Panasonic LP-V Series, LP-430 Series, LP-431 Series, LP-421 Series, LP-425 Series External Control Manual

...

Laser Marker

External Control Manual

LP-400 series

LP-V series

LP-W series

ME-LP400V-EX-6 No. 9000-0062-17V

2018.7

panasonic.net/id/pidsx/global

Preface

ME-LP400V-EX-6

Thank you for purchasing our product.

For full use of this product safely and properly, please read this document carefully.

This product has been strictly checked and tested prior to its delivery. However, please make sure that this product

operates properly before using it. In case that the product becomes damaged or does not operate as specied in this

document, contact the dealer you purchased from or our sales ofce.

General terms and conditions of this document

1. Before using this product, or before every starting operation, please conrm the correct functioning and performance

of this product.

2. Contents of this document could be changed without notice.

3. This document must not be partially or totally copied or revised.

4. All efforts have been made to ensure the accuracy of all information in this document. If there are any questions,

mistakes, or comments in this document, please notify us.

5. Please remind that we assume no liability for any results arising out of operations regardless of the above clauses.

Disclaimer

The applications described in this document are all intended for examples only. The purchase of our products described in

this document shall not be regarded as granting of a license to use our products in the described applications. We do NOT

warrant that we have obtained some intellectual properties, such as patent rights, with respect to such applications, or that

the described application may not infringe any intellectual property rights, such as patent rights, of a third party.

Trademark

• Windows is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

• QR Code is a registered trademarks of DENSO WAVE INCORPORATED.

• Adobe, the Adobe logo, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems

Incorporated in the United States and/or other countries.

• All other product names and companies provided in this document are trademarks or registered trademarks of their

respective companies.

2

Cautions in Handling

WARNING

CAUTION

ME-LP400V-EX-6

To reduce the risk of injury, loss of life, electric shock, re, malfunction, and damage to equipment or property, always

observe the following safety precautions.

The following symbols are used to classify and describe the level of hazard, injury, and property damage caused when the

denotation is disregarded and improper use is performed.

ALWAYS FOLLOW THESE IMPORTANT

SAFETY PRECAUTIONS!

DANGER

The following symbols are used to classify and describe the type of instructions to be observed.

This symbol is used to alert users to a specic operating procedure that must not be performed.

This symbols is used to alert users to a specic operating procedure that must be followed in order to

operate the unit safely.

This symbols is used to alert users to a specic operating procedure that must be performed carefully.

Denotes a potential hazard that will result in serious injury or death.

Denotes a potential hazard that could result in serious injury or death.

Denotes a hazard that could result in minor injury.

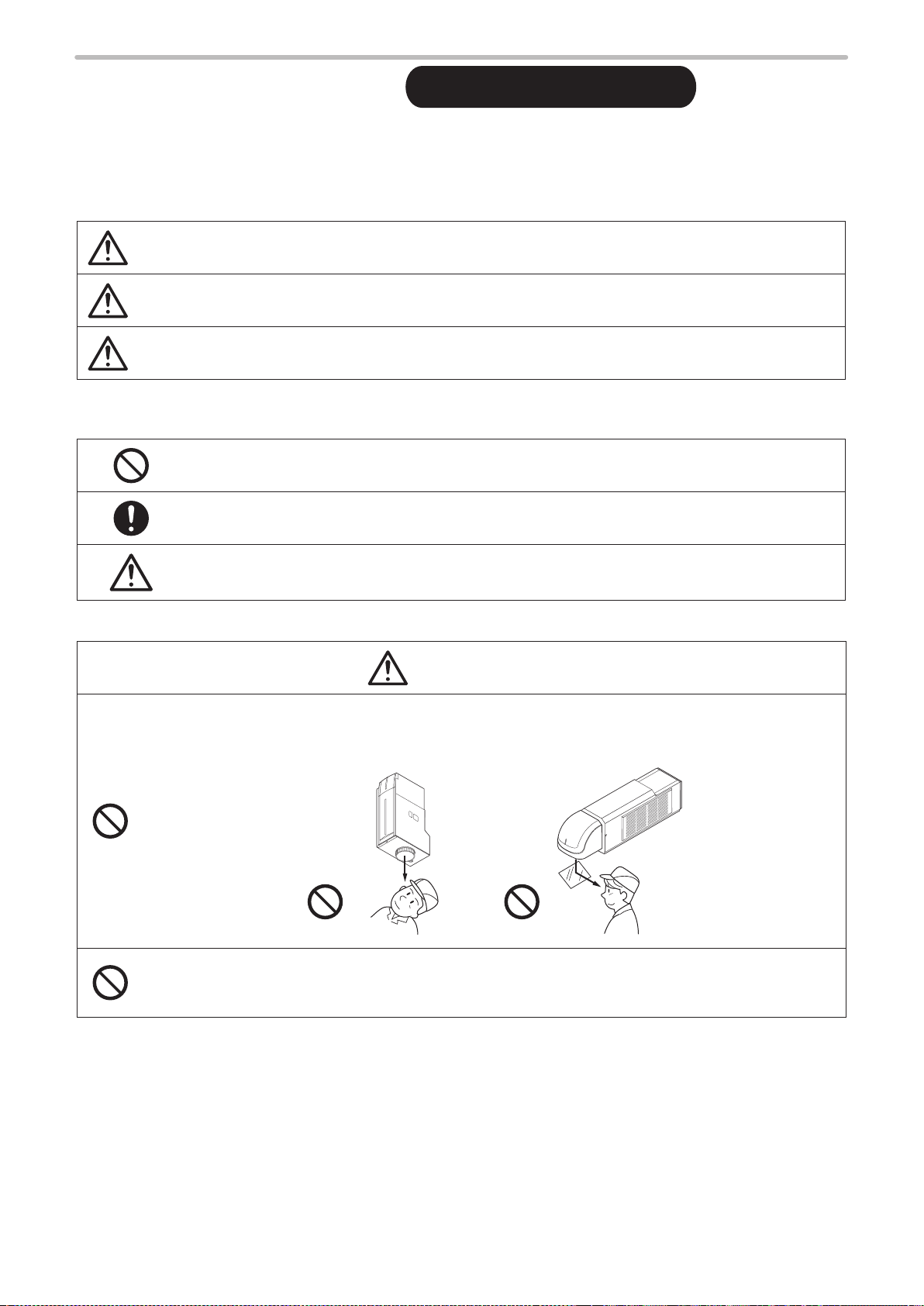

DANGER

• Never look at laser beam directly, through lens or through any other optical components. Laser beam

radiation into the eye causes blindness or serious damage to the eye.

Not only the direct beam of laser, but also diffused reected beam is harmful.

• Never touch laser beam and avoid human skin, clothing and any other ammable object from laser beam

exposure directly.

Burning into deep skin might result and there is a risk of re.

3

WARNING

• Do not use this product anywhere where re is strictly prohibited, near inammable gas, objects or organic

ME-LP400V-EX-6

solvents such as thinner or gasoline, or in dusty place. There is a risk of re.

• Do not use this product in wet place. In addition, never conduct wiring or maintenance work with wet hands

or when the product surface is wet. Otherwise, electric shock and/or malfunction may result.

• Never disassemble the product.

Doing so may cause exposure to the laser beam or electric shock.

• Do not insert hands or objects between the gaps of the exhaust port or inspiratory port.

There is a risk of electrical shock or injury.

• For LP-V / LP-W series, be careful neither to give strong power to the ber cable nor to nip it for installation.

Do not install the product to the systems that give excessive load acts on the ber cable, such as head

movement unit.

If the ber cable is damaged, laser beam comes out from the cable and it may cause laser exposures.

• Take laser protection measures required to use Class 4 laser products subject to the local laws and

regulations of the country or region in which this laser product is used.

• To protect the operators’ eyes, make it mandatory to wear goggles against laser beam

within the laser controlled area. The protective goggles can momentarily protect the

eyes against the scattered beam. Never look at the direct beam or reected beam

even when you are wearing the protective goggles.

• Construct an interlock systems such as a function to stop laser radiation for the maintenance door of the

protective enclosure.

• Set protective enclosure with proper reectance, durability and thermal resistance to enclose the laser

radiation area without leakage.

• After power supply of laser marker is turned off, laser safety manager must remove the key and keep it.

• Be sure to connect the head to the exclusive controller. It will cause exposure of laser beam and a failure if it

connects with any equipment other than the exclusive controller.

• Read all packaged guides and manuals thoroughly, and do not operate, install and connect the laser marker

with any other methods except the instructions provided in the manuals. Inappropriate use might cause

injury, electrical shock or exposure of laser beam.

4

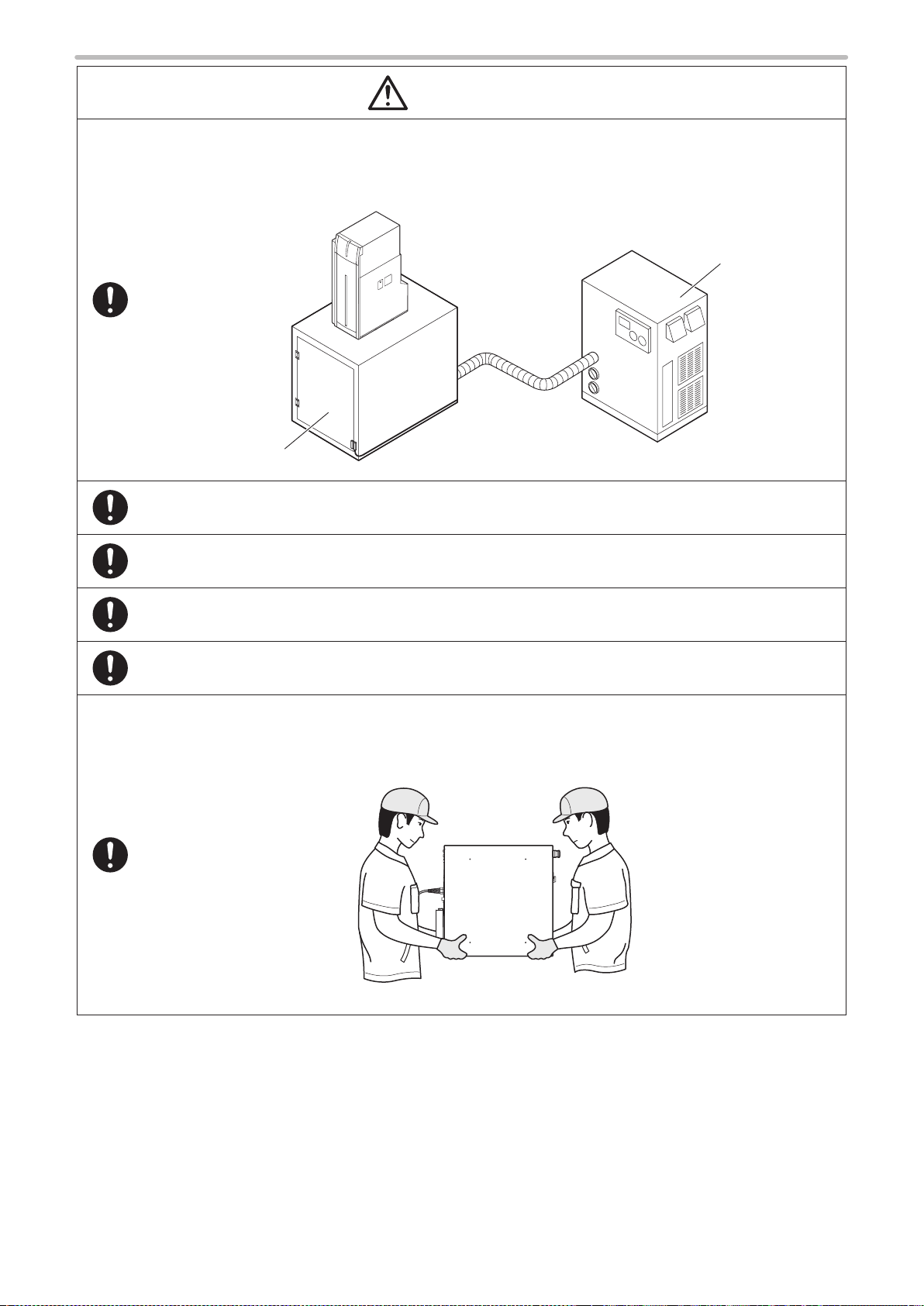

WARNING

• Remove the dust and/or gas which may be generated during the laser radiation with dust collector or

ME-LP400V-EX-6

exhauster. Use an appropriate dust collector or exhauster for dust or gas generated.

Depending on the material of the objects, harmful dust and/or gas to the human body and the laser marker

may be generated.

Dust collector

Protective enclosure

• When using the assist gas for laser processing, take safety precautions to protect operators from exposure,

ignition, toxic effect, excess or lack of oxygen.

• Prior to wiring, cable connecting, and/or maintenance work, ensure that all the power switches are turned

off. Otherwise, electrical shock may result.

• The wiring and maintenance must be conducted by the electrical engineers or under their supervision.

Incorrect work may cause electrical shock.

• Connect ground wire before using. A failure or electrical leakage that occurs when the unit is not properly

grounded may result in electric shock.

• To carry this product, wear the non-slip gloves and safety shoes, hold the bottom of the unit as shown below

gure. Carry the controller unit with two persons.

• Install this product in the stable place without vibration and shock.

• In case it falls down, it may cause injury.

Controller

5

For the Proper Use of Product

ME-LP400V-EX-6

• Be sure to observe the following matters to prevent a failure or a malfunction of this product and to maintain

the product performance properly.

Usage environment

• Do not use the product in a place with frequent vibrations or shocks. Moreover, please do not drop this product. It

may affect the precision component and optical component inside, which could impair the performance or result in a

failure.

• Do not use the system outdoors.

• The product is air-cooled. Please install not to bar the ow of air cooling. Avoid placing heat sources near the product.

• Be sure to use the product within the ambient temperature and humidity dened in the specications.

• Be careful not to have water, oil, ngerprints, dust, or dirt attached to the laser emission port of the head. This could

degrade the lasing performance and may result in a failure. If the laser emission port becomes dirty, use a dry soft

cloth to clean the port.

• If the air lter becomes dirt, clean the lter. Failure to do so may hinder the air ow, resulting in failure of this product.

Replace air lter periodically.

• Ensure that the dust or gas are removed by placing the intake duct of the dust collector or exhauster near the source

of dust or gas. Any dust or gas contamination on the laser emission port may cause failure or decrease the laser

marking or processing quality. In addition, when the laser beam is blocked by dust or gas, it may cause decrease in

laser marking or processing quality.

Installation and mounting

• Do not hold the cables and connectors at carrying this product.

• Do not touch the laser emission port on the bottom of the head. They may affect the laser marking quality badly.

• For LP-V / LP-W series, do not grasp the ber unit when carrying the head part.

• Carry the head as shown in the gure below.

LP-400 series

OK

LP-V/LP-W series

OK

• Do not install the product to the systems that give excessive load acts on the head and cables, such as head

movement unit. Failure to do so may damage the head precision parts or disconnect the cables, resulting in a failure.

• Be careful neither to give strong power to the cables nor to nip it for installation.

• Verify the minimum bend radius of each cable and install them without excess forces being applied.

• Do not hit the device with a tool such as a hammer at the installation. Do not use excessive force while tightening the

screws (nuts). It may cause a failure.

• Do not insert any objects between the gaps of the exhaust port or inspiratory port.

• Use anti-reection material (ex. black paint for metal) for an external shutter or a protective enclosure in a path of

laser beam. It may cause a failure of the components inside the laser marker head.

• If any other devices such as a sensor or a camera are installed near the laser marker, make sure that these devices

are installed in the place where laser beam and its reected beam do not damage to them.

NG

NG

Fiber cable

Laser emission port

Laser pointer emission port

6

For the Proper Use of Product

ME-LP400V-EX-6

• Be sure to observe the following matters to prevent a failure or a malfunction of this product and to maintain

the product performance properly.

Wiring

• Verify that the cables are wired correctly before powering on.

• For the connection of this product, use the dedicated cables attached to the product or the specied optional cables.

• Check the voltage uctuations of the power supply. Do not input the power supply exceeding the rating.

• If a surge occurs in the power supplied, connect a surge absorber to a source of the surge to absorb it.

• Be sure to take measures against surge before connecting any induction load such as DC relay to the load.

• The output has no protection function for short-circuit, therefore, do not connect the power supply or capacitive load

directly.

• Make sure to ground the frame ground terminal of this product.

• Install such that the controller housing and the head housing are at the same electric potential.

• Each connecting cable should not be used in the same raceway or connected in parallel to any device that generates

high-tension wires, power lines, large switching surge or the like. There is a risk of malfunction caused by induction.

• USB cable should not be connected in parallel with the controller power cable or the motor power cable.

• Make the wiring as short as possible to prevent a malfunction by the noise.

Operation

• Do not turn off the power supply until completing the system start.

• In case of turning ON the power supply after turning OFF, leave the interval at least 5 seconds between ON and OFF.

• The following items, Date, Lot, and Expiry Date are marked based on the internal clock of the laser marker. The

internal clock might be deviated due to error of the internal parts or degree of the battery drain, ambient temperature

and humidity. Therefore, be sure to check the time of the internal clock before the operation.

• Do not remove the USB media nor turn off the power during the data writing and reading operation.

Others

• Be sure to delete all registered data when transferring or discarding this product. Retained data might result in illegal

read out and leaking of information by a third-party with malicious intent.

7

How to Read this Document

ME-LP400V-EX-6

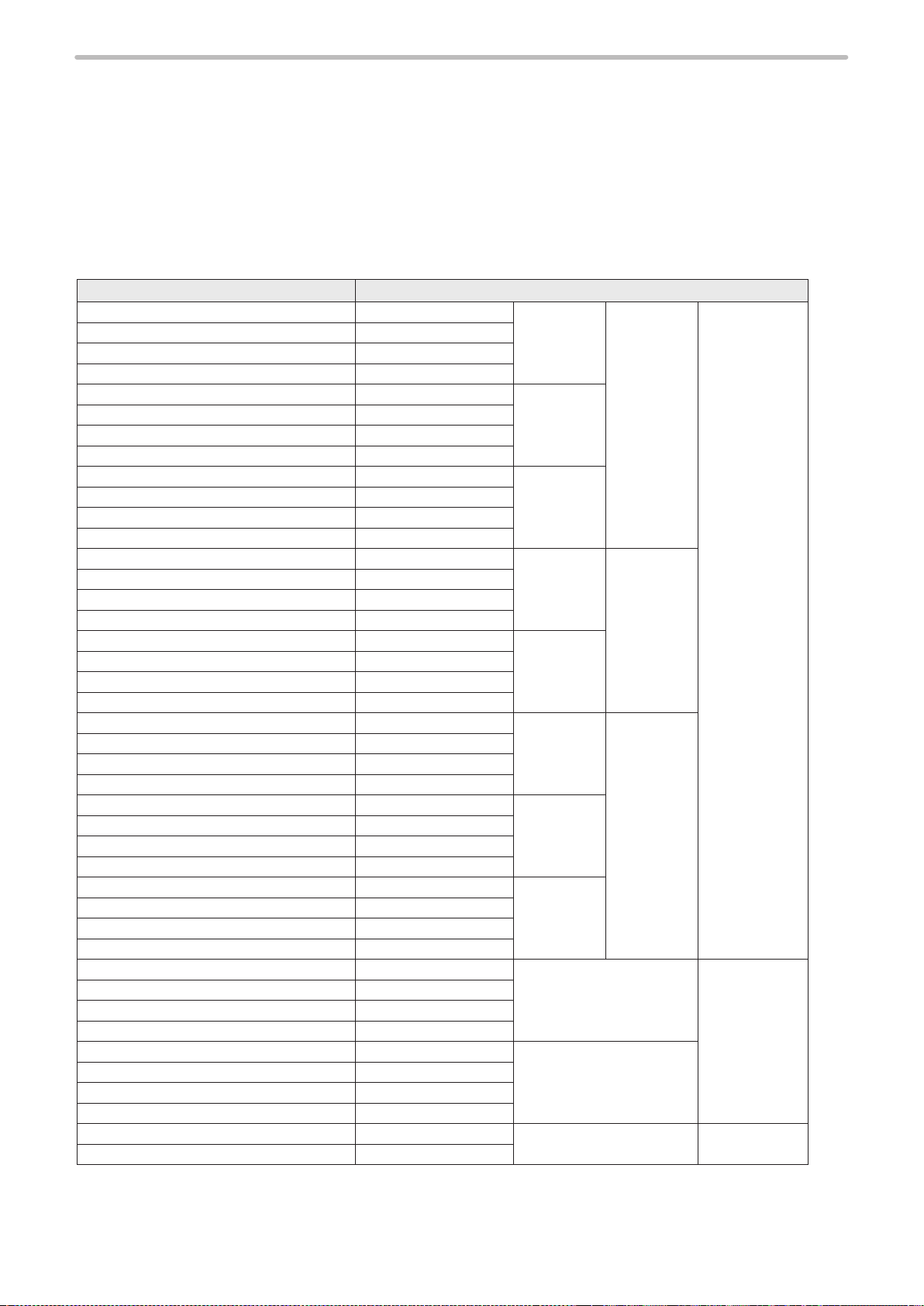

Target laser marker

⿎

This document is subject to the following Laser Marker models.

In this document, “laser marker” means this product.

If the setting contents or specications vary by models, the target models are specied in the text. (The target models are

not specied for items which are common to all models.) In the text, multiple models may be described collectively, as

shown in the table below.

Note that the illustration and the screen images may vary with model.

Target model Description in the text

LP-430U, LP-430TU LP-4xx(T)U LP-430 LP-4x0 LP-400 Series

LP-430U-A, LP- 430TU-A LP-4xx(T)U-A

LP-430U-C, LP-430TU-C LP-4xx(T)U- C

LP-430U-CHN, LP-430TU-CHN LP-4xx(T)U-CHN

LP-420S9U, LP-420S9TU LP-4xxS9(T)U LP-420

LP-420S9U-A, LP-420S9TU-A LP-4xxS9(T)U-A

LP-420S9U-C, LP-420S9TU- C LP-4xxS9(T)U-C

LP-420S9U-CHN, LP- 420S9TU-CHN LP-4xxS9(T)U-CHN

LP-410U, LP-410TU LP-4xx(T)U LP-410

LP-410U-A, LP-410TU-A LP-4xx(T)U-A

LP-410U-C, LP-410TU-C LP-4xx(T)U-C

LP-410U-CHN, LP-410TU-CHN LP-4xx(T)U-CHN

LP-435U, LP-435TU LP-4xx(T)U LP-435 LP-4x5

LP-435U-A, LP-435TU-A LP-4xx(T)U-A

LP-435U-C, LP-435TU-C LP-4xx(T)U- C

LP-435U-CHN, LP- 435TU-CHN LP-4xx(T)U-CHN

LP-425S9U, LP-425S9TU LP-4xxS9(T)U LP-425

LP-425S9U-A, LP-425S9TU-A LP-4xxS9(T)U-A

LP-425S9U-C, LP-425S9TU-C LP-4xxS9(T)U-C

LP-425S9U-CHN, LP- 425S9TU-CHN LP-4xxS9(T)U-CHN

LP-431U, LP-431TU LP-4xx(T)U LP-431 LP-4x1

LP-431U-A, LP-431TU-A LP-4xx(T)U-A

LP-431U-C, LP-431TU-C LP-4xx(T)U- C

LP-431U-CHN, LP-431TU-CHN LP-4xx(T)U-CHN

LP-421S9U, LP-421S9TU LP-4xxS9(T)U LP-421

LP-421S9U-A, LP-421S9TU-A LP-4xxS9(T)U-A

LP-421S9U-C, LP-421S9TU-C LP-4xxS9(T)U-C

LP-421S9U-CHN, LP- 421S9TU-CHN LP-4xxS9(T)U-CHN

LP-411U, LP-411TU LP-4xx(T)U LP-411

LP-411U-A, LP-411TU-A LP-4xx(T)U-A

LP-411U-C, LP- 411TU-C LP-4xx(T)U-C

LP-411U-CHN, LP-411TU-CHN LP-4xx(T)U-CHN

LP-V10U LP-VxxU LP-V10 LP-V Series

LP-V10U-A LP-VxxU-A

LP-V10U-C LP-VxxU-C

LP-V10U-CHN LP-VxxU-CHN

LP-V15U LP-VxxU LP-V15

LP-V15U-A LP-VxxU-A

LP-V15U-C LP-VxxU-C

LP-V15U-CHN LP-VxxU-CHN

LP-W052U LP-W052U LP-W052 LP-W Series

LP-W052U-A LP-W052U-A

8

Symbol indications

ME-LP400V-EX-6

⿎

Notice

Reference

Type of manuals

⿎

For this product the following manuals are prepared. Read each manuals and operate this product correctly and safely.

Save the manuals for future use.

• “Notice” denotes any instructions or precautions for using this product. To prevent the

damage or malfunction of the product, observe these precautions fully.

• “Reference” denotes any hints for operation, detail explanations, or references.

Operation/Maintenance Manual

This manual describes the safety precautions and the items required for the installation, operation and maintenance of

the laser marker.

• Precautions and safety measures: All users shall be required for reading this part.

• Specications and outer dimensions

• Setup and connecting method

• How to operate the laser marker and set the marking data using touch panel console or monitor and mouse.

• Maintenance

• Troubleshooting

External Control Manual

This manual describes how to control this product externally using I/O signals and serial communication (RS-232C/

Ethernet) commands.

Mainly the machine builder and system integrator shall be required for reading this manual.

• I/O control method (interfaces, signal layout, I/O rating, timing chart etc.)

• Command control method (serial communication interfaces, communication settings, command data formats etc.)

Laser Maker NAVI Operation Manual

This manual describes how to operate the laser marker and set the marking data using PC setting software “Laser

Marker NAVI”.

Reference

• The PDF data of each manual are included on an attached CD-ROM “Laser Marker Driver & Utility”.

• To read the PDF manual, Adobe Reader (Version 7 or later) of Adobe Systems Incorporated is required.

9

Contents

ME-LP400V-EX-6

Preface ……………………………………………………………………………… 2

Cautions in Handling

How to Read this Document

………………………………………………………………… 3

……………………………………………………… 8

1 Before External Control …………………………………………… 12

1-1 Operation Method for Laser Marker …………………………………………13

1-1-1 Operation procedure of test marking and run mode …………………… 14

1-1-2 Test marking and run mode operation …………………………………… 15

1-2 Operation by External Devices ………………………………………………16

1-2-1 Operation method using external control device ………………………… 16

1-2-2 Operation procedure with external control ………………………………… 17

1-3 Before External Control ………………………………………………………18

1-3-1 DIP switch setting …………………………………………………………… 19

1-3-2 Communication condition setting ………………………………………… 21

1-3-3 Shift to remote mode ………………………………………………………… 23

2 Control by I/O ……………………………………………………… 24

2-1 I/O Interface Specication ……………………………………………………25

2-1-1 I/O terminal block …………………………………………………………… 26

2-1-2 I/O connector ………………………………………………………………… 26

2-1-3 Signals and details of I/O terminal block ………………………………… 27

2-1-4 Signals and details of I/O connector ……………………………………… 33

2-2 Input/Output Rating ……………………………………………………………40

2-2-1 Input rating and input circuit ………………………………………………… 40

2-2-2 Output rating and output circuit …………………………………………… 41

2-3 Connecting I/O Terminal Block ………………………………………………42

2-3-1 Connecting samples (Independent operation of laser marker) ………… 42

2-3-2 Connecting sample with external devices ………………………………… 44

2-4 Timing Chart ……………………………………………………………………46

2-4-1 Basic input/output …………………………………………………………… 46

2-4-2 Marking trigger input ………………………………………………………… 47

2-4-3 Equidistant marking (Flying object marking) ……………………………… 47

2-4-4 Select le ……………………………………………………………………… 48

2-4-5 Time hold ……………………………………………………………………… 49

2-4-6 Counter end ………………………………………………………………… 49

2-4-7 Count-up/Count-down value correction …………………………………… 50

2-4-8 Counter reset ………………………………………………………………… 51

2-4-9 Rank/Offset marking ………………………………………………………… 52

2-4-10 Laser stop input …………………………………………………………… 53

2-4-11 Emergency stop input ……………………………………………………… 54

10

3 Control by Serial Communication (RS-232/Ethernet) ………… 56

ME-LP400V-EX-6

3-1 Preparation of Command Control ……………………………………………57

3-1-1 RS-232C ……………………………………………………………………… 57

3-1-2 Ethernet ……………………………………………………………………… 60

3-2 Command Reception Condition ………………………………………………62

3-3 Connection Check ………………………………………………………………63

3-4 Control Sample …………………………………………………………………64

3-5 Communication Data Format …………………………………………………68

3-5-1 Command data ……………………………………………………………… 68

3-5-2 Response data ……………………………………………………………… 69

3-5-3 Communication sequence ………………………………………………… 72

3-6 Communication Command List ………………………………………………74

3-7 Command Description …………………………………………………………78

Troubleshooting …………………………………………………… 141

Troubleshooting …………………………………………………………………… 142

Error Indication

Alarm ………………………………………………………………………………… 151

Warning

…………………………………………………………………… 151

……………………………………………………………………………… 154

Character Code Table ……………………………………………… 158

ASCII Code………………………………………………………………………… 159

Original Font

JIS Level-1 Font…………………………………………………………………… 161

JIS Level-2 Font…………………………………………………………………… 167

User Registration Character Font

……………………………………………………………………… 160

……………………………………………… 175

Index ………………………………………………………………… 176

Index ……………………………………………………………………………… 177

11

1 Before External Control

ME-LP400V-EX-6

1-1 Operation Method for Laser Marker

CAUTION

ME-LP400V-EX-6

• It is obligated by IEC/FDA/JIS that laser products shall incorporate a keyactuated master control. Actuation of this product is basically controlled by

the key switch located on the front of the controller. However, in considering

situations when the laser marker is operating as a part of a larger system, the

laser marker turns on if the key switch is already in ON position, and power is

supplied. In this case, be sure that the external system controls the operation

of the laser marker with a key-actuated master control.

The laser marker can be controlled by the following method:

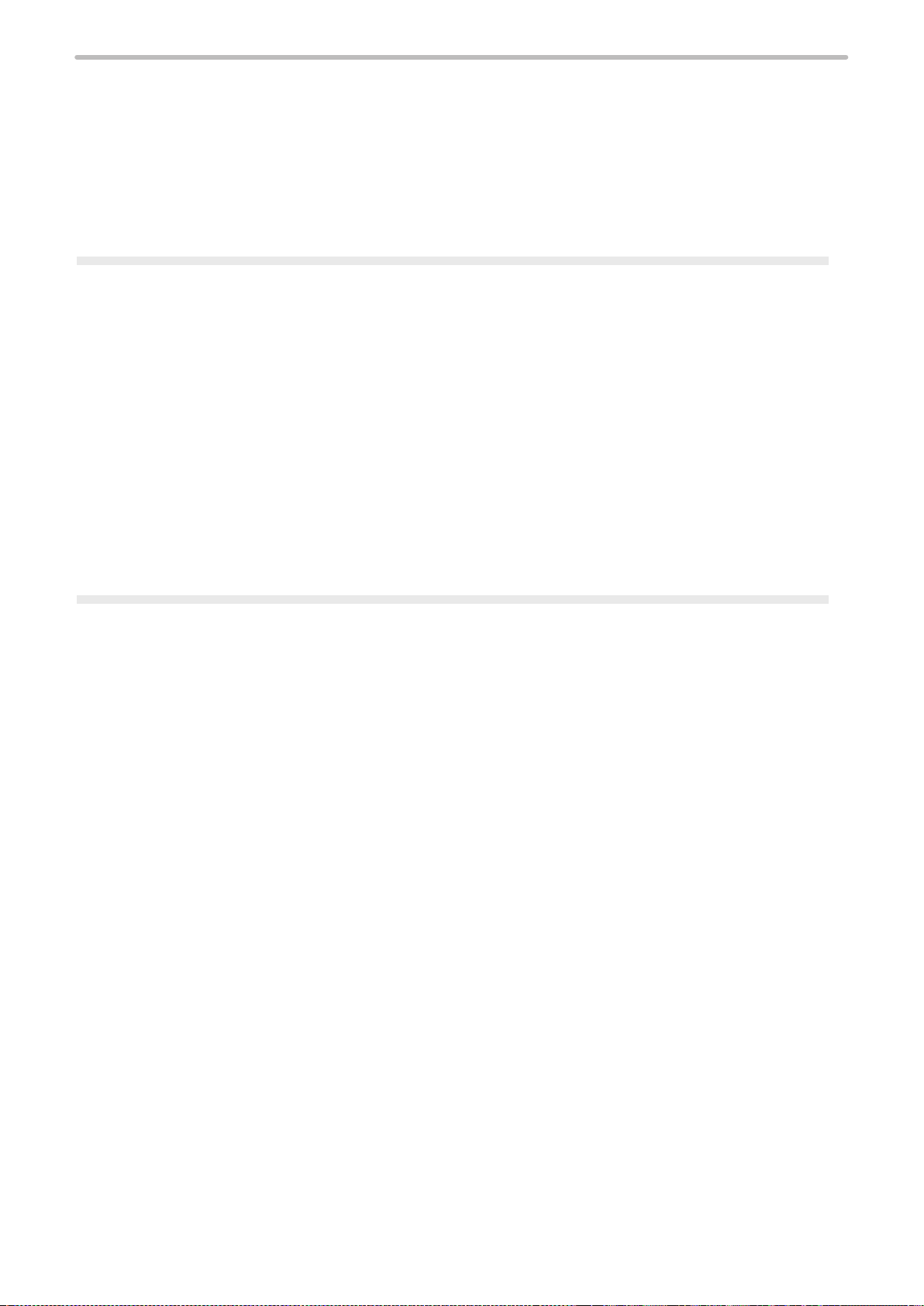

Control by the manually screen operation

To irradiate the laser by the screen operation, select the control methods from the followings:

• Test marking

Test marking executes the laser radiation manually with the selected

le.

Use Test marking when you want to check the marking results while

changing the setting parameters, such as during the testing to nd

the appropriate parameters or the maintenance work.

ABCI

• Run mode operation

Run mode is an operation method to congure the settings of the

laser marker by manual screen operation and to control the marking

start signal from the external devices such as switches or sensors

connected to I/O terminal.

Use this operation mode to congure the laser marker without using the

external control devices as PLC.

Reference

• Refer to “1-1-2 Test marking and run mode operation” (P.15).

• For the setting details, refer to Operation/Maintenance manual.

Control by external devices (remote control mode)

The operation method for automatic control.

I/O or communication commands control the operations such as

laser pumping and marking by connecting the laser marker to the

external control device as PLC.

The following external control methods are available. These

controls can be combined.

• I/O control

• Communication command control (RS-232C/Ethernet)

Touch panel console

or monitor and mouse

ABC

ABCD

Sensor for the

marking trigger

ABC

• For details on the external control, refer to “1-2 Operation by

Reference

External Devices” (P.16).

External control

device such as PLC

13

1-1-1 Operation procedure of test marking and run mode

ME-LP400V-EX-6

This section describes the basic operation procedures with the display operation connected to the controller.

Flow chart

⿎

Turn on power with key switch on controller.

For test marking For run mode operation

File selection

Edit the le

Turn on laser pumping. (Complete in 15 to 20 sec.)

Start test marking

Open internal shutter. (Self-opening)

Marking (Laser radiation)

Edit and overwrite the le

Select le to use in run operation.

Start run operation.

Marking trigger input

Input TRIG. IN (A4) on I/O terminal to start marking.

14

Save the le.

Turn off laser pumping.

Turn off power.

1-1-2 Test marking and run mode operation

ME-LP400V-EX-6

To irradiate the laser by the screen operation, operate the laser marker in test marking or run mode operation.

Test marking procedure

⿎

Test marking executes the laser radiation manually with the selected le.

Select “TEST” of the marking mode in the

1.

lower part of the screen.

Turn ON the laser pumping switch on the

2.

controller to start laser pumping.

To start marking, click “START”.

3.

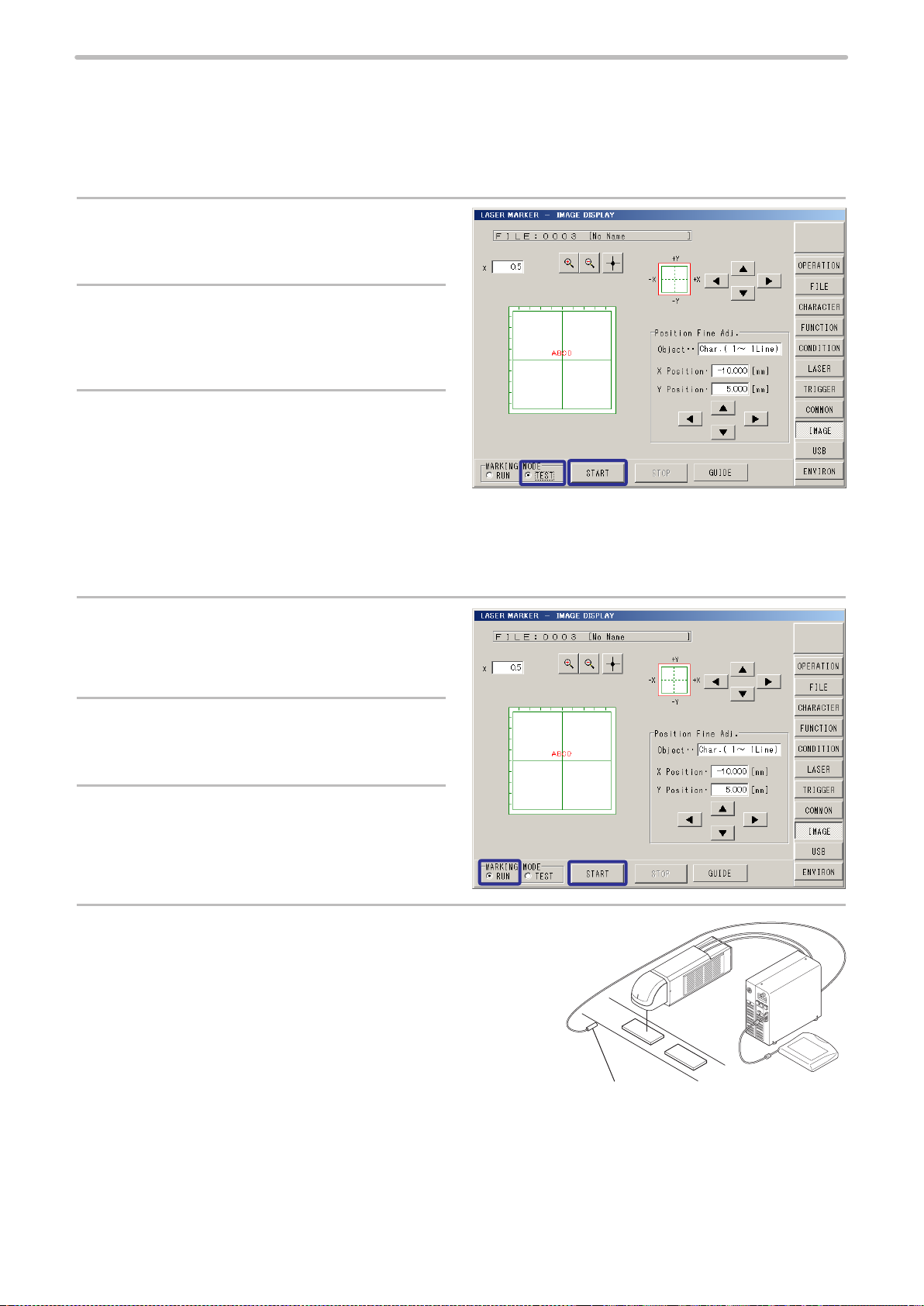

Run mode procedure

⿎

Run mode is an operation method to congure the settings of the laser marker by manual screen operation and to control

the marking start signal from the external devices such as switches or sensors connected to I/O terminal.

Set the marking mode to “RUN”.

1.

Turn ON the laser pumping switch on the

2.

controller to start laser pumping.

Click “START”.

3.

Under the RUN mode operation, the laser marker is in

the standby status for the marking start signal from I/O

terminal A4: TRIG. IN.

Laser radiation starts by inputting the marking trigger on

4.

the I/O terminal.

Connect a switch or sensor to A4: TRIG. IN. on the I/O terminal as

the input method of the marking start signal (trigger).

ABC

ABCD

Sensor for the

marking trigger

15

1-2 Operation by External Devices

ME-LP400V-EX-6

1-2-1 Operation method using external control device

To control the laser marker with the external control device, the following connecting methods are applicable:

External control using I/O : Remote mode operation

Controls the laser marker from external devices such as PLC using various I/O signals loaded into the laser marker.

For details, refer to “2 Control by I/O” (P.24).

I/O terminal block

I/O connector

ABC

PLC, etc.

External control by serial communication commands (RS-232C/Ethernet) : Remote mode operation

Controls the laser marker from external devices such as PLC using communication commands via RS-232C or Ethernet.

For details, refer to “3 Control by Serial Communication (RS-232/Ethernet)” (P.56).

Ethernet or

RS-232C

ABC

External control device

16

Reference

• It is available to the external control combining I/O, and serial communication commands.

• To input marking trigger with I/O and congure other settings with a screen operation manually, use Run mode. For

details, refer to “1-1-2 Test marking and run mode operation” (P.15).

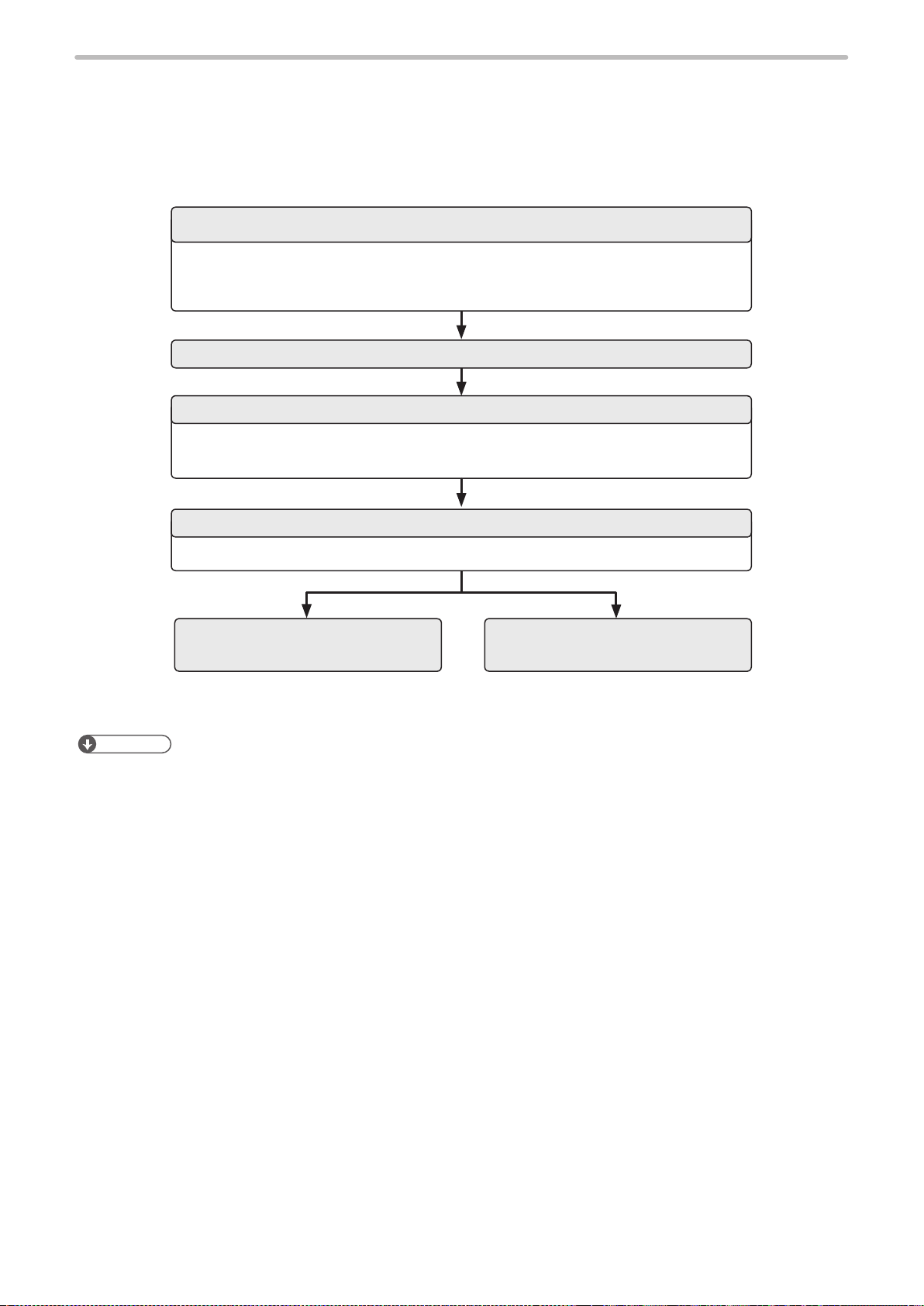

1-2-2 Operation procedure with external control

ME-LP400V-EX-6

Operation example when controlling the laser marker from external control devices such as

⿎

PLC

Turn ON key switch of laser marker controller

Remote mode ON

Refer to “1-3-3 Shift to remote mode” (P.23).

I/O control

Select le

Laser pumping ON

Open shutter

READY output ON

The device is ready for receiving the marking starting signal (trigger).

Marking trigger input ON

Marking (Laser radiation)

Reference

Control by serial communication commands

about 15 to 20 seconds

Control by using I/O

or communication

commands

• It is available to the external control combining I/O, and serial communication commands.

• Congure the environment setting on the I/O communication in advance before using external control. Refer to “1-3

Before External Control” (P.18).

17

1-3 Before External Control

ME-LP400V-EX-6

The following settings are required before the external control by using I/O or communication commands.

Setting ow to start external control

⿎

DIP switch setting

• DIP switch No. 2: Select control method, I/O or command for some specic operations.

• DIP switch No. 5 and No. 6: Select setting method of remote mode.

Refer to “1-3-1 DIP switch setting” (P.19).

Turn ON laser marker

Communication environment setting

Set I/O and communication conditions in the environment setting screen.

Refer to “1-3-2 Communication condition setting” (P.21).

Remote mode ON

Refer to “1-3-3 Shift to remote mode” (P.23).

I/O control

Reference

• For the installation and the setup of the laser marker, refer to Operation/Maintenance manual.

Control by serial communication

commands

18

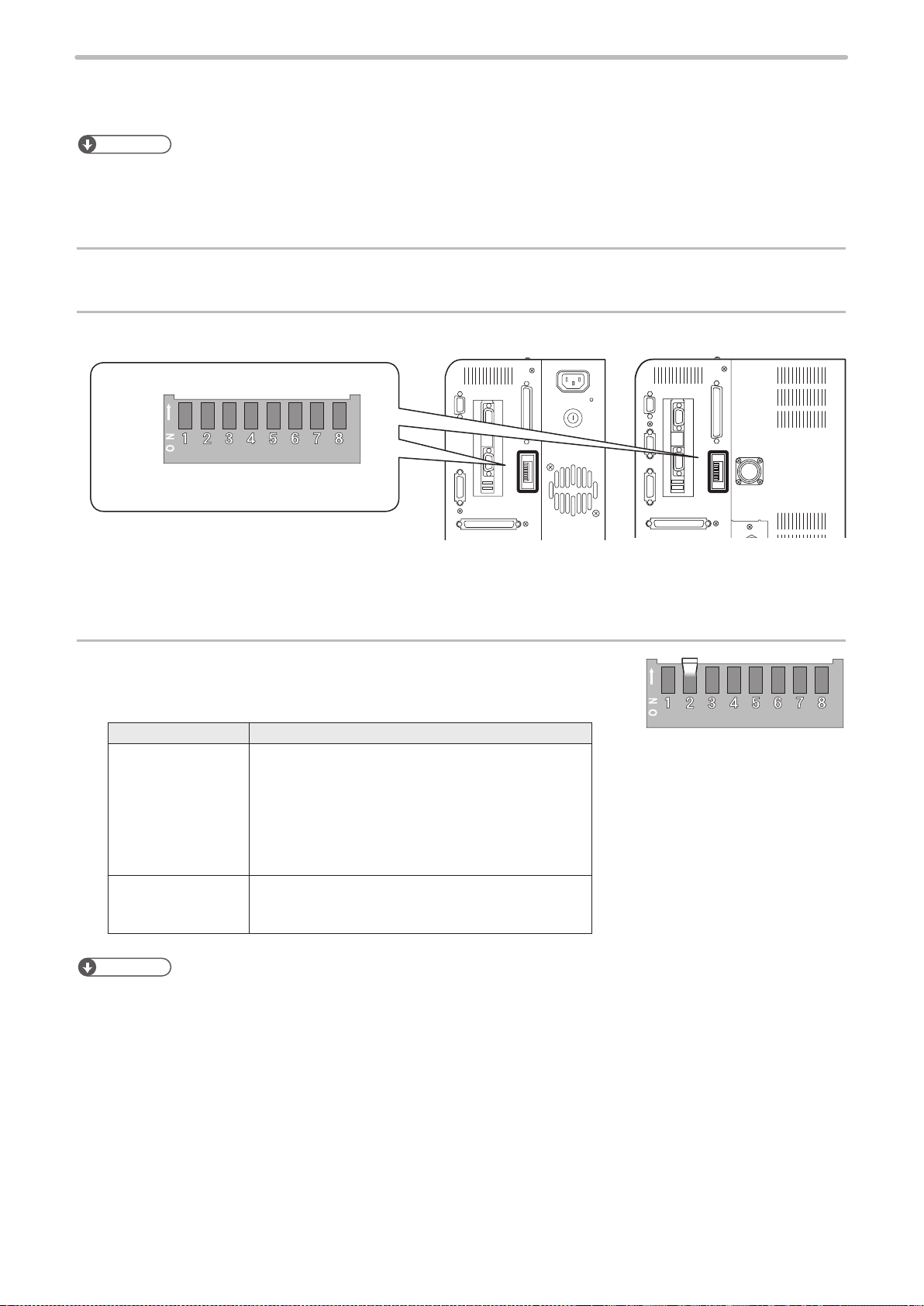

1-3-1 DIP switch setting

ME-LP400V-EX-6

Set the operational options for the external control with the DIP switch equipped on the controller rear side.

Reference

• The initial setting of all DIP switches is OFF.

• Turn OFF the power at DIP switch setting.

• For the details on DIP switch, refer to Operation/Maintenance manual.

Turn OFF the power of laser marker.

1.

Remove the DIP switch cover on the rear of the controller.

2.

ON

OFF

DIP switch

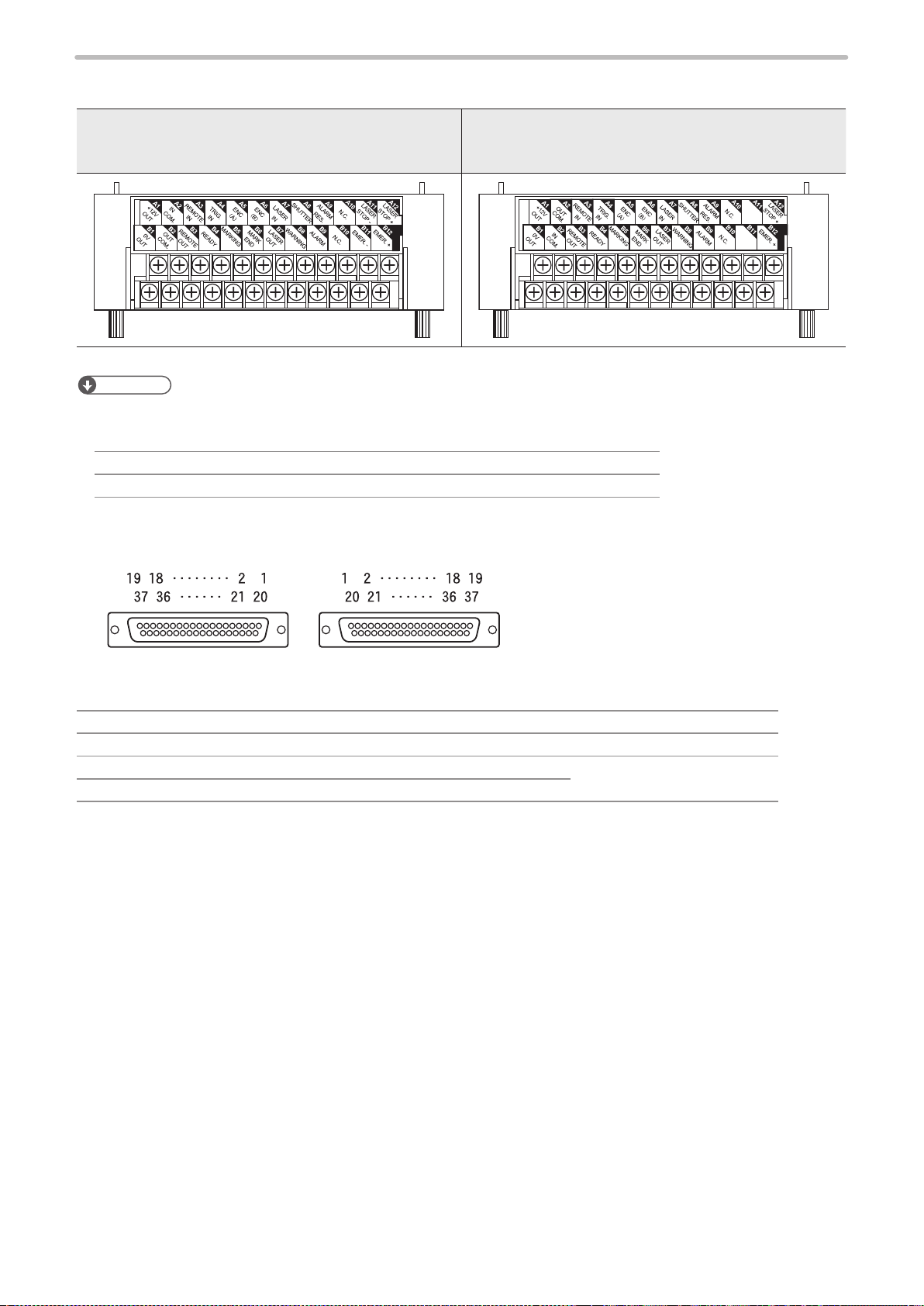

LP-400 series LP-V/LP-W series

Rear of controller

With DIP switch No. 2, select the control method, I/O or command

3.

for some specic operations.

DIP switch No. 2 Control method for specic operations

ON Control by serial communication commands for the

following operations

• Laser pumping (LSR)

• Shutter control (SHT)

• Guide laser (GID)

• Laser check radiation (SPT)

• Power check (PWR) (LP-V/LP-W series only)

OFF (initial setting) Control by I/O for the following operations

• Laser pumping

• Shutter control

Reference

• “Guide Laser Control”, “Laser Check Radiation” and “Power Check” cannot be controlled by I/O. They can be controlled

only by using serial communication in the remote mode.

19

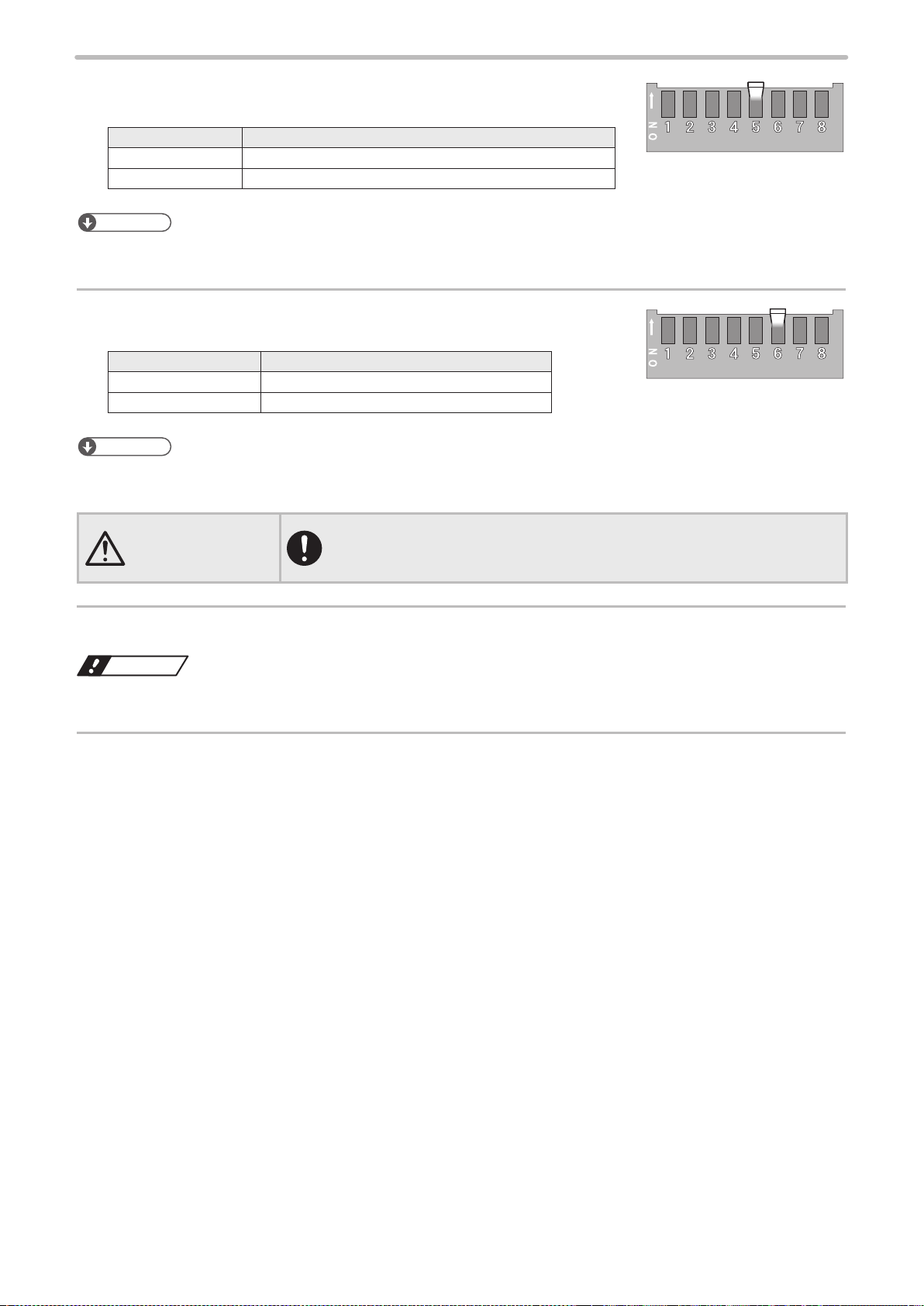

With DIP switch No. 5, select the setting method of the remote

CAUTION

ME-LP400V-EX-6

4.

mode.

DIP switch No. 5 Setting method of remote mode

ON Use the input signal of REMOTE IN (A3) on I/O terminal.

OFF(initial setting) Use the remote switch on the front of the controller.

Reference

• When DIP switch No. 5 is ON, the remote switch on the controller is not available.

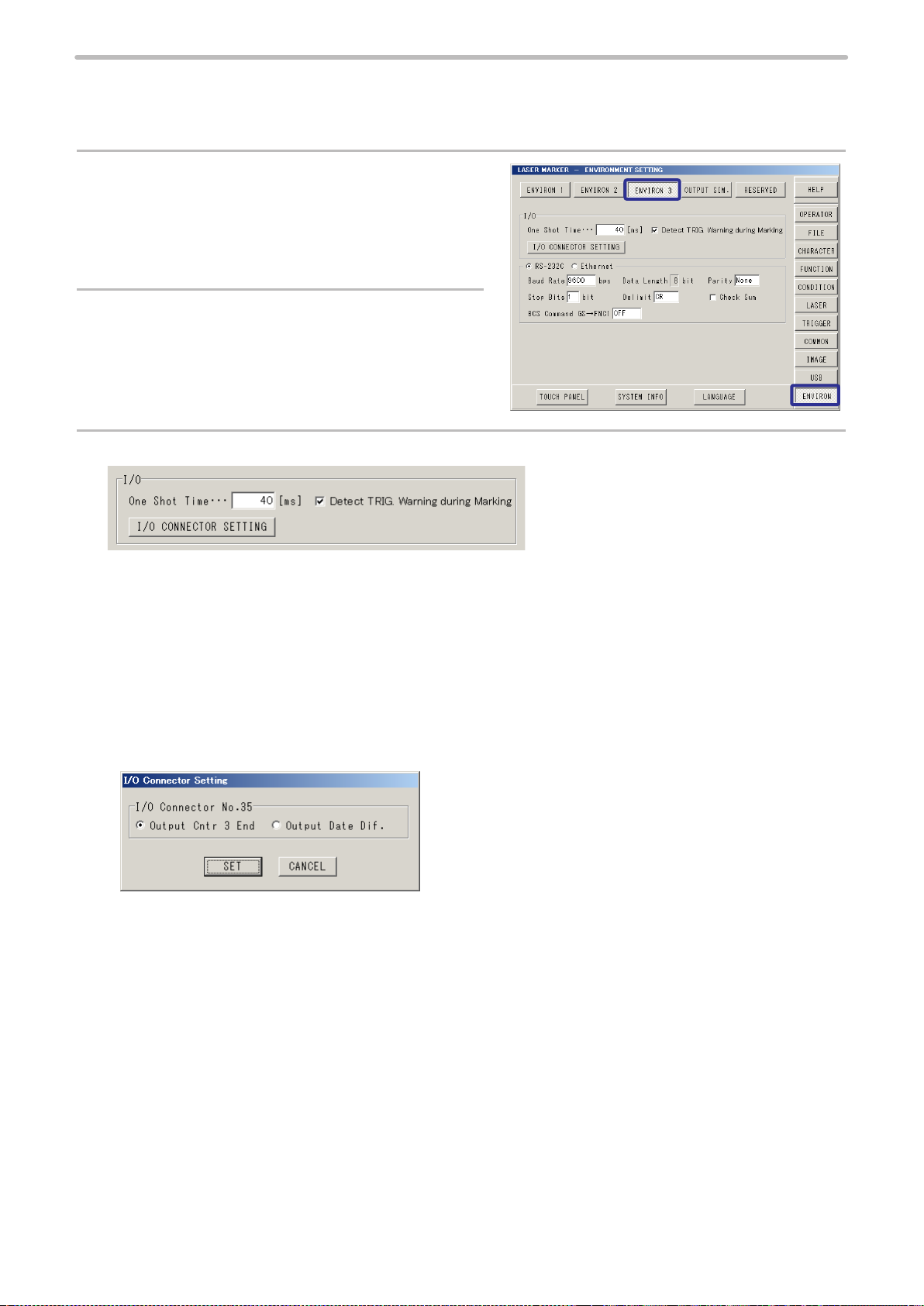

When DIP switch No. 5 is OFF, select the remote mode state at

5.

powered ON with DIP switch No. 6.

DIP switch No. 6 Remote mode state at powered ON

ON Starts up with remote mode ON

OFF (initial setting) Starts up with remote mode OFF

Reference

• When DIP switch No. 5 is ON, keep DIP switch No. 6 OFF.

• When DIP switch No. 6 is ON, “X5: REMOTE IN” signal on I/O terminal is not available.

• If the DIP switch No. 5 or No. 6 are used while turned on, construct a system

for re-pumping the laser manually as safety protection measures after the stop

of the laser radiation due to an emergency stop or an interlock.

Install the DIP switch cover to the controller.

6.

Notice

• A plastic cover is installed on the DIP switch. Install this cover always to avoid the dust penetration to the controller.

Turn ON the power of laser marker.

7.

20

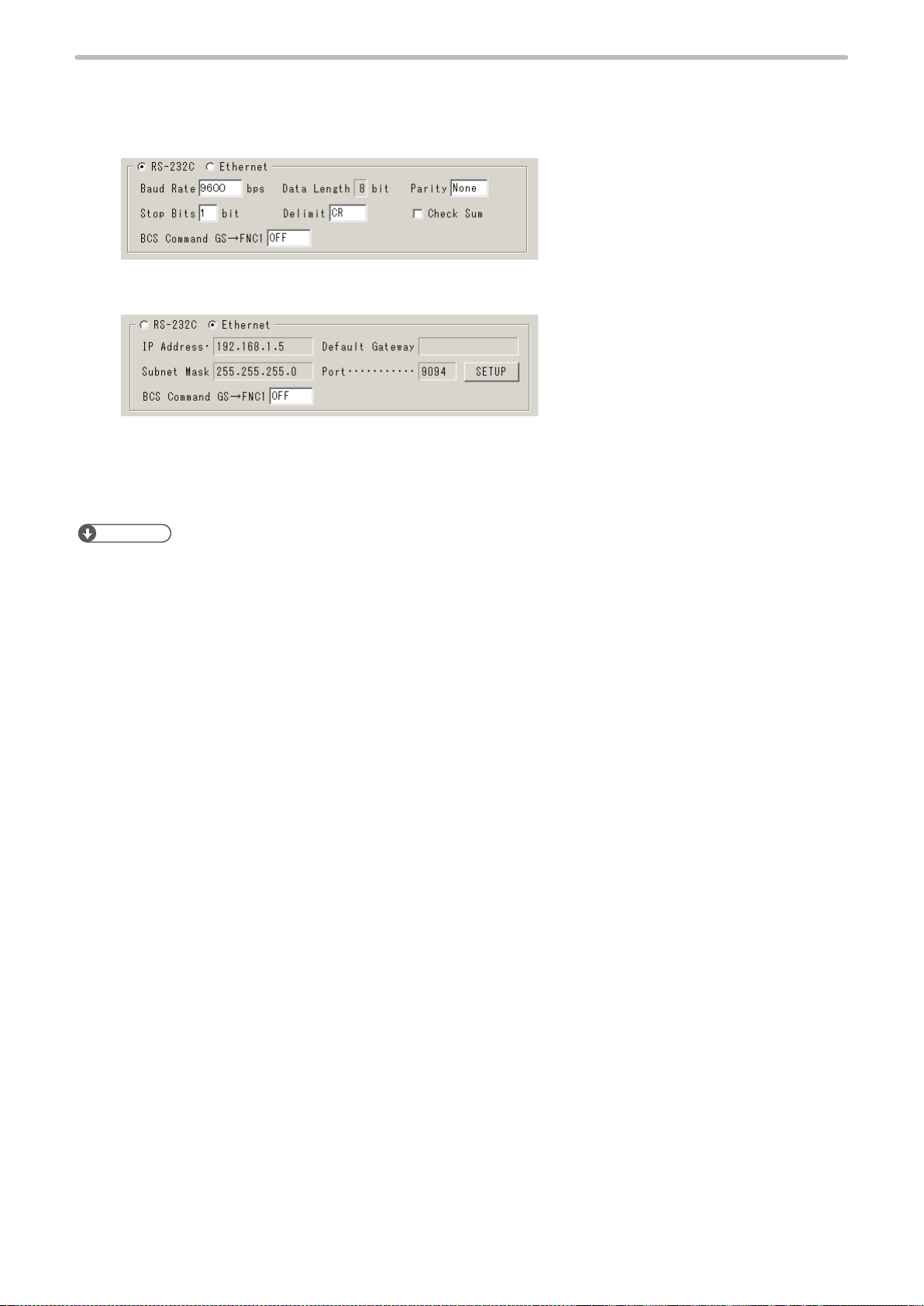

1-3-2 Communication condition setting

ME-LP400V-EX-6

To control the laser marker by using I/O or communication commands, congure the following items in advance on the

environment setting screen.

Select “ENVIRON” on the right menu.

1.

Select “ENVIRON 3”.

2.

To use I/O signals, congure the following output conditions:

3.

• One-shot time:

Sets the output duration for some signals such as MARK END OUT and SET OK OUT.

Setting range: 2 ms to 510 ms (initial value is 40 ms)

• Detect TRIG. Warning during Marking

Congure if you will output (ON) or will not output (OFF) the warning for the invalid trigger. With enabling this setting,

the warning is output when the marking trigger that cannot be accepted was input while the shutter is opened.

• I/O Connector Setting

Select the operation of I/O connector signal No. 35 from “Output Counter 3 End” or “Output Date Difference”.

21

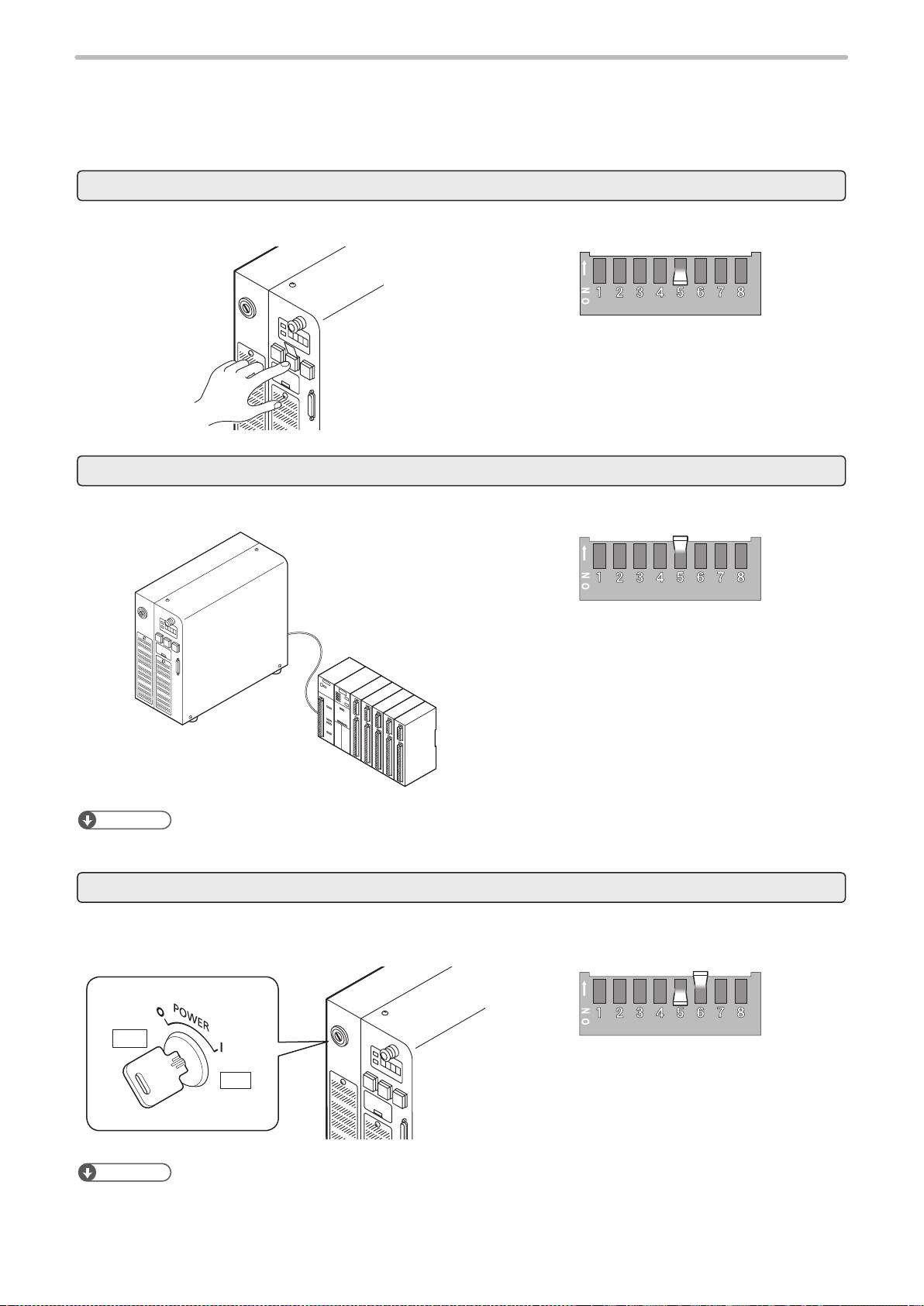

To use the serial communication commands, set communication conditions for Ethernet or RS-

ME-LP400V-EX-6

4.

232C.

• For RS-232C:

Congure the communication conditions of the laser marker corresponding to the external control device.

• For Ethernet:

Congure the communication conditions according to the network environment.

• BCS Command GS to FNC1

This setting is available only when the barcode “GS1 Data Matrix” is used. To set the barcode character by using

serial communication command “BCS”, select either “GS” (OFF) or “FNC1” (ON) as the separator of AI data with the

variable length.

Reference

• The laser marker can be controlled by I/O and communication commands combined.

• RS-232C and Ethernet cannot be used at the same time.

• The parameters on the environment setting screen are applied to the laser marker directly without saving.

• When using RS-232C, specify the “Flow control” to “None” at the communication port settings of the external control

device.

22

1-3-3 Shift to remote mode

ME-LP400V-EX-6

To control the laser marker externally using I/O or serial communication commands, set the operation mode to the remote

mode in one of the following methods.

Select the method to switch to the remote mode by setting the DIP switch on the rear side of the controller.

Use the remote switch on the front of the controller.

Turn ON the remote mode switch on the front of the controller.

Check that DIP switch No. 5 is OFF.

Refer to “1-3-1 DIP switch setting” (P.19).

Use input signal of X5 “REMOTE IN” on I/O terminal.

Turn ON the REMOTE IN (A3) of the I/O terminal on the rear of the controller.

A3: REMOTE IN

Check that DIP switch No. 5 is ON.

Refer to “1-3-1 DIP switch setting” (P.19).

Reference

• When DIP switch No. 5 is ON, the remote switch on the controller is not available.

Start the laser marker in the remote mode.

The laser marker starts up always in the remote mode state. Use the remote mode switch button of the controller for

releasing and resetting the remote mode.

OFF

ON

Reference

• When DIP switch No. 6 is ON, “X5: REMOTE IN” signal on I/O terminal is not available.

• The remote switch on the controller is available when DIP switch No. 6 is ON.

Check that DIP switch No. 5 is OFF, and No. 6 is ON.

Refer to “1-3-1 DIP switch setting” (P.19).

23

2 Control by I/O

ME-LP400V-EX-6

2-1 I/O Interface Specication

ME-LP400V-EX-6

The I/O terminal block and the I/O connector are available as the external control I/O interface of this product.

• I/O terminal block: Loaded with the basic input/output to control the laser marker.

• I/O connector: Loaded with the input/output for data conguration such as selecting a le number and the input/output

for the specic functions.

Reference

• Before using I/O, congure the DIP switch and the environment settings. Refer to “1-3 Before External Control” (P.18).

• I/O terminal block is removable from the controller at the wiring.

Rear of controller

LP-400 series LP-V/LP-W series

Laser marker side

I/O connector (female)

A12

A11

A2

A1

I/O terminal block

B12

B11

B2

B1

When terminal block is detached

1

2

12

13

Laser marker side

D-sub 25 pin connector (female)

14

15

24

25

25

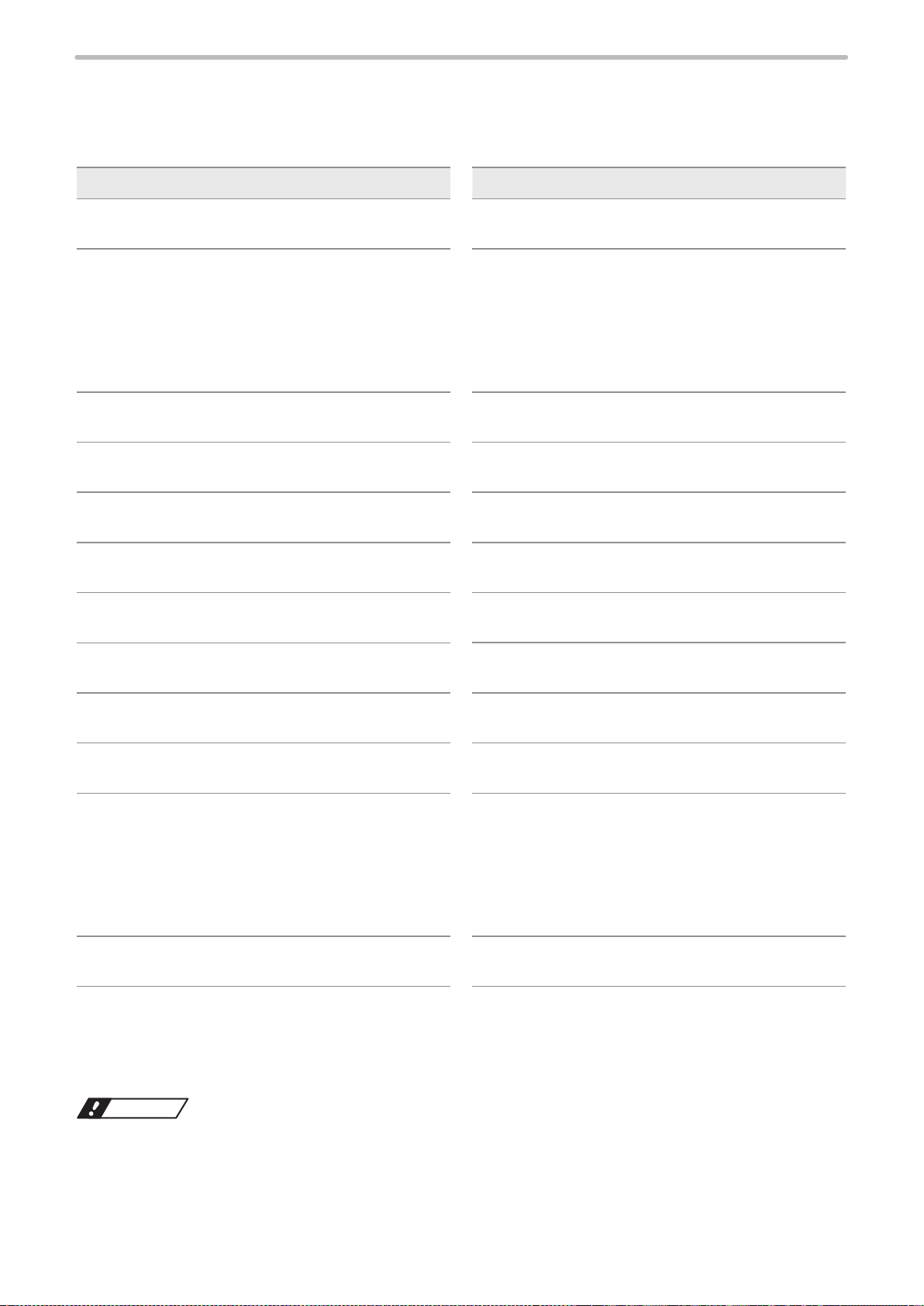

2-1-1 I/O terminal block

ME-LP400V-EX-6

I/O terminal block of the NPN type

[LP-4xx(T)U / LP-4xx(T)U-A / LP- 4xxS9(T)U /

LP-4xxS9(T)U-A / LP-VxxU / LP-VxxU-A / LP-W series]

Reference

• A2, A11, B2 and B11 on the I/O terminal block have different signals depending on the controller type of NPN or PNP.

• The connector type of I/O terminal block is as follows. (When the terminal block is removed.)

Laser marker side connector type Female D-sub 25 pin (Screw type: M2.6, female)

User side connector type Male D-sub 25 pin (Screw type: M2.6, male)

I/O terminal block of the PNP type

[LP-4xx(T)U-C / LP-4xxS9(T)U-C / LP-VxxU-C]

RESERVE

RESERVE

2-1-2 I/O connector

Laser marker side

(Female connector)

Laser marker side connector type Female D-sub 37 pin (Screw type: M2.6, female)

User side connector type Male D-sub 37 pin (Screw type: M2.6, male)

[Attached item] User side connector HDCB-37PF (05)

[Attached item] User side connector cover HDC-CTH1 (10)

User side: Attached accessory

(Male connector)

* This view is facing the connecting surface.

Hirose Electoric Co., Ltd.

26

2-1-3 Signals and details of I/O terminal block

ME-LP400V-EX-6

The I/O terminal block is loaded with the basic input/output to control the laser marker.

Signals in I/O terminal

⿎

No. *1 Signal name

A1

(12)

A2

(11)

A3

(12)

A4

(9)

A5

(8)

A6

(7)

A7

(6)

+12V OUT

I/O power supply +12V DC (Max. 300mA)

• For NPN models *2

IN COM.

Input common

• For PNP models (-C) *2

OUT COM.

Output common

REMOTE IN

Remote mode input

TRIG. IN

Marking trigger input

ENC. A

Encoder A-phase input

ENC. B

Encoder B-phase input

LASER IN

Laser pumping input

No. *1 Signal name

B1

(25)

B2

(24)

B3

(23)

B4

(22)

B5

(21)

B6

(20)

B7

(19)

0V OUT

I/O power supply 0V

• For NPN models *2

OUT COM.

Output common

• For PNP models (-C) *2

IN COM.

Input common

REMOTE OUT

Remote mode output

READY

Marking ready output

MARKING

Marking output

MARK END

Marking end output

LASER OUT

Laser pumping completion output

A8

(5)

A9

(4)

A10

(3)

A11

(2)

A12

(1)

*1 : The numbers in ( ) indicates the pin No. of the D-Sub connector when the terminal block is removed.

*2 : Signals of A2, A11, B2 and B11 are different depending on the controller type of NPN or PNP.

• NPN models: LP-4xx(T)U / LP-4xx(T)U-A / LP-4xxS9(T)U / LP-4xxS9(T)U-A / LP-VxxU / LP-VxxU-A / LP-W series

• PNP models (with “-C” in the end of the model name): LP-4xx(T)U-C / LP-4xxS9(T)U-C / LP-VxxU-C

SHUTTER

Shutter control input

ALARM RES.

Alarm reset input

N.C.

No connection

• For NPN models *2

LASER STOPOutput common for laser stop

• For PNP models (-C) *2

RESERVE

System reservation

LASER STOP +

Laser stop input

B8

(18)

B9

(17)

B10

(16)

B11

(15)

B12

(14)

WARNING

Warning output

ALARM

Alarm output

N.C.

No connection

• For NPN models *2

EMER.Output common for emergency stop

• For PNP models (-C) *2

RESERVE

System reservation

EMER.+

Emergency stop input

Notice

• Use the internal power (A1, B1) as the power supply for the I/O signals when operating the laser marker without external

power supply. Do not connect anything when using the external power supply.

• Do not connect anything to RESERVE terminals.

• Do not mix the connecting pattern for NPN and PNP.

27

Operation of input signal on I/O terminal block

ME-LP400V-EX-6

⿎

Reference

• The ON/OFF listed in this section refers to the ON/OFF operations. It does not refer to the voltage level (High/Low).

No. Name/Description

A1 +12V OUT: Internal power supply + 12V DC (max. output current 300mA)

Use this terminal as the power supply for the I/O signals when operating laser marker without external power

supply.

This terminal can be also used as the power supply for external devices such as a sensor or an encoder.

Notice

• Make sure to use B1 (0V OUT) for the 0V of the internal power A1 (+12V OUT). Do not mix the connecting pattern for

using external and internal power supply.

• Do not connect anything to this when using the external power supply for I/O control.

• When using the internal power supply (A1, B1), the total current of the power supply for the external device and the

consumption current for the I/O control should be less than 300mA.

A2

• For NPN models *1

IN COM.: Input common

The common terminal for each input of the I/O terminal and I/O connector. This A2 and No. 1 of I/O connector

are the common terminals connected internally.

For NPN models, this terminal is connected to the “+ (plus)” side of power which is used for control.

• For PNP models (“-C” in the end of the model name) *1

OUT COM.: Output common

The common terminal for each output of the I/O terminal and I/O connector. This A2 and No. 1 of I/O connector

are the common terminals connected internally.

For PNP models, this terminal is connected to the “+ (plus)” side of power which is used for control.

Notice

• Do not invert the power wiring of I/O terminal and I/O connector. It may cause a failure. When this terminal is connected

to the power supply, it is not necessary to supply the power to the other IN COM. or OUT COM. on I/O connector.

• At the factory shipments, IN COM. and OUT COM. of I/O terminals are connected to the power supply terminals by

short bars respectively. When using the external power supply or connecting to any external devices, remove the short

bars from the terminals to be used.

• Short-circuiting IN COM. and OUT COM. in supplying power might cause the short out and also cause the failure with

the laser marker. Be sure to check the wiring before starting the laser marker.

Reference

• Connect IN COM. and OUT COM. to the power supply respectively.

28

NPN type of laser marker: A2 [IN COM.] ― +V, B2 [OUT COM.] ― GND

PNP type of laser marker: B2 [IN COM.] ― GND, A2 [OUT COM.] ― +V

• For the connecting details, refer to “2-3 Connecting I/O Terminal Block” (P.42).

A3 REMOTE IN: Remote mode input

While this input is turned on, the laser marker operates in the remote mode which can be controlled externally

by I/O and serial communication commands.

To transit to the remote mode using this terminal, turn ON the DIP switch No. 5 in advance.

Refer to “1-3-3 Shift to remote mode” (P.23).

A4 TRIG. IN: Marking trigger input

Marking start signal. This signal can be accepted while READY OUT (B4) is turned ON.

Starts marking (laser radiation) by edge of input ON.

At equidistant marking to the ying object, marking is performed while this input is ON.

No. Name/Description

CAUTION

ME-LP400V-EX-6

A5A6ENC. A: Encoder A-phase input

ENC. B: Encoder B-phase input

Encoder input at marking to the ying object. Input up to 100kHz is possible for A and B phases respectively.

If either inputs of A and B phases are used, connect only ENC.A (A5) with the encoder and connect ENC.B (A6)

to IN COM.

A7 LASER IN: Laser pumping input

While this input is turned on, the laser is pumped to enable the radiation.

It takes approximately 15 to 20 seconds from turning on LASER IN (A7) to completion of laser pumping.

This terminal is available when the DIP switch No. 2 is turned OFF.

A8 SHUTTER: Shutter control input

While this input is turned on, the internal shutter opens. There is a delay time of around 200ms to max. 1

second from turning ON/OFF of SHUTTER (A8) for the actual shutter open / close operation time.

This terminal is available when the DIP switch No. 2 is turned OFF.

Reference

• For LP-400 series, the shutter cannot open until the laser pumping is completed.

• Do not use SHUTTER (A8) input as the emergency stop or the interlock. If

SHUTTER (A8) input becomes ON during laser emission, the shutter is closed

after the marking operation has been nished.

A9 ALARM RES.: Alarm reset input

The reset input for restoring the system from the alarm status.

Make sure to verify the safety by eliminating the alarm causes before turning this input ON.

For the alarms you are unable to reset such as the ones caused by hardware or system error, restart the laser

marker.

A10 N.C.: No connection

Do not use this terminal.

A11

• For NPN models *1

LASER STOP-: Output common for laser stop

This terminal is connected to OUT COM. (B2) internally.

Connect A11 with LASER STOP+ (A12) to release the laser stop warning or alarm and change the status of the

laser marker into valid for laser emitting.

The function relating to safety must be shut off mechanically. Therefore, it is recommended to wire these

terminals at no-voltage contact (dry contact).

• For PNP models (“-C” in the end of the model name) *1

RESERVE: System reser vation

Do not connect externally.

Notice

• A11 and B11 on the I/O terminal block are available only for NPN type of laser marker. For PNP type, do not use these

terminals.

A12 LASER STOP+: Laser stop input

*1 : Signals of A2, A11, B2 and B11 are different depending on the controller type of NPN or PNP.

Use this terminal to stop the laser radiation or disable the laser radiation temporarily by connecting with the

safety devices such as a door or a switch.

When between LASER STOP+ (A12) and OUT COM. (for NPN models; A11 or B2, for PNP models; A2) are

disconnected, the laser radiation will be disabled.

Opening this terminal, changes the status of the laser marker as follows.

• When laser is not emitted: The internal shutter is closed.

• During laser emission: The internal shutter is closed and laser pumping turns off.

The function relating to safety must be shut off mechanically. Therefore, it is recommended to wire these

terminals at no-voltage contact (dry contact).

• NPN models: LP-4xx(T)U / LP-4xx(T)U-A / LP-4xxS9(T)U / LP-4xxS9(T)U-A / LP-VxxU / LP-VxxU-A / LP-W series

• PNP models (with “-C” in the end of the model name): LP-4xx(T)U-C / LP-4xxS9(T)U-C / LP-VxxU-C

29

Operation of output signal on I/O terminal block

ME-LP400V-EX-6

⿎

Reference

• The ON/OFF listed in this section refers to the ON/OFF operations. It does not refer to the voltage level (High/Low).

Terminal

No.

B1 0V OUT: Internal power supply 0V

Name/Description

Use this terminal as the power supply for the I/O signals when operating laser marker without external

power supply.

This terminal can be also used as the power supply for external devices such as a sensor or an encoder.

Notice

• Make sure to use +12V OUT (A1) for the internal power supply with this 0V OUT (B1). Do not mix the connecting pattern

for using external and internal power supply.

• Do not connect anything to this when using the external power supply for I/O control.

• When using the internal power supply (A1, B1), the total current of the power supply for the external device and the

consumption current for the I/O control should be less than 300mA.

B2

• For NPN models *1

OUT COM.: Output common

The common terminal for each output of the I/O terminal and I/O connector. This B2, A11, B11 and No. 37

of I/O connector are the common terminals connected internally.

For NPN models, this terminal is connected to the “- (minus)” side of power which is used for control.

• For PNP models (“-C” in the end of the model name) *1

IN COM.: Input common

The common terminal for each input of the I/O terminal and I/O connector. This B2 and No. 37 of I/O

connector are the common terminals connected internally.

For PNP models, this terminal is connected to the “- (minus)” side of power which is used for control.

Notice

• Do not invert the power wiring of I/O terminal and I/O connector. It may cause a failure. When this terminal is connected

to the power supply, it is not necessary to supply the power to the other IN COM. or OUT COM. on I/O connector.

• At the factory shipments, IN COM. and OUT COM. of I/O terminals are connected to the power supply terminals by

short bars respectively. When using the external power supply or connecting to any external devices, remove the short

bars from the terminals to be used.

• Short-circuiting IN COM. and OUT COM. in supplying power might cause the short out and also cause the failure with

the laser marker. Be sure to check the wiring before starting the laser marker.

Reference

• Connect IN COM. and OUT COM. to the power supply respectively.

NPN type of laser marker: A2 [IN COM.] ― +V, B2 [OUT COM.] ― GND

PNP type of laser marker: B2 [IN COM.] ― GND, A2 [OUT COM.] ― +V

• For the connecting details, refer to “2-3 Connecting I/O Terminal Block” (P.42).

B3 REMOTE OUT: Remote mode output

This output turns ON while the laser marker is in the remote mode.

Make sure that this terminal is turned ON and start the external control by I/O or serial communication

commands.

30

Loading...

Loading...