Page 1

Table of contents

Tables

Figures

Preface

Explanation of list of

parameters

1

SINUMERIK

SINUMERIK 828D,

SINAMICS S120

Parameter description

Parameter Manual

SINAMICS parameters

Parameters for data sets

Appendix

2

3

A

Validfor

SINUMERIK828Dcontrolsystem

Software version

CNCsoftware 4.5

SINAMICS S120 4.5

02/2012

6FC5397-8DP40-3BA0

Page 2

Legal information- Warning notice system

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of SiemensAG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number:6FC5397-8DP40-3BA0

Ⓟ 02.2012 Technical data subject to change

Copyright © SiemensAG 2012.

All rights reserved

Page 3

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

• General documentation

• User documentation

• Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

• Ordering documentation/overview of documentation

• Additional links to download documents

• Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific

machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

• www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation

technology

• www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

3

Page 4

Preface

SINUMERIK

Target group

Benefits

Standard scope

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

This documentation is intended for project engineers, commissioning engineers, machine

operators and service and maintenance personnel.

The intended target group can use the Parameter Manual to test and commission the system

or the plant professionally and safely.

Utilization phase: Installation and commissioning phase

Technical Support

This documentation only describes the functionality of the standard version. Additions or

revisions made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

For the sake of simplicity, this documentation does not contain all detailed information about

all types of the product and cannot cover every conceivable case of installation, operation, or

maintenance.

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

Parameter description

4

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 5

Table of contents

Table of contents

Preface.........................................................................................................................................................3

1 Explanation of list of parameters .................................................................................................................7

1.1 Structure of the parameter descriptions for SINAMICS............................................................... 7

1.2 Meaning of the parameter descriptions ....................................................................................... 8

2 SINAMICS parameters .............................................................................................................................19

3 Parameters for data sets .........................................................................................................................853

3.1 Parameters for drive data sets (DDS) ..................................................................................... 853

3.2 What parameters are dependent on encoder data sets (EDS) ............................................... 857

3.3 Parameters for motor data sets (MDS).................................................................................... 859

A Appendix .................................................................................................................................................863

A.1 List of abbreviations................................................................................................................. 863

A.2 Documentation overview ......................................................................................................... 869

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

5

Page 6

Table of contents

Parameter description

6

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 7

Explanation of list of parameters

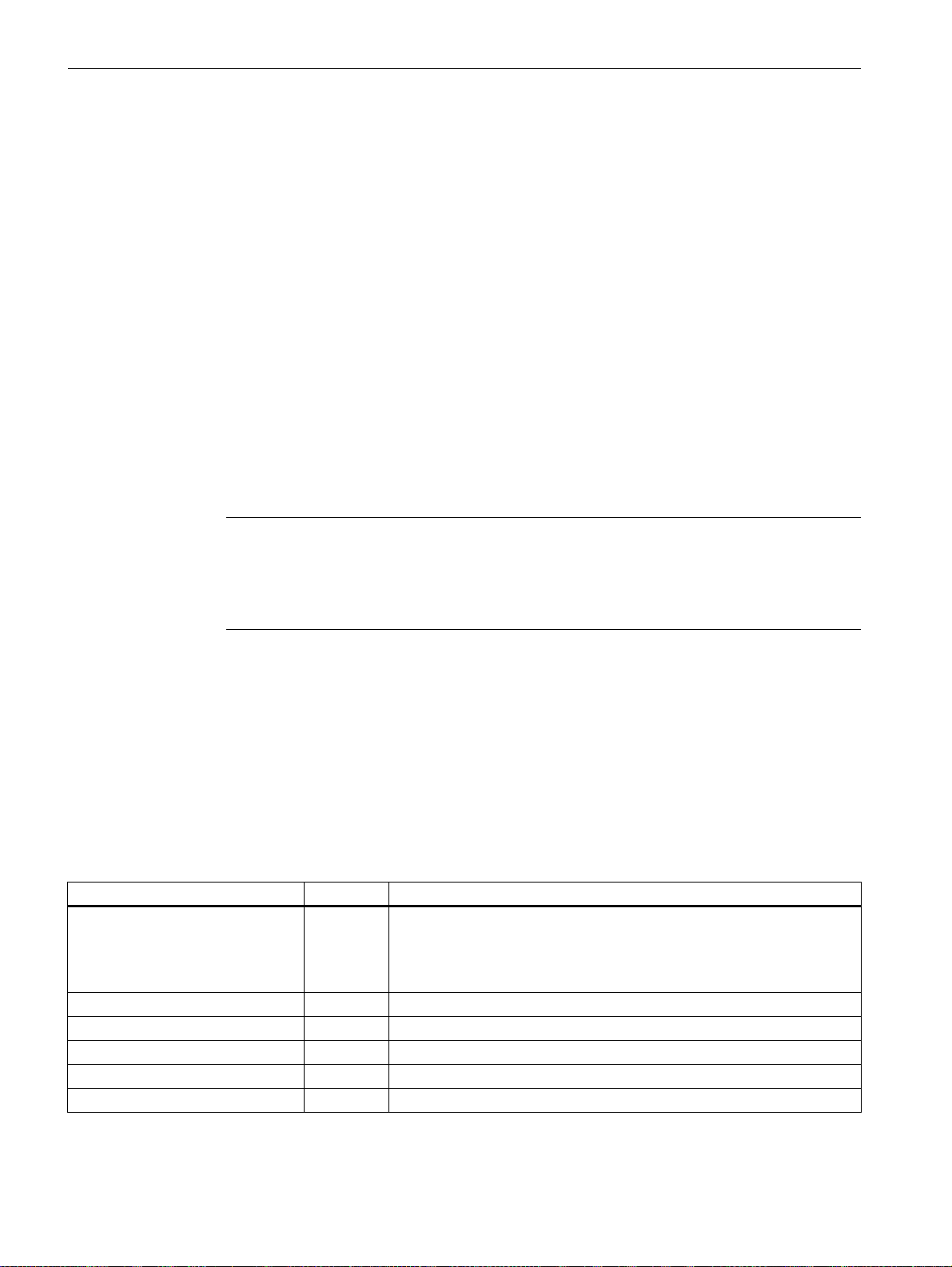

1.1 Structure of the parameter descriptions for SINAMICS

Basic structure of the parameter descriptions

The data in the following example has been chosen at random. The description of a

parameter includes as a maximum, the information listed below. Some of the information is

optional.

Example

The parameter list (see SINAMICS parameters (Page 19)) has the following structure:

--------------------------------------------- Start of the example --------------------------------------------------

----------------

1

Parameter

number

pxxxx[0…n]

Drive object

(function module)

Description: Text

Value: 0: Name and meaning of value 0

Recommendation: Text

Index: [0] = Name and meaning of bit 0

BICO: Full parameter name / abbreviated name

Can be changed

into: C1(x)

Data type:

Unsigned32

P group: Unit group: - Unit selection: p0100

Not for motor type:

FEM

Min. Max Factory setting

0.00 [Nm] 10.00. [Nm] 0.00 [Arms]

1: Name and meaning of value 1

2: Name and meaning of value 2

etc.

[1] = Name and meaning of bit 1

[2] = Name and meaning of bit 2

etc.

Calculated: - Access level: 2

Dynamic index: EDS,

p140

Scaling: p0200 Expert list: 1

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

7

Page 8

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Bit array: Bit signal name

[00] = Name and meaning of

bit 0

[01] = Name and meaning of

bit 1

[02] = Name and meaning of

bit 2

etc.

Dependency: Text

See also: pxxxx,rxxxx

See also: Fxxxxx, Axxxxx

Danger: Warning: Caution: Safety-related text with

Caution: Notice: Safety-related text

Note: Information which might be useful.

--------------------------------------------- End of the example ---------------------------------------------------

---------------

1 signal

Yes

Yes

Yes

0 signal

No

No

No

warning triangle

without warning triangle

FP

1.2 Meaning of the parameter descriptions

Parameter number

The parameter number consists of a leading "p" or "r", followed by the parameter number and

the index (optional).

Examples of the representation in the parameter list:

• p...

Adjustable parameter (read and write parameter)

• r...

Display parameters (read only)

• p0918

Adjustable parameter 918

• p0099[0...3]

Adjustable parameter 99, indices 0 to 3

• p1001[0...n]

Adjustable parameter 1001, indices 0 to n (n = configurable)

• r0944

Display parameter 944

Parameter description

8

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 9

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Other examples of the notation used in the documentation:

• p1070[1]

Adjustable parameter 1070, index 1

• p2098[1].3

Adjustable parameter 2098, index 1 bit 3

• r0945[2](3)

Display parameter 945, index 2 of drive object 3

• p0795.4

Adjustable parameter 795, bit 4

• r2129.0...15

Display parameter 2129 with bit array (maximum 16 bit)

The following applies to adjustable parameters:

The parameter value "when shipped" is specified under "Factory setting" with the relevant unit

in square parentheses. The value can be adjusted within the range defined by "Min" and

"Max".

The term "linked parameterization" is used in cases where changes to adjustable parameters

affect the settings of other parameters.

Linked parameterization is initiated, for example, as a result of the following actions and

parameters:

• Executing macros

p0015, p0700, p1000, p1500

• Setting a PROFIBUS telegram (BICO interconnections)

p0922

• Setting component lists

p0230, p0300, p0301, p0400

• Automatically calculating and preassigning

p0112, p0340, p0578, p3900

• Restore factory settings

p0970

The following applies to display parameters:

The fields "Min", "Max" and "Factory setting" are specified with a dash "-" and the relevant unit

in square parentheses.

Note

The parameter list can contain parameters that are not visible in the expert lists of the

respective commissioning software (e.g. parameters for trace functions)

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

9

Page 10

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

BICO: Full parameter name / abbreviated name

The following abbreviations can appear in front of the parameter name:

• BI: Binector Input Binector Input

This parameter selects the source of a digital signal.

• BO: Binector Output Binector Output

This parameter is available as a digital signal for interconnection with other parameters.

• CI: Connector Input Connector Input

This parameter selects the source of an "analog" signal.

• CO: Connector Output Connector Output

This parameter is available as an "analog" signal for interconnection with other

parameters.

• CO/BO: Connector/Binector Output Connector/Binector Output

This parameter is available as both an "analog" and a digital signal for interconnection with

other parameters.

Note

A Connector Input (CI) cannot be interconnected with just any Connector Output (CO,

signal source).

When interconnecting a connector input using the commissioning software, only the

signal sources that are actually possible are listed.

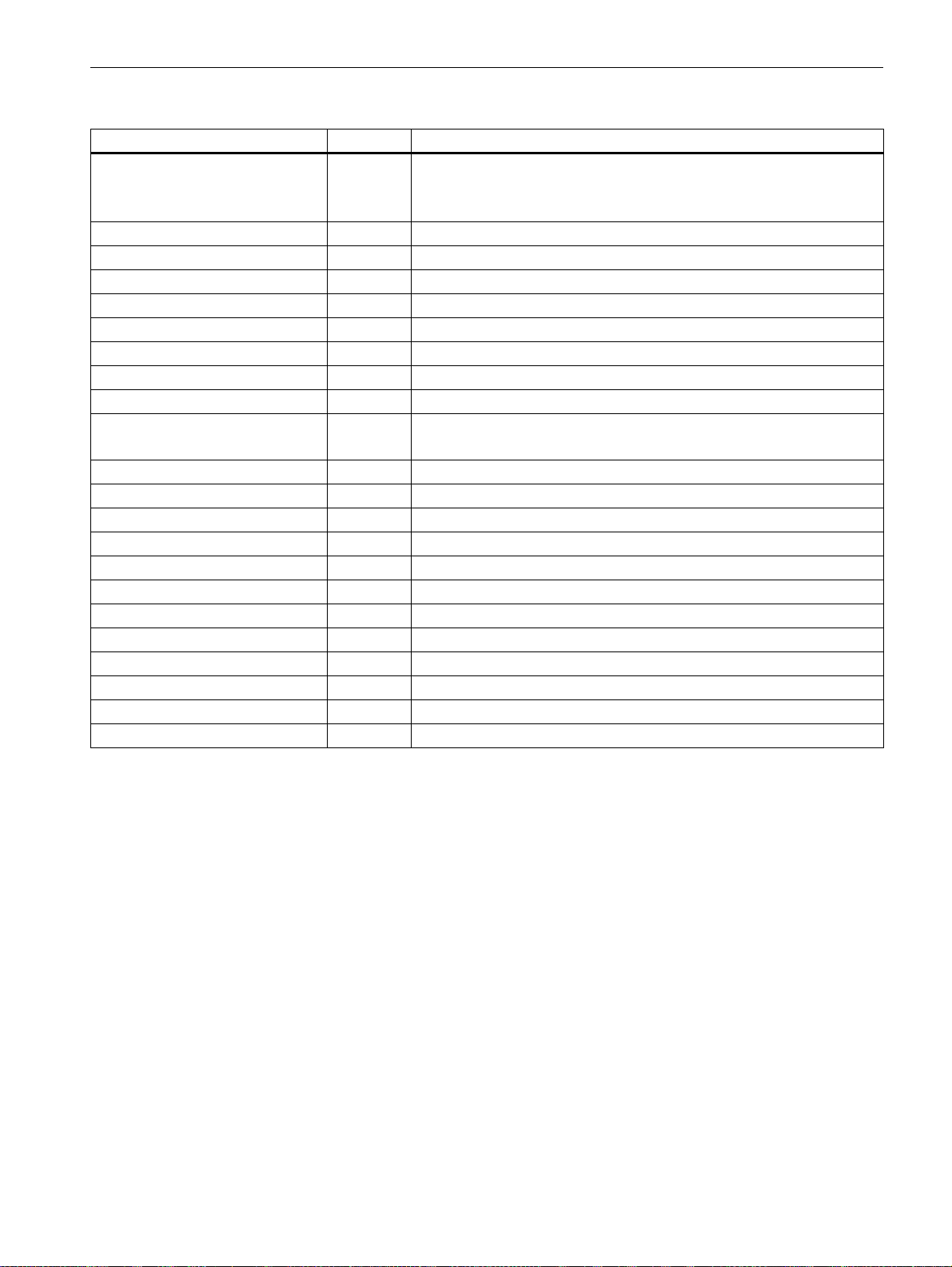

Drive object (function module)

A drive object (DO) is an independent, "self-contained" functional unit with its own

parameters, faults messages, and alarms.

For each parameter, it is specified in which drive object this parameter is located and for

which function module.

A parameter can belong to a single, multiple, or all drive objects.

The following information relating to "Drive object" and "Function module" can be displayed

under the parameter number:

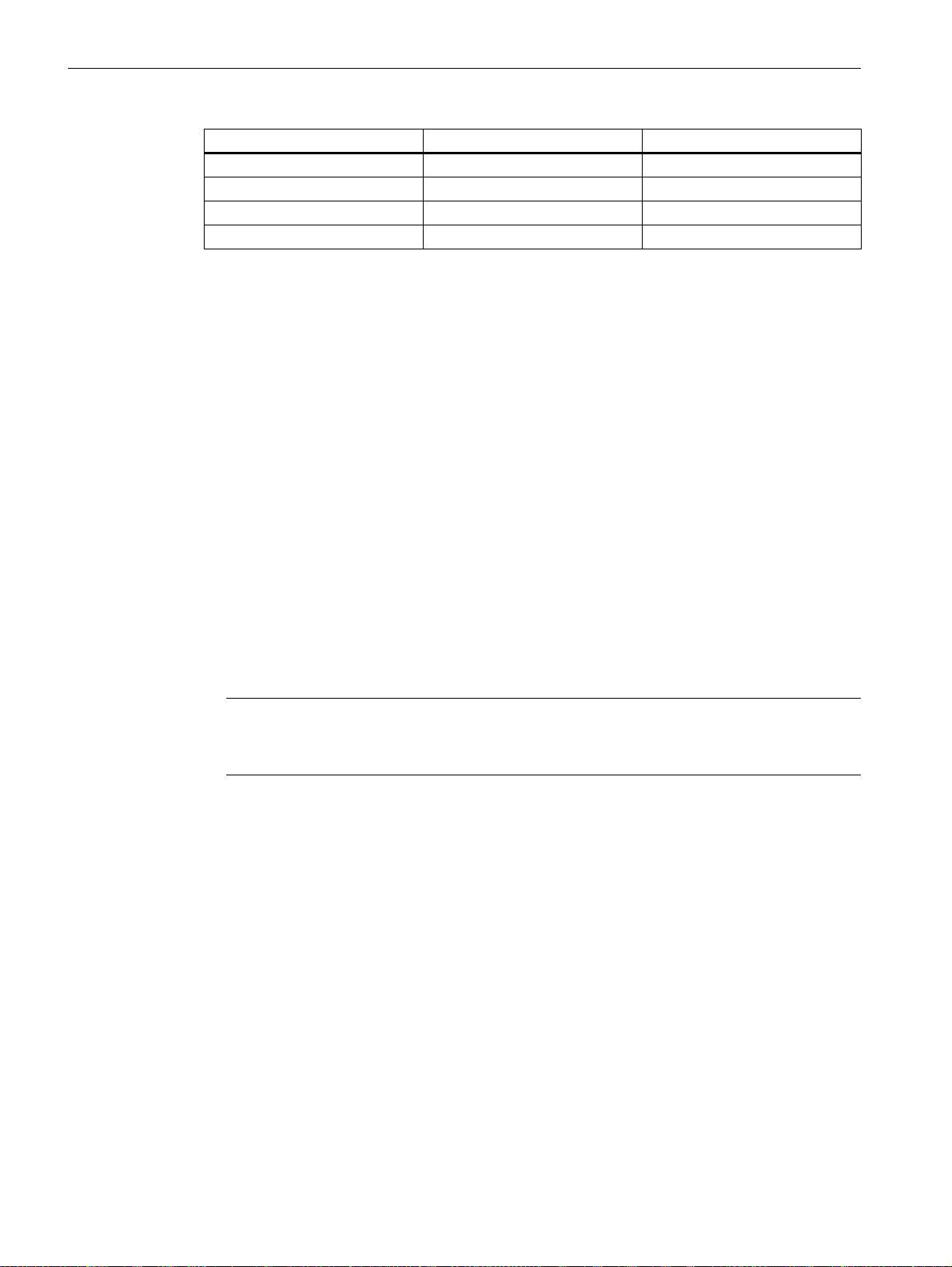

Drive object (function module) Type Meaning

A_INF_828 103 Active Infeed closed-loop control

Closed-loop controlled, self-commutated infeed/regenerative feedback

unit for generating

a constant DC-link voltage.

A_INF_828 (line transformer) Active Infeed closed-loop control with "line transformer" function module

A_INF_828 (Brk Mod Ext) Active Infeed closed-loop control with "Brk Mod Ext?" function module

A_INF_828 (Master/Slave) Active Infeed closed-loop control with "Master/Slave" function module

A_INF_828 (Parallel) Active Infeed closed-loop control with "Parallel?" function module

A_INF_828 (Recooling unit) Active Infeed closed-loop control with "Cooling unit" function module

10

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 11

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Drive object (function module) Type Meaning

B_INF_828 103 Basic Infeed closed loop control

Uncontrolled infeed unit (without energy recovery) to

rectify the line voltage for the DC link.

B_INF_828 (Brk Mod Ext) Basic Infeed closed-loop control with "Brk Mod Ext?" function module

B_INF_828 (Parallel) Basic Infeed closed-loop control with "Parallel?" function module

Basic Infeed closed-loop control with "Cooling unit" function module

CU_I_COMBI 102 Control Unit SINAMICS Integrated Combi

CU_I_828 103 Control Unit SINAMICS Integrated Booksize

CU_LINK 254 Object for Controller Extension 32 (CX32)

CU_NX_828 103

HUB 150 DMC20 DRIVE-CLiQ Hub Module

SERVO_COMBI 102 Servo drive

SERVO_COMBI (Safety rot) Servo drive with "Safety rot?" function module

SERVO_828 103 Servo drive

SERVO_828 (Safety rot) Servo drive with "Safety rot?" function module

SI_INF_COMBI 102

SI_INF_COMBI (Brk Mod Ext)

S_INF_828 (Parallel)

S_INF_828 103

S_INF_828 (Brk Mod Ext)

S_INF_828 (Recooling unit)

TM120 207 Terminal Module 120

TM54F_MA 205 Terminal Module 54F Master

TM54F_SL 206 Terminal Module 54F Slave

Can be changed

A "-" character indicates that the parameter can be changed in any object state and that the

change will become effective immediately.

The information "C1(x), C2(x), T, U" ((x): optional) means that the parameter can be changed

only in the specified drive object state and that the change will not take effect until the object

switches to another state. This can be one or more states.

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

11

Page 12

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

The following states may be specified:

• C1(x) Device commissioning C1: Commissioning 1

The device is being commissioned (p0009>0).

Pulses cannot be enabled.

The parameter can only be changed when the device commissioning

settings (p0009>0) are as follows:

• C1: Can be changed for all settings p0009>0.

• C1(x): Can only be changed when the settings are p0009 = x.

A modified parameter value does not take effect until the device

commissioning mode is exited with p0009 = 0.

• C2(x) Drive object commissioning C2: Commissioning 2

The drive is being commissioned (p0009=0 and p0010>0).

Pulses cannot be enabled.

The parameter can only be changed when the drive commissioning

settings (p0010>0) are as follows:

• C2: Can be changed for all settings p0010>0.

• C2(x): Can only be changed when p0010 = x.

A modified parameter value does not take effect until the device

commissioning mode is exited with p0010 = 0.

•U Run U: Run

Pulses are enabled.

• T Ready to run T: Ready to run

The pulses are not enabled and the status "C1(x)" or "C2(x)" is not active.

Calculated

Note

Parameter p0009 is CU specific (belongs to Control Unit).

Parameter p0010 is drive specific (belongs to each drive object).

The operating state of individual drive objects is displayed in r0002.

Specifies whether the parameter is influenced by automatic calculations.

The calculation attribute defines which activities influence the parameter.

The following attributes apply:

• CALC_MOD_ALL

– p0340 = 1

– Project download with commissioning software and send from p0340 = 3

• CALC_MOD_CON

– p0340 = 4

• CALC_MOD_EQU

– p0340 = 2

12

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 13

Access level

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

• CALC_MOD_LIM_REF

– p0340 = 1, 3, 5

– p0578 = 1

• CALC_MOD_REG

– p0340 = 1, 3

Note

For p3900 > 0, p0340 = 1 is also called automatically.

After p1910 = 1, p0340 = 3 is automatically called.

Specifies the access level required so that the parameter can be displayed and/or modified.

The required access level can be set via parameter p0003.

The system uses the following access levels:

Data types

1 = Standard

2 = Extended

3 = Expert

4 = Service

Please contact your local Siemens office for the password for parameters with access

level4 (Service).

Note

Parameter p0003 is CU-specific (available on the Control Unit).

The information on the data type can consist of the following two items (separated by a

slash):

• First item

Data type of the parameter

• Second item (for binector or connector input only)

Data type of the signal source to be interconnected (binector/connector output)

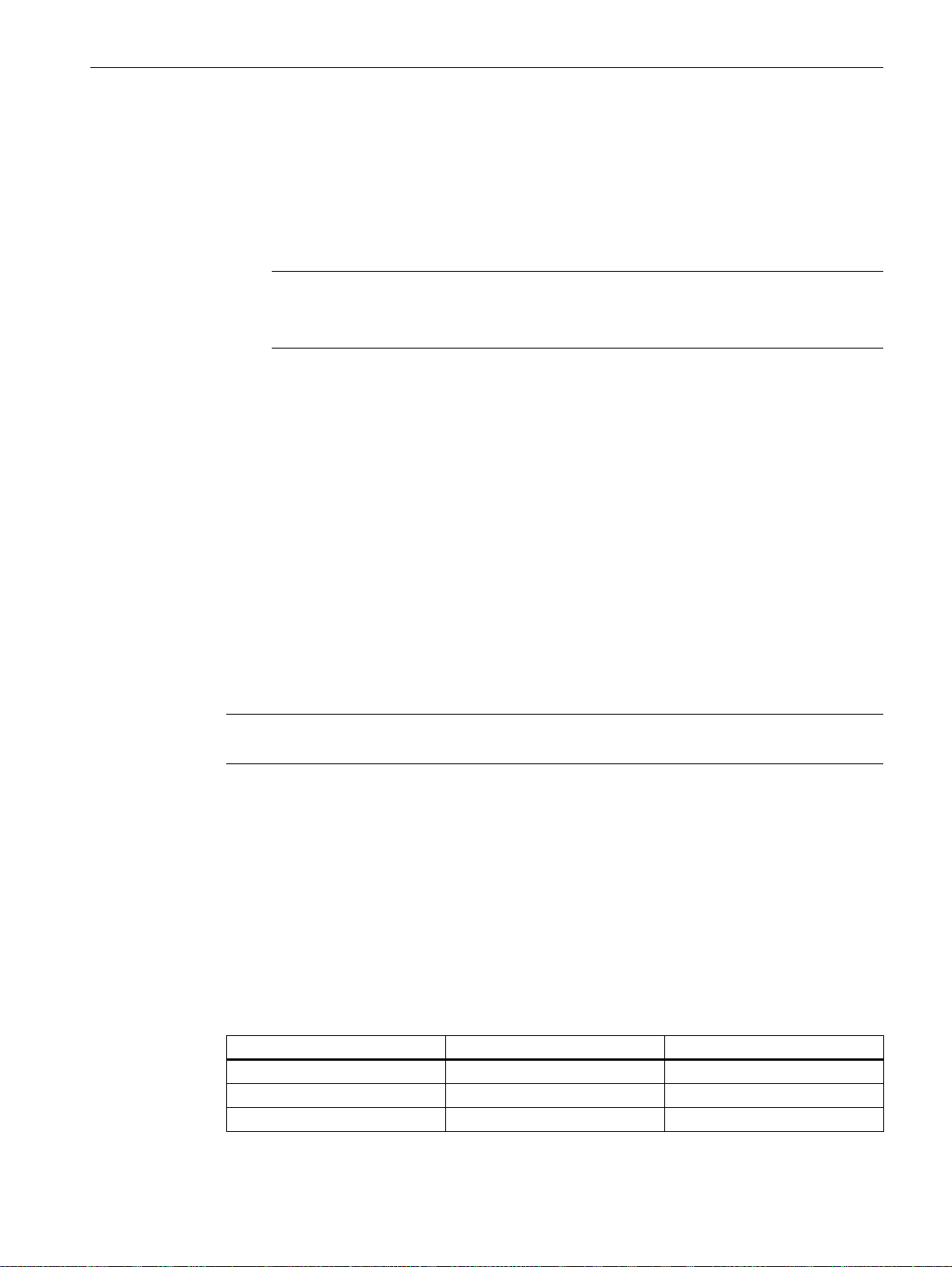

Parameters can have the following data types:

Data type (abbreviated name) Data type (full name) Meaning

I8 Integer8 8-bit integer number

I16 Integer16 16-bit integer number

I32 Integer32 32-bit integer number

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

13

Page 14

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Data type (abbreviated name) Data type (full name) Meaning

U8 Unsignet8 8 bits without sign

U16 Unsignet16 16 bits without sign

U32 Unsigned32 32 bits without sign

Float FloatingPoint32 32-bit floating point number

Dynamic index

For parameters with a dynamic index [0 to n], the following information is specified here:

• Data set (if this is available).

• Parameter for the number of indices (n = number - 1).

The following information can be contained in this field:

• "CDS, p0170" (Command Data Set, CDS count)

Example:

p1070[0] -> main setpoint [command data set 0]

p1070[1] -> main setpoint [command data set 1], etc.

• "DDS, p0180" (Drive Data Set, DDS count)

• "EDS, p0140" (Encoder Data Set, EDS count)

• "MDS, p0130" (Motor Data Set, MDS count)

• "PDS, p0120" (Power unit Data Set, PDS count)

• "p2615" (traversing blocks count)

Note

Information on the data sets can be taken from the following references:

/FH1/ SINAMICS S120 Function Manual Drive Functions Chapter "Data Sets"

P group (only when accessing via BOP (Basic Operator Panel))

Specifies the functional group to which the parameter belongs. The required parameter group

can be set via p0004.

Unit, unit group and unit selection

The standard unit of a parameter is specified in square parentheses after the values for "Min",

"Max", and "Factory setting".

14

For parameters where the unit can be changed, "Unit Group" and "Unit Selection" specify

which group this parameter belongs and which parameter can be used to change the unit.

Example:

Unit group: 7_1, Unit selection: p0505

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 15

The parameter belongs to Unit Group 7_1 and the unit can be changed using p0505.

Parameter values

• Min.

• Max

• Factory setting

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Note

Detailed information on changing units can be found in the following references:

/FH1/SINAMICS S120 Function Manual

/BA3/SINAMICS S150 Operating Instructions

Minimum value of the parameter [unit]

Maximum value of the parameter [unit]

Value when delivered [unit]

When commissioned for the first time, it is possible that another value is visible for certain

parameters (e.g.p1800).

Not for motor type

Specifies for which motor type this parameter has no significance

ASM: Asynchronous motor (induction motor)

FEM: Separately excited synchronous motor

PEM: Permanent-magnet synchronous motor

REL: Reluctance motor/SIEMOSYN motor

Scaling

Specification of the reference variable with which a signal value is automatically converted for

a BICO interconnection.

The following reference variables are possible:

• p2000 ... p2007: Reference speed, reference voltage, etc.

• TEMP: 100 °C = 100 %

Reason:

The setting of these parameters is determined by the operating environment of the Control

Unit (e.g.depending on the device type, macro, Power Module).

• PERCENT: 1.0 = 100 %

• 4000H: 4000 hex = 100 %

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

15

Page 16

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Expert list

Specifies whether this parameter is available in the expert list of the specified drive objects in

the commissioning software.

• 1: Parameter does exist in the expert list.

• 0: Parameter does not exist in the expert list.

NOTICE

Users assume full responsibility for using parameters marked "Expert list: 0" (parameter

does not exist in the expert list).

These parameters and their functionalities have not been tested and no further user

documentation is available for them (e.g. description of functions).

Further, for these parameters, support through "Technical Support" (hotline) is no longer

guaranteed.

Description

Explanation of the function of a parameter.

Values

Lists the possible values of a parameter.

Recommendation

Information about recommended settings.

Index

The name and meaning of each individual index are specified for indexed parameters.

The following applies to the values (Min, Max, Factory setting) of indexed adjustable

parameters:

• Min, Max:

• Factory setting:

The adjustment range and unit apply to all indices.

When all indices have the same factory setting, index 0 is specified with the unit to

represent all indices.

When the indices have different factory settings, they are all listed individually with the

unit.

16

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 17

Bit array

Dependency

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

For parameters with bit arrays, the following information is provided about each bit:

• Bit number and signal name

• Meaning with signal states 0 and 1

Conditions that must be fulfilled in conjunction with this parameter.

Also includes special effects that can occur between this parameter and others.

See also: List of other additional parameters to be considered.

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

17

Page 18

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

18

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 19

SINAMICS parameters

Product: 828D COMBI, Version: 4502400, Language: eng

Objects: A_INF_828, B_INF_828, CU_I_828, CU_I_COMBI, CU_LINK, CU_NX_828, HUB, S_INF_828, S_INF_COMBI, SERVO_828, SERVO_COMBI,

TM120, TM150, TM54F_MA, TM54F_SL

r0002 Infeed operating display / INF op_display

A_INF_828,

S_INF_828,

S_INF_COMBI

Description: Operating display for the infeed.

Value: 0: Operation - everything enabled

Dependency: Refer to: r0046

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

Note: OC: Operating condition

Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

21: Ready for operation - set "Operation enable" = "1" (p0852)

31: Rdy for sw on - pre-chrg running (p0857)

32: Ready for switching on - set "ON/OFF1" = "0/1" (p0840)

35: Switching on inhibited - carry out first commissioning (p0010)

41: Switching on inhibited - set "ON/OFF1" = "0" (p0840)

42: Switching on inhibited - set "OC/OFF2" = "1" (p0844, p0845)

44: Switching on inhibited - connect 24 V to terminal EP (hardware)

45: Switching on inhibited - remove fault cause, acknowledge fault

46: Switching on inhibited - exit comm mode (p0009, p0010)

60: Infeed de-activated/not operational

70: Initialization

200: Wait for booting/partial booting

250: Device signals a topology error

EP: Enable Pulses (pulse enable)

COMM: Commissioning

2

r0002 Infeed operating display / INF op_display

B_INF_828 Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

Description: Operating display for the infeed.

Value: 0: Operation - everything enabled

31: Rdy for sw on - pre-chrg running (p0857)

32: Ready for switching on - set "ON/OFF1" = "0/1" (p0840)

35: Switching on inhibited - carry out first commissioning (p0010)

41: Switching on inhibited - set "ON/OFF1" = "0" (p0840)

42: Switching on inhibited - set "OC/OFF2" = "1" (p0844, p0845)

44: Switching on inhibited - connect 24 V to terminal EP (hardware)

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

19

Page 20

SINAMICS parameters

45: Switching on inhibited - remove fault cause, acknowledge fault

46: Switching on inhibited - exit comm mode (p0009, p0010)

60: Infeed de-activated/not operational

70: Initialization

200: Wait for booting/partial booting

250: Device signals a topology error

Dependency: Refer to: r0046

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

Note: OC: Operating condition

COMM: Commissioning

r0002 Control Unit operating display / CU op_display

CU_I_828,

CU_I_COMBI,

CU_NX_828

Description: Operating display for the Control Unit (CU).

Value: 0: Operation

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 117 -

10: Ready

20: Wait for run-up

25: Wait for automatic FW update of DRIVE-CLiQ components

31: Commissioning software download active

33: Remove/acknowledge topology error

34: Exit commissioning mode

35: Carry out first commissioning

70: Initialization

80: Reset active

99: Internal software error

101: Specify topology

111: Insert drive object

112: Delete drive object

113: Change drive object number

114: Change component number

115: Run parameter download

117: Delete component

r0002 DRIVE-CLiQ Hub Module operating display / Hub op_display

HUB Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

Description: Operating display for the DRIVE-CLiQ Hub Module.

Value: 0: Module in cyclic operation

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

20

40: Module not in cyclic operation

50: Alarm

60: Fault

70: Initialization

120: Module de-activated

200: Wait for booting/partial booting

250: Device signals a topology error

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 21

SINAMICS parameters

r0002 Drive operating display / Drv op_display

SERVO_828,

SERVO_COMBI

Description: Operating display for the drive.

Value: 0: Operation - everything enabled

Dependency: Refer to: r0046

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

Note: OC: Operating condition

Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

10: Operation - set "enable setpoint" = "1" (p1142, p1152)

11: Operation - set "enable speed controller" = "1" (p0856)

12: Operation - RFG frozen, set "RFG start" = "1" (p1141)

13: Operation - set "enable RFG" = "1" (p1140)

14: Oper. - MotID, excit. running and/or brake opens, SS2, SOS

15: Operation - open brake (p1215)

16: Operation - withdraw braking with OFF1 using "ON/OFF1" = "1"

17: Operation - braking with OFF3 can only be interrupted with OFF2

18: Operation - brake on fault, remove fault, acknowledge

19: Operation - armature short-circ./DC brake act. (p1230, p1231)

21: Ready for operation - set "Operation enable" = "1" (p0852)

22: Ready for operation - de-magnetizing running (p0347)

23: Ready for operation - set "Infeed operation" = "1" (p0864)

31: Ready for switching on - set "ON/OFF1" = "0/1" (p0840)

35: Switching on inhibited - carry out first commissioning (p0010)

41: Switching on inhibited - set "ON/OFF1" = "0" (p0840)

42: Switching on inhibited - set "OC/OFF2" = "1" (p0844, p0845)

43: Switching on inhibited - set "OC/OFF3" = "1" (p0848, p0849)

44: Switching on inhibited - connect 24 V to terminal EP (hardware)

45: Switching on inhibited - rectify fault, acknowledge fault, STO

46: Switching on inhibited - exit comm mode (p0009, p0010)

60: Drive object de-activated/not operational

70: Initialization

200: Wait for booting/partial booting

250: Device signals a topology error

EP: Enable Pulses (pulse enable)

RFG: Ramp-function generator

COMM: Commissioning

MotID: Motor data identification

SS2: Safe Stop 2

SOS: Safe Operating Stop

STO: Safe Torque Off

r0002 TM120 operating display / TM120 op_display

TM120 Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

Description: Operating display for Terminal Module 120 (TM120)

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

21

Page 22

SINAMICS parameters

Value: 0: Module in cyclic operation

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

40: Module not in cyclic operation

50: Alarm

60: Fault

70: Initialization

120: Module de-activated

200: Wait for booting/partial booting

250: Device signals a topology error

r0002 TM150 operating display / TM150 op_display

TM150 Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

Description: Operating display for Terminal Module 150 (TM150)

Value: 0: Module in cyclic operation

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

40: Module not in cyclic operation

50: Alarm

60: Fault

70: Initialization

120: Module de-activated

200: Wait for booting/partial booting

250: Device signals a topology error

r0002 TM54F operating display / TM54F op_display

TM54F_MA,

TM54F_SL

Description: Operating display for Terminal Module 54F (TM54F).

Value: 0: Module in cyclic operation

Can be changed: - Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 250 -

40: Module not in cyclic operation

50: Alarm

60: Fault

70: Initialization

120: Module de-activated

200: Wait for booting/partial booting

250: Device signals a topology error

p0003 BOP access level / BOP acc_level

CU_I_828,

CU_I_COMBI,

CU_NX_828

Description: Sets the access level for reading and writing parameters via the Basic Operator Panel (BOP).

Can be changed: C1, U, T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 0

Min Max Factory setting

1 4 1

22

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 23

SINAMICS parameters

Value: 1: Standard

Note: Access level 1 (standard):

2: Extended

3: Expert

4: Service

Parameters for simplest possible operations.

Access level 2 (extended):

Parameters to operate the basic functions of the drive unit.

Access level 3 (experts):

Expert know-how is required for these parameters (e.g. BICO parameterization).

Access level 4 (service):

For these parameters, it is necessary that authorized service personnel enter the appropriate password (p3950).

p0005[0...1] BOP operating display selection / BOP op_disp sel

HUB, TM120,

TM150, TM54F_MA,

TM54F_SL

Description: Sets the parameter number and parameter index for display for p0006 = 2, 4 for the Basic Operator Panel (BOP).

Index: [0] = Parameter number

Dependency: Refer to: p0006

Note: Procedure:

Can be changed: U, T Calculated: - Access level: 2

Data type: Unsigned16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 65535 [0] 2

[1] 0

Examples for the SERVO drive object:

p0005[0] = 21, p0005[1] = 0: Actual speed smoothed (r0021)

p0005[0] = 25, p0005[1] = 0: Output voltage smoothed (r0025)

[1] = Parameter index

1.

The parameter number to be displayed should be set in index 0. Only the monitoring parameters (read-only parameters) can be set that actually exist for the actual drive object.

If the set parameter number is not indexed, or if there is an index in index 1 that lies outside the valid range of the set

parameter, then index 1 is automatically set to 0.

2.

The index that belongs to the parameter set in index 0 should be set in index 1. The permissible changes in index 1

always depend on the parameter number set in index 0.

p0006 BOP operating display mode / BOP op_ disp mode

HUB, TM120,

TM150, TM54F_MA,

TM54F_SL

Description: Sets the mode of the operating display for the Basic Operator Panel (BOP) in the operating states "ready for operation"

Value: 4: p0005

Dependency: Refer to: p0005

Note: Mode 0 ... 3 can only be selected if also r0020, r0021 are available on the drive object.

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Can be changed: U, T Calculated: - Access level: 3

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

4 4 4

and "operation".

Mode 4 is available for all drive objects.

23

Page 24

SINAMICS parameters

p0009 Device commissioning parameter filter / Dev comm par_filt

CU_I_828,

CU_I_COMBI,

CU_NX_828

Description: Sets the device and basic drive commissioning.

Value: 0: Ready

Notice: For p0009 = 10000 the following applies:

Note: The drives can only be powered up outside the device commissioning (the inverter enabled). In this case, p0009 must

Can be changed: C1, T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 10000 1

By appropriately setting this parameter, those parameters are filtered that can be written into in the various commissioning steps.

1: Device configuration

2: Defining the drive type/function module

3: Drive base configuration

4: Data set base configuration

29: Device download

30: Parameter reset

50: OA application configuration

55: OA application installation

101: Topology input

111: Insert drive object

112: Delete drive object

113: Change drive object number

114: Change component number

115: Parameter download

117: Delete component

10000: Ready (asynchron)

After the value has been modified, no further parameter modifications can be made and the status is shown in r3996.

Modifications can be made again when r3996 = 0.

be 0 (Ready) and the individual drive objects must have already gone into operation (p0010).

p0009 = 1: Device configuration

At the first commissioning of the device, after booting, the device is in the "device configuration" state. To start the

internal automatic first commissioning of the drive unit, p0009 should be set to 0 (Ready) after the ID for the actual

topology (r0098) was transferred into the ID for the target topology (p0099). To do this, it is sufficient to set a single

index value of p0099[x] the same as r0098[x]. Before the device has been completely commissioned, no other parameter can be changed. After the first commissioning was carried out, in this state, when required, other basic device configuration parameters can be adapted (e.g. the basic sampling time in p0110).

p0009 = 2: Defines the drive type / function module

In this state, the drive object types and/or the function modules can be changed or selected for the individual drive

objects. To do this, the drive object type can be set using p0107[0...15] and the function can be set using p0108[0...15]

(refer to p0101[0...15]).

p0009 = 3: Drive basic configuration

In this state, after the device has been commissioned for the first time, basic changes can be made for the individual

drive objects (e.g. sampling times in p0111, p0112, p0115 and the number of data sets in p0120, p0130, p0140,

p0170, p0180).

p0009 = 4: Data set basic configuration

In this state, after the device has been commissioned for the first time, for the individual drive objects changes can be

made regarding the assignment of the components (p0121, p0131, p0141, p0151, p0161) to the individual data sets

and the assignment of the power unit, motor and encoder to the drive data sets (p0185, ...).

p0009 = 29: Device download

If a download is made using the commissioning software, the device is automatically brought into this state. After the

download has been completed, p0009 is automatically set to 0 (ready). It is not possible to manually set p0009 to this

value.

24

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 25

SINAMICS parameters

p0009 = 30: Parameter reset

In order to bring the complete unit into the "first commissioning" state or to load the parameters saved using p0977, to

start, p0009 must be set to this value. p0976 can then be changed to the required value.

p0009 = 50: OA application configuration

In this state, after the device has been commissioned for the first time, changes can be made for the individual drive

objects regarding the activity (p4956) of the OA applications.

p0009 = 55: OA application installation

OA applications can be installed and/or uninstalled in this state.

p0009 = 101: Topology input

In this state, the DRIVE-CLiQ target topology can be entered using p9902 and p9903.

p0009 = 111: Insert drive object

This state allows a new drive object to be inserted using p9911.

p0009 = 112: Delete drive object

This state allows existing drive objects to be deleted using p9912 after the device has been commissioned for the first

time.

p0009 = 113: Change drive object number

This state allows the drive object number of existing drive objects to be changed using p9913 after the device has been

commissioned for the first time.

p0009 = 114: Change component number

This state allows the component number of existing components to be changed using p9914 after the device has been

commissioned for the first time.

p0009 = 115: Parameter download

This state allows the complete device and drive commissioning using the parameter services.

p0009 = 117: Delete component

This state allows components to be deleted using p9917 after the device has been commissioned for the first time.

p0010 Infeed commissioning parameter filter / INF comm par_filt

A_INF_828,

B_INF_828,

S_INF_828,

S_INF_COMBI

Description: Sets the parameter filter to commission an infeed unit.

Value: 0: Ready

Note: The drive can only be powered up outside the drive commissioning (inverter enable). To realize this, this parameter

Can be changed: C2(1), T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 30 1

Setting this parameter filters out the parameters that can be written into in the various commissioning steps.

1: Quick commissioning

2: Power unit commissioning

5: Technological application/units

29: Only Siemens int

30: Parameter reset

must be set to 0.

For p3900 not equal to 0, at the end of the quick commissioning, this parameter is automatically reset to 0.

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1.

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

25

Page 26

SINAMICS parameters

p0010 Drive commissioning parameter filter / Drv comm. par_filt

SERVO_828,

SERVO_COMBI

Description: Sets the parameter filter to commission a drive.

Value: 0: Ready

Notice: For p0010 = 10000 the following applies:

Note: The drive can only be powered up outside the drive commissioning (inverter enable). To realize this, this parameter

Can be changed: C2(1), T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: 2800, 2846

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 10000 1

Setting this parameter filters out the parameters that can be written into in the various commissioning steps.

1: Quick commissioning

2: Power unit commissioning

3: Motor commissioning

4: Encoder commissioning

5: Technological application/units

15: Data sets

17: Basic positioner commissioning

25: Position control commissioning

29: Only Siemens int

30: Parameter reset

95: Safety Integrated commissioning

10000: Ready with immediate feedback signal

After the value has been modified, no further parameter modifications can be made and the status is shown in r3996.

Modifications can be made again when r3996 = 0.

must be set to 0.

By setting p3900 to a value other than 0, the quick commissioning is completed, and this parameter is automatically

reset to 0.

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1.

p0010 = 10000 corresponds to p0010 = 0. Unlike with p0010 = 0, the parameter modification is applied immediately

and the calculations are made in the background. Further parameter modifications cannot be made while the calculations are being performed.

p0010 TM120 commissioning parameter filter / TM120 com par_filt

TM120 Can be changed: C2(1), T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 30 0

Description: Sets the parameter filter for commissioning a Terminal Module 120 (TM120).

Setting this parameter filters out the parameters that can be written into in the various commissioning steps.

For the BOP, this setting also causes the read access operations to be filtered.

Value: 0: Ready

29: Only Siemens int

30: Parameter reset

Dependency: Refer to: p0970

Note: Only the following values are possible: p0010 = 0, 30

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1.

Parameter description

26

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 27

SINAMICS parameters

p0010 TM150 commissioning parameter filter / TM150 com par_filt

TM150 Can be changed: C2(1), T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 30 0

Description: Sets the parameter filter for commissioning a Terminal Module 150 (TM150).

Setting this parameter filters out the parameters that can be written into in the various commissioning steps.

For the BOP, this setting also causes the read access operations to be filtered.

Value: 0: Ready

29: Only Siemens int

30: Parameter reset

Dependency: Refer to: p0970

Note: Only the following values are possible: p0010 = 0, 30

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1.

p0010 TM54F commissioning parameter filter / TM54F com par_filt

TM54F_MA Can be changed: C2(1), T Calculated: - Access level: 1

Data type: Integer16 Dynamic index: - Func. diagram: 2847

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 95 0

Description: Sets the parameter filter for commissioning a Terminal Module 54F (TM54F).

Setting this parameter filters out the parameters that can be written into in the various commissioning steps.

For the BOP, this setting also causes the read access operations to be filtered.

Value: 0: Ready

29: Only Siemens int

30: Parameter reset

95: Safety Integrated commissioning

Dependency: Refer to: p0970

Note: Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1.

p0013[0...49] BOP user-defined list / BOP list

HUB, TM120,

TM150, TM54F_MA,

TM54F_SL

Description: Sets the required parameters to read and write via the Basic Operator Panel (BOP).

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Can be changed: U, T Calculated: - Access level: 3

Data type: Unsigned16 Dynamic index: - Func. diagram: -

P-Group: Functions Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 65535 0

Activation:

1. p0003 = 3 (expert).

2. p0013[0...49] = requested parameter number

3. If required, enter p0011 = password in order to prevent non-authorized de-activation.

4. p0016 = 1 --> activates the selected user-defined list.

De-activation/change:

1. p0003 = 3 (expert).

2. If required, p0012 = p0011, in order to be authorized to change or de-activate the list.

27

Page 28

SINAMICS parameters

3. If required p0013[0...49] = required parameter number.

4. p0016 = 1 --> activates the modified user-defined list.

5. p0003 = 0 --> de-activates the user-defined list.

Dependency: Refer to: p0009, p0976

Note: The following parameters can be read and written on the Control Unit drive object:

- p0003 (access stage)

- p0009 (device commissioning, parameter filter)

- p0012 (BOP password acknowledgement (p0013))

The following applies for the user-defined list:

- password protection is only available on the drive object Control Unit and is valid for all of the drive objects.

- p0013 cannot be included in the user-defined list for all drive objects.

- p0003, p0009, p0011, p0012, p0976 cannot, for the drive object Control Unit, be included in the user-defined list.

- the user-defined list can be cleared and de-activated "restore factory setting".

A value of 0 means: Entry is empty.

p0015 Macro drive object / Macro DO

A_INF_828,

B_INF_828,

S_INF_828,

S_INF_COMBI,

SERVO_828,

SERVO_COMBI,

TM120, TM150

Can be changed: C2(1) Calculated: - Access level: 1

Data type: Unsigned32 Dynamic index: - Func. diagram: -

P-Group: Commands Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 999999 0

Description: Runs the corresponding macro files.

The selected macro file must be available on the memory card/device memory.

Example:

p0015 = 6 --> the macro file PM000006.ACX is run.

Dependency: Refer to: p0700, p1000, p1500, r8570

Caution: When executing a specific macro, the corresponding programmed settings are made and become active.

Notice: After the value has been modified, no further parameter modifications can be made and the status is shown in r3996.

Modifications can be made again when r3996 = 0.

No errors were issued during quick commissioning (p3900 = 1) when writing to parameters of the QUICK_IBN group!

Note: The macros in the specified directory are displayed in r8570. r8570 is not in the expert list of the commissioning soft-

ware.

Macros available as standard are described in the technical documentation of the particular product.

The parameter is not influenced by setting the factory setting.

p0015 Macro drive unit / Macro drv unit

CU_I_828,

CU_I_COMBI,

CU_NX_828

Description: Runs the corresponding macro files.

Dependency: Refer to: p0700, p1000, p1500, r8570

Caution: When executing a specific macro, the corresponding programmed settings are made and become active.

Can be changed: C1 Calculated: - Access level: 1

Data type: Unsigned32 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 999999 0

The selected macro file must be available on the memory card/device memory.

Example:

p0015 = 6 --> the macro file PM000006.ACX is run.

28

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 29

SINAMICS parameters

Notice: After the value has been modified, no further parameter modifications can be made and the status is shown in r3996.

Note: The macros in the specified directory are displayed in r8570. r8570 is not in the expert list of the commissioning soft-

Modifications can be made again when r3996 = 0.

ware.

Macros available as standard are described in the technical documentation of the particular product.

The parameter is not influenced by setting the factory setting.

r0018 Control Unit firmware version / CU FW version

CU_I_828,

CU_I_COMBI,

CU_NX_828

Description: Displays the firmware version of the Control Unit.

Dependency: Refer to: r0128, r0148, r0158, r0197, r0198

Note: Example:

Can be changed: - Calculated: - Access level: 1

Data type: Unsigned32 Dynamic index: - Func. diagram: -

P-Group: - Units group: - Unit selection: -

Not for motor type: - Scaling: - Expert list: 1

Min Max Factory setting

0 4294967295 -

The value 1010100 should be interpreted as V01.01.01.00.

r0020 Speed setpoint smoothed / n_set smth

SERVO_828,

SERVO_COMBI

Description: Displays the currently smoothed speed setpoint at the input of the speed controller or U/f characteristic (after the inter-

Dependency: Refer to: r0060

Note: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5020, 6799

P-Group: Displays, signals Units group: 3_1 Unit selection: p0505

Not for motor type: - Scaling: p2000 Expert list: 1

Min Max Factory setting

- [rpm] - [rpm] - [rpm]

polator).

The signal is not suitable as a process quantity and may only be used as a display quantity.

The speed setpoint is available smoothed (r0020) and unsmoothed (r0060).

r0021 CO: Actual speed smoothed / n_act smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed actual value of the motor speed.

Dependency: Refer to: r0022, r0063

Note: Smoothing time constant = 100 ms

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 1580, 1680,

P-Group: Displays, signals Units group: 3_1 Unit selection: p0505

Not for motor type: - Scaling: p2000 Expert list: 1

Min Max Factory setting

- [rpm] - [rpm] - [rpm]

The signal is not suitable as a process quantity and may only be used as a display quantity.

The speed actual value is available smoothed (r0021, r0022) and unsmoothed (r0063).

4710, 6799

29

Page 30

SINAMICS parameters

r0022 Speed actual value rpm smoothed / n_act rpm smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed actual value of the motor speed.

Dependency: Refer to: r0021, r0063

Note: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 1580, 1680,

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2000 Expert list: 1

Min Max Factory setting

- [rpm] - [rpm] - [rpm]

r0022 is identical to r0021, however, it always has units of rpm and contrary to r0021 cannot be changed over.

The signal is not suitable as a process quantity and may only be used as a display quantity.

The speed actual value is available smoothed (r0021, r0022) and unsmoothed (r0063).

r0024 CO: Line supply frequency smoothed / f_line smooth

A_INF_828,

S_INF_828,

S_INF_COMBI

Description: Displays the smoothed line supply frequency.

Dependency: Refer to: r0066

Note: Smoothing time constant = 300 ms

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8850, 8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2000 Expert list: 1

Min Max Factory setting

- [Hz] - [Hz] - [Hz]

The signal is not suitable as a process quantity and may only be used as a display quantity.

The line frequency is available smoothed (r0024) and unsmoothed (r0066).

A positive sign of the frequency is obtained when the line supply phases U, V and W are connected with the correct

phase sequence.

A negative sign of the frequency is obtained when the 3 line phases are interchanged therefore designating a negative

direction of the rotating field of the 3-phase line supply voltage.

4710, 6799

r0024 Output frequency smoothed / f_outp smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed converter frequency.

Dependency: Refer to: r0066

Note: Smoothing time constant = 100 ms

30

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 1690, 5300,

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2000 Expert list: 1

Min Max Factory setting

- [Hz] - [Hz] - [Hz]

The signal is not suitable as a process quantity and may only be used as a display quantity.

The output frequency is available smoothed (r0024) and unsmoothed (r0066).

5730, 6799

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 31

r0025[0...3] CO: Input voltage smoothed / U_inp smooth

A_INF_828,

S_INF_828,

S_INF_COMBI

Description: Displays the smoothed actual value of the input voltage.

Index: [0] = Voltage at input terminals of power unit from line supply model

Dependency: Refer to: r0072

Note: Smoothing time constant = 300 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8850, 8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2001 Expert list: 1

Min Max Factory setting

- [Vrms] - [Vrms] - [Vrms]

[1] = Voltage at VSM or at input terminals of the line filter

[2] = Voltage of the voltage source from the line supply model

[3] = Smoothed voltage of voltage source from line supply model

The signals are not suitable as process quantity and may only be used as display quantities.

The input voltages are available smoothed (r0025) and unsmoothed (r0072).

Re r0025[0]:

Pulsed voltage at the line supply input terminals of the power unit. The value is calculated from the modulation depth

r0074 and is therefore only correct in the closed-loop controlled mode and when the pulses are enabled.

Re r0025[1]:

Absolute voltage at the input terminals of the line filter or the connection point of a VSM. The value is calculated from

the VSM measured values r3661 and r3662 and is therefore equal to 0 if a VSM is not connected.

Re r0025[2]:

Estimated value for the voltage of the voltage source that is calculated in the voltage model of the line supply PLL.

Re r0025[3]:

Smoothed display value of the filtered source voltage from r0072[3].

SINAMICS parameters

r0025 CO: Output voltage smoothed / U_outp smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed output voltage of the power unit.

Dependency: Refer to: r0072

Note: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 1690, 5730,

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2001 Expert list: 1

Min Max Factory setting

- [Vrms] - [Vrms] - [Vrms]

The signal is not suitable as a process quantity and may only be used as a display quantity.

The output voltage is available smoothed (r0025) and unsmoothed (r0072).

r0026 CO: DC link voltage smoothed / Vdc smooth

A_INF_828,

B_INF_828,

S_INF_828,

S_INF_COMBI

Description: Displays the smoothed actual value of the DC link voltage.

Dependency: Refer to: r0070

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799,

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2001 Expert list: 1

Min Max Factory setting

- [V] - [V] - [V]

6799

8750, 8850, 8950

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

31

Page 32

SINAMICS parameters

Notice: This smoothed signal is not suitable for diagnostics or evaluation of dynamic operations. In this case, the unsmoothed

Note: A_INF, B_INF, S_INF: smoothing time constant = 300 ms

value should be used.

The signal is not suitable as a process quantity and may only be used as a display quantity.

The DC link voltage is available smoothed (r0026) and unsmoothed (r0070).

r0026 CO: DC link voltage smoothed / Vdc smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed actual value of the DC link voltage.

Dependency: Refer to: r0070

Notice: For SINAMICS S120 AC Drive (AC/AC) the following applies:

Note: SERVO, VECTOR: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 8750,

8850, 8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2001 Expert list: 1

Min Max Factory setting

- [V] - [V] - [V]

When measuring a DC link voltage < 200 V, for the Power Module (e.g. PM340) a valid measured value is not supplied. In this case, when an external 24 V power supply is connected, a value of approx. 24 V is displayed in the display

parameter.

The signal is not suitable as a process quantity and may only be used as a display quantity.

The DC link voltage is available smoothed (r0026) and unsmoothed (r0070).

r0027 CO: Absolute actual current smoothed / I_act abs val smth

A_INF_828,

S_INF_828,

S_INF_COMBI,

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed absolute actual current value.

Dependency: Refer to: r0068

Notice: This smoothed signal is not suitable for diagnostics or evaluation of dynamic operations. In this case, the unsmoothed

Note: A_INF, S_INF, VECTOR: Smoothing time constant = 300 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799,

8850, 8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [Arms] - [Arms] - [Arms]

value should be used.

SERVO: Smoothing time constant = 100 ms

The signal is not suitable as a process quantity and may only be used as a display quantity.

The absolute current actual value is available smoothed (r0027) and unsmoothed (r0068).

r0027 CO: Absolute actual current smoothed / I_act abs val smth

B_INF_828 Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8750

P-Group: Displays, signals Units group: 6_4 Unit selection: p0505

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [A] - [A] - [A]

Description: Displays the smoothed absolute actual current value.

Dependency: Refer to: r0068

Parameter description

32

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 33

SINAMICS parameters

Notice: This smoothed signal is not suitable for diagnostics or evaluation of dynamic operations. In this case, the unsmoothed

Note: Smoothing time constant = 300 ms

value should be used.

For Basic Line Modules of chassis format, the displayed value is invalid as these units do not have any current sensing.

The signal is not suitable as a process quantity and may only be used as a display quantity.

The absolute current actual value is available smoothed (r0027) and unsmoothed (r0068).

r0028 Modulation depth smoothed / Mod_depth smth

A_INF_828,

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed actual value of the modulation depth.

Dependency: Refer to: r0074

Note: A_INF: Smoothing time constant = 300 ms

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799,

8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [%] - [%] - [%]

SERVO, VECTOR: Smoothing time constant = 100 ms

The signal is not suitable as a process quantity and may only be used as a display quantity.

The modulation depth is available smoothed (r0028) and unsmoothed (r0074).

r0029 Reactive current actual value smoothed / I_react smooth

A_INF_828,

S_INF_828,

S_INF_COMBI

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8850, 8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [Arms] - [Arms] - [Arms]

Description: Displays the smoothed actual value of the reactive current component.

Note: Smoothing time constant = 300 ms

The signal is not suitable as a process quantity and may only be used as a display quantity.

The reactive current actual value is available smoothed (r0029) and unsmoothed (r0076).

r0029 Current actual value field-generating smoothed / Id_act smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed field-generating actual current.

Dependency: Refer to: r0076

Note: SERVO: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [Arms] - [Arms] - [Arms]

VECTOR: Smoothing time constant = 300 ms

The signal is not suitable as a process quantity and may only be used as a display quantity.

The field-generating current actual value is available smoothed (r0029) and unsmoothed (r0076).

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

33

Page 34

SINAMICS parameters

r0030 Active current actual value smoothed / I_active smooth

A_INF_828,

S_INF_828,

S_INF_COMBI

Description: Displays the smoothed actual value of the active current components.

Dependency: Refer to: r0078

Note: Smoothing time constant = 300 ms

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8850, 8950

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [Arms] - [Arms] - [Arms]

The signal is not suitable as a process quantity and may only be used as a display quantity.

The active current actual value is available smoothed (r0030) and unsmoothed (r0078).

r0030 Current actual value torque-generating smoothed / Iq_act smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed torque-generating actual current.

Dependency: Refer to: r0078

Note: SERVO: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: p2002 Expert list: 1

Min Max Factory setting

- [Arms] - [Arms] - [Arms]

VECTOR: Smoothing time constant = 300 ms

The signal is not suitable as a process quantity and may only be used as a display quantity.

The following applies for SERVO:

The torque-generating current actual value is available smoothed (r0030 with 100 ms, r0078[1] with p0045) and

unsmoothed (r0078[0]).

The following applies for VECTOR:

The torque-generating current actual value is available smoothed (r0030 with 300 ms) and unsmoothed (r0078).

r0031 Actual torque smoothed / M_act smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed torque actual value.

Dependency: Refer to: r0080

Note: Smoothing time constant = 100 ms

34

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799

P-Group: Displays, signals Units group: 7_1 Unit selection: p0505

Not for motor type: - Scaling: p2003 Expert list: 1

Min Max Factory setting

- [Nm] - [Nm] - [Nm]

The signal is not suitable as a process quantity and may only be used as a display quantity.

The active current actual value is available smoothed (r0031) and unsmoothed (r0080).

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

Page 35

SINAMICS parameters

r0032 CO: Active power actual value smoothed / P_actv_act smth

A_INF_828,

S_INF_828,

S_INF_COMBI,

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed actual value of the active power.

Dependency: Refer to: r0082

Notice: This smoothed signal is not suitable for diagnostics or evaluation of dynamic operations. In this case, the unsmoothed

Note: Significance for the drive: Power output at the motor shaft

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799,

8750, 8850, 8950

P-Group: Displays, signals Units group: 14_10 Unit selection: p0505

Not for motor type: - Scaling: r2004 Expert list: 1

Min Max Factory setting

- [kW] - [kW] - [kW]

value should be used.

Significance for the infeed: Line power drawn

For A_INF, B_INF and S_INF the following applies:

The active power is available smoothed (r0032 with 300 ms) and unsmoothed (r0082).

The following applies for SERVO:

The active power is available smoothed (r0032 with 100 ms, r0082[1] with p0045) and unsmoothed (r0082[0]).

For VECTOR and VECTORMV, the following applies:

The active power is available smoothed (r0032 with 100 ms) and unsmoothed (r0082).

r0032 CO: Active power actual value smoothed / P_actv_act smth

B_INF_828 Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 5730, 6799,

8750, 8850, 8950

P-Group: Displays, signals Units group: 14_10 Unit selection: p0505

Not for motor type: - Scaling: r2004 Expert list: 1

Min Max Factory setting

- [kW] - [kW] - [kW]

Description: Displays the smoothed actual value of the active power.

Dependency: Refer to: r0082

Notice: This smoothed signal is not suitable for diagnostics or evaluation of dynamic operations. In this case, the unsmoothed

value should be used.

For Basic Line Modules of chassis format, the displayed value is invalid as these units do not have any current sensing.

Note: Significance for the drive: Power output at the motor shaft

Significance for the infeed: Line power drawn

For A_INF, B_INF and S_INF the following applies:

The active power is available smoothed (r0032 with 300 ms) and unsmoothed (r0082).

The following applies for SERVO:

The active power is available smoothed (r0032 with 100 ms, r0082[1] with p0045) and unsmoothed (r0082[0]).

For VECTOR and VECTORMV, the following applies:

The active power is available smoothed (r0032 with 100 ms) and unsmoothed (r0082).

Parameter description

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0

35

Page 36

SINAMICS parameters

r0033 Torque utilization smoothed / M_util smooth

SERVO_828,

SERVO_COMBI

Description: Displays the smoothed torque utilization as a percentage.

Note: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 3

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8012

P-Group: Displays, signals Units group: - Unit selection: -

Not for motor type: - Scaling: PERCENT Expert list: 1

Min Max Factory setting

- [%] - [%] - [%]

The torque utilization is obtained from the required smoothed torque in reference to the torque limit, scaled using

p2196.

The signal is not suitable as a process quantity and may only be used as a display quantity.

The torque utilization is available smoothed (r0033) and unsmoothed (r0081).

For M_set total (r0079) > M_max offset (p1532), the following applies:

- demanded torque = M_set total - M_max offset

- actual torque limit = M_max upper effective (r1538) - M_max offset

For M_set total (r0079) <= M_max offset (p1532), the following applies:

- demanded torque = M_max offset - M_set total

- actual torque limit = M_max offset - M_max lower effective (r1539)

For the actual torque limit = 0, the following applies: r0033 = 100 %

For the actual torque limit < 0, the following applies: r0033 = 0 %

r0034 CO: Motor utilization / Motor utilization

SERVO_828,

SERVO_COMBI

Description: Displays the motor utilization from motor temperature model 1 (I2t) or 3.

Dependency: The motor utilization is only determined for permanent-magnet synchronous motors when the motor temperature

Notice: After the drive is switched on, the system starts to determine the motor temperature with an assumed model value.

Note: Smoothing time constant = 100 ms

Can be changed: - Calculated: - Access level: 2

Data type: FloatingPoint32 Dynamic index: - Func. diagram: 8017