Page 1

Machine / Setting Data

SINUMERIK 802D sl

Lists

Explanations

Machine Data

Overview

Setting Data

Overview

Machine Data

Description

Setting Data

Description

Interface Signals 6

1

2

3

4

5

Valid for

Control system Software version

SINUMERIK 802D sl 1

PLC User Interface - 7

SINAMICS Parameters 8

02.06 Edition

6FC5397−5CP10−0BA0

Page 2

Safety-related information

This manual contains important information related to your personal safety and the protection of

equipment. The notices referring to your personal safety are highlighted in the manual by a triangular

safety alert symbol, notices referring to property damage only have no safety alert symbol. These

notices shown below are graded according to the degree of danger:

Danger

!

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

!

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

!

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not

taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not

taken.

Notice

indicates that an undesirable event or state may arise if the relevant note is not observed.

If more than one degree of danger is present, the warning notice representing the highest degree of

danger will be used. A notice warning of injury to persons with a warning symbol may also include a

warning relating to property damage.

Qualified personnel

The device/system may only be set up and used in conjunction with this documentation.

Commissioning and operation of a device/system may only be performed by qualified personnel.

Qualified persons as far as the safety instructions given in this documentation are concerned are

those who have the necessary authorization to commission, ground and identify equipment, systems

and circuits in accordance with the relevant safety standards.

Use as prescribed

Note the following:

Warning

!

This device and its components may only be used for the applications described in the catalog or in

the technical descriptions, and only in combination with third-party devices and components which

have been approved or recommended by Siemens. This product can only function correctly and

safely if it is transported, stored, set up, and installed correctly, and operated and maintained as

recommended.

Trademarks

All designations with the trademark symbol ® are registered trademarks of Siemens AG. Other

designations in this documentation may be trademarks whose use by third parties for their own

purposes may infringe the rights of the owner.

Disclaimer of liability

We have checked the contents of this manual for agreement with the hardware and software

described. Since discrepancies cannot be precluded entirely, we cannot guarantee full agreement.

The information given in this publication is reviewed at regular intervals and any corrections that

might be necessary are made in the subsequent editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

DEUTSCHLAND

6FC5397−5CP10−0BA0

02/2006 Edition

Copyright Siemens AG 2006.

Subject to change without prior

notice

Page 3

Preface

SINUMERIK Documentation

The SINUMERIK Documentation is organized in 3 levels:

General Documentation:

User Documentation

Manufacturer/Service Documentation:

A monthly overview of publications with specification of the available languages can be found

on the Internet at:

http://www.siemens.com/motioncontrol

Follow the menu items ”Support”/”Technical Documentation”/”Overview of Publications”.

The Internet edition of DOConCD − DOConWEB − can be found at:

http://www.automation.siemens.com/doconweb

Information of our training offer and answers to frequently asked questions (”FAQs”) can be

found on the Internet at:

http://www.siemens.com/motioncontrol and there under the menu option ”Support”.

Target group

Utility value

Standard scope

The present publication is aimed at planning engineers, programmers and start−up engineers.

The present Lists Manual provides knowledge in respect of parameters and their effects on

the system.

The present documentation describes the functionality of the standard scope. Any amendments made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation can possibly also be performed on the

control system. However, the customer is not entitled to demand these functions when the

new equipment is supplied or servicing is carried out.

For reasons of clarity, this documentation does not contain all detailed information on all types of the product and can thus not consider any conceivable case of installation, operation

and maintenance.

Technical Support

If you have any questions, do not hesitate to call our hotline:

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

iii

Page 4

Preface

Time zones Europe and Africa

A&D Technical Support

Tel.: +49 (0) 180 / 5050 − 222

Fax: +49 (0) 180 / 5050 − 223

Internet: http://www.siemens.com

/automation/support−request

E−mail: mailto:adsupport@siemens.com

Time zones Asia and Australia

A&D Technical Support

Tel.: +86 1064 719 990

Fax: +86 1064 747 474

Internet: http://www.siemens.com/automation/support−request

E−mail: mailto:adsupport@siemens.com

Time zone America

A&D Technical Support

Tel.: +1 423 262 2522

Fax: +1 423 262 2289

Internet: http://www.siemens.com/automation/support−request

E−mail: mailto:adsupport@siemens.com

Questions regarding the Manual

If you have any questions (suggestions, corrections) regarding the Documentation, please

send a fax to the following number or an e−mail to the following address:

Fax: +49 (0) 9131 / 98 − 63315

E−mail: mailto:motioncontrol.docu@siemens.com

Fax form: see return fax form at the end of this publication

Internet address for SINUMERIK

http://www.siemens.com/sinumerik

EU Declaration of Conformity

The EU Declaration of Conformity in respect of the EMC Guideline can be obtained

on the Internet:

http://www.ad.siemens.de/csinfo

under the product order number 15257461

and from the appropriate regional office of the business area A&D MC of Siemens AG.

iv

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 5

Table of Contents

1 Machine and Setting Data − Explanations 1-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Specifications in the list 1-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Overview of the machine and setting data areas 1-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 List of Machine Data 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Display machine data 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 General machine data 2-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Channel−specific machine data 2-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Axis−specific machine data 2-49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Setting Data − Overview 3-65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Setting data 3-65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Channel−specific setting data 3-67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Axis−specific setting data 3-71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

4 Machine Data − Description 4-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Display machine data 4-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 General machine data 4-78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Channel-specific machine data 4-82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Axis-specific machine data 4-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Setting Data − Description 5-119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 General setting data 5-119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Channel-specific setting data 5-121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Spindle-specific setting data 5-123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Interface Signals 6-127 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 General 6-127 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Signals from/to HMI 6-129 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Program−control signals from HMI 6-129 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Signals from HMI 6-130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Signals from operator panel 6-131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 General selection/status signals from HMI 6-131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.5 General selection/status signals to HMI 6-132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Auxiliary function transfer from NC channel 6-134 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 NCK signals 6-137 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 General signals to NCK 6-137 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 General signals from NCK 6-138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Mode signals 6-140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Channel-specific signals 6-143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Signals to channel 6-143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Signals from the channel 6-154 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Axis/spindle-specific signals 6-162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Transferred axis−specific M and S functions 6-162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 Signals to axis/spindle 6-163 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.3 Signals from axis/spindle 6-174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

v

Page 6

Table of Contents

6.8 Tool management functions from NC channel 6-182 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 PLC User Interface 7-183 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Address ranges 7-183 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 User data 7-185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 User data 1 7-185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 User data2 7-185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Signals from MCP (connected to the MCPA module) 7-185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Signals to MCP (connected to the MCPA module) 7-186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.5 Reading/writing NC data: Job [F20.6] 7-186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.6 Read/write NC data: Result [F20.6] 7-186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Retentive data area 7-187 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 User alarm 7-188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 User alarm: Activation 7-188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 Variable for alarm 7-188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.3 Active alarm reaction 7-189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Signals from/to HMI 7-189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Program control signals from HMI (retentive area) 7-189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Program selection from PLC (retentive area) 7-190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Checkback signal ”Program selection from HMI (retentive area) 7-190 . . . . . . . . . . . . . . . . . . . . . .

7.5.4 Signals from HMI 7-190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.5 Signals from PLC 7-191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.6 Signals from operator panel (retentive area) 7-191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.7 General selection/status signals from HMI (retentive area) 7-191 . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.8 General selection/status signals to HMI (retentive area) 7-192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Auxiliary function transfer from NC channel 7-193 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 Decoded M signals: (M0−M99) 7-194 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.2 Transferred T functions 7-194 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.3 Transferred M functions 7-195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4 Transferred S functions 7-195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.5 Transferred D functions 7-195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.6 Transferred H functions 7-196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 NCK signals 7-197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.1 General signals to NCK 7-197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.2 General signals from NCK 7-197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.3 Signals to fast inputs and outputs 7-198 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.4 Signal from fast inputs and outputs 7-199 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.5 Operating mode signals 7-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 Channel signals 7-201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.1 Signals to NC channel 7-201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.2 Signals from NC channel 7-204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9 Axis/spindle signals 7-207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.1 Transferred M/S functions, axis-specific 7-207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.2 Signals to axis/spindle 7-207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.3 Signals from axis/spindle 7-211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10 PLC machine data 7-214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.1 INT values (MD 14510 USER_DATA_INT) 7-214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.2 HEX values (MD 14512 USER_DATA_HEX) 7-214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.3 FLOAT values (MD 14514 USER_DATA_FLOAT) 7-214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.4 User alarm: Configuration (MD 14516 USER_DATA_PLC_ALARM) 7-215 . . . . . . . . . . . . . . . . . .

7.11 Reading and writing PLC variables 7-215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.12 Tool management functions from NC channel 7-216 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 SINAMICS Parameters 8-217 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 7

List of Machine and Setting Data

List of Machine and Setting Data

10000, 4-78

10000 |AXCONF_MACHAX_NAME_TAB, 2-29

10074, 4-78

10074 |PLC_IPO_TIME_RATIO, 2-29

10088 |REBOOT_DELAY_TIME, 2-29

10200 |INT_INCR_PER_MM, 2-29

10210 |INT_INCR_PER_DEG, 2-29

10240, 4-79

10240 |SCALING_SYSTEM_IS_METRIC, 2-29

10350 |FASTIO_DIG_NUM_INPUTS, 2-29

10360 |FASTIO_DIG_NUM_OUTPUTS, 2-29

10366 |HW_ASSIGN_DIG_FASTIN, 2-30

10368 |HW_ASSIGN_DIG_FASTOUT, 2-30

10450 |SW_CAM_ASSIGN_TAB, 2-30

10460 |SW_CAM_MINUS_LEAD_TIME, 2-30

10461 |SW_CAM_PLUS_LEAD_TIME, 2-30

10814 |EXTERN_M_NO_MAC_CYCLE, 2-32

10815 |EXTERN_M_NO_MAC_CYCLE_NAME, 2-32

10816 |EXTERN_G_NO_MAC_CYCLE, 2-32

10817 |EXTERN_G_NO_MAC_CYCLE_NAME, 2-32

10818 |EXTERN_INTERRUPT_NUM_ASUP, 2-32

10820 |EXTERN_INTERRUPT_NUM_RETRAC, 2-33

10880 |MM_EXTERN_CNC_SYSTEM, 2-33

10881 |MM_EXTERN_GCODE_SYSTEM, 2-33

10882 |NC_USER_EXTERN_GCODES_TAB, 2-33

10884 |EXTERN_FLOATINGPOINT_PROG, 2-33

10886 |EXTERN_INCREMENT_SYSTEM, 2-33

10888 |EXTERN_DIGITS_TOOL_NO, 2-33

10890 |EXTERN_TOOLPROG_MODE, 2-33

10900 |INDEX_AX_LENGTH_POS_TAB_1, 2-33

10910 |INDEX_AX_POS_TAB_1, 2-33

10920 |INDEX_AX_LENGTH_POS_TAB_2, 2-34

10470 |SW_CAM_ASSIGN_FASTOUT_1, 2-30

10480 |SW_CAM_TIMER_FASTOUT_MASK, 2-30

10485 |SW_CAM_MODE, 2-30

10710 |PROG_SD_RESET_SAVE_TAB, 2-30

10713 |M_NO_FCT_STOPRE, 2-31

10714 |M_NO_FCT_EOP, 2-31

10715 |M_NO_FCT_CYCLE, 2-31

10716 |M_NO_FCT_CYCLE_NAME, 2-31

10717 |T_NO_FCT_CYCLE_NAME, 2-31

10718 |M_NO_FCT_CYCLE_PAR, 2-31

10719 |T_NO_FCT_CYCLE_MODE, 2-31

10735 |JOG_MODE_MASK, 2-31

10760 |G53_TOOLCORR, 2-31

10804 |EXTERN_M_NO_SET_INT, 2-31

10806 |EXTERN_M_NO_DISABLE_INT, 2-31

10808 |EXTERN_INTERRUPT_BITS_M96, 2-32

10930 |INDEX_AX_POS_TAB_2, 2-34

11100, 4-79

11100 |AUXFU_MAXNUM_GROUP_ASSIGN, 2-34

11160 |ACCESS_EXEC_CST, 2-34

11161 |ACCESS_EXEC_CMA, 2-34

11162 |ACCESS_EXEC_CUS, 2-34

11165 |ACCESS_WRITE_CST, 2-34

11166 |ACCESS_WRITE_CMA, 2-34

11167 |ACCESS_WRITE_CUS, 2-34

11170 |ACCESS_WRITE_SACCESS, 2-34

11171 |ACCESS_WRITE_MACCESS, 2-34

11172 |ACCESS_WRITE_UACCESS, 2-35

11210, 4-79

11210 |UPLOAD_MD_CHANGES_ONLY, 2-35

11240, 4-80

11240 |PROFIBUS_SDB_NUMBER, 2-35

10810 |EXTERN_MEAS_G31_P_SIGNAL, 2-32

10812 |EXTERN_DOUBLE_TURRET_ON, 2-32

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

11250 |PROFIBUS_SHUTDOWN_TYPE, 2-35

11310, 4-80

vii

Page 8

List of Machine and Setting Data

11310 |HANDWH_REVERSE, 2-35

11320, 4-80

11320 |HANDWH_IMP_PER_LATCH, 2-35

11346, 4-80

11346 |HANDWH_TRUE_DISTANCE, 2-35

11516 |USER_DATA_PLC_ALARM, 2-36

11717 |D_NO_FCT_CYCLE_NAME, 2-35

13060, 4-81

13060 |DRIVE_TELEGRAM_TYPE, 2-35

13070 |DRIVE_FUNCTION_MASK, 2-35

13080 |DRIVE_TYPE_DP, 2-35

13120 |CONTROL_UNIT_LOGIC_ADDRESS, 2-35

13200 |MEAS_PROBE_LOW_ACTIVE, 2-35 , 4-81

13220 |MEAS_PROBE_DELAY_TIME, 2-36

14510, 4-81

14510 |USER_DATA_INT, 2-36

20080, 4-82

20080 |AXCONF_CHANAX_NAME_TAB, 2-38

20090, 4-83

20090 |SPIND_DEF_MASTER_SPIND, 2-38

20094 |SPIND_RIGID_TAPPING_M_NR, 2-38

20095 |EXTERN_RIGID_TAPPING_M_NR, 2-38

20106 |PROG_EVENT_IGN_SINGLEBLOCK, 2-38

20107 |PROG_EVENT_IGN_INHIBIT, 2-38

20108 |PROG_EVENT_MASK, 2-39

20140, 4-83

20140 |TRAFO_RESET_VALUE, 2-39

20172 |COMPRESS_VELO_TOL, 2-39

202, 4-75

202 |FIRST_LANGUAGE, 2-23

20204 |WAB_CLEARANCE_TOLERANCE, 2-39

203, 4-75

14512, 4-81

14512 |USER_DATA_HEX, 2-36

14514, 4-81

14514 |USER_DATA_FLOAT, 2-36

14516, 4-81

15700 |LANG_SUB_NAME, 2-36

15702 |LANG_SUB_PATH, 2-36

17400 |OEM_GLOBAL_INFO, 2-36

17530 |TOOL_DATA_CHANGE_COUNTER, 2-36

18030 |HW_SERIAL_NUMBER, 2-36

18040 |VERSION_INFO, 2-36

18080 |MM_TOOL_MANAGEMENT_MASK, 2-37

18102 |MM_TYPE_OF_CUTTING_EDGE, 2-37

18120 |MM_NUM_GUD_NAMES_NCK, 2-37

18130 |MM_NUM_GUD_NAMES_CHAN, 2-37

18150 |MM_GUD_VALUES_MEM, 2-37

203 |DISPLAY_RESOLUTION, 2-23

20310 |TOOL_MANAGEMENT_MASK, 2-39

20320 |TOOL_TIME_MONITOR_MASK, 2-39

20360, 4-83

20360 |TOOL_PARAMETER_DEF_MASK, 2-39

204, 4-75

204 |DISPLAY_RESOLUTION_INCH, 2-23

20450 |LOOKAH_RELIEVE_BLOCK_CYCLE, 2-39

20460 |LOOKAH_SMOOTH_FACTOR, 2-39

205, 4-75

205 |DISPLAY_RESOLUTION_SPINDLE, 2-23

20500 |CONST_VELO_MIN_TIME, 2-39

20550 |EXACT_POS_MODE, 2-39

20552 |EXACT_POS_MODE_G0_TO_G1, 2-40

20610 |ADD_MOVE_ACCEL_RESERVE, 2-40

20624 |HANDWH_CHAN_STOP_COND, 2-40

20050, 4-82

20050 |AXCONF_GEOAX_ASSIGN_TAB, 2-38

20070, 4-82

20070 |AXCONF_MACHAX_USED, 2-38

viii

207 |USER_CLASS_READ_TOA, 2-23

20700, 4-83

20700 |REFP_NC_START_LOCK, 2-40

20730|G0_LINEAR_MODE, 2-40

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 9

List of Machine and Setting Data

20732 |EXTERN_G0_LINEAR_MODE, 2-40

20734 |EXTERN_FUNCTION_MASK, 2-40

208 |USER_CLASS_WRITE_TOA_GEO, 2-23

209 |USER_CLASS_WRITE_TOA_WEAR, 2-23

210 |USER_CLASS_WRITE_ZOA, 2-23

21000, 4-84

21000 |CIRCLE_ERROR_CONST, 2-40

21010 |CIRCLE_ERROR_FACTOR, 2-40

21020, 4-84

21020 |WORKAREA_WITH_TOOL_RADIUS, 2-40

21190 |TOFF_MODE, 2-40

21194 |TOFF_VELO, 2-40

21196 |TOFF_ACCEL, 2-41

212 |USER_CLASS_WRITE_SEA, 2-23

213 |USER_CLASS_READ_PROGRAM, 2-24

214 |USER_CLASS_WRITE_PROGRAM, 2-24

22256 |AUXFU_ASSOC_M1_VALUE, 2-42

223 |USER_CLASS_WRITE_PWA, 2-24

22400 |S_VALUES_ACTIVE_AFTER_RESET, 2-42

22410 |F_VALUES_ACTIVE_AFTER_RESET, 2-42

22534, 4-85

22534 |TRAFO_CHANGE_M_CODE, 2-42

22550, 4-85

22550 |TOOL_CHANGE_MODE, 2-42

22910 |WEIGHTING_FACTOR_FOR_SCALE, 2-42

22914 |AXES_SCALE_ENABLE, 2-42

22920 |EXTERN_FIXED_FEEDRATE_F1_ON, 2-42

22930 |EXTERN_PARALLEL_GEOAX, 2-42

24020 |FRAME_SUPPRESS_MODE, 2-42

24100, 4-85

24100 |TRAFO_TYPE_1, 2-43

24110, 4-85

215 |USER_CLASS_SELECT_PROGRAM, 2-24

217 |USER_CLASS_WRITE_CYCLES, 2-24

218 |USER_CLASS_WRITE_RPA, 2-24

219 |USER_CLASS_SET_V24, 2-24

22000, 4-84

22000 |AUXFU_ASSIGN_GROUP, 2-41

22010, 4-84

22010 |AUXFU_ASSIGN_TYPE, 2-41

22020, 4-85

22020 |AUXFU_ASSIGN_EXTENSION, 2-41

22030, 4-85

22030 |AUXFU_ASSIGN_VALUE, 2-41

22035 |AUXFU_ASSIGN_SPEC, 2-41

22040 |AUXFU_PREDEF_GROUP, 2-41

22050 |AUXFU_PREDEF_TYPE, 2-41

22060 |AUXFU_PREDEF_EXTENSION, 2-41

24110 |TRAFO_AXES_IN_1, 2-43

24120, 4-86

24120 |TRAFO_GEOAX_ASSIGN_TAB_1, 2-43

24130 |TRAFO_INCLUDES_TOOL_1, 2-43

24200 , 4-86

24200 |TRAFO_TYPE_2, 2-43

24210 , 4-86

24210 |TRAFO_AXES_IN_2, 2-43

24220 , 4-86

24220 |TRAFO_GEOAX_ASSIGN_TAB_2, 2-43

24230 |TRAFO_INCLUDES_TOOL_2, 2-43

247 |V24_PG_PC_BAUD, 2-24

24700 |TRAANG_ANGLE_1, 2-44

24710 |TRAANG_BASE_TOOL_1, 2-44

24720 |TRAANG_PARALLEL_VELO_RES_1, 2-44

24721 |TRAANG_PARALLEL_ACCEL_RES_1, 2-44

22070 |AUXFU_PREDEF_VALUE, 2-41

221 |USER_CLASS_DIR_ACCESS, 2-24

222 |USER_CLASS_PLC_ACCESS, 2-24

22254 |AUXFU_ASSOC_M0_VALUE, 2-42

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

24750 |TRAANG_ANGLE_2, 2-44

24760 |TRAANG_BASE_TOOL_2, 2-44

24770 |TRAANG_PARALLEL_VELO_RES_2, 2-44

24771 |TRAANG_PARALLEL_ACCEL_RES_2, 2-44

ix

Page 10

List of Machine and Setting Data

24800, 4-86

24800 |TRACYL_ROT_AX_OFFSET_1, 2-44

24805 |TRACYL_ROT_AX_FRAME_1, 2-44

24808 |TRACYL_DEFAULT_MODE_1, 2-45

24810, 4-86

24810 |TRACYL_ROT_SIGN_IS_PLUS_1, 2-45

24820, 4-86

24820 |TRACYL_BASE_TOOL_1, 2-45

24850 |TRACYL_ROT_AX_OFFSET_2, 2-45

24855 |TRACYL_ROT_AX_FRAME_2, 2-45

24858 |TRACYL_DEFAULT_MODE_2, 2-45

24860 |TRACYL_ROT_SIGN_IS_PLUS_2, 2-45

24870 |TRACYL_BASE_TOOL_2, 2-45

24900, 4-87

24900 |TRANSMIT_ROT_AX_OFFSET_1, 2-45

24905 |TRANSMIT_ROT_AX_FRAME_1, 2-45

26018 |NIBBLE_PRE_START_TIME, 2-47

26020 |NIBBLE_SIGNAL_CHECK, 2-47

27100 |ABSBLOCK_FUNCTION_MASK, 2-47

27400 |OEM_CHAN_INFO, 2-48

27800, 4-87

27800 |TECHNOLOGY_MODE, 2-48

27860, 4-88

27860 |PROCESSTIMER_MODE, 2-48

27880, 4-89

27880 |PART_COUNTER, 2-48

27882, 4-89

27882 |PART_COUNTER_MCODE, 2-48

280 |V24_PPI_ADDR_PLC, 2-24

281 |V24_PPI_ADDR_NCK, 2-24

28400 |MM_ABSBLOCK, 2-48

28402 |MM_ABSBLOCK_BUFFER_CONF, 2-48

24910, 4-87

24910 |TRANSMIT_ROT_SIGN_IS_PLUS_1, 2-46

24911, 4-87

24911 |TRANSMIT_POLE_SIDE_FIX_1, 2-46

24920, 4-87

24920 |TRANSMIT_BASE_TOOL_1, 2-46

24950 |TRANSMIT_ROT_AX_OFFSET_2, 2-46

24955 |TRANSMIT_ROT_AX_FRAME_2, 2-46

24960 |TRANSMIT_ROT_SIGN_IS_PLUS_2, 2-46

24961 |TRANSMIT_POLE_SIDE_FIX_2, 2-46

24970 |TRANSMIT_BASE_TOOL_2, 2-46

26000 |PUNCHNIB_ASSIGN_FASTIN, 2-46

26002 |PUNCHNIB_ASSIGN_FASTOUT, 2-46

26004 |NIBBLE_PUNCH_OUTMASK, 2-47

26006 |NIBBLE_PUNCH_INMASK, 2-47

26008 |NIBBLE_PUNCH_CODE, 2-47

289, 4-76

289 |CTM_SIMULATION_TIME_NEW_POS, 2-24

290, 4-76

290 |CTM_POS_COORDINATE_SYSTEM, 2-24

291, 4-76

291 |CTM_CROSS_AX_DIAMETER_ON, 2-25

292, 4-76

292 |CTM_G91_DIAMETER_ON, 2-25

30100 |CTRLOUT_SEGMENT_NR, 2-49

30110, 4-90

30110 |CTRLOUT_MODULE_NR, 2-49

30120, 4-90

30120 |CTRLOUT_NR, 2-49

30130, 4-90

30130 |CTRLOUT_TYPE, 2-49

30134, 4-90

26010 |PUNCHNIB_AXIS_MASK, 2-47

26012 |PUNCHNIB_ACTIVATION, 2-47

26014 |PUNCH_PATH_SPLITTING, 2-47

26016 |PUNCH_PARTITION_TYPE, 2-47

x

30134 |IS_UNIPOLAR_OUTPUT, 2-49

30200, 4-90

30200 |NUM_ENCS, 2-49

30220, 4-90

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 11

List of Machine and Setting Data

30220 |ENC_MODULE_NR, 2-50

30230, 4-91

30230 |ENC_INPUT_NR, 2-50

30240, 4-91

30240 |ENC_TYPE, 2-50

30270 |ENC_ABS_BUFFERING, 2-50

30300, 4-91

30300 |IS_ROT_AX, 2-50

30310, 4-91

30310 |ROT_IS_MODULO, 2-50

30320, 4-92

30320 |DISPLAY_IS_MODULO, 2-50

30350, 4-92

30350 |SIMU_AX_VDI_OUTPUT, 2-50

30465 |AXIS_LANG_SUB_MASK, 2-50

305 |G_GROUP1, 2-25

31050 |DRIVE_AX_RATIO_DENOM, 2-51

31060, 4-93

31060 |DRIVE_AX_RATIO_NUMERA, 2-51

31064 |DRIVE_AX_RATIO2_DENOM, 2-51

31066 |DRIVE_AX_RATIO2_NUMERA, 2-51

31070, 4-93

31070 |DRIVE_ENC_RATIO_DENOM, 2-51

31080, 4-93

31080 |DRIVE_ENC_RATIO_NUMERA, 2-51

311 |FG_GROUP2, 2-25

31122, 4-93

31122 |BERO_DELAY_TIME_PLUS, 2-51

31123, 4-93

31123 |BERO_DELAY_TIME_MINUS, 2-52

312 |FG_GROUP3, 2-25

313 |FG_GROUP4, 2-25

30500 |INDEX_AX_ASSIGN_POS_TAB, 2-50

306 |G_GROUP2, 2-25

30600 , 4-92

30600 |FIX_POINT_POS, 2-50

307 |G_GROUP3, 2-25

308 |G_GROUP4, 2-25

309 |G_GROUP5, 2-25

310 |FG_GROUP1, 2-25

31000, 4-92

31000 |ENC_IS_LINEAR, 2-51

31010, 4-92

31010 |ENC_GRID_POINT_DIST, 2-51

31020, 4-92

31020 |ENC_RESOL, 2-51

31030, 4-93

31030 |LEADSCREW_PITCH, 2-51

314 |FG_GROUP5, 2-25

32000, 4-94

32000 |MAX_AX_VELO, 2-52

32010, 4-94

32010 |JOG_VELO_RAPID, 2-52

32020, 4-94

32020 |JOG_VELO, 2-52

32100, 4-94

32100 |AX_MOTION_DIR, 2-52

32110, 4-95

32110 |ENC_FEEDBACK_POL, 2-52

32200, 4-95

32200 |POSCTRL_GAIN, 2-52

32210 |POSCTRL_INTEGR_TIME, 2-52

32220 |POSCTRL_INTEGR_ENABLE, 2-52

32230 |POSCTRL_CONFIG, 2-53

31040, 4-93

31040 |ENC_IS_DIRECT, 2-51

31044 |ENC_IS_DIRECT2, 2-51

31050, 4-93

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

32300 |MAX_AX_ACCEL, 2-53 , 4-95

32301 |JOG_MAX_ACCEL, 2-53

32320 |DYN_LIMIT_RESET_MASK, 2-53

32420 |JOG_AND_POS_JERK_ENABLE, 2-53 ,

4-95

xi

Page 12

List of Machine and Setting Data

32430 |JOG_AND_POS_MAX_JERK, 2-53 , 4-95

32431, 4-96

32431 |MAX_AX_JERK, 2-53

32432, 4-96

32432 |PATH_TRANS_JERK_LIM, 2-53

32436 |JOG_MAX_JERK, 2-53

32440 |LOOKAH_FREQUENCY, 2-53

32450, 4-96

32450 |BACKLASH, 2-53

32490 |FRICT_COMP_MODE, 2-54

32500 |FRICT_COMP_ENABLE, 2-54

32510 |FRICT_COMP_ADAPT_ENABLE, 2-54

32520 |FRICT_COMP_CONST_MAX, 2-54

32530 |FRICT_COMP_CONST_MIN, 2-54

32540 |FRICT_COMP_TIME, 2-54

32610 |VELO_FFW_WEIGHT, 2-54

34030, 4-98

34030 |REFP_MAX_CAM_DIST, 2-55

34040, 4-98

34040 |REFP_VELO_SEARCH_MARKER, 2-55

34050, 4-98

34050 |REFP_SEARCH_MARKER_REVERSE, 2-55

34060, 4-98

34060 |REFP_MAX_MARKER_DIST, 2-55

34070, 4-99

34070 |REFP_VELO_POS, 2-56

34080, 4-99

34080 |REFP_MOVE_DIST, 2-56

34090, 4-99

34090 |REFP_MOVE_DIST_CORR, 2-56

34092, 4-100

34092 |REFP_CAM_SHIFT, 2-56

32630, 4-96

32630 |FFW_ACTIVATION_MODE, 2-54

32640 |STIFFNESS_CONTROL_ENABLE, 2-54

32642 |STIFFNESS_CONTROL_CONFIG, 2-54

32644 |STIFFNESS_DELAY_TIME, 2-54

32700, 4-96

32700 |ENC_COMP_ENABLE, 2-55

32810, 4-97

32810 |EQUIV_SPEEDCTRL_TIME, 2-55

330 |CMM_POS_COORDINATE_SYSTEM, 2-26

33050, 4-97

33050 |LUBRICATION_DIST, 2-55

331 |CONTOUR_MASK, 2-26

332 |TOOL_LIST_PLACE_NO, 2-26

34000, 4-97

34000 |REFP_CAM_IS_ACTIVE, 2-55

34093, 4-100

34093 |REFP_CAM_MARKER_DIST, 2-56

34100, 4-100

34100 |REFP_SET_POS, 2-56

34110, 4-101

34110 |REFP_CYCLE_NR, 2-56

34120 |REFP_BERO_LOW_ACTIVE, 2-56

34200, 4-101

34200 |ENC_REFP_MODE, 2-56

34210 , 4-102

34210 |ENC_REFP_STATE, 2-56

34220 , 4-102

34220 |ENC_ABS_TURNS_MODULO, 2-57

343 |V24_PPI_ADDR_MMC, 2-26

344 |V24_PPI_MODEM_ACTIVE, 2-26

345 |V24_PPI_MODEM_BAUD, 2-26

34010, 4-97

34010 |REFP_CAM_DIR_IS_MINUS, 2-55

34020, 4-97

34020 |REFP_VELO_SEARCH_CAM, 2-55

xii

346 |V24_PPI_MODEM_PARITY, 2-26

34990 |ENC_ACTVAL_SMOOTH_TIME, 2-57

35000, 4-103

35000 |SPIND_ASSIGN_TO_MACHAX, 2-57

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 13

List of Machine and Setting Data

35010, 4-103

35010 |GEAR_STEP_CHANGE_ENABLE, 2-57

35012 |GEAR_STEP_CHANGE_POSITION, 2-57

35014 |GEAR_STEP_USED_IN_AXISMODE, 2-57

35020 |SPIND_DEFAULT_MODE, 2-57

35030 |SPIND_DEFAULT_ACT_MASK, 2-57

35040, 4-103

35040 |SPIND_ACTIVE_AFTER_RESET, 2-57

35100, 4-104

35100 |SPIND_VELO_LIMIT, 2-57

35110, 4-104

35110 |GEAR_STEP_MAX_VELO, 2-57

35112 |GEAR_STEP_MAX_VELO2, 2-58

35120, 4-104

35120 |GEAR_STEP_MIN_VELO, 2-58

35122 |GEAR_STEP_MIN_VELO2, 2-58

35400 |SPIND_OSCILL_DES_VELO, 2-59

35410, 4-107

35410 |SPIND_OSCILL_ACCEL, 2-59

35430, 4-107

35430 |SPIND_OSCILL_START_DI, 2-59

35440, 4-107

35440 |SPIND_OSCILL_TIME_CW, 2-59

35450, 4-107

35450 |SPIND_OSCILL_TIME_CCW, 2-59

35500, 4-108

35500 |SPIND_ON_SPEED_AT_IPO_START, 2-59

35510, 4-108

35510 |SPIND_STOPPED_AT_IPO_START, 2-59

35550 |DRILL_VELO_LIMIT, 2-59

356 |HMI_COL_TITLE_FOCUS_FORE, 2-26

357 |HMI_COL_TITLE_FOCUS_BACK, 2-26

35130, 4-104

35130 |GEAR_STEP_MAX_VELO_LIMIT, 2-58

35140, 4-105

35140 |GEAR_STEP_MIN_VELO_LIMIT, 2-58

35150, 4-105

35150 |SPIND_DES_VELO_TOL, 2-58

35160, 4-105

35160 |SPIND_EXTERN_VELO_LIMIT, 2-58

35200, 4-106

35200 |GEAR_STEP_SPEEDCTRL_ACCEL, 2-58

35210, 4-106

35210 |GEAR_STEP_POSCTRL_ACCEL, 2-58

35212 |GEAR_STEP_POSCTRL_ACCEL2, 2-58

35300, 4-106

35300 |SPIND_POSCTRL_VELO, 2-58

35310, 4-106

360 |SPINDLE_LOAD_DISPL1, 2-26

36000 |STOP_LIMIT_COARSE, 2-59 , 4-108

36010, 4-109

36010 |STOP_LIMIT_FINE, 2-59

36020 |POSITIONING_TIME, 2-60 , 4-109

36030 |STANDSTILL_POS_TOL, 2-60 , 4-109

36040 |STANDSTILL_DELAY_TIME, 2-60 , 4-109

36050, 4-109

36050 |CLAMP_POS_TOL, 2-60

36060, 4-110

36060 |STANDSTILL_VELO_TOL, 2-60

361, 4-76

361 |USER_MEAS_TOOL_CHANGE, 2-27

36100 |POS_LIMIT_MINUS, 2-60 , 4-110

36110 |POS_LIMIT_PLUS, 2-60 , 4-110

36120 |POS_LIMIT_MINUS2, 2-60 , 4-110

35310 |SPIND_POSIT_DELAY_TIME, 2-59

35350, 4-106

35350 |SPIND_POSITIONING_DIR, 2-59

35400, 4-106

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

36130 |POS_LIMIT_PLUS2, 2-60 , 4-110

362 |SPINDLE_LOAD_DISPL2, 2-27

36200 |AX_VELO_LIMIT, 2-60 , 4-111

36210, 4-111

xiii

Page 14

List of Machine and Setting Data

36210 |CTRLOUT_LIMIT, 2-60

363 |SPINDLE_LOAD_BAR_LIM2, 2-27

36300 |ENC_FREQ_LIMIT, 2-61 , 4-111

36302, 4-111

36302 |ENC_FREQ_LIMIT_LOW, 2-61

36310 |ENC_ZERO_MONITORING, 2-61 , 4-112

364 |SPINDLE_LOAD_BAR_LIM3, 2-27

36400 |CONTOUR_TOL, 2-61 , 4-112

365 |SPINDLE_LOAD_BAR_MAX, 2-27

36500, 4-112

36500 |ENC_CHANGE_TOL, 2-61

366 |SPINDLE_LOAD_BAR_COL1, 2-27

36600 |BRAKE_MODE_CHOICE, 2-61 , 4-112

36610 |AX_EMERGENCY_STOP_TIME, 2-61 , 4-113

36620, 4-114

36620 |SERVO_DISABLE_DELAY_TIME, 2-61

37040, 4-116

37040 |FIXED_STOP_BY_SENSOR, 2-62

37050, 4-116

37050 |FIXED_STOP_ALARM_MASK, 2-62

37060, 4-116

37060 |FIXED_STOP_ACKN_MASK, 2-63

371 |TOOL_REF_PROBE_AXIS2, 2-27

372 |TOOL_REF_PROBE_AXIS3, 2-27

373, 4-77

373 |MEAS_SAVE_POS_LENGTH2, 2-27

374 |TOOL_WEAR_LIMIT_VALUE, 2-27

37400, 4-116

37400 |EPS_TLIFT_TANG_STEP, 2-63

37402, 4-117

37402 |TANG_OFFSET, 2-63

375 |USER_CLASS_READ_CUS_DIR, 2-28

367 |SPINDLE_LOAD_BAR_COL2, 2-27

36710 |DRIFT_LIMIT, 2-61

36720, 4-114

36720 |DRIFT_VALUE, 2-61

368 |SPINDLE_LOAD_BAR_COL3, 2-27

369 |PROBE_MODE, 2-27

370 |TOOL_REF_PROBE_AXIS1, 2-27

37000, 4-114

37000 |FIXED_STOP_MODE, 2-61

37002, 4-114

37002 |FIXED_STOP_CONTROL, 2-62

37010, 4-115

37010 |FIXED_STOP_TORQUE_DEF, 2-62

37012, 4-115

37012 |FIXED_STOP_TORQUE_RAMP_TIME, 2-62

37014 |FIXED_STOP_TORQUE_FACTOR, 2-62

376 |USER_CLASS_WRITE_CUS_DIR, 2-28

37610 |PROFIBUS_CTRL_CONFIG, 2-63

37620 |PROFIBUS_TORQUE_RED_RESOL, 2-63

377 |USER_CLASS_WRITE_TO_MON_DAT, 2-28

378 |USER_CLASS_LADDER_VIEW, 2-28

37800 |OEM_AXIS_INFO, 2-63

379 |SPINDLE_DISP_MODE, 2-28

38000, 4-117

38000 |MM_ENC_COMP_MAX_POINTS, 2-63

383 |V24_PPI_ADDR_DRV1, 2-28

41010, 5-119

41010 |JOG_VAR_INCR_SIZE, 3-65

41110, 5-119

41110 |JOG_SET_VELO, 3-65

41130, 5-119

41130 |JOG_ROT_AX_SET_VELO, 3-65

37020, 4-115

37020 |FIXED_STOP_WINDOW_DEF, 2-62

37030, 4-115

37030 |FIXED_STOP_THRESHOLD, 2-62

xiv

41200, 5-120

41200 |JOG_SPIND_SET_VELO, 3-65

41500 |SW_CAM_MINUS_POS_TAB_1, 3-65

41501 |SW_CAM_PLUS_POS_TAB_1, 3-65

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 15

List of Machine and Setting Data

41520 |SW_CAM_MINUS_TIME_TAB_1, 3-66

41521 |SW_CAM_PLUS_TIME_TAB_1, 3-66

42000, 5-121

42000 |THREAD_START_ANGLE, 3-67

42010, 5-121

42010 |THREAD_RAMP_DISP, 3-67

42100, 5-121

42100 |DRY_RUN_FEED, 3-67

42101 |DRY_RUN_FEED_MODE, 3-67

42110, 5-121

42110 |DEFAULT_FEED, 3-67

42120 |APPROACH_FEED, 3-67

42140 |DEFAULT_SCALE_FACTOR_P, 3-67

42150 |DEFAULT_ROT_FACTOR_R, 3-67

42160 |EXTERN_FIXED_FEEDRATE_F1_F9, 3-67

42162 |EXTERN_DOUBLE_TURRET_DIST, 3-68

42520 |CORNER_SLOWDOWN_START, 3-69

42522 |CORNER_SLOWDOWN_END, 3-69

42524 |CORNER_SLOWDOWN_OVR, 3-69

42526 |CORNER_SLOWDOWN_CRIT, 3-69

42528 |CUTCOM_DECEL_LIMIT, 3-70

42940, 5-122

42940 |TOOL_LENGTH_CONST, 3-70

42950, 5-122

42950 |TOOL_LENGTH_TYPE, 3-70

42990 |MAX_BLOCKS_IN_IPOBUFFER, 3-70

42995 |CONE_ANGLE, 3-70

43120 |DEFAULT_SCALE_FACTOR_AXIS, 3-71

43200 |SPIND_S, 3-71

43202 |SPIND_CONSTCUT_S, 3-71

43206 |SPIND_SPEED_TYPE, 3-71

43210, 5-123

42200 |SINGLEBLOCK2_STOPRE, 3-68

42400 |PUNCH_DWELLTIME, 3-68

42402 |NIBPUNCH_PRE_START_TIME, 3-68

42404 |MINTIME_BETWEEN_STROKES, 3-68

42440 |FRAME_OFFSET_INCR_PROG, 3-68

42442 |TOOL_OFFSET_INCR_PROG, 3-68

42444 |TARGET_BLOCK_INCR_PROG, 3-68

42450 |CONTPREC, 3-68

42465 |SMOOTH_CONTUR_TOL, 3-68

42470 |CRIT_SPLINE_ANGLE, 3-68

42471 |MIN_CURV_RADIUS, 3-68

42475 |COMPRESS_CONTUR_TOL, 3-69

42480 |STOP_CUTCOM_STOPRE, 3-69

42490 |CUTCOM_G40_STOPRE, 3-69

42494 |CUTCOM_ACT_DEACT_CTRL, 3-69

42496 |CUTCOM_CLSD_CONT, 3-69

43210 |SPIND_MIN_VELO_G25, 3-71

43220, 5-123

43220 |SPIND_MAX_VELO_G26, 3-71

43230, 5-123

43230 |SPIND_MAX_VELO_LIMS, 3-71

43240 |M19_SPOS, 3-71

43250 |M19_SPOSMODE, 3-71

43400, 5-124

43400 |WORKAREA_PLUS_ENABLE, 3-71

43410, 5-124

43410 |WORKAREA_MINUS_ENABLE, 3-72

43420, 5-124

43420 |WORKAREA_LIMIT_PLUS, 3-72

43430, 5-124

43430 |WORKAREA_LIMIT_MINUS, 3-72

43500, 5-124

42500 |SD_MAX_PATH_ACCEL, 3-69

42502 |IS_SD_MAX_PATH_ACCEL, 3-69

42510 |SD_MAX_PATH_JERK, 3-69

42512 |IS_SD_MAX_PATH_JERK, 3-69

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

43500 |FIXED_STOP_SWITCH, 3-72

43510, 5-125

43510 |FIXED_STOP_TORQUE, 3-72

43700 |OSCILL_REVERSE_POS1, 3-72

xv

Page 16

List of Machine and Setting Data

43710 |OSCILL_REVERSE_POS2, 3-72

43720 |OSCILL_DWELL_TIME1, 3-72

43730 |OSCILL_DWELL_TIME2, 3-72

43740 |OSCILL_VELO, 3-72

43750 |OSCILL_NUM_SPARK_CYCLES, 3-73

43760 |OSCILL_END_POS, 3-73

43770 |OSCILL_CTRL_MASK, 3-73

43780 |OSCILL_IS_ACTIVE, 3-73

43790 |OSCILL_START_POS, 3-73

xvi

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 17

Machine and Setting Data − Explanations

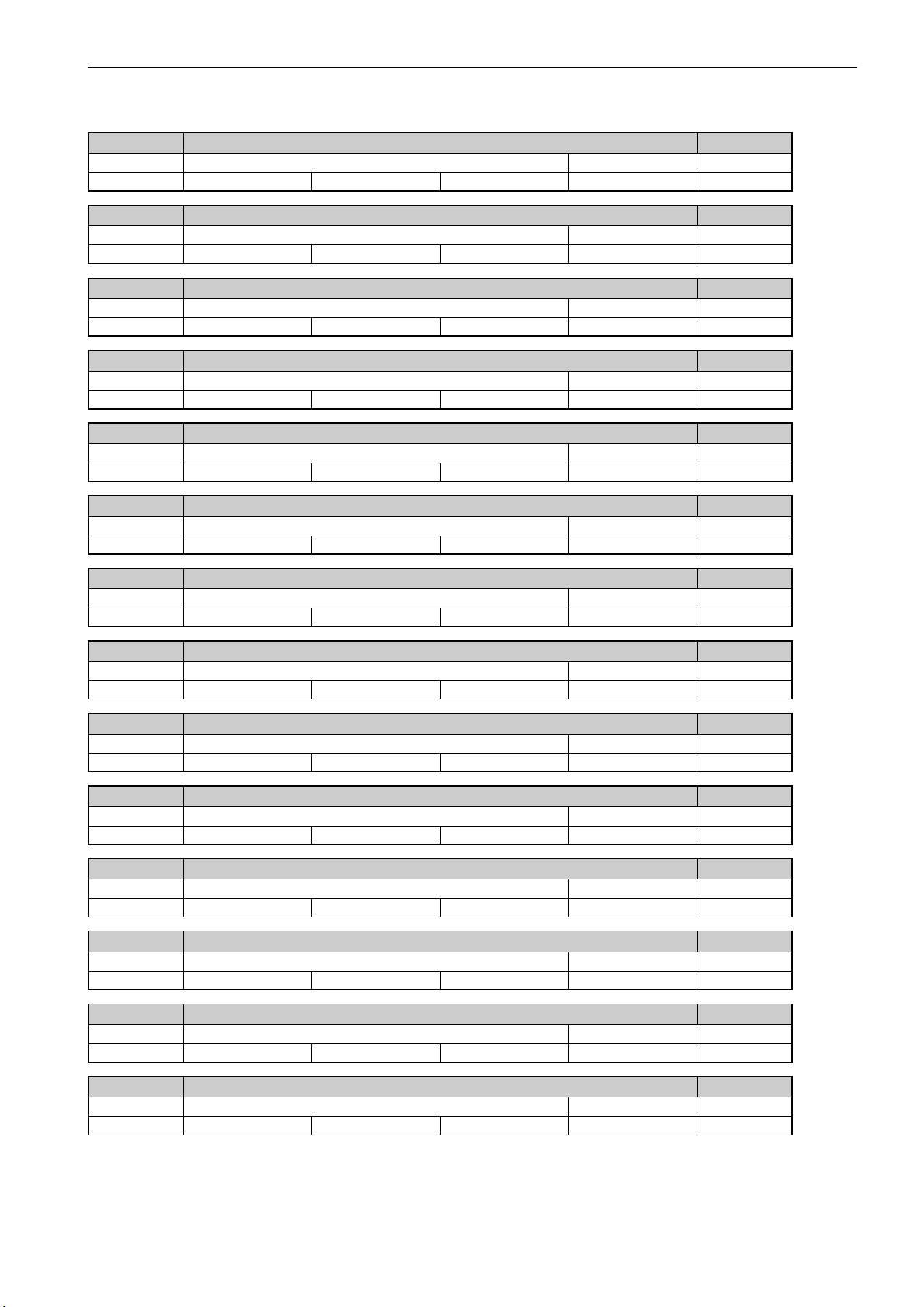

1.1 Specifications in the list

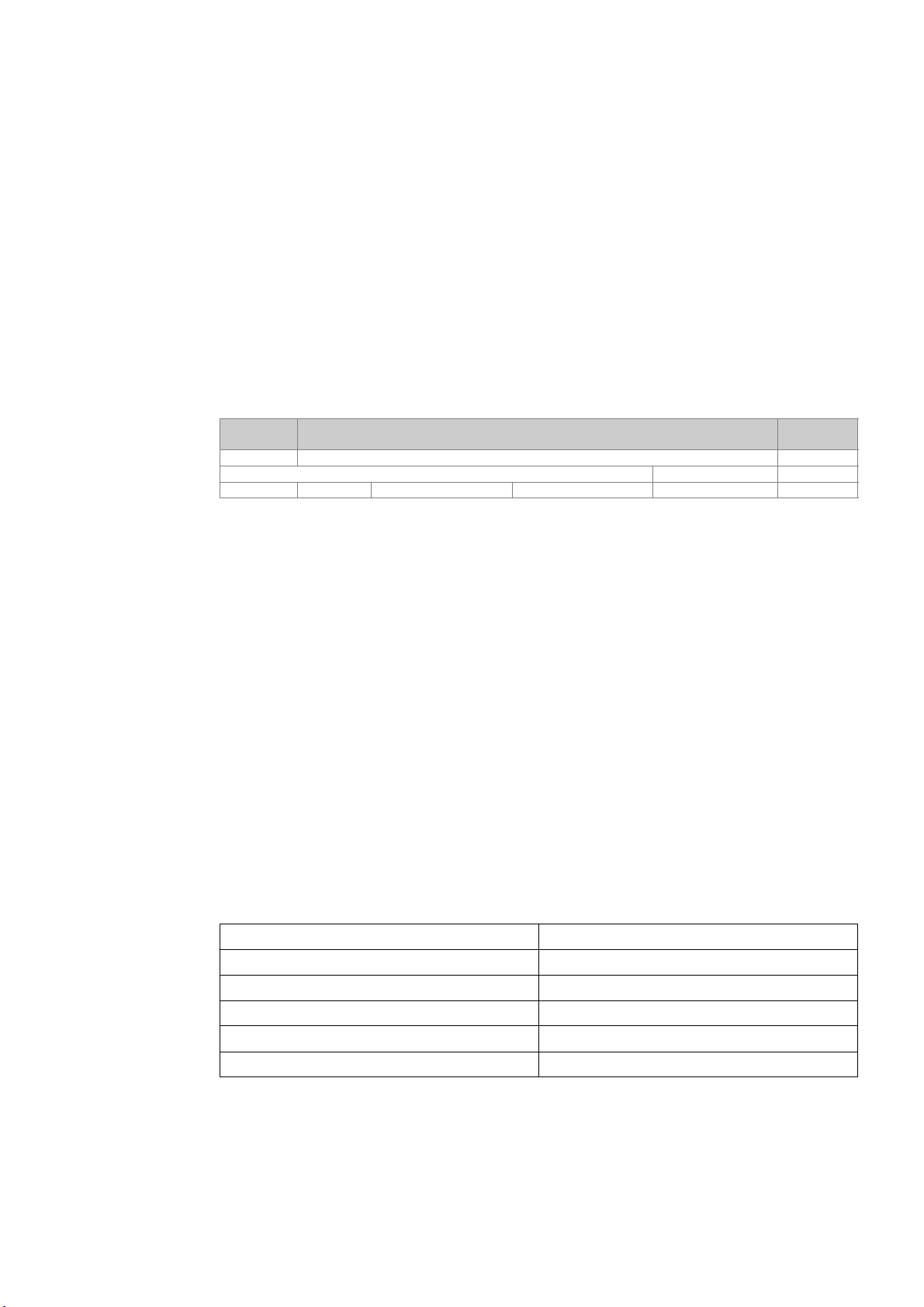

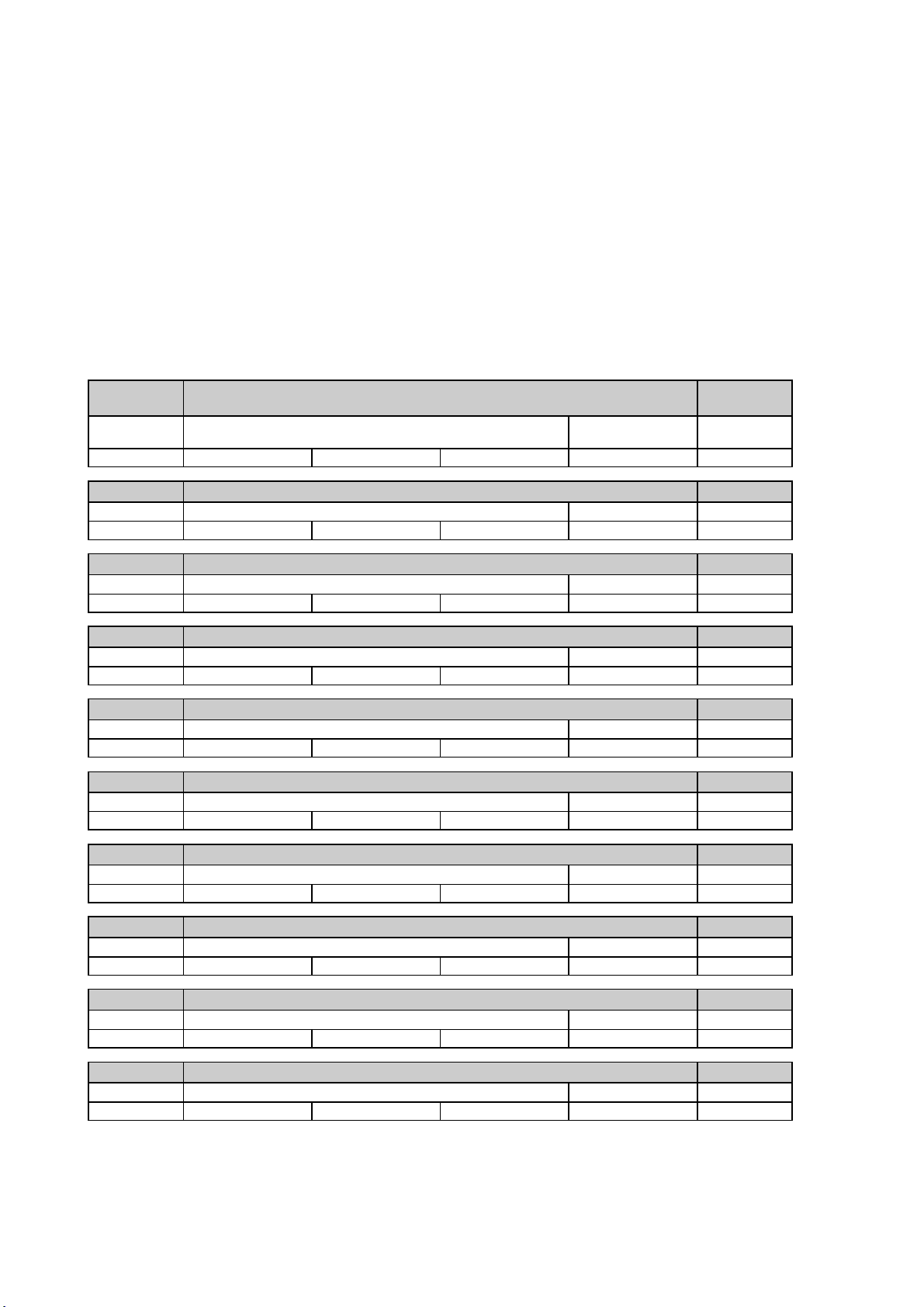

The machine and setting data are listed in the form of tables.

1

MD number

Unit Brief description Activation

Display filter Attributes Data type

System Dimension Default value Minimum value Maximum value Protection

The following information are specified:

Number and identifier

MD and SD are addressed via their numbers or their names (identifiers). The number and

the name, as well as the activation type and the unit are displayed on the screen of the control system.

Cross reference

For a detailed description of the appropriate data, please refer to the description of functions

or manual/guide specified.

Example: [F−S1] Description of Functions 802D sl, Chapter ”Spindle (S1)”

Unit/unit system

Depending on MD 10240 SCALING_SYSTEM_IS_METRIC, the physical units of the machine data (MD) differ as follows:

MD identifier Cross

reference

If there are machine data with no physical unit assigned, a hyphen (”−”) can be found in the

relevant field.

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

MD 10240 = 1 MD 10240 = 0

mm inch

mm/min inch/min

2

m/s

3

m/s

mm/rev. inch/rev.

inch/s

inch/s

2

3

1-17

Page 18

Machine and Setting Data − Explanations

1.1 Specifications in the list

Note

The default setting is MD 10240 SCALING_SYSTEM_IS_METRIC = 1 (metric).

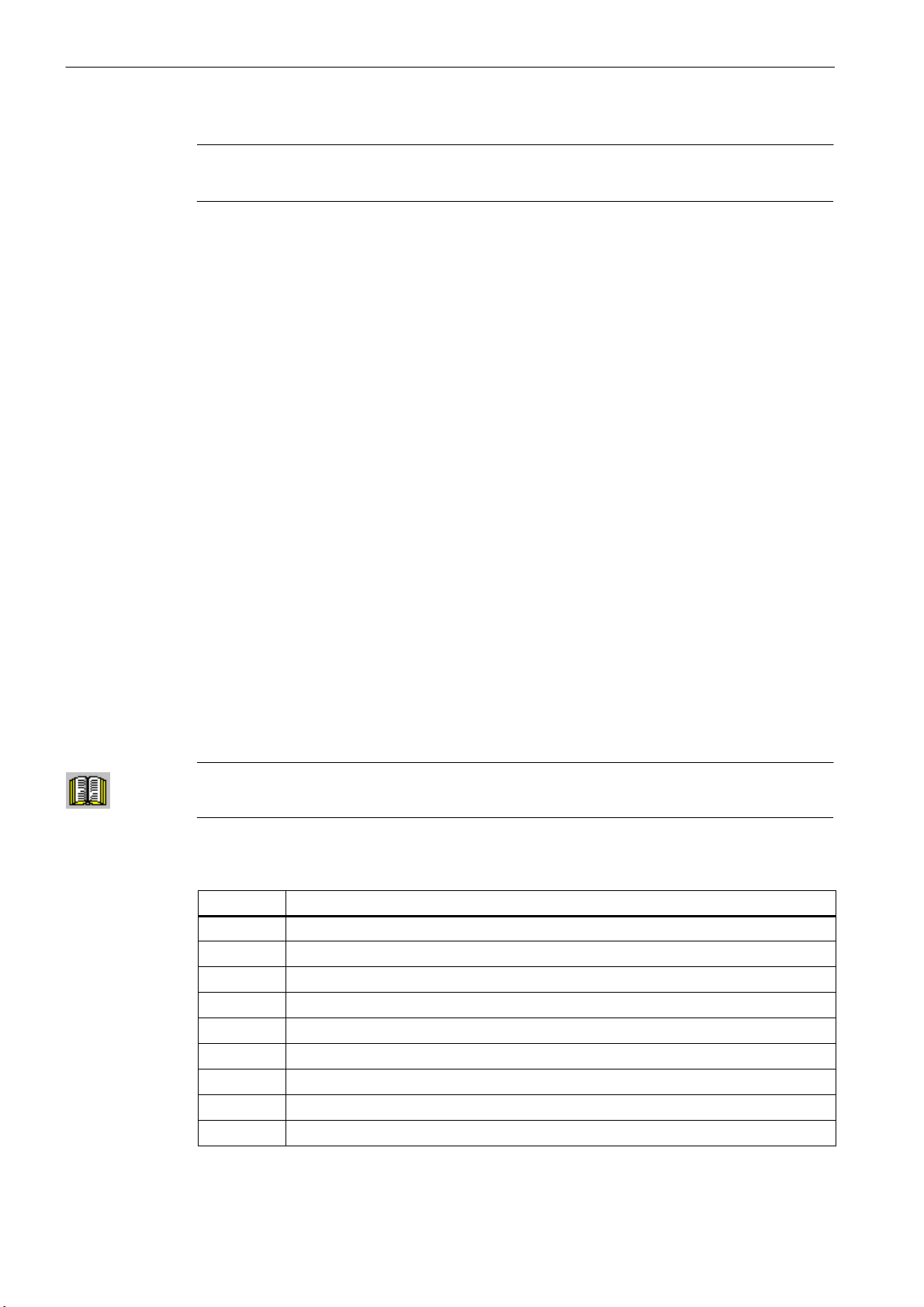

Activation

The activation stages are listed according to their priority. If any data is changed, it comes

into effect after:

POWER ON (po) Turning off / turning on the SINUMERIK 802D sl

NEW_CONF (cf) With RESET at the PLC interface (V3000 0000.7)

RESET (re) With RESET at the PLC interface (V3000 0000.7) or at the end of the pro-

gram M2/M30

IMMEDIATELY (im) After input of the value

Display filter

The number of machine data displayed in a specific area can be reduced thanks to a display

filter.

Display filters are offered for the following machine data areas:

General machine data

Channel−specific machine data

Axis−specific machine data

To parameterize the display filter for a machine data area, use the Select group softkey to

call the relevant machine data area.

Note for reader

SINUMERIK 802D sl, ”Operation and Programming...”, Chapter ”System”

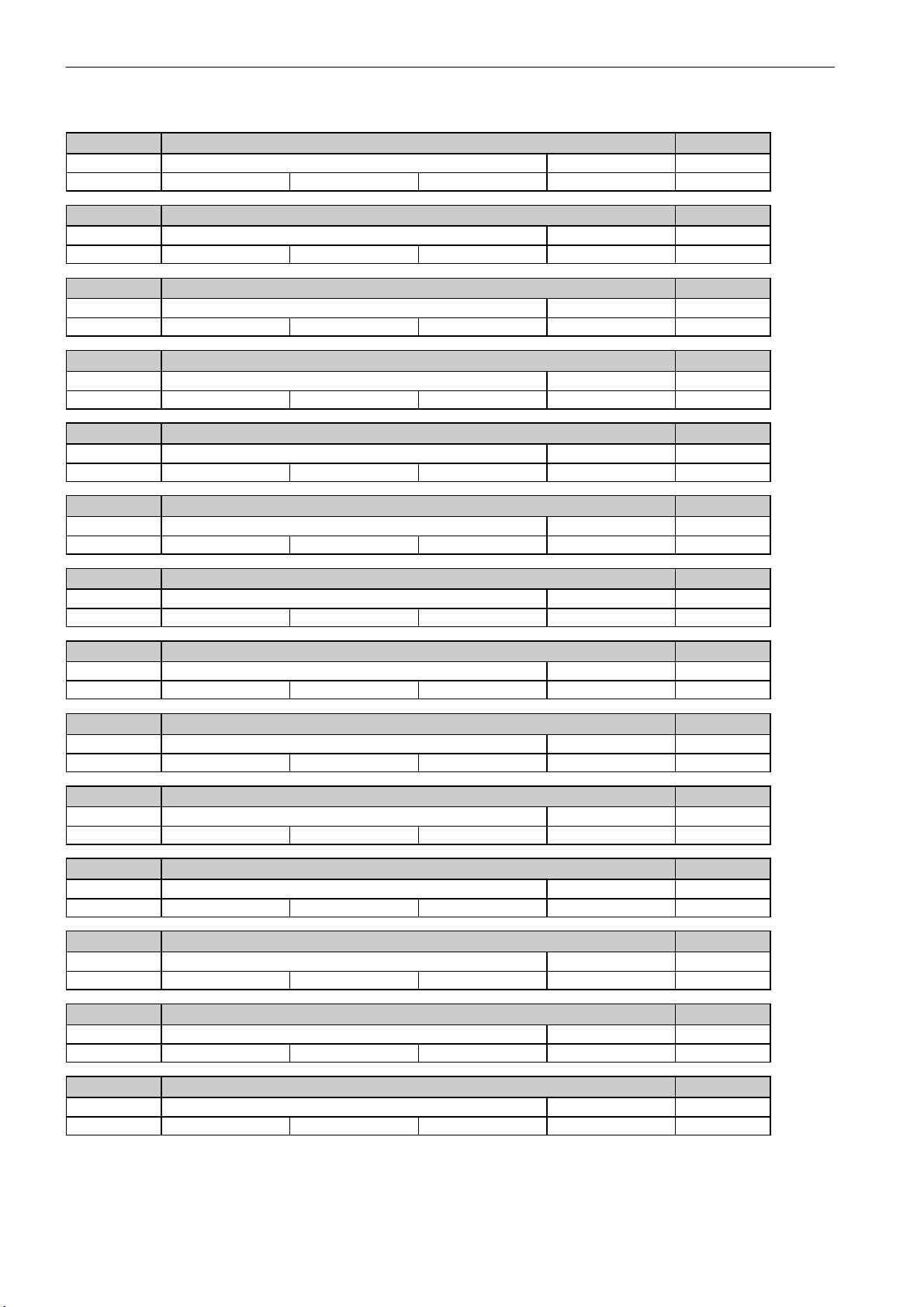

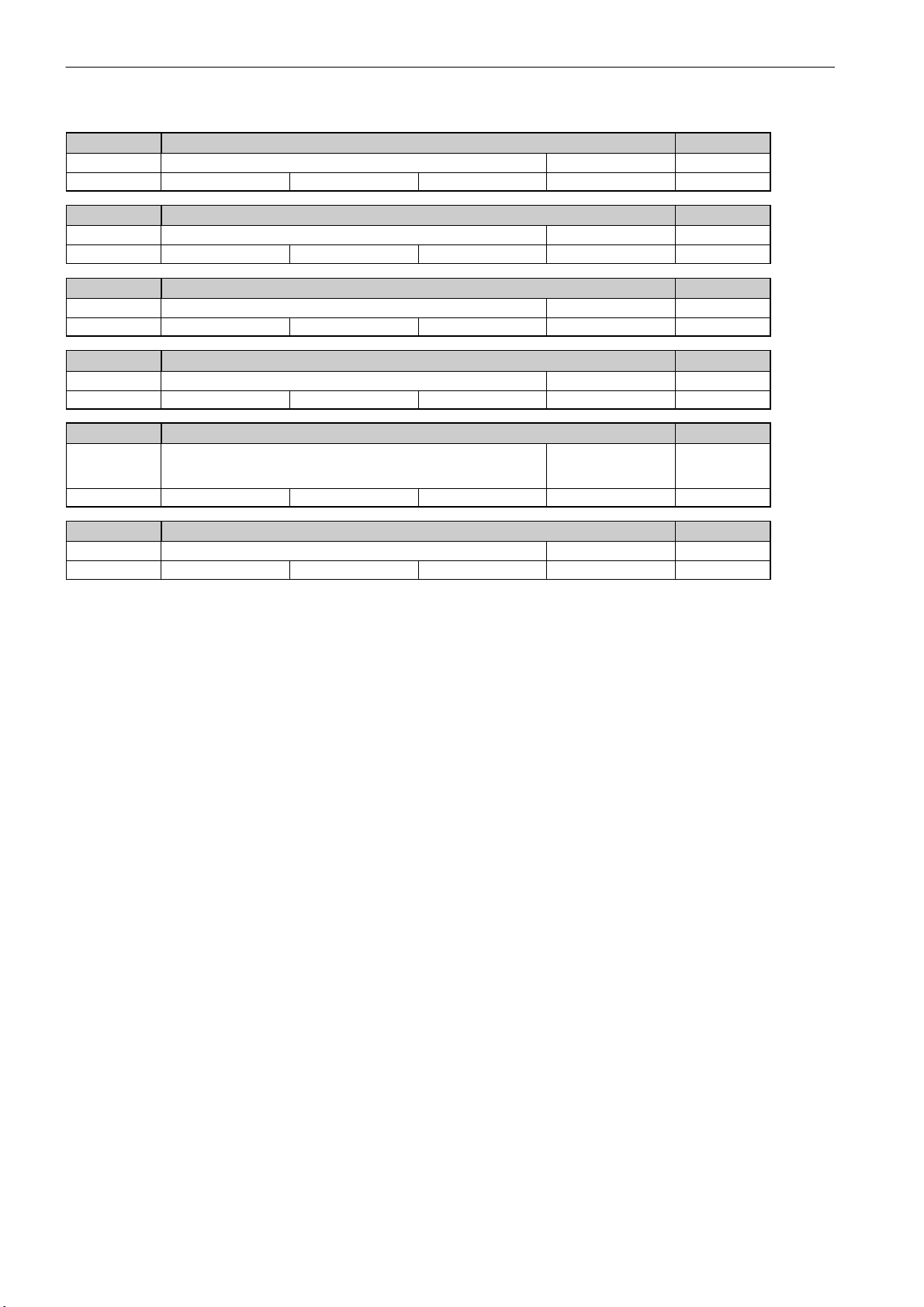

Table 1-1 Display filters in the individual data areas

Code

General machine data

N01 Configuration / scaling

N02 Memory configuration

N03 PLC machine data

N04 Drive control

N05 Status data / diagnosis

N06 Monitoring functions / limitations

N07 Auxiliary functions

N08 Corrections / compensations

Display filter

1-18

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 19

Machine and Setting Data − Explanations

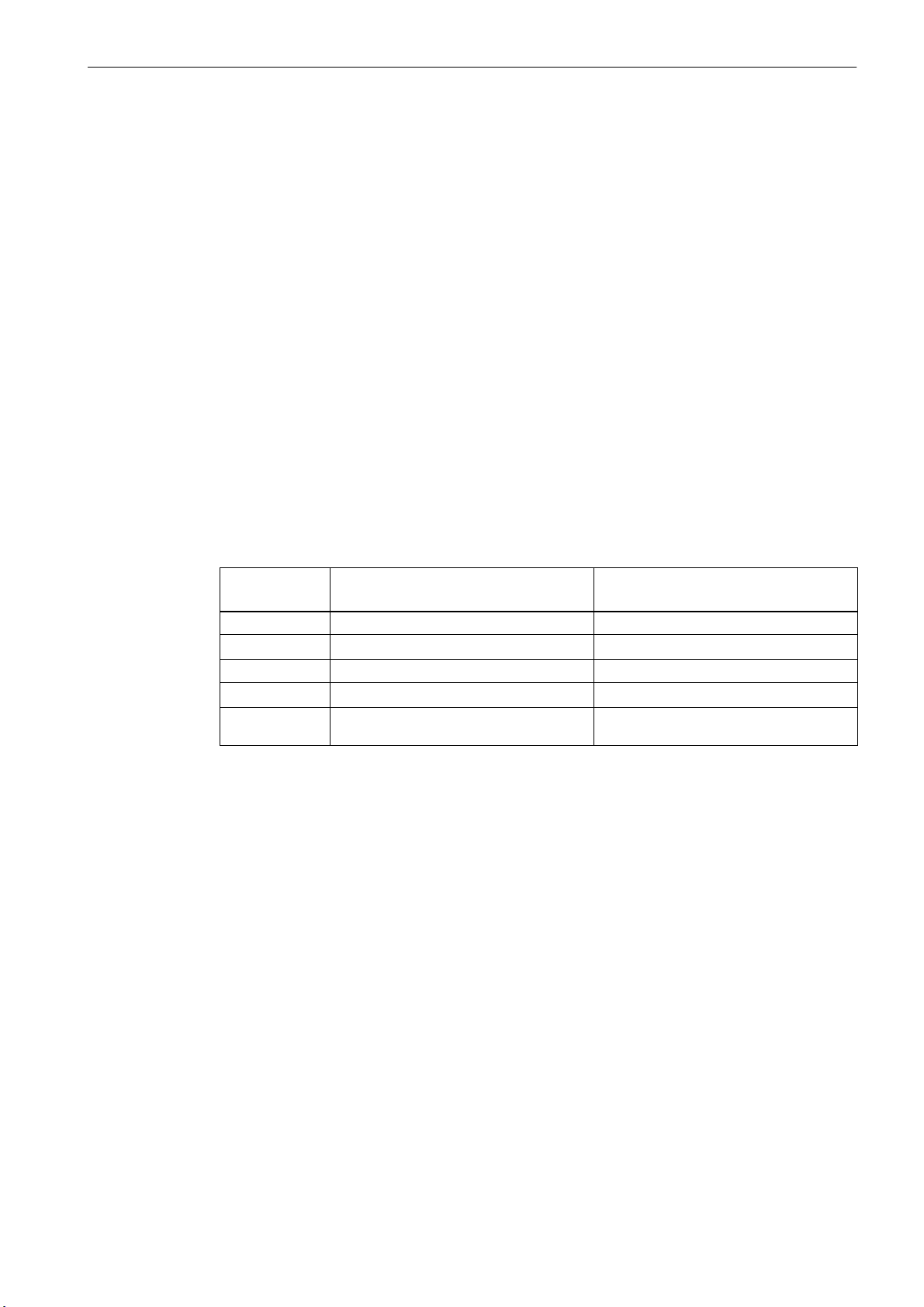

Table 1-1 Display filters in the individual data areas, cont’d

Code Display filter

N09 Technological functions

N10 I/O configuration

N11 Standard machine

Channel−specific machine data

C01 Configuration

C02 Memory configuration

C03 Default settings

C04 Auxiliary functions

C05 Speeds/velocities

C06 Monitoring functions / limitations

C07 Transformations

C08 Corrections / compensations

C09 Technological functions

C10 Standard machine

Axis−specific machine data

A01 Configuration (including memory)

A02 Measuring system

A03 Machine geometry

A04 Speeds, velocities / accelerations / jerk

A05 Monitoring functions / limitations

A06 Spindle

A07 Controller data

A08 Status data

A09 Corrections / compensations

A10 Technological functions

A11 Standard machine

1.1 Specifications in the list

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

1-19

Page 20

Machine and Setting Data − Explanations

1.1 Specifications in the list

Data type

BOOLEAN Boolean value: 1 (TRUE) or 0 (FALSE)

BYTE 8−bit value,

STRING Sequence of characters (max. 16)

WORD 16−bit value,

UNSIGNED WORD 16−bit value,

as an INTEGER value: -128 ... 127,

as a hexadecimal value: 00 ... FF

as a character as per ASCII character set, e.g. “a”

as an INTEGER value: -32768 ... 32767,

as a hexadecimal value: 0000 ... FFFF

as an INTEGER value: 0 ... 65535,

as a hexadecimal value: 0000 ... FFFF

System

INTEGER 16−bit value (here defined locally),

INTEGER value: -32768 ... 32767

DWORD 32−bit value,

as an INTEGER value: −2147483648 ... 2147483647,

as a hexadecimal value: 0000 0000 ... FFFF

UNSIGNED WORD 32−bit value,

as an INTEGER value: 0 ... 4294967295,

as a hexadecimal value: 0000 0000 ... FFFF FFFF

DOUBLE 64−bit value,

floating point value: " 4.19 10

-307

... " 1.67 10

308

Specifies the control system for which the data with the entered values applies. The following entries are possible:

default

The entered values apply for all SINUMERIK 802D sl.

Any deviations in the range of values must be entered in the following lines of the table. If

no ”default” entry exists, the data only applies for the control variants specified.

1-20

tm1 Turning/milling value

tm2 Turning/milling plus

tm3 Turning/milling pro

ng2 Nibbling/grinding plus

ng3 Nibbling/grinding pro

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 21

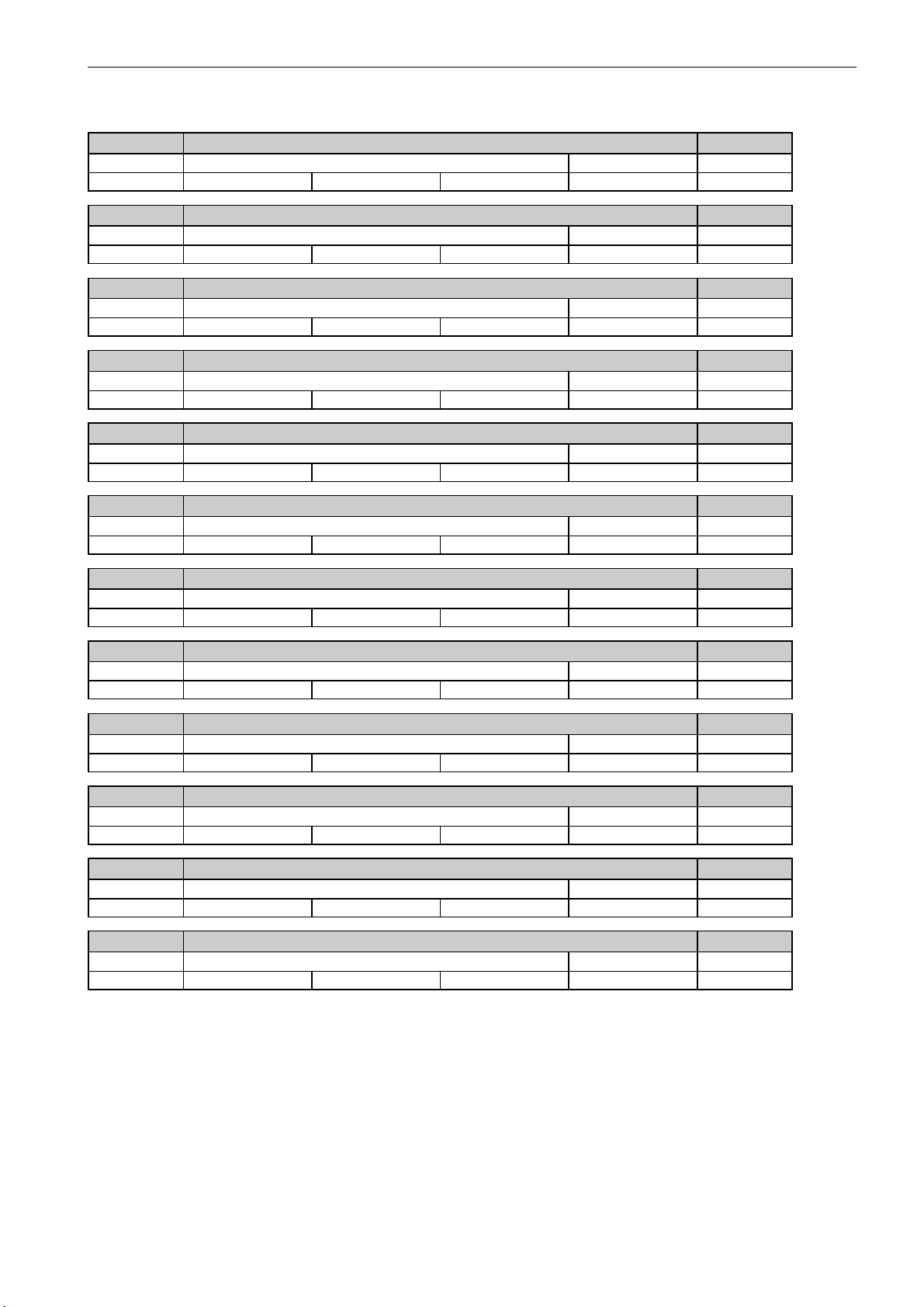

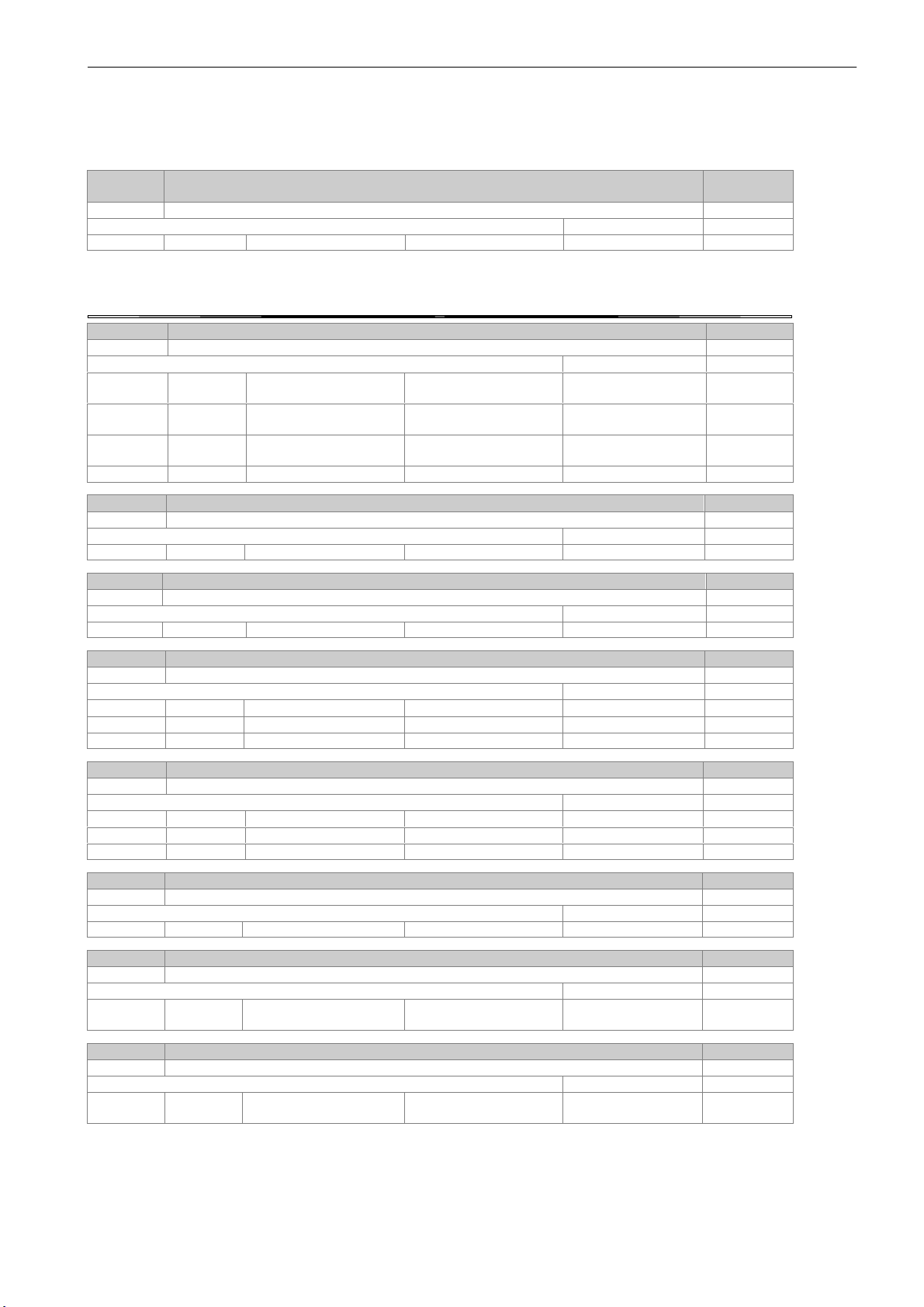

Default values

This value is used to specify a default value for the machine data. If the default values for

the channels are different, this is marked by a ” , ”.

Range of values (minimum/maximum value)

Specifies the input limits. If no range of values is specified, the data type determines the input limits, and the field is marked with ”***”.

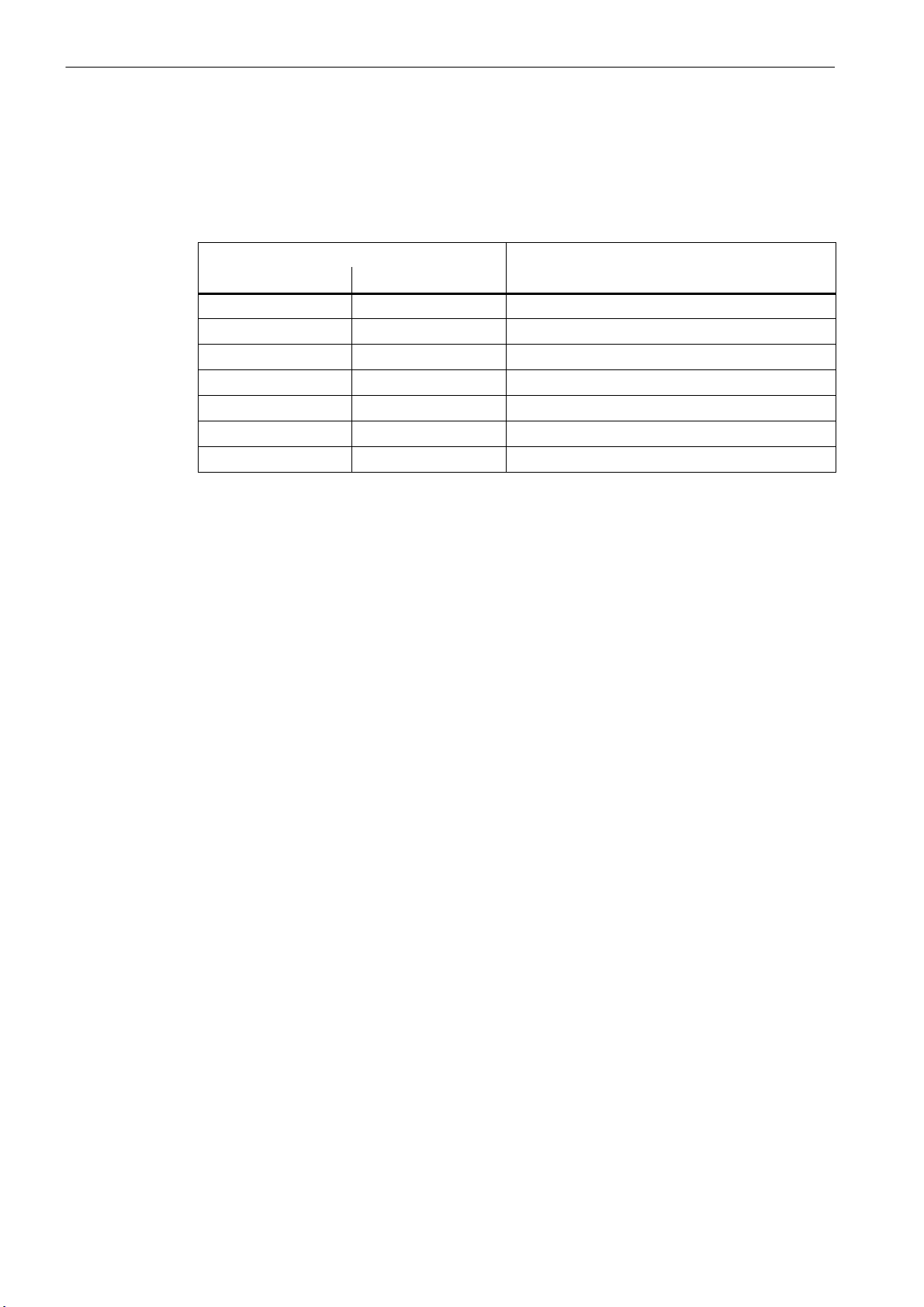

Protection levels

The SINUMERIK 802D sl provides a concept of protection levels for enabling data areas.

There are the protection levels 0 to 7 whereby 0 is the highest and 7 the lowest level.

The protection levels can be set for certain function areas (e.g. program editor) using the

display machine data (USER_CLASS...).

When the control system is delivered, certain default passwords are already set for the protection levels 1 to 3. If necessary, the appropriate authorized person can change these passwords.

Machine and Setting Data − Explanations

1.1 Specifications in the list

Table 1-2 Protection level concept

Protection

level

0 Siemens, reserved

1 Password: SUNRISE (default) Expert mode (OEM HIGH)

2 Password: EVENING (default) Machine manufacturer (OEM LOW)

3 Password: CUSTOMER (default) Authorized operator, setter

4 to 7 No password and

user interface from PLC NCK

Locked by Area

Authorized operator, setter or appropriate graduations as desired

Protection levels 1 ... 3

The protection levels 1 to 3 require a password. The passwords can be changed after activation. For example, if the passwords are no longer known, the control system must be reinitialized (booting with default machine data). This will reset all passwords to their defaults

according to the software release you have acquired.

The password remains set until it is reset by selecting the Delete password softkey.

POWER ON will not reset the password.

Protection levels 4 ... 7

Protection level 7 is set automatically if no password is set and no protection level interface

signal is set. The protection levels 4 to 7 can be set from the PLC user program even without a password by setting the bits in the user interface.

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

1-21

Page 22

Machine and Setting Data − Explanations

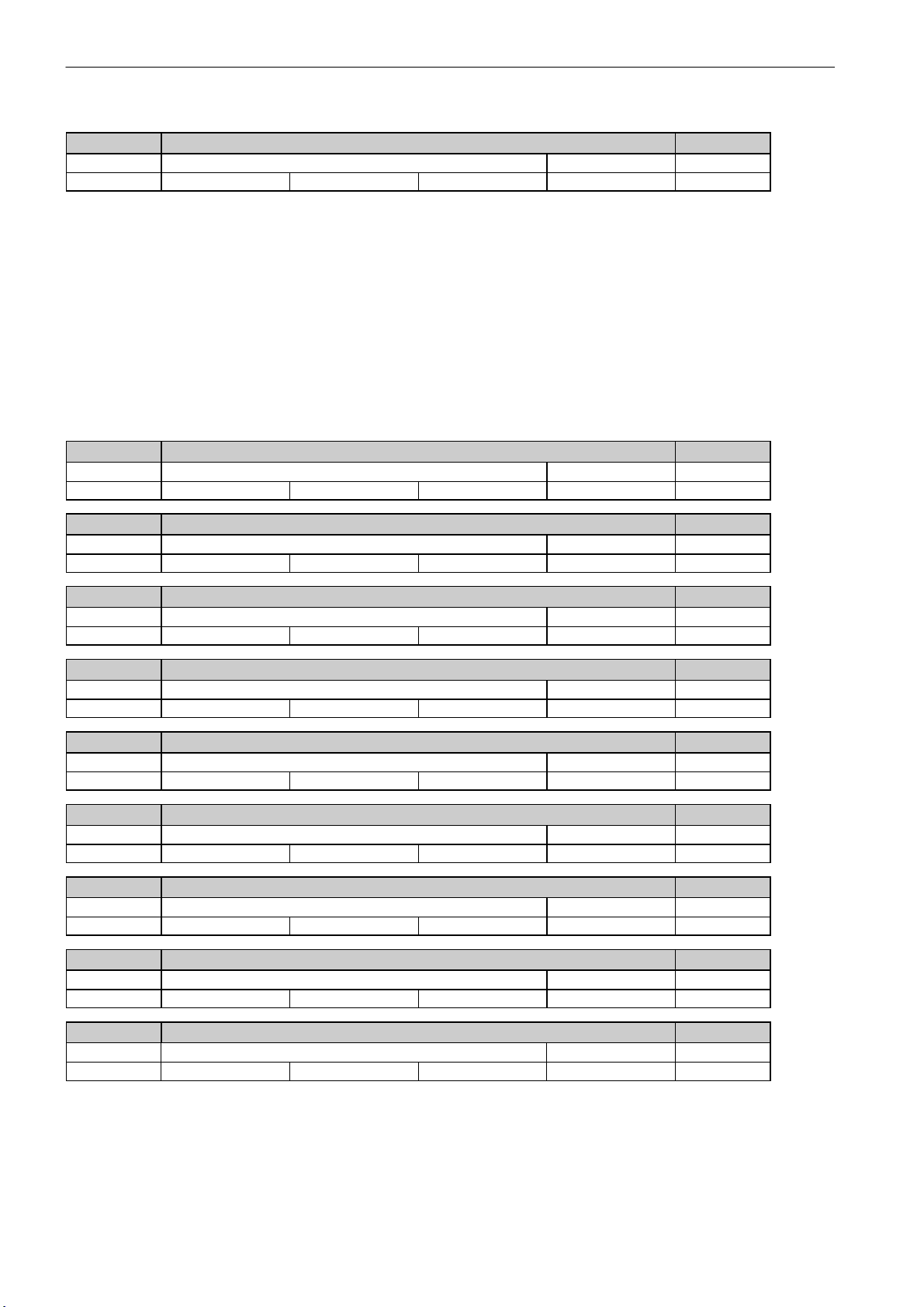

1.2 Overview of the machine and setting data areas

1.2 Overview of the machine and setting data areas

The machine and setting data are divided into the following areas:

Table 1-3 Overview of the machine and setting data areas

Area

from to

200 400 Display machine data

1 000 19 999 General machine data

20 000 29 999 Channel−specific machine data

30 000 39 999 Axis−specific machine data

41 000 41 999 General setting data

42 000 42 999 Channel−specific setting data

43 000 43 999 Axis−specific setting data

Designation

1-22

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 23

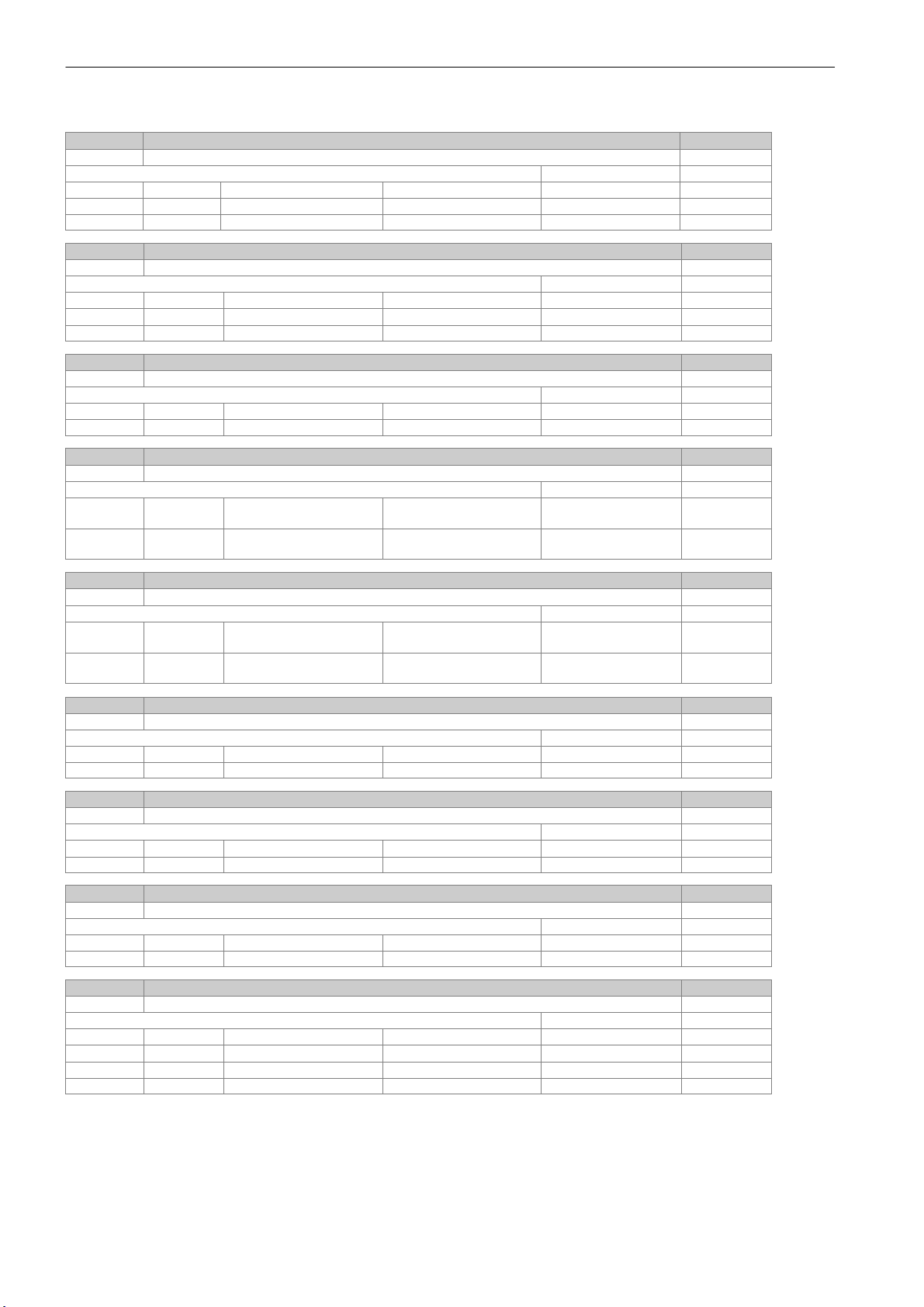

List of Machine Data

2.1 Display machine data

2

Number MD identifier

Schematic view Name, miscellaneous Activation

Unit Default value Minimum value Maximum value Data type

202 FIRST_LANGUAGE F−T3

decimal Foreground language POWER ON 2/3

0 2 1 2 BYTE

203 DISPLAY_RESOLUTION F−T3

decimal Display resolution immediately 2/3

0 3 0 5 BYTE

204 DISPLAY_RESOLUTION_INCH F−T3

decimal Display resolution immediately 2/3

0 4 0 5 BYTE

205 DISPLAY_RESOLUTION_SPINDLE F−T3

decimal Display resolution immediately 2/3

0 1 0 5 BYTE

207 USER_CLASS_READ_TOA

decimal Protection level for ”Read tool offsets, general” immediately 3/3

0 3 0 7 BYTE

Cross refe-

rence

Read/write

protection level

208 USER_CLASS_WRITE_TOA_GEO

decimal Protection level for ”Write tool geometry” immediately 3/3

0 3 0 7 BYTE

209 USER_CLASS_WRITE_TOA_WEAR

decimal Protection level for ”Write wear data” immediately 3/3

0 3 0 7 BYTE

210 USER_CLASS_WRITE_ZOA

decimal Protection level for ”Write settable work offset” immediately 3/3

0 3 0 7 BYTE

212 USER_CLASS_WRITE_SEA

decimal Protection level for ”Write setting data” immediately 3/3

0 7 0 7 BYTE

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-23

Page 24

List of Machine Data

2.1 Display machine data

213 USER_CLASS_READ_PROGRAM

decimal Protection level for ”Read part program” immediately 3/3

0 7 0 7 BYTE

214 USER_CLASS_WRITE_PROGRAM

decimal Protection level for ”Enter part program” immediately 3/3

0 3 0 7 BYTE

215 USER_CLASS_SELECT_PROGRAM

decimal Protection level for program selection immediately 3/3

0 3 0 7 BYTE

217 USER_CLASS_WRITE_CYCLES

decimal Protection level for ”Write cycles” immediately 3/3

0 3 0 7 BYTE

218 USER_CLASS_WRITE_RPA

decimal Protection level for ”Write R parameters” immediately 3/3

0 3 0 7 BYTE

219 USER_CLASS_SET_V24

decimal Protection level for ”Set V24” immediately 3/3

0 3 0 7 BYTE

221 USER_CLASS_DIR_ACCESS

decimal Protection level for directory access immediately 3/3

0 3 0 7 BYTE

222 USER_CLASS_PLC_ACCESS

decimal Protection level for PLC project immediately 2/2

0 3 0 7 BYTE

223 USER_CLASS_WRITE_PWA

decimal Protection level for protected working area immediately 2/3

0 7 0 7 BYTE

247 V24_PG_PC_BAUD

Bit pattern PG: Baud rate (300, 600, 1200, 2400, 4800, 9600, 19200, 38400) immediately 3/3

0 7 0 7 BYTE

280 V24_PPI_ADDR_PLC

PLC station address POWER ON 3/3

2 0 126 BYTE

281 V24_PPI_ADDR_NCK

NCK station address POWER ON 3/3

3 0 126 BYTE

289 CTM_SIMULATION_TIME_NEW_POS F−K1

decimal Simulation of actual-value refresh rate immediately 3/4

0 100 0 4000 INTEGER

290 CTM_POS_COORDINATE_SYSTEM F−K1

decimal Position of the coordinate system immediately 3/4

0 2 0 7 BYTE

2-24

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 25

List of Machine Data

2.1 Display machine data

291 CTM_CROSS_AX_DIAMETER_ON F−K1

decimal Diameter for ”Transverse axis active” immediately 3/4

0 1 0 1 BYTE

292 CTM_G91_DIAMETER_ON F−K1

decimal Incremental feed immediately 3/7

0 1 0 1 BYTE

305 G_GROUP1

decimal User-oriented G group for position display immediately 3/7

0 1 1 1000 INTEGER

306 G_GROUP2

decimal User−oriented G group for position display immediately 3/7

0 2 1 1000 INTEGER

307 G_GROUP3

decimal User-oriented G group for position display immediately 3/7

0 8 1 1000 INTEGER

308 G_GROUP4

decimal User-oriented G group for position display immediately 3/7

0 9 1 1000 INTEGER

309 G_GROUP5

decimal User-oriented G group for position display immediately 3/7

0 10 1 1000 INTEGER

310 FG_GROUP1

decimal User−oriented G group for position display (external language) immediately 3/7

0 1 1 1000 INTEGER

311 FG_GROUP2

decimal User−oriented G group for position display (external language) immediately 3/7

0 2 1 1000 INTEGER

312 FG_GROUP3

decimal User−oriented G group for position display (external language) immediately 3/7

0 8 1 1000 INTEGER

313 FG_GROUP4

decimal User−oriented G group for position display (external language) immediately 3/7

0 9 1 1000 INTEGER

314 FG_GROUP5

decimal User−oriented G group for position display (external language) immediately 3/7

0 10 1 1000 INTEGER

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-25

Page 26

List of Machine Data

2.1 Display machine data

330 CMM_POS_COORDINATE_SYSTEM

decimal Coordinate position of machine *) immediately 3/7

0 0 0 7 BYTE

*) Explanation:

Both the position and the size of the representation are handed over during initialization. The position of the coordinate system

can be influenced by the ”Axis direction” parameter in the header of the file.

The following positions are possible: Position

0

1 up to the left

2 down to the right

3 down to the left

4 to the right top

5 to the left up

6 to the right down

7 to the left down

up to the right

The positions of the elements must be specified in position 4 (mathematic coordinate system). The simulation will then automatically convert the representation to the relevant system.

331 CONTOUR_MASK

decimal Activating the 802 contour definition programming immediately 3/7

0 1 0 1 BYTE

X+ Z+

332 TOOL_LIST_PLACE_NO

decimal Activate location number in tool list immediately 3/3

0 0 0 1 INTEGER

343 V24_PPI_ADDR_MMC

decimal POWER ON 3/3

0 4 0 126

344 V24_PPI_MODEM_ACTIVE

decimal immediately 3/3

0 0 0 1 Byte

345 V24_PPI_MODEM_BAUD

decimal Baud rate for modem connection immediately 3/3

0 7 5 9 Byte

346 V24_PPI_MODEM_PARITY

decimal Parity for modem connection immediately 3/3

0 0 0 2 Byte

356 HMI_COL_TITLE_FOCUS_FORE

decimal Color settings title bar focus window foreground immediately 0/3

15 0 15 Byte

357 HMI_COL_TITLE_FOCUS_BACK

decimal Color settings title bar focus window background immediately 0/3

2 0 15 Byte

360 SPINDLE_LOAD_DISPL1

decimal Activate utilization display for spindle 1 immediately 3/3

0 0 1 INTEGER

2-26

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 27

List of Machine Data

2.1 Display machine data

361 USER_MEAS_TOOL_CHANGE

decimal Input enable for T/D no. in the ”Tool gauging” window immediately 3/3

0 0 1 Byte

362 SPINDLE_LOAD_DISPL2

decimal Activate utilization display for spindle 2 immediately 3/3

1 0 1 INTEGER

363 SPINDLE_LOAD_BAR_LIM2

decimal Activate utilization display for the spindle, limit value 2 immediately 2/2

100 0 9999999 INTEGER

364 SPINDLE_LOAD_BAR_LIM3

decimal Activate utilization display for the spindle, limit value 3 immediately 2/2

100 0 9999999 INTEGER

365 SPINDLE_LOAD_BAR_MAX

decimal Utilization display for the spindle, maximum immediately 2/2

120 0 120 INTEGER

366 SPINDLE_LOAD_BAR_COL1

decimal Utilization display color for the spindle, range 1 immediately 3/3

10 0 15 Byte

367 SPINDLE_LOAD_BAR_COL2

decimal Utilization display color for the spindle, range 2 immediately 3/3

9 0 15 Byte

368 SPINDLE_LOAD_BAR_COL3

decimal Utilization display color for the spindle, range 3 immediately 3/3

9 0 15 Byte

369 PROBE_MODE

decimal Measuring system type: 1: Probe, 2: Opt. measuring technique immediately 3/3

1 0 2 INTEGER

370 TOOL_REF_PROBE_AXIS1

decimal Absolute position of probe X immediately 2/2

0 −999999.999 999999.999 DOUBLE

371 TOOL_REF_PROBE_AXIS2

decimal Absolute position of probe Y immediately 2/2

0 −999999.999 999999.999 DOUBLE

372 TOOL_REF_PROBE_AXIS3

decimal Absolute position of probe Z immediately 2/2

9 −999999.999 999999.999 DOUBLE

373 MEAS_SAVE_POS_LENGTH2

decimal Activate tool gauging; select ”Save Pos” softkey for all values immediately 2/2

0 0 1 Byte

374 TOOL_WEAR_LIMIT_VALUE

decimal Limit value for wear control during input immediately 2/2

9.999 0 9.999 DOUBLE

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-27

Page 28

List of Machine Data

2.1 Display machine data

375 USER_CLASS_READ_CUS_DIR

decimal Protection level for ”Read user cycles” immediately 2/3

0 7 0 7 Byte

376 USER_CLASS_WRITE_CUS_DIR

decimal Protection level for ”Write user cycles” immediately 2/2

0 2 0 7 Byte

377 USER_CLASS_WRITE_TO_MON_DAT

decimal Protection level for ”Tool monitoring” immediately 2/3

0 3 0 7 Byte

378 USER_CLASS_LADDER_VIEW

decimal Protection level for ”Select user ladder view” immediately 2/2

0 2 0 7 Byte

379 SPINDLE_DISP_MODE

0: Default mode, display of spindle speed

decimal

0 0 0 2 Byte

1: Constant cutting rate, display with G96 set

2: Mixed display

immediately 3/3

383 V24_PPI_ADDR_DRV1

decimal Station address for the drives POWER ON 3/3

0 5 0 126 Byte

2-28

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 29

2.2 General machine data

List of Machine Data

2.2 General machine data

MD

number

Unit Brief description Activation

Display filter Attributes Data type

System * Dimension Default value Minimum value Maximum value Protection

* Values other than those in the default system

Note regarding the value definition:

TRUE corresponds to 1

10000 AXCONF_MACHAX_NAME_TAB

− Machine axis name POWER ON

N01, N11 − STRING

Default 6 ”X1”, ”Y1”, ”Z1”, ”SP”,

ng2 6 ”X1”, ”Z1”, ”C1”, ”A1”, ”B1”,

ng3 6 ”X1”, ”Z1”, ”C1”, ”A1”, ”B1”,

tm1 4 ”X1”, ”Y1”, ”Z1”, ”SP” − − 2/2

10074 PLC_IPO_TIME_RATIO

− Factor of the PLC task for main run POWER ON

N01, N05 − DWORD

Default − 1 1 50 2/2

10088 REBOOT_DELAY_TIME

s Reboot delay immediately

EXP − DOUBLE

Default − 0.2 0.0 1.0 2/2

MD identifier

FALSE corresponds to 0

− − 2/2

”A1”, ”PLCX1”

− − 2/2

”PLCX1”

− − 2/2

”PLCX1”

10200 INT_INCR_PER_MM

− Computational resolution for linear positions POWER ON

N01 − DOUBLE

Default − 1000.0 1.0 1.0e9 2/2

ng2 − 100000.0 1.0 1.0e9 2/2

ng3 − 100000.0 1.0 1.0e9 2/2

10210 INT_INCR_PER_DEG

− Computational resolution for angular positions POWER ON

N01 − DOUBLE

Default − 1000.0 1.0 1.0e9 2/2

ng2 − 100000.0 1.0 1.0e9 2/2

ng3 − 100000.0 1.0 1.0e9 2/2

10240 SCALING_SYSTEM_IS_METRIC

− Metric basic system POWER ON

N01 SCAL BOOLEAN

Default − TRUE − − 2/2

10350 FASTIO_DIG_NUM_INPUTS

− Number of active digital NCK input bytes POWER ON

N10 − BYTE

Default − 2 1 MAXNUM_DIG_

FASTIN_BYTES

10360 FASTIO_DIG_NUM_OUTPUTS

− Number of active digital NCK output bytes POWER ON

N10 − BYTE

Default − 2 0 MAXNUM_DIG_

FASTOUT_BYTES

2/2

2/2

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-29

Page 30

List of Machine Data

2.2 General machine data

10366 HW_ASSIGN_DIG_FASTIN

− Hardware assignment of external digital NCK inputs POWER ON

N10 − DWORD

Default 1 0x0 0x0 0x00010101 2/2

ng2 1 0x00010101 0x0 0x00010101 2/2

ng3 1 0x00010101 0x0 0x00010101 2/2

10368 HW_ASSIGN_DIG_FASTOUT

− Hardware assignment of external digital NCK outputs POWER ON

N10 − DWORD

Default 1 0x0 0x0 0x00010101 2/2

ng2 1 0x00010101 0x0 0x00010101 2/2

ng3 1 0x00010101 0x0 0x00010101 2/2

10450 SW_CAM_ASSIGN_TAB

− Assignment software cams to machine axes POWER ON

N09 − BYTE

ng2 8 0, 0, 0, 0, 0, 0, 0, 0 0 6 2/2

ng3 8 0, 0, 0, 0, 0, 0, 0, 0 0 6 2/2

10460 SW_CAM_MINUS_LEAD_TIME

s Lead or delay time at minus cams 1−16 POWER ON

N09 − DOUBLE

ng2 8 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,

0.0, 0.0

ng3 8 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,

0.0, 0.0

0 − 3/3

0 − 3/3

10461 SW_CAM_PLUS_LEAD_TIME

s Lead or delay time at plus cams 1−16 POWER ON

N09 − DOUBLE

ng2 8 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,

0.0, 0.0

ng3 8 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,

0.0, 0.0

10470 SW_CAM_ASSIGN_FASTOUT_1

− Hardware assignment for output of cams 1−8 to NCK I/Os POWER ON

N09 − DWORD

ng2 − 0 − − 2/2

ng3 − 0 − − 2/2

10480 SW_CAM_TIMER_FASTOUT_MASK

− Screenform for output of cam signals via timer interr. to NCU POWER ON

N09 − DWORD

ng2 − 0 − − 2/2

ng3 − 0 − − 2/2

10485 SW_CAM_MODE

− Behavior of SW cams POWER ON

N09 − DWORD

ng2 − 0 − − 2/2

ng3 − 0 − − 2/2

10710 PROG_SD_RESET_SAVE_TAB

− Setting data to be updated POWER ON

EXP, N01 − DWORD

ng2 30 0, 0, 0... − − 2/2

ng3 30 0, 0, 0... − − 2/2

tm2 30 0, 0, 0... − − 2/2

tm3 30 0, 0, 0... − − 2/2

0 − 3/3

0 − 3/3

2-30

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 31

List of Machine Data

2.2 General machine data

10713 M_NO_FCT_STOPRE

− M function with preprocessing stop POWER ON

EXP, N12, N07 − DWORD

Default 15 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1, −1, −1, −1, −1,

−1

10714 M_NO_FCT_EOP

− M function active for spindle after reset POWER ON

EXP, N07 − DWORD

Default − −1 − − 2/2

10715 M_NO_FCT_CYCLE

− M function to be replaced by a subroutine POWER ON

EXP, N12, N07 − DWORD

Default 10 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1

10716 M_NO_FCT_CYCLE_NAME

− Subroutine name for replacement of an M function POWER ON

EXP, N12, N07 − STRING

Default 10 − − 2/2

10717 T_NO_FCT_CYCLE_NAME

− Subroutine name for replacement of a T function POWER ON

EXP, N12, N07 − STRING

Default −1 − − 2/2

− − 2/2

− − 2/2

10718 M_NO_FCT_CYCLE_PAR

− M function replacement by parameters POWER ON

EXP, N12, N07 − DWORD

Default − −1 − − 2/2

10719 T_NO_FCT_CYCLE_MODE

− Parameterization of the T function replacement POWER ON

EXP, N12, N07 − DWORD

Default − 0 0 1 2/2

10735 JOG_MODE_MASK

− Enable jogging in the AUTOMATIC mode POWER ON

EXP, N01 − DWORD

Default − 0 0 0x1 2/2

10760 G53_TOOLCORR

− Effect with G53, G153 and SUPA POWER ON

N12 − BOOLEAN

tm1 − FALSE − − 2/2

tm2 − FALSE − − 2/2

tm3 − FALSE − − 2/2

10804 EXTERN_M_NO_SET_INT

− M function to activate ASUB POWER ON

EXP, N12 − DWORD

tm1 − 96 − − 2/2

tm2 − 96 − − 2/2

tm3 − 96 − − 2/2

10806 EXTERN_M_NO_DISABLE_INT

− M function to deactivate ASUB POWER ON

EXP, N12 − DWORD

tm1 − 97 − − 2/2

tm2 − 97 − − 2/2

tm3 − 97 − − 2/2

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-31

Page 32

List of Machine Data

2.2 General machine data

10808 EXTERN_INTERRUPT_BITS_M96

− Activate interrupt program (ASUB) POWER ON

EXP, N12 − DWORD

tm1 − 0 − − 2/2

tm2 − 0 − − 2/2

tm3 − 0 − − 2/2

10810 EXTERN_MEAS_G31_P_SIGNAL

− Assignment of the measuring inputs for G31 P.. POWER ON

EXP, N12 − BYTE

tm1 4 1, 1, 1, 1 0 3 2/2

tm2 4 1, 1, 1, 1 0 3 2/2

tm3 4 1, 1, 1, 1 0 3 2/2

10812 EXTERN_DOUBLE_TURRET_ON

− Double−resolver head with G68 POWER ON

EXP, N12 − BOOLEAN

tm1 − FALSE − − 2/2

tm2 − FALSE − − 2/2

tm3 − FALSE − − 2/2

10814 EXTERN_M_NO_MAC_CYCLE

− Macro call via M function POWER ON

EXP, N12 − DWORD

tm1 10 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1

tm2 10 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1

tm3 10 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1

− − 2/2

− − 2/2

− − 2/2

10815 EXTERN_M_NO_MAC_CYCLE_NAME

− Name of subroutine for M function macro call POWER ON

EXP, N12 − STRING

tm1 10 − − 2/2

tm2 10 − − 2/2

tm3 10 − − 2/2

10816 EXTERN_G_NO_MAC_CYCLE

− G function for macro call POWER ON

EXP, N12 − DOUBLE

tm1 50 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1, −1 ....

tm2 50 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1, −1 ....

tm3 50 −1, −1, −1, −1, −1, −1, −1,

−1, −1, −1, −1 ....

10817 EXTERN_G_NO_MAC_CYCLE_NAME

− Name of subroutine for G function macro call POWER ON

EXP, N12 − STRING

tm1 50 − − 2/2

tm2 50 − − 2/2

tm3 50 − − 2/2

10818 EXTERN_INTERRUPT_NUM_ASUP

− Interrupt number for ASUB start (M96) POWER ON

EXP, N12 − BYTE

tm1 − 1 1 8 2/2

tm2 − 1 1 8 2/2

tm3 − 1 1 8 2/2

− − 2/2

− − 2/2

− − 2/2

2-32

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 33

List of Machine Data

2.2 General machine data

10820 EXTERN_INTERRUPT_NUM_RETRAC

− Interrupt number f. rapid retraction (G10.6) POWER ON

EXP, N12 − BYTE

tm1 − 2 1 8 2/2

tm2 − 2 1 8 2/2

tm3 − 2 1 8 2/2

10880 MM_EXTERN_CNC_SYSTEM

− Def. of control system to be adapted POWER ON

N01, N12 − DWORD

tm1 − 1 1 3 2/2

tm2 − 1 1 3 2/2

tm3 − 1 1 3 2/2

10881 MM_EXTERN_GCODE_SYSTEM

− ISO_3 Mode: GCodeSystem POWER ON

N01, N12 − DWORD

Default − 0 0 2 2/2

10882 NC_USER_EXTERN_GCODES_TAB

− List of user−specific G commands, ext. language POWER ON

N12 − STRING

Default 60 − − 2/2

10884 EXTERN_FLOATINGPOINT_PROG

− Evaluation of progr. values without decimal point POWER ON

N12 − BOOLEAN

Default − TRUE − − 2/2

10886 EXTERN_INCREMENT_SYSTEM

− Increment system POWER ON

N12 − BOOLEAN

Default − FALSE − − 2/2

10888 EXTERN_DIGITS_TOOL_NO

− Number of digits for T number POWER ON

N12 − BYTE

Default − 2 0 8 2/2

10890 EXTERN_TOOLPROG_MODE

− Tool change program with ext. language POWER ON

N12 − DWORD

Default − 0 − − 2/2

10900 INDEX_AX_LENGTH_POS_TAB_1

− Number of positions for indexing axis table 1 RESET

N09 − DWORD

ng2 − 0 0 60 2/2

ng3 − 0 0 60 2/2

tm2 − 0 0 60 2/2

tm3 − 0 0 60 2/2

10910 INDEX_AX_POS_TAB_1

mm/inch,

degrees

N09 − DOUBLE

ng2 60 0.0, 0.0, 0.0, 0.0, 0.0 .... − − 2/2

ng3 60 0.0, 0.0, 0.0, 0.0, 0.0 .... − − 2/2

tm2 60 0.0, 0.0, 0.0, 0.0, 0.0 .... − − 2/2

tm3 60 0.0, 0.0, 0.0, 0.0, 0.0 .... − − 2/2

Indexing position table 1 RESET

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-33

Page 34

List of Machine Data

2.2 General machine data

10920 INDEX_AX_LENGTH_POS_TAB_2

− Number of positions for indexing axis table 2 RESET

N09 − DWORD

ng2 − 0 0 60 2/2

ng3 − 0 0 60 2/2

tm2 − 0 0 60 2/2

tm3 − 0 0 60 2/2

10930 INDEX_AX_POS_TAB_2

− Indexing position table 2 RESET

N09 − DOUBLE

ng2 60 0.0, 0.0, 0.0, 0.0.... − − 2/2

ng3 60 0.0, 0.0, 0.0, 0.0.... − − 2/2

tm2 60 0.0, 0.0, 0.0, 0.0.... − − 2/2

tm3 60 0.0, 0.0, 0.0, 0.0.... − − 2/2

11100 AUXFU_MAXNUM_GROUP_ASSIGN

− Number of auxiliary functions in AuxF groups POWER ON

N01, N07, N02 − DWORD

Default − 1 1 255 2/2

11160 ACCESS_EXEC_CST

− Right of execution for /_N_CST_DIR POWER ON

N01 − BYTE

Default − 7 − − 2/2

11161 ACCESS_EXEC_CMA

− Right of execution for /_N_CMA_DIR POWER ON

N01 − BYTE

Default − 7 − − 2/2

11162 ACCESS_EXEC_CUS

− Right of execution for /_N_CUS_DIR POWER ON

N01 − BYTE

Default − 7 − − 3/3

11165 ACCESS_WRITE_CST

− Write protection for /_N_CST_DIR POWER ON

N01 − DWORD

Default − −1 − − 2/2

11166 ACCESS_WRITE_CMA

− Write protection for directory /_N_CMA_DIR POWER ON

N01 − DWORD

Default − −1 − − 2/2

11167 ACCESS_WRITE_CUS

− Write protection for directory /_N_CUS_DIR POWER ON

N01 − DWORD

Default − −1 − − 3/3

ng2 − −1 − − 2/2

ng3 − −1 − − 2/2

11170 ACCESS_WRITE_SACCESS

− Write protection for _N_SACCESS_DEF POWER ON

N01 − BYTE

Default − 7 − − 2/2

11171 ACCESS_WRITE_MACCESS

− Write protection for _N_MACCESS_DEF POWER ON

N01 − BYTE

Default − 7 − − 2/2

2-34

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 35

List of Machine Data

2.2 General machine data

11172 ACCESS_WRITE_UACCESS

− Write protection for _N_UACCESS_DEF POWER ON

N01 − BYTE

Default − 7 − − 3/3

11210 UPLOAD_MD_CHANGES_ONLY

− MD backup only for changed MD immediately

N01, N05 − BYTE

Default − 0x0F − − 2/2

11240 PROFIBUS_SDB_NUMBER

− SDB1000 number POWER ON

N01, N05 − DWORD

Default 4 0, −1, 0, −1 −1 7 2/2

11250 PROFIBUS_SHUTDOWN_TYPE

− Profibus Shutdown handling POWER ON

EXP, N01 − BYTE

Default − 0 0 2 2/2

11310 HANDWH_REVERSE

− Threshold for handwheel direction reversal POWER ON

N09 − BYTE

Default − 2 − − 2/2

11320 HANDWH_IMP_PER_LATCH

− Handwheel pulses per locking position POWER ON

N09 − DOUBLE

Default 6 1., 1., 1., 1., 1., 1. − − 2/2

11346 HANDWH_TRUE_DISTANCE

− Handwheel travel or speed specification POWER ON

N01 − BYTE

Default − 0 0 3 2/2

11717 D_NO_FCT_CYCLE_NAME

− Name of subroutine for D code substitution POWER ON

EXP, N12, N07 − STRING

Default −1 − − 2/2

13060 DRIVE_TELEGRAM_TYPE

− Default message frame type for Profibus DP POWER ON

N04, N10 − DWORD

Default 31 102, 102, 102... − − 2/2

13070 DRIVE_FUNCTION_MASK

− Used DP functions POWER ON

N04, N10 − DWORD

Default 6 2, 2, 2, 2, 2, 2 − − 2/2

13080 DRIVE_TYPE_DP

− Drive type with Profibus POWER ON

EXP − BYTE

Default 31 0, 0, 0... 0 4 2/2

13120 CONTROL_UNIT_LOGIC_ADDRESS

− SINAMICS−CU logic address POWER ON

N04, N10 − DWORD

Default 7 6500 0 8191 7/2

13200 MEAS_PROBE_LOW_ACTIVE

− Polarity change of the probe POWER ON

N10, N09 − BOOLEAN

Default 2 FALSE, FALSE − − 3/3

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

2-35

Page 36

List of Machine Data

2.2 General machine data

13220 MEAS_PROBE_DELAY_TIME

s Detection of probe deflection delay time POWER ON

N10, N09 − DOUBLE

Default 2 0.0, 0.0 0 0.1 3/3

14510 USER_DATA_INT

− User data (INT) POWER ON

N03 − DWORD

Default 32 0, 0, 0... −32768 32767 7/3

14512 USER_DATA_HEX

− User data (HEX) POWER ON

N03 − DWORD

Default 32 0, 0, 0... 0 0x0FF 7/3

14514 USER_DATA_FLOAT

− User data (FLOAT) POWER ON

N03 − DOUBLE

Default 8 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,

0.0, 0.0

11516 USER_DATA_PLC_ALARM

− User data (HEX) POWER ON

N03 − BYTE

Default 64 0, 0, 0… − − 7/3

−3.40e38 3.40e38 7/3

15700 LANG_SUB_NAME

− Name of subroutine for substitution POWER ON

N01 − STRING

Default −1 − − 2/2

15702 LANG_SUB_PATH

− Path of subroutine for substitution POWER ON

N01 − BYTE

Default − 0 0 2 2/2

17400 OEM_GLOBAL_INFO

− OEM version info POWER ON

− − STRING

Default 5 − − 2/2

17530 TOOL_DATA_CHANGE_COUNTER

− Mark tool data change for HMI POWER ON

EXP, N01 − DWORD

Default − 0 0 0xF 2/2

18030 HW_SERIAL_NUMBER

− to be defined POWER ON

N05 READ STRING

Default 1 − − 2/2

18040 VERSION_INFO

− Version and (if necessary) date of PCMCIA card POWER ON

N05 READ STRING

ng2 4 ”802D sl−NG2” − − 2/2

ng3 4 ”802D sl−NG3” − − 2/2

tm1 4 ”802D sl−TM1” − − 2/2

tm2 4 ”802D sl−TM2” − − 2/2

tm3 4 ”802D sl−TM3” − − 2/2

2-36

SINUMERIK 802D sl Lists (LIS), 02/06 Edition

6FC5397−5CP10−0BA0

Page 37

List of Machine Data

2.2 General machine data

18080 MM_TOOL_MANAGEMENT_MASK

− Reserved memory for the tool management (SRAM) POWER ON

N02, N09 − DWORD

ng2 − 0x0 0 0xFFFF 2/2

ng3 − 0x0 0 0xFFFF 2/2

tm2 − 0x0 0 0xFFFF 2/2

tm3 − 0x0 0 0xFFFF 2/2

18102 MM_TYPE_OF_CUTTING_EDGE

− Type of D number programming (SRAM) POWER ON

N02, N09 − DWORD

Default − 0 0 1 2/2

18120 MM_NUM_GUD_NAMES_NCK

− Number of global GUD definitions (SRAM) POWER ON

N02 − DWORD