Page 1

SINUMERIK

SINUMERIK 840D sl

SINUMERIK 840D sl STEP 7 Toolbox

V17

Valid for

Control system

SINUMERIK 840D sl/840DE sl

Software

CNC software for 840D sl/840DE sl V4.5, V4.7, V4.8,

V4.91, V4.92, V4.93, V4.94, V4.95

Introduction

Fundamental safety

instructions

1

2

Conguration Manual

Product information

Conguring the NCU

Programming the PLC

Conguring networks

Conguring telegrams and

drive units

Conguring I/O

Tag selection with NC VAR

selector

3

4

5

6

7

8

9

07/2021

6FC5397-0GP40-0BA2

Importing user alarms

Safety conguration

10

11

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage

to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices

referring only to property damage have no safety alert symbol. These notices shown below are graded according to

the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualied Personnel

The product/system described in this documentation may be operated only by personnel qualied for the specic

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualied personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance

are required to ensure that the products operate safely and without any problems. The permissible ambient

conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identied by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may

be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: 6FC5397-0GP40-0BA2

Ⓟ 06/2021 Subject to change

Copyright © Siemens AG 2013 - 2021.

All rights reserved

Page 3

Table of contents

1 Introduction........................................................................................................................................... 7

1.1 About SINUMERIK ................................................................................................................ 7

1.2 About this documentation ................................................................................................... 7

1.2.1

1.3 Documentation on the internet............................................................................................ 8

1.3.1 Documentation overview SINUMERIK 840D sl....................................................................... 8

1.3.2 Documentation overview SINUMERIK operator components ................................................. 9

1.4 Feedback on the technical documentation ........................................................................... 9

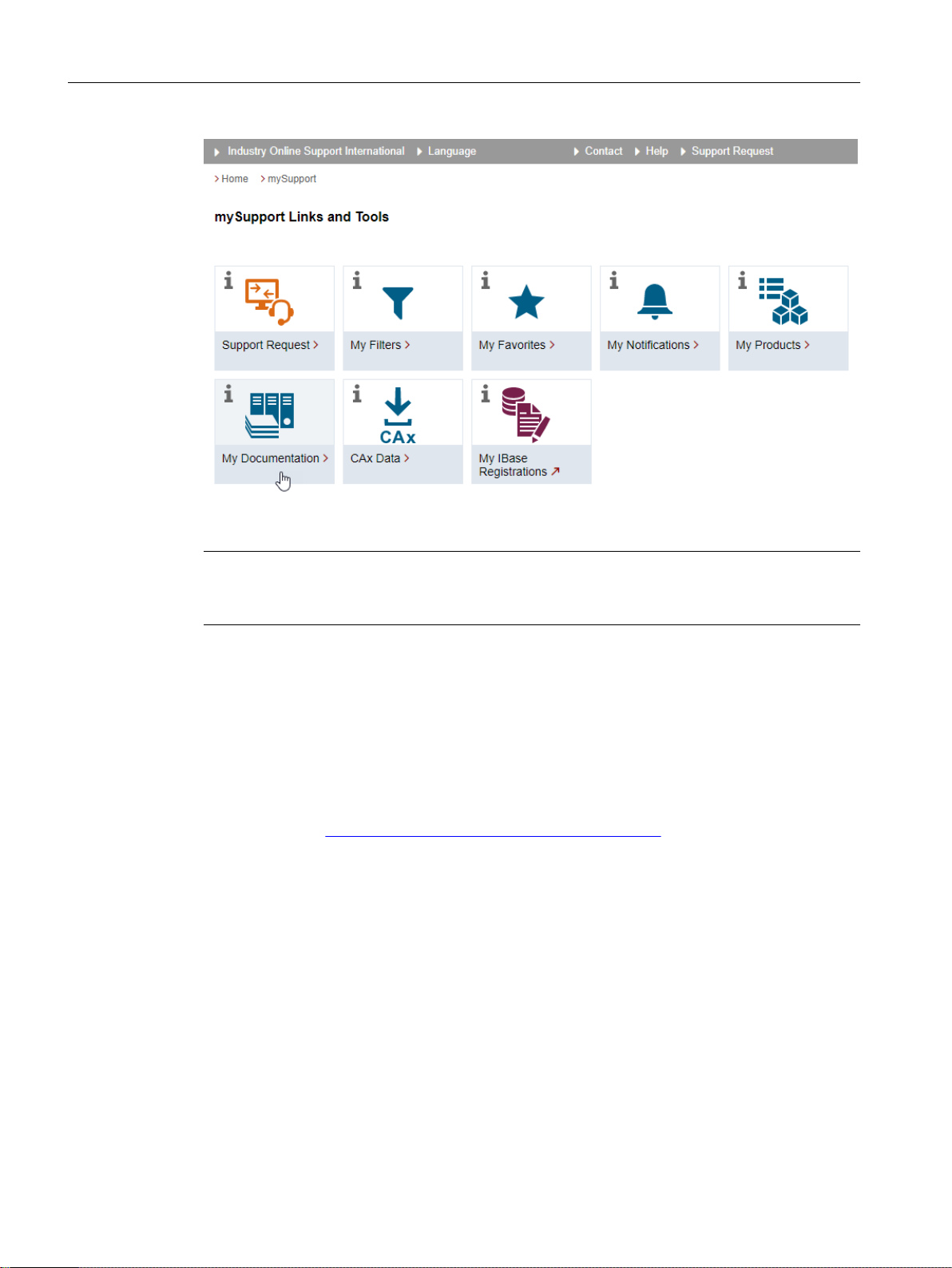

1.5 mySupport documentation .................................................................................................. 9

1.6 Service and Support........................................................................................................... 10

1.7 Important product information .......................................................................................... 12

2 Fundamental safety instructions......................................................................................................... 13

2.1 General safety instructions................................................................................................. 13

2.2 Equipment damage due to electric elds or electrostatic discharge ..................................... 17

2.3 Warranty and liability for application examples ................................................................... 17

Structure, content, target group

... ...................................................................................... 7

2.4 Security information .......................................................................................................... 17

2.5 Residual risks of power drive systems ................................................................................. 19

3 Product information............................................................................................................................. 21

3.1 Validity of the description................................................................................................... 21

3.2 Product features ................................................................................................................ 21

3.3 Installation notes ............................................................................................................... 22

3.4 Limitations for use ............................................................................................................. 23

4 Conguring the NCU............................................................................................................................ 25

4.1 SINUMERIK NCU................................................................................................................. 25

4.1.1 Structure of SINUMERIK NCU.............................................................................................. 25

4.1.2 Insert NCU ......................................................................................................................... 26

4.2 Insert NX module............................................................................................................... 27

4.3 Replacing a device or upgrading rmware .......................................................................... 32

4.3.1 Replacing the NCU ............................................................................................................. 32

4.3.2 Replacing an NX................................................................................................................. 32

4.3.3 Basic procedure ................................................................................................................. 33

4.4 Establish the communication connection ........................................................................... 36

4.5 Load hardware conguration into the PLC........................................................................... 37

4.6 Creating SINUMERIK PLC archives ....................................................................................... 40

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 3

Page 4

Table of contents

4.6.1 Creating a SINUMERIK PLC archive ...................................................................................... 40

4.6.2 Available SINUMERIK archive types..................................................................................... 43

4.6.3 External tools for SINUMERIK archives ................................................................................ 44

4.6.4 Creating a PLC hardware upgrade archive........................................................................... 44

4.6.5 Creating a PLC commissioning archive................................................................................ 46

4.6.6 Creating a PLC reload archive ............................................................................................. 48

5 Programming the PLC .......................................................................................................................... 51

5.1 General information about the PLC program....................................................................... 51

5.1.1 Introduction....................................................................................................................... 51

5.1.2 Execution structure............................................................................................................ 51

5.1.3 Using copy templates......................................................................................................... 54

5.1.4 Block listing as table........................................................................................................... 57

5.1.5 Blocks with user-specic adaptations.................................................................................. 61

5.1.6 Assignment overview......................................................................................................... 62

5.1.7 Generating blocks at runtime on the NCU........................................................................... 63

5.2 Opening the PLC basic program system library.................................................................... 64

5.3 Adding the PLC basic program............................................................................................ 65

5.4 Conicts when copying blocks ........................................................................................... 70

5.5 Correcting OB1 .................................................................................................................. 71

5.6 Upgrading the PLC basic program....................................................................................... 71

5.7 Copying blocks from one project into another..................................................................... 73

5.8 Use and handling of groups ............................................................................................... 76

5.9 Create blocks from external sources ................................................................................... 77

5.10 Exporting PLC symbols for SINUMERIK Operate................................................................... 78

5.10.1 Creating and loading PLC symbols...................................................................................... 78

5.10.2 Exporting PLC symbols ....................................................................................................... 80

5.10.3 Importing PLC symbols....................................................................................................... 82

5.11 Edit blocks ......................................................................................................................... 83

6 Conguring networks .......................................................................................................................... 85

6.1 Conguring an Ethernet Interface....................................................................................... 85

6.2 Conguring PROFIBUS DP ................................................................................................... 86

6.3 Conguring Integrated PROFIBUS (DP Integrated) ............................................................... 87

6.4 Conguring PROFINET........................................................................................................ 88

6.5 Conguring PROFINET IO with IRT....................................................................................... 89

6.5.1 Overview........................................................................................................................... 89

6.5.2 Rules and requirements...................................................................................................... 89

6.5.3 Isochronous-capable modules identication ....................................................................... 91

6.5.4 Conguring isochronous NC-controlled drives..................................................................... 93

6.5.5 Conguring I/O used by NC isochronously........................................................................... 94

6.5.6 Conguring the NCU .......................................................................................................... 95

6.5.7 Conguring PROFINET IO IRT devices .................................................................................. 96

6.5.8 Conguring IO modules or drive telegrams......................................................................... 98

6.5.9 Conguring the input delay for digital input modules........................................................ 101

SINUMERIK 840D sl STEP 7 Toolbox V17

4 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 5

Table of contents

6.5.10 Conguring sync domains ................................................................................................ 102

6.5.11 Match values between PROFINET IO and PROFIBUS Integrated .......................................... 103

6.5.12 Assigning drive addresses to the NCU machine data.......................................................... 104

6.5.13 Assigning I/O addresses to the NCU machine data............................................................. 105

7 Conguring telegrams and drive units.............................................................................................. 107

7.1 Overview......................................................................................................................... 107

7.2 Standard telegram conguration...................................................................................... 108

7.3 Viewing I/O addresses in the TIA Portal ............................................................................. 108

7.4 Changing the addressing schematic ................................................................................. 109

7.5 Resetting telegrams ......................................................................................................... 111

7.6 Displaying or adapting the telegram conguration............................................................ 112

7.6.1 Overview......................................................................................................................... 112

7.6.2 Calling the telegram conguration ................................................................................... 113

7.6.3 Structure of the "Telegram conguration" dialog ............................................................... 113

7.6.4 Changing the properties of send telegrams (actual value)................................................. 114

7.6.5 Changing the properties of receive telegrams (setpoint)................................................... 117

7.6.6 Adapting the number of drives......................................................................................... 119

7.7 Available telegram types.................................................................................................. 120

7.7.1 Telegrams for the transfer of standard data (PROFIdrive)................................................... 120

7.7.2 Telegrams in SINUMERIK Safety Integrated (SPL) mode ..................................................... 122

7.7.3 Telegrams for PROFIsafe communication.......................................................................... 122

7.7.4 Telegrams for SIC/SCC communication.............................................................................. 123

7.8 Adapting I/O start addresses............................................................................................. 124

7.8.1 Introduction..................................................................................................................... 124

7.8.2 PROFIdrive telegrams for standard data............................................................................ 125

7.8.3 PROFIdrive telegrams for Safety Integrated (SPL)............................................................... 128

7.8.4 PROFIsafe/PROFIdrive telegrams for Safety Integrated plus (F-PLC) .................................... 130

7.9 Deviations from the standard I/O addressing schematic..................................................... 133

7.9.1 Overview......................................................................................................................... 133

7.9.2 Matching of deviating I/O addresses................................................................................. 134

7.9.2.1 Matching I/O addresses for use of the optimized I/O addressing schematic ........................ 134

7.9.2.2 Matching user-specic adaptations................................................................................... 135

7.9.3 Viewing messages in the info area.................................................................................... 135

7.9.4 Availability of suitable I/O addresses ................................................................................ 136

8 Conguring I/O................................................................................................................................... 139

8.1 Inserting ADI4 module (840 sl)......................................................................................... 139

8.2 Installing general station description les for SINUMERIK I/O............................................. 142

8.3 Inserting the SINUMERIK I/O module PP72/48 ................................................................... 144

8.4 Inserting SINUMERIK MCP/MPP......................................................................................... 146

9 Tag selection with NC VAR selector ................................................................................................... 149

9.1 NC VAR selector ............................................................................................................... 149

9.2 Selecting tags and saving as STL le ................................................................................. 149

9.3 Adding a tag le (STL) in the TIA Portal ............................................................................. 151

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 5

Page 6

Table of contents

10 Importing user alarms ....................................................................................................................... 153

10.1 Overview......................................................................................................................... 153

10.2 Exporting TS les from SINUMERIK Operate ...................................................................... 153

10.3 Language assignment in language-dependent texts ......................................................... 154

10.4 Enable project languages ................................................................................................. 156

10.5 Importing SINUMERIK PLC alarm texts .............................................................................. 156

11 Safety conguration .......................................................................................................................... 159

11.1 Introduction..................................................................................................................... 159

11.2 Representation of safety-related resources in the TIA Portal .............................................. 159

11.3 Changing the Safety Integrated mode .............................................................................. 162

11.4 Parameterization of relevant properties ............................................................................ 163

11.5 Availability of I/O addresses at the mode change............................................................... 167

11.6 Licensing ......................................................................................................................... 169

11.6.1 Overview......................................................................................................................... 169

11.6.2 Software options for Safety Integrated (SPL)..................................................................... 170

11.6.3 Software options for Safety Integrated plus (F-PLC)........................................................... 171

11.7 Conguring Safety Integrated (SPL).................................................................................. 172

11.7.1 Introduction..................................................................................................................... 172

11.7.2 Conguring the F-peripherals ........................................................................................... 172

11.7.3 Parameterizing F-input modules....................................................................................... 174

11.7.4 Conguring drives with F-functions .................................................................................. 175

11.7.5 Parameterizing F-output modules..................................................................................... 177

11.7.6 Conguration of the PROFIsafe addresses (peripherals)..................................................... 177

11.7.7 Conguration of the PROFIsafe addresses (drives)............................................................. 181

11.7.8 Parameterizing PROFIsafe telegrams................................................................................. 183

11.8 Conguring Safety Integrated plus (F-PLC) ........................................................................ 184

11.8.1 Introduction..................................................................................................................... 184

11.8.2 Conguring Safety Integrated plus (F-PLC) ........................................................................ 186

11.8.3 Creating a second F-runtime group for Safety Integrated plus (F-PLC)................................ 188

11.8.4 Conguring PROFIsafe...................................................................................................... 190

11.8.5 Checking the PROFIsafe address ....................................................................................... 191

Index .................................................................................................................................................. 195

SINUMERIK 840D sl STEP 7 Toolbox V17

6 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 7

Introduction

1.1 About SINUMERIK

rom simple, standardized CNC machines to premium modular machine designs – the

F

SINUMERIK CNCs oer the right solution for all machine concepts. Whether for individual parts

or mass production, simple or complex workpieces – SINUMERIK is the highly dynamic

automation solution, integrated for all areas of production. From prototype construction and

tool design to mold making, all the way to large-scale series production.

1

Visit our website for more information SINUMERIK (

1.2 About this documentation

1.2.1

Target group

Benets

Standard scope

Structure, content, target group

This document is intended for rst-time users who want to familiarize themselves with the

product.

Conguration Manual enables the target group to apply the rules and guidelines to be

The

observed when conguring products and systems. It helps you select products and functions.

The Conguration Manual helps the target group create a system or plant conguration.

https://www.siemens.com/sinumerik).

This documentation only describes the functionality of the standard version. This may dier

from the scope of the functionality of the system that is actually supplied. Please refer to the

ordering documentation only for the functionality of the supplied drive system.

It may be possible to execute other functions in the system which are not described in this

documentation. This does not, however, represent an obligation to supply such functions with

a new control or when servicing.

For reasons of clarity, this documentation cannot include all of the detailed information on all

product types. Further, this documentation cannot take into consideration every conceivable

type of installation, operation and service/maintenance.

The machine manufacturer must document any additions or modications they make to the

product themselves.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 7

Page 8

Introduction

1.3 Documentation on the internet

Websites of third-party companies

This document may contain hyperlinks to third-party websites. Siemens is not responsible for

and shall not be liable for these websites and their content. Siemens has no control over the

information which appears on these websites and is not responsible for the content and

information provided there. The user bears the risk for their use.

1.3 Documentation on the internet

1.3.1 Documentation overview SINUMERIK 840D sl

You will nd extensive documentation on the functions of SINUMERIK 840D sl from version 4.8

SP4 at 840D sl documentation overview (https://support.industry.siemens.com/cs/ww/en/view/

109766213).

You can display documents or download them in PDF and HTML5 format.

The documentation is divided into the following categories:

• User: Operating

• User: Programming

• Manufacturer/Service: Functions

• Manufacturer/Service: Hardware

• Manufacturer/Service: Conguration/Setup

• Manufacturer/Service: Safety Integrated

• Manufacturer/Service: SINUMERIK Integrate/MindApp

• Information and training

• Manufacturer/Service: SINAMICS

SINUMERIK 840D sl STEP 7 Toolbox V17

8 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 9

1.5 mySupport documentation

1.3.2 Documentation overview SINUMERIK operator components

Comprehensive documentation about the SINUMERIK operator components is provided in the

Documentation overview SINUMERIK operator components (https://

support.industry.siemens.com/cs/document/109783841/technische-dokumentation-zusinumerik-bedienkomponenten?dti=0&lc=en-WW).

You can display documents or download them in PDF and HTML5 format.

The documentation is divided into the following categories:

• Operator Panels

• Machine control panels

• Machine Pushbutton Panel

• Handheld Unit/Mini handheld devices

• Further operator components

An overview of the most important documents, entries and links to SINUMERIK is provided at

SINUMERIK Overview - Topic Page (https://support.industry.siemens.com/cs/document/

109766201/sinumerik-an-overview-of-the-most-important-documents-and-links?

dti=0&lc=en-WW).

Introduction

1.4 Feedback on the technical documentation

If you have any questions, suggestions or corrections regarding the technical documentation

which is published in the Siemens Industry Online Support, use the link "Send feedback" link

which appears at the end of the entry.

1.5 mySupport documentation

With the "mySupport documentation" web-based system you can compile your own individual

documentation based on Siemens content, and adapt it for your own machine documentation.

To start the application, click on the "My Documentation" tile on the mySupport homepage

(https://support.industry.siemens.com/cs/ww/en/my):

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 9

Page 10

Introduction

1.6 Service and Support

The congured manual can be exported in RTF, PDF or XML format.

Note

Siemens content that supports the mySupport documentation application can be identied by

the presence of the "Congure" link.

1.6 Service and Support

Product support

You can nd more information about products on the internet:

Product support (https://support.industry.siemens.com/cs/ww/en/)

The following is provided at this address:

• Up-to-date product information (product announcements)

• FAQs (frequently asked questions)

• Manuals

• Downloads

• Newsletters with the latest information about your products

• Global forum for information and best practice sharing between users and specialists

• Local contact persons via our Contacts at Siemens database (→ "Contact")

• Information about eld services, repairs, spare parts, and much more (→ "Field Service")

SINUMERIK 840D sl STEP 7 Toolbox V17

10 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 11

Technical support

Country-specic telephone numbers for technical support are provided on the internet at

address (

If you have any technical questions, please use the online form in the "Support Request" area.

https://support.industry.siemens.com/cs/ww/en/sc/4868) in the "Contact" area.

Training

You can nd information on SITRAIN at the following address (https://www.siemens.com/

sitrain).

SITRAIN oers training courses for automation and drives products, systems and solutions from

Siemens.

Siemens support on the go

Introduction

1.6 Service and Support

With the award-winning "Siemens Industry Online Support" app, you can access more than

300,000 documents for Siemens Industry products – any time and from anywhere. The app can

support you in areas including:

• Resolving problems when implementing a project

• Troubleshooting when faults develop

• Expanding a system or planning a new system

Furthermore, you have access to the Technical Forum and other articles from our experts:

• FAQs

• Application examples

• Manuals

• Certicates

• Product announcements and much more

The "Siemens Industry Online Support" app is available for Apple iOS and Android.

Data matrix code on the nameplate

The data matrix code on the nameplate contains the specic device data. This code can be read

with a smartphone and technical information about the device displayed via the "Industry

Online Support" mobile app.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 11

Page 12

Introduction

1.7 Important product information

1.7 Important product information

Using OpenSSL

This product can contain the following software:

• Software developed by the OpenSSL project for use in the OpenSSL toolkit

• Cryptographic software created by Eric Young.

• Software developed by Eric Young

You can nd more information on the internet:

• OpenSSL (

• Cryptsoft (https://www.cryptsoft.com)

https://www.openssl.org)

Compliance with the General Data Protection Regulation

Siemens observes standard data protection principles, in particular the data minimization rules

(privacy by design).

For this product, this means:

The product does not process or store any personal data, only technical function data (e.g. time

stamps). If the user links this data with other data (e.g. shift plans) or if he/she stores personrelated data on the same data medium (e.g. hard disk), thus personalizing this data, he/she must

ensure compliance with the applicable data protection stipulations.

SINUMERIK 840D sl STEP 7 Toolbox V17

12 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 13

Fundamental safety instructions

2.1 General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

Touching live components can result in death or severe injury.

• Only work on electrical devices when you are qualied for this job.

• Always observe the country-specic safety rules.

Generally, the following steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be aected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specied on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any of

the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

2

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Electric shock due to connection to an unsuitable power supply

When equipment is connected to an unsuitable power supply, exposed components may carry

a hazardous voltage. Contact with hazardous voltage can result in severe injury or death.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV- (Protective

Extra Low Voltage) output voltages for all connections and terminals of the electronics

modules.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 13

Page 14

Fundamental safety instructions

2.1 General safety instructions

WARNING

Electric shock due to equipment damage

Improper handling may cause damage to equipment. For damaged devices, hazardous

voltages can be present at the enclosure or at exposed components; if touched, this can result

in death or severe injury.

• Ensure compliance with the limit values specied in the technical data during transport,

storage and operation.

• Do not use any damaged devices.

WARNING

Electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the cores of cables that are not used at one end

at the grounded housing potential.

WARNING

Electric shock if there is no ground connection

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when touched,

can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

NOTICE

Damage to equipment due to unsuitable tightening tools.

Unsuitable tightening tools or fastening methods can damage the screws of the equipment.

• Be sure to only use screwdrivers which exactly match the heads of the screws.

• Tighten the screws with the torque specied in the technical documentation.

• Use a torque wrench or a mechanical precision nut runner with a dynamic torque sensor and

speed limitation system.

SINUMERIK 840D sl STEP 7 Toolbox V17

14 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 15

Fundamental safety instructions

2.1 General safety instructions

WARNING

Spread of re from built-in devices

In the event of re outbreak, the enclosures of built-in devices cannot prevent the escape of

re and smoke. This can result in serious personal injury or property damage.

• Install built-in units in a suitable metal cabinet in such a way that personnel are protected

against re and smoke, or take other appropriate measures to protect personnel.

• Ensure that smoke can only escape via controlled and monitored paths.

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

Using radio devices or mobile telephones in the immediate vicinity of the components can

result in equipment malfunction. Malfunctions may impair the functional safety of machines

and can therefore put people in danger or lead to property damage.

• Therefore, if you move closer than 20 cm to the components, be sure to switch o radio

devices or mobile telephones.

• Use the "SIEMENS Industry Online Support app" only on equipment that has already been

switched o.

WARNING

Fire due to inadequate ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent re

and smoke. This can cause severe injury or even death. This can also result in increased

downtime and reduced service lives for devices/systems.

• Ensure compliance with the specied minimum clearance as ventilation clearance for the

respective component.

NOTICE

Overheating due to inadmissible mounting position

The device may overheat and therefore be damaged if mounted in an inadmissible position.

• Only operate the device in admissible mounting positions.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 15

Page 16

Fundamental safety instructions

2.1 General safety instructions

WARNING

Unexpected movement of machines caused by inactive safety functions

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

• Observe the information in the appropriate product documentation before commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system, including

all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted and

activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the Safety

Integrated manuals.

WARNING

Malfunctions of the machine as a result of incorrect or changed parameter settings

As a result of incorrect or changed parameterization, machines can malfunction, which in turn

can lead to injuries or death.

• Protect the parameterization against unauthorized access.

• Handle possible malfunctions by taking suitable measures, e.g. emergency stop or

emergency o.

SINUMERIK 840D sl STEP 7 Toolbox V17

16 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 17

Fundamental safety instructions

2.4 Security information

2.2 Equipment damage due to electric elds or electrostatic discharge

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or

devices that may be damaged by either electric elds or electrostatic discharge.

NOTICE

Equipment damage due to electric elds or electrostatic discharge

Electric elds or electrostatic discharge can cause malfunctions through damaged individual

components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of aluminum

foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive ooring

• Only place electronic components, modules or devices on conductive surfaces (table with

ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

2.3 Warranty and liability for application examples

Application examples are not binding and do not claim to be complete regarding conguration,

equipment or any eventuality which may arise. Application examples do not represent specic

customer solutions, but are only intended to provide support for typical tasks.

As the user you yourself are responsible for ensuring that the products described are operated

correctly. Application examples do not relieve you of your responsibility for safe handling when

using, installing, operating and maintaining the equipment.

2.4 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is necessary

to implement – and continuously maintain – a holistic, state-of-the-art industrial security

concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be connected to

an enterprise network or the internet if and to the extent such a connection is necessary and only

when appropriate security measures (e.g. rewalls and/or network segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit

https://www.siemens.com/industrialsecurity (https://www.siemens.com/industrialsecurity).

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 17

Page 18

Fundamental safety instructions

2.4 Security information

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they are available

and that the latest product versions are used. Use of product versions that are no longer

supported, and failure to apply the latest updates may increase customer’s exposure to cyber

threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS Feed

under

https://www.siemens.com/industrialsecurity (https://new.siemens.com/global/en/products/

services/cert.html#Subscriptions).

Further information is provided on the Internet:

Industrial Security Conguration Manual (https://support.industry.siemens.com/cs/ww/en/

view/108862708)

WARNING

Unsafe operating states resulting from software manipulation

Software manipulations, e.g. viruses, Trojans, or worms, can cause unsafe operating states in

your system that may lead to death, serious injury, and property damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security concept.

• Protect les stored on exchangeable storage media from malicious software by with suitable

protection measures, e.g. virus scanners.

• On completion of commissioning, check all security-related settings.

SINUMERIK 840D sl STEP 7 Toolbox V17

18 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 19

2.5 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must

take into account the following residual risks emanating from the control and drive components

of a drive system:

1. Unintentional movements of driven machine or system components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables and

connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specication

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic components

– External inuences/damage

Fundamental safety instructions

2.5 Residual risks of power drive systems

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open ames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specication

– External inuences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Inuence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specication

– Condensation/conductive contamination

– External inuences/damage

4. Electrical, magnetic and electromagnetic elds generated in operation that can pose a risk to

people with a pacemaker, implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Inuence of network-connected communication systems, e.g. ripple-control transmitters or

data communication via the network

For more information about the residual risks of the drive system components, see the relevant

sections in the technical user documentation.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 19

Page 20

Fundamental safety instructions

2.5 Residual risks of power drive systems

SINUMERIK 840D sl STEP 7 Toolbox V17

20 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 21

Product information

3.1 Validity of the description

These notes take precedence over statements in other documents.

Please read the notes carefully since important information for installation and use of the

software is included for you.

Notes that were no longer able to be taken into account in the online help can be found under

Limitations for use (Page 23).

3.2 Product features

Functional scope

Software component SINUMERIK 840D sl STEP 7 Toolbox V17 contains the following tools and

functions:

• Supplementation of the hardware catalog with the following modules of the SINUMERIK

840D sl (as of rmware V4.5 SP2 or higher):

3

– NCU 710.3

– NCU 720.3

– NCU 730.3

– NX10.3

– NX15.3

• Supplement of the hardware catalog to include the ADI4 module

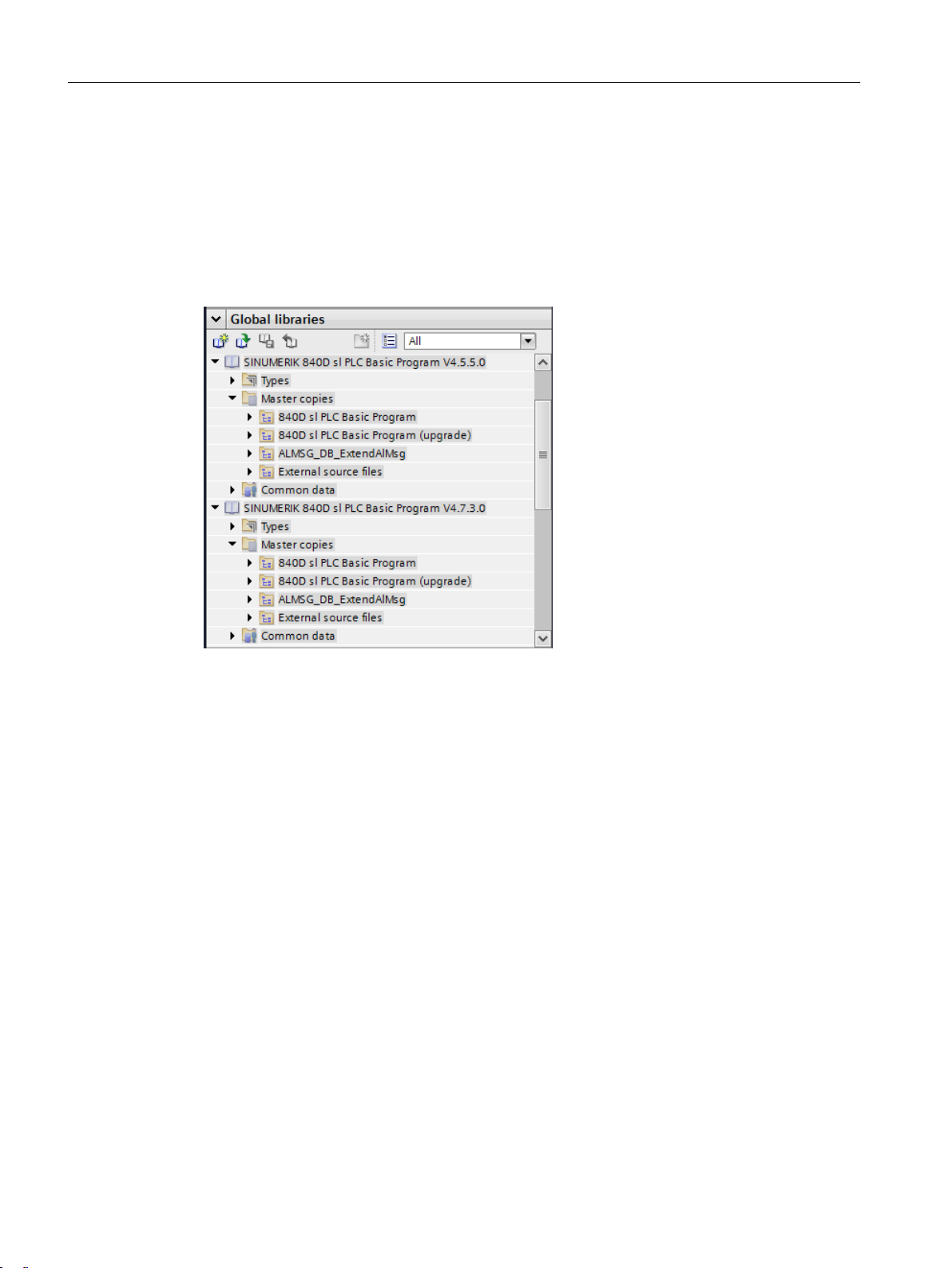

• SINUMERIK PLC basic program

The SINUMERIK 840D sl STEP 7 Toolbox V17 automatically installs the PLC basic program as

the "SINUMERIK 840D sl PLC Basic Program" system library. Matching the rmware versions

of the modules, there are dierent versions of the PLC basic program:

– SINUMERIK 840D sl PLC basic program V4.5.x.x

– SINUMERIK 840D sl PLC basic program V4.7.x.x

– SINUMERIK 840D sl PLC basic program V4.8.x.x

– SINUMERIK 840D sl PLC basic program V4.91.x.x

– SINUMERIK 840D sl PLC basic program V4.92.x.x

– SINUMERIK 840D sl PLC basic program V4.93.x.x

– SINUMERIK 840D sl PLC basic program V4.94.x.x

– SINUMERIK 840D sl PLC basic program V4.95.x.x

• Export of PLC symbols for SINUMERIK Operate

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 21

Page 22

Product information

3.3 Installation notes

• Importing SINUMERIK user alarm texts

• Creating SINUMERIK PLC archives

• Support of PROFINET IO IRT for NCK

• Support of SINUMERIK Safety Integrated and Safety Integrated plus

• NC VAR selector (external tool)

3.3 Installation notes

Software requirements

SINUMERIK STEP 7 Toolbox V17 is a TIA Portal option package with additional setup that requires

the following products to be installed:

• SIMATIC STEP 7 Professional V17

When installing SINUMERIK STEP 7 Toolbox V17, software components "SINUMERIK 840D sl

STEP 7 Toolbox V17" and "SINUMERIK ONE STEP 7 Toolbox V17" are automatically installed.

Hardware requirements and other system requirements

All of the hardware and system requirements of SIMATIC STEP 7 Professional apply.

You can nd the system requirements of STEP 7 Professional in the following documentation:

• STEP 7 Professional System Manual (https://support.industry.siemens.com/cs/products?

search=STEP%207%20Professional&dtp=Manual)

• TIA Portal online help, search term "System requirements STEP 7 Professional"

Installation

Before installing, exit all of the applications (e.g. TIA Portal) and execute the "Start.exe" setup

le in the master directory of the product DVD.

Uninstallation

Via the installation wizard of the TIA Portal, you can uninstall the software, which is entered in

the Windows dialog "Uninstall or change program":

"Control Panel > Programs > Uninstall Program > Siemens Totally Integrated Automation Portal"

Note

The NC VAR selector must be uninstalled separately.

SINUMERIK 840D sl STEP 7 Toolbox V17

22 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 23

3.4 Limitations for use

According to the state of the art, it can admittedly not be excluded - given the complexity of the

software products - that sporadic functional restrictions can occur under the greatly diering

system and application conditions.

In this context, please observe the current boundary conditions, functional restrictions and

workarounds on the Internet:

Product information

3.4 Limitations for use

Boundary conditions in Siemens Industry Online Support (

support.industry.siemens.com/cs/document/109751810)

https://

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 23

Page 24

Product information

3.4 Limitations for use

SINUMERIK 840D sl STEP 7 Toolbox V17

24 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 25

Conguring the NCU

4.1 SINUMERIK NCU

4.1.1 Structure of SINUMERIK NCU

Subcomponents of the NCU

A SINUMERIK NCU comprises the following integrated subcomponents:

• PLC

• NCK

• CP

• HMI (SINUMERIK Operate)

• SINAMICS Integrated (DRIVE)

These subcomponents are always a xed component of an NCU and can only be handled in

combination with the NCU. Subcomponents cannot be individually pasted, copied or moved in

the project or across projects (e.g. in libraries).

4

Note

Copying and pasting the NCU or the DP master system

You can copy and insert NCUs within a project. For this purpose, switch to the network view or

to the topology view of the project view.

The DP master system (PROFIBUS Integrated) cannot be individually copied, pasted or deleted.

It is considered as an integral part of the NCU.

If you copy an NCU, all integrated subcomponents are also copied, e.g. SINAMICS Integrated or

PROFIBUS Integrated.

Additional connectable components

Optionally, the following components can be connected to the NCU:

• NX10.3 and NX15.3 modules

These components are not inserted automatically when inserting an NCU, but must be

integrated manually (Page 27).

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 25

Page 26

Conguring the NCU

4.1 SINUMERIK NCU

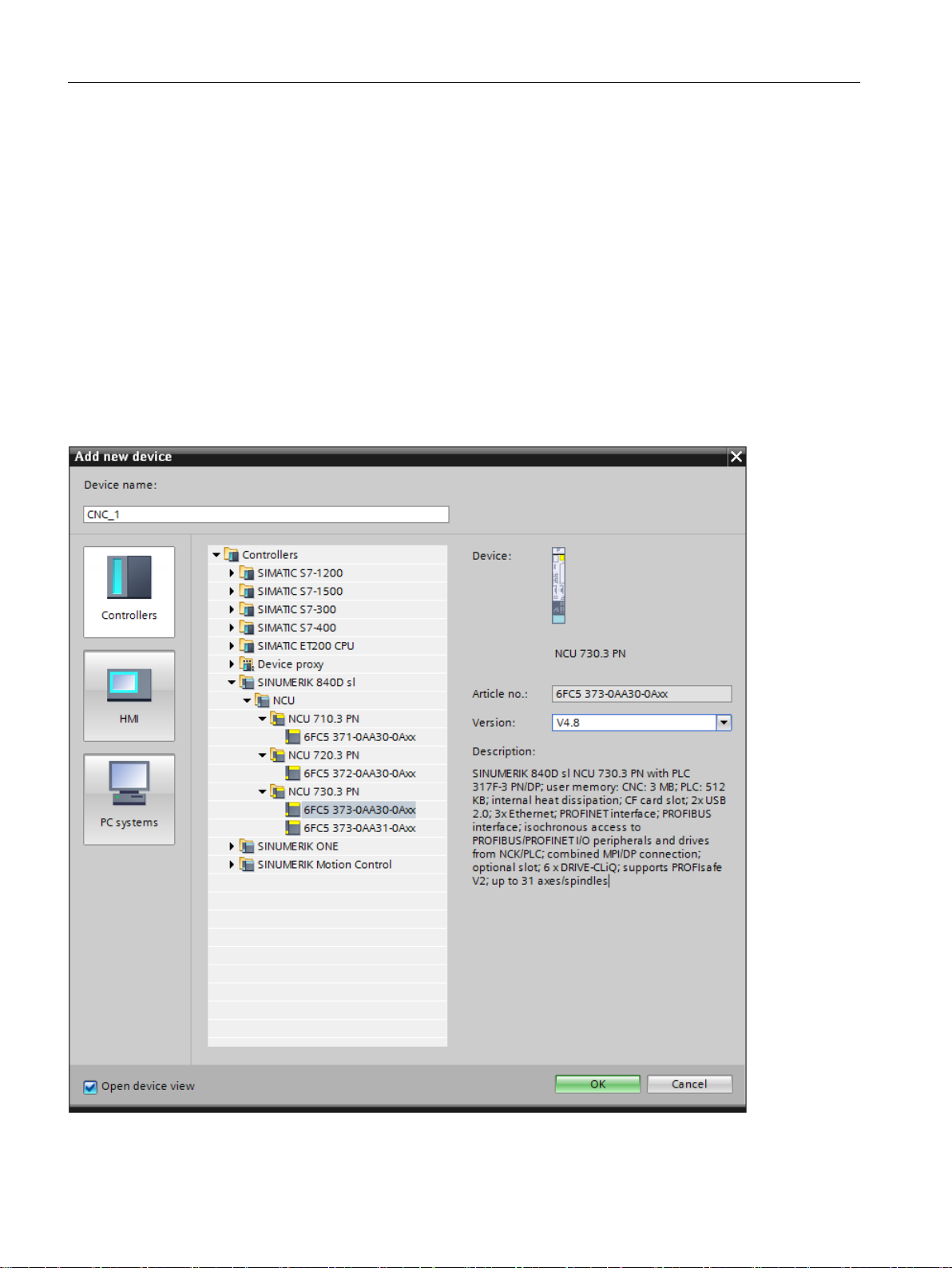

4.1.2 Insert NCU

Requirement

• A project is open in the TIA Portal.

Procedure

To insert a SINUMERIK NCU in the project view, proceed as follows:

1. Click "Add new device" in the project tree.

2. Click the "Controllers" button.

3. In the folder structure under "Controllers", expand the corresponding SINUMERIK device

family (e.g. SINUMERIK 840D sl) and required NCU and select these.

Figure 4-1 Selected NCU using the SINUMERIK 840D sl NCU 730.3 PN V4.8 as an example

SINUMERIK 840D sl STEP 7 Toolbox V17

26 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 27

4. Select the rmware version that matches the envisaged rmware version of the real NCU in

the "Version" drop-down list.

5. Conrm your selection with "OK".

Result

The SINUMERIK NCU is created as new device.

See also

Replacing a device or upgrading rmware (Page 32)

4.2 Insert NX module

Procedure

Conguring the NCU

4.2 Insert NX module

In order to insert an NX module into the project via the hardware catalog, proceed as follows:

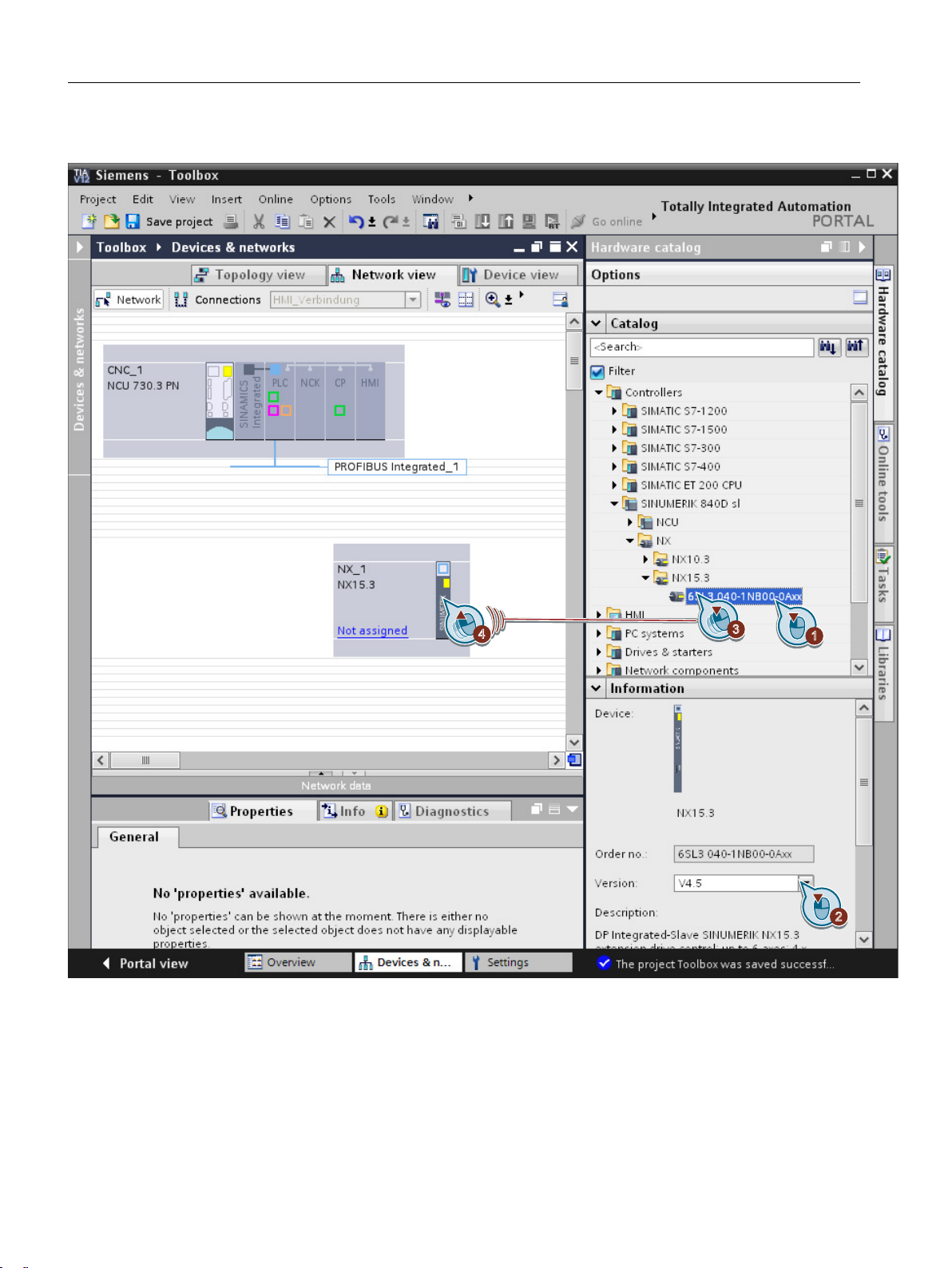

1. In the network view, navigate in the hardware catalog to the folder "Controller >

SINUMERIK 840D sl > NX" and select, for example, NX15.3 .

2. You can select the rmware version of the NX module at "Information" in the hardware

catalog. This must match the rmware version of SINAMICS Integrated. Firmware versions of

the congured hardware and the real hardware must match.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 27

Page 28

Conguring the NCU

4.2 Insert NX module

3. Use drag-and-drop to move the NX module from the hardware catalog to the network view.

28 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

SINUMERIK 840D sl STEP 7 Toolbox V17

Page 29

Conguring the NCU

4.2 Insert NX module

4. To connect the NX module with a master system, click "Not assigned" and select the master

system.

Note

Connection to DP Integrated

Note that the NX modules can only be connected to the DP Integrated of a SINUMERIK NCU,

and not to external PROFIBUS interfaces!

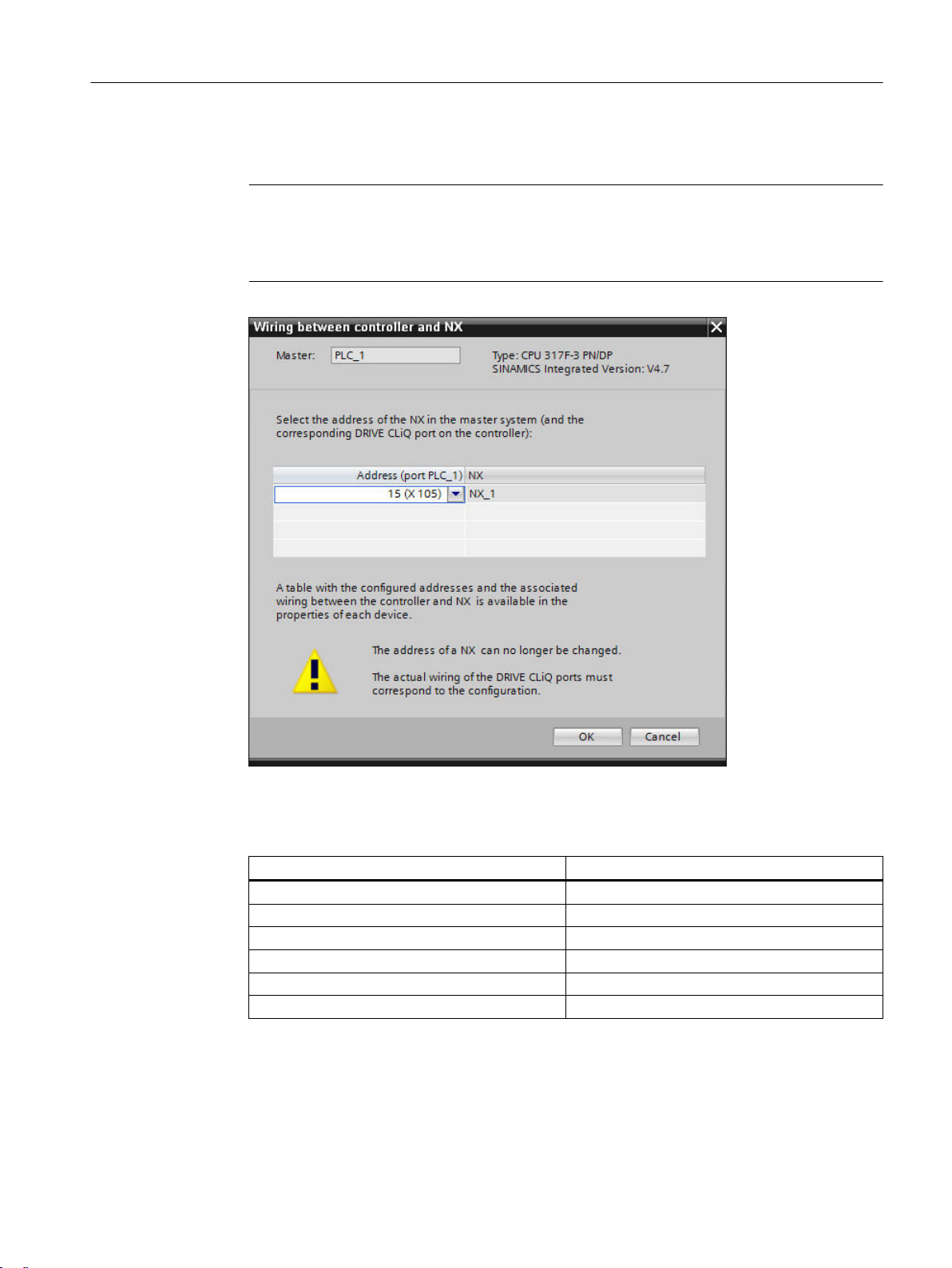

The NX is connected with the NCU and the "Wiring between control and NX" dialog opens.

5. In the "Wiring between control and NX" dialog, select the DP address of the NX in the master

system that matches your real wiring. The DP addresses of the NX modules are permanently

assigned to the DRIVE-CLiQ sockets of the NCU.

DP address of the NX in the master system DRIVE-CLiQ socket on the NCU

10 X100

11 X101

12 X102

13 X103

14 X104

15 X105

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 29

Page 30

Conguring the NCU

4.2 Insert NX module

Note

This setting cannot be undone

Please note that once set, the DP address of an NX cannot be subsequently changed. The NX

modules must be connected to the DRIVE-CLiQ socket of the NCU in the real wiring that

corresponds to the permanently assigned DP address.

If you have incorrectly set the DP address of an NX, delete this NX from the project and add

a new one.

The DP address of the NX module is specied in accordance with your setting and the

appropriate I/O addresses of the telegrams are set automatically.

Note

Default I/O addresses of the telegrams

Depending on the set DP address, the appropriate I/O addresses of the telegrams are set

automatically.

Change this setting only when the I/O addresses of your telegrams dier from the default

setting!

You can also nd information on the wiring between NCU and NX in the properties of the DP

Integrated interface on the NCU and NX under "PROFIBUS address".

SINUMERIK 840D sl STEP 7 Toolbox V17

30 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 31

Result

Conguring the NCU

4.2 Insert NX module

The NX module has been inserted into the project and connected to an NCU.

Note

Handling the NX module

The NX module can be assigned to another NCU. Generally, the previous conguration of the NX

module is kept.

However, this cannot always be performed in individual cases. For example, it is possible that

changes must again be applied to the telegram conguration regarding the assignment to the

process image and organization block.

If the DP address of the NX module is specied, then the I/O addresses matching the default

setting on the NCK side are entered.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 31

Page 32

Conguring the NCU

4.3 Replacing a device or upgrading rmware

4.3 Replacing a device or upgrading rmware

4.3.1 Replacing the NCU

You can replace dierent NCUs. By replacing a device within the same device family, you can

change to another NCU with a dierent expansion stage, with a dierent rmware version and

other properties.

Rules for replacing an NCU

• It is not possible to replace an NCU with another controller of a dierent device family.

(You may be able to perform a migration.)

• It is not possible to replace an NCU with an NCU of the same project stage with the same or

previous rmware version.

• If you replace an NCU by another NCU, then automatically all of the integrated

subcomponents of the NCU (SINAMICS Integrated, PLC, NCK, CP, HMI) are also replaced.

• If you have connected NX modules to an NCU and replace the NCU, the connection between

the devices remains, provided the used interfaces exist on both NCUs. If the used interface

on the replaced NCU does not exist, the connection will be separated.

4.3.2 Replacing an NX

You can replace a device with a dierent NX type. The version of an NX is determined by the

version of the NCU. Correspondingly, for a connected NX, you can only replace the type: An

NX10.3 can be replaced by an NX15.3 and vice versa.

Rules for replacing an NX

If you replace NX10.3 with NX15.3, please note that NX10.3 only supports a maximum of three

servo axes, whereas NX15.3 supports up to six servo axes.

For more information about the conguration of the drive objects, see Adapting the number of

drives (Page 119)

SINUMERIK 840D sl STEP 7 Toolbox V17

32 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 33

4.3.3 Basic procedure

Note

Changing the rmware version of the congured NCU or NX

• Loading is possible if the rmware version of the congured and real hardware match.

• Loading is not possible if the rmware version of the hardware congured oine is newer

than the rmware version of the real hardware.

Otherwise it is possible that you congure version-dependent non-identiable properties in

the TIA Portal that the real hardware does not support.

• Loading is possible if the rmware version of the hardware congured oine is older than the

rmware version of the real hardware.

To replace the rmware version for a group (NCU with NX), the replacement on the NCU must

be initiated. Interconnected NXs are then also replaced automatically.

Procedure

Conguring the NCU

4.3 Replacing a device or upgrading rmware

To replace a device, proceed as follows:

1. Switch to the device view.

2. Select the device that you want to replace in the "<Select device>" drop-down list.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 33

Page 34

Conguring the NCU

4.3 Replacing a device or upgrading rmware

3. Right-click the device and then select "Replace device" in the shortcut menu.

The "Replace device" dialog opens.

4. Select the new device in the folder structure.

SINUMERIK 840D sl STEP 7 Toolbox V17

34 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 35

Result

Conguring the NCU

4.3 Replacing a device or upgrading rmware

5. Select the required rmware version in the "Version" drop-down list.

Note

Solving compatibility problems

If the two devices are not compatible or only have restricted compatibility, you can nd more

information in Section "Compatibility information".

If required, click "Cancel" and correct the problems before continuing.

6. Conrm the dialog with "OK".

The device has been replaced.

If you uploaded the rmware version, your telegram conguration was retained. Note that the

default telegram I/O addresses of telegram 701 have changed as of V4.7 SP2.

See also: Telegram conguration and I/O addressing schematics, Resetting telegrams

More information

More information on device replacement can be found in the information system of the TIA

Portal, keyword "Replacing".

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 35

Page 36

Conguring the NCU

4.4 Establish the communication connection

4.4 Establish the communication connection

Procedure

To establish a communication connection between two devices, proceed as follows:

1. In the "Online" menu, select the "Accessible devices" command.

2. In the drop-down lists "Type of PG/PC interface" and "PG/PC interface", search for the interface

used.

If no devices are accessible at an interface, the connecting line between the PG/PC and the

device is interrupted. If devices are accessible, the connecting line is shown and the devices

accessible at the selected interface of the PG/PC are displayed in a list.

SINUMERIK 840D sl STEP 7 Toolbox V17

36 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 37

4.5 Load hardware conguration into the PLC

3. If you have connected a new device in the meantime, click the "Refresh" button to refresh the

list of accessible devices.

4. Using "Display", transfer to the project navigator the device that has been found in the

"Online accesses" folder.

The subfolder of the interface to which the selected device is connected is selected in the

project tree.

Note

Several identical devices

If several identical devices can be accessed from the PG, by clicking on the "Flash LED" button

you can then display which device corresponds to the entry in the list of accessible devices.

4.5 Load hardware conguration into the PLC

Requirement

Conguring the NCU

• The hardware conguration is compiled.

• A communication connection exists between the PG/PC (TIA Portal) and the NCU.

Note

Loading congurations to simulated environments

If you want to use the conguration in a simulated environment, you must activate the

simulation capability in the project properties before you load the conguration into the

simulated environment or compile the hardware/software.

Note

General reset before loading into a PLC with Safety Integrated plus (F-PLC)

If the actual hardware has been operated in Safety Integrated plus (F-PLC) mode and you now

want to load a congured hardware conguration with changed Safety Integrated mode, you

must perform a general reset of the PLC prior to the loading.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 37

Page 38

Conguring the NCU

4.5 Load hardware conguration into the PLC

Procedure

Proceed as follows to load the congured hardware conguration into the NCU:

1. In the project navigation, right-click the device name, e.g. "CNC_1", and select the "Hardware

conguration" command in the "Download to device" shortcut menu.

Note

Scope of the data to be downloaded

Alternatively, you can select one of the other commands to start downloading additional

data to the NCU in this step.

See TIA Portal help, keyword "General information on download".

The "Extended download" dialog opens.

Figure 4-2 Dialog using the PLC of a SINUMERIK 840D sl as an example

2. Make the following settings in the "Extended download" dialog:

– PG/PC interface: Network card used, e.g. "Intel[R] Ethernet Connection I217-V"

SINUMERIK 840D sl STEP 7 Toolbox V17

38 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 39

Conguring the NCU

4.5 Load hardware conguration into the PLC

– Connection with interface/subnet: Specic interface on the NCU or "Try all interfaces"

3. Click on "Start search" and then select the found PLC from "Compatible nodes in the target

subnet". Alternatively, you can specify an IP address directly in the "Compatible nodes in the

target subnet" list in the "Address" column.

4. Conrm the download with "Load".

The "Download preview" dialog opens.

Figure 4-3 "Download preview" dialog

Note

Consistency check

Before the loading, the consistency of the download is checked. This means that a check is

made as to whether the parameterized hardware of the TIA Portal project matches the

hardware that has been actually installed.

Note

Adapt the IP address?

If the IP address of your PG/PC is located in a dierent subnet than the PLC, a dialog box is

displayed as to whether the IP address in the PG/PC should be adapted.

5. In the "Download preview" dialog, check the settings and click "Load" to conrm the input.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 39

Page 40

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

Result

The PLC is stopped and the hardware conguring is loaded into the PLC. The "Results of the

loading action" dialog opens and displays the status of the loading action. The dialog restarts the

PLC after completion, provided the "Start" checkbox has not been deactivated.

4.6 Creating SINUMERIK PLC archives

4.6.1 Creating a SINUMERIK PLC archive

Introduction

Unlike TIA Portal project archives (*.zap*), SINUMERIK PLC archives (*.arc) contain precompiled

commissioning data that you can import directly to the NCU (e.g. with SINUMERIK Operate).

A SINUMERIK archive oers the following possibilities:

• Direct image of the data of a PLC taken into operation in a le

• Simplication of the series commissioning

• Commissioning of the PLC with the SINUMERIK archive directly on the NCU without using a

PG/PC, TIA Portal or STEP 7

• Transfer of the data to the NCU without establishing an online connection to the actual

hardware

SINUMERIK archives (*.arc) have nothing in common with TIA Portal project archives (*.zap*).

TIA Portal project archives are compressed les, each of which contains a complete project,

including the complete folder structure of the project. (See: Online help, keyword "TIA Portal

project archive").

You can create a PLC archive with the SINUMERIK Toolbox and load it to the NCU (e.g. with

SINUMERIK Operate) in order to simplify the actual commissioning.

You can create the following SINUMERIK archives:

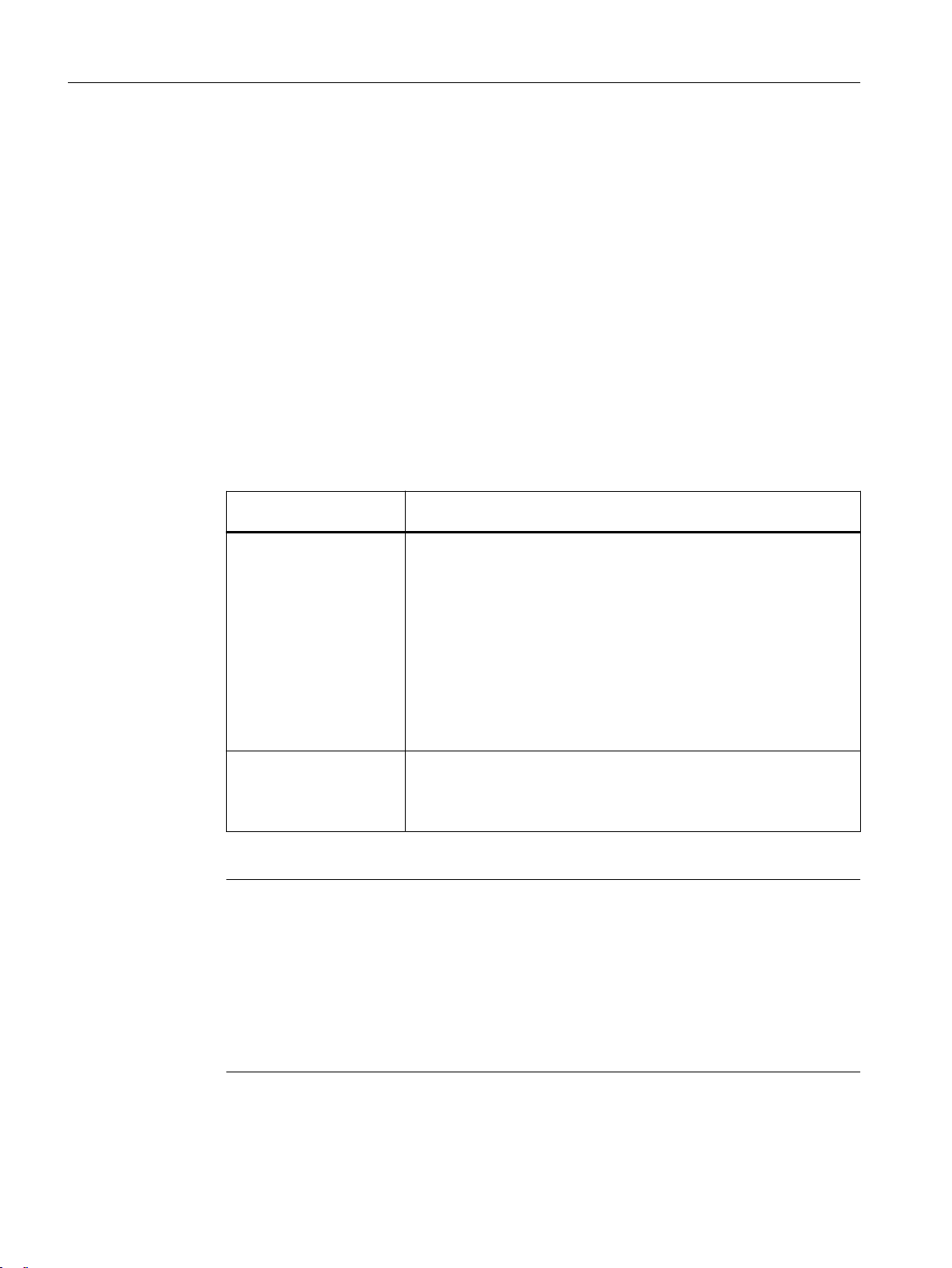

Archive type Command in the TIA

Portal

PLC hardware upgrade ar‐

chive (Page 44)

PLC commissioning ar‐

chive (Page 46)

PLC reload archive

(Page 48)

Only hardware...

Hardware and all pro‐

gram blocks...

Selected program

blocks...

Data included

• Hardware data (SDB) of the PLC

• Hardware data (SDB) of the PLC

• Program blocks of the PLC

• Hardware data (SDB) of the CP

• Program blocks of the PLC

SINUMERIK 840D sl STEP 7 Toolbox V17

40 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 41

Note

Editing SINUMERIK archives (.arc)

After you have created a SINUMERIK archive, you can open and edit it with various tools.

See: External tools for SINUMERIK archives (Page 44)

Note

Handling of F-blocks for SINUMERIK archives

Because F-blocks must always be saved together with the associated hardware conguration, Fblocks cannot be saved in reload archives.

Further information

• General information on NCU series commissioning archives can be found in Section "Saving

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

and managing data" of the "SINUMERIK 840D sl, SINAMICS S120 Commissioning CNC:NCK,

PLC, Drive for TIA" Commissioning Manual.

• Information about the dierences of the archives that were created with STEP 7 V5.x is

available at "Handling SINUMERIK archives".

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 41

Page 42

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

Overview

You can create SINUMERIK archives in various ways:

• In the menu bar at "Tools"

• In the shortcut menu of the NCU or PLC:

Figure 4-4 Creating a SINUMERIK archive

SINUMERIK 840D sl STEP 7 Toolbox V17

42 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 43

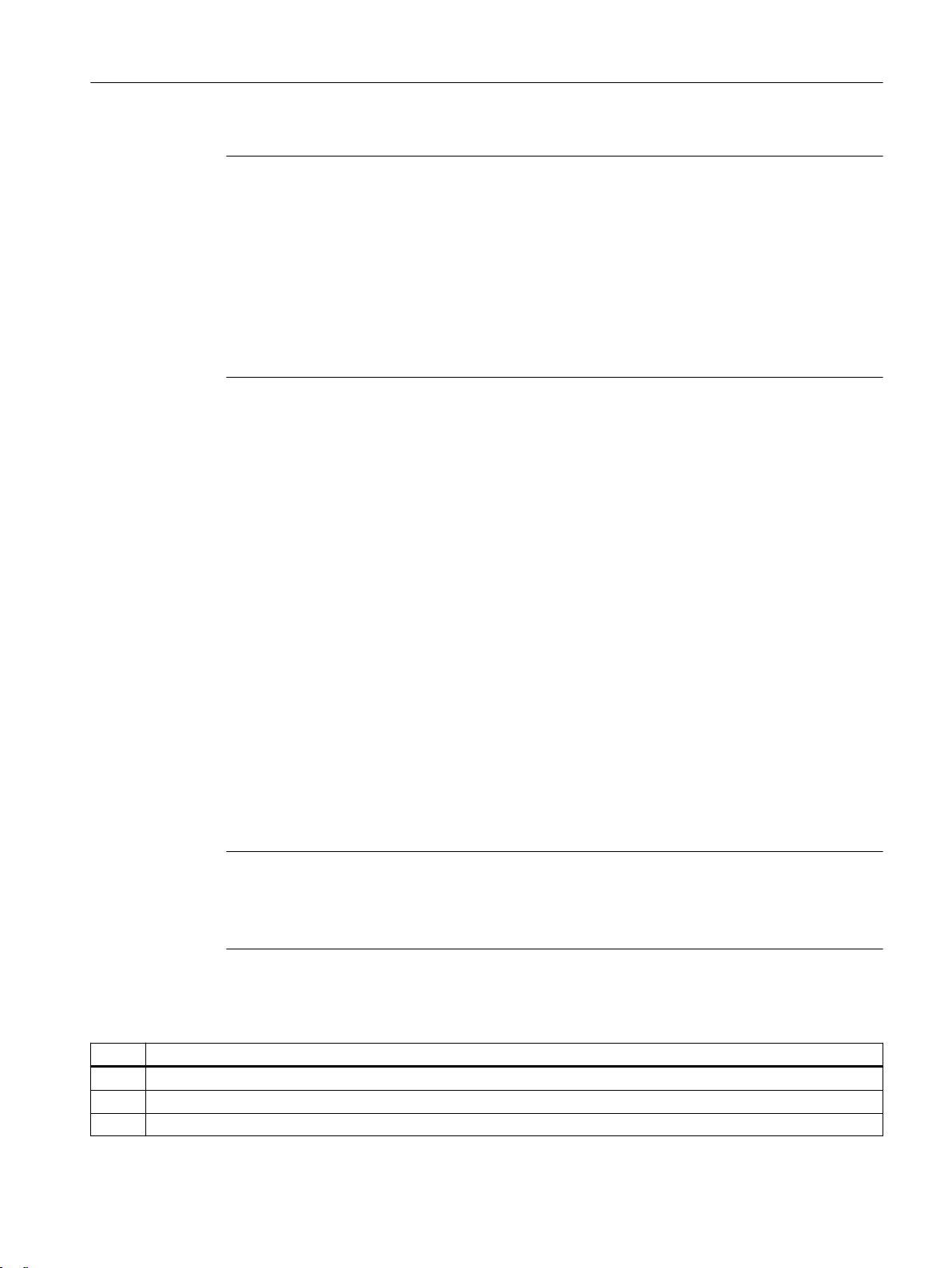

4.6.2 Available SINUMERIK archive types

There are dierent types of archives which you can create in dierent ways. Essentially, you

cannot use the TIA Portal to create archives that contain NC, drive or HMI data. However, you can

save a nely granular selection of translated program blocks as an archive in the TIA Portal with

the "PLC reload archive".

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

Archive type Command in the TIA

Portal

NCU commissioning ar‐

chive

PLC commissioning ar‐

chive (Page 46)

PLC hardware upgrade ar‐

chive (Page 44)

PLC reload archive

(Page 48)

Complete archive - <Ctrl> + <Alt> + S

Original status archive - Softkey "Commission‐

- Softkey "Commission‐

Hardware and all pro‐

gram blocks...

Only hardware...

Selected program

blocks...

Command in SINU‐

MERIK Operate

ing archive", option

button "Create commis‐

sioning archive"

Softkey "Commission‐

ing archive", option

button "Create commis‐

sioning archive"; only

enable "PLC data" in the

dialog

Softkey "Commission‐

ing archive", option

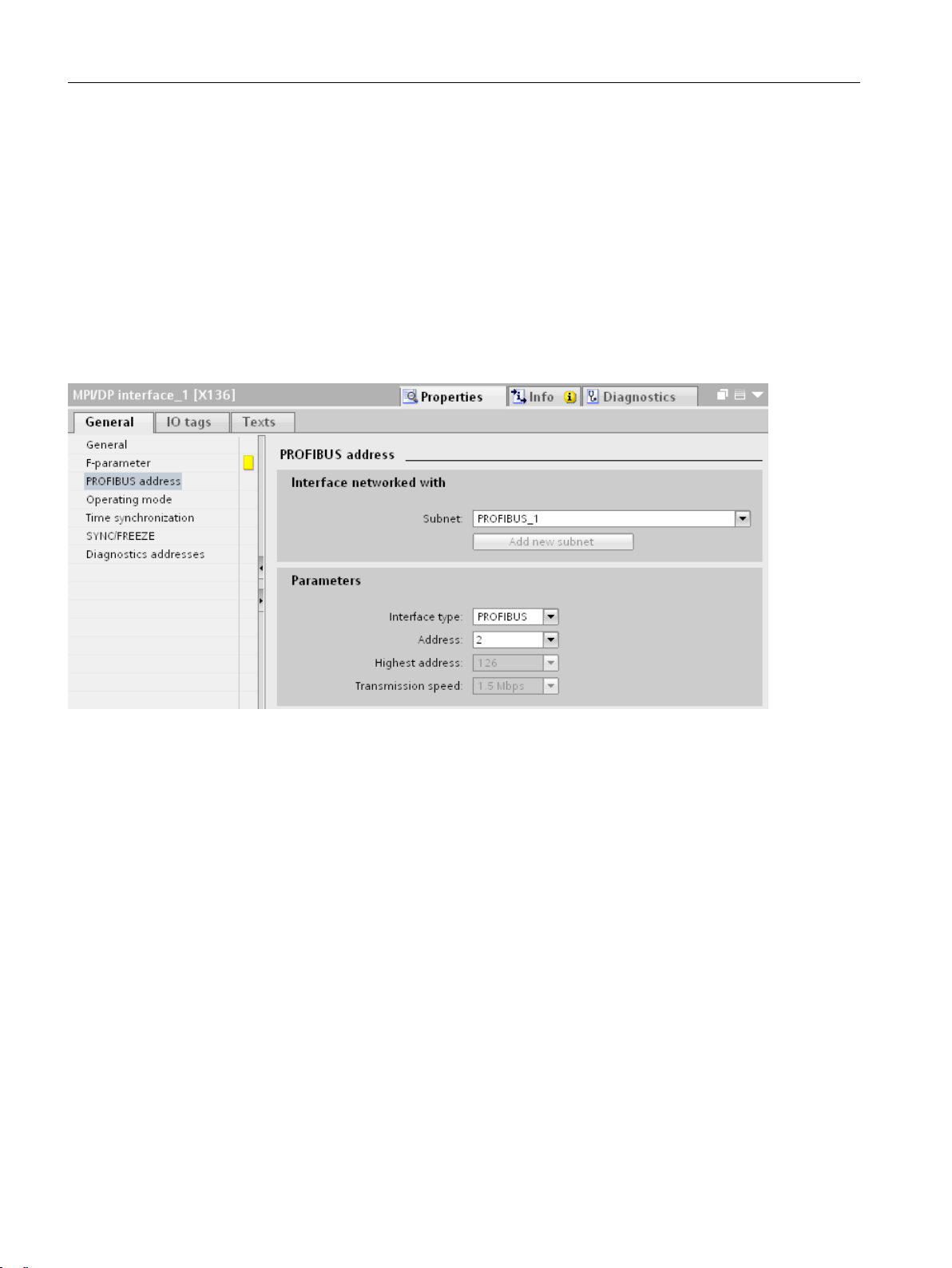

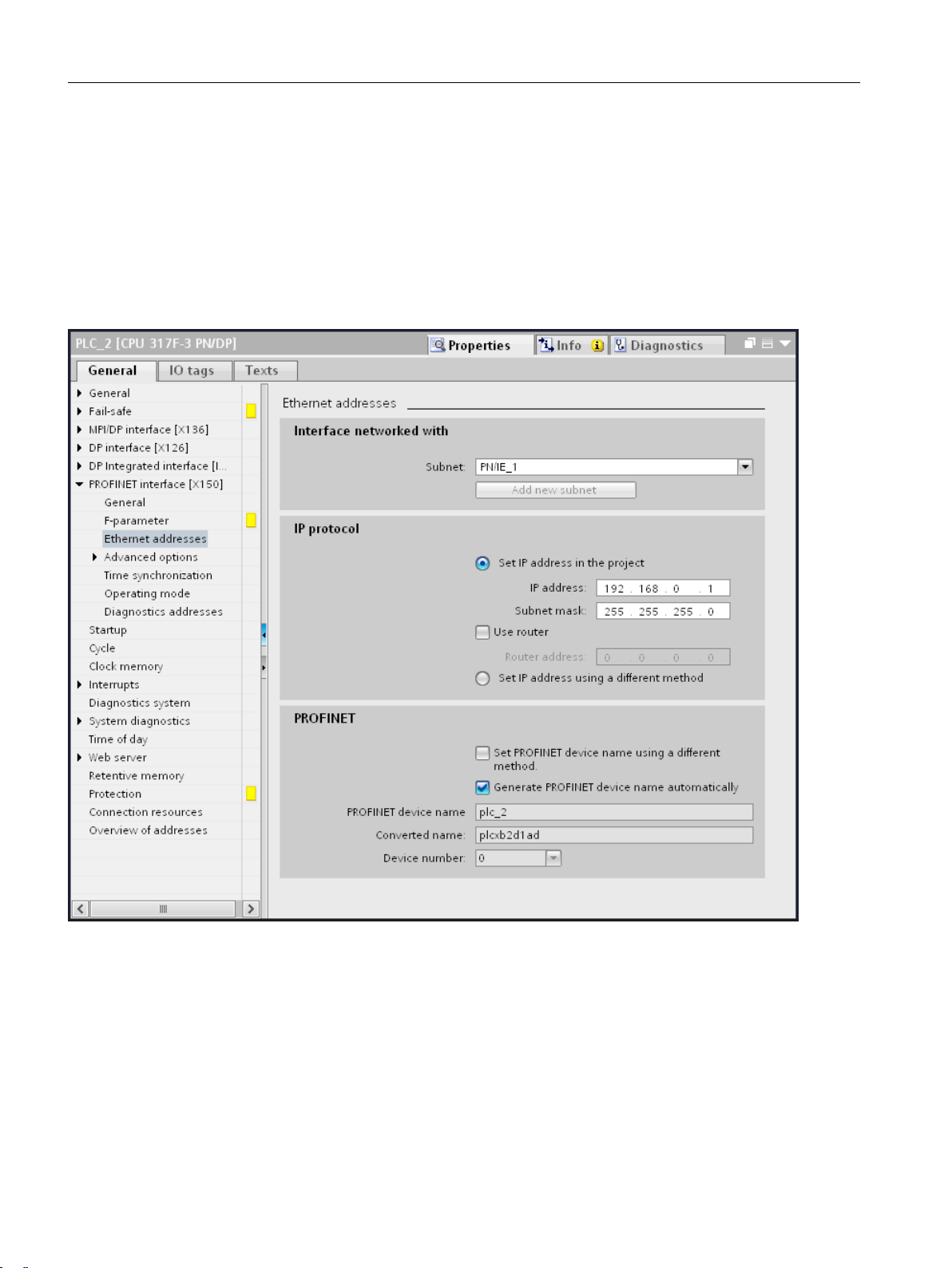

button "Create PLC

hardware upgrade ar‐

chive (only SDBs)"

-

ing archive", option

button "Create archive

original status"

Data contained

The contained data can be congured as fol‐

lows in the dialog:

• NC data

– With or without compensation data

– With or without compile cycles

• PLC data (all or none)

• Drive data (ACX format or ASCII format)

• HMI data (all HMI data or a congurable se‐

lection)

• Hardware data (SDB) of the PLC

• Program blocks of the PLC

• Hardware data (SDB) of the CP

• Hardware data (SDB) of the PLC

• Hardware data (SDB) of the CP

• Program blocks of the PLC

(congurable in the dialog)

All data (not congurable)

Original status (factory setting) of all subcom‐

ponents or a selection of specic subcompo‐

nents and data (congurable in the dialog)

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 43

Page 44

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

Note

Distinguishing between TIA Portal project archives and SINUMERIK archives

SINUMERIK archives (*.zap) have nothing in common with TIA Portal project archives (*.arc):

• SINUMERIK archives contain precompiled commissioning data that you can import directly to

the NCU.

• TIA Portal project archives are compressed les, each of which contains a complete project,

including the complete folder structure of the project.

See: TIA Portal online help, search term "TIA Portal project archive".

4.6.3 External tools for SINUMERIK archives

Overview

Various tools are available to open and edit the created SINUMERIK archives:

Tool Purpose Available from

SinuCom ARC Editing of SINUMERIK archives SinuCom commissioning/service tools in

the SIEMENS Industry Mall (https://

eb.automation.siemens.com/

mall/en/us/Catalog/Product/

6FC5250-7AY00-7AG0)

Create MyCong Extensive software, including functions

such as:

• Data comparison of SINUMERIK ar‐

chives

• Manipulation of SINAMICS data in

drive archives

• Creation of a SINAMICS archive with

dened topology

Create MyCong in the SIEMENS Indus‐

try Mall (https://

eb.automation.siemens.com/

mall/en/us/Catalog/Products/10167653)

4.6.4 Creating a PLC hardware upgrade archive

Requirement

• The data carrier to be used or storage location is available and has sucient storage space.

SINUMERIK 840D sl STEP 7 Toolbox V17

44 Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2

Page 45

Procedure

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

To create a hardware upgrade archive, proceed as follows:

1. In the project tree, right-click the device name, e.g. "CNC_1", and select "Create SINUMERIK

archive > Hardware only" in the shortcut menu.

The "Create SINUMERIK archive" dialog opens.

Figure 4-5 "Create SINUMERIK archive" dialog with hardware

2. Make the required settings:

Element Purpose

File name Enter the desired le name of the SINUMERIK archive in the text eld.

File extensions cannot be changed

The le extension (.arc) is not displayed and cannot be changed.

Path Click Browse and select a directory, or enter the directory directly.

Default storage location for data export

The used path is shown as the default setting the next time you export an archive.

To specify the default setting for the data export in the settings, switch to "General >

General > Data exchange > Storage location for data export" in the settings.

Author Name of the author or a person responsible for the project.

The default setting corresponds to the setting of the user name in the TIA Portal under:

"Extras > Settings > General > General settings > User name".

Comment Input of a comment for the SINUMERIK archive.

As default setting, the comment eld contains an entry indicating whether the archive

contains only hardware or hardware and all program blocks.

Press the shortcut keys <Shift+Return> to insert a line break.

3. Click "Create archive" to conrm your input.

Result

The SINUMERIK archive is created and stored in the path that you have specied.

SINUMERIK 840D sl STEP 7 Toolbox V17

Conguration Manual, 07/2021, 6FC5397-0GP40-0BA2 45

Page 46

Conguring the NCU

4.6 Creating SINUMERIK PLC archives

4.6.5 Creating a PLC commissioning archive

Requirement

• If possible, the "Program blocks" folder should not contain any program blocks of not

activated axes/spindles or the tool management.

You can also save unused program blocks in the archive, although this extends the time

required for creating and loading the archive.

• The data carrier to be used or storage location is available and has sucient storage space.

Note

Handling of F-blocks for SINUMERIK archives

The handling of F-blocks depends on the used Safety Integrated mode:

• If Safety Integrated is inactive or Safety Integrated (SPL) is active, F-blocks are not stored in

the SINUMERIK archive.

• In Safety Integrated plus (F-PLC) mode, F-blocks are saved in PLC commissioning archives.

Note the additional information in the Readme le for SINUMERIK Toolbox: "Start > Siemens

Automation > Documentation > Readmes > English".

SINUMERIK 840D sl STEP 7 Toolbox V17