Page 1

SINUMERIK SINUMERIK 828D Turning and Milling

SINUMERIK

SINUMERIK 828D Turning and Milling

Commissioning Manual

Preface

Scope of delivery and

requirements

Settings on the HMI

Commissioning the PLC

Commissioning the drive

Setting NCK machine data

Configuring cycles

Service Planner

Easy Extend

Tool management

Series start-up

References

List of abbreviations

1

2

3

4

5

6

7

8

9

10

A

B

Valid for:

NCU system software Version 2.6

HMI sl Version 2.6

09/2009

6FC5397-3DP20-0BA0

Page 2

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5397-3DP20-0BA0

Ⓟ 10/2009

Copyright © Siemens AG 2009.

Technical data subject to change

Page 3

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in three parts:

● General documentation

● User documentation

● Manufacturer/service documentation

Information on the following topics is available at

http://www.siemens.com/motioncontrol/docu:

● Ordering documentation:

Here you can find an up-to-date overview of publications.

● Downloading documentation:

Links to more information for downloading files from Service & Support.

Target group

Benefits

● Researching documentation online

Information on DOConCD and direct access to the publications in DOConWEB.

● Compiling individual documentation on the basis of Siemens contents with the My

Documentation Manager (MDM), refer to http://www.siemens.com/mdm

My Documentation Manager provides you with a range of features for generating your

own machine documentation.

● Training and FAQs

Information on our range of training courses and FAQs (frequently asked questions) is

available via the page navigation.

This documentation is intended for commissioning personnel.

The plant or system is readily assembled and wired. For the following steps, e.g. configuring

the individual components, the Commissioning Manual contains all necessary information or

at least references.

The intended target group can use the Commissioning Manual to test and commission the

system or the plant correctly and safely.

Utilization phase: Setup and commissioning phase

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

3

Page 4

Preface

Standard version

This documentation only describes the functionality of the standard version. Extensions or

changes made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control.

However, no claim can be made regarding the availability of these functions when the

equipment is first supplied or in the event of servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed

information about all types of the product and cannot cover every conceivable case of

installation, operation or maintenance.

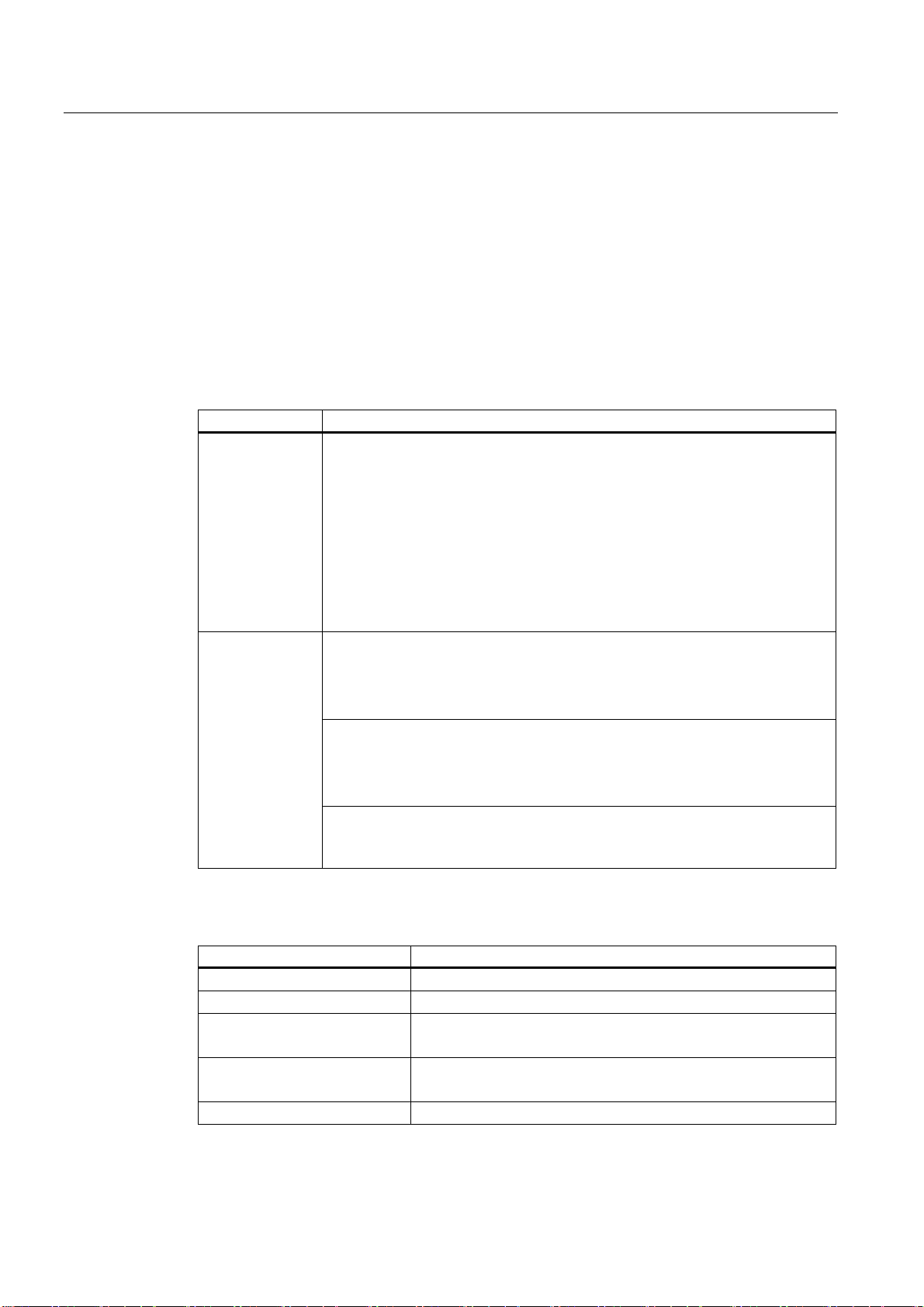

Structure of the documentation:

Target group Manual

User

Manufacturer

• SINUMERIK 828D/840D sl Operating Manual HMI sl Turning

• SINUMERIK 828D/840D sl Operating Manual HMI sl Milling

• SINUMERIK 828D/840D sl Programming Manual Fundamentals

• SINUMERIK 828D/840D sl Programming Manual Job Planning

• SINUMERIK 840D sl Programming Manual Measuring Cycles

• SINUMERIK 802D sl/828D/840D sl

Programming Manual, ISO Dialects Turning

Programming Manual, ISO Dialects Milling

• SINUMERIK 828D Diagnostics Manual

• SINUMERIK 828D Manual PPU

• SINUMERIK 828D Commissioning Manual Turning and Milling

• SINUMERIK 828D Service Manual Hardware and Software

• SINUMERIK 828D Parameter Manual

• SINUMERIK 828D/840D sl Function Manual Basic Functions

• SINUMERIK 828D/840D sl Function Manual Extended Functions

• SINUMERIK 840D sl Function Manual Tool Management

• SINUMERIK 802D sl/828D/840D sl Function Manual ISO Dialects

• SIMATIC NET System Manual GPRS/GSM Modem SINAUT MD720-3

• SIMATIC NET Operating Instructions Quad-Band GSM Antenna

SINAUT 794-4MR

Additional references:

Subject Manual

RCS Commander Online help

Programming Tool PLC828 Online help

Easy Screen SINUMERIK 840D sl Programming Manual Easy Screen

in: Commissioning Manual Base Software and HMI sl

Easy Message SINUMERIK 828D/840D sl Operating Manual HMI sl Turning

SINUMERIK 828D/840D sl Operating Manual HMI sl Milling

ePS Network Services ePS Network Services Function Manual and online help

Turning and Milling

4 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 5

Preface

Subject Manual

Networking SINUMERIK 840D sl Manual

Operator Components and Networking

SAFETY (safe standstill) SINAMICS S120/SINUMERIK 840D sl Manual Machine

Configuration

Questions about this documentation

If you have any queries (suggestions, corrections) in relation to this documentation, please

send a fax or e-mail to the following address:

Fax +49 9131 98 2176

E-mail mailto:docu.motioncontrol@siemens.com

A fax form is available at the end of this document.

SINUMERIK Internet address

http://www.siemens.com/sinumerik

Technical Support

If you have any technical questions, please contact our hotline:

Europe/Africa

Phone +49 180 5050 222

Fax +49 180 5050 223

0.14 €/min from the German fixed-line network; cell phone charges may vary.

Internet http://www.siemens.com/automation/support-request

Americas

Phone +1 423 262 2522

Fax +1 423 262 2200

E-mail mailto:techsupport.sea@siemens.com

Asia/Pacific

Phone +86 1064 757575

Fax +86 1064 747474

E-mail mailto:support.asia.automation@siemens.com

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

5

Page 6

Preface

Note

National telephone numbers for technical support are provided under the following Internet

address:

http://www.siemens.com/automation/partner

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be found on the Internet at:

http://support.automation.siemens.com

under the Product Order No. 15257461, or at the relevant branch office of I DT MC Division

of Siemens AG.

CompactFlash cards for users

● The SINUMERIK CNC supports the file systems FAT16 and FAT32 for

CompactFlash cards. You may need to format the memory card if you want to use a

memory card from another device or if you want to ensure the compatibility of the

memory card with the SINUMERIK. However, formatting the memory card will

permanently delete all data on it.

● Do not remove the memory card while it is being accessed. This can lead to damage of

the memory card and the SINUMERIK as well as the data on the memory card.

● If you cannot use a memory card with the SINUMERIK, it is probably because the

memory card is not formatted for the control system (e.g. Ext3 Linux file system), the

memory card file system is faulty or it is the wrong type of memory card.

● Insert the memory card carefully with the correct orientation into the memory card slot

(take note of arrows, etc.). This way you avoid mechanical damage to the memory card or

the device.

● Only use memory cards that have been approved by Siemens for use with SINUMERIK.

Even though the SINUMERIK keeps to the general industry standards for memory cards,

it is possible that memory cards from some manufacturers will not function perfectly in

this device or are not completely compatible with it (you can obtain information on

compatibility from the memory card manufacturer or supplier).

● The CompactFlash card from SanDisk "CompactFlash® 5000 Industrial Grade" has been

approved for SINUMERIK (Order Number 6FC5313-5AG00-0AA0).

Turning and Milling

6 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 7

Table of contents

Preface ...................................................................................................................................................... 3

1 Scope of delivery and requirements ........................................................................................................ 13

1.1 System overview ..........................................................................................................................13

1.2 Toolbox CD and other available tools ..........................................................................................14

1.3 This is the general sequence for commissioning.........................................................................15

1.4 Starting up the control..................................................................................................................16

1.5 Communication with the control...................................................................................................19

1.5.1 How to communicate with the control using the Programming Tool............................................19

1.5.2 Example: How to communicate with the control using the NCU Connection Wizard..................23

1.5.3 How to communicate with the control using the RCS Commander.............................................25

1.5.4 Communicating with the control via X130....................................................................................28

2 Settings on the HMI ................................................................................................................................. 31

2.1 Access levels ...............................................................................................................................31

2.2 How to set and change the password..........................................................................................33

2.3 Available system languages ........................................................................................................34

2.4 How to set the date and time .......................................................................................................35

2.5 Checking and entering licenses ...................................................................................................36

2.5.1 How to enter a license key...........................................................................................................37

2.5.2 How to determine the license requirement ..................................................................................38

2.6 Configuring user alarms...............................................................................................................40

2.6.1 Structure of user PLC alarms.......................................................................................................40

2.6.2 How to create user PLC alarms...................................................................................................42

2.6.3 Configuring the alarm log.............................................................................................................43

2.6.4 How to configure the log ..............................................................................................................44

2.6.5 Configuring user alarms with colors.............................................................................................46

2.6.6 How to configure colors for user alarms ......................................................................................47

2.7 Creating OEM-specific online help ..............................................................................................50

2.7.1 Structure and syntax of the configuration file...............................................................................50

2.7.2 Structure and syntax of the help book .........................................................................................52

2.7.3 Description of the syntax for the online help................................................................................53

2.7.4 Example: How to create an OEM-specific help ...........................................................................57

2.7.5 Example: How to create an online help for user PLC alarms......................................................60

3 Commissioning the PLC .......................................................................................................................... 63

3.1 Activating I/O modules .................................................................................................................64

4 Commissioning the drive ......................................................................................................................... 67

4.1 Configuring the drive....................................................................................................................67

4.1.1 Example of a drive configuration..................................................................................................67

4.1.2 Example: How to configure the drive ...........................................................................................69

4.1.3 Example: How to configure the infeed .........................................................................................76

4.1.4 Example: How to configure the external encoder........................................................................78

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

7

Page 8

Table of contents

4.1.5 Example: How to assign the axes............................................................................................... 83

4.1.6 Example: Setting machine data for an axis/spindle .................................................................... 88

4.1.7 Parameters for the axis/spindle test run ..................................................................................... 89

4.2 Terminal assignments ................................................................................................................. 91

4.2.1 Terminal assignment on X122 .................................................................................................... 91

4.2.2 Terminal assignment on X132 .................................................................................................... 92

4.2.3 Terminal assignment on X122 for a Numeric Control Extension................................................ 93

4.2.4 Example: Circuitry for a CU with line contactor........................................................................... 94

4.2.5 Connecting the probes................................................................................................................ 97

5 Setting NCK machine data..................................................................................................................... 101

5.1 Classification of machine data .................................................................................................. 101

5.2 Processing part programs from external CNC systems............................................................ 104

6 Configuring cycles ................................................................................................................................. 105

6.1 Settings for activating cycles..................................................................................................... 105

6.1.1 How to adapt the manufacturer cycles...................................................................................... 109

6.1.2 Standard cycle PROG_EVENT.SPF......................................................................................... 110

6.1.3 Setting the simulation and simultaneous recording (option)..................................................... 111

6.2 Drilling ....................................................................................................................................... 113

6.2.1 Technology cycles for drilling.................................................................................................... 113

6.2.2 ShopTurn: Drilling centered ...................................................................................................... 115

6.3 Milling ........................................................................................................................................ 116

6.3.1 Technology cycles for milling .................................................................................................... 116

6.3.2 Cylinder surface transformation (TRACYL) .............................................................................. 117

6.3.3 Example: Axis configuration for milling machines..................................................................... 118

6.3.4 ShopMill: Setting up cycles for milling....................................................................................... 121

6.4 Turning ...................................................................................................................................... 124

6.4.1 Technology cycles for turning ...........................................................................................

........ 124

6.4.2 Example: Residual material machining..................................................................................... 127

6.4.3 Example: Axis configuration for lathes...................................................................................... 129

6.4.4 Cylinder surface transformation (TRACYL) .............................................................................. 130

6.4.5 End face machining (TRANSMIT)............................................................................................. 133

6.4.6 Inclined axis (TRAANG) ............................................................................................................ 136

6.4.7 ShopTurn: Setting up cycles for turning.................................................................................... 139

6.4.8 ShopTurn: Counterspindle ........................................................................................................ 146

6.4.9 ShopTurn: Cylinder surface transformation (TRACYL) ............................................................ 150

6.4.10 ShopTurn: End face machining (TRANSMIT)........................................................................... 151

6.4.11 ShopTurn: Inclined axis (TRAANG) .......................................................................................... 152

6.5 Swivel ........................................................................................................................................ 153

6.5.1 Technology cycles for swiveling................................................................................................ 153

6.5.2 Setting the workpiece, tool and rotary table reference ............................................................. 156

6.5.3 ShopMill: Swivel plane and swivel tool ..................................................................................... 159

6.5.4 CYCLE800 checklist for the identification of the machine kinematics ...................................... 160

6.5.5 Commissioning of the kinematic chain (swivel data record)..................................................... 161

6.5.6 Example of the commissioning of swivel head 1 ...................................................................... 167

6.5.7 Example of the commissioning of swivel head 2 ...................................................................... 168

6.5.8 Example of the commissioning of a cardanic table................................................................... 170

6.5.9 Example of the commissioning of a swivel head/rotary table ................................................... 172

6.5.10 Example of the commissioning of a swivel table ...................................................................... 174

6.5.11 Manufacturer cycle CUST_800.SPF ......................................................................................... 176

Turning and Milling

8 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 9

Table of contents

6.6 High Speed Settings (Advanced Surface) .................................................................................182

6.6.1 Configuring the High Speed Settings function (CYCLE832) .....................................................182

6.6.2 How to adapt the High Speed Settings function (CYCLE832)...................................................184

6.7 Measuring cycles and measurement functions..........................................................................186

6.7.1 General settings for measuring..................................................................................................186

6.7.2 Manufacturer cycle CUST_MEACYC.SPF ................................................................................189

6.7.3 Measuring in the JOG mode......................................................................................................189

6.7.4 JOG: Measure workpiece during milling ....................................................................................191

6.7.5 JOG: Measure tool during milling...............................................................................................193

6.7.6 JOG: Measure tool during turning..............................................................................................197

6.7.7 Measuring in the AUTOMATIC mode ........................................................................................198

6.7.8 AUTO: General settings for the workpiece measurement .........................................................200

6.7.9 AUTO: Measure workpiece during milling .................................................................................202

6.7.10 AUTO: Measure workpiece during turning.................................................................................204

6.7.11 AUTO: Measure tool during milling............................................................................................205

6.7.12 AUTO: Measure tool during turning (CYCLE982)......................................................................213

7 Service Planner ..................................................................................................................................... 215

7.1 PLC user program......................................................................................................................217

7.2 Interfaces in the PLC user program...........................................................................................218

7.3 Functions on the HMI.................................................................................................................223

8 Easy Extend .......................................................................................................................................... 231

8.1 Overview of functions.................................................................................................................231

8.2 Configuration in the PLC user program .....................................................................................233

8.3 Display on the user interface .....................................................................................................235

8.4 Creating language-dependent texts...........................................................................................236

8.5 Description of the script language..............................................................................................237

8.5.1 Special characters and operators ........................................................................................

......238

8.5.2 Structure of the XML script ........................................................................................................239

8.5.3 CONTROL_RESET....................................................................................................................241

8.5.4 DATA..........................................................................................................................................241

8.5.5 DATA_ACCESS.........................................................................................................................241

8.5.6 DATA_LIST ................................................................................................................................242

8.5.7 DRIVE_VERSION ......................................................................................................................243

8.5.8 FILE............................................................................................................................................244

8.5.9 FUNCTION.................................................................................................................................245

8.5.10 FUNCTION_BODY ....................................................................................................................246

8.5.11 INCLUDE ...................................................................................................................................248

8.5.12 LET.............................................................................................................................................248

8.5.13 MSGBOX ...................................................................................................................................250

8.5.14 OP ..............................................................................................................................................251

8.5.15 OPTION_MD..............................................................................................................................252

8.5.16 PASSWORD ..............................................................................................................................253

8.5.17 PLC_INTERFACE......................................................................................................................253

8.5.18 POWER_OFF.............................................................................................................................254

8.5.19 PRINT ........................................................................................................................................254

8.5.20 WAITING....................................................................................................................................255

8.5.21 ?up .............................................................................................................................................256

8.5.22 XML identifiers for the dialog .....................................................................................................256

8.5.23 BOX............................................................................................................................................258

8.5.24 CONTROL..................................................................................................................................258

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

9

Page 10

Table of contents

8.5.25 IMG............................................................................................................................................ 260

8.5.26 PROPERTY .............................................................................................................................. 261

8.5.27 REQUEST................................................................................................................................. 262

8.5.28 SOFTKEY_OK, SOFTKEY_CANCEL ....................................................................................... 262

8.5.29 TEXT ......................................................................................................................................... 263

8.5.30 UPDATE_CONTROLS.............................................................................................................. 263

8.5.31 Addressing the parameters....................................................................................................... 264

8.5.32 Addressing the drive objects..................................................................................................... 266

8.5.33 XML identifiers for statements................................................................................................... 268

8.6 String functions ......................................................................................................................... 271

8.6.1 string.cmp.................................................................................................................................. 271

8.6.2 string.icmp................................................................................................................................. 272

8.6.3 string.left.................................................................................................................................... 273

8.6.4 string.right.................................................................................................................................. 273

8.6.5 string.middle.............................................................................................................................. 274

8.6.6 string.length............................................................................................................................... 275

8.6.7 string.replace............................................................................................................................. 275

8.6.8 string.remove ............................................................................................................................ 276

8.6.9 string.delete............................................................................................................................... 277

8.6.10 string.insert................................................................................................................................ 277

8.6.11 string.find................................................................................................................................... 278

8.6.12 string.reversefind....................................................................................................................... 279

8.6.13 string.trimleft.............................................................................................................................. 280

8.6.14 string.trimright ........................................................................................................................... 280

8.7 Trigonometric functions............................................................................................................. 282

8.8 Examples................................................................................................................................... 284

8.8.1 Example with control elements ................................................................................................. 284

8.8.2 Example with parameters to support the commissioning ......................................................... 285

8.8.3 User example for a power unit ...........................................................................................

....... 288

9 Tool management.................................................................................................................................. 291

9.1 Fundamentals ........................................................................................................................... 291

9.1.1 Structure of the tool management............................................................................................. 292

9.1.2 Components of the tool management....................................................................................... 293

9.1.3 Loading and unloading tools manually...................................................................................... 296

9.2 PLC - NCK user interface.......................................................................................................... 297

9.2.1 Relocating, unloading, loading tool, positioning magazine....................................................... 298

9.2.2 Tool change .............................................................................................................................. 304

9.2.3 Transfer-step and acknowledgment-step tables....................................................................... 311

9.3 Machine data for the tool management .................................................................................... 313

9.4 PLC Program Blocks................................................................................................................. 320

9.4.1 Acknowledgment process ......................................................................................................... 320

9.4.2 Types of acknowledgment ........................................................................................................ 321

9.4.3 Acknowledgment states ............................................................................................................ 322

9.4.4 Configuring step tables ............................................................................................................. 327

9.4.5 Configuring acknowledgment steps .......................................................................................... 330

9.4.6 Adjust the PLC user program.................................................................................................... 331

9.4.7 Information on magazine location ............................................................................................. 332

9.4.8 PI service: TMMVTL.................................................................................................................. 335

9.5 Example: Loading/unloading..................................................................................................... 336

9.6 Example: Change manual tools ................................................................................................ 338

Turning and Milling

10 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 11

Table of contents

9.7 Application example for turning machine...................................................................................342

9.7.1 Example: Turning machine with revolver magazine (MAG_CONF_MPF).................................342

9.7.2 Example: Acknowledgment steps (turning machine).................................................................347

9.7.3 Example: Tool change cycle for turning machine......................................................................348

9.7.4 Example: Tool change cycle for TCA command........................................................................350

9.7.5 Example: Turning machine with counterspindle ........................................................................351

9.7.6 Example: Test for empty buffer..................................................................................................351

9.7.7 Example: Transporting a tool from a buffer into the magazine..................................................352

9.7.8 Example: Repeat "Prepare tool change" order..........................................................................352

9.8 Application example for milling machine....................................................................................354

9.8.1 Example: Milling machine with chain magazine and dual gripper (MAG_CONF_MPF)............354

9.8.2 Flow chart: Tool change.............................................................................................................360

9.8.3 Example: Acknowledgment steps (milling machine)..................................................................369

9.8.4 Example: Tool change cycle for milling machine.......................................................................371

10 Series start-up ....................................................................................................................................... 373

10.1 Series start-up and archiving .....................................................................................................374

10.2 How to create and read in a series start-up archive ..................................................................376

10.3 Example: Data archiving "Easy Archive" (use case) .................................................................378

10.4 Parameterizing the V.24 interface..............................................................................................380

A References ............................................................................................................................................ 383

A.1 List of language codes used for file names ...............................................................................383

A.2 List of the alarm number ranges ................................................................................................384

A.3 List of the color codes ................................................................................................................385

A.4 Directory structure on the CompactFlash card ..........................................................................386

A.4.1 How to edit files in the file system..............................................................................................389

A.5 Definitions for license management...........................................................................................391

A.6 Rules for wiring with DRIVE-CLiQ .............................................................................................393

B List of abbreviations............................................................................................................................... 397

B.1 Abbreviations .............................................................................................................................397

B.2 Feedback on the documentation................................................................................................400

B.3 Overview of documentation .......................................................................................................402

Glossary ................................................................................................................................................ 403

Index........................................................................................................................

.............................. 409

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

11

Page 12

Table of contents

Turning and Milling

12 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 13

Scope of delivery and requirements

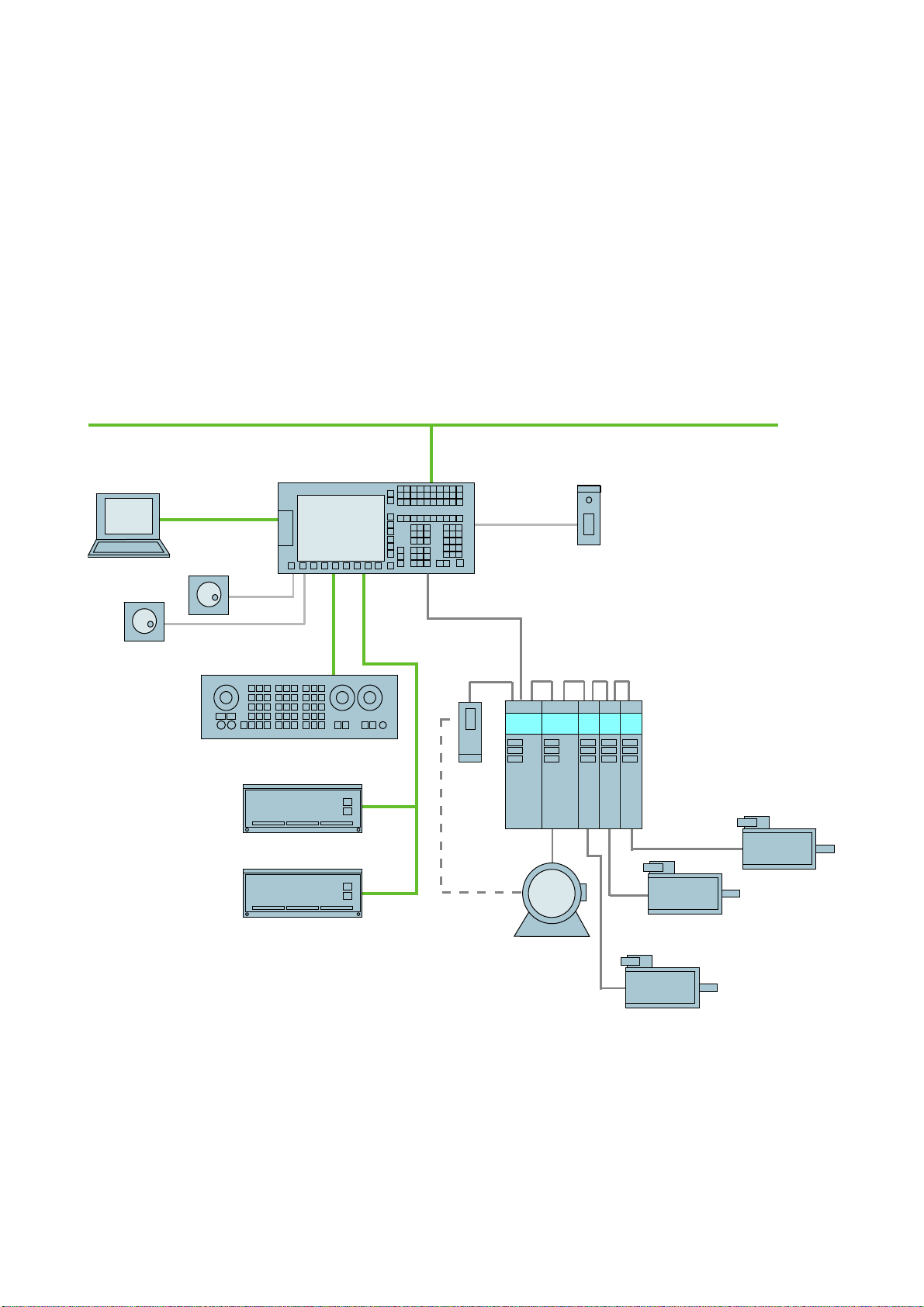

1.1 1.1 System overview

System design

The following configuration shows a typical example:

&RPSDQ\QHWZRUN,QGXVWULDO(WKHUQHW

6,180(5,.'

3HHUWRSHHU

3*3&

'5,9(&/L4

3/&,2LQWHUIDFHEDVHG

[KDQGZKHHOV

RQ352),1(7

1

6,1$870'

6,1$0,&66

0&331

33'31

33'$31

Figure 1-1 Configuration example

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

60&

6/0

600

,QGXFWLRQPRWRU

600

600

600

6\QFKURQRXV

PRWRU

6\QFKURQRXV

PRWRU

6\QFKURQRXV

PRWRU

13

Page 14

Scope of delivery and requirements

1.2 Toolbox CD and other available tools

1.2 1.2 Toolbox CD and other available tools

Toolbox CD

The Toolbox CD for SINUMERIK 828D has the following content:

● PLC Programming Tool for Integrated PLC

● Commissioning software for SINAMICS S120

● PLC Library (example)

PLC Programming Tool for Integrated PLC

The following tool is available for programming the PLC: PLC Programming Tool for

Integrated PLC. For the rest of this manual, this will be referred to using the abbreviation

"Programming Tool".

Commissioning software for SINAMICS S120

Until the SINAMICS S120 commissioning functionality is completely available via the user

interface, drive configuration and optimization is performed using the commissioning

software for SINAMICS S120. The PC is connected using the Ethernet interface on the front

of the SINUMERIK 828D.

Note

Ordering data

You can find the ordering data for the following tools in Catalog NC 61.

RCS Commander

The RCS Commander (Remote Control System) is a tool the commissioner can use to

exchange files between the PC and the control very easily, using drag and drop.

For data transmission, the PC is connected directly to the Ethernet interface on the front of

the control. For a point-to-point connection, time-consuming parameterization of the Ethernet

interface is not necessary. All settings are made automatically by the RCS Commander.

The RCS Commander can also access several NCUs sequentially via a company network.

STARTER drive/commissioning software

Drive commissioning for the SINUMERIK 828D can be performed using the STARTER drive

commissioning software. Simple commissioning procedures which are usually performed by

field service staff (such as activating direct measuring systems) can be executed directly via

the SINUMERIK 828D user interface. Advanced commissioning procedures which are

usually performed when the machine is being manufactured (such as drive optimization) can

be executed offline via the commissioning software used for SINAMICS S120.

Turning and Milling

14 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 15

Scope of delivery and requirements

1.3 This is the general sequence for commissioning

1.3 1.3 This is the general sequence for commissioning

Requirements

The mechanical and electrical installation of the system must be completed.

● Check the system visually for:

– Correct mechanical installation with secure electrical connections

– Connection of the power supply

– Connection of shielding and grounding

● Switching on the control and startup in "Normal startup":

Startup of the control is finished when the main screen is shown on the HMI.

Sequence overview

Commissioning of the SINUMERIK 828D is carried out in the following steps:

1. Install the software from Toolbox CD onto PG/PC

See chapter "Scope of delivery and requirements"

2. Create communication connection with the control

See chapter "Communication with the control"

3. Addressing the I/O

See chapter "Addressing the I/O modules"

4. Set HMI

See chapter "Settings on the HMI"

5. PLC functions

See Function Manual Basic Functions (P4)

6. Commission drive and connect probes

See chapter "Configuring drive"

7. Setting NCK machine data

See chapter "Setting NCK machine data"

8. Configuring cycles

See chapter "Configuring cycles"

9. Define maintenance tasks and maintenance intervals

See chapter "Service Planner"

10. Extend machine with additional devices

See chapter "Easy Extend"

11. Tool management

See chapter "Tool management"

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

15

Page 16

Scope of delivery and requirements

1.4 Starting up the control

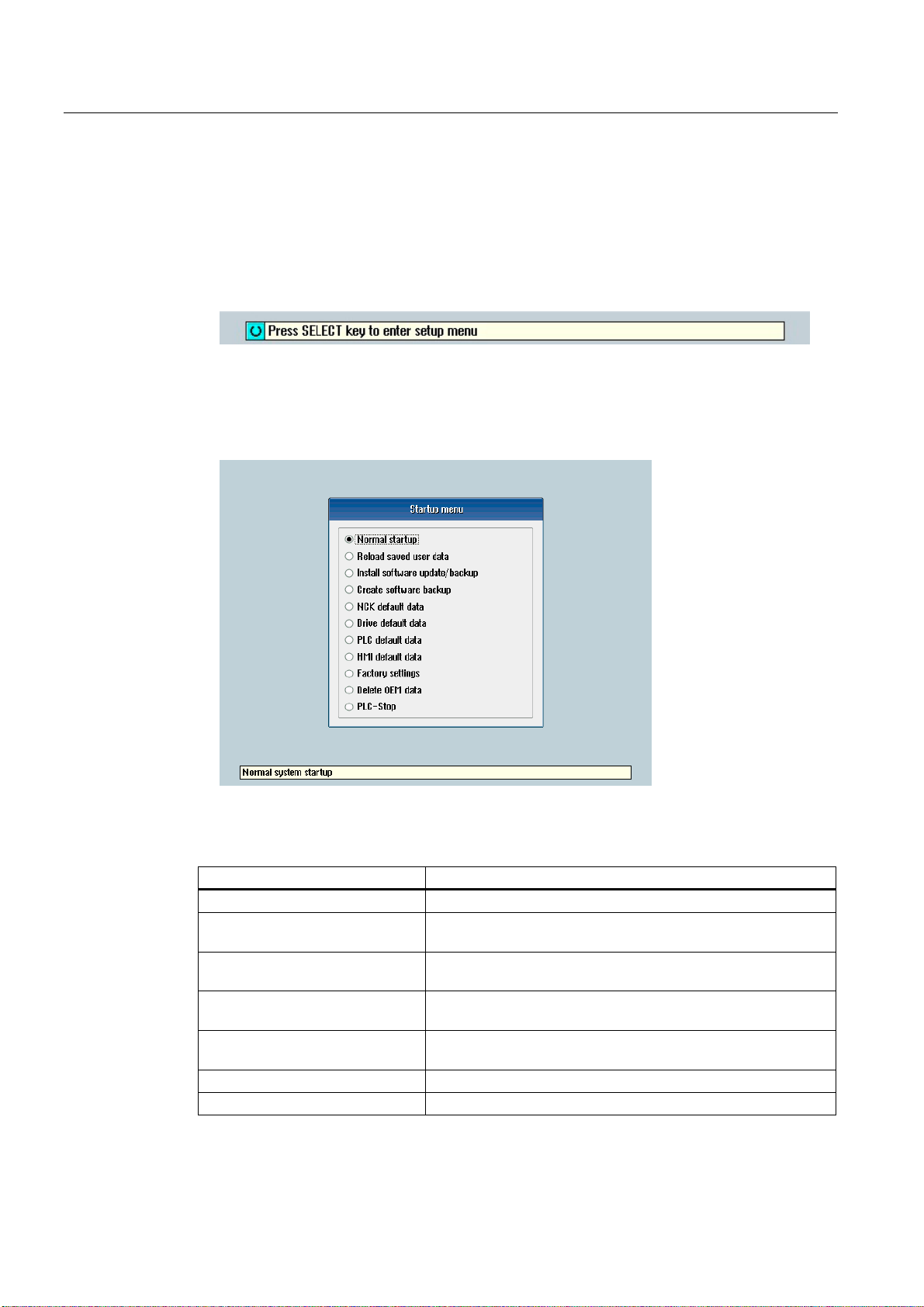

1.4 1.4 Starting up the control

Control startup

Procedure:

1. Switch the control on. The following display then appears during startup:

2. Press the <SELECT> key within three seconds.

3. Then press the following keys in succession:

Menu reset key, HSK2 (horizontal SK2), VSK2 (vertical SK2)

4. The "Setup menu" is displayed, "Normal startup" is the default setting.

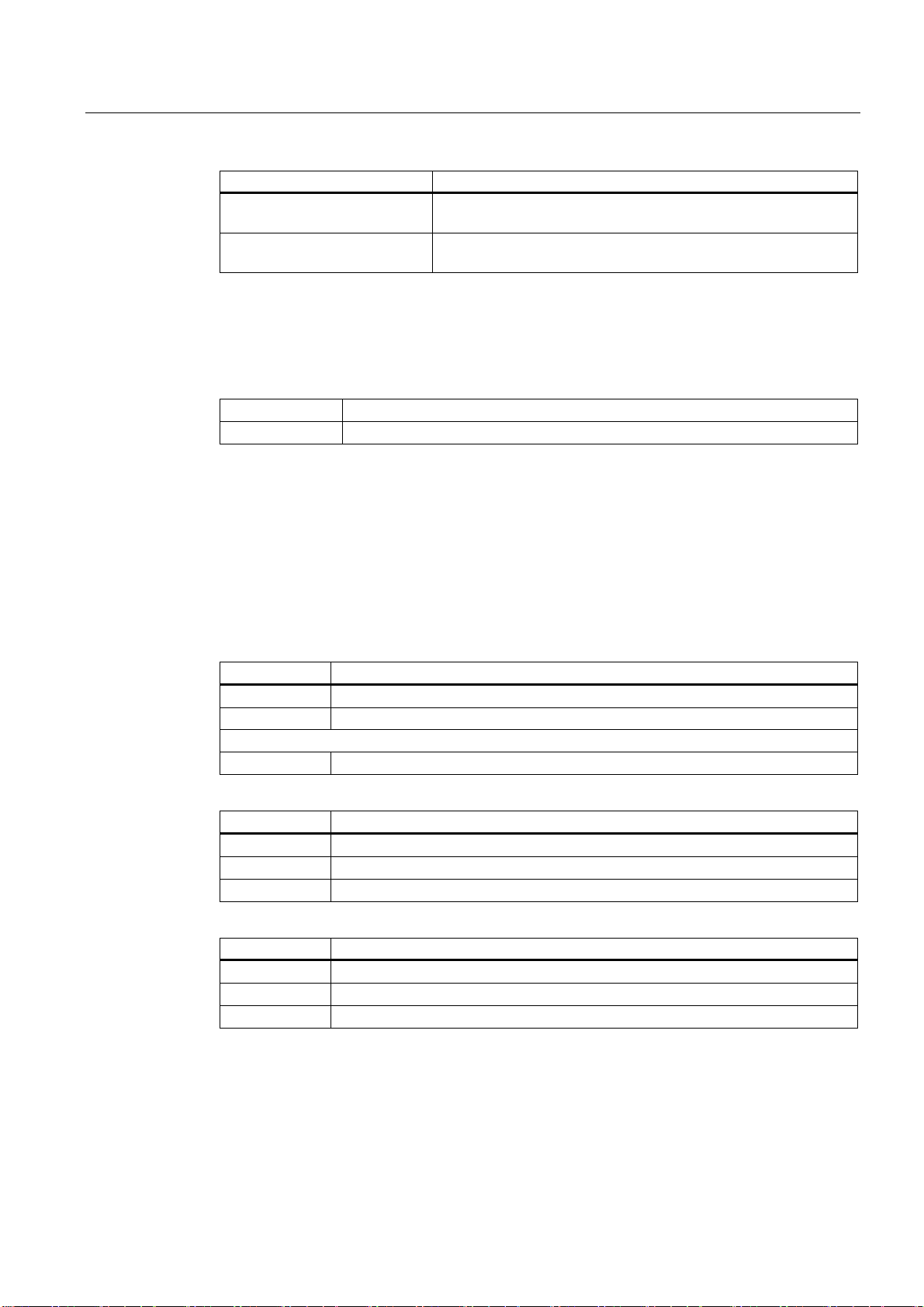

Operating modes for startup

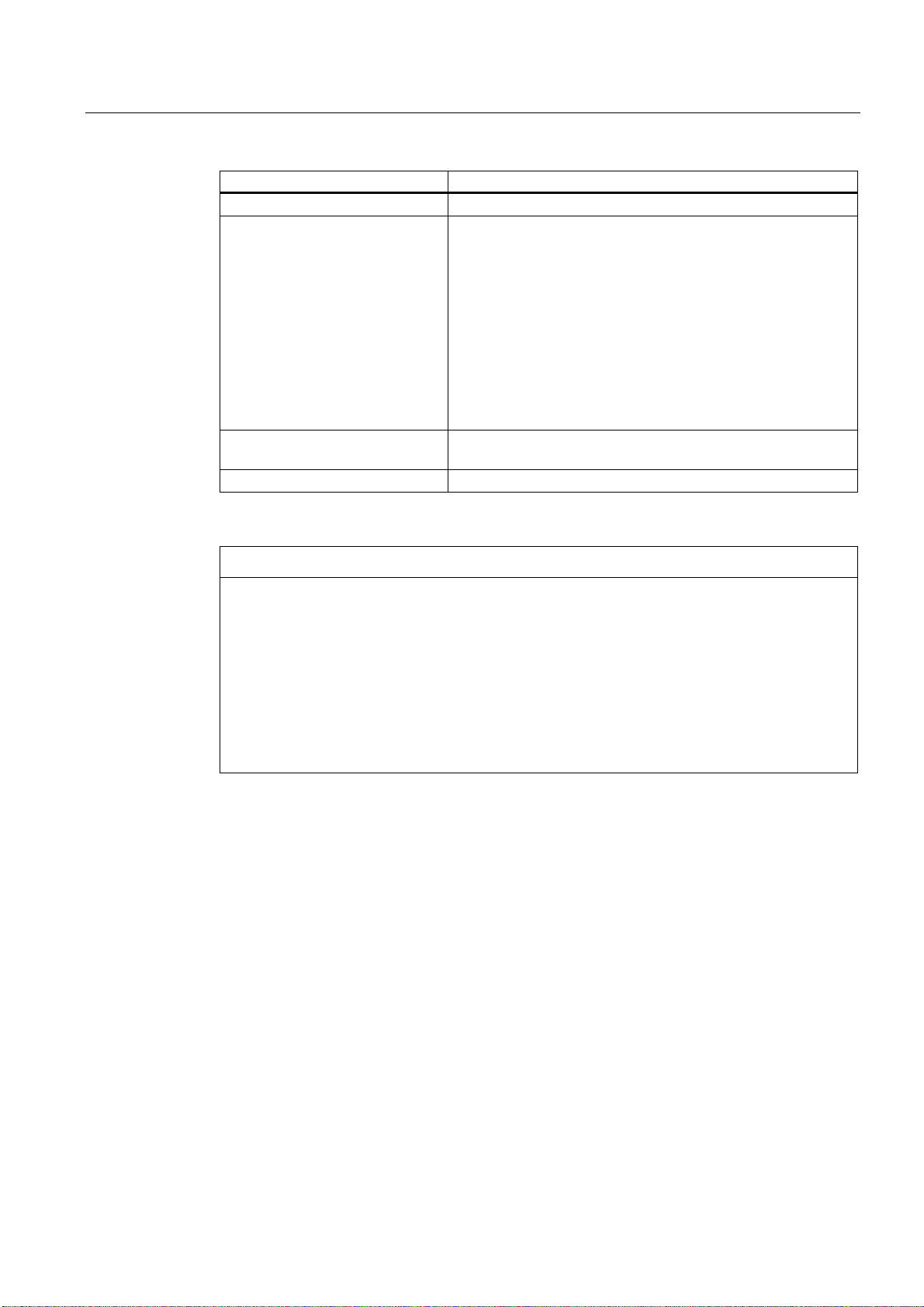

Selection Function

Normal startup The system carries out a normal startup.

Reload saved user data The system loads the stored user data ("Save data" softkey)

from the system CompactFlash card.

Install software update/backup An update is installed on the system CompactFlash card from

the user CompactFlash card or USB FlashDrive.

Create software backup A backup of the system CompactFlash card is saved to the user

CompactFlash card or USB FlashDrive.

NCK default data The system loads the Siemens NCK data default settings and

deletes the retentive data on the PLC.

Drive default data The SINAMICS user data is deleted.

PLC default data PLC general reset and load default NOP PLC program.

Turning and Milling

16 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 17

Scope of delivery and requirements

1.4 Starting up the control

Selection Function

HMI default data The HMI user data is deleted.

Factory settings Choice between two cases: No [case 1]/ Yes [case 2]

• Case 1:

The SINAMICS user data is deleted.

Siemens standard NCK data is loaded.

PLC general reset and load default NOP PLC program.

Save HMI user data.

• Case 2:

As case 1 and additionally:

Deletion of the data in the /oem and /addon directories.

Delete OEM data All the data under /oem and /addon is deleted: OEM archives;

OEM alarm texts; Easy Screen application.

PLC stop PLC is stopped.

NOTICE

Replacement of the system CompactFlash card between different PPUs

Because of the system-related dependency between the CompactFlash card and SRAM for

the data storage in the SINUMERIK 828D, the system CompactFlash card should be

considered as a permanently installed EEPROM and should not be replaced!

If this has to be performed for imperative reasons, the replacement of the system

CompactFlash card is detected during startup because of the stored serial number.

The reaction of the control is the loading of saved during startup (backup was performed

previously with "Save data" softkey). If no stored data is found, a startup is performed

automatically with the "NCK default data".

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

17

Page 18

Scope of delivery and requirements

1.4 Starting up the control

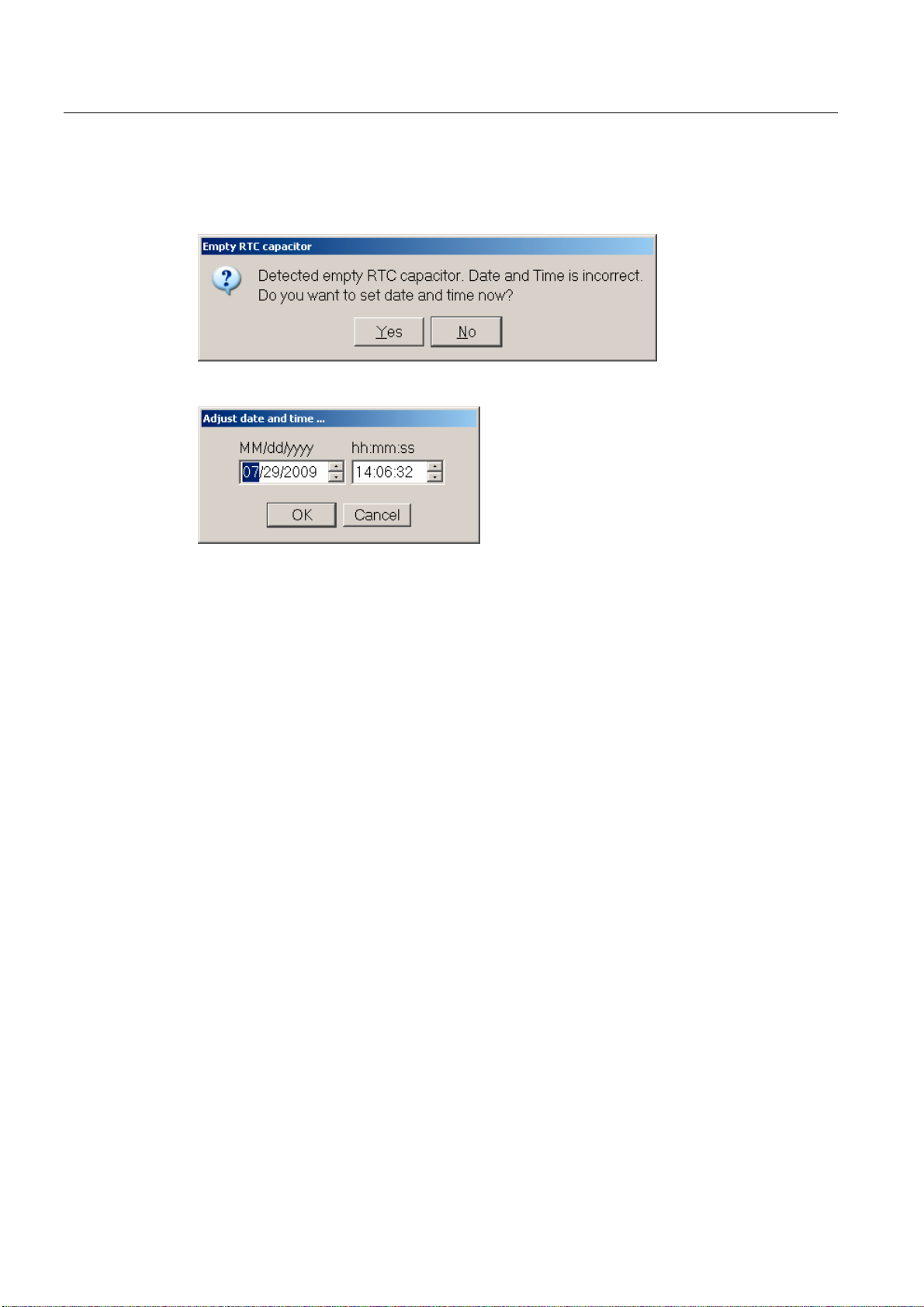

Empty RTC capacitor

If the RTC capacitor is discharged, the following message is issued during startup:

You can then reset the date and time:

The capacitor is then charged again when the control is switched on during startup.

Turning and Milling

18 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 19

Scope of delivery and requirements

1.5 Communication with the control

1.5 1.5 Communication with the control

Creating the connection

An Ethernet cable is needed to connect the control and PG/PC. The following Ethernet

interfaces are available on the control:

● Connection via X127 (behind the flap on the front):

Cable type: Crossed Ethernet cable

At interface X127, the control is preset as a DHCP server, delivering the IP

address192.168.215.1 for a direct connection (peer-to-peer connection).

● Connection via X130 (at the back):

Cable type: Uncrossed Ethernet cable

The interface X130 is the connection to the company network. The IP address that the

PG/PC receives here as a DHCP client is determined by the DHCP server from the

company network or fixed IP address is entered manually.

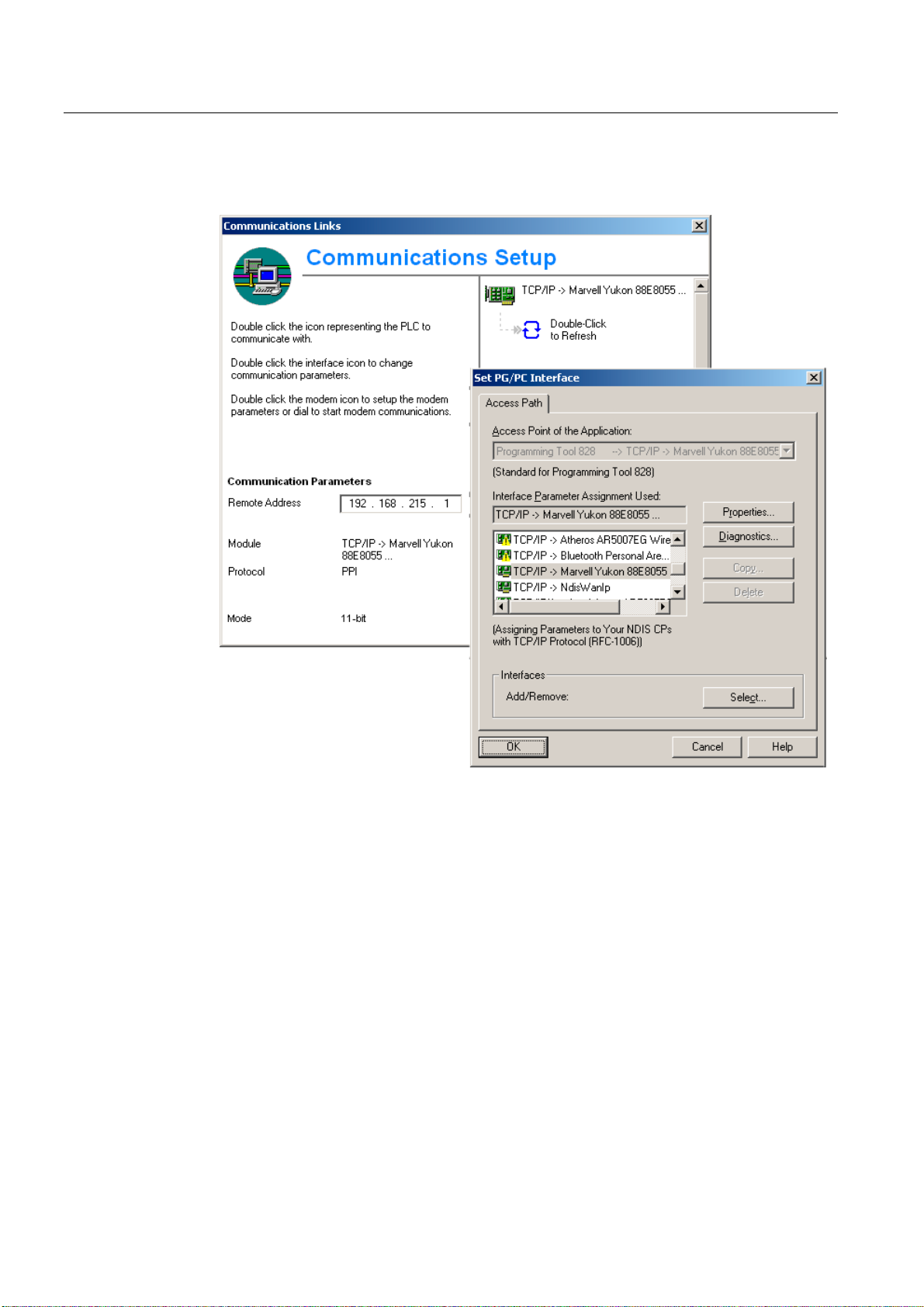

1.5.1 How to communicate with the control using the Programming Tool

Setting up the communications interface in the Programming Tool

Proceed as follows to set up the network connection in the Programming Tool:

1. Start the Programming Tool.

2. In the navigation bar, click the "Communication" icon or select "View" → "Communication"

from the menu.

3. In the left column, under "Communications parameters" enter 192.168.215.1as the

IP address for X127.

4. Double click on the icon "TCP/IP" at the top right.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

19

Page 20

Scope of delivery and requirements

1.5 Communication with the control

5. In the dialog "PG/PC interface" select the TCP/IP protocol of the PG/PC. Normally this is

the network card of the PC.

Figure 1-2 TCP/IP communications settings

6. Confirm with "OK".

Turning and Milling

20 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 21

Scope of delivery and requirements

1.5 Communication with the control

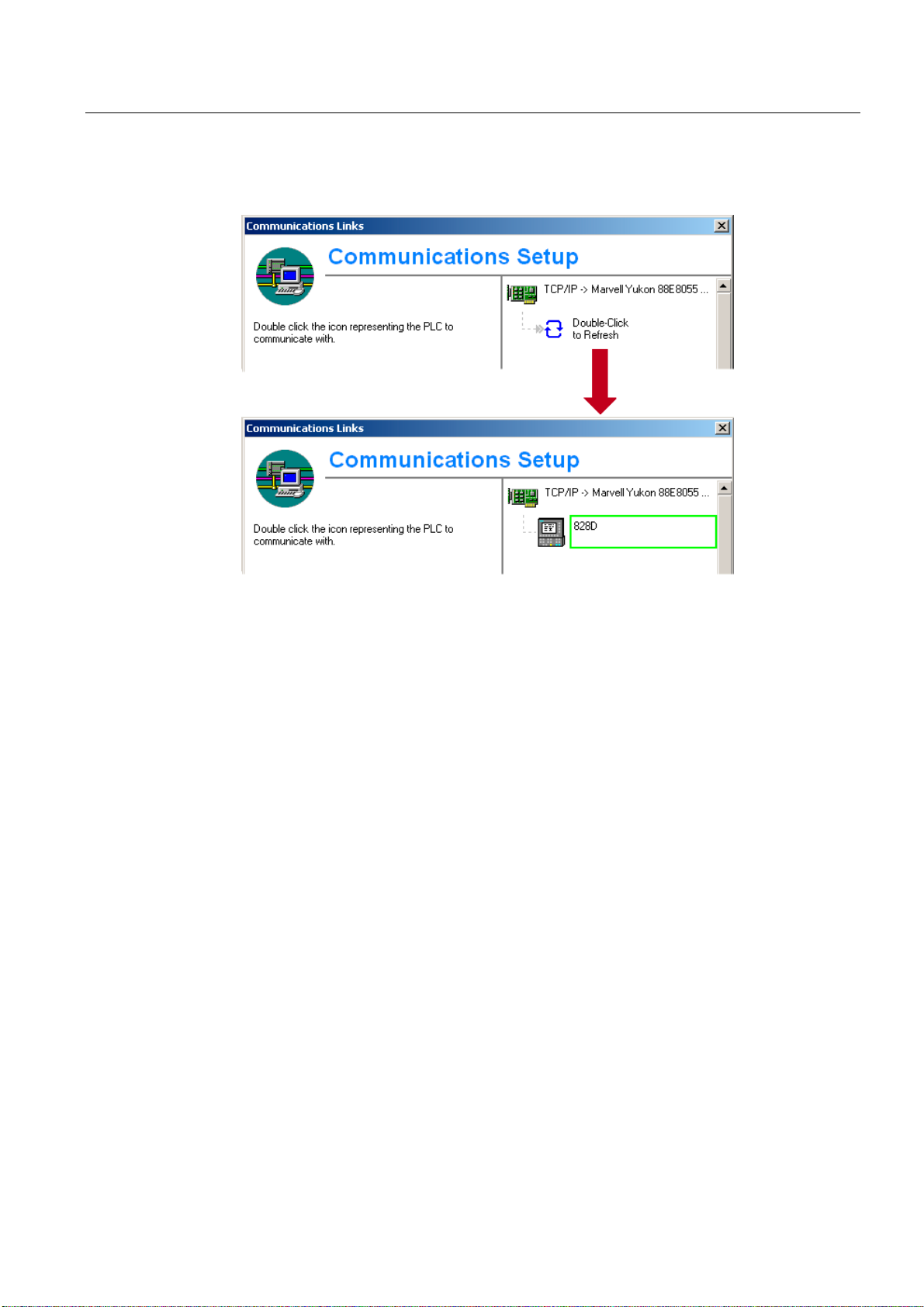

7. Connect by double clicking on the icon "Double click to update". If the connection is made

successfully, the icon will be displayed with a green border:

Figure 1-3 Online connection

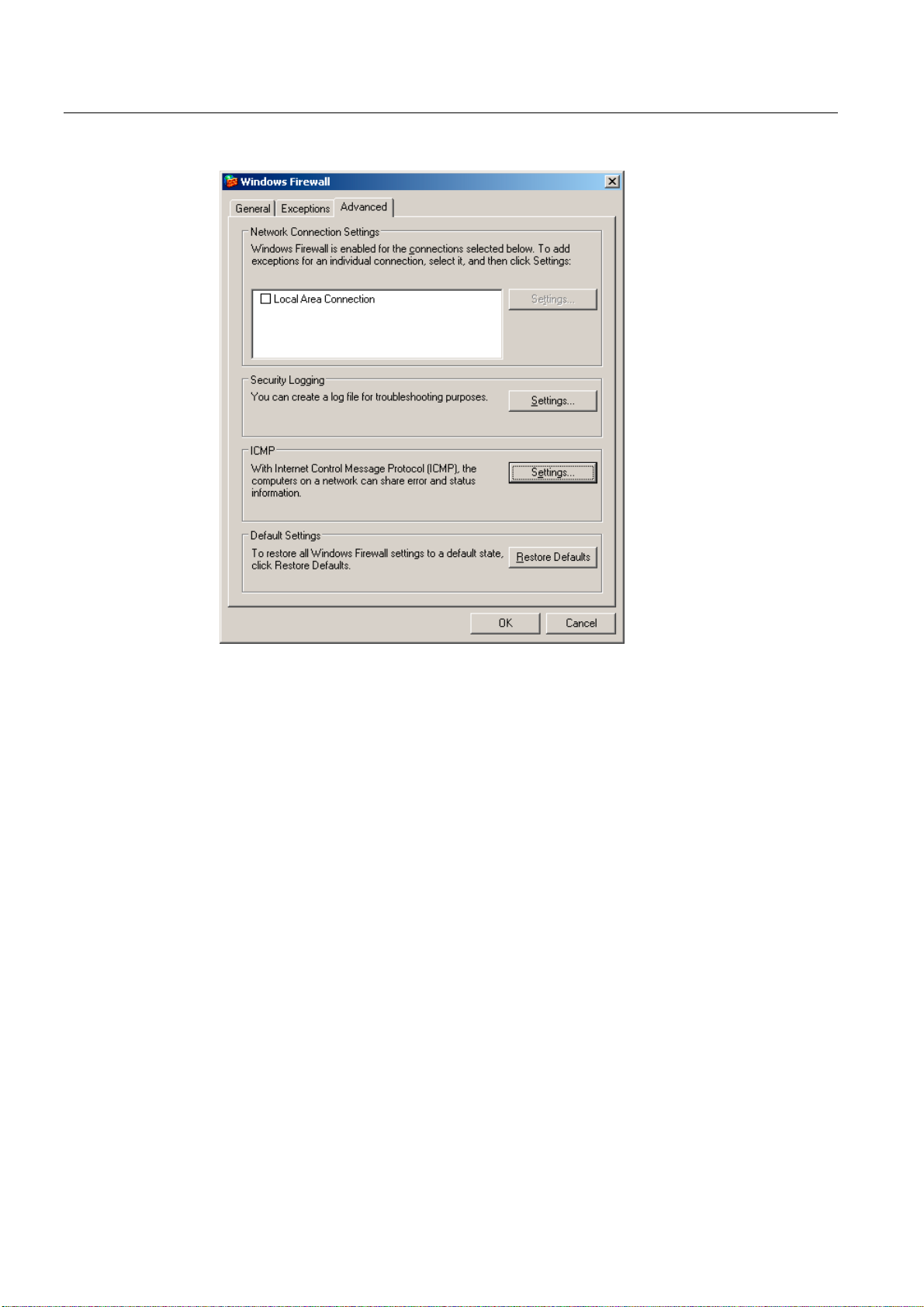

8. If the connection is unsuccessful, the following setting may have to be deactivated:

Select "Control Panel" → "Network Connections"→ "Local Area Connection" "Properties"→

"Advanced"→ "Windows Firewall" → "Settings"→ "Advanced": Deactivate the option "Local

Area Connection".

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

21

Page 22

Scope of delivery and requirements

1.5 Communication with the control

Figure 1-4 Deactivate option

Confirm with "OK" and repeat Step 7.

Turning and Milling

22 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 23

Scope of delivery and requirements

1.5 Communication with the control

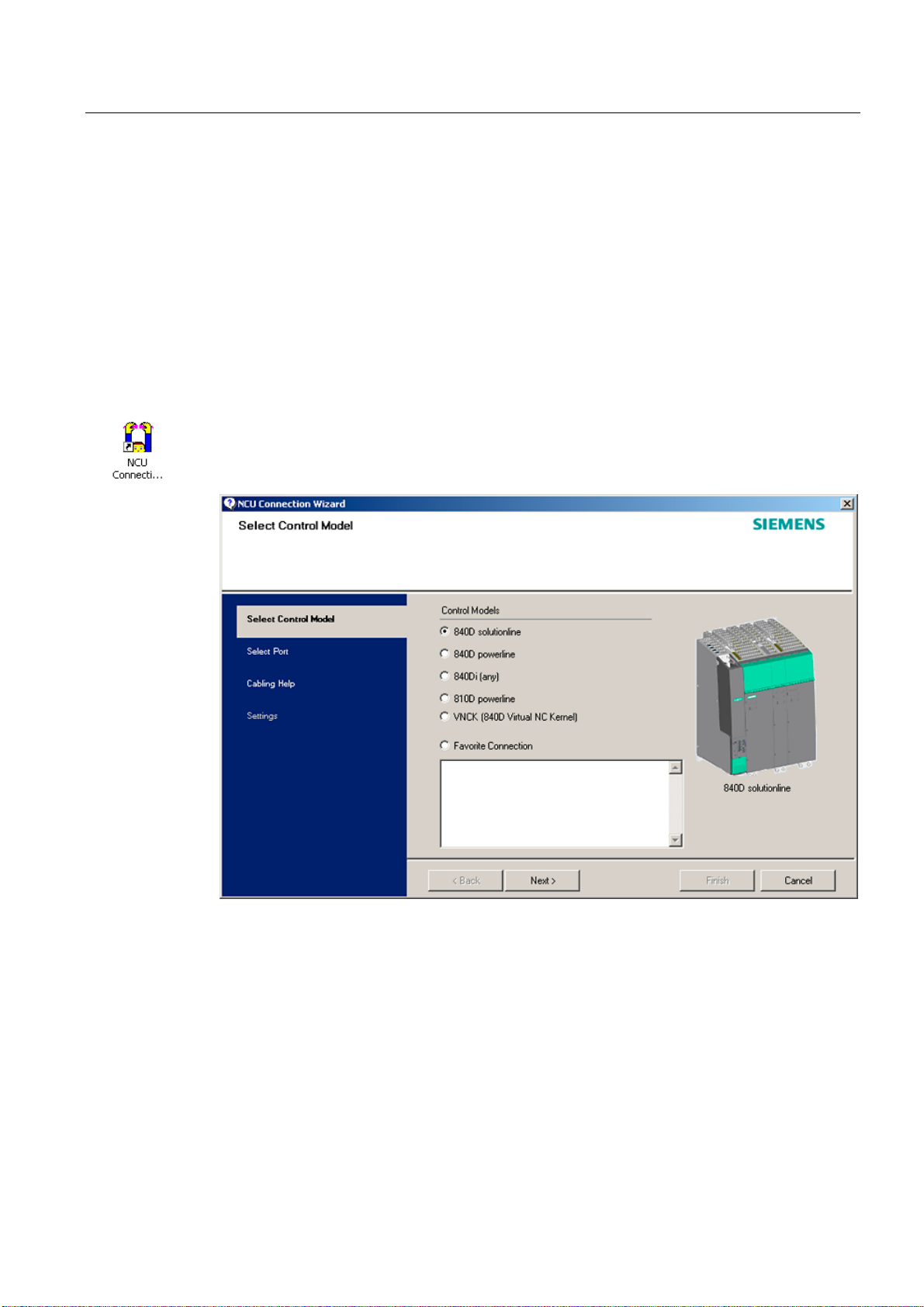

1.5.2 Example: How to communicate with the control using the NCU Connection Wizard

Requirements

The commissioning software for SINAMICS S120 is installed on the PG/PC. The "NCU

Connection Wizard" is part of this software.

The connection to the control has already been set up via the Programming Tool.

Create connection to control

Procedure for the PG/PC:

1. Start the "NCU Connection Wizard" via this link or via the Start menu.

2. In the "Select Control Model" dialog, select "840D solution line" for the NCU type

connection to the SINUMERIK 828D.

Figure 1-5 Select the NCU type

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

23

Page 24

Scope of delivery and requirements

1.5 Communication with the control

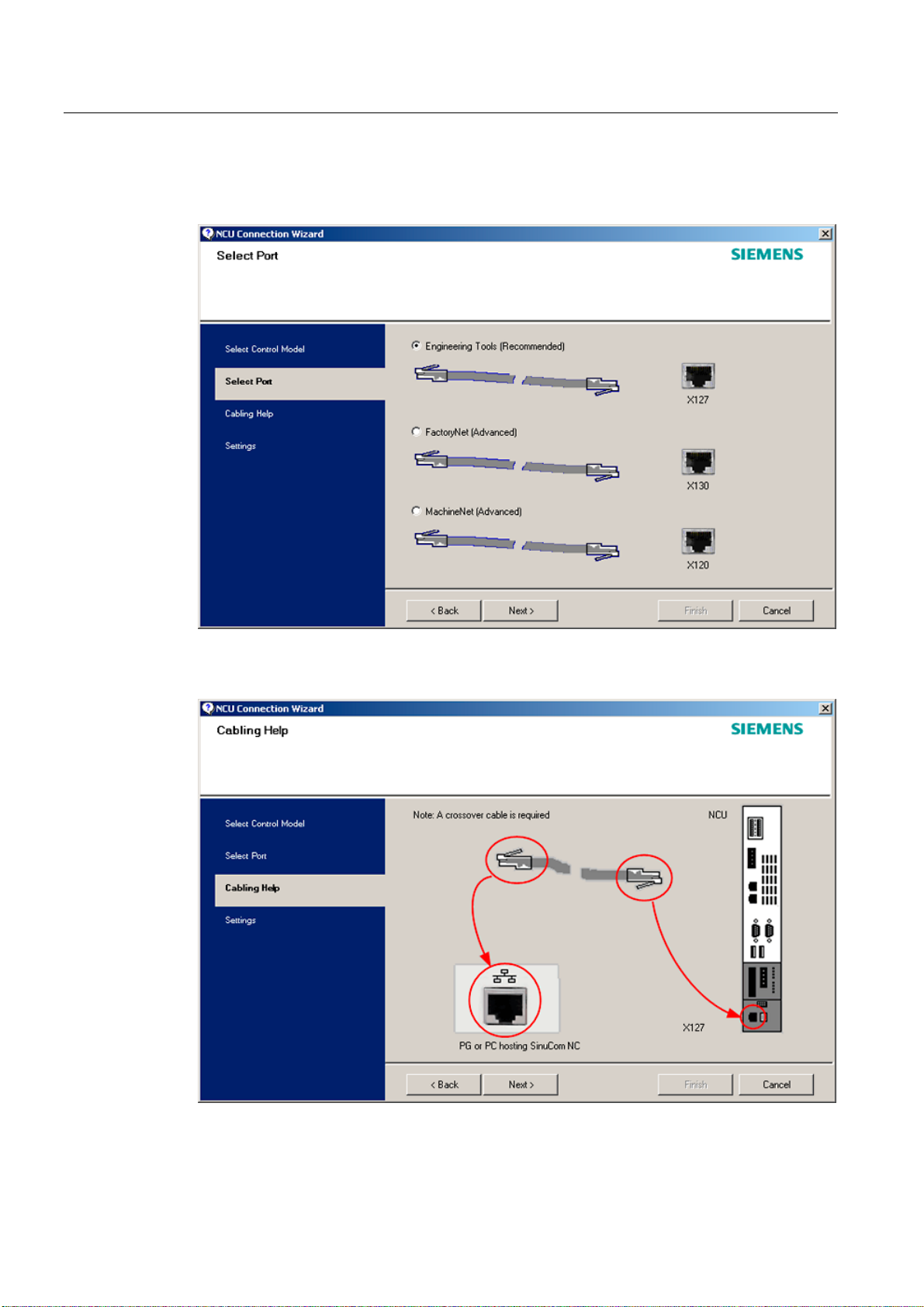

3. In the "Select Port" dialog, select the connection to the control that you have connected

via Ethernet.

Figure 1-6 Select connection

4. Confirm the cable connection for both devices in the"Cabling Help" dialog.

Figure 1-7 Cabling

Turning and Milling

24 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 25

Scope of delivery and requirements

1.5 Communication with the control

5. Check the IP address and enter the name for these settings in the "Settings" dialog.

Figure 1-8 Network settings

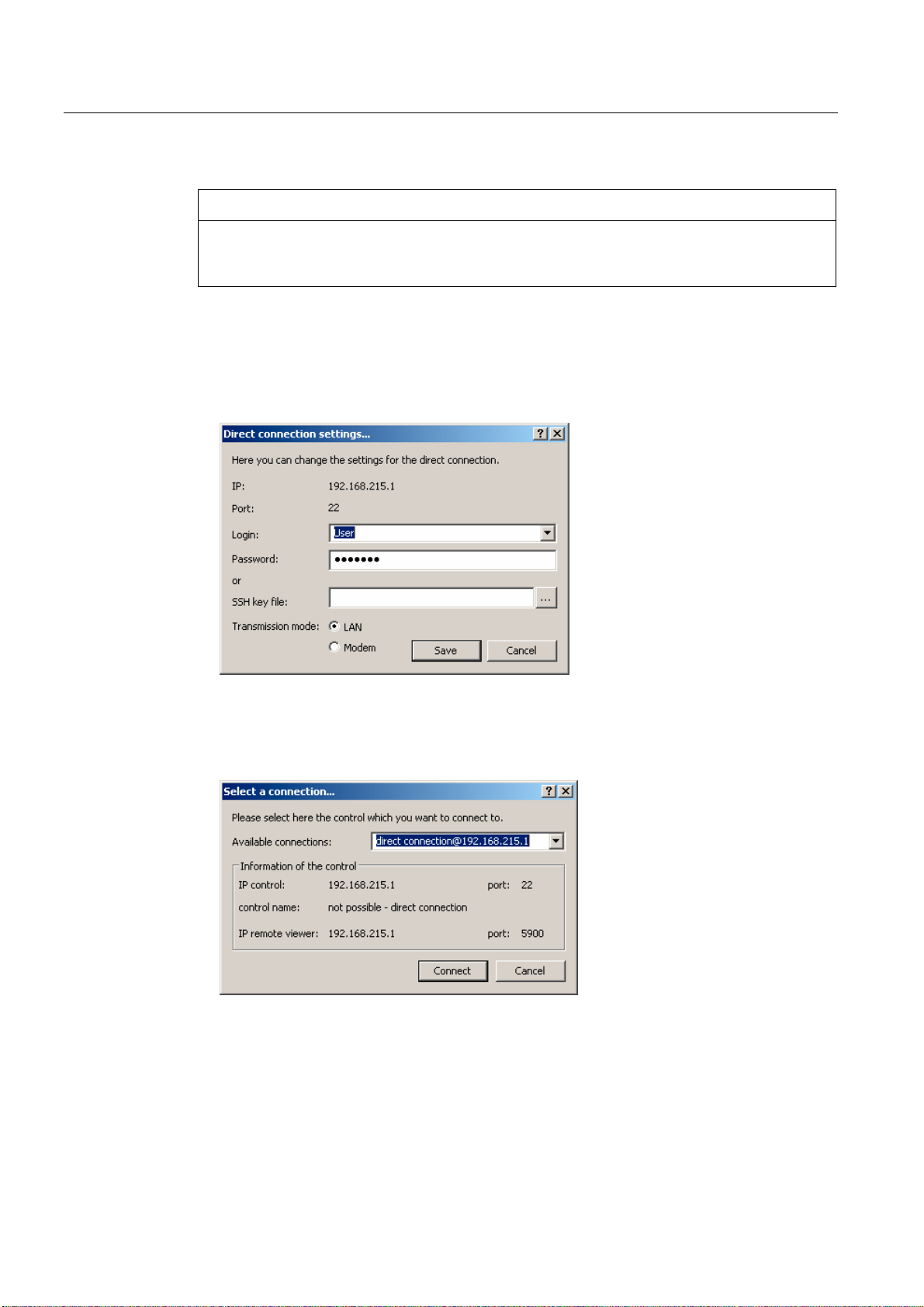

1.5.3 How to communicate with the control using the RCS Commander

Connection options

The following options are available for the "RCS Commander" to create a connection with

the control:

● Direct connection (peer-to-peer)

● Network connection

The current status of the connection is shown at the bottom in the RCS Commander status

bar.

Meaning of the buttons:

Connect

Disconnect

Remote control

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

25

Page 26

Scope of delivery and requirements

1.5 Communication with the control

Direct connection

NOTICE

Generally only one connection is permitted, i.e. several simultaneous connections to

different controls are not supported: So data exchange between two NCUs using "RCS

Commander" is not possible.

To create a direct connection:

1. The login data is entered in the dialog "Settings" → "Connection" → "Direct connection":

Figure 1-9 Dialog: Login data for direct connection

2. In the menu, select "Connection" → "Connect" → "Direct connection" or click the "Connect"

button.

The following dialog box is displayed:

Figure 1-10 Dialog: Direct connection

3. The last selected direct connection is highlighted. Using the "Connect" button, a

connection to the IP address196.168.215.1 is created.

This dialog does not appear when the direct connection is selected using the menu.

Turning and Milling

26 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 27

Scope of delivery and requirements

1.5 Communication with the control

Network connection

To create a network connection:

1. In the menu, select "Settings" → "Connection" → "Direct connection" or click the "Connect"

button.

Figure 1-11 Dialog: Network connection

2. In the menu, select "Connection" → "Connect" → "Network connection" or select – if

available – one of the previously selected connections.

3. Connection is made to the parameterized control.

Note

SSh key file

As an alternative to entering a password, the user may also use an SSh key for

authentication. Please refer to the Online Help for more information on this topic.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

27

Page 28

Scope of delivery and requirements

1.5 Communication with the control

1.5.4 Communicating with the control via X130

Connection to the company network

The NCU is connected to the company network via the Ethernet interface X130.

The company network is used, for example, to access the network drives.

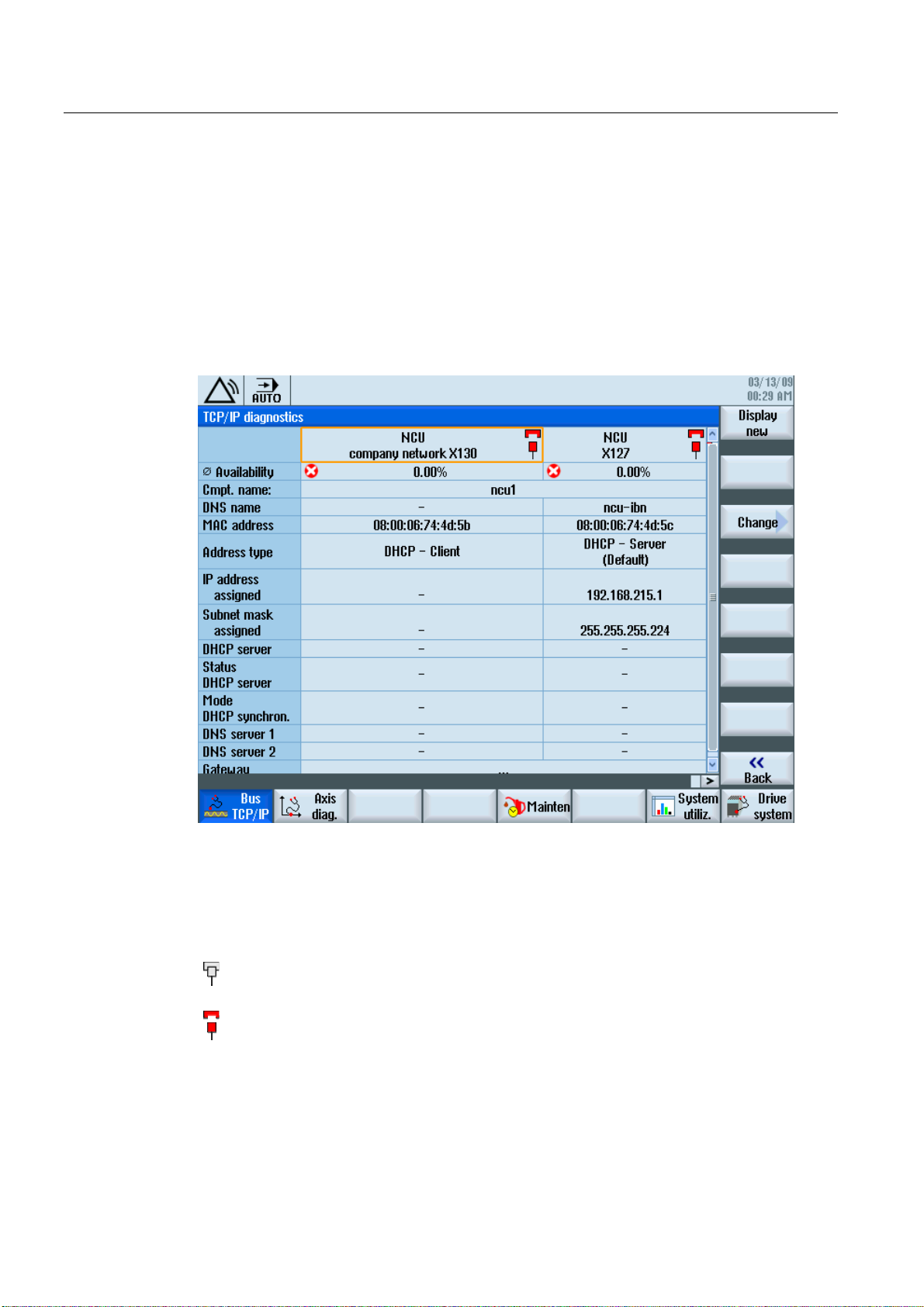

In the "Diagnostics" operating area select the "Bus TCP/IP " → "TCP/IP Diagnostics" →

"Details" softkey with the menu forward key in order to set the parameters for the

communication via X130.

Figure 1-12 Network settings

Connection properties

Company network X130

white Network cable inserted

red Network cable not inserted

Turning and Milling

28 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 29

Scope of delivery and requirements

1.5 Communication with the control

Availability

The availability describes the percentage of faulty data compared to the entire data

volume. Problems in the company network (e.g. logical drives that cannot be reached,

double IP address, etc.) as well as settling time during power up can result in fluctuations in

availability:

green Greater than 95%

yellow 50 - 95 %

red Less than 50%

Note

All information that is not available is marked in the relevant table line with a hyphen "-".

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

29

Page 30

Scope of delivery and requirements

1.5 Communication with the control

Turning and Milling

30 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 31

Settings on the HMI

2.1 2.1 Access levels

Access to functions and machine data

The user only has access to information corresponding to a particular access level and the

levels below it. The machine data is assigned different access levels.

The access concept controls access to functions and data areas. Access levels 0 to 7 are

available, where 0 represents the highest level and 7 the lowest level. Access levels 0 to 3

are locked using a password and 4 to 7 using the appropriate key-operated switch settings.

Access level Locked by Area Data class

0 --- System (reserved) System (S)

1 Password: SUNRISE Manufacturer Manufacturer (M)

2 Password: EVENING Servicing Individual (I)

3 Password: CUSTOMER User User (U)

4 Key-operated switch setting 3 Programmer, machine setter User (U)

5 Key-operated switch setting 2 Qualified operator User (U)

6 Key-operated switch setting 1 Trained operator User (U)

7 Key-operated switch setting 0 Semi-skilled operator User (U)

2

The password remains valid until it is reset with the "Delete Password" softkey.

The passwords can be changed after activation.

If, for example, the passwords are no longer known, reinitialization (power up with

"NCK default data") must be carried out. This resets all passwords to the default (see table).

POWER ON does not reset the password.

Note

PI LOGOUT

The password can also be deleted via the PLC.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

31

Page 32

Settings on the HMI

2.1 Access levels

Key-operated switch

Access levels 4 to 7 require a corresponding key-operated switch setting on the machine

control panel. Three keys of different colors are provided for this purpose. Each of these

keys provides access only to certain areas.

Meaning of the key-operated switch settings:

Access level Switch setting Key color

4-7 0 to 3 red

5-7 0 to 2 green

6-7 0 and 1 black

7 0 = Key removal position No key inserted

The key-operated switch setting must always be edited from the PLC user program and

applied to the interface accordingly.

Turning and Milling

32 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 33

Settings on the HMI

2.2 How to set and change the password

2.2 2.2 How to set and change the password

Set password

To change the access level, select the "Start-up" operating area:

1. Press the "Password" softkey.

2. Press the "Set password" softkey to open the following dialog:

Figure 2-1 Set password

Change password

3. Enter a password and confirm this with "OK" or with the <Input> key.

A valid password is acknowledged as set and the currently applicable access level is

displayed. Invalid passwords will be rejected.

4. You must delete the old password before activating a password for a lower access level

than the one activated.

The last valid password is deleted by pressing the "Delete password" softkey. Then the

current key-operated switch setting is valid.

To change the password:

1. Press the "Change password" softkey to open the following dialog:

Figure 2-2 Change password

2. Enter the new password in both fields and then confirm with the "OK" softkey. If both

passwords match, the new password becomes valid and is adopted by the system.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

33

Page 34

Settings on the HMI

2.3 Available system languages

2.3 2.3 Available system languages

System languages

In the basic configuration, the SINUMERIK 828D is delivered with the following system

languages:

● German

● English

● French

● Italian

● Spanish

● Portuguese (Brazil)

● Chinese (simplified)

● Chinese (traditional)

● Korean

All system languages are installed in the SINUMERIK 828D as delivered, so that a change of

language can be carried out directly via the user interface, without having to download

system language data.

Note

Additional languages

No CNC option needs to be ordered for the installation of additional languages not included

in the scope of delivery.

The language files can be ordered on the DVD Additional Languages for SINUMERIK.

Turning and Milling

34 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 35

Settings on the HMI

2.4 How to set the date and time

2.4 2.4 How to set the date and time

Requirement

Changes can only be made with the appropriate access authorization (as of "User" and

higher).

Setting the date and time

Procedure:

1. Select the "Start-up" operating area.

2. Press the "HMI" softkey.

3. Press the "Date/Time" softkey.

The "Date/Time" window opens.

4. Select the required formats for the date and time in the "Format" field.

5. Confirm the entry with the "OK" softkey.

The new date and time details are accepted and output on the first line in the "current"

fields.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

35

Page 36

Settings on the HMI

2.5 Checking and entering licenses

2.5 2.5 Checking and entering licenses

Use

The use of the installed system software and the options activated on a SINUMERIK control

system require that the licenses purchased for this purpose are assigned to the hardware. In

the course of this assignment, a license key is generated from the license numbers of the

system software, the options, as well as the hardware serial number. Here, a license

database administered by Siemens is accessed via the Internet. Finally, the license

information including the license key is transferred to the hardware.

The license database can be accessed using the Web License Manager.

Web License Manager

By using the Web License Manager, you can assign licenses to hardware in a standard Web

browser. To conclude the assignment, the license key must be entered manually on the

control via the user interface.

The Internet address of the Web License Manager is:

See also

http://www.siemens.com/automation/license

Note

SINUMERIK software products

If a license key has not been activated or does not exist for a SINUMERIK software product,

alarm 8080 is output by the control.

Definitions for license management (Page 391)

Turning and Milling

36 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 37

Settings on the HMI

2.5 Checking and entering licenses

2.5.1 How to enter a license key

Requirement

The appropriate licenses are required for the activated options. After licensing the options in

the Web License Manager, you receive a "license key" containing all options requiring a

license and which is only valid for your system CompactFlash card.

To set or reset options, "Manufacturer" access rights are required.

Entering the license key

Procedure:

1. Select the "Start-up" operating area.

2. Press the menu forward key.

3. Press the "Licenses" softkey.

The "Licensing" window opens and gives you the following options:

– Determine the license requirement ("All options" and "Missing licenses" softkeys)

– Softkey: "Exp. license requirement"

– Entry line: "Enter license key"

Figure 2-3 Entering the license key

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

37

Page 38

Settings on the HMI

2.5 Checking and entering licenses

2.5.2 How to determine the license requirement

Determining the license requirement

Procedure:

1. Press the "All options" softkey to list all the options that can be selected for this control.

2. Activate or deactivate the required options in the "Set" column:

– Mark the checkbox

– Enter the number of options

Options displayed in red are activated, however are not licensed or insufficiently

licensed.

- OR -

3. Press the "Missing licenses" softkey to display all options that are activated but not

licensed. In the "Set" column, you can deselect the options that you do not require.

Figure 2-4 Licensing (example)

Turning and Milling

38 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 39

Settings on the HMI

2.5 Checking and entering licenses

4. To activate new selected options, press the "Reset (po)" softkey. A safety prompt

appears.

With HMI options, you will need to restart the HMI. Corresponding prompts will appear in

the dialog line.

5. Press the "OK" softkey to trigger a warm restart.

- OR -

6. Press the "Cancel" softkey to cancel the process.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

39

Page 40

Settings on the HMI

$

2.6 Configuring user alarms

2.6 2.6 Configuring user alarms

Creating user PLC alarms

The PLC alarms in the area from 700 000 - 700 247 are configured by the machine

manufacturer. The access level "Manufacturer" is required with the appropriate password.

To enter the user PLC alarms via the user interface, select → "HMI"→ "Alarm texts" in the

"Start-up" operating area.

Then you receive the following selection:

Alarm texts for Name of the xml file

User cycle alarms oem_alarms_cycles

User PLC alarms oem_alarms_plc

User part program message texts oem_partprogram_messages

Loading user PLC alarms

The alarm text files are only loaded during startup.

● "Alarm" attribute: red, is shown in the "alarm list".

● "Message" attribute: black, is shown under "Messages".

Select <MENU SELECT>, then the menu forward key and press the "HMI restart" softkey to

load the alarm texts.

See also

You can find a detailed description of the alarms with system responses and deleting criteria

in: SINUMERIK 828D Diagnostics Manual

2.6.1 Structure of user PLC alarms

Structure of a user PLC alarm

The user PLC alarms have the following structure:

2LOSUHVVXUHWRRORZ

$[LV

DWUHVWSRVLWLRQG

ODUPQXPEHU

Figure 2-5 Alarm structure

Turning and Milling

40 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

9DULDEOH

$ODUPWH[W

Page 41

Settings on the HMI

2.6 Configuring user alarms

The table below shows the mode of operation of the PLC alarms:

1. The alarm is triggered with the appropriate number and output via the PLC signal.

2. If a variable has been configured to this alarm, the value of this variable is in the specified

data word of the PLC variable.

3. The NCK response when the alarm is triggered is defined in the MD14516[x] index (see

table below).

4. The alarm text can be freely selected and may be up to 255 characters long.

Alarm number PLC signal PLC variable Alarm response

(MD)

700 000 DB1600.DBX0.0 DB1600.DBW1000 14516[0] Alarm 1

700 001 DB1600.DBX0.1 DB1600.DBW1004 14516[1] Alarm 2

700 002 DB1600.DBX0.2 DB1600.DBW1008 14516[2] Alarm 3

700 003 DB1600.DBX0.3 DB1600.DBW1012 14516[3] Alarm 4

700 004 DB1600.DBX0.4 DB1600.DBW1016 14516[4] Alarm 5

700 005 DB1600.DBX0.5 DB1600.DBW1020 14516[5] Alarm 6

700 006 DB1600.DBX0.6 DB1600.DBW1024 14516[6] Alarm 7

Continuation:

700 247 DB1600.DBX30.7 DB1600.DBW1988 14516[247] Alarm 248

Alarm text

Defining the NCK response

The following NCK responses are possible:

MD14516[x] Meaning

Bit 0 NC start disabled

Bit 1 Read-in disable

Bit 2 Feed hold for all axes

Bit 3 EMERGENCY STOP

Bit 4 PLC in stop

Bit 5 Reserved

Bit 6 Definition for alarm or message

Bit 7 POWER ON

Bit 6=1: → alarm, Bit 6=0: → message

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

41

Page 42

Settings on the HMI

2.6 Configuring user alarms

Configuring alarm texts with variables

The following data types are permitted for variables in the alarm text:

Variable Meaning

%b Binary representation of a 32-bit value

%d Integer decimal number

%f 4 byte floating point number

%i Integer decimal number with sign

%o Integer octal number

%u Unsigned decimal number

%x Integer hexadecimal number

2.6.2 How to create user PLC alarms

Notes for processing

The following points should be observed when processing the files:

● The files should be edited externally on a PG/PC with a text editor (e.g. notepad) or with

● The created alarm text files are copied to the the following directory on the

● To enable the system to recognize the alarm text file, the file name must be written in

● The alarm text file is converted during system startup: A restart of the HMI is necessary to

Procedure

To edit a larger number of alarms, first create 2 or 3 alarms directly on the control. Then the

file oem_alarms_plc_xxx.ts is created and you have a "document template" with the correct

structure, which you can then extend with further alarms. The abbreviation "xxx" stands for

the language in which the file has been created.

1. Select the "Start-up" operating area.

2. Press the "HMI" softkey.

3. Press the "Alarm texts" softkey. The "Select file" window appears.

4. Select "oem_alarms_plc" to create user PLC alarm texts.

an XML editor. The structure must not be altered.

CompactFlash card: oem/sinumerik/hmi/lng

lower case letters.

activate the alarms.

5. Enter the alarm number in the "Number" field and the desired alarm text in the "Text"

field. The alarm numbers and their alarm texts do not have to be consecutive. If an alarm

is triggered without a configured text, only the alarm number is specified.

Turning and Milling

42 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 43

Settings on the HMI

2.6 Configuring user alarms

Searching within the alarm texts

To search for a text or a series of characters:

1. Press the "Find >" softkey. The "Find" window opens; and a new menu is displayed on

the vertical softkey bar.

2. Enter the search term in the "Text" field.

3. Place the cursor in the "Direction" field and choose the search direction (forward,

backward) with the "SELECT" key.

4. Activate the "Case-sensitive" checkbox when a distinction is to be made between upper

and lower case in the entered text.

5. Press the "Find + replace" softkey. The "Find and replace" window appears.

6. Press the "OK" softkey to start the search.

7. Press the "Cancel" softkey to cancel the search.

Other navigation options are:

● Softkey "Go to start":

The cursor jumps to the first entry of the selected alarm text file

● Softkey "Go to end":

The cursor jumps to the last entry of the selected alarm text file.

See also

List of language codes used for file names (Page 383)

Example: How to create an online help for user PLC alarms (Page 60)

2.6.3 Configuring the alarm log

Logging

Configure the alarm log in the "Diagnostics" operating area.

All alarms and messages are logged in chronological order with their raised and cleared time

stamps. The exception are messages of the type "msg" from the NC part program. All alarms

and messages that are no longer active when the log is displayed are also retained

(historical alarm events).

The alarm log is organized as a ring buffer (default setting). The oldest entries are

overwritten with new events in the following cases:

● When the maximum size is exceeded (permissible range: 0 - 32000).

● When the events happened before the last time the system was switched on.

Turning and Milling

Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

43

Page 44

Settings on the HMI

2.6 Configuring user alarms

Permanent backup

To save the alarm log permanently, the alarm log is written to the CompactFlash card.

NOTICE

Saving the alarm log

For permanent storage, the alarm log is written to the CompactFlash card which only allows

a limited number of write cycles.

• Therefore, ensure that the backup is only performed when there is a justifiable need!

• Make sure you undo the setting "on every event" if you no longer require storage of the

alarm log.

Default: The alarm log is not backed up.

See also

Filtering events: Set up a filter to limit the number of events in the alarm log. You can find

more details on this in:

● Commissioning Manual Basesoftware and HMI sl, chapter "Configuring alarms".

● List of the alarm number ranges (Page 384)

2.6.4 How to configure the log

Configuring the log

Procedure:

1. Select the "Diagnostics" operating area.

2. Press the "Alarm log" softkey.

3. Press the "Settings" softkey.

4. Enter the desired number in the "Number of entries" field to change the maximum number

5. Select the type of logging under "File write mode":

6. Press the "Save log" softkey to save the alarm log.

The settings become effective only after restarting the HMI.

of raised and cleared events.

Default is 500 events; permissible value range 0 - 32000.

– "Off" if the events are not to be written to a file.

– "On every event" if every event is to be written to a file.

– "Time controlled" if the file is to be overwritten after a particular time interval.

An additional "Time interval" input field appears in which you can specify the time in

seconds.

Turning and Milling

44 Commissioning Manual, 09/2009, 6FC5397-3DP20-0BA0

Page 45

Settings on the HMI

2.6 Configuring user alarms

Editing the configuration file

Procedure:

1. Copy the configuration file "oem_alarmprot_slaesvcconf.xml" from the

/siemens/sinumerik/hmi/template/cfg directory.