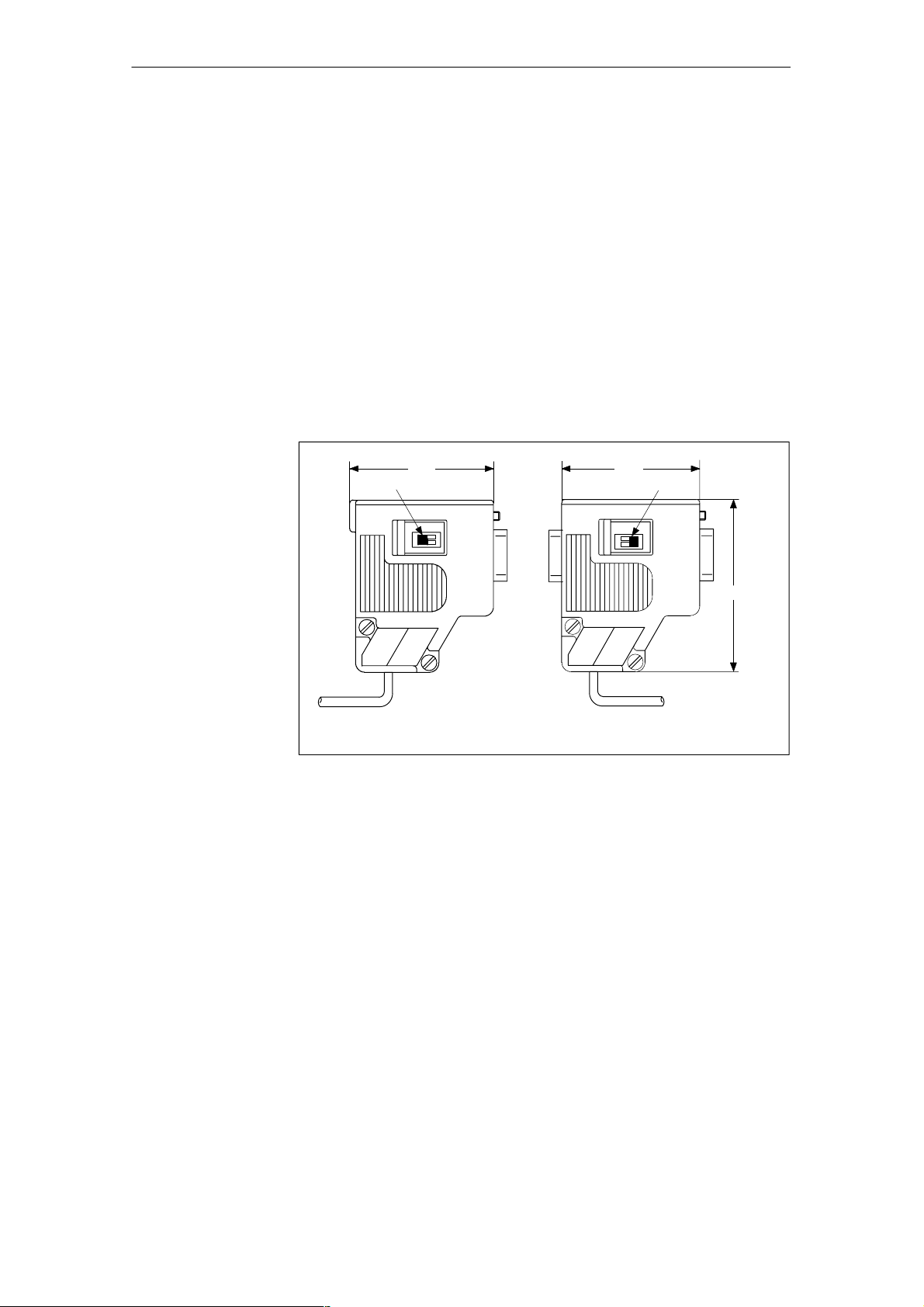

Maintaining

distances

130

Certain distances must be maintained with regard to cable routing and open

ventilation when mounting the NCU box.

49.6

Space for exhaust air

100443

24.8

466

480

127

A

23

Space for supply air

208

20

100

24.8

A

Fig. 3-4 NCU cassette for Sinumerik 840D, dimensional drawing and installation instructions

8

3-34

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 35

03.06

3 Structure and Installation

3.2 Installation of the SINUMERIK 840D

80

60

100

80

Cooling clearance

Variant 1 Variant 2

288

60

100

Cooling clearance

20

Cooling clearance

Fig. 3-5 Cable routing and ventilation space when mounting modules

Mounting the

link module

For installation, it is recommended that the front plate at the link module be removed and then reattached after the installation.

60

20

100

60

100

200

Cooling clearance

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

3-35

Page 36

3 Structure and Installation

3.2 Installation of the SINUMERIK 840D

Notes

03.06

3-36

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 37

Description of the NCU

4.1 Components

4

Configuration

The components of the SINUMERIK 840D are compatible with the module series SIMODRIVE 611D. The 840D is operated with the power supply of

SIMODRIVE 611 and the SIMODRIVE 611D drive modules.

NCU module

The NCU module (Numeric Control Unit) is the CPU of the SINUMERIK 840D. It

takes over all the CNC, PLC and communication tasks. It is available in various

performance variants:

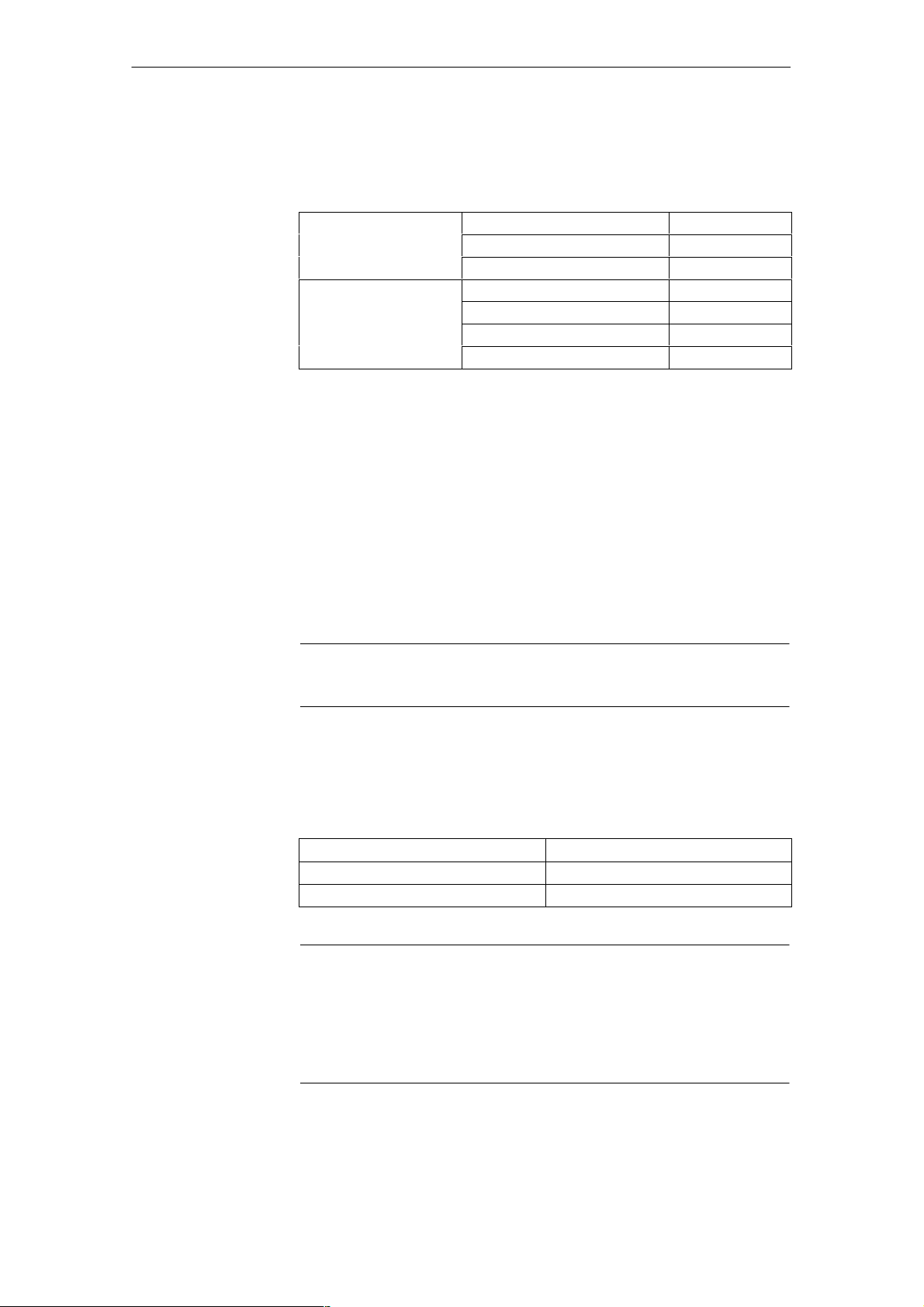

Table 4-1 Components from the NCU 5xx.3 series:

NCU

561.3 6FC5356-0BB11-

561.3 6FC5356-0BB13-

571.3 6FC5357-0BB11-

571.3 6FC5357-0BB13-

572.3 6FC5357-0BB22-

572.3 6FC5357-0BB23-

573.3 6FC5357-0BB33-

573.3 6FC5357-0BB33-

573.3 6FC5357-0BB33-

Order no. (MLFB) Processor CNC user

0AE1

0AA1

0AE1

0AA1

0AE0

0AA0/1

0AE2

0AE3

0AA0/1

Intel 486 DX4

100 MHz

Celeron

400 MHz

Intel 486 DX4

100 MHz

Celeron

400 MHz

AMD K6-2

233 MHz

Celeron

400 MHz

Pentium III

500 MHz

Celeron

650 MHz

Celeron

650 MHz

memory

min. / max.

0.25/1.5 MB PLC 315-2DP 96 / 288 KB Type 1 No

0.5/2.5 MB *) PLC 315-2DP 96 / 288 KB Type 3 No

0.25/1.5 MB PLC 315-2DP 96 / 288 KB Type 1 No

0.5/2.5 MB *) PLC 315-2DP 96 / 288 KB Type 3 No

0.25/1.5 MB PLC 315-2DP 96 / 288 KB Type 2 No

0.5/2.5 MB *) PLC 315-2DP 96 / 288 KB Type 3 No

2.5/2.5 MB *) PLC 315-2DP 96 / 288 KB Type 3 Yes

2.5/2.5 MB *) PLC 315-2DP 96 / 288 KB Type 3 No

2.5/2.5 MB *) PLC 315-2DP 96 / 288 KB Type 3 No

PLC PLC

memory

min. / max.

Front

plate

Fan

box

*) With technological cycles and measuring cycles, max. 1.5 MB available for users. With ShopMill/ShopTurn 1.2 MB

available to users in the basic configuration and no other CNC user memory options are possible.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-37

Page 38

4 Description of the NCU

4.1 Components

Table 4-2 Components from the NCU 5xx.4 series:

03.06

NCU

561.4 6FC5356-0BB12-

561.4 6FC5356-0BB14-

571.4 6FC5357-0BB12-

571.4 6FC5357-0BB14-

572.4 6FC5357-0BB23-

572.4 6FC5357-0BB24-

573.4 6FC5357-0BB34-

573.4 6FC5357-0BB34-

573.4 6FC5357-0BB34-

*) With technological cycles and measuring cycles, max. 1.5 MB available for users. With ShopMill/ShopTurn 1.2 MB

available to users in the basic configuration and no other CNC user memory options are possible.

Order no. (MLFB) Processor CNC user

0AE0

0AA0

0AE0

0AA0

0AE0

0AA0

0AE0

0AE1

0AA0

AMD K6-2

233 MHz

Celeron

400 MHz

AMD K6-2

233 MHz

Celeron

400 MHz

AMD K6-2

233 MHz

Celeron

400 MHz

Pentium III

500 MHz

Celeron

650 MHz

Celeron

650 MHz

memory

min. / max.

0.5/2.5 MB *) PLC 314C-2DP 96 / 480 KB Type 2 No

0.5/3 MB *) PLC 314C-2DP 96 / 480 KB Type 3 No

0.5/2.5 MB *) PLC 314C-2DP 96 / 480 KB Type 2 No

0.5/3 MB *) PLC 314C-2DP 96 / 480 KB Type 3 No

0.5/2.5 MB *) PLC 314C-2DP 96 / 480 KB Type 2 No

0.5/3 MB *) PLC 314C-2DP 96 / 480 KB Type 3 No

2.5/2.5 MB *) PLC 314C-2DP 96 / 480 KB Type 3 Ye s

2.5/2.5 MB *) PLC 314C-2DP 96 / 480 KB Type 3 No

2.5/3 MB *) PLC 314C-2DP 96 / 480 KB Type 3 No

PLC PLC

memory

min. / max.

Front

plate

Fan

box

Table 4-3 Components from the NCU 5xx.5 series:

NCU

561.5 6FC5356-0BB15-

571.5 6FC5357-0BB15-

572.5 6FC5357-0BB25-

573.5 6FC5357-0BB35-

573.5 6FC5357-0BB35-

**) Available to the user in the basic configuration:

Order no. (MLFB) Processor CNC user

0AA0

0AA0

0AA0

0AE0

0AA0

– with technological cycles and measuring cycles max. 1.5 MB

– with ShopMill/ShopTurn 1.2 MB

Celeron

400 MHz

Celeron

400 MHz

Celeron

650 MHz

Pentium III

933 MHz

Pentium III

933 MHz

memory

min. / max.

3 **) / 6 MB PLC 317-2DP 128 / 768 KB Type 3 No

3 **) / 6 MB PLC 317-2DP 128 / 768 KB Type 3 No

3 **) / 6 MB PLC 317-2DP 128 / 768 KB Type 3 No

3 **) / 6 MB PLC 317-2DP 128 / 768 KB Type 3 No

3 **) / 6 MB PLC 317-2DP 128 / 768 KB Type 3 No

Features of the NCU modules:

Standard PCMCIA card

4 High-speed NC inputs and 4 rapid NC outputs

2 Measuring pulse inputs

PLC PLC

memory

min. / max.

Front

panel

Fan

box

4-38

2 Handwheel inputs

Voltage and temperature monitoring

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 39

03.06

p

4 Descri

4.1 Components

tion of the NCU

NCU box

Fan box

PLC module

COM module

187.5 kBd/1.5 MBd

The NCU box is the module rack of the NCU module and consists of:

NC rack assembly with cable distributor

Battery/fan slide-in module

Sheet metal housing with integrated guide bars for accommodating the

NCU and the fan/battery slide-in modules and power supply unit

Order number: 6FC5247-0AA00-0AA3

The fan box is absolutely required for the 573.3 (Pentium III) and 573.4 (Pentium III) NCUs. Mount the fan box to the NCU box if necessary.

Order number: 6FC5247-0AA30-0AA0

As a submodule of the NCU, the PLC module supports machine monitoring and

represents a PLC-CPU that is compatible to the S7-300 family of products. Via

the P bus, three external lines can be connected for every eight S7-300 peripheral modules.

Reference: Installation manual for setting up the S7-300: CPU

The COM module is a submodule of the NCU. It is used for communication with

the PCU and peripherals.

Driver module

187.5 kBd/1.5 MBd

PCMCIA card

The driver module is a submodule of the NCU (...-...-0AEx). It forms the interface to the operator panel front, to the programming device, to the decentralized

peripherals and to S7-300 peripherals.

The NCU contains a plug-in unit for standard PCMCIA cards (PC card or NC

card), via which all flash cards of type II up to 8 MB storage capacity can be

operated.

The PCMCIA card serves as a bulk memory for the NC system software (NC

card).

In addition to the software upgrade, the PCMCIA card can also be used for series start-up; see

References: /IAD/ Commissioning Manual 840D

Caution

Plugging the PCMCIA card in and out while energized will cause data to be

lost!

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-39

Page 40

4 Descri

p

tion of the NCU

4.1 Components

03.06

Link module

(option for

NCU 573.3/4/5)

The link module is a submodule of the NCU 573.3/4/5. If it is plugged in, you

can reach the interface via the front plate of the NCU (above X122).

The module allows synchronization and an additional data exchange between

several NCU 573.3/4/5 in a group.

Order No.: 6FC5212-0AA01-1AA0

96.5

+0.4

2.4

–1.4

16.8

163.3

Link cable

37.4

Fig. 4-1 Link submodule

Standard Profibus cable

4-40

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 41

03.06

4.2 Mounting

4.2.1 NCU box without a fan box

4 Description of the NCU

4.2 Mounting

NCU mounting board

316

Driver

module

COM

module

PLC

module

480

443

MEMORY CARD

Cable distributor

Battery/fan

slide-in module

Power supply

unit

198

208

265

Sheet metal housing

Fig. 4-2 Example: complete NCU box without a fan box with NCU 561.3

50

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-41

Page 42

4 Descri

p

tion of the NCU

4.2 Mounting

4.2.2 NCU box with a fan box

316

Link submodule

03.06

Cut-out for

link module

Cable distributor

Battery/fan

slide-in module

Power

supply unit

Fan box

198

208

136

265

480

510

443

Sheet metal housing

MEMORY CARD

50

Fig. 4-3 Example: complete NCU box with fan box and NCU 573.3 (Pentium III)

An alarm is issued if a fan fails.Monitoring the

fans

4-42

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 43

03.06

p

Mounting

the fan box

4 Descri

1. Slide the back of the fan box into the locking mechanism on the NCU box.

Fan box

tion of the NCU

4.2 Mounting

Replacement

2. Push the front section into the guide until the spring locks.

Guide

For replacing the fan box

1. Apply pressure to the locking spring on the front section of the fan box and

2. Slide the fan box downward.

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-43

Page 44

4 Description of the NCU

4.2 Mounting

03.06

Fan box

Warning

!

Only trained personnel may replace a fan box. The regulations for handling

electrostatic sensitive devices must be observed.

Completely switch off the system. Check that it is safely isolated from the

supply and safeguard against unauthorized switch-on.

4-44

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 45

03.06

p

4.3 NCU module interfaces

4 Descri

4.3 NCU module interfaces

tion of the NCU

Brief description

of the interfaces

The NCU module has the following interfaces:

Operating panel front interface X101 (MPI 1.5 MBaud, floating)

PROFIBUS DP X102 interface

SIMATIC S7 I/O bus X111 (P/C bus)

Link interface (option for NCU 573.3/4/5)

Connection for handwheel, sensor, NC-I/O X121 (cable distributor)

Interface for programming device X122 (MPI 187.5 KBaud, non-isolated)

SIMODRIVE 611D interface X130A (611D module and NCU terminal block)

Device bus connection X172

PCMCIA slot X173

Displays for faults, status, start-up

Operating elements for start-up, general reset, reset

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-45

Page 46

4 Descri

p

tion of the NCU

4.3 NCU module interfaces

03.06

Interfaces,

Operator Controls

and Displays

For component assignments, see Section 4.1

–X101

–X102

Operator panel front interface

PROFIBUS DP interface

Reserved for service

–X112

–X122

+5V

PR

NF

PS

CF

PF

CB

CP

RESET

PFO

−

NMI

–X121 –X111

S3

S4

SIMATIC interface

PG-MPI interface

I/O interface

(cable distributor)

Various error and status LEDs

(H1/H2)

7-segment display (H3)

NMI button (S2)

RESET button (S1)

NCK start-up switch

PLC start-up switch

X130B

–X172

Fig. 4-4 Front plate type 1

X130A

MEMORY CARD

SIMODRIVE 611D interface

Reserved

Device bus interface

PCMCIA slot (X173)

4-46

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 47

03.06

4 Description of the NCU

4.3 NCU module interfaces

–X101

–X121 –X111

–X122

+5V

NF

CF

CB

CP

RESET

–X102

–X103

PR

PS

PF

PFO

T

Operator panel front interface

PROFIBUS DP Interface

Reserved

SIMATIC interface

PG-MPI interface

I/O interface

(cable distributor)

Various error and status LEDs

(H1/H2)

7-segment display (H3)

–X172

Fig. 4-5 Front plate type 2

S3

S4

X130A

MEMORY CARD

RESET button (S1)

NCK start-up switch

PLC start-up switch

SIMODRIVE 611D interface

Device bus interface

PCMCIA slot (X173)

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-47

Page 48

4 Description of the NCU

4.3 NCU module interfaces

03.06

–X101

–X121 –X111

POK

NF

CF

CB

CP

–X102

–X122

PR

PS

PF

PFO

DP

RESET

NMI

S3

S4

Operator panel front interface

PROFIBUS DP Interface

Slot for link module

(blank plate)

SIMATIC interface

PG-MPI interface

I/O interface

(cable distributor)

Various error and status LEDs

(H1/H2)

RESET button (S1)

7-segment display (H3)

NMI button (S2)

NCK start-up switch

PLC start-up switch

X130B

–X172

Fig. 4-6 Front plate type 3

X130A

MEMORY CARD

SIMODRIVE 611D interface

Reserved

Device bus interface

PCMCIA slot (X173)

4-48

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 49

03.06

p

4 Descri

tion of the NCU

4.3 NCU module interfaces

X101

Operator panel front interface (MPI)

Connector name: X101

Connector type: 9-pole sub D socket connector

Maximum cable length: 200 m

Special features: Isolation (safe isolation)

Table 4-4 Pin assignments on connector X101

X101

Pin Name Type Pin Name Type

1 Not assigned 6 2P5 VO

2 Not assigned 7 Not assigned

3 RS_OPI B 8 XRS_OPI B

4 RTSAS_BTSS O 9 RTSPG_BTSS I

5 2M VO

Signal names

XRS_BTSS, RS_BTSS differential RS485 data – BTSS

RTSAS_BTSS Request to Send AS – BTSS

RTSPG_BTSS Request to Send PG – BTSS

2M Signal Ground, isolated

2P5 + 5 V, isolated

P24ext, M24ext 24 V supply voltage

Signal type

B Bidirectional

O Output

VO Voltage Output

I Input

X102

PROFIBUS DP interface

Connector name: X102

Connector type: 9-pole sub D socket connector

Maximum cable length: 200 m

Special features: Isolation (safe isolation)

1.5 MBaud

Table 4-5 X102 pin assignments

X102

Pin Name Type Pin Name Type

1 Not assigned 6 VP VO

2 M24ext *) VO 7 P24ext *) VO

3 RS_PROFIBUSDP B 8 XRS_PROFIBUSDP B

4 RTSAS_PROFIBUSDP O 9 RTSPG_PROFIBUSDP I

5 DGND VO

*) 24 V only present if 24 V is fed to X121 (cable distributor).

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-49

Page 50

4 Description of the NCU

4.3 NCU module interfaces

Signal names

XRS_PROFIBUSDP,

RS_PROFIBUSDP Differential RS485 data – PROFIBUSDP

RTSAS_PROFIBUSDP Request to Send AS – PROFIBUSDP

RTSPG_PROFIBUSDP Request to Send PG – PROFIBUSDP

DGND Signal Ground, isolated

VP + 5 V, isolated

P24ext, M24ext 24 V supply voltage

Signal type

B Bidirectional

O Output

VO Voltage Output

I Input

03.06

X111

X112

(only NCUs with front

plate type 1)

SIMATIC interface

Connector name: X111

Connector type: 25-pole sub D socket connector

Maximum cable length: 10 m

Special features: Non-isolated (basic isolation)

Serial interface RS232 (reserved for service)

Connector name: X112

Connector type: 9-pole sub D male connector

Maximum cable length: 10 m

Special features: Non-isolated (no safe isolation)

Table 4-6 X112 pin assignments

X112

Pin Name Type Pin Name Type

1 Not assigned 6 Not assigned

2 RxD I 7 RTS O

3 TxD O 8 CTS I

4 Not assigned 9 Not assigned

5 G VO

4-50

Signal names

RxD Receive Data

TxD Transmit Data

RTS Request to Send

CTS Clear to Send

M Ground

Signal type

O Output

I Input

VO Voltage Output

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 51

03.06

p

4 Descri

tion of the NCU

4.3 NCU module interfaces

Only NCU 573.3/4/5

with link module

Link module interface

Connector name: None

Connector type: 9-pole sub D socket connector

Maximum cable length: 100 m

Table 4-7 Pin assignment of plug X112 at the link module

X112

Pin Name Type Pin Name Type

1 Not assigned 6 VP VO

2 Not assigned 7 Not assigned

3 RS_LINK B 8 XRS_LINK B

4 Not assigned 9 Not assigned

5 DGND VO

Signal names

XRS_LINK, RS_LINK Differential RS485 data – LINK

XRS_CLKCY; RS_CLKCY Differential RS485 data – CLKCY

DGND Signal Ground, isolated

VP +5 V, isolated

Signal type

B Bidirectional

O Output

VO Voltage Output

I Input

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-51

Page 52

4 Descri

p

tion of the NCU

4.3 NCU module interfaces

03.06

X121

I/O interface (cable distributor)

Connector name: X121

Connector type: 37-pole sub D male connector

Maximum cable length: 25 m for all functions

Special features: Isolation for binary inputs/

outputs, handwheels non-isolated

Table 4-8 X121 pin assignments

X121

Pin Name Type Pin Name Type

1 M24EXT VI 20 P24EXT VI

2 M24EXT VI 21 P24EXT VI

3 OUTPUT 1 O 22 OUTPUT 3 O

4 OUTPUT 0 O 23 OUTPUT 2 O

5 INPUT 3 I 24 MEXT VI

6 INPUT 2 I 25 MEXT VI

7 INPUT 1 I 26 MEXT VI

8 INPUT 0 I 27 MEXT VI

9 MEPUS 0 I 28 MEPUS 1 I

10 MEPUC 0 I 29 MEPUC 1 I

11 MPG1 XA I 30 MPG1 A I

12 MPG1 5 V VO 31 MPG1 0 V VO

13 MPG1 5 V VO 32 MPG1 0 V VO

14 MPG1 XB I 33 MPG1 B I

15 MPG0 XA I 34 MPG0 A I

16 MPG0 5 V VO 35 MPG0 0 V VO

17 MPG0 5 V VO 36 MPG0 0 V VO

18 MPG0 XB I 37 MPG0 B I

19 Not assigned

Signal names

MPG 0/1 5V supply voltage handwheel 0/1. 5 V, max. 500 mA

1)

MPG 0/1 0V supply voltage handwheel 0/1.0 V

MPG 0/1 A/XA differential handwheel input 0/1, A/XA

MPG 0/1 B/XB differential handwheel input 0/1, B/XB

MEPUS 0/1 measuring pulse signal 0/1

2)

MEPUC 0/1 measuring pulse common (reference ground) 0/1

INPUT [0...3] binary NC input 0...3

2)

MEXT external ground (reference ground for binary NC inputs)

OUTPUT [0...3] binary NC output 0...3

3)

M24EXT external 24 V infeed (–) for binary NC outputs

P24EXT external 24 V infeed (+) for binary NC outputs

1)

Max. 500 mA per handwheel, i.e. a total of max. 1 A

2)

High level: rated value 24 V, limits 15 ...30 V / 2 mA...15 mA

Low level: rated vale 0 V or open, limits –3...5 V

3)

The binary outputs are short-circuit proof.

Max. switching current per output: 500 mA (coincidence factor 100%).

For an inductive load, an external protective circuit is required for unloading

the inductivity

4-52

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 53

03.06

p

Signal type

O Output

VO Voltage Output

I Input

VI Voltage Input

4 Descri

tion of the NCU

4.3 NCU module interfaces

X122

PG-MPI interface

Connector name: X122

Connector type: 9-pole sub D socket connector

Maximum cable length: 200 m

Special features: Non-isolated (no safe isolation)

Table 4-9 X122 pin assignments

X122

Pin Name Type Pin Name Type

1 Not assigned 6 P5 VO

2 M24EXT *) VO 7 P24EXT *) VO

3 RS_KP B 8 XRS_KP B

4 RTSAS_KP O 9 RTSPG_KP I

5 G VO

*) 24 V only present if 24 V is fed to X121 (cable distributor).

Signal names

RS_KP, XRS_KP Differential RS485 data – C bus from PLC

RTSAS_KP Request to Send AS – C bus from PLC

RTSPG_KP Request to Send PG – C bus from PLC

M Ground

P5 5 V

Signal type

B Bidirectional

O Output

VO Voltage Output

I Input

X130A

SIMODRIVE 611D interface

Connector name: X130A

Connector type: 2x36-pole Micro Ribbon

Maximum cable length: 10 m

Special features: Non-isolated (no safe isolation)

© Siemens AG, 2006. All rights reserved

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

4-53

Page 54

4 Descri

p

tion of the NCU

4.3 NCU module interfaces

03.06

X172

Device bus interface

Connector name: X172

Connector type: 2x17-pole ribbon cable connector, male

Table 4-10 X172 pin assignments

X172

Pin Name Type Pin Name Type

1 HF1 VI 18 P27 VI

2 HF2 VI 19 M27 VI

3 HF1 VI 20 G VI

4 HF2 VI 21 Not assigned

5 Not assigned 22 G VI

6 Not assigned 23 Not assigned

7 Not assigned 24 G VI

8 Not assigned 25 Not assigned

9 P15 VI 26 G VI

10 Not assigned 27 Not assigned

11 P15 VI 28 Not assigned

12 Not assigned 29 Not assigned

13 N15 VI 30 Not assigned

14 Not assigned 31 SIM_RDY OC

15 N15 VI 32 Not assigned

16 I2T_TMP OC 33 Not assigned

17 Not assigned 34 Not assigned

X173

Signal names

HF 1, 2 Voltage supply " 57 V, 20 kHz

P15 + 15 V

M Ground

P27 + 27 V fan supply

M27 Reference ground to P27

N15 – 15 V

I2T_TMP I

2

t advance warning (NC-specific: fan/temperature alarm)

SIM_RDY Drive and NC operationally ready

Signal type

OC Open Collector

VI Voltage Input

PCMCIA slot

Connector name: X173

Connector type: 68-pole PCMCIA card connector, male

4-54

SINUMERIK 840D Configuring Manual NCU (PHD) – 03.06 Edition

© Siemens AG, 2006. All rights reserved

Page 55

03.06

p

Operator controls

and displays

Table 4-11 Operator controls and displays

4 Descri

tion of the NCU

4.3 NCU module interfaces

Designation

RESET (S1) Button Triggering a hardware reset to reset the control and drive followed by a

NMI (S2) Button Triggering an NMI request at the processor

S3 Rotary switch NCK-startup switch

S4 Rotary switch PLC-mode switch

H1 (left row) LED Illuminates if ...

H2 (right row) LED Illuminates, ...

Type Meaning Fea-

complete restart.

Position 0: normal mode

Position 1: startup position

Positions 2 to 7: reserved

Position 0: PLC–RUN

Position 1: PLC–RUN–P

Position 2: PLC–STOP

Position 3: MRES

+5V/POK: ... supply voltage is in tolerance range.

NF: ... NCK-Watchdog has activated and during the

startup phase.

CF: ... COM-Watchdog has activated.

CB: ... data transfer takes place via BTSS.

CP: ... data transfer takes place via PG MPI interface.

For NCUs with the MLFB ...-...-0AA0, the following applies:

NCU-internal voltage monitoring has switched off the power supply

(retentive) of the module if ...

POK : Off

NF : On

CF/CB/CP : undefined

H2 : undefined

Therefore, ensure that the recovery time after shutdown (re-activation via

power ON) is at least 10 s, because otherwise the voltage monitoring can

be activated.

PR: ... if PLC-status = RUN

PS: ... if PLC-status = STOP

PF: ... + PR + PS + PFO: if PLC Watchdog has activated.

PFO: ... if PLC status = FORCE

1)

T/DP

: PLC-DP-status:

– LED is off:

DP is not configured or

DP is configured, all slaves are found.

– LED is flashing:

DP is configured, at least one slave is missing.

– LED illuminates:

error (e.g. bus short-circuit, no token circulation)