Page 1

Programming Guide 11/2002 Edition

Fundamentals

SINUMERIK 840D/840Di/810D

Page 2

Page 3

Fundamental

Geometrical Principles

1

SINUMERIK 840D/840Di/810D

Fundamentals

Programming Guide

Fundamental

Principles

of NC Programming

Positional Data

Programming Motion

Commands

Path Action

Frames

Feedrate Control and

Spindle Motion

2

3

4

5

6

7

Valid for

Control Software Version

SINUMERIK 840D 6

SINUMERIK 840DE (export version) 6

SINUMERIK 840D powerline 6

SINUMERIK 840DE powerline 6

SINUMERIK 840Di 2

SINUMERIK 840DiE (export version) 2

SINUMERIK 810D 3

SINUMERIK 810DE (export version) 3

SINUMERIK 810D powerline 6

SINUMERIK 810D powerline 6

Tool Offsets

Miscellaneous

Functions

Arithmetic Parameters

and Program Jumps

Subprograms and

Repetition of Program

Sections

Tables

Appendix

8

9

10

11

12

A

11.02 Edition

Page 4

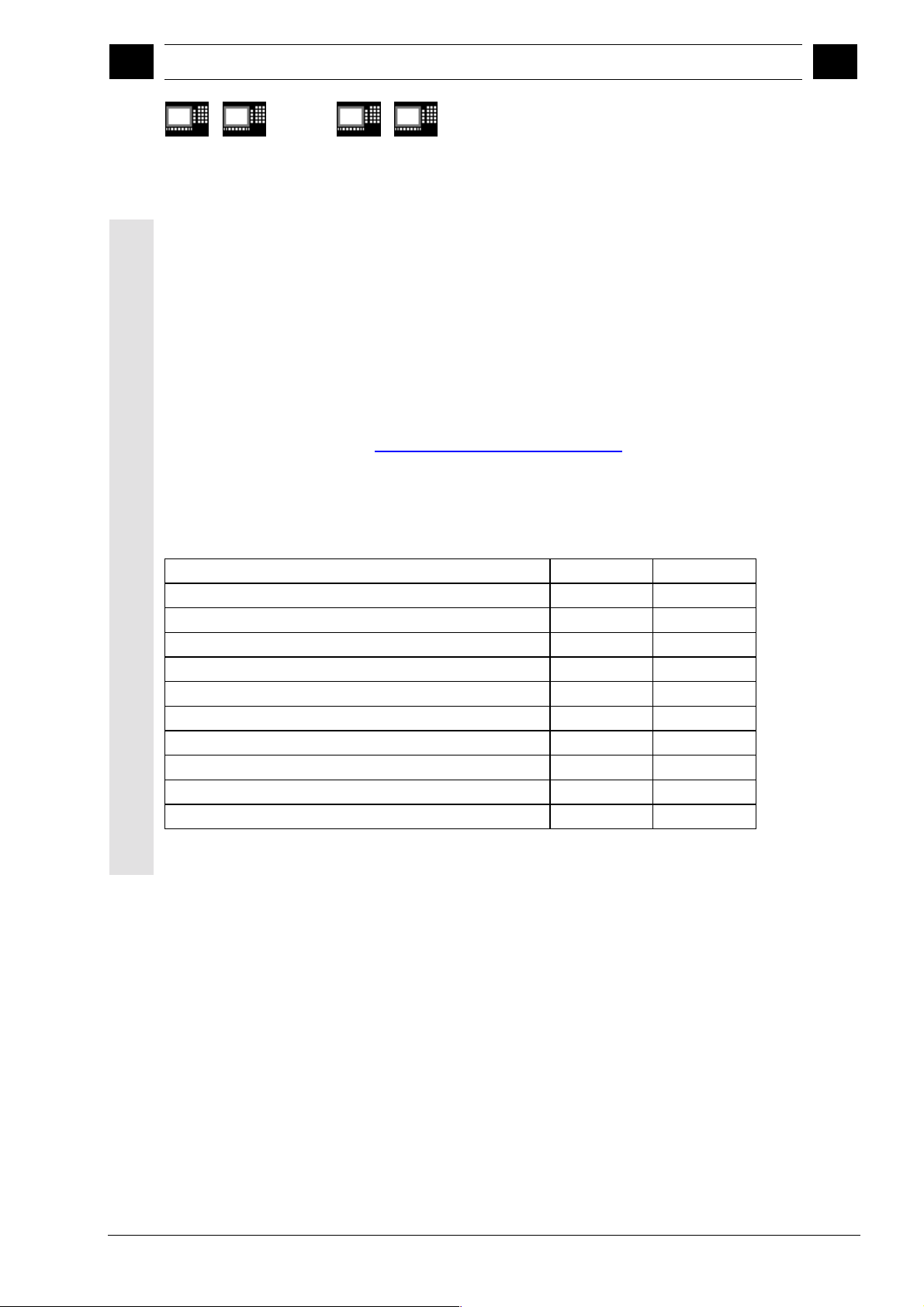

Contents 11.02

0

SINUMERIK® Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the "Remarks" column.

Status code in the "Remarks" column:

A .... New documentation.

B .... Unrevised edition with new order no.

C .... Revised edition with new status.

If factual changes have been made on the page since the last edition, this is indicated by a

new edition coding in the header on that page.

0

Edition Order No. Remarks

02.95 6FC5298-2AB00-0BP0 A

08.97 6FC5298-4AB00-0BP0 A

12.95 6FC5298-3AB00-0BP0 C

03.96 6FC5298-3AB00-0BP1 C

08.97 6FC5298-4AB00-0BP0 C

12.97 6FC5298-4AB00-0BP1 C

12.98 6FC5298-5AB00-0BP0 C

08.99 6FC5298-5AB00-0BP1 C

04.00 6FC5298-5AB00-0BP2 C

10.00 6FC5298-6AB00-0BP0 C

09.01 6FC5298-6AB00-0BP1 C

11.02 6FC5298-6AB00-0BP2 C

This manual is included in the documentation available on CD ROM (DOCONCD)

Edition Order No. Remarks

11.02 6FC5298-6CA00-0BG3 C

Trademarks

SIMATIC

trademarks of Siemens AG. Other names in this publication might be trademarks whose use by a third party for

his own purposes may violate the rights of the registered holder.

â

, SIMATIC HMIâ, SIMATIC NETâ, SIROTECâ, SINUMERIKâ and SIMODRIVEâ are registered

Further information is available on the Internet under:

http: //www.ad.siemens.de/si numer ik

This publication was produced with WinW ord V8.0

and Designer V4.0.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for damages.

All rights, including rights created by patent grant or registration of a utility model

or design, are reserved.

© Siemens AG, 1995–2002. All rights reserved

Order No. 6FC5298-6AB00-0BP2

Printed in Germany

Other functions not described in this documentation might be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

We have checked that the contents of this document correspond to the hardware

and software described. Nonetheless, differences might exist and therefore we

cannot guarantee that they are completely identical. The information given in this

publication is reviewed at regular intervals and any corrections that might be

necessary are made in the subsequent printings. We welcome suggestions for

improvement.

Subject to change without prior notice

Siemens Aktiengesellschaft

Page 5

11.02 Contents

0

Contents

Fundamental Geometrical Principles 1-21

0

1.1 Description of workpiece points ...................................................................................... 1-22

1.1.1 Workpiece coordinate systems ................................................................................. 1-22

1.1.2 Definition of workpiece positions............................................................................... 1-23

1.1.3 Polar coordinates ...................................................................................................... 1-25

1.1.4 Absolute dimension ................................................................................................... 1-26

1.1.5 Incremental dimension .............................................................................................. 1-27

1.1.6 Plane designations .................................................................................................... 1-28

1.2 Position of zero points ..................................................................................................... 1-29

1.3 Position of coordinate systems ....................................................................................... 1-29

1.3.1 Overview of various coordinate systems................................................................... 1-29

1.3.2 Machine coordinate system ...................................................................................... 1-31

1.3.3 Basic coordinate system ........................................................................................... 1-33

1.3.4 Workpiece coordinate system................................................................................... 1-34

1.3.5 Frame system ........................................................................................................... 1-34

1.3.6 Assignment of workpiece coordinate system to machine axes ................................ 1-36

1.3.7 Current workpiece coordinate system....................................................................... 1-36

1.4 Axes ................................................................................................................................1-37

1.4.1 Main axes/Geometry axes ........................................................................................ 1-38

1.4.2 Special axes .............................................................................................................. 1-39

1.4.3 Main spindle, master spindle..................................................................................... 1-39

1.4.4 Machine axes ............................................................................................................ 1-39

1.4.5 Channel axes ............................................................................................................ 1-39

1.4.6 Path axes ..................................................................................................................1-40

1.4.7 Positioning axes ........................................................................................................ 1-40

1.4.8 Synchronized axes .................................................................................................... 1-42

1.4.9 Command axes......................................................................................................... 1-42

1.4.10 PLC axes................................................................................................................... 1-42

1.4.11 Link axes (SW 5 and higher)..................................................................................... 1-43

1.4.12 Leading link axes (SW 6 and higher) ........................................................................ 1-45

1.5 Coordinate systems and workpiece machining............................................................... 1-48

Fundamental Principles of NC Programming 2-51

2.1 Structure and contents of an NC program ...................................................................... 2-52

2.2 Language elements of the programming language ........................................................ 2-53

2.3 Programming a sample workpiece.................................................................................. 2-75

2.4 First programming example for milling application.......................................................... 2-77

2.5 Second programming example for milling application .................................................... 2-78

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-5

Page 6

Contents 11.02

0

2.6 Programming example for turning application................................................................. 2-81

Positional Data 3-83

3.1 General information .........................................................................................................3-84

3.2 Absolute/incremental dimensions, G90/G91 ...................................................................3-85

3.2.1 G91 extension (SW 4.3 and higher) ..........................................................................3-88

3.3 Absolute dimensions for rotary axes, DC, ACP, ACN ..................................................... 3-89

3.4 Metric/imperial dimensions, G70/G71/G700/G710.......................................................... 3-91

3.5 Zero offset (frame), G54 to G599.................................................................................... 3-94

3.6 Selecting the working plane, G17 to G19 ........................................................................3-99

0

3.7 Programmable working area limitation, G25/G26 .........................................................3-102

3.8 Reference point approach, G74 ....................................................................................3-105

Programming Motion Commands 4-107

4.1 General information .......................................................................................................4-108

4.2 Traversing commands with polar coordinates, G110, G111, G112, AP, RP ................ 4-110

4.3 Rapid traverse movement, G0 ...................................................................................... 4-114

4.4 Linear interpolation, G1 .................................................................................................4-119

4.5 Circular interpolation, G2/G3, CIP .................................................................................4-122

4.6 Helical interpolation, G2/G3, TURN............................................................................... 4-135

4.7 Involute interpolation, INVCW, INVCCW ......................................................................4-137

4.8 Contour definitions......................................................................................................... 4-141

4.8.1 Straight line with angle ............................................................................................4-141

4.8.2 Two straight lines..................................................................................................... 4-142

4.8.3 Three straight lines ..................................................................................................4-143

4.8.4 End point programming with an angle..................................................................... 4-144

4.9 Thread cutting with constant lead, G33 .........................................................................4-145

4.9.1 Programmable run-in and run-out path (SW 5 and higher)..................................... 4-151

4.10 Linear progressive/degressive thread pitch change, G34, G35 (SW 5.2 and higher)... 4-153

4.11 Rigid tapping, G331, G332 ............................................................................................4-155

4.12 Tapping with compensating chuck G63 ........................................................................4-157

4.13 Stop during thread cutting .............................................................................................4-159

4.14 Approaching a fixed point, G75 ..................................................................................... 4-161

4.15 Travel to fixed stop ........................................................................................................ 4-163

0-6 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 7

11.02 Contents

0

4.16 Special turning functions ............................................................................................... 4-169

4.16.1 Position of workpiece .............................................................................................. 4-169

4.16.2 Dimensions for: Radius, diameter........................................................................... 4-170

4.17 Chamfer, rounding ........................................................................................................ 4-172

Path Action 5-177

5.1 Exact stop, G60, G9, G601, G602, G603 .................................................................... 5-178

5.2 Continuous-path mode, G64, G641, G642, G643........................................................ 5-181

5.3 Acceleration pattern, BRISK, SOFT, DRIVE ................................................................ 5-190

5.3.1 Acceleration modes................................................................................................. 5-190

5.3.2 Influence of acceleration modes on following axes................................................. 5-191

0

5.4 Overview of the various velocity controls ..................................................................... 5-194

5.5 Path velocity smoothing ............................................................................................... 5-195

5.6 Traversing with feedforward control, FFWON, FFWOF............................................... 5-196

5.7 Programmable contour accuracy, CPRECON, CPRECOF.......................................... 5-197

5.8 Dwell time, G4 .............................................................................................................. 5-198

5.9 Program sequence: Internal preprocessor stop ........................................................... 5-199

Frames 6-201

6.1 General......................................................................................................................... 6-202

6.2 Frame instructions........................................................................................................ 6-203

6.3 Programmable zero offset............................................................................................ 6-205

6.3.1 TRANS, ATRANS ................................................................................................... 6-205

6.3.2 G58, G59: Axial programmable ZO (SW 5 and higher) .......................................... 6-209

6.4 Programmable rotation, ROT, AROT ........................................................................... 6-212

6.5 Programmable frame rotations with solid angles, ROTS, AROTS and CROTS.......... 6-220

6.6 Programmable scale factor, SCALE, ASCALE ............................................................ 6-221

6.7 Programmable mirroring, MIRROR, AMIRROR........................................................... 6-224

6.8 Frame generation according to tool orientation, TOFRAME, TOROT ......................... 6-228

6.9 Deselect frame SUPA, DRFOF, CORROF, TRAFOOF ............................................... 6-230

Feedrate Control and Spindle Motion 7-235

7.1 Feedrate ........................................................................................................................ 7-236

7.2 Traversing positioning axes, POS, POSA, POSP ......................................................... 7-244

7.3 Position-controlled spindle operation, SPCON, SPCOF ............................................... 7-247

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-7

Page 8

Contents 11.02

0

7.4 Positioning spindles (position-controlled axis operation): SPOS, M19 and SPOSA .....7-248

7.5 Milling on turned parts: TRANSMIT............................................................................... 7-254

7.6 Cylinder surface transformation: TRACYL .................................................................... 7-256

7.7 Feedrate for positioning axes/spindles: FA, FPR, FPRAON, FPRAOF ........................7-257

7.8 Percentage feedrate override, OVR, OVRA ..................................................................7-260

7.9 Feedrate with handwheel override, FD, FDA ................................................................7-261

7.10 Percentage acceleration correction: ACC (Option) ....................................................... 7-265

7.11 Feedrate optimization for curved path sections, CFTCP, CFC, CFIN...........................7-266

7.12 Spindle speed S, direction of spindle rotation M3, M4, M5 ........................................... 7-269

0

7.13 Constant cutting rate, G96, G97, LIMS .........................................................................7-272

7.14 Constant grinding wheel peripheral speed, GWPSON, GWPSOF ...............................7-274

7.15 Constant workpiece speed for centerless grinding: CLGON, CLGOF ..........................7-277

7.16 Programmable spindle speed limitation, G25, G26....................................................... 7-279

7.17 Several feedrates in one block: F.., FMA.. ....................................................................7-280

7.18 Blockwise feedrate: FB... (as of SW 5.3) ...................................................................... 7-282

Tool Offsets 8-285

8.1 General information ...................................................................................................... 8-286

8.2 List of tool types............................................................................................................8-289

8.3 Tool selection/tool call T ............................................................................................... 8-293

8.3.1 Tool change with M06 (mill) .................................................................................... 8-293

8.3.2 Tool change with T command (rotate) .................................................................... 8-295

8.4 Tool offset D .................................................................................................................8-297

8.5 Tool selection T with tool management ........................................................................ 8-299

8.5.1 Turning machine with circular magazine .................................................................8-299

8.5.2 Milling machine with chain magazine ......................................................................8-300

8.6 Tool offset call D with tool management ...................................................................... 8-302

8.6.1 Turning machine with circular magazine .................................................................8-302

8.6.2 Milling machine with chain magazine ......................................................................8-303

8.7 Make active tool offset operative immediately.............................................................. 8-304

8.8 Tool radius compensation, G40, G41, G42 .................................................................. 8-305

8.9 Approach and retract from contour, NORM, KONT, G450, G451................................ 8-313

8.10 Compensation at outside corners, G450, G451 ...........................................................8-316

0-8 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 9

11.02 Contents

0

8.11 Smooth approach and retraction .................................................................................. 8-319

8.11.1 Extension approach and retract: G461/G462 (SW 5 and higher) ........................... 8-327

8.12 Collision monitoring, CDON, CDOF ............................................................................. 8-331

8.13 2 1/2 D tool offset, CUT2D, CUT2DF ........................................................................... 8-333

8.14 Tool length offset for orientable tools: TCARR, TCOABS, TCOFR ............................. 8-335

8.15 Grinding-specific tool monitoring in parts program TMON, TMOF............................... 8-338

8.16 Additive offsets (SW 5 and higher)............................................................................... 8-340

8.16.1 Select offset (by DL number) .................................................................................. 8-340

8.16.2 Define wear and setup values ................................................................................. 8-341

8.16.3 Delete additive offsets (DELDL) .............................................................................. 8-343

0

8.17 Tool offset – special features (SW 5 and higher)......................................................... 8-344

8.17.1 Mirroring of tool lengths........................................................................................... 8-345

8.17.2 Wear sign evaluation............................................................................................... 8-345

8.17.3 Tool length and plane change ................................................................................. 8-346

8.18 Tools with a relevant tool point direction (SW 5 and higher) ........................................ 8-349

Miscellaneous Functions 9-351

9.1 Auxiliary function outputs ............................................................................................. 9-352

9.1.1 M functions .............................................................................................................. 9-357

9.1.2 H functions .............................................................................................................. 9-360

Arithmetic Parameters and Program Jumps 10-361

10.1 Arithmetic parameters R ............................................................................................ 10-362

10.2 Unconditional program jumps .................................................................................... 10-365

10.3 Conditional program jumps ........................................................................................ 10-367

Subprograms and Repetition of Program Sections 11-369

11.1 Use of subprograms ................................................................................................... 11-370

11.2 Subroutine call............................................................................................................ 11-373

11.3 Subprogram with program repetition .......................................................................... 11-375

11.4 Program section repetition (SW 4.3 and higher) ........................................................ 11-376

Tables 12-385

12.1 List of statements ....................................................................................................... 12-386

12.2 List of addresses ........................................................................................................ 12-403

12.2.1 Address letters ...................................................................................................... 12-403

12.2.2 Fixed addresses.................................................................................................... 12-404

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-9

Page 10

Contents 11.02

0

12.2.3 Fixed addresses with axis extension .....................................................................12-405

12.2.4 Settable addresses................................................................................................12-407

12.3 List of G functions/preparatory functions.................................................................... 12-411

12.4 List of predefined subprograms.................................................................................. 12-423

12.4.1 Predefined subprogram calls................................................................................. 12-424

12.4.2 Predefined subprogram calls in motion-synchronous actions ...............................12-434

12.4.3 Predefined functions.............................................................................................. 12-435

12.4.4 Data types .............................................................................................................12-438

Appendix A-439

A Abbreviations ....................................................................................................................A-440

0

B Terms ................................................................................................................................A-448

C References........................................................................................................................A-474

D Index .................................................................................................................................A-489

E Commands, identifiers ......................................................................................................A-496

0-10 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 11

11.02 Preface

0

Structure of the manual

0

Preface

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Organization of documentation

SINUMERIK documentation is organized on three

different levels:

• General Documentation

• User documentation

• Manufacturer/Service Documentation

Target group

This Manual is intended for machine-tool users. It

provides detailed information that the user requires to

program the SINUMERIK 840D/840Di/810D control

system.

Standard scope

This Programming Guide describes the functionality

afforded by standard functions. Differences and

additions implemented by the machine-tool

manufacturer are documented by the machine-tool

manufacturer.

More detailed information about other publications

relating to SINUMERIK 840D/840Di and publications

that apply to all SINUMERIK controls (e.g. Universal

Interface, Measuring Cycles...) can be obtained from

your local Siemens branch office.

Other functions not described in this documentation

might be executable in the control. This does not,

however, represent an obligation to supply such

functions with a new control or when servicing.

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-11

Page 12

Preface 11.02

0

Structure of the manual

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

0

Applicability

This Programming Guide applies to the following

controls:

SINUMERIK 840D 6

SINUMERIK 840DE (export version) 6

SINUMERIK 840D powerline 6

SINUMERIK 840DE powerline 6

SINUMERIK 840Di 2

SINUMERIK 840DiE (export version) 2

SINUMERIK 810D 3

SINUMERIK 810DE (export version) 3

SINUMERIK 810D powerline 6

SINUMERIK 810D powerline 6

with operator panels OP 010, OP 010C, OP 010S,

OP 12 or OP 15 (PCU 20 or PCU 50)

SINUMERIK 840D powerline

From 09.2001 onwards, improved performance

versions of

• SINUMERIK 840D powerline and

• SINUMERIK 840DE powerline

will be available. For a list of available powerline

modules, please refer to Section 1.1 /PHD/ of the

hardware description /PHD/.

0-12 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

SINUMERIK 810D powerline

From 12.2001 onwards, improved performance

versions of

• SINUMERIK 810D powerline and

• SINUMERIK 810DE powerline

will be available. For a list of available powerline

modules, please refer to Section 1.1 of the hardware

description /PHC/.

Siemens AG, 2002. All rights reserved

Page 13

11.02 Preface

0

Structure of the manual

0

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Hotline

If you have any queries, please contact the following hotline:

A&D Technical Support Phone: ++49-(0)180-5050-222

Please send any queries about the documentation (suggestions or

corrections) to the following fax number or email address:

Fax form: see feedback sheet and the end of the publication.

http://www.ad.siemens.de/sinumerik

Internet address

Export version

The following functions are not available in the export

version:

Function 810DE 840DE

Five axis machining package

Handling transformation package (five axes)

Multi-axis interpolation (> four axes)

Helical interpolation 2D+6

Synchronized actions, stage 2

Measurements, stage 2

Adaptive control

Continuous dressing

Utilization of compile cycles (OEM)

Sag compensation, multi-dimensional

Fax: ++49-(0)180-5050-223

Email: adsupport@siemens.com

Fax: ++49-(0)0131-98-2176

Email: motioncontrol.docu@erlf.siemens.de

− −

− −

− −

− −

1)

−

−

−

−

O

1)

O

1)

O

1)

O

− −

1)

−

O

− Function not available

1)

Restricted functionality

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-13

Page 14

Preface 11.02

0

Structure of the manual

0

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Fundamentals

This Programming Guide Fundamentals is intended for

use by skilled machine operators with the appropriate

expertise in drilling, milling and turning operations.

Simple programming examples are used to explain the

commands and statements which are also defined

according to DIN 66025.

Advanced

The Programming Guide "Advanced" is intended for

use by technicians with in-depth, comprehensive

programming knowledge. By virtue of a special

programming language, the SINUMERIK 840D/810D

control enables the user to program complex workpiece

programs (e.g. for sculptured surfaces, channel

coordination, ...) and greatly facilitates the programming

of complicated operations.

The commands and statements described in this Guide

are not specific to one particular technology.

They can be applied for a variety of technologies, such

as

• Grinding

• Cyclical machines (packaging, woodworking)

• Laser power controls.

0-14 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 15

0

11.02 Preface

Structure of the manual

840D

NCU 571

Structure of descriptions

840D

NCU 572

NCU 573

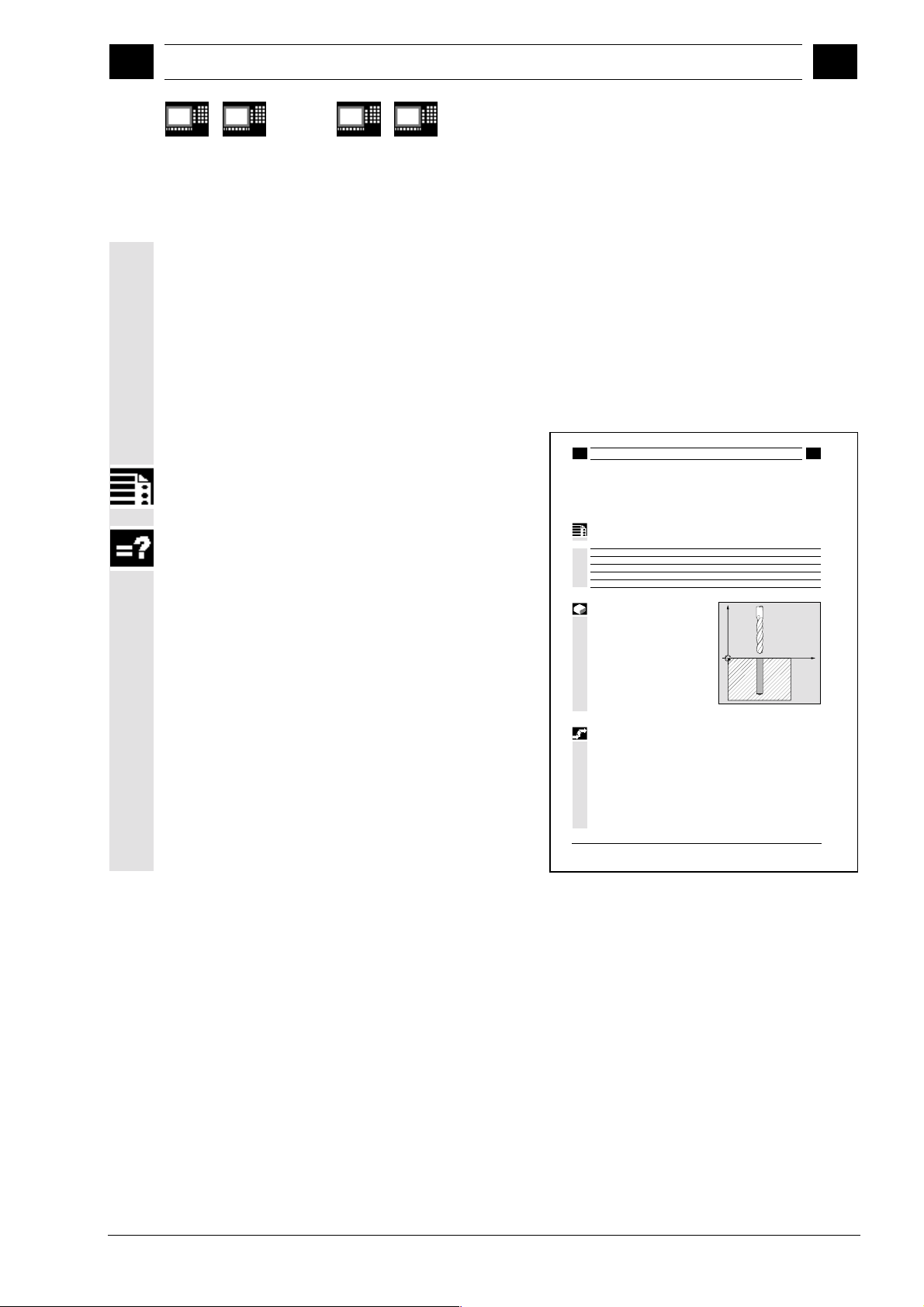

All cycles and programming options have been

described according to the same internal structure as

far as this is meaningful and practicable. The various

levels of information have been organized such that you

can selectively access the information you need for the

task in hand.

1. A quick overview

If you look up a rarely used command or the

meaning of a parameter, you can see at a glance

how the function is programmed and find helpful

explanations of the commands and parameters.

This information is always displayed at the top of the

page.

Note:

Due to lack of space, it has not been possible to

show all the modes of representation afforded by the

programming language for individual commands and

parameters. For this reason, we have illustrated

those command programming schemes that are

used most frequently in practice in a workshop

situation.

810D

840Di

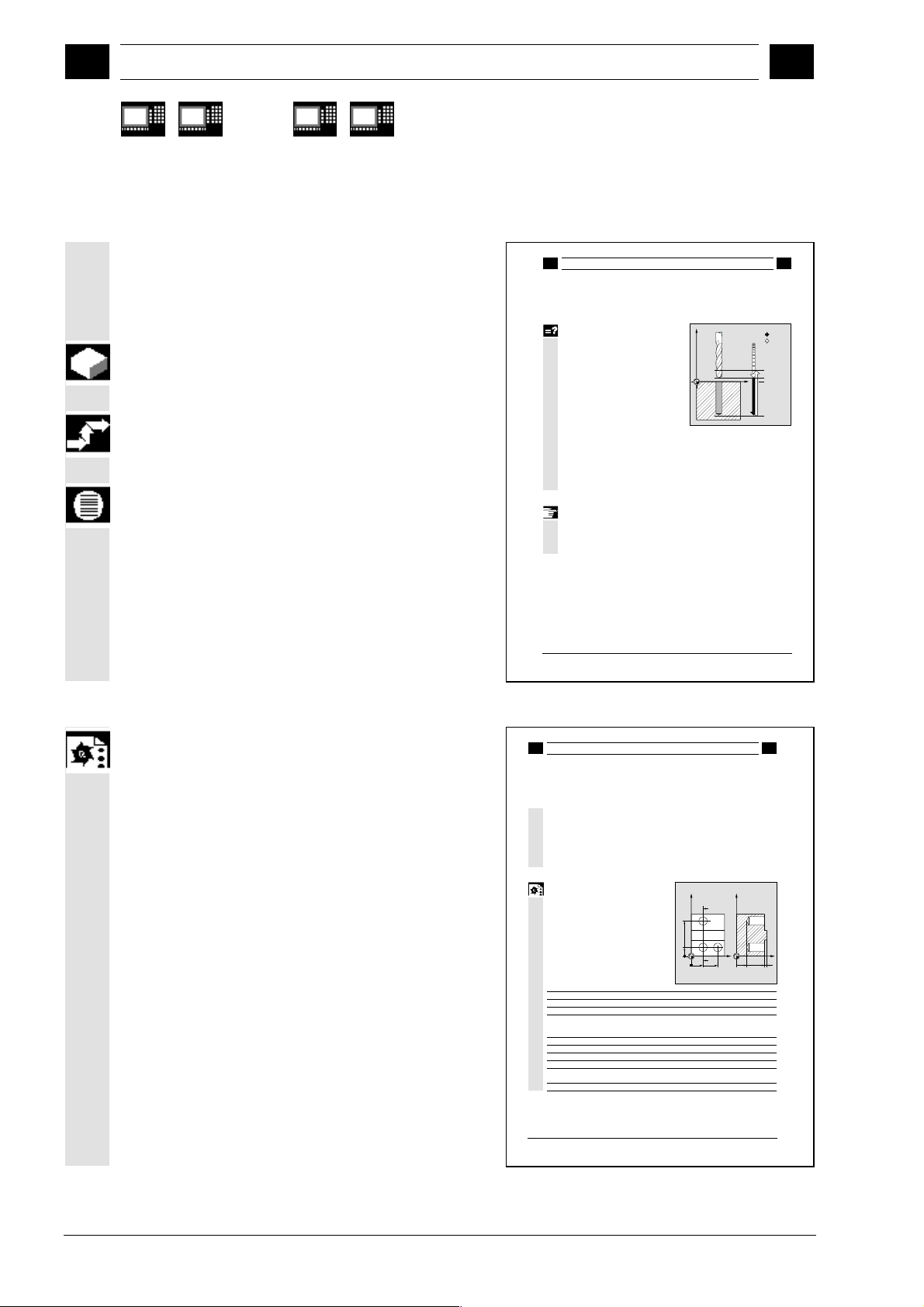

Drilling cycles and drilling patterns 03.96

2

2.1 Drilling cycles

2.1.2 Drilling, centering – CYCLE81

Programming

CYCLE81 (RTP, RFP, SDIS, DP)

RTP

real Retraction plane (absolute)

RFP

real Reference plane (absolute)

SDIS

real Safety clearance (enter without sign)

DP

real Final drilling depth (absolute)

DPR

real Final drilling depth relative to reference plane (enter without sign)

Function

The tool drills at the programmed spindle speed and

feedrate to the programmed final drilling depth.

Operating sequence

Position reached before the beginning of the

cycle:

The drilling position is the position in the two axes of

the selected plane.

The cycle implements the following motion

sequence:

•

Approach of the reference plane brought forward

by the safety clearance with G0

•

Travel to the final drilling depth at the feedrate

programmed in the calling program (G1)

•

Retraction to retraction plane with G0

2-36

Z

SINUMERIK 840D/810D/FM-NC Programming Guide, Cycles (PGZ) - 08.97 Edition.

Siemens AG 1997 All rights reserved.

0

2

X

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-15

Page 16

Preface 11.02

0

Structure of the manual

0

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

2. Detailed explanations

You will find detailed answers to the following

questions in the theory section:

Why is the command needed?

What does the command do?

How is it programmed and executed?

What do the parameters do?

What else do I need to know?

03.96 Drilling cycles and drilling patterns

2

Explanation of parameters

RFP and RTP

Generally, the reference plane (RFP) and the

retraction plane (RTP) have different values. In the

cycle it is assumed that the retraction plane lies in

front of the reference plane. The distance between

the retraction plane and the final drilling depth is

therefore greater than the distance between the

reference plane and the final drilling depth.

SDIS

The safety clearance (SDIS) refers to the reference

plane. which is brought forward by the safety

clearance. The direction in which the safety

clearance is active is automatically determined by

the cycle.

DP and DPR

The drilling depth can be defined either absolute

(DP) or relative (DPR) to the reference plane.

If it is entered as an absolute value, the value is

traversed directly in the cycle.

Additional notes

If a value is entered both for the DP and the DPR,

the final drilling depth is derived from the DPR. If the

DPR deviates from the absolute depth programmed

via the DP, the message "Depth: Corresponds to

value for relative depth" is output in the dialog line.

2.1 Drilling cycles

Z

2

G1

G0

RTP

RFP+SDIS

RFP

X

DP=RFP-DPR

The theoretical sections are primarily intended as

learning material for the NC entry-level user. You

should work through the manual at least once to get

an idea of the functional scope and capability of your

SINUMERIK control.

Siemens AG 1997 All rights reserved.

SINUMERIK 840D/810D/FM-NC Programming Guide, Cycles (PGZ) - 08.97 Edition.

2-37

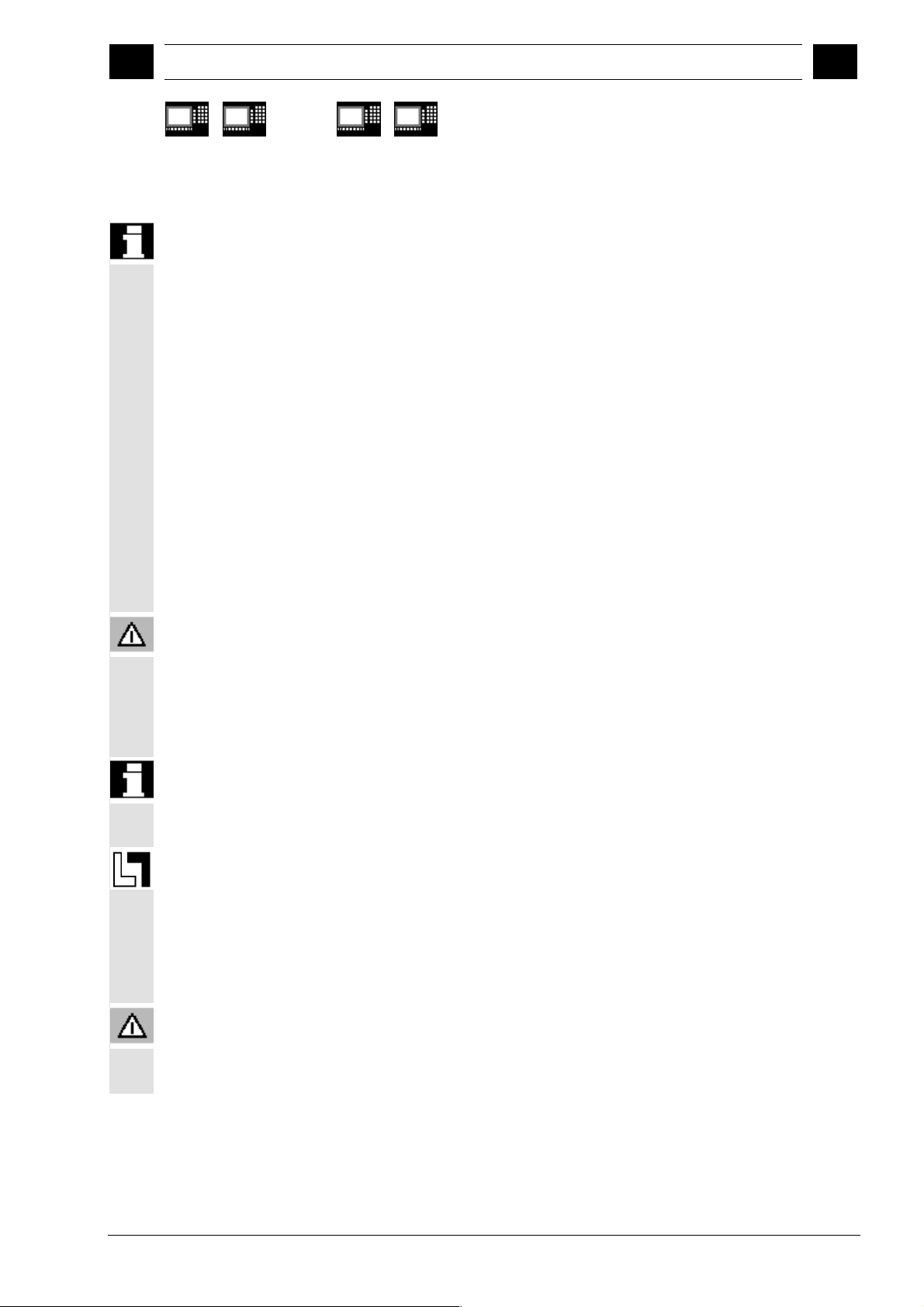

3. From theory to practice

The programming examples illustrate how commands

Drilling cycles and drilling patterns 03.96

2

2.1 Drilling cycles

08.97

2

can be applied in practice.

If the values for the reference plane and the

You will find an application example for virtually

every command after the theoretical section.

retraction plane are identical, a relative depth must

not be programmed. The error message

61101 "Reference plane incorrectly defined" is

output and the cycle is not executed. This error

message is also output if the retraction plane lies

behind the reference plane, i.e. the distance to the

final drilling depth is smaller.

Programming example

Drilling_centering

You can use this program to make 3 holes using the

drilling cycle CYCLE81, whereby this cycle is called

with different parameter settings. The drilling axis is

always the Z axis.

N10 G0 G90 F200 S300 M3

N20 D3 T3 Z110

N30 X40 Y120

N40 CYCLE81 (110, 100, 2, 35)

N50 Y30

N60 CYCLE81 (110, 102, , 35)

N70 G0 G90 F180 S300 M03

N80 X90

N90 CYCLE81 (110, 100, 2, , 65)

N100 M30

Y

Y

120

30

0

Specification of the technology values

Traverse to retraction plane

Traverse to first drilling position

Cycle call with absolute final drilling

depth, safety clearance and incomplete

parameter list

Traverse to next drilling position

Cycle call without safety clearance

Specification of the technology values

Traverse to next position

Cycle call with relative final drilling depth

and safety clearance

End of program

40B90

A - B

A

X

35

100 108

Z

Siemens AG 1997 All rights reserved.

2-38

SINUMERIK 840D/810D/FM-NC Programming Guide, Cycles (PGZ) - 08.97 Edition.

0-16 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 17

0

11.02 Preface

Structure of the manual

840D

NCU 571

Explanation of symbols

Operating sequence

840D

NCU 572

NCU 573

810D

840Di

0

Explanation

Function

Parameters

Programming example

Programming

Additional notes

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-17

Cross-references to other documentation or

sections

Notes and warnings

Machine manufacturer (MH n)

Ordering data option

n= number of the note per section to which

the machine manufacturer can refer.

Page 18

Preface 11.02

0

Structure of the manual

0

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Principle

Your SIEMENS 840D/840Di/810D has been

designed and constructed according to state-of-

the-art technology and approved safety

regulations and standards.

Additional equipment

The applications of SIEMENS controls can be

expanded for specific purposes through the addition of

special add-on devices, equipment and expansions

supplied by SIEMENS.

Personnel

Only appropriately trained, authorized and reliable

personnel may be allowed to operate this equipment.

The control must never be operated, even temporarily,

by anyone who is not appropriately skilled or trained.

The relevant responsibilities of personnel who set up,

operate and maintain the equipment must be clearly

defined; the proper fulfillment of these responsibilities

must be monitored.

Behavior

Before the control is started up, it must be ensured that

the Operator's Guides have been read and understood

by the personnel responsible. The operating company is

also responsible for constantly monitoring the overall

technical state of the control (visible faults and damage,

altered service performance).

Servicing

Repairs must be carried out according to the

information supplied in the service and maintenance

guide by personnel who are specially trained and

qualified in the relevant technical subject. All relevant

safety regulations must be followed.

0-18 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 19

11.02 Preface

0

Structure of the manual

0

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Note

The following is deemed to be improper usage and

exempts the manufacturer from any liability:

Any application which does not comply with the rules

for proper usage described above.

If the control is not in technically perfect condition or

is operated without due regard for safety regulations

and accident prevention instructions given in the

Instruction Manual.

If faults that might affect the safety of the equipment are

not rectified before the control is started up.

Any modification, bypassing or disabling of items of

equipment on the control that are required to ensure

fault-free operation, unlimited use and active and

passive safety.

Improper usage gives rise to unforeseen dangers to:

• Life and limb of personnel,

• The control, machine or other assets of the owner

and the user.

The following special symbols and keywords have been

used in this documentation:

Notes

This symbol appears in this documentation whenever it

is necessary to draw your attention to an important item

of information.

In this documentation, you will find this symbol with a

reference to an ordering option. The function described

is executable only if the control contains the designated

option.

Warnings

The following warnings with varying degrees of severity

appear in this document.

Danger

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury or in

substantial property damage

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 0-19

Page 20

Preface 11.02

0

Structure of the manual

0

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Warning

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury or in

substantial property damage.

Caution

Used with the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in

minor or moderate injury or in property damage.

Caution

Used without safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in

property damage.

Notice

Used without the safety alert symbol indicates a

potential situation which, if not avoided, may result in an

undesirable result or state.

0-20 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 21

11.02 Fundamental Geometrical Principles

1

Fundamental Geometrical Principles

1.1 Description of workpiece points ...................................................................................... 1-22

1.1.1 Workpiece coordinate systems................................................................................ 1-22

1.1.2 Definition of workpiece positions.............................................................................. 1-23

1.1.3 Polar coordinates ..................................................................................................... 1-25

1.1.4 Absolute dimension.................................................................................................. 1-26

1.1.5 Incremental dimension............................................................................................. 1-27

1.1.6 Plane designations................................................................................................... 1-28

1.2 Position of zero points ..................................................................................................... 1-29

1.3 Position of coordinate systems ....................................................................................... 1-29

1.3.1 Overview of various coordinate systems ................................................................. 1-29

1.3.2 Machine coordinate system .....................................................................................1-31

1.3.3 Basic coordinate system .......................................................................................... 1-33

1.3.4 Workpiece coordinate system.................................................................................. 1-34

1.3.5 Frame system .......................................................................................................... 1-34

1.3.6 Assignment of workpiece coordinate system to machine axes ............................... 1-36

1.3.7 Current workpiece coordinate system...................................................................... 1-36

1

1.4 Axes ................................................................................................................................1-37

1.4.1 Main axes/Geometry axes ....................................................................................... 1-38

1.4.2 Special axes............................................................................................................. 1-39

1.4.3 Main spindle, master spindle ................................................................................... 1-39

1.4.4 Machine axes........................................................................................................... 1-39

1.4.5 Channel axes ........................................................................................................... 1-39

1.4.6 Path axes ................................................................................................................. 1-40

1.4.7 Positioning axes....................................................................................................... 1-40

1.4.8 Synchronized axes................................................................................................... 1-42

1.4.9 Command axes........................................................................................................ 1-42

1.4.10 PLC axes ................................................................................................................. 1-42

1.4.11 Link axes (SW 5 and higher) ................................................................................... 1-43

1.4.12 Leading link axes (SW 6 and higher)....................................................................... 1-45

1.5 Coordinate systems and workpiece machining............................................................... 1-48

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-21

Page 22

Fundamental Geometrical Principles 11.02

1

1.1 Description of workpiece points

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

1.1 Description of workpiece points

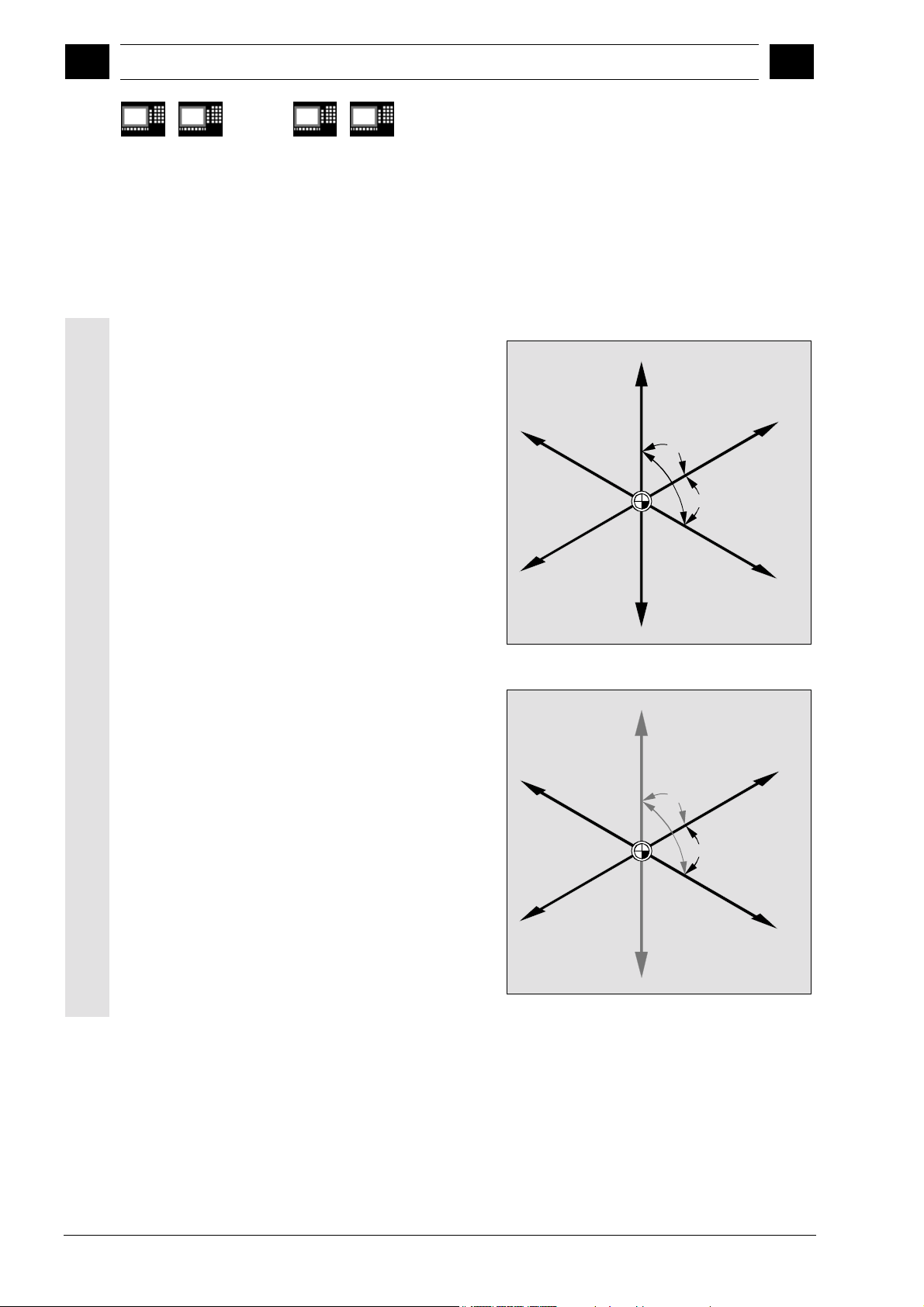

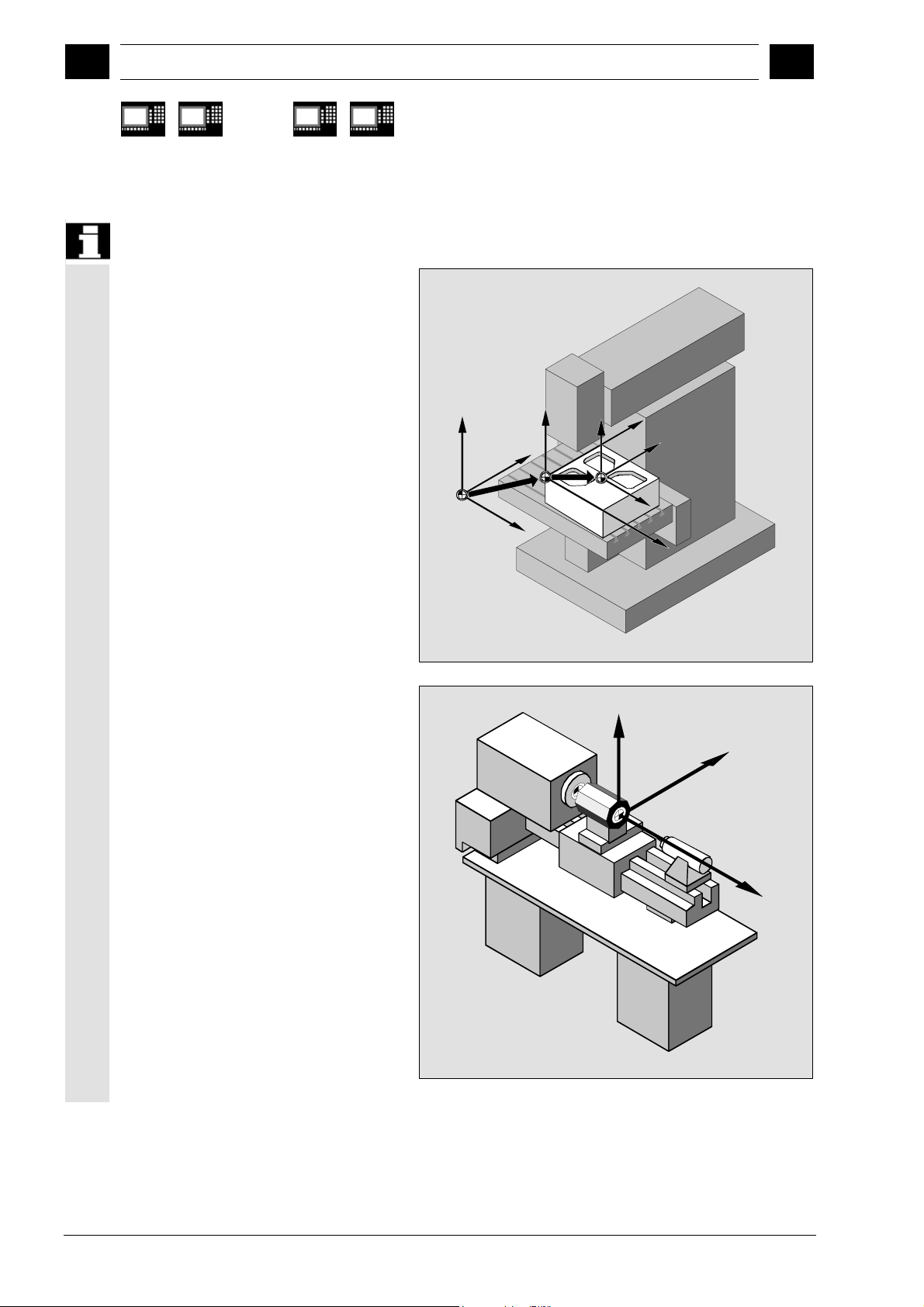

1.1.1 Workpiece coordinate systems

In order for the machine or control to operate with the

specified positions, these data must be made in a

reference system that corresponds to the direction of

motion of the axis slides. A coordinate system with

the axes X, Y and Z is used for this purpose.

DIN 66217 stipulates that machine tools must use

right-handed, rectangular (cartesian) coordinate

systems.

The workpiece zero (W) is the origin of the workpiece

coordinate system. Sometimes it is advisable or even

necessary to work with negative positional data.

Positions to the left of the origin are prefixed by a

negative sign (–).

Milling:

X-

Y-

Z+

W

Z-

90°

Y+

90°

90°

X+

Turning:

Z-

X-

Y+

W

Y-

90°

X+

90°

90°

Z+

1-22 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 23

11.02 Fundamental Geometrical Principles

1

1.1 Description of workpiece points

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

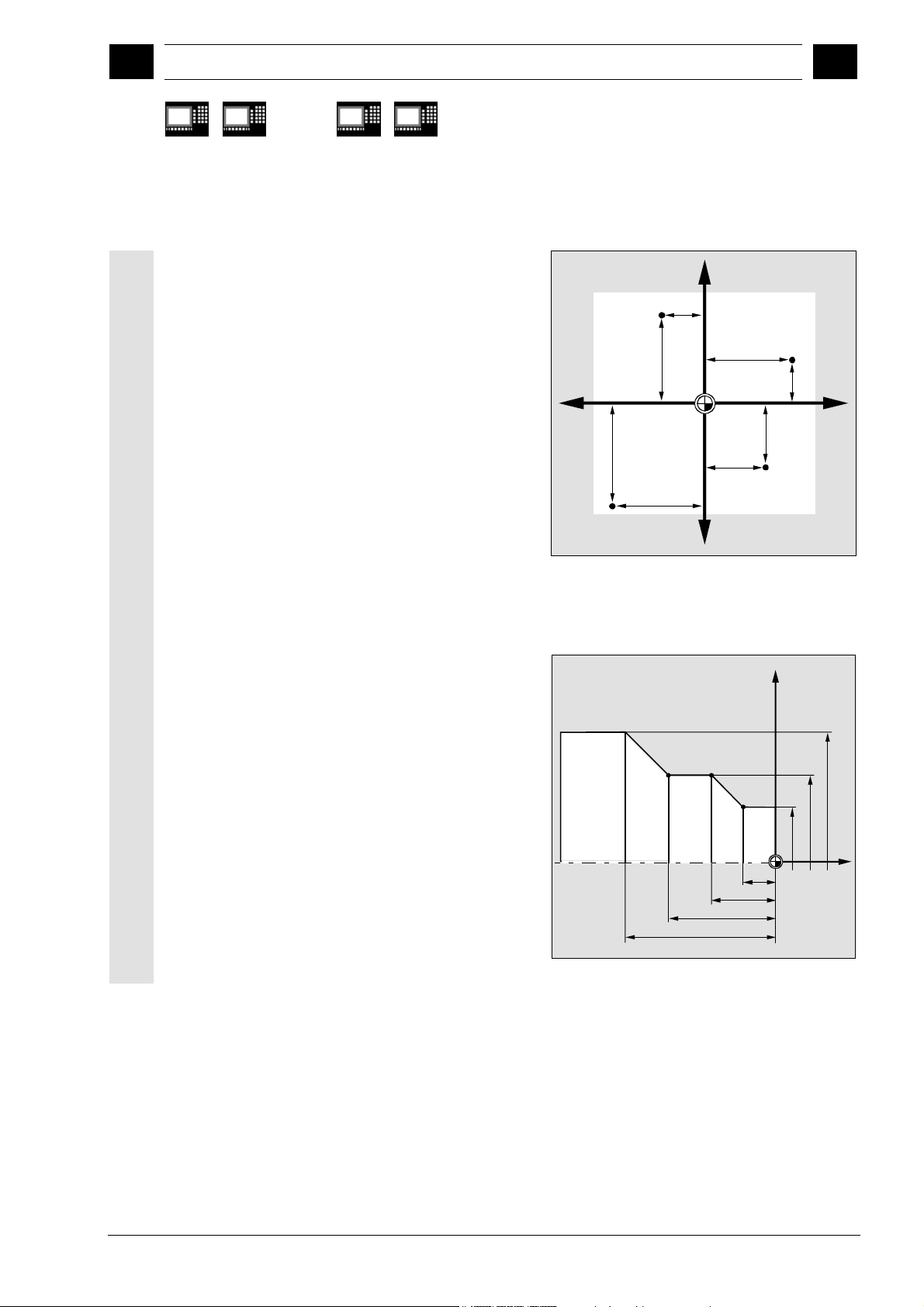

1.1.2 Definition of workpiece positions

To specify a position, imagine that a ruler is placed

along the coordinate axes. You can now describe

every point in the coordinate system by specifying the

direction (X, Y and Z) and three numerical values.

The workpiece zero always has the coordinates X0,

Y0 and Z0.

Example:

For the sake of simplicity, we will only use one plane

of the coordinate system in this example, i.e. the X/Y

plane. Points P1 to P4 then have the following

coordinates:

P1 corresponds to X100 Y50

P2 corresponds to X-50 Y100

P3 corresponds to X-105 Y-115

P4 corresponds to X70 Y-75

X-

Y+

50

P2

100

100

P1

50

X+

75

115

P3

105

70

P4

Y-

One plane is sufficient to describe the contour on a

turning machine.

Example:

Points P1 to P4 are defined by the following

coordinates:

P1 corresponds to X25 Z-7.5

P2 corresponds to X40 Z-15

P3 corresponds to X40 Z-25

P4 corresponds to X60 Z-35

P4

P3

35

P2

25

15

P1

7.5

X

Ø 60

Ø 40

Ø 25

Z

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-23

Page 24

Fundamental Geometrical Principles 11.02

1

1.1 Description of workpiece points

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

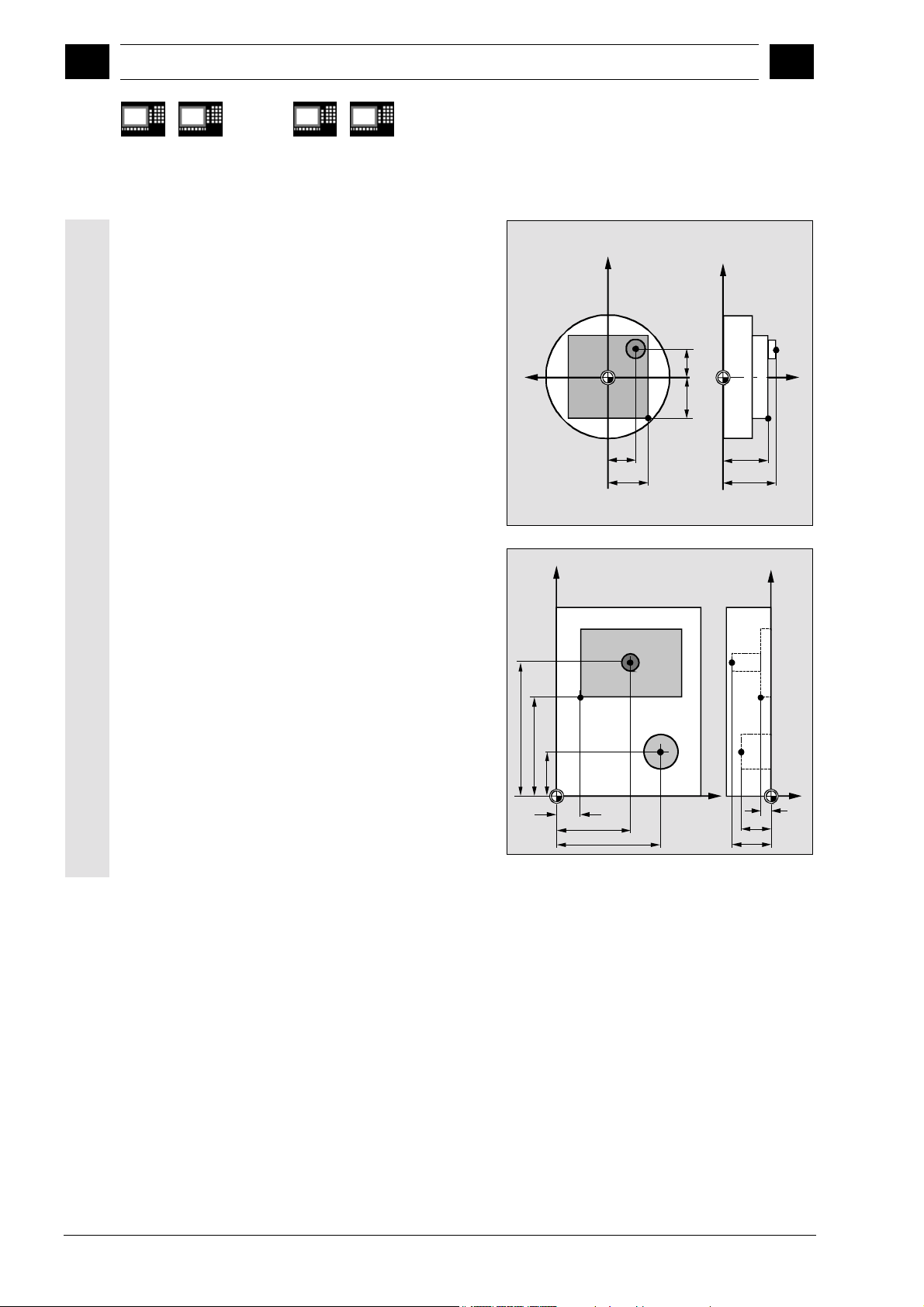

Example:

Points P1 and P2 are defined by the following

coordinates:

P1 corresponds to X-20 Y-20 Z23

P2 corresponds to X13 Y-13 Z27

The infeed depth must also be described in milling

operations. To do this, we need to specify a

numerical value for the third coordinate (Z in this

case).

Example:

Points P1 to P3 are defined by the following

coordinates:

60

Y+

Y+

X+

P1

13

P2

20

P2

P1

13

20

X+

P1

P2

Z+

P1

23

27

Y+

P2

P1

P1 corresponds to X10 Y45 Z-5

P2 corresponds to X30 Y60 Z-20

P3 corresponds to X45 Y20 Z-15

45

20

10

30

45

P3

X+

P3

15

20

Z+

5

1-24 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 25

11.02 Fundamental Geometrical Principles

1

1.1 Description of workpiece points

1

840D

NCU 571

840D

NCU 572

NCU 573

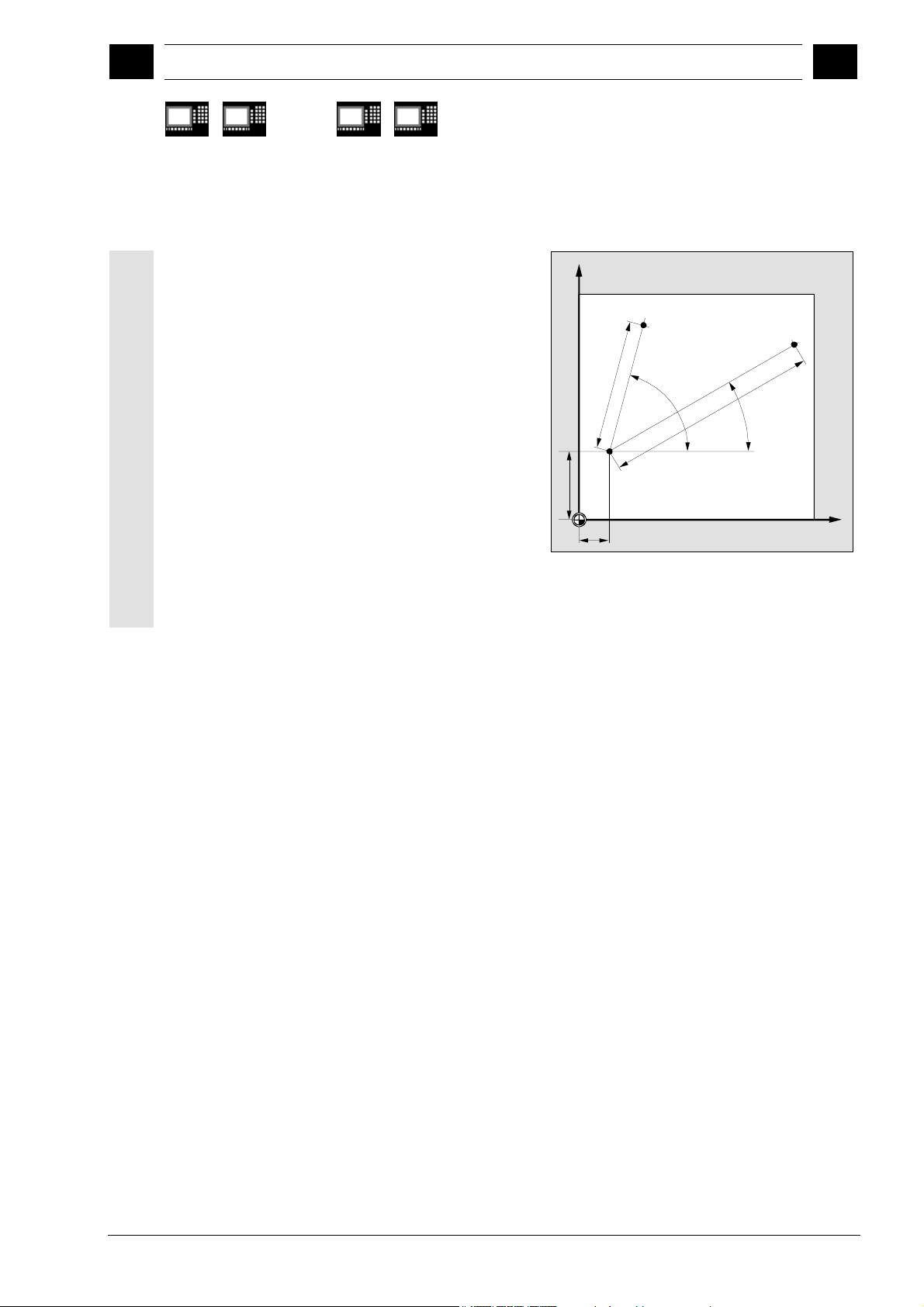

1.1.3 Polar coordinates

The coordinates used up to this point to specify points

in the coordinate system are called "Cartesian

coordinates".

However, there is another way to specify coordinates,

namely as "polar coordinates".

It is useful to use polar coordinates in cases where a

workpiece or part of a workpiece is dimensioned by

radius and angle. The origin of the dimensional

measurements is referred to as the "pole".

Example:

The points P1 and P2 can then be described – with

reference to the pole – as follows:

P1 corresponds to radius =100 plus angle =30°

P2 corresponds to radius =60 plus angle =75°

810D

840Di

Y

P2

P1

0

6

75°

Pole

30

15

0

0

1

30°

X

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-25

Page 26

Fundamental Geometrical Principles 11.02

1

1.1 Description of workpiece points

1

840D

NCU 571

840D

NCU 572

NCU 573

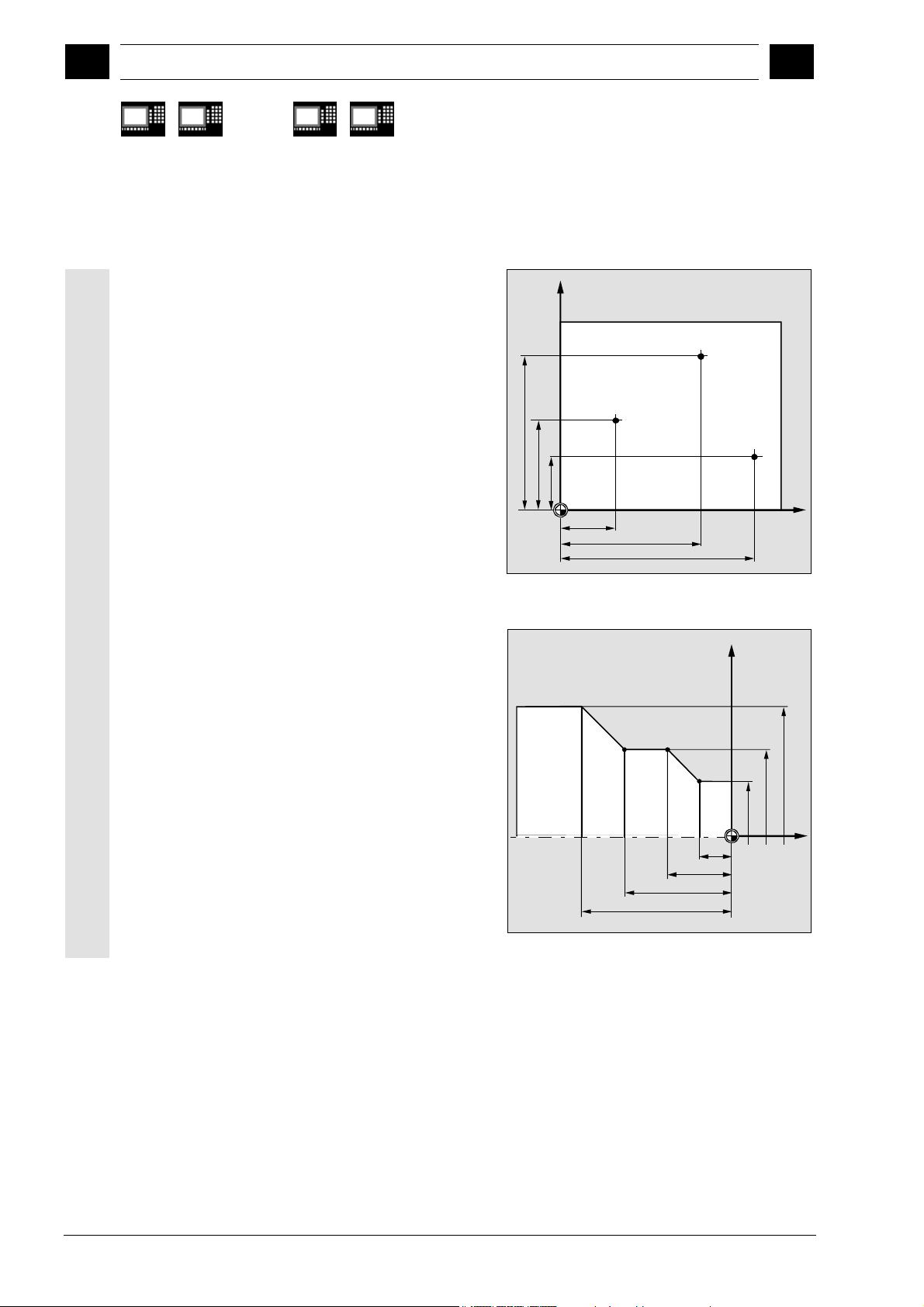

1.1.4 Absolute dimension

With absolute dimensions, all the positional

parameters refer to the currently valid zero point.

Applied to tool movement this means:

The absolute dimensions describe the

position to which the tool is to travel.

Example for milling:

The positional parameters for points P1 to P3 in

absolute dimensions referring to the zero point are

the following:

P1 corresponds to X20 Y35

P2 corresponds to X50 Y60

P3 corresponds to X70 Y20

810D

840Di

Y

P2

P1

60

P3

35

20

X

20

50

70

Example for turning:

The positional parameters for points P1 to P4 in

absolute dimensions referring to the zero point are

the following:

P1 corresponds to X25 Z-7.5

P2 corresponds to X40 Z-15

P3 corresponds to X40 Z-25

P4 corresponds to X60 Z-35

P4

P3

35

P2

25

15

P1

7.5

X

Ø 60

Ø 40

Ø 25

Z

1-26 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 27

11.02 Fundamental Geometrical Principles

1

1.1 Description of workpiece points

1

840D

NCU 571

840D

NCU 572

NCU 573

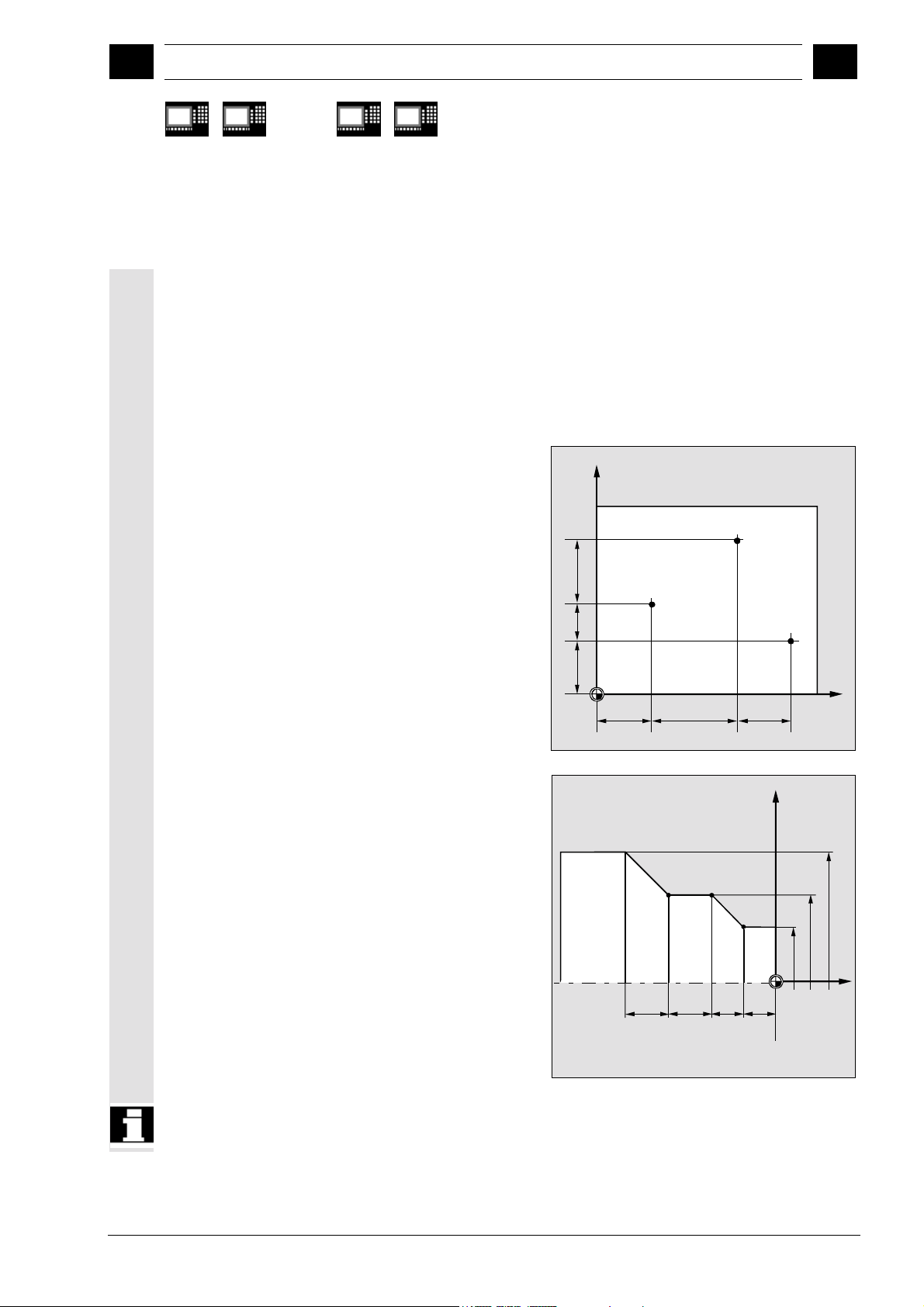

1.1.5 Incremental dimension

Production drawings are frequently encountered,

however, where the dimensions refer not to the origin,

but to another point on the workpiece.

In order to avoid having to convert such dimensions, it

is possible to specify them in incremental dimensions.

Incremental dimensions refer to the positional data for

the previous point. Applied to tool movement this

means:

The incremental dimensions describe the distance the

tool is to travel.

Example for milling:

The positional data for points P1 to P3 in incremental

dimensions are:

P1 corresponds to X20 Y35 ;(with reference to the

P2 corresponds to X30 Y20 ;(with reference to P1)

P3 corresponds to X20 Y-35 ;(with reference to P2)

810D

840Di

zero point)

1520

20

Y

P2

P1

P3

X

20

30

20

Example for turning:

The positional data for points P1 to P4 in incremental

dimensions are:

G90 P1 corresponds to X25 Z-7.5

;(with reference to the

zero point)

G91 P2 corresponds to X15 Z-7.5

;(with reference to P1)

G91 P3 corresponds to Z-10

;(with reference to P2)

G91 P4 corresponds to X20 Z-10

;(with reference to P3)

When DIAMOF or DIAM90 is active, the path setpoint

is programmed as a radius dimension with G91.

P4

10

P3

10

P2

7.5

X

P1

Ø 60

Ø 40

Ø 25

Z

7.5

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-27

Page 28

Fundamental Geometrical Principles 11.02

1

1.1 Description of workpiece points

1

840D

NCU 571

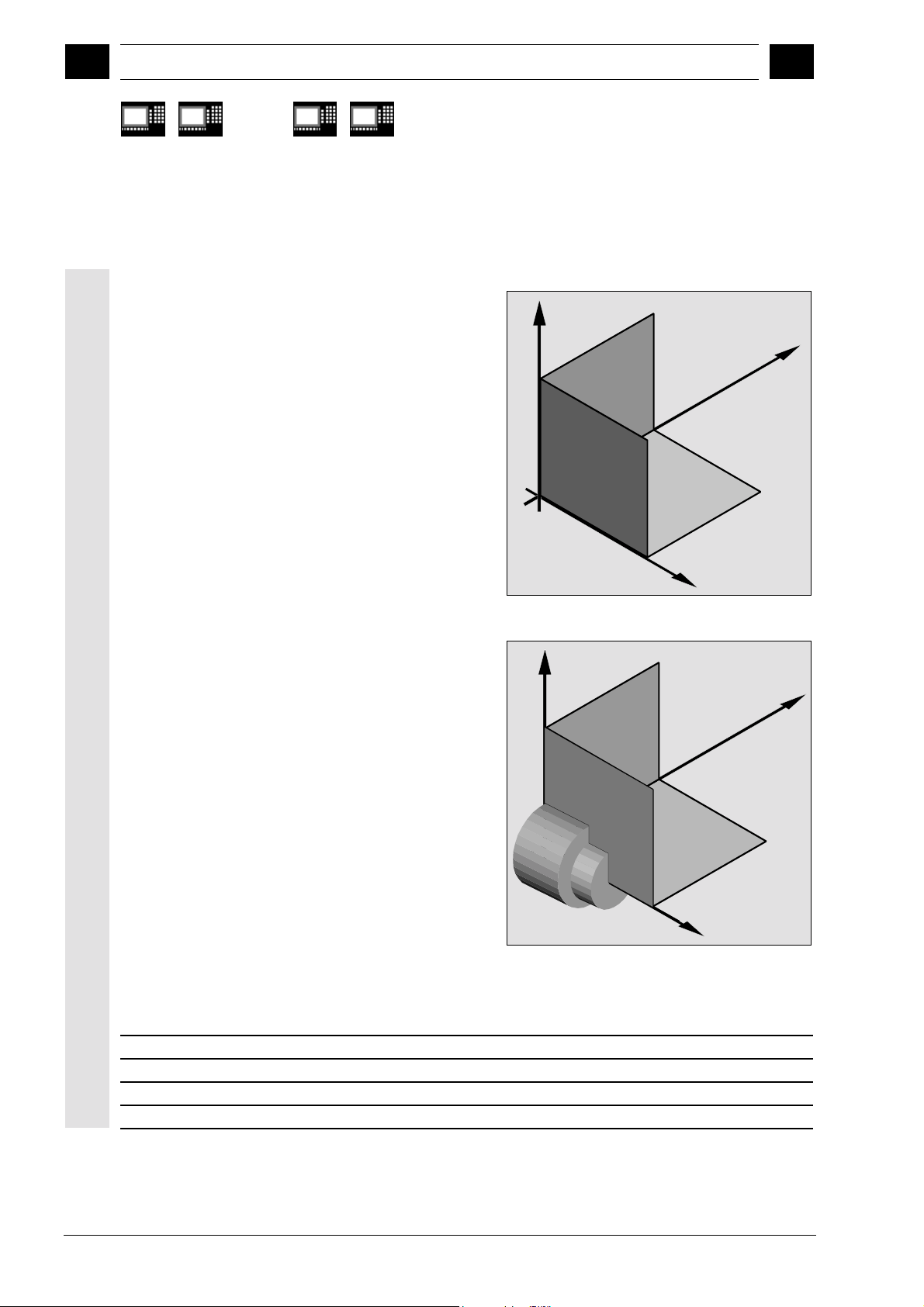

1.1.6 Plane designations

A plane is defined by means of two coordinate axes.

The third coordinate axis is perpendicular to this plane

and determines the infeed direction of the tool (e.g.

for 2½D machining).

When programming, it is necessary to specify the

working plane in order that the control can calculate

the tool offset values correctly. The plane is also

relevant to certain types of circular programming and

polar coordinates.

840D

NCU 572

NCU 573

810D

840Di

Milling:

G

Z

Y

1

8

G

1

9

G

1

7

X

Turning:

The working planes are specified as follows in the

NC program with G17, G18 and G19:

Plane Identifier Infeed direction

X/Y G17 Z

Z/X G18 Y

Y/Z G19 X

G

Y

X

1

9

G

1

7

G

Z

1

8

1-28 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 29

11.02 Fundamental Geometrical Principles

1

1.2 Position of zero points

1

840D

NCU 571

840D

NCU 572

NCU 573

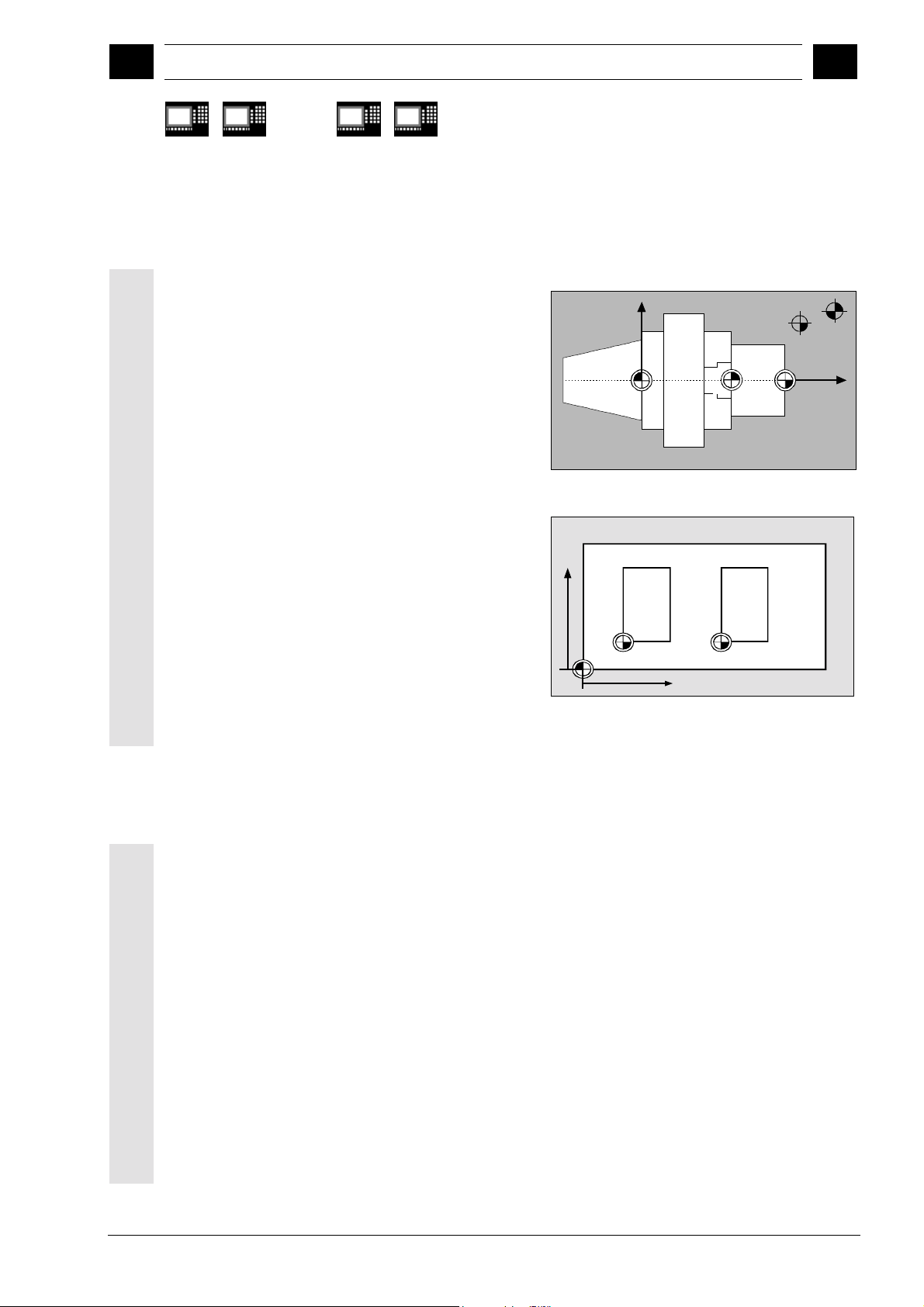

1.2 Position of zero points

The various origins and reference positions are

defined on the NC machine. They are reference

points

• for the machine to approach and

• refer to programming the workpiece dimensions.

They are:

M = Machine zero

A = Blocking point. Can coincide with the

workpiece zero (turning machines only)

W = Workpiece zero = Program zero

B = Start point. Can be defined for each program.

Start point of the first tool for machining.

R = Reference point. Position determined by

cam and measuring system. The distance to

the machine zero M must be known, so

that the axis position can be set to exactly

this value at this position.

The diagrams show the zero points and reference

points for turning machines and drilling/milling

machines.

810D

840Di

Y

W1 W2

M

X

R

B

M

X

A

W

Z

1.3 Position of coordinate systems

1.3.1 Overview of various coordinate systems

We distinguish between the following coordinate

systems:

• The machine coordinate system with the machine

zero M

• The basic coordinate system (this can also be the

workpiece coordinate system W)

• The workpiece coordinate system with the

workpiece zero W

• The current workpiece coordinate system with the

current offset workpiece zero Wa

In cases where various different machine coordinate

systems are in use (e.g. 5-axis transformation), an

internal transformation function mirrors the machine

kinematics on the coordinate system currently

selected for programming.

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-29

Page 30

Fundamental Geometrical Principles 11.02

1

1.3 Position of coordinate systems

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

The individual axis identifiers are explained in the

subsection headed "Axis types" in this section.

Z

Z

m

w

Y

m

M

X

m

W

Z

a

Wa

Y

w

Y

a

X

a

X

w

Y+

M

X+

W

Z+

1-30 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 31

11.02 Fundamental Geometrical Principles

1

1.3 Position of coordinate systems

1

840D

NCU 571

1.3.2 Machine coordinate system

840D

NCU 572

NCU 573

810D

840Di

The machine coordinate system comprises all the

physically existing machine axes.

Reference points and tool and pallet changing points

(fixed machine points) are defined in the machine

coordinate system.

Where the machine coordinate system is used for

programming (this is possible with some of the

G functions), the physical axes of the machine are

addressed directly. No allowance is made for

workpiece clamping.

The location of the coordinate system relative to the

machine depends on the machine type. The axis

directions follow the so-called "three-finger rule" of the

right hand (in accordance with DIN 66217).

Standing in front of the machine, the middle finger of

the right hand points away from the infeed direction of

the main spindle. The following then applies:

• The thumb points in the +X direction

• The index finger points in the +Y direction

• The middle finger points in the +Z direction

Zm

M

Ym

Xm

+Z

+Y

+X

In practice, this can look quite different on different

types of machine. The following are examples of

machine coordinate systems for various machines.

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-31

Page 32

Fundamental Geometrical Principles 11.02

1

1.3 Position of coordinate systems

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

-Y

+Z

+Z

-B

-Y

+X

+X

C+

Y+

C-

X+

Z+

+Z

B

+

B

-

+A

-A

+X

+Y

1-32 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 33

11.02 Fundamental Geometrical Principles

1

1.3 Position of coordinate systems

1

840D

NCU 571

1.3.3 Basic coordinate system

840D

NCU 572

NCU 573

810D

840Di

The basic coordinate system is a Cartesian

coordinate system, which is mirrored by kinematic

transformation (for example, 5-axis transformation or

by using Transmit with peripheral surfaces) onto the

machine coordinate system.

If there is no kinematic transformation, the basic

coordinate system differs from the machine

coordinate system only in terms of the axes

designations.

The activation of a transformation can produce

deviations in the parallel orientation of the axes. The

coordinate system does not have to be at a right

angle.

Zero offset, scaling, etc. are always executed in the

basic coordinate system.

The coordinates also refer to the basic coordinate

system when specifying the working field limitation.

Basic coordinate system

for face end

X

Y

Basic coordinate system

for peripheral surface

Workpiece coordinate system

for turning plane

W

X

Z

Y

Z

Y

MCS

MCS

MCS = Machine coordinate system BCS = Basic coordinate system

BZS = Basic zero system SZS = Settable zero system

WCS = Workpiece coordinate system

Y

BCS

DRF shift, external zero offset

BCS

Kinematic transformation

Y

Y

BZS

SZS

Programmable FRAME

SZS

G54...G599 settable FRAMES

BZS

Base offset (base frame)

Y

WCS

WCS

X

X

MCS

BCS

X

BZS

X

X

WCS

SZS

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-33

Page 34

Fundamental Geometrical Principles 11.02

1

1.3 Position of coordinate systems

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

1.3.4 Workpiece coordinate system

in the workpiece coordinate system. In other words,

the data in the NC program refer to the workpiece

coordinate system.

The workpiece coordinate system is always a

Cartesian coordinate system and assigned to a

specific workpiece.

Z

Y

X

1.3.5 Frame system

The frame is a self-contained arithmetic rule that

transforms one Cartesian coordinate system into

another Cartesian coordinate system.

It is a:

Spatial description of the workpiece coordinate

system

The following components are available within a

frame:

• Zero offset

• Rotate

• Mirror

• Scale

These components can be used individually or in any

combination.

Rotation

around the Z axis

Z0

e

s

f

f

o

o

r

e

Z

t

Z1=Z2

X0

Y0

Y1

Y2

X1

X2

1-34 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 35

11.02 Fundamental Geometrical Principles

1

1.3 Position of coordinate systems

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Mirroring of the Z axis

One way of machining inclined contours is to use

appropriate fixtures to align the workpiece parallel to

the machine axes.

M

X

Zero offset

X

Z

Z

W

W

Z

1

Zero offset

M

1

Y

Another way is to generate a coordinate system which

is oriented to the workpiece. The coordinate system

can be moved and/or rotated with programmable

frames.

This enables you to

• move the zero point to any position on the

workpiece

• align the coordinate axes parallel to the desired

working plane by rotation

• and thus machine surface clamped in inclined

positions, produce drill holes at different angles.

• perform multiside machining operations.

Z

Y

Z

0

X

Y1

Z

1

X

1

X

0

X

Y

0

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-35

Page 36

Fundamental Geometrical Principles 11.02

1

1.3 Position of coordinate systems

1

840D

NCU 571

Working plane, tool offsets

The conventions for the working plane and the tool

840D

NCU 572

NCU 573

810D

840Di

offsets must be observed – in accordance with the

machine kinematics – for machining operations in

inclined working planes. For further information,

please see Section 3.6 "Selection of working plane,

G17 to G19".

1.3.6 Assignment of workpiece coordinate system to machine axes

The location of the workpiece coordinate system in

relation to the basic coordinate system (or machine

ZM=Z

B

coordinate system) is determined by settable frames.

The settable frames are activated in the NC program

by means of commands such as G54.

M

YM=Y

Z

W

B

Y

W

1.3.7 Current workpiece coordinate system

Sometimes it is advisable or necessary to reposition

and to rotate, mirror and/or scale the originally

selected workpiece zero within a program.

The programmable frames can be used to reposition

(rotate, mirror and/or scale) the current zero point at a

suitable point in the workpiece coordinate system.

You will thus obtain the current workpiece coordinate

system.

Several zero offsets are possible in the same

program.

Current workpiece

coordinate system

Y

B

Frame 1

Z

1

Z

B

Frame 1...settable offset and rotation

Frame 2...programmable offset and rotation

X

B

Y

2

Z

2

Y

Frame 2

1

X

Workpiece

coordinate system

XM=X

1

X

W

B

X

2

1-36 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 37

11.02 Fundamental Geometrical Principles

1

1.4 Axes

1

840D

NCU 571

1.4 Axes

840D

NCU 572

NCU 573

810D

840Di

A distinction is made between the following types of

axis when programming:

• Machine axes

• Channel axes

• Geometry axes

• Special axes

• Path axes

• Synchronized axes

• Positioning axes

• Command axes

(motion-synchronized axes)

• PLC axes

• Link axes

• Leading link axes.

Geometry, synchronized and positioning axes are

programmed.

Path axes traverse with feedrate F in accordance with

the programmed travel commands.

Synchronized axes traverse synchronously to path

axes and take the same time to traverse as all path

axes.

Positioning axes traverse asynchronously to all other

axes. These traversing movements take place

independently of path and synchronized movements.

Command axes traverse asynchronously to all other

axes. These traversing movements take place

independently of path and synchronized movements.

PLC axes are controlled by the PLC and can traverse

asynchronously to all other axes. The traversing

movements take place independently of path and

synchronized movements.

Geometry axes Positioning axes

Machine axes

Geometry axes

Channel axes

Path axes PLC axes

Synchr on.

axes

Positioning

axes

Kinematic

Machine axes

transformati on

Special axes

Command

axes

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-37

Page 38

Fundamental Geometrical Principles 11.02

1

1.4 Axes

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

1.4.1 Main axes/Geometry axes

The main axes define a right-angled, right-handed

coordinate system. Tool movements are programmed

in this coordinate system.

In NC technology, the main axes are called geometry

axes. This is the term used in this Programming

Guide.

For turning machines:

Geometry axes X and Z are used, and sometimes Y.

For milling machines:

Geometry axes X, Y and Z are used.

A maximum of three geometry axes are used for

programming frames and the workpiece geometry

(contour).

Identifiers: X, Y, Z

The identifiers for geometry and channel

axes can be the same, as long as mirroring

is possible.

Geometry axis and channel axis names can be the

same in any channel in order that the same programs

can be executed.

The "Switchable geometry axes" function (see

Advanced) can be used to alter the geometry axes

grouping configured by machine data. Here any

geometry axis can be replaced by a channel axis

defined as a synchronous special axis.

Tools

X

(master spindle)

C axis

Turret

swivel axis

Z

Geometry

axesMain spindle

Tailstock

Additional

spindle

Special

axis

1-38 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 39

11.02 Fundamental Geometrical Principles

1

1.4 Axes

1

840D

NCU 571

1.4.2 Special axes

In contrast to the geometry axes, no geometrical

relationship is defined between the special axes.

Example:

Turret position U, tailstock V

1.4.3 Main spindle, master spindle

The machine kinematics determine which spindle is

the main spindle. This spindle is declared the master

spindle in the machine data. As a rule, the main

spindle is declared the master spindle.

This assignment can be changed with the program

command SETMS (spindle number) (see Chapter 7).

Special functions such as thread cutting apply to the

master spindle.

Identifiers: S or S0

840D

NCU 572

NCU 573

810D

840Di

1.4.4 Machine axes

The axis identifiers can be set in the machine data.

Standard identifiers:

X1, Y1, Z1, A1, B1, C1, U1, V1

There are also standard axis identifiers that can

always be used:

AX1, AX2, …, AXn

1.4.5 Channel axes

All axes which traverse in a channel.

Identifiers: X, Y, Z, A, B, C, U, V

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-39

Page 40

Fundamental Geometrical Principles 11.02

1

1.4 Axes

1

840D

NCU 571

1.4.6 Path axes

Path axes define the path and therefore the

movement of the tool in space.

The programmed feedrate is active for this path.

The axes involved in this path reach their position at

the same time. As a rule, these are the geometry

axes.

However, default settings define which axes are the

path axes and therefore determine the velocity. Path

axes can be specified in the NC program with

FGROUP (see Chapter 5).

840D

NCU 572

NCU 573

810D

840Di

1.4.7 Positioning axes

Positioning axes are interpolated separately, i.e. each

positioning axis has its own axis interpolator and its

own feedrate.

A distinction is made between positioning axes with

synchronization at the block end or over several

blocks.

POS axes: Block change occurs at the end of the

block when all the path and positioning axes

programmed in this block have reached their

programmed end point.

POSA axes: The movement of these positioning axes

can extend over several blocks.

POSP axes: The movement of these positioning axes

for approaching the end position takes place in

sections.

You will find further information on POS, POSA and

POSP in the section on "Traversing positioning axes,

POS, POSA, POSP".

1-40 SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 41

11.02 Fundamental Geometrical Principles

1

1.4 Axes

1

840D

NCU 571

Additional notes

Continuous-path mode (G64) for path axes is only

Positioning axes become synchronized axes if they

are traversed without the special POS/POSA

identifier.

possible if the positioning axes (POS) reach their final

position before the path axes.

Path axes that are programmed with POS/POSA are

removed from the path axis grouping for the duration

of this block.

Positioning axes are traversed by the NC program or

the PLC.

If an axis is to be traversed simultaneously by the

NC program and the PLC, an error message appears.

Typical positioning axes are:

• Loaders for workpiece loading

• Loaders for workpiece unloading

• Tool magazine/turret.

840D

NCU 572

NCU 573

810D

840Di

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D Programming Guide Fundamentals (PG) – 11.02 Edition 1-41

Page 42

Fundamental Geometrical Principles 11.02

1

1.4 Axes

1

840D

NCU 571

1.4.8 Synchronized axes

Synchronized axes traverse synchronously to the path

from the start position to the programmed end

position.

The feedrate programmed in F applies to all the path

axes programmed in the block, but does not apply to

synchronized axes. Synchronized axes take the same

time as the path axes to traverse.

A synchronized axis can be a rotary axis which is

traversed synchronously to the path interpolation.

1.4.9 Command axes

840D

NCU 572

NCU 573

810D

840Di

Command axes are started from synchronized

actions in response to an event (command). They can

be positioned, started and stopped fully asynchronous