QSC PLX-1202 Service manual

Technical Service Manual

PLX™ Series

▲▲

▲▲

▲ PLX 1202

▲▲

▲▲

▲ PLX 1602

▲▲

▲▲

▲ PLX 2402

▲▲

▲▲

▲ PLX 3002

TD-000078-00

TD-000078-00

+

PLX

1202

+

PLX 1602

+

PLX 2402

+

PLX 3002

PLX SERIES

SERVICE MANUAL

PLX

1202

PLX 1602

PLX 2402

PLX 3002

QSC Technical Services

Wats: I

-%OO-772-2034

Local:

1-714-957-7150

Fax: 1-714-754-6173

QSC Technical Support BBS

I -714-668-7567

1-800-856-6003

QSC Audio Products, Inc.

1675 MacArthur Blvd.

Costa Mesa,

CA

92626

http://www.qscaudio.com

Table of Contents

PLX Product Specifications ................................................................

Introduction ........................................................................................

Test and Calibration ............................................................................

Troubleshooting PLX ...........................................................................

PLX Parts List

.....................................................

.....................................................

................................................

................................................

.....................................................

.....................................................

................................................

................................................

.....................................................

.....................................................

................................................

................................................

.....................................................

.....................................................

................................................

................................................

PLX Semiconductors ..............................................................................

Chassis Drawings ...................................................................................

Schematics

.....................................................

.....................................................

.....................................................

.....................................................

PLX Series PCB Circut Board Drawings .................................................

1

2

3

13

PLX 1202 PCB Assembly (120V) 23

PLX 1202 PCB Assembly (230V) 25

PLX 1202 Chassis Assembly (120V) 28

PLX 1202 Chassis Assembly (230V) 28

PLX 1602 PCB Assembly (120V) 28

PLX 1602 PCB Assembly (230V) 31

PLX 1602 Chassis Assembly (120V) 34

PLX 1602 Chassis Assembly (230V) 34

PLX 2402 PCB Assembly (120V) 35

PLX 2402 PCB Assembly (230V) 38

PLX 2402 Chassis Assembly (120V) 41

PLX 2402 Chassis Assembly (230V) 41

PLX 3002 PCB Assembly (120V) 42

PLX 3002 PCB Assembly (230V) 45

PLX 3002 Chassis Assembly (120V) 48

PLX 3002 Chassis Assembly (230V) 49

50

53

PLX 1202 Main PCB Schematics 57

PLX 1602 Main PCB Schematics 62

PLX 2402 Main PCB Schematics 67

PLX 3002 Main PCB Schematics 72

73

PLX Product Specifications

PLX

1202

PLX 1602

PLX 2402

PLX

3002

PLXI

202

PLXI

602

PLX2402

PLX3002

Output

Power (per channel):

Continuous Average

Output

Power both channels driven:

8

ohms,

2OHz

-

2OkHz,

0.03%

THD

200watts

4

ohms,

2OHz

-

2OkHz,

0.05%

THD

325

watts

Con0nuous

Average

Output

Power bridged mono

ooeration:

300

waKs

425watts 550

watts

500

watts

700

watts 900watts

8 ohms,

2OHz

-

2OkHz,

0.1% THD

Voltage Gain (dB)

Sensitivity (for rated power @ 8 ohms)

Distortion

Frequency Response (LF Switched Off)

Damping Factor (1

kHz

and Below)

Noise

Input

Impedance

Dimensions

Faceplate Width

Faceplate Height

Chassis Depth

Weight

Net,

Lbs/kg

700

iatts

1100

watts 1500 watts

32

32

32

1.00vrms

1.20 Vrms

1.50 Vrms

SMPTE-IM

Less

than

0.01%

2OHz

to

2OkHz,

+I-0.2dB

8Hz

to

5OkHz,

+Ol-3dB

Greater

than

500

106dB

below rated output (20 Hz

to

20 kHz)

6k unbalanced,

12k

balanced

2000 watts

32

1.70

vrms

Standard 19” Rack Mounting

3.Y

3.r

13.2Y

13.2v

2119.5 2119.5

3.5” 3.Y

13.2Y 13.2Y

2119.5

2119.5

Introduction

This manual is prepared to assist service personnel with the repair and calibration of PLX power

amplifiers

.

The procedures described in this manual require advanced technical experience

and sophisticated audio test equipment.

CAUTION: To reduce the risk of electric shock,

do not remove the cover. No user-serviceable

parts inside. Refer servicing to qualified

personnel.

CAUTION

WARNING: To prevent fire or electric shock, do

not expose this equipment to rain or moisture.

Documentation

This manual contains schematics, printed circuit board (PCB) drawings, parts lists, and

mechanical assembly drawings. This information should be used in conjunction with the

test and troubleshooting guide.

The electrical and electronic components are identified by circuit identification numbers on

the schematics and the parts list. The test

&

troubleshooting sections refer to

designations shown in the schematics.

Equivalent Parts

Although many of the electronic components used in this product may be available from

electronic suppliers, some components are specially tested and approved by

WC.

A

product repaired with

non-WC

supplied components may not meet factory specifications.

Repairs performed using non-QSC parts may void the product warranty.

men

in doubt,

you may contact

QSC

Technical Services for assistance.

Parts orders to QSC should include the product model number, the part description, and

the QSC part number (from the parts list in this manual). Parts will be shipped via UPS,

F.O.B. Costa Mesa, California. Shipping, handling and COD charges may be added to

the cost of the parts.

Factory Repair

It may become necessary to return a product to the factory for repair. Call QSC Technical

Services for return instructions. QSC Technical Services may be reached at (800)

772-2834.

Test and Troubleshooting Equipment

-

Distortion Analyzer capable of 0.01% THD+N

-

High Power Load Bank

(8,4,8

2

ohms)

-

Function Generator 8 Digital Multimeter

-

2OMHz

Oscilloscope

-

Variac (0-140

VAC,

30-40A)

-Audio

Precision

-

System One

+

Thermometer

2

Test

&

Calibration

PLX 1202 Test Procedure

.

SET-UP

1.

Connect a test load to the output terminals of the amplifier.

2. Make sure Mode Switches 1

-

10 are in the default position (1 on, 10 on, all others off).

3. Connect a distortion analyzer with a resolution of

O.Ol%,

20-2OkHz

(or better) to the

output terminals of the amplifier. Enable the

8OkHz

low pass filter.

4. Connect a dual-channel oscilloscope to the following test points:

Chl

-

a

IOX

(vertical sensitivity

-

2V/cm)

scope probe to the channel speaker output.

Ch2

-

a IX scope probe (vertical sensitivity

-

O.lV/cm)

to the distortion analyzer

output.

5.

Set amp gain pots fully clockwise and turn on power switch.

6. Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.30

VRMS,

1

kHz

sine wave.

7. Plug the amplifier into a variac and set up an AC line current monitor.

. POWER UP 8 MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a

50

ohm

225W

resistor (100 ohm,

240VAC) in series with the high

(+)

lead on the AC cable during variac ramp up. If the switching power

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

&

calibration process.

I. Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

0.5A

a.c. at 60 Volts). This is slightly less for 240V.

Pause at

9OVAC

(2OOVAC European) for three seconds until the mute I protect circuit disengages.

Continue to

12OVAC

(240V European).

2. Verify that the fan is operating at low speed.

3. Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

l CHANNEL OUTPUT

I. Look for amplified signal on the scope for channel

1.

Switch the input signal and scope

to channel 2 and repeat output test. Check for noisy

/

contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

2. Select an 8 ohm load and confirm that this amplifier is producing 200 watts at 1 kHz just

below the point of clipping. Check both channels.

l BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

#7

in the on position. The gain control, limiter, and filter switch positions

on CH2 are disabled with Mode Switch

#7

on.

3.

Set load to both red output binding posts

(CHI

positive and CH2 negative).

4. Apply a 1.30

VRMS,

1

kHz

sinewave input to channel I of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 700 watts at 8 ohms.

5.

Turn power off and place the amplifier back into the Stereo mode with output

loads connected to each channel.

. BIAS

1. Let the amplifier cool down to room temperature.

2. With an input amplitude of

1.3OVrms

increase the input frequency to

2OkHz.

Reduce the

input signal 20dB (80%) from full output. Adjust the crossover

trimpot

VR43

(CHl)

and

VR166 (CH2) for about a

4OOmVpk-pk

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike. It is necessary to

disable the 80kHz

lowpass

filter on the analyzer for this test.

Further trim so that

the total distortion for that channel is less than 0.1% THD+N.

3. With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel 2.

. SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

1.3Vrms

sinewave (1

kHz)

input signal to both channels

of the amplifier.

Ensure that power is on and that the gain controls are fully up.

2. While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel. In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A

ac.

This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

should be

present just as it was before a short was applied for this test.

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

l FREQUENCY RESPONSE

1,

Set load to 8 ohms and scale the input generator to gain 1 watt of power from the

amplifier on each channel. Gain controls on the amplifier should be fully up.

2.

Check frequency response from

2OHz

to 20kHz

(+I-

0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to

2OkHz).

Check both

channels.

l POWER vs. DISTORTION TEST

I. Check to ensure that both channels will produce rated power at

2OHz,

2KHz,

and 20kHz.

into an 8 ohm load.

2. While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03% THD.

l THERMAL TEST

1. Set input frequency to 1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about 11

-

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase. This is not a problem as long as the case temperature on the output

transistors does not exceed

105

degrees C.

4

4.

Verify that the NTC circuit causes thermal shutdown after an extended period.

5. When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes

l CM TEST

1. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

1/4”

input jack halfway into each

channel and observe about 6

dB

of output voltage reduction. There will also be a 180

degree phase inversion at the output of the channel under test.

l OUTPUT NOISE

1. Set the amplifier gain controls all the way up, with a 1

kHz

1.3OVrms

sinewave

input

signal. Note the output level at full power just below clipping. Adjust gain if needed.

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

dB

down

from the full output power point measured. A signal to noise ratio should be better than

or equal to

107dB.

Check both channels.

l FINAL CHECK

This completes the amplifier test procedure for this model.Inspect the amplifier for

mechanical defects. Inspect the solder connections. Reassemble the amplifier and verify

the amplifier’s operation before returning the product to service.

PLX 1602 Test Procedure

.

SET-UP

1.

2.

3.

4.

5.

6.

7.

Connect a test load to the output terminals of the amplifier.

Make sure Mode Switches 1

-

10 are in the default position (1 on, 10 on, all others off)

Connect a distortion analyzer with a resolution of

O.Ol%,

20-20kHz

(or better) to the

output terminals of the amplifier.Enable the 80kHz low pass filter.

Connect a dual-channel oscilloscope to the following test points:

Chl

-

a 1 OX (vertical sensitivity

-

2V/cm)

scope probe to the channel speaker output.

Ch2

-

a IX scope probe (vertical sensitivity

-

O.lV/cm)

to the distortion analyzer

output.

Set amp gain pots fully clockwise and turn on power switch.

Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.30

VRMS,

1

kHz

sine wave.

Plug the amplifier into a variac and set up an AC line current monitor.

l POWER UP 8 MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a

50

ohm 225W resistor (100 ohm,

240VAC) in series with the high

(+)

lead on the AC cable during variac ramp up. If the switching power

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

&

calibration process.

Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

0.5A

a.c

at 60 Volts).

T/I;s

is

s/;ghf/y

less

for 240V. Pause at

9OVAC

(2OOVAC

European) for three seconds until the mute

I

protect circuit disengages.

Continue to

12OVAC

(24OV

European).

Verify that the fan is operating at low speed.

3. Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

. CHANNEL OUTPUT

1. Look for amplified signal on the scope for channel 1. Switch the input signal and scope

to channel 2 and repeat output test. Check for noisy

/

contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

2. Select an 8 ohm load and confirm that this amplifier is producing 300 watts at 1 kHz just

below the point of clipping. Check both channels.

. BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

#7

in the on position. The gain control, limiter, and filter switch positions

on CH2 are disabled with Mode Switch

#7

on.

3. Set load to both red output binding posts

(CHI

positive and CH2 negative).

4. Apply a 1.30

VRMS,

1

kHz

sinewave input to channel 1 of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 1000 watts at 8

ohms.

5.

Turn power off and place the amplifier under test back into the Stereo mode with output

loads connected to each channel.

l BIAS

I. Let the amplifier cool down to room temperature.

2. With an input amplitude of

1.3OVrms

increase the input frequency to 20kHz. Reduce the

input signal 20dB (80%) from full output. Adjust the crossover

trimpot

VR43

(CHl)

and

VR166 (CH2) for about a

4OOmVpk-pk

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike.

It is necessary to

disable the 80kHz

lowpass

filter on the analyzer for this test. Further trim so that

the total distortion for that channel is less than 0.1% THD+N.

3. With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel 2.

l SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

1.3Vrms

sinewave (1

kHz)

input signal to both channels

of the amplifier.Ensure that power is on and that the gain controls are fully up.

2. While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel.

In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A

ac. This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

should be

present just as it was before a short was applied for this test.

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

6

l FREQUENCY RESPONSE

I.

Set load to 8 ohms and scale the input generator to gain 1 watt of power from the

amplifier on each channel. Gain controls on the amplifier should be fully up.

2. Check frequency response from

2OHz

to 20kHz

(+I-

0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to 20kHz). Check both

channels.

l POWER vs. DISTORTION TEST

1. Check to ensure that both channels will produce rated power at

2OHz,

2KHz,

and 20kHz.

into an 8 ohm load.

2.

While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03% THD.

l THERMAL TEST

1.

Set input frequency to 1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about

II

-

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase. This is not a problem as long as the case temperature on the output

transistors does not exceed 105 degrees

C.

4. Verify that the NTC circuit causes thermal shutdown after an extended period.

5. When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes.

l CM TEST

1. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

1/4”

input jack halfway into each

channel and observe about 6

dB

of output voltage reduction. There will also be a 180

degree phase inversion at the output of the channel under test.

l OUTPUT NOISE

I. Set the amplifier gain controls all the way up, with a 1

kHz

1.3OVrms

sinewave

input

signal.

Note the output level at full power just below clipping. Adjust gain if needed.

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

dB

down

from the full output power point measured. A signal to noise ratio should be better than

or equal to

107dB.

Check both channels.

l FINAL CHECK

This completes the amplifier test procedure for this model.

Inspect the amplifier for

mechanical defects. inspect the solder connections. Reassemble the amplifier and

veri@

the amplifier’s operation before returning the product to service.

PLX 2402 Test Procedure

l SET-UP

1. Connect a test load to the output terminals of the amplifier.

2. Make sure Mode Switches 1

-

10

are in the default position (1 on, 10 on, all others off).

3. Connect a distortion analyzer with a resolution of

O.Ol%,

20-20kHz

(or better) to the

output terminals of the amplifier. Enable the 80kHz low pass filter.

4. Connect a dual-channel oscilloscope to the following test points:

Chl

-

a

1OX

(vertical sensitivity

-

2V/cm) scope probe to the channel speaker output.

Ch2

-

a IX scope probe (vertical sensitivity

-

0.

IV/cm)

to the distortion analyzer

output.

5. Set amp gain pots fully clockwise and turn on power switch.

6. Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.50

VRMS

1

kHz

sine wave.

7. Plug the amplifier into a variac and set up an AC line current monitor.

l POWER UP

&

MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a

50

ohm

225W

resistor (100 ohm,

240VAC) in series with the high

(+)

lead on the AC cable during variac ramp up. if the switching power

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

&

calibration process.

1. Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

0.5A

a.c

at 60 Volts).

This

is

slight/y

/ess

fof

24OV.

Pause at

9OVAC

(2OOVAC

European) for three seconds until the mute

/

protect circuit disengages.

Continue to

12OVAC

(24OV

European).

2. Verify that the fan is operating at low speed.

3.

Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

l CHANNEL OUTPUT

I. Look for amplified signal on the scope for channel

1.

Switch the input signal and scope

to channel 2 and repeat output test. Check for noisy

/

contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

2. Select an 8 ohm load and confirm that this amplifier is producing 425 watts at 1 kHz just

below the point of clipping. Check both channels.

l BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

#7

in the on position. The gain control, limiter, and filter switch positions

on CH2 are disabled with Mode Switch

#7

on.

3. Set load to both red output binding posts

(CHI

positive and CH2 negative).

4. Apply a 1.30

VRMS,

1

kHz

sinewave

input to channel 1 of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 1500 watts at 8

ohms.

5. Turn power off and place the amplifier under test back into the Stereo mode with output

loads connected to each channel.

l BIAS

1.

Let the amplifier cool down to room temperature.

2. With an input amplitude of

1.5OVrms,

increase the input frequency to

2OkHz.

Reduce the

input signal 20dB (80%) from full output. Adjust the crossover

trimpot

VR43

(CHl)

and

VR166 (CH2) for about a

4OOmVpk-pk

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike.

It is necessary to

disable the 80kHz

lowpass

filter on the analyzer for this test.Further trim so that

the total distortion for that channel is less than 0.1%

THD+N,

3. With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel

2.

l SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

1.3Vrms

sinewave (1

kHz)

input signal to both channels

of the amplifier.Ensure that power is on and that the gain controls are fully up.

2. While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel. In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A

ac. This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

should be

present just as it was before a short was applied for this test,

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

l FREQUENCY RESPONSE

1. Set load to 8 ohms and scale the input generator to gain 1 watt of power from the

amplifier on each channel. Gain controls on the amplifier should be fully up.

2. Check frequency response from

2OHz

to 20kHz

(+/-

0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to 20kHz). Check both

channels.

l POWER vs. DISTORTION TEST

1. Check to ensure that both channels will produce rated power at

2OHz,

2KHz,

and 20kHz.

into an 8 ohm load.

2. While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03%

THD.

l THERMAL TEST

1. Set input frequency to 1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about

11

-

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase, This is not a problem as long as the case temperature on the output

transistors does not exceed 105 degrees C.

4. Verify that the NTC circuit causes thermal shutdown after an extended period.

5,

When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes.

l CM TEST

I. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

114”

input jack halfway into each

channel and observe about 6

dB

of output voltage reduction. There will also be a 180

degree phase inversion at the output of the channel under test.

9

l OUTPUT NOISE

1. Set the amplifier gain controls all the way up, with a I

kHz

1.5OVrms

sinewave

input

signal.

Note the output level at full power just below clipping. Adjust gain if needed.

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

dB

down

from the full output power point measured. A signal to noise ratio should be better than

or equal to

107dB.

Check both channels.

l FINAL CHECK

This completes the amplifier test procedure for this model.Inspect the amplifier for

mechanical defects. Inspect the solder connections. Reassemble the amplifier and verify

the amplifier’s operation before returning the product to service,

PLX 3002 Test Procedure

l SET-UP

1. Connect a test load to the output terminals of the amplifier.

2. Make sure Mode Switches 1

-

10 are in the default position

(1

on, 10 on, all others off).

3.

Connect a distortion analyzer with a resolution of

O.Ol%,

20-20kHz

(or better) to the

output terminals of the amplifier. Enable the 80kHz low pass filter.

4. Connect a dual-channel oscilloscope to the following test points:

Chl

-

a

1OX

(vertical sensitivity

-

2V/cm)

scope probe to the channel speaker output.

Ch2

-

a

1X

scope probe (vertical sensitivity

-

O.lV/cm)

to the distortion analyzer

output.

5.

Set amp gain pots fully clockwise and turn on power switch.

6. Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.70

VRMS,

1

kHz

sine wave.

7. Plug the amplifier into a variac and set up an AC line current monitor.

. POWER UP 8 MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a

50

ohm 225W resistor (100 ohm,

240VAC) in series with the high

(+)

lead on the AC cable during variac ramp up. If the switching power

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

&

calibration process.

1.

Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

0.5A

a.c. at 60 Volts).

TIG.s

is

s/ight/y

less for

24UV.

Pause at

9OVAC

(2UOVAC

European) for three seconds until the mute

/

protect circuit disengages.

Continue to

12OVAC

(240V European).,

2. Verify that the fan is operating at low speed.

3. Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

l CHANNEL OUTPUT

1.

Look for amplified signal on the scope for channel 1. Switch the input signal and scope

to channel 2 and repeat output test. Check for noisy I contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

10

2. Select an 8 ohm load and confirm that this amplifier is producing

550

watts at 1 kHz just

below the point of clipping. Check both channels.

l BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

#7

in the on position. The gain control, limiter, and filter switch positions

on CH2 are disabled with Mode Switch

#

7 on.

3. Set load to both red output binding posts

(CHI

positive and CH2 negative).

4. Apply a 1.30

VRMS,

1

kHz

sinewave input to channel 1 of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 2000 watts at 8

ohms.

5. Turn power off and place the amplifier under test back into the Stereo mode with output

loads connected to each channel.

l BIAS

1.

Let the amplifier cool down to room temperature.

2. With an input amplitude of

1.7OVrms

increase the input frequency to 20kHz. Reduce the

input signal 20dB

(80°h)

from full output. Adjust the crossover

trimpot

VR43

(CHI)

and

VRl66

(CH2) for about a

4OOmVpk-pk

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike. It is necessary to

disable the 80kHz

lowpass

filter on the analyzer for this test.Further trim so that

the total distortion for that channel is less than 0.1% THD+N.

3,

With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel

2.

l SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

1.3Vrms

sinewave (1

kHz)

input signal to both channels

of the amplifier.Ensure that power is on and that the gain controls are fully up.

2,

While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel. In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A

ac. This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

should be

present just as it was before a short was applied for this test.

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

l FREQUENCY RESPONSE

1. Set load to 8 ohms and scale the input generator to gain I watt of power from the

amplifier on each channel. Gain controlson the amplifier should be fully up.

2. Check frequency response from

2OHz

to 20kHz

(+I-

0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to 20kHz). Check both

channels.

11

l POWER vs. DISTORTION TEST

1.

Check to ensure that both channels will produce rated power at

2OH2,

2KHz,

and 20kHz.

into an 8 ohm load.

2. While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03% THD.

l THERMAL TEST

I. Set input frequency to

1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about 11

-

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase. This is not a problem as long as the case temperature on the output

transistors does not exceed 105 degrees

C.

4. Verify that the NTC circuit causes thermal shutdown after an extended period.

5. When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes.

l CM TEST

1. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

114”

input jack halfway into each

channel and observe about

6

dB

of output voltage reduction. There

will

also be a 180

degree phase inversion at the output of the channel under test.

l OUTPUT NOISE

1. Set the amplifier gain controls all the way up, with a 1

kHz

1.7OVrms

sinewave

input

signal.

Note the output level at full power just below clipping. Adjust gain if needed.

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

dB

down

from the full output power point measured. A signal to noise ratio should be better than

or equal to

107dB.

Check both channels.

l FINAL CHECK

This completes the amplifier test procedure for this model.

Inspect the amplifier for

mechanical defects. Inspect the solder connections. Reassemble the amplifier and verify

the amplifier’s operation before returning the product to service.

12

T r o ubleshooting

PLX 1202 l PLX 1602 l PLX 2402 l PLX 3002

Power Supply

-

-

Replacing Blown

IGBTs.

In order to improve

EMI

performance, reduce cost, and increase current capacity, the PLX

IGBTs

are driven by an active, direct coupled integrated circuit, rather than a gate drive transformer.

IGBT

or

driver failure should be rare (when correctly assembled) but when the

IGBT’s

blow, it usually damages the

following parts:

CHECKLIST AFTER BLOWN

IGBT’S

Q96, Q97,

(IGBT’s

generally fail in pairs)

D78, D79,

R358,

R359,

gate drive coupling

comonents,

check after removing blown

IGBT’s.

Ul8,

lR2110

high-side gate driver, Fault current when low-side

IGBT

shorts to upper rail. Such currents

also typically damage the gate coupling parts noted above.

Ul9,

3525 controller, Blows from currents shorted

thru

Ul8,

or possibly by overvoltage on the supply rail

SOMETIMES

Ul4,

556,

powered from

5V

output of 3525, which may fail high when 3525 fails.

RARELY

Ul3,

which has fairly high supply voltage ratings.

PROBABLE CAUSES OF MASSIVE

IGBT

FAULTS

SHORTS IN CONTROL CIRCUIT.

The parts operate well within their ratings and should hold up well in the field. The usual cause of failure is

when both

IGBT’s

turn on at once, shorting Pri-Hi to Pri-Lo. This occurs when something causes the drive

signal to one part to remain on when the other part is supposed to turn on. Shorts from solder or debris are

one obvious cause.

SHORTS IN THE LOAD.

Although there is peak current shutdown, shorts in the power amplifier transistors or secondary-side supply

components can cause currents to increase too quickly to prevent damage.

OVERVOLTAGE ON THE BIAS SUPPLY.

If the TOP-210 bias supply fails to operate, no harm occurs, the unit simply does not operate.

However, open circuit (missing part) in several key components can cause the Bias supply voltage to be

much too high, This blows the 2110 and thus the

IGBT’s.

QUICK TEST OF BIAS SUPPLY.

Ramp the AC voltage up slowly to 25% of regular voltage (30V for

12OV

unit). If the bias supply is working

normally, the green “power” LED should come on between 30 and

35Vz

with its usual, steady

“half-brighr

start-up level. If the LED comes on at

2OV,

or not until

5OV,

or blinks, DO NOT RAISE VOLTAGE PAST 60V

until you have measured the bias voltage. The switching will not start until you reach

9OV,

so you can save

the

IGBT’s

from blowing.

Confirm that bias voltage at Cl38 is

18-19V.

Open or missing

D63,

64, 65, 66, 67 or R349 will break the

feedback to U16 and cause overvoltage.

13

Troubleshooting “TOP-210” Bias Supply.

QUICK TEST OF BIAS SUPPLY.

Ramp the AC voltage up slowly to 25% of regular voltage (30V for

12OV

unit). If the bias supply is working

normally, the green “power” LED should come on between 30 and

35V,

with its usual, steady

“half-brighf’

start-up level.

CAUTION: if the LED comes on at

2OV,

or not until

5OV,

or blinks, DO NOT RAISE VOLTAGE PAST 60V

until you have measured the bias voltage. The switching will not start until you reach

9OV,

so you can save

the

IGBT’s

from blowing.

Confirm that bias voltage at Cl38 is

18-19V.

BIAS SUPPLY VOLTAGE MUCH TOO HIGH

D63,64,65,66,67

or R349 open or missing -- breaks feedback to U16

NO BIAS SUPPLY VOLTAGE

U16 missing or blown.

Tl missing, reversed, or open primary

D62 open or missing.

BIAS VOLTAGE ERRORS

The exact voltage is controlled by the feedback through

D63,

64_

65, 66, 67 and R349 as follows:

Cl38 is the

“+18V’

rail with about

18.8V

typical.

D63,

64, 65 each subtract a diode drop

(0.7V)

from Cl38.

Cl39

,

is the

“+16V”

rail with about

16.6V

typcial.

D66,

a

IOV

zener

diode

,

plus diode

D67,

subtract about 1 IV from

+16.6V.

R349 subtracts about

0.5V,

bringing the net voltage at

Ul6,

feedback pin 4, to about

5.lV.

Ul6

uses this feedback to adjust the “on” time at pin 5, in order

toraise

or lower the

flyback

voltage

charging Cl38 and thus maintain regulation of the

+16V

and

+18V

supplies

C142,

R356,

and R349 form a closed-loop stability circuit which prevents the regulated voltage from

“hunting”.

Q99

and associated R374 reduce the voltage of the Bias supply by 33% when the AC voltage is turned off.

This prevents the Power LED from showing at half brightness after turn-off, since U16 continues to run

from the main filters for some time after shut down R375 and 376 sense the output of

Ul3:3,

the “Loss of

AC” comparator, and cause

Q99

to turn on. If

Q99

is shorted, the bias voltages will remain 33% low when

AC is turned on.

REPLACING BLOWN TOP-210.

If U16 has blown, check T-l for continuity after removing

Ul6.

Its primary may be open. Pins I-2 It should

measure about 15 ohms

Replacing Blown Output Transistors

OUTPUT TRANSISTOR SHORTED

Stmrk

in one device tend to cause the opposing device to blow as

well,

If an output transistor shorts:

Drive transistor will be shorted

(Q26,

Q27,

Q71,

Q72)

CXNne

transistors will short in pairs (Q39

&

Q40,

Q36

&

Q37,

Q84

8

Q85,

Q81

8,

Q82)

The rest will short in fours

(Q28,

Q29,

Q34

&

Q35;

Q73,

Q74,

Q79

8,

Q80)

IGBT’s

8 their associated components may

fail

14

CHECK EMITTER AND BASE RESISTORS WHILE DEVICES ARE REMOVED,

Each output transistor has an associatated pair of 0.47 ohm resistors in parallel.

Each BANK of output transistors has a 15 ohm resistor from base to rail (emitter bus).

Audio Outputs, Troubleshooting Current Limit

WEAK CURRENT LIMIT -- PREMATURE CLIPPING.

The usual symptom of weak output current is premature clipping of one or more peaks of the audio voltage.

This could be caused by missing step, weak current limit, or dead output section.

PREMATURE CLIPPING at 60% VOLTAGE, SIMILAR AT ALL IMPEDANCES:

This points to a step problem (2402, 3002 only). See Step Troubleshooting.

If the amplifier reaches full voltage at 8 ohms, but prematurely clips at 4 ohms or 2 ohms, we can assume

the step is OK but the output current is too low (see below).

NO OUTPUT AT ALL ON ONE POLARITY.

This indicates complete failure (open circuit) in the circuit leading to the dead output polarity. Check the

series components in the current splitter for missing or open:

Ch 1:

Positive,

Ql9,

R381,

Q20,

R70,

DIO,

D14. Negative:

Q22,

R382,

Q21,

R71,

Dl

I,

D12

Ch 2:

Positive,

Q64,

R383,

Q65,

Rl93,

D35,

D39. Negative:

Q67,

R384,

Q66,

Rl94,

D36,

D37

CONSTANT, PREMATURE CLIPPING, WORSE AT LOW IMPEDANCES.

First, check the clamping voltages on

C21

(Ch

I+),

C22 (Ch I-),

C56

(Ch

2+),

C57

(Ch

2-),

as shown in

table below. At idle, all four voltages should all be similar. If one is out, check parts according to the

following table

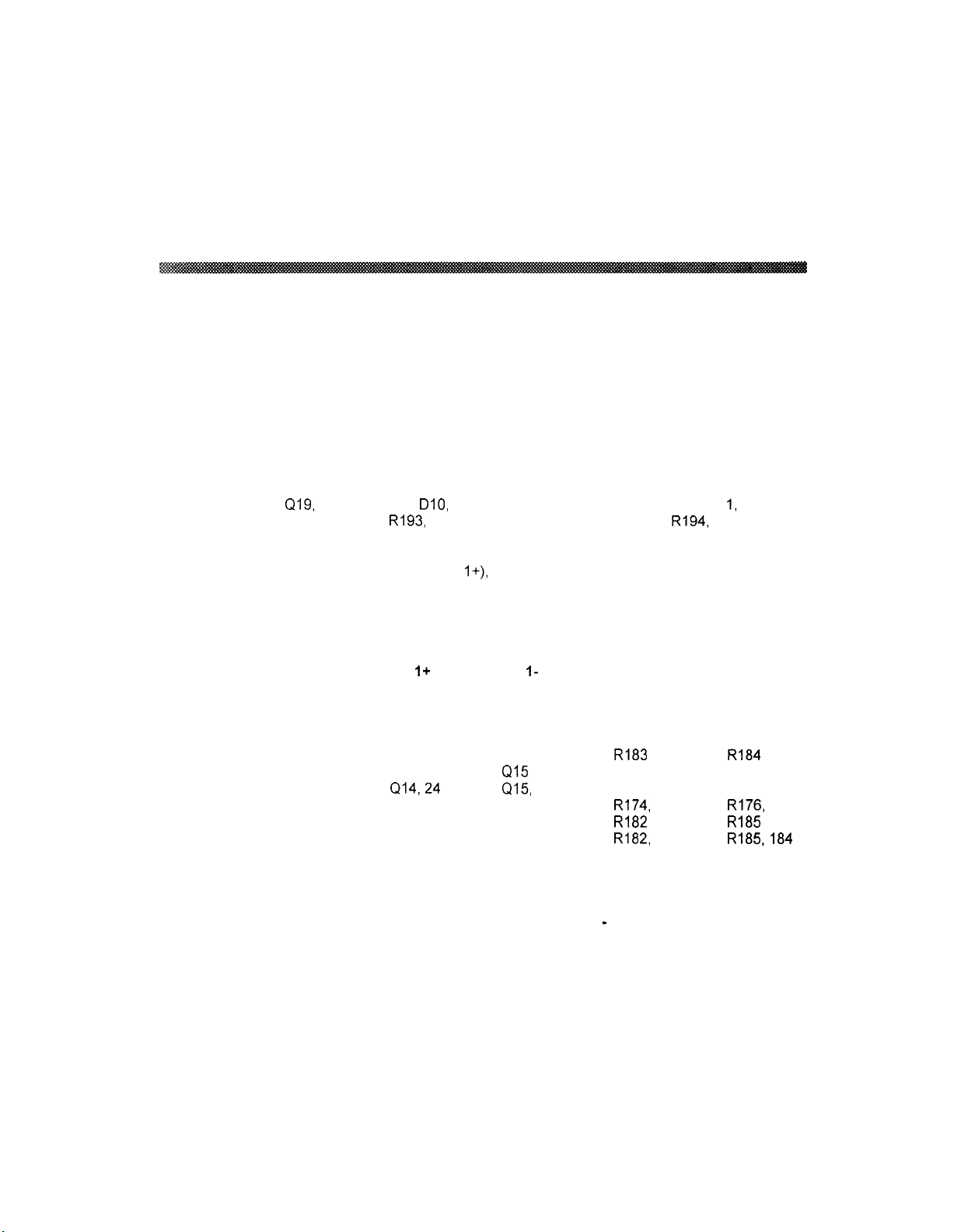

CLAMPING VOLTAGES ARE WRONG AT IDLE

CHANNEL-POLARITY

Measure voltage on:

3002 and 2402, about

6V.

1602, about

4,6V,

1202 about

4.9V.

Voltage too high: missing resistor:

or missing transistor:

Voltage

0-0.3V:

shorted transistor

or missing resistor

Voltage

0.7V,

missing resistor:

Voltage wrong: wrong value

CH

I+

CH

l-

c21

c22

R60

Q14

Ql4,24

R

51,

72

R59

R59,60

R61

Ql5

Ql5,

25

R53,

75

R62

R62,61

CH

2+

C56

RI83

Q59

Q59,69

Rl74,

195

RI82

Rl82,

183

CH

2-

c57

RI84

Q60

Q60,70

Rl76,

198

RI85

Rl85,184

The exact voltage varies with temperature. Look for the mismatching value on the weak cell.

A too-low voltage causes early clamping of that output section, as explained in the previous several pages.

If the voltage is correct and current is still low, also check for missing

-

unsoldered output device, or emitter

resistors.

15

Audio Power Stage, Current Limit Troubleshooting

CURRENT LIMITS WHICH COLLAPSE PREMATURELY.

An immediate collapse of ALL current limits at full power could be premature triggering of “Power Supply

Cutback”, which is described in the section below. Cutback after several seconds of full power operation at

two ohms is normal.

Cutback of one or more output sections, at full temperature, while approaching full power into two ohms is

also normal. However, cutbacks at 4 ohms, or when cold into two ohms, indicate problems with the

transistor power measuring circuitry.

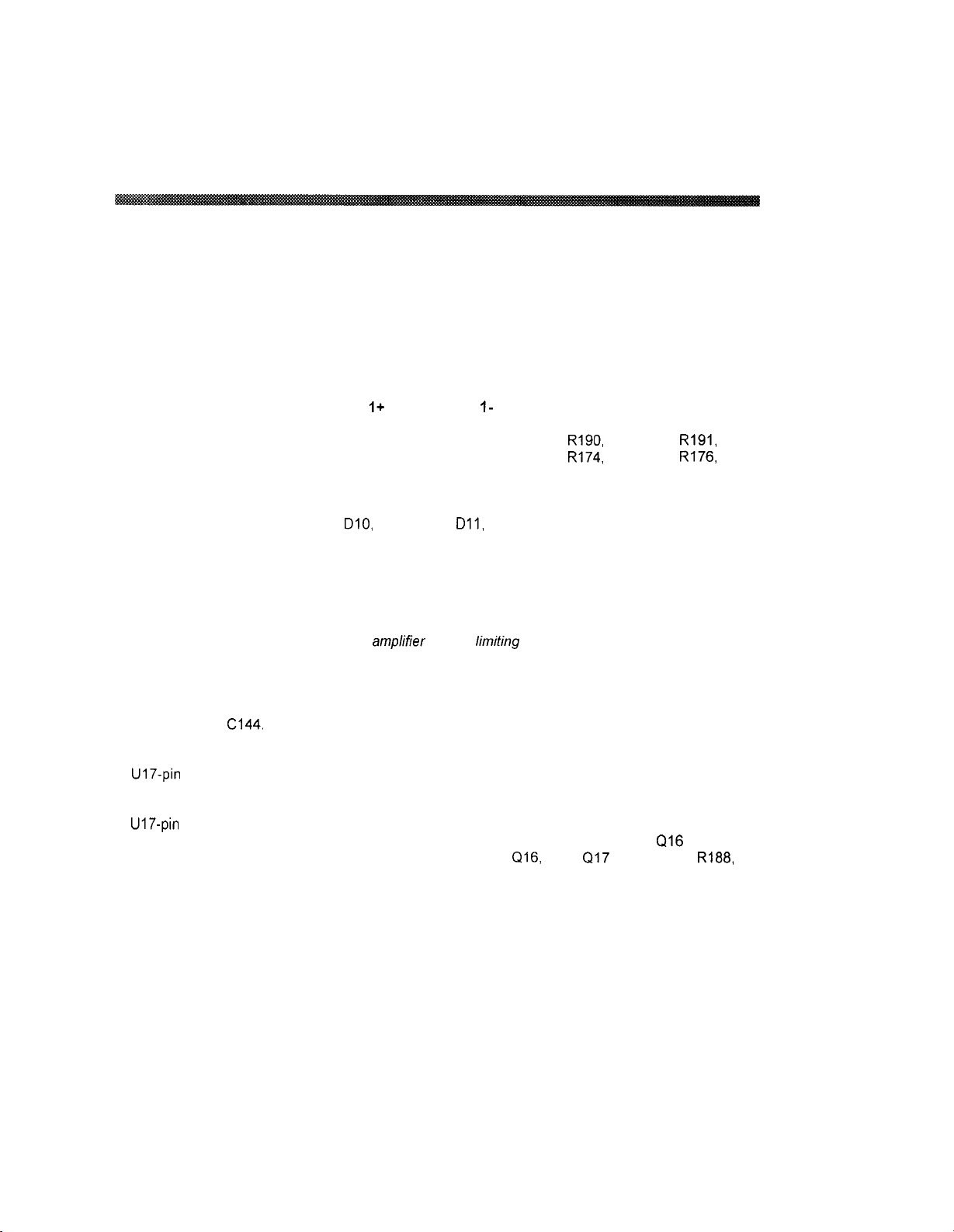

CLAMPING VOLTAGES COLLAPSE TOO SOON.

CHANNEL-POLARITY

CH

I+

CH

l-

CH

2+

CH

2-

Measure voltage on:

c21

c22

C56

c57

Cuts back too easily: low value,

R67,

73

R68,

74

Rl90,

196

Rl91,

197

or high value:

R

51,

72

R53,

75

Rl74,

195

Rl76,

198

or missing diode:

D9

D8

D34

D33

CLAMPING VOLTAGES ARE CORRECT, CURRENT STILL WEAK.

Shorted diode

DIO,

14

Dll,

12

D35,

39

D36,

37

Missing-unsoldered output device or emitter resistor.

TROUBLESHOOTING “POWER SUPPLY CUTBACK”.

As noted in the section on Power Supply, the amplifier’s current limit cuts back when necessary to protect

the power supply. Because the Observed effect is a reduced output voltage, in response to prolonged

operation above the long-term current limit, we commonly refer to this behavior as “power supply cutback”,

but we must remember that it is actually

amp/Tier

current

hmifhg

in response to an overload signal sent

from the power supply. Full power operation into 2 ohms (both channels) should produce a 50% cutback of

current after several seconds.

If both channels of the amplifier fail to cut back after about 3 seconds, 2-ohms, both channels driven, the

cutback signal is probably missing. CAUTION: Prolonged operation under these conditions could blow

IGBT

or burn out

Cl44.

Test for 6-10 seconds maximum.

Check the output (secondary side) pins of U17 (sh 4). Confirm presence of

+6V

on pin

5.

Pin 4 should

normally be at about

OV,

and go high (I-5V) after 3 seconds at full power,

If

Ul7-pin

4 does not go high, check U17 itself. If it appears OK, trace the circuitry driving U17 (PRIMARY

SIDE, CAUTION). Check for continuity through

L6:2

to Pri-Lo, check missing or open

R343,

D61,

Q95,

R347,

all of which drive optocoupler U17. A short in R346 or Cl31 will also prevent drive to U17.

If

Ul7-pin

4 goes high on schedule, and BOTH channels fail to cut back, trace voltage on

“PS_OL”

bus to

R273 (sh

3),

which connects to “MUTE+” bus. Continue tracing voltage on MUTE+ to

Ql6

(sh I) and

Q61

(sh 2). If only ONE channel fails to cut back, look for missing

Ql6,

R 65,

Ql7

(sh I) or

Q61,

Rl88,

Q62

(sh 2).

Cl31 controls the speed of cutback.. If missing, the amplifier current limits will enter cutback almost

immediately at or above full power, 4 ohms.

SHORT CIRCUIT CURRENT DOESN’T CUT BACK.

CAUTION: DO NOT MAINTAIN A SHORTED LOAD IF CUTBACK FAILS TO OCCUR WITHIN 1 SECOND.

It will be necessary to measure the output current with a DC current probe, or by noting the voltage across

a low value resistance with a DC scope, in order to determine which output cell is failing to cut back.

Failure to cut back could indicate either lack of clamping, or lack of voltage cutback. Measure the voltage

on the respective clamp capacitor. If the voltage decreases, but current limiting does not cut back, check

the clamping transistor.

:

16

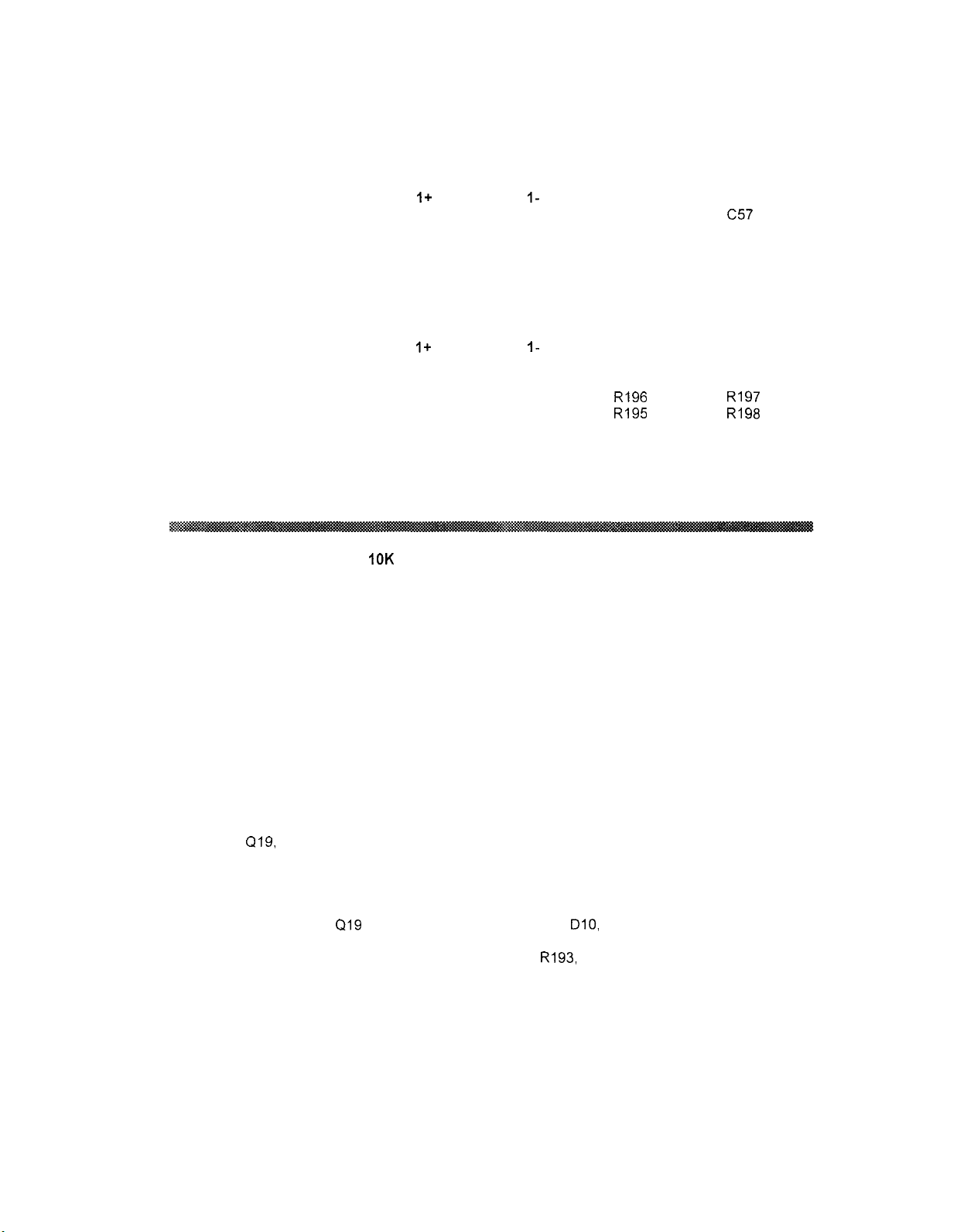

CLAMPING VOLTAGE DECREASES, BUT NO CURRENT CUTBACK

CHANNEL-POLARITY CH

I+

CH

l-

CH

2+

CH

2-

Measure voltage on:

c21

c22

C56

C5?

Check clamp transistor

Q18

Q23

Q63 Q68

If the measured voltage on the clamp capacitor is not decreasing to about 50% during the short, check the

circuitry which measures the current during short circuit,

CLAMPING VOLTAGE DOES NOT DECREASE TO 50% DURING SHORT.

CHANNEL-POLARITY

CH

I+

CH

l-

CH

2+

CH

2-

Measure voltage on:

c21

c22

C56

c57

Missing cutback transistor, resistor

Q24,

R67

Q25,

R68

Q69,

RI90

Q70,

RI91

Missing voltage sense resistor,

R 73 R 74

RI96 RI97

Shorted or low value shunt resistor R72

R75

RI95

RI98

Troubleshooting Thermal Tracking

MOUNTING PROBLEMS WITH IOK SENSING NTC.

The thermal sensing for fan and bias tracking depends on a 1 OK NTC which is mounted in a hole in the

heat sink. The hole is filled with thermal grease to improve coupling. If the NTC is not straight while

mounting the heat sink, it may short out against the side of its hole. It is mounted on a standoff which

protrudes into the hole, so this should not occur if care is taken while installing the heatsink.

If shorted to the heat sink, the amplifier output voltage is coupled to the NTC. If the short is to the grounded

lead of the

NTC,

it may not damage anything. If to the other end, a large voltage is put across the NTC

which will probably damage it.

SHORT FROM “LIVE” END OF NTC TO HEAT SINK:

Replace affected NTC

BE AWARE! This can short (relatively) quietly and then appear to be operating normally. Poor bias

tracking can indicate this problem. Sometimes this short will not happen until the amplifier is driven past IV

input.

NTC BENT OVER AND SHORTED TO DRIVER TRANSISTORS.

May touch

Ql9,

Q26,

or

Q64,

Q71.

This causes severe overcurrent to the affected output cell, possibly damaging the parts in series with the

shorted transistor. It may also blow the power supply.

Replace affected

NTC,

drive transistors, check components in series with drive transistor

Ch 1:

Ql9

shorted, check,

R381,

Q20,

R70,

DIO,

D14.

Q26 shorted, check ALL outputs and opposing driver transistor on this channel.

Ch 2:

Q64 shorted, check

R383,

Q65,

Rl93,

D35,

D39.

Q71

shorted, check ALL outputs and opposing driver transistor on this channel.

17

Audio Output, Troubleshooting Stability Feedback

HIGH FREQUENCY OSCILLATIONS

SEVERE-DRAWS CURRENT-GROSS DISTORTION

C27 (62) missing or wrong, or series R367 (368)

C 25, 26 (60, 61) missing

Secondary filter capacitors missing or open (unlikely that ALL are defective).

SEVERE, BUT DOES NOT DRAW LARGE CURRENT

R22 (146) open.

MARGINAL -- MAY APPEAR ONLY AS EXCESS DISTORTION

Cl4 (49) missing

Cl 6 (50) missing or too large

C28 (63) missing

C 25 or 26 (60 or 61) missing or too large

Cl95 or 196 missing (input board).

EXCESSIVE OSCILLATION JUST BELOW CLIPPING, 2-4 ohms

Cl 7 (52) missing

NOTE: about 0.1% oscillation right below clipping at 2 ohms is normal.

EXCESSIVE SWITCHING INTERFERENCE.

Switching interference may LOOK like an instability, however it is at a much lower frequency

(1lOkH.z)

than

most instabilities. It will be more visible at low frequencies

(2OOHz)

and at lower impedances.

Missing jumper at

R224.

Missing

Cl29,

134 on output board.

Grounds not connected to chassis at output board and front chassis mounting screw.

FEEDBACK PROBLEMS: GAIN INCORRECT

Gain of output stage set by

R23,

31 (147, 153)

Gain of Ch 1 volume control buffer stage set by RI

1,

16.

Gain of Ch 2 volume control buffer stage set by

Rl37,

139. Make sure

Q48

is turned on

-

grounding

RI37

at Q48 should not affect gain. Check RI 32 (drives Q48).

Gain of balanced input is set by 4 matched resistors

R9,

8, 12, 13 (129, 130, 135, 136). Confirm both sides

of balanced input are working. Check

R5,

6 (123, 124).

Audio Output, Troubleshooting Clipping, Limiting

EXCESS STICKING (TOO MUCH DISTORTION DURING CLIP LIMITING)

Cl4 (49) much too large (also causes increased high frequency distortion).

R38 (161) missing.

R38-39

(161-162) have wrong values.

Q9,

10 (54, 55) missing

R34 (157) or

R35

(158) missing

Q8

(53) missing

18

CLIP LIMITING DOESN’T WORK:

BOTH CHANNELS:

Check U3 missing,

Check U3 supply voltages, +I

3VCL,

-13VCL,

on

C73*

74

ONLY ONE CHANNEL BAD:

Probe output of U2

(7),

pin 7 while clipping. If output exceeds 4V during clipping, check

:

R38 (161) missing.

R38-39

(161-162)

have wrong values.

Q9,

10 (54, 55) missing.

R34 (157) or

R35

(158) missing

Q8 (53) missing

If output at pin 7 clamps at

3.5.4V

as expected, check parts surrounding U3:

R32 (154) missing

Q7 (52) missing

R28 (151) missing

Q6 (51) missing

RI8

(141) missing

RI9 (142) missing

SW I:1 (1:lO) not making contact

Check each pin on U3

CLIP LIMITING OSCILLATES:

Cl 3 (48) missing.

R21,

27 (144, 150) missing

Troubleshooting Step Problems

EXCESSIVE STEP DISTORTION (STEP GLITCH)

Close scrutiny of the distortion trace, and scope probing of the switched waveform, will help determine the

cause of excess step distortion, The step should switch when the output voltage is within IO-12 volts of its

respective rail, This switching margin should be fairly constant from

20-

20kHz. The switching event itself

should be a fairly uniform up and down ramp, moving at about 25 volts/us, therefore taking about

2us

to

complete its transition.

Step Switching Too Close

to

the

Rail:

This will cause increased step glitch, especially at low impedances. If present at all frequencies,

check the reference voltages:

Negref: 17.5 volts above its intermediate rail:

D88,

R276-7-8.

PosRef:

20V below its intermediate rails:

D87,

R256,

257,

D53.

Confirm correct values in output voltage divider: R48 loaded by

R49-50

(Rl71,

and

Rl72-173).

If present

only at high frequencies, check the value of the speed up capacitor

C20

(C55)

in the output voltage divider,

or look for slow switching (see below).

19

Step Chattering.

If the step repeatedly switches on and off, usually at a low frequency, it creates an oscillation burst

which increases step glitch at low frequency. The tendency is usually worse at low impedances

and low frequencies. 2-3 “false trials” at very low frequency, 2 ohms, is normal, but prolonged

bursts of maximum frequency chattering may cause FET failure.

Positive step: check hysteresis resistor R66 (RI 89)

Negative step: check hysteresis resistor R69 (RI 92) and capacitor Cl 87 (Cl 93).

Slow or Fast Switching.

Slow switching reduces step glitch but puts more strain on the FET. Fast switching increases step

glitch. The usable limit is

17-27

volts/us,

If both slopes are equally off speed, check the slope capacitors:

Positive,

C30

(C65)

and Negative, C29 (C64).

If only one slope is slow, check the resistors and buffer transistors:

Positive step:

R78,

79,

Dl5,

Q30-31

(R201,

202,

D40,

Q7576)

Negative step:

R83,

84,

Dl7,

Q32-33

(R206,

207,

D42,

Q77-78).

Step FET Oscillation.

Certain FET types oscillate at extremely high frequency while ramping up and down. This injects

interference into the amplifier which increases the step glitch. Such problems are supposed to be

found while

(dis)qualifying

specific FET types. If they crop up in production, Engineering needs to

know.

STEP WON’T TURN ON (Premature Clipping)

If the step refuses to switch high, the amp will clip prematurely, at the intermediate rail, at any load. Make

sure the clipping is not

acually

current cutback, usually evident only at 2 ohms. Probe the output voltage

and intermediate rail voltages to confirm clip point and lack of step action. Trace the circuit from the step

FET back via gate drive to drive circuit to locate cracks, missing part etc. Check DC power on step driver

(14V

on EACH positive step drivers,

12V

on BOTH negative drivers). Check voltage of

PosRef

(20V below

+65V

rail) or Negref

(17.5V

above

-65V

rail). Look for severe mismatches of the comparator resistor

ladders.

STEP STUCK ON (Switched Rail Voltage Stuck On Full)

If the positive step is stuck on, (evidenced by permanent high voltage on switched rail) the FET is probably

bad, since the positive gate drive cannot sustain DC turn-on due to the bootstrapping. If the negative step

is stuck on, it could be a bad

FET,

or the gate drive circuit could be holding the FET on, which will easily be

confirmed by measuring the gate voltage. Malfunctioning gate drive circuitry should be checked as noted

above under “Won’t Turn On”.

REPEATED FET FAILURE.

Repeated failure of step

FET’s

is usually caused by failure to fully switch ON or OFF (lingering in the linear

region). The actual failure usually occurs at 2 ohms, where the dissipation is highest. After replacing the

FET,

the step waveform should be monitored, starting at light load to avoid repeated failure, and advancing

briefly to heavier loads while closely watching the waveform. You will need to use an isolated scope probe

which allows voltage readings to be taken with respect to the intermediate rails, or to FET sources.

FET Does Not Fully Turn On:

Generally causes problems at low frequency, 2 ohms.

Confirm that the step FET remains fully on for the entire cycle

(2OHz).

If not, confirm weak gate

drive and determine cause.

Weak positive drive: check voltage on C32

(C51)

for

14V.

Check

C31

(C66),

low RIO4

(R227),

missing D18

(Dl48).

Check

R78,

Dl5,

Q30

(R201,

D40,

Q75).

Weak negative drive: check voltage on

C67,

12V.

Check

R83,

Dl7,

Q32

(R206,

D42,

Q77).

20

FET Turns On or Off Very Slowly:

Generally causes problems at high frequency, 2 ohms.

If both slopes are equally slow, check the slope capacitors:

Positive,

C30

(035)

and Negative, C29 (034).

If only one slope is slow, check the resistors and buffer transistors:

Positive step:

R78,

79,

Dl5,

Q30-31

(R201,

202,

D40,

Q75-76)

Negative step:

R83,

84,

Dl7,

Q32-33

(R206,

207,

D42,

Q77-78).

Severe Step Oscillation.

Generally observed at low frequency, low impedance, right at threshold.

Positive step: check hysteresis resistor

R66

(RI 89)

Negative step: check hysteresis resistor

R69

(RI 92) and capacitor Cl 87 (Cl 93)

Troubleshooting DC Fault Shutdown

NORMAL BEHAVIOR OF THE CIRCUIT.

Any amplifier fault which causes a non-symmetrical output, such as premature clipping of one polarity, a

missing step,

etc,

may trigger DC fault shutdown. This indicates normal operation of the circuit

TRACING THE CAUSE OF FALSE TRIGGERS.

If amplifier is shutting down for no apparent cause, the source of the false signal must be found. Be sure the

output is checked with a DC coupled scope in order to confirm absence of an actual DC offset. The circuit

will trip on DC offsets exceeding about

4V.

The optocoupler’s input can be safely disabled by shorted

Ul5,

pins I-2 together. This will indicate if false

triggering is before or after

Ul5.

The output of

UlO:l,

pin 1 should be monitored. If it goes low during DC shutdown, it is sending the false

signal.

SHUTDOWN OCCURS AS SOON AS SWITCHING STARTS.

Disable

Ul5

as noted above, determine if there is a DC fault condition. CAUTION: use

50-ohm

resistor in

series with AC line to limit fault current in case of shorted outputs.

If amplifier output looks OK, check UlO:l output. If low, check voltage on pins 2 and 3

UlO:l,

pin 2: should be zero (no signal)

UlO:l,

pin

31

should be about

2V!

set by

R243,

244, 245.

Check R348 at Ul.5.

SHUTDOWN OCCURS ABOVE ABOUT 4V OUTPUT:

Q87,

C7,

R240

or D48 missing.

Confirm D48 is pulled low

(-13V),

holding Q87 on. If not, check RI 17, 118, Q42

NOTE: this control voltage responds to the Br Mono switch, pole

7.

Check R348 at

Ul5.

Bad connection at step diodes

(D21,

D22,

D46,

D47)

21

Loading...

Loading...