Page 1

CONCRETE THICKNESS GAUGE (CTG

-

2)

PATENT PENDING

System Reference Manual

CTG-2 with WinCTG2 Software Version 1.7

Page 2

NOTICES

Errors and Omissions

This document is believed to be accurate, but Olson Instruments, Inc. will not be

responsible for any errors or omissions which may be found. Further, Olson Instruments

will not be responsible for any damages resulting from any errors or omissions.

Proprietary Information

This document, as well as all software written by Olson Instruments, Inc., is proprietary

to Olson Instruments, Inc. This manual may not be sold, reproduced, or used with any

other product other than the Olson Instruments CTG-2 unless approved by Olson

Instruments, Inc. Further, this manual and the accompanying software may not be used

by any party other than the original purchaser without prior approval of Olson

Instruments, Inc.

Warranty

(See Sales Contract Documents)

Copyright

Copyright 2016 by Olson Instruments, Inc. All rights reserved. No part of this publication

may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying, recording, or by any information storage or retrieval system,

without prior written permission of the above named copyright holder.

Written by:

Olson Instruments, Inc.

12401 W. 49th Avenue

Wheat Ridge, Colorado

USA 80033-1927

Office: (303)423-1212

Fax: (303)423-6071

E-Mail: equip@olsoninstruments.com

Revised: August 2017

1

Page 3

Table of Contents

INTRODUCTION ............................................................................................................................................................ 3

1.1 Organization and Scope of Manual .................................................................................................................. 4

1.2 Test Methodology ............................................................................................................................................. 4

2.0 HARDWARE ........................................................................................................................................................ 5

2.1 Hardware Component Listing ........................................................................................................................... 5

2.2 Location and Replacement of Batteries............................................................................................................ 6

2.3 Hardware Setup ............................................................................................................................................... 7

3.0 WinCTG2 SOFTWARE SETUP ......................................................................................................................... 10

3.1 Prerequisite Software ..................................................................................................................................... 10

3.2 Software Installation ....................................................................................................................................... 10

3.3 Software Updates ........................................................................................................................................... 10

3.4 Software Uninstallation................................................................................................................................... 10

4.0 DATA AQUISITION ............................................................................................................................................ 12

4.1 General Information about the WinCTG2 Software ........................................................................................ 12

4.2 IE Data Acquisition without Velocity Calibration ............................................................................................. 13

4.3 IE Data Acquisition with Known-Thickness Velocity Calibration ..................................................................... 21

4.4 View Mode ..................................................................................................................................................... 23

4.5 Thick Concrete Testing .................................................................................................................................. 24

4.6 Units ............................................................................................................................................................... 25

4.7 Volume ........................................................................................................................................................... 25

4.8 Save Parameters ........................................................................................................................................... 25

4.9 Reset Parameters .......................................................................................................................................... 26

4.10 Operation Notes and Tips ............................................................................................................................ 26

5.0 WinCTG2 SOFTWARE ANALYSIS .................................................................................................................... 29

5.1 Start Program ................................................................................................................................................. 29

5.2 Open Data Files ............................................................................................................................................. 30

5.3 Filtering .......................................................................................................................................................... 30

5.4 Windowing ...................................................................................................................................................... 31

5.5 Concrete Velocity ........................................................................................................................................... 33

5.6 Open Next Data File ....................................................................................................................................... 33

6.0 WinCTG2 SOFTWARE EXPORTING OPTIONS ............................................................................................... 34

6.1 Copy or Save Image....................................................................................................................................... 34

6.2 Export Test Results to Comma Separated Format ......................................................................................... 34

6.3 Export Raw Data to Comma Separated Format ............................................................................................. 35

7.0 WinCTG2 SOFTWARE LANGUAGE OPTIONS ................................................................................................ 36

8.0 CARE AND MAINTENANCE .............................................................................................................................. 37

APPENDIX A................................................................................................................................................................ 38

2

Page 4

INTRODUCTION

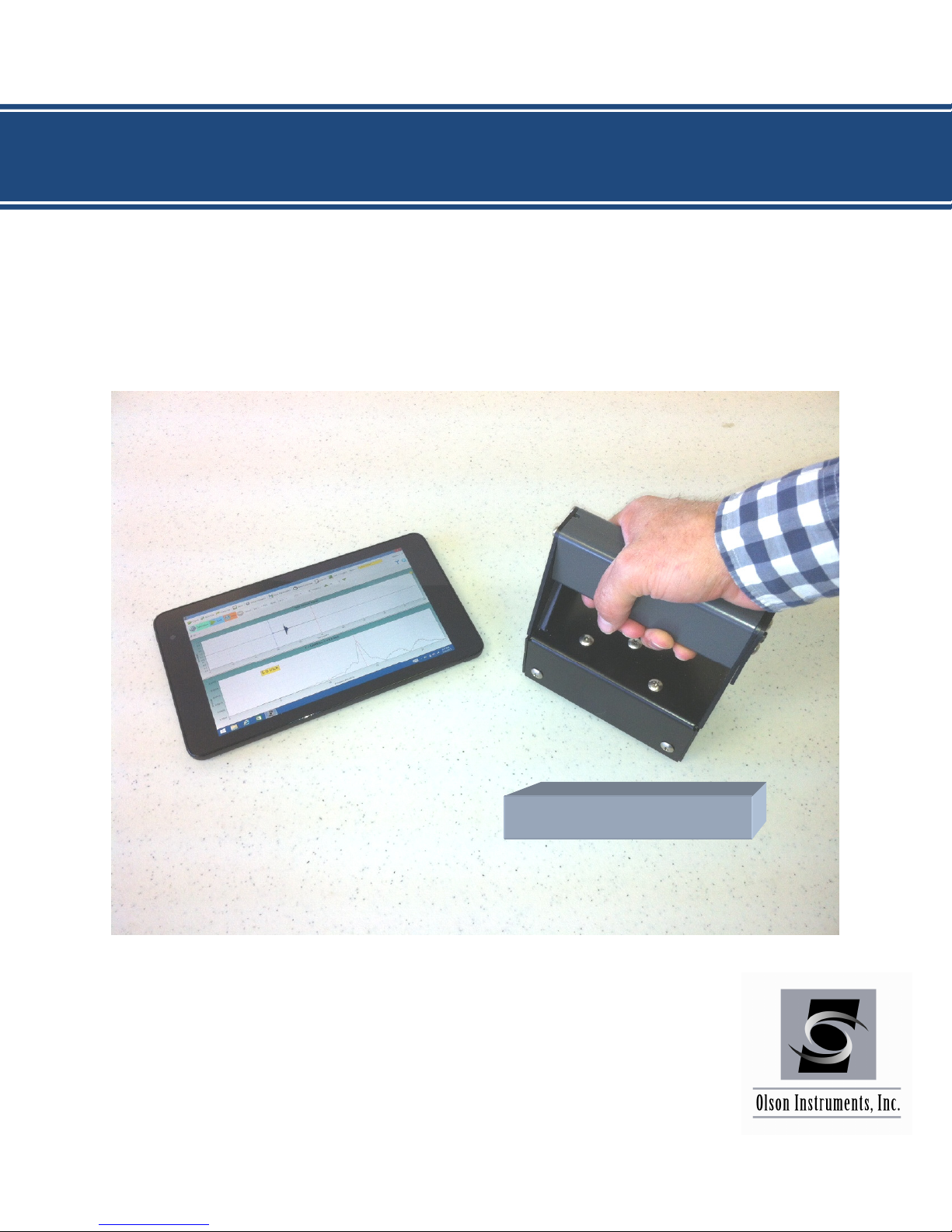

The Olson Instruments CTG-2 system is commonly used for thickness evaluation and

rapid flaw detection on concrete and masonry structural materials. The method is

normally applied to plate-like objects such as slabs and walls, but is also used on

columns, mat foundations, and beams. The method requires access to only one side for

testing.

The CTG-2 is a powerful, hand-held device meant to be used with most Windows 7 and

Windows 8 laptop computers or tablets. The CTG-2 is designed to measure the

thickness of concrete slabs and walls in the range of approximately 3.2 inches (8.1 cm)

out to about 6 feet (1.8 m) without the need for drilling, coring, or other means. Test

results are acquired and analyzed with Olson’s WinCTG2 software, making the CTG-2

system a fully functional Impact Echo (IE) based thickness measuring system, capable

of analyzing echoes from multiple cracks and other flaws. In addition, a summary of test

results can be saved in comma separated format for use in an excel spreadsheet.

The WinCTG2 software features a graphical display of both the raw time signal as well

as the received signal spectrum (which can be saved and recalled), which allows visual

indication of data quality, easy differentiation of bad data, and even the location of

partial cracking damage. This unit can also be used to determine relative concrete

quality (by measuring concrete compression wave velocity) for test cylinders and other

samples with known thicknesses. The device can also be used for thickness

measurements of many materials other than concrete, such as plastics, stone, etc.,

depending on the properties and internal structure of the material being tested.

The CTG-2, when used with the default concrete velocity value of 12,000 fps, has an

accuracy of up to approximately 10%. This accuracy can be improved to approximately

2% when the unit is calibrated for velocity at a location of known thickness.

To confirm functionality of the CTG-2, it is advised to test the unit on a slab of known

thickness or on a 6” x 12” concrete cylinder which can be readily obtained from a

concrete supplier.

The CTG-2 with automated solenoid and displacement transducer comes with a phoneplug-to-phone-plug cable used to connect the unit to a laptop or tablet. A microphone

adaptor is included to ensure the cable will work with different microphone/headset

ports. A USB jump drive is supplied with the necessary software and a microUSB-toUSB cable is included so the software on the USB jump drive can be downloaded onto

Windows devices. The user must supply a Windows 7 or Windows 8 laptop/tablet.

Details of the hardware and its usage are included in Section 2.0. Suggested Windows

devices that are known to work with the CTG-2 are listed in Appendix A.

3

Page 5

1.1 Organization and Scope of Manual

The CTG-2 is a sturdy battery powered unit designed for easy, fast, and reliable

operation by anyone with no special training required for basic operation. This manual

covers step-by-step hardware assembly, software setup, simplified operation

instructions for data acquisition, data analysis, and output generation. If any problems

with the system appear that are not covered in this manual, please call Olson

Instruments at the number included in the front of this manual.

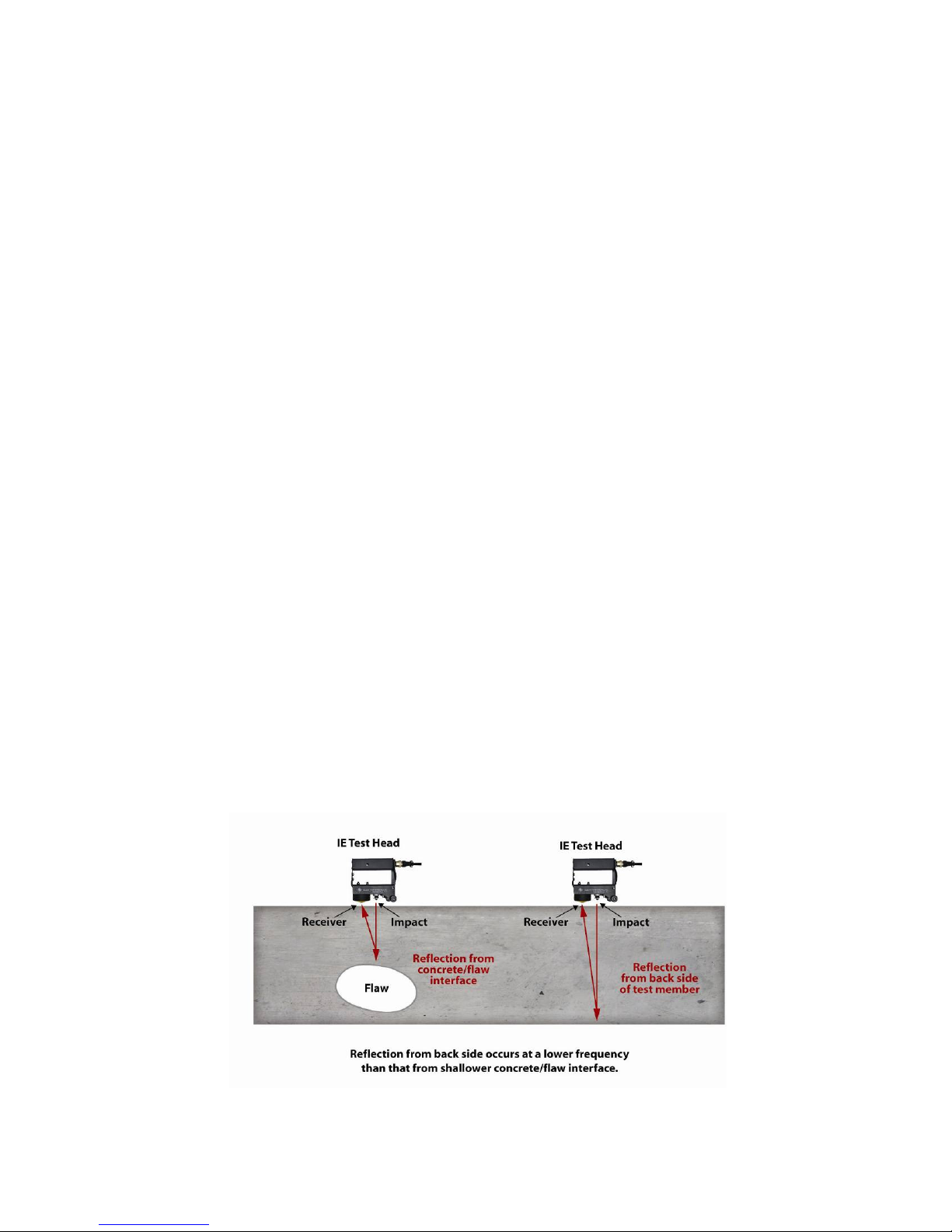

1.2 Test Methodology

The Impact Echo tests performed with the CTG-2 involve impacting the

concrete/masonry member with an impactor solenoid and identifying the reflected wave

energy with a displacement transducer as shown in the figure below. Note that the

solenoid impactor and displacement transducer are built into the IE head. The test head

is pressed against the top of the tested member and held while tests are performed at

each test point. The resonant echoes of the displacement responses are usually not

apparent in the time domain, but are more easily identified in the frequency domain.

Therefore, amplitude spectra of the displacement responses are calculated by

performing a Fast Fourier transform (FFT) analysis to determine the resonant echo

peak(s). The relationship among the resonant echo depth frequency peak (f), the

compression wave velocity (VP) and the echo depth (D) is expressed in the following

equation:

D = βVp/(2*f) (1)

where β is a geometric shape factor ranging in value from 0.8 for a pier/column shape to

0.96 for a slab/wall shape. A slab/wall shape has a single thickness resonance while

beam and column shapes have multiple resonances due to their cross-sectional shape.

4

Page 6

2.0 HARDWARE

The CTG-2 system consists of a few basic components

packaged into a carrying case. The carrying case with

foam insert stores the CTG-2 IE test head and cables. It

includes a small compartment to store four CR123A 3V

spare batteries. A description of each of the included

components as well as their connection and operation is

included in the following sections.

2.1 Hardware Component Listing

COMPONENT NAME

COMPONENT NAME

COMPONENT NAMECOMPONENT NAME

QTY

QTY

QTYQTY

DESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

CTG

CTG----2 IE

2 IE Test

Test Head

CTGCTG

2 IE 2 IE

Phone

Phone----Plug

Plug----to

PhonePhone

PlugPlug

Phone

Phone----Plu

Plugggg Cable

PhonePhone

PluPlu

Microphone Adaptor

Microphone Adaptor

Microphone AdaptorMicrophone Adaptor

Olson Jump Drive

Olson Jump Drive

Olson Jump DriveOlson Jump Drive

Test Test

to----

toto

Cable

CableCable

Head

HeadHead

The test head includes an automated solenoid

impactor to create the impact and a

1111

1111

1111

1111 Jump Drive with Olson WinCTG2 Software.

displacement transducer sensor to receive the

signal. Includes four CR123A 3V lithium photo

batteries.

To connect the IE Test Head to the Microphone

Adaptor.

To connect the Phone-Plug-to-Phone-Plug

Cable to the Windows device.

USB to MicroUSB

USB to MicroUSB

USB to MicroUSB USB to MicroUSB

Adapt

Adaptor

AdaptAdapt

or

oror

1111

To connect Jump Drive with Olson WinCTG2

Software to Windows Device.

5

Page 7

i

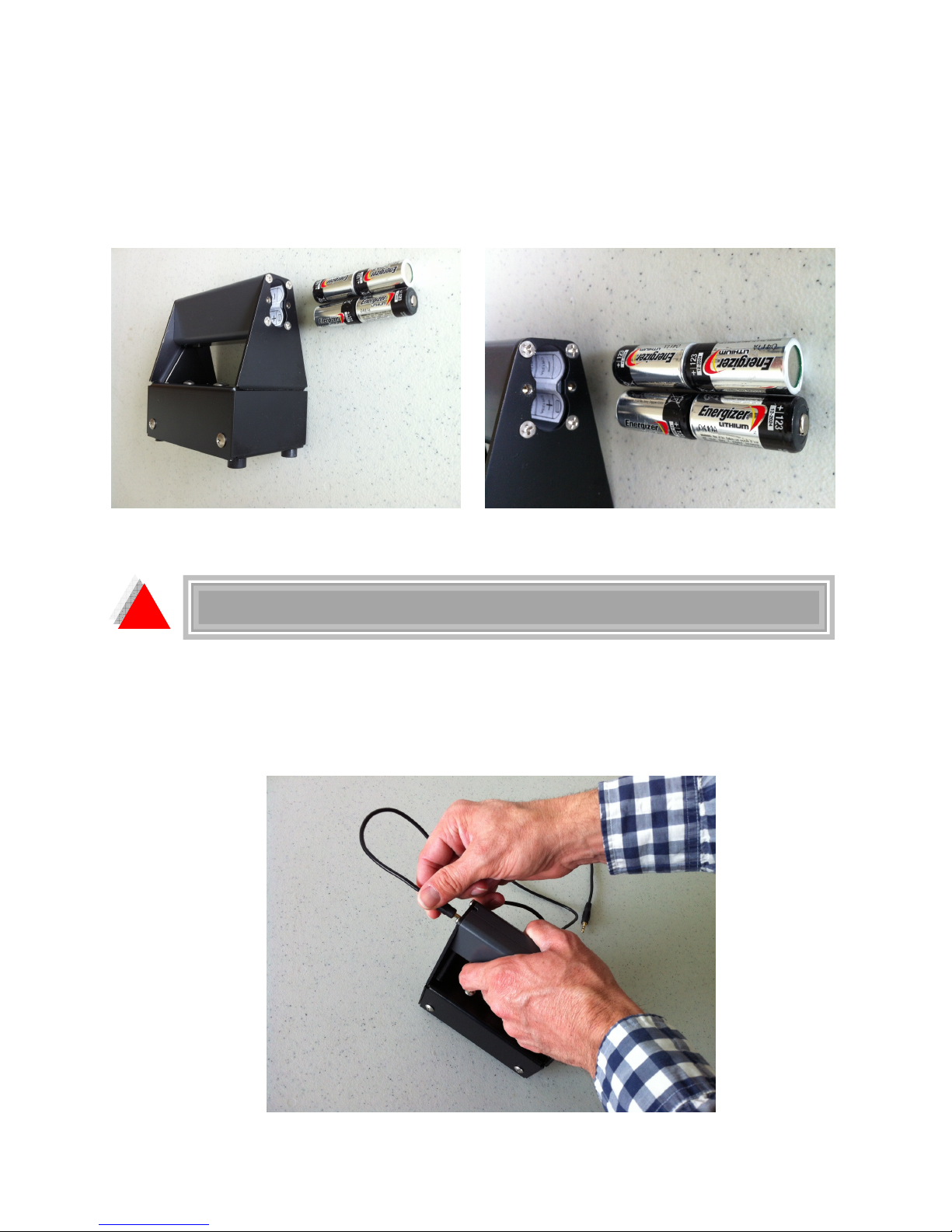

2.2 Location and Replacement of Batteries

The CTG-2 is provided with four CR123A 3V nonrechargeable long life lithium photo

batteries to power the system. (If desired, rechargeable CR123A 3V batteries can be

purchased and used with the unit.) The CTG-2 unit is designed to turn on when the

toggle switch on the base of the unit is flipped into the on position, making the indicator

light at the top of the handle illuminate green.

When the batteries are losing power, the green light will not illuminate. Instead, the red

light will come on. To ensure accurate readings, the batteries must be replaced at this

time. When light fails to illuminate (either green or red), the batteries have lost power

and MUST be replaced.

Location of the Batteries: the four CR123A batteries that power the CTG-2 IE test

head are located inside the handle of the test head.

Battery Replacement: To replace the batteries, follow these steps:

1. Using the toggle switch located at the base of the IE head, turn off the unit and

2. Use a Phillips screwdriver to remove the 2 screws at the rear of the handle as

We recommend carrying spare batteries, and have provided a space for

them in the carrying case.

make sure the green light on the handle is not illuminated.

shown in the picture below. Remove the battery compartment cover.

6

Page 8

3. Turn the front of the unit upward to allow the batteries to slide out.

4. Insert new batteries following the polarity diagram inside the handle as shown in

the pictures below.

5. Replace the battery cover and screws.

!

2.3 Hardware Setup

1. Connect the Phone-Plug-to-Phone-Plug Cable to the IE Test Head as shown in the

picture below.

Do not expose the CTG-2 system or the batteries to water.

7

Page 9

2. Connect the other end of the Phone-Plug-to-Phone-Plug Cable to the Microphone

Adaptor, if necessary (laptops and desktops will not normally require the microphone

adaptor). There are two jacks on the Microphone Adaptor. One is identified with a

microphone icon. The other is identified with a headset icon. Select the appropriate

jack. Tablets will normally require the microphone jack. Note: the CTG-2 unit will

NOT work with tablets that have only a headphone jack. The tablet MUST support a

headset OR microphone.

3. Connect the other end of the Microphone Adaptor to the Windows Device. Or, if

using a laptop/desktop, connect the other end of the Phone-Plug-to-Phone-Plug

Cable to the Windows Device.

8

Page 10

4. Flip the toggle switch on the base of the IE test head to activate the unit. When the

green light is illuminated, the IE test head is powered up and ready to collect data.

5. The picture below shows the complete CTG-2 system ready to acquire data. In this

case, an 8” tablet is being used. We recommend a minimum 8” size tablet. We

recommend that the tablet be used in “landscape” mode.

9

Page 11

3.0 WinCTG2 SOFTWARE SETUP

This section covers the steps required to install the WinCTG2 software on a tablet,

laptop or desktop computer from the supplied installation jump drive.

3.1 Prerequisite Software

Windows .Net Framework 4 is required for the WinCTG2 software and is installed

automatically with the program. The software is fully compatible with Windows 7 and

Windows 8 (32 or 64 bit) operating systems.

3.2 Software Installation

1. Uninstall any previous version of WinCTG2.

2. Using the USB to MicroUSB adaptor, connect the provided jump drive to the

Windows device. Copy the WinCTG2 Setup directory on the jump drive to the

desktop on the device. On the Windows device, open WinCTG2

Setup/Release/setup.exe. The software will be installed using a Setup Wizard.

Select “Next” as appropriate. Select “Yes” when prompted to confirm changes.

Select “Close” to exit. The default location for the software installation is “C:/Olson

Instruments/WinCTG2” unless the user changes the location during the installation

process.

3.3 Software Updates

To update the software, completely uninstall the WinCTG2 Setup software per Section

3.4 and install the new version of WinCTG2 Setup by selecting the “Setup” executable

in the “Release” directory. The program will install a shortcut on your desktop.

3.4 Software Uninstallation

The following steps are required to uninstall the WinCTG2 Software on a desktop or

laptop computer.

1. Click on “Start/Control” Panel

2. Select “Programs and Features”

3. Highlight WinCTG2 Setup, select “Uninstall”

The following steps are required to uninstall the WinCTG2 Software on a tablet.

1. Turn on tablet. The “Start” panel should present.

2. Touching the screen, flick to reach the “Apps” panel below.

10

Page 12

3. Touching the screen, flick to reach the Dell “Apps” panel to the right.

4. Select “Control Panel”.

5. Select “Programs”.

6. Select “WinCTG2 Setup”.

7. Select “Uninstall”.

8. Select “Yes” to confirm uninstallation.

9. Select “Yes” to confirm changes.

The uninstall process will begin automatically, removing all installed components

including shortcuts. This uninstall process might take up to five minutes. Do not exit the

installation until it is completed.

11

Page 13

4.0 DATA AQUISITION

This section includes instructions for data collection with the WinCTG2 Software. If you

have an area of known thickness that can be used for velocity calibration, please refer

to Section 4.3 before testing.

4.1 General Information about the WinCTG2 Software

The WinCTG2 software is comprised of 3 different panels: the Data Parameter panel,

the Filter panel, and the Waveform Data panel. Each panel (except the waveform data

panel) is collapsible if not needed (especially during the data acquisition process) to

enlarge the waveform data panel. Figure 1 below shows an overview of the program

layout. The shortcuts to turn on each panel are located on the upper right corner of the

screen. The function of each shortcut is described below:

• Toggles the filter panel on/off

• Toggles the parameter panel on/off

Filter Panel

Waveform Data Panel

Parameter Panel

Figure 1 – WinCTG2 Layout for IE Test Results

12

Page 14

4.2 IE Data Acquisition without Velocity Calibration

It is not necessary to calibrate for velocity in order to perform the Impact Echo test and

collect data using the system’s default value of 12,000 fps (3,657 m/s) as an average

velocity for sound concrete. But the operator should understand that using the default

value results in up to approximately a 10% error in the results as compared to

approximately a 2% error when the unit is calibrated for velocity at a location of known

thickness.

1. Turn on your tablet or laptop (with the hardware connected and turned on as

described in Section 2.0) and select the WinCTG2 shortcut on the desktop. The

software will open as shown in Figure 2 below. Within the Waveform Data Panel, the

top plot box shows the current time domain data and the bottom plot box shows the

frequency spectrum. Per the “Status” field in the Main Menu, the program is currently

in “Stand by” mode.

Figure 2 – Main Screen for WinCTG2 Software

2. Filename Feature: Fill in the “Date” field and “Project Name” field as desired.

3. Geometry Feature: If you have laid out a grid for data collection and want the

software to keep track of your X and Y coordinates, use the Geometry Feature to

document the coordinates. In the “Length (X)” field, enter the total length you plan to

13

Page 15

test in the X direction and in the “Length (Y)” field, enter the total length you plan to

test in the Y direction. Select the “Moving X” checkbox if you plan to move from test

point to test point in the X direction. Select the “Moving Y” checkbox if you plan to

move from test point to test point in the Y direction. In the “Start X” field, enter a

value for the start point in the X direction as well as the “Interval X” (or distance

between test points) in the X direction. Finally, in the “Start Y” field, enter a value for

the start point in the Y direction as well as the “Interval X” (or distance between test

points) in the Y direction.

Unless changed, a default value of 6 inches will be used for “Expected Concrete

Thickness”. This value is used to limit the amount of data analyzed and presented by

the software so it is important to alter this number as appropriate, however, 6 inches

is an appropriate value to use for slabs ranging in thickness from 4 inches to 8

inches.

4. At this point, the user has two options for collecting and saving data. The “Setup

Filename” option in the Main Menu can be used to set up automatic file naming for

files that will be saved (this is the suggested mode). Or the “Start” option in the

Toolbar can be used to start testing without setting up automatic file naming. When

using this mode, the user will be prompted to name each file individually. Note that

the “View” option in the Toolbar can also be used as discussed in Section 4.4 to

view data without saving or recording files.

14

Page 16

Set up Automatic File Naming: To set up sequential numbering of the files to be

collected, select the “Setup Filename” option found in the Main Menu. This will open

a dialogue box as shown in Figure 3 below. Enter the directory where the data is to

be saved along with an alphabetical prefix and a numerical suffix. (The alphabetical

prefix will remain fixed and the numerical suffix will increase with each test.) When

finished, select “Start” to close the dialogue box then select the “Start” option found

on the Toolbar to start collecting data.

Figure 3 – Set Up Filenames

15

Page 17

Start Testing without Setting up Automatic File Naming: To start collecting data

without using the “Setup Filename” option, select the “Start” option found on the

Toolbar. A “Save As” dialogue box will open as shown in Figure 4 below. Enter the

individual filename desired. When finished, select “Save” to close the dialogue box

and proceed with testing.

Figure 4 – Start Testing without Setting up Filenames

5. After selecting the “Start” option on the Toolbar, the system is now waiting to receive

data (in the form of an impact) as reported in the “Status” field which is currently in

“Ready to Test” mode. See Figure 5 below.

i

i

Some Windows devices will trigger when the “Start” or “View”

option is selected. When this happens, reject the data and

proceed with the testing instructions below.

If the IE head is repositioned after the “Start” or “View” option is

selected, data acquisition will be triggered. When this happens,

reject the data and proceed with the testing instructions below.

16

Page 18

surface.

Figure 5 – System Waiting to Receive Data

6. With the IE head powered up and the green light on the top of the handle

illuminated, press the trigger button on the underside of the handle. The unit will fire

the solenoid on the CTG-2 head and create an impact. The displacement transducer

sensor on the CTG-2 head will record the data and the software will display the data

on the screen as shown in Figure 6 below. The program is now waiting for you to

either accept or reject the data as reported in the “Status” field which is currently in

“Accept or Reject” mode.

i

When placing the CTG-2 on a test surface, place the rear feet

down first then rotate the unit down into position. This will

ensure proper contact between the sensor tip and the test

!

Gently rotate the sensor tip onto the test surface as a sudden

impact to the sensor might result in damage to the sensing

element.

17

Page 19

Figure 6 – Data Displayed with Thickness Reported above the Frequency Spectrum Plot

7. Good data can be identified by a waveform signal in the Time Domain (top plot) that

ranges from 0.1 volt to 0.8 volt AND the presence of a prominent peak in the

Frequency Spectrum (bottom plot). (In Figure 6 above, the data was collected on a

6” x 12” cylinder so there are additional resonant peaks displayed in the data.) The

following Figures 7A through 7D, demonstrate both acceptable and unacceptable

data. It is recommended to verify repeatability of results by taking at least two tests

at the same location.

i

The default value for volume (or gain) is 10. The available volume

varies in different tablets/laptops and the initial setting might not

be appropriate to collect good data. If the waveform signal does

not range from 0.1 volt to 0.8 volt, carefully adjust the volume as

described in Section 4.6 and retest. Caution must be used when

adjusting the volume as a high volume can result in noisy data.

18

Page 20

Figure 7A – Example of Good Data and a Single Prominent Peak in the Frequency Spectrum

Figure 7B – Example of Poor Data (Noise) and many Peaks/Hash in the Frequency Spectrum

19

Page 21

Figure 7C – Example of Nonexistent Data and Noise Peaks in the Frequency Spectrum

Figure 7D – Example of Good Data and Multiple Peaks in the Frequency Spectrum that might

Indicate the Presence of Multiple Cracks

20

Page 22

8. If the data is acceptable, select the green box (with a checkmark) found in the

Toolbar to accept and save the data. If the data is not acceptable, select the red box

(marked with an X) found in the Toolbar to reject the data. After you have rejected

the data, the program will wait for another impact. The program will continue to wait

after every impact until you have accepted a record. Only then will it allow you to

move on to the next test point.

9. Repeat the steps above until all the records are collected.

10. During the display of the data (before accepting or rejecting), several user options

are available to allow additional data processing and display. First, a cursor function

is available on the Frequency Spectrum (bottom plot) to allow the user to obtain the

thickness values of peaks other than the largest one. Simply click on or touch the

screen at the desired location. Next, the data can be windowed in or out by dragging

the blue or red cursor to the desired location on the Time Domain plot (top plot).

Finally, the frequency filtering can be changed by adjusting the filter bar in the Filter

Panel located above the Waveform Panel.

11. After the data has been accepted (and saved), the data can be recalled by selecting

the “Open” option found in the Main Menu then selecting the desired filename.

4.3 IE Data Acquisition with Known-Thickness Velocity Calibration

The CTG-2 measures thicknesses of concrete by measuring the time required for an

echo to bounce off the back side of the concrete member being tested. The thickness if

then computed by using this travel time along with the speed of sound in the concrete.

The speed of sound in concrete can vary over a range of 10,000 to 14,000 feet per

second or 3,000 to 4,300 meters per second depending on the mix design, aggregate

type, and age of the concrete. Lower strength mixes typically have velocities in the

lower range, while high strength mixes have higher velocities. The default velocity used

in the WinCTG2 software is 12,000 ft/s (3,657 m/s) which is a typical value found in

normal slabs and walls with 3,000 – 4,000 psi concrete mixes. Using this velocity with

no additional calibration should give thicknesses within 10% or less of the actual value

for most concrete structures. To increase accuracy, the unit can be calibrated.

The WinCTG2 software includes a feature that allows accurate calibration of the

concrete velocity at any location where the user knows the actual concrete thickness

and can collect good-quality data. This allows the user to improve the accuracy of

readings from up to approximately a 10% error to approximately a 2% error. Typical

locations for calibration include next to coreholes, cutouts, slab edges, etc. It can also

be done on walls near holes or edges, or other known-thickness features that were

placed with the same concrete mix as the structure being tested. To use, select the

21

Page 23

“Calibration” option on the Toolbar. This will open a “Calibration Form” dialogue box as

shown in Figure 8 below.

Figure 8 – Calibrate for Velocity at Location of Known Thickness

Enter the value of the thickness measured at the test location. If you want to save the

calibration file, select “Yes” and save the file, giving it a name like “cal1”. Otherwise,

select “No” if you don’t want to save the file.

At a location 6” – 12” from the known thickness location, press the test head firmly

against the test surface and press the trigger button on the underside of the handle. The

solenoid in the test head will immediately fire and a waveform will be collected. The data

should show a clear, prominent IE echo peak and corresponding velocity. When you

accept the data, a small dialogue box will appear and report the velocity as shown in

Figure 9 below. If you want to accept this value, select on “Yes” and the velocity will be

changed in the “Vel” field. If you don’t want to accept this value, select “No” and the

velocity will not be changed.

22

Page 24

Figure 9 – Calibrate for Velocity at Location of Known Thickness

The velocity calibration mode can also be used to measure relative velocities of

concrete in a member with known thicknesses (such as a wall) to find degraded or lowstrength zones.

4.4 View Mode

View mode can be used when it is not necessary to save your data files or if you want to

perform a quick succession of tests to scope out a job before you start saving data. To

use, select the “View” option on the Toolbar. Note that the “Status” field will report that it

is in “Ready to Test” mode. The system is now waiting to receive data (in the form of an

impact). With the IE head powered up and the green light on the top of the handle

illuminated, press the trigger button on the underside of the handle. The unit will fire the

solenoid on the CTG-2 head and create an impact. The displacement transducer sensor

on the CTG-2 head will record the data and the software will display the data on the

screen as shown in Figure 10 below. The program is now waiting for you select the

“View” option again for further testing. When you are ready to start to saving data, select

the “Start” option or “Setup Filename” option and proceed with testing according to

Section 4.2 or 4.3.

23

Page 25

Figure 10 – Testing in View Mode

4.5 Thick Concrete Testing

The CTG-2 is primarily designed to measure concrete thicknesses ranging from

approximately 3.2 inches (8.1 cm) to about 20 inches (50.8 cm), however, it is possible

to measure thicknesses up to 6 feet (2 m) by using the following procedure:

First, change the “Expected Concrete Thickness” Value (found in the Geometry Feature

on the Parameter Panel) from the default value of 6 inches (152.4 mm) to a number that

represents the approximate expected thickness of the member you are testing.

Now, start the testing using one of the three test mode options (Setup Filename, Start or

View). With the IE head powered up and the green light on the top of the handle

illuminated, press the unit firmly against the concrete member to be tested and use a

small external hammer to impact the top of the concrete. The displacement transducer

sensor on the CTG-2 head will record the data and the software will display the data on

the screen.

When testing thick concrete, it is important to select the proper hammer to obtain the

best quality data. For tests on concrete expected to be between 2 and 3 feet (0.6 to 1m)

thick, a 1 pound (0.5 kg) steel hammer is the best choice. For thicker structures, use of

a 3 pound (1.5 kg) or larger hammer will result in clearer data.

24

Page 26

4.6 Units

The units can be changed from Metric to English or vice versa during data collection.

Select the “Unit” option found on the Main Menu, as shown in Figure 11 below, to

change the units.

Units

Figure 11 – Units

4.7 Volume

The volume (or gain) can be changed during data collection by adjusting the green

“Volume” option arrows upward or downward or by typing a new value in the “Volume”

field found on the Toolbar, as shown in Figure 12 Below.

Figure 12 – Volume

Volume

4.8 Save Parameters

The parameters (such as “Expected Concrete Thickness” and “Velocity”) can be saved

by selecting the “Save Parameters” option found in the Main Menu as shown in Figure

13 below. Upon exiting the program, you will get another opportunity to save

parameters. Be careful when you save parameters; they will be saved by the program

for future use the next time you open the software. If you have calibrated for velocity,

this velocity may not be valid for your next job.

Figure 13 – Save Parameters

25

Page 27

4.9 Reset Parameters

To return the parameters to the factory settings, select the “Reset Parameter” option

found in the Main menu as shown in Figure 14 below.

Figure 14 – Reset Parameters

4.10 Operation Notes and Tips

Concrete Thickness Readings: The CTG-2 is primarily designed to work on plate-like

structures with dimensions that are at least 6 times the thickness. Structures which are

block-like will give unreliable readings due to additional resonances present in the

structure. When testing slabs or walls, it is important to check the Frequency Spectrum

plot to assure that a prominent peak has been selected by the software.

Expected Concrete Thickness: Within any concrete structure, there might be

additional resonances present. To minimize the chance for false readings, the CTG-2

requires an “Expected Concrete Thickness” value from which the default filter frequency

value is computed. This limits the thickness range of the CTG-2 and attenuates

frequencies outside the range of interest. When changing this value, be certain to exit

the field to ensure that the value is accepted (use tab to exit or click on another field).

Solenoid Positioning: The automatic solenoid impactor must be positioned over an

even concrete surface. If the solenoid is positioned over a hole/depression or over a

bump/high spot, unreliable results may occur.

Delamination Conditions: If the user attempts to measure thin concrete that is outside

the range of the CTG-2 unit (indicated by a hollow, drummy noise at the time of impact),

multiple peaks will be displayed in the Frequency Spectrum plot. Delamination

conditions may be a result of thin concrete or damaged, cracked concrete. These sorts

of results will also appear if a test is attempted on a table top or metal surface, or if a

test is done through unbonded tile or other topping material.

Thick Concrete: If the user attempts to measure thick concrete that is outside the

range of the CTG-2, multiple invalid peaks might be displayed in the Frequency

Spectrum plot.

Typical Velocity Ranges: If a location of known thickness is not available, the

accuracy of the thickness readings can still be improved over the default velocity of

12,000 fps by inputting a typical value from the table below based on the estimated

strength of the concrete.

26

Page 28

2,000 – 3,000 psi: 11,000 fps

3,000 – 4,000 psi: 12,000 fps (default value)

4,000 – 6,000 psi: 13,000 fps

6,000 – 8,000 psi: 14,000 fps

Note that these values are general guidelines which will increase the accuracy of the

measurements to 5% of full scale for cases where a direct calibration cannot be done.

Note that the accuracy of the unit improves to 2% if a direct calibration can be done.

Pan Pour: When testing a corrugated pan pour slab, test in a straight line that is

transverse to the direction of the corrugations, making note of the “thinner” concrete

zones and the “thicker” concrete zones. Note that the areas between the thin zones and

thick zones may produce data with two peaks or more. Data from these areas will

probably not be useful. After the thick zones have been identified, test parallel to the

corrugations in the thick zone if you want to identify the maximum thickness of the pan

pour. Position the axis of the CTG-2 unit parallel to the direction of the corrugations.

Calibration of the CTG-2 on slab on metal deck (pan deck) concrete: The CTG-2

has the greatest accuracy (typically 2%) if a test at a known-thickness location is

conducted and used to calibrate the concrete velocity. However, for the special case of

pan-deck slabs, it is also possible to obtain a reasonable calibration (typically about 4%

or better) by using the known dimensions of the metal deck pan.

To measure the velocity of the concrete in a pan deck slab, take a minimum of two

thickness readings using the default velocity value of 12,000 ft/sec. One should be

centered over a “Thick” part of the slab (D1 below) and the other centered over a “thin”

part of the deck (D2 below). Find these locations by performing a series of close-spaced

(0.5 to 1 inch) tests along a line to find points which are at the centers of typical thick

and thin sections of the slab. Then, using the known deck height variation (H1 as shown

below, from specifications or from direct measurement on the slab bottom), use the

following equation to compute the calibrated velocity (Vc):

Vc = 12,000 * (H1/(D1-D2))

(where 12,000 fps is the default velocity and Vc is the new calibrated velocity)

27

Page 29

Concrete

Top of

H1

D2

Metal Pan

D1

Software Troubleshooting: If the software does not work as expected, the best

recourse is to reset the parameters, close the program and restart the program.

Signal Troubleshooting: If the CTG-2 unit is operating correctly (with the green light

illuminated on the handle) and ‘no data’ or ‘noisy data’ is being received when the status

bar reads “Ready to Test”, check for the following:

1. Make sure you are using the Microphone Adaptor, if necessary. The Microphone

Adaptor might not be necessary on a laptop/desktop but will probably be necessary on

a tablet.

2. If you are using the microphone adaptor, make sure that it is plugged into the

Windows 7 device, not the CTG-2 unit.

3. If your data does not show a clear, prominent peak in the Frequency Spectrum

(bottom plot), check to make sure your volume is not set too high. Try lowering it to 10

and work your way up in intervals of 10 if necessary.

4. A noisy signal without a prominent peak in the Frequency Spectrum may indicate that

the concrete is too thin to test (less than ~ 3.2 inches). Verify that your unit is working

correctly by returning to a previous location that has been successfully tested.

5. A noisy signal without a prominent peak in the Frequency Spectrum may indicate that

the concrete is thicker than the range specified in “Expected Concrete Thickness”. Try

increasing this value to see if the results improve.

General Tips: Practice with your CTG-2 on a location of known concrete thickness

before you take the unit to the first jobsite. Get familiar with your equipment and know

what to expect from its performance.

General Troubleshooting: If the CTG-2 unit does not impact after pressing the trigger

button (or if the impact is not hard/loud enough), the solenoid impactor might be stuck.

Carefully pull the impactor out with your fingernails and clean with a Q-tip dampened

with alcohol.

28

Page 30

5.0 WinCTG2 SOFTWARE ANALYSIS

This section includes instructions for data analysis with the WinCTG2 Software.

5.1 Start Program

Select the WinCTG2 shortcut on the desktop. The software will open as shown in Figure

15 below.

Figure 15 - Main Screen for WinCTG2 Software

29

Page 31

5.2 Open Data Files

1. Select the “Open” option found in the Main Menu. The “Open” dialogue box will

appear as shown in Figure 16 below. Navigate to the .ctg data files saved earlier and

select the data file you want to open. After you have opened a file, the “Status” field

will report that you are in “Analysis Mode”

Figure 16 – Open File for Analysis

5.3 Filtering

Interactive filtering is implemented in this software. A Butterworth filter of 4th order is

used. The type of pass-band can be selected in the Filter Panel. The default pass-band

filter for IE data is “Highpass” which is the recommended filter for most IE situations.

The frequencies can be set using the arrows below the slider bar as shown in Figure 17

below or can be typed into the filtering fields (F1 and F2). There are three options for

pass-band filtering:

• Lowpass – Passes the frequencies below the right mark. This type of pass-band

is NOT recommended for general Impact Echo data analysis.

• Highpass – Passes the frequencies above the left mark. This type of pass-band

is recommended for Impact Echo data analysis.

30

Page 32

• Bandpass – Passes the frequencies between the left and right mark. This type of

pass-band can be used for Impact Echo data analysis if there is interference from

low frequency noise.

The following guidelines can be used for selecting appropriate filters:

1. When the expected concrete thickness is less than 3 inches, a bandpass filter of

10,000 to 50,000 Hz is appropriate

2. When the expected concrete thickness is between 3 inches and 6 inches, a

highpass filter of 6000 Hz is appropriate.

3. When the expected concrete thickness is between 6 inches and 12 inches, a

highpass filter of 3000 Hz is appropriate.

4. When the expected thickness is greater than 12 inches, a highpass filter of 1000

Hz is appropriate.

Left Mark – To set the high pass value

Right Mark – To set the low pass value Filter Pass

Figure 17 – Filter Panel

5.4 Windowing

Interactive time-domain windowing is implemented in this software. Two cursors (left

blue and right red) found on the top plot box can be dragged into the data to window the

front and back of the time domain waveform. This feature is useful to eliminate any front

interference from the solenoid (front end) and/or the interference from double hitting or

other noise (back end). Figures 18A and 18B show the effect on the frequency

spectrum before and after windowing is applied to a typical time domain data waveform

with noise present. Notice that the spectrum from the windowed time domain data in

Figure 18B is smoother than the un-windowed data in Figure 18A.

31

Page 33

Figure 18A – Time domain and Spectrum before Windowing is Applied

Figure 18B – Time domain and Spectrum after Windowing is Applied

32

Page 34

5.5 Concrete Velocity

The default concrete velocity used for concrete thickness calculation (or depth of the

echo) is 12,000 fps. This is an average velocity value for typical sound concrete. But

sound concrete velocity values range from 10,000 fps (weaker concrete) to 14,000 fps

(strong concrete). If this velocity needs to be modified, simply enter the new velocity

value in the “Vel” field found on the Toolbar as shown in Figure 19 below.

Concrete Velocity

Figure 19 – Concrete Velocity

i

Typical concrete velocity is 12,000 – 13,000 ft/sec or 3,600 – 4,000 m/s. Higher

strength concrete may have a higher velocity. Young concrete (less than 7

days old) may have a slower velocity. Poor concrete may also have a slower

velocity.

5.6 Open Next Data File

If the data filenames have a fixed alphabetical prefix and are numbered sequentially in

the suffix, it is possible to scroll quickly through the data. Note that this is the normal

way files are saved on the CTG-2. Use the buttons “Next File” and “Prev File” to quickly

open the files, as shown in Figure 20.

Quick File Opening

Figure 20 – Quick File Opening

33

Page 35

6.0 WinCTG2 SOFTWARE EXPORTING OPTIONS

This section describes options for exporting images and a summary table of test results.

6.1 Copy or Save Image

After the IE file is opened, either the top or bottom plot (Time Domain or Frequency

Spectrum) can be copied to the clipboard for easy pasting into reports or other

documents. Just right click on the desired plot (hold your finger on the screen if using a

tablet) then select “Copy” to save to your clipboard or select “Save Image As” and use

the “Save as Type” dropdown menu to save as an .emf, .png, .gif, .jpg, .tif, or .bmp for

later use.

6.2 Export Test Results to Comma Separated Format

The WinCTG2 software allows the export of test results to comma separated format

which can be entered into an Excel Spreadsheet. Select the “Export” option found in the

Main Menu and the “Export Output” dialogue box will appear as shown in Figure 21

below. Enter the desired directory then enter the alphabetical filename prefix, the first

numerical suffix, the total number of records collected under that filename setup and the

name you want to give to the file.

Figure 21 – Export Test Results to Comma Separated Format

34

Page 36

A summary table of test results will be saved in a .txt file with data arranged in columns

as shown in Figure 22 below. The column format is as follows:

1. File Name

2. X location of the test (ft or m)

3. Y location of the test (ft or m)

4. Frequency associated with the measured thickness (Hz)

5. Measured thickness (inches or mm)

The columns of information are separated by commas, so when importing the data into

a spreadsheet, be sure to click on the “commas as delimiters” checkboxes.

Figure 22 – Results Exported to Excel Spreadsheet

6.3 Export Raw Data to Comma Separated Format

The WinCTG2 software allows the export of individual waveform (raw) data in comma

separated format to an Excel Spreadsheet. After opening an existing file, click anywhere

on the waveform plot then use the hot key “W” to export. A “Save As” dialogue box will

appear on the screen. Name the .csv file and click on “Save”. The .csv file will be saved

in the same directory as the data file.

35

Page 37

7.0 WinCTG2 SOFTWARE LANGUAGE OPTIONS

The WinCTG2 Software can be operated in several different languages. To browse for

different languages, select the “Language” option located at the far right of the Main

Menu.

Language Option

Figure 23 – Language Options

36

Page 38

8.0 CARE AND MAINTENANCE

The CTG-2 unit is rugged but it is not indestructible. Certain precautions should be

taken to ensure the reliable operation of the unit.

1. Take care not to drop the CTG-2 as damage might result.

2. Do not slide sensor tip or rubber feet along the test surface.

3. Use the toggle switch on the base of the IE head to turn the unit off when not in use.

This will prolong battery life.

4. The CTG-2 should be kept clean and free of mud and dirt, as mud can interfere with

the operation of the automatic solenoid impactor and small rocks or other objects on

the sensor can result in poor data or low signal amplitudes.

5. The CTG-2 should not be exposed to direct rain or other moisture. Do not submerge

the CTG-2. If the unit falls into water, immediately remove the batteries, disconnect

the cable, remove the bottom cover, clean off any mud or dirt, and allow the unit to

dry out.

37

Page 39

APPENDIX A

_______________________________________________________

SUGGESTED WINDOWS DEVICES

The Olson Instruments CTG-2 unit should work with most desktops, laptops and betterquality tablets. The CTG-2 unit will NOT work with tablets that have only a headphone

jack. The tablet MUST support a headset OR microphone. In addition, some

inexpensive tablets that support a microphone might not have an adequate microphone.

The following is a list of tablet models that have been tested at our facility and are

known to work with the CTG-2. This list will change over time so contact us at

info@olsonengineering with questions and to report models you have found to work.

Toshiba Encore 8

Dell Venue 8 Pro 3000

Microsoft Surface Pro 3

Acer Iconia W4

We recommend a minimum 8” size tablet for the best software display. We recommend

that the tablet be used in “landscape” mode.

38

Loading...

Loading...