Page 1

User's Guide 11/2002 Edition

Measuring Cycles

SINUMERIK 840D/840Di/810D

Page 2

Page 3

Part 1: User's Guide

SINUMERIK 840D/840Di/810D

Measuring Cycles

User's Guide

Introduction

Description of Parameters

Measuring Cycle Auxiliary

Programs

Measuring in JOG

Measuring Cycles for

Milling and Machining

Centers

1

2

3

4

5

Valid for

Control Software version

SINUMERIK 840D 6

SINUMERIK 840DE (export version) 6

SINUMERIK 840D powerline 6

SINUMERIK 840DE powerline 6

SINUMERIK 840Di 2

SINUMERIK 840DiE (export version) 2

SINUMERIK 810D 3

SINUMERIK 810DE (export version) 3

SINUMERIK 810D powerline 6

SINUMERIK 810DE powerline 6

Measuring Cycles for

Turning Machines

Miscellaneous Functions

Part 2: Description of

Functions

Hardware, Software and

Installation

Supplementary

Conditions

Data Description

Examples

6

7

8

9

10

11

11.02 Edition

Data Fields, Lists

Appendix

12

A

Page 4

Contents 11.02

0

SINUMERIK® Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the "Remarks" column.

Status code in the "Remarks" column:

A .... New documentation.

B .... Unrevised edition with new Order No.

C .... Revised edition with new status.

If factual changes have been made on the page since the last edition, this is indicated by a

new edition coding in the header on that page.

0

Edition Order No. Remarks

09.95

03.96

6FC5298-3AA01-0BP0

6FC5298-3AA70-0BP1

A

C

12.97 6FC5298-4AA70-0BP0 C

12.98 6FC5298-5AA70-0BP0 C

08.99 6FC5298-5AA70-0BP1 C

06.00 6FC5298-5AA70-0BP2 C

10.00 6FC5298-6AA70-0BP0 C

09.01 6FC5298-6AA70-0BP1 C

11.02 6FC5298-6AA70-0BP2 C

This manual is included in the documentation available on CD ROM (DOCONCD)

Edition Order No. Remarks

11.02 6FC5 298-6CA00-0BG3 C

Trademarks

SIMATIC

POSMO

be trademarks which, if used by third parties, could infringe the rights of their owners.

Further information is available on the Internet under:

http:/www.ad.siemens.de/sinumeri k

This publications was produced with WinW ord V 8.0 and Designer V 7.0.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for damages.

All rights, including rights created by patent grant or registration of a utility model

or design, are reserved.

© Siemens AG, 1995–2002. All rights reserved

®

, SIMATIC HMI®, SIMATIC NET®, SIROTEC®, SINUMERIK®, SIMODRIVE® and SIMODRIVE

®

are registered trademarks of Siemens AG. Other product names used in this documentation may

Other functions not described in this documentation might be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

We have checked that the contents of this document correspond to the hardware

and software described. Nonetheless, differences might exist and therefore we

cannot guarantee that they are completely identical. The information contained in

this document is, however, reviewed regularly and any necessary changes will be

included in the next edition. We welcome suggestions for improvement.

Subject to change without prior notice

Order No. 6FC5298-6AA70-0BP2

Printed in Germany

Siemens Aktiengesellschaft

Page 5

11.02 Contents

0

Contents

Part 1: User's Guide

Introduction 1-15

0

1.1 Basics.............................................................................................................................. 1-16

1.2 General preconditions ..................................................................................................... 1-17

1.3 Plane definition................................................................................................................ 1-19

1.4 Suitable probes ............................................................................................................... 1-20

1.5 Workpiece probe, calibration tool in TO memory............................................................ 1-22

1.5.1 Workpiece probe in TO memory for milling machines and machining centers ........ 1-22

1.5.2 Workpiece probe, calibration tool in TO memory on turning machines .................... 1-23

1.6 Measuring principle ......................................................................................................... 1-25

1.7 Measuring strategy and compensation value calculation for tools with automatic

tool offset......................................................................................................................... 1-28

1.8 Parameters for checking the dimension deviation and compensation............................ 1-31

1.9 Effect of empirical value, mean value and tolerance parameters ................................... 1-37

1.10 Reference points on the machine and workpiece ........................................................... 1-38

1.11 Measurement variants for milling machines & machining centers .................................. 1-39

1.11.1 Workpiece measurement for milling machines......................................................... 1-39

1.11.2 Measurement variants for fast measurement at a single point ................................. 1-40

1.11.3 Measurement variants for workpiece measurement paraxial ................................... 1-40

1.11.4 Measurement variants for workpiece measurement at random angles .................... 1-42

1.11.5 Measuring a surface at a random angle ................................................................... 1-43

1.12 Measurement variants for lathes.................................................................................... 1-44

1.12.1 Tool measurement for lathes .................................................................................... 1-44

1.12.2 Workpiece measurement for turning machines: Single-point measurement............ 1-45

1.12.3 Workpiece measurement for turning machines: Two-point measurement ............... 1-47

1.13 Measuring cycles interface............................................................................................. 1-48

1.13.1 Displaying measuring result screens ........................................................................ 1-48

1.13.2 Setting parameters.................................................................................................... 1-50

Description of Parameters 2-53

2.1. Parameter concept for measuring cycles........................................................................ 2-54

2.2 Parameter overview ........................................................................................................2-56

2.2.1 Input parameters ....................................................................................................... 2-56

2.2.2 Result parameters..................................................................................................... 2-57

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 0-5

Page 6

Contents 11.02

0

2.3 Description of the most important defining parameters...................................................2-58

2.3.1 Measurement variant: _MVAR ..................................................................................2-58

2.3.2 Number of measuring axis: _MA............................................................................... 2-61

2.3.3 Tool number and tool name: _TNUM and _TNAME .................................................2-62

2.3.4 Offset number _KNUM.............................................................................................. 2-63

2.3.5 Offset number _KNUM with flat D number structure................................................. 2-65

2.3.6 Variable measuring speed: _VMS............................................................................. 2-66

2.3.7 Compensation angle position for monodirectional probe: _CORA............................ 2-66

2.3.8 Tolerance parameters: _TZL, _TMV, _TUL, _TLL, _TDIF and _TSA....................... 2-67

2.3.9 Multiplication factor for measurement path 2a: _FA..................................................2-68

2.3.10 Probe type/Probe number: _PRNUM ........................................................................2-69

2.3.11 Empirical value/mean value: _EVNUM ..................................................................... 2-70

2.3.12 Multiple measurement at the same location: _NMSP ...............................................2-71

2.3.13 Weighting factor k for averaging: _K .........................................................................2-71

0

2.4. Description of output parameters ...................................................................................2-72

2.4.1 Measuring cycle results in _OVR ..............................................................................2-72

2.4.2 Measuring cycle results in _OVI ................................................................................2-73

Measuring Cycle Auxiliary Programs 3-75

3.1 Package structure of measuring cycles.......................................................................... 3-76

3.2 Measuring cycle subroutines ..........................................................................................3-77

3.2.1 CYCLE103: Parameter definition for measuring cycles ............................................3-78

3.2.2 CYCLE116: Calculation of center point and radius of a circle................................... 3-79

3.3 Measuring cycle user programs .....................................................................................3-81

3.3.1 CYCLE198: User program prior to calling measuring cycle ......................................3-81

3.3.2 CYCLE199: User program at the end of a measuring cycle .....................................3-82

3.4 Subpackages..................................................................................................................3-83

Measuring in JOG 4-85

4.1 General preconditions .................................................................................................... 4-86

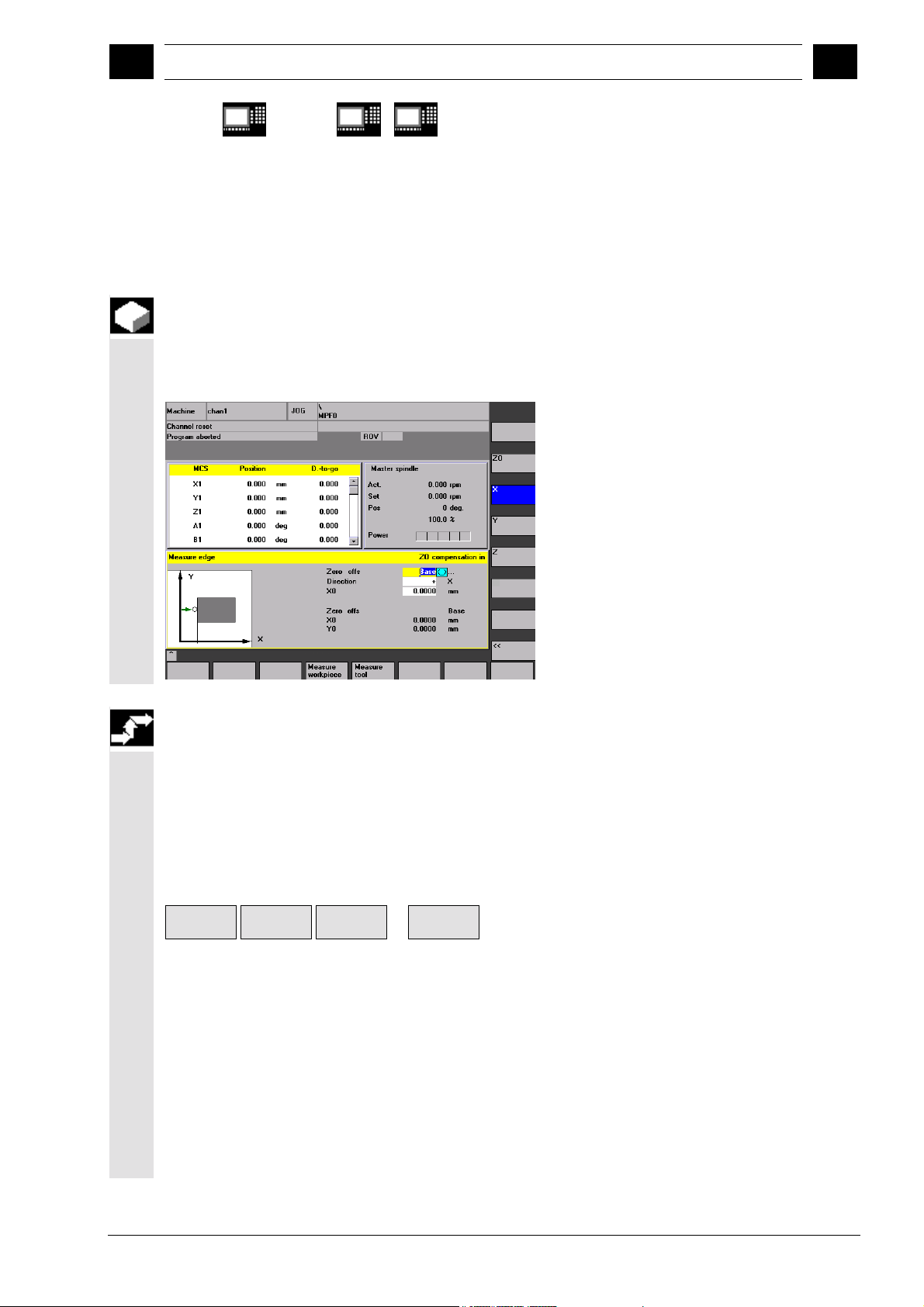

4.2 Workpiece measurement ............................................................................................... 4-89

4.2.1 Operation and function sequence of workpiece measurement .................................4-90

4.2.2 Measuring an edge.................................................................................................... 4-91

4.2.3 Measuring a corner ................................................................................................... 4-92

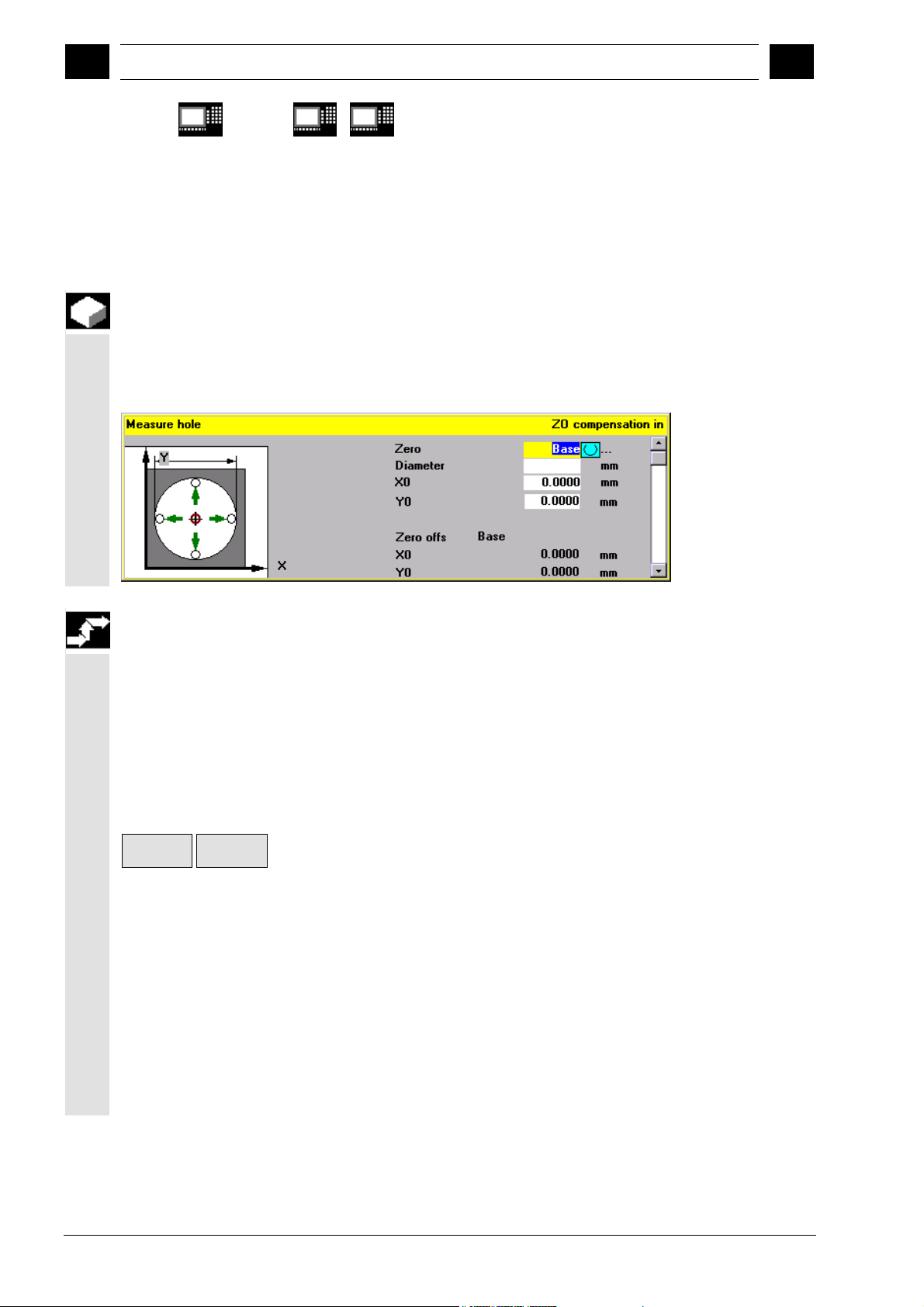

4.2.4 Measuring a hole .......................................................................................................4-94

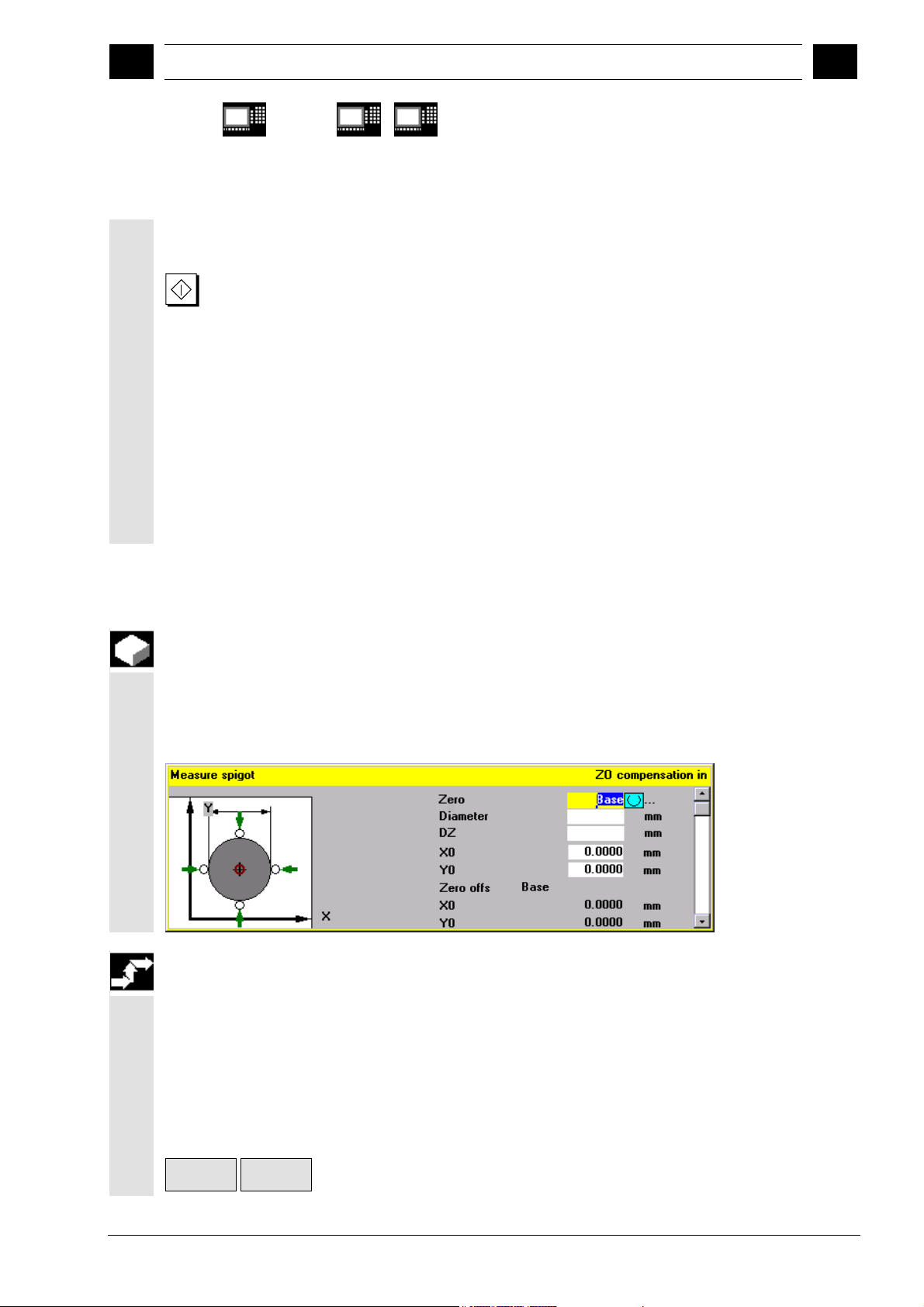

4.2.5 Measuring a spigot .................................................................................................... 4-95

4.2.6 Calibrating the measuring probe ...............................................................................4-96

4.3 Tool measurement .........................................................................................................4-99

4.3.1 Operation and function sequence of tool measurement ...........................................4-99

4.3.2 Tool measurement ..................................................................................................4-100

4.3.3 Calibrating the tool measuring probe ...................................................................... 4-101

0-6 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 7

11.02 Contents

0

Measuring Cycles for Milling and Machining Centers 5-103

5.1 General preconditions ................................................................................................... 5-104

5.2 CYCLE971 Tool measuring for milling tools ................................................................. 5-106

5.2.1 CYCLE971 Measuring strategy............................................................................... 5-108

5.2.2 CYCLE971 Calibrate tool probe .............................................................................. 5-110

5.2.3 CYCLE971 Measure tool......................................................................................... 5-114

5.3 CYCLE976 Calibrate workpiece probe.......................................................................... 5-119

5.3.1 CYCLE976 Calibrate workpiece probe in any hole (plane) with known

hole center .............................................................................................................. 5-122

5.3.2 CYCLE976 Calibrate workpiece probe in any hole (plane) with unknown hole

center (measuring cycles SW 4.4 and higher) ........................................................ 5-124

5.3.3 CYCLE976 Calibrate workpiece probe on a random surface ................................. 5-126

5.3.4 Calibrate workpiece probe in applicate with calculation of probe length

(measuring cycles SW 4.4. and higher) .................................................................. 5-128

0

5.4 CYCLE977 Workpiece measurement: Hole/shaft/groove/web/rectangle (paraxial) ..... 5-130

5.4.1 CYCLE977 Measure hole, shaft, groove, web, rectangle ....................................... 5-134

5.4.2 CYCLE977 ZO calculation in hole, shaft, groove, web, rectangle .......................... 5-140

5.5 CYCLE978 Workpiece measurement: Surface ............................................................ 5-146

5.5.1 CYCLE978 ZO calculation on a surface (single point measuring cycle)................. 5-149

5.5.2 CYCLE978 Single-point measurement ................................................................... 5-152

5.6 CYCLE979 Workpiece measurement: Hole/shaft/groove/web (at a random angle)..... 5-156

5.6.1 CYCLE979 Measure hole, shaft, groove, web ........................................................ 5-159

5.6.2 CYCLE979 ZO calculation in hole, shaft, groove, web ........................................... 5-164

5.7 CYCLE998 Angular measurement (ZO calculation) ..................................................... 5-169

5.8 CYCLE961 Automatic setup of inside and outside corner ............................................ 5-180

5.8.1 Automatic setup of corner with distances and angles specified.............................. 5-180

5.8.2 Automatic setup of corner by defining 4 points (measuring cycles ≥ SW 4.5) ........ 5-185

Measuring Cycles for Turning Machines 6-189

6.1 General preconditions .................................................................................................. 6-190

6.2 CYCLE972 Tool measurement ....................................................................................6-192

6.2.1 CYCLE972 Calibrating the tool probe ..................................................................... 6-194

6.2.2 CYCLE972 Determine dimensions of calibration tools ........................................... 6-197

6.2.3 CYCLE972 Measure tool......................................................................................... 6-198

6.3 CYCLE982 Tool measurement (SW 5.3 and higher)................................................... 6-203

6.3.1 CYCLE982 Calibrate tool measuring probe ............................................................ 6-208

6.3.2 CYCLE982 Measure tool......................................................................................... 6-210

6.3.3 CYCLE982 Automatic tool measurement ............................................................... 6-221

6.3.4 Incremental calibration (SW 6.2 and higher)........................................................... 6-228

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 0-7

Page 8

Contents 11.02

0

6.3.5 Incremental measurement (SW 6.2 and higher) .....................................................6-231

6.3.6 Milling tool: suppression of starting angle positioning with _STA1 (≥ SW 6.2)........6-237

6.4 CYCLE973 Calibrate workpiece probe .........................................................................6-238

6.4.1 CYCLE973 Calibrate in the reference groove (plane) .............................................6-240

6.4.2 CYCLE973 Calibrate on a random surface .............................................................6-242

6.5 CYCLE974 Workpiece measurement ..........................................................................6-244

6.5.1 CYCLE974 Single-point measurement ZO calculation ...........................................6-246

6.5.2 CYCLE974 Single-point measurement ...................................................................6-249

6.5.3 CYCLE974 Single-point measurement with reversal ..............................................6-253

6.6 CYCLE994 Two-point measurement............................................................................ 6-257

6.7 Complex example for workpiece measurement ...........................................................6-262

0

Miscellaneous Functions 7-265

7.1 Logging of measuring results .......................................................................................7-266

7.1.1 Storing the log .........................................................................................................7-266

7.1.2 Handling of log cycles.............................................................................................. 7-267

7.1.3 Selecting the log contents .......................................................................................7-269

7.1.4 Log format ...............................................................................................................7-271

7.1.5 Log header ..............................................................................................................7-272

7.1.6 Variable for logging.................................................................................................. 7-273

7.1.7 Example of measuring result log .............................................................................7-274

7.2 Cycle support for measuring cycles..............................................................................7-276

7.2.1 Files for cycle support.............................................................................................. 7-277

7.2.2 Loading the cycle support........................................................................................ 7-277

7.2.3 Assignment of calls and measuring cycles.............................................................. 7-278

7.2.4 Description of parameterization cycles.................................................................... 7-279

7.3 Measuring cycle support in the program editor (≥ SW 6.2) ..........................................7-290

7.3.1 Menus, cycle explanation ........................................................................................ 7-290

7.3.2 New functions of the input forms .............................................................................7-291

7.3.3 GUD variables for adaptation of measuring cycle support ......................................7-297

Part 2: Description of Functions

Hardware, Software and Installation 8-301

8.1 Overview....................................................................................................................... 8-302

8.2 Hardware requirements ................................................................................................8-303

8.2.1 General hardware requirements.............................................................................. 8-303

8.2.2 Probe connection..................................................................................................... 8-303

8.2.3 Measuring in JOG ................................................................................................... 8-303

8.3 Software requirements .................................................................................................8-308

8.3.1 General measuring cycles.......................................................................................8-308

0-8 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 9

11.02 Contents

0

8.3.2 Measuring in JOG ................................................................................................... 8-309

8.4 Function check .............................................................................................................8-310

8.5 Start-up sequences ......................................................................................................8-312

8.5.1 Start-up flowchart for measuring cycles and probe circuit ...................................... 8-312

8.5.2 Starting up the measuring cycle interface for the MMC 102 ...................................8-315

Supplementary Conditions 9-317

Data Description 10-319

10.1 Machine data for machine cycle runs......................................................................... 10-320

10.2 Cycle data................................................................................................................... 10-323

10.2.1 Data concept for measuring cycles ....................................................................... 10-323

10.2.2 Data blocks for measuring cycles: GUD5.DEF and GUD6.DEF........................... 10-324

10.2.3 Central values .......................................................................................................10-328

10.2.4 Central bits ............................................................................................................ 10-333

10.2.5 Central strings ....................................................................................................... 10-336

10.2.6 Channel-oriented values ....................................................................................... 10-337

10.2.7 Channel-oriented bits ............................................................................................ 10-339

0

10.3 Data for measuring in JOG ........................................................................................ 10-344

10.3.1 Machine data for ensuring ability to function ......................................................... 10-344

10.3.2 Modifying the GUD7 data block ............................................................................ 10-346

10.3.3 Settings in data block GUD6 ................................................................................. 10-349

10.3.4 Loading files for measuring in JOG....................................................................... 10-351

Examples 11-353

11.1 Determining the repeat accuracy ............................................................................... 11-354

11.2 Adapting the data for a particular machine ................................................................ 11-355

Data Fields, Lists 12-359

12.1 Machine data.............................................................................................................. 12-360

12.2 Measuring cycle data ................................................................................................. 12-360

12.3 Alarms ........................................................................................................................ 12-361

Appendix A-369

A Overview of measuring cycle parameters ....................................................................A-371

B Abbreviations................................................................................................................A-405

C Terms ...........................................................................................................................A-407

D References...................................................................................................................A-415

E Index.............................................................................................................................A-429

F Identifiers......................................................................................................................A-434

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 0-9

Page 10

Preface 11.02

0

Structure of the manual

0

840 D

NCU 571

840 D

NCU 572

NCU 573

810 D 840 Di

Preface

Organization of documentation

The SINUMERIK documentation is organized on 3 different levels:

• General Documentation

• User Documentation

• Manufacturer/Service Documentation

Target group

This manual is aimed at machine tool users. It provides detailed information for

operating the SINUMERIK 840D, 810D.

Standard scope

This Operator's Guide describes only the functionality of the standard scope.

A description of add-on features or modifications made by the machine builder are

not included in this guide.

For more detailed information on SINUMERIK 840D, 810D publications and other

publications covering all SINUMERIK controls (e.g. universal interface, measuring

cycles...), please contact your local Siemens office.

Other functions not described in this documentation might be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

Validity

This User's Guide is valid for the following controls:

SINUMERIK 810D, 840D, 840Di, MMC 100 and MMC 102/103.

Software versions stated in the User's Guide refer to the 840D and their 810D

equivalent, e.g. SW 6 (840D) corresponds to SW 3 (810D).

SINUMERIK 840D powerline

From 09.2001

• SINUMERIK 840D powerline and

• SINUMERIK 840DE powerline

are available, with improved performance. A list of the available

powerline modules can be found in the hardware description

/PHD/ in Section 1.1

SINUMERIK 810D powerline

From 12.2001

• SINUMERIK 810D powerline and

• SINUMERIK 810DE powerline

are available, with improved performance. A list of the available

powerline modules can be found in the hardware description

/PHC/ in Section 1.1

0-10 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 11

11.02 Preface

0

Structure of the manual

0

840 D

NCU 571

Hotline

Internet address

840 D

NCU 572

NCU 573

810 D 840 Di

Explanation of symbols

Procedure

Please address any questions to the following hotline:

A&D Technical Support Phone: ++49-(0)180-5050-222

Fax: ++49-(0)180-5050-223

Email: adsupport@siemens.com

If you have any questions (suggestions, corrections) concerning

the documentation, please fax or e-mail them to the following

address:

Fax: ++49-(0)0131-98-2176

Email: motioncontrol.docu@erlf.siemens.de

Fax form: See answer form at the end of the document.

http://www.ad.siemens.de/sinumerik

Ordering option

Explanation

Function

Parameters

Programming example

Programming

Further notes

Cross-reference to other documentation, chapters,

sections, or subsections

Notes and indication of danger

Additional notes or background information

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 0-11

Page 12

Preface 11.02

0

Use as intended

0

840 D

NCU 571

Warnings

The following warnings are used with graded severity.

840 D

NCU 572

NCU 573

810 D 840 Di

Danger

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury or in

substantial property damage.

Warning

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury or in

substantial property damage.

Caution

Used with the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in

minor or moderate injury or in property damage.

Caution

Used without safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in

property damage.

Notice

Used without the safety alert symbol indicates a

potential situation which, if not avoided, may result in an

undesirable result or state.

0-12 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 13

11.02 Preface

0

Use as intended

0

840 D

NCU 571

Basis

Your SIEMENS SINUMERIK 840D, 804Di, 810D is

state of the art and is manufactured in accordance

with recognized safety regulations, standards and

specifications.

Add-on equipment

Using special add-on equipment and expanded

configurations from SIEMENS, SIEMENS controls

can be adapted to suit your specific application.

Personnel

Only authorized and reliable personnel with the

relevant training must be allowed to handle the

control. Nobody without the necessary training must

be allowed to work on the control, not even for a

short time.

840 D

NCU 572

NCU 573

810 D 840 Di

The responsibilities of the personnel employed for

setting, operating and maintenance must be clearly

defined and supervised.

Behavior

Before the control is started up, it must be ensured

that the Operator's Guide has been read and understood by the personnel responsible. The operating

company is also responsible for constantly

monitoring the overall technical state of the control

(faults and damage apparent from the outside and

changes in response).

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 0-13

Page 14

Preface 11.02

0

Use as intended

0

840 D

NCU 571

Service

Repairs must only be carried out in accordance with the

information given in the Service and Maintenance Guide

by personnel trained and qualified in the relevant

field. The relevant safety regulations must be observed.

Note

The following is contrary to the intended purpose and

exonerates the manufacturer from any liability:

Any use whatsoever beyond or deviating from the

application stated in the above points.

If the control is not in perfect technical condition, or

is operated without awareness for safety or the dangers

involved or without observing the instructions given in

the instruction manual.

840 D

NCU 572

NCU 573

810 D 840 Di

If faults that can reduce safety are not remedied before

the control is started up.

Any modification, overriding or deactivation of

equipment on the control used for the perfect

functioning, unrestricted use or active and passive

safety.

This can result in unforeseen dangers for:

• the health and life of people,

• the control, machine and other property of the

operating company and user.

0-14 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 15

12.97 Introduction

09.01

1

Introduction

1.1 Basics.............................................................................................................................. 1-16

1.2 General preconditions ..................................................................................................... 1-17

1.3 Plane definition................................................................................................................ 1-19

1.4 Suitable probes ............................................................................................................... 1-20

1.5 Workpiece probe, calibration tool in TO memory............................................................ 1-22

1.5.1 Workpiece probe in TO memory for milling machines and machining centers ....... 1-22

1.5.2 Workpiece probe, calibration tool in TO memory on turning machines ................... 1-23

1.6 Measuring principle ......................................................................................................... 1-25

1

1.7 Measuring strategy and compensation value calculation for tools with automatic

tool offset......................................................................................................................... 1-28

1.8 Parameters for checking the dimension deviation and compensation............................ 1-31

1.9 Effect of empirical value, mean value and tolerance parameters ................................... 1-37

1.10 Reference points on the machine and workpiece ........................................................... 1-38

1.11 Measurement variants for milling machines & machining centers .................................. 1-39

1.11.1 Workpiece measurement for milling machines........................................................ 1-39

1.11.2 Measurement variants for fast measurement at a single point................................ 1-40

1.11.3 Measurement variants for workpiece measurement paraxial .................................. 1-40

1.11.4 Measurement variants for workpiece measurement at random angles................... 1-42

1.11.5 Measuring a surface at a random angle .................................................................. 1-43

1.12 Measurement variants for lathes ..................................................................................... 1-44

1.12.1 Tool measurement for lathes ................................................................................... 1-44

1.12.2 Workpiece measurement for turning machines: Single-point measurement........... 1-45

1.12.3 Workpiece measurement for turning machines: Two-point measurement.............. 1-47

1.13 Measuring cycles interface.............................................................................................. 1-48

1.13.1 Displaying measuring result screens ....................................................................... 1-48

1.13.2 Setting parameters................................................................................................... 1-50

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-15

Page 16

Introduction 12.97

1

1.1 Basics

08.99

1

840 D

NCU 571

1.1 Basics

Measuring cycles are general subroutines designed to

solve specific measurement tasks. They can be suitably

adapted to the problem at hand by means of parameter

settings.

With regard to measurement applications, a distinction

must generally be made between tool measurement

and workpiece measurement.

Workpiece measurement

For workpiece measurement, a measuring probe is

moved up to the clamped workpiece in the same way as

a tool. The flexibility of the measuring cycles makes it

possible to perform nearly all measurements which may

need to be taken on a milling machine.

An automatic tool offset or an additive ZO can be

applied to the result of the tool measurement.

The measurement variants which can be implemented

with the measuring cycles available in this configuration

are described on the following pages.

840 D

NCU 572

NCU 573

810 D 840Di

Tool measurement

To perform tool measurement, the changed tool, which

in the case of a lathe is usually located in the turret, is

moved up to the probe which is either permanently fixed

or swiveled into the working range. The automatically

derived tool geometry is entered in the relevant tool

offset data record.

1-16 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 17

12.97 Introduction

11.02

1

1.2 General preconditions

1

840 D

NCU 571

840 D

NCU 572

NCU 573

1.2 General preconditions

Certain preconditions need to be fulfilled before

measuring cycles can be used.

These conditions are described in greater detail in Part

2 Description of Functions (from Chapter 8 onwards).

The following checklist is useful in determining whether

all such preconditions are fulfilled:

Machine

• All machine axes are designed in accordance with

DIN 66217

Availability of cycles

• The data blocks:

GUD5.DEF and

GUD6.DEF

have been loaded into the control ("Definitions"

directory in file system) and

• the measuring cycles have been loaded into the

standard cycle directory of the control followed by a

power ON operation.

Initial position

• The reference points have been approached.

• All axes are positioned prior to the cycle call in such

a way that the setpoint position can be approached

without a change in direction.

• The start position can be reached without collisions

by means of linear interpolation.

Displaying measuring result screens

It is only possible to display measurement result

screens with an MMC/PCU.

810 D 840Di

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-17

Page 18

Introduction 12.97

1

1.2 General preconditions

09.01

1

840 D

NCU 571

Programming

• The inch/metric units system selected in the

• The milling radius compensation and the

• All parameters for the cycle call have been defined

• The cycle is called no later than at the 5th program

• Neither of the operating modes "Block search" or

• The specified default setting of the supplied data

• With measuring cycles SW 4.4 and higher,

• With measuring cycles SW 4.4 and higher,

840 D

NCU 572

NCU 573

machine data for the basic setting is active.

programmable frame are deselected prior to the

cycle call.

beforehand.

level.

"Dry run" is active since these are automatically

skipped by the measuring cycles.

blocks is required to ensure that all example

programs run correctly.

measurement in a programmed measurement

system that differs from the basic system is possible,

i.e. in a metric basic system with active G70 and in

an inch basic system with active G71.

measurement in a programmed measurement

system that differs from the basic system is possible

with technology data switched over. This means in a

metric basic system with active G700 and in an inch

basic system with active G710.

810 D 840Di

Software status ID

In the delivery status of the measuring cycles, the

current software status of the control is entered in

parameter _SI[1] in the GUD6 block, i. e. 5 for SW 5.

This parameter must be changed to match the

measuring cycles to older software releases.

Example:

When using measuring cycles status 5.x.x on a control

with SW 4, à_SI[1] = 4

Precondition:

In order to use the measuring cycles, the software

status of the control must be ≥ 3.

1-18 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 19

12.97 Introduction

1

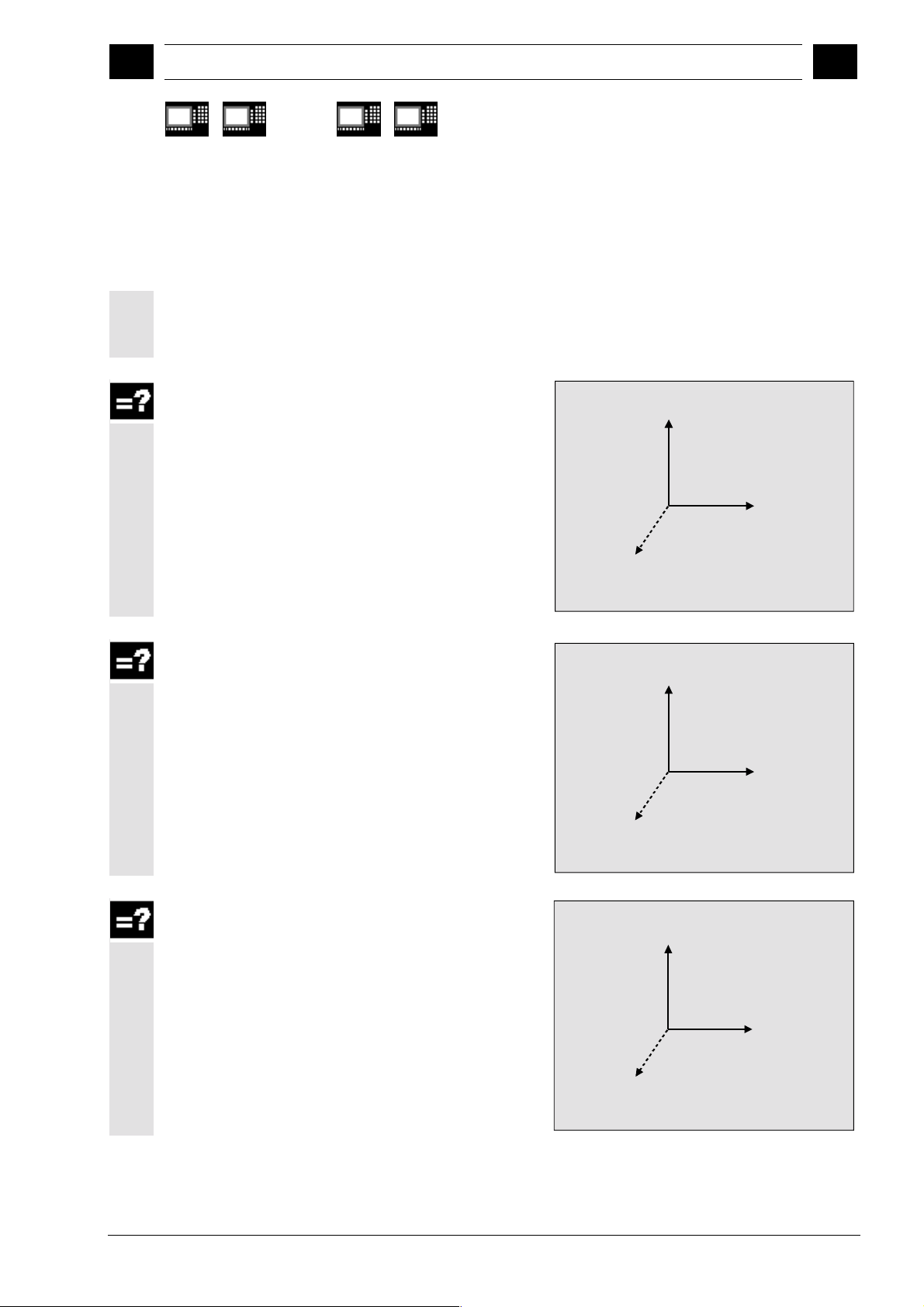

1.3 Plane definition

1

840 D

NCU 571

1.3 Plane definition

Tool radius compensation planes G17, G18 or G19 can

be selected. Lengths 1, 2 and 3 are assigned as follows

to the axes depending on the tool type used:

G17 plane

Tool type 100

Length 1 applies to Z

Length 2 applies to Y

Length 3 applies to X

840 D

NCU 572

NCU 573

810 D 840Di

Y

Ordinate

Abscissa X

Z

Applicate

G18 plane

Tool type 100

Length 1 applies to Y

Length 2 applies to X

Length 3 applies to Z

G19 plane

Tool type 100

Length 1 applies to X

Length 2 applies to Z

Length 3 applies to Y

X

Ordinate

Abscissa Z

Y

Applicate

Z

Ordinate

Abscissa Y

X

Applicate

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-19

Page 20

Introduction 12.97

1

1.4 Suitable probes

1

840 D

NCU 571

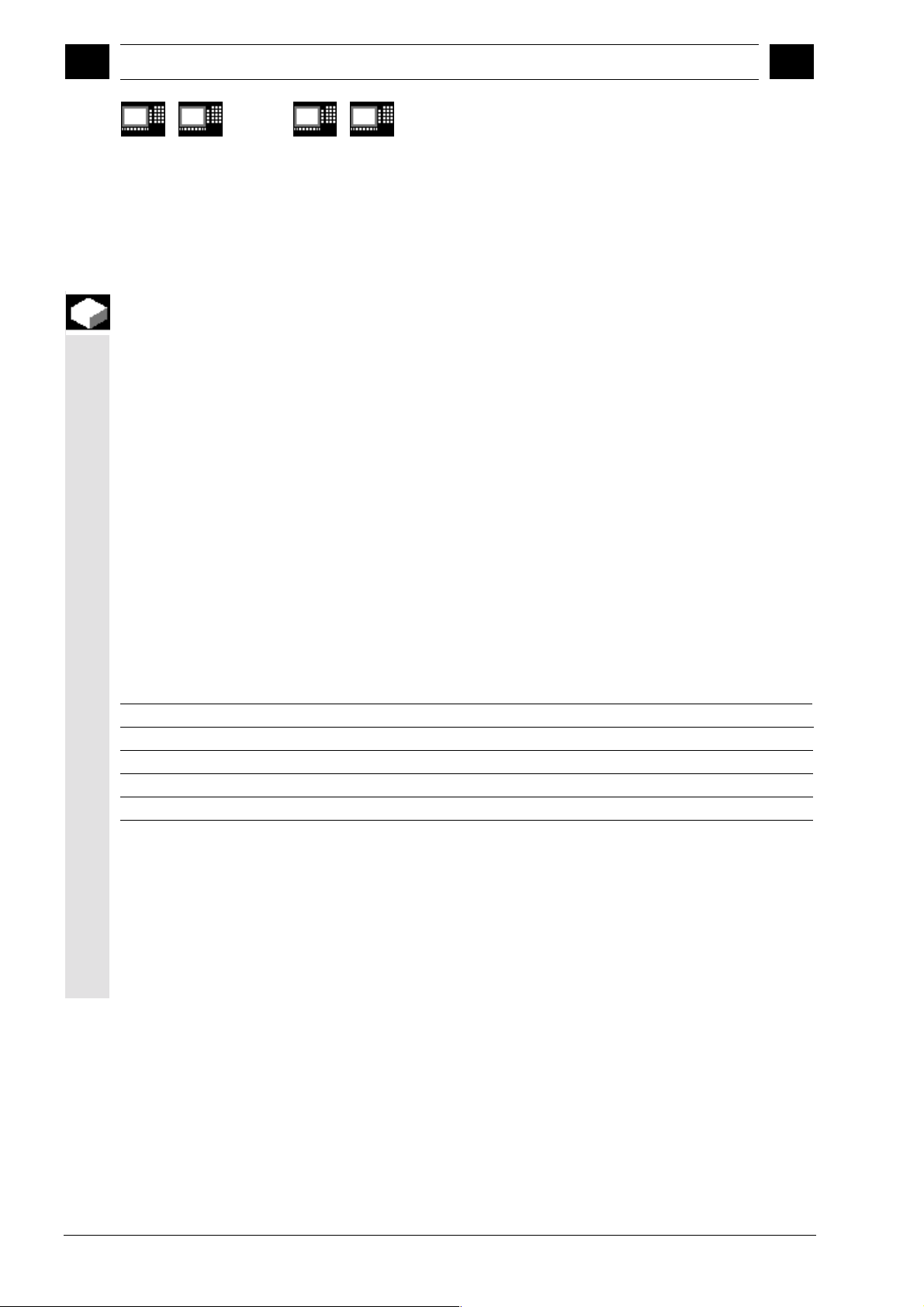

1.4 Suitable probes

Function

In order to measure tool and workpiece dimensions, a

touch-trigger probe is required that supplies a constant

signal (rather than a pulse) when deflected.

The probe must be capable of virtually bounce-free

switching. This is normally achieved by adjusting the

probe mechanically.

The probe type is defined in the measuring cycles in a

parameter.

Various types of probes made by different

manufacturers are available on the market. Probes are

classified in three groups according to the number of

directions in which they can be deflected.

Classification of probe types

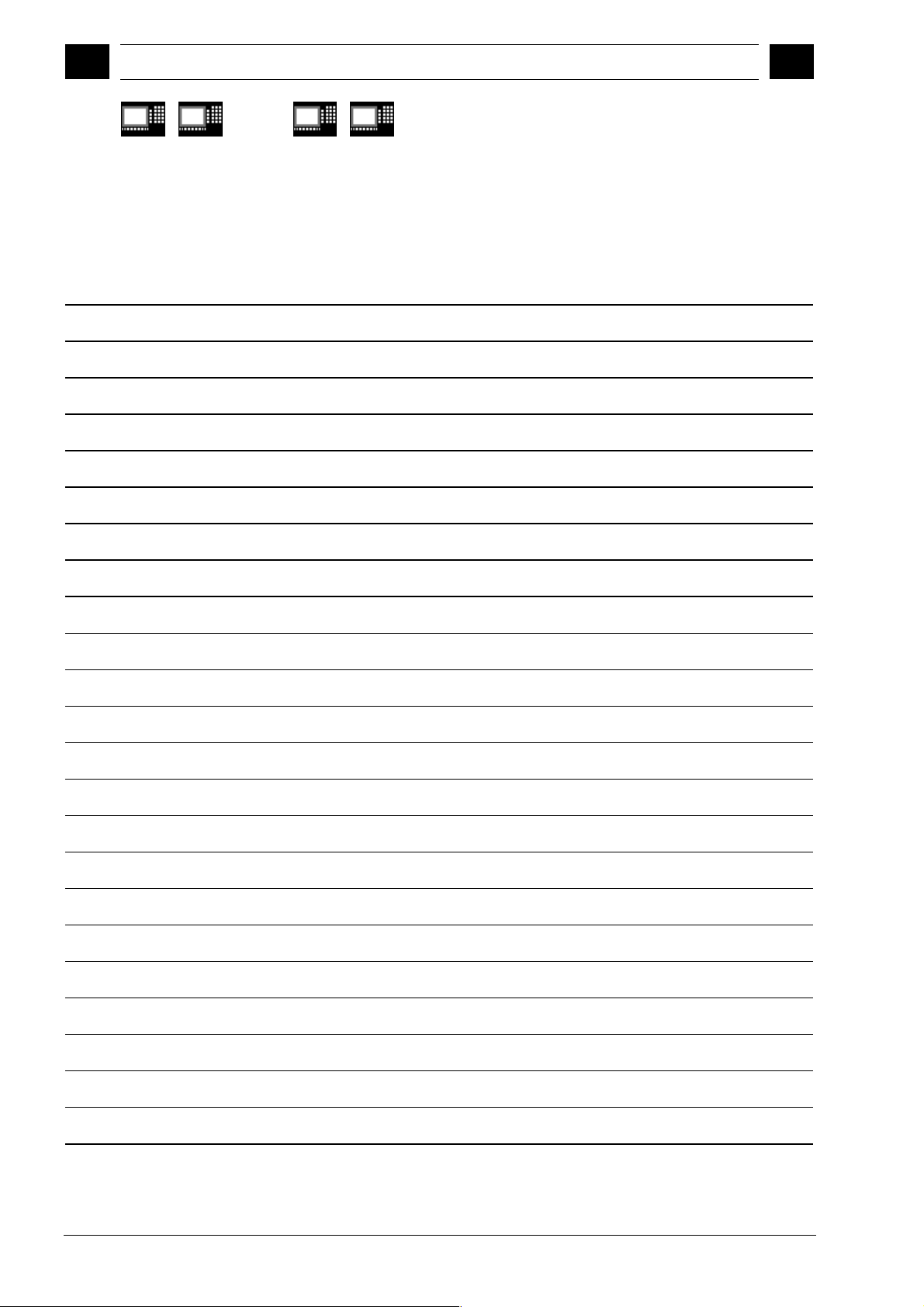

Probe type Turning machines Milling mach. and mach. centers

Multidirectional

Bidirectional

Monodirectional

While a bidirectional probe can be used for turning

machines, with milling machines and machining centers

it is also possible to use a mono probe for workpiece

measuring.

The probe is defined in the measuring cycles in a

parameter.

840 D

NCU 572

NCU 573

Tool measurement Workpiece measurement Workpiece measurement

X X X

- X X

- - X

810 D 840Di

1-20 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 21

12.97 Introduction

1

1.4 Suitable probes

1

840 D

NCU 571

Multidirectional probe (3D)

With this type, measuring cycles for workpiece

measurement can be used without limitation.

Bidirectional probe

This probe type is used for workpiece measurement on

milling machines and machining centers.

This probe type is treated in the same way as a

monodirectional probe for workpiece measurement on

milling machines and machining centers.

840 D

NCU 572

NCU 573

810 D 840Di

Monodirectional probe

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-21

This probe type can only be used for workpiece

measurement on milling machines and machining

centers with slight limitations; reference is made to this

in the cycles concerned.

In order to be able to use this type of probe on milling

machines and machining centers, it must be possible to

position the spindle with the NC function SPOS and to

transmit the switching signal of the probe through 360°

to the receiving station (at the machine column).

Page 22

Introduction 12.97

y

y

1

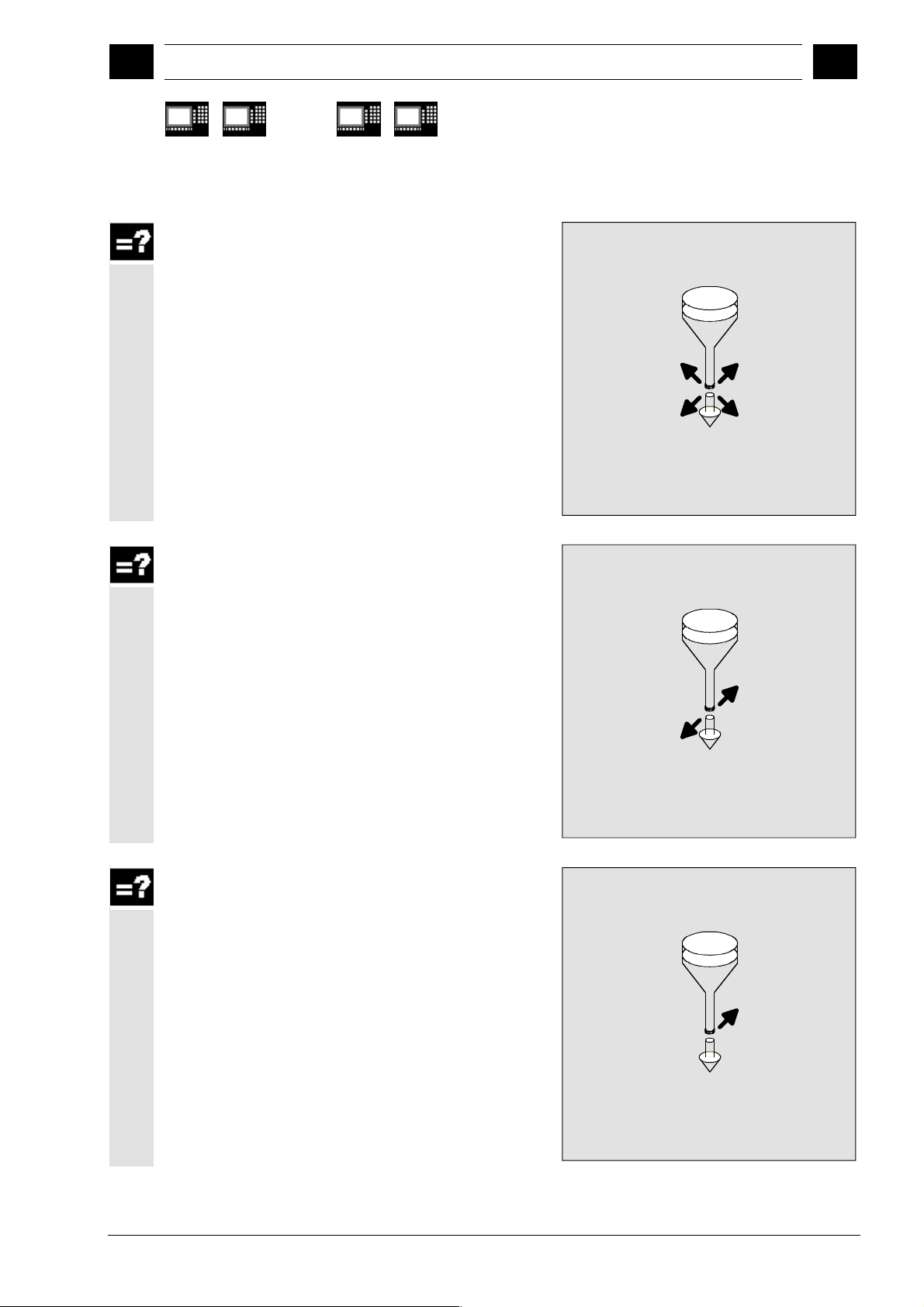

1.5 Workpiece probe, calibration tool in TO memor

1

840 D

NCU 571

The probe must be mechanically aligned in the spindle in

such a way that measurements can be taken in the following directions at the 0 degree position of the spindle.

X-Y plane G17 positive X direction

Z-X plane G18 positive Z direction

Y-Z plane G19 positive Y direction

The measurement will take longer when using a

1.5 Workpiece probe, calibration tool in TO memory

1.5.1 Workpiece probe in TO memory for milling machines and machining centers

monodirectional probe since the spindle must be

positioned in the cycle several times by means of SPOS.

Workpiece probe

On milling machines and machining centers, the probe

is classified as tool type 1x0 and must therefore be

entered as such in the TO memory.

In SW 4 and higher, tool type 710 (3D probe) can also

be used.

Entry in TO memory

840 D

NCU 572

NCU 573

810 D 840Di

P1 710 Tool type

P3 L1 Geometr

P6 r Geometry

P21 L1 Tool base dimension

L1

L1

_CBIT[14]=1

_CBIT[14]=0

r

1-22 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 23

12.97 Introduction

y

11.02

1

1.5 Workpiece probe, calibration tool in TO memor

1

840 D

NCU 571

1.5.2 Workpiece probe, calibration tool in TO memory on turning machines

840 D

NCU 572

NCU 573

810 D 840Di

On turning machines, the probes are treated as tool

type 500 with the permissible tool edge positions 5 to 8

and must therefore be entered like this in the TO

memory. Measuring cycle SW 6.2 and higher also

allows you to enter probe type 580 with tool edge

positions 5 to 8. Due to their spatial positions, the

probes are divided into the following types:

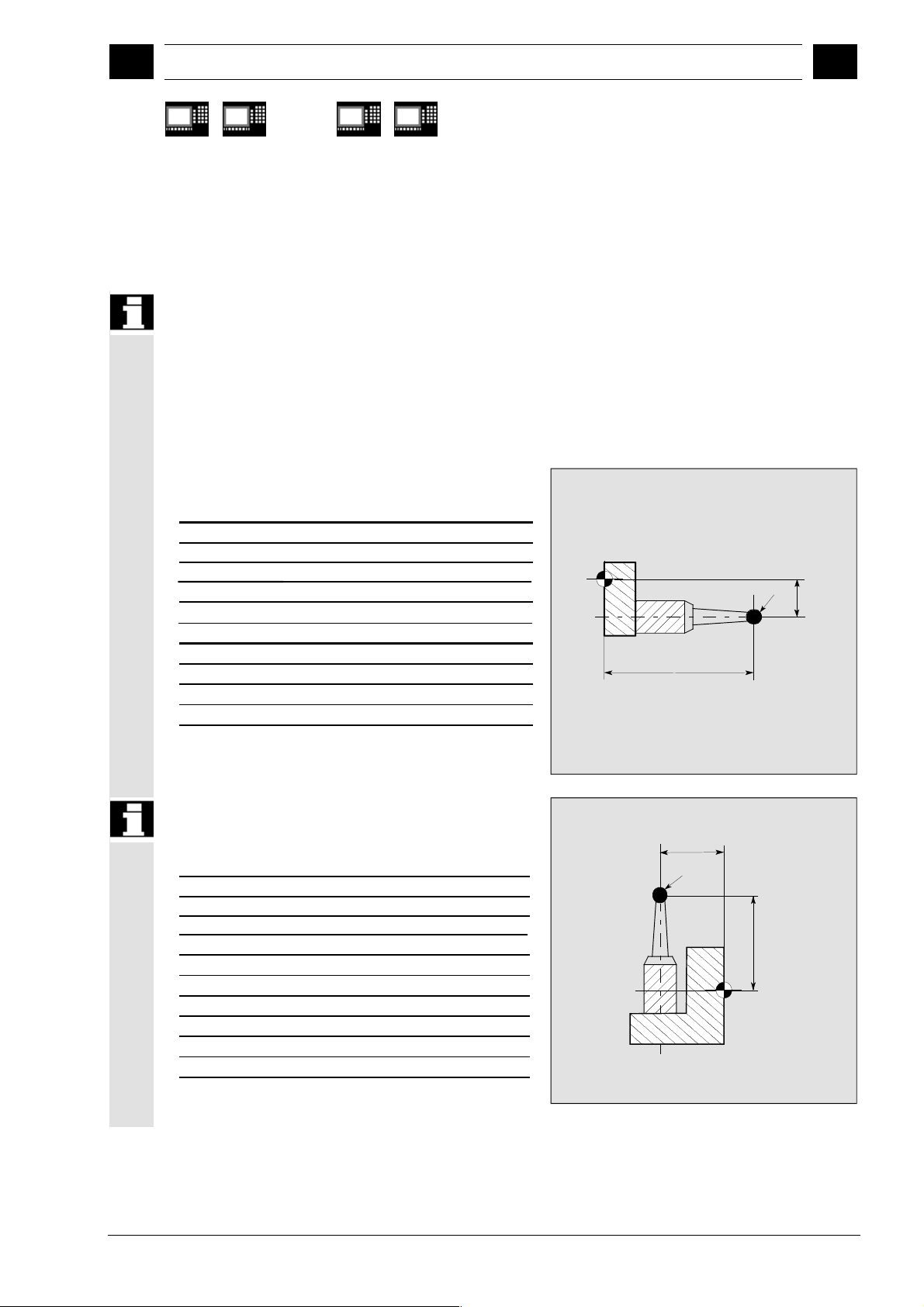

Workpiece probe SL 5

Entry in TO memory

P1 500 Tool type

P2 5 Tool edge position

P3 L1 Geometry

F

P4 L2 Geometry

P6 r Geometry

P12 L1 Wear

P13 L2 Wear

L2

P15 r Wear

P21 L1 Tool base dimension

P22 L2 Tool base dimension

r

L1

Workpiece probe SL 6 (8)

(data in brackets is in front of turning center)

Entry in TO memory

L2

r

P1 500 Tool type

P2 6 (8) Tool edge position

P3 L1 Geometry

P4 L2 Geometry

P6 r Geometry

L1

F

P12 L1 Wear

P13 L2 Wear

P15 r Wear

P21 L1 Tool base dimension

P22 L2 Tool base dimension

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-23

Page 24

Introduction 12.97

y

1

1.5 Workpiece probe, calibration tool in TO memor

1

840 D

NCU 571

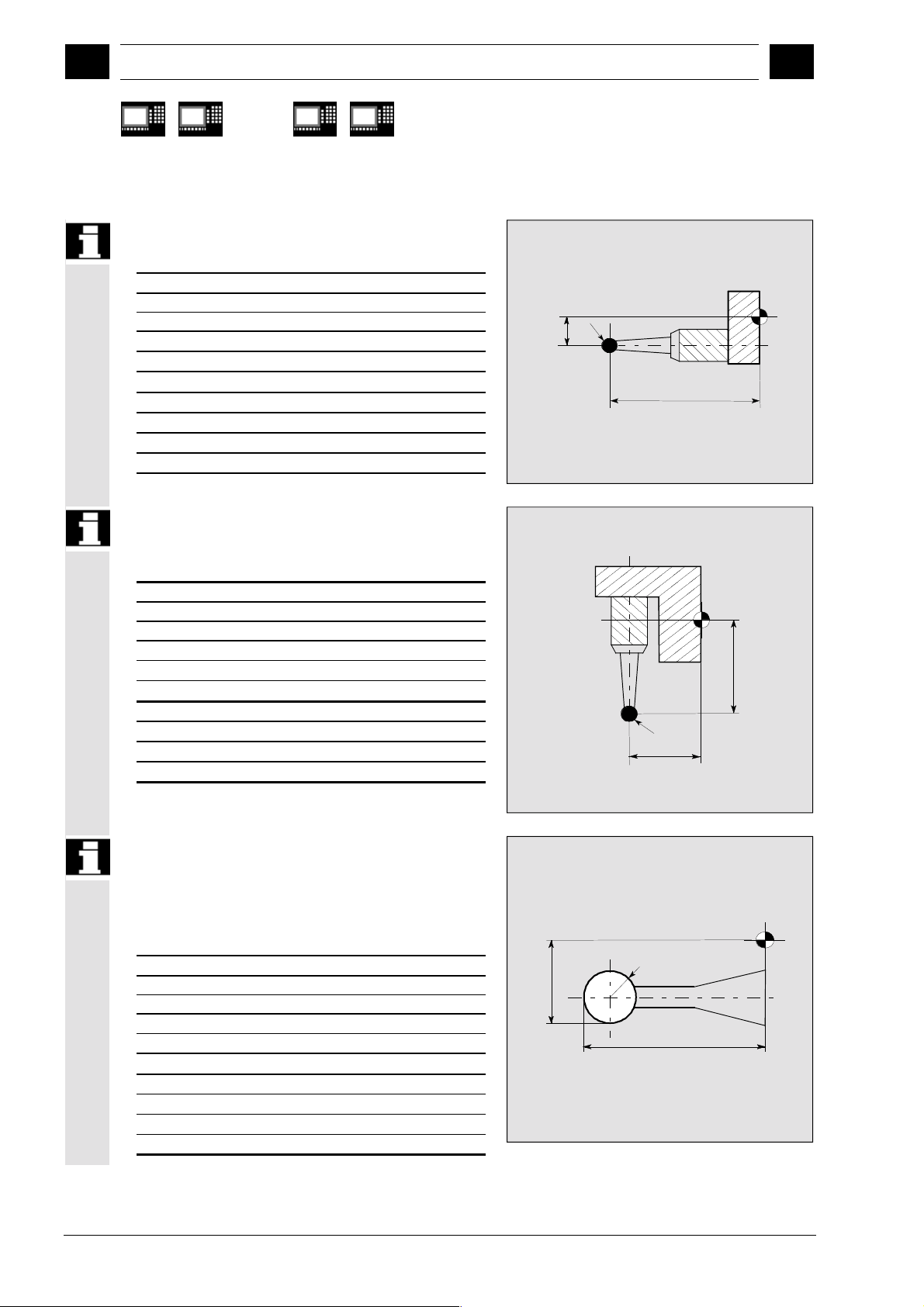

Workpiece probe SL 7

Entry in TO memory

840 D

NCU 572

NCU 573

810 D 840Di

P1 500 Tool type

P2 7 Tool edge position

P3 L1 Geometry

L1

F

r

P4 L2 Geometry

P6 r Geometry

P12 L1 Wear

L2

P13 L2 Wear

P15 r Wear

P21 L1 Tool base dimension

P22 L2 Tool base dimension

Workpiece probe SL 8 (6)

(data in brackets is in front of turning center)

Entry in TO memory

P1 500 Tool type

P2 8 (6) Tool edge position

P3 L1 Geometry

F

P4 L2 Geometry

P6 r Geometry

L1

P12 L1 Wear

P13 L2 Wear

P15 r Wear

P21 L1 Tool base dimension

P22 L2 Tool base dimension

r

L2

Calibration tool

On turning machines, the calibration tool is classified as

a tool with tool edge position 3 and must therefore be

entered as such in the TO memory.

Entry in TO memory

P1 500 Tool type

P2 3 Tool edge position

L1

r

F

P3 L1 Geometry

P4 L2 Geometry

P6 r Geometry

L2

P12 L1 Wear

P13 L2 Wear

P15 r Wear

P21 L1 Tool base dimension

P22 L2 Tool base dimension

Siemens AG, 2002. All rights reserved

1-24 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Page 25

12.97 Introduction

1

1.6 Measuring principle

1

840 D

NCU 571

1.6 Measuring principle

840 D

NCU 572

NCU 573

810 D 840Di

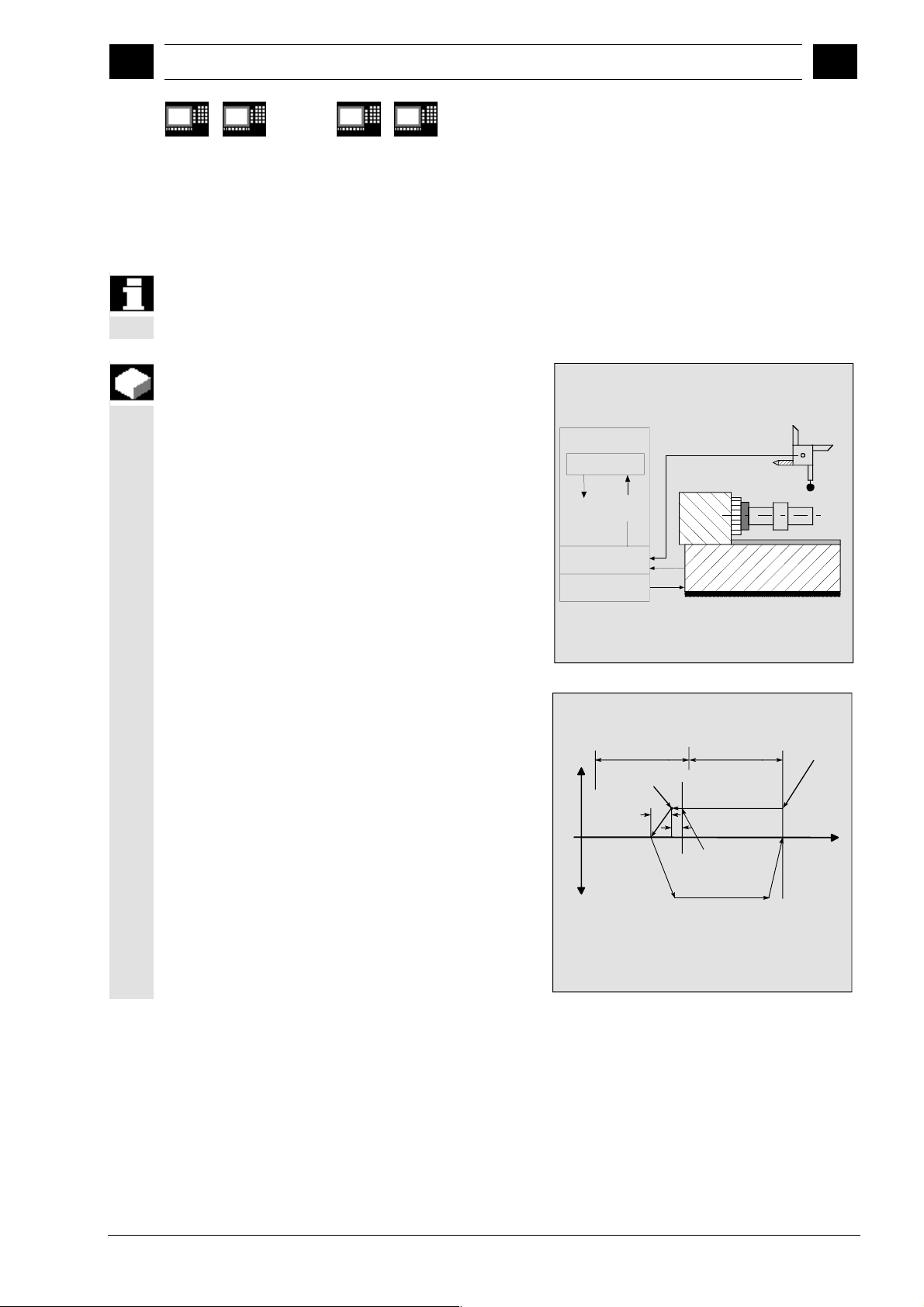

Two inputs for the connection of touch trigger probes

are provided on the I/O device interface of the

SINUMERIK 840D and the FM-NC control systems.

Function

Evaluation of the measuring probe signal

If a measuring point is to be approached, a traverse

command is transmitted to the position control loop and

the probe is moved towards the measuring point. A

point behind the expected measuring point is defined as

setpoint position. As soon as the probe makes contact,

the actual axis value at the time the switching position is

reached is measured and the drive is stopped. The

remaining "distance-to-go" is deleted.

NC

Meas. cycle

Delete

distanceto-go

Act. val. acquis.

Position control

Actual

value

"On-the-fly" measurement

The principle of "on-the-fly" measurement is

implemented in the control. The advantage of this

method is that the probe signal is processed directly in

the NC.

Set position

Meas. dist. a

V

Delete

dist.-to-go

-V

S

=Traversing path by signal processing

1

=Following error

S

2

1) Actual value loaded with probe signal

Meas. dist. a

Act. position

S

2

S

1

Probe switching

point

1)

G0

Start position

= End position

G0

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-25

Page 26

Introduction 12.97

1

1.6 Measuring principle

1

840 D

NCU 571

Start position/setpoint position

In the measuring procedure used, a position is specified

as setpoint value for the cycle at which the signal of the

touch-trigger probe is expected.

Since it is unlikely that the probe will respond at

precisely this point, the start position is approached by

the control in rapid traverse mode or at a defined

positioning velocity. The set position is then approached

at the feedrate specified in the parameter for

measurement speed. The switching signal is then

anticipated over a distance of a maximum length of 2a

from the start position.

Load actual value/delete distance-to-go

At the instant the switching signal is output by the

probe, the current position is stored internally "on-thefly" as the actual value followed by execution of the

"Delete distance-to-go" function.

Measuring path a/measuring speed

The path increment a is normally 1 mm, but can be

increased with a parameter when measuring cycles are

called.

The approach speed automatically increases from

150 mm/min to 300 mm/min if the value for a is defined

as greater than 1.

The maximum approach speed (measurement speed)

is thus dependent upon

• the permissible deflection path of the probe used

• the delay until "delete distance to go" is executed

• the deceleration behavior of the axis.

and

840 D

NCU 572

NCU 573

810 D 840Di

1-26 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 27

12.97 Introduction

11.02

1

1.6 Measuring principle

1

840 D

NCU 571

Calculation of the deceleration path

840 D

NCU 572

NCU 573

810 D 840Di

Since an optimal measurement speed can be set for

measuring cycles via a parameter, it must be ensured

that safe deceleration can take place within the

deflection path of the probe.

The required deceleration path can be calculated as

follows:

2

sb = v t +

s

b

Deceleration path in m

v

·

s

∆

1

2a

+ ∆s

∆

s

2

v Approach speed in m/s

t Delay in s

b Deceleration in m/s

2

s Following error in m

Measuring accuracy

The repeat accuracy of the 840D and FM-NC controls

for "on-the-fly measurement" is ±1 µm.

The measuring accuracy which can be obtained is thus

dependent on the following factors:

• Repeat accuracy of the machine

• Repeat accuracy of the probe

• Resolution of the measuring system

Example: Path-time diagram

s [mm]

Deceleration

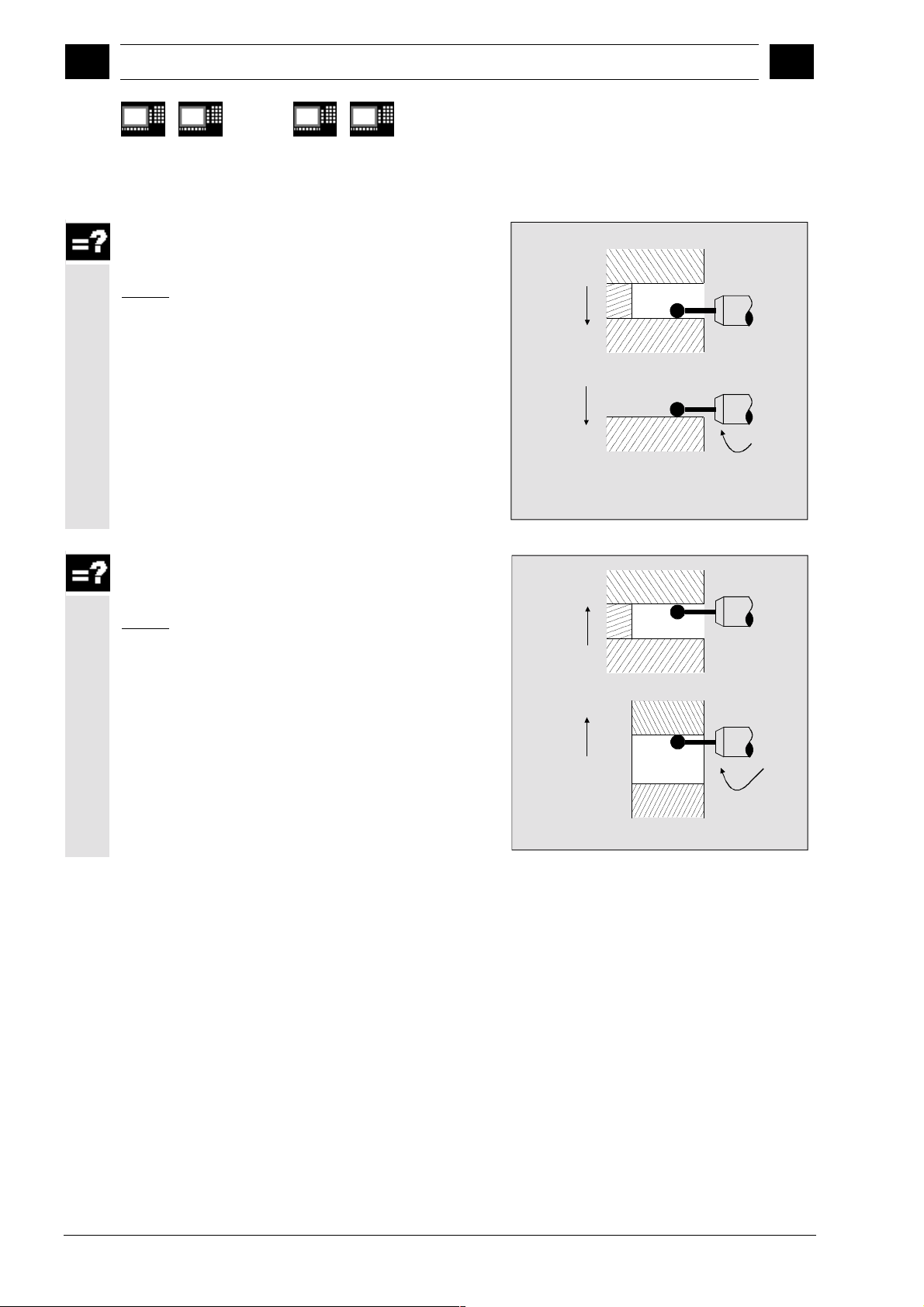

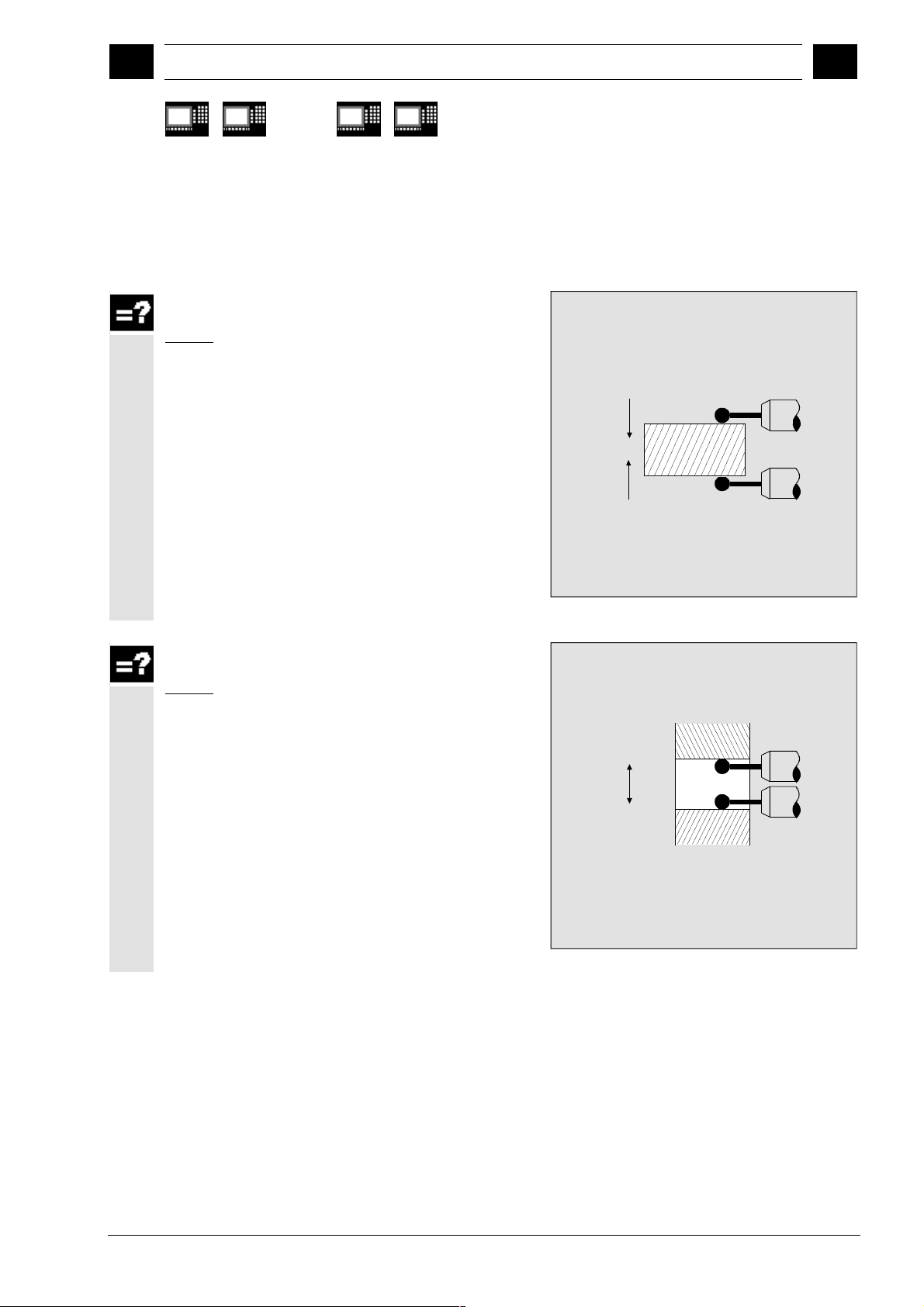

2

b = 1m/s

10

Ds

2

(11 mm)

Ds

1

(1.66 mm)

The deflection of the probe up to zero spee d of the axis is

approximately 12.6 mm with an approach speed of 6 m/min

and a delay of 1 m/s

Kv-Factor

1m/min

=

K

v

5

min

Zero speed

0

1 m/min

10

(16 ms) Delay until distance-to-go is deleted

2

!

6 m/min

Approach speed v

4 m/min

10 10

Axis

zero speed

Zero speed

t [ms]

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-27

Page 28

Introduction 12.97

1

1.7 Measuring strategy and compensation value calculation for tools

08.99

1

840 D

NCU 571

1.7 Measuring strategy and compensation value calculation for tools with automatic tool

840 D

NCU 572

NCU 573

810 D 840Di

offset

The actual workpiece dimensions must be measured

exactly in order to be able to determine and

compensate the actual dimensional deviations on the

workpiece.

Function

When taking measurements on the machine, the actual

dimensions are derived from the path measuring

systems of the position-controlled feed axes. For each

dimensional deviation determined from the set and

actual workpiece dimensions there are many causes

which essentially can be classified in 3 categories:

• Dimensional deviations with causes that are

n o t subject to a particular trend,

scatter of the feedforward axes or differences in

measurement between the internal measurement

(measuring probe) and the external measuring

device (micrometer, measuring equipment, etc.).

In this case, it is possible to apply so-called

empirical values, which are stored in separate

memories. The set/actual difference determined is

automatically compensated by the empirical value.

• Dimensional deviations with causes that a r e

subject to a particular trend

thermal expansion of the leadscrew.

These deviations are compensated by specifying

fixed threshold values.

• Accidental dimensional deviations, e.g. due to

temperature fluctuations, coolant or slightly soiled

measuring points.

, e.g. tool wear or

e.g. positioning

1-28 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 29

12.97 Introduction

1

1.7 Measuring strategy and compensation value calculation for tools

1

840 D

NCU 571

840 D

NCU 572

NCU 573

810 D 840Di

Assuming the ideal case, only those dimensional

deviations which are subject to a trend can be taken

into account for compensation value calculation. Since,

however, it is hardly ever known to what extent and in

which direction accidental dimensional deviations

influence the measurement result, a strategy (floating

average value generation) is needed which derives a

compensation value from the actual/set difference

measured.

Mean value calculation

Mean value calculation in combination with a higherorder measurement weighting has proved a suitable

means to do this.

The formula of the mean value generation chosen is:

Mv D

−

Mv Mv

=−

new old

old i

k

Mv

Mv

Mean value new = amount of compensation

new

Mean value prior to last measurement

old

k Weighting factor for average value calculation

D

Actual/set difference measured

i

(minus empirical value, if any)

The mean value calculation takes account of the trend

of the dimensional deviations of a machining series,

weighting factor k from which the mean value is

where

derived is selectable.

A new measurement result affected by accidental

dimensional deviations only influences the new tool

offset to some extent, depending on the weighting

factor.

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-29

Page 30

Introduction 12.97

1

1.7 Measuring strategy and compensation value calculation for tools

08.99

1

840 D

NCU 571

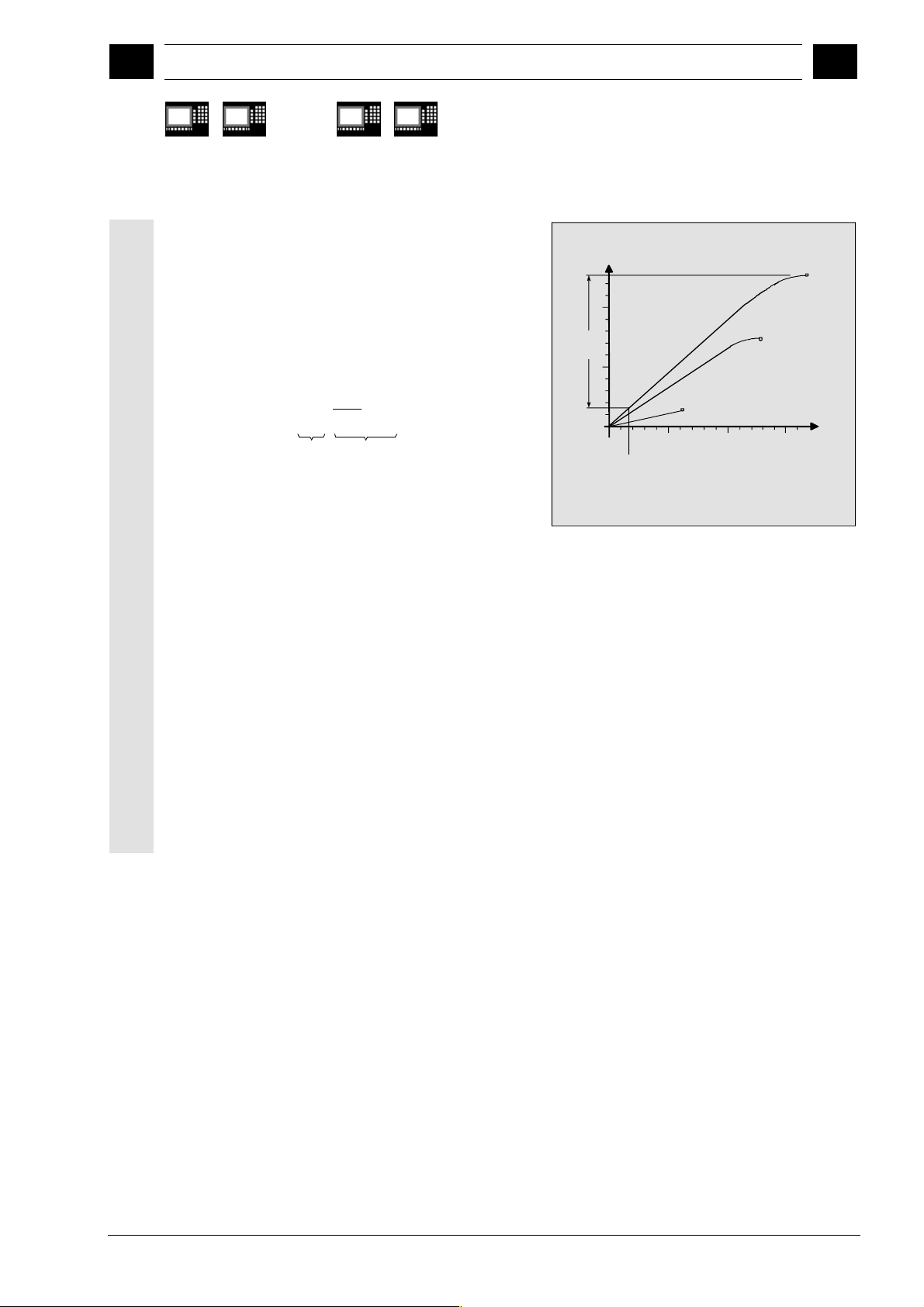

Computational characteristic of the mean value

840 D

NCU 572

NCU 573

810 D 840Di

with different weightings k (effects)

• The greater the value of k, the slower the formula

will respond when major deviations occur in

computation or counter compensation. At the same

time, however, accidental scatter will be reduced as

k increases.

• The lower the value of k, the faster the formula will

react when major deviations occur in computation or

counter compensation. However, the effect of

accidental variations will be that much greater.

• The mean value Mv is calculated starting at 0 over

the number of workpieces i, until the calculated

average value exceeds the range of "zero

compensation". From this limit on, the calculated

average value is applied for compensation.

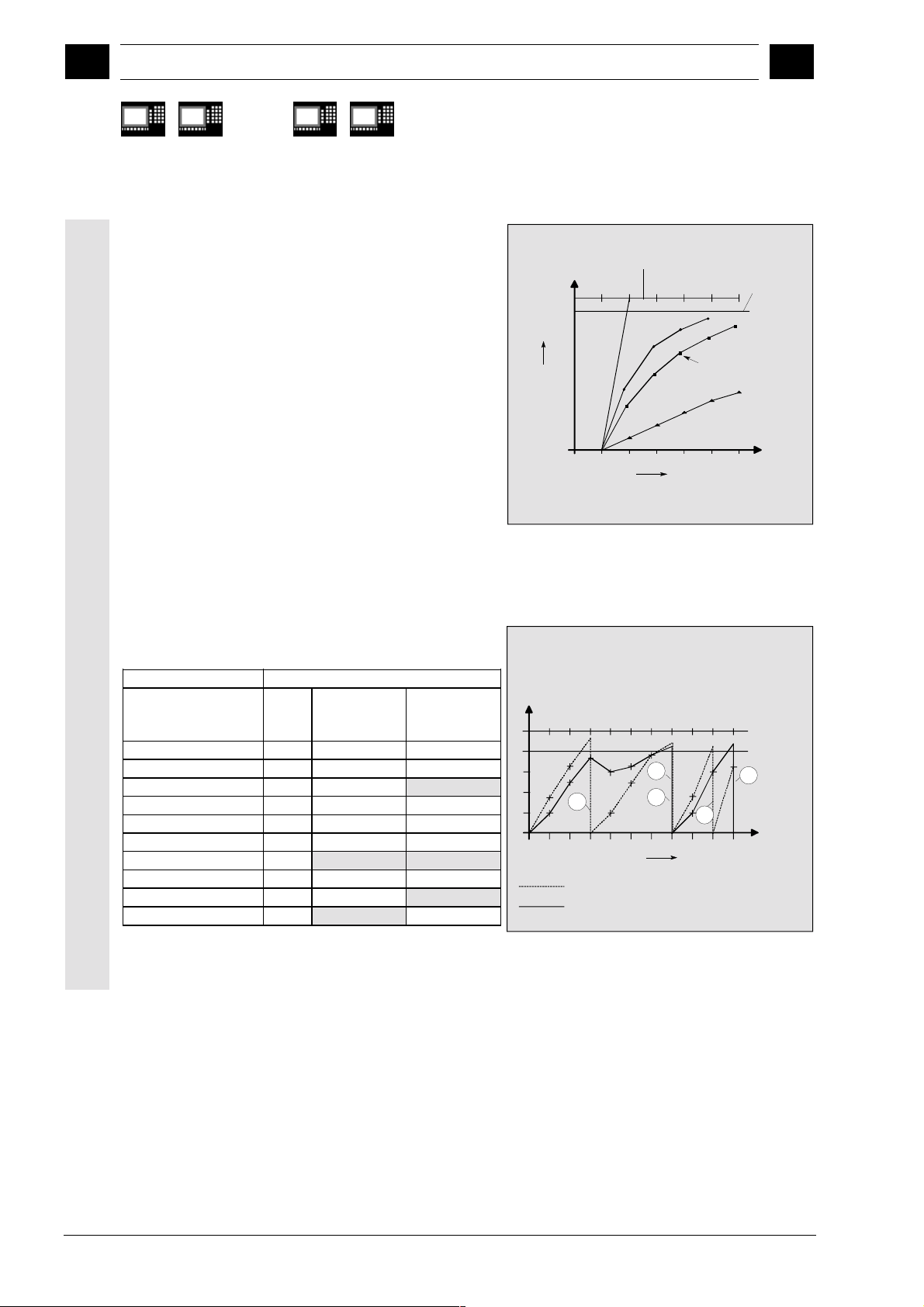

Example of mean value generation

Lower limit = 40 µm

D

[µm]

Mean value

i

k=3

[µm]

Mean value

k=2

[µm]

1st measurement 30 10 15

2nd measurement 50 23.3 32.5

3rd measurement 60 35.5 46.2

4th measurement 20 30.3 10

5th measurement 40 32.6 25

6th measurement 50 38.4 37.5

7th measurement 50 42.3

43.75

8th measurement 30 10 15

9th measurement 70 30 42.5

10th measurement 70 43.3

35

Set/actual difference

D

i

Mean

value

calculated

Setpoint

1234 560

Characteristic of mean values

with two different weighting factors k

D

i

50

40

30

20

10

3

12345678910

k=2

k=3

Lower limit = "Zero offset"

k=1

k=2

k=3

Number of averaging operations

(workpieces)

1

4

Number of averaging operations

(workpieces)

Mean value

calculated

k=10

Set/actual difference

Zero compensation

2

5

1-30 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 31

12.97 Introduction

08.99

1

1.8 Parameters for checking the dim. deviation and compensation

1

840 D

NCU 571

1.8 Parameters for checking the dim. deviation and compensation

Explanation

For constant deviations not subject to a trend the

dimensional deviation measured can be compensated

by an empirical value for certain measurement variants.

For other compensations resulting from dimensional

deviations, symmetrical tolerance bands are assigned

to the set dimension which result in different responses.

Empirical value _EVNUM

The empirical values are used to suppress dimensional

deviations

The empirical values are stored in the GUD field

_EV empirical value.

_EVNUM specifies the number of the empirical value

memory. The actual/set difference determined by the

measuring cycle is corrected by this value

further correction measures are taken.

This is the case

• for workpiece measurement with automatic tool

• for tool measurement

• for single-point measurement with automatic

The tolerance bands (range of permissible dimensional

tolerance) and the responses derived from them have

been specified as follows:

840 D

NCU 572

NCU 573

that are not subject to a trend.

offset

ZO compensation

810 D 840Di

before any

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-31

Page 32

Introduction 12.97

1

1.8 Parameters for checking the dim. deviation and compensation

05.98

1

840 D

NCU 571

•

840 D

NCU 572

NCU 573

810 D 840Di

For workpiece measurement with automatic

tool offset

_TSA

_TDIF

_TLL, _TUL

_TMV

_TZL

Safe area

Dimensional difference check

Workpiece tolerance

2/3 workpiece tolerance

Zero compensation (lower limit)

Setpoint

Alarm: "Safe area overrun"

Alarm: "Permissible dimensional difference overrrun"

Compensation of current

deviation

Alarm: "Oversize", "Undersize"

Compensation of current

deviation

Averaging (_EVNUM, _K) and

compensation by mean value

Averaging is stored

The workpiece set dimension is placed in the center

of the permissible ± tolerance limit applied.

For tool measurement

•

_TSA

_TDIF

_TZL

Safe area

Dimensional difference check

Zero compensation (lower limit)

Setpoint = Tool data

Alarm: "Safe area overrun"

Alarm: "Permissible dimensional difference overrun"

Tool memory is

compensated

Tool memory

unchanged

1-32 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 33

12.97 Introduction

05.98

1

1.8 Parameters for checking the dim. deviation and compensation

1

840 D

NCU 571

•

840 D

NCU 572

NCU 573

810 D 840Di

For workpiece measurement with zero offset

_TSA

Safe area

Setpoint

For workpiece probe calibration

•

_TSA

Safe area

Alarm: "Safe area overrun"

Compensation of

ZO memory

Alarm: "Safe area overrun"

_TZL

Zero compensation (lower limit)

Setpoint =_WP[]-data

For tool probe calibration

•

_TSA

_TZL

Safe area

Zero compensation (lower limit)

Setpoint=_TP[]-data

_WP[] data is compensated

_WP[] data

unchanged

Alarm: "Safe area overrun"

_TP[] data is compensated

_TP[] data

unchanged

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-33

Page 34

Introduction 12.97

1

1.8 Parameters for checking the dim. deviation and compensation

08.99

1

840 D

NCU 571

Safe area _TSA

The safe area is active for all measurement variants

and does not affect the offset value; it is used for

diagnosis.

If this value is reached,

• a defect in the probe,

• an incorrect setpoint position or

• an illegal deviation from the setpoint position

may be the cause.

AUTOMATIC operation is interrupted and the program

cannot continue. An alarm text appears to warn the

user.

Dimensional difference control _TDIF

_TDIF is active only for workpiece measurement with

automatic tool offset and for tool measurement.

This limit has no effect on generation of the

compensation value either. When it is reached, the tool

is probably worn and needs to be replaced.

840 D

NCU 572

NCU 573

810 D 840Di

An alarm text is displayed to warn the operator and the

This tolerance limit is generally used by the PLC for tool

program can be continued by means of an NC start.

management purposes (twin tools, wear monitoring).

Tolerance of the workpiece _TLL, _TUL

Both parameters are active only for tool measurement

with automatic tool offset.

When measuring a dimensional deviation ranging

between "2

difference control", this is regarded 100% as tool

compensation. The previous average value is erased.

It is therefore possible to effect fast counteraction if

major dimensional deviations occur.

/3 tolerance of workpiece" and "Dimensional

1-34 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 35

12.97 Introduction

08.99

1

1.8 Parameters for checking the dim. deviation and compensation

1

840 D

NCU 571

840 D

NCU 572

NCU 573

810 D 840Di

AUTOMATIC operation is interrupted when the tolerance

limit of the workpiece is exceeded. "Oversize" or

"undersize" is displayed to the operator depending on the

tolerance zone position. Machining can be continued by

means of NC start.

2/3 workpiece tolerance _TMV

_TMV is active only for workpiece measurement with

automatic tool offset.

Within the range of "Lower limit" and "2

/3 workpiece

tolerance" the mean value is calculated according to the

formula described in Section "Measuring strategy".

Mv

• If Mv

is compared with the zero compensation range:

new

is greater than this range, compensation is

new

corrected by Mv

and the associated mean value

new

memory is cleared.

• If Mv

is less than this range, no compensation is

new

carried out to prevent excessively abrupt

compensations from being made.

Mean value_EVNUM

_EVNUM is active only for workpiece measurement with

automatic tool offset.

When calculating the mean value in a series of

machining operations, the mean value determined by the

measurement at the same measurement location on the

previous workpiece can be taken into account

(_CHBIT[4]=1).

The mean values are stored in the GUD field

values

. _EVNUM also specifies the number of the mean

value memory in this GUD field.

Weighting factor for mean value calculation _K

_K is active only workpiece measurement with automatic

tool offset. The weighting factor k can be applied to allow

different weighting to be given to an individual

measurement.

A new measurement result thus has only a limited effect

on the new tool offset as a function of _K.

_MV mean

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-35

Page 36

Introduction 12.97

1

1.8 Parameters for checking the dim. deviation and compensation

1

840 D

NCU 571

Bottom limit (zero compensation area) _TZL

_TZL active for

• Workpiece measurement with automatic tool offset

• Tool measurement and calibration for milling tools

This tolerance range corresponds to the amount of

maximum accidental dimensional deviations. It has to

be determined for each machine.

No tool compensation is made within these limits.

However, the average value of this measuring point is

updated and re-stored with the actual/set difference

measured for workpiece measurement with automatic

tool offset, compensated by an empirical value if

necessary.

840 D

NCU 572

NCU 573

and tool probes

810 D 840Di

1-36 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 37

12.97 Introduction

05.98

1

1.9 Effect of empirical value, mean value and tolerance parameters

1

840 D

NCU 571

1.9 Effect of empirical value, mean value and tolerance parameters

840 D

NCU 572

NCU 573

810 D 840Di

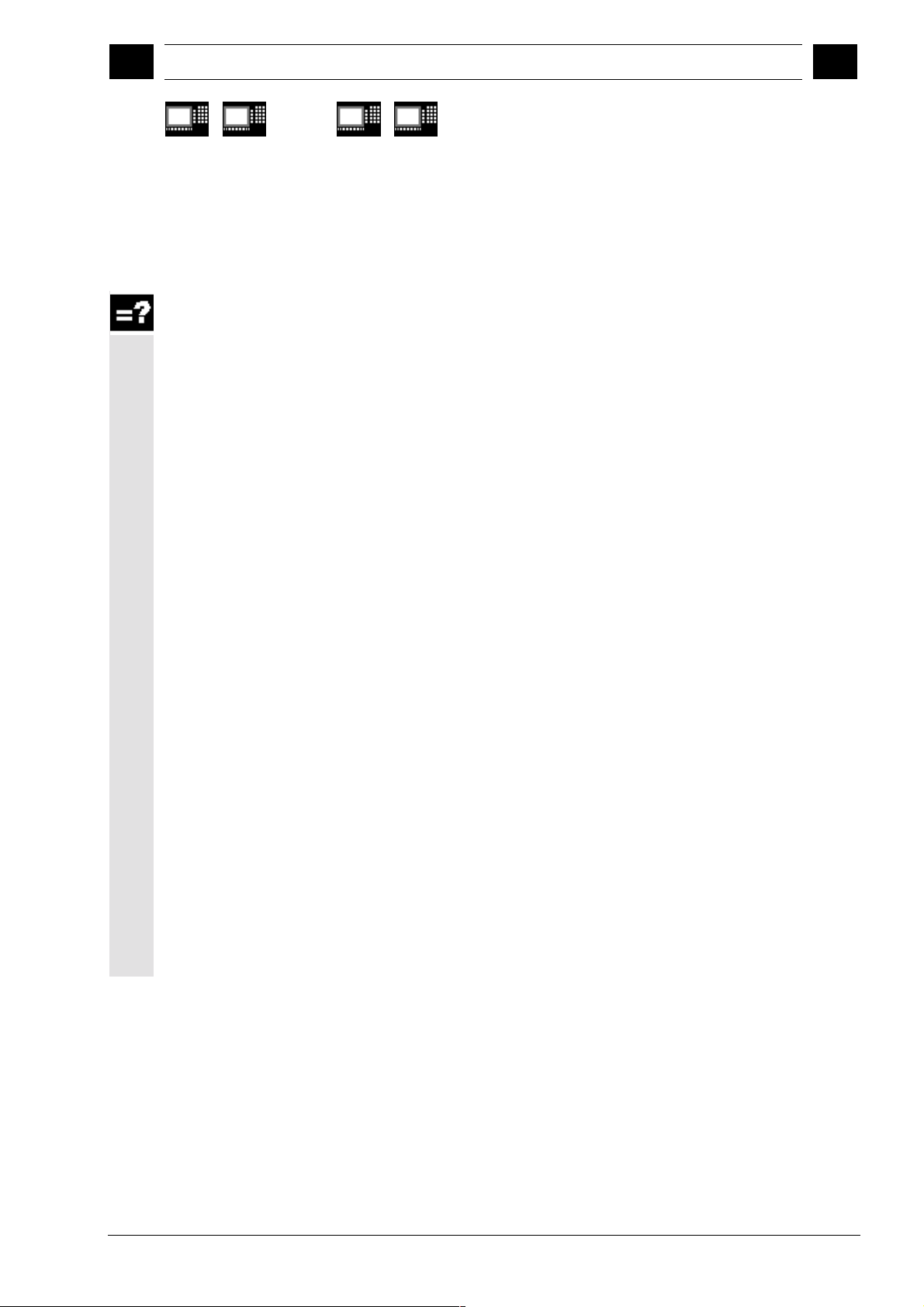

The following flowchart shows the effect of empirical

value, mean value and tolerance parameters by way of

a workpiece measurement with automatic tool offset.

Measuring cycle

Measure

Calculate act/set difference

Difference

minus

empirical value

No

Difference >

safe area _TSA

Yes

No

Compensation strategy

Calculate mean value considering

weighting factor _K

Mean value >

lower limit _TZL

Store mean value

(only for _CHBIT[4]=1)

No

Difference >

workpiece tol.

_TUL/_TLL

Difference >

2/3 workpiece

tol. _TMV

Smoothed

YesNo

compensation

Compensation

by mean value

Delete

mean value

Difference >

dimensional diff.

control _TDIF

Yes

Display:

Oversize

or

undersize

100 % compens.

YesNo

Delete

mean value

Compensation

by difference

Yes

Display:

Permiss. Dimensional difference

exceeded

Repeat

measurement

No

Alarm 61303

Alarm:

Safe area

exceeded

Display:

Safe area

exceeded

No

Yes

Yes

End

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-37

Page 38

Introduction 12.97

1

1.10 Reference points on the machine and workpiece

1

840 D

NCU 571

840 D

NCU 572

NCU 573

810 D 840Di

1.10 Reference points on the machine and workpiece

Function

The actual axis values of different actual value

systems must be measured depending on the

measuring process applied. While, for example, the

machine actual value can be used to advantage to

calculate the tool length, the workpiece zero is

important for measuring workpiece dimensions and

calculating the tool wear compensation. The

machine actual value is the dimension between the

machine zero and the tool reference point.

M = Machine zero

M' = Machine zero offset by DRF

C = Control zero resulting from PRESET offset

W = Workpiece zero

F = Tool reference point

Y

Spindle

chuck

MM'C W

Workpiece

X

PF

F

Y

PF

X

1-38 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 39

12.97 Introduction

1

1.11 Measurement variants for milling machines & machining centers

1

840 D

NCU 571

1.11 Measurement variants for milling machines & machining centers

840 D

NCU 572

NCU 573

810 D 840Di

The measurement variants which can be implemented

with measuring cycles for milling machines and

machining centers are illustrated in diagrams below.

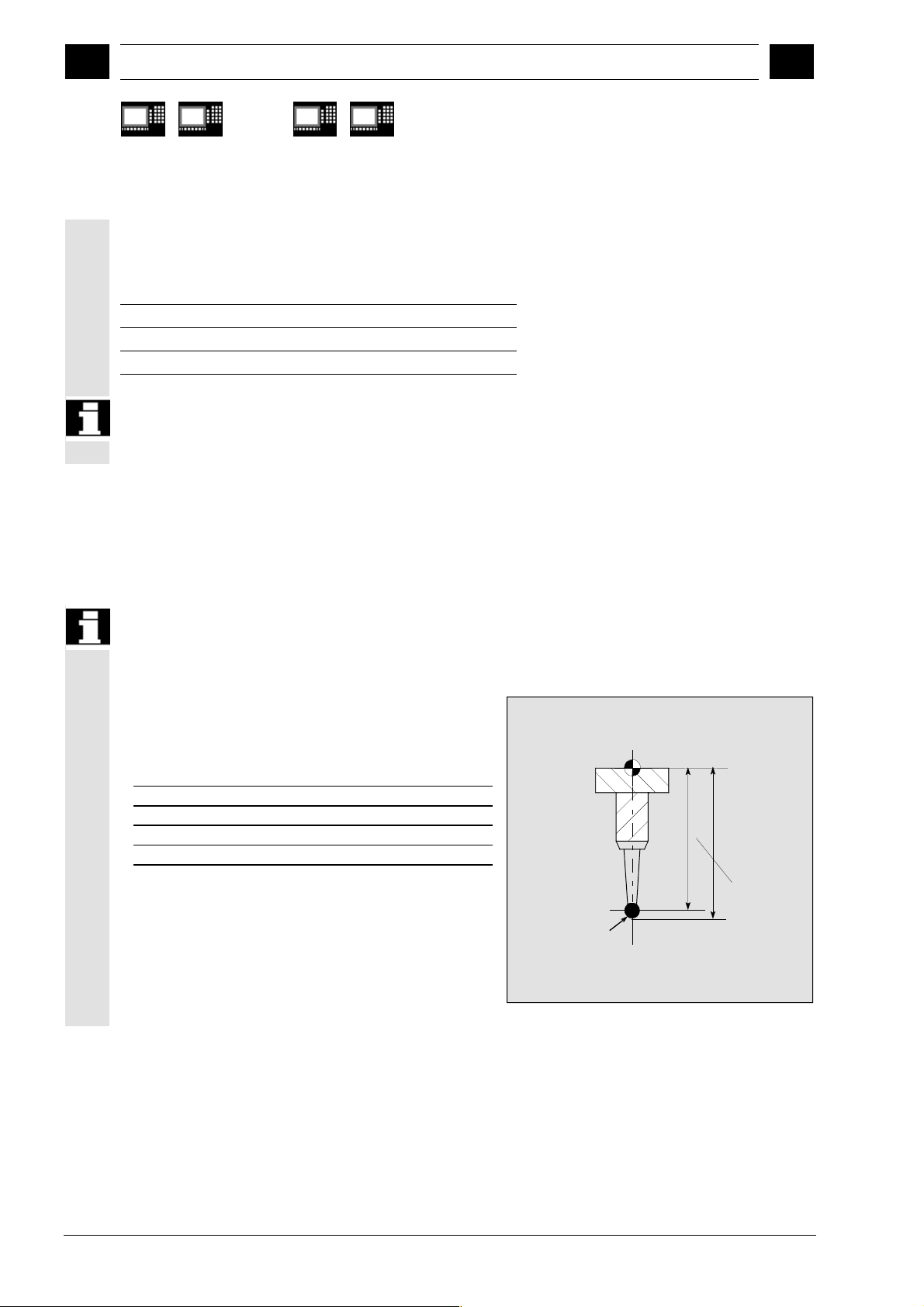

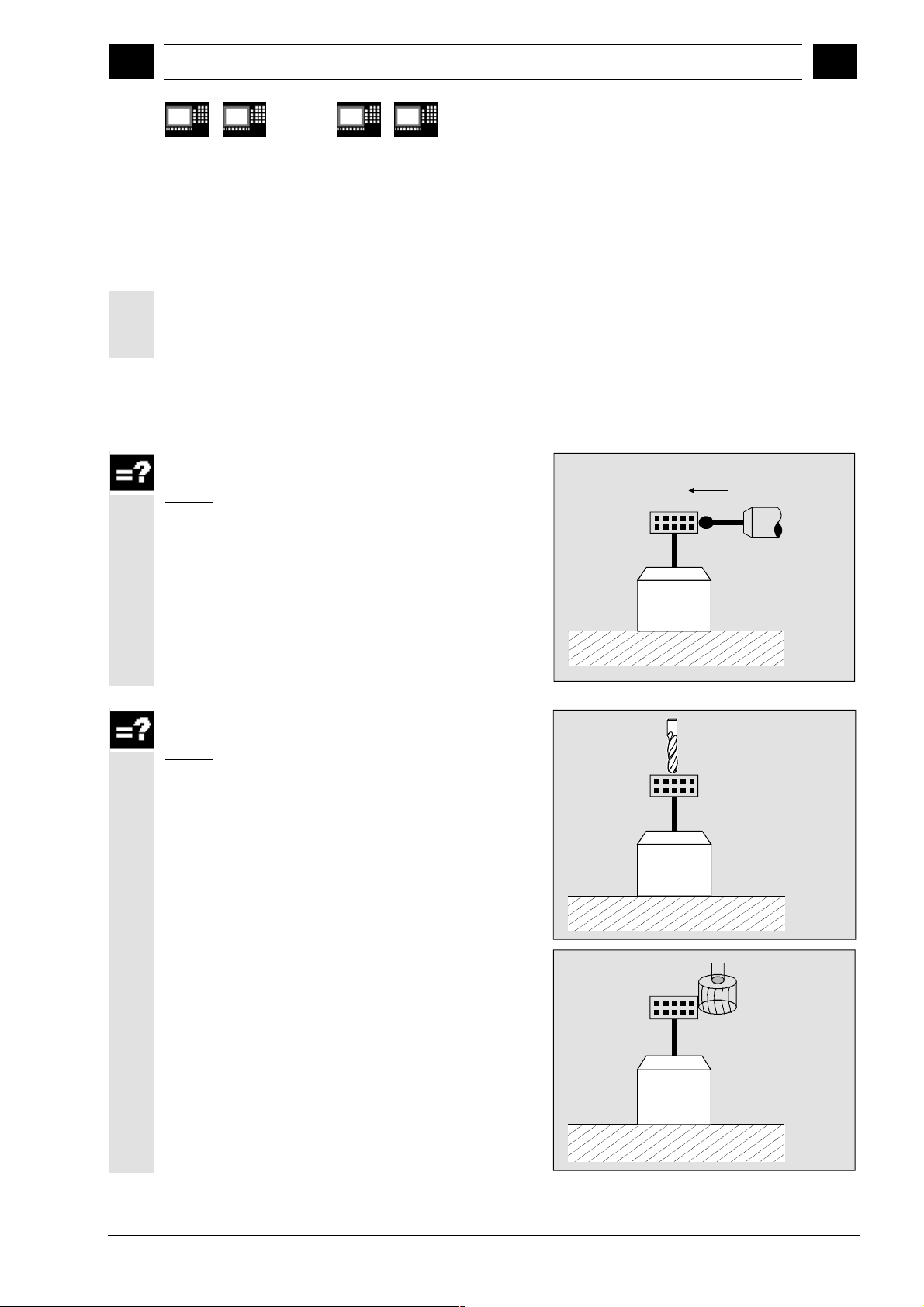

1.11.1 Workpiece measurement for milling machines

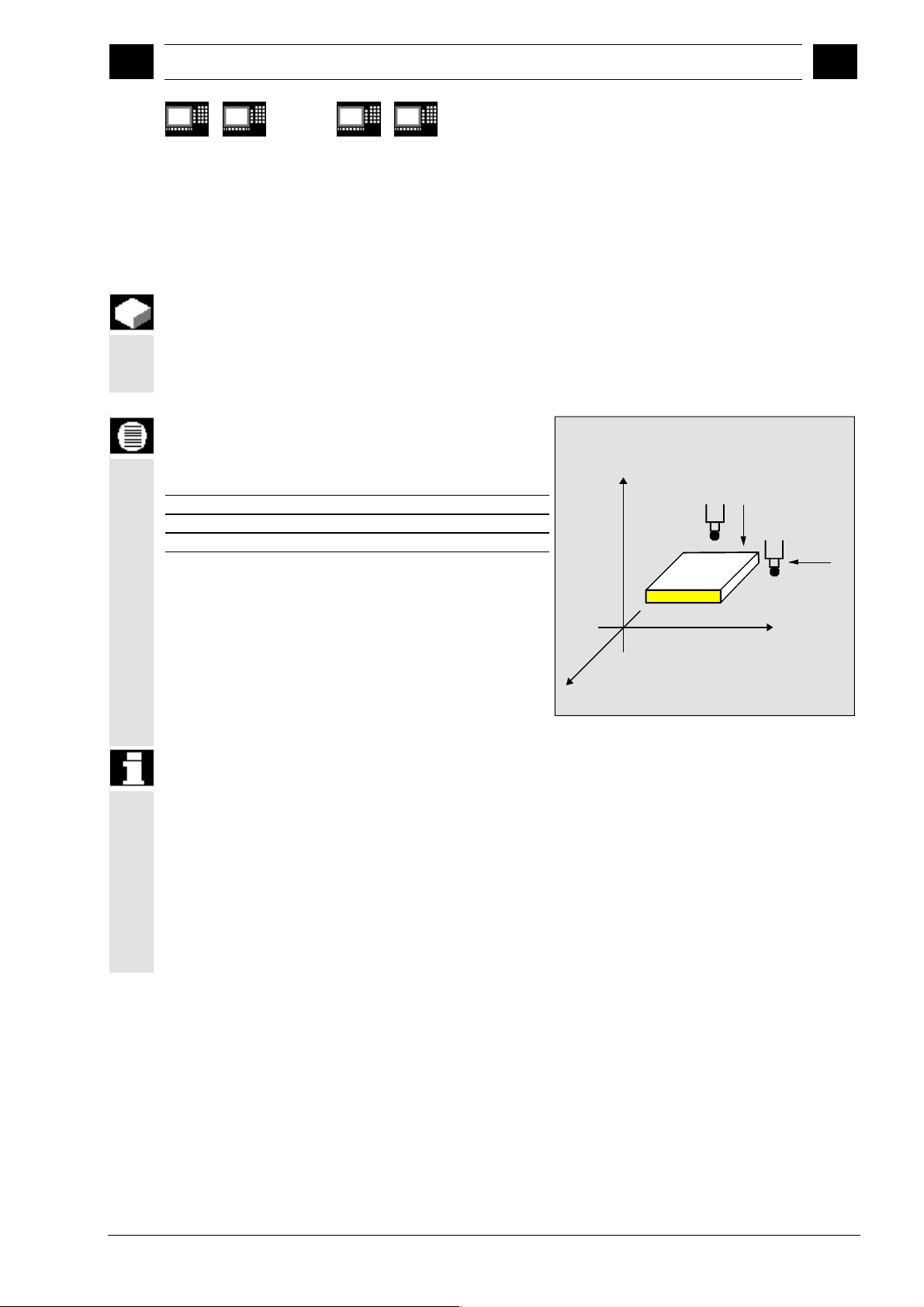

Tool probe calibration

Result:

Probe switching point with reference to machine zero

Calibration tool

Measuring the tool

Result:

Tool length

Length

Drill

Tool radius

Radius

Mill

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-39

Page 40

Introduction 12.97

1

1.11 Measurement variants for milling machines & machining centers

1

840 D

NCU 571

1.11.2 Measurement variants for fast measurement at a single point

Function

CYCLE978 makes it easy to take a measurement at

one point of a surface.

The measuring point is approached paraxially.

Depending on the measurement variant, the result may

influence the selected tool offset or zero offset.

Workpiece measurement, blank measurement

Result:

Position, deviation,

Zero offset

840 D

NCU 572

NCU 573

810 D 840Di

W

Workpiece measurement, single-point

1.11.3 Measurement variants for workpiece measurement paraxial

measurement

Result:

Actual dimension, deviation,

tool offset

Function

The following measurement variants are provided for

the paraxial measurement of a hole, shaft, groove or

web. They are executed by the cycle CYCLE977.

1-40 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 41

12.97 Introduction

1

1.11 Measurement variants for milling machines & machining centers

1

840 D

NCU 571

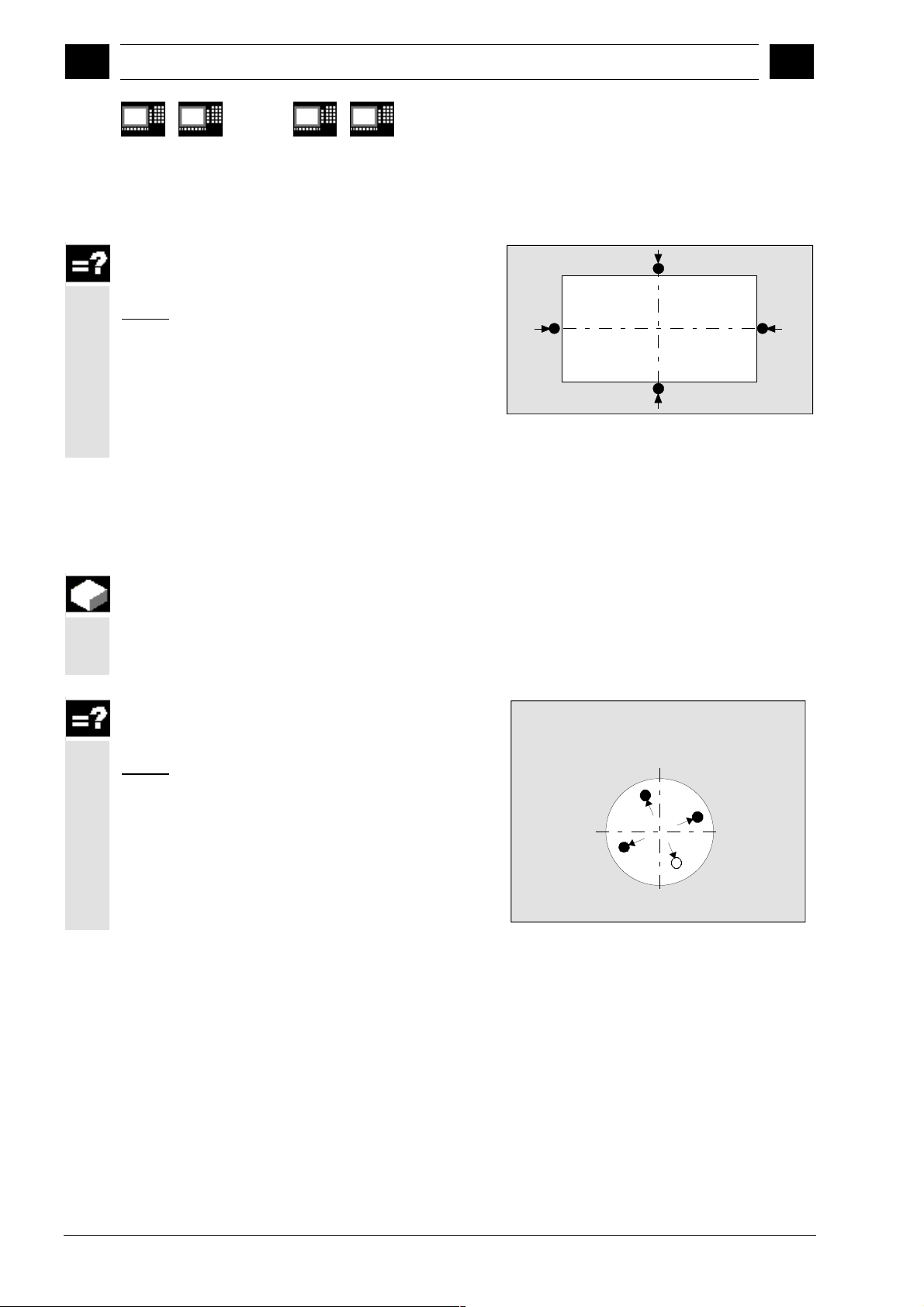

Workpiece measurement, measuring the hole

Result:

Actual dimension (diameter),

deviation, center point,

tool offset,

zero offset

Workpiece measurement, measuring the shaft

Result:

Actual dimension (diameter),

deviation, center point,

tool offset,

zero offset

Workpiece measurement, measuring the

groove

840 D

NCU 572

NCU 573

810 D 840Di

Result:

Actual dimension (groove width),

deviation, groove center,

tool offset,

zero offset

Workpiece measurement, measuring the web

Result:

Actual dimension (web width),

deviation, web center,

tool offset,

zero offset

Workpiece measurement, measuring the

inside rectangle

Result:

Actual value rectangle length and width,

actual dimension rectangle center,

deviation rectangle length and width,

deviation rectangle center,

tool offset,

zero offset

Siemens AG, 2002. All rights reserved

SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition 1-41

Page 42

Introduction 12.97

1

1.11 Measurement variants for milling machines & machining centers

1

840 D

NCU 571

Workpiece measurement, measuring the

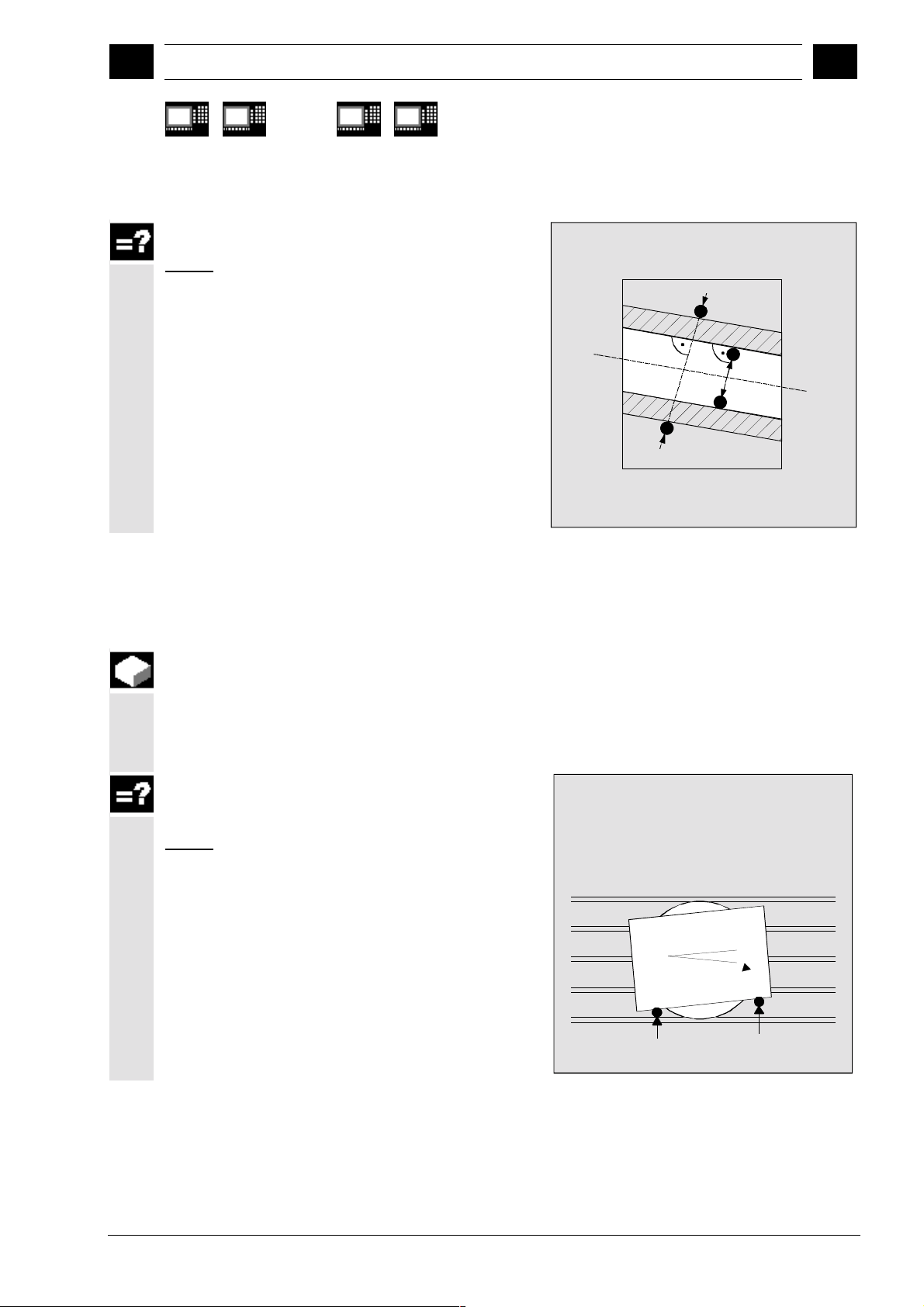

1.11.4 Measurement variants for workpiece measurement at random angles

outside rectangle

Result:

Actual value rectangle length and width,

actual dimension rectangle center,

deviation rectangle length and width,

deviation rectangle center,

tool offset,

zero offset

Function

840 D

NCU 572

NCU 573

810 D 840Di

The following measurement variants are provided for

the measurement of a bore, shaft, groove or web at

random angles. They are executed by CYCLE979.

Triple-point (quadruple-point) measurement at

random angles

Result:

Actual dimension (diameter),

deviation, center point,

tool offset,

zero offset

Hole, shaft, circle segment

1-42 SINUMERIK 840D/840Di/810D User's Guide Measuring Cycles (BNM) – 11.02 Edition

Siemens AG, 2002. All rights reserved

Page 43

12.97 Introduction

1

1.11 Measurement variants for milling machines & machining centers

1

840 D

NCU 571

Two-point measurement at random angles

Result:

Actual dimension (groove width, web width),

deviation, groove center, web center,

zero offset

840 D

NCU 572

NCU 573

810 D 840Di

Groove, web

1.11.5 Measuring a surface at a random angle

Function

The zero offset can be compensated after

measurement of a surface at a random angle by means

of CYCLE998.

Workpiece measurement, angular

measurement

Result: