Page 1

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Turning

SINUMERIK

SINUMERIK 802D sl

Turning

Programming and Operating Manual

Valid for

Control Software release

SINUMERIK 802D sl T/M 1.4 SP7

_________________

Foreword

_________________

Description

_________________

Software interface

Turning On, Reference

_________________

Point Approach

_________________

Set up

_________________

Manually Controlled Mode

_________________

Automatic mode

_________________

Part Programming

_________________

System

_________________

Programming

_________________

Cycles

_________________

Network operation

_________________

Data backup

_________________

PLC diagnostics

_________________

Appendix

1

2

3

4

5

6

7

8

9

10

11

12

13

A

11/2012

6FC5398-1CP10-7BA0

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5398-1CP10-7BA0

Ⓟ 08/2013 Technical data subject to change

Copyright © Siemens AG 2000 - 2012.

All rights reserved

Page 3

Foreword

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific

machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

● www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

● www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

3

Page 4

Foreword

SINUMERIK

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

Target group

This publication is intended for programmers, planning engineers, machine operators and

system operators.

Benefits

With the Programming and Operating Manual, the target group can develop, write, test and

debug programs and software user interfaces.

In addition, it enables the target group to operate the hardware and software of a machine.

Standard scope

This documentation only describes the functionality of the standard version. Extensions or

changes made by the machine tool manufacturer are documented by the machine tool

manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

For the sake of simplicity, this documentation does not contain all detailed information about

all types of the product and cannot cover every conceivable case of installation, operation, or

maintenance.

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be found on the Internet at:

http://support.automation.siemens.com

Here, enter the number 15257461 as the search term or contact your local Siemens office.

Turning

4 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 5

Table of contents

Foreword ...................................................................................................................................................

1 Description...............................................................................................................................................

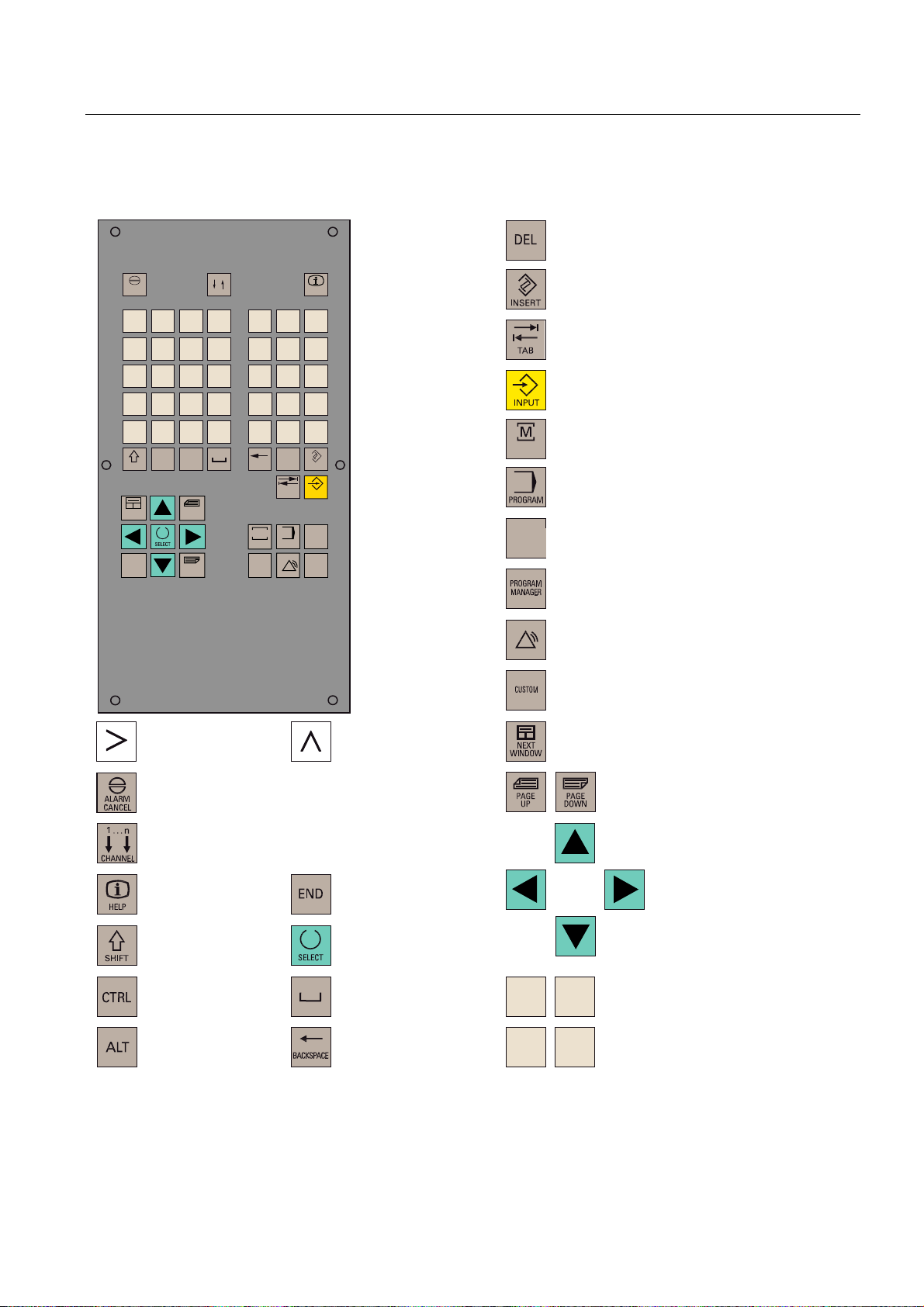

1.1 Control and display elements.......................................................................................................

1.2 Error and status displays .............................................................................................................

1.3 Key definition of the full CNC keyboard (vertical format).............................................................

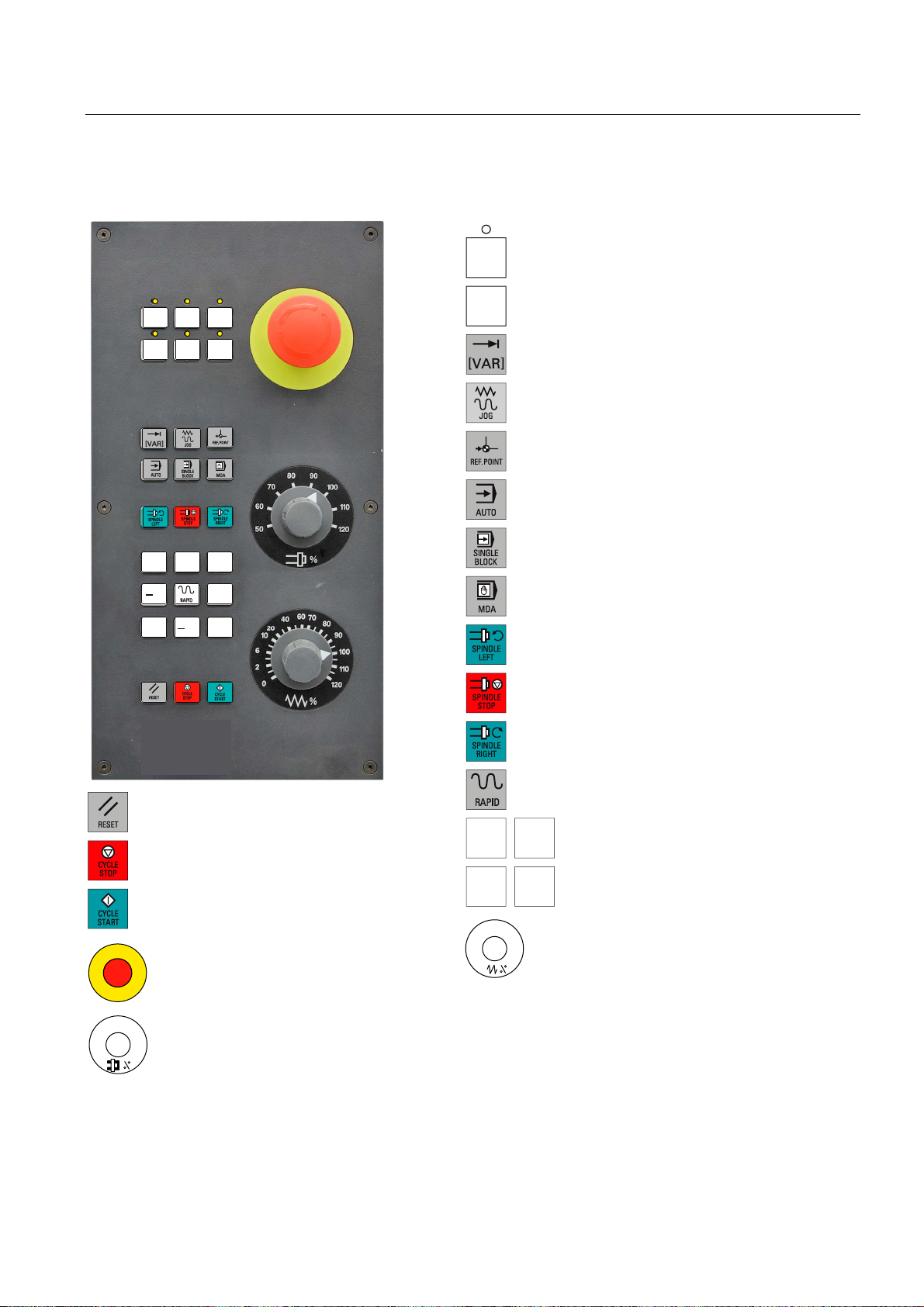

1.4 Key definition of the machine control panel .................................................................................

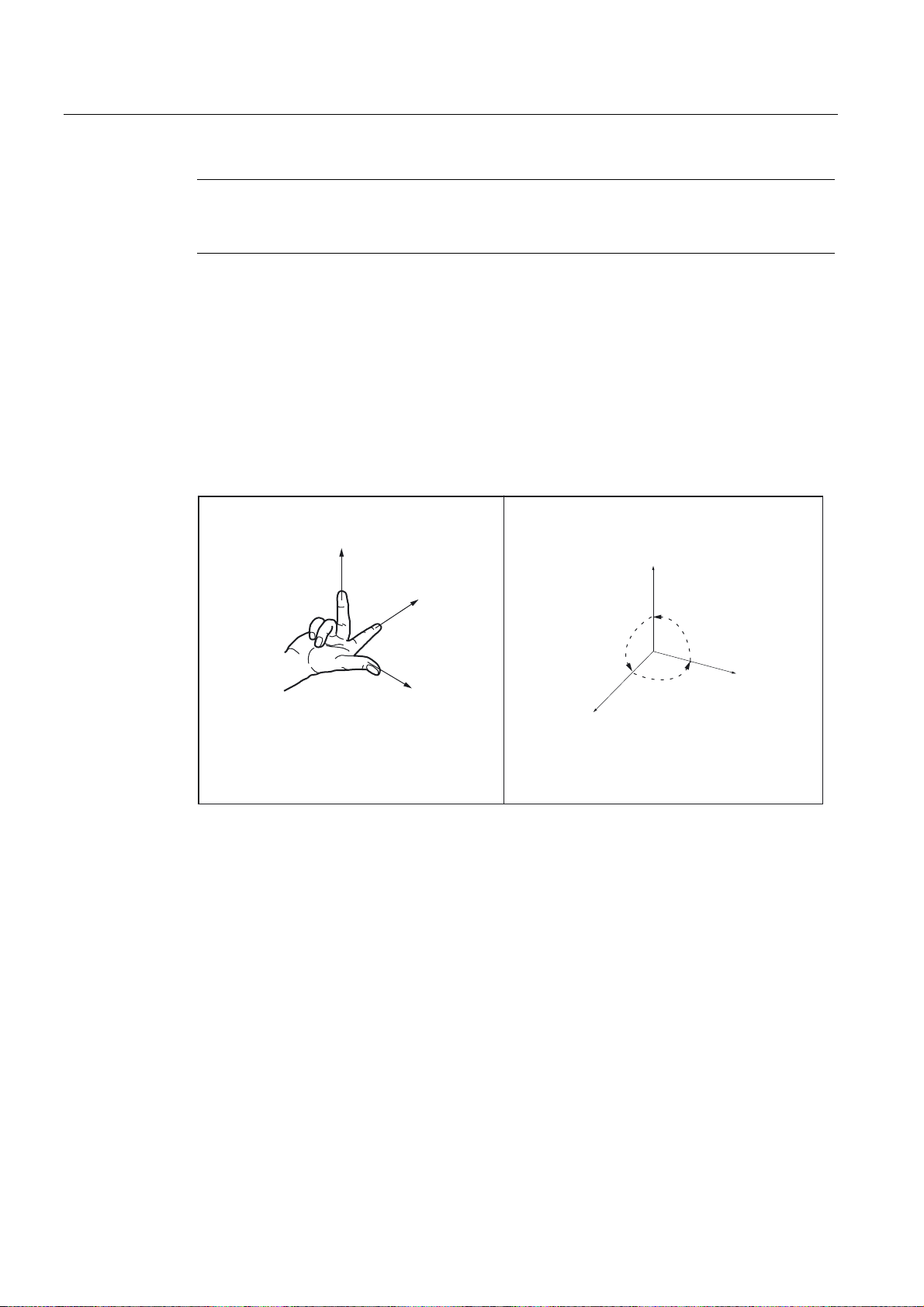

1.5 Coordinate systems .....................................................................................................................

2 Software interface....................................................................................................................................

2.1 Screen layout ...............................................................................................................................

2.2 Standard softkeys ........................................................................................................................

2.3 Operating areas ...........................................................................................................................

2.4 The help system...........................................................................................................................

3 Turning On, Reference Point Approach...................................................................................................

3.1 Switching on, reference point approach ......................................................................................

4 Set up ......................................................................................................................................................

4.1 Entering tools and tool offsets......................................................................................................

4.1.1 Entering tools and tool offsets......................................................................................................

4.1.2 Create new tool............................................................................................................................

4.1.3 Determining the tool offsets (manually) .......................................................................................

4.1.4 Determining tool offsets using a probe (auto)..............................................................................

4.1.5 Determining the tool offsets using optical measuring instruments ..............................................

4.1.6 Probe settings..............................................................................................................................

3

11

11

12

13

15

16

19

19

23

23

25

27

27

29

29

29

34

36

42

44

45

4.2 Tool monitoring ............................................................................................................................

4.3 Entering / modifying a work offset................................................................................................

4.3.1 Determining the work offset.........................................................................................................

4.4 Program setting data....................................................................................................................

4.5 R parameters - "Offset/Parameter"operating area.......................................................................

5 Manually Controlled Mode .......................................................................................................................

5.1 Manually Controlled Mode ...........................................................................................................

5.2 JOG mode - "Position" operating area.........................................................................................

5.2.1 Assigning handwheels .................................................................................................................

5.3 MDA mode (manual input) "Position" operating area .................................................................

5.3.1 Teach-in.......................................................................................................................................

5.3.2 Face turning.................................................................................................................................

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

47

49

50

51

55

57

57

58

62

63

67

70

5

Page 6

Table of contents

6 Automatic mode....................................................................................................................................... 73

6.1 AUTOMATIC mode .....................................................................................................................

6.2 Select and start a part program ..................................................................................................

6.3 Block search................................................................................................................................

6.4 Simultaneous recording ..............................................................................................................

6.5 Stop / cancel a part program.......................................................................................................

6.6 Reapproach after cancellation ....................................................................................................

6.7 Repositioning after interruption ...................................................................................................

6.8 Execute from external .................................................................................................................

7 Part Programming....................................................................................................................................

7.1 Part programming overview ........................................................................................................

7.2 Enter new program......................................................................................................................

7.3 Editing part programs or text files ...............................................................................................

7.4 Simulation....................................................................................................................................

7.5 Calculate contour elements.......................................................................................................

7.6 Free contour programming........................................................................................................

7.6.1 Program a contour ....................................................................................................................

7.6.2 Define a start point....................................................................................................................

7.6.3 Softkeys and parameters..........................................................................................................

7.6.4 Undercuts for turning technology..............................................................................................

7.6.5 Parameterize contour element..................................................................................................

7.6.6 Graphic representation of the contour ......................................................................................

7.6.7 Specify contour elements in polar coordinates, close the contour ...........................................

7.6.8 Parameter description of straight line/circle contour elements .................................................

7.6.9 Cycle support ............................................................................................................................

7.6.10 Programming example for turning application ..........................................................................

73

78

80

82

84

85

85

86

89

89

93

94

98

102

108

110

112

114

119

122

125

126

129

131

131

8 System...................................................................................................................................................

8.1 "System" operating area ...........................................................................................................

8.2 SYSTEM - "Start-up" softkeys...................................................................................................

8.3 SYSTEM - "Machine data" softkeys..........................................................................................

8.4 SYSTEM - "Service display" .....................................................................................................

8.4.1 SYSTEM - "Service display" .....................................................................................................

8.4.2 Action log...................................................................................................................................

8.4.3 Servo trace................................................................................................................................

8.4.4 Version/HMI details...................................................................................................................

8.4.5 Service MSG.............................................................................................................................

8.4.6 Date, time..................................................................................................................................

8.5 SYSTEM - "PLC" softkeys ........................................................................................................

8.6 SYSTEM - "Start-up files" softkeys ...........................................................................................

8.7 SYSTEM - "Commissioning wizard" softkeys ...........................................................................

Turning

135

135

140

141

148

148

149

150

154

157

163

165

172

177

6 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 7

Table of contents

8.8 Alarm display..............................................................................................................................179

9 Programming.........................................................................................................................................

9.1 Fundamental Principles of NC Programming ............................................................................

9.1.1 Program names .........................................................................................................................

9.1.2 Program structure ......................................................................................................................

9.1.3 Word structure and address.......................................................................................................

9.1.4 Block format...............................................................................................................................

9.1.5 Character set..............................................................................................................................

9.1.6 Overview of instructions - Turning .............................................................................................

9.1.7 Interactively call the window from the part program (MMC) ......................................................

9.2 Positional data ...........................................................................................................................

9.2.1 Programming dimensions ..........................................................................................................

9.2.2 Absolute / incremental dimensioning: G90, G91, AC, IC...........................................................

9.2.3 Dimensions in metric units and inches: G71, G70, G710, G700 ...............................................

9.2.4 Radius / diameter dimensions: DIAMOF, DIAMON, DIAM90....................................................

9.2.5 Programmable work offset: TRANS, ATRANS..........................................................................

9.2.6 Programmable scaling factor: SCALE, ASCALE.......................................................................

9.2.7 Workpiece clamping - settable work offset: G54 to G59, G500, G507 to 554, G53, G153.......

9.2.8 Programmable working area limitation: G25, G26, WALIMON, WALIMOF ..............................

9.3 Axis movements.........................................................................................................................

9.3.1 Linear interpolation with rapid traverse: G0...............................................................................

9.3.2 Linear interpolation with feedrate: G1........................................................................................

9.3.3 Circular interpolation: G2, G3 ....................................................................................................

9.3.4 Circular interpolation via intermediate point: CIP.......................................................................

9.3.5 Circle with tangential transition: CT ...........................................................................................

9.3.6 Thread cutting with constant lead: G33 .....................................................................................

9.3.7 Programmable run-in and run-out path for G33: DITS, DITE ....................................................

9.3.8 Thread cutting with variable lead: G34, G35 .............................................................................

9.3.9 Thread interpolation: G331, G332 .............................................................................................

9.3.10 Fixed point approach: G75.........................................................................................................

9.3.11 Reference point approach: G74.................................................................................................

9.3.12 Measuring with touch-trigger probe: MEAS, MEAW..................................................................

9.3.13 Feedrate F..................................................................................................................................

9.3.14 Exact stop / continuous-path control mode: G9, G60, G64 .......................................................

9.3.15 Acceleration pattern: BRISK, SOFT...........................................................................................

9.3.16 Percentage acceleration override: ACC ....................................................................................

9.3.17 Traversing with feedforward control: FFWON, FFWOF.............................................................

9.3.18 3. and 4th axis............................................................................................................................

9.3.19 Dwell Time: G4...........................................................................................................................

9.3.20 Travel to fixed stop.....................................................................................................................

9.3.21 Feed reduction with corner deceleration (FENDNORM, G62, G621)........................................

9.3.22 Coupled axes .............................................................................................................................

9.3.22.1 Coupled motion (TRAILON, TRAILOF) .....................................................................................

9.3.22.2 Master/slave group (MASLDEF, MASLDEL, MASLON, MASLOF, MASLOFS) .......................

181

181

181

181

182

183

185

186

201

203

203

204

206

207

208

209

211

212

214

214

215

216

220

221

221

225

226

228

229

231

231

233

234

236

237

238

239

240

241

244

245

245

249

9.4 Spindle movements ...................................................................................................................

9.4.1 Spindle speed S, directions of rotation ......................................................................................

9.4.2 Spindle speed limitation: G25, G26 ...........................................................................................

9.4.3 Spindle positioning.....................................................................................................................

9.4.3.1 Spindle positioning (SPOS, SPOSA, M19, M70, WAITS) .........................................................

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

253

253

254

255

255

7

Page 8

Table of contents

9.4.4 Gear stages............................................................................................................................... 263

9.4.5 2. Spindle ..................................................................................................................................

263

9.5 Special turning functions ...........................................................................................................

9.5.1 Constant cutting rate: G96, G97 ...............................................................................................

9.5.2 Rounding, chamfer....................................................................................................................

9.5.3 Contour definition programming................................................................................................

9.6 Tool and tool offset....................................................................................................................

9.6.1 General information (turning)....................................................................................................

9.6.2 Tool T (turning)..........................................................................................................................

9.6.3 Tool offset number D (turning)..................................................................................................

9.6.4 Selecting the tool radius compensation: G41, G42 ..................................................................

9.6.5 Corner behavior: G450, G451...................................................................................................

9.6.6 Tool radius compensation OFF: G40........................................................................................

9.6.7 Special cases of the tool radius compensation.........................................................................

9.6.8 Example of tool radius compensation (turning).........................................................................

9.6.9 Use of milling cutters.................................................................................................................

9.6.10 Special handling of tool compensation (turning).......................................................................

9.7 Miscellaneous function M..........................................................................................................

9.8 H function ..................................................................................................................................

9.9 Arithmetic parameters, LUD and PLC variables .......................................................................

9.9.1 Arithmetic parameter R.............................................................................................................

9.9.2 Local User Data (LUD)..............................................................................................................

9.9.3 Reading and writing PLC variables...........................................................................................

9.10 Program jumps..........................................................................................................................

9.10.1 Jump destination for program jumps.........................................................................................

9.10.2 Unconditional program jumps ...................................................................................................

9.10.3 Conditional program jumps .......................................................................................................

9.10.4 Program example for jumps......................................................................................................

265

265

267

270

272

272

273

274

278

280

281

282

283

284

286

287

288

289

289

291

293

294

294

294

295

297

9.11 Subroutine technique ................................................................................................................

9.11.1 General information...................................................................................................................

9.11.2 Calling machining cycles (turning) ............................................................................................

9.11.3 Execute external subroutine (EXTCALL) ..................................................................................

9.12 Timers and workpiece counters ................................................................................................

9.12.1 Runtime timer............................................................................................................................

9.12.2 Workpiece counter ....................................................................................................................

9.13 Language commands for tool monitoring..................................................................................

9.13.1 Tool monitoring overview ..........................................................................................................

9.13.2 Tool life monitoring....................................................................................................................

9.13.3 Workpiece count monitoring......................................................................................................

9.14 Milling on turning machines.......................................................................................................

9.14.1 Milling of the front face - TRANSMIT ........................................................................................

9.14.2 Milling of the peripheral surface - TRACYL...............................................................................

10 Cycles....................................................................................................................................................

10.1 Overview of cycles ....................................................................................................................

10.2 Programming cycles..................................................................................................................

Turning

299

299

302

302

305

305

307

308

308

311

313

317

317

319

327

327

328

8 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 9

Table of contents

10.3 Graphical cycle support in the program editor ...........................................................................330

10.4 Drilling cycles .............................................................................................................................

10.4.1 General information ...................................................................................................................

10.4.2 Requirements.............................................................................................................................

10.4.3 Drilling, centering - CYCLE81....................................................................................................

10.4.4 Drilling, counterboring - CYCLE82:............................................................................................

10.4.5 Deep-hole drilling - CYCLE83....................................................................................................

10.4.6 Rigid tapping - CYCLE84...........................................................................................................

10.4.7 Tapping with compensating chuck - CYCLE840 .......................................................................

10.4.8 Reaming1 (boring 1) – CYCLE85 ..............................................................................................

10.4.9 Boring (boring 2) – CYCLE86 ....................................................................................................

10.4.10 Boring with stop 1 (boring pass 3) – CYCLE87 .........................................................................

10.4.11 Drilling with stop 2 (boring 4) - CYCLE88 ..................................................................................

10.4.12 Reaming 2 (boring 5) – CYCLE89 .............................................................................................

10.4.13 Row of holes - HOLES1.............................................................................................................

10.4.14 Circle of holes - HOLES2...........................................................................................................

10.5 Turning cycles ............................................................................................................................

10.5.1 Requirements.............................................................................................................................

10.5.2 Groove - CYCLE93 ....................................................................................................................

10.5.3 Undercut (forms E and F to DIN) - CYCLE94............................................................................

10.5.4 Cutting with relief cut – CYCLE95..............................................................................................

10.5.5 Thread undercut - CYCLE96 .....................................................................................................

10.5.6 Thread cutting - CYCLE97.........................................................................................................

10.5.7 Chaining of threads – CYCLE98................................................................................................

10.6 Error messages and error handling ...........................................................................................

10.6.1 General Information ...................................................................................................................

10.6.2 Error handling in the cycles........................................................................................................

10.6.3 Overview of cycle alarms ...........................................................................................................

10.6.4 Messages in the cycles..............................................................................................................

331

331

332

335

338

340

344

348

354

356

360

362

364

366

370

374

374

376

384

389

402

407

414

421

421

421

421

423

11 Network operation..................................................................................................................................

11.1 Interfaces and functions of the RCS802 tool .............................................................................

11.2 Working on the basis of a network connection ..........................................................................

11.3 User management .....................................................................................................................

11.4 User log in - RCS log in .............................................................................................................

11.5 Setting the connections on the RCS802 tool .............................................................................

11.6 Establishing an RS232 connection to the control ......................................................................

11.7 Establishing a peer-to-peer Ethernet connection to the control.................................................

11.8 Establish the Ethernet network connection to the control (only with SINUMERIK 802D sl

pro).............................................................................................................................................

11.9 Additional network functions ......................................................................................................

11.9.1 Sharing directories .....................................................................................................................

11.9.2 Connecting / disconnecting network drives ...............................................................................

12 Data backup ..........................................................................................................................................

12.1 Data transfer via RS232 interface..............................................................................................

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

425

426

427

428

429

430

431

432

434

436

436

437

441

441

9

Page 10

Table of contents

12.2 Creating / reading in / reading out a start-up archive................................................................ 443

12.3 Reading in / reading out PLC projects ......................................................................................

12.4 Copying and pasting files ..........................................................................................................

13 PLC diagnostics.....................................................................................................................................

13.1 Screen layout ............................................................................................................................

13.2 Operating options......................................................................................................................

A Appendix................................................................................................................................................

A.1 Miscellaneous ...........................................................................................................................

A.1.1 Pocket calculator.......................................................................................................................

A.1.2 Editing asian characters............................................................................................................

A.1.2.1 Simplified Chinese ....................................................................................................................

A.1.2.2 Traditional Chinese (as used in Taiwan)...................................................................................

A.1.2.3 Importing the dictionary.............................................................................................................

A.1.2.4 Korean.......................................................................................................................................

A.2 Overview of documentation.......................................................................................................

Index......................................................................................................................................................

446

446

447

448

449

461

461

461

462

463

466

469

470

472

473

Turning

10 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 11

Description

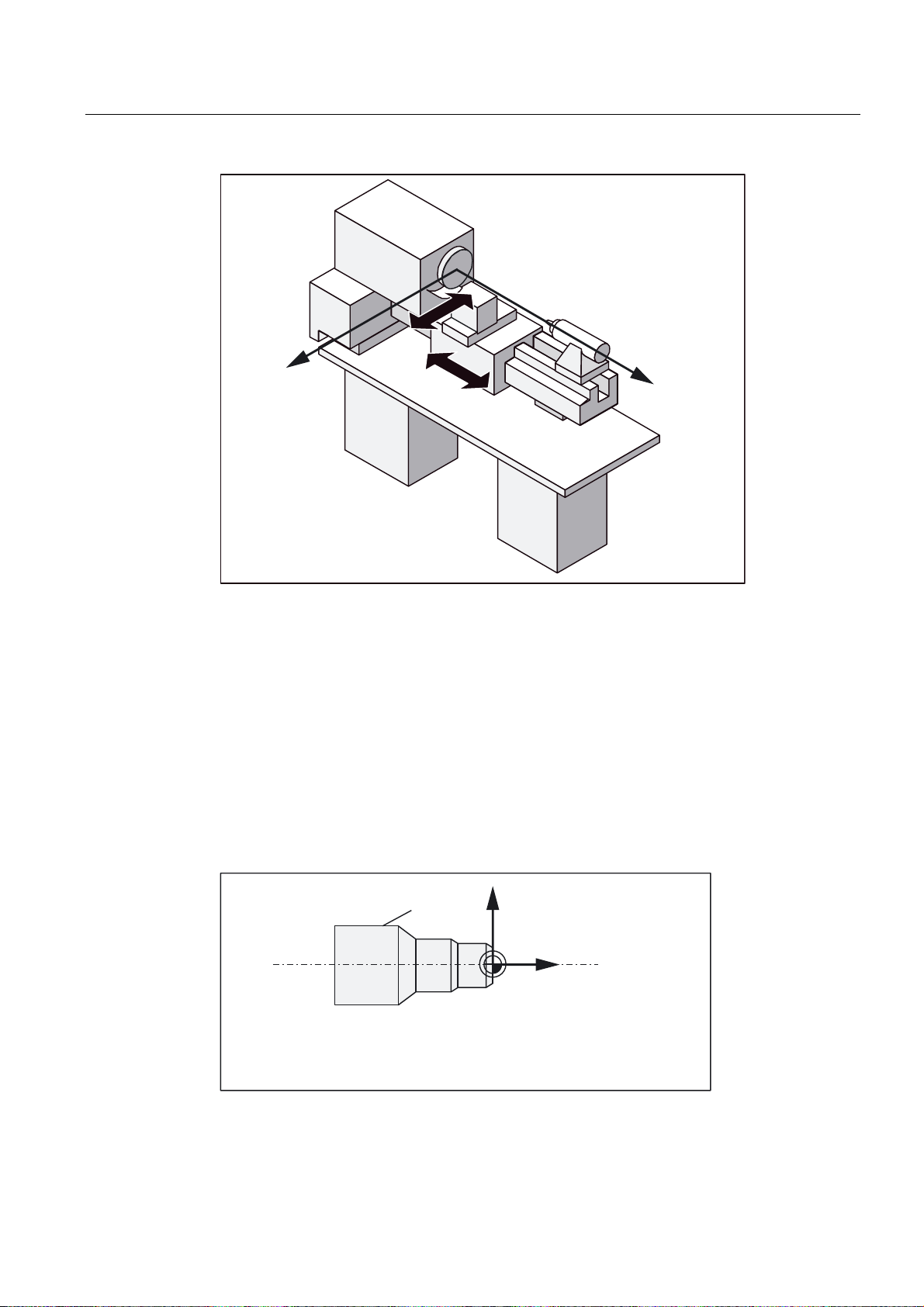

1.1 Control and display elements

Operator control elements

The defined functions are called up via the horizontal and vertical softkeys. For a description,

please refer to this manual:

1

9HUWLFDOVRIWNH\V

Figure 1-1 CNC operator panel

+RUL]RQWDOVRIWNH\V

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

11

Page 12

Description

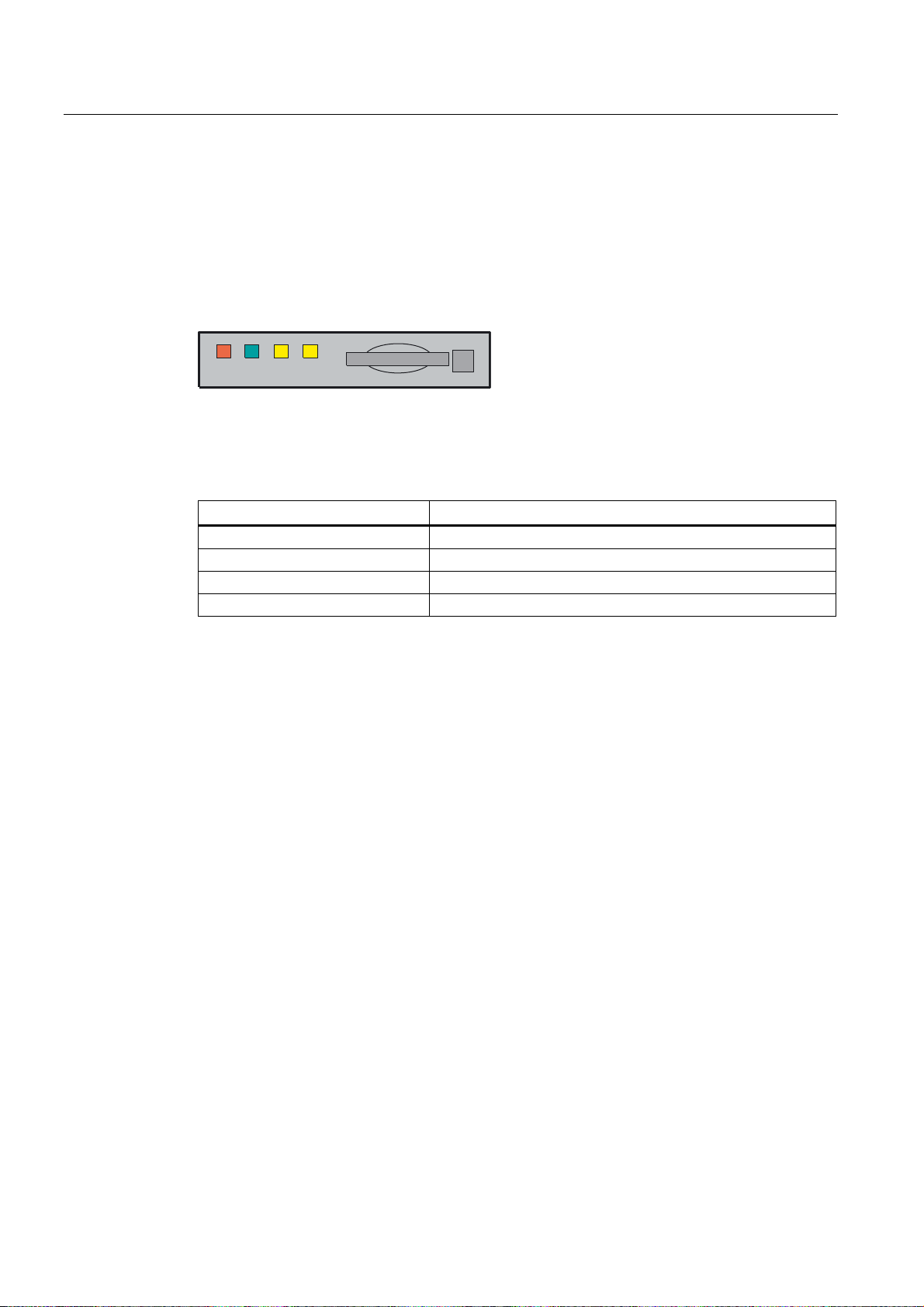

1.2 Error and status displays

1.2 Error and status displays

LED displays on the CNC operator panel (PCU)

The following LEDs are installed on the CNC operator panel.

(55 5'< 1& &)

The individual LEDs and their functions are described in the table below.

Table 1- 1 Status and error displays

LED Significance

ERR (red) Serious error, remedy through power OFF/ON

RDY (green) Ready for operation

NC (yellow) Signoflife monitoring

CF (yellow) Reading from/writing to CF card

References

You can find information on error description in the SINUMERIK 802D sl Diagnostics Manual

Turning

12 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 13

Description

1.3 Key definition of the full CNC keyboard (vertical format)

1.3 Key definition of the full CNC keyboard (vertical format)

&OHDUNH\

$/$50

&$1&(/

2

8

;

0

>

)

6+,)7

1(;7

:,1'2:

(1'

Q

&+$11(/

1

9

<

$

,

-

6

'

&75/

?

(

*

:

=

ಱ

.

7

_

+

$/7

3$*(

83

3$*(

'2:1

3

4

&

@

5

/

"

%

%$&.63$&(

0

326,7,21

3URJUDP

0DQDJHU

#

'(/

7$%

352*5$0

6<67(0

$/$50

+(/3

!

,16(57

,1387

2))6(7

3$5$0

&86720

,QVHUWNH\

7DEXODWRU

(17(5,QSXWNH\

326,7,21RSHUDWLQJDUHDNH\3RVLWLRQ

326,7,21

RSHUDWLQJDUHD

352*5$0RSHUDWLQJDUHDNH\

RSHUDWLQJDUHDSURJUDP

2))6(7

3$5$0

2))6(73$5$0RSHUDWLQJDUHDNH\

3DUDPHWHURSHUDWLQJDUHD

352*5$00$1$*(5RSHUDWLQJDUHDNH\

3URJUDP0DQDJHURSHUDWLQJDUHD

6<67(0

$/$50

6<67(0$/$50RSHUDWLQJDUHDNH\

6\VWHP$ODUPRSHUDWLQJDUHD

&86720RSHUDWLQJDUHDNH\

8VHURSHUDWLQJDUHD

(7&NH\

$FNQRZOHGJHDODUPNH\

1RIXQFWLRQ

,QIRNH\

6KLIWNH\

&RQWURONH\

$/7NH\

5HFDOONH\

6HOHFWLRQNH\WRJJOHNH\

6SDFH

'HOHWHNH\%DFNVSDFH

1RWDVVLJQHG

6FUROONH\V

&XUVRUNH\V

$

:

=

-

$OSKDQXPHULFNH\V

'RXEOHDVVLJQPHQWRQWKHVKLIWOHYHO

1XPHULFNH\V

'RXEOHDVVLJQPHQWRQWKHVKLIWOHYHO

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

13

Page 14

Description

1.3 Key definition of the full CNC keyboard (vertical format)

Hot keys

In the part program editor and in the input fields of the HMI, the following functions can be

carried out with certain shortcut keys on the full CNC keyboard:

Shortcut key Function

<CTRL> and <C> Copy selected text

<CTRL> and <B> Select text

<CTRL> and <X> Cut selected text

<CTRL> and <V> Paste copied text

<CTRL> and <P> Generates a screenshot of the actual screen and

saves the image on CompactFlash Card

(customer CF Card) under "screen802dsl.bmp "

<CTRL> and <R> HMI restart

<CTRL> and <S> Data backup in case of backlight failure

The series start-up archive (Drive/NC/PLC/HMI)

is exported with the most recent data onto the

CompactFlash card with the name

"802Dslibn.arc".

<ALT> and <L> Toggling between only upper case letters and

upper and lower case letters

<ALT> and <H> or <HELP> key Call help system

<ALT> and <S> Switch-in and switch-out the Editor for Asian

characters

Turning

14 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 15

Description

1.4 Key definition of the machine control panel

1.4 Key definition of the machine control panel

8VHUGHILQHGNH\ZLWK/('

8VHUGHILQHGNH\ZLWKRXW/('

,1&5(0(17

,QFUHPHQW

-2*

5()(5(1&(32,17

5HIHUHQFHSRLQW

$8720$7,&

6,1*/(%/2&.

;

6LQJOHEORFN

=

=

;

5(6(7

&<&/(6723

1&6723

&<&/(67$57

1&67$57

(0(5*(1&<2))

;

=

;

=

0$18$/'$7$

0DQXDOLQSXW

63,1'/(67$57&&:

&RXQWHUFORFNZLVH

63,1'/(6723

63,1'/(67$57&:

&ORFNZLVH

5$3,'75$9(56(29(5/$<

5DSLGWUDYHUVHRYHUULGHRYHUOD\

;D[LV

=D[LV

)HHGUDWHRYHUULGH

)HHGUDWHRYHUULGH

6SLQGOH6SHHG2YHUULGH

6SLQGOHRYHUULGH

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

15

Page 16

Description

1.5 Coordinate systems

Note

This documentation assumes an 802D standard machine control panel (MCP). Should you

use a different MCP, the operation may be other than described herein.

1.5 Coordinate systems

As a rule, a coordinate system is formed from three mutually perpendicular coordinate axes.

The positive directions of the coordinate axes are defined using the so-called "3-finger rule"

of the right hand. The coordinate system is related to the workpiece and programming takes

place independently of whether the tool or the workpiece is being traversed. When

programming, it is always assumed that the tool traverses relative to the coordinate system

of the workpiece, which is intended to be stationary.

=

;

<

=

90°

<

90°

90°

;

Figure 1-2 Determining the axis directions to one another; coordinate system for programming

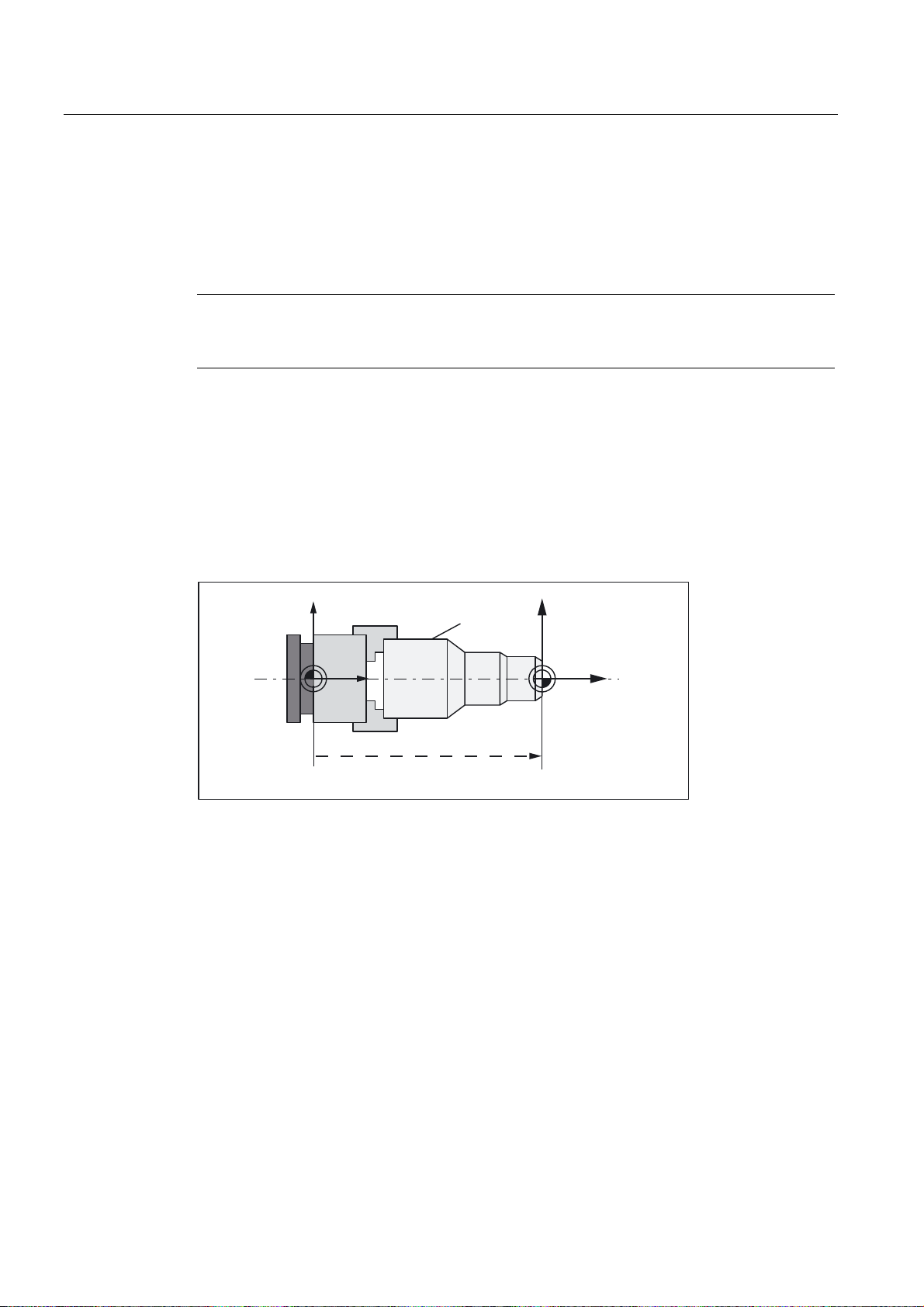

Machine coordinate system (MCS)

The orientation of the coordinate system relative to the machine depends on the respective

machine type. It can be rotated in different positions.

The directions of the axes follow the "3-finger rule" of the right hand. Seen from in front of the

machine, the middle finger of the right hand points in the opposite direction to the infeed of

the main spindle.

Turning

16 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 17

Description

1.5 Coordinate systems

;

Figure 1-3 Machine coordinate axes using the example of a turning machine

The origin of this coordinate system is the machine zero.

This point is only a reference point which is defined by the machine manufacturer. It does not

have to be approachable.

The traversing range of the machine axes can by in the negative range.

Workpiece coordinate system (WCS)

To describe the geometry of a workpiece in the workpiece program, a right-handed, rightangled coordinate system is also used.

The workpiece zero can be freely selected by the programmer in the Z axis. In the X axis, it

lies in the turning center.

=

:RUNSLHFH

: ZRUNSLHFH]HUR

Figure 1-4 Workpiece Coordinate System

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

;

:RUNSLHFH

:

=

:RUNSLHFH

17

Page 18

Description

=

;

:

;

=

0b

1.5 Coordinate systems

Relative coordinate system (REL)

In addition to the machine and workpiece coordinate systems, the control system provides a

relative coordinate system. This coordinate system is used for setting reference points that

can be freely selected and have no influence on the active workpiece coordinate system. All

axis movements are displayed relative to these reference points.

Note

You can activate and display the actual value of the relevant coordinate system by pressing

the vertical softkey "MCS/WCS REL" in the Position operating area.

Clamping the workpiece

For machining, the workpiece is clamped on the machine. The workpiece must be aligned

such that the axes of the workpiece coordinate system run in parallel with those of the

machine. Any resulting offset of the machine zero with reference to the workpiece zero is

determined along the Z axis and entered in a data area intended for the settable work offset.

In the NC program, this offset is activated during program execution, e.g. using a

programmed G54.

0DFKLQH

0b

Figure 1-5 Workpiece on the machine

Current workpiece coordinate system

The programmed work offset TRANS can be used to generate an offset with reference to the

workpiece coordinate system resulting in the current workpiece coordinate system resulting

in the current workpiece coordinate system (see section "Programmable work offset:

TRANS").

0DFKLQH

:RUNSLHFH

:RUNSLHFH

:RUNSLHFH

HJ*

Turning

18 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 19

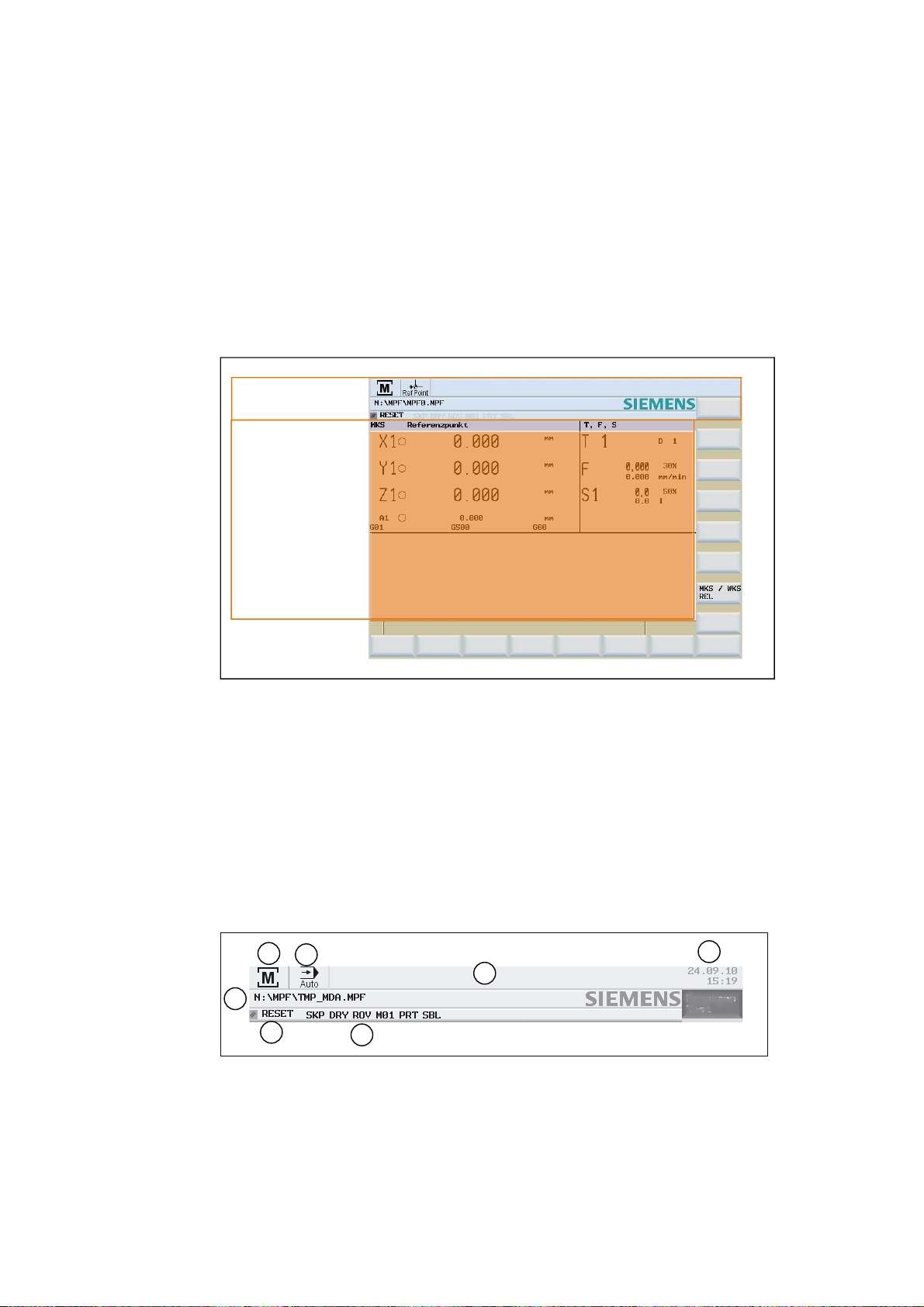

Software interface

2.1 Screen layout

6WDWXVDUHD

$SSOLFDWLRQDUHD

7LS

DQGVRIWNH\DUHD

Figure 2-1 Screen layout

2

Status area

The screen is divided into the following main areas:

● Status area

● Application area

● Note and softkey area

Figure 2-2 Status area

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

19

Page 20

Software interface

2.1 Screen layout

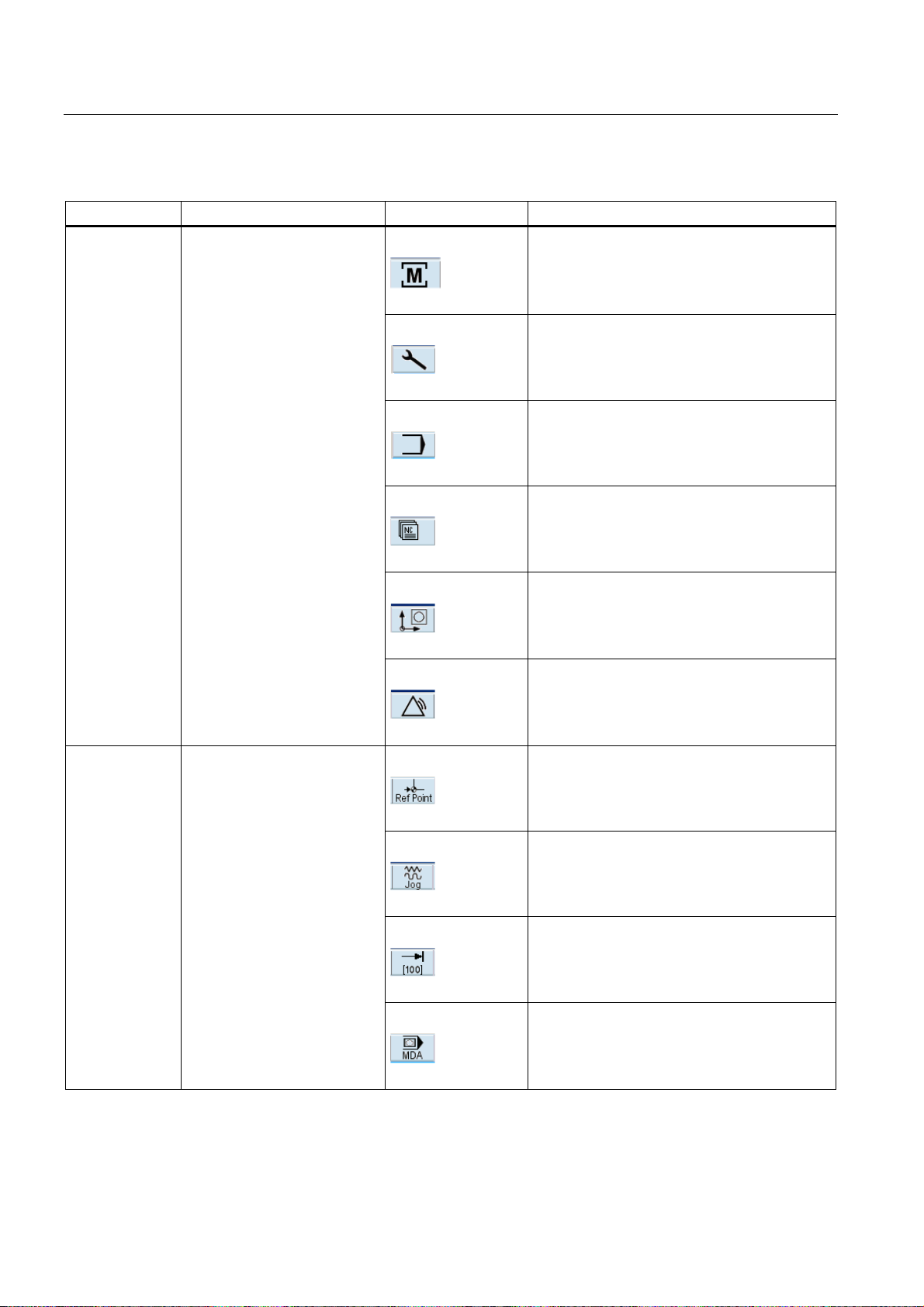

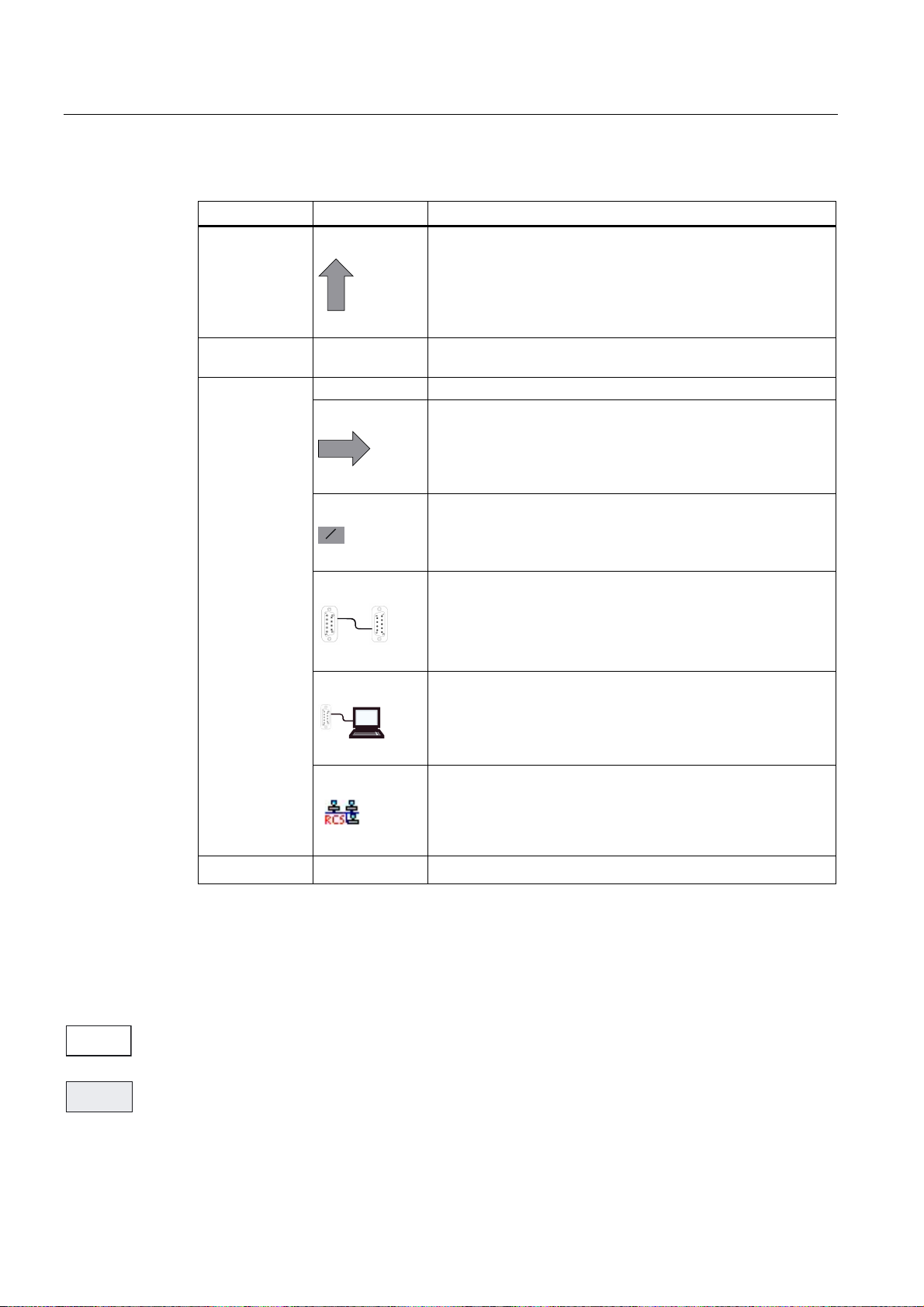

Table 2- 1 Explanation of the screen controls in the status area

Numbering Display Icon Significance

①

Active operating area

Position (operating area key <POSITION>)

System (operating area key <SYSTEM>)

Program (operating area key <PROGRAM>)

Program Manager (operating area key

<PROGRAM MANAGER>)

Parameter (operating area key <OFFSET

PARAM>)

Alarm (operating area key <ALARM>)

②

Active mode

Approaching a reference point

JOG

JOG INC; 1 INC, 10 INC, 100 INC, 1000 INC,

VAR INC

(incremental evaluation in the JOG mode)

MDA

Turning

20 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 21

Software interface

2.1 Screen layout

Numbering Display Icon Significance

AUTOMATIC

③

④

⑤

⑥

⑦

Alarm and message line In addition, the following is displayed:

1. Alarm number with alarm text, or

2. Message text

Selected part program (main program)

Program state

Program control in automatic

mode

Date and time From version 1.4 SP 6 and higher, the date and

RESET Program canceled / default state

RUN Program is running

STOP Program stopped

SKP Skip: Skip block

DRY Dry Run: Dry run feedrate

ROV Rapid Override: Rapid traverse override

M01 Conditional stop

PRT Program test

SBL Single Block: Single block

the time are displayed.

Note and softkey area

Figure 2-3 Note and softkey area

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

21

Page 22

Software interface

2.1 Screen layout

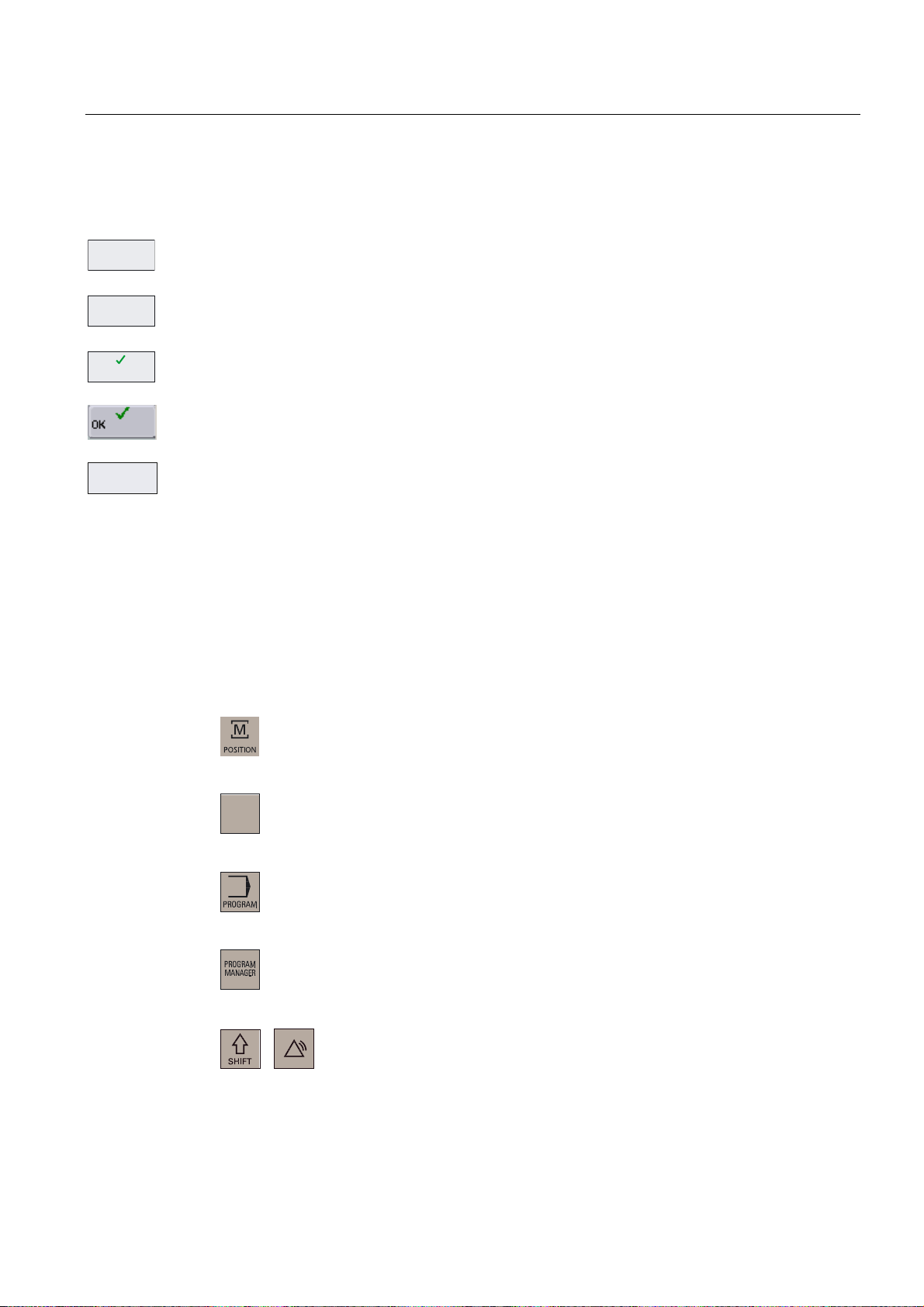

Table 2- 2 Explanation of the screen controls in the note and softkey area

Screen item Display Significance

①

RECALL symbol

Pressing the <RECALL> key lets you return to the higher menu

level.

②

③

Information line

Displays notes and information for the operator and fault states

HMI status information

ETC is possible (pressing this key displays the horizontal

softkey bar providing further functions.)

ಯ/ಯ

Mixed notation active (uppercase/lowercase letters)

RS232 connection active

④

Softkey bar vertical and horizontal

Display of the softkeys in the document

To make the softkeys easier to locate, the horizontal and vertical softkeys are displayed in

different basic colors.

Horizontal softkey

Vertical softkey

Connection to commissioning and diagnostic tools (e.g.

Programming Tool 802) active

RCS network connection active

Turning

22 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 23

Software interface

;

2.2 Standard softkeys

2.2 Standard softkeys

%DFN

Use this softkey to close the screen.

$ERUW

Use this softkey to cancel the input; the window is closed.

$FFHSW

Selecting this softkey will complete your input and start the calculation.

Selecting this softkey will complete your input and accept the values you have entered.

8VHU

IXQFWLRQ

User-specific functions are called in the operating areas <POSITION>, <OFFSET

PARAMETER> and <SYSTEM>. The softkey is only visible if the machine manufacturer

saved special functions.

Refer to the following documentation for softkey activation: Operating Instructions,

SINUMERIK 802D sl Turning, Milling, Grinding, Chapter: Activating "User function" softkey.

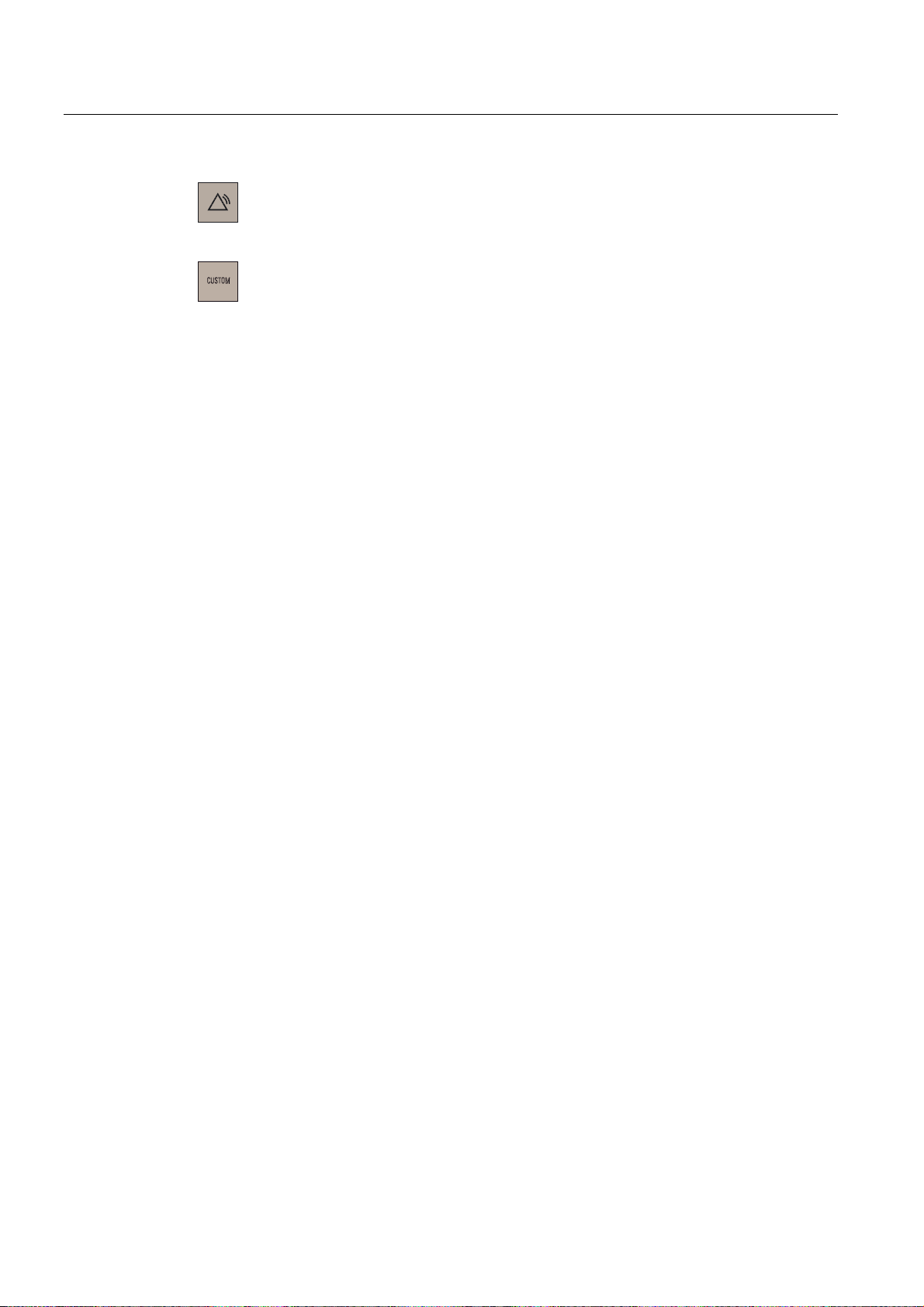

2.3 Operating areas

The functions of the control system can be carried out in the following operating areas:

2))6(7

3$5$0

6<67(0

$/$50

POSITION

Machine operation

OFFSET PARAM Entering the compensation values and setting data

PROGRAM

Creation of part programs

PROGRAM

Part program directory

MANAGER

SYSTEM

Diagnostics, commissioning

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

23

Page 24

Software interface

2.3 Operating areas

Protection levels

6<67(0

$/$50

ALARM

Alarm and message lists

CUSTOM

Users can call their own application

To change to another operating area, press the relevant key on the CNC full keyboard (hard

key).

The SINUMERIK 802D sl provides a concept of protection levels for enabling data areas.

The control system is delivered with default passwords for the protection levels 1 to 3.

Protection level 1 Experts password

Protection level 2 Manufacturer password

Protection level 3 User password

These control the various access rigths.

In the menus listed below the input and modification of data depends on the protection level

set:

● Tool offsets

● Work offsets

● Setting data

● RS232 settings

● Program creation / program correction

Turning

24 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 25

Software interface

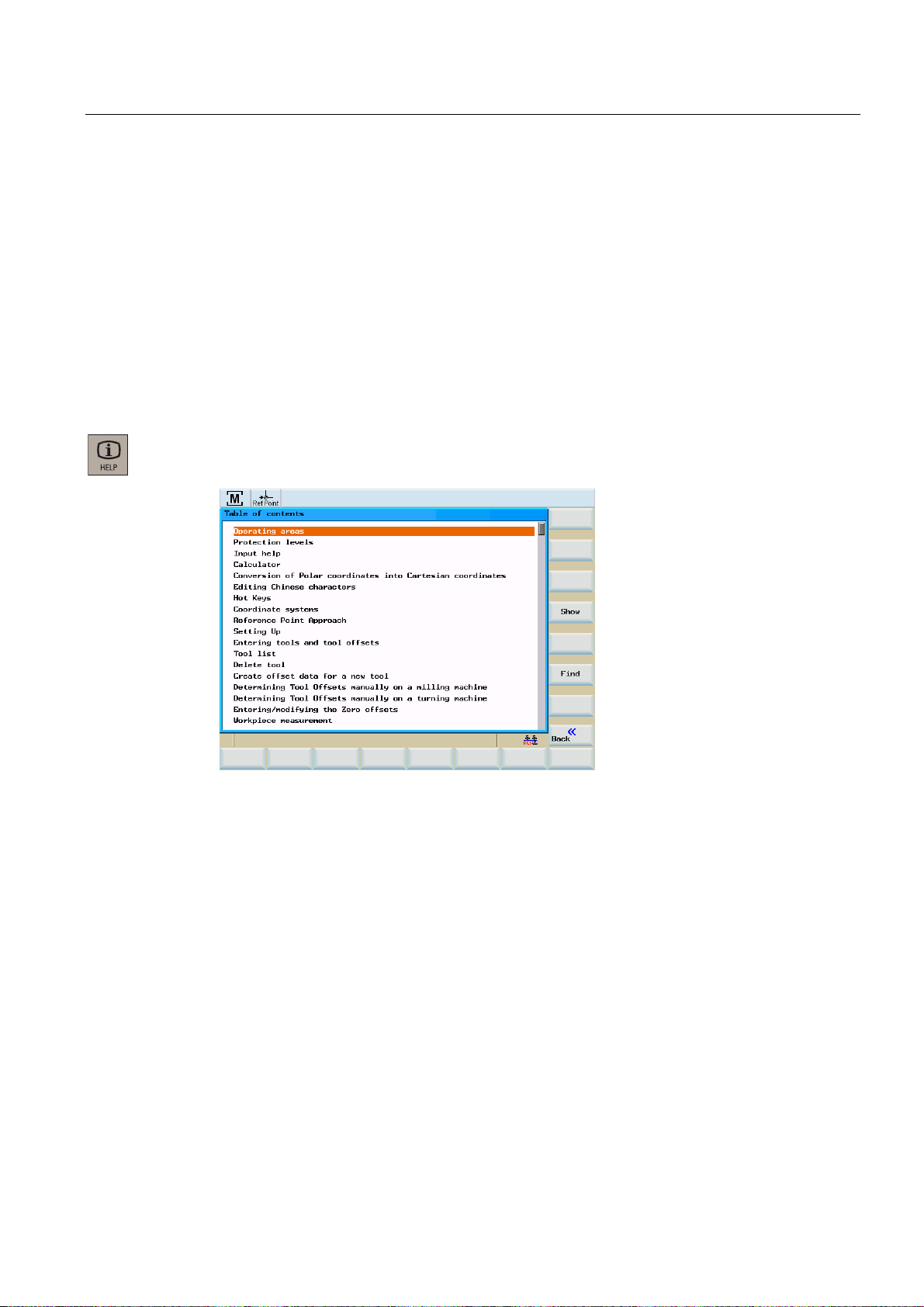

2.4 The help system

2.4 The help system

Comprehensive online help is stored in the control system. Some help topics are:

● Product brief of all important operating functions

● Overview and product brief of the NC commands

● Explanation of the drive parameters

● Explanation of the drive alarms

Operating sequence

You can call the help system from any operating area either by pressing the Info key or by

using the key combination <ALT+H>.

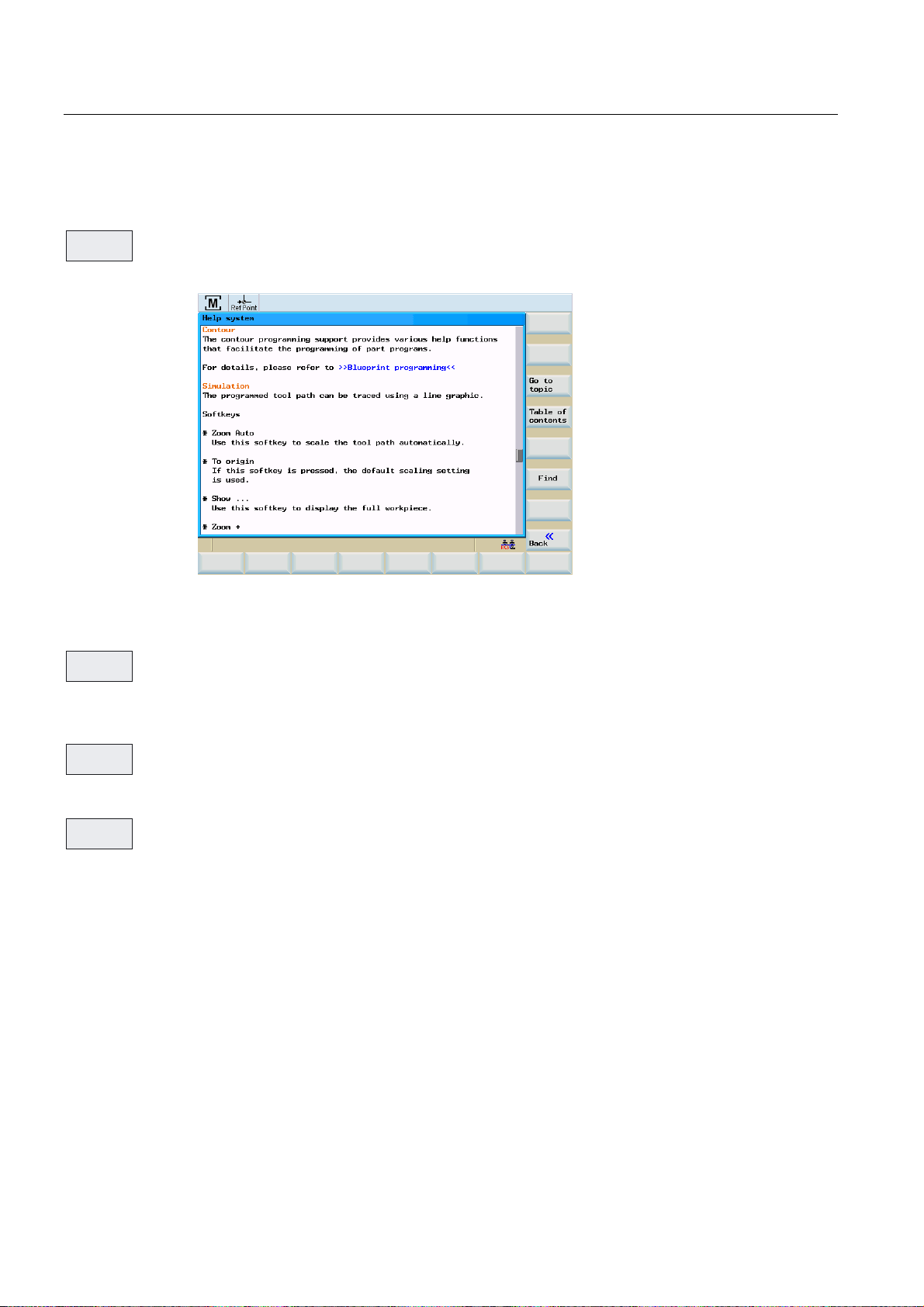

Figure 2-4 Help system: Table of contents

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

25

Page 26

Software interface

2.4 The help system

Softkeys

6KRZ

*RWR

7RSLF

This function opens the selected topic.

Figure 2-5 Help system: Description of the topic

Use this function to select cross references. A cross reference is marked by the characters

">>....<<". This softkey is only displayed if a cross reference is displayed in the application

area.

%DFNWR

7RSLF

If you select a cross-reference, the "Back to topic" softkey will also be displayed. Select this

function to go back to the previous screen.

)LQG

Use this function to search for a term in the table of contents. Type the term you are looking

for and start the search process.

Help in the "Program editor" area

The help system offers an explanation for each NC operation. To display the infotext directly,

position the cursor after the appropriate operation and press the Info key. The NC instruction

must be written using uppercase letters.

Turning

26 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 27

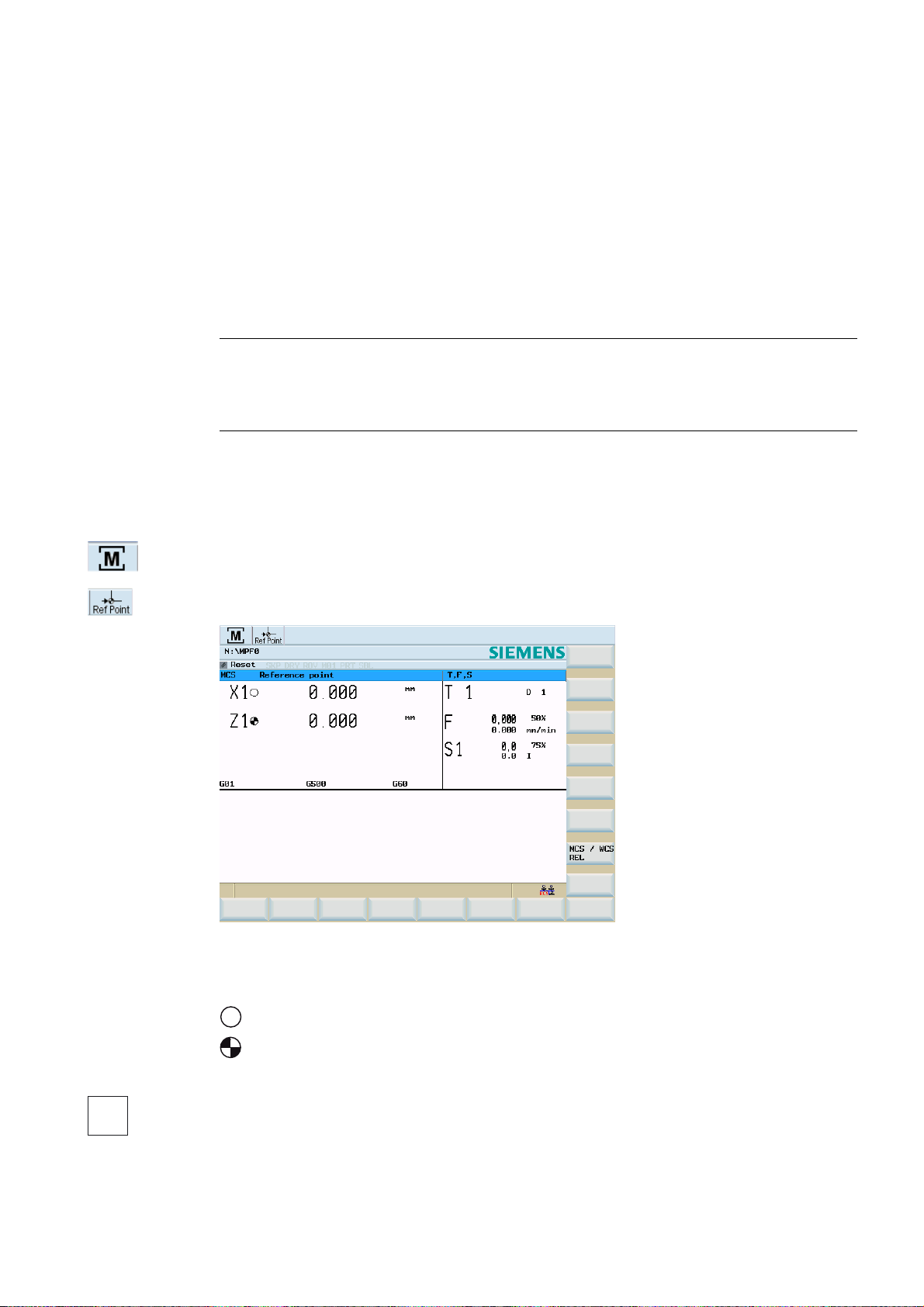

Turning On, Reference Point Approach

3.1 Switching on, reference point approach

Operating sequence

Note

When turning on the SINUMERIK 802D sl and the machine, please also observe the

machine documentation, since turning on and reference point approach are machinedependent functions.

First, switch on the power supply for the CNC and the machine.

After the control system has booted, you are in the "Position" operating area, in the

"Reference point approach" mode.

The 'Reference point' window is active.

3

Figure 3-1 Reference-point approach start screen

The "Reference point" window displays whether the axes are referenced.

$[LVPXVWEHUHIHUHQFHG

$[LVLVUHIHUHQFHGV\QFKURQL]HG

;

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Press the arrow keys.

27

Page 28

Turning On, Reference Point Approach

3.1 Switching on, reference point approach

=

If you select the wrong approach direction, no motion is carried out.

One after the other, move each axis to the reference point.

You can exit the function by selecting another operating mode (MDA, AUTOMATIC or JOG).

To access the functions described below, you need to select <JOG> mode.

Turning

28 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 29

Set up

Preliminary remarks

Before you can work with the CNC, set up the machine, the tools, etc. as follows:

● Enter the tools and the tool offsets.

● Enter/modify the work offset

● Enter the setting data.

4.1 Entering tools and tool offsets

4.1.1 Entering tools and tool offsets

Functionality

4

The tool offsets consist of several data describing the geometry, the wear and the tool type.

Each tool contains a defined number of cutting edge parameters dependent on the particular

tool type. Tools are identified by a number (T number).

See also Chapter "

Operating sequences

2))6(7

3$5$0

7RRO

OLVW

Press the <OFFSET PARAM> key.

The function opens the "Tool list" window with the tool offset data. The window contains a list

of the tools that have been created. Use the cursor keys and the Page Up / Page Down keys

to navigate in this list.

Position the cursor bar on the input field to be modified and enter the value(s).

Confirm with <Input> or by moving the cursor.

Tool and tool compensation (Page 272)"

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

29

Page 30

Set up

4.1 Entering tools and tool offsets

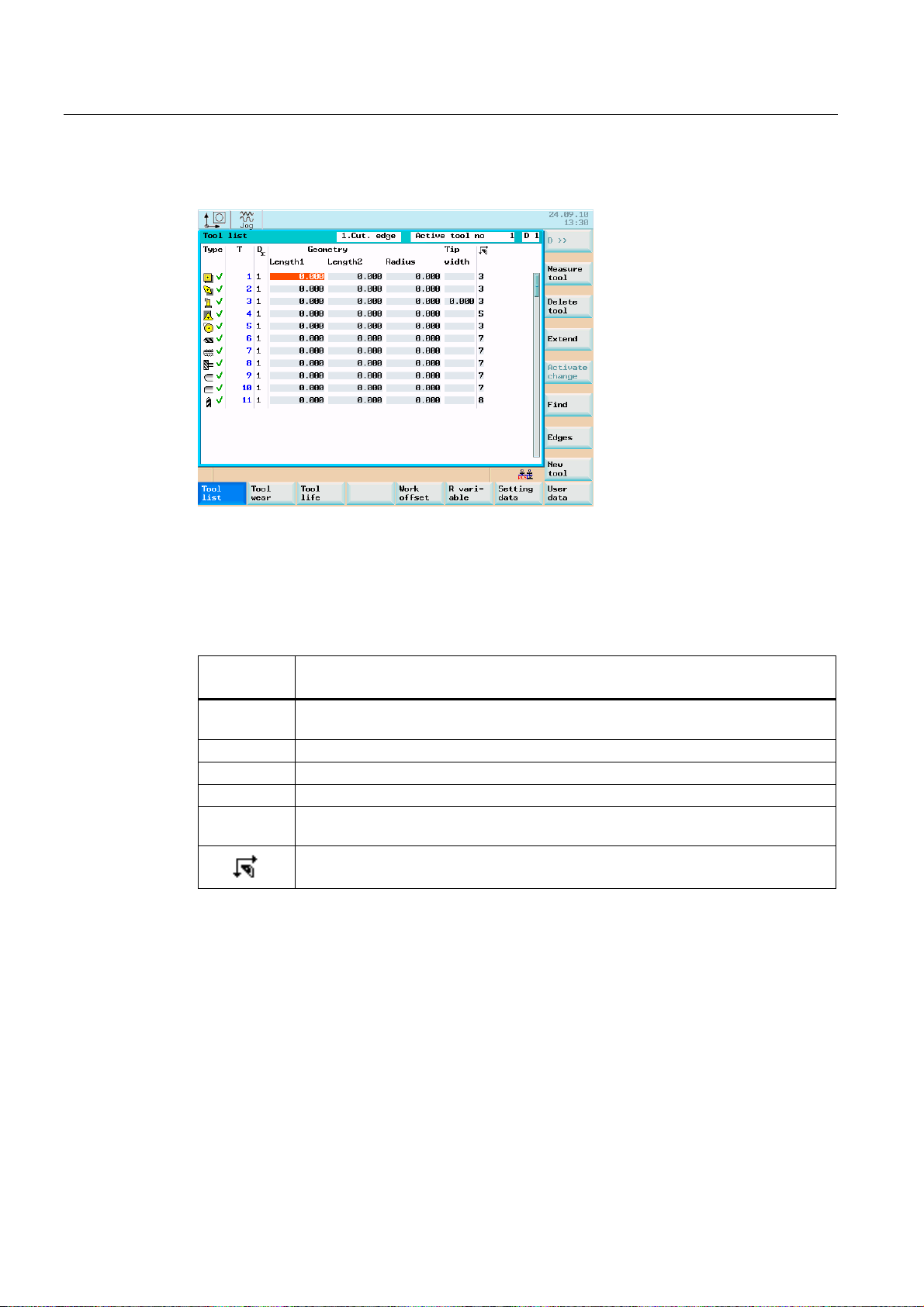

Standard tool list

Figure 4-1 Tool list

The tool nose radius compensation parameters of the T tools are shown in the tool list.

Contents of the tool list:

Table 4- 1 Tool list

Symbol/

Header

Type Cutting edge type of the tool and tool monitoring symbols (refer to the Chapter "Tool

T Tool number

D∑ Number of tool cutting edges

Geometry Tool geometry

Cutting tip

width

Content

monitoring")

Tip width of the cutting edge

Cutting edge position of the cutting edge

The following is displayed in the "tool list" line:

● The particular cutting edge number for all tools. Can be selected using softkey "D >>".

● The tool number and cutting edge number currently selected at the machine (e.g. 2, D 1)

Turning

30 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 31

Set up

4.1 Entering tools and tool offsets

Tool wear, standard

7RRO

ZHDU

The function opens the "tool wear" window. The window contains a list of the tools that have

been created and the wear data of the currently selected cutting edge. Use the cursor keys

and the Page Up / Page Down keys to navigate in this list.

Figure 4-2 Tool wear, standard

User-defined tool list

After having activated display MD394 DISPLAY_TOOL_LIST_SISTER_TOOL with "1", you

may define the following additional cutting edge parameters for the tool:

● Sister tool

● Wear limit

Note

The input values from the user fields "Sister tool" and "Wear limit" from the "Tool list" tab

are stored in the tool variables $TC_DP24 (wear limit) and $TC_DP25 (sister tool).

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

31

Page 32

Set up

4.1 Entering tools and tool offsets

Figure 4-3 User-defined tool list

([WHQGHG

Softkeys

0HDVXUH

WRRO

0HDVXULQJ

0DQXDO

0HDVXULQJ

$XWR

&DOLEUDWH

SUREH

Deleting a

tool

([WHQGHG

For special tools, use the "extended" softkey function, which provides a complete cutting

edge parameter list.

Use this softkey to determine the tool offset data (only effective in the JOG mode!).

Use this softkey to determine the tool offset data manually.

Use this softkey to determine the tool offset data semi-automatically (only applies in

conjunction with a probe).

Calibrating the measuring probe.

The tool is deleted and removed from the tool list.

A complete list of the cutting edge parameters is displayed using the "Extended" function.

Turning

32 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 33

Set up

4.1 Entering tools and tool offsets

Figure 4-4 Input screen for special tool

For the meanings of the cutting edge parameters, please refer to the Section

"Programming".

&XWWLQJ

HGJHV

Opens a lower-level menu bar offering all functions required to create and display further

edges.

D >>

1HZFXWWLQJ

HGJH

5HVHWFXWWLQJ

HGJH

'HOHWH

FXWWLQJHGJH

&KDQJH

DFWLYH

&KDQJH

W\SH

6HDUFK

Use this softkey to select the next higher edge number.

Use this softkey to create a new edge.

Use this softkey to reset all offset values of the edge to zero.

Cutting edge is deleted.

Modified values are activated.

This function is intended to change the tool type. Select the tool type using the appropriate

softkey.

Find tool number:

Type the number of the tool you are looking for and use the "OK" softkey to start the search.

If the tool you are looking for exists, the cursor is positioned on the appropriate line.

1HZWRRO

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Use this softkey to create tool offset data for a new tool.

33

Page 34

Set up

4.1 Entering tools and tool offsets

4.1.2 Create new tool

Operating sequence

1HZWRRO

This function offers another two softkey functions to select the tool type "Turning tool", "Drill"

or "Milling tool". After selecting the tool type, enter the desired "Tool number" (3 digits max.)

in the input field and select the "Cutting edge position" and the "Type".

Figure 4-5 "New tool" window

Figure 4-6 Input of the tool number and cutting edge position of a turning tool

Turning

34 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 35

Set up

4.1 Entering tools and tool offsets

Note

The coordinate system of tools for turning depends on the following display machine data:

MD290 CTM_POS_COORDINATE_SYSTEM

= 0 -> position of the tool after the turning center

= 2 -> position of the tool before the turning center

For drills and milling tools, the cutting edge position that corresponds to the machining

direction is selected.

Figure 4-7 Entering a tool number and cutting edge position for a drill

Figure 4-8 Input of the tool number and cutting edge position of a milling tool

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

35

Page 36

Set up

4.1 Entering tools and tool offsets

2.

list.

4.1.3 Determining the tool offsets (manually)

Select "OK" to confirm your input. A data record loaded with zero will be included in the tool

Functionality

7RRO

PHDVXUHPHQW

Note

Assignment of Length 1 or Length 2 to the axis is dependent on the tool type (turning tool,

drill) (see the following figures).

For the turning tool, the reference point for the X axis is a diameter dimension!

Note

The axis coordinates used for the calculation refer to the machine coordinate system.

This function can be used to determine the unknown geometry of a tool T.

Using the actual position of the point F (machine coordinate) and the reference point, the

control system can calculate the offset value assigned to length 1 or length 2 for the axis.

) 7RROKROGHUUHIHUHQFHSRLQW

00DFKLQH]HURSRLQW

::RUNSLHFH]HUR

7KHRIIVHWYDOXHLQWKH;D[LV

LVDGLDPHWHUYDOXH

;

PDFKLQH

0

;DFWXDOSRVLWLRQ

:RUNSLHFH

HJ*

'LDPHWHU

:

)

=DFWXDOSRVLWLRQ

=

PDFKLQH

Figure 4-9 Determining the length offsets using the example of a turning tool

Turning

36 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 37

Set up

4.1 Entering tools and tool offsets

) 7RROKROGHU UHIHUHQFH SRLQW

00DFKLQH]HURSRLQW

::RUNSLHFH]HUR

;

PDFKLQH

:RUNSLHFH

=DFWXDOSRVLWLRQ

Prerequisite

0

HJ*

:

)

=

PDFKLQH

Figure 4-10 Determining the length offsets using the example of a drill: Length 1 / Z axis

Note

The figure "Determining the length offsets using the example of a drill: Length 1/Z axis" will

only apply, if setting data SD42950 $SC_TOOL_LENGTH_TYPE and

SD42940 $SC_TOOL_LENGTH_CONST are equal to "0". Otherwise Length 2 will apply for

the drilling and the milling tool.

A tool must be loaded to use the "Measure tool" function.

Display machine data

The following display machine data define the display in the "Tool measurement manual"

window:

● MD290 CTM_POS_COORDINATE_SYSTEM

– = 0 -> position of the tool after the turning center

– = 2 -> position of the tool before the turning center

● MD361 USER_MEAS_TOOL_CHANGE

– = 0 -> not possible to edit the "T" and "D" fields

The "T" tool currently selected at the machine and its tool offset "D" are manually

measured.

– = 1 -> it is possible to edit the "T" and "D" fields

Tools, that have not been selected at the machine can also be manually measured.

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

37

Page 38

Set up

4.1 Entering tools and tool offsets

7RRO

PHDVXUHPHQW

0HDVXULQJ

0DQXDO

Figure 4-11 Selecting manual or semiautomatic measuring

The "Tool measurement manual" window is opened with the default setting "Measure length

1 in the X axis".

Figure 4-12 "Tool measurement manual" window, Length1 (L)

Workpiece parameters and operating sequence to manually measure the tool "Length1"

Enter the following workpiece parameters for the particular length calculation of the tool:

● The thickness of a spacer can be taken into account in the calculation in the distance field

(a).

● Enter the workpiece diameter in the "Ø" field.

Turning

38 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 39

Set up

4.1 Entering tools and tool offsets

6DYH

SRVLWLRQ

● With the cutting edge of the tool, move in the X axis up to the edge of the clamped

workpiece or to the spacer. Press "Save position".

The actual position that has been approached is taken into account in the control.

6HW

OHQJWK

● Press "Set Length1".

The length value is calculated and saved in the tool offset data.

Workpiece parameters and operating sequence to manually measure the tool "Length2"

/HQJWK

To determine length 2, press "Length2".

Figure 4-13 "Tool measurement manual" window, for Length2 (L)

Enter the following workpiece parameters for the particular length calculation of the tool:

● The thickness of a spacer can be taken into account in the calculation in the distance field

(a).

● Enter the workpiece edge in the field "Z0", if "ABS" was pre-selected in the adjacent

toggle field.

Note

As the known machine coordinate you may also use the work offset already determined

(e.g G54 value). This should be selected in the toggle field for the reference point.

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

39

Page 40

Set up

4.1 Entering tools and tool offsets

Workpiece parameters and operating sequence to manually measure a drill "Length1"

Figure 4-14 Tool measurement window, length1 (L) for a drill

Enter the following workpiece parameters for the particular length calculation of the tool:

● The thickness of a spacer can be taken into account in the calculation in the distance field

(a).

● Enter the workpiece edge in the field "Z0", if "ABS" was pre-selected in the adjacent

toggle field.

Note

As the known machine coordinate you may also use the work offset already determined

(e.g G54 value). This should be selected in the toggle field for the reference point.

With the cutting edge of the tool, move in the Z axis up to the edge of the clamped

workpiece or to the spacer. Then press "Set Length1", the length value is calculated and

saved in the tool offset data.

Turning

40 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 41

Set up

4.1 Entering tools and tool offsets

Workpiece parameters and operating sequence to manually measure a driven milling tool "Length2"

Figure 4-15 Manually measuring a driven milling tool

6DYH

SRVLWLRQ

6HW

OHQJWK

Enter the following workpiece parameters for the particular length calculation of the tool:

● The thickness of a spacer can be taken into account in the calculation in the distance field

(a).

● Enter the workpiece diameter in the "Ø" field.

● Enter the milling tool radius in the "Radius" field.

● With the cutting edge of the tool, move in the X axis up to the edge of the clamped

workpiece or to the spacer. Press "Save position".

The actual position that has been approached is taken into account in the control.

● Press "Set Length2".

The length value is calculated and saved in the tool offset data.

Note

The effect of the softkey is determined by display machine data

MD373 MEAS_SAVE_POS_LENGTH2.

= 0 -> the softkey is only active when measuring length 1

= 1 -> the softkey is always active

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

41

Page 42

Set up

4.1 Entering tools and tool offsets

4.1.4 Determining tool offsets using a probe (auto)

Operating sequence

7RRO

PHDVXUHPHQW

Press the "Measure tool" softkey.

0HDVXULQJ

$XWR

The "Measure tool automatically" window is opened.

Figure 4-16 "Tool measurement auto" window for Length1 (L)

Figure 4-17 "Tool measurement auto" window, Length2 (L)

Turning

42 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 43

Set up

4.1 Entering tools and tool offsets

Display machine data

The following display machine data defines the display in the "Tool measurement auto"

window:

● MD290 CTM_POS_COORDINATE_SYSTEM

– = 0 -> position of the tool after the turning center (refer to the diagrams above)

– = 2 -> position of the tool before the turning center

"Tool measurement auto" screen form

This screen form allows you to enter the tool number and tool offset number.

After the screen form has been opened, the input fields are filled with the data of the tool

currently working.

The tool can be either

● the currently active tool of the NC (loaded via a part program) or

● a tool loaded by the PLC.

If the tool was loaded by the PLC, the tool number in the input screen can be different than

that in the T,F,S window.

If you change the tool number, no automatic tool change will be performed using this

function. However, the measurement results are assigned to the entered tool.

Measuring process

The measuring probe is approached using traversing keys.

After the "Probe tripped" symbol has appeared, release the traversing key and wait until the

measuring process is completed.

During the automatic measurement, a dial gauge is displayed, which symbolizes the

measuring process currently active.

Note

To create the measuring program, the safety clearance parameters from the "Settings"

screen form and the feedrate from the "Probe data" screen form are used (see chapter

"Probe settings").

If several axes are moved simultaneously, no offset data can be calculated.

Turning

Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

43

Page 44

Set up

4.1 Entering tools and tool offsets

Procedure for "Probe tripped"

A solid circle on the screen indicates that the measuring probe has been tripped.

Release the axis direction key after tripping of the probe.

After release of the axis direction key, the control automatically creates an internal

measuring program in the program memory and starts it.

This measuring program causes the probe to be approached max. three times in order to

deliver measured values to the control.

If no measured value is transferred to the control after the third approach of the probe, a

message will be displayed informing the operator that no measured values could be

collected.

All axes involved in the measuring process must be approached this way.

4.1.5 Determining the tool offsets using optical measuring instruments

Figure 4-18 Measuring using an optical measuring instrument (for the T and D input fields, please

refer to "Measuring using a probe")

Measuring process

For measuring, traverse the tool until its tip appears in the crosshair. With a milling tool, use

the highest point of the cutting edge to determine the tool length.

Then press the "Set length" softkey to calculate the offset values.

Turning

44 Programming and Operating Manual, 11/2012, 6FC5398-1CP10-7BA0

Page 45

Set up

4.1 Entering tools and tool offsets

4.1.6 Probe settings

6HWWLQJV

3UREHGDWD

Select the "Settings" softkey.

The screen form below is used to store the coordinates of the probe and to set the axis

feedrate for the automatic measuring process.

All position values refer to the machine coordinate system.

Figure 4-19 "Probe data" input screen

Probe calibration

&DOLEUDWH

SUREH

Parameter Significance