okuma OSP E100 Instruction Manual

Fixture Offset Function

(Intended for MU-400VA)

INSTRUCTION MANUAL

(OSP-E100 ver 1.3)

Maker’s Subprogram (MSB)

Pub. No. 5082-E (ME51-429-R1)

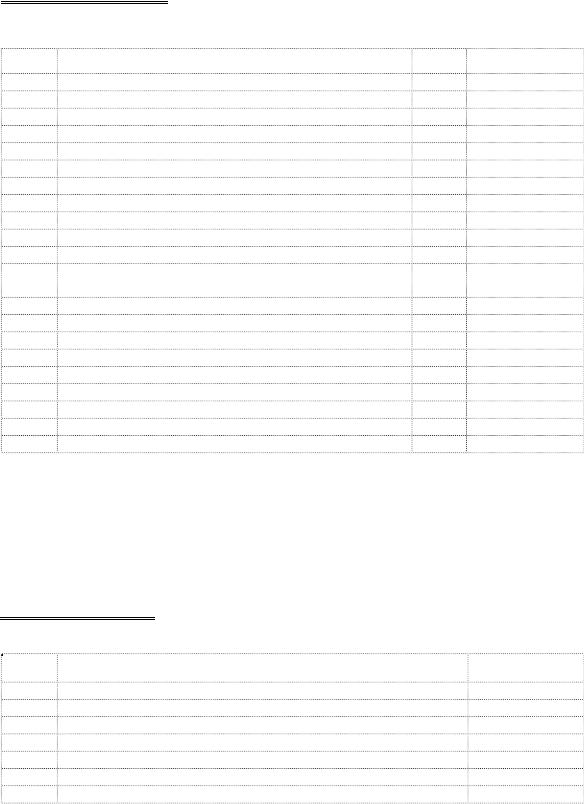

Table of Contents

NO. |

INDEX |

Page Remarks |

1 |

Overview |

P1 |

2 |

Command Format |

P2 |

3 |

Setting Pivot Distance |

P2 |

4 |

Setting Zero at Rotary Table Mounted Position |

P3 |

5 |

Relation between Machine Zero and Pivot Distance |

P3 |

6 |

Method of Determining Pivot Distance through Actual |

P4 |

|

Machining (Example) |

|

7 |

Example of Using Fixture Offset Function |

P5 |

8 |

Reference Data Fig. 1 |

P6 |

Revision History

No. |

Revisions |

|

Revised on |

―― |

Initial edition ver.1.1 |

|

03.06.17 |

|

2nd edition ver.1.2 |

MSB information added |

03.08.04 |

|

3rd edition ver.1.3 |

Revised explanation of command format |

03.08.21 |

1. Overview

For the machine having a rotary axis or a tilting axis, if there is a difference between the rotation/tilting center and programming zero, the programming zero position varies with the angle of rotation or tilting.

The fixture offset function compensates this variation by rewriting the zero offset values according to the specified rotation or tilting angle.

The rotary and tilting axes to which this offset function applies are shown in the table below.

The fixture offset is a function for setting zero position by calculation and not the function for guaranteeing the positioning accuracy.

When positioning accuracy is particularly required, set the zero position for each plane and use this function only for the initial machining. Then, compensate each zero position based on the gauging result of the initially machined workpiece.

Type |

Rotary Axis |

Tilting Axis |

|

Machine with |

C |

A |

|

C/A-axes |

|||

|

|

Z+

C+

A+

Y+

1

Loading...

Loading...