Page 1

1768 CompactLogix System

Catalog Numbers

Quick Start

1768-L43 and 1768-L45 CompactLogix Controllers

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that

each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell

) describes some important differences

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage,

or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Allen-Bradley, Rockwell Automation, Rockwell Software, Inc., CompactLogix, ControlLogix, FactoryTalk ME, Kinetix, Logix5000, Point I/O, Panelview Plus, PowerFlex, RSLinx, RSLinx Classic, RSLinx Enterprise,

RSLogix, RSLogix 5000, RSLogix 5000 with PhaseManager, RSView Machine Edition, RSView ME, RSView SE, RSView Studio, RSView Enterprise, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

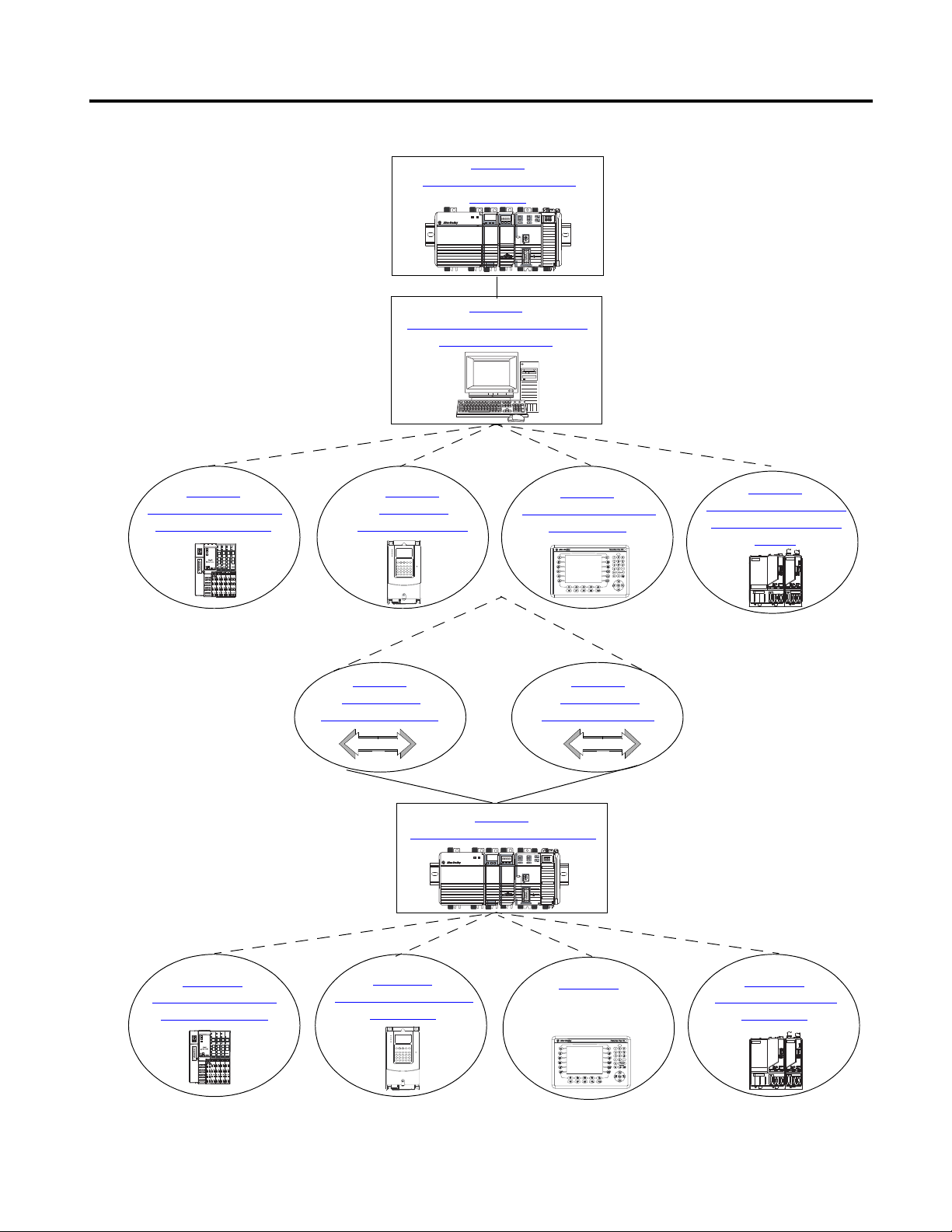

Follow the path that matches your hardware and network configuration.

Chapter 12

Create a PanelView Plus

Application

Chapter

13

Create a Kinetix 6000

Application

Chapter 11

CCreate a PowerFlex 70

Application

Chapter 1

Prepare the CompactLogix

Hardware

Chapter 2

Prepare the Computer and Load

Controller Firmware

Chapter 3

Prepare the Distributed

POINT I/O Hardware

Chapter 6

Prepare the Kinetix 6000

Multi-axis Servo Drive

System

Chapter 5

Prepare the PanelView

Plus Terminal

Chapter 7

Configure the

EtherNet/IP Network

Chapter 8

Configure the

DeviceNet Network

Chapter 9

Create a Project in RSLogix 5000

Chapter 10

Add Distributed Point

I/O Modules to the

Required

Optional

depending on your system

Optional

depending on your network

Required

Optional

depending on your system

Required

Chapter 4

Prepare the

PowerFlex 70 Drive

Where to Start

3Publication IASIMP-QS003B-EN-P - October 2009 3

Page 4

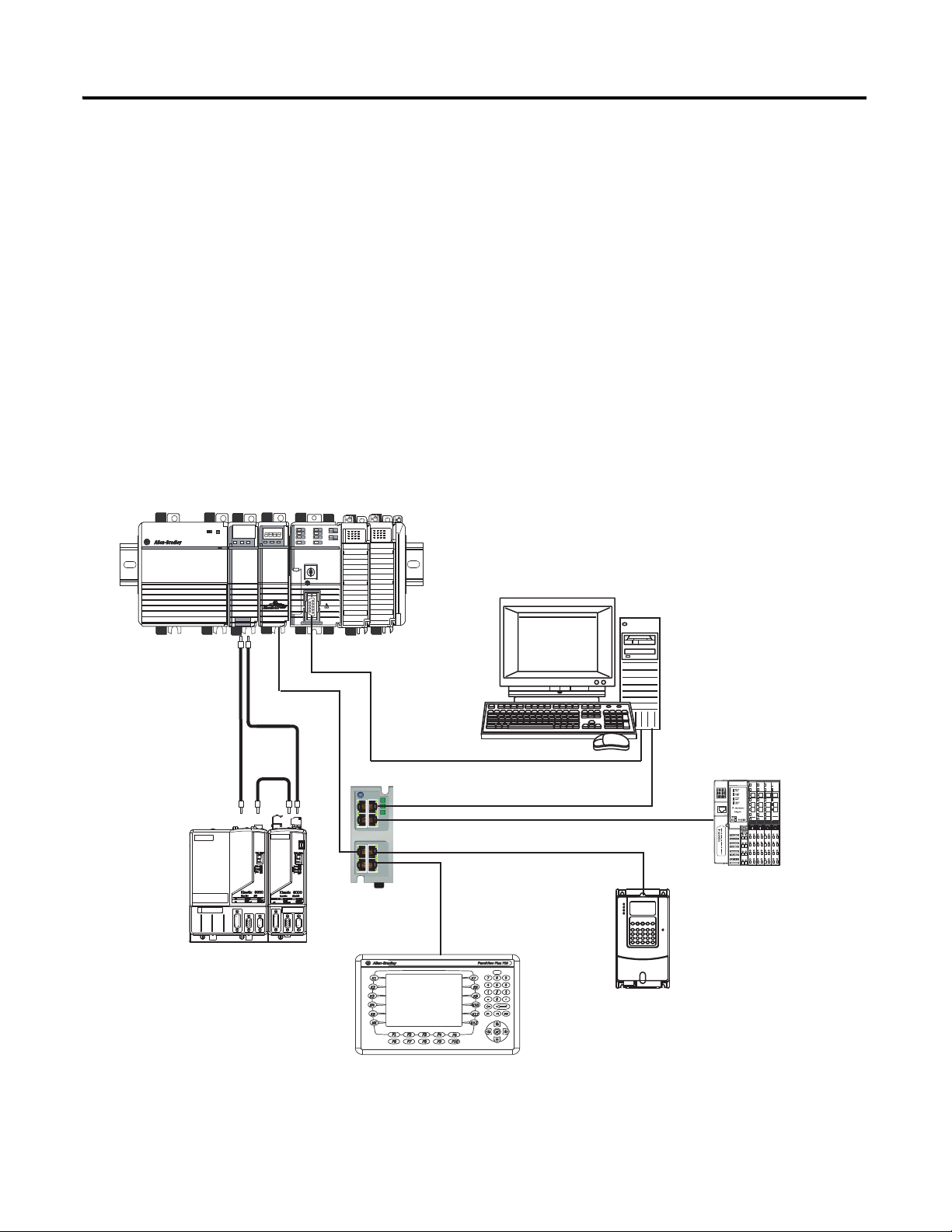

Where to Start

1768-L43 CompactLogix Controller with

1768-ENBT EtherNet/IP and 1768-M04SE SERCOS Modules

Computer with Ethernet Port

Distributed POINT I/O

with 1734-AENT Adapter

PowerFlex 70 Drive with

20-COMM-E Adapter

2711P PanelView Plus Terminal

with Built-in EtherNet/IP Port

Ethernet Switch

1756-CP3

EtherNet/IP

SERCOS

2094 Kinetix 6000

Multi-axis Servo Drive System

Serial

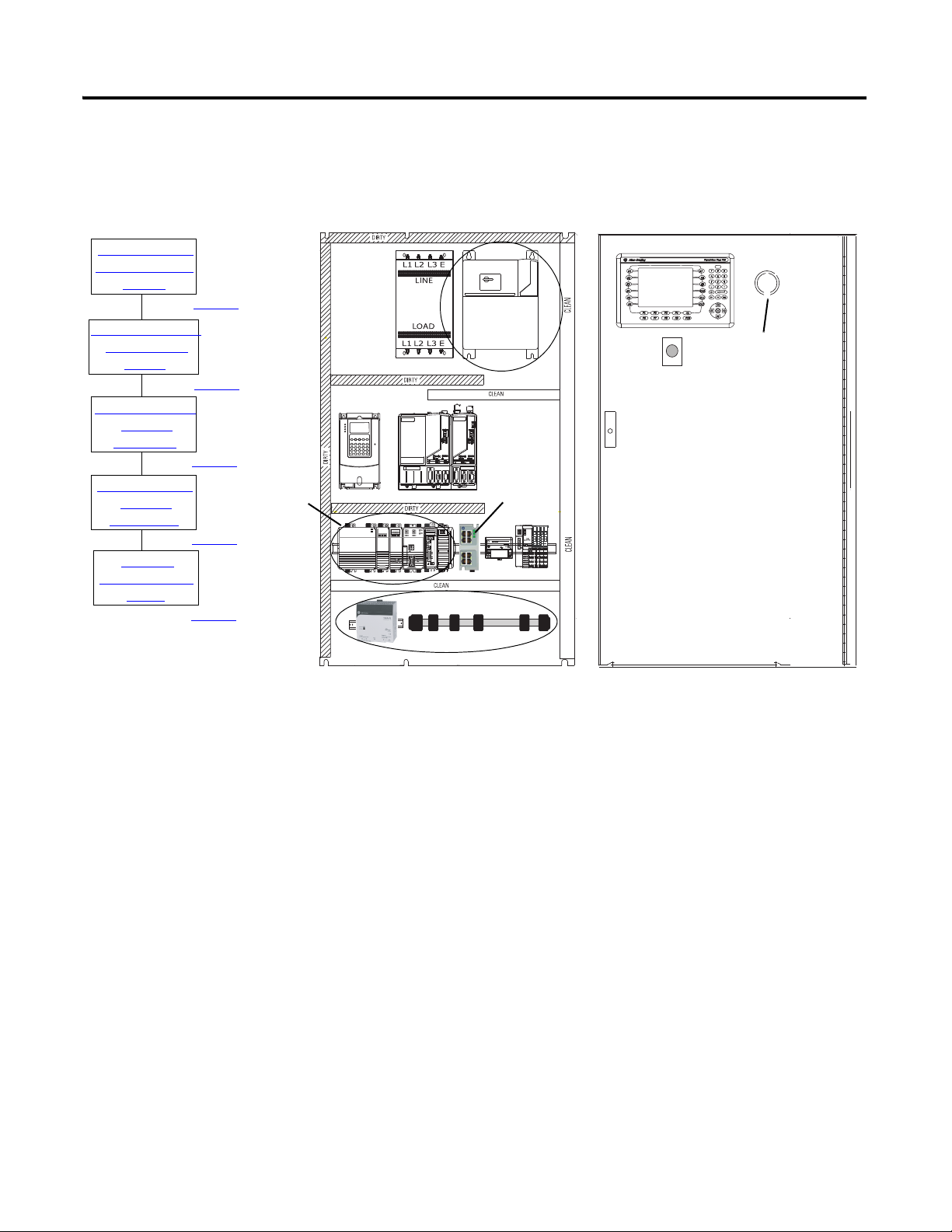

How Hardware Is Connected

This quick start demonstrates CompactLogix L43 and L45 control systems using a single

EtherNet/IP or DeviceNet network for cost-effectiveness and simplified setup. You may

choose to use a multiple network system requiring a combination of EtherNet/IP and

DeviceNet procedures shown in this quick start.

Rockwell Automation also offers many devices other than those in the examples. See your

local Rockwell Automation representative for other device options.

Option 1: 1768-L43 and 1768-L45 Systems with EtherNet/IP Network

4 Publication IASIMP-QS003B-EN-P - October 2009

Page 5

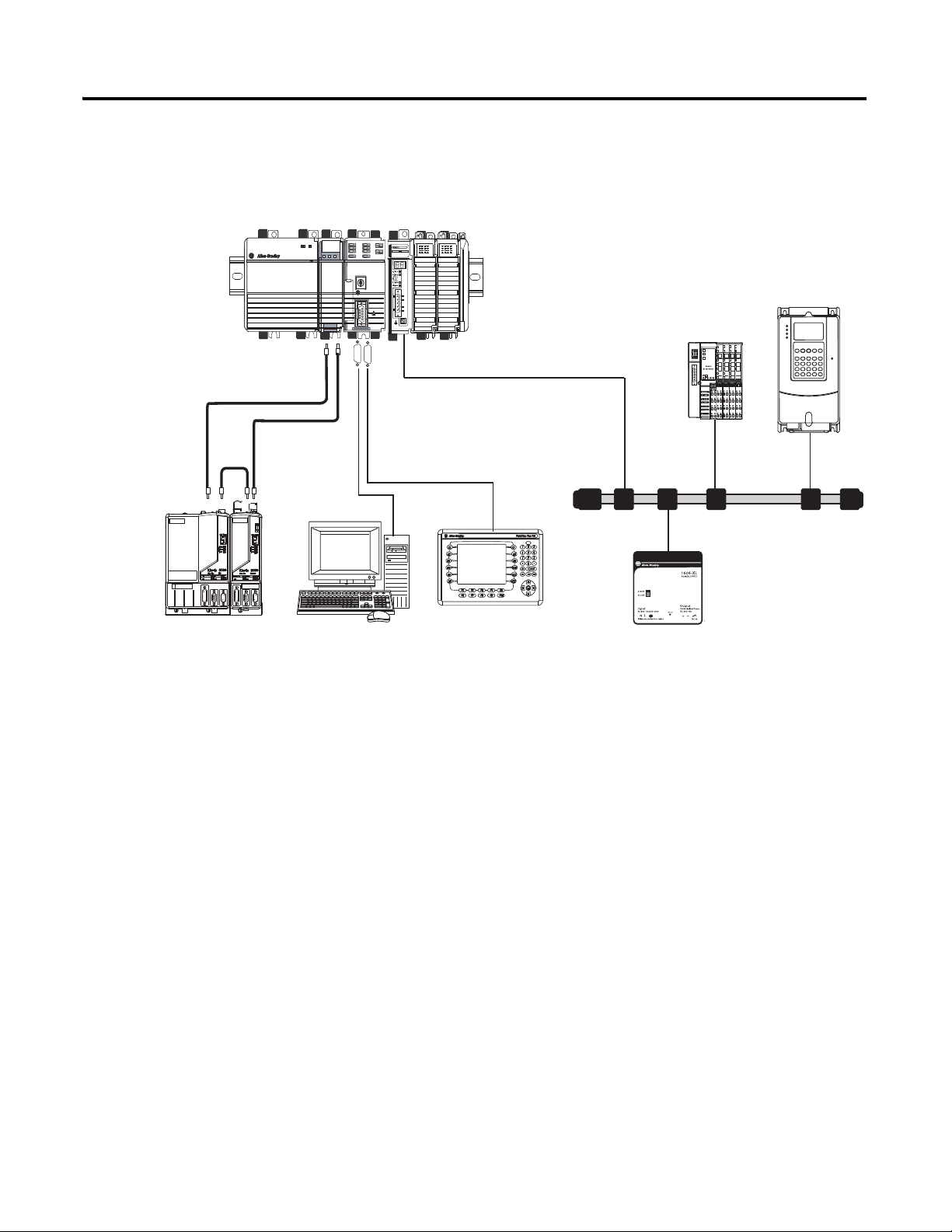

Option 2: 1768-L43 and L45 Systems with DeviceNet Network

1768-L43 CompactLogix Controller with

1768-M04SE SERCOS and 1769-SDN DeviceNet Modules

Distributed POINT I/O

with 1734-ADN Adapter

PowerFlex 70 Drive with

20-COMM-D Adapter

DeviceNet Power Supply

1606-XLDNET8

2711P PanelView Plus Terminal

Computer

Serial

DeviceNet

SERCOS

DeviceNet with KwikLink

flat cable and micro connectors

2094 Kinetix 6000

Multi-axis Servo Drive System

2706-NC13

1756-CP3

Where to Start

Publication IASIMP-QS003B-EN-P - October 2009 5

Page 6

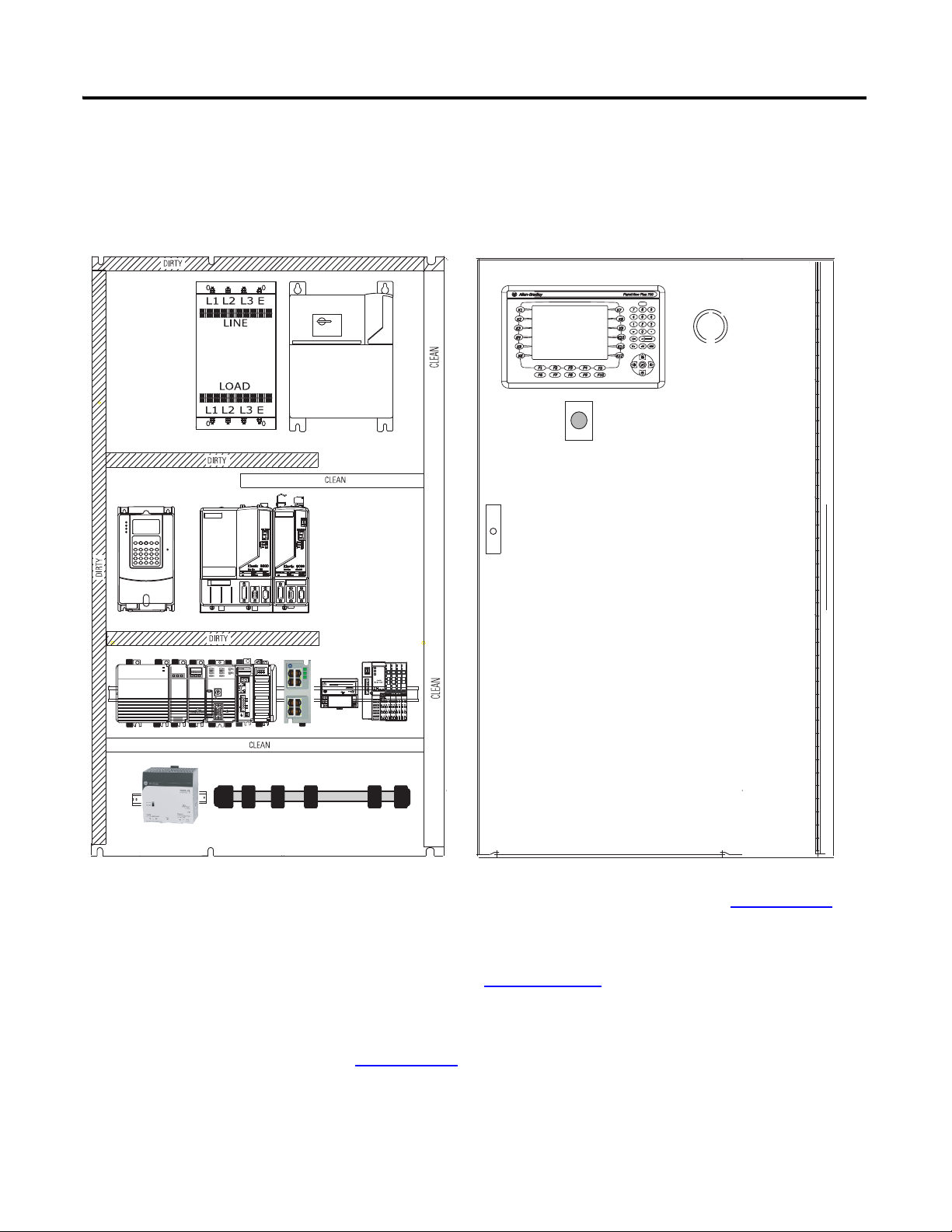

Where to Start

PanelView Plus

AC Line

Filter

Line Interface

Module

PowerFlex 70

Kinetix 6000 Drive Modules

DeviceNet Power Supply

Distributed POINT I/O

Ethernet Switch

1768-L43 CompactLogix System

DeviceNet KwikLink System

E-Stop

Through-the-door

Disconnect

1794-PS3

Sample System Panel Layout

The sample panel layout shows the general orientation of 1768-L43 and 1768-L45 system

components for both EtherNet/IP and DeviceNet networks used in this quick start.

For additional panel layout assistance, the Kinetix Accelerator Toolkit CD in Appendix

provides CAD enclosure, component, and wiring diagrams, in DXF format, for most

Rockwell Automation motion components. Refer to the System Design for Control of

Electrical Noise Reference Manual, publication GMC-RM001

For panel layout instructions specific to the Kinetix 6000 drives, refer to the Kinetix 6000

Installation Manual, publication 2094-IN001

B

, for best practice techniques.

.

6 Publication IASIMP-QS003B-EN-P - October 2009

Page 7

Prepare the CompactLogix

Hardware

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Required Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts List: Option 1, 1768-L43 System with EtherNet/IP . . . . . . . . . 15

Parts List: Option 2, 1768-L43 System with DeviceNet . . . . . . . . . . . 17

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

About the 1768 CompactLogix Controller. . . . . . . . . . . . . . . . . . . . . . 23

Mount and Wire the Line Interface Module. . . . . . . . . . . . . . . . . . . . . 24

Assemble the 1768 CompactLogix System. . . . . . . . . . . . . . . . . . . . . . 25

Make EtherNet/IP Network Connection. . . . . . . . . . . . . . . . . . . . . . . 28

Make DeviceNet Network Connections. . . . . . . . . . . . . . . . . . . . . . . . 29

Wire the 1768-PA3 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Prepare the Computer and Load

Controller Firmware

Prepare the Distributed POINT I/O

Hardware

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Make Network Connections for Personal Computer. . . . . . . . . . . . . . 38

Install RSLogix Programming Software . . . . . . . . . . . . . . . . . . . . . . . . 39

Configure a Serial Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Set the IP Address for the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configure the EtherNet/IP Driver in RSLinx Software . . . . . . . . . . . 48

Load the Controller Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Install Additional Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Mount and Connect the Network Adapter. . . . . . . . . . . . . . . . . . . . . . 55

Mount the POINT I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mount and Wire the POINT I/O Power Supply. . . . . . . . . . . . . . . . . 58

Wire the Adapter and I/O Modules to the Power Supply. . . . . . . . . . 59

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7 Publication IASIMP-QS003B-EN-P - October 2009

Page 8

Table of Contents

Prepare the PowerFlex 70 Drive

Prepare the PanelView Plus

Terminal

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Mount and Wire the PowerFlex 70 Drive. . . . . . . . . . . . . . . . . . . . . . . 63

Configure the Communication Adapter . . . . . . . . . . . . . . . . . . . . . . . . 65

Connect Communication Adapter to the PowerFlex 70 Drive . . . . . . 66

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Mount and Wire the PanelView Plus Terminal . . . . . . . . . . . . . . . . . . 71

Make Network Connections for PanelView Plus. . . . . . . . . . . . . . . . . 72

Assign IP Address for PanelView Plus . . . . . . . . . . . . . . . . . . . . . . . . . 73

Upgrade Terminal Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Prepare the Kinetix 6000

Multi-axis Servo Drive System

Configure the EtherNet/IP

Network

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Mount and Bond the Power Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Mount the Integrated Axis and Axis Module . . . . . . . . . . . . . . . . . . . . 80

Wire Power to the Integrated Axis Module . . . . . . . . . . . . . . . . . . . . . 82

Wire Servo Motors to Integrated Axis and Axis Modules . . . . . . . . . . 83

Connect the SERCOS Fiber Optic Cables . . . . . . . . . . . . . . . . . . . . . . 84

Set the SERCOS Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Assign IP Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Browse the EtherNet/IP Network in RSLinx Classic Software . . . . . 91

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8 Publication IASIMP-QS003B-EN-P - October 2009

Page 9

Configure the DeviceNet Network

Create a Project in RSLogix 5000

Programming Software

Table of Contents

Chapter 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Apply Power to the DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . . 94

Set the Node Address of the DeviceNet Scanner . . . . . . . . . . . . . . . . 95

Create a DeviceNet Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . 97

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Create a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Configure 1768-ENBT Ethernet Module. . . . . . . . . . . . . . . . . . . . . . 104

Configure 1769-SDN DeviceNet Module . . . . . . . . . . . . . . . . . . . . . 105

Configure 1769 Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Verify I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Add Ladder Logic to Test Local 1769 Compact I/O Modules. . . . . 109

Set the Project Path and Download to the Controller . . . . . . . . . . . . 112

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Add Distributed Point I/O Modules

to the Project

Chapter 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Add Distributed I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Configure the DeviceNet Subnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Configure the 1734-ADN Properties . . . . . . . . . . . . . . . . . . . . . . . . . 123

Create a DeviceNet Scanlist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Add Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Create DeviceNet Tags and Add Ladder Logic . . . . . . . . . . . . . . . . . 130

Download the Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Test the Distributed I/O Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Publication IASIMP-QS003B-EN-P - October 2009 9

Page 10

Table of Contents

Create a PowerFlex 70 Application

Create a PanelView Plus

Application

Chapter 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Add the Drive to Your RSLogix 5000 Project . . . . . . . . . . . . . . . . . . 139

Edit the Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Create a DeviceNet Scanlist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Create DeviceNet Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Download the Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Test the PowerFlex 70 Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Chapter 12

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Create a New Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Create an RSLinx Enterprise Configuration in

FactoryTalkView ME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Create Device Shortcuts to the Controller . . . . . . . . . . . . . . . . . . . . . 166

Create the OB16_Light Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Create a Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Test the Indicator and Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Add a Goto Configuration Mode Button . . . . . . . . . . . . . . . . . . . . . . 176

Assign Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Assign an Initial Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Transfer the Application to the PanelView Plus Terminal. . . . . . . . . 179

Test the Application on the PanelView Plus Terminal . . . . . . . . . . . 181

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Chapter 13

Create a Kinetix 6000 Application

10 Publication IASIMP-QS003B-EN-P - October 2009

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Enable Coordinated System Time Master . . . . . . . . . . . . . . . . . . . . . 185

Create the Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Configure Your Logix SERCOS Module . . . . . . . . . . . . . . . . . . . . . . 187

Configure Your Kinetix IAM and AM Modules . . . . . . . . . . . . . . . . 189

Configure Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Save and Download Your Program. . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Test the Kinetix Application File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Page 11

Network Information

Kinetix Accelerator Toolkit

Motion Anaylzer

Table of Contents

Appendix A

Network Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Appendix B

Sample Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Simplified Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Preconfigured HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Preconfigured Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Diagnostic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Kinetix Accelerator Toolkit CD . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Appendix C

Motion Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Publication IASIMP-QS003B-EN-P - October 2009 11

Page 12

Table of Contents

12 Publication IASIMP-QS003B-EN-P - October 2009

Page 13

Preface

About This Publication

This quick start provides examples and procedures for 1768-L43 and 1768-L45

CompactLogix systems. It includes version 18 release updates for RSLogix 5000

programming software. These procedures cover many common user tasks, such as:

• connecting the controller to multiple devices including local and distributed I/O, drives,

Kinetix 6000 servo drives, and a PanelView Plus terminal.

• connecting and configuring EtherNet/IP, DeviceNet, and serial networks using

CompactLogix systems.

• creating and monitoring controller programs.

The examples are designed to get devices installed and communicating with each other in the

simplest way possible. The programming examples are not complex, and offer easy solutions

to verify that devices are communicating properly.

The beginning of each chapter contains the following information. Read these sections

carefully before beginning work in each chapter.

• Before You Begin - This section lists the steps that must be completed and decisions

that must be made before starting that chapter. Because the chapters in this quick start

do not have to be completed in the order in which they appear, this section defines the

minimum amount of preparation required before completing the current chapter.

• What You Need - This section lists the tools that are required to complete the steps in

the current chapter. This includes, but is not limited to, hardware and software.

• Follow These Steps - This section illustrates the steps in the current chapter and

identifies which steps are required to complete the examples using specific networks.

Also note that the electronic version of this publication contains links to pages within

publications for easier navigation. Click on any chapter title, chapter number, topic title, or

page number to follow a link to the item.

13Publication IASIMP-QS003B-EN-P - October 2009 13

Page 14

Audience

This quick start was created to assist experienced or new industrial control users not familiar

with the CompactLogix controllers or Integrated Architecture products of Rockwell

Automation.

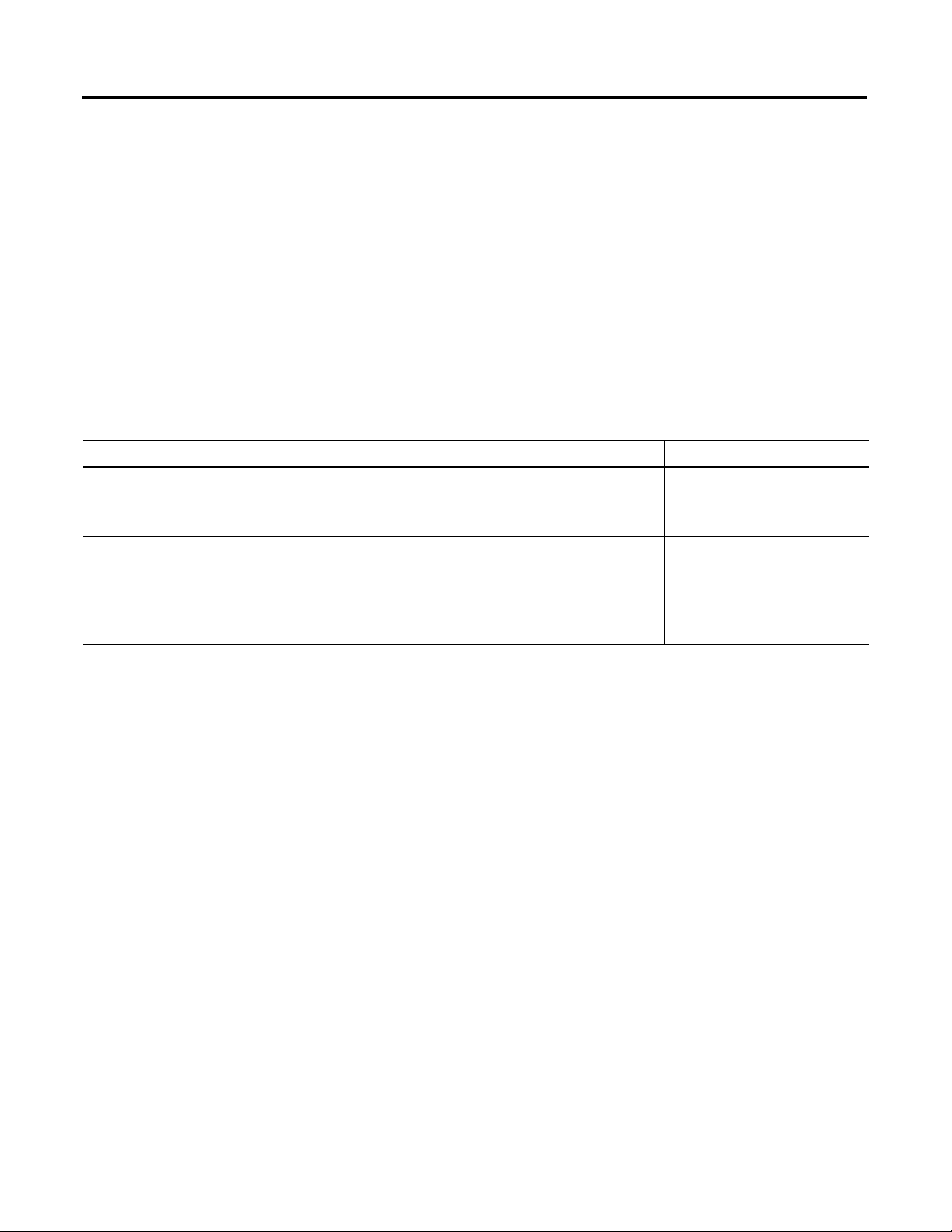

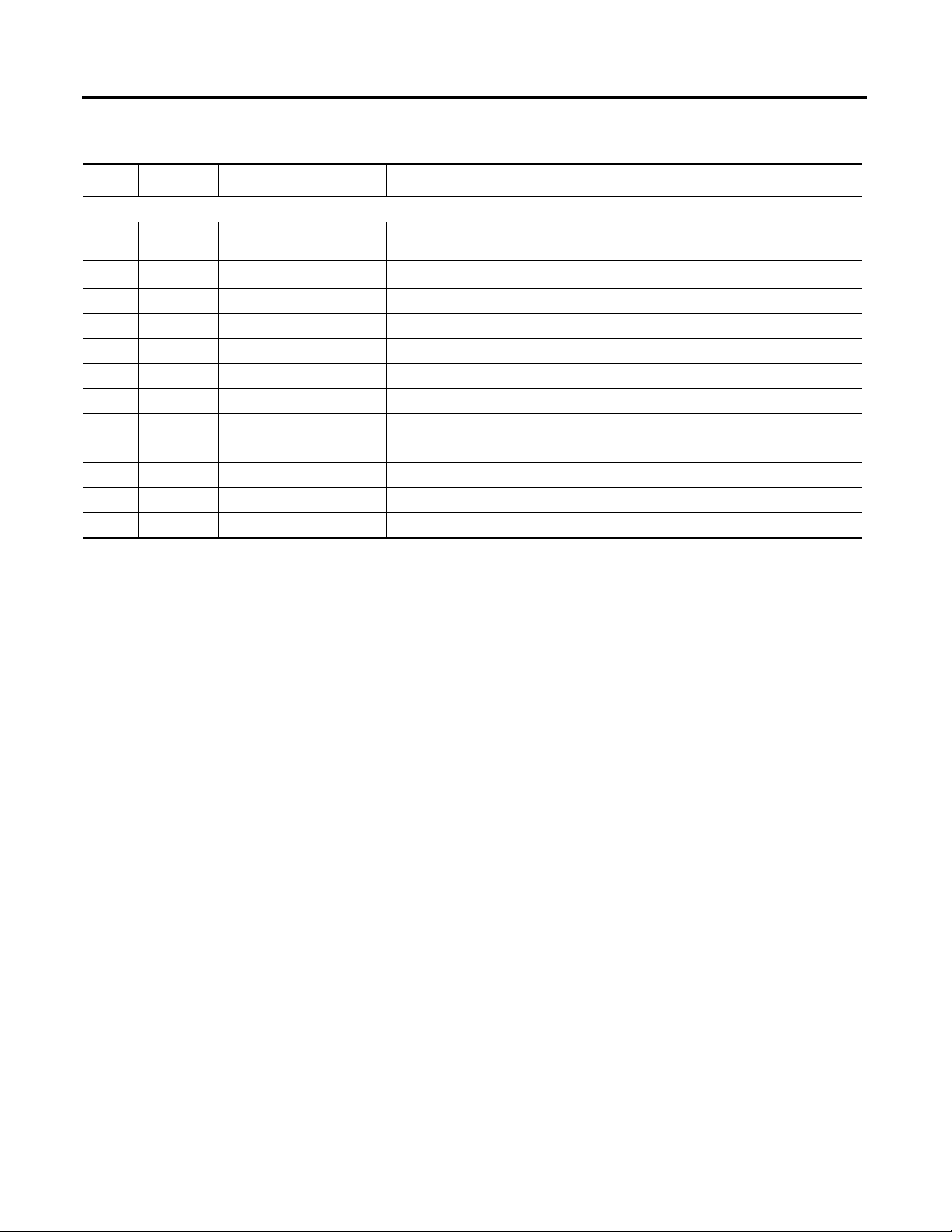

Required Software

The table lists software required to complete the examples in this quick start. Some software

is required regardless of the 1768 CompactLogix system you use and other software is

dependent on the network and devices in the system.

Rockwell Automation Version Required for

RSLogix 5000 programming software 18

RSNetWorx for DeviceNet software 7.0 DeviceNet network

FactoryTalkView Machine Edition software

Includes:

• Factory Talk Services

• RSLinx Enterprise

• RSLinx Lite (Classic)

All 1768-L43 and 1768-L45

systems

PanelView Plus terminals

14 Publication IASIMP-QS003B-EN-P - October 2009

Page 15

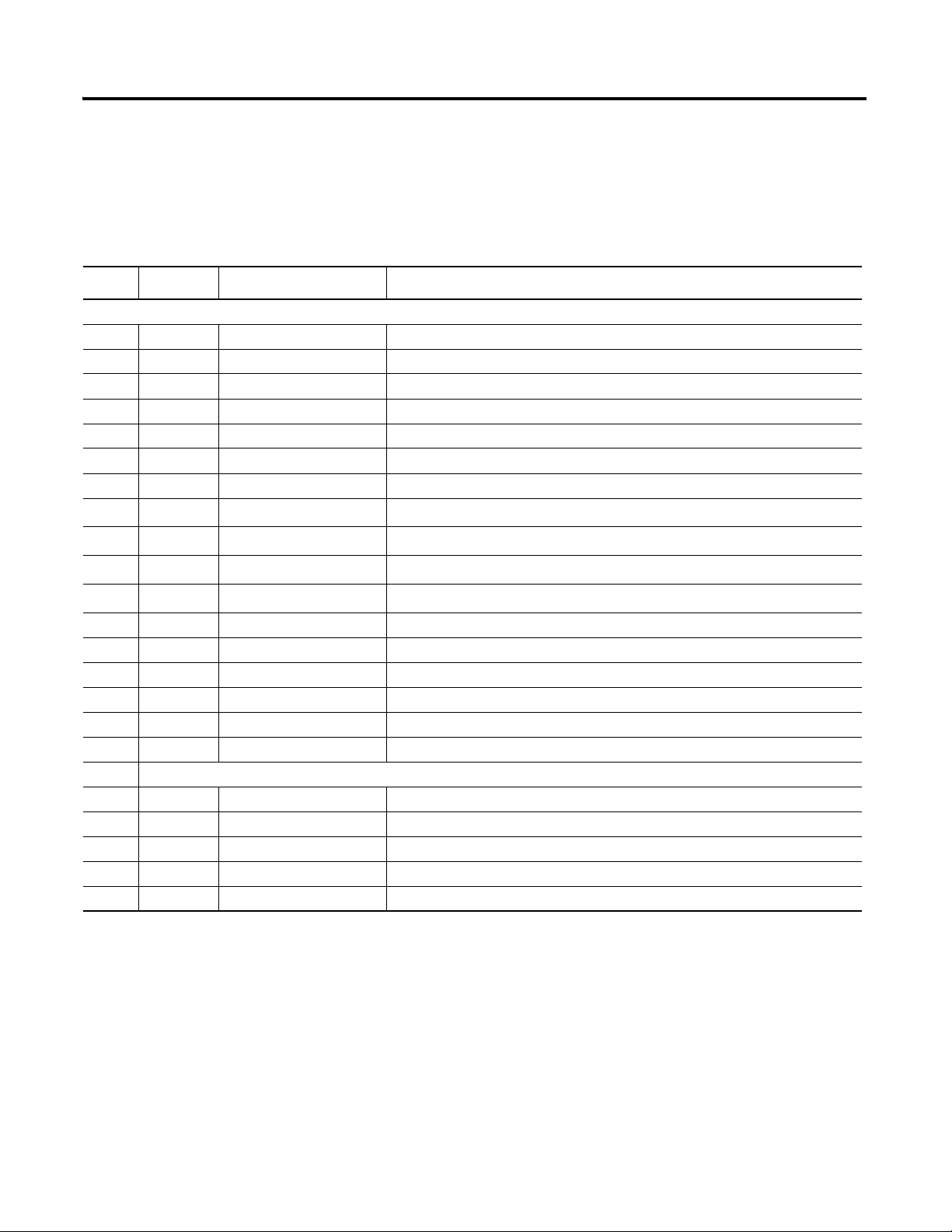

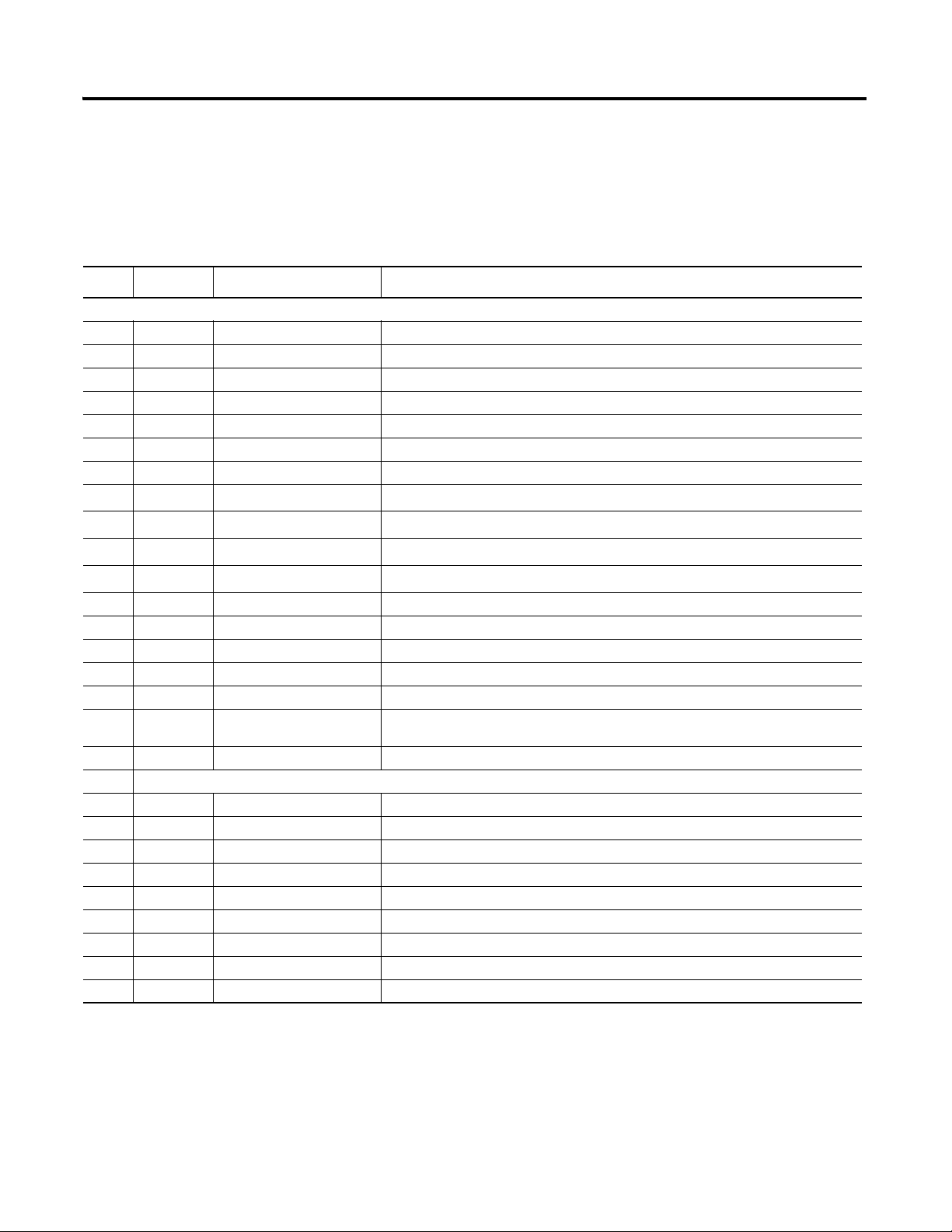

Parts List: Option 1, 1768-L43 and 1768-L45 Systems with EtherNet/IP

The table lists the parts for the 1768-L43 and 1768-L45 systems with an EtherNet/IP

network and a 200/230V Kinetix 6000 Multi-axis Servo Drive System.

Parts List: Option 1, 1768-L43 and 1768-L45 Systems with EtherNet/IP Network

General Configuration

Quantity Catalog Number Description

1 1768-L43 and 1768-L45 CompactLogix Controller

1 1768-PA3 CompactLogix Power Supply

1 1769-ECR Compact I/O Right End Cap/Terminator

1 1769-IF4 Compact 4 Channel Analog Current/Voltage Input Module

1 1769-IQ16 Compact 16 Point 24V dc Sinking/Sourcing Input Module

1 1769-IF4XOF2 Compact 8 Bit Resolution, High Speed 4 In/2 Out Analog Combination Module

1 1769-OF2 Compact 2 Channel Analog Current/Voltage Output Module

1

1

1

1

1 1734-TB Wiring Base w/ Removable IEC Screw Terminals (Quantity of 10)

1 1794-PS13 FLEX I/O 85-264V ac to 24V dc 1.3A Power Supply

1 20AB4P2A3AYNNNNN PowerFlex 70 Drive.

1 2711P-B10C4D1 PanelView Plus 10 inch color keypad/touch terminal with EtherNet/IP and RS-232

1 1747-CP3 or 1756-CP3 RS-232 cable for connection between the 1768-L43 controller and personal computer

1 64-134 DIN rail (steel not aluminum), 1 m

EtherNet/IP Configuration

1 1768-ENBT CompactLogix EtherNet/IP Communication Module

1 1734-AENT POINT I/O Ethernet Adapter

1 20-COMM-E PowerFlex 70 EtherNet/IP Adapter

1 Ethernet Switch

6 Non Rockwell Automation Ethernet CAT5 Straight-through cables

1769-OB16

1734-IB4

1734-OB4E

1734-OE2C

(2)

(1)

(2) (3)

(2)

Compact 16 Point 24V dc Sourcing Output Module

POINT I/O 4 Sink Input Module

POINT I/O 4 Protected Output Module

POINT I/O 2 Current Output Analog Module

Publication IASIMP-QS003B-EN-P - October 2009 15

Page 16

Parts List: Option 1, 1768-L43 and 1768-L45 Systems with EtherNet/IP Network

Quantity Catalog Number Description

Kinetix 6000 Servo Drive System - 200/230V (The quantity, size, and cat. nos. for the Kinetix equipment will vary by application motion requirements.)

1

1

1768-M04SE

2094-AL75S

(4)

SERCOS interface module installs in 1768 CompactLogix controller and connects to

Integrated Axis modules or Axis modules.

Line Interface Module (LIM), 230V, 75 A

1 140U-H-RVM12R Through-the-door Disconnect for LIM

1 2090-XXLF-X330B Line Filter, 3-phase, 30 A ac

1 2094-PRS2 Power Rail, 2-slot, Slim

1 2094-AC09-M02 Integrated Axis Module (IAM), 6 kW Converter and 19 A Inverter Output

1 2094-AM01 Axis Module (AM), 9 A Inverter Output

1 MPL-A310P-MK22AA MP-Series Low Inertia Motor, 0.73 kW Output with Absolute, Multi-turn Feedback

2 2090-XXNPMP-16S03 Motor Power Cable: 3 m (9.8 ft)

2 2090-UXNFBMP-S03 Motor Feedback Cable, 3 m (9.8 ft)

2 2090-SCEP0-9 SERCOS Fiber Optic Cable, 0.9 m (2.9 ft)

1 2090-SCEP0-1 SERCOS Fiber Optic Cable, 0.1 m (5.1 in.)

(1)

The 1769-OB16 is the only Compact I/O module used in this quick start. The other modules are added as examples only and are not required.

(2)

Use POINT I/O modules at series C or later to complete examples in this quick start.

(3)

The 1734-OB4E module is the only POINT I/O module used in this quick start. The other modules are added as examples only and are not required.

(4)

The 2094-AL75S line interface module (LIM) is optional. Individual components can be purchased separately instead of the LIM.

16 Publication IASIMP-QS003B-EN-P - October 2009

Page 17

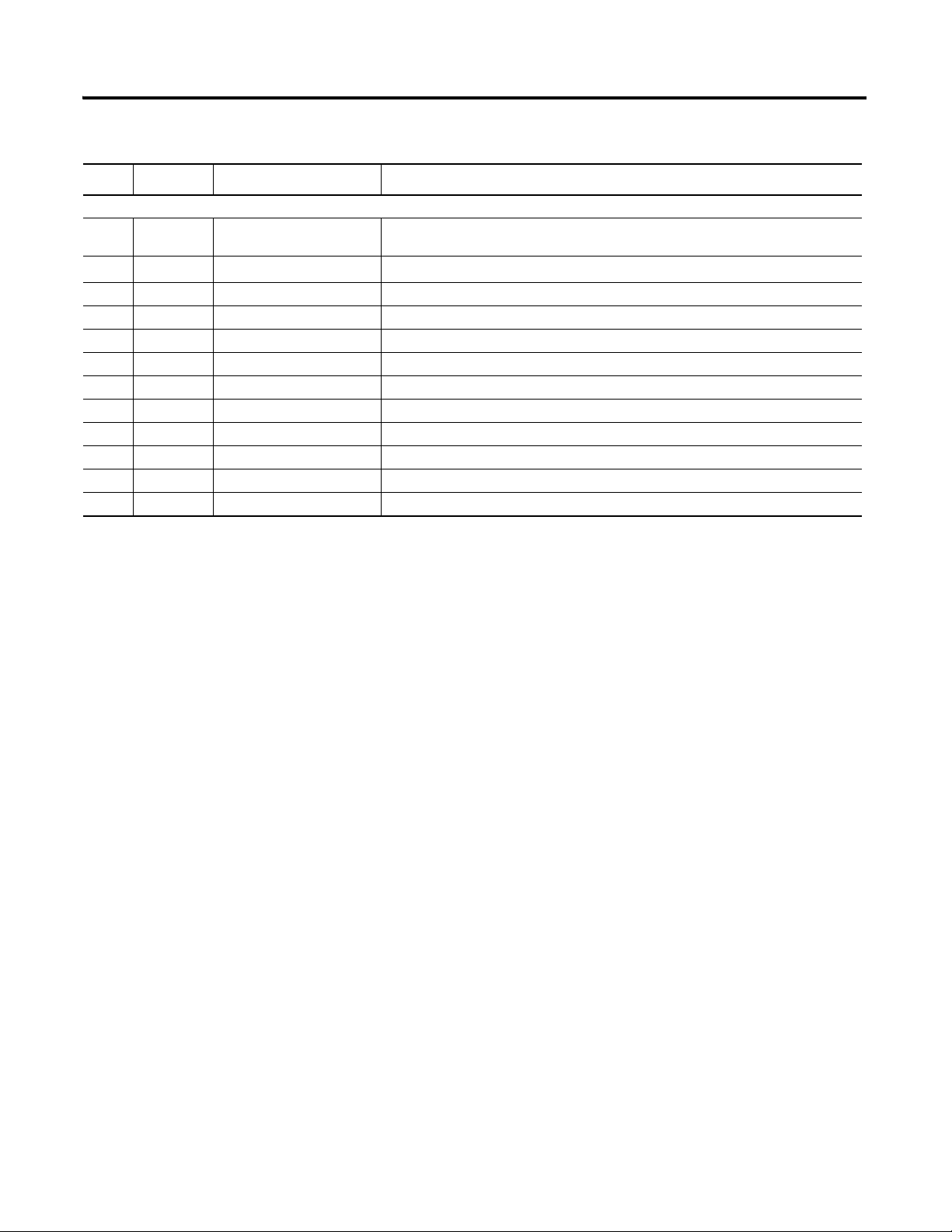

Parts List: Option 2, 1768-L43 and 1768-L45 Systems with DeviceNet

The table lists the parts for a 1768-L43 and 1768-L45 Systems with DeviceNet I/O, serial

connections, and a 200/230V Kinetix 6000 Multi-axis Servo Drive System.

Parts List: Option 2, 1768-L43 and 1768-L45 Systems with DeviceNet Network

General Configuration

Quantity Catalog Number Description

1 1768-L43 and 1768-L45 CompactLogix Controller

1 1768-PA3 CompactLogix Power Supply

1 1769-ECR Compact I/O Right End Cap/Terminator

1 1769-IF4 Compact 4 Channel Analog Current/Voltage Input Module

1 1769-IQ16 Compact 16 Point 24V dc Sinking/Sourcing Input Module

1 1769-IF4XOF2 Compact 8 Bit Resolution, High Speed 4 In/2 Out Analog Combination Module

1 1769-OF2 Compact 2 Channel Analog Current/Voltage Output Module

1

1

1

1

1 1734-TB Wiring Base w/ Removable IEC Screw Terminals (Quantity of 10)

1 1794-PS13 FLEX I/O 85-264V ac to 24V dc 1.3A Power Supply

1 20AB4P2A3AYNNNNN PowerFlex 70 Drive

1 2711P-B10C4D1 PanelView Plus 10 inch color keypad/touch terminal with EtherNet/IP and RS-232

1 1747-CP3 or 1756-CP3 RS-232 cable for connection between the 1768-L43 controller and personal computer

1 2711-NC13 RS-232 cable for connection between the PanelView Plus terminal and the 1768-L43

1 64-134 DIN rail (steel not aluminum), 1 m

DeviceNet Configuration

1 1769-SDN Compact DeviceNet Scanner

1 1734-ADN POINT I/O DeviceNet Adapter

1 20-COMM-D PowerFlex 70 DeviceNet Adapter

1 1606-XLDNET8 DeviceNet Power Supply

1 1485C-P1E75 KwikLink Flat Cable, 75 m

2 1485A-T1E4 KwikLink Terminator/Resistor

3 1485P-P1E4-R5 KwikLink Sealed Micro Connector

3 1485K-P1F5-C KwikLink QD Cordset Micro Right-Angle Male

1 1485T-P1E4-B1 KwikLink Power Tap Module

1769-OB16

1734-IB4

1734-OB4E

1734-OE2C

(2)

(1)

(2) (3)

(2)

Compact 16 Point 24V dc Sourcing Output Module

POINT I/O 4 Sink Input Module

POINT I/O 4 Protected Output Module

POINT I/O 2 Current Output Analog Module

controller or personal computer

Publication IASIMP-QS003B-EN-P - October 2009 17

Page 18

Parts List: Option 2, 1768-L43 and 1768-L45 Systems with DeviceNet Network

Quantity Catalog Number Description

Kinetix 6000 Servo Drive System - 200/230V (The quantity, size, and cat. nos. for the Kinetix equipment will vary by application motion requirements.)

1

1

1768-M04SE

2094-AL75S

(4)

SERCOS interface module installs in 1768 CompactLogix controller and connects to

Integrated Axis modules or Axis modules.

Line Interface Module (LIM), 230V, 75 A

1 140U-H-RVM12R Through-the-door Disconnect for LIM

1 2090-XXLF-X330B Line Filter, 3-phase, 30 A ac

1 2094-PRS2 Power Rail, 2-slot, Slim

1 2094-AC09-M02 Integrated Axis Module (IAM), 6 kW Converter and 19 A Inverter Output

1 2094-AM01 Axis Module (AM), 9 A Inverter Output

1 MPL-A310P-MK22AA MP-Series Low Inertia Motor, 0.73 kW Output with Absolute, Multi-turn Feedback

2 2090-XXNPMP-16S03 Motor Power Cable: 3 m (9.8 ft)

2 2090-UXNFBMP-S03 Motor Feedback Cable, 3 m (9.8 ft)

2 2090-SCEP0-9 SERCOS Fiber Optic Cable, 0.9 m (2.9 ft)

1 2090-SCEP0-1 SERCOS Fiber Optic Cable, 0.1 m (5.1 in.)

(1)

The 1769-OB16 module is the only Compact I/O module used in this quick start. The other modules are added as examples only and are not required.

(2)

Use POINT I/O modules at series C or later to complete examples in this quick start.

(3)

The 1734-OB4E module is the only POINT I/O module used in this quick start. The other modules are added as examples only and are not required.

(4)

The 2094-AL75S line interface module (LIM) is optional. Individual components can be purchased separately instead of the LIM.

18 Publication IASIMP-QS003B-EN-P - October 2009

Page 19

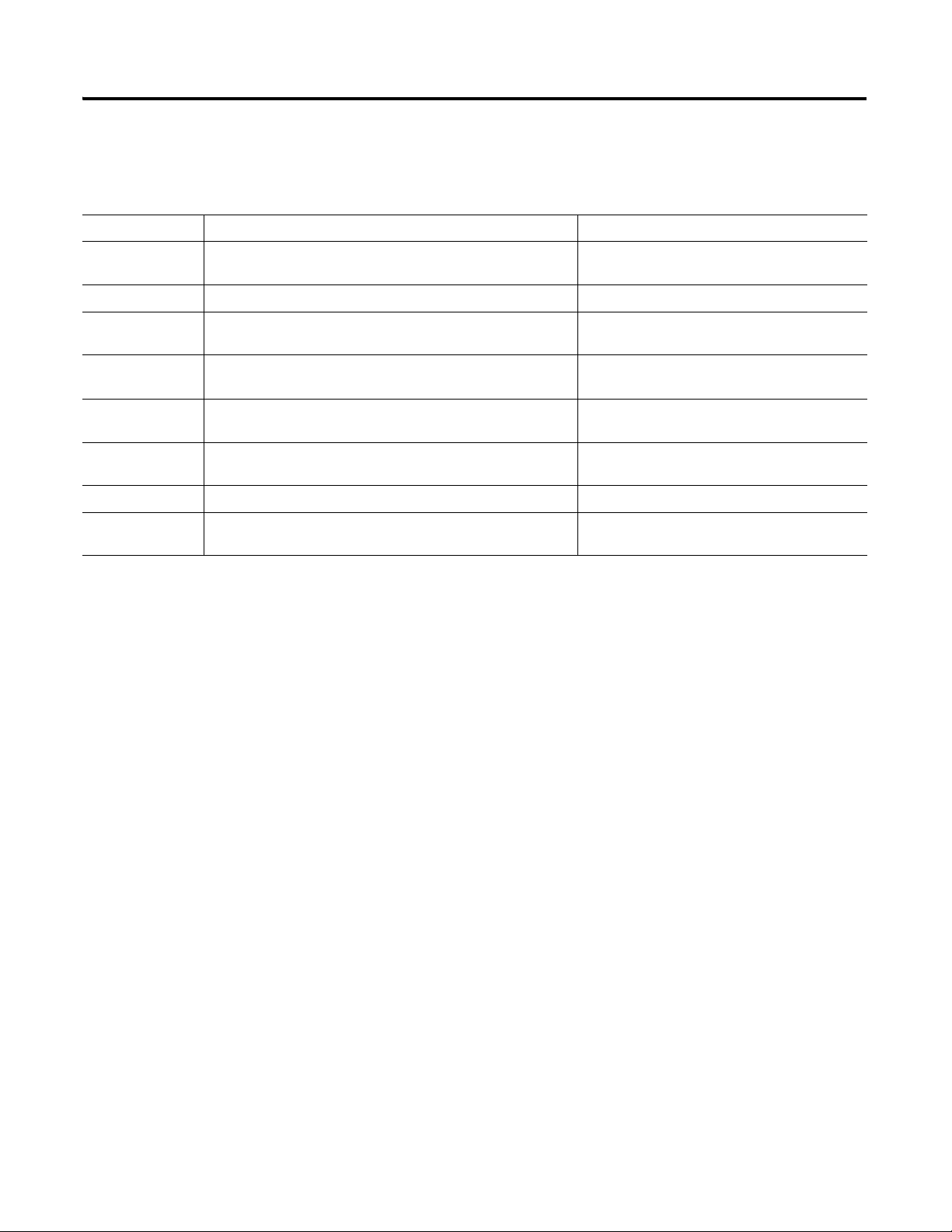

Conventions

This manual uses the following conventions.

Convention Meaning Example

Courier

font

Check or uncheck Click to activate or deactivate a checkbox. Check the Disable Keying checkbox.

Click

Double-click

Type or enter text exactly as shown. Type cmd.

Click the left mouse button once while the cursor is positioned

on object or selection.

Click the left mouse button twice in quick succession while the

cursor is positioned on object or selection.

Click Browse.

Double-click the application icon.

Expand

Right-click

Select Click to highlight a menu item or list choice. Select New Module from the pull-down list.

> Shows nested menu selections as menu name followed by menu

Click the + to the left of a given item /folder to show its

contents.

Click the right mouse button once while the cursor is positioned

on object or selection.

selection.

Expand 1768 Bus under I/O Configuration.

Right-click the 1768 Bus icon.

Select File

>Menu.

Publication IASIMP-QS003B-EN-P - October 2009 19

Page 20

Notes:

20 Publication IASIMP-QS003B-EN-P - October 2009

Page 21

Chapter

1

Prepare the CompactLogix Hardware

Introduction

In this chapter, you install your CompactLogix hardware including the controller, power

supply, 1768 SERCOS module, and the 2094 line interface module. The line interface module

will power the 1768 CompactLogix and Kinetix 6000 system components. Depending on

your configuration, you also install the 1768 EtherNet/IP module, 1769 DeviceNet module,

and local 1769 I/O modules.

Before You Begin

Determine which network and appropriate hardware to use.

• For an EtherNet/IP network (option 1), use the 1768-ENBT module with the

controller.

• For a DeviceNet (option 2), use the 1769-SDN module with the controller.

• For a motion application (option 1 or 2), use a 1768-M04SE SERCOS module with the

controller.

What You Need

• 2094-AL75S line interface module (optional)

• 1768-L43 or 1768-L45 CompactLogix controller

• 1768-PA3 CompactLogix power supply

• 1769-ECR end cap

• 1768-ENBT EtherNet/IP module for an EtherNet/IP network (option 1)

– Ethernet switch and standard CAT5 Ethernet cable for EtherNet/IP network

• 1768-M04SE SERCOS module for motion on either network (option 1 or 2)

• 1769-SDN DeviceNet module for a DeviceNet network (option 2)

– 1606-XLDNET8 power supply and KwikLink Power Tap module for DeviceNet

network

– KwikLink right-angle male cables with sealed microconnectors, connected to a flat

cable with terminator/resistor on each end for a DeviceNet network

• 1769 Compact I/O modules

• Serial 1756-CP3 cable for EtherNet/IP and DeviceNet networks

21Publication IASIMP-QS003B-EN-P - October 2009 21

Page 22

Chapter 1 Prepare the CompactLogix Hardware

page 25

Assemble the 1768

CompactLogix

System

Make EtherNet/IP

Network

Connection

Wire the

1768-PA3 Power

Supply

page 28

page 32

page 24

Mount and Wire

the Line Interface

Module

Make DeviceNet

Network

Connections

page 29

1768

CompactLogix

System

Line Interface

Module

Ethernet

Switch

DeviceNet Network

Through-the-door

Disconnect for

LIM Module

Follow These Steps

Complete the appropriate steps to assemble your 1768-L43/L45 CompactLogix hardware.

22 Publication IASIMP-QS003B-EN-P - October 2009

Page 23

Prepare the CompactLogix Hardware Chapter 1

Slot 0

Slot 1

Slot 2

Slot 2

Slot 1

Slot 0

Slot 3

1768

1769

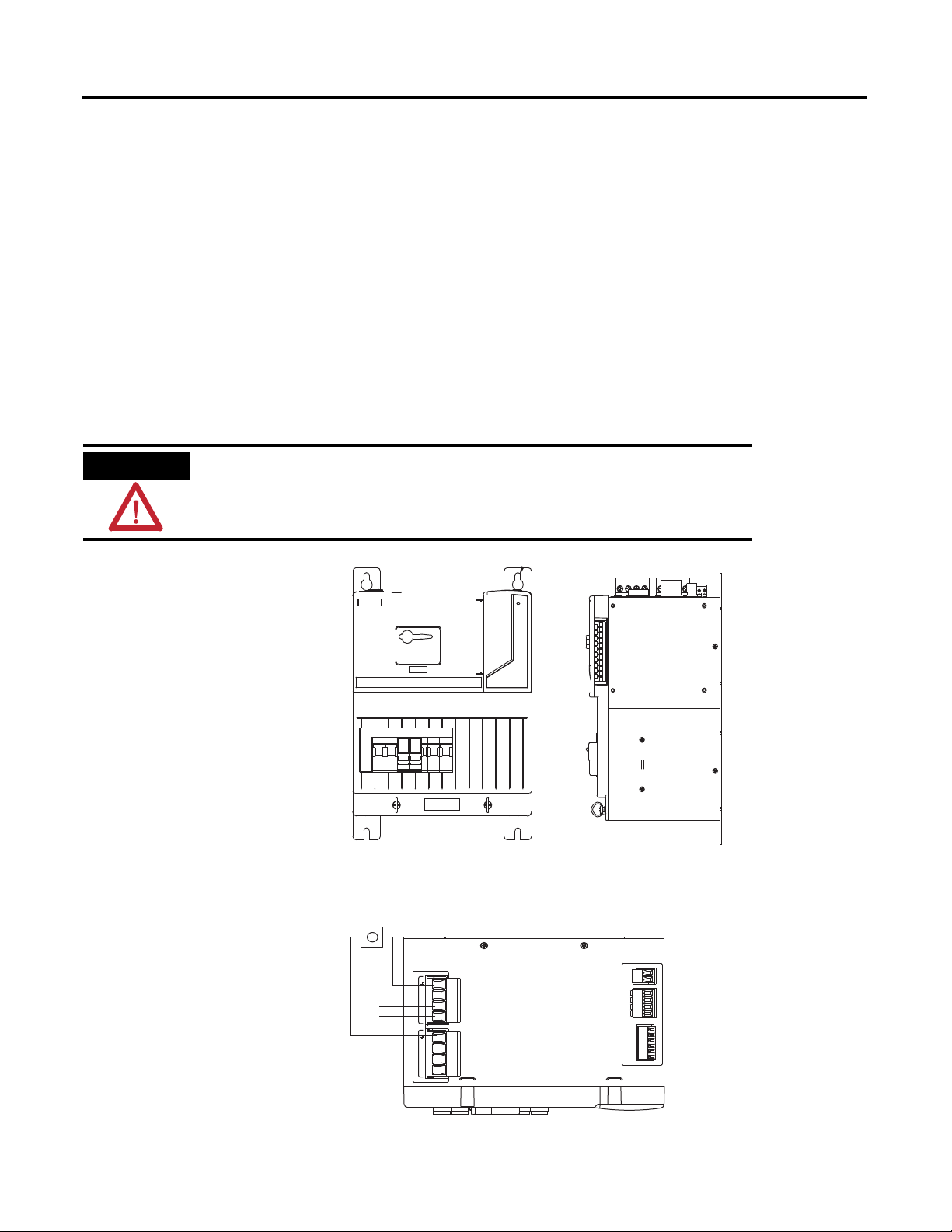

About the 1768 CompactLogix Controller

The 1768-L43 and 1768-L45 CompactLogix controllers combine a 1768 backplane and a

1769 backplane. The 1768 backplane supports the 1768 controller, the 1768 power supply,

and a maximum of two 1768 modules, such as the EtherNet/IP module and the SERCOS

interface module. The 1769 backplane supports 1769 modules, such as the 1769 DeviceNet

module and 1769 I/O modules.

Publication IASIMP-QS003B-EN-P - October 2009 23

Page 24

Chapter 1 Prepare the CompactLogix Hardware

WARNING

Mount and Wire the Line Interface Module

2094-AL75S or Equivalent Hardware, Required for EtherNet/IP and DeviceNet Systems

The line interface module (LIM) serves as the power connection and the generation point for

the complete power needs of most control panels. The LIM module provides the control of

three-phase power and the drive logic power, and also serves as the source and circuit

protection of power for the controller, I/O, and other panel devices. A single LIM module

can replace nine individual components, eliminating up to 100 interconnecting wire

terminations. The 2094-AL75S line interface module (LIM) is optional. Individual

components can be purchased separately instead of purchasing the LIM.

Verify that all incoming power is turned off before wiring power to the LIM

module or any other devices in this chapter.

1. Lay out the position of

the LIM module in the

enclosure.

2. Attach the LIM module

to the cabinet by using

M6 (1/4 in.) bolts.

3. Tighten all mounting

fasteners.

4. Mount the

through-the-door

disconnect switch for the

LIM module.

5. Wire 230V 3-phase

incoming power to the

LIM module and

6. Bond the ground

terminal to the panel.

L3

L2

L1

MAIN VAC

L3

L2

L1

195-265 VAC LINE, 50/60 Hz

L3'

L2'

L1'

195-265 VAC LOAD, 50/60 Hz

1 2 3 4

1 2 3 4

CONTROL VAC

CTRL2

1 2

CTRL1

230 VAC SUPPLY

AUX2

AUX2

AUX1

AUX1

1 2 3 4

I/O_COM

24 VDC SUPPLY

I/O_PWR

I/O_COM

I/O_PWR

I/O_COM

I/O_PWR

1 2 3 4 5 6

24 Publication IASIMP-QS003B-EN-P - October 2009

Page 25

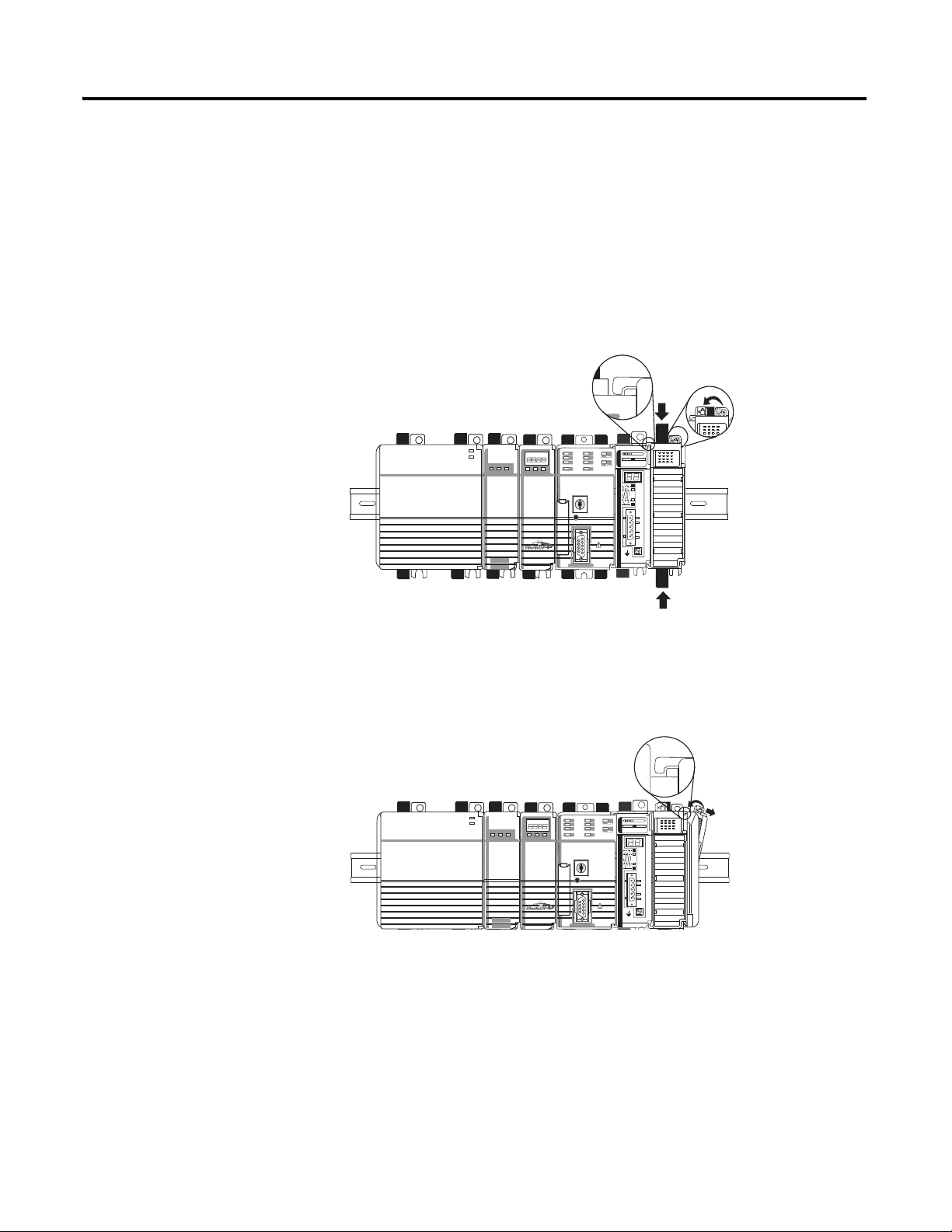

Prepare the CompactLogix Hardware Chapter 1

a

b

2

b

c

d

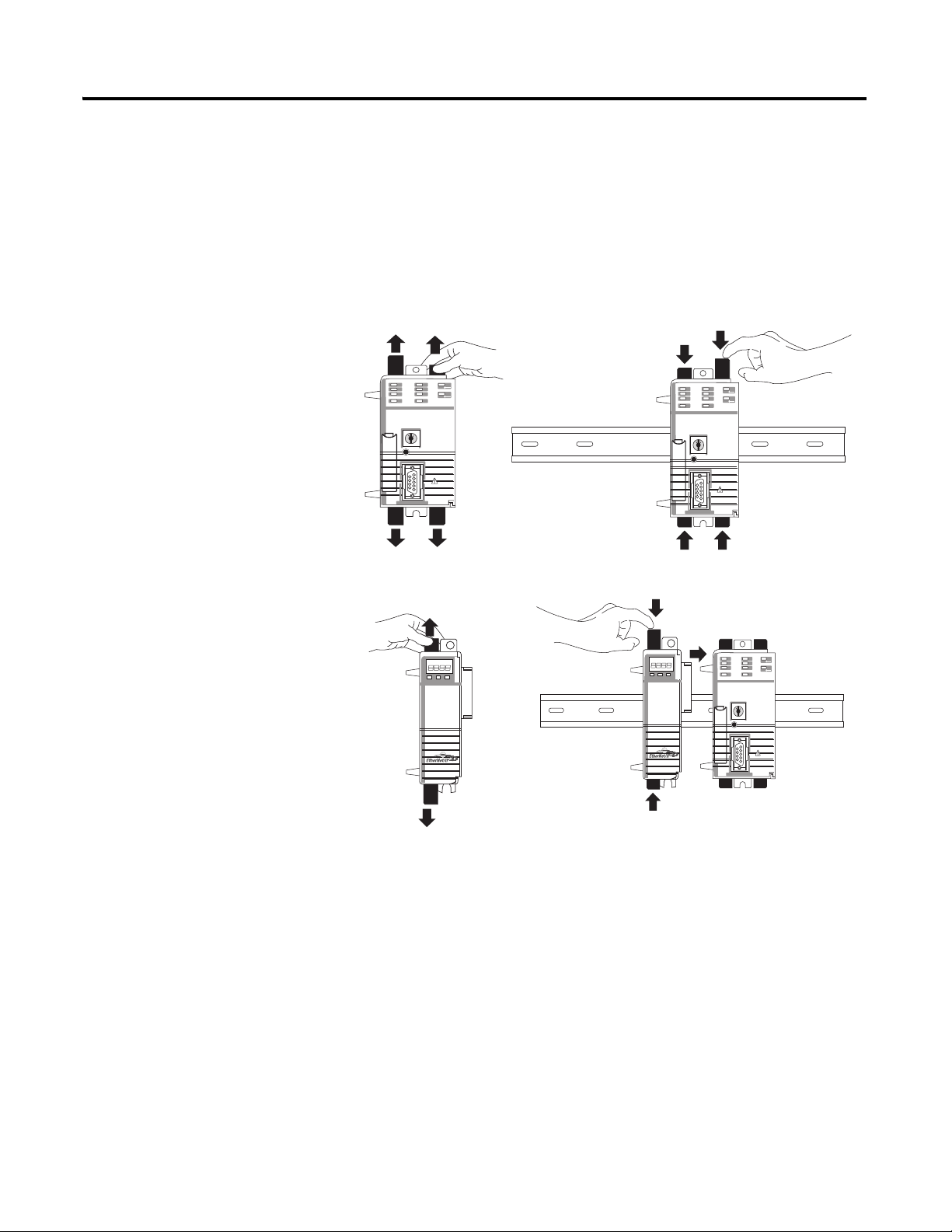

Assemble the 1768 CompactLogix System

1768-L43 Controller, 1768-L45 Controller, 1768-PA3 Power Supply, 1768-ENBT,

1768-M04SE, 1769-SDN, 1769 Local I/O Modules, 1769-ECR End Cap Terminator

1. Mount the 1768-L43 or

1768-L45 controller on

the DIN rail.

a. Pull locking tabs out.

b. Slide controller into

position and push

locking tabs in.

2. If you have an

EtherNet/IP module:

a. locate the Ethernet

(MAC) address on the

side of module and

record address in

Appendix A.

b. pull locking tabs out.

c. align module to the left

of controller on DIN

rail and slide the mating

connector into the

1768-L43 or 1768-L45

controller.

d. push locking tabs in.

Publication IASIMP-QS003B-EN-P - October 2009 25

Page 26

Chapter 1 Prepare the CompactLogix Hardware

b

a

c

a

b

c

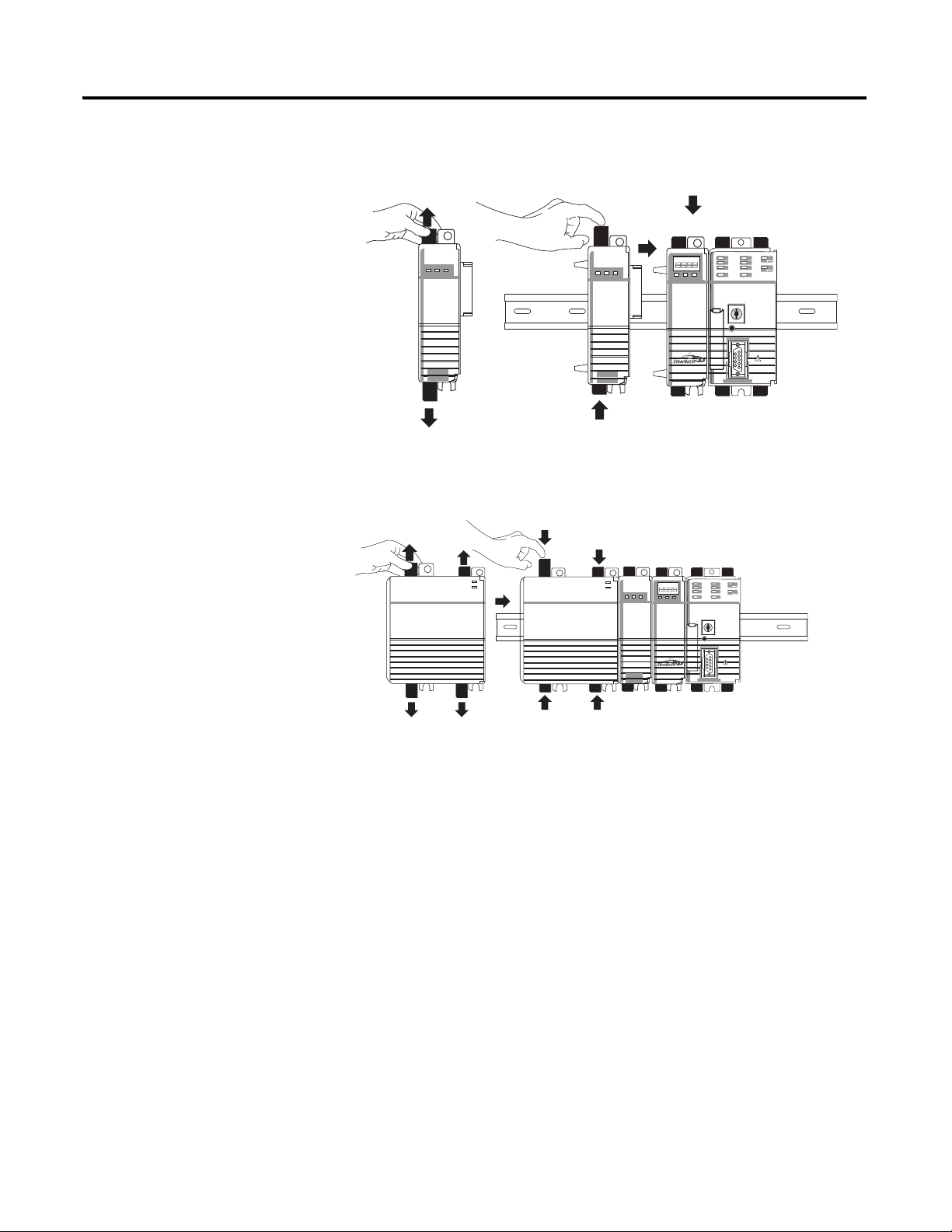

3. Mount the SERCOS

1768-M04SE module.

a. Pull locking tabs out.

b. Align SERCOS module

to the left of

EtherNet/IP module

or controller and slide

into place.

c. Push locking tabs in.

4. Mount the power supply

on the DIN rail.

a. Pull locking tabs out.

b. Align supply to the left

of the SERCOS

module and slide into

place.

c. Push locking tabs in.

5. If you have a 1769-SDN

DeviceNet module,

locate the series letter and

firmware revision on the

side of the module and

record in Appendix A.

26 Publication IASIMP-QS003B-EN-P - October 2009

Page 27

6. Mount the 1769-SDN

b

c

d

b

c

a

and 1769 I/O modules to

the right of the controller

on DIN rail.

In this quick start, the

1769-SDN module is

directly to the right of the

controller in slot 1.

a. Pull locking tabs out.

b. Slide module along

tongue-and-groove

slots on the side of the

controller or modules.

c. Push locking tabs in.

Prepare the CompactLogix Hardware Chapter 1

d. Slide white locking tab

to the left.

A maximum of three

modules can be mounted

between the 1769-SDN

and the power supply.

7. Mount the 1769-ECR

end cap terminator.

a. Pull locking tab to the

right.

b. Slide end cap on rail.

c. Pull locking tab to the

left.

Publication IASIMP-QS003B-EN-P - October 2009 27

Page 28

Chapter 1 Prepare the CompactLogix Hardware

IO_PWR1

IO_COM1

IO_PWR1

IO_COM1

IO_PWR1

IO_COM1

COIL_E1

COIL_E2

ALRM_M

SHIELD

ALRM_B

ALRM_COM

CONSTAT_11

CONSTAT_12

CONSTAT_21

CONSTAT_22

CONSTAT_31

CONSTAT_32

CONSTAT_53

CONSTAT_54

SHIELD

1

3

5

7

9

11

13

15

17

19

21

2

4

6

8

10

12

14

16

18

20

IOL

3

4

24VDC (+)

DC NEUT (-)

CHS GND

Line Interface Module

I/O Power

Front View

8

1

Computer

POINT I/O

connection

PowerFlex 70

connection

PanelView Plus

connection

Ethernet CAT5 Cable

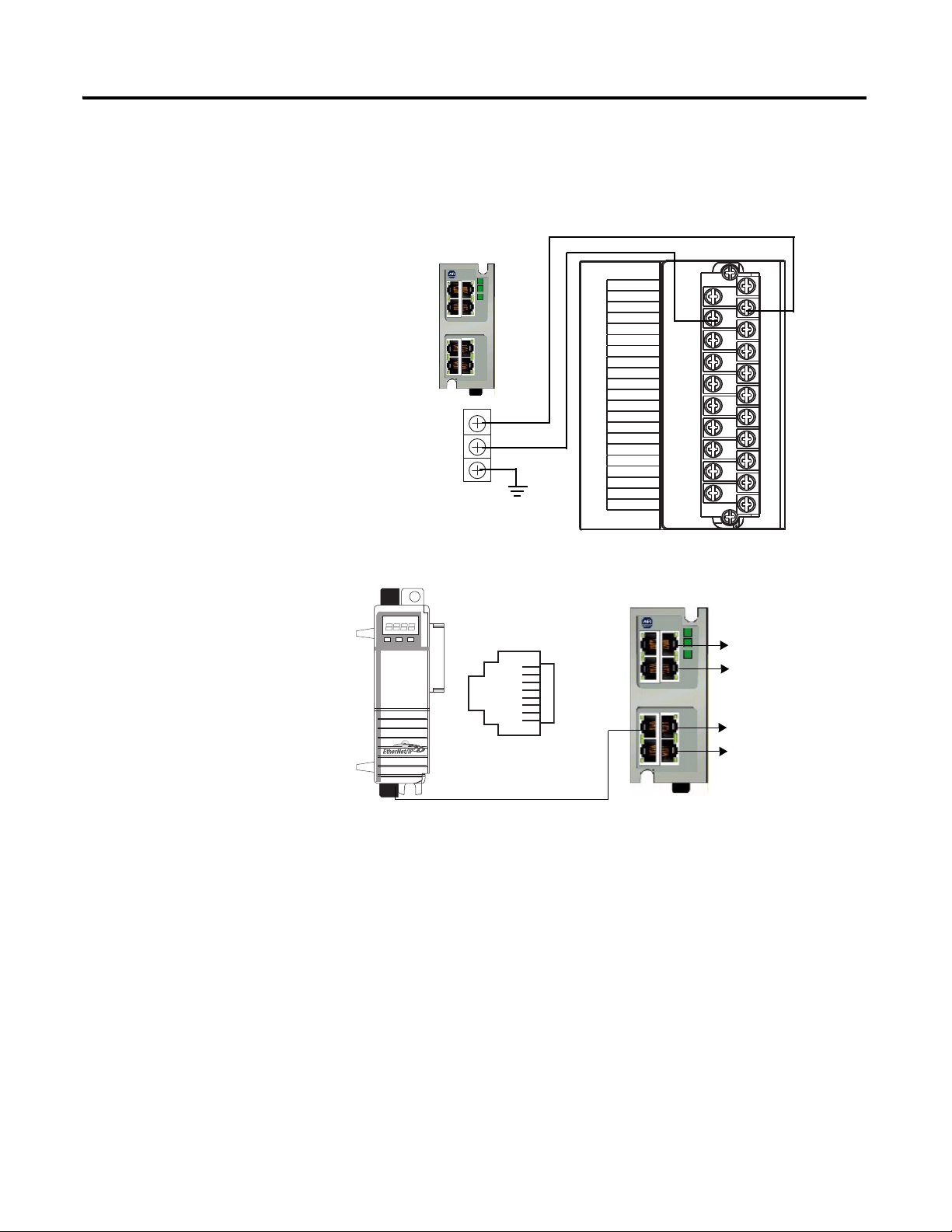

Make EtherNet/IP Network Connection

1. Mount the Ethernet

switch to the DIN rail.

2. Connect the Ethernet

switch power terminals to

the I/O power terminals

on the front of the line

interface module.

3. Connect a CAT5

Ethernet cable between

the Ethernet port on the

bottom of 1768-ENBT

module and the Ethernet

switch.

4. Do not turn on incoming

power.

28 Publication IASIMP-QS003B-EN-P - October 2009

Page 29

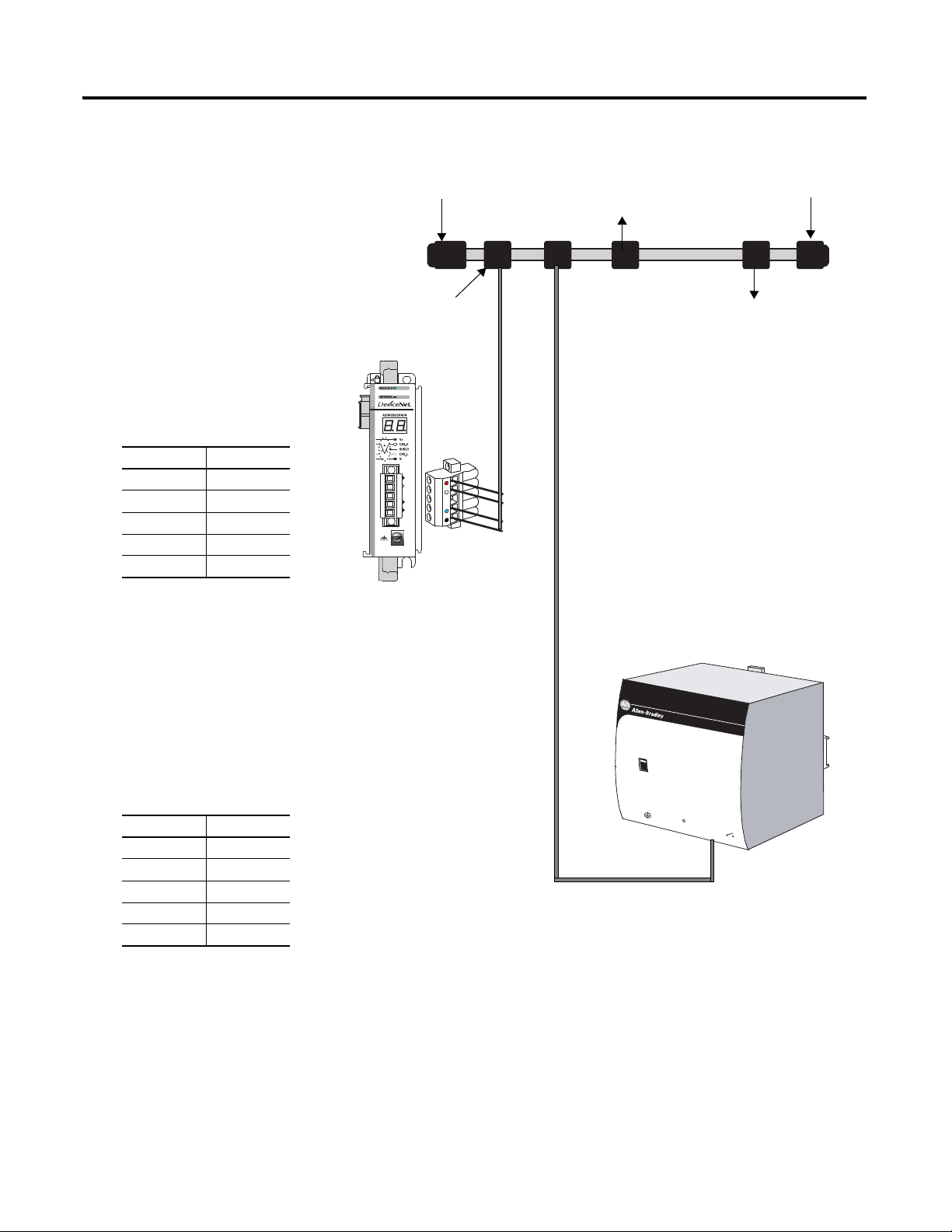

Make DeviceNet Network Connections

Input

AC 100-120/200-240V

N L

Isolate power before disconnecting

1606-XL

POWER SUPPLY

DC ok

Output

200W Limited Power

DC 24V / 8A

+ –

DC ok

AC 120V

AC 240V

1. Attach and lock the

1606-XLDNET8

DeviceNet power supply

to a DIN rail by pressing

the tab at the top of the

supply.

Prepare the CompactLogix Hardware Chapter 1

Publication IASIMP-QS003B-EN-P - October 2009 29

Page 30

Chapter 1 Prepare the CompactLogix Hardware

PowerFlex 70 Drive

with

20-COMM-D

Distributed

POINT I/O

Connection with

1734-ADN Adapter

1606-XLDNET8

DeviceNet Power Supply

KwikLink Sealed

Terminator

KwikLink Sealed

Terminator

KwikLink Sealed

Micro Connector

2. Assemble the DeviceNet

network cable system

using the KwikLink flat

cable, terminators, and

sealed micro connectors

for each device.

See instructions included

with devices.

3. Wire a KwikLink QD

Micro Cordset to the

1769-SDN connector.

Connect To

Red V+

White CAN High

Bare Shield

Blue CAN Low

Black V-

4. Connect the QD Micro

5. Connect the DeviceNet

6. Connect the DeviceNet

Cordset to a KwikLink

sealed microconnector on

the network.

KwikLink power tap to

the power supply Output

connector.

Connect To

Red +

White Not Used

Shield Not Used

Blue Not Used

Black —

power tap to the

DeviceNet network.

AC 120V

AC 240V

Input

AC 100-120/200-240V

N L

Isolate power before disconnecting

DC ok

1606-XL

POWER SUPPLY

Output

200W Limited Power

DC 24V / 8A

+ –

DC ok

30 Publication IASIMP-QS003B-EN-P - October 2009

Page 31

WARNING

Verify that all incoming power is turned off before wiring power.

Input

AC 100-120/200-240V

N L

Isolate power before disconnecting

1606-XL

POWER SUPPLY

DC ok

Output

200W Limited Power

DC 24V / 8A

+ –

DC ok

AC 120V

AC 240V

Line Interface Module

230V AC AUX Power

Top View

L (line)

N (neutral)

7. Wire the DeviceNet

power supply to the 230V

AC Aux Power Output

connector on the line

interface module.

8. Place the switch in the

position that matches

your supply voltage.

Prepare the CompactLogix Hardware Chapter 1

9. Do not turn on incoming

power.

Publication IASIMP-QS003B-EN-P - October 2009 31

Page 32

Chapter 1 Prepare the CompactLogix Hardware

L1

L2/N

Protective Earth Ground

Line Interface Module

230V AC AUX Power

Top View

Wire the 1768-PA3 Power Supply

Required for EtherNet/IP and DeviceNet Systems

1. Wire the 1768-PA3 power

supply to the 230V AC

Aux Power Output

Connector on the line

interface module.

2. Do not turn on incoming

power.

32 Publication IASIMP-QS003B-EN-P - October 2009

Page 33

Additional Resources

Resource Description

Prepare the CompactLogix Hardware Chapter 1

CompactLogix Controller Installation

Instructions, publication 1768-IN004

CompactLogix EtherNet/IP Communication

Module Installation Instructions, publication

1768-IN002

Compact I/O DeviceNet Scanner Module

Installation Instructions, publication

1769-IN060

Compact Logix SERCOS Interface Module

Installation Instructions, publication

1768-IN005

1768 CompactLogix Power Supply, publication

1768-IN001

KwikLink General Purpose DeviceNet Media

Installation Instructions, publication

1485-IN001

1769 CompactLogix Selection Guide,

publication 1769-SG001

Provides details on how to install controller firmware, configure the serial and

EtherNet/IP driver, and troubleshoot system power and controller operation.

Provides details on how to install, configure and troubleshoot the module.

Provides details on how to install, configure and troubleshoot the module.

Provides information on available fiber optic cables, and details on how to install,

configure and troubleshoot the module.

Provides details on power considerations, master control relay, safety circuits,

grounding, power dissipation, input power requirements, and how to interpret the

status indicators.

Provides details on how to install a DeviceNet network cable system.

Provides details on selecting 1769 CompactLogix system components.

Publication IASIMP-QS003B-EN-P - October 2009 33

Page 34

Chapter 1 Prepare the CompactLogix Hardware

Notes:

34 Publication IASIMP-QS003B-EN-P - October 2009

Page 35

Chapter

2

Prepare the Computer and Load Controller Firmware

Introduction

In this chapter, you configure network communication on your computer and install the

necessary programming and configuration software.

Before You Begin

• Assemble the CompactLogix hardware (Chapter 1).

• Verify that your computer meets the software’s system requirements for your edition of

RSLogix 5000 software.

• Refer to Required Software on page 14

for your system requirements.

What You Need

• Personal computer

• 1756-CP3 serial cable to configure serial driver and update controller firmware

• Ethernet CAT5 cable to configure EtherNet/IP driver (option 1)

• RSLogix 5000 programming software (see page 14

• RSLinx Classic software, version 2.54 or later (packaged with RSLogix 5000

programming software).

• RSNetWorx for DeviceNet software for the DeviceNet network (option 2)

• BOOTP/DHCP server utility (packaged with RSLogix 5000 programming software)

• A Network Interface Card (NIC) and its associated Windows driver installed (the NIC

and driver are standard on most computers)

• An Ethernet Address (MAC) for each device.

• A planned IP Address for each device. If you are using an isolated network, determine a

numbering convention for your IP addresses.

for edition and version information)

• ControlFlash software (packaged with RSLogix 5000 programming software)

35Publication IASIMP-QS003B-EN-P - October 2009 35

Page 36

Chapter 2 Prepare the Computer and Load Controller Firmware

page 52

page 49

page 48

page 46

page 38

Set the IP

Address for

the Computer

Make Network

Connections for

Personal

Terminology

Configure the

EtherNet/IP

Driver in RSLinx

Software

Load the Controller

Firmware

Install Additional

Software

page 37

Install RSLogix

Programming

Configure a

Serial Driver

page 39

page 44

Follow These Steps

Complete the appropriate steps.

36 Publication IASIMP-QS003B-EN-P - October 2009

Page 37

Prepare the Computer and Load Controller Firmware Chapter 2

Terminology

Ethernet networks use these types of addresses.

Term Definition

Ethernet Address Each Ethernet device has a unique Ethernet address (sometimes called a MAC address). The

address appears as twelve digits separated by colons (for example, xx:xx:xx:xx:xx:xx). It is

usually on a label on the device itself.

Each digit is a number in hexadecimal (0 to 9 or A through F). No other device in the world will

have the same address, and it can not be changed.

You use the Ethernet address to identify a device so you can assign it an IP address.

IP Address In addition to the Ethernet address, an IP address identifies a node on an Ethernet network.

The IP address can be manually set. or you can use special software to automatically assign it.

An IP Address consists of four decimal integers separated by periods (xxx.xxx.xxx.xxx). Each xxx

is a decimal value from 0…255. For example, an IP Address could be 192.168.1.092 The

selection of IP Addresses is beyond the scope of this quick start, so please contact your

network administrator or use the ones provided in the examples.

Once you set an IP address for a device, you generally reference the device by its IP address.

The examples in this quick start use IP Addresses to define communication paths to the

devices.

Publication IASIMP-QS003B-EN-P - October 2009 37

Page 38

Chapter 2 Prepare the Computer and Load Controller Firmware

1756-CP3

EtherNet/IP

Serial

Ethernet CAT 5

Serial

1756-CP3

Make Network Connections for Personal Computer

Network Connections Required for EtherNet/IP System

1. Connect a CAT5

Ethernet cable between

the Ethernet port on the

computer and the

Ethernet switch.

This connection is used

to configure the

EtherNet/IP driver in

RSLinx software.

2. Connect the 1756-CP3

cable between the CH0

serial port on the

controller and a computer

COM port.

This connection is used

to configure the serial

driver and load controller

firmware.

Network Connections Required for DeviceNet System

Connect the 1756-CP3 cable

between the CH0 serial port

on the controller and the

COM port on the computer.

This connection is used to

configure the serial driver and

load controller firmware.

38 Publication IASIMP-QS003B-EN-P - October 2009

Page 39

Prepare the Computer and Load Controller Firmware Chapter 2

3. Accept the default

software products for

installation and click

Next.

Throughout the installation, click Next to use default RSLogix 5000 installation settings

except when indicated in the steps below.

1. Begin the RSLogix 5000

software installation.

2. Choose your language and

click Continue.

4. Enter your user name, organization, and

software serial number, then click Next.

Install RSLogix Programming Software

Required for all controllers

Publication IASIMP-QS003B-EN-P - October 2009 39

Page 40

Chapter 2 Prepare the Computer and Load Controller Firmware

7. Select your

activation type

and click Next.

This quick start uses

FactoryTalk

Activation software

to activate RSLogix

5000 software. For

more information,

see the FactoryTalk

Activation FAQ,

publication

Ftalk-FA017.

5. Accept the license agreement and

click Next.

8. Click Next to

install only the

latest version of

RSLogix 5000

software (version

18).

9. Verify that

RSLogix 5000

Tools and Files is

checked and click

Next.

6. Click Next to install the program

files to the default directory.

40 Publication IASIMP-QS003B-EN-P - October 2009

Page 41

10. Click Next to

install the typical

firmware kits.

11. Click Next to install

typical RSLogix

Architect tools.

12. Click Next to install

the typical set of

EDS files and

RSLinx software.

Prepare the Computer and Load Controller Firmware Chapter 2

Publication IASIMP-QS003B-EN-P - October 2009 41

Page 42

Chapter 2 Prepare the Computer and Load Controller Firmware

13. Click Install to

complete the

installation.

The installation

dialog box displays

progress while the

software installs.

TIP

As the installation progresses, you may be prompted to complete additional set-up tasks depending on

your system configuration. Follow those prompts and enter information as indicated in the dialog boxes to

complete your installation.

After a few moments, the

FactoryTalk Installation Wizard

starts.

14. Click Next.

15. Enter the Serial number and

Product key from the

certification letter packaged with

your software.

16. Click Next.

42 Publication IASIMP-QS003B-EN-P - October 2009

Page 43

17. Select your host ID and click

Next.

The activation completes if the

computer is connected to the

Internet.

If Internet access is not

available, call Rockwell

Automation Technical Support

to complete your activation.

18. Click Finish to close the

Activation Wizard.

Prepare the Computer and Load Controller Firmware Chapter 2

Publication IASIMP-QS003B-EN-P - October 2009 43

Page 44

Chapter 2 Prepare the Computer and Load Controller Firmware

1. Launch RSLinx

software.

2. Under Communications, select Configure

Drivers.

3. Select RS-232 DF1 devices.

4. Click Add New.

5. Click OK to keep the default

name.

Configure a Serial Driver

Required for all controllers

44 Publication IASIMP-QS003B-EN-P - October 2009

Page 45

The Serial driver is added to the

Configured Drivers list.

10. Verify that the Status of the driver

is Running, and click Close.

11. Click the RSWho icon to view

the driver.

All of the configured, active drivers

display.

6. Select the Comm Port to which you

connected the 1756-CP3 cable.

7. For Device, select

Logix5550/CompactLogix.

8. Click Auto Configure.

9. Click OK.

Expand the serial driver to see

connected devices.

Prepare the Computer and Load Controller Firmware Chapter 2

Publication IASIMP-QS003B-EN-P - October 2009 45

Page 46

Chapter 2 Prepare the Computer and Load Controller Firmware

1. On your desktop, right-click My

Network Places and select

Properties.

2. Double-click the Local Area

Connection.

3. Click Properties.

4. On the General tab, select Internet

Protocol (TCP/IP) and click

Properties.

5. Select Use the following IP address

and enter an IP address and Subnet

mask for your computer using the

example shown or enter your own

address.

For more information about selecting

an IP Address, see page 7-81

.

6. Click OK.

7. Record the IP address and subnet mask in the Network Worksheet on the back cover.

8. Click OK.

Set the IP Address for the Computer

Required for all controllers, regardless of network choice

46 Publication IASIMP-QS003B-EN-P - October 2009

Page 47

9. Click the Support tab.

10. Verify that the IP Address and Subnet

Mask match what you entered on the

Appendix A.

If these numbers do not match what

you entered, contact your network

administrator to verify that your IP

address is correct.

11. Close the Local Area Connection

Status dialog box.

Prepare the Computer and Load Controller Firmware Chapter 2

Publication IASIMP-QS003B-EN-P - October 2009 47

Page 48

Chapter 2 Prepare the Computer and Load Controller Firmware

1. If RSLinx software is not open, launch RSLinx software.

2. From the Communications

menu, choose Configure

Drivers.

3. From the Available

Driver Types, select

Ethernet/IP Driver.

4. Click Add New.

5. Click OK to keep the default

name.

6. Click OK to Browse Local

Subnet.

Configure the EtherNet/IP Driver in RSLinx Software

Required for 1768-L43, 1768-L45, and PanelView Plus

48 Publication IASIMP-QS003B-EN-P - October 2009

Page 49

Load the Controller Firmware

TIP

The EtherNet/IP driver is

added to the Configured

Drivers list.

7. Verify that the driver’s

Status is Running, and click

Close.

Prepare the Computer and Load Controller Firmware Chapter 2

Required for All Systems

This procedure shows how to load firmware in the controller using a serial connection. It is faster to load

the firmware using an EtherNet/IP connection. For details, see the controller installation instructions.

1. Turn on incoming power

to the CompactLogix

power supply.

2. Launch the ControlFlash

software.

Publication IASIMP-QS003B-EN-P - October 2009 49

Page 50

Chapter 2 Prepare the Computer and Load Controller Firmware

18.0

3. Click Next when the

Welcome screen appears.

4. Select the controller

catalog number and click

Next.

5. Move the keyswitch on

controller to Program.

6. If the Current Revision

matches the firmware

revision you want, click

Cancel, then skip to the

next section.

Otherwise, select the

revision level to which

you want to update the

controller and click Next.

If you are not sure what

revision to use, select the

latest.

50 Publication IASIMP-QS003B-EN-P - October 2009

Page 51

7. Click Finish, then click

18.0

ATTENTION

Yes to start the firmware

update.

When the controller is

updated, the status box

displays Update

complete.

8. Close ControlFlash by

clicking Cancel, then Yes.

Prepare the Computer and Load Controller Firmware Chapter 2

The 1768-L43 and 1768-L45 controllers are compatible with firmware version 16.23, or

later. If you encounter errors, contact Technical Support.

Publication IASIMP-QS003B-EN-P - October 2009 51

Page 52

Chapter 2 Prepare the Computer and Load Controller Firmware

Install Additional Software

• If your network configuration includes a PanelView Plus terminal, install FactoryTalk

Machine Edition software and RSLinx Enterprise software from the FactoryTalk View

Machine Edition package.

• If you are using a DeviceNet network, install RSNetWorx for DeviceNet software. Also

install the DeviceNet Tag Generator Tool under optional steps of the RSNetWorx for

DeviceNet install.

Additional Resources

Resource Description

CompactLogix Controller Installation

Instructions 1768-IN004

Provides other methods for loading firmware in the controller.

FactoryTalk Activation FAQ, publication

FTalk-FA017

ControlFlash Firmware Upgrade Kit, publication

1756-QS105

Provides answers to FactoryTalk Activation questions, including how the FactoryTalk

Activation differs from master disk activation.

Provides details regarding the installation of ControlFlash software and execution of

firmware upgrades.

52 Publication IASIMP-QS003B-EN-P - October 2009

Page 53

Chapter

Prepare the Distributed POINT I/O Hardware

Introduction

In this chapter, you install the 1734 POINT network adapter and the 1734 POINT I/O

modules.

Before You Begin

• Assemble your CompactLogix hardware (Chapter 1).

3

• Determine which of these network adapters to use:

– For an EtherNet/IP network (option 1), use the 1734-AENT adapter.

– For an DeviceNet network (option 2), use the 1734-ADN adapter.

• Select the appropriate mounting base for the I/O modules:

– For the 1734-IT2I module, use the 1734-TBCJC mounting base

– For all other modules, use the 1734-TB or 1734-TBS mounting base.

What You Need

• POINT I/O adapter: 1734-AENT or 1734-ADN

• POINT I/O mounting bases: 1734-TB or 1734-TBS, and 1734-TBCJC

• A digital POINT I/O module. This example uses 1734-OB4E, however, other POINT

I/O modules can also be used but are not required.

• 1794-PS3 or 1794-PS13 power supply

• DIN rail

• Standard CAT5 Ethernet cable for EtherNet/IP system (option 1)

53Publication IASIMP-QS003B-EN-P - October 2009 53

Page 54

Chapter 3 Prepare the Distributed POINT I/O Hardware

page 59

page 58

page 57

page 56

page 59

page 58

page 57

Mount and

Connect the

Network Adapter

Mount the POINT

I/O Modules

Mount and Wire

the POINT I/O

Power Supply

Wire the Adapter

and I/O Modules to

the Power Supply

page 55

Mount and

Connect the

Network Adapter

Mount the POINT

I/O Modules

Mount and Wire

the POINT I/O

Power Supply

Wire the Adapter

and I/O Modules to

the Power Supply

EtherNet/IP

DeviceNet

Distributed POINT I/O

Power

Supply

Follow These Steps

If you have POINT I/O, complete the steps for your network.

DIRTY

L1 L2 L3 E

LINE

DIRTY

LOAD

L1 L2 L3 E

DIRTY

DIRTY

CLEAN

CLEAN

CLEAN

CD V4

2

rewoP

O

YLPPU

W

S RE

P

971

3SP-4

MOC

V42

CLEAN

54 Publication IASIMP-QS003B-EN-P - October 2009

Page 55

Prepare the Distributed POINT I/O Hardware Chapter 3

00:00:BC:21:44:8A

Ethernet Address

p

E

t

h

e

r

n

e

t

A

d

d

r

e

s

s

Example Address

Mount and Connect the Network Adapter

1734-AENT EtherNet/IP Adapter for EtherNet/IP System

1. Locate the Ethernet

Address (MAC) and the

major revision on the

POINT Adapter and

record both in Appendix

A.

The address is used to set

the IP address.

2. Set the address to a value

greater than or equal to

256.

This example uses 999.

3. Remove the protective

cover from the right side

of the adapter.

4. Press the adapter onto

the DIN rail.

5. Connect an Ethernet

cable between the

Ethernet connector on

the adapter and the

Ethernet switch.

For EtherNet/IP

systems, skip to page 57

Mount the Point I/O

Modules.

,

Publication IASIMP-QS003B-EN-P - October 2009 55

Page 56

Chapter 3 Prepare the Distributed POINT I/O Hardware

retpad

A

suta

t

S

teNeciveD

sutat

S

suBtnioP

s

utat

S

NDA-4371

dleiF

rewoP

m

e

tsyS

rewoP

PowerFlex 70 Drive

with

20-COMM-D

KwikLink Sealed

Terminator

KwikLink Sealed

Terminator

KwikLink Sealed

Micro Connector

1769-SDN

DeviceNet Module

1606-XLDNET8

Power Supply

1734-ADN DeviceNet Adapter for DeviceNet System

1. Remove the protective

cover from the right side

of the adapter.

2. Press the adapter onto

the DIN rail.

3. Set the node address to

02 for this example.

4. Wire the KwikLink QD

Micro Cordset to the

1734-ADN connector.

Connect To

Red V+

White CAN High

Bare Shield

Blue CAN Low

Black V-

5. Connect the QD Micro

Cordset to a KwikLink

sealed micro connector

on the DeviceNet

network.

56 Publication IASIMP-QS003B-EN-P - October 2009

Page 57

Mount the POINT I/O Modules

IMPORTANT

Wiring Base

Tongue-and-groove slots

Handle

Module

Required for EtherNet/IP and DeviceNet Systems

The 1734-IT21 must be mounted in the 1734-TBCJC wiring base. All other

modules can be mounted in either the 1734-TB or 1734-TBS wiring bases.

1. Using a small, flathead

screwdriver, rotate the

keyswitch on the wiring

base to 1.

Prepare the Distributed POINT I/O Hardware Chapter 3

This quick start uses the

1734-OB4E output

module.

2. Press the module into the

wiring base.

3. Snap the handle up.

4. Complete steps 1-3 with

all POINT I/O modules.

5. Slide the first module and

wiring base assembly

along the side of the

adapter and press it onto

DIN rail.

6. Repeat with all of the I/O

assemblies.

2

3

1

4

8

7

1

5

6

Publication IASIMP-QS003B-EN-P - October 2009 57

Page 58

Chapter 3 Prepare the Distributed POINT I/O Hardware

WARNING

Upper-lip of DIN rail latch

GR

L2/N

L1

L2

L1

Optional LIM 230V AC

AUX Power Output Connector

Top View

Mount and Wire the POINT I/O Power Supply

1794-PS3 or 1794-PS13 Power Supply for EtherNet/IP and DeviceNet Systems

Verify that all incoming power is turned off before wiring power.

1. Hook the upper-lip of the

power module onto the

DIN rail.

2. Press the module onto

the DIN rail.

3. Wire the POINT I/O

power supply to the 230V

AC Aux Power Output

connector on the line

interface module.

58 Publication IASIMP-QS003B-EN-P - October 2009

Page 59

Prepare the Distributed POINT I/O Hardware Chapter 3

COM

24V

Wire the Adapter and I/O Modules to the Power Supply

Required for EtherNet/IP and DeviceNet Systems

1. Connect the 12/24V dc

common and power wires

from the power supply to

the adapter.

Refer to the installation

instructions for the

1734-AENT or

1734-ADN adapters.

2. Refer to the individual

POINT I/O installation

instructions for wiring

the I/O modules.

3. Turn on incoming power.

Publication IASIMP-QS003B-EN-P - October 2009 59

Page 60

Chapter 3 Prepare the Distributed POINT I/O Hardware

Additional Resources

Resource Description

POINT I/O EtherNet/IP Adapter Installation

Instructions, publication 1734-IN590

POINT I/O DeviceNet Adapter Installation

Instructions, publication 1734-IN026

POINT I/O Wiring Base Assembly Installation

Instructions, publication 1734-IN511

POINT I/O Cold Junction Compensation Wiring

Base Assembly Installation Instructions,

publication 1734-IN583

POINT I/O Protected Output Module Installation

Instructions, publication 1734-IN056

FLEX I/O DC Power Supply Module Installation

Instructions, publication 1794-IN069

Point I/O Selection Guide, publication

1734-SG001

Provides details regarding installation of the adapter and technical specifications.

Provides details regarding installation of the adapter and technical specifications.

Provides details on how to install and remove the wiring base, and terminal block.

Provides details regarding installation of the Cold Junction Compensated Terminal

Block wiring base.

Provides details on how to install, wire, communicate with, and troubleshoot the

protected output module.

Provides details on how to mount and wire the power supply.

Provides details on selecting 1734 POINT I/O components.

60 Publication IASIMP-QS003B-EN-P - October 2009

Page 61

Chapter

4

Prepare the PowerFlex 70 Drive

Introduction

In this chapter, you mount and wire power to a PowerFlex 70 drive. You also configure the

communication adapter and make network connections.

Before You Begin

• Assemble your CompactLogix hardware (Chapter 1).

• Determine which network adapter to use on the PowerFlex 70 drive:

– For an EtherNet/IP network (option 1), use the 20-COMM-E adapter.

– For a DeviceNet network (option 2), use the 20-COMM-D adapter.

What You Need

• PowerFlex 70 drive

• PowerFlex 70 communication adapter

– 20-COMM-E for an EtherNet/IP network (option 1)

– 20-COMM-D for a DeviceNet network (option 2)

• Standard CAT5 Ethernet cable for EtherNet/IP system (option 1)

61Publication IASIMP-QS003B-EN-P - October 2009 61

Page 62

Chapter 4 Prepare the PowerFlex 70 Drive

page 65

page 65

DIRTY

DIRTY

CLEAN

CLEAN

CLEAN

DIRTY

CLEAN

DIRTY

L1 L2 L3 E

L1 L2 L3 E

LINE

LOAD

rewoP

CD V4

2

YLPPU

S RE

W

O

P

3SP-4

971

V42

MOC

page 67

page 63

Connect

Communication

Adapter to the

PowerFlex 70 Drive

Configure the

Communication

Adapter

Mount and Wire

the PowerFlex 70

Drive

page 66

page 63

Connect

Communication

Adapter to the

PowerFlex 70 Drive

Configure the

Communication

Adapter

Mount and Wire

the PowerFlex 70

Drive

EtherNet/IP

DeviceNet

Follow These Steps

If you have a PowerFlex 70 Drive, complete the steps for your network.

62 Publication IASIMP-QS003B-EN-P - October 2009

Page 63

Mount and Wire the PowerFlex 70 Drive

WARNING

Required for EtherNet/IP and DeviceNet Systems

Verify that all incoming power is turned off before wiring power.

1. Mount the PowerFlex 70

drive to the control

enclosure subpanel using

the four mounting slots

provided.

Prepare the PowerFlex 70 Drive Chapter 4

For mounting

instructions, refer to the

PowerFlex 70 User

Manual, publication

20A-UM001.

2. Loosen the screw and

remove the cover.

Publication IASIMP-QS003B-EN-P - October 2009 63

Page 64

Chapter 4 Prepare the PowerFlex 70 Drive

L1RL2SL3TBR1

+DC

BR2

BRKT1UT2VT3W

PE PE

Optional LIM 240V AC

3-Phase Load Connector

Motor

fuse

fuse

fuse

Top View

3. Remove a knockout from

the bottom plate on the

drive for routing the

power line conductors.

4. Wire the PowerFlex 70

240V AC, 3-phase line

power terminals to the

240V AC, 3-phase Load

connector on the line

interface module.

Fuse according to

PowerFlex power rating.

5. Wire the PE Chassis

ground terminal on the

PowerFlex 70 to earth

ground.

6. Connect the 240V

3-phase motor to the

PowerFlex T1, T2, T3,

PE terminals.

64 Publication IASIMP-QS003B-EN-P - October 2009

Page 65

Configure the Communication Adapter

2

1

0

9

8

3

4

5

6

7

2

1

0

9

8

3

4

5

6

7

Tens

Digit

Ones

Digit

PGM

500K

250K

125K

AUTO

HW Address 00:00:BC:32:00:35

For example:

20-COMM-D DeviceNet Adapter for DeviceNet System

1. Set the node address on

the adapter to 13 for this

quick start.

2. Set the adapter to AUTO

for autobaud.

Prepare the PowerFlex 70 Drive Chapter 4

20-COMM-E EtherNet/IP Adapter for EtherNet/IP System

Locate the Ethernet Address

(MAC) on the label of the

adapter and record this

address in Appendix A

This address is used to set the

IP address.

.

Publication IASIMP-QS003B-EN-P - October 2009 65

Page 66

Chapter 4 Prepare the PowerFlex 70 Drive

POINT I/O with

1734-ADN Adapter

KwikLink Sealed

Terminator

KwikLink Sealed

Terminator

KwikLink Sealed

Micro Connector

1606-XLDNET8

Power Supply

1769-SDN

DeviceNet Module

Connect Communication Adapter to the PowerFlex 70 Drive

20-COMM-D DeviceNet Adapter for DeviceNet System

1. Connect the flat-ribbon

cable between the adapter

and the PowerFlex 70

drive.

2. Fold the cable under

adapter without creasing

and secure adapter on

drive using the captive

screws.

3. Remove a knockout from

4. Wire the KwikLink QD

5. Connect the QD Micro

the bottom plate on the

drive and route the

DeviceNet network cable

through the hole.