Panasonic MADL*01 Series, MBDL*21 Series, MADL*11 Series, MADL*05 Series, MBDL*25 Series Reference Specifications

...

No.SX-DSV03015

REFERENCE SPECIFICATIONS

MODEL

Product Name: AC servo driver

Part Number : MINAS-A6 series (Basic type)

Issued on Sept. 1, 2015

Revised on Sept. 14, 2016

Motor Business Unit, Electromechanical Control Business Division

Automotive & Industrial Systems Company, Panasonic Corporation

7-1-1 Morofuku , D aito-City, Osaka 574-0044 Japan

No. SX-DSV03015

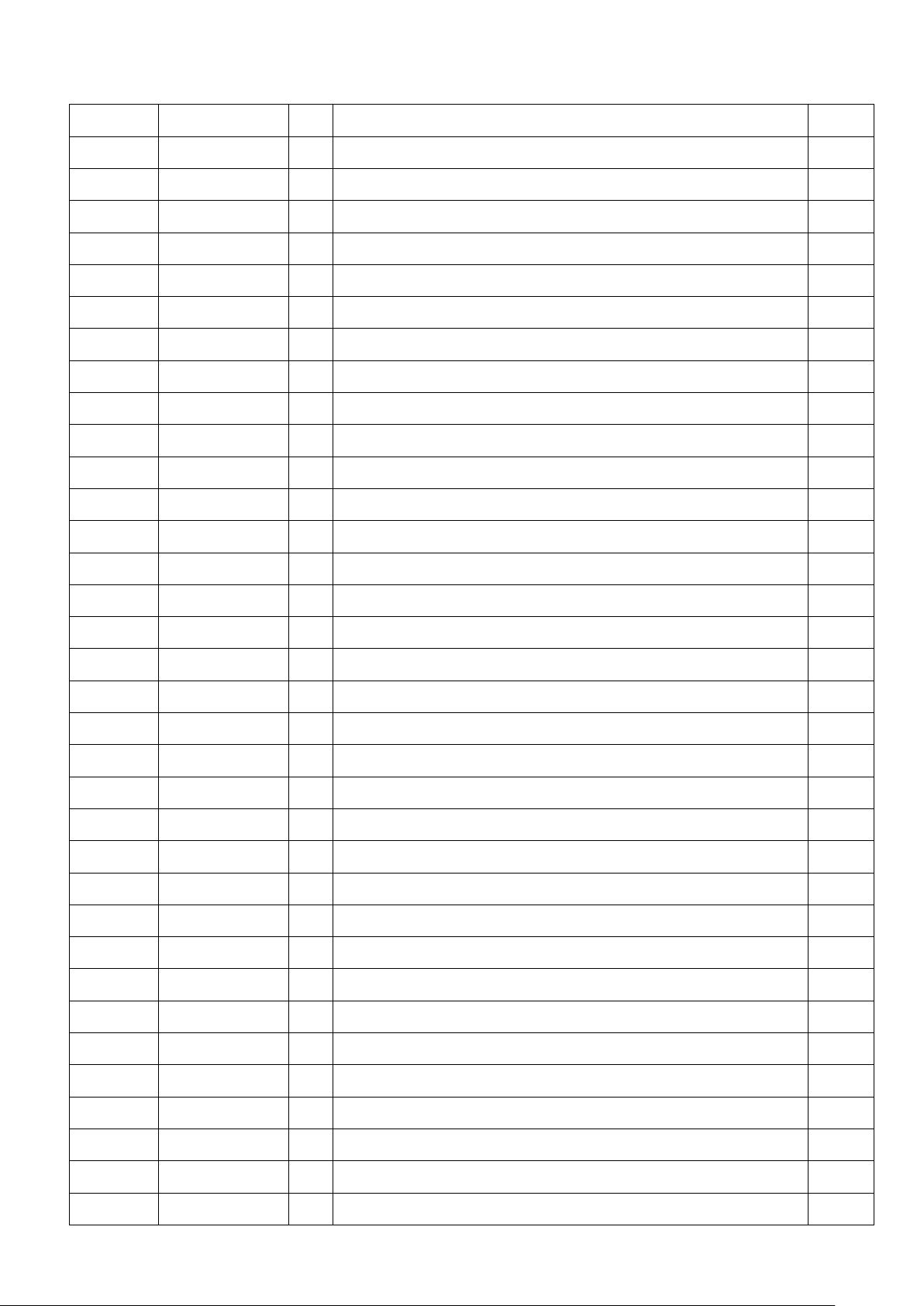

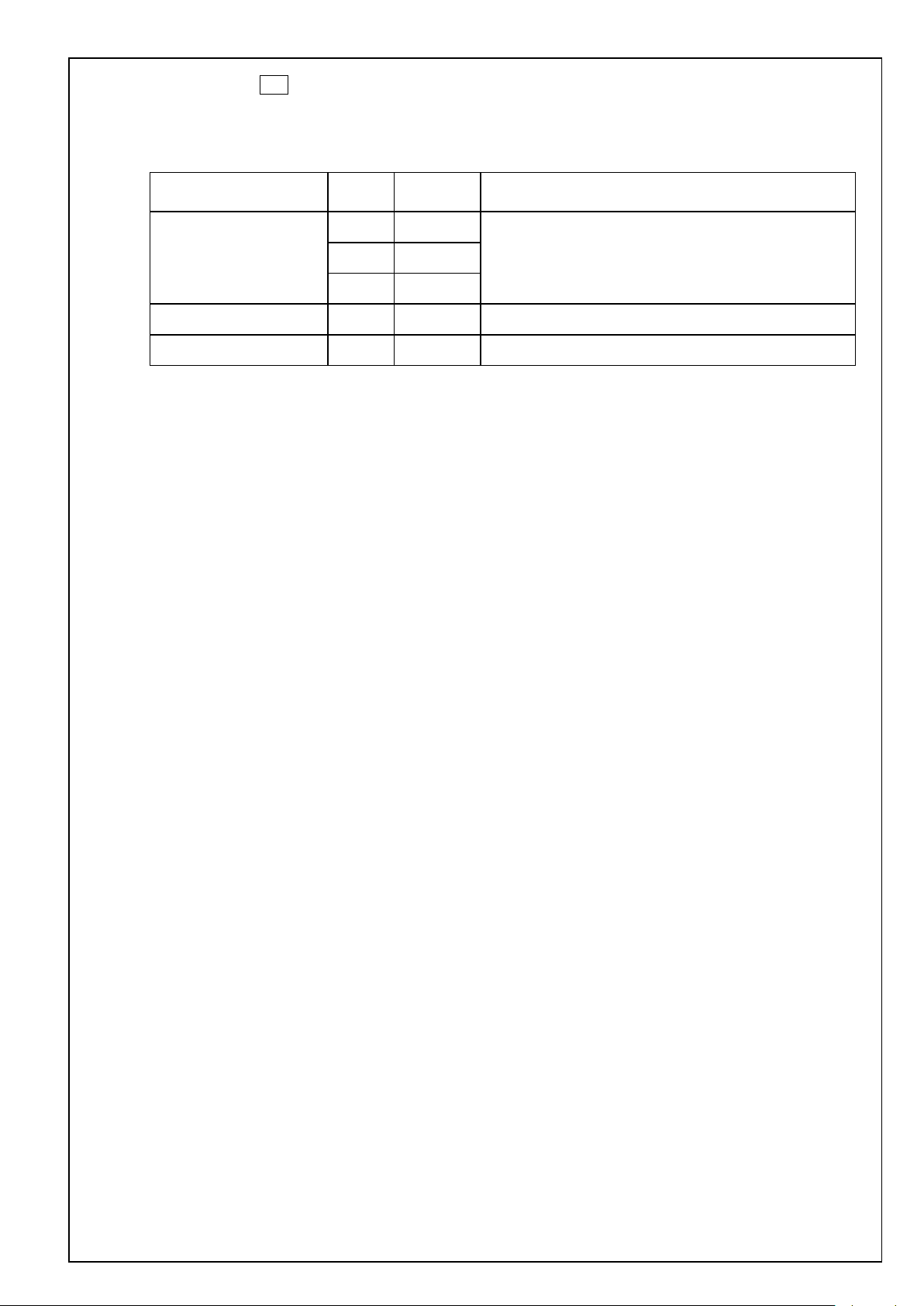

REVISIONS

Date Page Rev. Description Signed

Spt. 1, 2015

Nov. 1, 2015

Sept.14,2016

P1, P3,P53, P65

P5

P56 ADDED THE HARMONIC SUPPRESSION MEASURES

- NEWLY ISSUED -

- 1.0 DEFAULT VALUE OF THE PARAMETERS CHANGED -

P1 2.0 UPDATE THE MODEL DESIGNATION CODE -

P1 CHANGED THE NAME OF COMPANY

ADDED THE MODEL OF MEDLN93SE

ADDED THE FUNCTIONS

P63~65

CORRECT THE INRUSH CURRENTS AT CONTROL POWER SUPPLY

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015

Contents

1. Scope ································································································································· 1

2. Model designation code ············································································································ 1

3. Product line-up ······················································································································ 2

4. General specifications ·············································································································· 4

4-1 General specification ········································································································· 4

4-2 Specifications by model ······································································································ 5

5. Appearance and part names ········································································································ 6

6. Configuration of connectors and terminal blocks ··············································································· 11

6-1 Power connector XA , XB , XC , XD and terminal block ························································ 11

6-2 USB connector X1 ··········································································································· 15

6-3 Parallel I/O connector, X4 ·································································································· 16

6-4 Encoder connector X6 ······································································································· 20

7. Dimensions ·························································································································· 23

8. Wiring ································································································································ 35

8-1 Used cables and maximum cable lengths ·················································································· 35

8-2 Various connectors ············································································································ 35

8-3 Precautions for wiring ········································································································ 36

9. Compliance with global standards ································································································ 49

9-1 Conforming standards ········································································································ 49

9-2 European EC directive········································································································ 49

9-3 Peripheral device configuration ····························································································· 50

9-4 List of peripheral devices applicable to servo driver ····································································· 53

9-5 Compliance with UL stand a r d ······························································································· 55

9-6 Radio waves act (South Korea) precautions ··············································································· 56

9-7 Compliance with SEMI F47 instantaneous stop standard ······························································· 56

9-8 Harmonic suppression measures ···························································································· 56

10. Safety precautions ················································································································· 57

11. Life and warranty ·················································································································· 61

11-1 Life expectancy of the driver ······························································································· 61

11-2 Typical life ··················································································································· 61

11-3 Warranty period ·············································································································· 61

12. Others ······························································································································· 62

13. Specification for each model ····································································································· 63

The maximum value of torque limit setup

Default value of the parameters

Motor Business Unit, Panasonic Corporation

Custom specification (Alphanumeric)

Size

1. Scope

These specifications relate to the servo driver for the AC servo system that is comprised of the AC servo motor

manufactured and supplied by Motor Business Unit, Electromechanical Control Business Division, Automotive &

Industrial amplifier Systems Company, Pan ason ic C orporat ion .

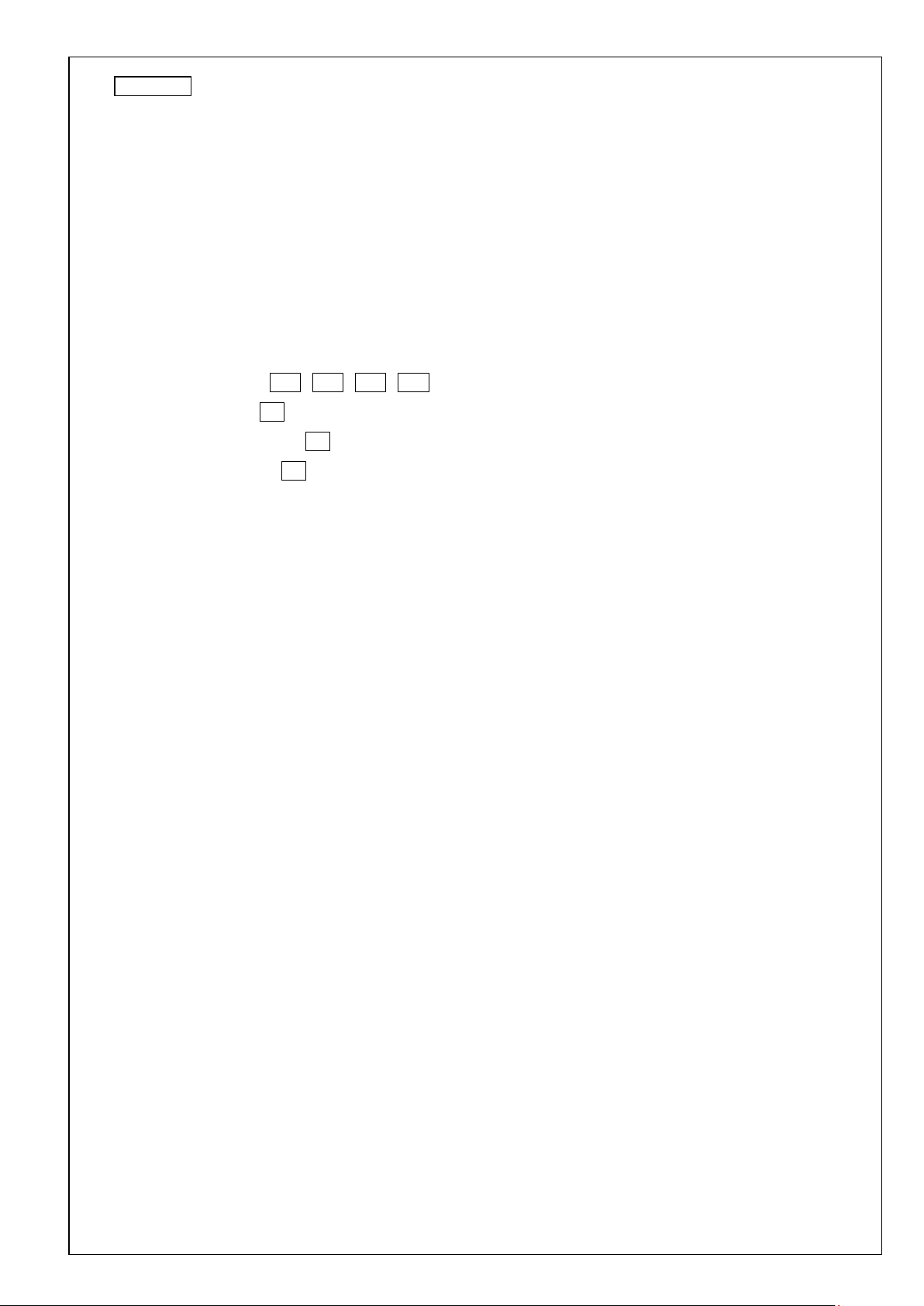

2. Model designation code

Notation of the machine designation code is as follows:

A : Size A

B : Size B

C : Size C

D : Size D

E : Size E

F : Size F

AC Servo drive

L : A6 series

Safety function

N : Without functional safety

Maximum instantaneous

output current

0 : 6 A

1 : 8 A

2 : 12 A

3 : 22 A

4 : 24 A

5 : 40 A

8 : 60 A

9 : 80 A

A : 100 A

B : 120 A

1 2 3 4 5 6 7 8 9 10 11 12

M A D L N 1 5 S E * * *

User Interface

• Rotary type

Power supply voltage

No. SX-DSV03015 - 1 -

E : Basic type

1 : Single phase 100 V

3 : 3 phase 200 V

5 : Single or 3 phase 200 V

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 2 -

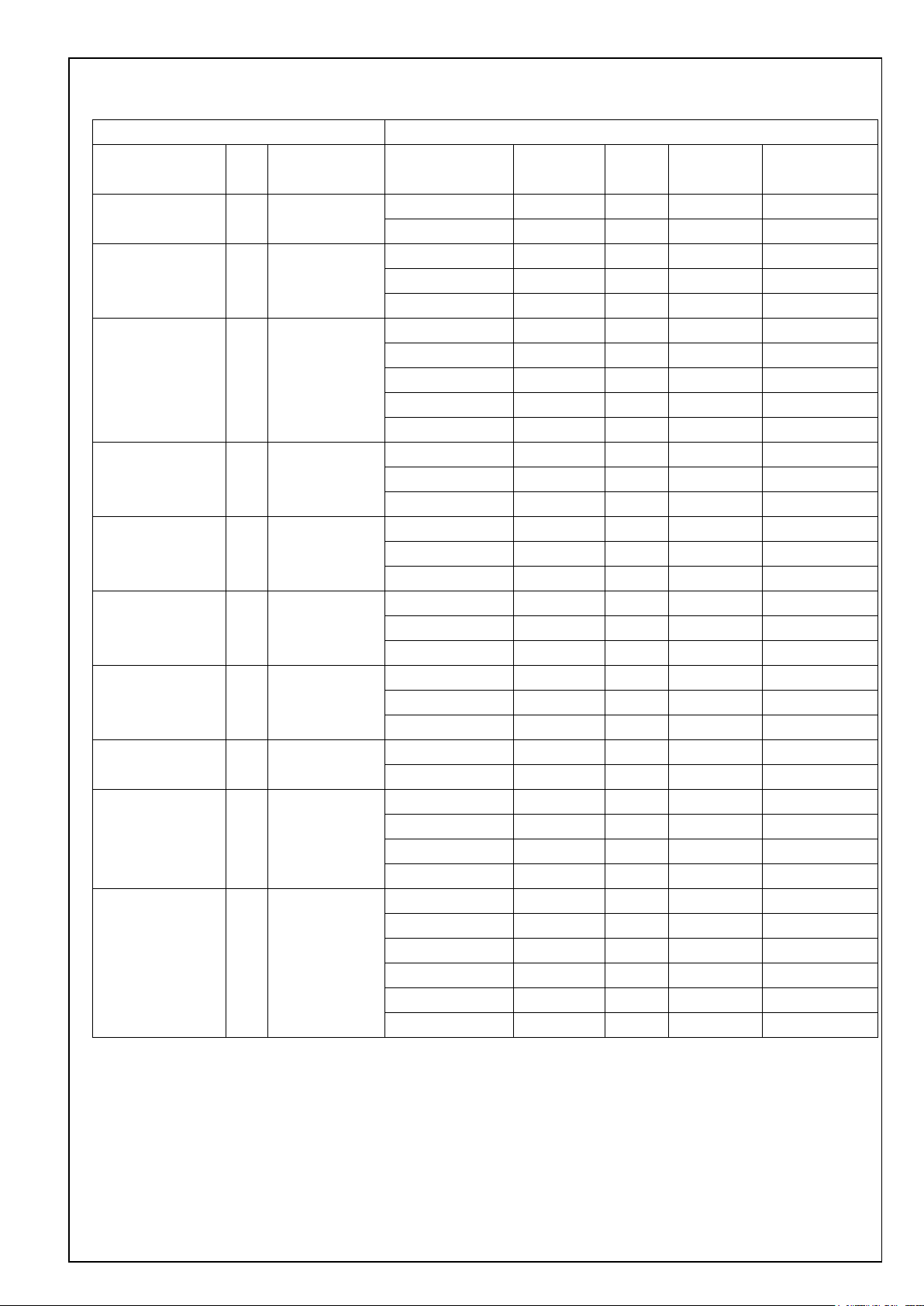

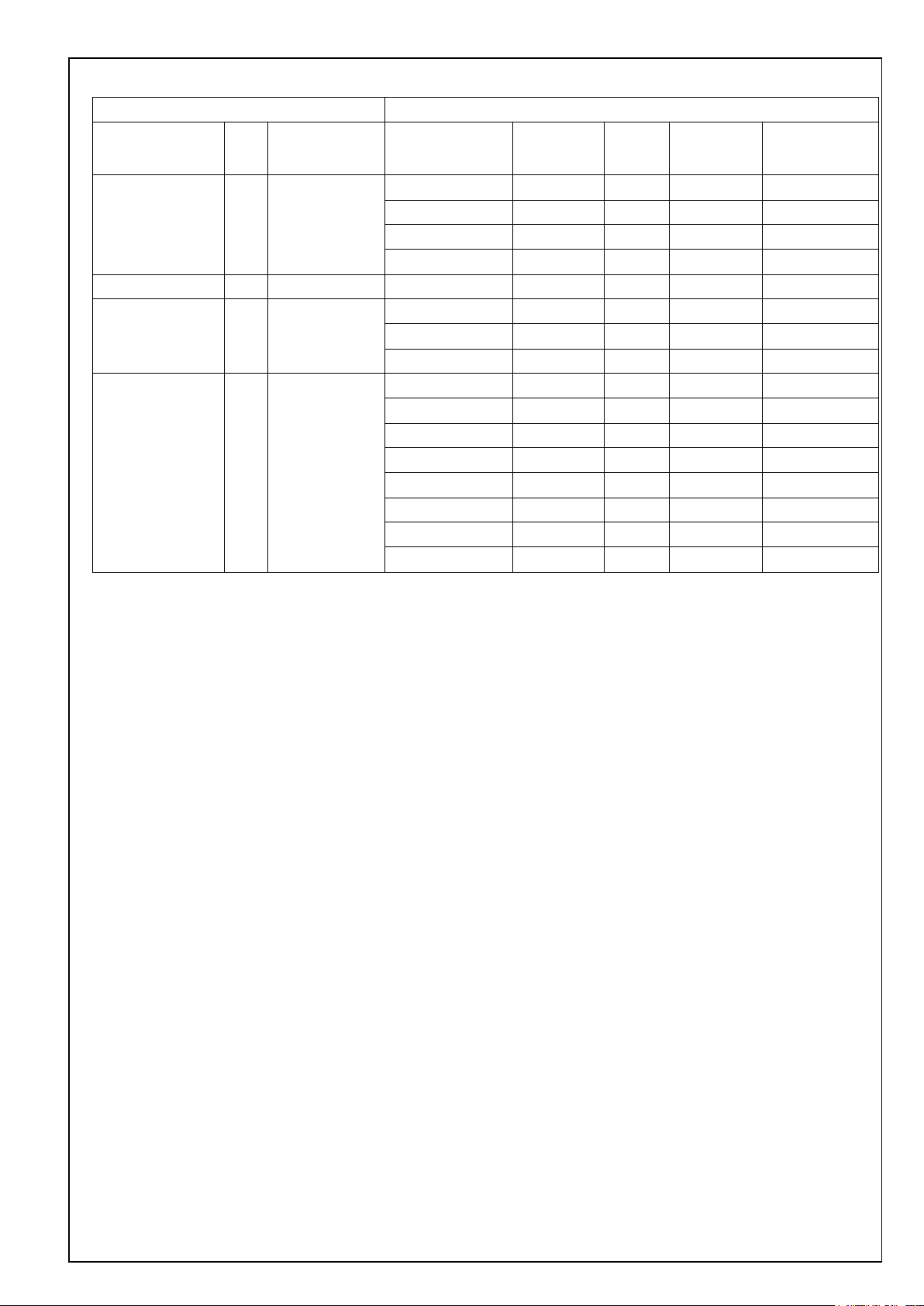

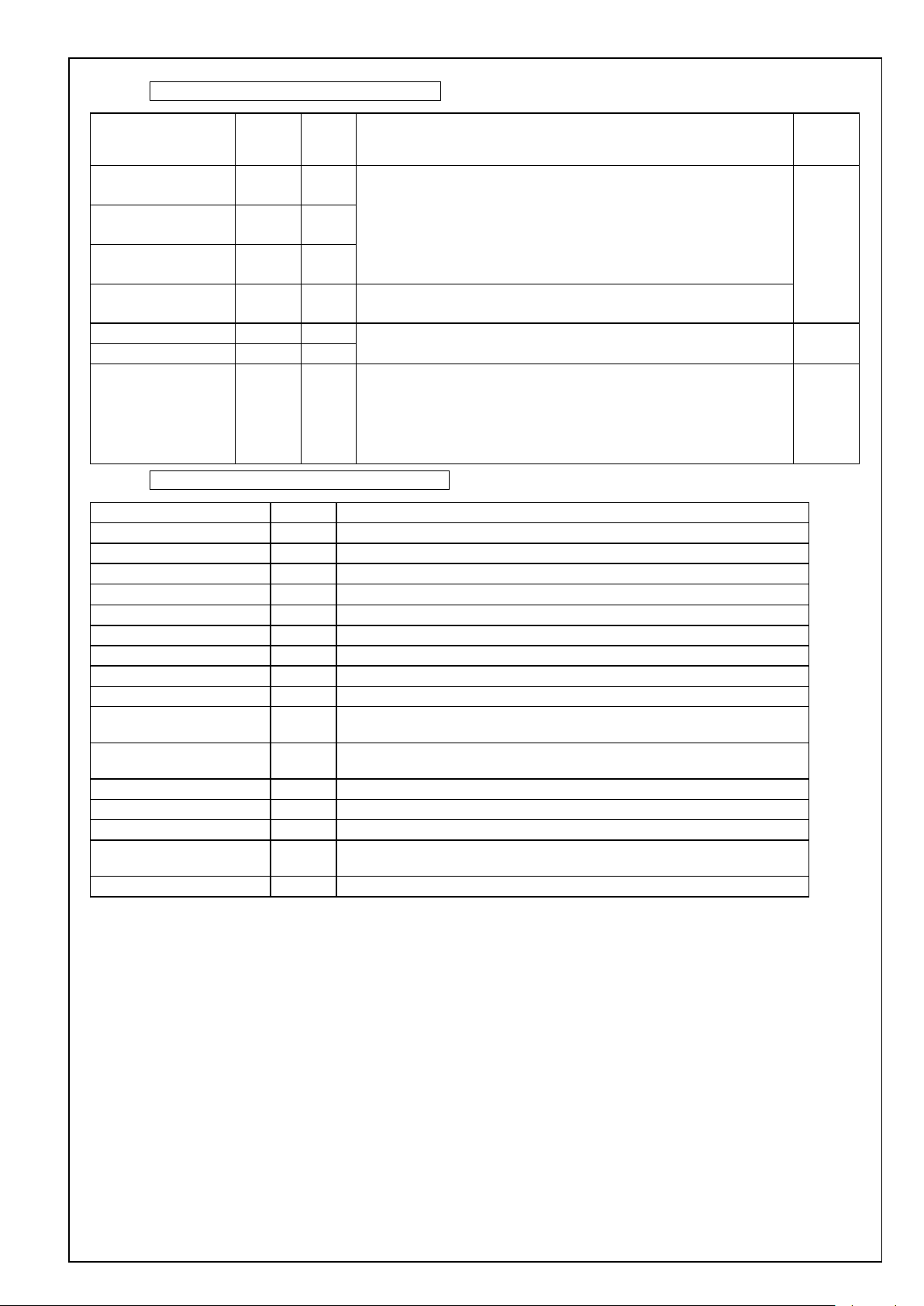

3. Product line-up

Servo driver Motor used

Model Size

Power supply

input

Model

Voltage

specification

Rated

output

Rated speed

MADLN01SE A Single MSMF5AZL1** 100 V 50 W 3000 r/min 7 cores, 23 bits

100 V MHMF5AZL1** 100 V 50 W 3000 r/min

MADLN11SE A Single MSMF011L1** 100 V 100 W 3000 r/min

100 V MQMF011L1** 100 V 100 W 3000 r/min

MHMF011L1** 100 V 100 W 3000 r/min

MADLN05SE A Single / 3 phase MSMF5AZL1** 200 V 50 W 3000 r/min

200 V MHMF5AZL1** 200 V 50 W 3000 r/min

MSMF012L1** 200 V 100 W 3000 r/min

MQMF012L1** 200 V 100 W 3000 r/min

MHMF012L1** 200 V 100 W 3000 r/min

MADLN15SE A Single / 3 phase MSMF022L1** 200 V 200 W 3000 r/min

200 V MQMF022L1** 200 V 200 W 3000 r/min

MHMF022L1** 200 V 200 W 3000 r/min

MBDLN21SE B Single MSMF021L1** 100 V 200 W 3000 r/min

100 V MQMF021L1** 100 V 200 W 3000 r/min

MHMF021L1** 100 V 200 W 3000 r/min

MBDLN25SE B Sin gle / 3 phase MSMF042L1** 200 V 400 W 3000 r/min

200 V MQMF042L1** 200 V 400 W 3000 r/min

MHMF042L1** 200 V 400 W 3000 r/min

MCDLN31SE C Single MSMF041L1** 100 V 400 W 3000 r/min

100 V MQMF041L1** 100 V 400 W 3000 r/min

MHMF041L1** 100 V 400 W 3000 r/min

MCDLN35SE C Single / 3 phase MSMF082L1** 200 V 750 W 3000 r/min

200 V MHMF082L1** 200 V 750 W 3000 r/min

MDDLN45SE D Single / 3 phase MGMF092L1** 200 V 850 W 1500 r/min

200 V MSMF092L1** 200 V 1.0 kW 3000 r/min

MDMF102L1** 200 V 1.0 kW 2000 r/min

MHMF102L1** 200 V 1.0 kW 2000 r/min

MDDLN55SE D Single / 3 phase MHMF092L1** 200 V 1.0 kW 3000 r/min

200 V MSMF102L1** 200 V 1.0 kW 3000 r/min

MGMF132L1** 200 V 1.3 kW 1500 r/min

MSMF152L1** 200 V 1.5 kW 3000 r/min

MDMF152L1** 200 V 1.5 kW 2000 r/min

MHMF152L1** 200 V 1.5 kW 2000 r/min

Encoder

specification

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 3 -

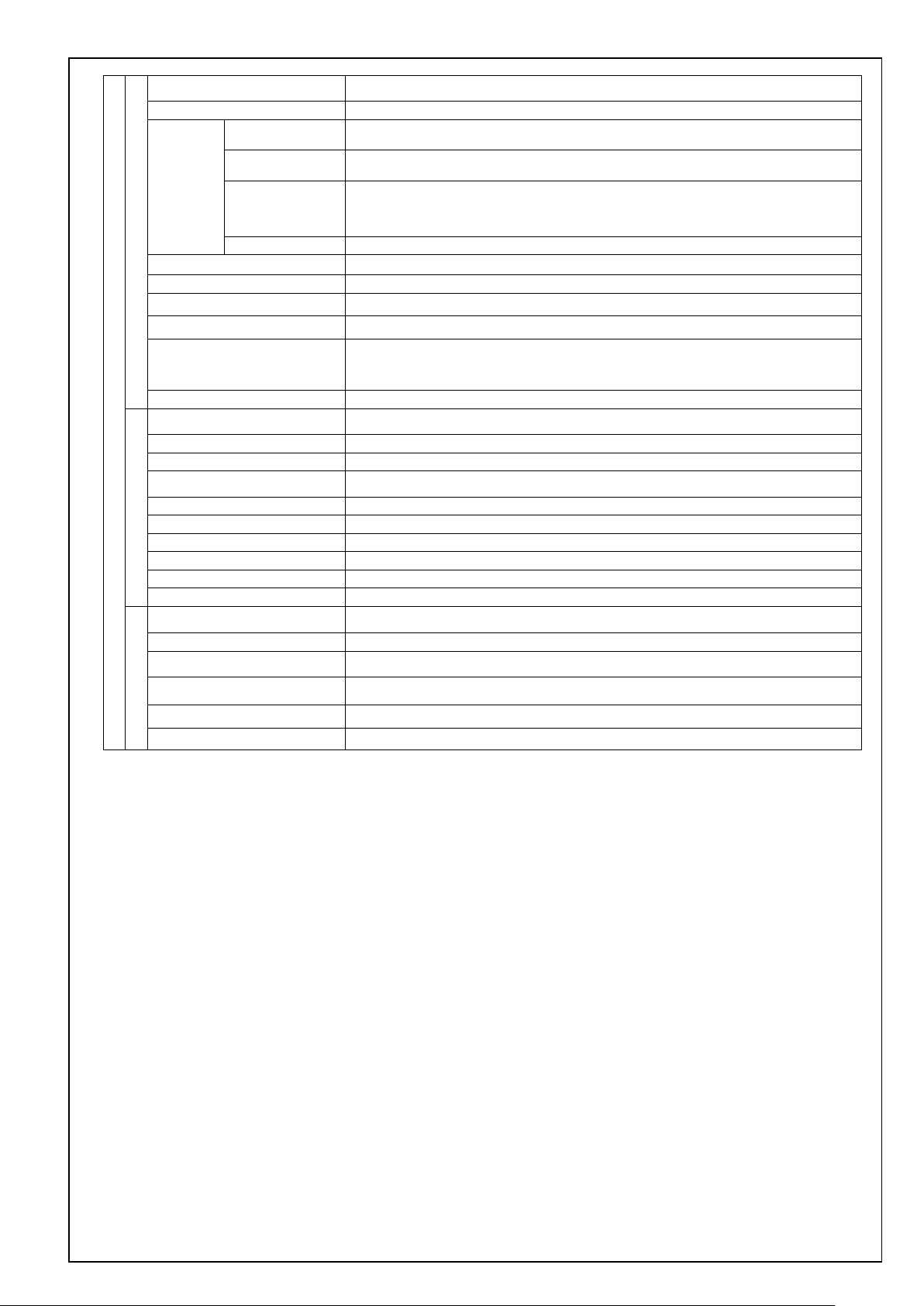

Servo driver Motor used

Model Size

Power supply

input

Model

Voltage

specification

Rated

output

Rated speed

MEDLN83SE E 3 phase MGMF182L1** 200 V 1.8 kW 1500 r/min 7 co r es, 23 bits

200 V MSMF202L1** 200 V 2.0 kW 3000 r/min 7 cores, 23 bits

MDMF202L1** 200 V 2.0 kW 2000 r/min 7 cores, 23 bits

MHMF202L1** 200 V 2.0 kW 2000 r/min 7 cores, 23 bits

MEDLN93SE E 3 phase 200 V MGMF242L1** 200 V 2.4 kW 1500 r/min 7 cores, 23 bits

MFDLNA3SE F 3 phase MSMF302L1** 200 V 3.0 kW 3000 r/min 7 cores, 23 bits

200 V MDMF302L1** 200 V 3.0 kW 2000 r/min 7 cor es, 23 bits

MHMF302L1** 200 V 3.0 kW 2000 r/min 7 cores, 23 bits

MFDLNB3SE F 3 phase MGMF292L1** 200 V 2.9 kW 1500 r/min 7 co r es, 23 bits

200 V MSMF402L1** 200 V 4.0 kW 3000 r/min 7 co res, 23 bits

MDMF402L1** 200 V 4.0 kW 2000 r/min 7 cor es, 23 bits

MHMF402L1** 200 V 4.0 kW 2000 r/min 7 cores, 23 bits

MGMF442L1** 200 V 4.4 kW 1500 r/min 7 cor es, 23 bits

MSMF502L1** 200 V 5.0 kW 3000 r/min 7 cores, 23 bits

MDMF502L1** 200 V 5.0 kW 2000 r/min 7 cor es, 23 bits

MHMF502L1** 200 V 5.0 kW 2000 r/min 7 cores, 23 bits

Encoder

specification

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 4 -

Storage temperature: -20 – 65 degrees C (Max.temperature gu arantee : 80 degrees C for 72 hours no condensation*)

Height above the sea

Height above the sea level: 1000 meters or less

Vibration

5. 88 m/s2 or less, 10 – 60 Hz

Insulation voltage

Resistant to 1500 V AC between primary power supply and ground for a minute (Sensed current: 20 mA)

Control method

IGBT PWM method, sinusoidal drive

Encoder feedback

23Bit(resolution:8388608) 7cores-serial absolute encoder

Function of each multi-funct i o n i np ut is assigned by the parameter.

Function of each multi-function output is assigned by the parameter.

Analogue signal

Output

2 outputs for analog monitor

High speed line driver interface can be connected.

collector output also available for Z or EXZ signal

Communication

USB

USB interface to connect to computers for parameter setting or status monitoring.

Front panel

5 key switches, 6-digit 7-se g ment LED

Regeneration

Size A, B: External r egen resistor only Size C - F: Built-in regen resistor (External regen is also available)

Dynamic brake

Size A - F: Built-in

4. General specifications

4-1 General specification

100 V

Input

power

supply

200 V

Operation conditions

Basic specifications

Control signal

Main circuit power

Control circuit power Single phase 100 - 120 V

Main circuit

power

Control circuit

power

Temperature

Humidity Operation and storage humidity 20 - 85 % RH or less (no condensation*)

A - D

E - F 3 phase 200 - 240 V

A - D

E - F Single phase 200 - 240 V

Input

Output

Multi-function input x 10

Multi-function output x 5 + dedicated output x 1 (alarm output)

Single phase 100 - 120 V

Single/3 phase 200 - 240 V

Single phase 200 - 240 V

+ 10%

50/60 Hz

- 15%

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

Operation tempera ture: 0 - 55 degrees C (no freezing)

2 inputs

Input

Pulse signal

Output

Control mode

Please note that condensation tend to occur when temperature fall.

Both open collector and line driver interface can be connected.

4 outputs

Line driver output for encoder pulses (A/B/Z signal) or external feedba c k pulses (EXA/EXB/EXZ sig nal) open

Selectable from the fo llowing 3 modes by parameter:

[1]position cont rol [2]velocity control [3]position/velocity c ontrol

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 5 -

Deviation counter clear, command pulse input inhibition, command division/multiplication switching,

vibration suppression control sw itc hing, etc.

1/1000 to 8000 times

Smoothing Filter

Available

ion origin return invalidation sett ing is s et to

invalid)

Internal command velocity selection 1, Internal command velocity selection 2, Internal command velocity selection 3,

speed zero clamp, etc.

Control output

Speed arrival, etc.

0 to 10s/1000 r/min r/min Setting is possible for acceleration and deceleration respectively. S shaped

acceleration/deceleration is possible.

Velocity command filter

Available

Block operation

Not available

This function identifies the load inertia real-time and automatically sets up the gain that meets the stiffness setting

when the motor is running with ho st and inte r nal driver operation co mmands.

Overvoltage, undervoltage, overspeed, overload, overheat, overcurrent, encoder failure, positional overdeviation,

command pulse division, EEPROM failure, etc.

Control input

Control output Positioning co mpletion, etc.

Max command pulse

frequency

Command pulse input

Pulse input

Vibration suppression control Maximum of 3 may be used simultaneously

Position control

Model type vibration damping filter Maximum of 2 may be used simultaneously

2 degrees of freedom control Available

Load fluctuation suppression control Available

mode

Command pulse scaling

(Electronic gear)

500 K[pulse/s] (w hen using the photo coup ler input)

8 M[pulse/s] (when using the line receiver input of A-phase /B-phase)

Differential inp ut . D iffe rential input can be selected by parameters. ((1) Positive direction/ negative direction,

(2) A-phase/B-phase (3) Command/ direction)

Although electronic g ear rati o of the en coder resolu tion (num erator) and command number of pulses per revoluti on of the

motor (denominator) can be arbitrarily set in the range of 1 to 223 f or th e numerator and in the rang e of 1 to 223 f or the

denominator, this product should be u sed within the afor ementioned range.

Primary delay filter or FIR filter is selectable for command input.

Position compare output function

Block operation Available

Contro l i np u t

Function

Internal velocity command It is possible to switch 8 speeds of internal velocity with control input.

Soft start/down function

Speed zero clamp I nternal velocity command can be clamped to 0 with speed zero clamp input.

Velocity control

2 degrees of freedom control Available

Load fluctuation suppression control Available

Position compare output function Not available

Auto-tuning

Pulse signal output division function Number of pulses can be arbitrarily set. (However, the number of encoder pulses is the maximum number.)

Protectio n f u nction

Alarm data trace back function Reference of history of alarm data is available.

Common

Infinite rotation absolute funct ion Available

Deterioration diagnosis function Available

[Condition] Block operation valid setting

Return to origin completed state in incre me nt mo de (when block operat

4-2 Specifications by model

Refer to specification for each model.

Motor Business Unit, Panasonic Corporation

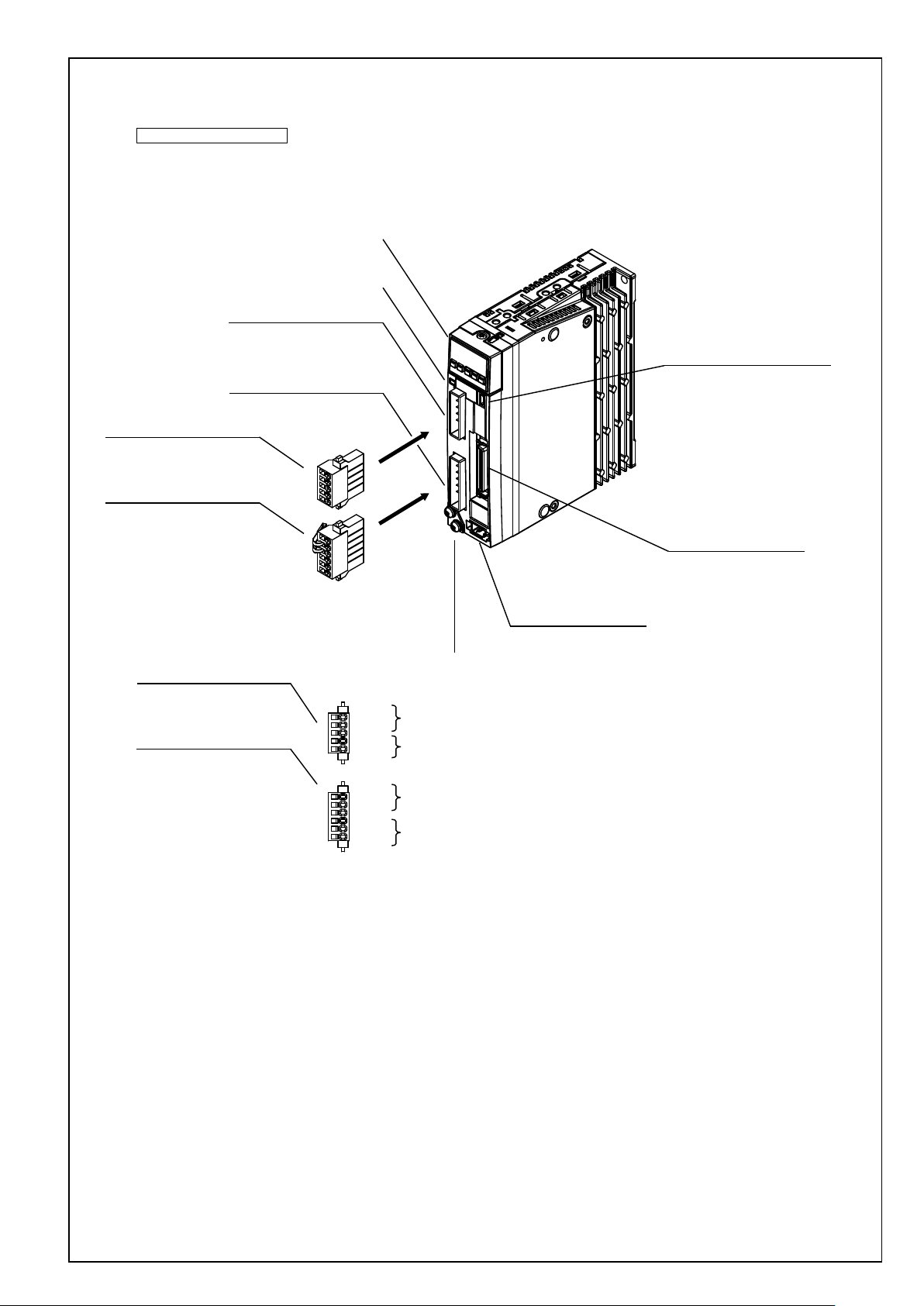

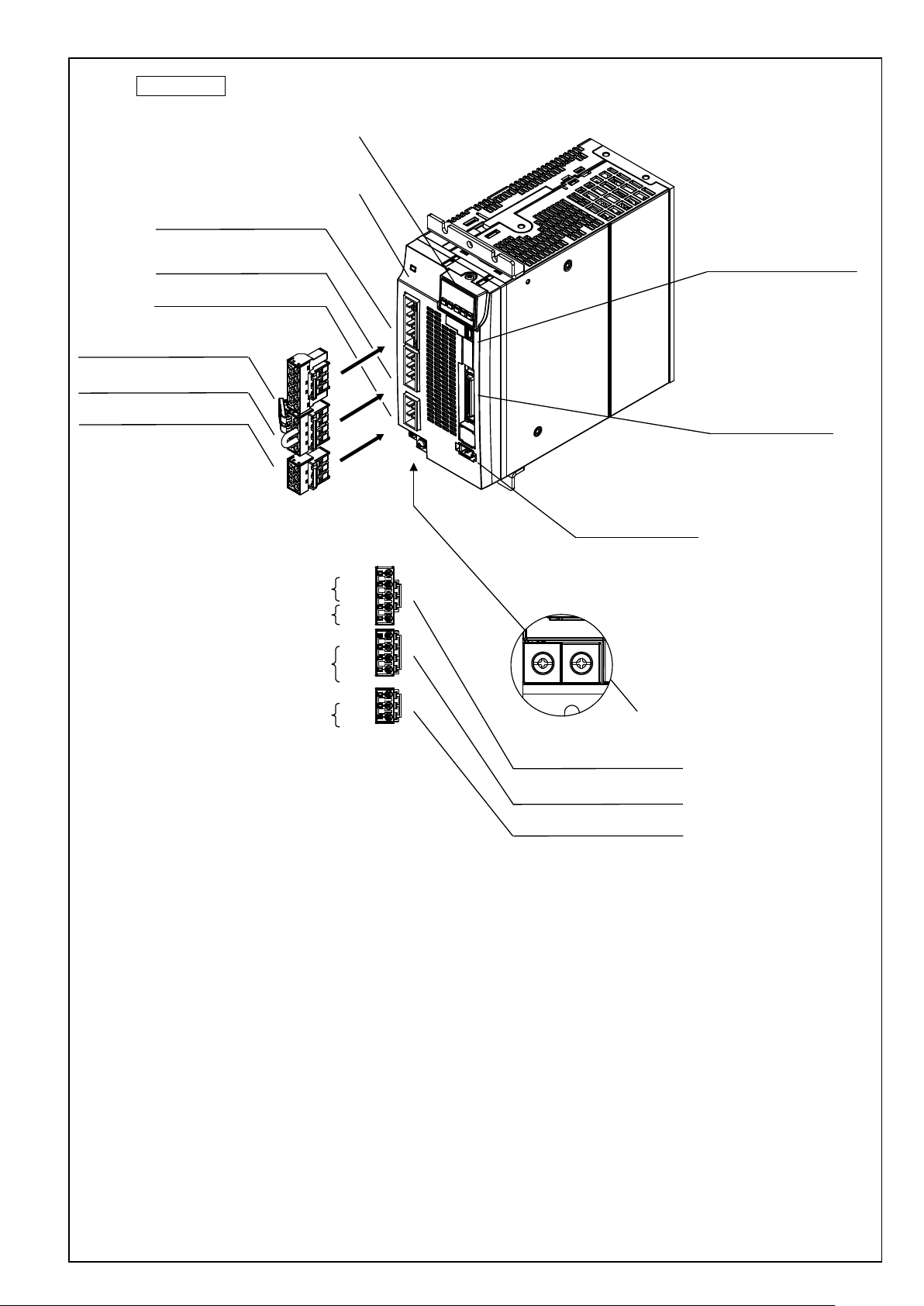

5. Appearance and part names

100 V,200 V size A, B

XA:Power supply input connection

05JFAT-SAXGGKK-A (JST)

(or equivalent)

Front panel

Charge lamp

XA: Power supply input

S05B-F32SK-GGXR (JST)

(or equivalent)

XB: Motor output

S06B-F32SK-GGXR (JST)

(or equivalent)

No. SX-DSV03015 - 6 -

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

XB:Motor connection

06JFAT-SAXGGKK-A (JST)

(or equivalent)

XA:Power supply input connection

XB:Motor connection

L1

L2

L3

L1C

L2C

P

N

B

U

V

W

Earth connection screw

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 7 -

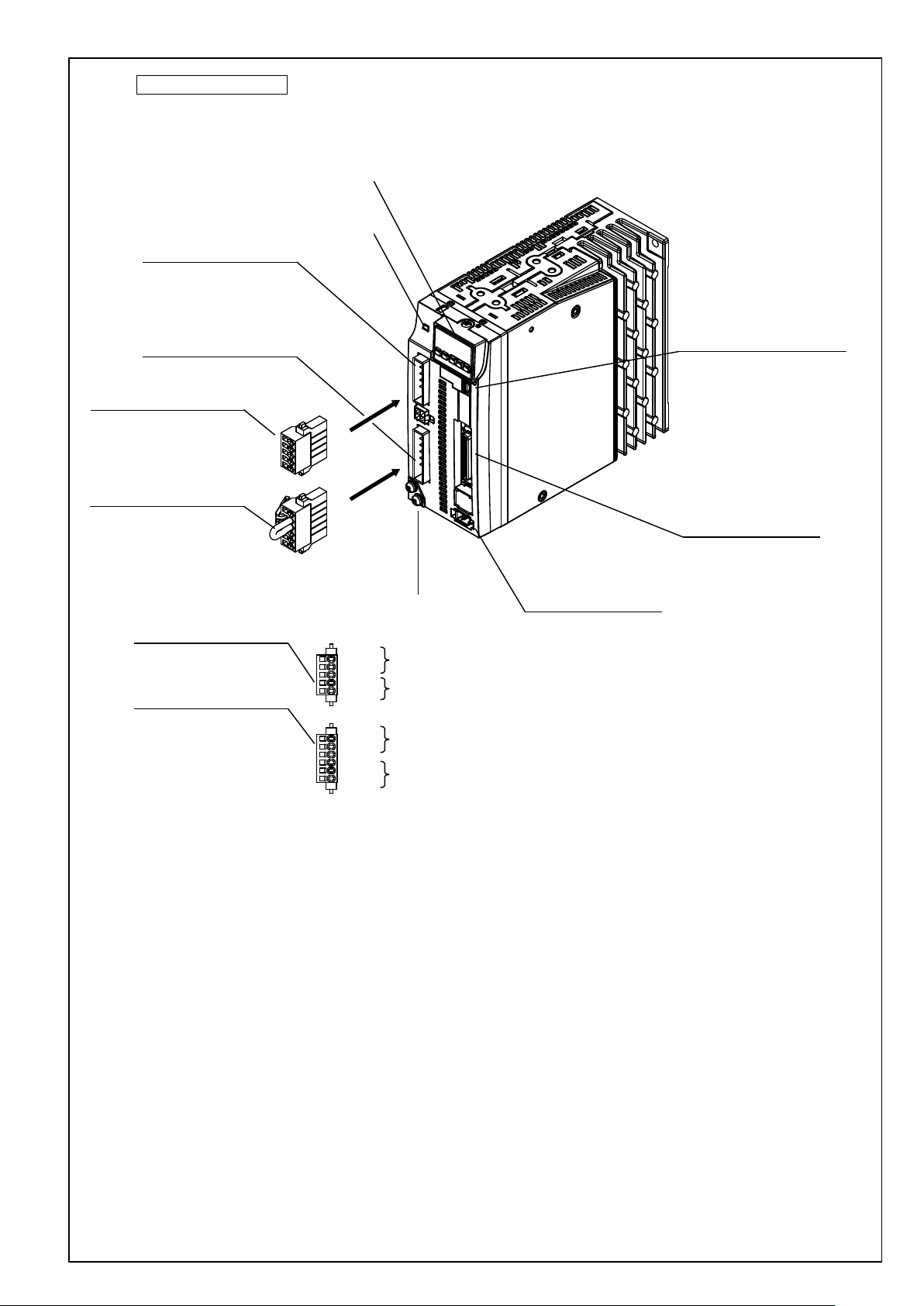

100 V,200 V size C, D

Front panel

Charge lamp

XA: Power supply input

S05B-F32SK-GGXR (JST)

(or equivalent)

XB: Motor output

S06B-F32SK-GGXR (JST)

(or equivalent)

XA:Power supply input connection

05JFAT-SAXGGKK-A (JST)

(or equivalent)

XB:Motor connection

06JFAT-SAXGGKK-A (JST)

(or equivalent)

XA:Power supply input connection

XB:Motor connection

Earth connection screw

L1

L2

L3

L1C

L2C

P

RB

B

U

V

W

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 8 -

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

Charge lamp

Front panel

Earth connection screw

XA:Power supply input connection

XC:Regenerative resistor connection

XB:Motor connection

XA:Power supply input connection

05JFAT-SAXGSA-L (JST)

(or equivalent)

XC:Regenerative resistor connection

04JFAT-SAXGSA-L (JST)

(or equivalent)

XB:Motor connection

03JFAT-SAXGSA-L (JST)

(or equivalent)

XA: Power supply input

S05B-JTSLSK-GSANXR (JST)

(or equivalent)

XB: Motor output

S03B-JTSLSK-GSANXR (JST)

(or equivalent)

XC: Regenerative resistor connection

S04B-JTSLSS-GSANXR (JST)

(or equivalent)

L1

L2

L3

L1C

L2C

P

RB

B

N

U

V

W

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

200 V size E

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 9 -

200 V size F

Front panel

Charge lamp

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

Earth connection screw

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

L1

L2

L3

L1C

L2C

P

RB

B

N

U

V

W

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 10 -

Model number

Serial number

e.g.):

P 1 5 0 7 0 0 0 1 N

Lot number

Month of

production

Year of production

(Lower 2 digit of AD year)

Input/output voltage

Number of phase

Rated input/output

current

Input/output

frequency

Rated output of

applicable motor

QR code

standard mark

Country of

origin

Manufacture date

e.g.):

2 0 1 5 0 7 0 1

Manufacture date

Manufacture month

Manufacture year

Name plate

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 11 -

Connector

pin No.

Terminal

symbol

+ 10 %

- 15 %

Use L1 and L3 terminal for single phase input

+ 10 %

- 15 %

+ 10 %

- 15 %

+ 10 %

- 15 %

When a trip happens due to a regenerative load protection error, connect

3

U

2 V 1

W

6. Configuration of connectors and terminal blocks

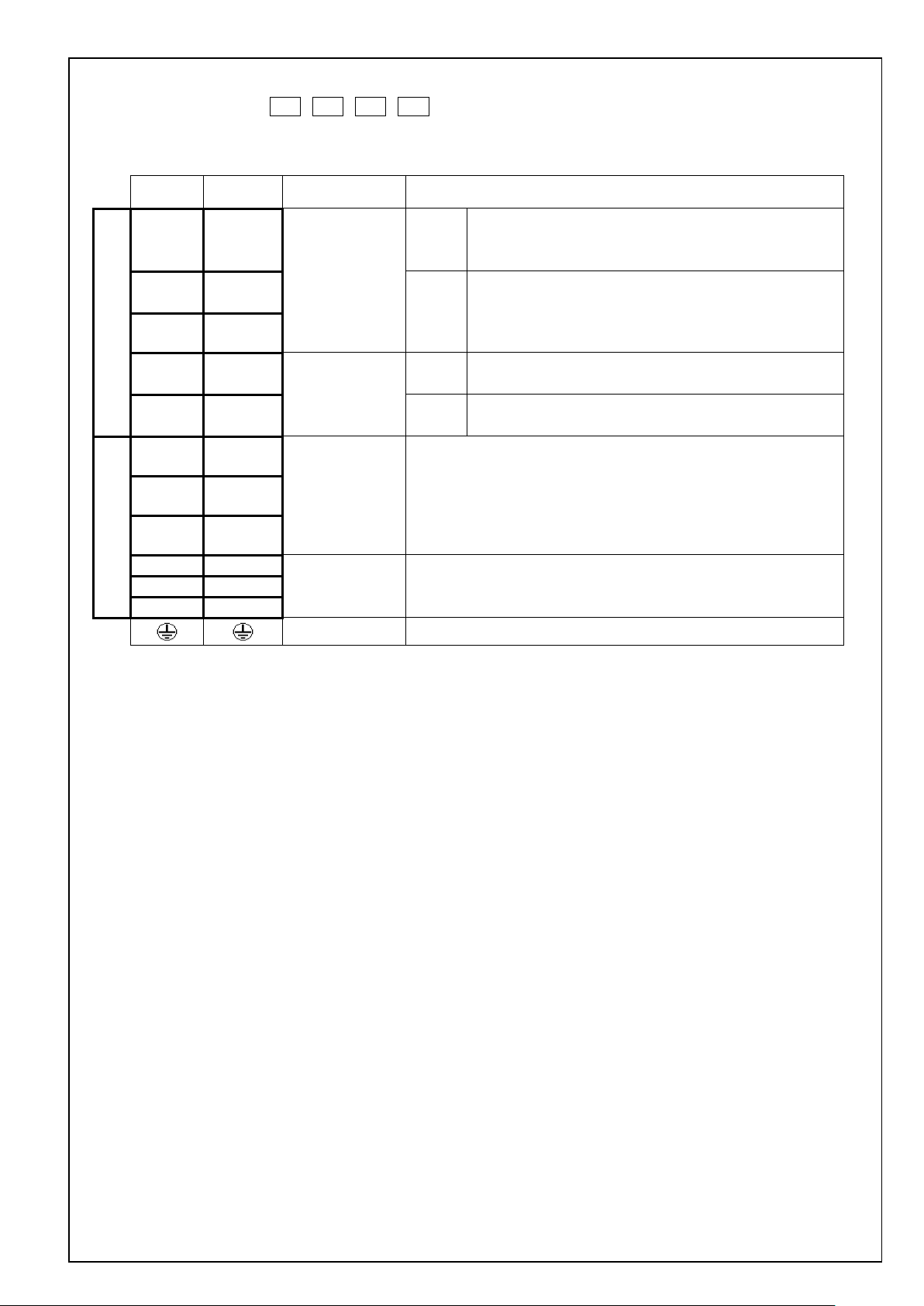

6-1 Power connector XA , XB , XC , XD and terminal block

[1] Size A, B of 100 V and 200 V system

XA

XB

5 L1

4 L2

3 L3 Use L1 and L3 terminal for single phase input

2 L1C

1 L2C 200 V Single phase 200-240 V

6 P

5 N

4 B

Name Description

Single phase 100-120 V

Single or 3 phase 200-240 V

an external regenerative resistor (prepared by customer) between P and

B.

U: U phase V: V phase W: W phase

Main power

supply input

Control power

supply input

Regen resistor

connection

Motor connection

Earth

100 V

200 V

100 V Single phase 100-120 V

Then, specify the extern al regenerative resistor for the parameter

Pr0.16.

Do not connect N terminal.

Connect each phase of the motor winding.

Earth terminal for grounding

50/60 Hz input

50/60 Hz input

50/60 Hz input

50/60 Hz input

* Tighten the earth screws M4 with the 0.7-0.8 Nm torque respectively.

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 12 -

Connector

pin No.

Terminal

symbol

+ 10 %

- 15 %

Use L1 and L3 terminal for single phase input

+ 10 %

- 15 %

+ 10 %

- 15 %

+ 10 %

- 15 %

Normally, short out the circuit between B and RB. (Sizes C, D)

3

U

2 V 1

W

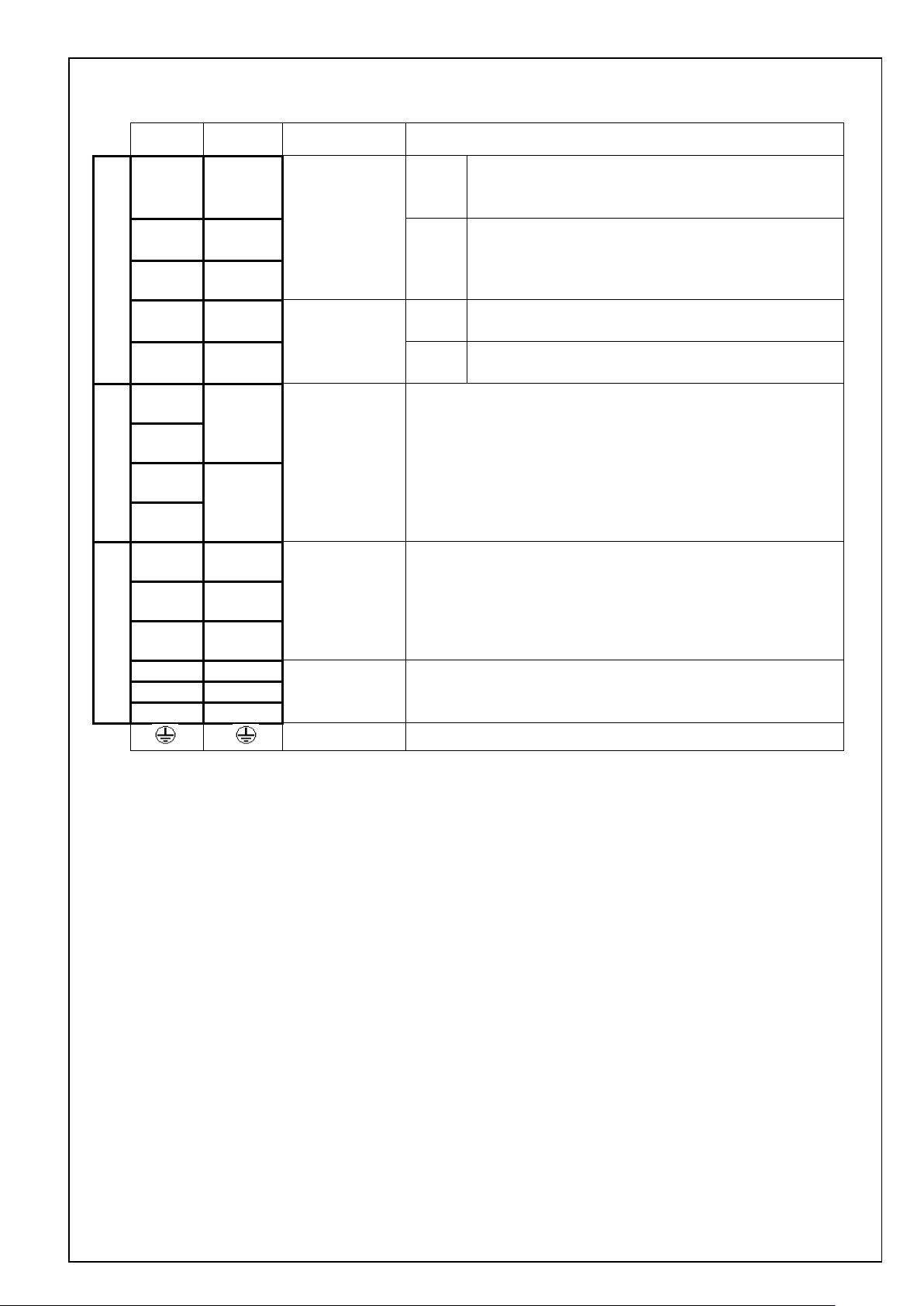

[2] Size C, D of 100 V and 200 V system

Name Description

XA

XC

XB

5 L1

Main power s upply

4 L2

3 L3 Use L1 and L3 terminal for single phase input

2 L1C

1 L2C 200 V Single phas e 200 – 240 V

4

N

3

2

P

1

6 P

5 RB

4 B

input

Control power

supply input

- Do not connect.

Regen resistor

connection

100 V

200 V

100 V Single phase 100-120 V

When a trip happens due to a re ge ner ati ve load prote c ti on e rror , o pen t h e

Then, specify the extern al regenerative resistor for the parameter

Pr0. 16.

Single phase 100-120 V

Single or 3 pha se 20 0 – 240 V

circuit between B and RB and conn ect an external regenerative resistor

(prepared by customer) bet w een P and B.

50/60 Hz input

50/60 Hz input

50/60 Hz input

50/60 Hz input

Motor connection

Earth

Connect each phase of the motor winding.

U: U phase V: V phase W: W phase

Earth terminal for grounding

* Tighten the earth screws M4 with the 0.7-0.8 Nm torque respectively.

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 13 -

Connector

pin No.

Terminal

symbol

5

L1

4

L2 3 L3

2

L1C

1

L2C

3

U

2 V 1

W

[3] Size E of 200 V system

Name Description

XA

XC

XB

4 P

3 RB

2 B

1 N

Earth Earth terminal for grounding

Main power s upply

input

Control power

supply input

Regen resistor

connection

Motor connection

200 V 3 phase 200 - 240 V

200 V Single phase 200 - 240 V

Normally, short out the circuit between RB and B.

When a trip happens due to a regenerative load protection error, open the

circuit between RB and B and connect an external regenerative resisto r

(prepared by customer) between P and B.

Then, specify the external regenerative resistor for parameter Pr0. 1 6.

Do not connect N terminal.

Connect each phase of the motor winding.

U: U phase V: V phase W: W phase

+ 10 %

- 15 %

+ 10 %

- 15 %

50/60 Hz input

50/60 Hz input

* Tighten the earth screws M4 with the 0.7-0.8 Nm torque respectively.

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 14 -

Terminal

bottom)

1

L1

2

L2 3 L3 4 L1C

- 15 %

5

L2C

Normally, short out the circuit between RB and B.

When a trip happens due to a regenerative load protection error, open the

7

RB 8 B

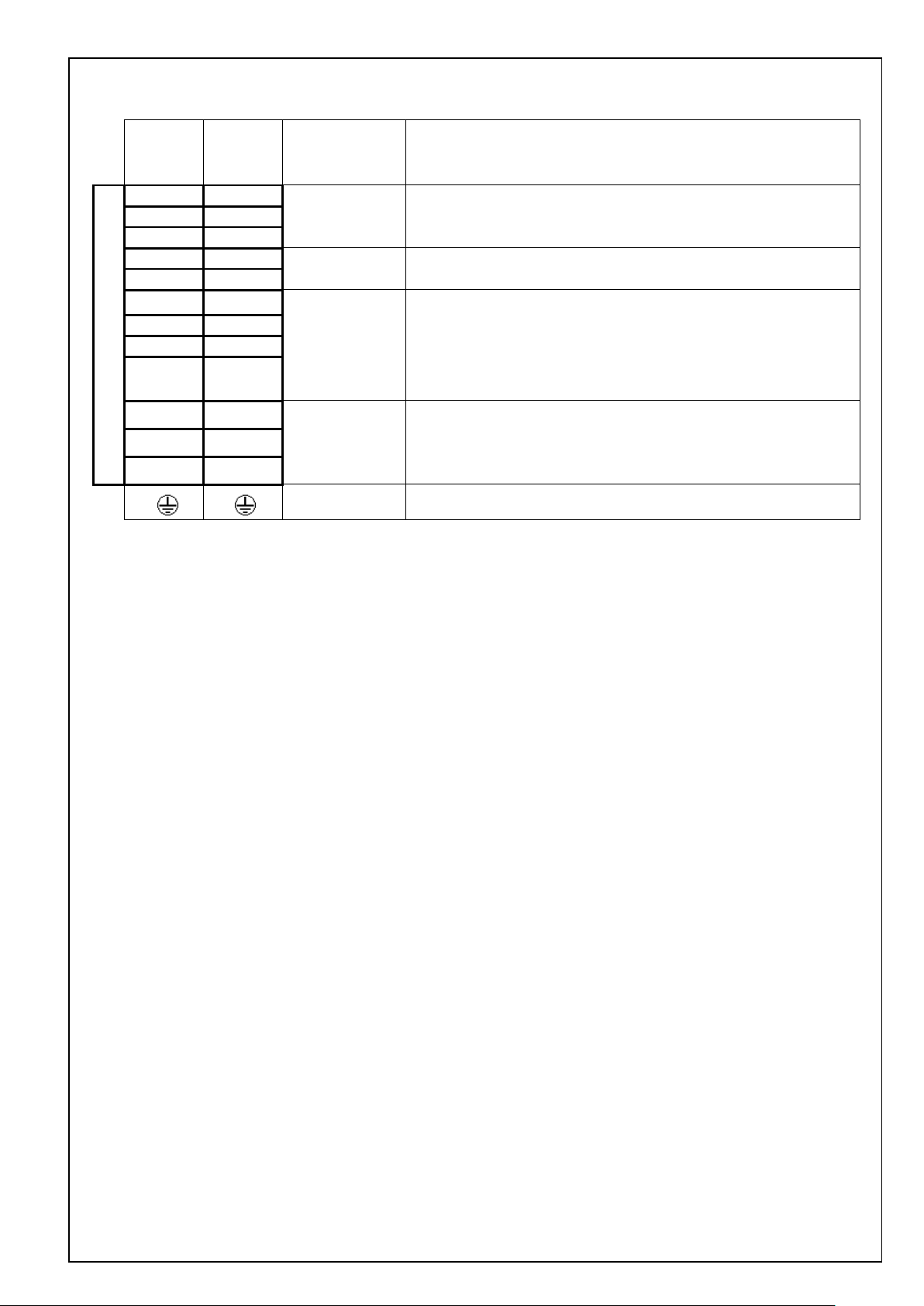

[4] Size F of 200V system

Terminal block is used instead of connector.

Terminal block

No.

(Upper to

6 P

9 N

10 U

11 V

12 W

Terminal

symbol

Name Description

Main power s upply

input

Control power

supply input

Regen resistor

connection

Motor connection

Earth

3 phase 200 - 240 V

Single phase 200 - 240 V

circuit between RB and B and connect an external regenerative resistor

(prepared by customer) b etween P and B.

Then, specify the external regenerative resistor for parameter Pr0. 16.

Do not connect N terminal.

Connect each phase of the motor winding.

U: U phase V: V phase W: W phase

Earth terminal for grounding

+ 10 %

- 15 %

+ 10 %

50/60 Hz input

50/60 Hz input

* Tighten the earth s crews M5 with the 1.4 -1.6 Nm torques respectively.

* Tighten the terminal block screws M5 with the 1.0-1.7 Nm torques respectively.

* Tighten the fixin g s crew M3 for the terminal block cover with the 0.2 Nm torque.

* If the maximum value of tightening torque is exceeded, the terminal block could be damaged.

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 15 -

Connector

6-2 USB connector X1

By connecting to a computer or a controller via USB interface, the following operations are available

parameter reference / change parameter save / load monitoring of status checkin g ala rm status or alarm history

Name Symbol

VBUS 1

USB signal

D+ 3

For manufacturer use

Signal ground GND 5 Signal ground

−

pin No

Communicate with a computer or a controller D- 2

4 Do not connect

Description

Motor Business Unit, Panasonic Corporation

nector

pin No.

Multi-function input 1

SI1

8

Multi-function input 2

SI2

9

Multi-function input 3

SI3

26

Multi-function input 4

SI4

27

Multi-function input 5

SI5

28

SI6

29

SI7

30

SI8

31

Multi-function input 9

SI9

32

Multi-function input 10

SI10

33

Name

Symbol

Description

When turned ON, the servo is turned on (power is supplied to the motor).

Po sitive overtravel limit.

Negative overtravel limit.

When this input is OF F, a ne ga tiv e tor que doe s not occ ur.

Deviation counter clear

CL

Clears the position deviation counter.

Command pulse inhibition

INH

Ignores the position comm a nd pul se.

Preset velocity 1

INTSPD1

Preset velocity 2

INTSPD2

Preset velocity 3

INTSPD3

Speed zero clamp

Sets the speed command to zero.

Anti-vibration switch 1

Anti-vibration switch 2

Gain switch

GAIN

Input to switch the gains.

Torque limit switch

TL-SEL

Switches the torque limits.

Alarm clear

A-CLR

Digital input to clear the alarm.

Command scaling switch

VC-SIGN

Specifies the sign of the speed command during the speed control.

Torque comm a nd sig n

TC-SIGN

Specifies the sign of the torque command during the torque control.

Command scaling switch 1

DIV1

Switches the scaling numerators of the command pulse.

Allows you to switch up to 4 numerators by combining DIVs 1, 2.

Command sca ling sw i tch 2

DIV2

Forced alarm input

E-STOP

Generates Err87. 0 "Abnormal forced alarm input."

Inertia ratio switch

Switches the inertia ratios.

6-3 Parallel I/O connector, X4

Common digital inputs

Name Symbol

Power supply input COM+ 7

Con

-

Description Circuit

・Connect to the + terminal of an external DC power supply (12 to 24 V)

・Use a 12 V (±5 %) to 24 V (±5 %) power supply

・Insulat ion i s needed against the prim ary s ide pow e r sup ply .

Please do not connect th em wit h the same power supply.

No. SX-DSV03015 - 16 -

Multi-function input 6

Multi-function input 7

Multi-function input 8

Functions allocatable to multi-function inputs

Servo ON SRV-ON

Control mode switch

Positive overtravel limit

Negative overtravel limit

C-MODE

POT

NOT

The function changes according to the parameter settin gs. See below. i-1

When turned OFF, t he s er vo is t urn ed of f a nd the m otor p ow er i s tur ne d of f .

Switches the contr ol m ode s.

Make sure to connect this so that the contact point will be opened when the movable

module positively exceeded the movable range.

When this input is OF F, a pos it ive t orq ue does no t occ ur .

Make sure to wire this input to be activated as the work over travels the limit in the

negative direction.

Preset s peed.

Allows you to set up t o 8 int er na l ve loci tie s by com bi ning I NT SPDs 1 - 3.

ZEROSPD

VS-SEL1

VS-SEL2

Switches the appli e d fr eque nc ies f or anti-vibration control.

J-SEL

Motor Business Unit, Panasonic Corporation

No. SX-DSV03015 - 17 -

Con

pin No.

Command direction

Con

Pin No.

kpps for line driver input, and

Command direction

Input signals (command pulse train) and their functions

A suitable interface can be chosen from two kind of interface based on the specification of command pulses.

A. Pulse train interface with line driver

Command pulse

input 1

input 1

Command pulse

input 2

input 2

Name Symbol

PULSH1 44

PULSH2 45

SIGNH1 46

SIGNH2 47

-nector

Input t er min al for the position command pulse. It can be select ed by setting

corresponding parameters.

Disabled in such control modes as the speed control or the torque control,

which does not require position commands.

The maximum allowable input frequency is 8 Mpps.

B. Pulse train interface with optocoupler

Name Symbol

OPC1 1

PULS1 3

PULS2 4

OPC2 2

SIGN1 5

-nector

Input t er min al for the position command pulse. It can be selected by setting

corresponding parameters.

Disabled in such control modes as the speed control or the torque control,

which does not require position commands.

The maximum allowable input frequency is 500

200 kpps for open collector input.

Description Circuit

Di-2

Description Circuit

Di-1

SIGN2 6

Motor Business Unit, Panasonic Corporation

Con

pin No.

SO1-

SO1+

10

11

SO2-

34

SO4-

SO4+

38

39

ALM-

36

Multi-function outp ut 5

SO5

12

Multi-function outp ut 6

SO6

40

The power capacity varies depending on a composition of I/O circuit.0.5A

Name

Symbol

Description

Servo alarm

ALM

Digital output to indicate the driver is in alarm status..

Motor holding break releas e

BRK-OFF

Digital output to provide the timing signal to control the motor holding brake.

Zero speed

ZSP

Outputs the zero speed detection signals.

Torque limited

TLC

Outputs the torque limit signal.

In-position

INP

Outputs the positioning completion signal.

At speed

AT-SPD

Outputs the at-speed signal.

V-COIN

V-COIN

Outputs the speed coincidence signal.

Outputs the warning output signal configured in Pr4. 40 "Warning output

selection 1".

Outputs the warning output signal configured in Pr4. 41 "Warning output

Position command ON/OFF

P-CMD

Outputs meaning positional command applied.

Speed in –limit output

V-LIMIT

Outputs meaning the speed is limited at torque control mode.

Alarm attribute output

Output s meani ng occur an alarm that can be cleared.

Turns on output transistor when the speed command is applied while the speed is

Servo on status output

SRV-ST

Turn on output transistor when servo is on.

Output signals (Common) and their functions

Name Symbol

Multi-function outp ut 1

-nector

No. SX-DSV03015 - 18 -

Description Circuit

Multi-function outp ut 2

Multi-function output 4

Servo alarm

Power supply input

SO2+

ALM+

COM- 41

The function changes according to the parameter settin gs. See below.

35

Digital output to indicate alarm status.

37

The function changes according to the parameter settin gs. See below. o-3

・Connect to the - terminal of an external DC power supply (12 to 24 V)

・

or more is recommended.

・Insulat ion i s needed against the prim ary s ide pow e r sup ply

Please do not connect the m w ith t he sa m e pow e r supply.

Functions allocatable to multi-function outputs

Servo ready S-RDY Digital output to indicate the driver is ready to be enabled.

Positioning comple tion 2 INP2 Outp uts the positioning completion signal 2.

Warning output 1 WARN1

o-1

Warning output 2 WARN2

Speed command ON/OFF V-CMD

ALM-ATB

selection 2".

controlled.

Motor Business Unit, Panasonic Corporation

Loading...

Loading...