Page 1

SINUMERIK

SINUMERIK 840D sl / 828D

Fundamentals

Programming Manual

Preface

Fundamental Geometrical

Principles

Fundamental Principles of

NC Programming

Creating an NC program

Tool change

Tool offsets

Spindle motion

Feed control

Geometry settings

Motion commands

Tool radius compensation

Path action

Coordinate transformations

(frames)

Auxiliary function outputs

Supplementary commands

Other information

Tables

Appendix

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A

Valid for

Control

SINUMERIK 840D sl / 840DE sl

SINUMERIK 828D

Software Version

CNC software 4.5 SP2

03/2013

6FC5398-1BP40-3BA1

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5398-1BP40-3BA1

Ⓟ 04/2013 Technical data subject to change

Copyright © Siemens AG 1995 - 2013.

All rights reserved

Page 3

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific

machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

● www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

● www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

3

Page 4

Preface

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

SINUMERIK

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

Target group

This publication is intended for:

● Programmers

● Project engineers

Benefits

With the programming manual, the target group can develop, write, test, and debug

programs and software user interfaces.

Standard scope

This Programming Manual describes the functionality afforded by standard functions.

Extensions or changes made by the machine tool manufacturer are documented by the

machine tool manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed

information about all types of the product and cannot cover every conceivable case of

installation, operation or maintenance.

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

Fundamentals

4 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 5

Preface

Information on structure and contents

"Fundamentals" and "Job planning" Programming Manual

The description of the NC programming is divided into two manuals:

1. Fundamentals

This "Fundamentals" Programming Manual is intended for use by skilled machine

operators with the appropriate expertise in drilling, milling and turning operations. Simple

programming examples are used to explain the commands and statements which are

also defined according to DIN 66025.

2. Job planning

The "Job planning" Programming Manual is intended for use by technicians with in-depth,

comprehensive programming knowledge. By virtue of a special programming language,

the SINUMERIK control enables the user to program complex workpiece programs (e.g.

for free-form surfaces, channel coordination, ...) and makes programming of complicated

operations easy for technologists.

Availability of the described NC language elements

All NC language elements described in the manual are available for the SINUMERIK

840D sl. The availability regarding SINUMERIK 828D can be found in table "Operations:

Availability for SINUMER

IK 828D (Page 455)".

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

5

Page 6

Preface

Fundamentals

6 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 7

Table of contents

Preface ...................................................................................................................................................... 3

1 Fundamen

1.1 Workpiece pos

1.1.1 Workpiece c

1.1.2 Cartesian c

1.1.3 Polar coordinates .......................................................................................................

1.1.4 Abso

1.1.5 Incr

1.2 Working planes

1.3 Zero points

1.4 Coordinate sys

1.4.1 Mach

1.4.2 Basi

1.4.3 Basi

1.4.4 Settable ze

1.4.5 Workpiece c

1.4.6 What is the relation

2 Fundamen

2.1 Name of an NC program.....................................................................................................

2.2 Struct

2.2.1 Blocks

2.2.2 Block

2.2.3 Value assi

2.2.4 Comments................................................................................................................

2.2.5 Skipping block

tal Geometrical Principles ....................................................................................................... 13

itions.....................................................................................................................13

oordinate systems....................................................................................................13

oordinates..................................................................................................................14

lute dimensions....................................................................................................................18

emental dimension.................................................................................................................20

............................................................................................................................21

and reference points .................................................................................................22

tems .....................................................................................................................24

ine coordinate system (MCS)..............................................................................................24

c coordinate system (BCS) ...................................................................................................27

c zero system (BZS) .............................................................................................................29

ro system (SZS).........................................................................................................30

oordinate system (WCS)..........................................................................................31

ship between the various coordinate systems?............................................31

tal Principles of NC Programming........................................................................................... 33

ure and contents of an NC program...................................................................................35

and block components .....................................................................................................35

rules....................................................................................................................................37

gnments.......................................................................................................................38

s ............................................................................................................................39

..................17

.........33

....................39

3 Creating

3.1 Basi

3.2 Available c

3.3 Program header ............................................................................................................

3.4 Program exa

3.4.1 Example 1: Firs

3.4.2 Example 2: NC program for turning

3.4.3 Example 3: NC program for milling

4 Tool chan

4.1 Tool change without tool m

4.1.1 Tool change with T c

4.1.2 Tool ch

4.2 Tool change with tool management (opti

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

an NC program.......................................................................................................................... 43

c procedure ...........................................................................................................................43

haracters.....................................................................................................................44

mples.......................................................................................................................47

t programming steps ...........................................................................................47

.............................................................................................48

..............................................................................................50

ge............................................................................................................................................. 53

anagement........................................................................................53

ommand......................................................................................................53

ange with M6....................................................................................................................54

on)................................................................................56

...............45

7

Page 8

Table of contents

4.2.1 Tool change with T command with active tool management (option)......................................... 56

4.2.2 Tool change with M6 with active tool management (option)....................................................... 58

4.3 Behavio

5 Tool o

ffsets.............................................................................................................................................. 61

5.1 General information about the tool offsets

r with faulty T programming ........................................................................................... 60

.................................................................................. 61

5.2 Tool length compensation..................................................................................................

5.3 Tool radius

5.4 Tool compens

5.5 Tool types

5.5.1 General information about the tool types

5.5.2 Milling tools

5.5.3 Drills ..................................................................................................................

5.5.4 Grinding tools ..........................................................................................................

5.5.5 Turning tools

5.5.6 Specia

5.5.7 Chaining rule ...........................................................................................................

5.6 Tool offset call (D)

5.7 Change in the tool offset data

compensation........................................................................................................... 63

ation memory........................................................................................................ 64

.................................................................................................................................... 65

.................................................................................... 65

................................................................................................................................. 66

.......................... 68

.................... 69

............................................................................................................................... 70

l tools................................................................................................................................ 71

.................... 72

....................................................................................................................... 73

..................................................................................................... 75

5.8 Programmable tool offset (TOFFL, TOFF, TOFFR).................................................................... 76

6 S

pindle mot

6.1 Spindle speed (S), spi

ion......................................................................................................................................... 81

ndle direction of rotation (M3, M4, M5).................................................... 81

......... 62

6.2 Cutting rate (

6.3 Cons

6.4 Cons

6.5 Programmable sp

7 Feed cont

rol........................................................................................................................................... 101

tant cutting rate (G96/G961/G962, G97/G971/G972, G973, LIMS, SCC) ......................... 92

tant grinding wheel peripheral speed (GWPSON, GWPSOF)............................................ 97

SVC)....................................................................................................................... 85

indle speed limitation (G25, G26)................................................................... 99

7.1 Feedrate (G93, G94, G95, F, FGROUP, FL, FGREF)

7.2 Travers

7.3 Position-controlled spindle mode (SP

7.4 Positioning spindles

7.5 Feedrate for pos

7.6 Programmable feedrate ov

7.7 Programmable acc

e positioning axes (POS, POSA, POSP, FA, WAITP, WAITMC) ................................. 110

CON, SPCOF) ............................................................... 113

(SPOS, SPOSA, M19, M70, WAITS)....................................................... 115

itioning axes / spindles (FA, FPR, FPRAON, FPRAOF) ................................ 123

erride (OVR, OVRRAP, OVRA) ..................................................... 127

eleration override (ACC) (option)................................................................ 129

7.8 Feedrate with handwheel override (FD

7.9 Feedrate opti

7.10 S

everal feedrate values in one block (F, ST, SR, FMA, STA, SRA)......................................... 137

7.11 Non-modal

7.12 Tooth feedrat

mization for curved path sections (CFTCP, CFC, CFIN)..................................... 135

feedrate (FB) .......................................................................................................... 141

e (G95 FZ) ........................................................................................................... 142

.............................................................. 101

, FDA) .......................................................................... 131

Fundamentals

8 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 9

Table of contents

8 Geometry settings.................................................................................................................................. 149

8.1 Settable zero offset (G54 to G57, G505 to G599, G53, G500, SUPA, G153)...........................149

8.2 Selection of the worki

8.3 Dimensions

8.3.1 Abso

8.3.2 Incr

lute dimensions (G90, AC).................................................................................................156

emental dimensions (G91, IC) .............................................................................................159

................................................................................................................................156

8.3.3 Absolute and incremental dimensi

8.3.4 Abso

8.3.5 Inch

8.3.6 Channel

lute dimensions for rotary axes (DC, ACP, ACN)..............................................................163

or metric dimensions (G70/G700, G71/G710) ...................................................................165

-specific diameter/radius programming (DIAMON, DIAM90, DIAMOF,

ng plane (G17/G18/G19).........................................................................153

ons for turning and milling (G90/G91) .................................162

DIAMCYCOF) ............................................................................................................................168

8.3.7

Axis-specific

diameter/radius programming (DIAMONA, DIAM90A, DIAMOFA,

DIACYCOFA, DIAMCHANA, DIAMCHAN, DAC, DIC, RAC, RIC)............................................170

8.4

9 Motion commands

Position of workpiec

................................................................................................................................. 177

9.1 General information about the travel commands

9.2 Trav

el commands with Cartesian coordinates (G0, G1, G2, G3, X..., Y..., Z...)........................179

9.3 Travel commands

9.3.1 Referenc

9.3.2 Trav

e point of the polar coordinates (G110, G111, G112).................................................180

el commands with polar coordinates (G0, G1, G2, G3, AP, RP)........................................182

e for turning................................................................................................175

.......................................................................177

with polar coordinates ..................................................................................180

9.4 Rapid traverse motion (G0, RTLION, RTLIOF) .........................................................................186

9.5 Linear interpolation (G1) .................................................................................................

...........190

9.6 Circular interpolation

9.6.1 Circular interpolation types

9.6.2 Circular

9.6.3 Circular

9.6.4 Circular

interpolation with center point and end point (G2/G3, X... Y... Z..., I... J... K...) ...........196

interpolation with radius and end point (G2/G3, X... Y... Z..., CR) ...............................199

interpolation with opening angle and center point (G2/G3, X... Y... Z.../ I... J...

..................................................................................................................192

(G2/G3, ...) .....................................................................................192

K..., AR)......................................................................................................................................201

9.6.5

Circular

9.6.6 Circular

interpolation with polar coordinates (G2/G3, AP, RP)..................................................203

interpolation with intermediate point and end point (CIP, X... Y... Z..., I1... J1...

K1...)...........................................................................................................................................205

9.6.7

Circular

9.7 Helica

9.8 Invo

9.9 Contour definitions .......................................................................................................

interpolation with tangential transition (CT, X... Y... Z...)..............................................208

l interpolation (G2/G3, TURN) .........................................................................................211

lute interpolation (INVCW, INVCCW)..................................................................................214

..............219

9.9.1 Contour definition programming.................................................................................................219

9.9.2 Contour definitions

9.9.3 Contour definitions

9.9.4 Contour definitions: Three s

9.9.5 Contour definitions: End point programming with angle

9.10 Thread cutting

: One straight line.........................................................................................220

: Two straight lines.......................................................................................221

traight lines ....................................................................................225

............................................................228

............................................................................................................................229

9.10.1 Thread cutting with constant lead (G33, SF) .............................................................................229

9.10.2 Programmed run-in and run-out path (DI

9.10.3 Thre

ad cutting with increasing or decreasing lead (G34, G35) .................................................237

TS, DITE):..................................................................235

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

9

Page 10

Table of contents

9.10.4 Fast retraction during thread cutting (LFON, LFOF, DILF, ALF, LFTXT, LFWP, LFPOS,

POLF, POLFMASK, POLFMLIN).............................................................................................. 239

9.11 Tapping

9.11.1 Tapping without compensating chuck (G331, G332)

9.11.2 Tapping with compensating chuck (G63)

9.12 Chamfer, rounding (CHF, CHR, RND,

10 Tool r

adius compensation...................................................................................................................... 257

10.1 Tool radius

10.2 Appro

10.3 Compensa

..................................................................................................................................... 243

................................................................ 243

.................................................................................. 248

RNDM, FRC, FRCM)................................................... 250

compensation (G40, G41, G42, OFFN) ................................................................. 257

aching and leaving contour (NORM, KONT, KONTC, KONTT)...................................... 267

tion at the outside corners (G450, G451, DISC) ..................................................... 274

10.4 Smooth approach and retraction...........................................................................................

10.4.1 Appro

ach and retraction (G140 to G143, G147, G148, G247, G248, G347, G348, G340,

G341, DISR, DISCL, DISRP, FAD, PM, PR) ............................................................................ 278

Appro

10.4.2

10.5 Collisi

ach and retraction with extended retraction strategies (G460, G461, G462).................. 289

on detection (CDON, CDOF, CDOF2) ............................................................................ 293

10.6 2D tool compensation (CUT2D, CUT2DF)................................................................................ 296

10.7 Keep tool ra

10.8 Tools with a relevant cutting edge positi

11 Pa

th action............................................................................................................................................. 305

11.1 Exac

t stop (G60, G9, G601, G602, G603)................................................................................ 305

dius compensation constant (CUTCONON, CUTCONOF) ................................... 300

on............................................................................... 302

.... 278

11.2 Contin

12 Coordinat

12.1 Frames ...................................................................................................................

12.2 Frame instructions

12.3 Programmable ze

12.3.1 Zero offset (TRANS, ATRAN

12.3.2 Axial z

uous-path mode (G64, G641, G642, G643, G644, G645, ADIS, ADISPOS)................. 308

e transformations (frames) ..................................................................................................... 319

................... 319

..................................................................................................................... 321

ro offset......................................................................................................... 326

S)................................................................................................. 326

ero offset (G58, G59)...................................................................................................... 330

12.4 Programmable rotation (ROT, AROT, RPL) ............................................................................. 333

12.5 Programma

12.6 Programmable sc

ble frame rotations with solid angles (ROTS, AROTS, CROTS) ........................... 340

aling factor (SCALE, ASCALE)..................................................................... 342

12.7 Programmable mirroring (MIRROR, AMIRROR) ...................................................................... 345

12.8 Frame

generation according to tool orientation (TOFRAME, TOROT, PAROT):..................... 351

12.9 Deselect frame (G53, G153, SUPA, G500) .............................................................................. 354

12.10 Des

13 Auxiliary function outputs

13.1 M functions

14 Supplementary co

electing overlaid movements (DRFOF, CORROF) ............................................................ 355

....................................................................................................................... 359

................................................................................................................................ 362

mmands .................................................................................................................... 367

14.1 Output messages

Fundamentals

(MSG) .......................................................................................................... 367

10 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 11

Table of contents

14.2 Writing string in OPI variable (WRTPR).....................................................................................369

14.3 Working area limitation ..............................................................................................................370

14.3.1 Wo

14.3.2 Working area limitation in WCS/SZS (WALCS0 ... WALCS10)

rking area limitation in BCS (G25/G26, WALIMON, WALIMOF)..........................................370

.................................................373

14.4 Reference point approach (G74) ...........................................................................................

14.5 Approaching a fix

14.6 Travel to fix

ed point (G75) ................................................................................................377

ed stop (FXS, FXST, FXSW) ..................................................................................381

14.7 Dwell time (G4) ..........................................................................................................

14.8 Internal preprocess

15 Other

information................................................................................................................................... 389

15.1 Axes

...........................................................................................................................................389

15.1.1 Main axes/Geometry

15.1.2 Special ax

15.1.3 Main spindle,

15.1.4 Mach

ine axes.............................................................................................................................392

es...............................................................................................................................391

ing stop........................................................................................................388

axes .........................................................................................................390

master spindle .....................................................................................................392

15.1.5 Channel axes ...........................................................................................................

15.1.6 Path axe

15.1.7 Posi

15.1.8 Synchroniz

15.1.9 Command axes

s ...................................................................................................................................393

tioning axes.........................................................................................................................393

ed axes.....................................................................................................................394

..........................................................................................................................394

15.1.10 PLC axes..............................................................................................................

15.1.11 Link

axes....................................................................................................................................395

15.1.12 Lead link axes ........................................................................................................

15.2 From travel

15.3 Path calculation

command to machine movement ...........................................................................399

..........................................................................................................................399

....376

................386

..................392

......................395

....................397

15.4 Addresse

s ..................................................................................................................................400

15.5 Identifier ...............................................................................................................

15.6 Constant

16 Tables......................................................

s...................................................................................................................................404

.............................................................................................. 407

16.1 Operations...............................................................................................................

16.2 Operations: Availability for SINUMERIK

16.3 Addresse

16.3.1 Address letters

16.3.2 Fixed address

16.3.3 Settable addresses

16.4 G Functions

s ..................................................................................................................................479

...........................................................................................................................479

es.........................................................................................................................480

....................................................................................................................484

................................................................................................................................490

828D ..........................................................................455

16.5 Predefined procedures....................................................................................................

16.6 Predefined procedures in synchroni

zed actions........................................................................535

16.7 Predefined functions .....................................................................................................

16.8 Currently set language in the HMI

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

.............................................................................................550

......................402

...................407

...........511

.............536

11

Page 12

Table of contents

A Appendix................................................................................................................................................ 551

A.1 List of abbreviations .................................................................................................................. 551

A.2 Docu

Glos

Index

mentation overview........................................................................................................... 560

sary ................................................................................................................................................ 561

...................................................................................................................................................... 583

Fundamentals

12 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 13

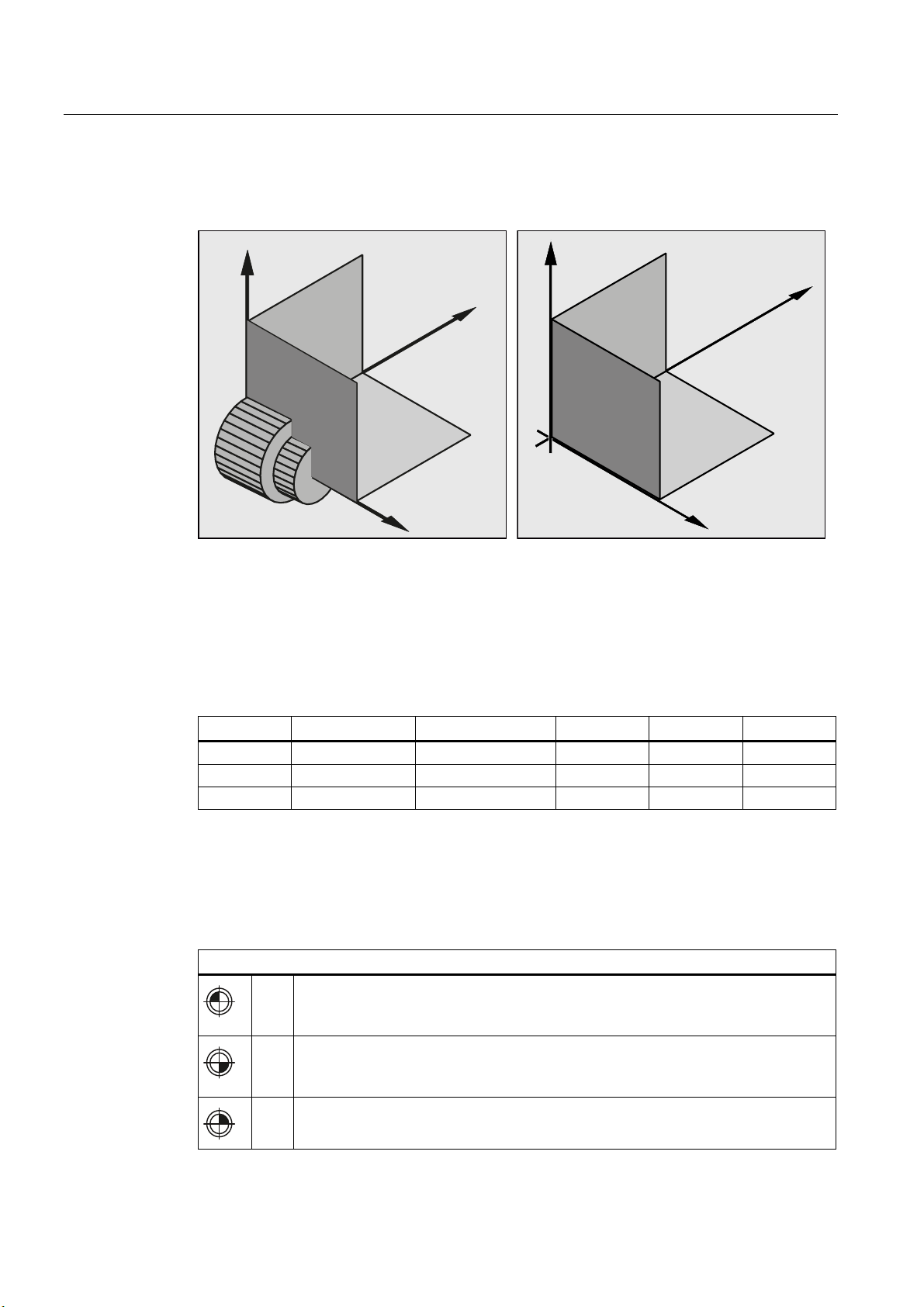

Fundamental Geometrical Principles

1.1 Workpiece positions

1.1.1 Workpiece coordinate systems

In order that the machine or the controller can work with the positions specified in the NC

program, these specifications have to be made in a reference system that can be transferred

to the directions of motion of the machine axes. A coordinate system with the axes X, Y and

Z is used for this purpose.

DIN 66217 stipulates that machine tools must use clockwise, right-angled (Cartesian)

coordinate systems.

<

= ;

r

1

=

; <

r

r

r:

;

<

Workpiece coordinate system for turning

The workpiece zero (W) is the origin of the workpiece coordinate system.

Sometimes it is advisable or even necessary to work with negative position specifications.

For this reason, positions that are to the left of the zero point are assigned a negative sign ("-").

=

<

Workpiece coordinate system for milling

:

=

r

r

;

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

13

Page 14

Fundamental Geometrical Principles

1.1 Workpiece positions

1.1.2 Cartesian coordinates

The axes in the coordinate system are assigned dimensions. In this way, it is possible to

clearly describe every point in the coordinate system and therefore every workpiece position

through the direction (X, Y and Z) and three numerical values The workpiece zero always

has the coordinates X0, Y0, and Z0.

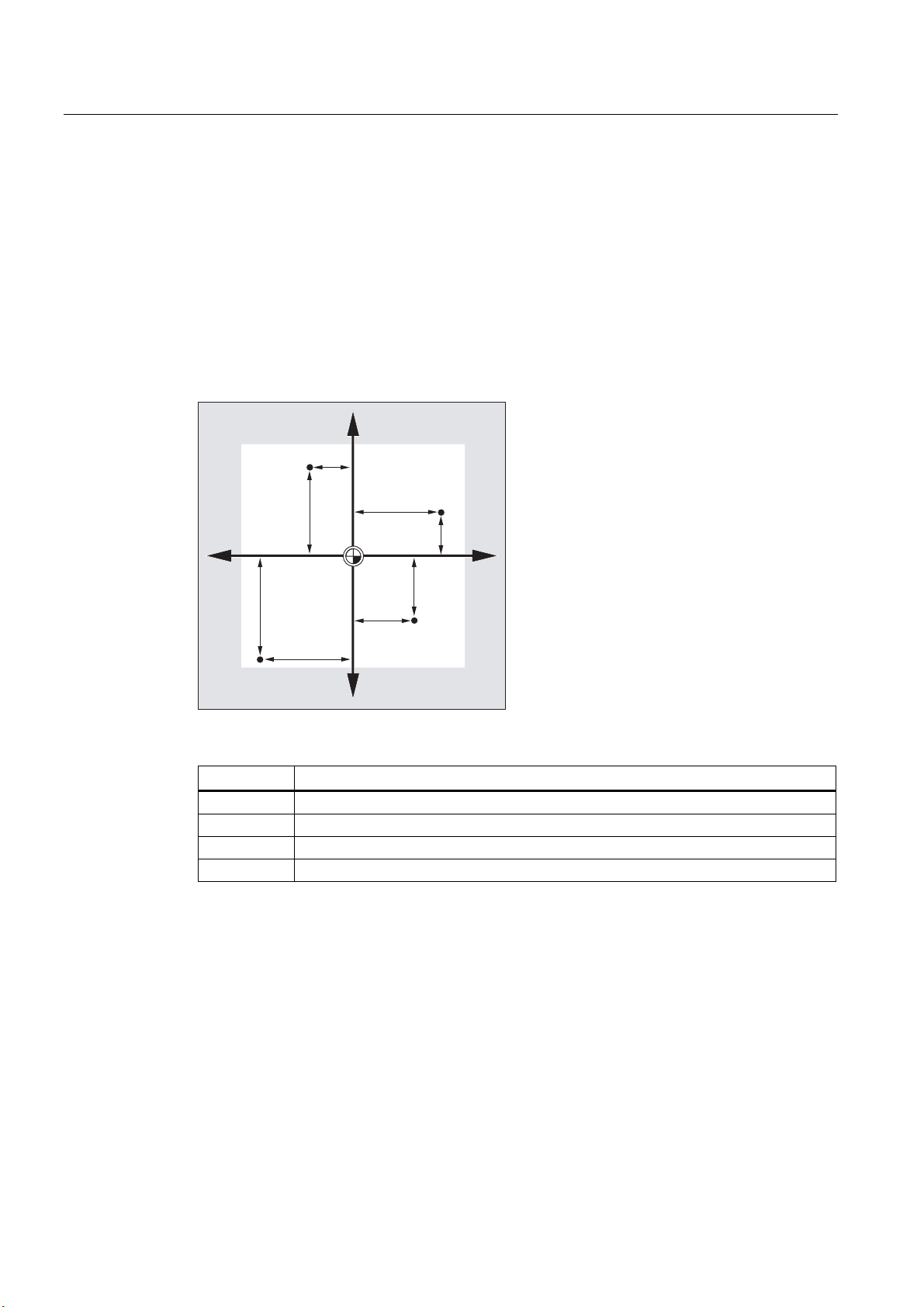

Position specifications in the form of Cartesian coordinates

To simplify things, we will only consider one plane of the coordinate system in the following

example, the X/Y plane:

<

3

;

3

<

3

;

3

Points P1 to P4 have the following coordinates:

Position Coordinates

P1 X100 Y50

P2 X-50 Y100

P3 X-105 Y-115

P4 X70 Y-75

Fundamentals

14 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 15

Fundamental Geometrical Principles

1.1 Workpiece positions

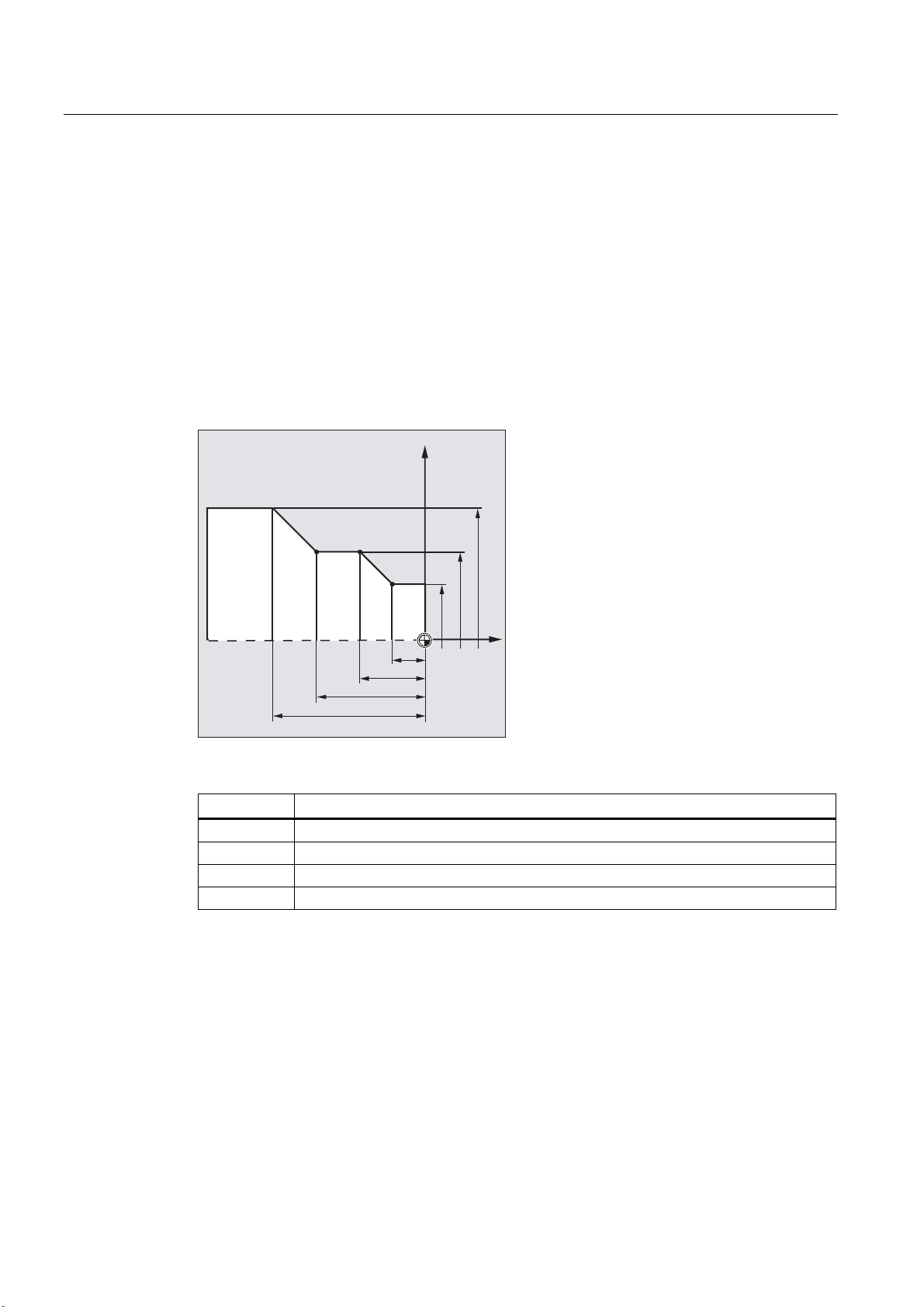

Example: Workpiece positions for turning

With lathes, one plane is sufficient to describe the contour:

;

3

3 3

3

=

Points P1 to P4 have the following coordinates:

Position Coordinates

P1 X25 Z-7.5

P2 X40 Z-15

P3 X40 Z-25

P4 X60 Z-35

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

15

Page 16

Fundamental Geometrical Principles

1.1 Workpiece positions

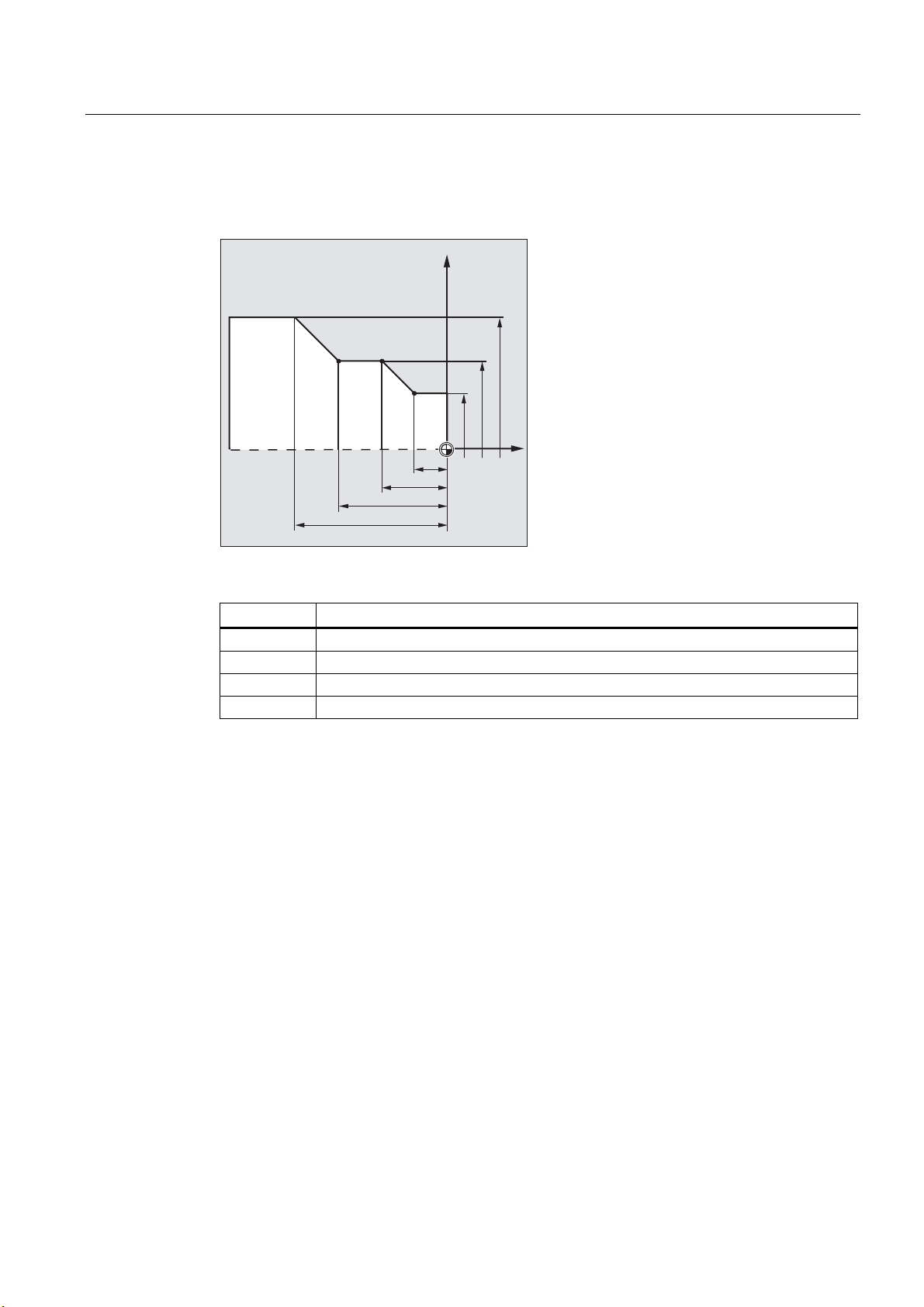

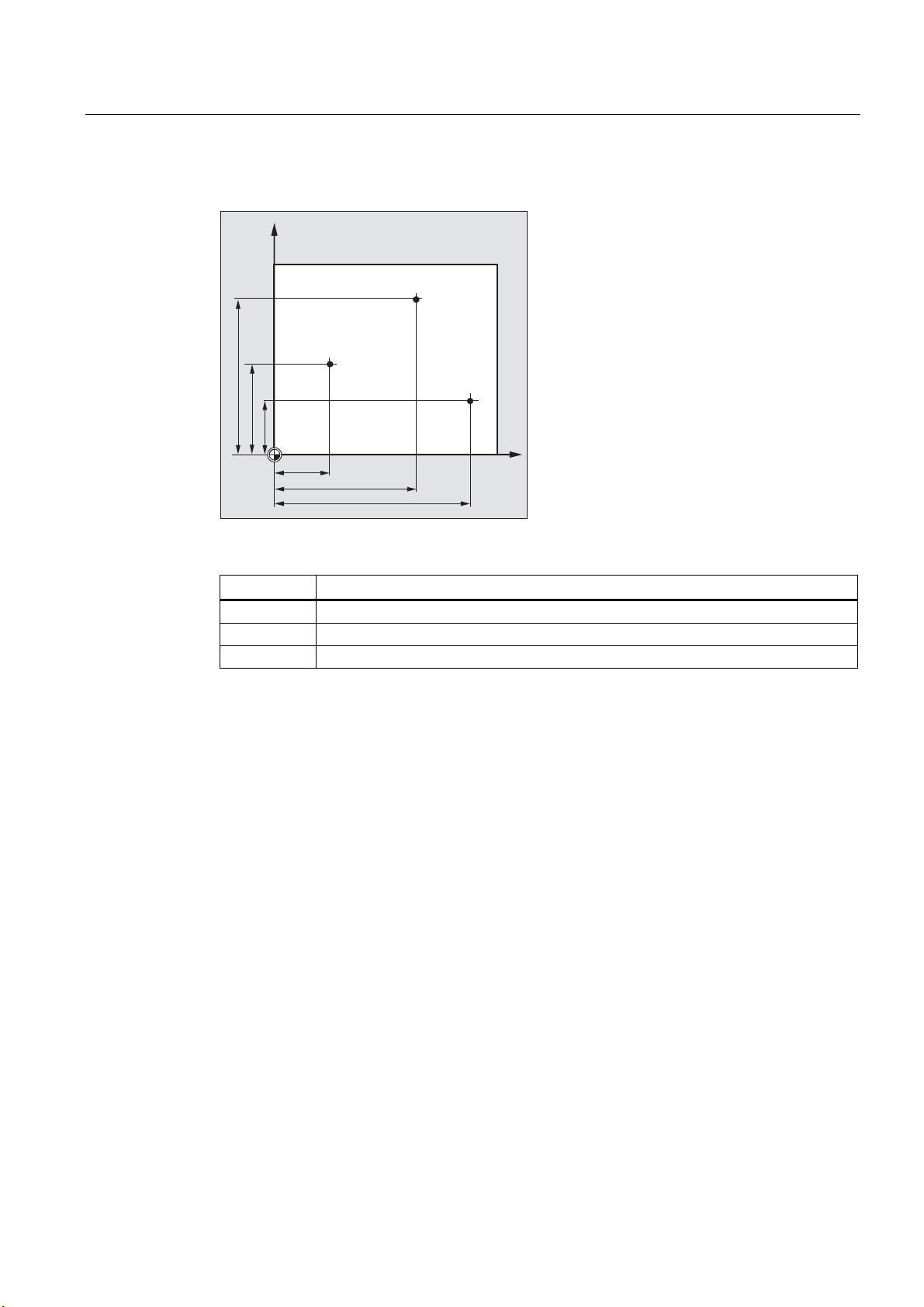

Example: Workpiece positions for milling

For milling, the feed depth must also be described, i.e. the third coordinate (in this case Z)

must also be assigned a numerical value.

<

3

3

3

;

3

3

3

<

=

Points P1 to P3 have the following coordinates:

Position Coordinates

P1 X10 Y45 Z-5

P2 X30 Y60 Z-20

P3 X45 Y20 Z-15

Fundamentals

16 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 17

Fundamental Geometrical Principles

1.1 Workpiece positions

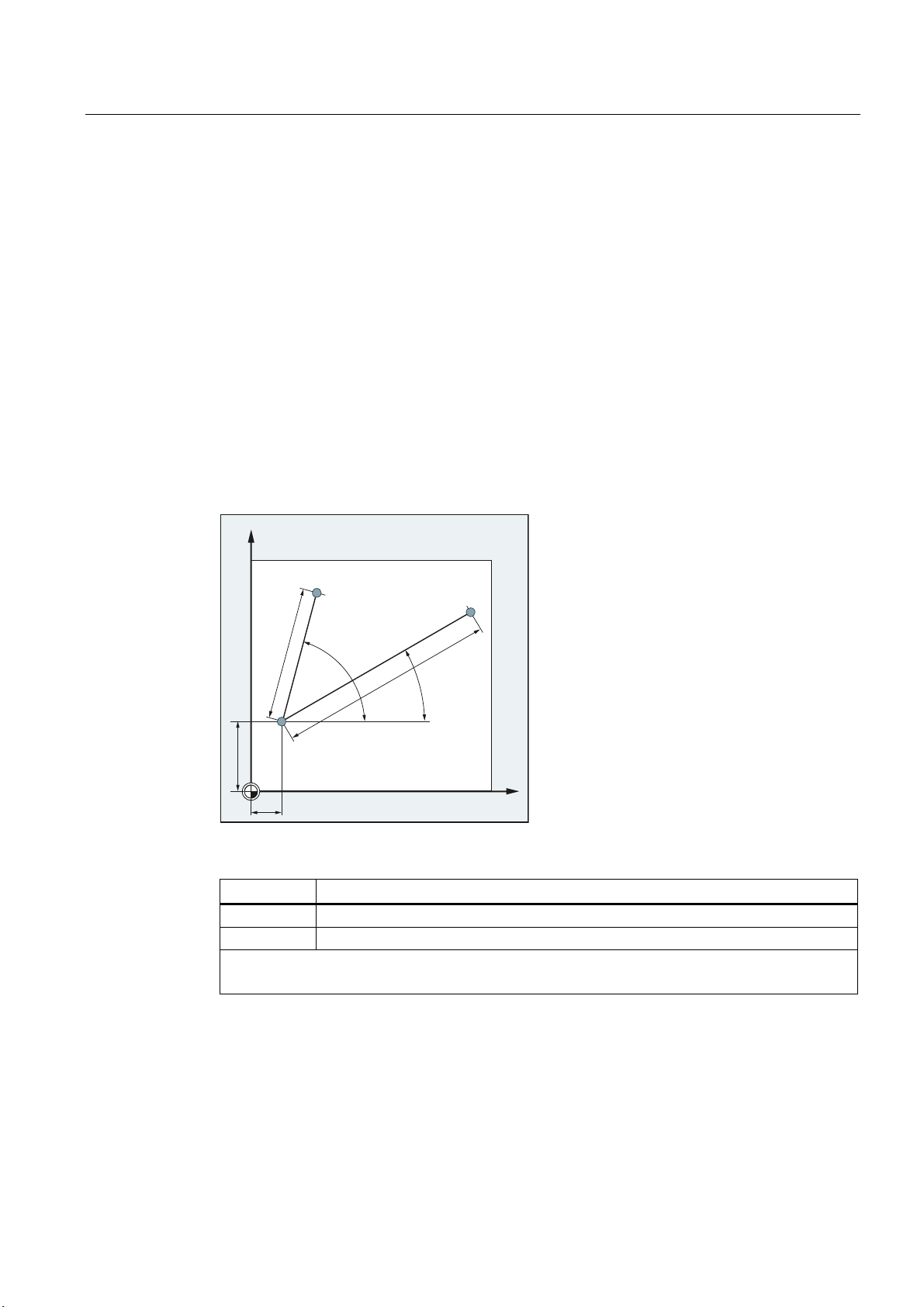

1.1.3 Polar coordinates

Polar coordinates can be used instead of Cartesian coordinates to describe workpiece

positions. This is useful when a workpiece or part of a workpiece has been dimensioned with

radius and angle. The point from which the dimensioning starts is called the "pole".

Position specifications in the form of polar coordinates

Polar coordinates are made up of the polar radius and the polar angle.

The polar radius is the distance between the pole and the position.

The polar angle is the angle between the polar radius and the horizontal axis of the working

plane. Negative polar angles are in the clockwise direction, positive polar angles in the

counterclockwise direction.

Example

<

3

3

r

3ROH

r

;

Points P1 and P2 can then be described – with reference to the pole – as follows:

Position Polar coordinates

P1 RP=100 AP=30

P2 RP=60 AP=75

RP: Polar radius

AP: Polar angle

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

17

Page 18

Fundamental Geometrical Principles

1.1 Workpiece positions

1.1.4 Absolute dimensions

Position specifications in absolute dimensions

With absolute dimensions, all the position specifications refer to the currently valid zero

point.

Applied to tool movement this means:

the position, to which the tool is to travel.

Example: Turning

;

3

3 3

3

=

In absolute dimensions, the following position specifications result for points P1 to P4:

Position Position specification in absolute dimensions

P1 X25 Z-7.5

P2 X40 Z-15

P3 X40 Z-25

P4 X60 Z-35

Fundamentals

18 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 19

Fundamental Geometrical Principles

1.1 Workpiece positions

Example: Milling

<

3

3

3

In absolute dimensions, the following position specifications result for points P1 to P3:

;

Position Position specification in absolute dimensions

P1 X20 Y35

P2 X50 Y60

P3 X70 Y20

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

19

Page 20

Fundamental Geometrical Principles

1.1 Workpiece positions

1.1.5 Incremental dimension

Position specifications in incremental dimensions

In production drawings, the dimensions often do not refer to a zero point, but to another

workpiece point. So that these dimensions do not have to be converted, they can be

specified in incremental dimensions. In this method of dimensional notation, a position

specification refers to the previous point.

Applied to tool movement this means:

The incremental dimensions describe the distance the tool is to travel.

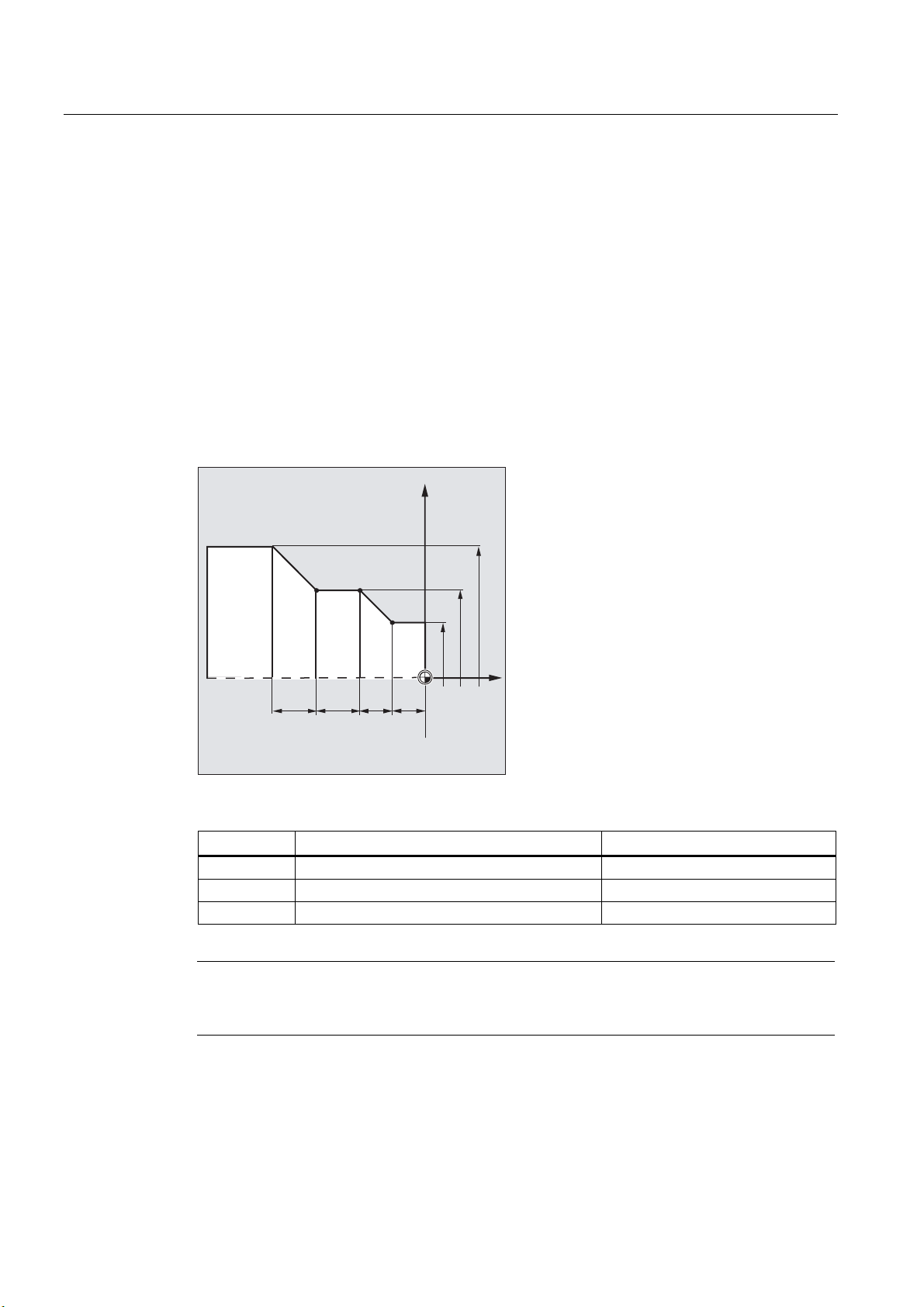

Example: Turning

;

3

3 3

3

=

In incremental dimensions, the following position specifications result for points P2 to P4:

Position Position specification in incremental dimensions The specification refers to:

P2 X15 Z-7.5 P1

P3 Z-10 P2

P4 X20 Z-10 P3

Note

With

DIAMOF or DIAM90 active, the set distance in incremental dimensions (G91) is

programmed as a radius dimension.

Fundamentals

20 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 21

Fundamental Geometrical Principles

1.2 Working planes

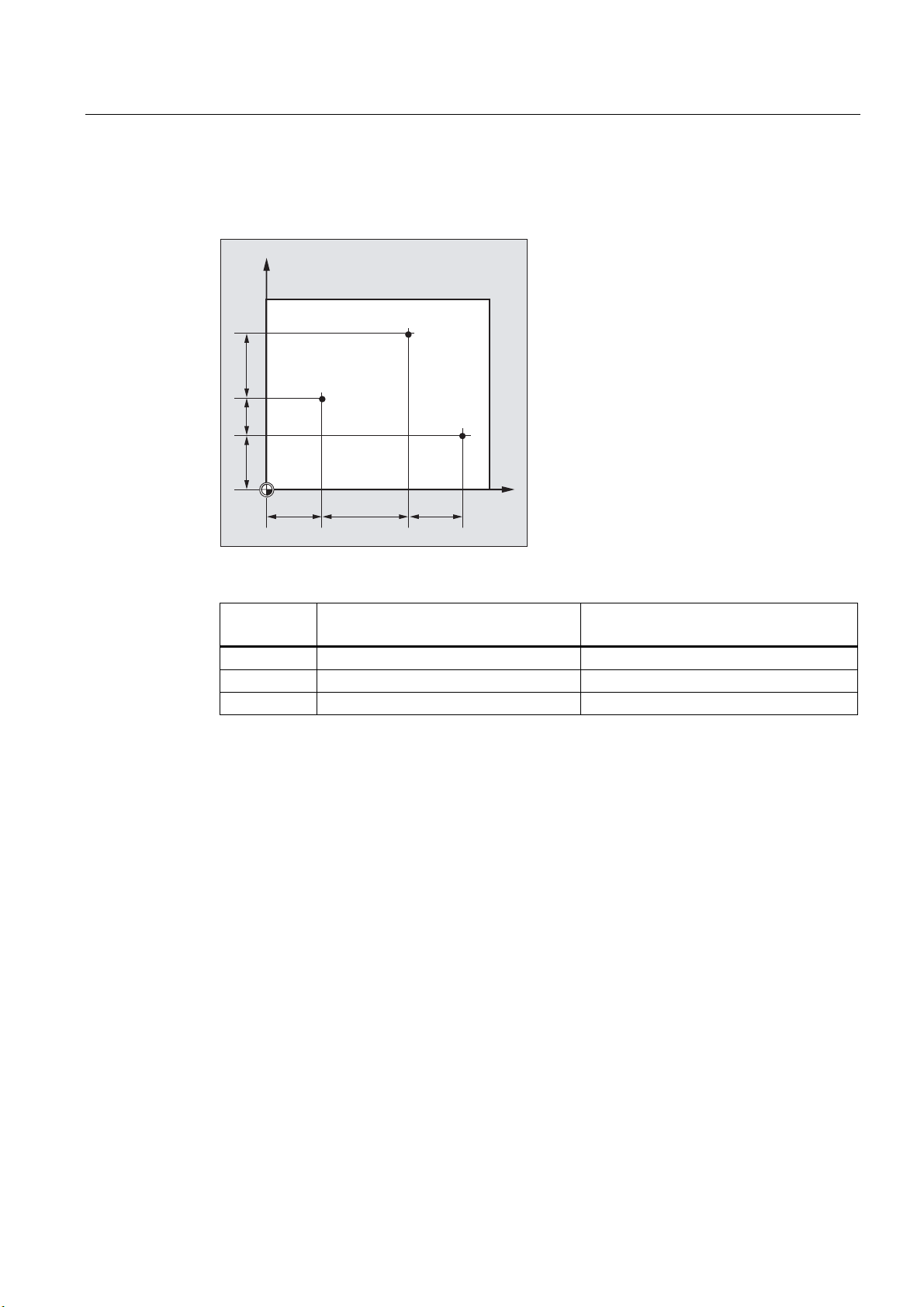

Example: Milling

The position specifications for points P1 to P3 in incremental dimensions are:

<

3

3

In incremental dimensions, the following position specifications result for points P1 to P3:

Position Position specification in incremental

dimensions

P1 X20 Y35 Zero point

P2 X30 Y20 P1

P3 X20 Y -35 P2

1.2 Working planes

An NC program must contain information about the plane in which the work is to be

performed. Only then can the control unit calculate the correct tool offsets during the

execution of the NC program. The specification of the working plane is also relevant for

certain types of circular-path programming and polar coordinates.

3

;

The specification refers to:

Two coordinate axes define a working plane. The third coordinate axis is perpendicular to

this plane and determines the infeed direction of the tool (e.g. for 2D machining).

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

21

Page 22

Fundamental Geometrical Principles

1.3 Zero points and reference points

Working planes for turning/milling

<

*

*

Working planes for turning

Programming of the working planes

The working planes are defined in the NC program with the G commands G17, G18 and G19 as

follows:

*

=

=

;

*

Working planes for milling

<

*

*

;

G command Working plane Infeed direction Abscissa Ordinate Applicate

G17

G18

G19

X/Y Z X Y Z

Z/X Y Z X Y

Y/Z X Y Z X

1.3 Zero points and reference points

Various zero points and reference points are defined on an NC machine:

Zero points

M Machine zero

The machine zero defines the machine coordinate system (MCS). All other reference

points refer to the machine zero.

W Workpiece zero = program zero

The workpiece zero defines the workpiece coordinate system in relation to the

machine zero.

A Blocking point

Can be the same as the workpiece zero (only for lathes).

Fundamentals

22 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 23

Fundamental Geometrical Principles

1.3 Zero points and reference points

Reference points

R Reference point

Position defined by output cam and measuring system. The distance to the machine

zero M must be known so that the axis position at this point can be set exactly to this

value.

B Starting point

Can be defined by the program. The first machining tool starts here.

T Toolholder reference point

Is on the toolholder. By entering the tool lengths, the controller calculates the distance

between the tool tip and the toolholder reference point.

N Tool change point

Zero points and reference points for turning

Zero points for milling

;

%

:$0

1

=

5

<

0

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

::

;

23

Page 24

Fundamental Geometrical Principles

1.4 Coordinate systems

1.4 Coordinate systems

A distinction is made between the following coordinate systems:

● Machine coordinate system (MCS) (Page 24) with the machine zero M

● Basic coordinate system (BCS) (Page 27)

● Basic zero system (BZS) (Page 29)

● Settable zero system (SZS) (Page 30)

● Workpiece coordinate system (WCS) (Page 31) with the workpiece zero W

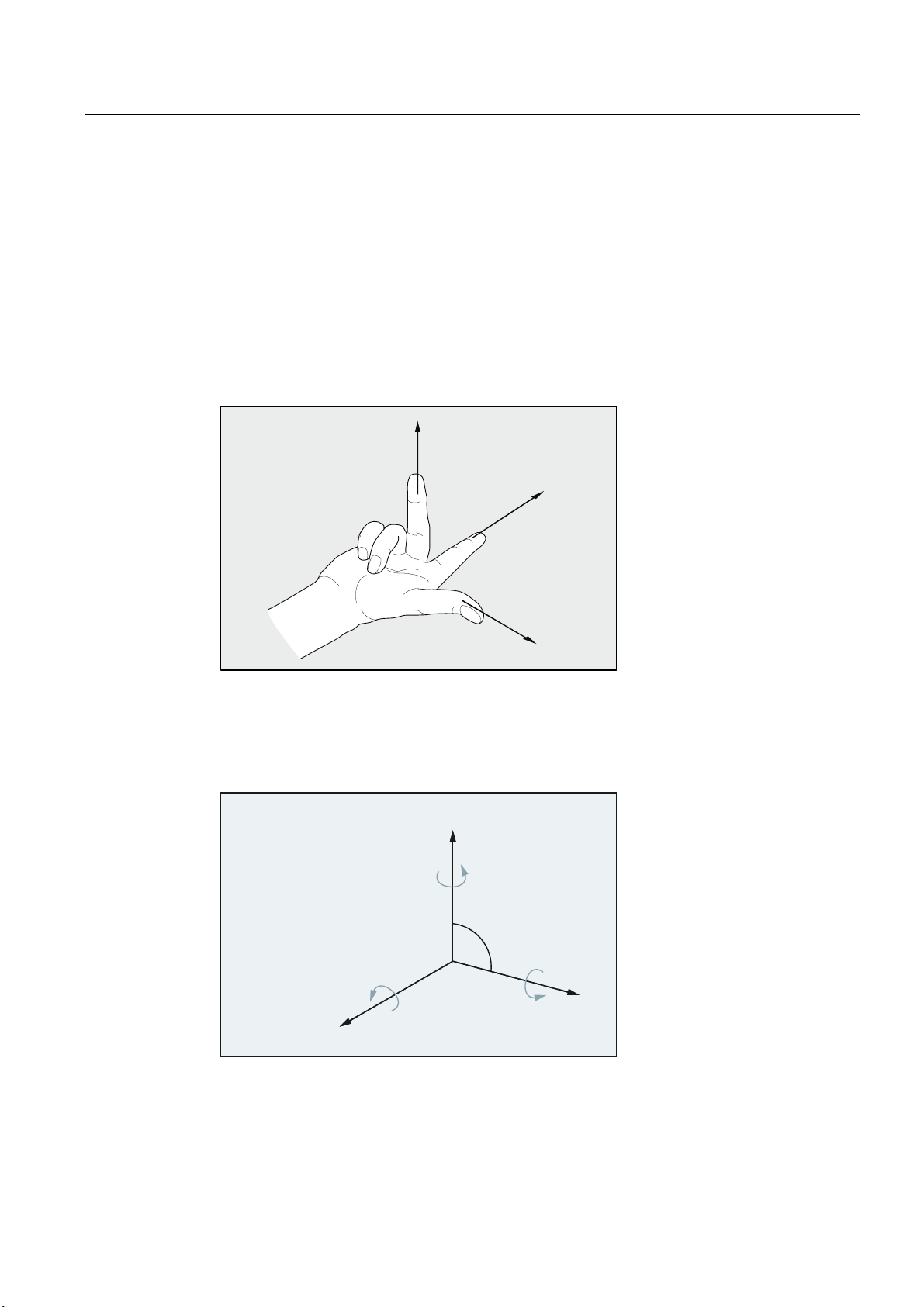

1.4.1 Machine coordinate system (MCS)

The machine coordinate system comprises all the physically existing machine axes.

Reference points and tool and pallet changing points (fixed machine points) are defined in

the machine coordinate system.

=P

0

<P

;P

If programming is performed directly in the machine coordinate system (possible with some

G functions), the physical axes of the machine respond directly. Any workpiece clamping that

is present is not taken into account.

Note

If there are various machine coordinate systems (e.g. 5-axis transformation), then an internal

transformation is used to map the machine kinematics on the coordinate system in which the

programming is performed.

Fundamentals

24 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 25

Fundamental Geometrical Principles

1.4 Coordinate systems

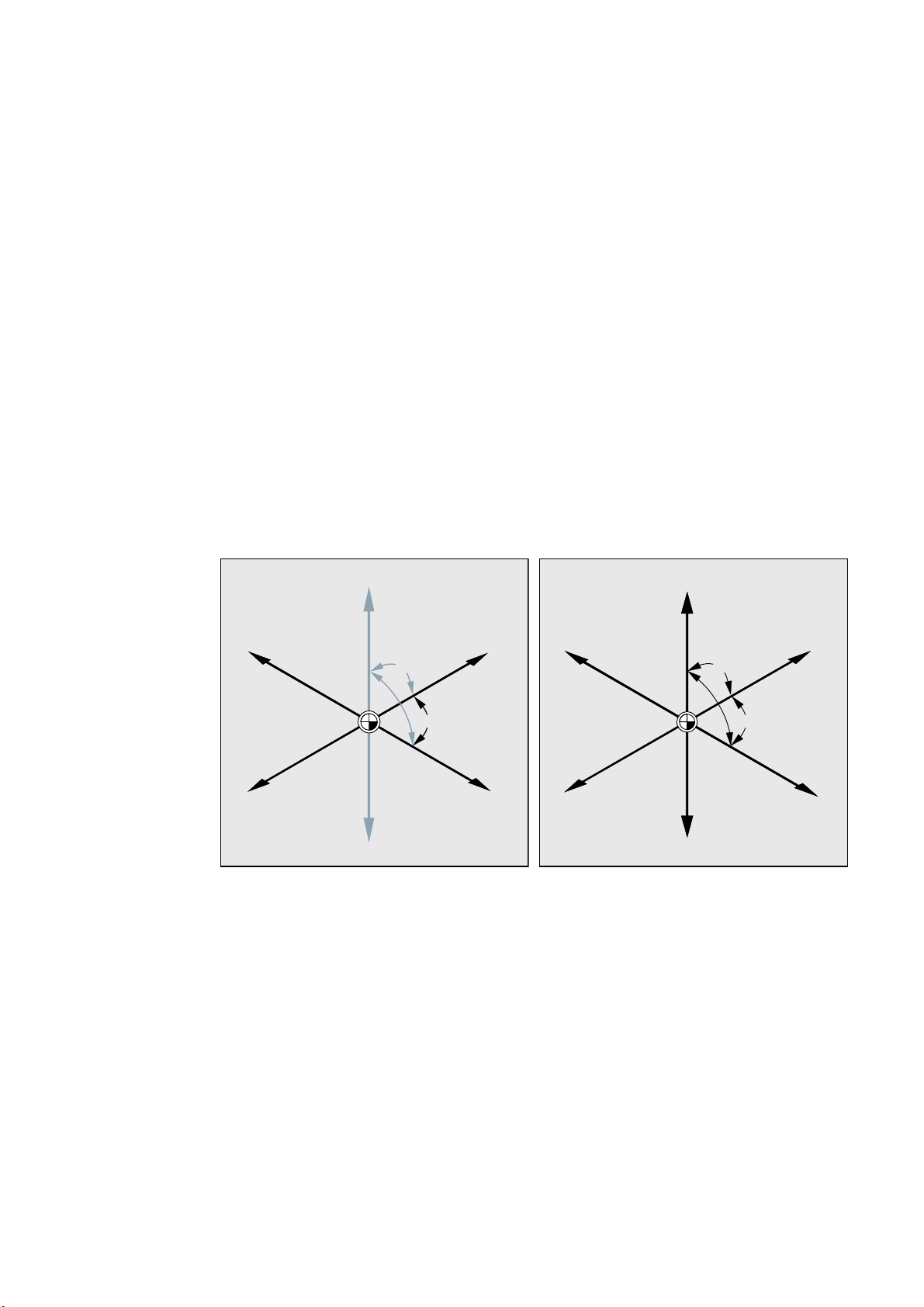

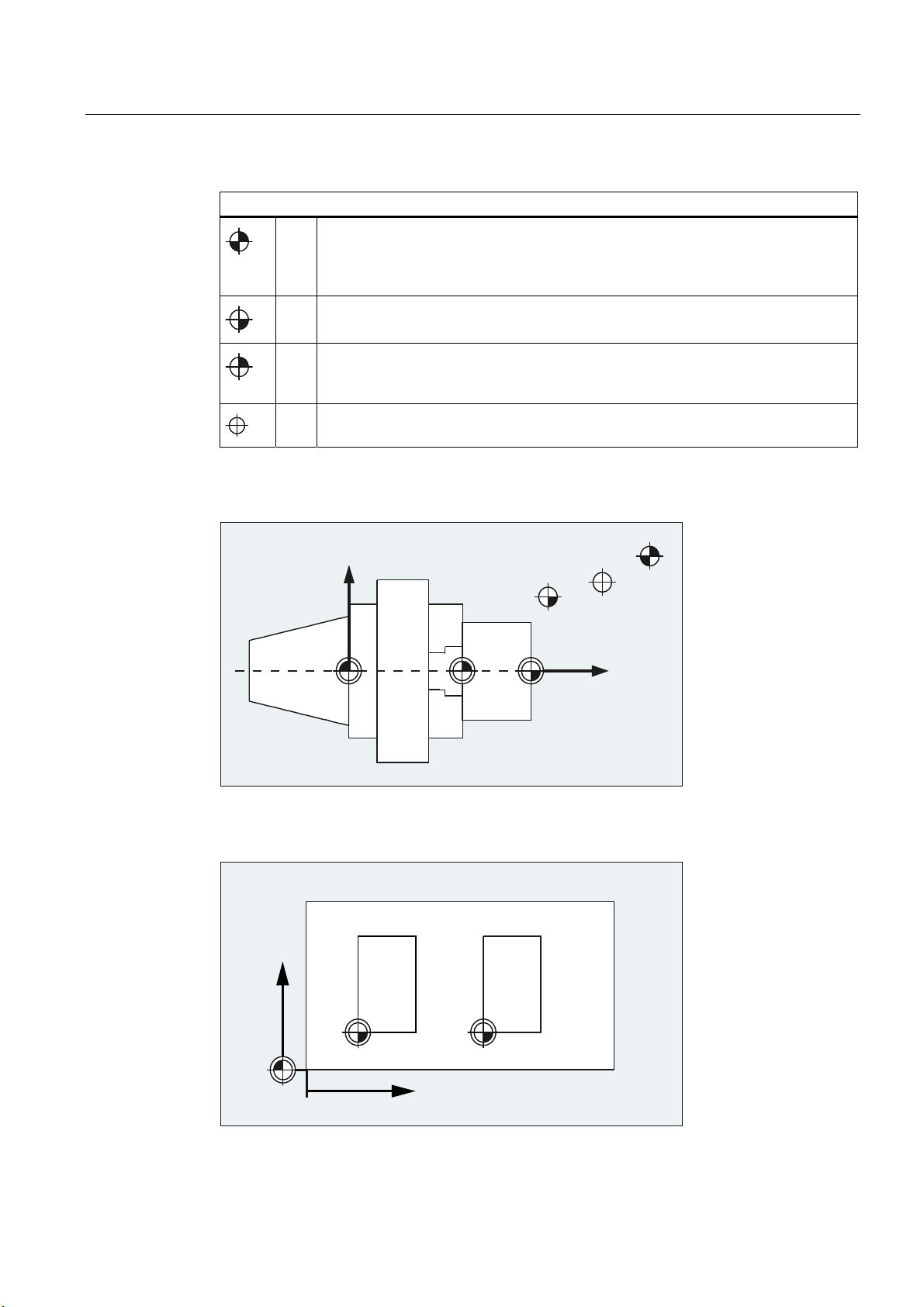

Three-finger rule

The orientation of the coordinate system relative to the machine depends on the machine

type. The axis directions follow the so-called "three-finger rule" of the right hand (according

to DIN 66217).

Seen from in front of the machine, the middle finger of the right hand points in the opposite

direction to the infeed of the main spindle. Therefore:

● the thumb points in the +X direction

● the index finger points in the +Y direction

● the middle finger points in the +Z direction

=

<

;

Figure 1-1 "Three-finger rule"

Rotary motions around the coordinate axes X, Y and Z are designated A, B and C. If the

rotary motion is in a clockwise direction when looking in the positive direction of the

coordinate axis, the direction of rotation is positive:

;<=

PXWXDOO\RUWKRJRQDO

D[HV

$%&

5RWDU\D[HV

URWDWLQJDURXQG;<=

&

<

%

r

;

$

=

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

25

Page 26

Fundamental Geometrical Principles

1.4 Coordinate systems

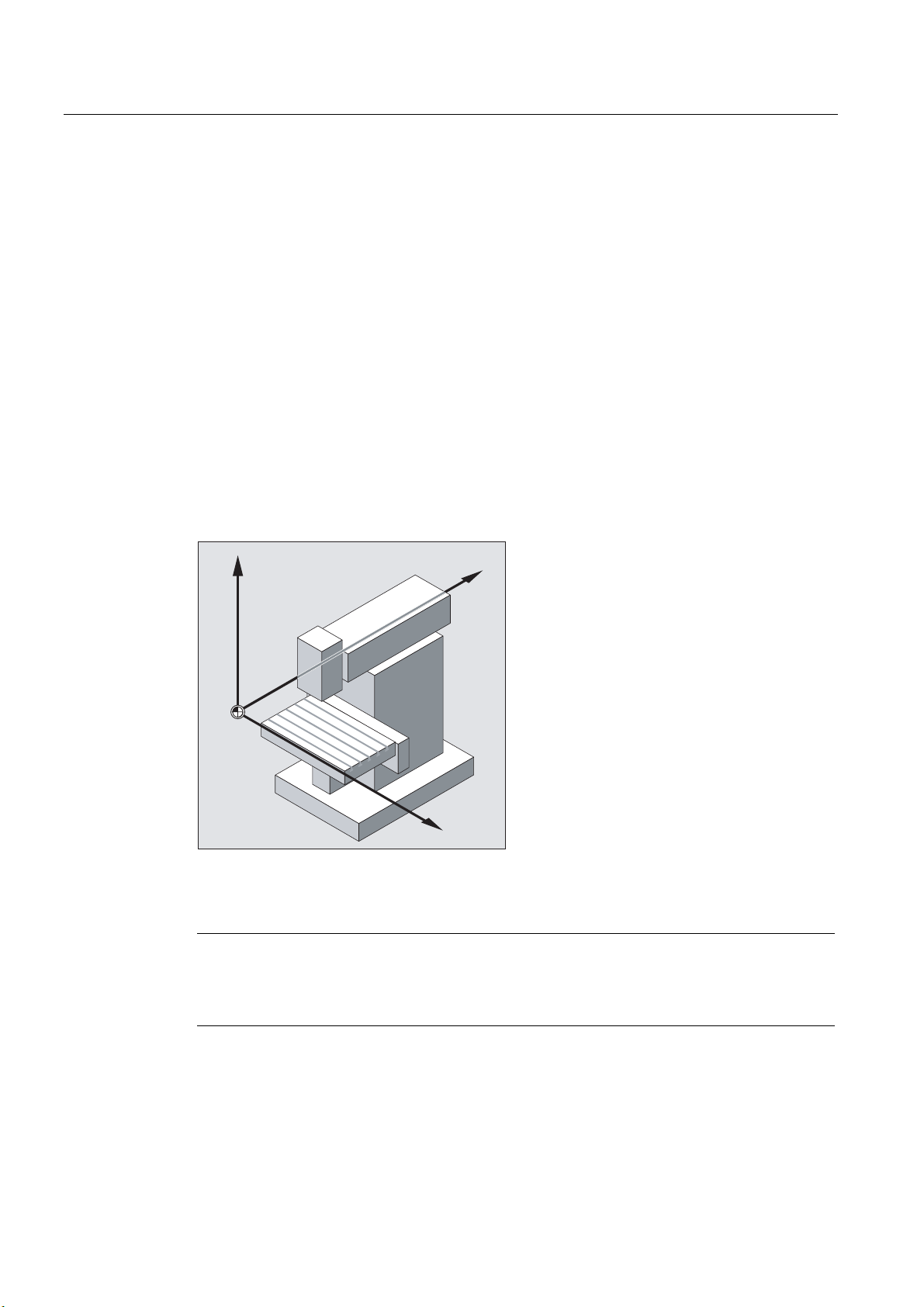

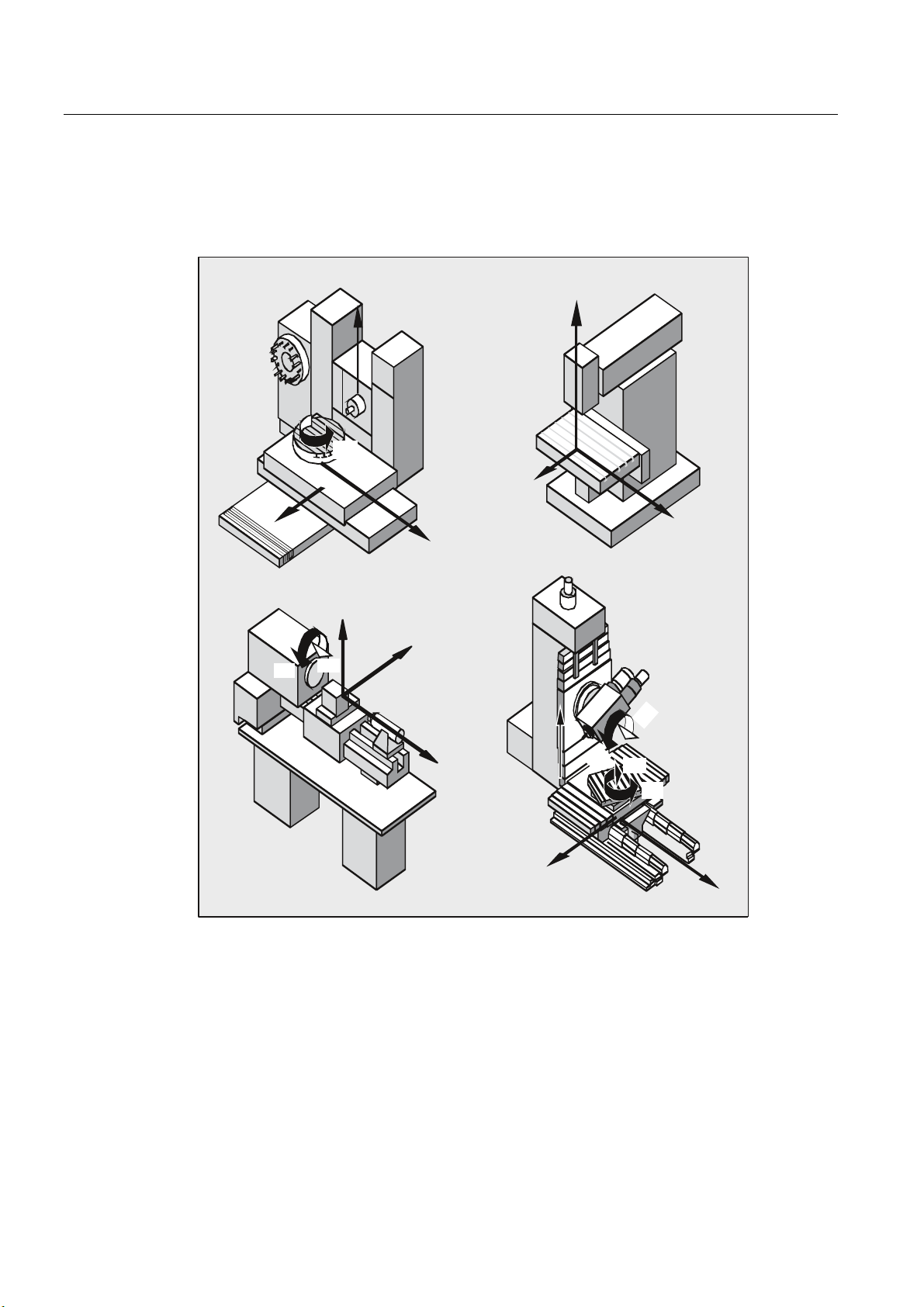

Position of the coordinate system in different machine types

The position of the coordinate system resulting from the "three-finger rule" can have a

different orientation for different machine types. Here are a few examples:

=

&

&

%

<

<

;

;

<

=

=

;

%

=

;

%

&

&

<

Fundamentals

26 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 27

Fundamental Geometrical Principles

1.4 Coordinate systems

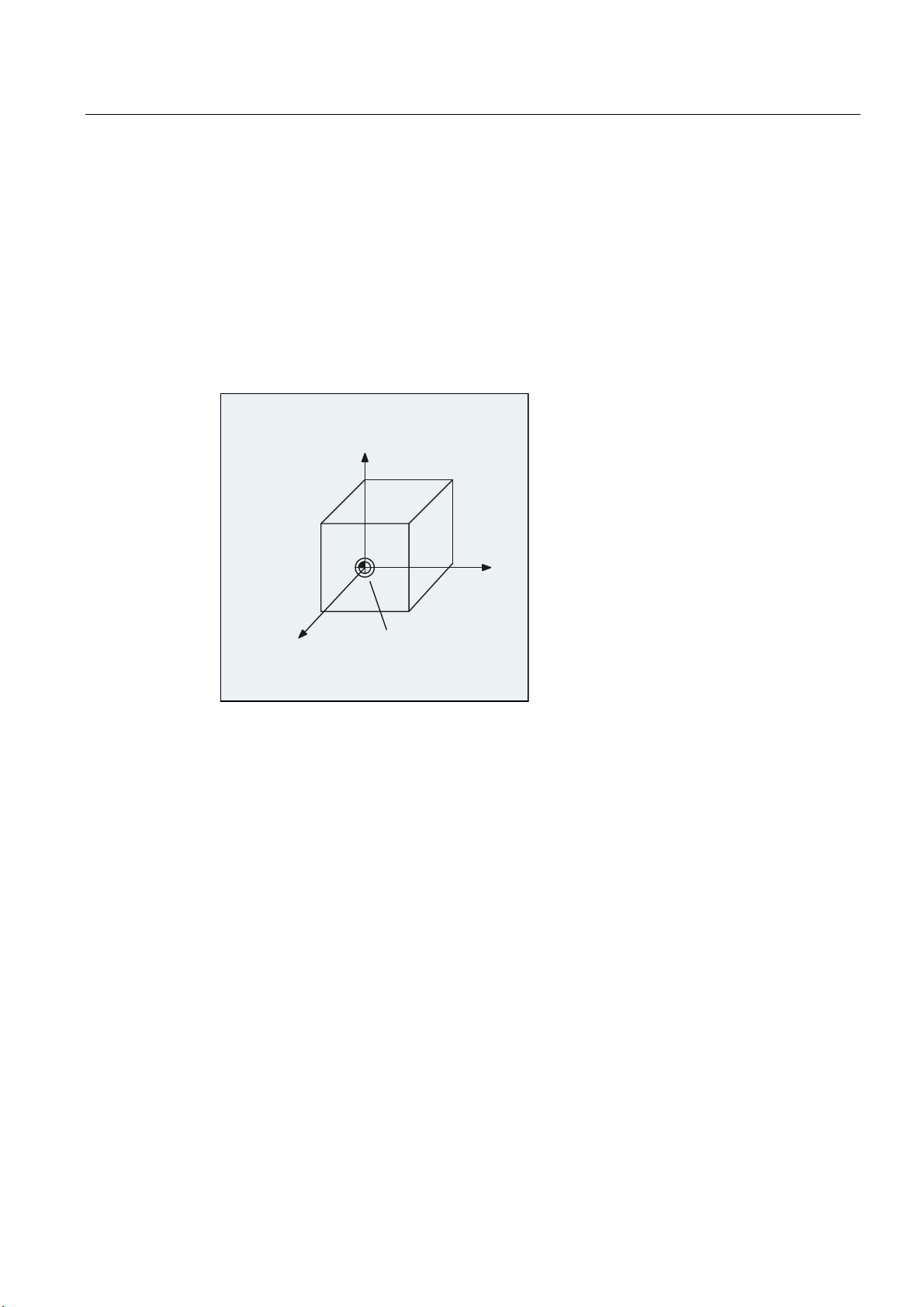

1.4.2 Basic coordinate system (BCS)

The basic coordinate system (BCS) consists of three mutually perpendicular axes (geometry

axes) as well as other special axes, which are not interrelated geometrically.

Machine tools without kinematic transformation

BCS and MCS always coincide when the BCS can be mapped onto the MCS without

kinematic transformation (e.g. 5-axis transformation, TRANSMIT/TRACYL/TRAANG).

On such machines, machine axes and geometry axes can have the same names.

<

0DFKLQH

FRRUGLQDWH

V\VWHP %&6

=

Figure 1-2 MCS = BCS without kinematic transformation

0DFKLQH]HURSRLQW

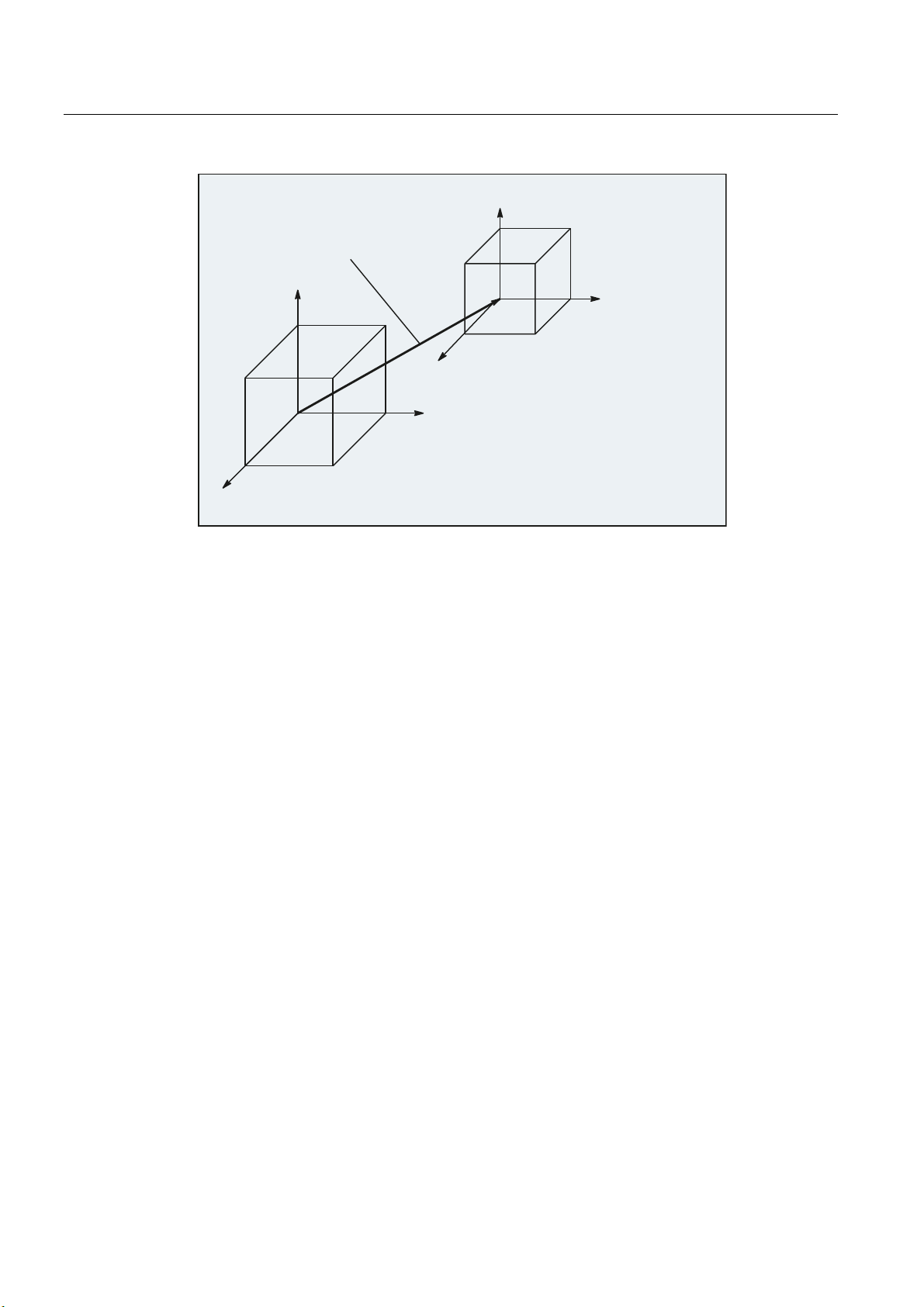

Machine tools with kinematic transformation

BCS and MCS do not coincide when the BCS is mapped onto the MCS with kinematic

transformation (e.g. 5-axis transformation, TRANSMIT/TRACYL/TRAANG).

On such machines the machine axes and geometry axes must have different names.

;

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

27

Page 28

Fundamental Geometrical Principles

1.4 Coordinate systems

<

%&6

.LQHPDWLF

WUDQVIRUPDWLRQ

<

0&6

;

%&6

Figure 1-3 Kinematic transformation between the MCS and BCS

Machine kinematics

The workpiece is always programmed in a two or three dimensional, right-angled coordinate

system (WCS). However, such workpieces are being programmed ever more frequently on

machine tools with rotary axes or linear axes not perpendicular to one another. Kinematic

transformation is used to represent coordinates programmed in the workpiece coordinate

system (rectangular) in real machine movements.

References

Function Manual Expansion Functions; M1: Kinematic transformation

=

%&6

;

0&6

%DVLFFRRUGLQDWHV\VWHP%&6

0DFKLQHFRRUGLQDWHV\VWHP0&6

=

0&6

Function Manual, Special Functions; F2: Multi-axis transformations

Fundamentals

28 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 29

Fundamental Geometrical Principles

1.4 Coordinate systems

1.4.3 Basic zero system (BZS)

The basic zero system (BZS) is the basic coordinate system with a basic offset.

<

%DVLFRIIVHW

<

;

%DVLF]HURV\VWHP%=6

=

;

%DVLFFRRUGLQDWHV\VWHP%&6

=

Basic offset

References

The basic offset describes the coordinate transformation between BCS and BZS. It can be

used, for example, to define the palette window zero.

The basic offset comprises:

● External zero offset

● DRF offset

● Overlaid movement

● Chained system frames

● Chained basic frames

Function Manual, Basic Functions; Axes, Coordinate Systems, Frames (K2)

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

29

Page 30

Fundamental Geometrical Principles

1.4 Coordinate systems

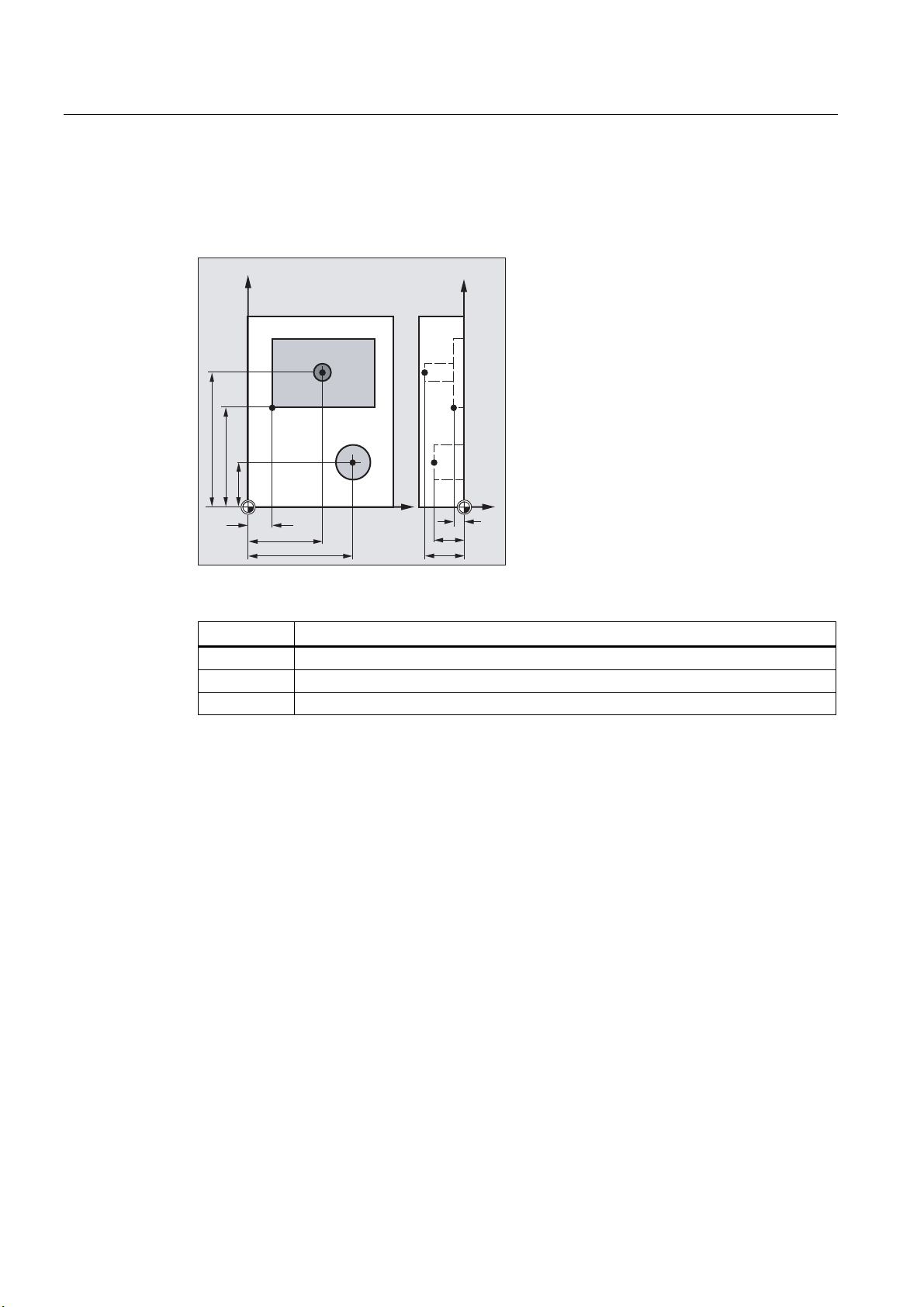

1.4.4 Settable zero system (SZS)

Settable zero offset

The "settable zero system" (SZS) results from the basic zero system (BZS) through the

settable zero offset.

Settable zero offsets are activated in the NC program with the G commands

G505...G599 as follows:

<

**

<

;

=

;

%DVLF]HURV\VWHP%=6

=

6HWWDEOH

]HURV\VWHP6=6

G54...G57 and

If no programmable coordinate transformations (frames) are active, then the "settable zero

system" is the workpiece coordinate system (WCS).

Programmable coordinate transformations (frames)

Sometimes it is useful or necessary within an NC program, to move the originally selected

workpiece coordinate system (or the "settable zero system") to another position and, if

required, to rotate it, mirror it and/or scale it. This is performed using programmable

coordinate transformations (frames).

See Section: "Coordinate transformations (frames)"

Fundamentals

30 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Note

Programmable coordinate transformations (frames) always refer to the "settable zero

system".

Page 31

Fundamental Geometrical Principles

1.4 Coordinate systems

1.4.5 Workpiece coordinate system (WCS)

The geometry of a workpiece is described in the workpiece coordinate system (WCS). In

other words, the data in the NC program refers to the workpiece coordinate system.

The workpiece coordinate system is always a Cartesian coordinate system and assigned to

a specific workpiece.

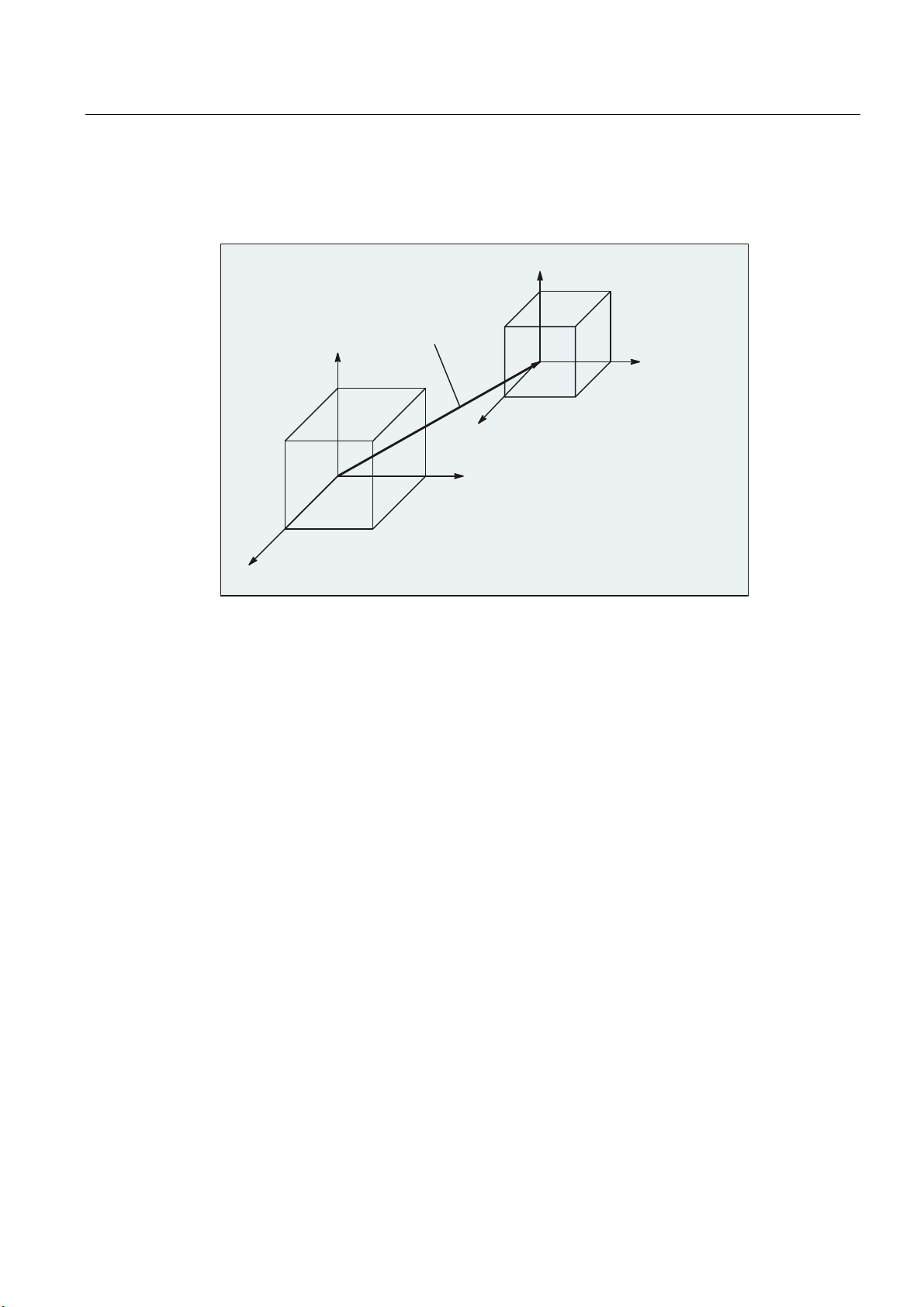

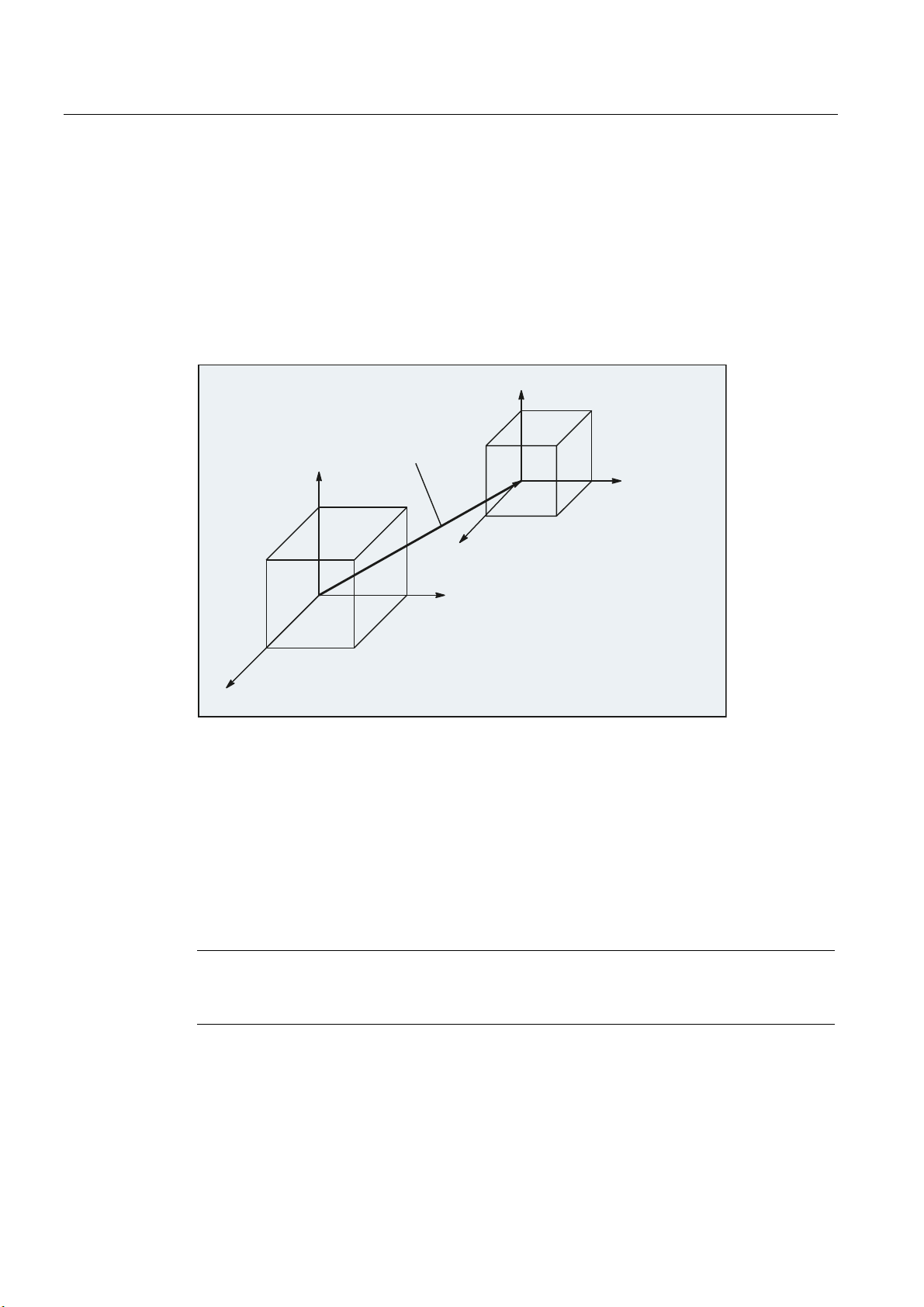

1.4.6 What is the relationship between the various coordinate systems?

The example in the following figure should help clarify the relationships between the various

coordinate systems:

3URJUDPPDEOH

FRRUGLQDWHWUDQVIRUPDWLRQ

]

6=6

]

]

\

:&6

[

\

[

]

\

:&6

[

\

:RUNSLHFH

[

3DOOHW

:RUNSLHFH

]

0&6

%&6

%DVLFRIIVHW

]

6HWWDEOHZRUNRIIVHW

%=6

6HWWDEOH

ZRUNRIIVHW

\

*

\

*

6=6

[

[

3URJUDPPDEOH

FRRUGLQDWHWUDQVIRUPDWLRQ

① A kinematic transformation is not active, i.e. the machine coordinate system and the basic

coordinate system coincide.

② The basic zero system (BZS) with the pallet zero result from the basic offset.

③ The "settable zero system" (SZS) for Workpiece 1 or Workpiece 2 is specified by the settable

zero offset G54 or G55.

④ The workpiece coordinate system (WCS) results from programmable coordinate

transformation.

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

31

Page 32

Fundamental Geometrical Principles

1.4 Coordinate systems

Fundamentals

32 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 33

Fundamental Principles of NC Programming

2.1 Name of an NC program

Rules for program names

Note

DIN 66025 is the guideline for NC programming.

Each NC program has a different name; the name can be chosen freely during program

creation, taking the following conditions into account:

● The name should not have more than 24 characters as only the first 24 characters of a

program name are displayed on the NC.

● Permissible characters are:

– Letters: A...Z, a...z

2

– Numbers: 0...9

– Underscores: _

● The first two characters should be:

– Two letters

Or

– An underscore and a letter

If this condition is satisfied, then an NC program can be called as subprogram from

another program just by specifying the program name. However, if the program name

starts with a number then the subprogram call is only possible via the

Examples:

● _MPF100

● SHAFT

● SHAFT_2

CALL statement.

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

33

Page 34

Fundamental Principles of NC Programming

2.1 Name of an NC program

Note

To avoid complications with Windows applications, avoid using the following program

names:

CON, PRN, AUX, NUL

COM1, COM2, COM3, COM4, COM5, COM6, COM7, COM8, COM9

LPT1, LPT2, LPT3, LPT4, LPT5, LPT6, LPT7, LPT8, LPT9

For further restrictions on the program names, see "Identifier (Page 402)".

Files in punch tape format

Externally created program files that are read into the NC via the V.24 interface must be

present in punch tape format.

The following additional rules apply for the name of a file in punch tape format:

● The program name must begin with "%":

References

%<Name>

● The program name must have a 3-character identifier:

%<Name>_xxx

Examples:

● %_N_SHAFT123_MPF

● %Flange3_MPF

Note

The name of a file stored internally in the NC memory starts with "_N_".

For further information on transferring, creating and saving part programs, see the Operating

Manual.

Fundamentals

34 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 35

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

2.2 Structure and contents of an NC program

2.2.1 Blocks and block components

Blocks

An NC program consists of a sequence of NC blocks. Each block contains the data for the

execution of a step in the workpiece machining.

Block components

NC blocks consist of the following components:

● Commands (statements) according to DIN 66025

● Elements of the NC high-level language

Commands according to DIN 66025

The commands according to DIN 66025 consist of an address character and a digit or

sequence of digits representing an arithmetic value.

Address character (address)

The address character (generally a letter) defines the meaning of the command.

Examples:

Address character Meaning

G G function (preparatory function)

X Position data for the X axis

S Spindle speed

Digit sequence

The digit sequence is the value assigned to the address character. The sequence of digits

can contain a sign and decimal point. The sign always appears between the address letter

and the sequence of digits. Positive signs (+) and leading zeroes (0) do not have to be

specified.

$GGUHVV

*

$GGUHVV

'LJLWVHTXHQFH

'LJLWVHTXHQFH

; 6

$GGUHVV

'LJLWVHTXHQFH

%ORFN

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

35

Page 36

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

Elements of the NC high-level language

As the command set according to DIN 66025 is no longer adequate for the programming of

complex machining sequences in modern machine tools, it has been extended by the

elements of the NC high-level language.

These include, for example:

● Commands of the NC high-level language

In contrast to the commands according to DIN 66025, the commands of the NC high-level

language consist of several address letters, e.g.

–

OVR for speed override

–

SPOS for spindle positioning

● Identifiers (defined names) for:

– System variables

– User-defined variables

– Subprograms

– Keywords

– Jump markers

– Macros

Note

An identifier must be unique and cannot be used for different objects.

● Comparison operators

● Logic operators

● Arithmetic functions

● Check structures

References:

Programming Manual, Job Planning; Section: "Flexible NC programming"

Effectiveness of commands

Commands are either modal or non-modal:

● Modal

Modal commands retain their validity with the programmed value (in all following blocks)

until:

– A new value is programmed under the same command

– A command is programmed that revokes the effect of the previously valid command

● Non-modal

Non-modal commands only apply for the block in which they were programmed.

Fundamentals

36 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 37

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

End of program

The last block in the execution sequence contains a special word for the end of program: M2,

M17 or M30.

2.2.2 Block rules

Start of block

NC blocks can be identified at the start of the block by block numbers. These consist of the

character "N" and a positive integer, e.g.

N40 ...

The order of the block numbers is arbitrary, however, block numbers in rising order are

recommended.

Note

Block numbers must be unique within a program in order to achieve an unambiguous result

when searching.

End of block

Block length

A block ends with the character LF (LINE FEED = new line).

Note

The LF character does not have to be written. It is generated automatically by the line

change.

A block can contain a maximum of 512 characters (including the comment and end-of-block

character LF).

Note

Three blocks of up to 66 characters each are normally displayed in the current block display

on the screen. Comments are also displayed. Messages are displayed in a separate

message window.

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

37

Page 38

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

Order of the statements

In order to keep the block structure as clear as possible, the statements in a block should be

arranged in the following order:

N… G… X… Y… Z… F… S… T… D… M… H…

Address Meaning

N

G

X,Y,Z

F

S

T

D

M

H

Note

Address of block number

Preparatory function

Positional data

Feedrate

Spindle speed

Tool

Tool offset number

Additional function

Auxiliary function

Certain addresses can be used repeatedly within a block, e.g.

G…, M…, H…

2.2.3 Value assignments

Values can be assigned to the addresses. The following rules apply:

● An "=" sign must be inserted between the address and the value if:

– The address comprises more than one letter

– The value includes more than one constant.

The "="-sign can be omitted if the address is a single letter and the value consists of only

one constant.

● Signs are permitted.

● Separators are permitted after the address letter.

Examples:

X10

X1=10

X=10*(5+SIN(37.5))

Note

Value assignment (10) to address X, "=" not required

Value assignment (10) to address (X) with numeric extension (1),

"=" required

Value assignment by means of a numeric expression, "=" required

A numeric extension must always be followed by one of the special characters "=", "(", "[",

")", "]", ",", or an operator, in order to distinguish an address with numeric extension from an

address letter with a value.

Fundamentals

38 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 39

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

2.2.4 Comments

To make an NC program easier to understand, comments can be added to the NC blocks.

A comment is at the end of a block and is separated from the program section of the NC

block by a semicolon (";").

Example 1:

Program code Comments

N10 G1 F100 X10 Y20 ; Comment to explain the NC block

Example 2:

Program code Comment

N10 ; Company G&S, order no. 12A71

N20 ; Program written by H. Smith, Dept. TV 4 ;on November

21, 1994

N50 ; Section no. 12, housing for submersible pump type TP23A

Note

Comments are stored and appear in the current block display when the program is running.

2.2.5 Skipping blocks

NC blocks, which are not to be executed in every program pass (e.g. execute a trial program

run), can be skipped.

Programming

Blocks, which are to be skipped are marked with an oblique "/" in front of the block number.

Several consecutive blocks can also be skipped. The statements in the skipped blocks are

not executed; the program continues with the next block, which is not skipped.

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

39

Page 40

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

Example:

1

1

1

1

1

1

1

1

1

1

1

1

3URJUDPH[HFXWLRQ

Program code Comment

N10 ; Is executed

/N20 … ; Skipped

N30 … ; Is executed

/N40 … ; Skipped

N70 … ; Is executed

Skip levels

Blocks can be assigned to skip levels (max. 10), which can be activated via the user

interface.

Programming is performed by assigning a forward slash, followed by the number of the skip

level. Only one skip level can be specified for each block.

Example:

Program code Comment

/ ... ; Block is skipped (1st skip level)

/0 ... ; Block is skipped (1st skip level)

/1 N010... ; Block is skipped (2nd skip level)

/2 N020... ; Block is skipped (3rd skip level)

...

/7 N100... ; Block is skipped (8th skip level)

/8 N080... ; Block is skipped (9th skip level)

/9 N090... ; Block is skipped (10th skip level)

Fundamentals

40 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 41

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

Note

The number of skip levels that can be used depends on a display machine data item.

Note

System and user variables can also be used in conditional jumps in order to control program

execution.

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

41

Page 42

Fundamental Principles of NC Programming

2.2 Structure and contents of an NC program

Fundamentals

42 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 43

Creating an NC program

3.1 Basic procedure

The programming of the individual operation steps in the NC language generally represents

only a small proportion of the work in the development of an NC program.

Programming of the actual instructions should be preceded by the planning and preparation

of the operation steps. The more accurately you plan in advance how the NC program is to

be structured and organized, the faster and easier it will be to produce a complete program,

which is clear and free of errors. Clearly structured programs are especially advantageous

when changes have to be made later.

As every part is not identical, it does not make sense to create every program in the same

way. However, the following procedure has shown itself to be suitable in the most cases.

Procedure

1. Prepare the workpiece drawing

– Define the workpiece zero

– Draw the coordinate system

3

– Calculate any missing coordinates

2. Define the machining sequence

– Which tools are used when and for the machining of which contours?

– In which order will the individual elements of the workpiece be machined?

– Which individual elements are repeated (possibly also rotated) and should be stored in

a subroutine?

– Are there contour sections in other part programs or subroutines that could be used

for the current workpiece?

– Where are zero offsets, rotating, mirroring and scaling useful or necessary (frame

concept)?

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

43

Page 44

Creating an NC program

3.2 Available characters

3. Create a machining plan

Define all machining operations step-by-step, e.g.

– Rapid traverse movements for positioning

– Tool change

– Define the machining plane

– Retraction for checking

– Switch spindle, coolant on/off

– Call up tool data

– Feed

– Path correction

– Approaching the contour

– Retraction from the contour

– etc.

4. Compile machining steps in the programming language

– Write each individual step as an NC block (or NC blocks).

5. Combine the individual steps into a program

3.2 Available characters

The following characters are available for writing NC programs:

● Upper-case characters:

A, B, C, D, E, F, G, H, I, J, K, L, M, N,(O),P, Q, R, S, T, U, V, W, X, Y, Z

● Lower-case characters:

a, b, c, d, e, f, g, h, i, j, k, l, m, n, o, p, q, r, s, t, u, v, w, x, y, z

● Numbers:

0, 1, 2, 3, 4, 5, 6, 7, 8, 9

● Special characters:

See the table below.

Special characters Meaning

% Program start character (used only for writing programs on an external PC)

( For bracketing parameters or expressions

) For bracketing parameters or expressions

[ For bracketing addresses or indexes

] For bracketing addresses or indexes

< Less than

Fundamentals

44 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 45

Creating an NC program

3.3 Program header

Special characters Meaning

> Greater than

: Main block, end of label, chain operator

= Assignment, part of equation

/ Division, block suppression

* Multiplication

+ Addition

- Subtraction, minus sign

" Double quotation marks, identifier for character string

' Single quotation marks, identifier for special numerical values: hexadecimal,

binary

$ System variable identifiers

s_ Underscore, belonging to letters

? Reserved

! Reserved

. Decimal point

, Comma, parameter separator

; Comment start

& Format character, same effect as space character

LF End of block

Tab character Separator

Blank Separator (blank)

Note

Take care to differentiate between the letter "O" and the digit "0".

Note

No distinction is made between upper- and lower-case characters (exception: Tool call).

Note

Non-printable special characters are treated like blanks.

3.3 Program header

The NC blocks that are placed in front of the actual motion blocks for the machining of the

workpiece contour, are called the program header.

The program header contains information/statements regarding:

● Tool change

● Tool offsets

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

45

Page 46

Creating an NC program

3.3 Program header

● Spindle motion

● Feed control

● Geometry settings (zero offset, selection of the working plane)

Program header for turning

The following example shows the typical structure of an NC program header for turning:

Program code Comment

N10 G0 G153 X200 Z500 T0 D0 ; Retract toolholder before tool turret is

rotated.

N20 T5 ; Swing in tool 5.

N30 D1 ; Activate cutting edge data record of the

tool.

N40 G96 S300 LIMS=3000 M4 M8 ; Constant cutting rate (Vc) = 300 m/min, speed

limitation = 3000 rpm, direction of rotation

counterclockwise, cooling on.

N50 DIAMON ; X axis will be programmed in diameter.

N60 G54 G18 G0 X82 Z0.2 ; Call zero offset and working plane, approach

starting position.

...

Program header for milling

The following example shows the typical structure of an NC program header for milling:

Program code Comment

N10 T="SF12" ; Alternative: T123

N20 M6 ; Trigger tool change

N30 D1 ; Activate cutting edge data record of the tool

N40 G54 G17 ; Zero offset and working plane

N50 G0 X0 Y0 Z2 S2000 M3 M8 ; Approach to the workpiece, spindle and

...

If tool orientation / coordinate transformation is being used, any transformations still active

should be deleted at the start of the program:

Program code Comment

N10 CYCLE800() ; Resetting of the swiveled plane

N20 TRAFOOF ; Resetting of TRAORI, TRANSMIT, TRACYL, ...

...

coolant on

Fundamentals

46 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 47

Creating an NC program

3.4 Program examples

3.4 Program examples

3.4.1 Example 1: First programming steps

Program example 1 is to be used to perform and test the first programming steps on the NC.

Procedure

1. Create a new part program (name)

2. Edit the part program

3. Select the part program

4. Activate single block

5. Start the part program

References:

Operating Manual for the existing user interface

Note

In order that the program can run on the machine, the machine data must have been set

appropriately (→ machine manufacturer!).

Note

Alarms can occur during program verification. These alarms have to be reset first.

Program example 1

Program code Comment

N10 MSG("THIS IS MY NC PROGRAM") ; Message "THIS IS MY NC PROGRAM"

N20 F200 S900 T1 D2 M3 ;Feedrate, spindle, tool, tool offset,

N30 G0 X100 Y100 ; Approach position in rapid traverse

N40 G1 X150 ; Rectangle with feedrate, straight

N50 Y120 ; Straight line in Y

N60 X100 ; Straight line in X

N70 Y100 ; Straight line in Y

N80 G0 X0 Y0 ; Retraction in rapid traverse

N100 M30 ; End of block

displayed in the alarm line

spindle clockwise

line in X

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

47

Page 48

Creating an NC program

3.4 Program examples

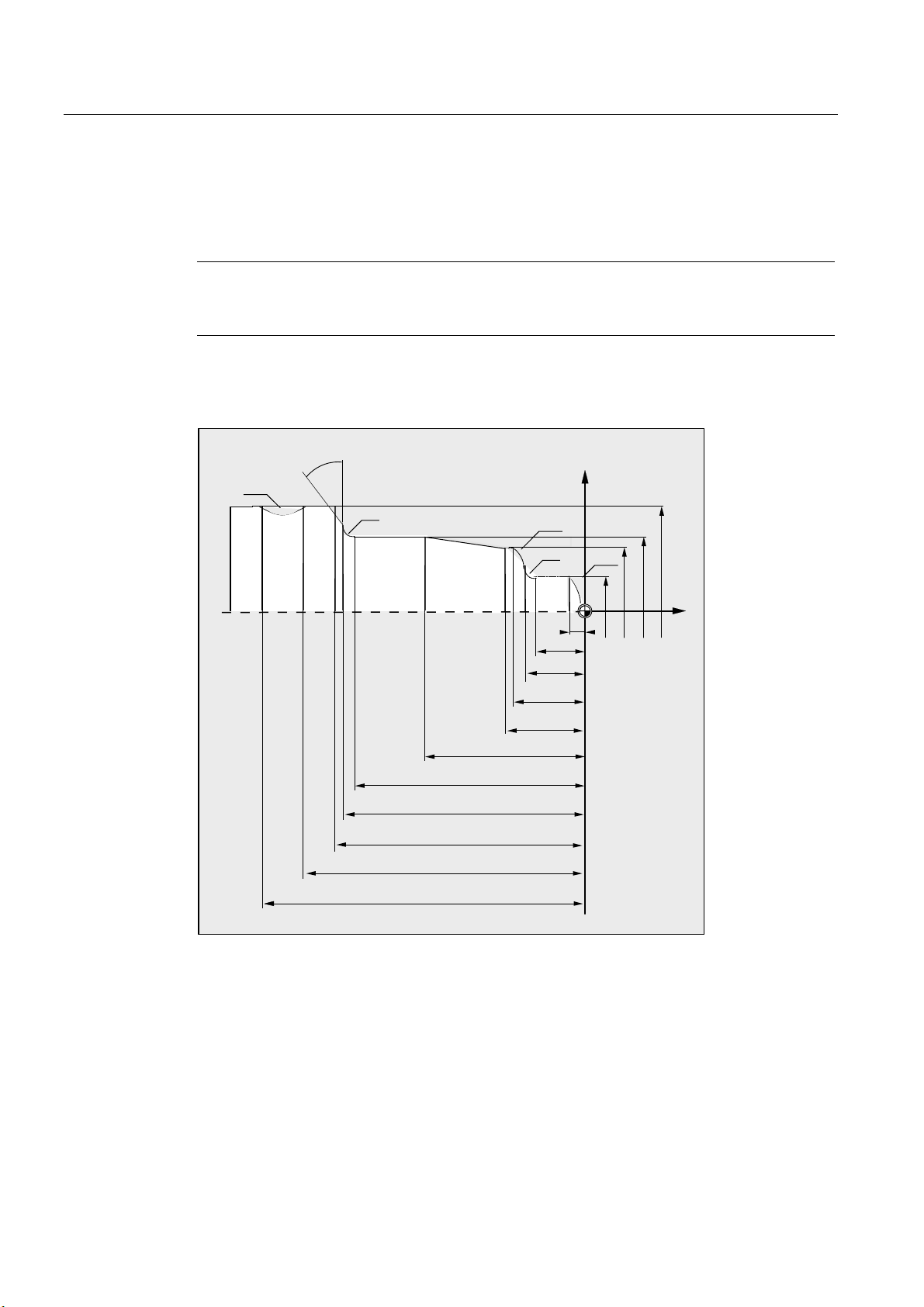

3.4.2 Example 2: NC program for turning

Program example 2 is intended for the machining of a workpiece on a lathe. It contains

radius programming and tool radius compensation.

Dimension drawing of the workpiece

Note

In order that the program can run on the machine, the machine data must have been set

appropriately (→ machine manufacturer!).

5

r

5

5

5

;

5

=

Figure 3-1 Top view

Fundamentals

48 Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

Page 49

Creating an NC program

3.4 Program examples

Program example 2

Program code Comment

N5 G0 G53 X280 Z380 D0 ; Starting point

N10 TRANS X0 Z250 ; Zero offset

N15 LIMS=4000 ; Speed limitation (G96)

N20 G96 S250 M3 ; Select constant cutting rate

N25 G90 T1 D1 M8 ; Select tool selection and offset

N30 G0 G42 X-1.5 Z1 ; Set tool with tool radius compensation

N35 G1 X0 Z0 F0.25

N40 G3 X16 Z-4 I0 K-10 ; Turn radius 10

N45 G1 Z-12

N50 G2 X22 Z-15 CR=3 ; Turn radius 3

N55 G1 X24

N60 G3 X30 Z-18 I0 K-3 ; Turn radius 3

N65 G1 Z-20

N70 X35 Z-40

N75 Z-57

N80 G2 X41 Z-60 CR=3 ; Turn radius 3

N85 G1 X46

N90 X52 Z-63

N95 G0 G40 G97 X100 Z50 M9 ; Deselect tool radius compensation and approach

tool change location

N100 T2 D2 ; Call tool and select offset

N105 G96 S210 M3 ; Select constant cutting rate

N110 G0 G42 X50 Z-60 M8 ; Set tool with tool radius compensation

N115 G1 Z-70 F0.12 ; Turn diameter 50

N120 G2 X50 Z-80 I6.245 K-5 ; Turn radius 8

N125 G0 G40 X100 Z50 M9 ; Retract tool and deselect tool radius

compensation

N130 G0 G53 X280 Z380 D0 M5 ; Approach tool change location

N135 M30 ; End of program

Fundamentals

Programming Manual, 03/2013, 6FC5398-1BP40-3BA1

49

Page 50

Creating an NC program

3.4 Program examples