Panasonic SA-VK31GC Service Manual

A

A

CD Stereo System

SA-VK31GC

SA-VK31GS

Colour

(S)... Silver Type

ORDER NO. MD0405174C3

Specifications

n AMPLIFIER SECTION

PMPO 2500 W

RMS power output

THD 10% both channels driven

1 kHz (Low channel) 75 W per channel (6 Ω)

10kHz (High channel) 75 W per channel (6 Ω)

Total Bi-Amp power 150 W per channel

UX

Input sensitivity 250 mV

Input Impedance 13.3 kΩ

Phone jack

Terminal Stereo, 3.5 mm jack

MIC jack

Sensitivity 0.7 mV, 680 Ω

Terminal Mono, 3.5 mm jack (2 system)

n FM TUNER SECTION

Frequency range 87.50 - 108.00 MHz (50 kHz steps)

Sensitivity 2.5µV (IHF)

S/N 26 dB 2.2 µV

ntenna terminal(s) 75 Ω (unbalanced)

n AM TUNER SECTION

Frequency range 522 - 1629 kHz (9 kHz steps)

520 - 1630 kHz (10 kHz steps)

Sensitivity

S/N 20 dB (at 999 kHz) 560 µV/m

n CASSETTE DECK SECTION

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s

Overall frequency response (+3 dB, -6 dB at DECK OUT)

NORMAL (TYPE I) 35 Hz - 14 kHz

S/N 50 dB (A weighted)

Wow and flutter 0.18 % (WRMS)

Fast forward and rewind time Approx. 120 seconds with

C-60 cassette tape

n CD SECTION

Discs played [8 cm or 12 cm]

(1) CD- Audio (CD-DA)

(2) Video CD

(3) CD-R/RW (CD-DA, MP3 disc)

(4) MP3

Sampling frequency 44.1 kHz

Decoding 16 bit linear

© 2004 Panasonic AVC Networks Singapore Pte.

Ltd. (RCB registration number: 197701580H) All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SA-VK31GC / SA-VK31GS

Pickup

Beam source/wavelength Semiconductor laser/780 nm

Number of channels Stereo

Frequency response 20 Hz - 20 kHz (+1, -2 dB)

Wow and flutter Below measurable limit

Digital filter 8fs

D/A converter MASH (1 bit DAC)

Video

Video signal system PAL625/50, PAL525/60, NTSC

Output level Composite video, 1 Vp-p, 75 Ω

Terminal Pinjack(1system)

MP3

Bit rate 32 kbps-320 kbps

Sampling frequency 32 kHz, 44.1 kHz, 48kHz

n GENERAL

Power Supply AC 110 V/127 V/220-230 V/240 V,

50/60Hz

Power consumption 251 W

Dimensions (W x H x D) 250 x 330 x 358 mm

Mass 7.9kg

Power consumption in standby mode: 0.85 W

n SYSTEM

SC-VK31 (GC) Music center: SA-VK31 (GC)

Front speaker: SB-VK31 (GC)

SC-VK31 (GS) Music center: SA-VK31 (GS)

Front speaker: SB-VK31 (GC)

Note:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

3. HIGH stands for High Frequency. LOW stands for Low

Frequency.

CONTENTS

Page Page

1 Safety precautions (for GS only)

2 Before Use (For GC Only)

3 Before Repair and Adjustment

4 Protection Circuitry

5 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

6 Handling the Lead Solder

6.1. About lead free solder (PbF)

7 Handling Precautions For Traverse Deck

8 Precaution of Laser Diode

9 Accessories

10 Operation Procedures

11 Operation Checks and Main Component Replaceme nt

Procedures

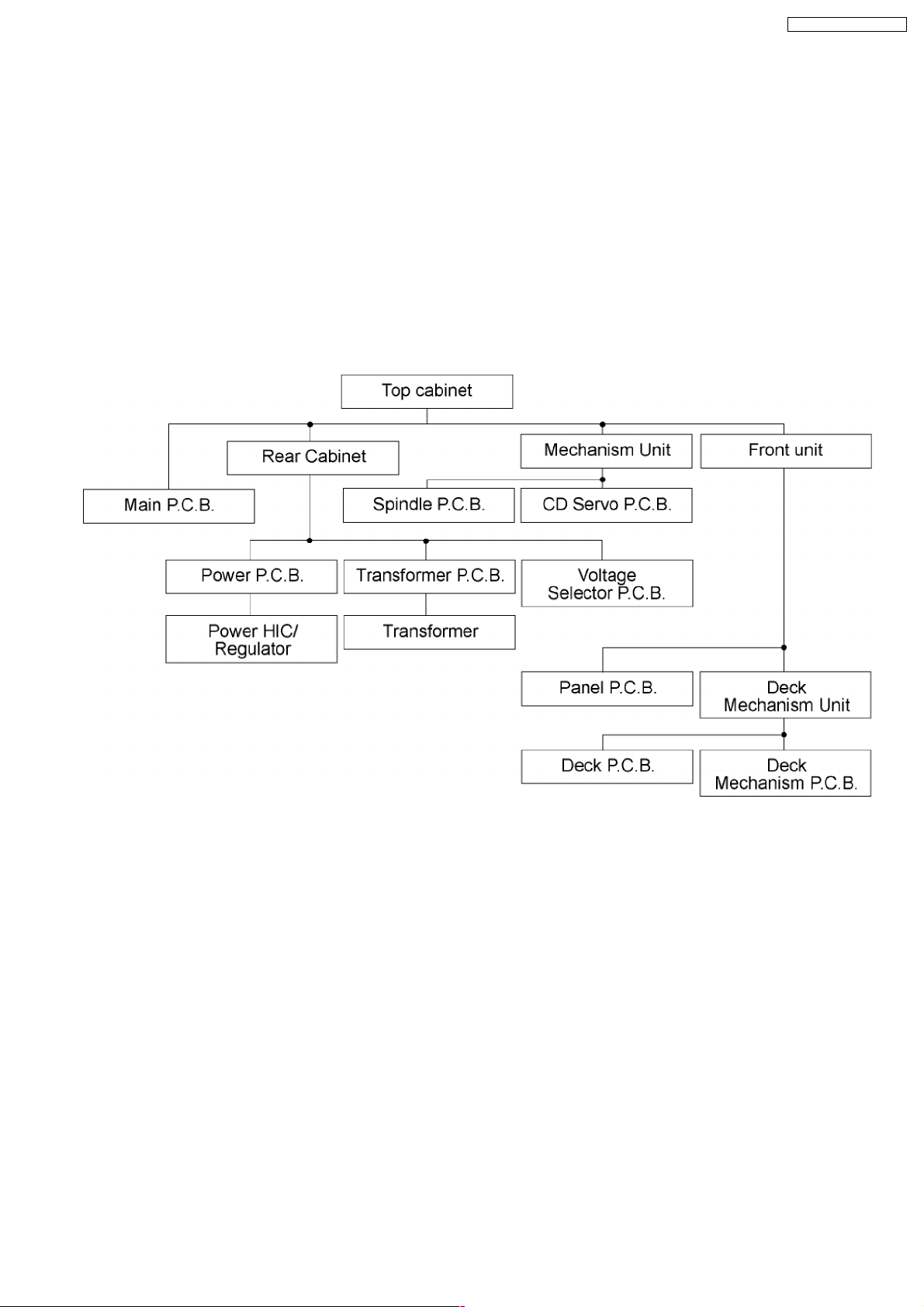

11.1. Disassembly of Top Cabinet and Rear Panel

11.2. Disassembly of CD Mechanism Unit

11.3. Disassembly Main P.C.B., Transformer P.C.B. & MP3

P.C.B.

11.4. Disassembly of Panel P.C.B. & Tact Switch P.C.B.

11.5. Disassembly of Deck Mechanism Unit & Deck P.C.B.

11.6. CD Mechanism Main Component Replacement

Procedures

11.7. Disassembly Deck Mechanism

11.8. Replacement for the cassette lid ass 馳

11.9. Measure for tape trouble

12 Service Position

4

5

5

5

6

6

6

7

8

9

10

11

12

14

15

16

17

17

30

34

34

35

12.1. Checking the Main P.C.B., Power P.C.B., Transformer

P.C.B. and Voltage Selector P.C.B.

12.2. Checking the Panel P.C.B., Tact Switch P.C.B., Deck

P.C.B. & Deck Mechanism P.C.B.

13 Descriptio n of Error Code

13.1. Abnormality Detection for DECK Mechanism

13.2. Abnormality detection for CD/Changer Block

13.3. Power Supply Related Error Detection

14 Self-Diagn ostic Function

14.1. Self-diagnostic display

14.2. How to enter the Self-Diagnostic Function

14.3. Cassette Mechanism Test (For error code H01, H02, H03,

F01)

14.4. CD Mechanism Test (F15, F26, F16, F17, F27, F28, F29,

H15)

14.5. To clear all Error code

14.6. How to get out from Self-Diagnostic function

14.7. Power Amplifier Failure (F61)

15 CD Test Mode Function

15.1. How to set CD test mode

15.2. CD Automatically Adjustment result indication

16 Measurem ents and Adjustments

16.1. Cassette Deck Section

16.2. Tuner Section

16.3. Alignment Points

17 Block Diagram

35

36

37

37

37

37

38

38

38

38

39

39

39

39

39

39

39

41

41

42

43

44

2

SA-VK31GC / SA-VK31GS

18 Schematic Diagram 52

18.1. (A) CD Servo Circuit

18.2. (B) Tuner/Main Circuit

18.3. (B) Main Circuit

18.4. (C) Panel Circuit & (D) Tact Switch Circuit

18.5. (E) Deck Circuit & (F) Deck Mechanism Circuit

18.6. (G) Power Circuit

53

55

56

62

66

68

18.7. (H) Transformer Circuit, (I) Voltage Selector Circuit, (J) CD

Detect circuit, (K) Spindle Position Circuit & (L) CD

Loading Circuit

18.8. (M) VCD Module Circuit

19 Printed Circuit Board

19.1. (A) CD Servo P.C.B. (Side A & B)

19.2. (B) Main P.C.B.

19.3. (C) Panel P.C.B.

19.4. (D) Tact Switch P.C.B.

19.5. (E) Deck P.C.B. & (F) Deck Mechanism P.C.B.

19.6. (G) Power P.C.B.

19.7. (H) Transformer P.C.B. & (I) Voltage Selector P.C.B.

70

71

74

74

76

78

80

81

82

84

19.8. (J) CD Detect P.C.B., (K) Spindle Position P.C.B., (L) CD

Loading P.C.B. & (N) Tuner Pack P.C.B.

86

19.9. (M) VCD P.C.B. (Side A & B)

20 Wiring Connection Diagram

21 Illustration of IC 痴, Transistors and Diodes

22 Terminal Function of IC 痴

22.1. IC7001 (AN22004A-NF) Servo Amplifier

22.2. IC7002 (MN662790RSC) Servo Processor/ Digital Signal

Processor/ Digital Filter/ D/A Converter

22.3. IC7003 (AN8739SBTE2) Focus Coil/ Tracking Coil/

Traverse Motor/ Spindle Motor Driver

22.4. IC2801 (MN101C30AEA) Mechacon IC

22.5. IC600 (C2BBGF000511) Microprocessor

23 Troubleshooting Guide

24 Parts Location and Replacement Parts List

24.1. Deck Mechanism (RAA3412-S)

24.2. CD Loading Mechanism (RD-DAC026-S)

24.3. Cabinet

24.4. Electrical Parts List

24.5. Packing Materials & Accessories Parts List

24.6. Packaging

87

88

90

91

91

91

92

92

93

94

95

96

99

102

105

116

116

3

SA-VK31GC / SA-VK31GS

1 Safety precautions (for GS only)

4

SA-VK31GC / SA-VK31GS

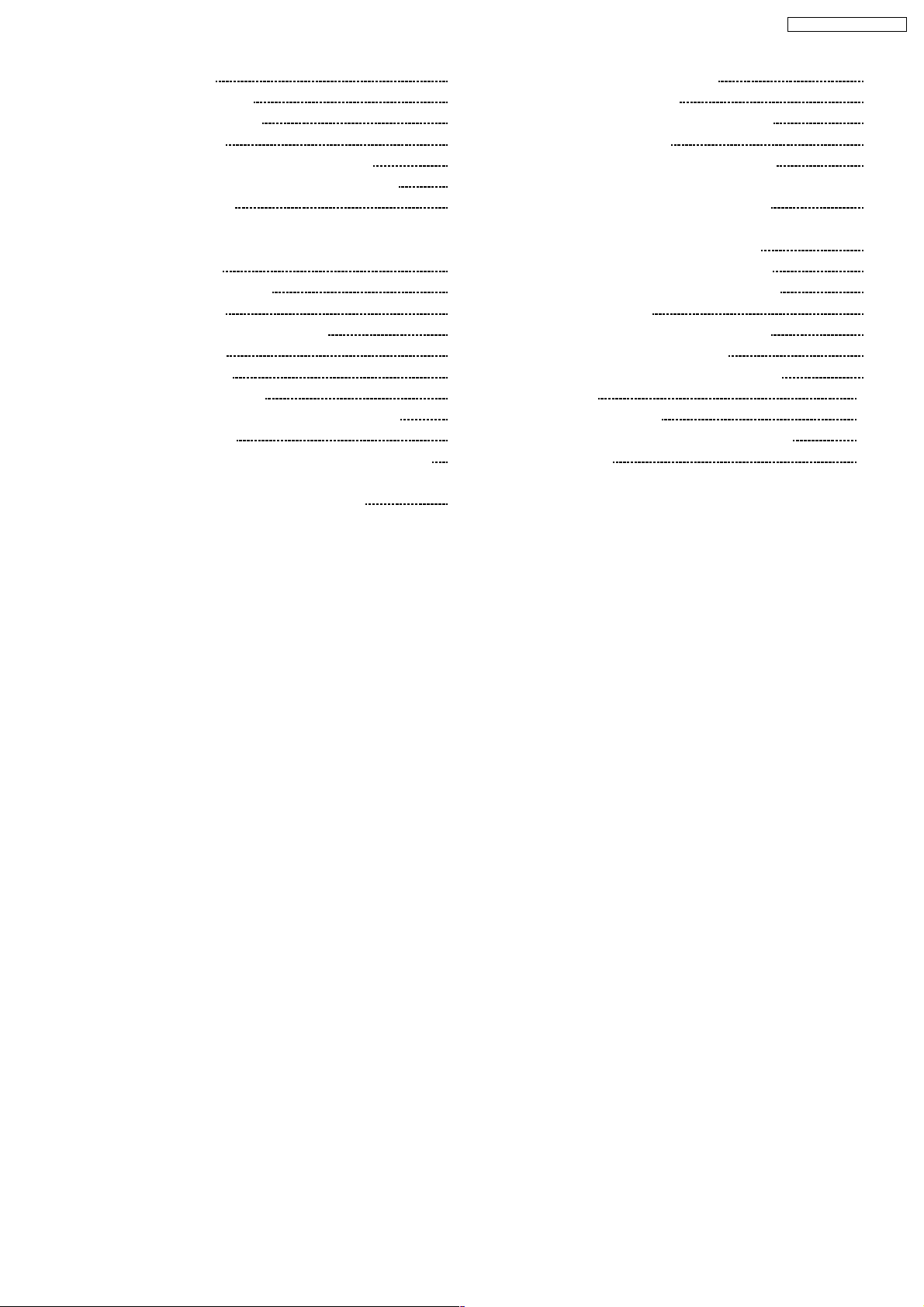

2 Before Use (For GC Only)

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will

be used. (If the power supply in your area is 117V or 120V, set to the “127V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

3 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C950, C5820 and C5820 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 110V, 50/60 Hz and AC 240V, 50 Hz in NO SIGNAL mode should be ~650mA and ~600mA

respectively.

4 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

No sound is heard when the power is turned on.

·

Sound stops during a performance.

·

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5

SA-VK31GC / SA-VK31GS

5 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place theassembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

6 Handling the Lead Solder

6.1. About lead free solder (PbF)

Distinction of PbF P.C.B. :

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point that standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher.

Please use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F

(370 ± 10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· When soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

6

SA-VK31GC / SA-VK31GS

7 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

· Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. The short land between the No.4(LD) and No.5(GND) pins on the flexible board (FFC) is shorted with a solder build-up to

prevent damage to the laser diode.To connect to the PC board, be sure to open by removing the solder build-up, and finishthe

work quickly.

3. Take care not to apply excessive stress to the flexible board (FFC).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

· Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is placed, and ground

the sheet.

Caution :

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when Replacing the Traverse Deck :

The traverse deck has a short point shorted with solder to protect the laer diode against electroststics breakdown. Be sure to

remove the solder from the short point before making connections.

7

SA-VK31GC / SA-VK31GS

8 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 780 nm

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Do not look at pick up lens.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

8

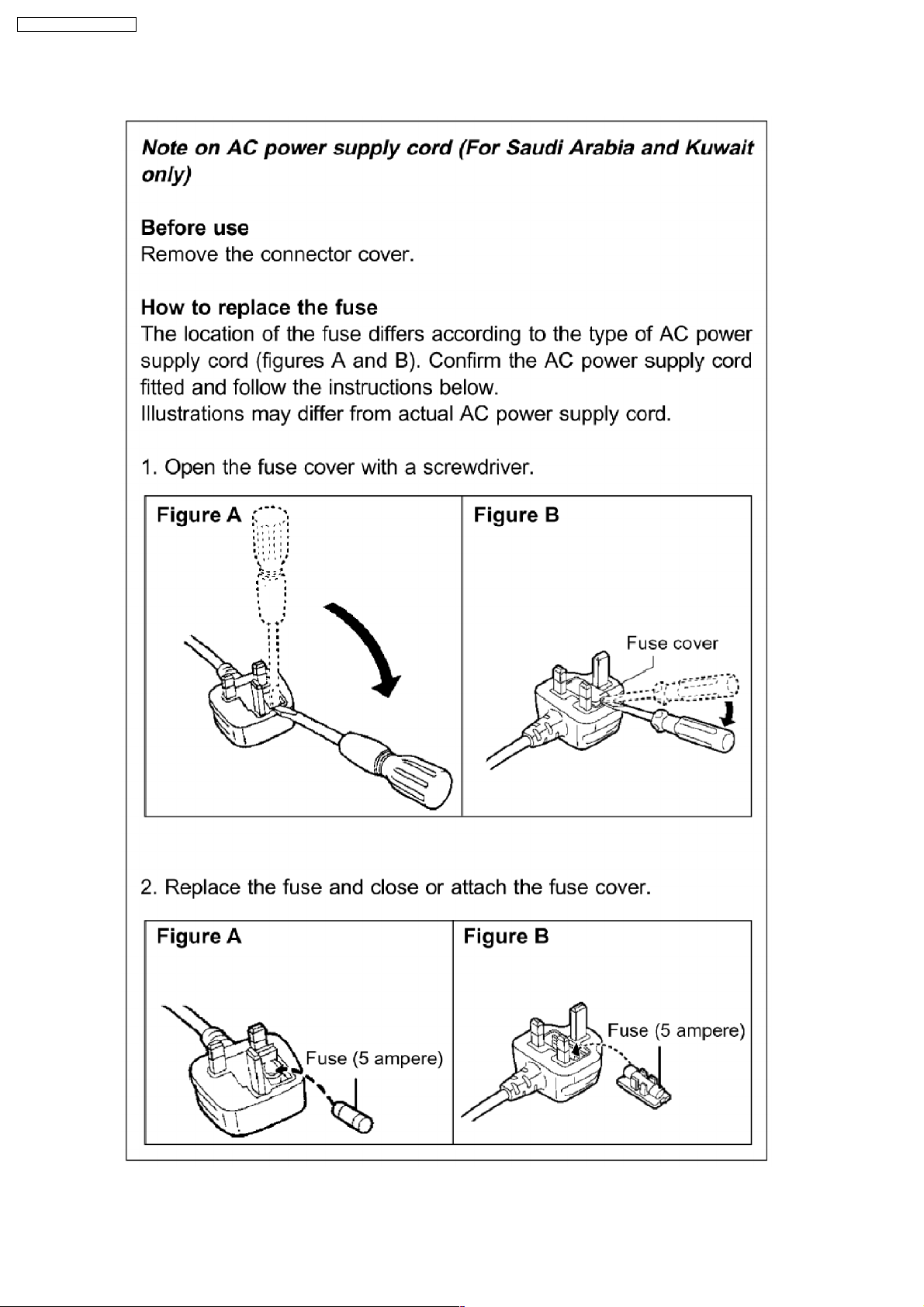

9 Accessories

SA-VK31GC / SA-VK31GS

AC power supply cord

(For GC only)

AC power supply cord

(For GS only)

FM indoor antenna

AM loop antenna

Video connection cable

Remote control

transmitter

9

SA-VK31GC / SA-VK31GS

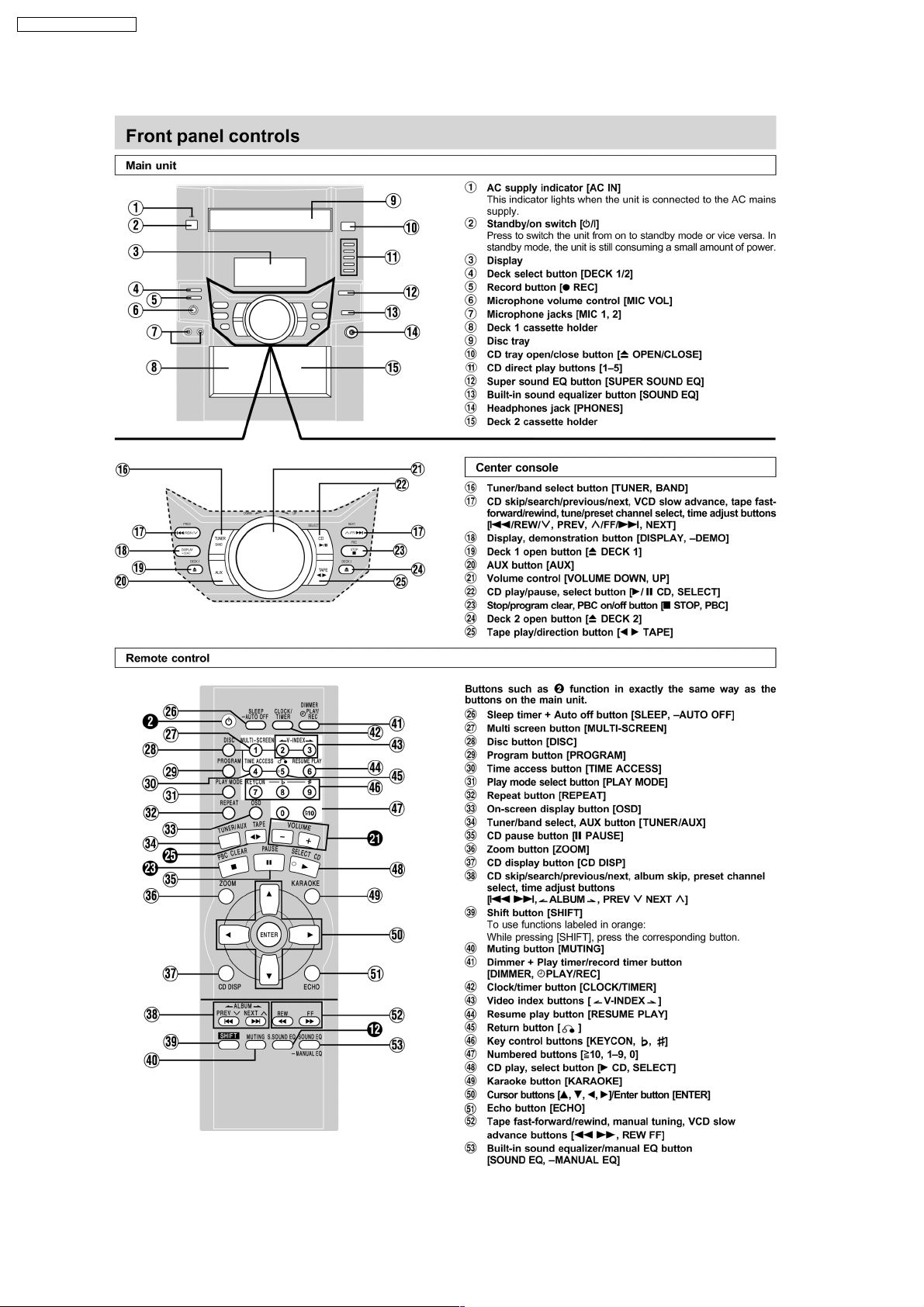

10 Operation Procedures

10

SA-VK31GC / SA-VK31GS

11 Operation Checks and Main Component Replacement

Procedures

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the

main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

11

SA-VK31GC / SA-VK31GS

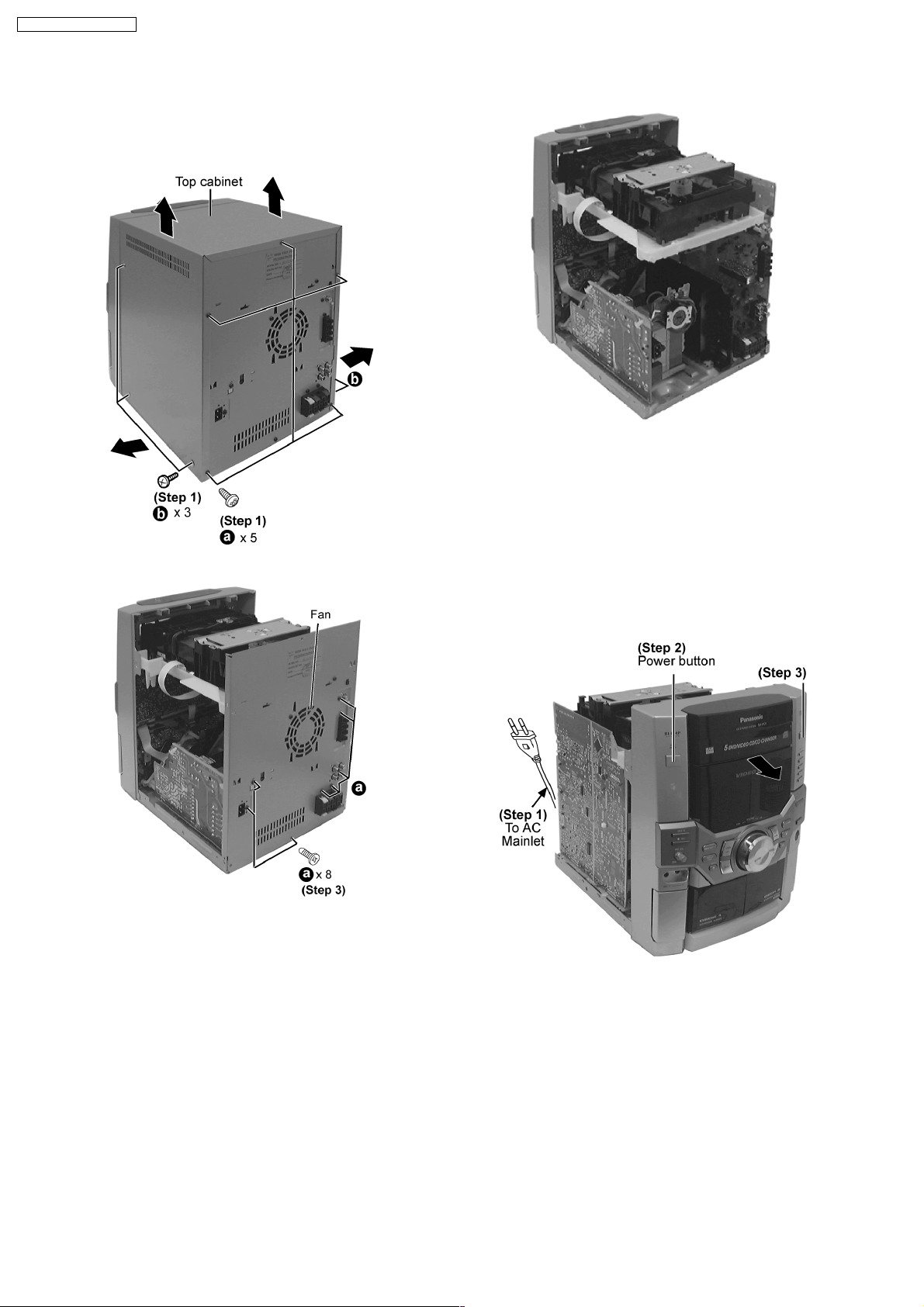

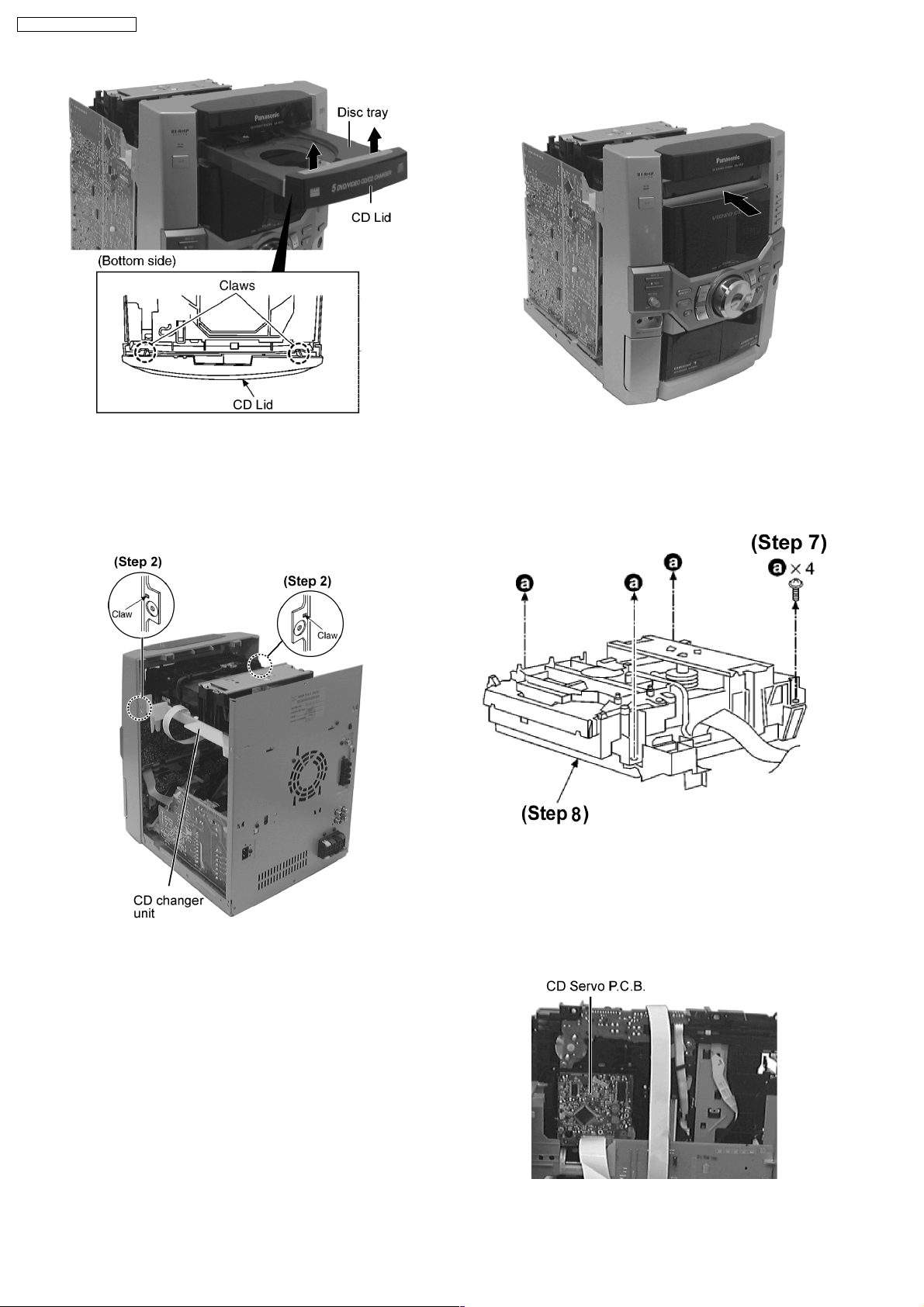

11.1. Disassembly of Top Cabinet and Rear Panel

Step 1 Remove 3 screws each side and 5 screws at rear panel.

Step 2 Lift up both sides of cabinet ass’y, push the cabinet

ass’y toward the rear and remove the cabinet ass’y.

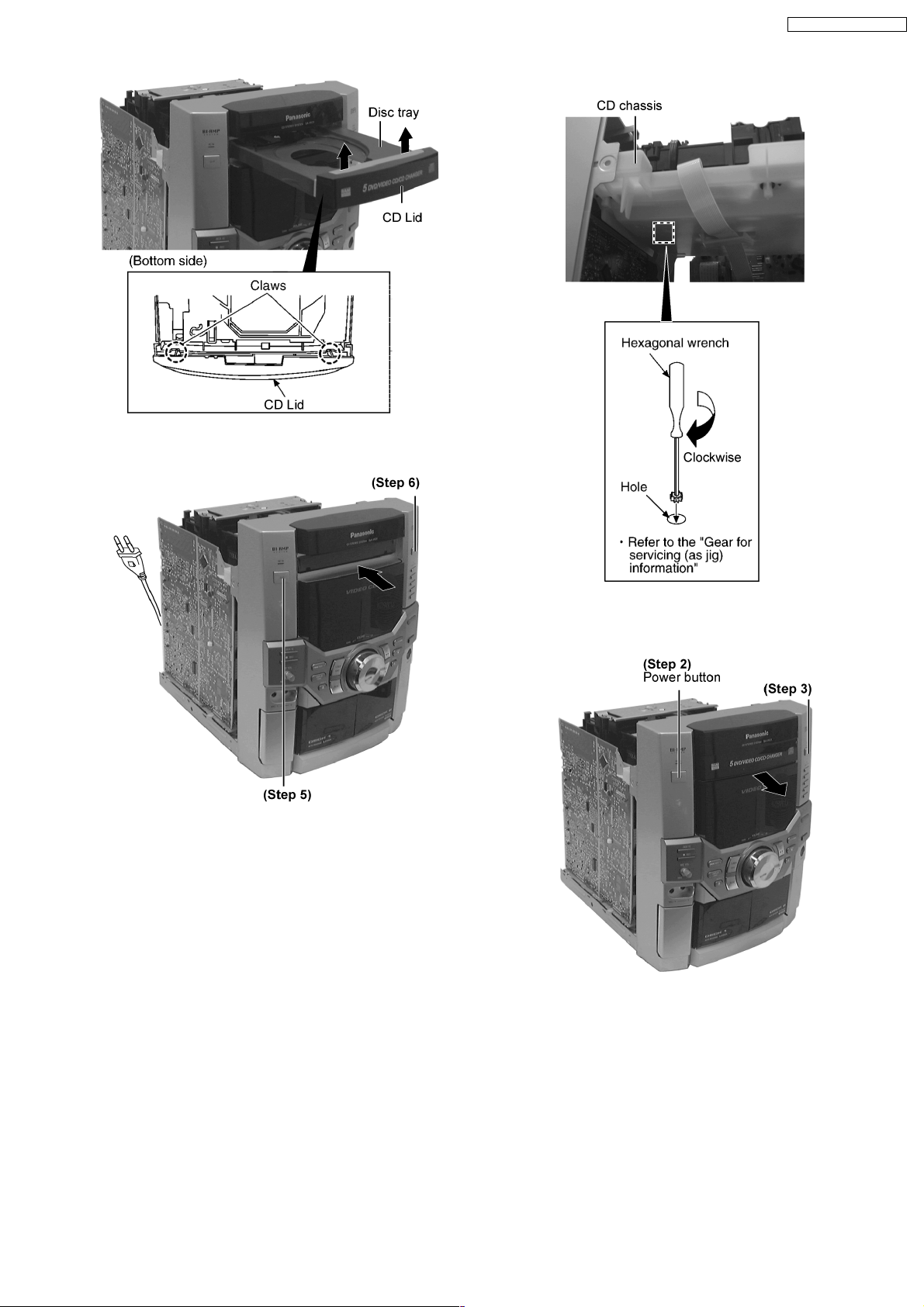

11.1.1. Disasembly for CD Lid

· Disassembly of Rear Panel

Step 3 Remove 8 screws and disconnect wire at CN305 (Fan)

at rear cabinet as shown.

(The CD changer unit can be removed after the CD Lid is

removed)

· Follow the (Step 1) - (Step 2) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

When opening the disc tray automatically (Using Power

Supply)

Step 1 Connect the AC power cord.

Step 2 Press the POWE R button to power up the main unit.

Step 3 Press the OPEN/CLOSE button, the disc tray will be

open automatically.

12

Step 4 Release the 2 claws, and then remove the CD Lid.

Step 5 Press the POWE R button to turn the power on.

SA-VK31GC / SA-VK31GS

[Open the disc tray manually (Using service tools)]

Step 6 Press the OPEN/CLOSE button, the disc tray will be

close.

Step 1 Insert the gear tool into the hole on the underside of CD

chassis and then rotate in the direction of arrow. The disc tray

will be open.

Step 2 Release the 2 claws, and then remove the CD lid cover.

13

SA-VK31GC / SA-VK31GS

11.2. Disassembly of CD Mechanism Unit

Step 3 Repeat Step 2 but rotate the gear tools in anti-clockwise

direction.

Step 4 The disc tray will be close.

· Follow the (Step 1) - (Step 3) of Item 11.1 - Disassembly of Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly for CD Lid

Step 1 Detach the FFC boards (CN309 & CN310).

Step 3 Remove 4 screws.

Step 4 Remove the CD chassis.

Step 5 Lay the CD mechanism unit as shown.

· Note:

Step 2 Release the claws of both ends, and then lift up the CD

Mechanism Unit.

For disassembly of CD mechanism unit, please refer to

Section 11.6 of this manual.

14

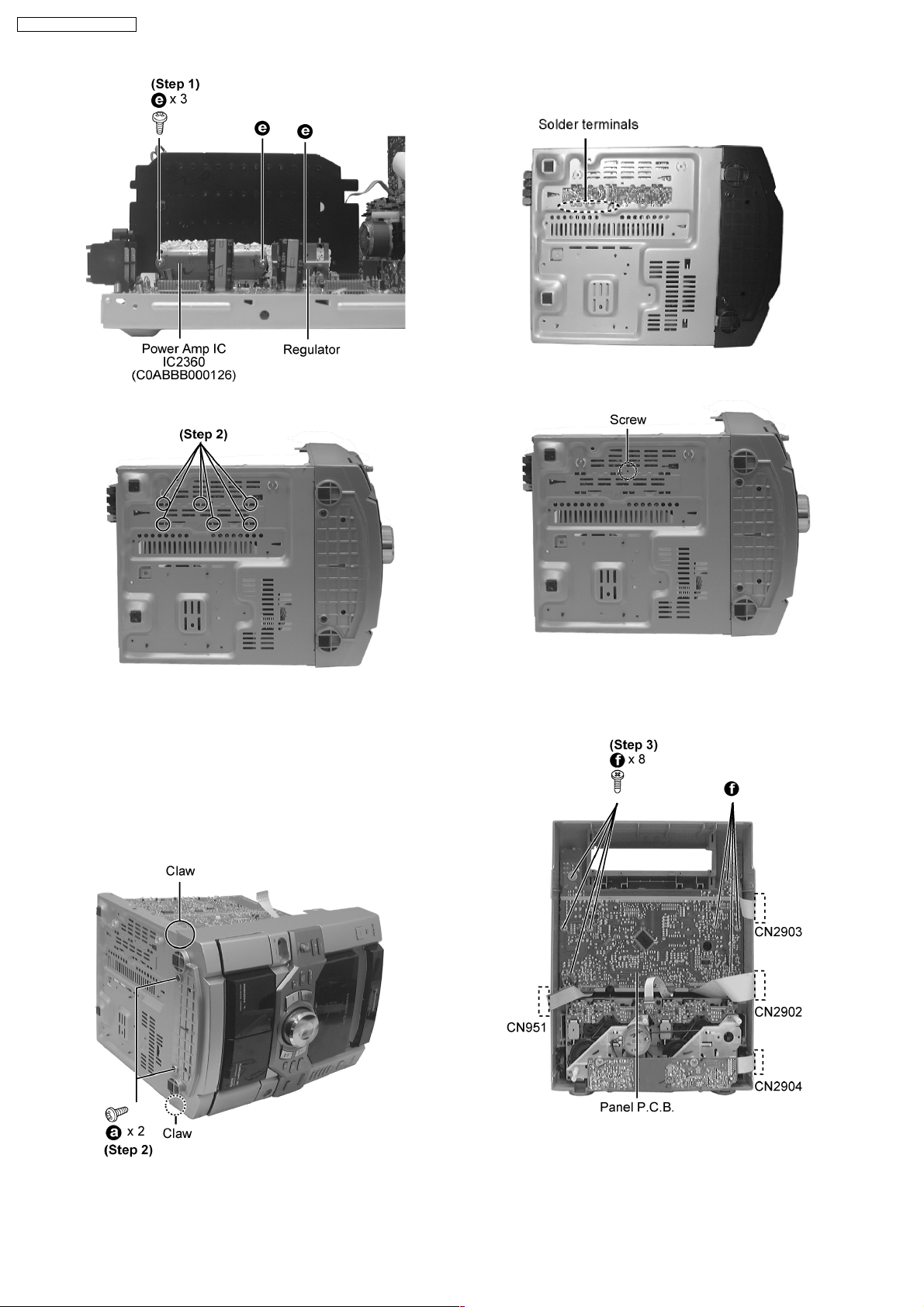

11.3. Disassembly Main P.C.B., Transformer P.C.B. & MP3 P.C.B.

11.3.1. Disassembly for the Main P.C.B.

· Follow the (Step 1) - (Step 3) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly

for CD Lid

· Follow the (Step 1) - (Step 5) of Item 11.2 - Disassembly for

the CD Mechanism Unit

Step 1 Disconnect FFC at CN2902, CN2903 & CN2904 from

Panel P.C.B.

11.3.3. Disassembly of the Power P.C.B.

SA-VK31GC / SA-VK31GS

Step 2 Lift up Main P.C.B. by disconnect CN500 & CN501 as

arrow shown above.

11.3.2. Disassembly of the Transformer

P.C.B. & Voltage Selector P.C.B.

· Follow the (Step 1) - (Step 3) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly

for CD Lid

· Follow the (Step 1) - (Step 5) of Item 11.2 - Disassembly for

the CD Mechanism Unit

· Follow the (Step 1) - (Step 2) of Item 11.3.1 - Disassembly

for the Main P.C.B.

Step1 Remove 3 screws, disconnect connector CN951.

· Follow the (Step 1) - (Step 2) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly

for CD Lid

· Follow the (Step 1) - (Step 5) of Item 11.2 - Disassembly of

the CD Mechanism Unit

· Follow the (Step 1) - (Step 2) of Item 11.3.1 - Disassembly

for the Main P.C.B.

· Follow the (Step 1) of Item 11.3.2 - Disassembly for the

Transformer P.C.B.

Step 1 Remove 2 screws fixed to the Main P.C.B.

Step 2 Remove the 2 screws fixed at heat sink.

NOTE:

Insulate Power P.C.B. with insulation material to avoid short

circuit.

· Replacement of Power Amplifier IC & Voltage Regulator

15

SA-VK31GC / SA-VK31GS

Step 1 Break the joint with a metal cutter as shown below.

Step 2 Unsolder the terminals of Power Amp IC, transistor and

replace the components.

Step 3 Fix back the cutted portion with a screw as shown.

11.4. Disassembly of Panel P.C.B. & Tact Switch P.C.B.

· Follow the (Step 1) - (Step 6) of Item 11.1.

· Follow the (Step 1) - (Step 6) Disassembly for the CD Lid of

Item 11.1.1.

· Follow the (Step 1) - (Step 6) Disassembly for the CD

Changer Unit of Item 11.1.2.

Step 1 Lay the unit as shown below.

Step 3 Remove the 8 screws.

Step 4 Disconnect FFC Boards (CN951, CN2903, CN2902 &

Step 2 Remove 2 screws, release 2 claws, and then draw the

front panel ass’y forward.

CN2904).

· Disassembly of Tact Switch P.C.B.

16

SA-VK31GC / SA-VK31GS

Step 5 Disconnect connector CP600.

Step 6 Pull out the volume knob.

Step 7 Pull Panel P.C.B. forward.

11.5. Disassembly of Deck Mechanism Unit & Deck P.C.B.

· Follow the (Step 1) - (Step 3) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly

for CD Lid

· Follow the (Step 1) - (Step 5) of Item 11.2 - Disassembly for

the CD Mechanism Unit

Step 1 Detach FFC board. (CN951, CN2902, CN2903 &

CN2904)

Step 2 Disconnect FFC flat cable from the connector

(CN2903).

Step 3 Remove the 5 screws.

Step 4 Push the lever upward, and then open the cassette lid

ass’y (For DECK1 and DECK2).

Step 5 Tilt the cassette mechanism unit in the direction of

arrow (1), and then remove it in the direction of arrow (2).

· For replacement of Deck P.C.B.

Step 6 Unsolder the motor terminals.

Step 7 Remove 4 screws.

Step 8 Remove Deck P.C.B.

11.6. CD Mechanism Main Component Replacement Procedures

· Follow the (Step 1) - (Step 3) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly

for CD Lid

· Follow the (Step 1) - (Step 5) of Item 11.2 - Disassembly for

the CD Mechanism Unit

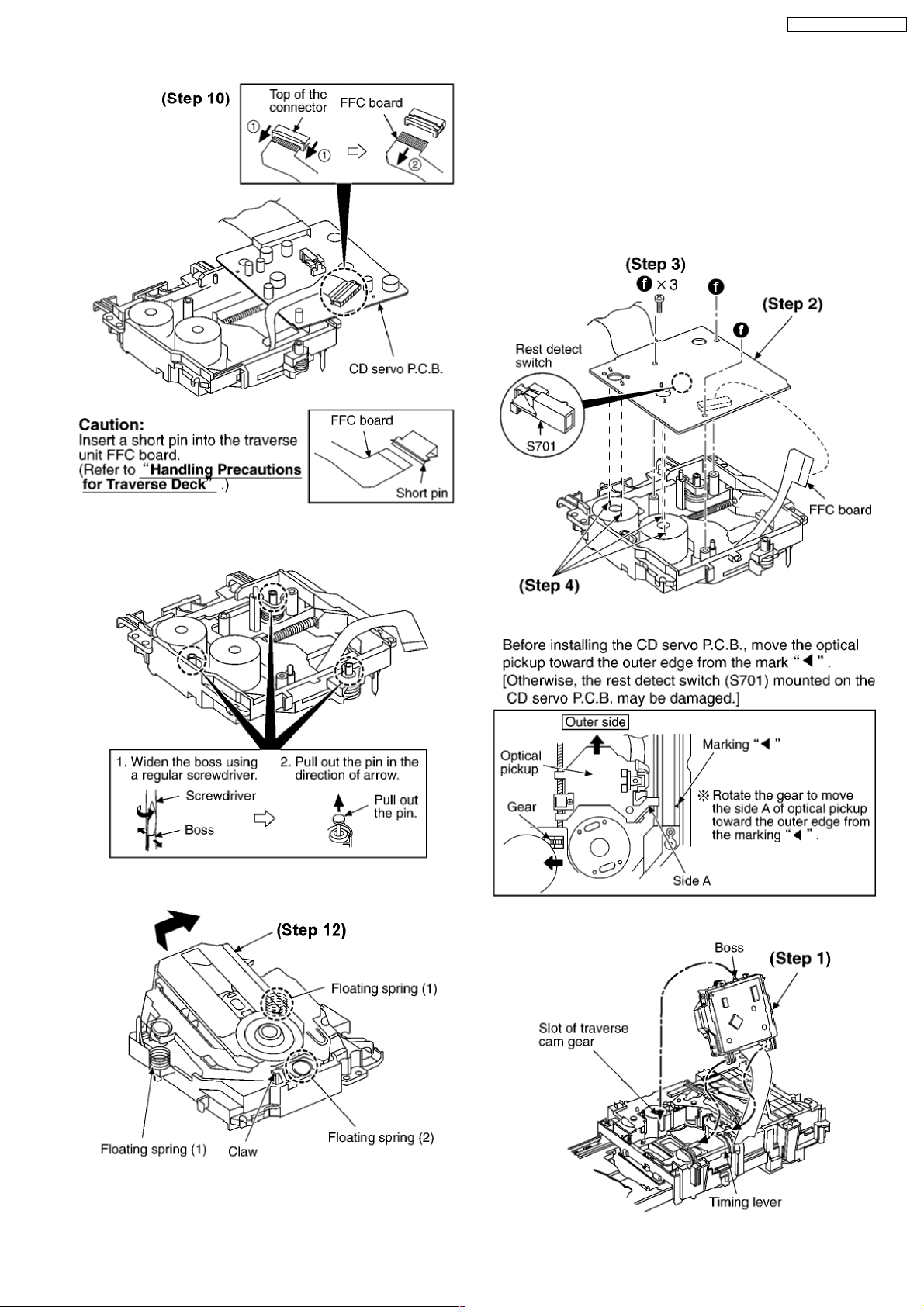

11.6.1. Replacement of the Traverse Deck

Step 1 Remove the CD changer unit.

17

SA-VK31GC / SA-VK31GS

Step 2 Insert the gear with hexagonal wrench into the hole.

Step 4 With pressing the claw (A), rotate the hexagonal wrench

clockwise. (The slide plate R moves for a little amount.)

Step 5 Pressing the claw (B) in the direction of arrow (1), the

connection lever moves in the direction of arrow (2).

Step 6 Lift up the traverse deck ass’y.

Step 3 Rotate the hexagonal wrench in the direction of arrow

(clockwise), and then open the disc tray fully.

Step 7 Remove the traverse deck ass’y from the timing lever.

Caution:

When removing or inserting the traverse deck avoid touching

the OPU lens and pressing onto the turntable.

Step 8 Remove 3 screws.

Step 9 Unsolder the motor terminals (4 points).

18

SA-VK31GC / SA-VK31GS

Note:

Be careful not to lose the 3 floating spring because those will

also be removed on removal of the traverse deck ass’y.

· Installation of the CD Servo P.C.B. after replacement

Step 1 Connect the FFC board.

Step 2 Install the CD servo P.C.B. in the traverse deck ass’y.

Step 3 Remove 3 screws.

Step 4 Solder.

Step 10 Remove the FFC board from the connector, and then

remove the CD Servo P.C.B.

Step 11 Remove the pin.

· Note for installation of the CD servo P.C.B.

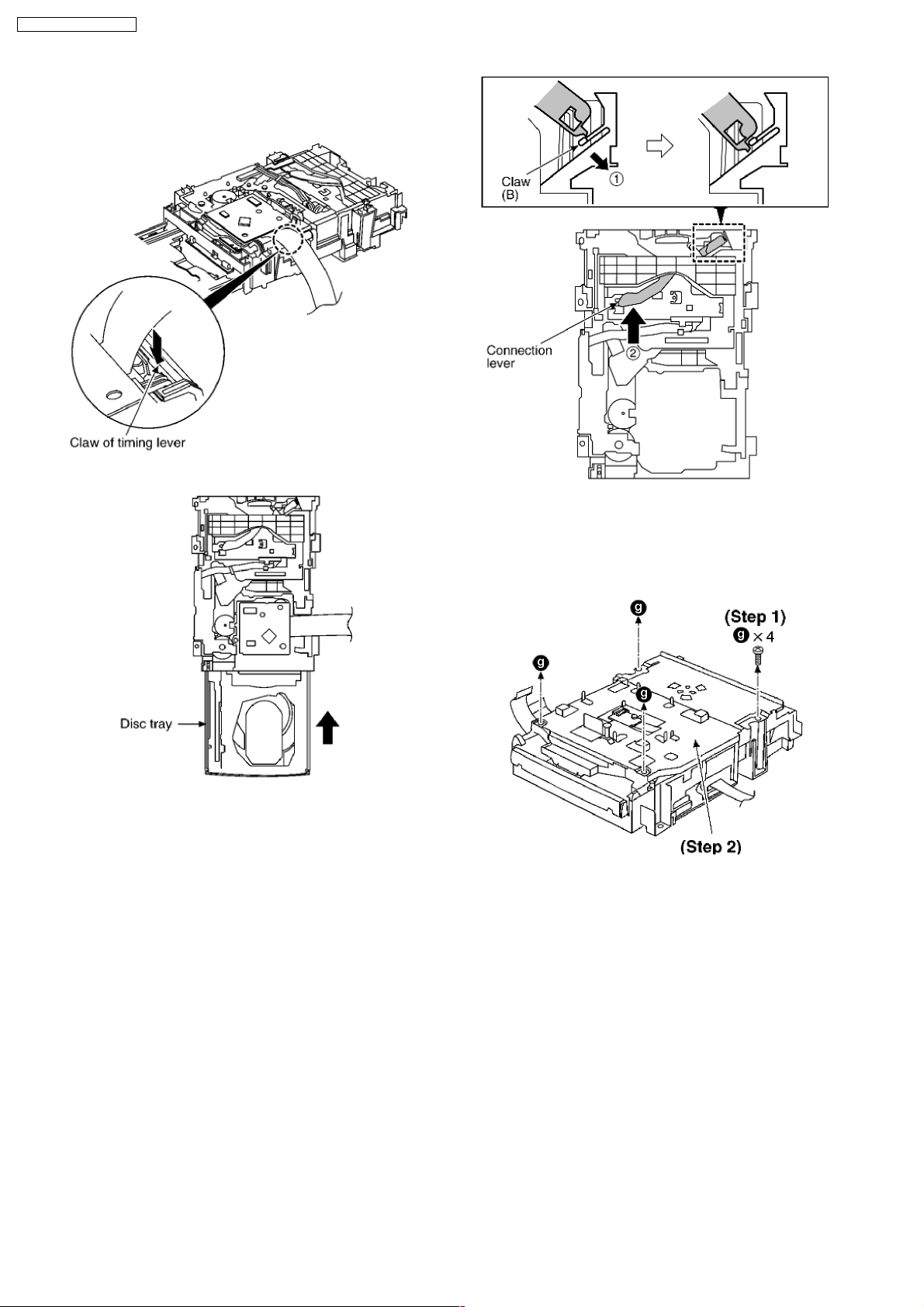

· Installation for traverse deck ass’y

Step 12 Release the claw, and then remove the traverse deck

ass’y.

19

SA-VK31GC / SA-VK31GS

Step 1 Install the traverse deck ass’y to the timing lever.

Step 2 Align the boss of traverse deck ass’y with the slot of

traverse cam gear.

Step 3 Force the claw of timing lever.

Step 4 Force the disc tray fully.

Step 5 With pressing the claw (B) in the direction of arrow (1),

force the connection lever in the direction of arrow (2).

11.6.2. Replacement for the Disc Tray

Step 1 Remove 4 screws.

Step 2 Remove the upper plate.

Step 3 Remove 3 screws.

20

SA-VK31GC / SA-VK31GS

Step 4 With lifting the claw in the direction of (1), draw the CD

Detect P.C.B. in the direction of arrow (2).

Step 5 Remove the mechanism cover.

Step 6 Insert the gear with hexagonal wrench into the hole.

Step 8 Release the both claws, and then draw the disc tray.

Step 9 With forcing the left guide bar manually because the left

guide bar interfers with claw, draw the disc tray.

[Installation of the disc tray after replacement]

Step 7 Rotate the hexagonal wrench in the direction of arrow,

and then open the disc tray fully.

Step 1 Slide the drive rack fully in the direction of arrow.

21

SA-VK31GC / SA-VK31GS

11.6.3. Disassembly and reassembly for

mechanism base drive unit

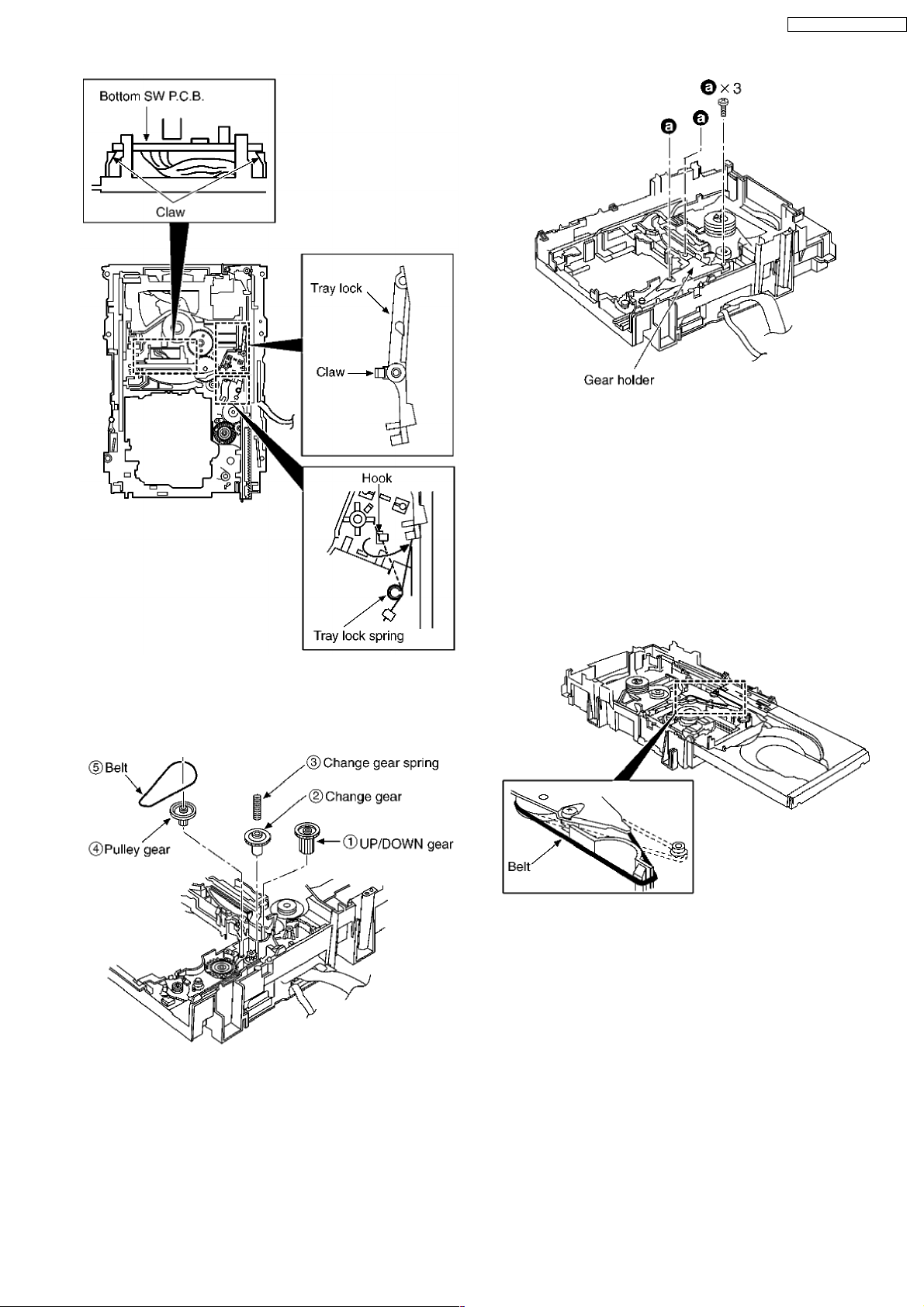

Step 1 Remove 3 screws.

Step 2 Holding the drive rack not to move, install the disc tray.

Step 3 Align the drive rack with the drive gear.

NOTE:

Force the right guide bar of tray base manually not to move

upwards.

Step 2 Release the claw, and then remove the gear holder.

Step 3 Remove the belt and change gear spring.

NOTE:

Take care not to lose the change gear spring.

Step 4 Remove the pulley gear, change gear and UP/DOWN

gear.

Step 4 Holding the disc tray manually, push the disc tray in the

direction of the arrow.

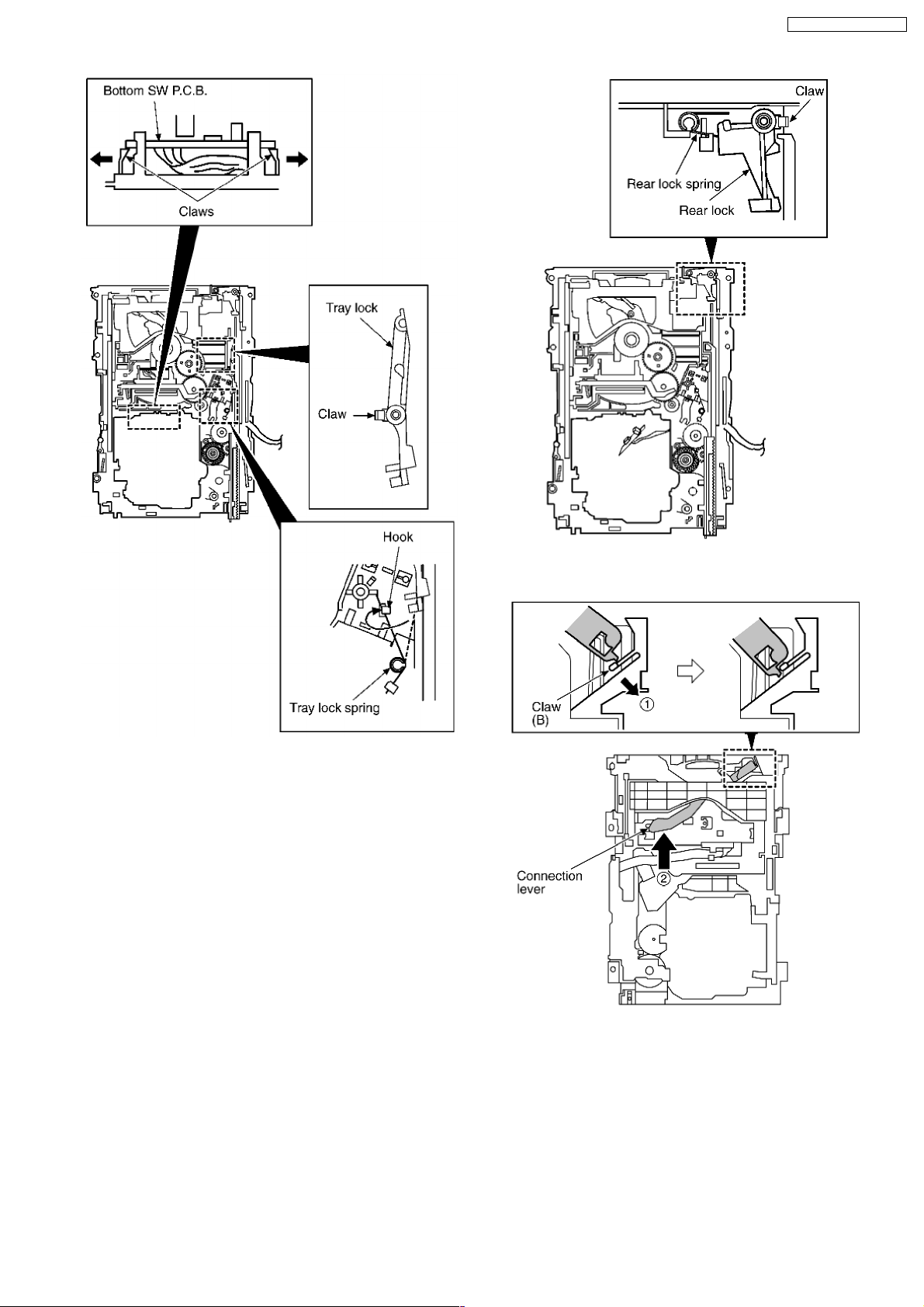

Step 5 Release the 2 claws, and then remove the bottom SW

P.C.B..

22

SA-VK31GC / SA-VK31GS

Step 6 Install the tray lock spring to hook temporary.

Step 7 Release the claw, and then remove the tray lock.

Step 8 Release the claw, and then remove the rear lock.

Step 9 Pressing the claw (B) in the direction of arrow (1), force

the connection lever in the direction of arrow (2).

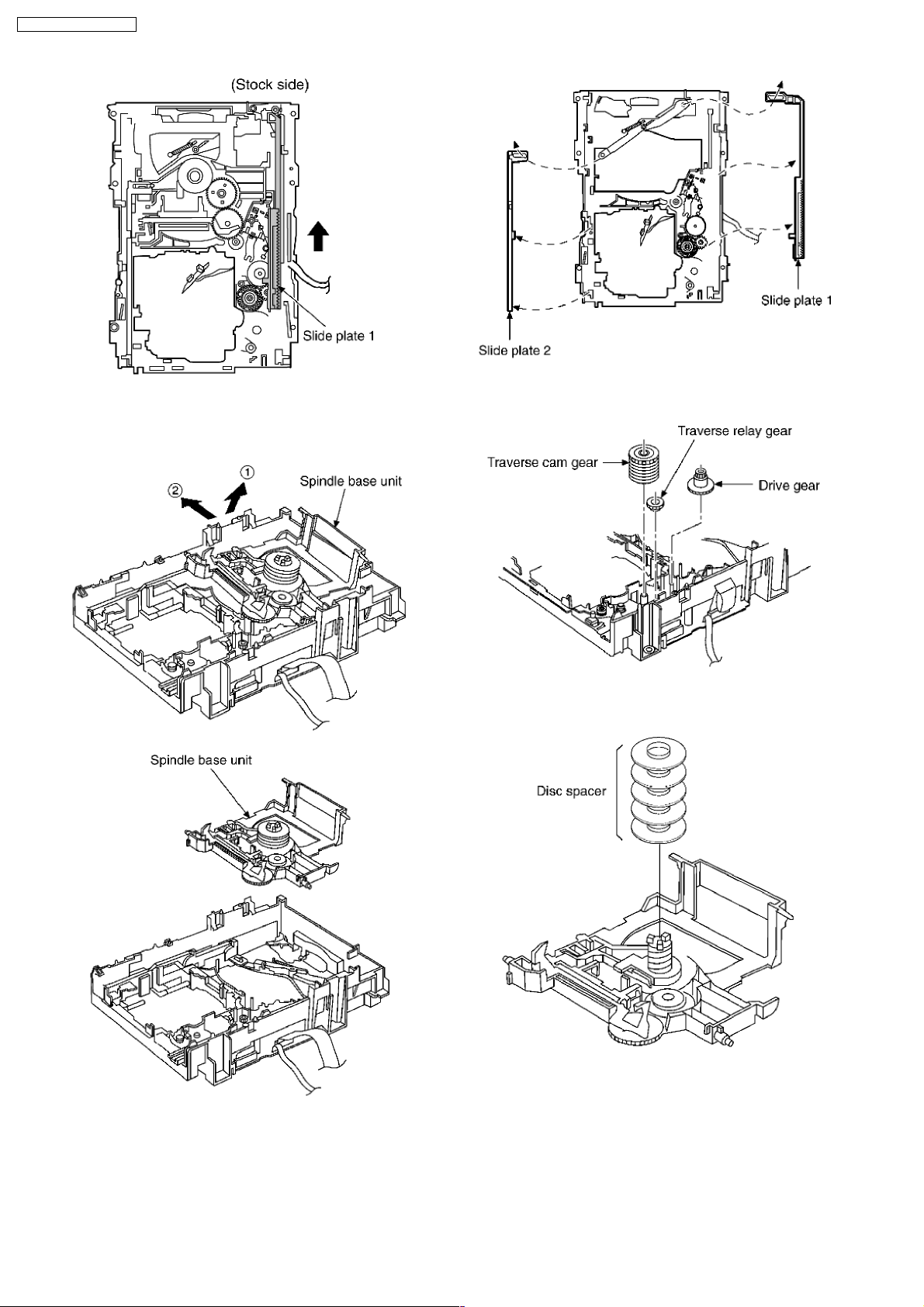

Step 10 Move the slide plate 1 to the end of stock side.

23

SA-VK31GC / SA-VK31GS

Step 11 Lift up the left end of spindle base unit in the direction

of arrow (1), and then remove the unit in the direction of arrow

(2).

Step 13 Remove the traverse relay gear, traverse cam gear

and drive gear.

Step 12 Remove slide plate 1 and slide plate 2.

[Dissassembly/reassembly for the spindle base unit]

Step 1 Draw the 5 disc spacers.

Step 2 Pushing the claw, slide the support plate in the direction

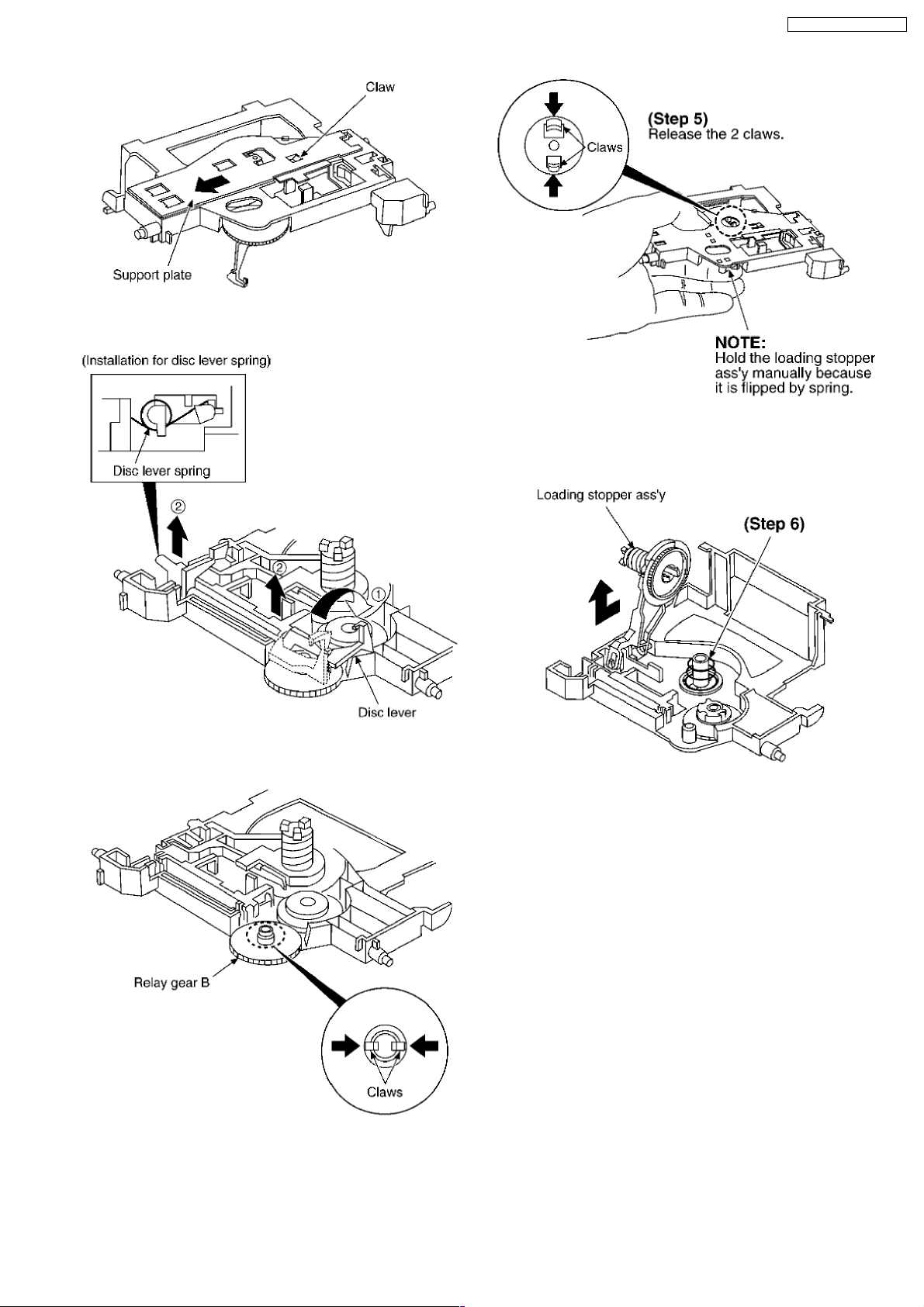

of arrow, and then remove it.

24

Step 3 Rotate the disc lever in the direction of arrow (1), draw

the disc lever.

SA-VK31GC / SA-VK31GS

NOTE:

Hold the loading stopper ass’y manually bacause it is flipped by

spring.

NOTE:

Take care not to lose the disc lever spring.

Step 4 Release the 2 claws, and then draw the relay gear B.

Step 5 Release the 2 claws as shown below.

Step 6 Remove the cushion spring.

Step 7 Remove the loading stopper ass’y in the direction of

arrow.

25

SA-VK31GC / SA-VK31GS

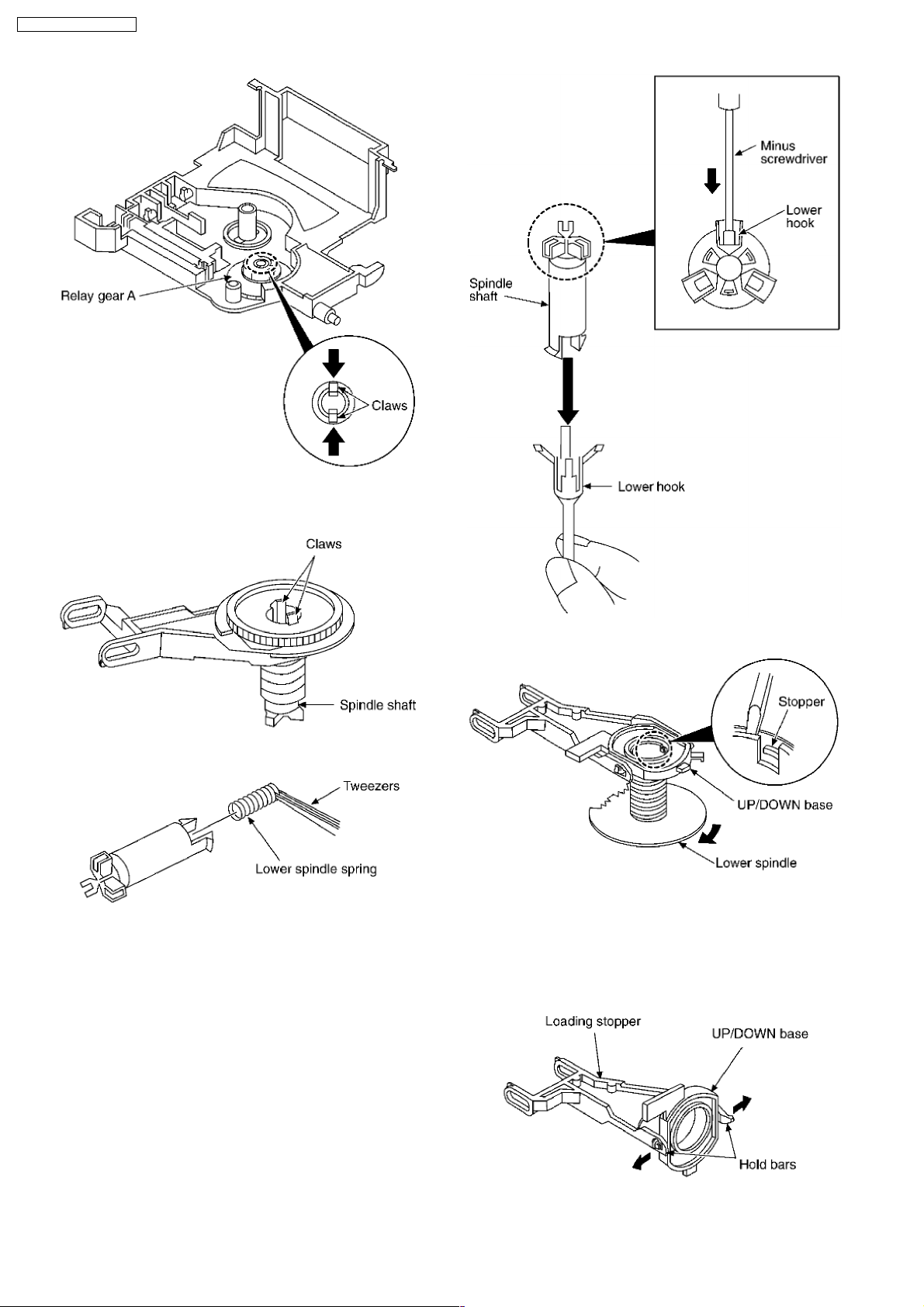

Step 8 Release the 2 claws, and then remove the relay gear A.

Step 9 Release the 2 claws, and then remove the spindle shaft.

Step 10 Remove the lower spindle spring with tweezers.

Step 11 Force the lower hook with thin tip of minus screwdriver.

Step 12 Squeeze the shaft of lower hook, and then draw it.

Step 13 Rotate the lower spindle in the direction of arrow until

the lower spindle interferes with stopper.

Step 14 Insert the thin tip of minus screwdriver between the

lower spindle and UP/DOWN base, and then slacken the lower

spindle to release the stopper. Then, rotate the lower spindle

and remove it.

Step 15 Rotate the UP/DOWN base at a 90° angle. Then,

26

SA-VK31GC / SA-VK31GS

spread the hold bars of loading stopper and remove the

UP/DOWN base.

[Installation for loading stopper ass’y]

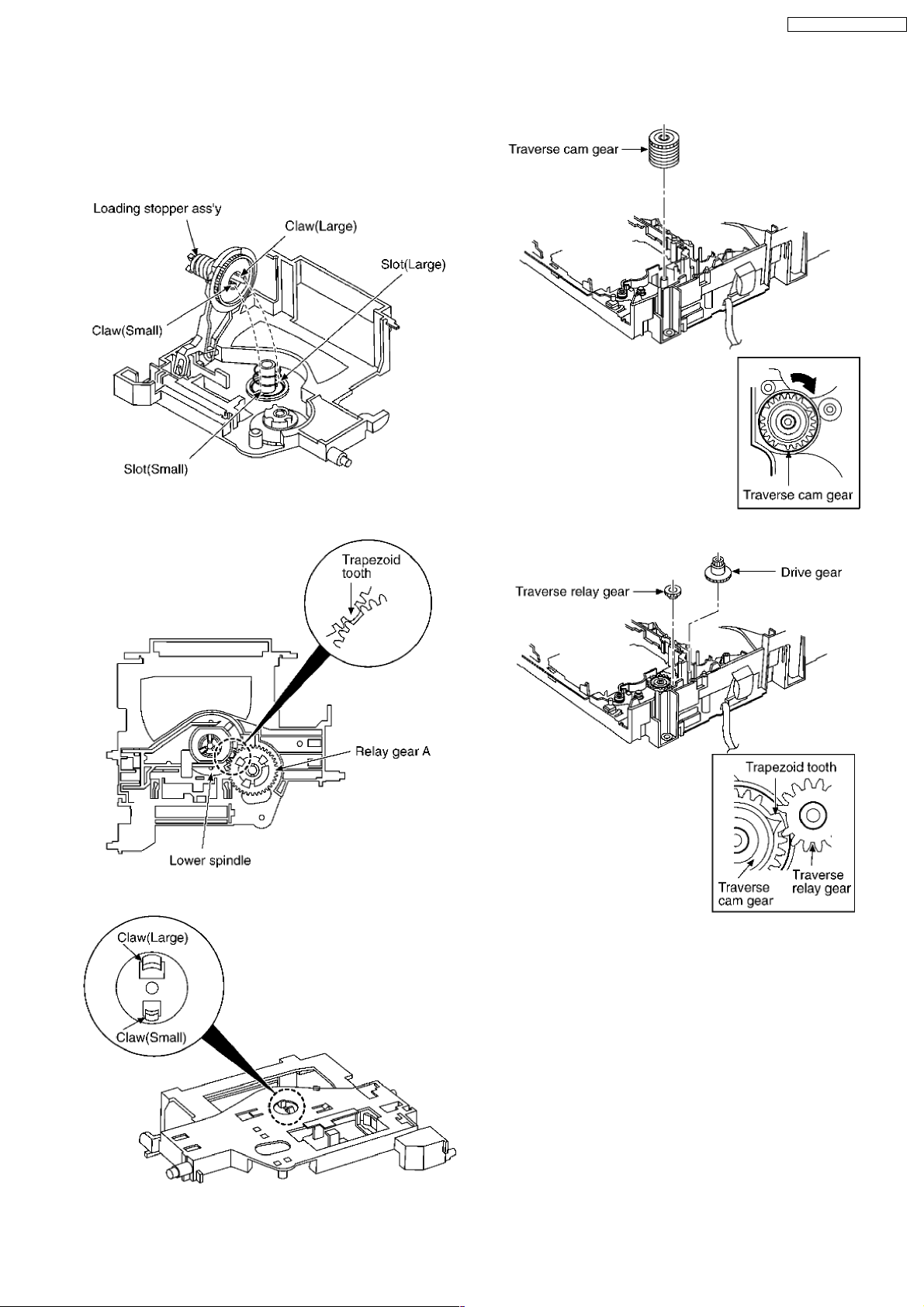

Step 1 Align the claw of loading stoppers ass’y with the slot of

spindle base. (Caution should be exercised when alignment of

claw due to the size of claws.)

Step 2 Lower the loading stopper ass’y, and then align the

lower spindle with the trapezoid tooth of relay gear A.

Step 1 Install the traverse cam gear.

Step 2 Rotate the traverse cam gear to the direction of arrow.

Step 3 Install the drive gear and traverse relay gear.

Step 3 Force the loading stopper ass’y, latch the claw firmly.

[Reassembly for mechanism base drive unit]

*When installing the traverse relay gear, align the trapezoid

tooth of gear with tooth of traverse cam gear.

27

SA-VK31GC / SA-VK31GS

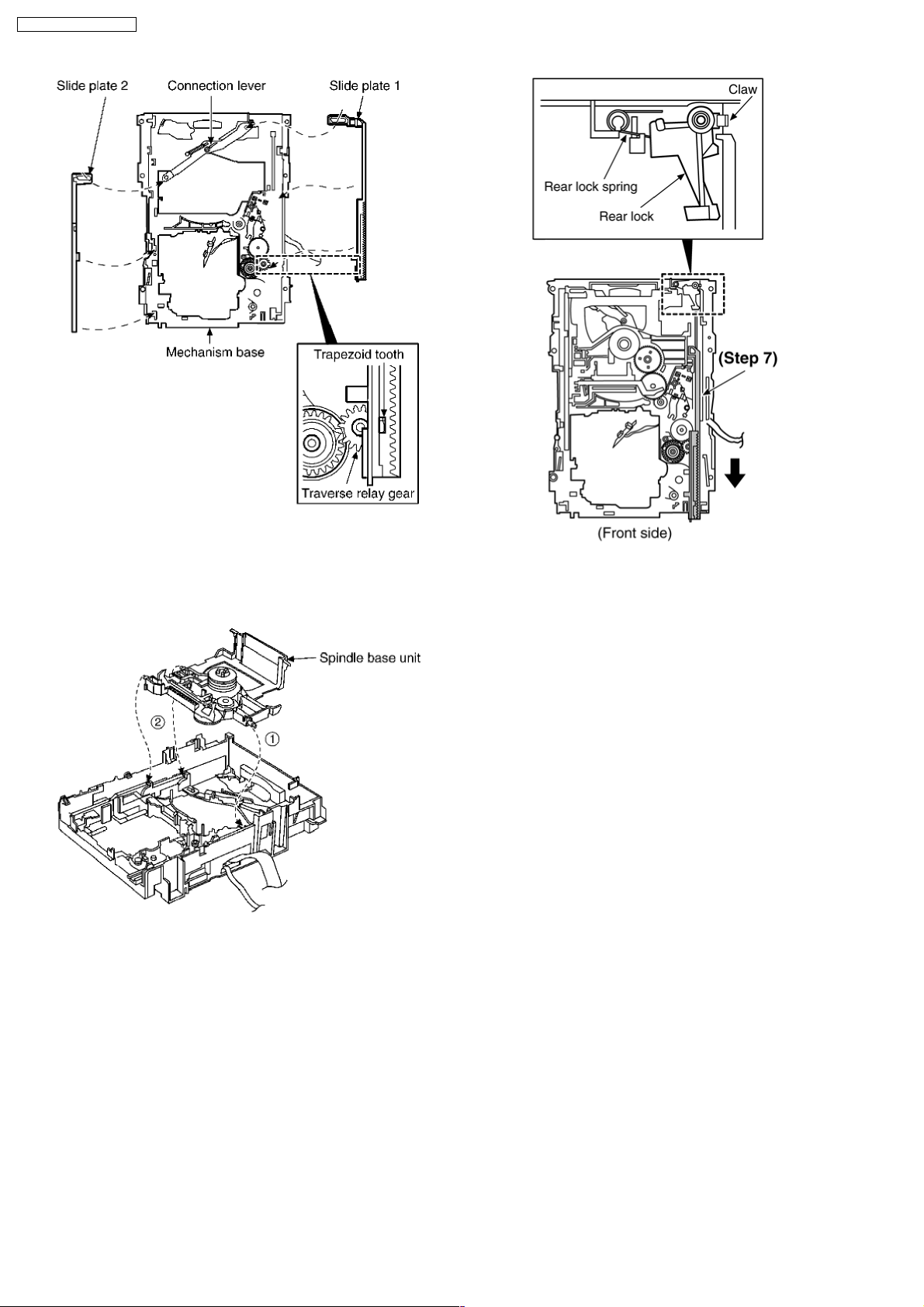

Step 4 Install the slide plate 2 to the mechanism base, and

then match to the connection lever.

Step 5 Install the slide plate 1 to the mechanism base, and

then match to the connection leve and align the trapezoid tooth

of traverse relay gear with the slide plate 1.

Step 6 Install the spindle base unit. (First, slide plate 1.)

Step 7 Move the slide plate 1 to forward fully.

Step 8 Install the rear lock. (The claw should be latched.)

Step 9 Install the Spindle Position P.C.B.. (The claw should be

latched.)

Step 10 Install the tray lock. (The claw should be latched.)

28

SA-VK31GC / SA-VK31GS

Step 14 Install the tray base, traverse ass’y, mechanism cover

and upper plate.

[Operation check after servicing]

Check the proper operation of following items with gear and

hexagonal screwdriver.

1. Open/close of tray base.

2. Moving the tray base to the stock side.

3. UP/DOWN operation of spindle base unit.

4. UP/DOWN operation of traverse ass’y.

Step 11 Remove the tray lock spring from hook,and then latch

to the tray lock.

Step 12 Install the UP/DOWN gear, change gear, change gear

spring, pulley gear and belt in the order of (1) - (5).

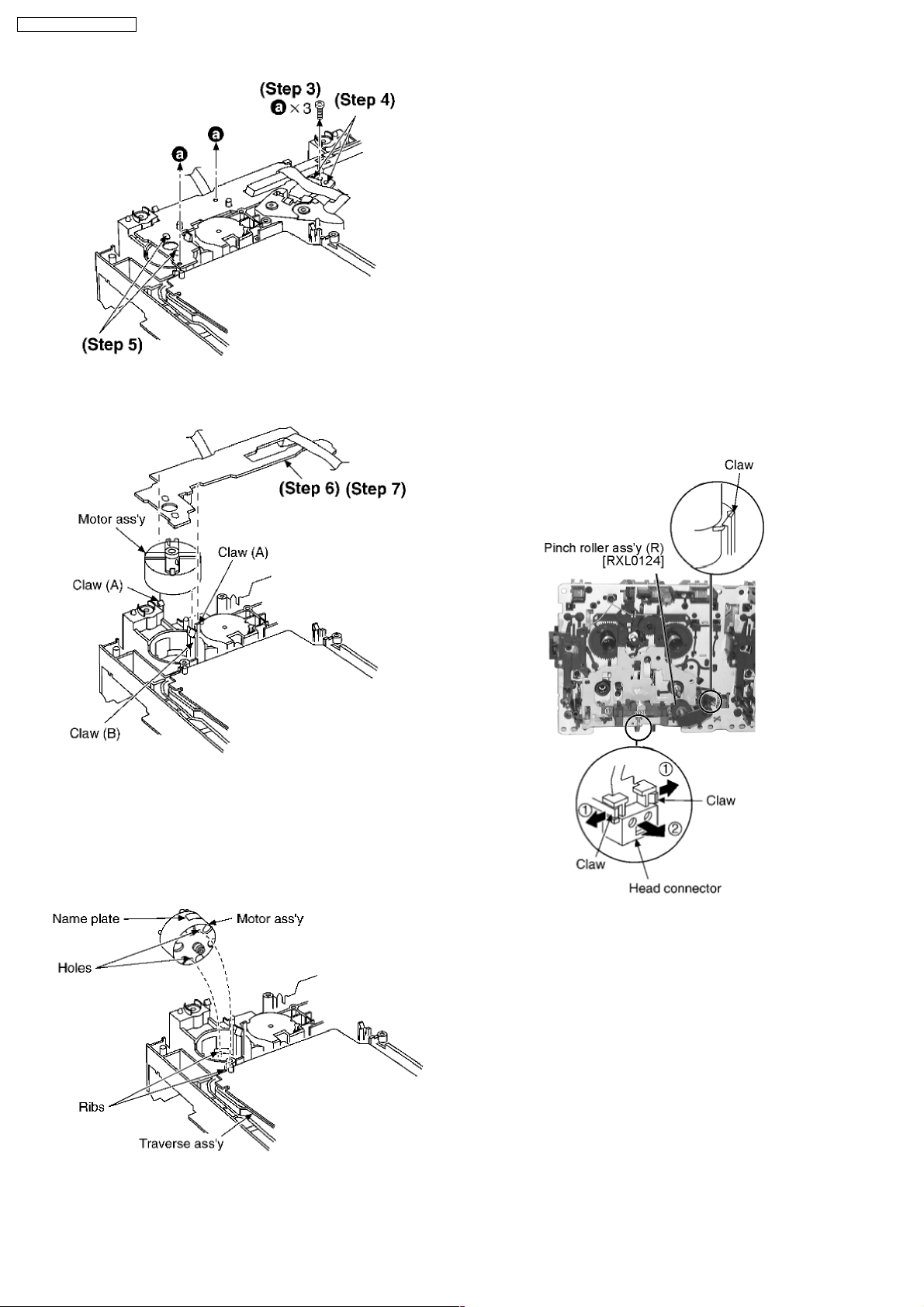

11.6.4. Replacement for the motor ass’y

Step 1 Install the belt temporarily.

NOTE:

Take care not apply the grease to the belt.

Step 2 Upset the CD loading unit.

Step 3 Remove 3 screws.

Step 13 Install the gear holder, and then tighten the screw (a).

29

SA-VK31GC / SA-VK31GS

Step 4 Unsolder the plunger terminals (2 points).

Step 5 Unsolder the motor terminals (2 points).

11.7. Disassembly Deck Mechanism

11.7.1. Replacement for the pinch roller

ass’y and head block

· Follow the (Step 1) - (Step 2) of Item 11.1 - Disassembly of

Top Cabinet and Rear Panel

· Follow the (Step 1) - (Step 6) of Item 11.1.1 - Disassembly

for CD Lid

· Follow the (Step 1) - (Step 2) of Item 11.2 - Disassembly for

the CD Mechanism Unit

· Follow the (Step 1) of Item 11.3 - Disassembly for the Main

P.C.B. & Transformer P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly for

the Panel P.C.B. & Tact Switch P.C.B.

· Follow the (Step 1) - (Step 5) of Item 11.5 - Disassembly for

the Deck Mechanism Unit & Deck P.C.B.

* The mechanism as shown below is for DECK1. For the

one of DECK 2, perform the same procedures.

Step 6 Release the 2 claws (A), and then remove the Motor

P.C.B.

Step 7 Release the claw (B), and then remove the motor ass’y.

[Notice for motor ass’y installation]

1. Locate the name plate of motor to the traverse ass’y.

2. Align the hole of motor with the ribs.

Step 1 Release the 2 claws, and then remove the pinch roller

(R), (F).

Step 2 Release ther 2 claws, and then remove the head

connector.

30

Loading...

Loading...