Page 1

Diagnostics Guide 12/2004 Edition

sinumerik

SINUMERIK 802D sl

Turning, Milling

Page 2

Page 3

SINUMERIK 802D sl

Diagnostics Guide Turning, Milling

Alarms

Glossary /

Abbreviations

Appendix

Sinamics Alarms

1

2

3

Valid for

Control Software version

SINUMERIK 802D sl as of version 1

12/2004 Edition

Page 4

SINUMERIK® Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is indicated by the code in the "Remarks" column.

Status code in the "Remarks" column:

A .... New documentation

B .... Unrevised reprint with new Order No.

C .... Revised edition with new status.

If factual changes have been made on the page since the last edition, this is indicated by a new

edition coding in the header on that page.

Edition Order No. Remarks

12.04 6FC5398-2CP10-0BA0

A

Checked Siemens quality for Software and Training

according to DIN ISO 9001, Reg. No. 2160-01

This document was created using WinWord V 8

and Designer V 6.0.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for damages.

All rights, including rights created by patent grant or registration or a utility model or

design, are reserved.

© Siemens AG, 2004. All rights reserved

Order No. 6FC5398-2CP10-0BA0

Printed in Germany

Other functions not described in this documentation might be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

We have checked the contents of this manual for agreement with the hardware

and software described. Since deviations cannot be precluded entirely, we cannot

guarantee full agreement. However, the data in this manual is reviewed regularly

and any necessary corrections will be included in subsequent editions.

Suggestions for improvement are welcomed.

Technical data subject to change

Siemens Aktiengesellschaft.

Page 5

12.04

Preface

This manual is intended as a work of reference. It allows the operator at

the machine tool:

- To correctly assess special situations when operating the machine.

- To ascertain the reaction of the system to the special situation.

- To utilize the possibilities for continued operation following the

special situation.

- To follow references to other documentation containing further

details.

Scope

This manual describes the alarms from the NC kernel (NC) area,

PROFIBUS, the cycles and PLC.

Further alarms from the area HMI (Human Machine Interface) can

occur. These alarms are displayed on the operator panel in the form of

self-explanatory text. They do not constitute part of this Diagnostics

Guide.

For special situations in conjunction with the integrated PLC, please

refer to the SIMATIC S7-200 documentation.

Sorting

Safety

NC alarms

The alarms are sorted in ascending numerical order in the Diagnostics

Guide. There are gaps in the sequence.

Danger

Please check the situation in the plant on the basis of the description

of the active alarm(s). Eliminate the causes for the occurrence of the

alarms and acknowledge in the manner indicated. Failure to observe

this warning will place your machine, workpiece, stored settings and

possibly even your own safety at risk.

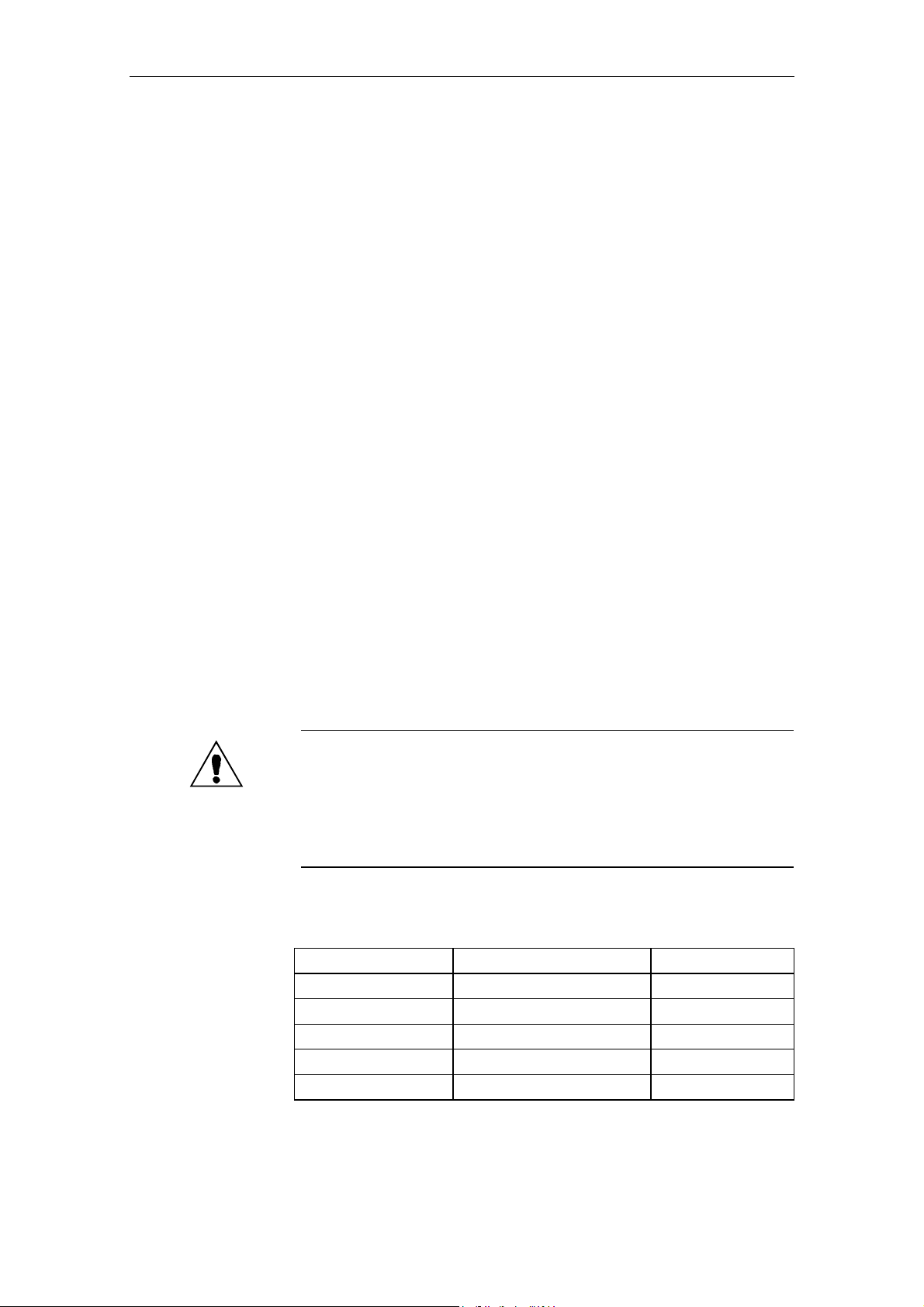

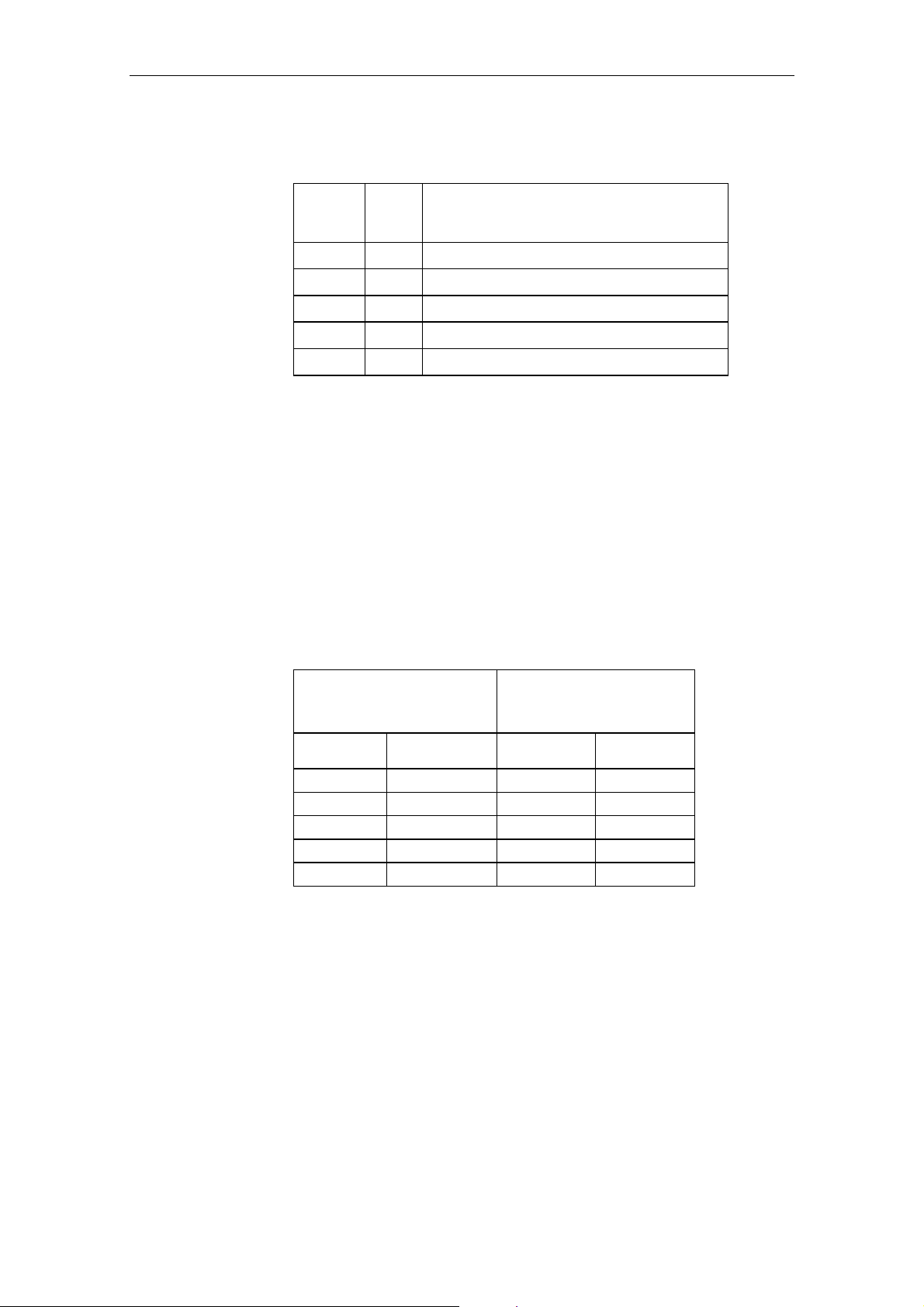

Table 1_1 Number ranges from alarm numbers

000 000 - 009 999 General alarms

010 000 - 019 999 Channel alarms

020 000 - 029 999 Axis/spindle alarms

030 000 - 099 999 Functional alarms

060 000 - 064 999 SIEMENS cycle alarms

065 000 - 069 999 User cycle alarms

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG)

v

Page 6

12.04

HMI alarms/

messages

PLC alarms/

messages

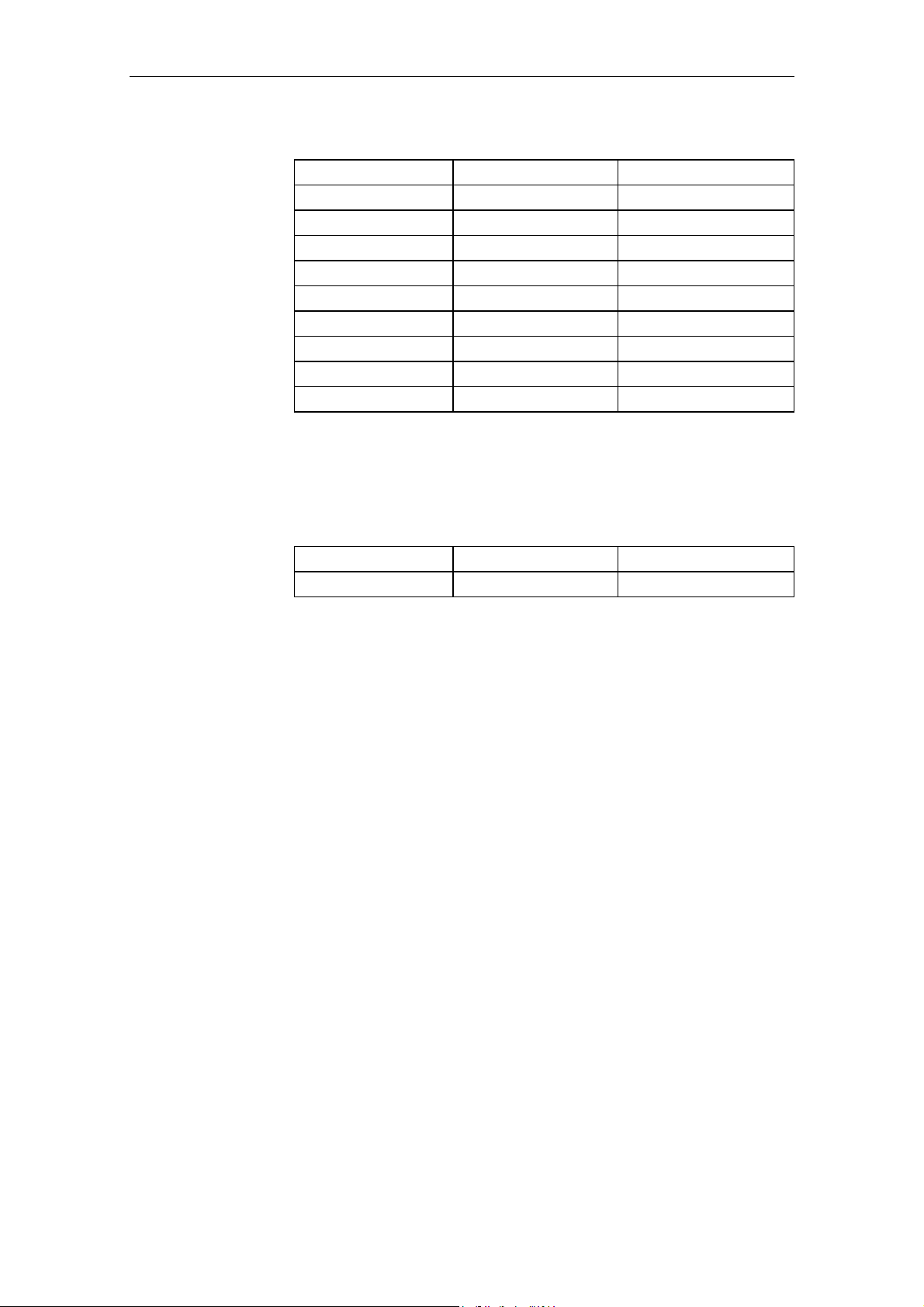

Table 1_2 Number ranges from alarm numbers, continued

100 000 - 100 999 Basic system HMI0

101 000 - 101 999 Diagnostics

102 000 - 102 999 Services

103 000 - 103 999 Machine

104 000 - 104 999 Parameters

105 000 - 105 999 Programming

106 000 - 106 999 Reserve

107 000 - 107 999 OEM

110 000 - 110 999 Reserved

120 000 - 120 999 Reserved

Table 1_3 Number ranges from alarm numbers, continued

400 000 - 499 999 General alarms

700 000 - 799 999 User area

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

vi SINUMERIK 802D sl (DG)

Page 7

12.04

Contents

Alarms ....................................................................................................................................... 1-9

1.1 Overview of NC alarms ........................................................................................... 1-10

PROFIBUS alarms ................................................................................................ 1-226

1.2

1.3

Cycle alarms .........................................................................................................1-234

1.4 ISO alarms ............................................................................................................1-245

1.5 PLC alarms ........................................................................................................... 1-249

1.6 List of actions ........................................................................................................ 1-252

Glossary / Abbreviations ..................................................................................................... 2-261

2.1 Abbreviations ..................................................................................................... 2-261

2.2 Glossary ................................................................................................................ 2-265

Appendix: Sinamics Alarms................................................................................................3-267

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG)

vii

Page 8

12.04

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

viii SINUMERIK 802D sl (DG)

Page 9

12.04 1 Alarms

Alarms

1

Alarms with alarm number 1xxx are system errors that represent

internal error states. The internal error number provides the developer

with important information on the cause and location of the error.

These system error alarms are not described in detail. Should these

still occur with controls delivered, please note the alarm number, the

alarm text and the internal system error number and contact the

Hotline Germany

SIEMENS AG, A&D MC

Phone: 0180 525 80 08

Fax: 0180 525 80 09

Hotline China

Siemens Numerical Control Ltd.

Development & Engineering Division

Phone: (025) 2 18 18 88 (Ext. 305)

Fax: (025) 2 18 16 66

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-9

Page 10

1 Alarms 12.04

1.1 Overview of NC alarms

2000

Explanation

Reactions

Remedy

Program continuation

2001

Explanation

Reactions

Remedy

Program continuation

PLC sign-of-life monitoring

The PLC must give a sign of life within the specified period. An alarm is issued

if this does not happen.

NC Start disable.

NC not ready.

NC Stop on alarm.

Alarm display.

Interface signals are set.

This alarm also occurs after a PLC Stop.

(PLC Stop with programming tool,

PLC Stop from commissioning switch,

PLC Stop from alarm)

If none of these cases apply, contact the hotline stated at the beginning of the

document and state the number of the operating system error.

Switch the control OFF - ON.

PLC has not started up

The PLC must give at least one sign of life within the specified period after

Power On.

NC Start disable.

NC not ready

NC Stop on alarm

Alarm display

Interface signals are set

Contact the hotline stated at the beginning of the document.

Switch the control OFF - ON.

2130

Explanation

Reactions

Remedy

Program continuation

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-10 SINUMERIK 802D sl (DG)

5 V/24 V encoder or 15 V D/A converter undervoltage

A failure has occurred in the power supply to the encoder (5V/24V) or D/A

converter (+/-15 V).

NC not ready.

NC start inhibit in this channel.

NC Stop on alarm.

NC switches to follow-on mode.

Alarm display.

Interface signals are set.

Re-reference axes in this channel.

Please inform the authorized personnel/service department. Check the encoder

and cable for short-circuits (the fault must not recur when you remove the

cable). Check the voltage supply.

Switch the control OFF - ON.

Page 11

12.04 1 Alarms

2900

Explanation

Reactions

Remedy

Program continuation

3000

Explanation

Reactions

Remedy

Program continuation

Reboot is carried out with a delay

This alarm indicates a delayed reboot.

The alarm occurs only when the reboot is carried out by the HMI and the

MD 10088 REBOOT_DELAY_TIME is set higher than zero.

The alarm can be suppressed with SUPPRESS_ALARM_MASK BIT 20.

NC switches to follow-up mode.

NC not ready.

Channel not ready.

NC start inhibit in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

The alarm reaction delay is canceled.

All channel-specific alarm reactions delayed on alarm, alarm display.

See MD 10088 REBOOT_DELAY_TIME and

MD 11410 SUPPRESS_ALARM_MASK

Switch the control OFF - ON.

Emergency stop

The EMERGENCY STOP request is present at the NC/PLC interface

(V 26000000.1).

NC Start disable.

NC is not ready.

NC Stop on alarm.

Alarm display.

Interface signals are set.

Check that an EMERGENCY STOP cam was not approached and that no

EMERGENCY STOP button was pressed. Check PLC user program.

Corrected the cause of EMERGENCY STOP and acknowledge it via the

NC/PLC interface (V 26000000.2).

Clear with the RESET key. Restart part program.

4000

Explanation

Reactions

Remedy

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-11

Channel %1 machine data %2 contains a gap in the axis assignment

%1 = channel number

%2 = string: MD identifier

The assignment of a machine axis to a channel by the machine data 20070

AXCONF_MACHAX_USED must be contiguous. At system power-up (Power

On) gaps are detected and displayed as an alarm.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Configure MD 20070 AXCONF_MACHAX_USED for the axis assignment in the

channel without gaps; i.e. with increasing channel indices, a machine axis must

be assigned until a zero is entered for the first time (no machine axis).

Page 12

1 Alarms 12.04

All MD with higher indices must then contain a zero (0).

The order of the machine axis numbers is not relevant.

Program continuation

4002

Explanation

Channel

axis

index

1.

Channel

Machine axis number

0 1 AXCONF_MACHAX_USED [CH1, AX1] = 1

1 2 AXCONF_MACHAX_USED [CH1, AX2] = 2

2 3 AXCONF_MACHAX_USED [CH1, AX3] = 3

3 4 AXCONF_MACHAX_USED [CH1, AX4] = 4

4 5 AXCONF_MACHAX_USED [CH1, AX5] = 5

Assignment of channel axes to machine axes

Switch the control OFF - ON.

Channel %1 machine data %2[%3] contains an axis that is not defined in

the channel

%1 = channel number

%2 = string: MD identifier

%3 = index: MD array index

Only axes that have been activated in the channel via MD 20070

AXCONF_MACHAX_USED [kx]=m may be declared by means of MD 20050

AXCONF_GEOAX_ASSIGN_TAB [gx]=k.

gx ... geometry axis index: k ... channel axis number

kx ... channel axis index m ... machine axis No.

MD 20050

AXCONF_GEOAX_ASSIGN_TAB

(contains channel axis No. k) (contains machine axis No. m)

MD 20070

AXCONF_MACHAX_USED

Reactions

Geometry axis

index

1. Channel Channel axis

index

1. Channel

0 1 0 1

1 2 1 2

2 3 2 3

3 4

4 5

Assignment of geometry axes to channel axes

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-12 SINUMERIK 802D sl (DG)

Page 13

12.04 1 Alarms

Remedy

Program continuation

4004

Explanation

Reactions

Remedy

Program continuation

Please inform the authorized personnel/service department.

Check and correct MD 20050 AXCONF_GEOAX_ASSIGN TAB and

MD 20070 AXCONF_MACHAX_USED.

MD array MD 20070 AXCONF_MACHAX_USED, in which the channel-specific

machine axis number to be controlled by this channel is entered. These

resulting ”Channel axes” are given a name by MD 20080

AXCONF_CHANAX_NAME_TAB and assigned to a geometry axis by MD

20050 AXCONF_GEOAX_ASSIGN_TAB by entering the corresponding

channel axis in this MD array for each geometry axis.

Switch the control OFF - ON.

Channel %1 machine data %2 axis %3 defined repeatedly as geometry

axis

%1 = channel number

%2 = string: MD identifier

%3 = axis index

An axis may only be defined once as a geometry axis.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Correct MD 20050 AXCONF_GEOAX_ASSIGN_TAB

Switch the control OFF - ON.

4010

Explanation

Reactions

Remedy

Program continuation

Machine data %1[%2] contains invalid identifier

%1 = string: MD identifier

%2 = index: MD array index

When defining names for machine axes, one of the following syntax rules for

the identifier to be entered has been violated:

1. The identifier must be an NC address letter (A, B, C, I, J, K, U, V, W, X, Y,

Z), possibly with a numerical extension.

2. The identifier must begin with 2 arbitrary capital letters but not with $

(reserved).

3. The identifier must not be a vocabulary word of the NC language (e.g.

SPOS).

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Enter the identifier for user-defined names with correct syntax in the displayed

MD.

Machine axes: MD 10000 AXCONF_MACHAX_NAME_TAB

Switch the control OFF - ON.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-13

Page 14

1 Alarms 12.04

4011

Explanation

Reactions

Remedy

Program continuation

Channel %1 Machine data %2[%3] contains invalid identifier

%1 = channel number

%2 = string: MD identifier

%3 = index: MD array index

When defining names in the channel-specific tables for geometry axes and

channel axes, one of the following syntax rules for the identifier to be entered

has been violated:

1. The identifier must be an NC address letter (A, B, C, I, J, K, U, V, W, X, Y,

Z), possibly with a numerical extension.

2. The identifier must begin with 2 arbitrary capital letters but not with $

(reserved for system variable).

3. The identifier must not be a vocabulary word of the NC language (e.g.

SPOS).

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Enter the identifier for user-defined names with correct syntax in the displayed

MD

Geometry axes: MD 20060 AXCONF_GEOAX_ASSIGN_TAB

Channel axes: MD 10000 AXCONF_MACHAX_NAME_TAB

Switch the control OFF - ON.

4012

Explanation

Reactions

Remedy

Program continuation

4020

Explanation

Reactions

Machine data %1[%2] contains invalid identifier

%1 = string: MD identifier

%2 = index: MD array

The selected identifier is invalid. The following are valid identifiers:

• AX1 - AXn: Machine axis identifiers

Alarm display.

Interface signals are set.

NC not ready.

Channel not ready.

NC start inhibit in this channel.

NC stop for alarm.

Use the correct identifier.

Switch the control OFF - ON.

Identifier %1 used several times in machine data %2

%1 = string: Identifier

%2 = string: MD identifier

To determine the name in the channel-specific tables (arrays) for machine

axes an identifier already existing in the control has been used.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-14 SINUMERIK 802D sl (DG)

Page 15

12.04 1 Alarms

Remedy

Program continuation

4021

Explanation

Reactions

Remedy

Program continuation

4030

Explanation

Reactions

Remedy

Program continuation

Please inform the authorized personnel/service department.

Select for the identifier to be entered a character string that is not yet used in

the system (max. 32 characters).

Cancel alarm in all channels of this mode group by pressing RESET.

Channel %1 identifier %2 used several times in machine data %3

%1 = channel number

%2 = string: identifier

%3 = string: MD identifier

To determine the name in the channel-specific tables for geometry axes and

channel axes an identifier already existing in the control has been used.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Select for the identifier to be entered a character string that is not yet used in

the system (max. 32 characters).

Switch the control OFF - ON.

Channel %1 axis identifier missing in machine data %2[%3]

%1 = channel number

%2 = string: MD identifier

%3 = index: MD array index

An axis identifier is expected for the displayed MD in accordance

with the axis configuration in the AXCONF_MACHAX_USED

and MD 20050 AXCONF_GEOAX_ASSIGN_TAB.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Check axis configuration and enter the missing identifier into the MD or, should

the axis not exist, specify for this channel axis the machine axis 0 in MD 20070

AXCONF_MACHAX_USED. If this concerns a geometry axis that is not to be

used (this applies only for 2-axis machining, e.g. on lathes), then channel axis 0

must be entered additionally in MD 20050 AXCONF_GEOAX_ASSIGN_TAB

for the relevant geometry axis.

Switch the control OFF - ON.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-15

Page 16

1 Alarms 12.04

4032

Explanation

Reactions

Remedy

Program continuation

4040

Explanation

Reactions

Remedy

Program continuation

Channel %1 wrong identifier for facing axis in %2

%1 = channel number

%2 = string: MD identifier

According to the axis configuration in MD 20150 GCODE_RESET_VALUES or

MD 20100 DIAMETER_AX_DEF, a facing axis identifier is expected at the

specified location.

Alarm display

Interface signals are set

NC Stop on alarm

NC not ready

NC start disable

Please inform the authorized personnel/service department.

Add the correct identifier.

Switch the control OFF - ON.

Channel %1 axis identifier %2 not consistent with machine data %3

%1 = channel number

%2 = string: axis identifier

%3 = string: MD identifier

The use of the specified axis identifier in the displayed MD is not consistent the

channel's axis configuration stated in the MD 20070

AXCONF_MACHAX_USED and MD 20050 AXCONF_GEOAX_ASSIGN_TAB.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Check and correct the identifier used in the MD 10000 AXCONF_

MACHAX_NAME_TAB, MD 20080 AXCONF_CHANAX_NAME_TAB and/or

MD 20050 AXCONF_GEOAX_NAME_TAB.

Switch the control OFF - ON.

4045

Explanation

Reactions

Remedy

Program continuation

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-16 SINUMERIK 802D sl (DG)

Channel %1 conflict between machine data %2 and machine data %3

%1 = channel number

%2 = string: MD identifier

%3 = string: MD identifier

Using the specified machine data %1 leads to a conflict with machine data %2.

NC not ready.

NC start inhibit in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm

Correct the specified machine data.

Switch the control OFF - ON.

Page 17

12.04 1 Alarms

4050

Explanation

Reactions

Remedy

Program continuation

NC code identifier %1 cannot be reconfigured to %2

%1 = String: Old identifier

%2 = String: New identifier

Renaming of an NC code was not possible for one of the following reasons:

• The old identifier does not exist

• The new identifier is within another type range.

NC codes/vocabulary words can be reconfigured per machine data as long as

you stay within the type range.

Type 1: "true" G codes: G02, G17, G33, G64, ...

Type 2: named G codes: CIP, TRANS, ...

Type 3: addresses which can be set: X, Y, I, J, K, MEAS

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

Correct MD 10712 NC_USER_CODE_CONF_NAME_TAB (protection level 1).

The list must be built up as follows:

Even address: Identifier to be modified

Following odd address: New identifier

E.g.: NC_USER_CODE_CONF_NAME_TAB[10] = "ROT"

NC_USER_CODE_CONF_NAME_TAB [11] = " "

deletes the function ROT from the control

Switch the control OFF - ON.

4060

Explanation

Reaction

Remedy

Program continuation

4062

Explanation

Reaction

Remedy

Program continuation

Standard machine data loaded

Startup with defaults values by means of:

• Operation (e.g. commissioning switch)

• MD 11200 INIT_MD

• Loss of remanent data

• Startup operation with backup data, without saving current data

Alarm display

After automatically loading the standard MDs, the individual MDs must be

entered/loaded in the relevant system.

Clear the alarm with the cancel key. Load specific machine data again.

Backup data loaded

The user data saved in the flash memory are loaded to the SRAM.

Alarm display

Load specific machine data again.

Clear the alarm with the RESET key.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-17

Page 18

1 Alarms 12.04

4065

Explanation

Reactions

Remedy

Program continuation

4070

Explanation

Reaction

Remedy

Program continuation

Buffered memory was restored from backup copy (potential loss of data!)

A possible inconsistency was detected in the buffered memory during power-up.

The buffered memory was initialized with the last backup copy. Changes in the

buffered memory, which have been made since the last backup copy update,

have been lost. The reason for this procedure is that the backup time is

exceeded. Make sure that the required operating time of the control

corresponds to the specifications in your Installation & Start-Up Guide.

The current backup copy of the buffered memory has been created by the last

internal data backup carried out via the "Save data" softkey on the HMI.

Alarm display

Interface signals are set

NC Start disable

Restart the control.

Scaling machine data modified

The control uses internal physical units (mm, degrees, s, for paths, velocities,

acceleration, etc.). During programming or data storage, some of these values

are input and output using different units (rev./min, m/s2, etc.).

The conversion is carried out using scaling factors which can be entered

(system-specific MD array 10230 SCALING_FACTORS USER_DEF[n] (n ...

Index number 0 - 10) when the relevant masking bit is set to "1".

If the masking bit is set to "0" then scaling takes place with the internal standard

factors.

The following machine data influence the scaling of other MDs:

MD 10220 SCALING_USER_DEF_MASK

MD 10230 SCALING_FACTORS_USER_DEF

MD 10240 SCALING_SYSTEM_IS_METRIC

MD 10250 SCALING_VALUE_INCH

MD 30300 IS_ROT_AX

After these data are changed, the NC must be restarted. Only then will the input

of dependent data be performed correctly.

Alarm display.

Please inform the authorized personnel/service department.

If the alarm has been displayed after downloading an MD file which is

consistent within itself, then the download operation must be repeated with a

new NC power-up. (The file contains scaling-dependent machine data in front of

the scaling factors).

Clear the alarm with the cancel key. No further operator action required.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-18 SINUMERIK 802D sl (DG)

Page 19

12.04 1 Alarms

4071

Explanation

Reaction

Remedy

Program continuation

4075

Explanation

Reaction

Remedy

Program continuation

Check the position of the absolute encoder

A machine data that affects the position of an absolute encoder has been

changed. Please check the position values.

Alarm display.

Please inform the authorized personnel/service department.

Clear the alarm with the Cancel key or with NC START.

Machine data %1 (and maybe others) not altered due to missing access

authorization %2

%1 = string: MD identifier

%2 = write-protection level of MD

On executing a TOA file, an attempt has been made to write an item of data

with a higher protection level than the access authorization currently set in the

control.

The item of data affected was not written.

This alarm is set only when access violation is detected for the first time.

Alarm display.

Set the required access level per password entry or delete the machine data

concerned from the MD file.

Clear the alarm with the cancel key. No further operator action required.

4076

Explanation

Reaction

Remedy

Program continuation

%1 Machine data could not be altered with access authorization %2

%1 = number of MD

%2 = access authorization set

On executing a TOA file, an attempt has been made to write data with a higher

protection level than the access authorization currently set in the control.

The data affected was not written.

This alarm is issued when acknowledging Alarm 4075. It can be cleared only

with Power On.

Alarm display.

Set the required access level by means of keyswitch or password entry or

delete the machine data concerned from the MD file program.

Switch the control OFF - ON.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-19

Page 20

1 Alarms 12.04

4077

Explanation

Reaction

Remedy

Program continuation

New value %1 of MD %2 not set. Requested %3 bytes too much %4

memory.

%1 = New value of machine data

%2 = Machine data number

%3 = Number of bytes to many requested

%4 = Type of memory

An attempt was made to enter a new value in the specified memory

configuration machine data.

The change is not made, since it would result in the user memory being

deleted. This is because the memory requested exceeded the available

capacity.

The third parameter specifies the number of bytes by which the maximum user

memory was exceeded.

The fourth parameter specifies the type of memory whose limit was exceeded.

"D" stands for dynamic or non-buffered user memory (this is where the LUD

variables are stored and the interpolation buffer size is entered, for example).

The capacity of this memory type is defined by the current memory expansion

and the value in MD18210 MM_USER_MEM_DYNAMIC.

"S" stands for static or buffered user memory (typically the part programs but

also compensation data, R parameters and tool data). The capacity of this

memory type is defined by the current memory expansion and the value in

MD 18230 MM_USER_MEM_BUFFERED.

Alarm display.

If the modification was unintentional, simply continue.

The alarm has no negative effects.

The remedy depends on the access authorization and the current memory

expansion of the NC.

The intended change is mot possible -> try again with a lower value. Observe

how the value of the byte number changes.

Buy more memory? This option depends on the particular model used.

The NC user memory setting may be smaller than possible. The MDs (see

above) can be altered using the relevant access authorization.

Clear the alarm with the cancel key. No further operator action required.

4090

Explanation

Reactions

Remedy

Program continuation

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-20 SINUMERIK 802D sl (DG)

Too many faults during power up

More than <n> errors occurred during control power-up.

Alarm display.

NC Start disable.

Set the machine data correctly.

Page 21

12.04 1 Alarms

4110

Explanation

Reaction

Remedy

Program continuation

4111

Explanation

Reaction

Remedy

Program continuation

Factor IPO cycle increased to %1 ms

%1 = String (new IPO cycle)

The IPO cycle divisor was set to a value which was not an integral multiple of

the position control cycle divisor.

The divisor (MD 10070 IPO_SYSCLOCK_TIME_RATIO) was increased.

IPO_SYSCLOCK_TIME_RATIO has been modified on systems with

PROFIBUS DP because of the modified DP cycle in the SDB (MD 10050

SYSCLOCK_CYCLE_TIME).

Alarm display.

Machine data 10070 IPO_SYSCLOCK_TIME_RATIO has been modified.

Clear the alarm with the RESET key. Restart part program.

Increase PLC cycle to %1 ms

The PLC cycle divisor was set to a value which was not an integral multiple of

the IPO cycle divisor.

The divisor (MD 10 074 PLC_IPO_TIME_RATIO) has been increased.

Alarm display.

Adapt machine data.

Switch the control OFF - ON.

4112

Explanation

Reaction

Remedy

Program continuation

4113

Explanation

Reaction

Remedy

Program continuation

Servo cycle changed to %1 ms

%1 = String (new servo cycle)

MD 10060 POSCTRL_SYSCLOCK_TIME_RATIO has been modified because

of the modified DP cycle in SDB1000 (10050 SYSCLOCK_CYCLE_TIME).

Alarm display.

Machine data 10060 POSCTRL_SYSCLOCK_TIME_RATIO RATIO has been

modified.

Clear the alarm with the RESET key. Restart part program.

Sysclock cycle changed to %1 ms

%1 = String (new PLC cycle)

MD 10050 SYSCLOCK_CYCLE_TIME has been modified because of the

modified DP cycle in the SDB.

Alarm display.

Machine data 10050 SYSCLOCK_CYCLE_TIME has been modified.

Clear the alarm with the RESET key. Restart part program.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-21

Page 22

1 Alarms 12.04

4114

Explanation

Reaction

Remedy

Program continuation

4150

Explanation

Reactions

Remedy

Program continuation

Error in DP cycle of the SDB

%1 = String (new PLC cycle)

The DP cycle in the SDB contains an error and cannot be set.

The default value of MD 10050 SYSCLOCK_CYCLE_TIME is set.

Alarm display.

Correct the SDB.

Switch the control OFF - ON.

Channel %1 invalid M function subprogram call configured

%1 = Channel number

In MD MD 10715 M_NO_FCT_CYCLE, an M function that is occupied by the

system has been specified for the configuration of the subprogram call and

cannot be replaced by a subprogram call (M0 to M5, M17, M19, M30, M40 to

M45, M70). When external language is active, M96 to M99 are also blocked

Alarm display.

NC Start disable.

Interface signals are set.

NC not ready.

NC Stop on alarm.

Configure an M function which is not used by the system (M0 to M5, M17, M19,

M30, M40 to M45 and M70) in MD 10715 M_NO_FCT_CYCLE.

4152

Explanation

Reactions

Remedy

Program continuation

Illegal configuration of the "Block display with absolute values" function

The "Block display with absolute values" function has been illegally

parameterized:

- An illegal block length has been set with MD 28400 MM_ABSBLOCK:

While ramping up, the machine data will be checked for the following value

range:

0, 1, 128 to 512

- An invalid display range has been set with MD 28402

MM_ABSBLOCK_BUFFER_CONF[]. While ramping up, the machine data will

be checked for the following upper and lower limits:

0 <= $MC_MM_ABSBLOCK_BUFFER_CONF[0] <= 8

0 <= $MC_MM_ABSBLOCK_BUFFER_CONF[1] <= (MD 28060

MM_IPO_BUFFER_SIZE + MD 28070 MM_NUM_BLOCKS_IN_PREP).

Alarm 4152 is issued if the limits are violated.

Alarm display.

Interface signals are set.

Channel not ready.

NC Stop on alarm.

NC Start disable.

Configure block length/display range within the permissible limits.

Switch the control OFF - ON.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-22 SINUMERIK 802D sl (DG)

Page 23

12.04 1 Alarms

4160

Explanation

Reactions

Remedy

Program continuation

4181

Explanation

Reactions

Remedy

Program continuation

Channel %1 invalid M function number for spindle switchover configured

%1=Channel number

An M function was specified in MD 20094 SPIND_RIGID_TAPPING_M_NR to

configure the M function number for spindle switchover to axis mode. The M

function number is assigned by the system and cannot be used for the

switchover (M1 to M5,M17, M30, M40 to M45).

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Configure an M function which is not used by the system (M1 to M5, M17, M30,

M40 to M45) in MD 20094 SPIND_RIGID_TAPPING_M_NR.

Channel %1 invalid assignment of an M auxiliary function number

%1 = channel number

In machine data 22254 AUXFU_ASSOC_M0_VALUE or 22256

AUXFU_ASSOC_M1_VALUE, a number has been specified for the

configuration of a new predefined M function which is occupied by the system,

and cannot be used for an assignment. (M0 to M5, M17, M30, M40 to M45).

Alarm display.

Interface signals are set.

Channel not ready.

NC Start disable in this channel.

NC Stop on alarm.

Configure an M function in machine data 22254 AUXFU_ASSOC_M0_VALUE

or 22256 AUXFU_ASSOC_M1_VALUE which is not occupied by the system

(M1 to M5, M17, M30, M40 to M45).

Switch the control OFF - ON.

4182

Explanation

Reactions

Channel %1 invalid M auxiliary function number in %2%3, MD reset

%1 = channel number

%2 = machine data identifier

%3 = if necessary, MD index

In the specified machine data, a number has been specified for the

configuration of an M function which is occupied by the system, and cannot be

used for an assignment.

(M0 to M5, M17, M30, M40 to M45 and also M98, M99 with applied ISO

dialect).

The value set by the user has been reset to the default value by the system.

Alarm display.

Interface signals are set.

Channel not ready.

NC Start disable in this channel.

NC Stop on alarm.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-23

Page 24

1 Alarms 12.04

Remedy

Program continuation

4183

Explanation

Reactions

Remedy

Program continuation

Configure an M function in the specified machine data which is not occupied by

the system (M0 to M5, M17, M30, M40 to M45 and also M98, M99 with applied

ISO dialect).

Clear the alarm with the RESET key. Restart part program.

Channel %1 M auxiliary function number %2 used several times

(%3 and %4)

%1 = channel number.

%2 = M auxiliary function number.

%3 = machine data identifier.

%4 = machine data identifier.

In the specified machine data, a number has been used several times for the

configuration of an M function.

Alarm display.

Interface signals are set.

Channel not ready.

NC Start disable in this channel.

NC Stop on alarm.

Check the specified machine data and create a unique assignment of M

auxiliary function numbers.

Switch the control OFF - ON.

4184

Explanation

Reactions

Remedy

Program continuation

4185

Explanation

Channel %1 illegally predefined auxiliary function in %2%3, MD reset

%1 = channel number

%2 = machine data identifier

%3 = if necessary, MD index

In the specified machine data, a predefined auxiliary function has been illegally

configured.

The value set by the user has been reset to the default value by the system.

Channel not ready.

NC start inhibit in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Configure a valid value in the specified machine data.

Clear the alarm with the RESET key. Restart part program.

Channel %1 illegal auxiliary function configured %2 %3 %4

%1 = channel number.

%2 = type of auxiliary function.

%3 = extension.

%4 = auxiliary function value.

An auxiliary function has been illegally configured.

Predefined auxiliary functions cannot be reconfigured by user-defined auxiliary

functions.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-24 SINUMERIK 802D sl (DG)

Page 25

12.04 1 Alarms

Reactions

Remedy

Program continuation

4200

Explanation

Reactions

Remedy

Program continuation

Channel not ready

NC start inhibit in this channel

Interface signals are set

Alarm display

NC stop for alarm

Reconfigure the auxiliary function.

Clear the alarm with the RESET key. Restart part program.

Channel %1 geometry axis %2 must not be declared a rotary axis

%1 = channel number

%2 = axis name

The geometry axes represent a Cartesian coordinate system and therefore the

declaration of a geometry axis as rotary axis leads to a definition conflict.

NC not ready.

NC Stop on alarm.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/service department.

Remove rotary axis declaration for this machine axis.

For this purpose, the geometry axis index for the displayed geometry axis must

be determined by means of the machine data array 20060

AXCONF_GEOAX_NAME_TAB. The channel axis number is stored with the

same index in the MD array 20050 AXCONF_GEOAX_ASSIGN_TAB. The

channel axis number minus 1 provides the channel axis index under which the

machine axis number is found in the MD array 20070

AXCONF_MACHAX_USED.

Switch the control OFF - ON.

4210

Explanation

Reactions

Remedy

Program continuation

Channel %1 spindle %2 declaration as rotary axis missing

%1 = channel number

%2 = axis name, spindle number

If a machine axis is to be operated as a spindle, this machine axis must be

declared as a rotary axis.

NC not ready.

NC Stop on alarm.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/service department.

Set rotary axis declaration for this machine axis in the axis-specific MD 30300

IS_ROT_AX.

Switch the control OFF - ON.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-25

Page 26

1 Alarms 12.04

4215

Explanation

Reactions

Remedy

Program continuation

4220

Explanation

Reactions

Remedy

Program continuation

Channel %1 spindle %2 declaration as modulo axis missing

%1 = channel number

%2 = axis name, spindle number

The spindle functionality requires a modulo axis (positions in [deg]).

NC not ready.

NC Stop on alarm.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/service department.

Set MD 30310 ROT_IS_MODULO.

Switch the control OFF - ON.

Channel %1 spindle %2 declared repeatedly

%1 = channel number

%2 = axis name, spindle number

The spindle number exists more than once in the channel.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Please inform the authorized personnel/service department.

The spindle number is stored in the axis-specific MD array 35000

SPIND_ASSIGN_TO_MACHAX. The channel to which this machine axis/

spindle is assigned is listed in the machine axis index. (The machine axis

number is given in the MD array 20070 AXCONF_MACHAX_USED).

Switch the control OFF - ON.

4225

Explanation

Reactions

Remedy

Program continuation

Channel %1 axis %2 declaration as rotary axis missing

%1 = channel number

%2 = axis name, axis number

The modulo functionality requires a rotary axis (positions in [deg]).

NC not ready.

NC Stop on alarm.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/service department.

Set MD 30300 IS_ROT_AX.

Switch the control OFF - ON.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-26 SINUMERIK 802D sl (DG)

Page 27

12.04 1 Alarms

4230

Explanation

Reaction

Remedy

Program continuation

4240

Explanation

Reactions

Remedy

Program continuation

Channel %1 data alteration from external not possible in current channel

state

%1 = channel number

It is not allowed to enter this data while the part program is being executed (e.g.

setting data for spindle speed limitation or for dry run feedrate).

Alarm display.

The data to be entered must be altered before starting the part program.

Clear the alarm with the cancel key. No further operator action required.

Runtime overflow for IPO cycle or position controller cycle, IP %1

%1 = Program position

The settings for the interpolation and position control cycle were modified

before the last power-up such that too little computing time is now available for

the requisite cyclic task.

The alarm occurs immediately after power-up if too little runtime is available

even when the axes are stationary and the NC program has not started.

However, task overflow can occur only when computation-intensive NC

functions are called during program execution.

NC not ready.

NC Start disable.

NC Stop on alarm.

The NC switches to follow-on mode.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/service department.

Take greater care when optimizing the clock times NC MD 10050

SYSCLOCK_CYCLE_TIME,

MD 10060 POSCTRL_SYSCLOCK_TIME_RATIO and/or

MD 10070 IPO_SYSCLOCK_TIME_RATIO.

The test should be performed with an NC program that represents the highest

load on the control. For safety, a margin of 15 to 25% should be added to the

times determined in this way.

Switch the control OFF - ON.

4260

Explanation

Reactions

Remedy

Program continuation

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-27

Machine data %1 illegal

%1 = String: MD identifier

The selected cam pair was not activated by MD 10450

SW_CAM_ASSIGN_TAB or more than one cam pair has been selected.

Alarm display.

Interface signals are set.

NC start inhibit in this channel.

NC stop on alarm.

Activate the cam pair or select only one cam pair.

Switch the control OFF - ON.

Page 28

1 Alarms 12.04

4270

Explanation

Reactions

Remedy

Program continuation

Machine data %1 assigns not activated NCK input/output byte %2

%1 = string: MD identifier

%2 = index

The specified machine data assigns a digital input/output byte or an analog

input/output signal the processing of which has not been activated to an NC

function.

Alarm display.

Interface signals are set.

NC not ready.

Channel not ready.

NC start inhibit in this channel.

NC stop on alarm.

Please inform the authorized personnel/service department. Correct machine

data.

Active required inputs/outputs via MD:

• MD 10350 FASTIO_DIG_NUM_INPUTS

• MD 10360 FASTIO_DIG_NUM_OUTPUTS

• MD 10300 FASTIO_ANA_NUM_INPUTS

• MD 10310 FASTIO_ANA_NUM_OUTPUTS

Activation of fast inputs/outputs does not require the corresponding hardware

configuration to be available at the control. All functions using fast

inputs/outputs can also be made use of by the PLC specification/modification

defined in the VDI interface, if the response time requirements are reduced

accordingly.

Activated inputs/outputs increase the computation time requirement of the

interpolation cycle because the PLC manipulation signals are handled cyclically.

Note: Deactivate any inputs/outputs not in use.

Switch the control OFF - ON.

4275

Explanation

Reactions

Remedy

Program continuation

Machine data %1 and %2 both assign the same NCK output byte no. %3

several times

%1 = string: MD identifier

%2 = string: MD identifier

%3 = No. of output

The specified machine data assign two NC functions to the same digital/analog

output.

Alarm display.

Interface signals are set.

NC not ready.

Channel not ready.

NC Start disable in this channel.

NC Stop on alarm.

Please inform the authorized personnel/service department. Correct machine

data.

Switch the control OFF - ON.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-28 SINUMERIK 802D sl (DG)

Page 29

12.04 1 Alarms

4300

Explanation

Reactions

Remedy

Program continuation

4310

Explanation

Reactions

Remedy

Program continuation

Declaration in MD %1 is not allowed for geometry axis/spindle %2

%1 = string: MD identifier

%2 = axis name, spindle number

Geometry axes and spindles cannot be operated as concurrent positioning

axes.

NC not ready.

NC stop on alarm.

NC start inhibit in this channel.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/service department. Reset MD 30450

IS_CONCURRENT_POS_AX for the axis concerned.

Switch the control OFF - ON.

Declaration in MD %1 index %2 is not allowed

%1 = string: MD identifier

%2 = index in MD array

The MD values must be written in the array in ascending order.

NC not ready.

NC Stop on alarm.

NC start inhibit.

Alarm display.

Interface signals are set.

Correct the MD

Clear the alarm with the RESET key. Restart part program.

4320

Explanation

Reactions

Remedy

Program continuation

Axis %1 function %2 %3 and %4 not allowed

%1 = string: Axis identifier

%2 = string: MD identifier

%3 = string: Bit

%4 = string: MD identifier

The functions declared by the machine data specified cannot be activated at the

same time for one axis.

Channel not ready.

NC start inhibit in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Deactivate one of the functions.

Switch the control OFF - ON.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-29

Page 30

1 Alarms 12.04

4340

Explanation

Reactions

Remedy

Program continuation

4343

Explanation

Reactions

Remedy

Program continuation

Channel %1 invalid transformation type in transformation no. %2

%1 = channel number

%2 = transformation number

An invalid, i.e. undefined, number was entered in one of the machine data

24100 TRAFO_TYPE_1.

This alarm occurs only if a certain type of transformation is not possible in the

specified control type.

Alarm display

Interface signals are set

NC Stop on alarm

Channel not ready

NC start disable

Valid transformation type entered

Switch the control OFF - ON.

Channel %1 attempt made to change the machine data of an active

transformation

%1 = channel number

An attempt was made to change the machine data of an active transformation

in or to activate the machine data with RESET or NEWCONFIG.

Alarm display.

Interface signals are set.

NC Stop on alarm at end of block.

Interpreter stop.

Set valid machine data

Clear the alarm with the RESET key. Restart part program.

4346

Explanation

Reactions

Remedy

Program continuation

Channel %1 invalid geoaxis assignment in machine data %2[%3]

%1 = channel number

%2 = name of machine data

%2 = transformation number

Machine data TRAFO_GEOAX_ASSIGN_TAB_1/2 contains an invalid entry.

The following causes for the error are possible:

- The entry references a channel axis that does not exist.

- The entry is zero (no axis) but the transformation needs the relevant axis as

a channel axis.

Alarm display.

Interface signals are set.

Correction block with reorganization.

NC Stop on alarm at end of block.

Correct the entry in TRAFO_GEOAX_ASSIGN_TAB_1/2 or

TRAFO_AXES_IN_1/2.

Clear the alarm with the RESET key. Restart part program.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-30 SINUMERIK 802D sl (DG)

Page 31

12.04 1 Alarms

4347

Explanation

Reactions

Remedy

Program continuation

4350

Explanation

Reactions

Remedy

Program continuation

Channel %1 invalid channel axis assignment in machine data %2[%3]

%1 = channel number

%2 = name of the machine data

%3 = transformation number

Machine data TRAFO_AXIS_IN_1/2 contains an invalid entry.

The following causes for the error are possible:

- The entry references a channel axis which does not exist.

- The entry is zero (no axis) but the transformation needs the relevant axis as a

channel axis.

Alarm display.

Interface signals are set.

Correction block with reorganization.

NC Stop on alarm at end of block.

Correct the entry in TRAFO_AXES_IN_1/2.

Clear the alarm with the RESET key. Restart part program.

Channel %1 axis identifier %2 machine data %3 not consistent with

machine data %4

%1 = channel number

%2 = string: Axis identifier

%3 = string: MD identifier

%4 = string: MD identifier

MD 32410 JOG_AND_POS_JERK_ENABLE (jerk limitation) and MD 35240

ACCEL_TYPE_DRIVE (acceleration reduction) have been defined as the initial

setting for an axis.

However, the two functions cannot be activated at the same time for one axis.

Alarm display.

Interface signals are set.

Channel not ready.

NC start inhibit in this channel.

NC stop on alarm.

Please inform the authorized personnel/service department. Resetting of 32410

JOG_AND_POS_JERK_ENABLE or MD 35240 ACCEL_TYPE_DRIVE.

Switch the control OFF - ON.

4400

Explanation

Reaction

Remedy

Program continuation

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-31

MD alteration will cause reorganization of buffered memory (loss of data!)

An MD has been altered that configures the buffered memory. If the NC powers

up with the altered data, this will lead to reorganization of the buffered memory

and thus to the loss of all buffered user data (part programs, tool data, GUD,

leadscrew error compensation, ...).

Alarm display.

If the control includes user data that has not yet been saved, then a data

backup must be performed before the next NC power-up. By manually resetting

the altered MD to the value it had before the last power-up, reorganization of

the memory can be avoided.

Clear the alarm with the cancel key. No further operator action required.

Page 32

1 Alarms 12.04

4402

Explanation

Reaction

Remedy

Program continuation

4502

Explanation

Reaction

Program continuation

%1 causes the machine data to be reset

%1 = machine data

If this machine data is set, the current values of the machine data are

overwritten with the pre-set values on next power up. Under certain

circumstances, this can result in loss of data (also in the backed-up memory).

Alarm display.

Please inform the authorized personnel/service department. If the control

includes user data that has not yet been saved, then a data backup must be

performed before the next NCK power-up. By manually resetting the altered MD

to the value it had before the last power-up, reorganization of the memory can

be avoided.

Clear the alarm with the cancel key. No further operator action required.

Channel %1 Anachronism: %2(%3) -> %4

%1 = channel number

%2 = string: MD identifier

%3 = string: MD identifier

%4 = string: MD identifier

Previously, in MD 20110 RESET_MODE_MASK Bit4 and Bit5, the reset

behavior of the 6th or 8th G group was determined. This setting is now made in

MD 20152 GCODE_RESET_MODE.

In order to ensure compatible handling of "old" data backups, the "old" values

are taken from MD 20110 RESET_MODE_MASK and entered in MD 20152

GCODE_RESET_MODE.

Alarm display.

Clear the alarm with the cancel key. No further operator action required.

5000

Explanation

Reaction

Remedy

Program continuation

Unable to execute communication request

The communication request (data exchange between NC and HMI,

for example: load an NC part program) cannot be executed due lack of

memory. Cause: too many parallel communication requests

Alarm display.

No remedy possible – the operation that produced to alarm must be repeated.

Clear the alarm display with Cancel.

Clear the alarm with the cancel key. No further operator action required.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-32 SINUMERIK 802D sl (DG)

Page 33

12.04 1 Alarms

6000

Explanation

Reactions

Remedy

Program continuation

6010

Explanation

Memory reorganized using standard machine data

The memory management was not able to allocate the NC user memory with

the values in the machine data. Because the total memory is available as

dynamic or static memory for the NC user (e.g. for: the number of tool offsets,

the number of directories and files, etc.) and is therefore not sufficient.

Alarm display.

Interface signals are set.

NC Start disable.

NC Stop on alarm.

Redefine the NC memory structure!

A specific MD for NC user memory allocation cannot be given as the cause of

the alarm. Therefore, the MD initiating the alarm must be determined on the

basis of the default values in the machine data by changing the user-specific

memory structure step by step.

Usually, not just one MD has been chosen too large and therefore it is

advisable to reduce the memory area by a certain proportion in several MDs.

Clear the alarm with the RESET key. Restart part program.

Channel %1 data block %2 not or not completely created, error code %3

%1 = channel number

%2 = string (module name)

%3 = internal error ID

Data management has detected an error in power-up. The specified data block

may not have been created. The error number specifies the type of error. If the

error number >100000, then there is a fatal system error. Otherwise, the user

memory area was made too small. In this case the (user) error codes have the

following meaning:

Error number Explanation

1 No memory space available

2 Maximum number of possible symbols exceeded

3 Index 1 lies outside valid range of values

4 Name in channel already exists

5 Name in NC already exists

If the alarm occurs after cycle programs, macro definitions or definitions for

global user data (GUD) have been introduced, the machine data for the NC

user memory configuration have been incorrectly configured. In all other cases,

modifications to machine data that are already correct produce errors in the

user memory configuration.

The following block names (2nd parameter) are known in the NC (all system

and user data blocks; in general, only problems in the user data blocks can be

remedied by user intervention)

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-33

Page 34

1 Alarms 12.04

_N_NC_OPT - System-internal: Option data, NC global

_N_NC_SEA - System-internal: Setting data, NC global

_N_NC_TEA - System-internal: Machine data, NC global

_N_NC_CEA - System-internal: 'cross error compensation'

_N_NC_PRO - System-internal: Protection zones, NC global

_N_NC_GD1 - User: 1st GUD block defined by

_SGUD_DEF, NC global

_N_NC_GD2 - User: 2nd GUD block defined by

_N_MGUD_DEF, NC global

_N_NC_GD3 - User: 3rd GUD block defined by

_N_UGUD_DEF, NC global

_N_NC_GD4 - User: 4th GUD block defined by

_N_GUD4_DEF, NC global

_N_NC_GD5 - User: 5th GUD block defined by

_N_GUD5_DEF, NC global

_N_NC_GD6 - User: 6th GUD block defined by

_N_GUD6_DEF, NC global

_N_NC_GD7 - User: 7th GUD block defined by

_N_GUD7_DEF, NC global

_N_NC_GD8 - User: 8th GUD block defined by

_N_GUD8_DEF, NC global

_N_NC_GD9 - User: 9th GUD block defined by

_N_GUD9_DEF, NC global

_N_NC_MAC - User: Macro definitions

_N_NC_FUN - User: Cycle programs

_N_CHc_OPT - System-internal: Option data, channel-specific

_N_CHc_SEA - System-internal: Setting data, channel-specific

_N_CHc_SEA - System-internal: Machine data, channel-specific

_N_CHc_PRO - System-internal: Protection zones, channel-specific

_N_CHc_UFR - System-internal: Frames, channel-specific

_N_CHc_RPA - System-internal: Arithmetic parameters, channel-specific

_N_CHc_GD1 - User: 1st GUD block defined by

_N_SGUD_DEF, channel-specific

_N_CHc_GD2 - User: 2nd GUD block defined by

_N_MGUD_DEF, channel-specific

_N_CHc_GD3 - User: 3rd GUD block defined by

_N_UGUD_DEF, channel-specific

_N_CHc_GD4 - User: 4th GUD block defined by

_N_GUD4_DEF, channel-specific

_N_CHc_GD5 - User: 5th GUD block defined by

_N_GUD5_DEF, channel-specific

_N_CHc_GD6 - User: 6th GUD block defined by

_N_GUD6_DEF, channel-specific

_N_CHc_GD7 - User: 7th GUD block defined by

_N_GUD7_DEF, channel-specific

_N_CHc_GD8 - User: 8th GUD block defined by

_N_GUD8_DEF, channel-specific

_N_CHc_GD9 - User: 9th GUD block defined by

_N_GUD9_DEF, channel-specific

_N_AXa_OPT - System-internal: option data, axial

_N_AXa_SEA - System-internal: setting data, axial

_N_AXa_TEA - System-internal: machine data, axial

_N_AXa_EEC - System-internal: leadscrew error compensation data, axial

_N_AXa_QEC - System-internal: quadrant error compensation data, axial

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-34 SINUMERIK 802D sl (DG)

Page 35

12.04 1 Alarms

_N_TOt_TOC - System-internal: tool holder data, TOA-specific

_N_TOt_TOA - System-internal: tool data, TOA-specific

_N_TOt_TMA - System-internal: magazine data, TOA-specific

c = Channel number

a = Machine axis number

t = TOA unit number

Reactions

Remedy

There are further internal system data blocks with identifier.

Alarm display.

Interface signals are set.

NC not ready.

NC Start disable.

NC Stop on alarm.

Correct the machine data or undo the change.

Please inform the authorized personnel/service department.

• There are two determining machine data for cycle programs:

MD 18170 MM_NUM_MAX_FUNC_NAMES = max. number of all

Cycle programs

Error number = 2 shows that this value is too small

MD 18180 MM_NUM_MAX_FUNC_PARAM = max. number of all

parameters defined in the cycle programs

Error number = 2 shows that this value is too small

(If this MD is modified, the memory backup is retained)

Program continuation

6020

Explanation

Reaction

• The following applies to macro definitions:

MD 18160 MM_NUM_USER_MACROS = max. number of all

Macro definitions

Error number = 2 shows that this value is too small

(If this MD is modified, the memory backup is retained)

• The following applies to GUD variables:

MD 18118 MM_NUM_GUD_MODULES = max. number of all

GUD data blocks per area (NC/channel)

(if GD1, GD2, GD3, GD9 are defined, the value must be 9

MD 4 MM_NUM_ GUD_NAMES_NCK = max. number of all

global GUD variables

Error number = 2 shows that this value is too small

MD 18130 MM_NUM_GUD_NAMES_CHAN = max. number of all

Channel-specific GUD variables in the channel

Error number = 2 shows that this value is too small

MD 18150 MM_GUD_VALUES_MEM = max. memory values

all GUD variables together

Error number = 1 shows that this value is too small

Switch the control OFF - ON.

Clear the alarm with the RESET key. Restart part program.

Machine data have been altered - now memory is reorganized

Machine data have been changed that define the NC user memory allocation.

Data management has restructured the memory in accordance with the altered

machine data.

Alarm display.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-35

Page 36

1 Alarms 12.04

Remedy

Program continuation

6030

Explanation

Reaction

Remedy

Program continuation

6035

Explanation

Reaction

Remedy

Program continuation

No remedial action is required. Any user data that are required must be input

again.

Clear the alarm with the RESET key. Restart part program.

Limit of user memory has been adapted

Data management checks during power-up the actually available physical user

memory (DRAM, DPRAM and SRAM) with the values in the system-specific

machine data 18210

MM_USER_MEM_DYNAMIC, MD 18220 MM_USER_MEM_DPR and

MD 18230 MM_USERMEM_BUFFERED.

Alarm display.

No remedial action is required. The new maximum permissible value can be

read from the reduced machine data.

Clear the alarm with the RESET key. Restart part program.

Instead of %1 KB the system has only %2 KB of free user memory of type

"%3"

%1 = free memory defined for the control model in KB

%2 = actual maximum amount of free memory in KB

%3 = type of memory, "D" = non-buffered, "S" = buffered

The alarm can only occur after a 'cold start' (=NCK start-up with standard

machine data). The alarm is only a notice. There is no interference with any

NCK functions. It shows that the NCK has less free user memory available than

specified by Siemens for this control variant. The value of the actually available

free user memory can also be taken from the machine data 18050

INFO_FREE_MEM_DYNAMIC, 18060 INFO_FREE_MEMS_STATIC.

Siemens supplies NCK with default settings that, depending on the model, have

certain (free) memory space available for the specific settings of the actual

applications. The original factory setting of NCK systems is thus that the alarm

does not occur with a cold start.

Alarm display.

The cause of this message may be that the NCK is running on hardware that is

not intended for this NCK version (i.e. it has insufficient memory).

If the application runs properly with the remaining free user memory (i.e. can be

started up without any errors), the message can simply be ignored.

Clear the alarm with the RESET key.

6410

Explanation

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-36 SINUMERIK 802D sl (DG)

TO unit %1 tool "%2" / duplo no. %3 has reached prewarning limit with

D = %4

%1 = TO unit

%2 = Tool identifier (name)

%3 = Duplo number

%4 = D number

Page 37

12.04 1 Alarms

Tool monitoring:

This message informs that the specified D offset has reached its prewarning

limit for a time- or quantity-monitored tool.

If possible, the D number is displayed; if not, value 0 is assigned to the 4th

parameter.

The actual type of tool monitoring is a tool property (see $TC TP9).

If replacement tools are not being used,

the duplo number specified has no meaning.

The alarm is triggered through the MMC or PLC (=OPI interface). The channel

context is not defined. The TO unit is specified for this reason.

Reactions

Remedy

Program continuation

Alarm display.

Interface signals are set.

For information only. The user must decide what to do.

Clear the alarm with the cancel key. No further operator action required.

6411

Explanation

Reactions

Remedy

Program continuation

Channel %1 tool "%2" / duplo no. %3 has reached prewarning limit with

D = %4

%1 = TO unit

%2 = Tool identifier (name).

%3 = Duplo number

%4 = D number

Tool monitoring:

This message informs that the specified D offset has reached its prewarning

limit for a time- or quantity-monitored tool.

If possible, the D number is displayed; if not, value 0 is assigned to the 4th

parameter.

The actual type of tool monitoring is a tool property (see $TC TP9).

If replacement tools are not being used,

the duplo number specified has no meaning.

The alarm originates during NC program execution.

Alarm display.

Interface signals are set.

For information only. The user must decide what to do.

Clear the alarm with the cancel key. No further operator action required.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-37

Page 38

1 Alarms 12.04

6412

Explanation

Reactions

Remedy

Program continuation

6413

Explanation

Reactions

Remedy

Program continuation

TO unit %1 tool "%2" / duplo no. %3 has reached monitoring limit with

D = %4

%1 = TO unit

%2 = Tool identifier (name)

%3 = Duplo number

%4 = D number

Tool monitoring:

This message informs that the specified D offset has reached its monitoring

limit for a time- or quantity-monitored tool.

If possible, the D number is displayed; if not, value 0 is assigned to the 4th

parameter.

The actual type of tool monitoring is a tool property (see $TC TP9).

If replacement tools are not being used, the duplo number specified has no

meaning.

The alarm is triggered through the MMC or PLC (=OPI interface). The channel

context is not defined. The TO unit is specified for this reason.

Alarm display.

Interface signals are set.

For information only. The user must decide what to do.

Clear the alarm with the cancel key. No further operator action required.

Channel %1 tool %2 / duplo no. %3 has reached monitoring limit with

D = %4

%1 = TO unit

%2 = Tool identifier (name)

%3 = Duplo number

%4 = D number

Tool monitoring:

This message informs that the specified D offset has reached its monitoring

limit for a time- or quantity-monitored tool.

If possible, the D number is displayed; if not, value 0 is assigned to the 4th

parameter.

The actual type of tool monitoring is a tool property (see $TC TP9).

If replacement tools are not being used, the duplo number specified has no

meaning.

The alarm originates during NC program execution.

Alarm display.

Interface signals are set.

For information only. The user must decide what to do.

Clear the alarm with the cancel key. No further operator action required.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-38 SINUMERIK 802D sl (DG)

Page 39

12.04 1 Alarms

6430

Explanation

Reactions

Remedy

Program continuation

Workpiece counter: Table of monitored cutting edges overflowed

No further entry of cutting edges possible in the workpiece counter table.

As many cutting edges can be noted for the workpiece counter as are possible

in total in the NCK.

This means that if for each tool each cutting edge is used precisely once for a

workpiece then the limit is reached.

If several workpieces are made on several tool holders/spindles simultaneously,

it is possible to note MD18100 MM_NUM_CUTTING_EDGES_IN_TOA cutting

edges for the workpiece counter for all of the workpieces.

If this alarm occurs, it means that cutting edges used subsequently are no

longer quantity monitored until the table has been emptied again, e.g. by means

of the NC language command SETPIECE or by the relevant job from MMC,

PLC (PI service).

Alarm display.

Interface signals are set.

NC Start disable.

- Have you forgotten to decrement the workpiece counter?

Then program SETPIECE in the part program or in the PLC program, insert

the command correctly.

- If the part program or the PLC is correct, then more memory should be set for

the tool cutting edges via machine data 18100

MM_NUM_CUTTING_EDGES_IN_TOA (only people with proper access

rights can do this!).

Clear the alarm with the cancel key. No further operator action required.

6431

Explanation

Reactions

Remedy

Program continuation

Function not allowed. Tool management/monitoring is not active

Occurs when a data management function is called which is not available

because ToolMan is deactivated. For example, the language commands GETT,

SETPIECE, GETSELT, NEWT, DELT.

Alarm display.

Interface signals are set.

Interpreter stop.

NC Start disable.

• Please inform the authorized personnel/service department.

• Make sure of how the NC is supposed to be configured! Is tool management

or tool monitoring needed but not activated?

• Are you using a part program that is meant for a numerical control with tool

management/tool monitoring? And now this part program is started on the

numerical control without tool management/tool monitoring This does not

work. Either run the part program on the appropriate NC control or edit the

part program.

• Activate tool management/tool monitoring by setting the appropriate

machine data.

See MD 18080 MM_TOOL_MANAGEMENT_MASK,

MD 20310 TOOL_MANAGEMENT_MASK.

• Check that the necessary option is set.

Clear the alarm with the cancel key. No further operator action required.

© Siemens AG, 2004. All rights reserved 6FC5398-2CP10-0BA0

SINUMERIK 802D sl (DG) 1-39

Page 40

1 Alarms 12.04

6432

Explanation

Reactions

Remedy

Program continuation

6500

Explanation

Reaction

Remedy

Program continuation

6510

Explanation

Reaction

Remedy

Program continuation

Function cannot executed. No tool assigned to spindle. Channel %1

%1=Channel number

If an attempt is made to perform an operation in the part program that requires

a tool to be assigned to the tool holder/spindle. This can be the quantity

monitoring function, for example.

Alarm display.

Interface signals are set.

• Select another function, another spindle/spindle, position tool on

spindle/spindle.

Clear the alarm with the Cancel key or with NC START

NC memory full

Too many part programs have been unloaded. The task cannot be executed.

During first start-up the files in the NC file system (part of the NC memory) may

be affected, for example initialization files, NC programs, etc.

Alarm display.

Delete or empty files (e.g. part programs).

Clear the alarm with the cancel key. No further operator action required.

Too many part programs in the NC memory

The number of files in the NC file system (part of the NC memory) has reached

the maximum number possible.

Alarm display.

Delete or empty files (e.g. part programs).

Clear the alarm with the cancel key. No further operator action required.

6530

Explanation

Reaction

Remedy

Program continuation

6540

Explanation

Reaction

Remedy

Program continuation

Too many files in directory

The number of files in one directory of the NC has reached the maximum limit.

Alarm display.

Delete or empty files (e.g. part programs) in the subdirectory affected.

Clear the alarm with the cancel key. No further operator action required.

Too many directories in the NC memory

The number of directories in the NC file system (part of the NC memory) has

reached the maximum number possible.

Alarm display.

Delete or empty directories (e.g. workpiece) that are not required.

Clear the alarm with the cancel key. No further operator action required.

6FC5398-2CP10-0BA0 © Siemens AG, 2004. All rights reserved

1-40 SINUMERIK 802D sl (DG)

Page 41

12.04 1 Alarms

6550

Explanation

Reaction

Remedy

Program continuation

6560

Explanation

Reaction

Remedy

Program continuation

6570

Explanation

Reaction

Remedy

Program continuation

Too many subdirectories

The number of subdirectories in a directory of the NC has reached the

maximum limit.

Alarm display.

Please inform the authorized personnel/service department.