OSP-U100M

OSP-U10M

ALARM & ERROR LIST

(3rd Edition)

Pub. No. 4187-E-R2 (ME37-004-R3) Oct. 2002

4187-E P-(i)-R2

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself

from hazards arising from unforeseen accidents. However, operators must not rely exclusively on

these safety devices: they must also become fully familiar with the safety guidelines presented below

to ensure accident-free operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating To Machine Installation

(1) Install the machine at a site where the following conditions (the conditions for achievement of the

guaranteed accuracy) apply.

• Ambient Temperature : 17 to 25 °C

• Ambient humidity : 75% or less (no condensation)

• Site not subject to direct sunlight or excessive vibration; environment as free of dust, acid, corrosive gases, and salt spray as possible.

(2) Prepare a primary power supply that complies with the following requirements.

• Voltage : 200V

• Voltage fluctuation : ±10% max.

• Power supply frequency : 50/60 Hz

• Do not draw the primary power supply from distribution panel that also supplies a major noise

source (for example an electric welder or electric discharge machine) since this could cause

malfunction of the NC unit.

• If possible connect the machine to a ground not used by any other equipment. If there is no

choice but to use a common ground, the other equipment must not generate a large amount of

noise (such as an electric welder or electric discharge machine).

(3) Installation Environment

Observe the following points when installing the electrical control cabinet.

• Make sure that the NC unit will not be subject to direct sunlight.

• Make sure that the electrical control cabinet will not be splashed with chips, water, or oil.

• Make sure that the electrical control cabinet and operation panel are not subject to excessive

vibrations or shock.

• The permissible ambient temperature range for the electrical control cabinet is 0 to 40°C.

• The permissible ambient humidity range for the electrical control cabinet is 30 to 95% (no condensation).

• The maximum altitude at which the electrical control cabinet can be used is 1000 m (3281 ft.).

2. Points To Check Before Turning On The Power

(1) Close all the doors of the electrical control cabinet and operation panel to prevent the entry of

water, chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

3. Precautions Relating To Operation

(1) After turning on the power, carry out inspection and adjustment in accordance with the daily

inspection procedure described in this instruction manual.

(2) Use tools whose dimensions and type are appropriate for the work undertaken and the machine

specifications. Do not use badly worn tools since they can cause accidents.

(3) Do not for any reason touch the spindle or tool while spindle indexing is in progress since the

spindle could rotate: this is dangerous.

4187-E P-(ii)-R2

SAFETY PRECAUTIONS

(4) Check that the workpiece and tool are properly secured.

(5) Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6) Do not remove, chips by hand while machining is in progress since this is dangerous. Always

stop the machine first, then remove the chips with a brush or broom.

(7) Do not operate the machine with any of the safety devices removed. Do not operate the

machine with any of the covers removed unless it is necessary to do so.

(8) Always stop the machine before mounting or removing a tool.

(9) Do not approach or touch any moving part of the machine while it is operating.

(10) Do not touch any switch or button with wet hands. This is extremely dangerous.

(11) Before using any switch or button on the operation panel, check that it is the one intended.

4. Precautions Relating to the ATC

(1) The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that a

tool could be released and fall in the event of an unforeseen accident, exposing you to danger:

do not touch or approach the ATC mechanism during ATC operation.

(2) Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3) Remove chips adhering to the magazine at appropriate intervals since they can cause misopera-

tion.

Do not use compressed air to remove these chips since it will only push the chips further in.

(4) If the ATC stops during operation for some reason and it has to be inspected without turning the

power off, do not touch the ATC since it may start moving suddenly.

4187-E P-(iii)-R2

SAFETY PRECAUTIONS

5. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

6. Precautions During Maintenance Inspection and When Trouble

Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the following points when performing maintenance inspections or during checking when trouble has occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need to

be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were and

secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the electrical control cabinet or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Electrical Control Cabinet

a) Switch the main power disconnect switch OFF before opening the electrical control cabi-

net door.

b) Even when the main power disconnect switch is OFF, there may some residual charge in

the servo amplifier and spindle drive unit, and for this reason only service personnel are

permitted to perform any work on these units. Even then, they must observe the following

precautions.

• Servo amplifier

Discharge the residual voltage one minute after turning off the breaker inside the unit.

• Spindle drive unit

Discharge the residual voltage one minute after turning off the main power disconnect

switch.

4187-E P-(iv)-R2

SAFETY PRECAUTIONS

c) The electrical control cabinet contains the NC unit, and the NC unit has a printed circuit

board whose memory stores the machining programs, parameters, etc. In order to ensure

that the contents of this memory will be retained even when the power is switched off, the

memory is supplied with power by a battery. Depending on how the printed circuit boards

are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

(11) Periodic Inspection of the Electrical Control Cabinet

a) Cleaning the cooling unit

The cooling unit in the door of the electrical control cabinet serves to prevent excessive

temperature rise inside the electrical control cabinet and increase the reliability of the NC

unit.

Inspect the following points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7. General Precautions

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine opera-

tors must wear safety equipment such as safety shoes and safety goggles.

(4) Machine operators must read the instruction manual carefully and make sure of the correct pro-

cedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

4187-E P-(v)-R2

SAFETY PRECAUTIONS

8. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of particular

importance. Read the instructions marked with these symbols carefully and follow them.

: Indicates an imminent hazard which, if not avoided, will result in death or serious

injury.

: Indicates unsafe practices which, if not avoided, could result in death or serious injury.

: Indicates unsafe practices which, if not avoided, could result in minor injuries or dam-

age to devices or equipment.

: Indicates precautions relating to operation or use.

4187-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

PAGE

SECTION 1 SAFETY PRECCLASSIFICATION OF ALARMS . . . . . . . . . . . . . . . . . . . . . 1

SECTION 2 CPU ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 3 ALARM P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION 4 ALARM A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

SECTION 5 ALARM B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

SECTION 6 ALARM C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

SECTION 7 ALARM D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

SECTION 8 ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

4187-E P-1-R2

SECTION 1 CLASSIFICATION OF ALARMS

SECTION 1 CLASSIFICATION OF ALARMS

Alarms related with the OSP are classified into six types such as CPU alarm, Alarm P, A, B, C and D.

Alarm Classifications

Alarm Machine Conditions When ALARM Lamp Comes ON Operative NC Functions Thereafter

CPU Stops NC operation.

Stops;

- axis feed

- spindle rotation

- coolant supply

Axis drive power is switched OFF.

CPU status is displayed on the operation panel.

P Stops NC operation.

Stops;

- axis feed

- spindle rotation

- coolant supply

Axis drive power is switched OFF.

Alarm display is given on the operation panel.

AStops;

- axis feed

- spindle rotation

- coolant supply

Axis drive power is switched OFF.

Alarm display is given on the operation panel.

B The commands in the active block are completed.

Spindle rotation and coolant supply do not stop.

Axis drive power is not switched OFF.

Alarm display is given on the operation panel.

C The part program being run is executed to the end (up

to M02 command).

Spindle rotation and coolant supply do not stop.

Axis drive power is not switched OFF.

Alarm display is given on the operation panel.

D This alarm does not give any influence to the machine

operation.

Alarm display is given on the operation panel.

The display format of CPU alarm, alarm P, A, B, C and D is indicated on pages 2 and 4.

All NC functions are inoperative.

Concerning the control, cancel the alarm by turning

power on again after turning it off once.

All NC functions are inoperative.

Concerning the control, cancel the alarm by turning

power on again after turning it off once.

Operations for display are possible.

The machine remains inoperative until the control is

reset and the alarm condition is removed.

Operations for display are possible.

The machine remains inoperative until the control is

reset and the alarm condition is removed.

Operations for display are possible.

New program cannot be executed until the alarm is

released.

Operations on the operation panel are all operative. Alarm status cannot be reset unless the cause

of alarm is removed.

Display Format of CPU Alarms (Bus error)

4187-E P-2-R2

SECTION 1 CLASSIFICATION OF ALARMS

Display Format of CPU Alarms (Address error)

4187-E P-3-R2

SECTION 1 CLASSIFICATION OF ALARMS

Display Format of CPU Alarms (Typical exception)

4187-E P-4-R2

SECTION 1 CLASSIFICATION OF ALARMS

4187-E P-5-R2

SECTION 1 CLASSIFICATION OF ALARMS

Display Format of Alarm P, A, B, C and D

Object Number and Object Message

The object number and the object message show the programming system and the control axis where the

alarm has occurred by the number and message as shown in the table blow:

Object No. Meaning Object message

01 Linear axis X-axis

02 Linear axis Y-axis

03 Linear axis Z-axis

04 Linear axis U-axis

05 Linear axis V-axis

06 Linear axis W-axis

07 Rotary axis A-axis

08 Rotary axis B-axis

09 Rotary axis C-axis

10 Crossrail (EC-W) axis WA-axis

11 ATC magazine axis 1 MA-axis

12 ATC magazine axis 2 MB-axis

13 ATC magazine axis 3 MC-axis

14 Tool change arm swing axis TS-axis

15 Tool change arm insert/extract axis TI-axis

16 APC axis 1 PA-axis

17 APC axis 2 PB-axis

18 Multi-pallet magazine axis PL-axis

19 Attachment axis AT-axis

20 Attachment magazine axis 1 AA-axis

21 Attachment magazine axis 2 AB-axis

22 ATC carrier axis CA-axis

23 ATC carrier axis CB-axis

• As indicated above, the object numbers and messages to be used are determined by the machine specifications.

4187-E P-6-R2

SECTION 1 CLASSIFICATION OF ALARMS

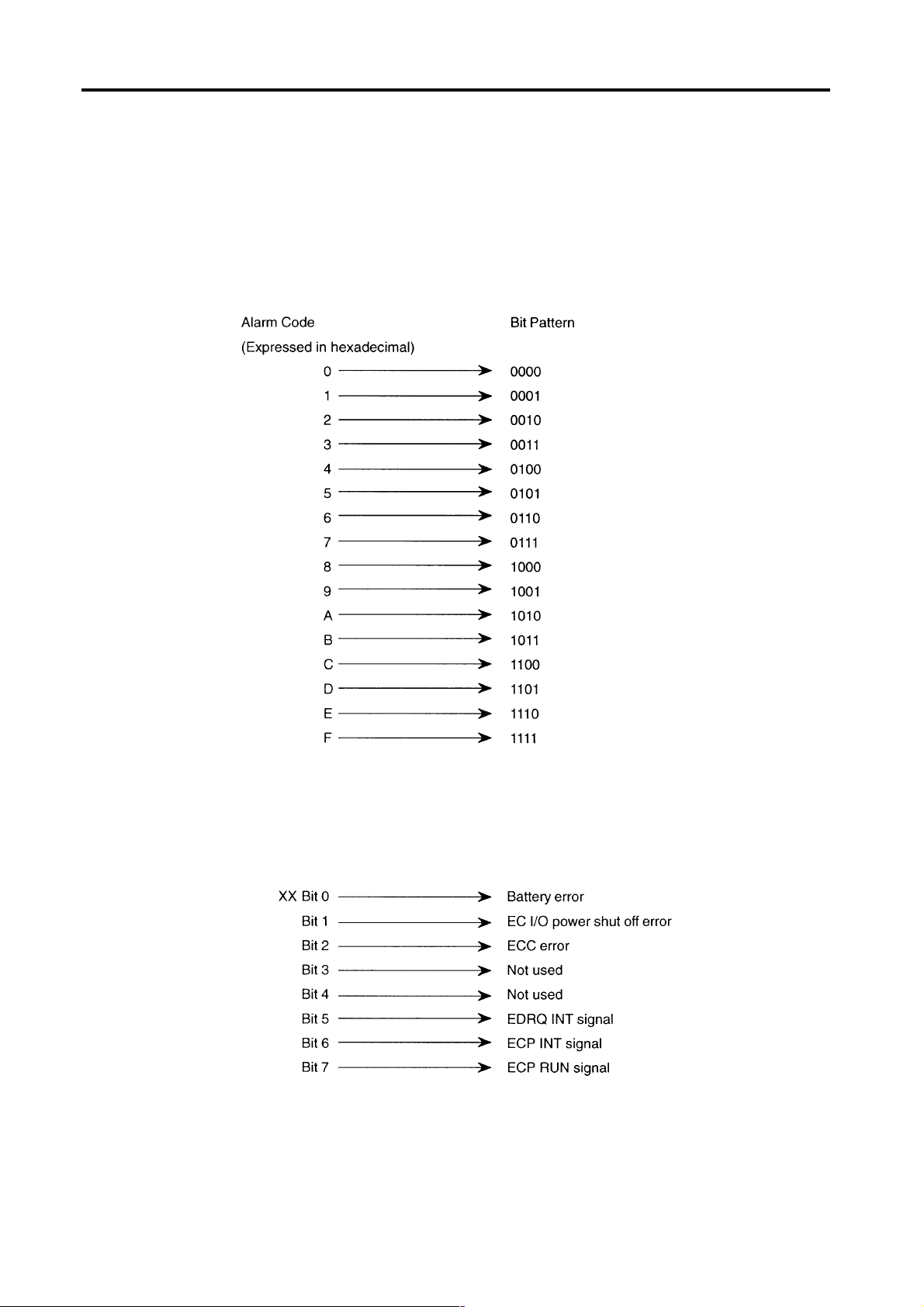

Alarm Codes:

In this manual, alarm codes are explained using such as “X”, “XX”, and “XXYY”.

Explanation is given in the following methods:

1) The alarm code indicated in this text can be used directly as the key to find the contents of error.

2) The alarm code indicated in this text should first be converted into bit expression (pattern), which is

then used as the key to find the contents of error.

In the case of 2), the procedure to convert the alarm code into bit pattern is shown below.

Bit conversion method:

How to check alarm contents:

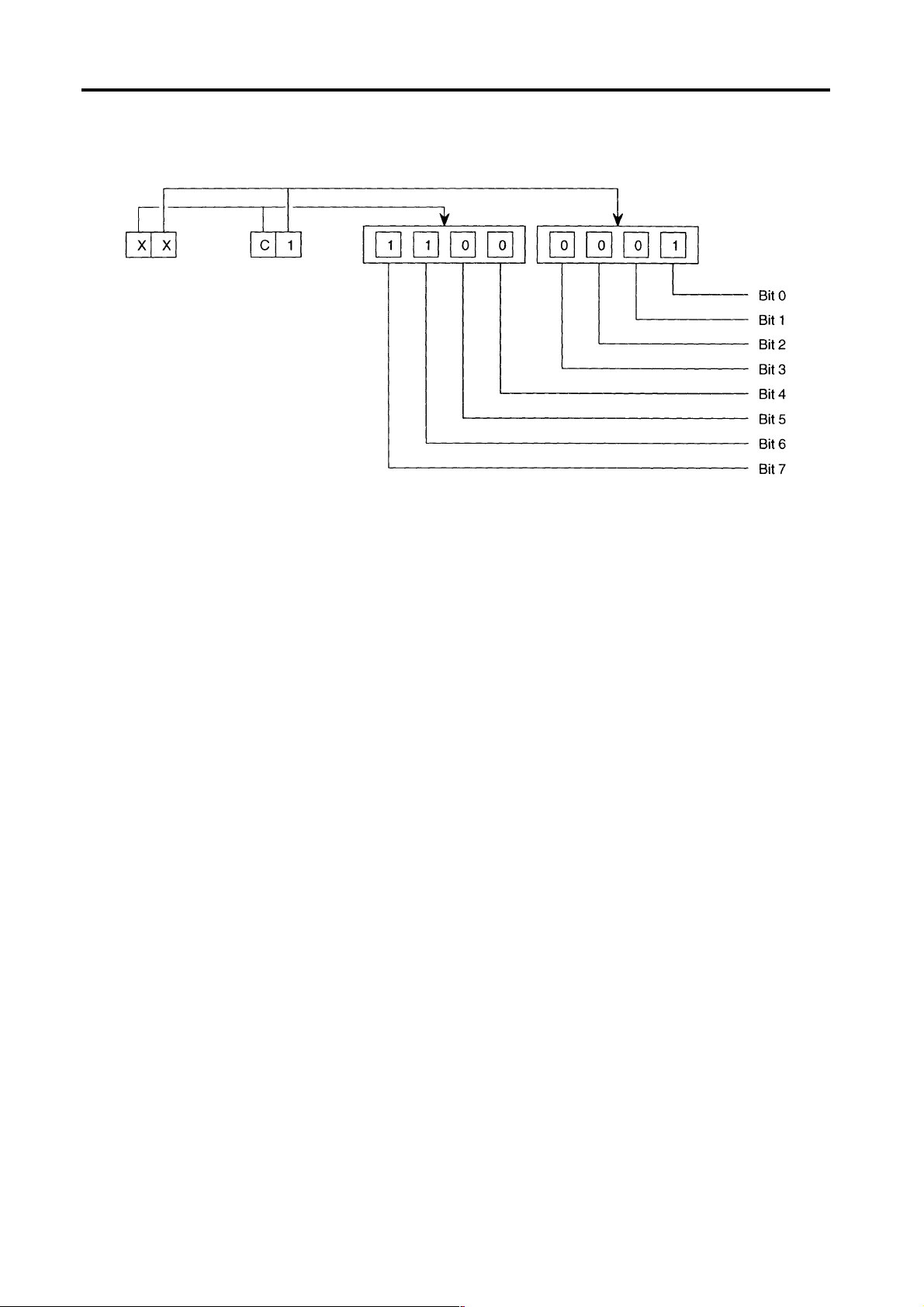

The method to find the details of the alarm indicated by the bit pattern is explained below using an example

Example:

[Code] XX

4187-E P-7-R2

SECTION 1 CLASSIFICATION OF ALARMS

If an alarm occurs, a hexadecimal number is displayed. If “$C1” is displayed, for example, first convert this

“$C1” into bits.

After the conversion, it is known that Bit0, Bit6, and Bit7 are ON. See the information above and you will find

that these error codes correspond to “battery error”, "ECP INT signal”, and "ECP RUN signal”, respectively.

Error Display Format

4187-E P-8-R2

SECTION 1 CLASSIFICATION OF ALARMS

SECTION 2 CPU ALARM

Alarm No. Alarm Message

1BUS

2 ADDRESS

3 ILLEGAL INSTRUCTION

4 ZERO DIVIDE

5 CHK INSTRUCTION

6 TRAPV INSTRUCTION

7 PRIVILEGE VIOLATION

8 TRACE

9 LINE 1010 EMULATOR

10 LIN E 1111 EMULATO R

11 EXCEPTION VECTOR

12 SPURIOUS INTERRUPT

13 INTERRUPT

14 TRAP INSTRUCTION

15 USER INTERRUPT

16 COPROCESSOR PROTOCOL VIOLATION

17 FORMAT

18 UNINITIALIZED INTERRUPT

19 FPCP UNORDERED CONDITION

20 FPCP INEXACT RESULT

21 FPCP DIVIDE BY ZERO

22 FPCP UNDERFLOW

23 FPCP OPERAND

24 FPCP OVERFLOW

25 FPCP SIGNALING NAN

4187-E P-9-R2

SECTION 2 CPU ALARM

★ 1 BUS ERROR

This alarm is caused when the bus error exception has occurred with the CPU.

Details of BUS error:

When the bus error occurs, the CPU status is displayed in hexadecimal numbers.

At the same time, the red LED at the CPU rack lights up.

The bus error includes the following five types of errors:

1) Cycle time over error

2) ECC error

3) Protect error

4) Loop error

5) System bus error

6) Double-bus error

Note:Error display is not available in the case of double-bus error.

[Index] None

[Character-string] None

[Code] CPU status

[Probable Faulty Locations]

1) Printed circuit boards

2) Mother board

3) Loose card edge connector connection

4) Loose flat cable connection

5) Switch settings

[Measures to Take]

Depending on the type of error encountered, check the following points.

1) ECC error. . . . . . . . . . . . Mainboard, Memory board

2) Protect error . . . . . . . . . . Main board

3) Cycle time over error . . . Judge the faulty PCB from the access address.

4) Loop error. . . . . . . . . . . . PCB which generates the interruption in question; judge the interruption level from

the . . . . . . . . . . . . . . . . . status register.

5) System bus error . . . . . . All main boards

6) Double-bus error . . . . . . All PCB's

Then, carry out the following steps.

1) Check the switch settings.

Make sure that the boards are free of foreign material.

Make sure that flat cables are inserted correctly.

Make sure that card edge connectors are clean.

2) Change the card insertion slots; check if the problem occurrence status changes.

3) Replace the suspectable boards.

4187-E P-10-R2

SECTION 2 CPU ALARM

★ 2 ADDRESS

This error occurs when the CPU has accessed word operands, long word operands or instructions by an

odd number address.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 3 ILLEGAL INSTRUCTION

This error occurs when the CPU has read an unallowable instruction.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 4 ZERO DIVIDE

This error occurs when the CPU executes a division command with a divisor of <#007F>0".

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 5 CHK INSTRUCTION

This error occurs when the CPU executes the CHK instruction under certain conditions (such that the

register value is less than 0 or that the register value is greater than the upper limit in the operand word.)

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board

4187-E P-11-R2

SECTION 2 CPU ALARM

★ 6 TRAPV INSTRUCTION

This error occurs when the overflow condition bit is turned on in the status register when the TRAPV

instruction is executed by the CPU.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 7 PRIVILEGE VIOLATION

This error occurs when the CPU executes a privilege instruction (instructions that can be executed only in

the supervisor condition) in the user condition.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 8 TRACE

This error occurs when the CPU executes an instruction in the trace condition.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 9 LINE 1010 EMULATOR

This error occurs when the instruction having the word pattern of <#007F>1010" is executed.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 10 LINE 1111 EMU LATOR

Thi s error o ccurs w hen the i nstruc t ion havi ng the w ord pat tern of “1111” is ex ecuted.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

4187-E P-12-R2

SECTION 2 CPU ALARM

★ 11 EXCEPTION VECTOR

This error occurs when the CPU has referenced the exception vector which is not referenced normally.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 12 SPURIOUS INTERRUPT

This error occurs when a spurious interruption to the CPU has been made.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 13 INTERRUPT

This error occurs when an unusual interruption to the CPU has been made.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations]

1) All printed circuit boards which generate interruption

2) Error in setting interruption level

[Measures to Take]

1) Check the setting of interruption level setting switches at individual printed circuit boards.

2) Judge the interruption level from the value at the status register (SR) when an error has occurred.

The third digit from the right-most digit indicates the interruption level.

Change the printed circuit board which generates the judged interruption.

3) Replace the main board.

4) Replace the mother board.

★ 14 TRAP INSTRUCTION

This error occurs when the CPU has referenced the TRAP exception vector which is not referenced normally.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

4187-E P-13-R2

SECTION 2 CPU ALARM

★ 15 USER INTERRUPT

This error occurs when unusual user interruption has occurred.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replace the main board.

★ 16 COPROCESSOR PROTOCOL VIOLATION

This error occurs when communication fails between the CPU and the coprocessor.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 17 FORMAT

This error occurs when the CPU detects an improper value as a result of data check required for operation control.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 18 UNINITIALIZED INTERRUPT

This error occurs when an interruption occurs before initialization of the vector numbers of peripheral

devices.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 19 FPCP UNORDERED CONDITION

This error occurs when the floating-point coprocessor attempts execution of a comparison command with

non-numerals.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

4187-E P-14-R2

SECTION 2 CPU ALARM

★ 20 FPCP INEXACT RESULT

This error occurs when the floating-point coprocessor loses some digits in arithmetic operation.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 21 FPCP DIVIDE BY ZERO

This error occurs when the floating-point coprocessor attempts division by a number having a denominator of “0” in execution of a division command.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 22 FPCP UNDERFLOW

This error occurs when the floating-point coprocessor obtains a value too small to express as a result of

arithmetic operation.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 23 FPCP OPERAND

This error occurs when the floating-point coprocessor executes an arithmetic instruction having no solution.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

★ 24 FPCP OVERFLOW

This error occurs when the floating-point coprocessor obtains a value too large to express as a result of

arithmetic operation.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

4187-E P-15-R2

SECTION 2 CPU ALARM

★ 25 FPCP SIGNALING NAN

This error occurs when the floating-point coprocessor executes an arithmetic instruction having operands

of signaling non-numerals.

[Index] None

[Character-string] None

[Code] None

[Probable Faulty Locations] Main board

[Measures to Take] Replaces the main board

SECTION 3 ALARM P

Alarm No. Alarm Message

0721 DeviceNet error

0722 FCP Board Error

0723 I/O Data Combined File Reading

0800 Spindle D/A control data file read

0801 TCP/IP illegal

0802 Load information file not found

0803 File load illegal

0804 MSB file is not same

0805 MOP-TOOL PARAMETER PBU LOAD

0806 MOP-TOOL TOOL-DATA PBU LOAD

0807 ACP panel status receive error

0808 Speed change ratio failure

0809 FCP illegal

0810 NCIO data file read

0811 FCP IO link communication error

0812 MCS start

0813 MCS communication error

0814 MCS data file

0815 PLC Real time task loop error

0816 PLC initial error

0817 MCS Error

0818 ADP START

0829 SPMC Program load

0830 SPMC Execution stop

0831 SPM Exception processing

0832 SPM System Call error

0833 MCS Option-program-file not send

0834 MCS Servo-data error

0835 MCS Communication

0839 Specification Condition Failure

0840 Super-Hi-NC specification unmatching

0841 FCP4 illegal

0842 Safety-monitor Spec Error

0850 MCS Undefined alarm number

0851 MCS Exception processing

0852 MCS Processing trouble

0853 MCS CON APA deviation

0854 MCS Power-Supply-Unit Error

0855 MCS Converter-link error

0856 MCS DC-bus voltage alarm

0857 MCS Motor over current

0858 MCS Power unit over heat

4187-E P-16-R2

SECTION 3 ALARM P

Alarm No. Alarm Message

0859 MCS Power unit over load

0860 MCS Supply voltage flutter

0861 MCS Power unit version error

0862 MCS Winding-change failed

0863 MCS Encoder-link error

0864 MCS Encoder error

0865 MCS Encoder initialize failed

0866 MCS Encoder with shaft error

0867 MCS Encoder with shaft initial

0868 MCS ABSO SCALE error

0869 MCS ABSO SCALE initialize

0870 MCS Magnetic encoder alarm

0871 MCS Resolver alarm

0872 MCS Pulse generator count over

0873 MCS Motor over heat

0874 MCS Servo-link error

0875 MCS Servo-link disconnect

0876 MCS Servo-link protocol error

0877 MCS Servo data error

0878 MCS Illegal command

0879 MCS CON speed over

0880 MCS Speed command over

0881 MCS DIFF over

0882 MCS APA speed over

0883 MCS Full-closed APA error

0884 MCS Over speed

0885 MCS Velocity deviation over

0886 MCS Collision detected

0887 MCS Urgent-stop time over

0888 MCS Belt is broken

0889 MCS Axis change control error

0890 MCS Independent encoder init

0891 MCS APA error

0892 MCS Motor over load

0893 MCS Safety Speed Monitor E-LINK Error

0900 SVP start conditions uncertain

0901 SVP processing trouble

0902 SVP CON APA deviation

0903 SVP error

0904 SVP exception processing

0905 SVP APA pattern data

0906 SVP APA speed

0907 SVP CON speed

4187-E P-17-R2

SECTION 3 ALARM P

Alarm No. Alarm Message

0908 SVP DIFF over

0909 SVP servo amp

0910 SVP APA check data

0911 SVP speed command over

0912 SVP servo data setting

0913 SVP Belt is broken

0914 SVP F-TYPE encoder error

0915 SVP full closed loop error

0916 SVP F-TYPE encoder with shaft error

0917 SVP F with shaft APA pattern data

0918 SVP cannot plant error offset data

0919 SVP encoder application (MOTOR SHAFT)

0920 SVP encoder application (WITH SHAFT)

0921 SVP collision detection

0922 SVP SA overload

0923 SVP SA communication error

0924 SVP SA version error

0925 SVP SA motor cable overcurrent

0926 SVP SA inverter bridge short circuit

0927 SVP SA overheating

0928 SVP SA power circuit overvoltage

0929 SVP SA power circuit low voltage

0930 SVP SA regenerative resistor overheat

0931 SVP SA control circuit power voltage

0932 SVP SA error

0933 SVP board version error

0934 SVP control error

0935 SVP data file read

0936 SVP data file data address

0937 SVP data file check

0938 VAC start

0939 VAC data file read

0940 Time sharing task control

0941 Real time task control

0942 Real time task loop error

0943 Main processor name incorrect

0944 Slave processor name incorrect

0945 Memory board / battery life

0946 TFP illegal

0947 TFP data file read

0948 TFP Field net communication error

0949 IO DIAGNOSTICS data file read

0950 IO MACRO data file read

4187-E P-18-R2

SECTION 3 ALARM P

Alarm No. Alarm Message

0951 SMP illegal

0952 Processor Board not equip

0954 Peripheral processor start

0955 Spec. code: data file

0956 Backup data file read

0957 Graphic Back up data file read

0958 Pitch compensate data file read

0959 IGF Specification unmatching

0960 IGF Backup data file read

0961 IGF illegal

0962 CCP Roader file load

0963 CCP Application file load

0964 CCP Parameter file load

0965 Configuration file format error

0966 Configuration file open error

0967 Array limit check table is bad

0968 No specification

0969 Memory size is not same

0970 Synchronous axis specification code

0971 Cache data / initialization error

0972 SVP INDEXING high-speed indexing over

0973 SVP INDEXING low-speed indexing over

0974 SVP INDEXING unclamp time over

0975 SVP INDEXING clamp time over

0976 SVP INDEXING positioning direction

0977 SVP INDEXING incorrect command

0978 SVP INDEXING servo data setting

0981 SVP LE sum check error

0982 SVP LE data error

0983 SVP LE incre. abso. error

0984 SVP LE comparator AD error

0985 SVP LE face rotation error

0986 SVP LE initial transfer data error

0987 SVP LE application error

0988 DNC-DT Preload task start error

0989 CPU information table data unsuitable

0990 TASK generate error

0991 TASK information table data unsuitable

0992 PLC backup data file read

0993 TCP/IP board error

0994 TCP/IP configuration file error

0995 Machine axis data file

0996 PLC axis data file

4187-E P-19-R2

SECTION 3 ALARM P

Alarm No. Alarm Message

0997 PLC monitor backup data file read

0998 PLC sequence program load

0999 Synchronous tap's data file read

4187-E P-20-R2

SECTION 3 ALARM P

★ 0721 DeviceNet error

* This alarm is common to OSP-U100, E100 and P100.

[Index] None

[Character-string]

CH* SC$

*: Channel where an error occurred

$: Sequence counter

[Code] XXYYZZZZ

XX : MacID of the slave where the error occurred

YY : Error status of the slave identified by XX.

0x00:Normal state or absence of slave

0x46:Double use of MacID

0x48:The device has stopped communication.

0x49:The device ID information does not match the value in the scan list.

0x4D:The data size is different from the set value.

0x4E:No response from the device in connection

0x50:The device is in idle mode.

0x53:An error was received in connection.

0x54:The response time out occurred in connection.

0x56:The device has entered the idle state.

0x5B:Bus OFF

0x5C:Network power supply OFF

(When the alarm has been caused not by the slave but by other reason such as communication delay,

XXYY becomes OxFFFF.)

ZZZZ :Scanner error status

bit0: Memory check error (at memory initialization)

bit1: Scan list initialization error

bit2: Scan list matching check error (MacID)

bit3: Scan list matching check error (Input data)

bit4: Scan list matching check error (Output data)

bit5: Double use of MacID

bit6: Status error of network power supply

bit7: Memory parity error

bit8: Input data receiving error (once)

bit9: Input data receiving error (twice in a low)

bit10:Output data sending error (once)

bit11: Output data sending error (twice in a low)

bit12: Slave communication delay (once)

bit13:Slave communication delay (twice in a low)

bit14:Bus OFF

bit15:Diagnostic information access control error

[Probable Faulty Locations]

• Hardware failure

• Software failure

4187-E P-21-R2

SECTION 3 ALARM P

★ 0722 FCP Board Error

The FCP board is in abnormal state.

[Character-string]

AAAABB

AAAA: Name of task under execution

BB: Running program module

[Code]

VWXXYYZZ

V=1 Indicates FCP-DN board

W=0

XXYYZZ is the same as the code displayed with Alarm P809.

W=1 Indicates OS error.

XX=00 PLT0 task

XX=01 PLT1 task

XX=09 PLSY task

XX=10 PLR2 task

XX=20 PLR3 task

YYZZ=(Indicates the content.)

YYZZ=0001 Task forced termination failure

YYZZ=0002 Task start failure

YYZZ=0003 Task restart failure

YYZZ=0004 Task restart failure within a waiting time of 1.6 ms

W=2 Indicates internal memory check error

XXYYZZ indicates the head address in the check area.

4187-E P-22-R2

SECTION 3 ALARM P

★ 0723 I/O Data Combined File Reading

The NC failed to read I/O data combined file.

[Code]

Load status of I/O data combined file (in hexadecimal)

2-> File open error (no file)

3-> File read error (no data)

4-> File attribute error (not 'PBU1')

5-> File close error

6-> File size error (smaller)

7-> File size error (larger)

100-> Machine type for PLC is wrong.

200-> PLC class is wrong.

300-> File version is wrong.

★ 0800 Spindle D/A control data file read

The NC failed to properly read the spindle D/A control data file.

[Index] None

[Character-string] None

[Code] XY

X = Gear set number (Initially found problem gear set number. If Y = any of 1 to 6, X will not be displayed.)

Y =1 No data file

2 Data file type is not PBU1.

3 Larger data file size

4 Improper data file size

5 The number of gear sets does not match the data file size.

6 The number of gear sets is other than 1 to 4.

7 Motor speed limit or spindle speed limit is 0.

8 Maximum spindle speed is 0.

[Probable Faulty Locations] Error in creation of the spindle D/A control data file

[Measures to Take] Correctly create a spindle D/A control data file.

[Related Specifications] Spindle D/A control specification

★ 0801 TCP/IP illegal

During activation of DNC-T1, T2, T3,or DT function, a CPU error occurred on TCP/IP board.

[Index] None

[Character-string] None

[Code] XXYYZZ

XX -> Board status in hexadecimal

bit7bit6bit5bit4bit3bit2 bit1 bit0

RUNHALTCPUOFF0SNMI00 0

YY -> Bus error status in hexadecimal

bit7bit6bit5bit4bit3bit2 bit1 bit0

0 00 0PROT DAI LOOP ECC

ZZ -> Always 0

[Probable Faulty Locations]

1) Hardware error on TCP/IP board

2) Software error on TCP/IP firmware

4187-E P-23-R2

SECTION 3 ALARM P

★ 0802 Load information file not found

In file creation by the custom software production system, the load information file which agrees with the

specification code was not found.

Or,a file described in the load information file was not found.

[Index] None

[Character-string] Problem file name

[Code] None

However, there may be a case where an error message is output in the console line.

[Probable Faulty Locations] Defective installation, software production error, or specification code error

[Measures to Take]

Reinstall the software.

Reissue the install floppy disk.

★ 0803 File load illegal

In file creation by the custom software production system, the software which agrees with the specification code was not found

[Index] None

[Character-string] Problem software file name

[Code]

1 -> The file ended without loading any character.

3 -> The file ended during file loading.

9 -> The device name was wrongly specified.

10 -> The file name was wrongly specified.

11 -> The file was not found.

[Probable Faulty Locations] Defective installation, software production error, or specification code error

[Measures to Take]

1) Reinstall the software.

2) Reissue the install floppy disk.

★ 0804 MSB file is not same

The MSB file used for IMAP-B and interactive programming B does not satisfy the NC software requirements.

[Index] None

[Character-string] None

[Code] X

1 -> The MSB file for IMAP-B and interactive programming B is not compatible with the NC software.

[Probable Faulty Locations] A wrong MSB file is selected for the NC software.

[Measures to Take] Use an MSB file of revision B or later for IMAP-B and interactive programming B.

★ 0805 MOP-TOOL PARAMETER PBU LOAD

The backup file (MMTUB*.PBU) is not found, or its type or size is wrong.

[Index] None

[Character-string] None

[Code] X

1 -> The parameter PBU file (MMTUB*.PBU) is not found in MD0:

2 -> The parameter PBU file (MMTUB*.PBU) does not start from “PBU1” or has an improper length (other

than 18 sectors).

[Probable Faulty Locations]

1) If the alarm occurred during normal NC operation, the PBU file has been deleted or its data has been

destroyed.

2) If the alarm occurred without NC operation after installation of control floppy disk, the PBU file type was

wrong or no PBU file was stored in the memory.

[Measures to Take]

1) If the alarm occurred before NC operation, create a correct control floppy.

2) If the alarm occurred during NC operation, reinstall the control floppy disk.

[Related Specifications] OSP7000M built-in type MOP-TOOL

4187-E P-24-R2

SECTION 3 ALARM P

★ 0806 MOP-TOOL TOOL-DATA PBU LOAD

The backup file (MMTUA*.PBU) is not found, or its type or size is wrong.

[Index] None

[Character-string] None

[Code] X

3 -> The tool data PBU file (MMTUA*.PBU) is not found in MD0:

4 -> The tool data PBU file (MMTUA*.PBU) does not start from “PBU1” or has an improper length (other than

125 sectors).

[Probable Faulty Locations]

1) If the alarm occurred during normal NC operation, the PBU file has been deleted or its data has been

destroyed.

2) If the alarm occurred without NC operation after installation of control floppy disk, the PBU file type was

wrong or no PBU file was stored in the memory.

[Measures to Take]

1) If the alarm occurred before NC operation, create a correct control floppy.

2) If the alarm occurred during NC operation, reinstall the control floppy disk.

[Related Specifications] OSP7000M built-in type MOP-TOOL

★ 0807 ACP panel status receive error

The ACP board received abnormal data on operation panel status.

ObjectNone

[Character-string] None

[Code] XX (operation panel status data)

bit7: Invalid panel status

bit6: Operation panel CPU error

bit3 to 5: Software version applied to operation panel firmware

bit0 to 2: Operation panel type

★ 0808 Speed change ratio failure

For the machine with scroll machining function, a speed change ratio of X, Y, Z, or C-axis is defectively

set. Or, a wrong type of position encoder is used.

[Index] None

[Character-string] None

[Code]

1 -> X-axis speed change ratio is set by a code.

2 -> Y-axis speed change ratio is set by a code.

3 -> Z-axis speed change ratio is set by a code.

4 -> C-axis speed change ratio is set by a code.

5 -> X-axis speed change ratio exceeds the setting range.

6 -> Y-axis speed change ratio exceeds the setting range.

7 -> Z-axis speed change ratio exceeds the setting range.

8 -> C-axis speed change ratio exceeds the setting range.

9 -> A wrong type of position encoder is used.

[Probable Faulty Locations]

Defective speed change ratio data in the servo data PBU file or wrong encoder type

[Measures to Take] Correct the data in the servo data PBU file.

[Related Specifications] Scroll machining function

4187-E P-25-R2

SECTION 3 ALARM P

★ 0809 FCP illegal

The FCP board is in abnormal state.

[Index] None

[Character-string] ’AAAABB’

AAAA->Name of task being processed

BB-> Program module number (hexadecimal) being executed

However, no character-string appears when transmission of the module is stopped or double bus error

occurs.

[Code] XXYYZZ

XX:

01 -> Transmission module has stopped.

YYZZ=0000

02 -> Exception error

YY:Exception error number(*1)

ZZ:FCP Bus error status(*2)

03 -> Double bus error

YY:Exception error number(*1)

ZZ:FCP Bus error status(*2)

04 -> FCP was reset as soon as SNMI occurred at FCP.

YY:SNMI status(*3)

ZZ:FCP Bus error status(*2)

*1 -> Exception error No.

01 -> Bus error

02 -> Address error

03 -> Illegal instruction

04 -> Zero divide

05 -> CHK instruction error

06 -> TRAPV instruction error

07 -> Privilege violation error

08 -> Trace error

09 -> Line 1010 emulator

0A -> Line 1111 emulator

0B -> Exception vector error

0C -> Spurious interruption error

0D -> Interruption error

0E -> TRAP instruction error

0F -> User interruption error

*2 -> FCP Bus error status

bit7-> System bus error

bit6 -> System bus parity error

bit5 -> Cycle over error

bit4 -> Protect error

bit3 -> Loop error

bit2 -> Loop error cancel

bit1 -> Memory parity error

bit0 -> Always 0

*3 -> SNMI status

bit7 -> Bus error at FCP

bit6 -> FCP executed SNMI command.

bit5 -> Oscillator module stopped oscillation.

4187-E P-26-R2

SECTION 3 ALARM P

★ 0810 NCIO data file read

The NC failed to read I/O data file.

[Index] None

[Character-string] None

[Code] I/O data file load status (in hexadecimal)

2 -> File open error (no file)

3 -> File read error (no data)

4 -> File attribute error (not ábPBU1*/)

5 -> File close error

6 -> File size error (smaller size)

7 -> File size error (larger size)

100 -> Wrong PLC machine type

200 -> Wrong PLC class

300 -> Wrong file version

[Measures to Take]Consult the machine maker.

★ 0811 FCP IO link communication error

A communication error occurred in the I/O link on FCP board.

[Index] None

[Character-string] None

[Code] XxYYZZZZ

XX:

01 -> Channel number where FCP board error was detected

x=0 -> Errors (other than below)

x=1 -> Faulty connection of optical fibers

x=2 -> Initialization error

YY:

bit7 -> Double transmission error

bit6 -> Double reception error

bit5 -> Format error

bit4 -> CRC error

bit3 -> Parity error (transmission/reception buffer)

bit2 -> Disconnection command detected

bit1 -> Time out error

bit0 -> Undefined

ZZZZ:

bit15 ->Slave station error detected

bit14 ->Undefined

bit13 ->Undefined

bit12 ->Start bit error

bit11 ->Stop bit error

bit10 ->Undefined

bit9, 8 -> 00 ... Master station, slave station

-> 01 ... Repeater No. 1

-> 10 ... Repeater No. 2

bit7 to 0-> Slave station number where the error was detected (master station: $00)

[Measures to Take] Consult the machine maker.

4187-E P-27-R2

SECTION 3 ALARM P

★ 0812 MCS start

An error occurred in initialization of MCS when the power was supplied.

[Index] None or axis name

[Character-string] Varies with the code.

[Code] XXXXYYYY

XXXX: Kind of generated alarm

YYYY: Further information on the alarm (Varies with XXXX.)

XXXX

FFFF...YYYY is 00UV. Where, U: Faulty channel number - 1

0= Channel 1

1= Channel 2

4187-E P-28-R2

SECTION 3 ALARM P

2= Channel 3

V: Cause of alarm (V=1 indicates that servo link mode has not been established.)

2 -> Two or more safety speed monitors are connected with one channel.

FF01...Memory error occurred in read/write test of the servo link I/O buffer.

YYYY=0 (always)

Character-string shows the address where the error occurred.

FF00...Communication LSI caused an error in read/write test of the servo link I/O buffer.

YYYY=Error status

Character-string shows the address where the error occurred.

F000...

YYYY=bit 7:Same ID number used

bit 6:Improper ID number

bit 5:Missing ID number

bit 4:Too many CH4 controllers

bit 3:Too many CH3 controllers

bit 2:Too many CH2 controllers

bit 1:Too many CH1 controllers

bit 0:

With this error, connection data appears in the screen center.

EF00...The servo link does not connect with all the required axes or connects with an improper axis.

YYYY=ID number of required axis controller

Character-string shows the problem axis name.

With this alarm, connection data appears in the screen center.

EE00...An error occurred in downloading an optional file.

High-order digit of YYYY shows the cause while low-order part is an error code.

If high-order digit=

1: File is not in OSP format.

2: File attribute is not contiguous.

3: File opening error. Low-order part is an error code.

4: Error in initial data reading. Low-order part is an error code.

5: File does not start with “MCS1”.

6: File name is not followed by “OPFS”.

7: The number of file sets is 0.

8: Data reading error. Low-order part is an error code.

9: File data has a sector length of 0.

A: The number of bytes transferred is 0.

B: File data has a sector length smaller than the number of bytes transferred.

C: Data reading error. Low-order part is an error code.

ED00...An error occurred when manual mode is switched to auto mode. High-order digit of YYYY shows the

cause while low-order part is an error code.

High order digit=1: World clock does not start.

EC01...Time difference occurred in setting CH1 timer.

YYYY is the difference.

EC02...Time difference occurred in setting CH2 timer.

YYYY is the difference.

EC03...Time difference occurred in setting CH3 timer.

YYYY is the difference.

D001...In buffering the initial data in AT (auto) receive mode, the software synchronization bit does not come on

within 3 [s].

4187-E P-29-R2

SECTION 3 ALARM P

YYYY is always 0.

D002...In buffering the initial data in AT (auto) receive mode, the buffer A received a wrong format code.

Two low-order characters of YYYY are the received format code.

D003...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

first block.

YYYY is the received format code.

D004...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

second block.

YYYY is the received format code.

D005...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

third block.

YYYY is the received format code.

D006...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

fourth block.

YYYY is the received format code.

D007...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

fifth block.

YYYY is the received format code.

D008...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

sixth block.

YYYY is the received format code.

D009...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

seventh block.

YYYY is the received format code.

D00A...In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the

eighth block.

YYYY is the received format code.

D010...In buffering the initial data in AT (auto) receive mode, the received self-diagnostic data is not $55.

YYYY is the received diagnostic data.

D011...In buffering the initial data in AT (auto) receive mode, the buffer A received the bit data which is wrong at

bit No. 0 and No. 1.

YYYY is the received data.

D012...In buffering the initial data in AT (auto) receive mode, the buffer A received the bit data which is wrong at

bit No. 2 and No. 3.

YYYY is the received data.

D013...In buffering the initial data in AT (auto) receive mode, the buffer A received the bit data which is wrong at

bit No. 4 and No. 5.

YYYY is the received data.

D080...Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 441C.

YYYY is the received data.

D081...Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 2428.

D090...Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 4405.

YYYY is the received data.

D091...Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 4404.

YYYY is the received data.

D092...Initial data buffered in AT (auto) receive mode includes wrong offset data for compensating positioning

points.

YYYY is the received data.

[Probable Faulty Locations]

- Invertor unit (Check the LED of the invertor unit.)

- Improper ID number set in MCS

- Specification code setting error

- Erroneous connection with MCS

★ 0813 MCS communication error

When the power was supplied, an error occurred in communication with MCS.

If servo link information is displayed at the center of the screen, judge the cause by taking into consider-

ation the message in the servo link information.

[Index] None

[Character-string]

[command name]-[channel No.]-network address (controller No.)

[Code] XXXXYYYY

XXXX:

1 -> The NC received the data that the NC had broadcasted.

YYYY: information of the received frame

2 -> Data is received from a station other than the slave station that broadcasted the data.

YYYY: information of the received frame

3 -> The received data size is 2 bytes or less.

YYYY: always 0

4 -> Data is received from a station other than the slave station that sent the date.

YYYY: information of the received frame

5 -> The NC received the data that the NC had transmitted in a way other than broadcasting.

YYYY: information of the received frame

6 -> Data is received from a the station of which network address is 0.

YYYY: information of the received frame

7 -> Data reception response is not sent within 1 or 0.1 second after data transmission.

YYYY: Always 0

'SI' command is specified before at least one MCS is normally activated in the link or before the power is sup-

plied.

Open the box and check the LEDs of all the MCS units connected to the error-caused channel.

Normal units are indicated with '22'.

8 -> Data transmission does not end within 0.1 second.

YYYY: Always 0

9 -> Communication error occurred after reception of data.

YYYY: Error status

A -> Communication error occurred while the NC was waiting for data reception or immediately after data

transmission.

YYYY: Error status

B -> Communication error occurred while the NC was waiting for data transmission.

YYYY: Error status

C -> Data transmission was attempted during data transmission.

YYYY: NC operation status

D -> Data transmission was attempted in the state of communication error.

YYYY: Error status

E -> An error command was received.

Two high-order digits of YYYY are a code (45: exception; 41: alarm; 57: warning; 54: error) while low-order digits

are the number.

[Refer to the shake-hand communication error list (5-10) in external specification for MCS controller function.]

100 -> The received first 2 bytes are improper as a response to the transmitted data.

YYYY: Received first 2 bytes

4187-E P-30-R2

SECTION 3 ALARM P

4187-E P-31-R2

SECTION 3 ALARM P

101 -> The received data size is improper as a response to the transmitted data.High-order digits of YYYY is the

received data size while the low-order half is a normal value.

102 -> Data No. 1 attached to the received data is improper.

YYYY: Two high-order bytes of the data judged to be improper

SI command : slave station connection No.

AS command : slave station connection No.

ID command : communication code + auxiliary code

103 -> Data No. 2 attached to the received data is improper.

YYYY: Two high-order bytes of the data judged to be improper

SI command : cumulative relay time

ID command : data ID

104 -> Data No. 3 attached to the received data is improper.

YYYY: two high-order bytes of the data judged to be improper

ID command : reserved

105 -> Data No. 4 attached to the received data is improper.

YYYY: Two high-order bytes of the data judged to be improper

ID command : ID data (4 bytes or less)

106 -> Data No. 5 attached to the received data is improper.

YYYY: Two high-order bytes of the data judged to be improper

SI command : The number of controllers

ID command : ID data (8 bytes)

200 -> Data sizes differ from those specified with ID numbers.

Faulty software

[Probable Faulty Locations]

- Invertor unit (Check the LED of the invertor unit.)

- FCP board

- MCS connection error

- MCS connection cable is faulty

-Faulty software

★ 0814 MCS data file

When the power was supplied, an error occurred in reading or transferring the servo link data file.

Or, the data file includes abnormal data.

[Index]

[Character-string]

[axis name] [device name] [file name] or none

[Code] XYZZAAAA

X: Axis kind; Y: Rough classification; ZZ: Minute classification; AAAA: Data

X: 1= NC-controlled axis

2= spindle

3= PLC-controlled axis

Y:0= Error in reading servo data file

ZZ:

01= Error occurred in retrieval of the file. AAAA=error code AAAA indicates that the data file does not exist at

000B: or the required axis data does not exists in the file.

02= File attribute is not contiguous.

03= File is not in OSP format.

04= File opening error. AAAA=error code

05= File data reading error. AAAA=error code

4187-E P-32-R2

SECTION 3 ALARM P

06= File does not start with "PBU1".

07= File name is not followed by "M1".

08= The relevant axis data has exceeded the maximum number of data sets stored in the file before the spec-

ified number of data sets are transferred.

09= File closing error. AAAA=error code

0A= A set of data size is larger than 8 sectors. AAAA=number of data sectors

0B= Data reading error. AAAA=error code

0C= The data file does not contain the previously specified number of data sets.

0D= The data serial number does not match.

0E= The data type does not match.

0F= The whole number of data sets does not match.

10= File closing error. AAAA=error code

11= Servo data does not exist in the file where NC axis data exists.

Y: 1= Error in checking servo data file

ZZ:

01= The NC axis data file of NC axis control for heavy workpiece specification is not found.

02= Axis specification (rotary or limited) or unit system does not match. AAAA=axis specification data

03= Acceleration/deceleration method does not match.

04= Inductosyn is not provided.

05= The number of data sets is abnormal (the number of spindle data sets is not within 1 to 32). AAAA=the

number of data sets

06= The speed-time constant characteristic data includes faulty data with reversed inequality.

AAAA=Two high-order digits show the axis number while low-order digits are the error content.

High-order AA:

00 -> X-axis

01 -> Y-axis

02 -> Z-axis

03 -> 4th axis

04 -> 5th axis

Low-order AA:

11 -> FT1max=0

12 -> FT1max<FT1min

13 -> FT1max=FT1min and T1max<T1min

14 -> FT1max>FT1min and T1max<T1min

21 -> FT2max=0 (FT2max is determined by internal calculation.)

22 -> FT2max<FT2min

23 -> FT2max=FT2min and T2max<T2min

24 -> FT2max>FT2min and T2max<T2min

=31 -> FT1pmax=0

=32 -> FT1pmax<FT1pmin

=33 -> FT1pmax=FT1pmin and T1pmax<T1pmin

=34 -> FT1pmax>FT1pmin and T1pmax<T1pmin

=41 -> FT2pmax=0(FT2pmax is determined by internal calculation.)

=42 -> FT2pmax<FT2pmin

=43 -> FT2pmax=FT2pmin and T2pmax<T2pmin

=44 -> FT2pmax>FT2pmin and T2pmax<T2pmin (50 to 5E are the alarms related with turning cut parameters.)

=50 -> In the parameters used only for turning cut, the set numbers of the basic three axes do not match.

=51 -> In the parameters used only for turning cut, the T1min values of the basic three axes do not match.

=52 -> In the parameters used only for turning cut, the T1max values of the basic three axes do not match.

=53 -> In the parameters used only for turning cut, the T1pmax values of the basic three axes do not match.

=54 -> In the parameters used only for turning cut, the FT1min values of the basic three axes do not match.

=55 -> In the parameters used only for turning cut, the FT1max values of the basic three axes do not match.

=56 -> In the parameters used only for turning cut, the FTpmax values of the basic three axes.

=57 -> FT1max=0

=58 -> FT1max<FT1min

=59 -> FT1max>FT1min and T1max<T1min

=5A ->FT1max=FT1min and T1max<T1min

=5B -> FT1pmax=0

=5C ->FT1pmax<FT1pmin

=5D ->FT1pmax>FT1pmin and T1pmax<T1pmin

=5E ->FT1pmax=FT1pmin and T1pmax<T1pmin

07= The servo data to be used with the NC axis data for heavy workpiece specification is not found.

AAAA is the weight set as the NC axis data.

[Probable Faulty Locations]

- Axis data file

★ 0815 PLC Real time task loop error

The real time task indicated by the character-string failed to end within the preset processing time.

[Index] None

[Character-string] AAAABB

AAAA -> Task name being processed when the loop error was detected.

BB -> Program module number being executed (hexadecimal)

[code]

XXXXXXXX-> Program counter value (hexadecimal) at the time of error detection

[Probable Faulty Locations]

- Level 2 or level 3 task in the PLC sequence program failed to end processing within the preset time.

- Timing error of synchronous signal

- Wrongly set synchronous signal frequency

4187-E P-33-R2

SECTION 3 ALARM P

★ 0816 PLC initial error

An error was detected in the checking process for activating the PLC.

[Index] None

[Character-string] None

[Code] XX

=1 -> NC-PLC synchronous parameter is not found.

[Measures to Take] Consult the machine maker.

★ 0817 MCS Error

An error occurred under the control by MCS.

[Index] Axis name or none

[Character-string] None

[Code] XXZZAAAA

XYZZ: 0

AAAA:

1= Processing does not end within 5 seconds after MCS reset 1.

2= Processing does not end within 5 seconds after MCS reset 2.

3 = Processing does not end within 5 seconds after PLC reset processing 1.

4 = Processing does not end within 5 seconds after PLC reset processing 2.

X: 1 to 3

X: Channel number

YZZAAAA: Communication error status

ZZ: Slave station where the error has occurred.

bit 7: Error occurred during data transmission/reception at slave station No. 8.

bit 6: Error occurred during data transmission/reception at slave station No. 7.

bit 0: Error occurred during data transmission/reception at slave station No. 0.

AAAA: Cause of the error

bit 15: Error occurred (always 1)

bit 14 -12: Always 0

11 -> Access error in MT mode

10 -> Transmission loop error in AT mode

9: Excessive number of data pieces at reception IF

8: Disconnection error

7: Always 0

6: Modulation code error

5: Reception CRC error

4: Format error

3: Double transmission error

2: Double reception error

1: Memory parity error

0: Time-out error

[Probable Faulty Locations]

- MCS controller is defective.

- Defect of FCP board servo link

- Defective software

4187-E P-34-R2

SECTION 3 ALARM P

★ 0818 ADP START

An alarm occurred while the AD conversion processor board was initialized after power ON.

[Index] None

[Character-string] None

[Code] X

X=1: Synchronous counter value remains 1.

X=2: A system alarm occurred when the synchronous counter value was 1.

X=3: Synchronous counter value remains 3.

X=4: A system alarm occurred when the synchronous counter value was 3.

[Probable Faulty Locations] 1 ADP(AD conversion processor board)

[Measures to Take] Replace the ADP(AD conversion processor board).

[Related Specifications] Thermal deviation compensation

★ 0829 SPMC Program load

Error occurred when loading program of SUPER MAIN CARD(SPMC).

[Code] XYYZAAAA

X : Module number of load program

YY : Subroutine number in module

Z : Error number in subroutine

AAAA : A numerical value is entered as the case may be.

[Probable Faulty Locations]

1) Defective installation or software production error

2) Faulty software

3) Faulty SPMC

4) Faulty SUPER MAIN BOARD(SPMB)

★ 0830 SPMC Execution stop

A replying value to the execution beginning request, the reset request, or the data transfar request from

SUPER MAIN CARD (SPMC) was not prescribed one.

[Code] XXYY

XX=10:No reply was sent within 20 seconds after sending the execution beginning request to SPMC.

XX=18:No reply was sent within 20 seconds after sending the reset request to SPMC.

XX=20:The replying value from SPMC to the data transfar request was not prescribed one.

YY : In case of 32 to 61, the possibility that the exception occurs in SPMC is high and ($YY-$32) shows an

exception kind.

In the case except it, the possibility of faulty software is high.

[Probable Faulty Locations]

1) Faulty SPMC

2) Faulty SUPER MAIN BOARD(SPMB)

3) Faulty software

4187-E P-35-R2

SECTION 3 ALARM P

★ 0831 SPM Exception processing

Fatal abnormality has occurred in processing by hardware or software of SUPER MAIN CARD(SPMC).

[Code]

200 -> Machine Check Exception

300 -> Data Access Exception

400 ->Instruction Access Exception

600 -> Alignment Exception

700 -> Program Exception

800 -> Floating-Point Unavailable Exception

D00 ->Trace Exception

1000 -> Instruction Translation Miss Exception

1100 -> Data Load Translation Miss Exception

1200 -> Data Store Translation Miss Exception

1300 -> Instruction Address Breakpoint Exception

1400 -> System Management Interrupt

[Probable Faulty Locations]

1) Faulty SPMC

2) Faulty SUPER MAIN BOARD(SPMB)

3) Faulty software

★ 0832 SPM System Call error

In the system call processing with the SUPER MAIN CARD(SPMC), error was detected.

[Code] 2XXXXXXX

XXXXXXX: Error code which was returned from system call.

[Probable Faulty Locations] Faulty software

★ 0833 MCS Option-program-file not send

The optional program file for MCS has not been transferred to the MCS.

[Index] Axis name or none

[Character-string] None

[Code] None

[Probable Faulty Locations]

- MCS optional program file has not been transferred.

- MCS optional program file is not found.

- MCS optional program file does not contain the program that matches the MCS software version.

[Measures to Take]

- Install the MCS optional program file.

- Change the MCS optional program file.

★ 0834 MCS Servo-data error

Erroneous servo data has been transferred to MCS.

[Index] Axis name or none

[Character-string] None

[Code]XXXXYYZZ

XXXX =ID number

YY = Parameter number

ZZ = Error content

01: Out of setting range

02: Set timing error

03: No data transfer

04: Calculation error

05: Others

[Probable Faulty Locations]

- The servo data file does not match the MCS software version.

- NC software

[Measures to Take]

- Change the servo data file.

4187-E P-36-R2

SECTION 3 ALARM P

★ 0835 MCS Communication

An error occurred during shake-hand communication with MCS.

[Index] Axis name or none

[Character-string] Shake-hand communication error number (2 digits), error data (8 digits), and [command

name]-[channel number]-net address (controller number)

[Code] None

[Probable Faulty Locations]

- Faulty application software

-Faulty MCS software

[Measures to Take]

- Change the application software.

- Change the MCS software.

★ 0839 Specification Condition Failure

Specification code, software system,or the hardware configuration is faulty.

[Index] None

[Character-string] None

[Code] X

=1 -> Operation processor required for Hi-cut specification is not provided on the compact main board.

[Probable Faulty Locations]

=1 NC specification configuration defect or hardware configuration assign defect

[Measures to Take]

=1 Remove the Hi cut specification code, or use the compact main board (UCMB+F) with the operation processor.

★ 0840 Super-Hi-NC specification unmatching

The actual NC specifications do not match the requirements for Super Hi-NC function or NURBS com-

mand function.

[Index] None

[Character-string] None

[Code]

1 -> The 2nd main board is not a high-speed main board. Or, the 3rd main board is not a super main board.

[Probable Faulty Locations] High-speed main board or super main board

[Measures to Take]

Change the 2nd main board to a high-speed main board, and the 3rd main board to a super main board.

[Relating Specification] Super Hi-NC Function, NURBS Command function

4187-E P-37-R2

SECTION 3 ALARM P

★ 0841 FCP4 illegal

FCP4 board became abnormal.

[Index] None

[Character-string] AAAABB

AAAA: Task name being executed

BB Program module number being executed (hexadecimal number)

[Code] WWXXYYZZ

If WW is omitted, XXYYZZ is the same with the code displayed with the alarm 809 "FCP illegal".

If WW is 0, refer to [Measures to Take].

WW=10 The OS is abnormal.

XX: Task

XX=00 PLT0 task

XX=01 PLT1 task

XX=09 PLSY task

XX=10 PLR2 task

XX=20 PLR3 task

YYZZ: Contents of failure

YYZZ=0001 Forced termination of the task failed.

YYZZ=0002 Task start failure

YYZZ=0003 Failure in waiting for task start

YYZZ=0004 Failure in waiting for task start by 1.6ms delay

WW=20 The built-in memory is abnormal.

XXYYZZ: Top address of the checked area

[Measures to Take]

If the code is 0, there is a following possibility only when the FCP board is changed to the FCP4 board.

When the data trace is set to "Effective" with the power ON in the settings for data trace function, and the NC

read the settings of backup data where the trace data has been set.

In this case, 1 byte of sector 6@81 is set to 0 in the PLC variable data file (PLCUA*.PUB) in MD0.

★ 0842 Safety-monitor Spec Error

In the safety speed monitor function, an abnormality was found in the specification conditions.

[Index] None

[Character-string] None

[Code] WXXYYZZ

W=1 The connected position of the safety speed monitor for the displayed axis is different from the position

registered in software.

The guard number of each axis in the safety speed monitor data file for the axis control is different from

the monitor position to which the axis is connected.

W=2 The guard number of the displayed axis is other than 1 to 9.

XX: shows the controller ID of the axis where the abnormal was found (hexadecimal number).

YY: Guard numbers in the safety speed monitor data file for axis control of axis for which the abnormal was

found (hexadecimal number).

ZZ: The number of the safety speed monitor checked when the alarm is generated

W=3 The (second) safety speed monitor does not exist in the specifications for the machine with attachment

spindle.

[Measures to Take]

W=1 Check if the safety speed monitor is connected to the correct position.

W=2 Change in safety speed monitor data file for axis control.

W=3 Or, add the safety speed monitor.

4187-E P-38-R2

SECTION 3 ALARM P

★ 0850 MCS Undefined alarm number

The MCS caused an error related with axis control.

[Index] Axis name or none (spindle)

[Character-string] Alarm number in decimal

[Code] Alarm code

[Probable Faulty Locations]

- Depends on the number indicated in the character-string.

Inform us of the code and the character string.

★ 0851 MCS Exception processing

A fatal alarm occurred while the MCS invertor unit and MCS software are executing their processing.

[Index] Axis name or none (spindle)

[Character-string] Cause of alarm detected

"#1" ->Control board error

"#2" ->Voltage drop of +-12 V battery for control board

"#3"-> OPF error

"#11" -> Voltage drop of 5 V battery for control board

"#12" -> Invertor bridge shorted

"#13" -> IPM protective function activated

"#14" -> Motor overcurrent

"#20" -> INT loop error

"#21" -> INT5 loop error

"#22" -> INT4 loop error

"#23" -> INT3 loop error

"#24" -> INT2 loop error

"#25" -> INT1 loop error

"#26" -> Access denied

4187-E P-39-R2

SECTION 3 ALARM P

"#27" -> Ram check error in initialization

"#28" -> Party error

"#29" -> Watchdog error

"#30" -> IRQ7 interruption

"#31" -> NMI interruption

"#32" -> General illegal command

"#33" -> Slot illegal command

"#34" -> CPU address error

"#35" -> DMA address error

"#36" -> Undefined trap error

"#37" -> Undefined interruption

"#38" -> DMAC

"#39" -> ITU

"#40" -> SCI

"#41" -> REF

"#42 -> A/D

"#43" -> System reserved

"#44" -> User break

[Code]

In the case of #1, the code shows the error content of thecontrol board.

In the case of #3, the code shows the error content of the optional program file.

1: Identification code "OPF1" error

2: End code "ED" error

3: Sum check error

4: Board name error

In the case of #11-14, #20-21, #25-26 and #30-31, the code shows the data in the error status register.

[Probable Faulty Locations]

In the case of #1,

- Invertor unit

In the case of #3,

- Optional program file

- Optional program file incompatible with invertor unit

In the case of #2 or #11,

- Power unit (when this alarm occurred in several invertor units)

In the case of #12, #13, or #14,

- Invertor unit

In other cases,

- Invertor unit

★ 0852 MCS Processing trouble

MCS

[Index] Axis name or none (spindle)

[Character-string] None

[Code] XXZZAAAA

XX:

04 -> The self-diagnostic data has an error. (ZZ: Received data)

06 -> Software sync bit or format code of buffer A is wrong.

07 -> Software sync bit or format code of buffer B is wrong.

08 -> An error occurred in data communication.

ZZ shows the data kind. AAAA is always 0.

ZZ:

1 -> Speed command (8408)

2 -> Laser linear scale value (4413)

3 -> Backlash (4406)

4 -> Actual position without positioning error compensation (440A)

5 -> Positioning error compensation amount

6 -> Full-closed loop encoder value (4410)

7 -> Semi-closed loop encoder value (4411)

8 -> ODIFF(4415)

10 -> APA in divided stroke (4404)

11 -> Acceleration/deceleration time for positioning (4422)

12 -> Zero offset amount

13 -> In-position width (4420)

14 -> Maximum of divided stroke (4405)

15 -> Point data change

=16: ODIF amount (4415)

=17: Checking point table number (140D)

=18: Changing point table number (1409)

[Probable Faulty Locations]

- Faulty MCS controller

-Faulty software

4187-E P-40-R2

SECTION 3 ALARM P

★ 0853 MCS CON APA deviation

Difference between CON and APA values has exceeded the allowable limit. The CON-APC deviation is

the absolute value of difference between [calculated value written in MCS] and [actual position read from

MCS]. The NC control software monitors this deviation. The MCS normally monitors DIFF value.

This alarm appears if the MCS causes a fatal error and cannot monitor the DIFF value.

[Index] Axis name

[Character-string] None

[Code] Absolute value of deviation in hexadecimal (reference unit)

[Probable Faulty Locations]

- Faulty MCS controller

- Mismatch between MCS data and NC data

★ 0854 MCS Power-Supply-Unit Error

The power unit caused an error.

[Index] Axis name or none (spindle)

[Character-string] None

[Code] AAAAAAXX

AAAAAA is always 0.

X Alarm number

0: DC voltage alarm

1: Abnormal input voltage

2: Abnormal control power

3: Abnormal control status

4: Overload in regenerative circuit

4187-E P-41-R2

SECTION 3 ALARM P

5: Heat sink overheat

6: CPU error

7: Spare

Y: Power unit status