Piaggio MP3 400 Service Manual

SERVICE STATION MANUAL

664502(IT)-664503(EN)-664504(FR)-664505 (DE)-664506(ES)-664507(PT)-664508(NL)-664509 (EL)

MP3 400 i.e.

SERVICE STATION

MANUAL

MP3 400 i.e.

The descriptions and illustrations given in this publication are not binding. While the basic specifications as described and illustrated in this manual remain unchanged, PIAGGIO-GILERA reserves the right, at any time and without being required to update this publication beforehand, to make any changes to components, parts or accessories, which it considers necessary to improve the product or which are required for manufacturing or construction reasons.

Not all versions shown in this publication are available in all Countries. The availability of single versions should be checked at the official Piaggio sales network.

"© Copyright 2007 - PIAGGIO & C. S.p.A. Pontedera. All rights reserved. Reproduction of this publication in whole or in part is prohibited."

PIAGGIO & C. S.p.A. - After-Sales

V.le Rinaldo Piaggio, 23 - 56025 PONTEDERA (Pi)

SERVICE STATION MANUAL

MP3 400 i.e.

This service station manual has been drawn up by Piaggio & C. Spa to be used by the workshops of Piaggio-Gilera dealers. It is assumed that the user of this manual for maintaining and repairing Piaggio vehicles has a basic knowledge of mechanical principles and vehicle repair technique procedures. Any significant changes to vehicle characteristics or to specific repair operations will be communicated by updates to this manual. Nevertheless, no mounting work can be satisfactory if the necessary equipment and tools are unavailable. It is therefore advisable to read the sections of this manual concerning special tools, along with the special tool catalogue.

N.B. Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious damage to the vehicle and sometimes even the invalidity of the guarantee.

INDEX OF TOPICS

CHARACTERISTICS |

CHAR |

|

|

|

|

TOOLING |

TOOL |

|

|

|

|

MAINTENANCE |

MAIN |

|

|

|

|

TROUBLESHOOTING |

TROUBL |

|

|

|

|

ELECTRICAL SYSTEM |

ELE SYS |

|

|

|

|

ENGINE FROM VEHICLE |

ENG VE |

|

|

|

|

ENGINE |

ENG |

|

|

|

|

INJECTION |

INJEC |

|

|

|

|

SUSPENSIONS |

SUSP |

|

|

|

|

BRAKING SYSTEM |

BRAK SYS |

|

|

|

|

COOLING SYSTEM |

COOL SYS |

|

|

|

|

CHASSIS |

CHAS |

|

|

|

|

PRE-DELIVERY |

PRE DE |

|

|

|

|

TIME |

TIME |

|

|

INDEX OF TOPICS

CHARACTERISTICS |

CHAR |

Characteristics |

MP3 400 i.e. |

|

|

This section describes the general specifications of the vehicle.

Rules

This section describes general safety rules for any maintenance operations performed on the vehicle.

Safety rules

-If work can only be done on the vehicle with the engine running, make sure that the premises are wellventilated, using special extractors if necessary; never let the engine run in an enclosed area. Exhaust fumes are toxic.

-The battery electrolyte contains sulphuric acid. Protect your eyes, clothes and skin. Sulphuric acid is highly corrosive; in the event of contact with your eyes or skin, rinse thoroughly with abundant water and seek immediate medical attention.

-The battery produces hydrogen, a gas that can be highly explosive. Do not smoke and avoid sparks or flames near the battery, especially when charging it.

-Fuel is highly flammable and it can be explosive given some conditions. Do not smoke in the working area, and avoid open flames or sparks.

-Clean the brake pads in a well-ventilated area, directing the jet of compressed air in such a way that you do not breathe in the dust produced by the wear of the friction material. Even though the latter contains no asbestos, inhaling dust is harmful.

Maintenance rules

-Use original PIAGGIO spare parts and lubricants recommended by the Manufacturer. Non-original or non-conforming spares may damage the vehicle.

-Use only the appropriate tools designed for this vehicle.

-Always use new gaskets, sealing rings and split pins upon refitting.

-After removal, clean the components using non-flammable or low flash-point solvent. Lubricate all the work surfaces except the tapered couplings before refitting.

-After refitting, make sure that all the components have been installed correctly and work properly.

-For removal, overhaul and refit operations use only tools with metric measures. Metric bolts, nuts and screws are not interchangeable with coupling members with English measurement. Using unsuitable coupling members and tools may damage the scooter.

-When carrying out maintenance operations on the vehicle that involve the electrical system, make sure the electric connections have been made properly, particularly the ground and battery connections.

CHAR - 2

MP3 400 i.e. |

Characteristics |

|

|

Vehicle identification

Chassis prefix (A)

ZAPM59101

Engine prefix (B):

M474M

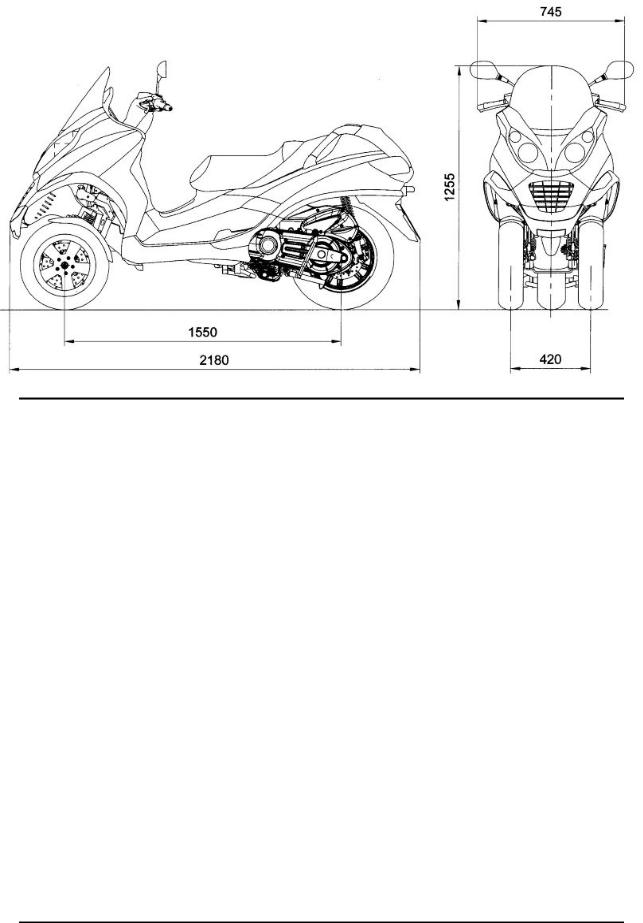

Dimensions and mass

WEIGHTS AND DIMENSIONS

Specification |

Desc./Quantity |

Kerb weight |

253 ± 5 kg |

Maximum weight allowed |

445 kg |

Maximum height |

1.225 mm |

Width |

745 mm |

Wheelbase |

1.550 mm |

Length |

2.180 mm |

Track |

420 mm |

CHAR - 3

Characteristics |

MP3 400 i.e. |

|

|

Engine

|

|

ENGINE |

|

|

Specification |

Desc./Quantity |

|

|

Type |

Single-cylinder, 4-stroke |

|

|

Cubic capacity |

399 cm³ |

|

|

Bore x stroke |

85.8 X 69 mm |

|

|

Compression ratio |

10.6 ± 0.5 : 1 |

|

|

Engine idle speed |

1,500 ± 100 rpm |

|

|

Timing system |

Four valves, single overhead camshaft, chain driv- |

|

|

|

en. |

|

|

Valve clearance |

Inlet: 0.15 mm |

|

|

|

Outlet: 0.15 mm |

|

|

MAX. power |

24 kW at 7,250 rpm |

|

|

MAX torque |

38 Nm at 5.250 rpm |

|

|

Lubrication |

Engine lubrication with trochoidal pump (inside the |

|

|

|

crankcase), oil filter and pressure adjustment by- |

|

|

|

pass. |

|

|

Lubrication pressure |

3.5 ÷ 4 bar |

|

|

Minimum lubrication pressure (100° C) |

0.8 bar |

|

|

Fuel supply |

Electronic injection with Ø38-mm throttle body and |

|

|

|

electric fuel pump. |

|

|

Cooling |

Forced coolant circulation system. |

|

|

Fuel |

Unleaded petrol (95 RON) |

|

|

|

|

|

CHAR - 4

MP3 400 i.e. |

Characteristics |

|

|

Transmission

|

TRANSMISSION |

Specification |

Desc./Quantity |

Transmission |

Automatic expandable pulley variator with torque |

|

server, V belt, automatic clutch. |

Final reduction |

Gear reduction unit in oil bath. |

Capacities

|

|

CAPACITY |

|

|

Specification |

Desc./Quantity |

|

|

Engine oil |

1.7 l |

|

|

Transmission oil |

250 cm³ |

|

|

Cooling system fluid |

~ 1.8 l |

|

|

Fuel tank (reserve) |

~ 12 l (~2 l) |

|

|

|

|

|

Electrical system |

|

|

|

|

|

ELECTRICAL SYSTEM |

|

|

Specification |

Desc./Quantity |

|

|

Start-up |

Electric |

|

|

Ignition |

Electronic, inductive, high efficiency ignition, inte- |

|

|

|

grated with the injection system, with variable ad- |

|

|

|

vance and separate HV coil. |

|

|

Ignition advance |

Three-dimensional map managed by control unit |

|

|

Spark plug |

CHAMPION RG 6 YC |

|

|

Alternative spark plug |

NGK CR7EKB |

|

|

Battery |

12 V / 14 Ah, SEALED BATTERY |

|

|

Generator |

In alternating current |

|

|

|

|

|

Frame and suspensions |

|

|

|

FRAME AND SUSPENSIONS

|

Specification |

Desc./Quantity |

|

|

Chassis |

Tubular and sheet steel |

|

|

Front suspension |

The tilt mechanism is composed of an articulated |

|

|

|

parallelogram suspension with die-cast aluminium |

|

|

|

control arms and two side headstocks plus shock |

|

|

|

absorbers with hydraulic locking system. |

|

|

Front suspension travel |

85 mm |

|

|

Rear suspension |

Two double-acting shock absorbers, adjustable to |

|

|

|

four positions at preloading. |

|

|

Rear suspension travel |

110 mm |

|

|

|

|

|

CHAR - 5

Characteristics |

MP3 400 i.e. |

|

|

Brakes

|

BRAKES |

|

|

|

|

Specification |

Desc./Quantity |

|

|

|

Front brake |

Ø 240 mm double disk with hydraulic control acti- |

|

|

|

|

vated by the handlebar right-hand lever. |

|

|

|

Rear brake |

disc brake, diameter 240 mm, with hydraulic servo |

|

|

|

|

operated from the handlebar with the left-hand lev- |

|

|

|

|

er. |

|

|

|

|

|

|

|

Wheels and tyres |

|

|

|

|

|

WHEELS AND TYRES |

|

|

|

|

Specification |

Desc./Quantity |

|

|

|

Wheel rim type |

Light alloy rims. |

|

|

|

Front rim |

12'' x 3.00 |

|

|

|

Rear rim |

14'' x 4.50 |

|

|

|

Front tyre |

Tubeless 120/70-12" 51S or 51P |

|

|

|

Rear tyre |

Tubeless 140/70 - 14" 68S or 68P reinf |

|

|

|

Front tyre pressure (with passenger) |

1.6 bar (1.8 bar) |

|

|

|

Rear tyre pressure (with passenger) |

2.4 bar (2.6 bar) |

|

|

|

|

|

|

|

Tightening Torques |

|

|

|

|

|

STEERING |

|

|

|

|

Name |

Torque in Nm |

|

|

|

Steering lower ring nut (central headstock) |

22 ÷ 27 loosen by 90° |

|

|

|

Steering upper ring nut (central headstock) |

27 |

÷ 33 |

|

|

Handlebar fixing screw |

50 |

÷ 55 |

|

|

Fixing screws for handlebar control assembly U- |

7 ÷ 10 |

|

|

|

bolts |

|

|

|

|

CHASSIS |

|

|

|

|

Name |

Torque in Nm |

|

|

|

Swinging arm set screw bushing |

5 |

÷ 7 |

|

|

Engine arm bolt - frame arm |

32.5 ÷ 40 |

|

|

|

Swinging arm set screw bushing nut |

54 |

÷ 60 |

|

|

Engine-swinging arm bolt |

98 ÷ 118 |

|

|

|

Frame-swinging arm bolt |

54 |

÷ 60 |

|

|

Centre stand bolt |

31 |

÷ 39 |

|

|

FRONT SUSPENSION |

|

|

|

|

Name |

Torque in Nm |

|

|

|

Shock absorber lower clamp |

19 |

÷ 26 |

|

|

Upper shock absorber clamp |

19 |

÷ 29 |

|

|

Front wheel fixing screws |

19 |

÷ 24 |

|

|

Steering arm bolt nut |

20 |

÷ 25 |

|

|

Tilt calliper fixing screws |

20 |

÷ 25 |

|

|

Front wheel shaft |

74 |

÷ 88 |

|

|

Arm coupling screws |

45 |

÷ 50 |

|

CHAR - 6

MP3 400 i.e. |

Characteristics |

|

|

Name |

Torque in Nm |

|

Screws fixing arms to side headstocks |

45 |

÷ 50 |

Screws fixing arms to central headstock |

45 |

÷ 50 |

Screws fixing the half-arm coupling flange |

20 |

÷ 25 |

Fixing screws for tilt locking disc section |

20 |

÷ 25 |

Side headstock upper ring nut |

20 - 24 |

|

Side headstock lower ring nut |

12 |

÷ 15 |

Screw fixing sliding stem to shock absorber |

45 |

÷ 50 |

Clamp for sliding stem locking device |

6.5 ÷ 10.5 |

|

Fixing nuts for constant-velocity universal joints |

18 |

÷ 20 |

Potentiometer to anti-tilting device clamp |

8 ÷ 10 |

|

Electric motor to anti-tilting device clamp |

11 |

÷ 13 |

Clamp fixing pump bolt to anti-tilting device |

11 |

÷ 13 |

Pump to anti-tilting device clamp |

11 |

÷ 13 |

Pressure switch to distribution frame |

18 |

÷ 20 |

Sensor to tilt gripper clamp |

2.5 |

÷ 2.9 |

Pipe terminals to fifth wheel check spring |

7 ÷ 11 |

|

Joint to anti-tilting device pump |

20 |

÷ 25 |

Lower fitting for shock absorber sliding locking |

20 |

÷ 25 |

clamp pipes |

|

|

Upper fitting for shock absorber sliding locking |

20 |

÷ 25 |

clamp pipes |

|

|

REAR SUSPENSION

Name |

Torque in Nm |

|

Upper shock absorber clamp |

33 |

÷ 41 |

Shock absorber lower clamp |

33 |

÷ 41 |

Shock absorber-crankcase attachment bracket |

20 |

÷ 25 |

Rear wheel axle |

104 |

÷ 126 |

Muffler arm clamping screws |

27 |

÷ 30 |

FRONT BRAKE |

|

Name |

Torque in Nm |

Calliper coupling screw |

22 ÷ 27 |

Oil bleed screw |

8÷12 |

Disc tightening screw (°) |

5 - 6 |

Brake fluid pump - hose fitting |

16 ÷ 20 |

Brake fluid pipe-calliper fitting |

20 ÷ 25 |

Screw tightening calliper to the support |

20 ÷ 25 |

Calliper upper pipe fitting |

20 ÷ 25 |

REAR BRAKE |

|

Name |

Torque in Nm |

Oil bleed screw |

12÷16 |

Rear brake disc screws(°) |

5 ÷ 6.5 |

Rear brake calliper-pipe fitting |

20 ÷ 25 |

Rigid / flexible pipe fitting |

13 ÷ 18 |

Rear brake pump-pipe fitting |

16 ÷ 20 |

Rear brake calliper fixing screws |

20 ÷ 25 |

pad fastening pin screws |

20 ÷ 25 |

CHAR - 7

Characteristics |

MP3 400 i.e. |

|

|

REAR BRAKE

Product |

Description |

Specifications |

(°) Loctite 243 |

Medium strength threadlock |

Apply LOCTITE 243 medium- |

|

|

strength threadlock |

MUFFLER

Name |

Torque in Nm |

|

Muffler heat guard fixing screw |

4 |

÷ 5 |

Screw for fixing muffler to the support arm |

20 |

÷ 25 |

Lambda probe clamp on exhaust manifold |

40 |

÷ 50 |

Exhaust manifold-muffler joint clamp |

12 |

÷ 13 |

Manifold - muffler diaphragm tightening clamp |

16 |

÷ 18 |

LUBRICATION

Name |

Torque in Nm |

Oil pump cover screws |

0.7 ÷ 0.9 |

Screws fixing oil pump to the crankcase |

5 - 6 |

THERMAL UNIT AND TIMING SYSTEM

Name |

Torque in Nm |

||

Spark plug |

12 |

÷ 14 |

|

Head fixing stud bolts: |

*** |

||

Head fixing nuts |

10 |

- 12 |

|

Exhaust / intake head fixing nuts: |

10 |

- 12 |

|

Head lubrication control jet |

5 |

- 7 |

|

coolant temperature sensor: |

10 |

- 12 |

|

Lambda probe on exhaust manifold |

10 |

- 12 |

|

injector fixing screw |

3 |

÷ 4 |

|

Counterweight screw |

7 ÷ 8.5 |

||

Tensioner sliding block fixing screw: |

10 |

- 14 |

|

Rpm timing sensor fixing screw: |

3 |

- 4 |

|

Valve lifter mass stop bell fixing screws: |

30 |

- 35 |

|

Inlet manifold screws |

11 |

÷ 13 |

|

Tappet cover fixing screws: |

7 |

- 9 |

|

Throttle body fixing screws |

11 |

÷ 13 |

|

Head fixing screws |

10 |

- 12 |

|

Camshaft retaining bracket screws: |

4 |

÷ 6 |

|

Tightener screw: |

5 |

- 6 |

|

Tightener fastening screws: |

11 |

÷ 13 |

|

*** Apply a preliminary torque of 7 Nm in a crossed sequence. - Tighten by 90° in a crossed sequence. - Tighten again by 90° in a crossed sequence.

TRANSMISSION COVER

Name |

Torque in Nm |

||

Driven pulley nut |

92 - 100 |

||

Drive pulley nut |

160 |

- 175 |

|

Anti-vibration roller screw |

16.7 |

- 19.6 |

|

M8 retainers for transmission cover |

23 |

- 26 |

|

M6 retainer |

11 |

÷ 13 |

|

Anti-vibration roller retainer |

17 |

- 19 |

|

Clutch ring nut |

65 |

- 75 |

|

Air conveyor screws |

11 |

÷ 12 |

|

Water pump cover screws |

3 |

÷ 4 |

|

CHAR - 8

MP3 400 i.e. |

Characteristics |

|

|

Name |

Torque in Nm |

Outside transmission cover screws |

7 ÷ 9 |

Flywheel cover screws |

11 - 13 |

FLYWHEEL COVER

Name |

Torque in Nm |

|

Chain guide sliding block retain plate fastening |

3 |

÷ 4 |

screws |

|

|

Flywheel fixing nut |

115 - 125 |

|

Stator retainers |

8 - 10 |

|

Blow-by recovery duct fixing screws |

3 - 4 |

|

Screw fixing freewheel to flywheel |

13 |

÷ 15 |

Stator cable harness guide bracket screws |

3 - 4 |

|

Supporting screws with bulkhead |

0.3 - 0.4 |

|

Minimum oil pressure sensor |

12 |

÷ 14 |

Water pump impeller |

4 |

÷ 5 |

CRANKCASE AND CRANKSHAFT

Name |

Torque in Nm |

|

Countershaft fixing nut |

25 |

- 29 |

Engine oil filter |

12 |

- 16 |

Engine oil drainage plug |

24 ÷ 30 |

|

Engine-crankcase coupling screws |

11 ÷ 13 |

|

Oil pump screws |

5 |

- 6 |

Gear mounting on crankshaft screws |

10 -12 |

|

Bulkhead screws for oil pump housing cover |

8 - 10 |

|

COOLING

Name |

Torque in Nm |

|

Water pump rotor cover |

3 |

÷ 4 |

Thermostat cover screws |

3 |

÷ 4 |

Bleed screw: |

|

3 |

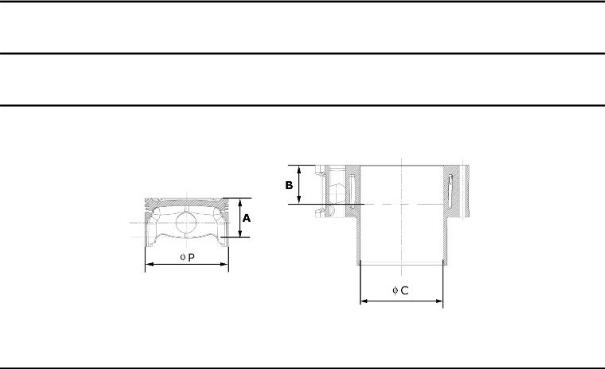

Overhaul data

Assembly clearances

Cylinder - piston assy.

CHAR - 9

Characteristics |

MP3 400 i.e. |

|

|

HEIGHT AT WHICH THE DIAMETER SHOULD BE MEASURED

Specification |

Desc./Quantity |

A |

43.2 mm |

B |

43 mm |

|

CYLINDERPISTON |

Specification |

Desc./Quantity |

Cylinder diameter C |

85.8 - +0.018 -0.01 mm |

Piston Ø P |

85.768 ± 0.014 mm |

CYLINDER - PISTON |

|

COUPLING CATEGORIES

Name |

Initials |

Cylinder |

Piston |

Play on fitting |

CylinderPiston |

A |

85.790÷85.797 |

85.754÷85.761 |

0.029÷0.043 |

CylinderPiston |

B |

85.797÷85.804 |

85.761 ÷ 85.768 |

0.029÷0.043 |

CylinderPiston |

C |

85.804÷85.811 |

85.768÷85.775 |

0.029÷0.043 |

CylinderPiston |

D |

85.811÷85.818 |

85.775÷85.782 |

0.029÷0.043 |

CATEGORIES OF COUPLING

N.B.

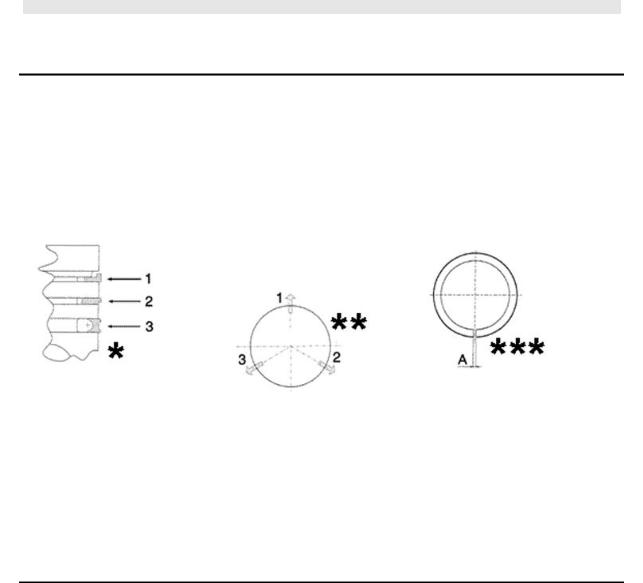

THE PISTON MUST BE INSTALLED WITH THE ARROW FACING TOWARDS THE EXHAUST SIDE, THE PISTON RINGS MUST BE INSTALLED WITH THE WORD «TOP» OR THE STAMPED MARK FACING UPWARDS.

Piston rings

*Fit rings «2» and «3» with the word «TOP» facing upwards. ** Position the openings in the rings as shown here.

***Value «A» of sealing ring inside the cylinder.

CHAR - 10

MP3 400 i.e. |

Characteristics |

|

|

Check the size of the sealing ring opening:

Compression ring: 0.15 ÷ 0.35 mm. Max. value 0.5 mm

Oil scraper ring: 0.25 ÷ 0.50 mm. Max. value 0.65 mm

Oil scraper ring: 0.25 ÷ 0.50 mm. Max. value 0.65 mm

Rings/housing coupling clearances:

Carefully clean the sealing ring housings.

Place a thickness gauge between the ring and the housing as shown in the drawing and check the coupling clearances.

Top ring Standard coupling clearance:

0.01÷0.06 mm

Maximum clearances allowed after use: 0.10 mm

Intermediate ring Standard coupling clearance:0.02÷0.07 mm

Maximum clearances allowed after use: 0.10 mm

Oil scraper ring Standard coupling clearance:

0.01÷0.06 mm

Maximum clearances allowed after use: 0.10 mm

Replace the piston if clearances exceed the maximum limits specified in the table.

Crankcase - crankshaft - connecting rod

Crankcase / countershaft coupling

Besides considering it should match the crankshaft, the crankcase is chosen according to the centre to centre distance between the seat of the crankshaft and that of the contra-rotating shaft.

Both the centre to centre distance and the pair of gears driving the contra-rotating shaft are divided into two types (A and B) to be matched (A with A and B with B).

This selection is useful to keep the difference between the working distance of the gears and their distance without clearance at a given value in order to avoid abnormal noise.

TYPE A

Specification |

Desc./Quantity |

Centre to centre distance of the gears without |

76.937 ÷ 76.867 |

clearance |

|

Centre to centre distance on the crankcase |

77.022 ÷ 76.992 |

CHAR - 11

Characteristics |

MP3 400 i.e. |

|

|

TYPE B

Specification |

Desc./Quantity |

Centre to centre distance of the gears without |

76.907 ÷ 76.837 |

clearance |

|

Centre to centre distance on the crankcase |

76.992 ÷ 76.962 |

The gears with centre to centre distance without clearance between 76.867 and 76.907 are considered universal and can be fitted to either crankcase type.

Either the pair of gears or the crankcase is identified with the letter referring to the type (on the crankcase, this mark is found at the cylinder mouth, flywheel side).

Characteristic

crankshaft / crankcase axial clearance:

0.1 ÷ 0.405 mm

Diameter of crankshaft bearings.

Measure the capacity on both axes x-y.

|

CRANKSHAFT |

Specification |

Desc./Quantity |

Cat. 1 |

Standard diameter: 40.020÷40.026 |

Cat. 2 |

Standard diameter: 40.026÷40.032 |

CHAR - 12

MP3 400 i.e. |

Characteristics |

|

|

Crankshaft alignment

Specific tooling

020335Y Magnetic support for dial gauge

MAX. ADMISSIBLE DISPLACEMENT

|

Specification |

Desc./Quantity |

|

|

A = |

0.15 mm |

|

|

B = |

0.010 mm |

|

|

C = |

0.010 mm |

|

|

D = |

0.10 mm |

|

|

|

|

|

AXIAL CLEARANCE BETWEEN CRANKSHAFT AND CONNECTING ROD

|

Name |

Description |

Dimensions |

Initials |

Quantity |

|

|

Transmission-side |

|

1±0.025 |

A |

D = 0.20 - 0.50 |

|

|

shoulder |

|

|

|

|

|

|

Half-shaft, trans- |

|

20-0.05 |

B |

D = 0.20 - 0.50 |

|

|

mission side |

|

|

|

|

|

|

Connecting rod |

|

22 -0.10 -0.15 |

C |

D = 0.20 - 0.50 |

|

|

Flywheel-side |

|

1.8±0.025 |

F |

D = 0.20 - 0.50 |

|

|

shoulder |

|

|

|

|

|

|

Flywheel side half- |

|

19.6 -0.05 |

E |

D = 0.20 - 0.50 |

|

|

shaft |

|

|

|

|

|

|

Complete crank- |

|

65 +0.10 -0.05 |

G |

D = 0.20 - 0.50 |

|

|

shaft |

|

|

|

|

|

|

|

|

|

|

|

|

CHAR - 13

Characteristics |

MP3 400 i.e. |

|

|

Slot packing system

Shimming system for keeping the compression ratio

DISTANCE «A» IS A PROTRUSION OR RECESS VALUE OF THE PISTON CROWN WITH RESPECT TO THE CYLINDER PLANE. DISTANCE «A» HELPS DETERMINE THE THICKNESS OF GASKET «B» THAT HAS TO BE FITTED TO THE CYLINDER HEAD IN ORDER TO RESTORE COMPRESSION RATIO. BASE GASKET «B» MUST BE THICKER THE MORE THE PLANE FORMED BY THE PISTON TOP PROTRUDES FROM THE PLANE FORMED BY THE CYLINDER HEAD. ON THE OTHER HAND, THE MORE THE PISTON TOP IS RECESSED INTO THE CYLINDER TOP PLANE, THE SMALLER THE GASKET THICKNESS.

Characteristic

Compression ratio

10.6 ± 0.5 : 1

BASE GASKET THICKNESS

Name |

Measure A |

Thickness |

«A» MEASURE TAKEN |

- 0.185 - - 0.10 |

0.4 ± 0.05 |

«A» MEASURE TAKEN |

- 0.10 - + 0.10 |

0.6 ± 0.05 |

«A» MEASURE TAKEN |

+ 0.10 ÷ + 0.185 |

0.8 ± 0.05 |

N.B.

VALUES INDICATED WITH «-» REFER TO PISTON CROWN RECESSES WITH RESPECT TO THE CYLINDER PLANE.

N.B.

DISTANCE «A» MUST BE MEASURED WITHOUT ANY GASKET FITTED AT «B»

Products

RECOMMENDED PRODUCTS TABLE

Product |

Description |

Specifications |

AGIP ROTRA 80W-90 |

Rear hub oil |

SAE 80W/90 Oil that exceeds the |

|

|

requirements of API GL3 specifi- |

|

|

cations |

AGIP CITY HI TEC 4T |

Oil to lubricate flexible transmis- |

Oil for 4-stroke engines |

|

sions (throttle control) |

|

AGIP FILTER OIL |

Oil for air filter sponge |

Mineral oil with specific additives |

|

|

for increased adhesiveness |

AGIP GP 330 |

Grease for brake levers, throttle |

White calcium complex soap- |

|

|

based spray grease with NLGI 2; |

|

|

ISO-L-XBCIB2 |

AGIP CITY HI TEC 4T |

Engine oil |

SAE 5W-40, API SL, ACEA A3, |

|

|

JASO MA Synthetic oil |

AGIP BRAKE 4 |

Brake fluid |

FMVSS DOT4 Synthetic fluid |

CHAR - 14

MP3 400 i.e. |

Characteristics |

|

|

|

Product |

Description |

Specifications |

|

|

SPECIAL AGIP PERMANENT |

coolant |

Monoethylene glycol-based anti- |

|

|

fluid |

|

freeze fluid, CUNA NC 956-16 |

|

|

|

|

|

|

CHAR - 15

Characteristics |

MP3 400 i.e. |

|

|

CHAR - 16

INDEX OF TOPICS

TOOLING |

TOOL |

Tooling |

MP3 400 i.e. |

||

|

|

|

|

|

|

SPECIFIC TOOLS CORRECT |

|

|

Stores code |

Description |

|

|

001330Y |

Tool for fitting steering seats |

|

|

|

|

|

|

001467Y002 |

Driver for OD 73 mm bearing |

|

001467Y006 |

Pliers to extract 20 mm bearings |

|

|

001467Y007 |

Driver for OD 54 mm bearing |

001467Y008 |

Pliers to extract 17 mm ø bear- |

|

ings |

|

|

001467Y014 |

Pliers to extract ø |

15-mm bear- |

|

ings |

|

TOOL - 2

MP3 400 i.e. |

Tooling |

|

|

Stores code |

Description |

020331Y |

Digital multimeter |

020333Y |

Single battery charger |

|

|

020334Y |

Multiple battery charger |

020335Y |

Magnetic support for dial gauge |

|

|

020357Y |

32 x 35 mm adaptor |

020358Y |

37x40-mm adaptor |

020359Y |

42x47-mm adaptor |

TOOL - 5

Tooling |

MP3 400 i.e. |

|

|

Stores code |

Description |

020360Y |

Adaptor 52 x 55 mm |

|

|

020364Y |

25-mm guide |

020376Y |

Adaptor handle |

|

|

020382Y012 |

bush (valve removing tool) |

020412Y |

15 mm guide |

|

|

020424Y |

Driven pulley roller casing fitting |

|

punch |

|

020431Y |

Valve oil seal extractor |

|

|

|

|

|

|

|

|

|

TOOL - 6

MP3 400 i.e. |

Tooling |

|

|

Stores code |

Description |

020434Y |

Oil pressure control fitting |

020439Y |

17 mm guide |

|

|

020444Y |

Tool for fitting/ removing the driv- |

|

en pulley clutch |

020456Y |

Ø 24 mm adaptor |

|

|

020458Y |

Puller for lower bearing on steer- |

|

ing tube |

TOOL - 7

Tooling |

MP3 400 i.e. |

|

|

Stores code |

Description |

020459Y |

Punch for fitting bearing on steer- |

|

ing tube |

|

|

020460Y |

Scooter diagnosis and tester |

020467Y |

Flywheel extractor |

|

|

020468Y |

Piston fitting ring |

|

020469Y |

Reprogramming kit for scooter |

|

|

|

diagnosis tester |

|

|

|

|

|

|

|

|

|

TOOL - 8

MP3 400 i.e. |

Tooling |

|

|

Stores code |

Description |

020470Y |

Pin retainers installation tool |

020471Y |

Pin for countershaft timing |

|

|

020472Y |

Flywheel lock wrench |

020474Y |

Driving pulley lock wrench |

|

|

020475Y |

Piston position checking tool |

|

020476Y |

Stud bolt set |

|

|

|

|

|

|

|

|

|

TOOL - 9

Tooling |

MP3 400 i.e. |

|

|

Stores code |

Description |

020478Y |

Punch for driven pulley roller cas- |

|

ing |

020479Y |

Countershaft lock wrench |

|

|

020480Y |

Petrol pressure check set |

020481Y |

Control unit interface wiring |

|

|

020482Y |

Engine support |

|

020483Y |

30 mm guide |

|

|

|

|

|

|

|

|

|

TOOL - 10

Loading...

Loading...